Page 1

Professional Shop Manual

“C” and “D” Series Mowers

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provid e su pp lem ental information to assist the trained technician. Untrained or inexperienced individuals should seek the assistance of an experienced and tr ained professional. Read, understand, a nd follow all

instructions and use common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied with the equipment. No liability can be accepted for any inaccuracies or omission in this publication,

although care has been taken to make it as complete a nd accura te as possib le at the time of publica tion. However, due to

the variety of outdoor power equipment and continuing product changes that occur over time, updates will be made to these

instructions from time to time. Therefore, it may be necessary to obtain the latest materials before servicing or repairing a

product. The company reserves the right to make changes at any time to this publication without prior notice and without

incurring an obligation to make such changes to previously published versions. Instructions, photographs and illustrations

used in this publication are for reference use only and may not depict actual model and component parts.

© Copyright 2010 MTD Products Inc. All Rights Reserved

MTD Products Inc - Product Training and Education Department

FORM NUMBER - 769-07008

06/2011

Page 2

Page 3

Table of Contents

Chapter 1: Introduction

About the text format ..........................................................................................1

Safety................................................................................................................. 2

Fasteners ...........................................................................................................3

Assembly Instructions ........................................................................................3

The “C” Series Mower ........................................................................................4

The “D” Series Mower ........................................................................................4

Understanding Model and Serial Numbers ........................................................5

Maintenance chart ..............................................................................................6

Fastener Tightening Torques .............................................................................6

Chapter 2: Blade and Belt

Blades ................................................................................................................ 7

Blade Removal ...................................................................................................8

Blade Sharpening .............................................................................................10

Belt Removal 1....................................................................................................1

Belt Replacement .............................................................................................14

Chapter 3: Controls and Cables

Engine Control Cable....................................................................................... 17

Drive Control Housing Assembly ......................................................................19

Drive Control Housing Removal and Disassembly ...........................................20

Drive Clutch Control Cable Removal and Replacement: ................................. 25

Drive Speed Control Cable Removal and Replacement:................................. 26

Chapter 4: Deck and transmission

Trail Shield .......................................................................................................27

Side Discharge Door / Mulch Plug ..................................................................28

Deckwash Fitting ..............................................................................................30

Rear Grass Door ..............................................................................................31

Front Wheels ....................................................................................................33

Front Axle ......................................................................................................... 36

Front Axle Cover ..............................................................................................39

Handlebars .......................................................................................................40

Transmission and Rear Axle Inspection ...........................................................41

Transmission and Rear Axle Removal .............................................................42

Transmission and variable speed pulley.......................................................... 45

Rear baffle removal ..........................................................................................49

Transmission Internal Workings....................................................................... 52

I

Page 4

II

Page 5

Introduction

CHAPTER 1: INTRODUCTION

Professional Service Manual Intent: This manual is intended to provide service dealers with repair and overhaul

procedures for the “C” and “D” series mowers.

Disclaimer: The information contained in this manual is correct at the time of writing. Both the product and the infor-

mation about the product are subject to change without notice.

About the text format

Certain flags and key words are used to indicate the nature of the text that accompanies them. They are as follows:

Indicates a potentially hazardous situation that, if not avoided, may result in minor or

! CAUTION! CAUTION

! WARNING! WARNING

moderate injury. It may also be used to alert against unsafe practices.

Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates an imminently hazardous situation that, if not avoided, will result in death or

! DANGER! DANGER

NOTE: “NOTE” is used to point-out helpful information that may not fit as a step in a procedure.

1. Numbered steps

1a. Sub steps

the actions required to complete a step.

• Bullet points: Indicate sub-steps or points of interest, without implying order or relative importance.

Disclaimer: This manual is intended for use by trained, professional tech nicians.

• Common sense in operation and safety is assumed.

serious injury. This signal word is to be limited to the most extreme situations.

indicate specific things that should be done, and the order in which they should be done.

will be lettered and nested within steps. Two or more sub steps may be combined to describe

• In no event shall MTD be liable for poor text interpretation, or poor e xecution of the procedures described

in the text.

• If the person using this manual is uncomfortable with any procedures they encounter, they should seek

the help of a qualified technician.

1

Page 6

C and D series mowers

Safety

This Service Manual is meant to be used along with the Operator’s Manual. Read the Operator’s Manual and

familiarize yourself with the safety and operational instructions for the equipment being worked on. Keep a copy of

the Operator’s Manual for quick reference. Operato r’s manuals may be viewed for free at the br and support website.

It will be necessary to have the complete model and serial number for the equipment.

• Be prepared in case of emergency:

! CAUTION! CAUTION

! WARNING! WARNING

Keep a fire extinguisher nearby

Keep a first aid kit nearby

Keep emergency contact numbers handy

• Replace any missing or damaged safety labels on shop equipment.

• Replace any missing or damaged safety labels on equipment being serviced.

• Gro om in g an d at tire :

Do not wear loose fitting clothing that may become entangled in equipment.

Long hair should be secured to prevent entanglement in equipment.

Jewelry is best removed.

• Protective gear: includes, but is not limited to

Clear eye protection

Protective gloves

Armored footwear

Hearing protection

Chemically resistant gloves

Respirator

while working around any machinery

where necessary

when working around any machinery

when working in noisy environments

when working with chemicals or solvents

when working with chemical or solvents

! CAUTION! CAUTION

! DANGER! DANGER

2

Appropriate tinted eye protection

• Remember that some hazards have a cumulative effect. A single exposure may

cause little or no harm, but continual or repeated exposure may cause very serious harm.

• Clean spills and fix obviously dangerous conditions as soon as they are noticed.

• Lift and support heavy objects safely and securely.

• Be aware of your surroundings and potential hazards that are inherent to all

power equipment. All the labels in the world cannot protect a tech nician from a n

instant of carelessness.

Exhaust fumes from running engines contain carbon monoxide (CO). Carbon monoxide is a colorless odorless gas that is fatal if inhaled in sufficient quantity. Only run engines

in well ventilated areas. If running engines indoors, use an exhaust evacuation system with

adequate make-up air ventilated into the shop.

when cutting or welding

Page 7

Introduction

Fasteners

• The fasteners used on the equipment described in this manual, and the engine that powers it are a combination of metric and fractional inch. For this reason, wrench sizes are frequently identified in the text, and

measurements are given in U.S. and metric scales.

• If a fastener has a locking feature that has worn, replace the fastener or apply a small amount of releasable thread locking compound such as Loctite® 242 (blue).

• Some fasteners like cotter pins are single-use items that are not to be reused. Other fasteners such as

lock washers, retaining rings, and internal cotter pins (hairpin clips) may be reused if they do not show

signs of wear or damage. This manual leaves that decision to the judgement of the technician.

Assembly Instructions

• Torque specifications may be noted in the part of the text that covers assembly. They may be summarized in tables along with special instructions regarding locking or lubrication. Whichever method is more

appropriate will be used. In many cases, both will be used so that the manual is handy as a quick-reference guide as well as a step-by-step procedure guide that does not require the user to hunt for information.

• Lubricant quantity and specification may be noted in the part of the text that covers maintenance, and

again in the section that covers assembly. They may also be summarized in tables along with special

instructions. Whichever method is more appropriate will be used. In many cases, the information will be

found in several places in the manual so that the manual is handy as a quick-r eference g uide as we ll as a

step-by-step procedure guide that does not require the user to hunt for information.

• The level of assembly instructions provided will be determined by the complexity of reassembly, and by

the potential for damage or unsafe conditions to arise from mistakes made in assembly.

• Some instructions may refer to other parts of the manual for subsidiary procedures. This avoids repeating

the same procedure two or three times in the manual.

3

Page 8

C and D series mowers

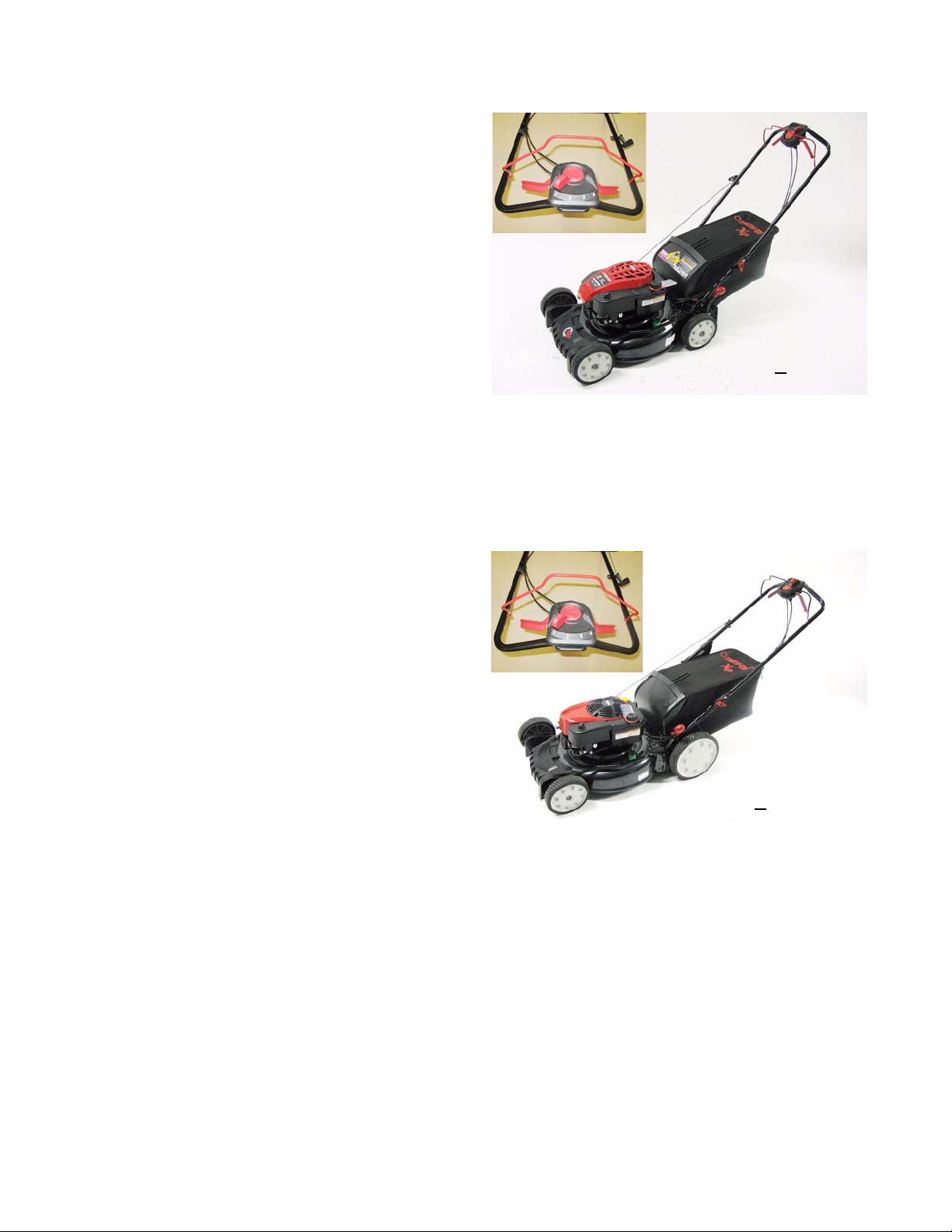

The “C” Series Mower

The “C” series mower is a 21” (53cm) platform introduced for the 2011 season. “C” series refers to the 5th

character in the model number. See Figure 1.1.

• Rear wheel drive with variable speed transmission.

• Drive co nt ro l for th e Troy-Bilt version is by a

unique two-lever clutch control with a 4-position

speed selector.

• The deck is designed to be used as a rear discharge, side discharge, or mulching mower,

easily reconfigured by the customer.

• Like the A and B series mowers, the wheels

and drive system of the C and D series mowers

are carried by plastic housings that mount to

the front and rear of the deck.

• A single lever sets mowing height.

• 8” (20cm) front wheels and rear wheels

Inset: bail, clutch,

speed control

Model: 12AKC

Figure 1.1

39B011

The “D” Series Mower

The “D” series mower is a high wheel version of the

“C” series mower. See Figure 1.2.

• Rear wheel drive with variable speed transmission.

• Drive co nt ro l for th e Troy-Bilt version is by a

unique two-lever clutch control with a 4-position

speed selector.

• The deck is designed to be used as a rear discharge, side discharge, or mulching mower,

easily reconfigured by the customer.

• Like the A and B series mowers, the wheels

and drive system of the C and D sereis mowers

are carried by plastic housings that mount to

the front and rear of the deck.

• A single lever sets mowing height.

• 8” (20cm) front wheels and 11” (28cm) rear wheels

The C and D series mowers used in this manual are branded “T roy-Bilt TB330XP” an d “T roy-Bilt TB350XP” . The

decks are grey with red controls and labels. They are powered by Briggs&Stratton 175cc OHV engines. These mowers may be built in a variety of brands powered by a variety of engines. When ordering parts, identify the mower by

the 11-digit model number and 11-digit serial number.

Inset: bail, clutch

speed control

Model: 12AKD39B011

Figure 1.2

NOTE: Use only the correct OEM parts when making repairs to the mower or its engine.

4

Page 9

Understanding Model and Serial Numbers

Figure 1.3

A sample model number of an “C” series mower is 12AKC39B011. See Figure 1.3.

The break down of what the model number

• 12 . . . . . . . . . . . . . . . . indicates that this is a self propelled mower

means is as follows:

Introduction

• . . .A . . . . . . . . . . . . . . indicates the sales revision

• . . . . . K . . . . . . . . . . . . indicates 4-speed varia ble drive with recoil start

• . . . . . . . C . . . . . . . . . indicates rear-wheel drive and wheel size

• . . . . . . . . . 3 . . . . . . . . indicates single lever height adjustment and grass discharge modes.

• . . . . . . . . . . 9B . . . . . . indicates the engine

• . . . . . . . . . . . . . . 011 . indicates the brand or retailer

The serial number is 1L210K30336. The serial number

• 1 . . . . . . . . . . . . . . . . . engineering level

• . L . . . . . . . . . . . . . . . . month of production (A= Jan. B= Feb. C= Mar. D= April...J = Dec.)

• . . 21 . . . . . . . . . . . . . . day of the month

• . . . . .0. . . . . . . . . . . . . last digit of the year, repeats every decade

• . . . . . . K . . . . . . . . . . . plant it was built in (K = Tupelo MS)

• . . . . . . . 3 . . . . . . . . . . assembly line number

• . . . . . . . . 0336 . . . . . . sequence number

Technical and service information is available to our company authorized service center personnel through our company corporate offices, regional p ar ts d istributors and region al service center field suppo rt person nel. Please cont act

the Central Service Distributor in your area or our cont act our corp orate of fices directly for furt her service informa tion.

reads as follows:

MTD Products LLC

P.O. Box 368022

Cleveland, OH 44136

Telephone: (800 ) 800-7310

www.mtdproducts.com

5

Page 10

C and D series mowers

Maintenance chart

Maintenance item Each use Each 25 hrs. use Each 50 hrs. use

Check engine oil

Check air filter

Check for loose/bent blade

Check & gap spark plug Replace if worn

Check cooling fins After prolonged storage

Check/clean spark arrestor

Change oil

Change air filter

Note on air filter Air filter and pre-filter life vary dramatically with operating conditions

Drain or preserve fuel Before prolonged storage

Fog or lube cylinder Before prolonged storage

Rotate engine to TDC Before prolonged storage

NOTE: Refer to the engine manufacturer’s manual #769-03354A for complete engine service information.

*

*

*

*

*

* and before prolonged storage

*

Fastener Tightening Torques

Description U.S. Measurement Metric

Blade Bolt 450-600 in-lb. 50-70 Nm

Wheel nuts 130-170 in-lb. 12-18 Nm

Height adjuster link shoulder screws 45-50 in-lb. 6-7 Nm

Front axle retainers 40-50 in-lb. 3.5-4.5 Nm

Front axle cover 30-40 in-lb. 3.5-4.5 Nm

Rear baffle 30-40 in-lb. 3.5-4.5 Nm

Rear axle lower bracket 30-40 in-lb. 3.5-4.5 Nm

Transmission input pulley nut 100-160 in-lb. 12-18 Nm

Engine mount bolts 20-25 ft-lb. 28-34 Nm

Transmission cover bolts 15-20 in-lb 1-2 Nm

Lower belt cover bolts 45-50 in-lb. 6-7 Nm

Deckwash bolt 45-50 in-lb. 6-7 Nm

6

Page 11

Blade and Belt

CHAPTER 2: BLADE AND BELT

Blades

The condition of the blades will greatly effect the quality of the cut.

The blades should be sharpened and balanced after every 10 hours of cutting , or when a ch ange in cut quality or

performance is noticable. Inspect the blade every couple hours o f use. Blade sharpen ing needs var y with local conditions. A dull blade tears the grass instead of cutting it. Torn grass blades leaves a rough look and makes the grass

vulnerable to diseases.

Blades need to be examined for damage before sharpening. Blades must be balanced after sharpening to

reduce the vibrations felt from the deck.

Bent blades are a sign of a blade impact. The blades must be replaced and the engine inspected for a bent

crankshaft if a bent blade is found. A bent blade or a bent crankshaft will cause other damage to the mower. A typical

customer complaint would be that part s are vibr ating an d falling-off the mower. In extreme cases, when the mower is

run with a bent blade or crankshaft, the engine can tear loose from the deck.

! CA UTION! CA UTION

Do not attempt to straighten a bent blade or crankshaft. The bent p art must be rep laced. In the case of the crankshaft, solutions include, replacing the crankshaft, replacing the short block, replacing the complete engine, or replacing the mower.

! CA UTION! CA UTION

Bent blades and bent crankshafts are seldom warrantable damage.

Blades come in a variety of styles; side discharge, mulching, bagging, combination, there are even de-thatching

blades on the market. The C and D Series mowers come equipped with a 3-in-1 blade from the factory. The outer

part of the leading edge cuts the grass. A wing on the back edge lif ts the grass for the next blade and propels clippings toward the bag or side discharge chute if the path to either is open. A stepped-up cutting edge just in-board of

the outer cutting edge mulches clippings as they fall, if the side and/or rear discharge chute(s) are closed and the

mulch plug is in place.

The air flow in the cutting deck is generated by the spinning blade. If the blade is mounted upside down, the air

flow will be reversed pushing the grass down instead of standing up.

NOTE: Blades that are mounted upside down increase the risk of impact damage.

Running a mower with a bent blade will cause damage to the mower and can create a thrown

object hazard. As soon as damage or vibration is noted, the mo wer sh ould b e t a ken out of service until the problem is repaired.

Straightening a be nt blade or crankshaf t incr eases the damage to the met al. This can create a

thrown object hazard.

! CA UTION! CA UTION

An incorrect or improperly mounted blade can create a thrown object hazard.

7

Page 12

C and D series mowers

Blade Removal

To remove the cutting blade:

Before tipping the mower to work on it, make sure it will not start unexpectedly, spill

! WARNING! WARNING

fuel, or create a burn hazard. The engine should be cool, the fuel tank should be

empty or nearly empty, and the ignition system should be fully disabled.

1. Make the mower safe to tip-up.

1a. Allow the engine to cool if it has been run

recently.

1b. Drain the fuel tank to a level that will prevent

spillage.

1c. Disconnect and ground the spark plug wire.

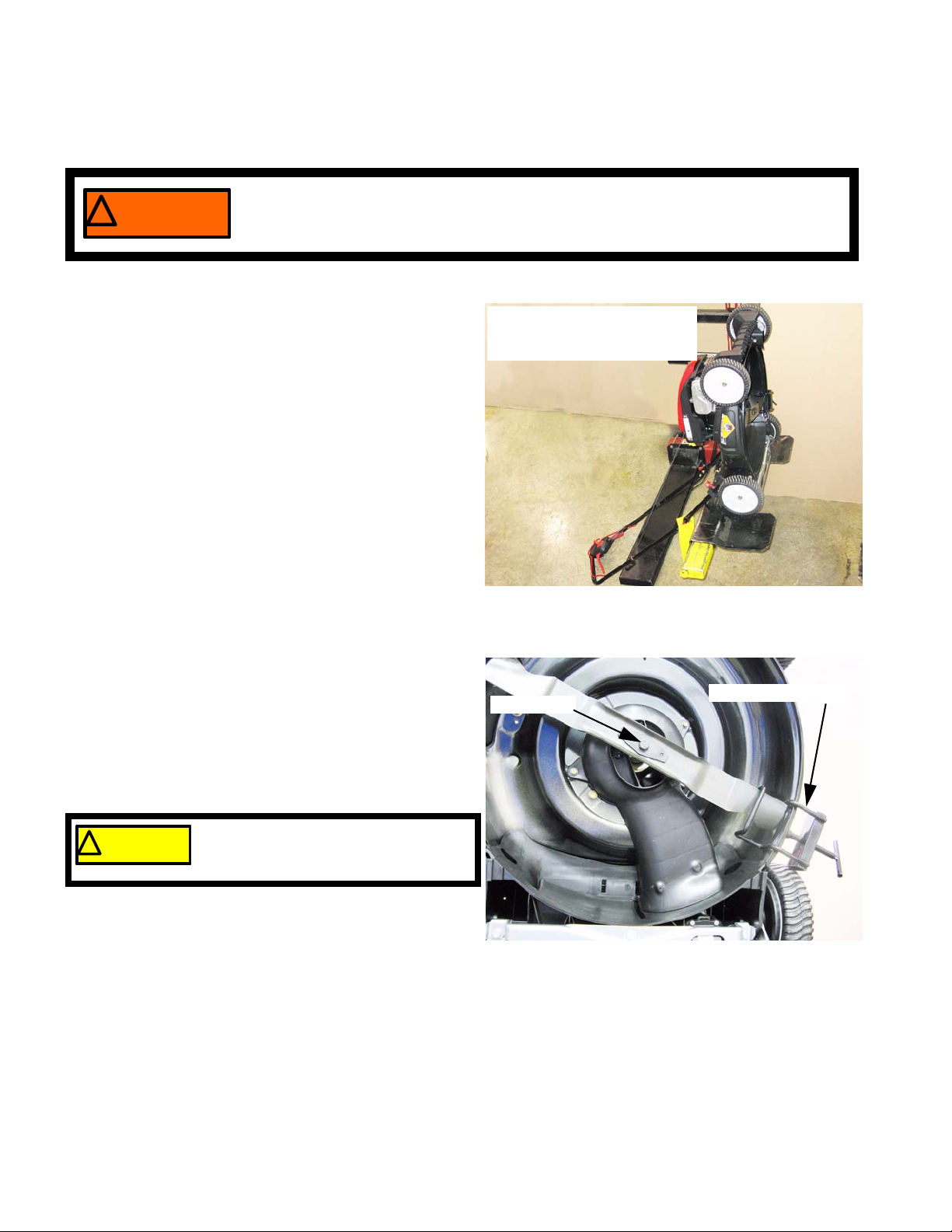

2. Tip the mower with the muffler side down, or tilt the

mower back on a lift or workbench. Secure the

mower safely so that it will not fall. See Figure 2.1.

3. Block the blade from rotating using a block of wood

or a blade holder tool.

NOTE: MTD blade holding tool, part number 490-

850-0005, can be used block the blade.

See Figure 2.2.

Mower secured in vertical

position on a lift provides

easy access under the deck.

Figure 2.1

Blade bolt

Blade holding tool

4. Remove the blade bolt and diamond-shaped

Belleville blade spring using a 5/8” wrench.

Use care around the blade while

! CA UTION! CA UTION

8

removing or tightening the bolt. The

blade can spin and cause injury.

Figure 2.2

Page 13

Blade and Belt

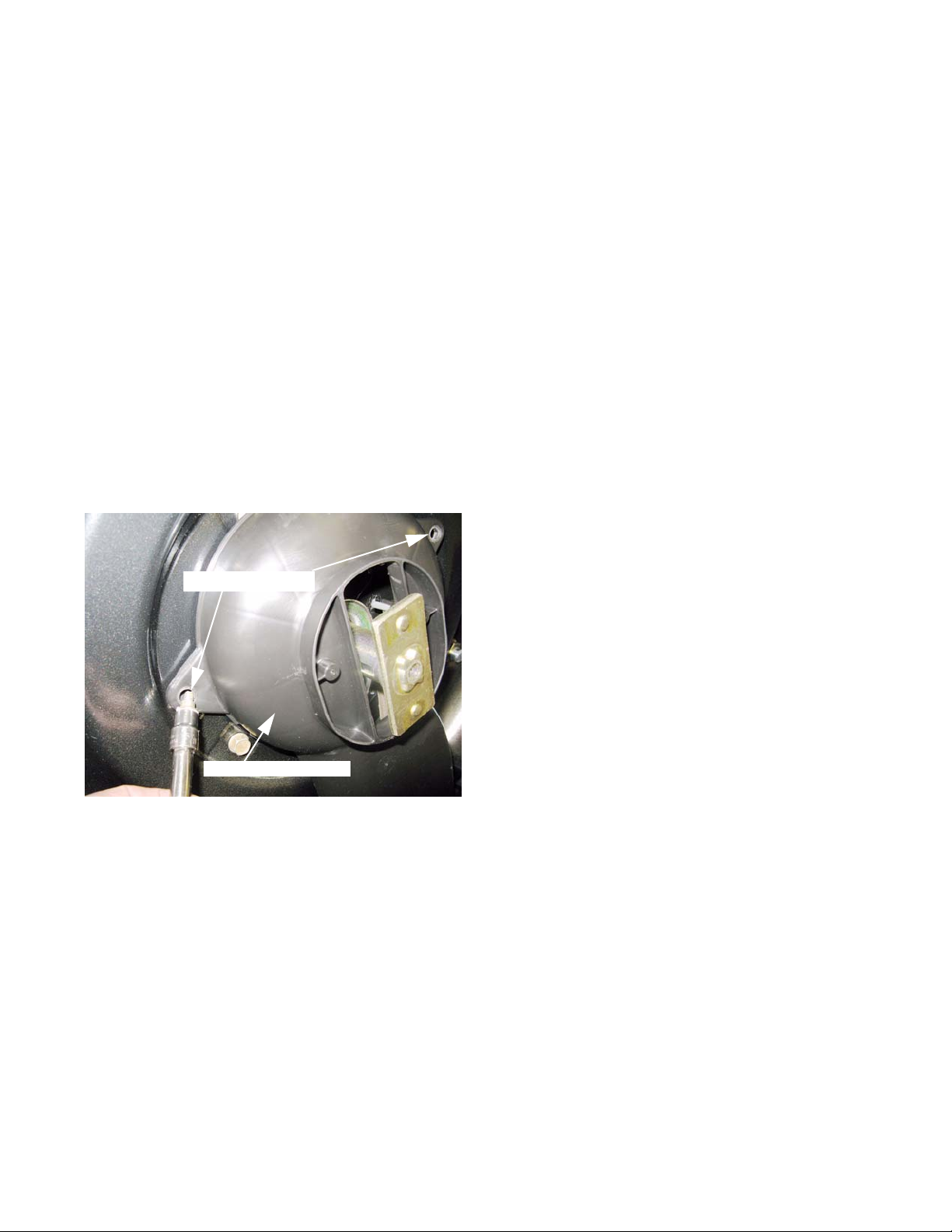

Bowtie feature

Drive pins

Figure 2.3

8. Check the blade adapter, crankshaft and hardware for damage: See Figure 2.3.

• The end of the crankshaft should not wobble or orbit when the crankshaft is rotated.

• The key in the blade adaptor and the keyway in the crankshaft should engage firmly. The blade adaptor

should not spin on the crankshaft.

• The bowtie-shaped boss and embossed pins on the blade adaptor should not be deformed. Corresponding holes in the blade should match the blade adaptor and fit securely over the bosses (drive features) on

the blade adaptor.

Blade adaptor

Blade

Bellville spring

Blade bolt

5. Lift away the blade.

6. Inspect the blade. If it is bent or worn beyond proper

sharpening, replace it with a new blade.

7. Sharpen and balance the blade if it is not badly worn.

NOTE: If the customer complains of vibration or parts fall-

ing off, or if the mower is showing signs of vibr ation

fatigue damage, there is reason to suspect a bent

blade and/or bent crankshaft.

• The blade bolt should not be damaged, and the bellville spring that fits between the bolt head and the

blade should still have tension.

9. Install the blade with the blade adapter and Belleville

450-600in.-lb.

Figure 2.4

11. Put the mower back in its normal operating position, and insure that it is safe to operate.

12. Test-run the mower in a safe place. Do not put an unsafe mower back into service.

spring washer properly positioned: See Figure 2.4.

• The part number and the word “BOTTOM” should

face the ground when the mower is in its normal

operating position.

• The wings at the ends of the blade should point up,

into the deck shell.

• The lips on the center span of the blade should curve

down, away from the blade adaptor

NOTE: Aftermarket blades in non MTD brands or Arnold

brand may not have the correct shape drive feature, and may not meet safety requirements for

thrown objects.

10. Tighten the blade bolt to a torque of 450-600 in.-lb.

(50-70 Nm).

9

Page 14

C and D series mowers

Blade Sharpening

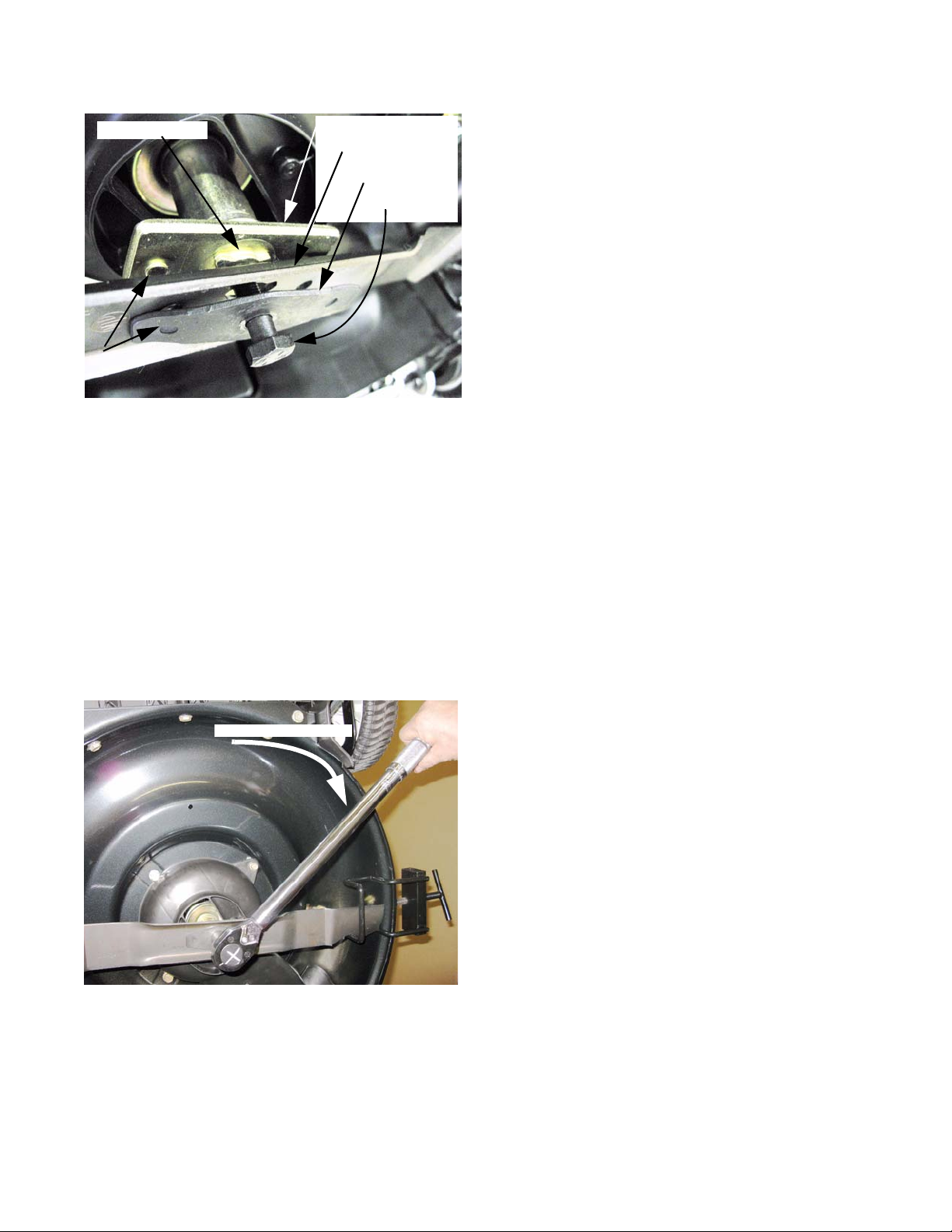

Use proper safety equipment when sharpening blades: wear eye protection and keep all

! CA UTION! CA UTION

1. Determine if the blade is too worn to sharpen:

• The minimum width of the blade at its narrowest point should be no less than 1-5/8”

(4.1275cm).

• There should be no bending, metal separation,

or obvious physical damage.

• The wings should still have a square trailing

edge that is 50% of the thickness of the original

blank (blade stock).

• There should be no damage to the drive feature.

2. To sharpen the cutting blades: See Figure 2.5.

• Dress the original bevel of the cutting edge.

• Do not sharpen the bottom edge of the blade,

and do not extend the bevel beyond the length

of the original cutting edge.

guards in place on the grinder used for sharpening.

Blade sharpening

on a bench grinder

Figure 2.5

• Remove equal amounts of metal from both ends

of the blade, maintaining the original 29° to 32°

angle.

3. Balance the blade after sharpening: dress the edge of

whichever end of the blade is heavier until the blade

stays level on the balancer. See Figure 2.6.

A poorly balanced blade will cause

! CA UTION! CA UTION

NOTE: MTD blade balancer AR-SBB-102 or the

excessive vibration and may cause

damage to the mower and result in

personal injury.

blade balancing kit, AR-BSK-1 can be used to

balance the blade.

Blade balancing:

NOTE: the blade is positioned upsidedown for better fit on the balancer

Figure 2.6

10

Page 15

Blade and Belt

Belt Removal

The traction drive clutch and ground speed are co ntrolled by two cables on the C & D series mowe rs. The clutch

cable tilts the transmission back, tightening the drive belt. When the belt is tight ened , it drive s the input pulle y on the

transmission. The second cable moves a cam that clo ses t he sheaves of the pulley, changing the effective circumference of the pulley, and changing the drive ratio.

NOTE: Use only the correct OEM part number belt.

• A belt that is too long may not engage fully and may not provide the full range of speeds, losing top speed.

• A belt that is too short may not disengage fully, and may drive the transmission even when the clutch lever

is released.

• A belt that does not have the same profile or wrapping may not perform as intended.

• The belts used on the C & D series mowers come from various belt manufacturers, but are made to MTD

specifications. These specifications are tailored to the mower design, and seldom work-out to standard

belt lengths. If MTD went to the trouble and expense of designing a belt for the application, there is a reason they did so.

NOTE: If the belt has broken prematurely, identify and correct the cause of the failure before returning the

mower to service.

Shoulder screws

Lower belt cover

Figure 2.7

1. Confirm that the mower is set to its lowest ground

speed position, indicated by a 1 at the speed control

on the handlebar.

2. Remove the blad e by following the steps describe d in

the blade section of this chapter.

3. Rotate the crankshaft to align the blade adaptor to

the opening in the lower belt cover.

4. Remove the two shoulder screws that hold the lower

belt cover to the deck. See Figure 2.7.

5. Remove the lower belt cover.

11

Page 16

C and D series mowers

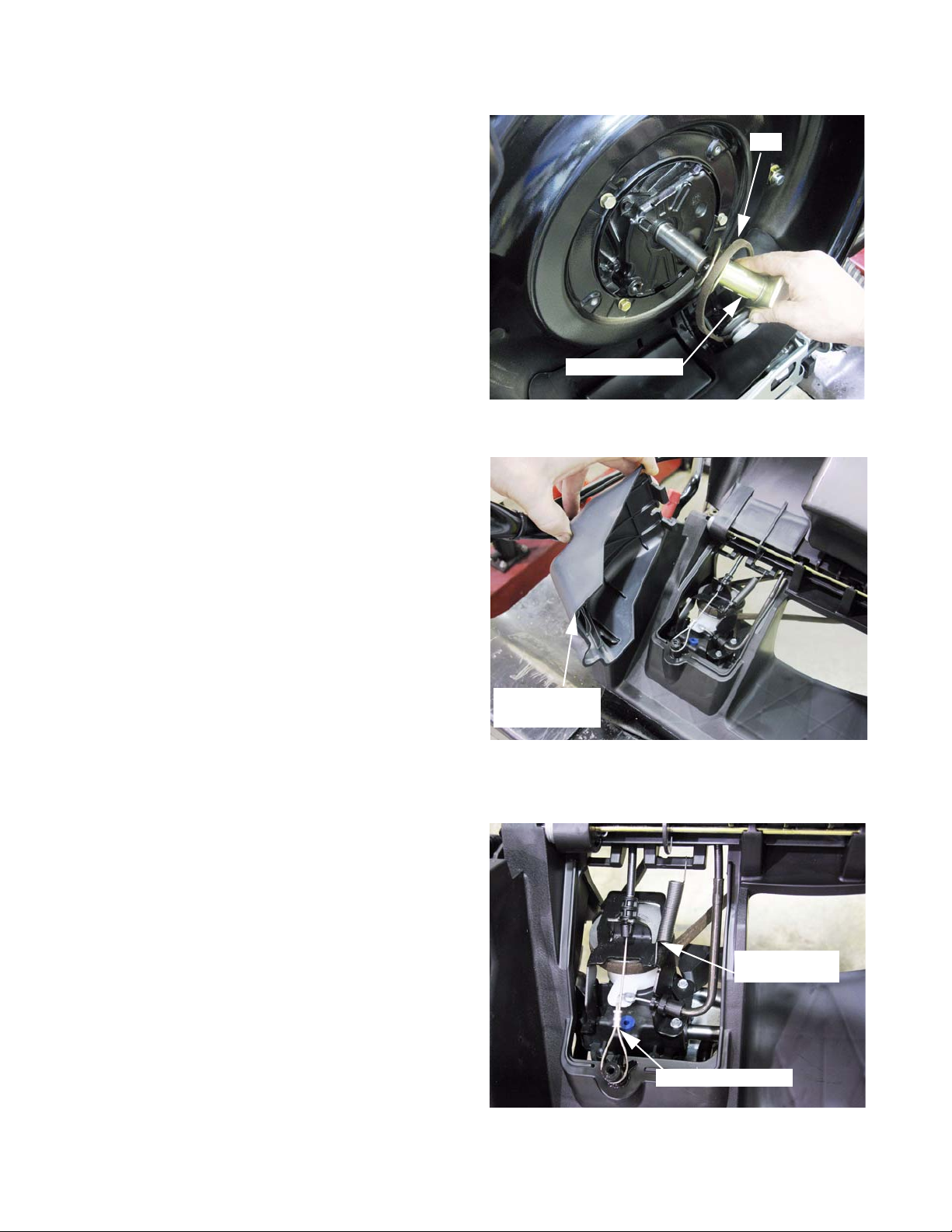

6. Slide the blade adaptor / drive pulley off of the

crankshaft. The belt will come off with it.

See Figure 2.8.

7. At the back of the mower, lift the rear grass door to

reveal the upper belt cover. Secure the grass door

with a prop or a strap.

8. Remove the screw that secures the upper belt

cover. Tilt the back of the cover up, and draw the

cover back to release the tabs that locate the front

edge of the cover.

Belt

Blade adaptor

Figure 2.8

9. Lift the transmission cover off of the mower.

See Figure 2.9.

10. Unhook the loop in the drive clutch cable from the

post that the upper belt cover screw goes into.

11. Unhook the clutch release spring from the brackets

that hold it, and remove it from the mower.

See Figure 2.10.

Transmission

cover

Figure 2.9

Clutch

release spring

Drive clutch cable

12

Figure 2.10

Page 17

Blade and Belt

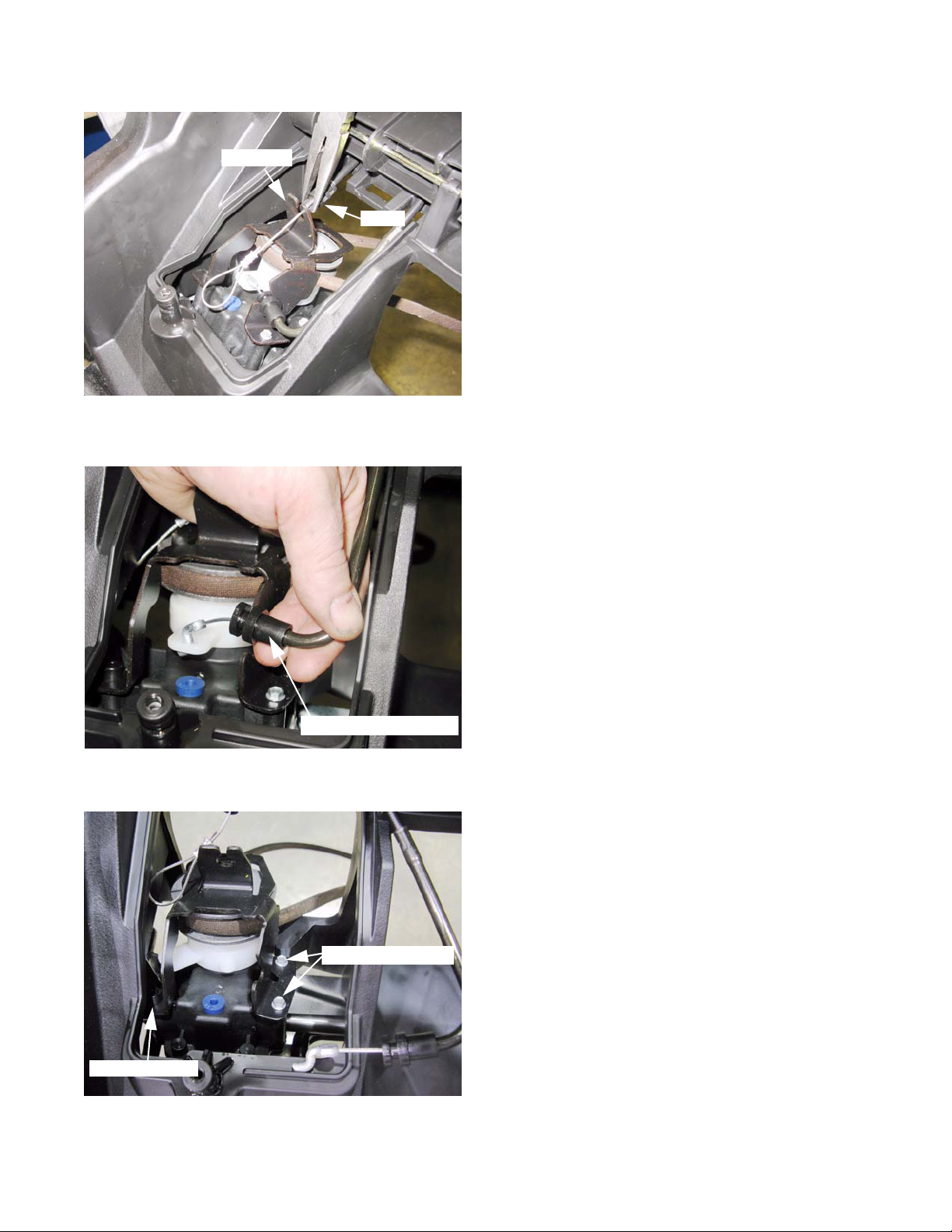

Bracket

Figure 2.11

Barb

NOTE: It is not strictly necessary to disconnect the cables,

but doing so will make alignment and installation of

the belt keeper / bracket easier during reassembly.

12. Squeeze the barb on the bottom end of th e dr ive

clutch cable to release it from its bracket.

See Figure 2.11.

13. Pry the curved end of the speed control cable housing out of its bracket, and unhook the Z-fitting from

the arm on the speed control cam. See Figure 2.12.

Locating post

Speed control cable

Figure 2.12

14. Remove the two screws that hold the combination

belt keeper / cable bracket to the transmission using

a 1/4” wrench. See Figure 2.13.

NOTE: There is a locating post on the side of the bracket

that is opposite the two screws.

Mounting screws

Figure 2.13

13

Page 18

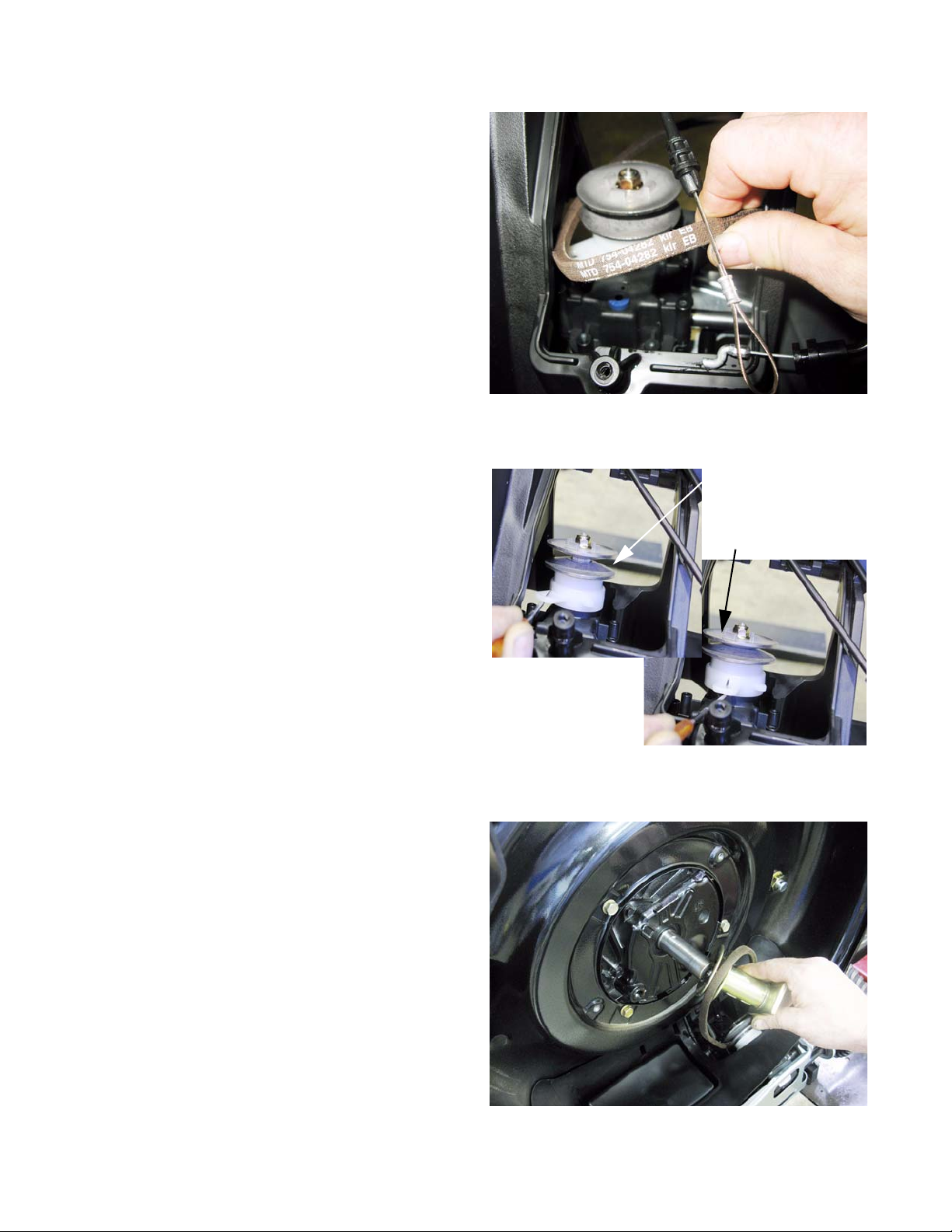

C and D series mowers

15. Work the belt off of the transmission pulley and

remove it from the mower. See Figure 2.14.

16. Check the belt, pulleys, and cables for any problems

that might cause premature belt failu r e:

• Work the drive clutch control and check the

cable for full travel and smooth operation.

• Work the speed control, and check the cable for

full travel and smooth operation.

• Check the pulley sheaves for signs of belt slippage like polished contact surfaces or belt

debris / dust.

• Look for signs that foreign objects may have

damaged the belt.

17. Work the speed control cam through its full range of

travel to confirm that it move freely. See Figure 2.15.

18. Repair any problems that will damage the new belt.

Belt Replacement

1. Put the new belt onto the transmission pulley,

extending the belt toward the crankshaft.

Figure 2.14

Sheaves spread:

high speed

Sheaves together:

low speed

Figure 2.15

2. Slip the belt into the pulley on the blade adaptor,

then slide the blade adaptor onto the crankshaft .

See Figure 2.16.

3. Install the blade adaptor/pulley onto the crankshaft.

14

Figure 2.16

Page 19

Blade and Belt

Left leg

Locating post

4. Position and attach the belt keeper / bracket to the

transmission. See Figure 2.17.

• The left leg of the bracket locates over a post on the

transmission housing.

• The right leg of the bracket is secured with two

screws that go into the plastic transmission housing.

• Do not over tighten the screws.

Right leg

Figure 2.17

5. Reinstall the clutch control cable, the ground speed

control cable, and the clutch release spring.

See Figure 2.18.

6. Rock the transmission back, or squeeze the clutch

lever to tighten the belt.

Figure 2.18

Figure 2.19

Cables and spring

reinstalled

7.Install the lower belt cover, being careful to route the belt

inside of all four metal belt guide pins that are molded into

the cover. See Figu re 2.19.

Belt guide pins

Belt guide pins

Lower belt cover

Figure 2.20

15

Page 20

C and D series mowers

8. Install the blade, and tighten the blade bolt to a torque of 450-600 in.-lb. (50-70 N-m)

9. Check the operation of the new belt:

See Figure 2.21.

9a. With the spark plug still disconnected, support

the rear of the mower so that the wheels are

off the ground, while the front wheels rest on

the ground.

9b. Operate the drive clutch to confirm that the

transmission rocks back to engage the drive

belt, then rocks forward to de-clutch the drive

belt when the clutch control is released.

9c. Use your left hand to hold the safety bail and

drive clutch lever. Pull the recoil rope with

your right hand, and move the speed control

lever through its full range of travel using your

left thumb. The speed cam should open and

close the sheave on the transmission pulley

in response to the speed control input.

NOTE: The sheave will open when the transmission pulley is stationary, moving from a speed drive ratio to a

power drive ratio (from 1 to 4 on the speed selector). The belt and transmission pulley must be rotating

for the sheave to close without placing undue stress on the speed control cam.

Figure 2.21

10. Install the transmission cover and test run the

mower in a safe area. See Figure 2.22.

10a. Test all operational and safety features before

returning the mower to service.

10b. Adjust the thumb roller on the bottom side of

the speed control assembly to set the correct

belt tension.

• Rolling the adjuster toward the front of the

mower will increase belt tension. There is an

embossed arrow pointing in this direction, adjacent to the roller.

• Rolling the adjuster toward the rear of the

mower will decrease belt tension.

• Too Tight: If the speed control lever jumps

from Speed #4 to Speed #3, or from Speed #3

to Speed #2, when the drive clutch lever is

engaged with the engine running, the belt tension is too high.

• Too Tight: If the mower wa nts to “creep ” when the speed control lever is in Speed #4 and the drive clutch

lever is not squeezed, the belt tension is too tight. If rolling the adjuster toward the rear of the mower does

not stop the creeping, further investigation is required.

• Too Loose: If the mower does not have sufficien t drive force to spin it s wheels on smooth concrete (not a

broomed or florette surface) with the drive clutch engaged, and the speed control lever set for Speed #1,

the belt tension is too low, and the adjuster should be rolled toward the front of the mower to tighten the

belt.

Figure 2.22

16

Page 21

Blade and Belt

CHAPTER 3: CONTROLS AND CABLES

Engine Control Cable

The engine control cable operates the engine brake. When the bail is pulled against the handle bar, the engine

control cable pulls the engine brake pad away from the flywheel releasing the brake.

The engine brake has an ignition switch built into it. When the brake is engaged, the ignition switch shorts the

ignition module to ground. This turns off the ignition, stopping the engine.

Safety bail

Figure 3.1

Engine speed

measured with

a tachometer

To check the operation of the engine control Cable:

1. Start the engine, and confirm that it operates at the

correct engine RPM to keep the blade tip speed as

near as possible to 19,000 ft./minute (5,790 meters/

minute) without going over. See Figure 3.1.

NOTE: For 21” (53.3cm.) mowers, that limit is 3,45 8 RPM.

Staying safely below that limit, MTD specs the

engines on the C and D series mowers to run at

3,200 +

2. If the engine speed is substantially under 3,200 or at

all over 3,200 RPM, adjust the engine speed according to the engine manufacturer’s instructions.

3. Release the safety bail, and check the amount of

time it takes for the blade to stop rotating.

NOTE: The CSPC Code of Federal Regulations #16, part

1205 dictates that the blade should stop rotating

within 3 seconds of releasing the safety bail.

4. If the blade does not stop within 3 seconds, check

the operation of the cable. See Figure 3.2.

• If the cable moves freely throughout its full range of

travel, the problem lies in the engine. Repair the

engine stop-switch or brake according to the engine

manufacturer’s instructions.

100 RPM.

Figure 3.2

Control cable-

• If the cable does not move freely throughout its full

range of travel, disconnect the cable from the bail to

confirm where the source of the bind is. The cable is

more vunerable than the bail.

5. Isolate the bail from the cable following the instructions for removing the bail and cable from the mower.

17

Page 22

C and D series mowers

To Remove / Replace the Engine Control Cable:

1. Make sure the engine is off and cool enough to

safely work around.

2. Squeeze the side of the bail that the cable attaches

to inward.

3. When the end of the bail clears the hole in the handlebar that it pivots in, move the bail away from the

hole and release the pressure. See Figure 3.3.

4. Unhook the Z-fitting from the safety bail.

NOTE: The opposite side of the bail has a 180

bend in it, so that it hooks into the handlebar.

5. If the safety bail is to be removed: After the z-fitting

is unhooked, pivot the bail upwards to release the

hooked end from the right side of the handlebar.

See Figure 3.4.

0

Z-fitting

Figure 3.3

6. Pry the cable clip off of the handlebar.

See Figure 3.5.

180 deg. bend in bail

Figure 3.4

Cable clip

Cable

Hook Tool

18

Figure 3.5

Page 23

Blade and Belt

7. Use the slack created in the cable to relea se the Z-fitting from the engine stop control on the engine.

See Figure 3.6.

Barb

Slack

Figure 3.6

Z-Fitting

8. Use a pair of needle nose pliers to squeeze the barb

at the engine end of the cable housing, releasing it

from the the bracket on the engine.

9. To install the new cable, reverse the steps used to

remove the old one.

10. Test run the mower in a safe place, and check all of

the mower’s safety features before returning it to service. Do not return an unsafe mower to service.

Drive Control Housing Assembly

Speed control

Drive clutch levers

Figure 3.7

Description: The drive control housing on the C and D

Series mowers is unique in that it has two drive clutch

levers and a 4-position speed control lever. The two clutch

levers allow operation with either hand. See Figure 3.7.

The operational description will be broken by function:

• Clutch Engagement

• Speed control

The operational descriptions are followed by detailed disassembly/reassembly instructions.

19

Page 24

C and D series mowers

Clutch engagement:

• Within the housing, the two levers cross one

another. See Figure 3.8.

• A secondary lever pivots on the same fulcrum

as the right-hand side control lever.

• A post on the secondary lever extends into the

travel path of both control levers, so that the

movement of either control lever will move the

secondary lever.

• Clutch cable travel is controlled by the thumb

knob at the top end of the clutch control cable

housing.

• The clutch operates by tipping the transmission

back so that the pulley is drawn into the belt.

See Figure 3.9.

• The var i able sp ee d me ch a nis m wo rks by

spreading or closing the sheaves of the input

pulley on the transmission. This changes the

effective circumference of the pulley, but also

changes the length of the belt’s path of travel.

• This change in the path of travel changes the

amount of tension on the belt.

Left-hand

side clutch

control lever

Thumb knob

Variable

speed pulley

Control housing, upside down

Secondary lever

Right-hand

side clutch

control lever

Figure 3.8

Drive speed

control cable

• To compensate for variations in belt clutching

tension across the range of ground speed

selections, the bracket that holds the top of the

clutch cable moves in coordination with the

speed control lever.

Drive Control Housing Removal and Disassembly

1. Remove the large wing nuts on the carriage bolts

that fasten the upper handlebars to the lower handlebars. See Figure 3.10.

2. Fold the handlebars forward to provide access to

the bottom of the drive control housing.

3. Position the mower so that the length of the cables

will allow the control housing to be placed on a suitable work surface.

Clutch control cable

Figure 3.9

Fold handles to provide easy

access to the bottom of the

control housing.

20

Figure 3.10

Page 25

Blade and Belt

Shoulder screws

Top half of control

housing

Screws

4. The control housin g is held together and fastened to

the upper handlebar by four screws.

5. Remove all four screws using a 3/8” wrench. The

shoulder screws go through the handlebar.

See Figure 3.11.

6. Carefully separ ate the two h alves of the control housing just enough to allow the housing to be removed

from the handlebar.

Figure 3.11

7. Move the control housing to the workbench, and

carefully separate the bottom half of the housing from

the top half of the housing. See Figure 3.12 .

Clutch control cable

Figure 3.12

Bottom half of

control housing

Secondary lever

8. Lift the secondary lever off of the fulcrum post that it

shares with the leftt-hand side control lever.

See Figure 3.13.

9. Slip the cable-end barrel out of the hole in the secondary lever.

NOTE: The levers are embossed with indications of their

position and order of assembly into the control

box. The first parts removed would be the last

parts installed.

• The ribbed side of the secondary lever is embossed

“UP3”.

Figure 3.13

• The next visible surface after the secondary lever is

removed is the top of the left hand side control lever,

embossed “UP2”.

• The right hand side control lever is embossed “UP1”.

21

Page 26

C and D series mowers

10. Lift the right-hand side “UP2” control lever off of the

tall fulcrum post and out of the control housing.

See Figure 3.14.

11. Lift the right-hand side “UP1” control lever off of the

short fulcrum post and out of the control housing.

See Figure 3.15.

Tall post

UP 1

r

Figure 3.14

r

UP 2

Short post

12. Use a pair of needle nose pliers to compress and

remove the detent spring from the speed control

actuator. See Figure 3.16.

NOTE: DO NOT over compress the spring.

Squeeze it only as tight as is necessary to

remove it.

NOTE: Some early production 2011 mowers may

have a small flat washer tucked between the

flat end of the detent spring and the edge of

the control housing. This is intentional.

Washer

Figure 3.15

r

Speed

control

actuator

Detent spring

Figure 3.16

22

Page 27

Blade and Belt

Speed

control

actuator

Speed

control

cable

r

Figure 3.17

r

13. Lift the flanged end of the speed control cable out of

its pocket in the control housing. See Figure 3.17.

14. Pivot the cable to align with the slot in the speed control actuator,and separate the cable-end barrel from

the actuator.

15. Use two small straight-blade screwdrivers to release

the speed fcontrol actuator from the speed control

lever. See Figure 3.18.

NOTE: This is most easily done with the speed control

lever fixed in a bench vise. Use padding to prevent

damage to the lever.

Clutch cable

bracket

Speed control

lever

Figure 3.18

r

Figure 3.19

16. Lift the speed control actuator out of the drive control

housing. See Figure 3.19.

NOTE: The two slots that the lock tabs pass through to

fasten the actuator to the lever are different

lengths. This makes it impossible to attach the

actuator to the lever in the wrong direction.

17. At this point, the clutch cable bracket and the speed

control lever can be separated from the drive control

housing.

23

Page 28

C and D series mowers

Reasembly notes:

18. The pinion gear on the speed control lever must be

centered in the rack that moves the clutch cable

bracket. See Figure 3.20.

• As the speed control lever pivots the actuator in

one direction, the clutch cable bracket moves in

the opposite direction.

• The actuator draws the speed control cable in,

closing the sheave on the transmission pulley.

- AND-

• The clutch bracket eases the clutch cable tension to counter-act the tightening of the belt that

results from the growth of the circumference of

the pulley.

19. Reassemble the drive control housing by reversing

the process of disassembling it.

20. Carefully slip the housing back over the handlebars, and secure it with the four screws.

21. Test run the mower in a safe place before returning it to service.

21a. Check all safety features.

21b. Test the speed control mechanism while the engine is running, to make sure the full range of speeds is

available.

Clutch cable

bracket

Rack teeth

Speed

control lever

r

Figure 3.20

21c. Adjust the thumb roller on the bottom side of

the speed control assembly to set the correct

belt tension.

• Rolling the adjuster toward the front of the

mower will increase belt tension. There is an

embossed arrow pointing in this direction , adjacent to the roller.

• Rolling the adjuster toward the rear of the

mower will decrease belt tension.

• Too Tight: If the speed control lever jumps

from Speed #4 to Speed #3, or from Speed #3

to Speed #2, when the drive clutch lever is

engaged with the engine running, the belt tension is too high.

• Too Tight: If the mower wants to “creep” when

the speed control lever is in Speed #4 and the

drive clutch lever is not squeezed, the belt tension is too tight. If rolling the adjuster toward the rear of the

mower does not stop the creeping, further investigation is required.

• Too Loose: If the mower does not have sufficien t drive force to spin it s wheels on smooth concrete (not a

broomed or florette surface) with the drive clutch engaged, and the speed control lever set for Speed #1,

the belt tension is too low, and the adjsuter should be rolled toward the front of the mower to tighten the

belt.

Clutch tension adjuster

Handle folded-up for service access

r

Figure 3.21

24

Page 29

Drive Clutch Control Cable Removal and Replacement:

Blade and Belt

r

transmission

cover

Figure 3.22

r

et

Barb/

Bracket

1. Disconnect the top (adjustable) end of the clutch control cable. Use the instructions in the Drive Control

Housing section of this chapter.

2. With the grass collector bag removed, lift the grass

door at the back of the mower, and secure it with a

prop or a strap.

3. Remove the transmission cover using a 3/8” wrench.

See Figure 3.22.

4. Unhook the loop at the lower end of the cable from

the post that the belt cover screw goes into.

See Figure 3.23.

5. Squeeze the barb on the end of the cable housing to

release it from the belt keeper/bracket above the

transmission.

Figure 3.23

r

Drive clutch cable

Figure 3.24

Loop

6. Lower the grass door.

7. Draw the lower end of th e clutch control cable out of

the opening between the grass door and the rear

edge of the deck. See Figure 3.24.

NOTE: The outboard cable is the clutch cable.

8. Install the new cable by reversing the steps used to

remove the cable.

9. Run and test the mower in a safe place before

returniong it to service.

9a. Check all safety features.

9b. Test the speed control mechanism while the

engine is running, to make sure the full range

of speeds is available.

9c. Adjust the thumb roller on the bottom side of

the speed control assembly as described in

the drive control housing assembly section of

this chapter.

25

Page 30

C and D series mowers

Drive Speed Control Cable Removal and Replacement:

1. Disconnect the top (adjustable) end of the clutch

control cable. Use the instructions in the Drive Control Housing section of this chapter.

2. With the grass collector bag removed, lift the grass

door at the back of the mower, and secure it with a

prop or a strap.

3. Remove the transmission cover using a 3/8” wrench.

See Figure 3.25.

r

Transmission

cover

Figure 3.25

4. Carefully pry the L-shaped speed control cable

housing out of the belt keeper / bracket at the back

of the transmisssion. See Figure 3.26.

5. Manuever the cable to release the Z-fitting that connects the cable to the speed control cam that

moves the lower sheave of the variable speed pulley.

6. Lower the grass door.

7. Draw the lower end of the clutch control cable ou t of

the opening between the grass door and the re ar

edge of the deck. See Figure 3.27.

NOTE: The inboard cable is the speed control

cable.

8. Install the new cable by reversing the steps used to

remove the cable.

9. Set the speed control for position #4, leaving maximum slack in the cable.

r

Z-Fitting

Speed

control cable

Figure 3.26

r

Speed control cable

10. Run and test the mower in a safe place befor e

returning it to service.

10a. Check all safety features.

10b. Test the speed control mechanism while the

engine is running, to make sure the full range

of speeds is available.

10c. Adjust the thumb roller on the bottom side of

the speed control assembly as described in

the drive control housing assembly section of this chapter.

26

Figure 3.27

Page 31

Trail Shield

! CA UTION! CA UTION

Deck and Transmission

CHAPTER 4: DECK AND TRANSMISSION

Never operate a mower without the trail shield. It is a safety device that is required by law.

The trail shield is designed to drag on the ground behind the mower. This helps keep the oper-

ator from getting their feet under the mowing deck.

To remove and replace a trail shield:

1. Disconnect and ground the spark plug wire to prevent

accidental starting of the engine.

2. Lift and safely support the back of the mower. It

should be far enough up to allow convenient reach

under the rear of the mower deck.

3. Fold-back the oute r edges of the trail shield, so that it

can be pivoted forward. See Figure 4.1.

Trail Shield

Mounting post

Tongue

Figure 4.1

Groove

Figure 4.2

NOTE: The trail shield mounts to the r ear baf fle. The Term

“rear baffle” on this mower reffers to the rear structure that carries the wheels, transmission, handlebars, trail shield, and rear grass door.

4. Align the tong ues on the mounting post s at each end

of the trail shield with the grooves in the trail shield

mounting recess on the rear baffle.

See Figure 4.2.

5. Pull down on the trial shield, bowing it until the

mounting posts can be withdrawn from the mounting

recesses in the rear baffle.

6. Install the trail shield by reversing the steps used to

remove it.

7. Test run the mower in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

27

Page 32

C and D series mowers

Side Discharge Door / Mulch Plug

Never operate a mower without the side discharge door properly in-place. It is a safety device

! CA UTION! CA UTION

ing mode, it keeps clippings under the deck. In side discharge mode it locks the side discharge chute

securely in place.

1. The combination side discharge door and mulch

plug is spring loaded so that it stays firmly in place.

2. Repair it if: See Figure 4.3.

• The safety label has become illegible.

• The discharge door is damaged so that it does

not contain clippings and light yard debris to the

underside of the deck.

• The discharge door, its spring, or hinge mechanism do not cause it to properly close or secure

the side discharge chute.

that is required by law.

The side discharge door is designed to contain grass clippings and light yard debris. In mulch-

NOTE: The side discharge doors that are sold as

service parts will include the bracket, hinge

pin, and torsion spring. The bracket, pin,

and spring are available separately, but the

door will typically be replaced as an assembly.

3. Disconnect and ground the spark plug wire to prevent accidental starting of the engine.

4. To remove the side discharge door assembly from

the deck, remove the single screw that fastens the

hinge from beneath the deck using a 3/8” wrench.

See Figure 4.4.

Figure 4.3

Hinge

Screw

Figure 4.4

28

Page 33

Withdraw pin

Figure 4.5

Question-mark

shaped tail

Deck and Transmission

NOTE: The side discharge door will typically be serviced

as an assembly, and there is little need to sepa-

rate the parts of the assembly in the field. Disassembly is not reccomended, but if it is necessary

for any reason, the following procedure can be

used.

5. To separate the door from the hinge: See Figure 4.5.

5a. Clamp the discharge door and hinge to a work-

bench so that the hinge is easily accessible.

5b. Grasp the rear edge of the hing pin with a pair

of locking pliers and withdraw the pin.

NOTE: There is a notch on the rear edge of the side dis-

charge door to provide clearance for removing the

hinge pin.

NOTE: There are two extruded bosses on the bottom of

the hinge. They seat into holes in the mower deck

to align the hinge.

Trough

NOTE: There is a trough formed near the front leg of the

hinge. The L-shaped tail of the closure spring fits

into this trough on assembly. See Figure 4.6.

Boss

Figure 4.6

6. For assembly: Clamp the side discharge door to a

workbench top. See Figure 4.7.

7. Insert the question mark-shape d tail of the spring

through the small hole in the side discharge door.

8. Position the hinge with the L-shaped spring t ail in the

trough.

9. Roll the hinge into position, and secure it by inserting

the hinge pin. St ake the hinge pin with a punch once

it is installed, so that it does not back out.

Figure 4.7

29

Page 34

C and D series mowers

10. To Install the side discharge door on the mower

deck: See Figure 4.8.

10.1. Position the hinge so that the alignment bosses fit

into the alignment holes in the deck.

10.2. Install the screw that fastens the hinge to the deck,

and tighten it to a torque of 45-50 in-lbs (6-7 Nm).

11. Test run th e mo wer in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

Deckwash Fitting

1. The C and D Sereis mowers are available with deck-

wash fittings. These fittings resemble fittings that

MTD has used on previous equipment, but the

mounting is different.

Alignment bosses

Alignment holes

Figure 4.8

2. Removing the quick-connect hose coupling reveals

the new plastic fitting. See Figure 4.9.

3. Remove the shoulder screw that holds the fitting to

the deck using a 3/8” wrench. See Figure 4.10.

4. Tilt the fitting away from the screw to remove it from

the port in the deck.

5. When installing a deckwash fitting, tighten the screw

to a torque of 45-50 in-lb. (6-7 Nm).

NOTE: Do not install a deckash fitting on a mower

deck that did not originally have a hole for

one.

Figure 4.9

30

Figure 4.10

Page 35

Deck and Transmission

Rear Grass Door

Never operate a mower without the rear grass door properly in-place. It is a safety device that

! CA UTION! CA UTION

mode, it keeps clippings under the deck. With the rear grass collector in place, it locks the grass bag

securely in place and prevents

Repair the rear grass door if:

• The safety labels have become illegible.

• The rear grass door is damaged so that it does not contain clippings and light yard debris to the underside

of the deck.

• The rear grass door, its spring, or hinge mechanism do not cause it to properly close or secure the grass

collector.

NOTE: The rear grass door is included with the rear sub-frame assembly. The springs are available sepa-

is required by law.

The rear grass door is designed to contain grass clippings and light yard debris. In mulching

rately. This procedure covers door removal for the purpose of replacing the torsion springs.

To remove and replace the rear grass door:

1. Disconnect and ground the spark plug wire to prevent

accidental starting of the engine.

Torsion spring, right side

Hinge Pin

2. Lift the rear grass door and secure it in the raised

position with a block or a cord.

3. Grasp the grass door hinge pin with a pair of locking

pliers, and slide it toward the right side of the mower.

See Figure 4.11.

4. Withdraw the hinge pin (inset).

Figure 4.11

5. Lift the grass door off of the mower, keeping track of

the torsion springs that keep it closed.

See Figure 4.12.

Figure 4.12

31

Page 36

C and D series mowers

NOTE: The grass door torsion springs are mirror

image of each other. There is a left spring

and a right spring.

• The inner tail of each spring hooks through the

L-shaped hole in the grass door.

See Figure 4.13.

• The body of the spring fits into a recess in the

outboard edge of the grass door.

• The outer (L-shaped) tail of the spring hooks

over the top lip of the rear baffle when it is correctly installed. See Figure 4.14.

6. Position the rear grass door on the rear sub-frame .

Outer tail

Inner tail

Figure 4.13

7. Hook the ends of the left torsion springs over the lip

near the front edge of the rear sub-frame.

8. Press the door down to load the torsion springs.

9. Insert the hinge pin from the right-hand side.

See Figure 4.15.

• It should take roughly 15 lbs. (6 kg.) of force to

push the pin. If it is significantly looser, consider replacing the complete rear subframe and

grass door assembly. See Figure 4.15.

• Push the hinge pin in far enough to expose the

small gap in the rear baffle.

L-shaped tail of

torsion spring

Figure 4.14

Hinge pin

32

Belt tension gauge

Figure 4.15

Page 37

Front Wheels

Cotter pin, installed from

beneath the deck

Figure 4.16

Deck and Transmission

10. Push a 5/32” x 1-1/2” (4mm x 40mm) cotter pin

through the gap, coming up from the bottom. Bend

both ends of the cotter pin down around the hinge

loop. See Figure 4.16.

1 1. Confirm that the grass door pivots freely, fits properly

against the grass bag, and closes fully.

12. Test run the mower in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

All of the wheels (drive and non drive) are held on with

nylock nuts.

Figure 4.17

Front wheel

Double-beveled washer

To remove/replace a wheel:

1. Loosen the nut that secures each wheel that is to be

removed, using a 9/16” wrench.

2. Lift and safely support the mower so that the wheel or

wheels to be removed are off the ground.

3. Remove the wheel nut. See Figure 4.17.

4. Slide the wheel off of the axle. Capture the washers

on the front wheels, if they are present.

5. The front wheels may have special double-beveled

washers between the wheel and the nut.

See Figure 4.18.

6. Install the wheel by following the previous steps in

reverse order.

NOTE: Service wheels may not need the washer. Check

the fit of the wheel on the axle to see if the washer

is needed.

NOTE: Apply a small amount of a dry lubricant such as

graphite or PTFE (Tefflon) to the axle shaft before

sliding the wheel on.

NOTE: Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the lock

nut or replace it with a new one.

Figure 4.18

NOTE: Tighten the wheel nut s to a torque of 80-100 in lbs

(9-11 Nm)

33

Page 38

C and D series mowers

8” (20cm) rear wheels

7. Rear wheel removal is similar to the process for

removing the front wheels, but they lack the doublebeveled washer, and they contain a drive gear.

See Figure 4.19.

NOTE: The drive gear is not availab le as a sepa rate

service part, though it can be removed by

taking out 3 screws. Use a 5/16” wrench to

remove the screws.

NOTE: If the drive gear is worn, it is likely that the

pinion gear that turns it will be worn as well.

The wheel and pinion gear should be

replaced as a pair.

11” (28cm) rear wheels

8. Removal of the 11” rear wheels is similar to removal

of the 8” rear wheels, except that there is a wheel

cover. See Figure 4.20.

9. The wheel cover fastens near the hub. Pry-out the

edge of the wheeel cover to reach the fastenin g

point, but removal force should be applied as close

as possible to the center of the wheel cover.

10. Remove the nut from the axle using a 9/16” wrench.

Drive gear in

rear wheel

Figure 4.19

Wheel cover

fastener

11. Slide the wheel off of the axle. See Figure 4.21.

NOTE: The drive gear is not availab le as a sepa rate

service part, though it can be removed by

taking out 3 screws. Use a 5/16” wrench to

remove the screws.

NOTE: If the drive gear is worn, it is likely that the

pinion gear that turns it will be worn as well.

• The wheel and pinion gear should be replaced

as a pair.

• The bearings used in the 11” rear wheels are

not available separately from MTD. Replace

the wheel if the bearings have failed.

34

Figure 4.20

Pinion gear

Figure 4.21

Page 39

Pinion gear

Dust cover

Figure 4.22

Deck and Transmission

12. The pinion gear slides off of the transmission drive

shaft. See Figure 4.22.

NOTE: Apply a small amount of anti-seize compound to

the splines when installing the pinon gear, but do

not use a grease lubricant on the teeth of the

gears. Grease will attract dust, becoming an

abrasive paste rather than a lubricant.

NOTE: The 42-tooth ring gear i nside the 8” wheel is driven

by a 10-tooth pinion gear. The 52-tooth ring gear

inside the 11” wheel is driven by a 9-tooth pinion

gear. The tr ansmissions are identical. The 9-tooth

pinoin gear will fit into the 8” wheel, but it will not

mesh with the ring gear. The 10-tooth pinion is

taller than the 9-tooth pinion, and it will not allow

the 11” wheel to seat fully on its axle.

13. The dust covers of the 8” wheel and the 11” wheels

slip off easily once the wheels are removed.

See Figure 4.23.

Figure 4.23

14. Assembly notes:

15. Reinstall the dust covers and pinion gear if removed.

NOTE: Apply a small amount of a dry lubricant such as

graphite or PTFE (Tefflon®) to the axle shaft

before sliding the wheel on.

NOTE: Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the lock

nut or replace it with a new one.

16. Tighten the wheel nut s to a torque of 80-100 in lbs (911 Nm)

17. Test run the mower in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

35

Page 40

C and D series mowers

Front Axle

To remove and replace the axle:

1. Remove the wheels by following the procedure

described in the previous section of this chapter.

2. Set the height adjuster to the highest mowing position. See Figure 4.24.

NOTE: There is a lift assist spring on the front axle.

Raising the deck relieves most of the tension

from the spring. It also brings the height

adjuster link to rest against the stop on the

front axle.

NOTE: The 8” (20cm) and 11” (28cm) rear wheels

use different height adjuster links. Becuse

of this, the front axle geometry differs

between the C and D series mowers. Service procedures are similar.

3. The height adjuster link connects to the left side of

the axle. The wheel bracket on the right side of the

axle is a mirror image of the wheel bracket on the

left side of the axle, including the bolt hole for the

height adjuster link.

C-series mower with

under-shot height

adjuster link.

D-series mower

with over-shot

height adjuster link.

Figure 4.24

Lever tool

4. A simple lever tool can be made usting some flat

stock and a roll pin or bolt.

5. Use the tool to relieve any remaining tension on the

lift assist spring, taking shear load off of the threads

of the shoulder bolt. See Figure 4.25.

6. Remove the the shoulder bolt and wave washer that

connect the height adjuster link to the front axle

using a 3/8” wrench.

Tool in use

Figure 4.25

36

Page 41

Retainer

Deck and Transmission

7. Ease the front axle back into a postition that completely relaxes the lift assist spring.

8. Remove the fro nt axle retainers using a 3/8” wrench.

See Figure 4.26.

Front axle

Figure 4.26

9. With the retainers off, the axle will still be held in

place by two spring tabs on each end of the axle.

See Figure 4.27.

Spring tabs

Figure 4.27

Figure 4.28

10. Press a socket or similar round tool into the gap

between each pair of tabs, gently spreading them to

release the axle. See Figure 4.28.

37

Page 42

C and D series mowers

1 1. The spring is captive on the front axle weldment.

See Figure 4.29.

12. To install the front axle, position the tail fo the spring

into the locator slot.

Figure 4.29

• The hook end of the spring should be between

the elbow in the front axle weldment and the

plastic front axle cover.

• The elbow bend in the front axle should be oriented to the rear.

• Torsion force from the spring should cause the

axle to pivot, pushing the stub axle toward the

ground, applying lifting force to the deck.

See Figure 4.30.

13. Push the axle assembly past the plastic sp rin g t abs ,

into the pocket that locates it in the front axle cover.

14. When the axle is in position, secure it with the axle

retainers. See Figure 4.31.

NOTE: The axle retainers are off-set. When

installed correctly, the outboard edge of the

retainers fits flush against th e in sid e edge of

the front axle cover.

NOTE: Tighten the screws that hold the axle retain-

ers to a new front axle cover to 30-40 in-lbs

(3.5-4.5 Nm).

Figure 4.30

38

Retainer: Note offset

Figure 4.31

Page 43

Screw and

wave washer

Front Axle Cover

Height adjuster link

Figure 4.32

Deck and Transmission

15. Reconnect the height adjuster link. Tighten the

screw to a torque of 45-50 in-lbs. (4-5 Nm).

See Figure 4.32.

16. Reinstall the wheels.

NOTE: Apply a small amount of a dry lubricant such as

graphite or PTFE (Tefflon®) to the axle shaft

before sliding the wheel on.

NOTE: Apply a small amount of releasable thread locking

compound such as Loctite® 242 (blue) to the lock

nut or replace it with a new one.

17. Tighten the wheel nuts to a torque of 80-100 in-lbs.

(9-11 Nm).

18. Test run the mower in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

Front axle cover

Mounting screws

Figure 4.33

NOTE: The front axle cover is the plastic structure

attached to the front of the mower deck. The front

axle mounts to it.

1. Remove the front wheels and axle as described previously in this chapter.

2. Remove the 5 scr ews that hold the front axle cover to

the mower deck using a 1/2” wrench or a T-40 Torx

driver. See Figure 4.33.

3. Install the replacement front axle cover by reversing

the steps used to remove it.

NOTE: Tighten the screws that hold th e front axle cover to

to the mower deck to 30-40 in-lbs (3.5-4.5 Nm).

4. Test run the mower in a safe area and check all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

39

Page 44

C and D series mowers

Handlebars

NOTE: Most service procedures tha t wou ld inv olve

removal of the handlebars will also involve

removal of the rear baffle. We have written

the procedures around this assumption, disconnecting the handlebars and removing

them completely from the mower.

1. Disconnect and ground the spark plug wire to prevent accidental starting of the mower.

2. Hold the safety bail against the handlbar and pull the

starter rope about 6” (15cm). Tie a slip-knot in the

starter rope near the recoil housing. Release the

rope from the eye bolt on the handlebar.

See Figure 4.34.

3. It is easier to disconnect the drive control cables at

the bottom end than at the top. Disconnect the

speed control and clutch cables as described in

Chapter 3 of this manual. See Figure 4.35.

Slip knot in recoil rope

Figure 4.34

4. Disconnect the engine control cable, as described in

Chapter 3.

5. Remove both of the wing screws that hold the lower

handlebar to the rear baffle. See Figure 4.36.

6. Withdraw the handlebar from the baffle, and put it

aside.

7. After the handlebar is removed, reinstall the wing

screws, so that the captive nuts do not fall out of the

rear baffle.

8. Reinstall the handlebar by reversing the steps used

to remove it.

Speed control cable

Clutch control cable

Figure 4.35

Wing screw

9. Test run the mowe r in a saf e area and che ck all of

the safety features before returning it to service. Do

not put an unsafe mower into service.

40

Captive nut

Figure 4.36

Page 45

Transmission and Rear Axle Inspection

Deck and Transmission

Checking the transmission:

1. To avoid replacing a transmission that does not have

any mechanical problems, it is important to understand what it does when it is working properly. Check

the transmission before removing it.

Figure 4.37

Rear wheel

removed

Check belt

Check pulleys

Check cables

Check spring

Spin-test

2. Disconnect and ground the spark plug wire to avoid

starting the engine accidentally.

3. Remove the rear wheels, as described previoulsy in

this chapter. See Figure 4.37.

• Make a visual inspection of the pinion gear and spur

gear that drive the wheel.

• Confirm that the splines that drive the pinion gears

are not stripped.

4. Lift and secure the rear grass door, and remove the

upper belt cover as described in Chapter 2 of this

manual.

5. Inspect the belt, sh eave, cables, and tensioning

mechanism. See Figure 4.38.

• The belt should not be significantly worn or damaged.

• Confirm that the correct MTD part number belt is on

the mower.

• Check the operation of the clutch cable and the

engagement of the belt, as described in chapter 3.

• Check the operation of the speed control cable, as

Figure 4.38

• Rotating either output shaft in either direction should be possible without significant drag, and without

causing the input shaft or the other output shaft to move. If an output shaft will not turn in one direction,

rotate it slightly in the opposite direction, or turn the input shaft counter-clockwise to discngage the drive

pawl. This is normal operation.

• Rotating the input shaft counter-clockwise should be possible without significant drag, and without causing either of the output shafts to move.

• Rotating the input shaft clockwise should cause the output shafts to rotate in the direction that will cause

forward drive at the wheels.

• While being driven, the output shafts should be able to exceed the speed that they are driven at. This

allows differential action while the mower is being turned left or right with the self-propel mech anism

engaged. It also allows the operator to push the mower faster than the drive mechanism is moving it.

7. If the conditions listed above are all true for the transmission in question, the problem is likely to be external.

Look harder at the belt, sheaves, the drive pinions inside the wheels, and the control mechanism to find the

drive system problem.

8. If the conditions listed above are not all true for the tran smission in question, the pr oblem is likely to be interna l

to the transmission. Replace the transmission to fix the drive problem.

described in chapter 3.

6. The transmission should behave as follows:

41

Page 46

C and D series mowers

Transmission and Rear Axle Removal

The transmission and rear axle assembly are removed

from the mower together:

1. After checking the transmission, the mower will be

in the following condition:

• The spark plug wire will be disconnected and

grounded.

• The back of the mower will be safely supported,

and the rear wheels will be removed.

• The rear grass door will be propped or strapped

in the open position.

• The upper belt cover will be removed.

2. Remove the left front wheel from the mower, as

described previously in this chapter.

3. Slide the pinion gears off of both transmission output shafts.

4. Remove the dust covers from both wheel brackets.

See Figure 4.39.

NOTE: The lift assist spring that acts on the front

axle will keep tension on the height control

link. To disconnect the height control link

from the wheel bracket on the rear axle, isolate the spring tension. This will take shear

load off of the shoulder bolt that connects

the height control link to the rear wheel

bracket.

Rear wheel, dust cover

and pinion gear removed

Figure 4.39

Wood block tool to tak e the

force of the lift assist spring

5. Block the height adjuster link at the front axle.

See Figure 4.40.

• A linkage block tool can be made from a 2x4 or

similar dimensional lumber.

• Drill a hole of at least 7/8” (2.22cm) in the 2x4,

and trim the end to fit between the axle shoulder and the inside elbow of the height adjuster link.

• Place the wood block onto the left front axle so that it limits the travel of the height adjuster mechanism;

fixing the distance between the axle and the height adjuster link.

Figure 4.40

42

Page 47

Height adjuster

control link

Deck and Transmission

6. Remove the shoulder screw that connects the height

control link to the left rear wheel bracket using a 3/8”

wrench. See Figure 4.41.

7. Pivot the height control link forward, out of the way,

or remove it completely.

Figure 4.41

8. Disconnect the clutch and speed control cables from

the transmission, as described in Chapter 3.

Figure 4.42

9. Remove the drive belt from the transmission input

pulley, as described in Chapter 2. See Figure 4.42.

10. Position the mower for easy access to the screws