Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OperatOr’s Manual

Table of Contents

Safe Operation Practices ........................................ 2

Assembly & Set-Up .................................................. 4

Controls & Operation .............................................. 5

Service ...................................................................... 7

Troubleshooting ...................................................... 9

Replacement Parts ................................ supplement

Warranty ................................................ supplement

Chipper Shredder — Models CS2210, CS3310, CS4265 & CS4325

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

NOTE: This Operator’s Manual covers several models. Features may vary by model. Not all features in this manual are applicable to all models

and the model depicted may differ from yours.

P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Form No. 769-21010

(March 21, 2019)

Page 2

Important Safe Operation Practices

WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself

and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may

result in personal injury. When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to State of California to cause

cancer and birth defects or other reproductive harm.

DANGER: This machine was built to be operated according to the safe operation practices in this manual. As with any type of power equipment,

carelessness or error on the part of the operator can result in serious injury. This machine is capable of amputating fingers, hands, toes and feet and

throwing debris. Failure to observe the following safety instructions could result in serious injury or death.

1

Training

1. Read, understand, and follow all instructions

on the machine and in the manual(s) before

attempting to assemble and operate.

Keep this manual in a safe place for future

and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper

operation. Know how to stop the machine and

disengage them quickly.

3. Never allow children under 16 years of age to

operate this machine. Children 16 and over

should read and understand the instructions

and safe operation practices in this manual

and on the machine and be trained and

supervised by an adult.

4. Never allow adults to operate this machine

without proper instruction.

5. Keep bystanders, pets, and children at least 75

feet from the machine while it is in operation.

Stop machine if anyone enters the area.

6. Keep in mind that the operator or user

is responsible for accidents or hazards

occurring to other people, their property, and

themselves.

Preparation

1. Thoroughly inspect the area where the

equipment is to be used. Remove all rocks,

bottles, cans, or other foreign objects which

could be picked up or thrown and cause

personal injury or damage to the machine.

2. Always wear safety glasses or safety goggles

during operation and while performing an

adjustment or repair, to protect your eyes.

Thrown objects which ricochet can cause

serious injury to the eyes.

3. Wear sturdy, rough-soled work shoes and

close-fitting slacks and shirts. Loose fitting

clothes or jewelry can be caught in movable

parts. Never operate this machine in bare feet

or sandals. Wear leather work gloves when

feeding material in the chipper chute.

4. Before starting, check all bolts and screws for

proper tightness to be sure the machine is in

safe working condition. Also, visually inspect

machine for any damage at frequent intervals.

5. Maintain or replace safety and instructions

labels, as necessary.

6. Never attempt to make any adjustments

while the engine is running, except

where specifically recommended by the

manufacturer.

Safe Handling of Gasoline:

To avoid personal injury or property damage use

extreme care in handling gasoline. Gasoline is

extremely flammable and the vapors are explosive.

Serious personal injury can occur when gasoline is

spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline

container.

b. Never fill containers inside a vehicle or

on a truck or trailer bed with a plastic

liner. Always place containers on the

ground away from your vehicle before

filling.

c. When practical, remove gas-powered

equipment from the truck or trailer and

refuel it on the ground. If this is not

possible, then refuel such equipment

on a trailer with a portable container,

rather than from a gasoline dispenser

nozzle.

d. Keep the nozzle in contact with the rim

of the fuel tank or container opening at

all times until fueling is complete. Do

not use a nozzle lock-open device.

e. Extinguish all cigarettes, cigars, pipes

and other sources of ignition.

f. Never fuel machine indoors.

g. Never remove gas cap or add fuel while

the engine is hot or running. Allow

engine to cool at least two minutes

before refueling.

h. Never over fill fuel tank. Fill tank to

no more than ½ inch below bottom

of filler neck to allow space for fuel

expansion.

i. Replace all fuel tank and container caps

securely.

j. If gasoline is spilled, wipe it off the

engine and equipment. Move unit to

another area. Wait 5 minutes before

starting the engine.

k. To reduce fire hazards, keep machine

free of grass, leaves, or other debris

build-up. Clean up oil or fuel spillage

and remove any fuel soaked debris.

l. Never store the machine or fuel

container inside where there is an open

flame, spark or pilot light as on a water

heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

1. Do not put hands and feet near rotating parts

or in the feeding chambers and discharge

opening. Contact with the rotating impeller

can amputate fingers, hands, and feet.

2. Before starting the machine, make sure

the chipper chute, feed intake, and cutting

chamber are empty and free of all debris.

3. Thoroughly inspect all material to be shredded

and remove any metal, rocks, bottles, cans,

or other foreign objects which could cause

personal injury or damage to the machine.

4. If it becomes necessary to push material

through the shredder hopper, use a small

diameter stick. Do not use your hands or feet.

5. If the impeller strikes a foreign object or if your

machine should start making an unusual noise

or vibration, immediately shut the engine

off. Allow the impeller to come to a complete

stop. Disconnect the spark plug wire, ground it

against the engine and perform the following

steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten

to assure continued safe operation.

6. Do not allow an accumulation of processed

material to build up in the discharge area.

This can prevent proper discharge and result

in kickback of material through the feed

opening.

7. Do not attempt to shred or chip material

larger than specified on the machine or in this

manual. Personal injury or machine damage

could result.

8. Never attempt to unclog either the feed

intake or discharge opening while the engine

is running. Shut the engine off, wait until all

moving parts have stopped, disconnect the

spark plug wire and ground it against the

engine before clearing debris.

9. Never operate without the shredder hopper,

chipper chute, or chute deflector properly

attached to the machine. Never empty or

change discharge bag while the engine is

running.

10. Do not change the engine governor settings

or overspeed the engine. The governor

controls the maximum safe operating speed of

the engine.

11. Keep your face and body back and to the side

of the chipper chute while feeding material

into the machine to avoid accidental kickback

injuries.

12. Never operate this machine without good

visibility or light.

13. Do not operate this machine on a paved,

gravel or non-level surface.

14. Do not operate this machine while under the

influence of alcohol or drugs.

15. Muffler and engine become hot and can cause

a burn. Do not touch.

2

Page 3

16. Never pick up or carry machine while the

engine is running.

17. If situations occur which are not covered in

this manual, use care and good judgement.

Contact Customer Support for assistance and

the name of the nearest service dealer.

18. Never run an engine indoors or in a poorly

ventilated area. Engine exhaust contains

carbon monoxide, an odorless and deadly gas.

19. Never attempt to unclog either the feed intake

or discharge opening, remove or empty bag,

or inspect and repair the machine while the

engine is running. Shut the engine off and

wait until all moving parts have come to a

complete stop. Disconnect the spark plug wire

and ground it against the engine.

20. If the machine should start to vibrate

abnormally, stop the engine and checck

immediately for the cause. Vibration is

generally a warning sign of trouble.

21. Stop the engine when leaving the operating

position, and when making any repairs,

adjustments, and inspections.

22. Take all possible precautions as recommended

by the manufacturer when leaving the

machine unattended. Disengage power takeoff, shift into neutral, stop the engine, and

remove the key.

23. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect.

24. Never operate the machine at high transport

speeds on hard or slippery surfaces.

25. Use extreme caution when reversing or pulling

the machine towards you.

Maintenance & Storage

1. Never tamper with safety devices. Check their

proper operation regularly.

2. Check bolts and screws for proper tightness

at frequent intervals to keep the machine

in safe working condition. Also, visually

inspect machine for any damage and repair,

if needed.

3. Before cleaning, repairing, or inspecting, stop

the engine and make certain the impeller and

all moving parts have stopped. Disconnect

the spark plug wire and ground it against the

engine to prevent unintended starting.

4. Keep all guards, deflectors and safety devices

in place and operating properly.

5. Maintain or replace safety and instruction

labels, as necessary.

6. Follow this manual for safe loading,

unloading, transporting, and storage of this

machine.

7. Never store the machine or fuel container

inside where there is an open flame, spark

or pilot light such as a water heater, furnace,

clothes dryer, etc.

8. Allow machine to cool at least 5 minutes

before storing.

9. Always refer to the operator’s manual for

proper instructions on off-season storage.

10. If the fuel tank has to be drained, do this

outdoors.

11. Observe proper disposal laws and regulations

for gas, oil, etc. to protect the environment.

12. According to the Consumer Products

Safety Commission (CPSC) and the U.S.

Environmental Protection Agency (EPA), this

product has an Average Useful Life of seven

(7) years, or 60 hours of operation. At the end

of the Average Useful Life have the machine

inspected annually by an authorized service

dealer to ensure that all mechanical and

safety systems are working properly and not

worn excessively. Failure to do so can result in

accidents, injuries or death.

Do not modify engine

To avoid serious injury or death, do not modify

engine in any way. Tampering with the governor

setting can lead to a runaway engine and cause it to

operate at unsafe speeds. Never tamper with factory

setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with California

and federal EPA emission regulations for SORE

(Small Off Road Equipment) are certified to operate

on regular unleaded gasoline, and may include

the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary

Air Injection (SAI) and Three Way Catalyst (TWC) if so

equipped.

Spark Arrestor

WARNING: This machine is equipped

with an internal combustion engine and

should not be used on or near any

unimproved forest-covered,

brushcovered or grass-covered land

unless the engine’s exhaust system is

equipped with a spark arrestor meeting

applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in

effective working order by the operator. In the State

of California the above is required by law (Section

4442 of the California Public Resources Code). Other

states may have similar laws. Federal laws apply on

federal lands.

A spark arrestor for the muffler is available through

your nearest engine authorized service dealer or

contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the machine before attempting to

assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and operate

WARNING— ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades inside

BYSTAN DERS

Keep bystanders, pets, and children at least 75 feet from the machine while it is in operation. Stop machine

if anyone enters the area.

WARNING— THROWN DEBRIS

Never operate without the chute deflector properly attached to the machine.

EYE PROTECTION

Always wear safety glasses or safety goggles when operating this machine.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and follow the warnings and

instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

3Section 1 — important Safe operation practiceS

Page 4

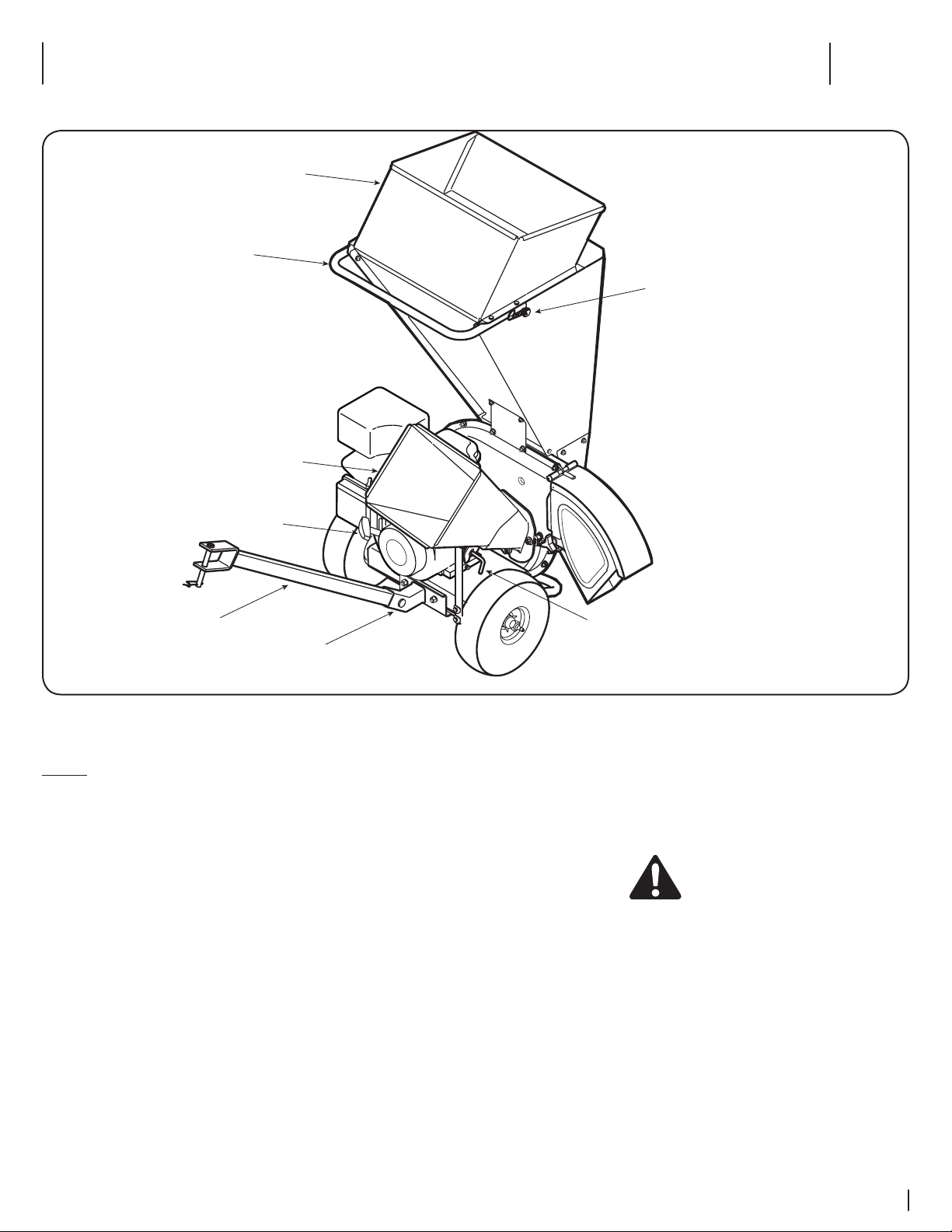

Assembly & Set-Up

B

A

1

2

3

4

Thank You

Thank you for purchasing this product. It was carefully engineered to provide

excellent performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment. It instructs you

how to safely and easily set up, operate and maintain your machine. Please be

sure that you, and any other persons who will operate the machine, carefully

follow the recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent product information

available at the time. Review this manual frequently to familiarize yourself with the

machine, its features and operation. Please be aware that this Operator’s Manual

may cover a range of product specifications for various models. Characteristics

and features discussed and/or illustrated in this manual may not be applicable to

all models. We reserve the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Contents of Carton

• Chipper Shredder (1) • Operator’s Manual (1) • Engine Operator’s Manual (1) • Bottle of Oil (1)

• Tow Bar (1) (If Equipped) • Ba g (1) • Safety Glasses (1)

If applicable, the power testing information used to establish the power rating

of the engine equipped on this machine can be found at www.opei.org or the

engine manufacturer’s web site.

If you have any problems or questions concerning the machine, phone your

local authorized service dealer or contact us directly. We want to ensure your

complete satisfaction at all times.

Throughout this manual, all references to right and left side of the machine are

observed from the operating position.

2

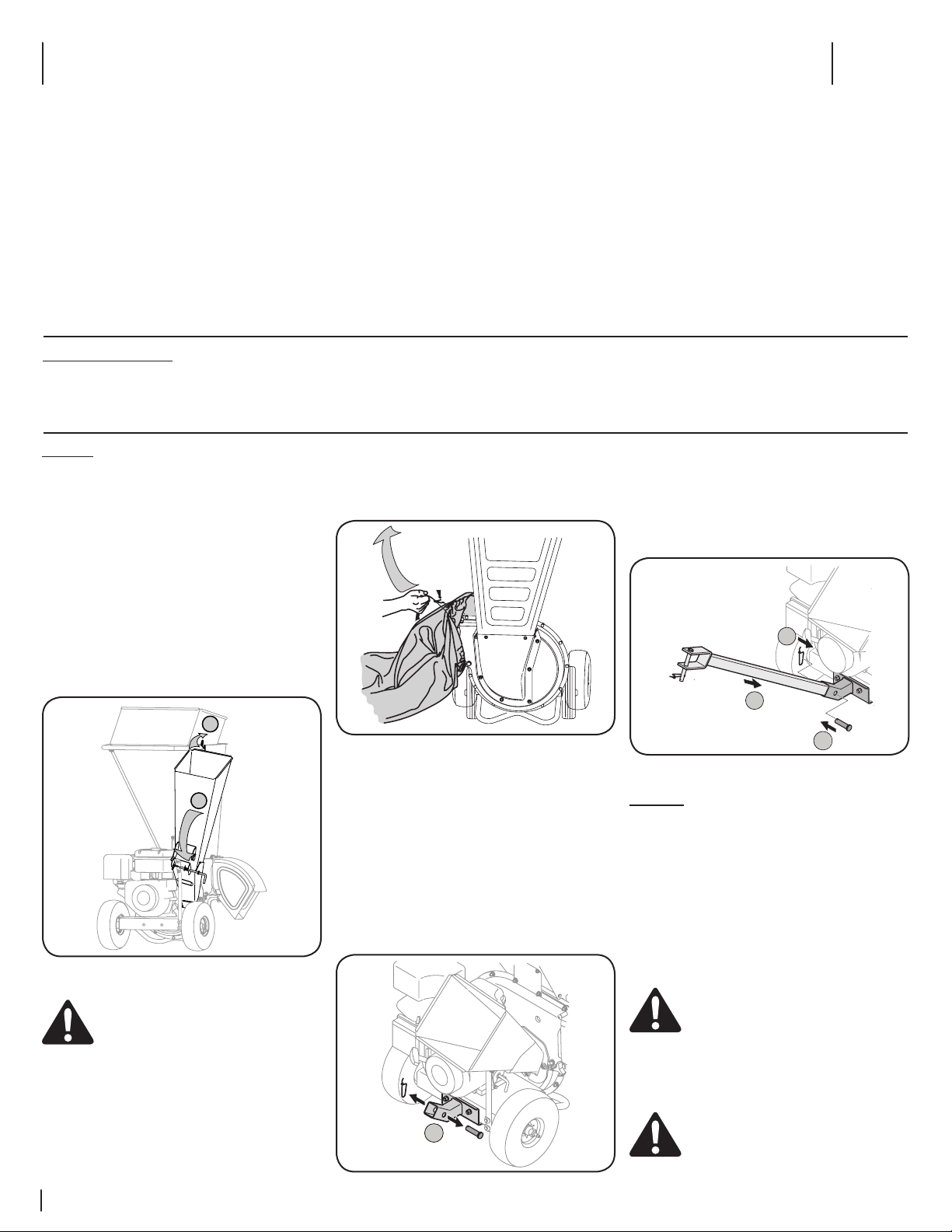

Assembly

NOTE: This unit is shipped without gasoline or oil in

the engine. Fill up gasoline and oil as instructed in

the accompanying engine manual BEFORE operating

your chipper shredder.

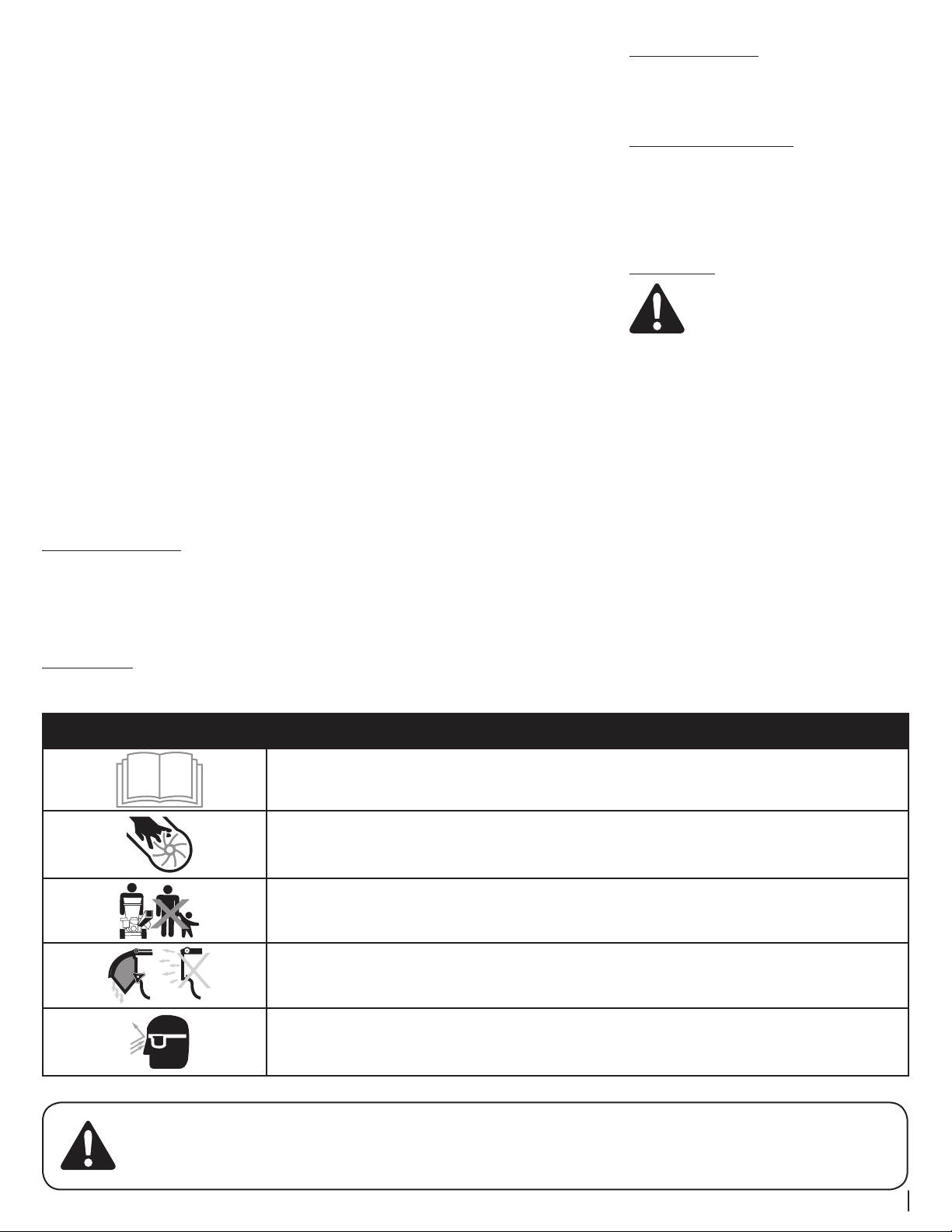

Chipper Chute (Model Series CS3310 & 4325)

For shipping reasons, the unit is crated with its

chipper chute in a raised position. To pivot it

downward, proceed as follows:

1. Pull the spring latch upward. See A in Figure

2-1.

2. Gently pivot the chipper chute down until it

clicks into the lock rod. See B in Figure 2-1.

Figure 2-1

WARNING: Never operate the chipper

shredder with the chipper chute in the

raised position. Doing so may result in

property damage or serious injury to the

operator or bystanders.

4

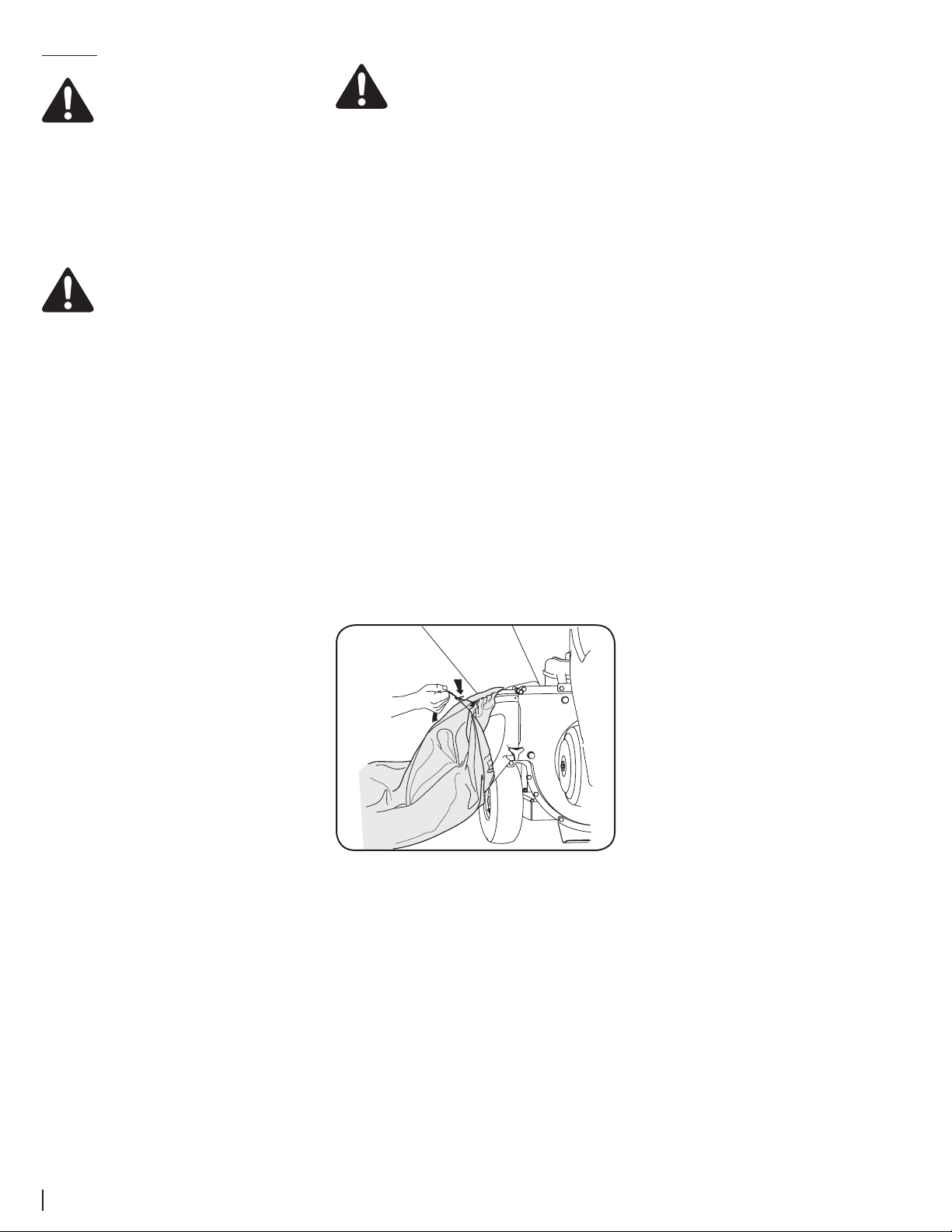

Bag

To attach the bag:

1. Place the opening of the bag completely over

the chute deflector. See Figure 2-2.

Figure 2-2

2. Position the bag so that the wing knobs which

secure the chute deflector to the impeller

housing are completely covered.

3. Pull on the draw-strap until the bag is tight

around chute deflector opening.

Tow Bar (If Equipped)

To attach the tow bar:

1. Remove the spring pin and clevis pin from the

end of the tow bar receiver. See Figure 2-3.

Figure 2-3

2. Insert the tow bar into the receiver. See Figure

2-4.

3. Reinsert the clevis pin through aligning holes

in both the tow bar and the receiver. See

Figure 2-4.

4. Fasten with the spring pin to secure. See

Figure 2-4.

Figure 2-4

Set-Up

Gas and Oil Fill-Up

Refer to the separate engine owner’s manual for

additional engine information.

1. Add oil provided before starting unit for the

first time out of the box. See the separate

engine owner’s manual for instructions for

adding the engine oil.

2. Service the engine with gasoline as instructed

in the separate engine owner’s manual.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel the machine indoors or while

the engine is hot or running. Extinguish

cigarettes, cigars, pipes and other sources

of ignition.

WARNING: Never fill fuel tank indoors

with engine running or until the engine

has been allowed to cool for at least two

minutes after running.

Page 5

Controls and Operation

Chipper Chute

Handle

Hopper

Recoil Starter

T

ow B

Receiver

ar

Lock Rod

Spring Latch

3

Controls

Chipper Chute

Branches up to two inches (model series CS2210 and

CS4265) or three inches (model series CS3310 and CS

4325) in diameter may be fed into the chipper chute

for chipping.

Hopper

Leaves, twigs, and branches up to 1/2-inch in

diameter may be placed into the hopper for

shredding.

IMPORTANT: Never place branches with a diameter

greater than 1/2-inch in the hopper. Doing so can

result in serious damage to your unit’s shredder

blade, flails or impeller.

Tow Bar (If Equipped)

Use the tow bar to tow the chipper shredder behind

a tractor to a job site.

Receiver (If Equipped)

Use the receiver to secure the tow bar to the chipper

shredder when towing the chipper shredder with a

tractor.

Figure 3-1

Handle

Use the handle when manually transporting the

chipper shredder.

Recoil Starter

The recoil starter is located on the engine. refer to

the seperate engine operator’s manual for engine

starting instructions.

Engine Controls

See the engine operator’s manual packed with your

unit for the location and function of the controls on

the engine.

Spring Latch (CS3310 and CS 4325)

The spring latch is located on the top of the hopper.

It is used to release or lock the chipper chute in a

raised position for storage or for transporting. See

Figu re 3-1.

WARNING: Never operate the chipper

shredder with the chipper chute in the

raised position. Use the spring latch to

lower the chipper chute into the

operating position before starting the

engine.

Lock Rod (Model Series CS3310 and CS 4325)

The lock rod is located on the chipper chute support.

It is used to release or lock the chipper chute in a

lowered position for operation.

Chute Deflector

Debris is discharged from the machine’s reduction

chamber through the chute deflector.

5

Page 6

Operation

WARNING: The operation of any

chipper shredder can result in foreign

objects being thrown into the eyes,

which can damage your eyes severely.

Always wear the safety glasses provided

with this unit or eye shields before

chipping or shredding and while

performing any adjustments or repairs.

Starting Engine

Refer to the engine operator’s manual for engine

starting instructions.

Shredding

WARNING: Never operate the chipper

shredder without chipper chute lowered

into the operating position.

Yard waste such as leaves and pine needles can be

placed in the hopper for shredding. After material

has been processed by the shredder blade and flails,

it will be forced out of the chute deflector, and, if

attached, into a debris collection bag.

Observe the following guidelines when shredding

yard debris:

• Never attempt to shred material other than

normal yard debris (leaves, twigs, pine cones,

etc.).

• Avoid shredding fibrous plants such as tomato

vines until they are thoroughly dried out.

Fresh vines do not shred well and tend to wrap

themselves around the impeller and flails.

• Place reasonable amounts of debris into the

hopper at a time. Do not overload the hopper.

• Allow the material in the hopper to be drawn

into the blades and shredded before adding

additional debris to the hopper. Failure to due

so may result in a clogged hopper, clogged

chute deflector or a stalled engine.

• Avoid placing twigs longer than 24 inches into

the hopper. Twigs longer than 24 inches may

result in a clogged hopper.

IMPORTANT: Never place branches with a

diameter greater than 1/2-inch in the hopper.

Doing so can result in serious damage to the

unit’s shredder blade, flails or impeller.

Clearing the Hopper

Should the hopper become clogged with debris

during operation, proceed as follows:

1. Grasp the handle with both hands and gently

agitate the chipper shredder to help loosen

debris, drawing it into the impeller.

If the clog does not clear, proceed as follows:

1. Stop engine.

2. Use your hands to remove any debris found

near the top of the hopper.

3. Use a branch (or other available device, i.e.

broomstick) to dislodge debris located toward

the base of the hopper.

4. Restart engine.

NOTE: If you’re unable to pull the starter

rope as a result of accumulated debris near

the impeller, follow instructions under the

heading Cleaning the Reduction Chamber in

the “Maintenance & Adjustments” section of

this manual.

Chipping

WARNING: Never operate the chipper

shredder without chipper chute lowered

into the operating position.

Branches up to two inches (model series CS2210) or

three inches (model series CS3310) in diameter can

be fed into the chipper chute. Observe the following

guidelines when chipping branches:

• Keep both hands firmly on the branch as you

feed it into the chipper chute.

• Never feed more than one branch into the

chipper chute at a time.

• Never feed anything other than branches (or

wood) into the chipper chute.

• Apply intermittent pressure (force, in short

pulses) while feeding larger branches into the

chipper chute, to avoid bogging or stalling the

engine.

IMPORTANT: Never feed branches with a

diameter greater than two (2) inches (Model

Series CS2210) or three (3) inches (model series

CS3310) into the chipper chute. Doing so can

result in serious damage to your unit’s chipper

blades, flails or impeller.

NOTE: For best performance, always operate

the unit with sharp chipper blades. If a

noticeable loss in performance is encountered

while chipping branches, the chipper blades

should be replaced.

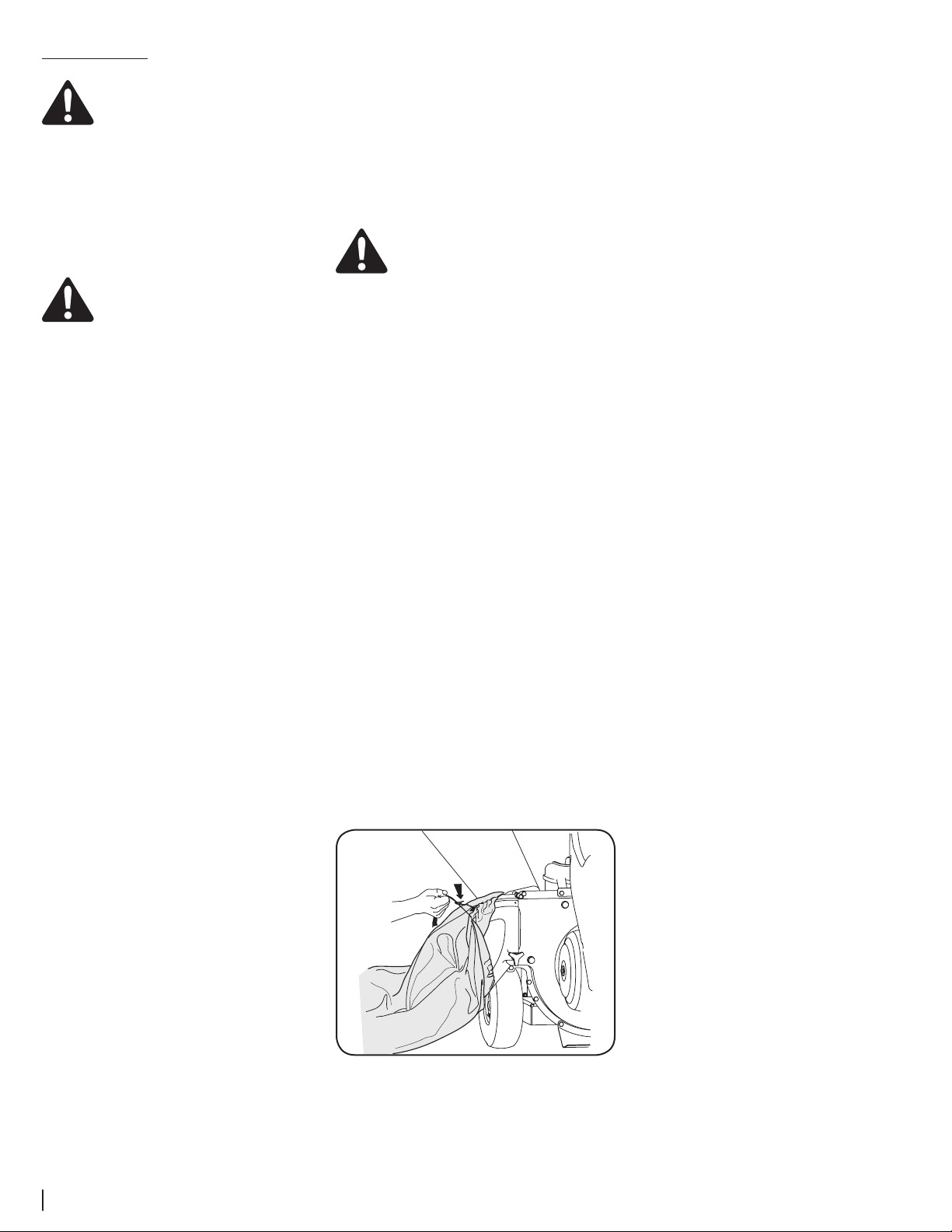

Emptying the Bag

1. Stop engine.

2. Squeeze the locking buckle to release the

bag’s drawstrap before loosening it from the

chute deflector. See Figure 3-2.

Figure 3-2

3. Empty the bag and reattach to the chute

deflector opening. Refer to the “Assembly and

Setup” section of this manual.

6 Section 3 — controlS an d operation

Page 7

Service

A

C

B

A

C

B

4

Service

General Recommendations

• Always observe safety rules when performing

any maintenance.

• The warranty on this chipper shredder does

not cover items that have been subjected to

operator abuse or negligence. To receive full

value from warranty, operator must maintain

the equipment as instructed here.

• Changing of engine-governed speed will void

engine warranty.

• All adjustments should be checked at least

once each season.

• Periodically check all fasteners and make sure

these are tight.

WARNING: Always stop engine,

disconnect spark plug, and ground

against engine before, cleaning,

lubricating, or performing any type of

maintenance on your machine.

Lubrication

1. Lubricate the chipper chute hinge with a light

oil once a season.

2. Lubricate the pivot points on the chute

deflector with light oil once a season.

3. Follow the separate engine manual packed

with your unit for engine lubrication

instructions.

Equipment Care

• Clean the chipper shredder thoroughly after

each use.

• Wash bag periodically with water. Allow to dry

thoroughly in shade.

• If the reduction chamber becomes clogged,

remove and clean as instructed below.

• Allow the unit to run and clear out all debris

for a short time before shutting the unit down

before storage.

NOTE: Cleaning with a forceful spray of water

is not recommended as it could contaminate

the fuel system.

Engine Care

Refer to the Maintenance section of the Engine

Owner/ Operator manual packed with your unit.

Read and follow instructions carefully.

• Check engine oil level before each use as

instructed in the separate engine manual.

• Clean or replace air cleaner every 25 hours

under normal conditions. Clean every few

hours under extremely dusty conditions. To

service the air cleaner, refer to the engine

manual.

• The spark plug should be cleaned and the gap

reset once a season. Check engine manual for

correct plug type and gap specifications.

• Clean engine regularly with a cloth or brush.

Keep the top of the engine clean to permit

proper air circulation. Remove all grass, dirt,

and combustible debris from muffler area.

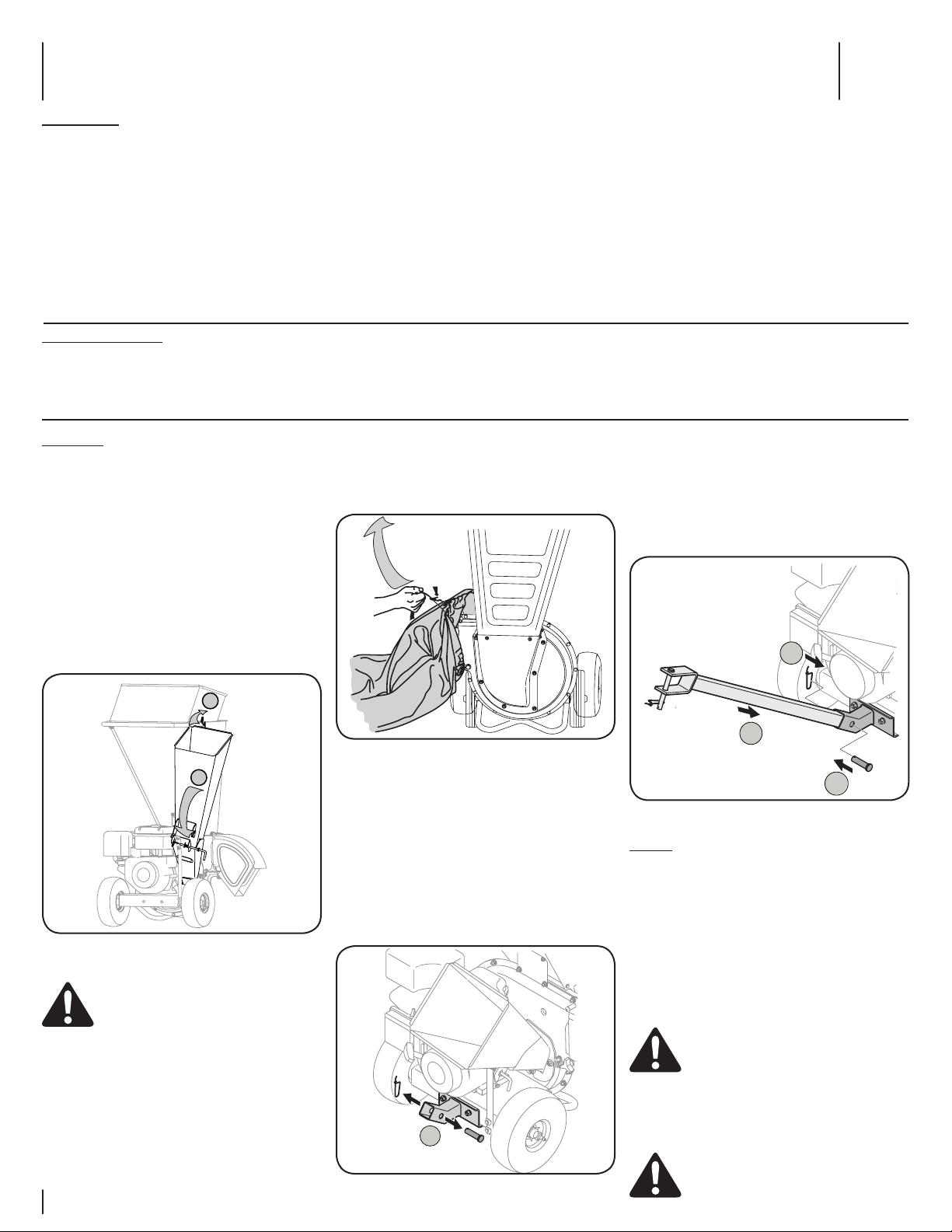

Cleaning The Reduction Chamber

WARNING: The impeller’s shredder

blade and chipper blades are sharp. Wear

leather work gloves to protect your hands

when cleaning out the reduction

chamber.

If the reduction chamber becomes clogged with

debris, the shredder screen can be pivoted upward

so that you can clean the surrounding area. To do so,

proceed as follows:

1. Stop engine, disconnect spark plug, and make

certain the chipper shredder has come to a

complete stop.

WARNING: The muffler and surrounding

area will be hot if the engine has been

running. Use caution and protect your

hands if working near the muffler.

2. If attached, remove debris bag.

Remove the two wing knobs on either side

of the chute deflector and pivot the chute

deflector upward. See A in Figure 4-1.

Figure 4-1

3. Remove the hairpin clip from the clevis pin

which extends through the housing and

shredder screen. See B in Figure 4-1. Remove

clevis pin.

4. Pivot the shredder screen upward. See C in

Figure 4-1. Clean the surrounding area by

scraping away debris.

5. Confirm that the spark plug wire is

disconnected and away from the spark plug.

Pull on the starter rope two-to-three times to

clear any remaining debris from the reduction

chamber.

6. When the area is clean, pivot the shredder

screen downward and re-secure with the

clevis pin and hairpin clip removed earlier.

7. Reattach the debris collection bag to the chute

deflector, if desired.

Chipper Blade Care

WARNING: The impeller’s chipper blades

are sharp. Wear leather work gloves to

protect your hands.

1. Stop engine, disconnect spark plug, and make

certain the chipper shredder has come to a

complete stop.

2. Pivot the shredder screen upward as

instructed under the heading Cleaning the

Reduction Chamber.

3. Remove the chipper chute support brace from

the frame by removing the two hex bolts and

saddle washers which secure it. See A in Figure

4-2.

Figure 4-2

4. Remove the chipper chute by removing three

hex nuts and washers which secure it to the

impeller housing. See B in Figure 4-2.

5. Rotate the impeller by hand until one of the

two chipper blades is visible through the

impeller housing opening.

6. Remove the blade by removing the internal

hex screws, lock washers and hex nuts which

secure it to the impeller. See C in Figure 4-2.

Retain the hardware.

NOTE: Use a 3/16” hex key (Allen) wrench on

the outside of the blade and a 1/2” box (or

socket) wrench on the inside of the impeller.

Hold the Allen wrench stationary and rotate

the box (or socket) wrench to loosen the nut.

7. Install a replacement blade with the hardware

removed earlier or sharpen.

IMPORTANT: When sharpening the blade,

protect hands by using gloves. Follow the

original angle of grind and make sure to

remove an equal amount from each blade.

8. To replace the other blade, rotate the impeller

to expose the second blade and repeat the

steps above.

NOTE: Make certain blades are reassembled

with the sharp edge outward (toward the

chipper chute). Torque hardware to between

20 ft.-lbs and 25 ft.-lbs.

7

Page 8

Shredder Blade Care

A

C

B

WARNING: The shredder blade is sharp.

Wear leather work gloves to protect your

hands.

1. Stop engine, disconnect spark plug, and make

certain that all moving parts have come to a

complete stop.

2. Remove the two flange nuts (and hex bolts)

which secure the hopper support bracket to

the impeller housing. Retain the hardware. See

Figure 4-3.

Figure 4-3

3. Pivot the shredder screen upward as

instructed under the heading Cleaning the

Reduction Chamber.

4. Remove six flange nuts which secure hopper

inlet guide to impeller housing. See A in Figure

4-4.

8. Remove the hex bolt, lock washer, and flat

washer to completely free shredder blade. See

C in Figure 4-4.

IMPORTANT: If sharpening the blade for

reuse, follow the original angle of grind as

a guide. Make certain each cutting edge

receives an equal amount of grinding to

prevent an unbalanced blade. Remove metal

from the heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade,

tighten center bolt to between 45 ft.-lbs and

58 ft.-lbs and the two out bolts to between 20

ft.-lbs and 25 ft.-lbs.

Off-Season Storage

• Allow the unit to run and clear out all debris

for a short time before shutting the unit down

before storage.

• When storing the chipper shredder in an

unventilated or metal storage shed, care

should be taken to rustproof the non-painted

surfaces. Using a light oil or silicone, coat the

equipment, especially any springs, bearings,

and cables.

• Remove all dirt from exterior of engine and

equipment.

• Follow lubrication recommendations.

• Refer to engine manual for correct engine

storage instructions.

• Store equipment in a clean, dry area. Do not

store in an area where equipment is present

that may use a pilot light or has a component

that can create a spark.

9. Remove the hairpin clip from the clevis pin

which extends through the housing and

shredder screen. See B in Figure 4-1. Remove

clevis pin.

10. Pivot the shredder screen upward. See C in

Figure 4-1. Clean the surrounding area by

scraping away debris.

11. Confirm that the spark plug wire is

disconnected and away from spark plug. Pull

on the starter rope two-to-three times to

clear any remaining debris from the reduction

chamber.

12. When the area is cleaned, pivot the shredder

screen downward and re-secure with the

clevis pin and hairpin clip removed earlier.

13. Reattach the debris collection bag to the chute

deflector, if desired.

Figure 4-4

5. Carefully separate the hopper assembly from

the impeller housing and set it aside.

6. Insert a piece of wood into the chute deflector

opening to stabilize the impeller and prevent

it from rotating when removing the shredder

blade.

7. Remove the two internal hex screws, hex

lock nuts, and lock washers which secure the

shredder blade to the impeller. See B in Figure

4-4.

NOTE: Use a 3/16” hex key (Allen) wrench

on the outside of the shredder blade and a

1/2” box (or socket) wrench on the inside of

the shredder blade. Hold the Allen wrench

stationary and rotate the box (or socket)

wrench to loosen the nut.

8 Section 4 — Service

Page 9

Troubleshooting

Problem Cause Remedy

5

Engine fails to start 1. Throttle lever (if equipped) not in correct starting

position.

2. Engine switch (if equipped) in OFF position.

3. Spark plug wire disconnected.

4. Choke not in CHOKE position (if equipped).

5. Fuel tank empty or stale fuel.

6. Fuel shut-off valve closed (if equipped).

7. Faulty spark plug.

Engine runs erratic 1. Spark plug boot loose.

2. Unit running on CHOKE (if equipped).

3. Blocked fuel line or stale fuel.

4. Low engine RPM.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

Engine overheats 1. Engine oil level low.

2. Dirty air cleaner.

1. Move throttle lever to FAST or START position.

2. Move engine switch to ON position.

3. Connect wire to spark plug.

4. Move choke lever to CHOKE position.

5. Fill tank with clean, fresh gasoline.

6. Turn on fuel shut-off valve.

7. Clean, adjust gap, or replace.

1. Connect and tighten spark plug boot.

2. Move choke lever to OFF position.

3. Clean fuel line; fill tank with clean, fresh

gasoline.

4. Always run engine at full throttle.

5. Drain fuel tank. Refill with fresh fuel.

6. Refer to engine manual.

7. See authorized service dealer.

1. Fill crankcase with proper oil.

2. Refer to engine manual.

Occasional skips

(hesitates) at

high speed

Excessive Vibration 1. Loose parts or damaged impeller. 1. See authorized service dealer.

Unit does not discharge 1. Discharge area clogged.

Rate of discharge slows

considerably or composition of

discharged material changes

1. Spark plug gap too close.

2. Carburetor idle mixture adjustment improperly set.

2. Foreign object lodged in impeller.

3. Low engine RPM.

1. Low engine RPM.

2. Chipper blade dull.

1. Remove spark plug and adjust gap. See Engine

Manual for gap specifications.

2. See authorized service dealer.

1. Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside of

discharge opening.

2. Stop engine and disconnect spark plug wire.

Remove lodged object.

3. Always run engine at full throttle.

1. Always run engine at full throttle.

2. Replace chipper blade or see your authorized

service dealer.

9

Page 10

Notes

Page 11

Medidas de seguridad • Montaje • Funcionamiento • Servicio • Solución de problemas • Garantía

Manual del OperadOr

Índice

Medidas de Seguridad ............................................ 2

Armado e Instalación .............................................. 4

Controles y Funcionamiento .................................. 5

Servicio ..................................................................... 7

Solución de Problemas ........................................... 9

Repuestos ............................................... suplemento

Garantía ................................................. suplemento

Trituradora Astilladora —

Modelos CS2210, CS3310, CS4265 y CS4325

ADVERTENCIA

LEA Y CUMPLA TODAS LAS NORMAS E INSTRUCCIONES DE SEGURIDAD DE ESTE MANUAL ANTES

DE INTENTAR HACER FUNCIONAR ESTA MÁQUINA.

SI NO RESPETA ESTAS INSTRUCCIONES PUEDE PROVOCAR LESIONES PERSONALES.

NOTA: Este manual del operador cubre varios modelos. Las características técnicas pueden variar de acuerdo al modelo. No todas las

características incluidas en este manual se aplican a todos los modelos y el modelo ilustrado puede ser diferente al suyo.

P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Formulario No. 769-21010

(21 de marzo de 2019)

Page 12

Importantes Medidas de Seguridad

ADVERTENCIA: Este símbolo indica instrucciones de seguridad importantes que, de no cumplirse, pueden poner en peligro su seguridad personal y/o material y la

de otras personas. Lea y cumpla todas las instrucciones de este manual antes de intentar hacer funcionar esta máquina. Si no cumple estas instrucciones puede

provocar lesiones personales.

Cuando vea este símbolo. ¡TENGA EN CUENTA LAS ADVERTENCIAS!

PROPOSICIÓN 65 DE CALIFORNIA

ADVERTENCIA: El escape del motor de este vehículo, algunos de sus elementos y ciertos componentes del vehículo contienen o liberan sustancias químicas

que el Estado de California considera que pueden producir cáncer, defectos de nacimiento u otros problemas reproductivos.

PELIGRO: Esta máquina está diseñada para operar de acuerdo con las normas de seguridad contenidas en este manual. Al igual que con cualquier tipo de

máquina eléctrica, un descuido o error por parte del operador puede producir lesiones graves. Esta máquina puede amputar dedos, manos y pies y puede arrojar

residuos. Si no se respetan las siguientes instrucciones de seguridad, se pueden ocasionar lesiones graves o la muerte.

1

Capacitación

1. Lea, entienda y cumpla todas las instrucciones

incluidas en la máquina y en los manuales antes de

intentar armarla y hacerla funcionar. Guarde este

manual en un lugar seguro para consultas futuras y

periódicas, así como para pedir repuestos.

2. Familiarícese con todos los controles y con el uso

adecuado de los mismos. Sepa cómo parar la

máquina y desactivar los controles rápidamente.

3. No permita nunca que los menores de 16 años

utilicen esta máquina. Los menores de 16 años en

adelante deben leer y entender las instrucciones

y las normas de seguridad contenidas en

este manual y sobre la máquina, y deben ser

capacitados y supervisados por un adulto.

4. Nunca permita que los adultos operen esta

máquina sin recibir antes la instrucción apropiada.

5. Mantenga a los observadores, mascotas y niños

a no menos de 70 pies de la máquina siempre

que esté funcionando. Pare la máquina si alguien

ingresa a la zona.

6. Tenga en cuenta que el operador o usuario es

responsable de los accidentes o peligros que se

produzcan a otras personas, a su propiedad y a

ellos mismos.

Preparativos

1. Inspeccione minuciosamente el área donde

utilizará el equipo. Retire todas las piedras,

botellas, latas y otros objetos extraños que

puedan ser levantados o arrojados causando

lesiones personales o daños a la máquina.

2. Para protegerse los ojos utilice siempre anteojos

o antiparras de seguridad mientras hace

funcionar la máquina o mientras le hace ajustes o

reparaciones. Los objetos arrojados que rebotan

pueden lesionar gravemente los ojos.

3. Utilice zapatos de trabajo resistentes, de suela

fuerte, así como pantalones y camisas ajustados.

Las prendas sueltas y las alhajas se pueden

enganchar en las piezas móviles. Nunca opere

esta máquina descalzo o con sandalias. Utilice

guantes de trabajo de cuero cuando introduzca

material en el canal de la astilladora.

4. Antes de encender la máquina controle que

todos los pernos y tornillos estén bien ajustados

para garantizar que la máquina se encuentra

en condiciones seguras de operación. Además,

realice inspecciones visuales de la máquina a

intervalos frecuentes buscando daños.

5. Mantenga o reemplace las etiquetas de seguridad

y de instrucciones según sea necesario.

6. Nunca intente realizar ajustes mientras el motor

está en marcha, excepto cuando el fabricante lo

recomiende específicamente.

Manejo seguro de la gasolina:

Para evitar lesiones personales o daños materiales tenga

mucho cuidado al manipular la gasolina. La gasolina es

sumamente inflamable y sus vapores son explosivos. Si

se derrama gasolina sobre el cuerpo o la ropa se puede

lesionar gravemente ya que podría prenderse fuego.

2

Lávese la piel y cámbiese de ropa de inmediato.

a. Utilice sólo recipientes para gasolina

autorizados.

b. Nunca llene los recipientes dentro de un

vehículo o de un camión o remolque con

recubrimiento plástico. Coloque siempre

los recipientes en el piso y lejos del

vehículo antes de llenarlos.

c. Cuando sea posible, saque el equipo a

gasolina del camión o remolque y llénelo

sobre el suelo. Si eso no es posible, llene el

equipo en un remolque con un recipiente

portátil, en lugar de hacerlo desde la

boquilla del surtidor de gasolina.

d. Mantenga la boquilla en contacto con el

borde del tanque de combustible o con la

abertura del recipiente en todo momento,

hasta terminar de cargar. No utilice un

dispositivo para mantener abierta la

boquilla.

e. Apague todos los cigarrillos, cigarros,

pipas y otras fuentes de combustión.

f. Nunca cargue combustible en la máquina

en interiores.

g. Nunca saque el tapón del combustible ni

agregue combustible mientras el motor

está caliente o en marcha. Deje que el

motor se enfríe por lo menos dos minutos

antes de cargar combustible.

h. Nunca llene en exceso el tanque de

combustible. Llene el tanque no más de ½

pulgada por debajo de la base del cuello

de llenado para dejar espacio para la

expansión del combustible.

i. Reemplace de manera segura todas las

tapas de tanque de combustible y las

tapas de los contenedores.

j. Limpie el combustible que se haya

derramado sobre el motor y el equipo.

Traslade la unidad a otro lugar. Espere 5

minutos antes de arrancar el motor.

k. Para reducir el riesgo de incendio,

mantenga la máquina limpia de pasto,

hojas y residuos acumulados. Limpie

los derrames de aceite o combustible y

retire todos los residuos impregnados de

combustible.

l. Nunca guarde la máquina o el recipiente

de combustible en un espacio cerrado

donde haya una llama expuesta, chispas

o llama piloto, como por ejemplo de

calentadores de agua, calefactores de

ambientes, hornos, secadores de ropa y

otros aparatos a gas.

Funcionamiento

1. No acerque las manos o los pies a las piezas

rotatorias ni a las cámaras de alimentación o la

abertura de descarga. El contacto con el propulsor

giratorio puede amputar dedos, manos y pies.

2. Antes de encender la máquina compruebe que el

canal de la astilladora, el alimentador y la cámara

de corte están vacío y sin residuos.

3. Inspeccione minuciosamente todo el material

que desea triturar y saque los objetos metálicos,

piedras, botellas, latas u otros objetos extraños

que pueden ocasionar lesiones o dañar la

máquina.

4. Si es necesario empujar el material por la tolva de

la trituradora use un palo de poco diámetro. No

utilice las manos ni los pies.

5. Si el propulsor golpea un objeto extraño o si la

máquina empieza a producir un sonido poco

común o una vibración, apague el motor de

inmediato. Deje que el propulsor se detenga

por completo. Desconecte el cable de la bujía,

póngalo haciendo masa contra el motor y siga los

pasos siguientes:

a. Inspeccione la máquina para ver si está

dañada.

b. Repare o reemplace las piezas dañadas.

c. Controle si hay piezas flojas y ajústelas

para garantizar que la máquina continúe

funcionando de forma segura.

6. No permita que se acumule material procesado en

el área de descarga. El mismo puede obstaculizar

la descarga correcta y provocar el retorno del

material a través de la abertura del alimentador.

7. No intente triturar ni astillar material de mayor

tamaño al especificado en la máquina o en este

manual. Podría ocasionar lesiones personales o

daño a la máquina.

8. Nunca intente destapar el alimentador o la

abertura de descarga mientras el motor está

en marcha. Apague el motor y espere hasta

que todas las piezas móviles se hayan detenido

por completo, desconecte el cable de la bujía y

póngalo a tierra contra el motor antes de sacar los

residuos.

9. Nunca opere la máquina sin que la tolva de la

trituradora, el canal de la astilladora o el canal

deflector estén correctamente conectados a

la máquina. Nunca vacíe ni cambie la bolsa de

descarga mientras el motor está en marcha.

10. No cambie los ajustes del regulador ni acelere

demasiado el motor. El regulador controla la

velocidad máxima de óptimo funcionamiento del

motor.

11. Mantenga el rostro y el cuerpo detrás y hacia

un costado del canal de la astilladora mientras

introduce material dentro de la máquina para

evitar lesiones por retrocesos accidentales.

12. Nunca opere esta máquina si no tiene buena

visibilidad o luz.

13. No opere esta máquina en superficies

pavimentadas, con grava o desniveladas.

14. No opere esta máquina estando bajo los efectos

del alcohol o de las drogas.

15. El silenciador y el motor se calientan y pueden

causar quemaduras. No los toque.

16. Nunca levante o cargue la máquina cuando el

motor esté encendido.

Page 13

17. Si se presentan situaciones que no están previstas

en este manual, tenga cuidado y use el sentido

común. Póngase en contacto con Asistencia

al Cliente para solicitar ayuda y el nombre del

distribuidor de servicio más cercano.

18. Nunca encienda el motor en espacios cerrados o

en una zona con poca ventilación. El escape del

motor contiene monóxido de carbono, un gas

inodoro y letal.

19. Nunca intente destapar el alimentador o la

abertura de descarga, ni trate de sacar o vaciar la

bolsa ni revisar o reparar la máquina mientras el

motor está en marcha. Apague el motor y espere

hasta que todas las piezas móviles se hayan

detenido por completo. Desconecte el cable de la

bujía y póngalo a tierra contra el motor.

20. Si la máquina comienza a vibrar de

manera anormal, pare el motor y verifique

inmediatamente la causa. La vibración es

generalmente una señal de advertencia de

problemas.

21. Detenga el motor cuando abandone la posición

de operación y cuando realice reparaciones,

ajustes e inspecciones.

22. Tome todas las precauciones posibles según lo

recomendado por el fabricante al dejar la máquina

desatendida. Desconecte la toma de fuerza,

cambie a neutral, pare el motor y retire la llave.

23. No haga funcionar el motor en un espacio

confinado donde puedan acumularse humos

peligrosos de monóxido de carbono.

24. Nunca opere la máquina a altas velocidades de

transporte en superficies duras o resbaladizas.

25. Tenga mucho cuidado al invertir o tirar de la

máquina hacia usted.

Mantenimiento y Almacenamiento

1. Nunca altere los dispositivos de seguridad.

Controle periódicamente que funcionen

correctamente.

2. Controle frecuentemente que los pernos y

tornillos estén bien ajustados para mantener la

máquina funcionando con seguridad. Además,

realice inspecciones visuales de la máquina

buscando daños y si es necesario repárela.

3. Antes de limpiar, reparar o inspeccionar la

máquina, pare el motor y compruebe que el

propulsor y todas las partes móviles se hayan

detenido. Desconecte el cable de la bujía y

póngalo haciendo masa contra el motor para

evitar que se encienda accidentalmente.

4. Mantenga todos los protectores, deflectores y

dispositivos de seguridad colocados y en buenas

condiciones.

5. Mantenga o reemplace las etiquetas de seguridad

y de instrucciones según sea necesario.

6. Consulte este manual para cargar, descargar,

transportar y almacenar con seguridad esta

máquina.

7. Nunca almacene la máquina o el recipiente de

combustible en un espacio cerrado donde haya

una llama expuesta, chispas o llama piloto como

por ejemplo, de calentadores de agua, hornos,

secarropas, etc.

8. Deje que la máquina se enfríe al menos 5 minutos

antes de guardarla.

9. Consulte siempre el manual del operador

para obtener instrucciones correctas sobre el

almacenamiento fuera de temporada.

10. Si tiene que drenar el tanque de combustible,

hágalo al aire libre.

11. Cumpla con las normas y reglamentaciones sobre

la manera de eliminar gasolina, aceite, etc. para

proteger el medio ambiente.

12. Según la Comisión de Seguridad de Productos

para el Consumidor de los EE.UU. (CPSC) y la

Agencia de Protección Ambiental de los EE.UU.

(EPA), este producto tiene una vida útil media

de siete (7) años o 60 horas de funcionamiento.

Al finalizar la vida útil media haga inspeccionar

anualmente esta unidad por un distribuidor de

servicio autorizado para cerciorarse de que todos

los sistemas mecánicos y de seguridad funcionan

correctamente y no tienen excesivo desgaste. Si

no lo hace, puede ocasionar accidentes, lesiones

o la muerte.

No modifique el motor

Para evitar lesiones graves o la muerte, no modifique

el motor de ninguna manera. Si altera los ajustes del

regulador, el motor se puede desbocar y funcionar a

velocidades inseguras. Nunca altere los ajustes de fábrica

del regulador del motor.

Aviso sobre las Emisiones

Los motores certificados que cumplen con las normas

sobre emisiones federales de la EPA y de California para

SORE (Equipos pequeños todo terreno) pueden funcionar

con gasolina sin plomo común y pueden incluir los

siguientes sistemas de control de emisiones: Modificación

de motor (EM), catalizador oxidante (OC), inyección de

aire secundaria (SAI) y catalizador de tres vías (TWC) si

están instalados.

Amortiguador de Chispas

ADVERTENCIA: Esta máquina está

equipada con un motor de combustión

interna y no debe utilizarse en un terreno

agreste cubierto de bosque, malezas o pasto

o cerca de él salvo que el sistema de escape

del motor incluya un amortiguador de

chispas que cumpla con la legislación local o

estatal vigente (si corresponde).

Si se utiliza un amortiguador de chispas el operador

lo debe mantener en buenas condiciones de uso. En

el Estado de California, las medidas anteriormente

mencionadas son exigidas por ley (Artículo 4442 del

Código de Recursos Públicos de California). Es posible

que existan leyes similares en otros estados. Las leyes

federales se aplican en territorios federales.

Puede conseguir el amortiguador de chispas para el

silenciador a través de su distribuidor autorizado de

motores más cercano o poniéndose en contacto con el

departamento de servicios, P.O. Box 361131 Cleveland,

Ohio 44136-0019.

Símbolos de Seguridad

En esta página se muestran y describen los símbolos de seguridad que pueden aparecer en este producto. Lea, comprenda y siga todas las instrucciones incluidas con la máquina

antes de intentar armarla y hacerla funcionar.

Símbolo Descripción

LEA LOS MANUALES DEL OPERADOR

Lea, entienda y siga todas las instrucciones incluidas en los manuales antes de intentar armarla y hacerla

funcionar.

ADVERTENCIA – CUCHILLAS GIRATORIAS

Mantenga las manos alejadas de las aberturas de alimentación y descarga cuando la máquina está

funcionando. Adentro hay cuchillas giratorias.

OBSERVADORES

Mantenga a los observadores, las mascotas y los niños por lo menos a 75 pies de la máquina siempre que

esté funcionando. Pare la máquina si alguien ingresa a la zona.

ADVERTENCIA – ARROJA DESECHOS

Nunca opere la máquina sin tener el canal deflector correctamente colocado en la máquina.

PROTECCIÓN OCULAR

Use siempre anteojos o antiparras de seguridad cuando opere esta máquina.

ADVERTENCIA: Su Responsabilidad. Esta máquina eléctrica sólo puede ser usada por personas que lean, comprendan y respeten las

advertencias e instrucciones que aparecen en este manual y sobre la máquina.

¡GUARDE ESTAS INSTRUCCIONES!

3Sección 1 — importanteS medidaS de Seguridad

Page 14

Armado y Montaje

B

A

1

2

3

4

Muchas gracias

Gracias por comprar este producto. Ha sido cuidadosamente diseñado para brindar

excelente rendimiento si se lo hace funcionar y se lo mantiene correctamente.

Por favor lea todo este manual antes de hacer funcionar el equipo. El manual le indica

cómo configurar, hacer funcionar y mantener la máquina de manera fácil y segura. Por

favor asegúrese de que usted, y cualquier otra persona que utilice la máquina, siga

atentamente y en todo momento las medidas de seguridad recomendadas. De lo

contrario, se podrían producir lesiones personales o daños materiales.

Toda la información contenida en este manual hace referencia a la más reciente

información de producto disponible en el momento de la impresión. Revise el

manual frecuentemente para familiarizarse con la máquina, sus características y su

funcionamiento. Por favor tenga en cuenta que este Manual del Operador puede

abarcar una variedad de especificaciones para productos de diversos modelos. Es

posible que las características y funciones incluidas y/o ilustradas en este manual

no se apliquen a todos los modelos. Nos reservamos el derecho de modificar las

especificaciones de los productos, diseños y equipos sin previo aviso y sin generar

responsabilidad por obligaciones de ningún tipo.

Contenido de la caja

• Trituradora Astilladora (1) • Manual del Operador (1) • Manual del Operador del Motor (1) • Botella de aceite (1)

• Barra de remolque (1)(Si está equipado) • Bolsa (1) • Anteojos de seguridad (1)

Si corresponde, la información sobre las prueba de potencia utilizada para determinar

la potencia nominal del motor equipado en esta máquina se puede consultar en www.

opei.org o en el sitio web del fabricante del motor.

Si tiene algún problema o duda con respecto a la máquina, llame a su distribuidor

local o comuníquese directamente con nosotros. En página de suplemento encontrará

los números de teléfono, el sitio web y la dirección postal de la Atención al cliente.

Queremos garantizar su entera satisfacción en todo momento.

En este manual, todas las referencias al lado derecho e izquierdo de la máquina se hacen

observándola desde la posición de operación.

El fabricante del motor es el responsable de todas las cuestiones relacionadas con el

rendimiento, potencia de salida, especificaciones, garantía y mantenimiento del motor.

Para obtener mayor información consulte el manual del operador del motor, que

acompaña a su máquina en un paquete por separado.

2

Armado

NOTA: Esta unidad se despacha sin gasolina ni

aceite en el motor. Llene con gasolina y aceite como

se indica en el manual del motor adjunto ANTES de

hacer funcionar la trituradora astilladora.

Canal de la astilladora (modelo serie CS3310 y 4325)

Por razones de envío, la unidad se despacha en una

caja con el canal de la astilladora en posición elevada.

Para girarla hacia abajo proceda de la siguiente

manera:

1. Tire del pasador con resorte hacia arriba. Vea A

en la Figura 2-1.

2. Gire suavemente el canal de la astilladora

hacia abajo hasta que se trabe en la varilla de

seguridad. Vea B en Figura 2-1.

Figura 2-1

ADVERTENCIA: No opere nunca la

trituradora astilladora con el canal de la

astilladora en la posición elevada. De

hacerlo puede ocasionar daños materiales

o lesiones graves al operador o a los

observadores.

4

Bolsa

Para colocar la bolsa:

3. Ponga la abertura de la bolsa completamente

sobre el canal deflector. Vea la Figura 2-2.

Figura 2-2

4. Ubique la bolsa de manera que cubra

totalmente las perillas mariposa que sujetan el

deflector del canal a la caja del propulsor.

5. Jale de la tira de extracción hasta que la bolsa

quede ajustada alrededor de la abertura del

canal deflector.

Barra de remolque (Si está equipado)

Para acoplar la barra de remolque:

6. Saque el pasador de resorte y el pasador de

horquilla del extremo del receptor de la barra

de remolque. Vea la Figura 2-3.

Figura 2-3

7. Inserte la barra de remolque en el receptor. Vea

la Figura 2-4.

8. Vuelva a insertar el pasador de horquilla en los

orificios de alineación de la barra de remolque

y del receptor. Vea la Figura 2-4.

9. Sujete con el pasador de resorte para asegurar.

Vea la Figura 2-4.

Figura 2-4

Montaje

Llenado de gasolina y aceite

Consulte en el manual del motor para información

adicional sobre el motor.

10. Agregue el aceite provisto antes de hacer

arrancar la unidad por primera vez luego de

desembalarla. En el manual del propietario

del motor encontrara las instrucciones para

agregar aceite de motor.

11. Realice el mantenimiento del motor con

gasolina como se indica en el manual del

propietario del motor adjunto.

ADVERTENCIA: Tenga mucho cuidado al

trabajar con gasolina. La gasolina es

sumamente inflamable y sus vapores son

explosivos. Nunca agregue combustible a

la máquina en espacios cerrados ni

mientras el motor está caliente o en

marcha. Apague cigarrillos, cigarros, pipas

y otras fuentes de combustión.

ADVERTENCIA: Nunca cargue el tanque

de combustible en espacios cerrados con

el motor en marcha o hasta que haya

dejado que se enfríe por lo menos dos

minutos después de haber estado en

marcha.

Page 15

Controles y Funcionamiento

Tolva

Manija

Canal de la astilladora

Arrancador de retroceso

3

Cerrojo de resorte

Barra de remolque

Eje de dirección

Controles

Canal de la astilladora

Se pueden introducir ramas de hasta dos pulgadas

(modelo serie CS2210) o de tres pulgadas (modelo

serie CS3310) de diámetro en el canal de la astilladora

para astillar.

Tolva

Las hojas, ramas pequeñas y ramas de hasta 1/2

pulgada de diámetro se pueden colocar dentro de la

tolva para ser trituradas.

IMPORTANTE: No coloque nunca en la tolva ramas

con un diámetro superior a 1/2 pulgadas. De hacerlo

se puede dañar gravemente la cuchilla trituradora, las

pantallas o el propulsor de la unidad.

eje de dirección

Use el receptor para asegurar la barra de remolque

a la trituradora astilladora cuando remolque la

trituradora astilladora con un tractor.

Figura 3-1

Manija

Use la manija cuando transporte manualmente la

trituradora astilladora.

Arrancador de retroceso

El arrancador de retroceso se encuentra sobre el

motor. Consulte el manual del operador del motor

aparte para ver las instrucciones de arranque del

motor.

Controles del motor

Consulte el manual del operador del motor

despachado con su unidad para ver la ubicación y

función de los controles del motor.

Varilla de seguridad

Pasador con Resorte (CS3310 y CS 4325)

El pasador con resorte está ubicado en la parte

superior de la tolva. Se usa para soltar o trabar el

canal de la astilladora en una posición elevada para

almacenarla o transportarla. Vea la Figura 3-1.

ADVERTENCIA: No opere nunca la

trituradora astilladora con el canal de la

astilladora en la posición elevada. Use el

pasador con resorte para bajar el canal de

la astilladora hasta la posición de

funcionamiento antes de arrancar el

motor.

Varilla de Seguridad (CS3310 y CS 4325)

La varilla de seguridad está ubicada en el soporte del

canal de la cortadora. Se usa para soltar o trabar el

canal de la astilladora en una posición más baja para

funcionar.

Deflector

Los escombros se descarga de cámara de reducción

de la máquina a través del deflector de la tolva.

5

Page 16

Funcionamiento

ADVERTENCIA: Al hacer funcionar una

trituradora astilladora es posible que

arroje objetos extraños a los ojos, lo cual

puede dañarlos seriamente. Utilice

siempre los anteojos de seguridad

provistos con esta unidad o protectores

para ojos antes de astillar o triturar o

mientras realiza ajustes o reparaciones.

Encendido del motor

Consulte las instrucciones para arrancar el motor en el

manual del operador del motor.

Triturado

ADVERTENCIA: No utilice nunca la

trituradora astilladora sin haber bajado el

canal de la astilladora hasta la posición de

funcionamiento.

Los desechos como hojas y agujas de los pinos se

pueden colocar en la tolva para triturarlos. Después

de procesar el material con la cuchilla trituradora y

los agitadores, es empujado fuera del deflector del

canal y, si está instalada, hacia el interior de la bolsa

recolectora de residuos.

Respete las siguientes pautas cuando triture los

desechos acumulados en el patio:

• Nunca intente triturar otra cosa que los

desechos normales acumulados en el patio

(hojas, ramas, piñas, etc.).

• Evite triturar plantas fibrosas como los tallos de

tomates hasta que estén totalmente secas. Las

plantas de tomates frescas no se trituran bien y

tienden a enroscarse alrededor del propulsor y

los agitadores.

• Coloque cantidades razonables de desechos en

la tolva por vez. No recargue la tolva.

• Deje que el material que se encuentra en la

tolva sea atraído por las cuchillas y triturado

antes de agregar más desechos dentro de la

misma. De lo contrario, se puede tapar la tolva,

el deflector del canal o calar el motor.

• Evite colocar en la tolva ramas cuya longitud

exceda las 24 pulgadas. Las ramas de más de 24

pulgadas de largo pueden tapar la tolva.

IMPORTANTE: No coloque nunca en la

tolva ramas con un diámetro superior a

1/2 pulgadas. De hacerlo se puede dañar

gravemente la cuchilla trituradora, los

agitadores o el propulsor de la unidad.

4. Use una rama (o algo similar, como una escoba)

para desalojar los desechos ubicados cerca de

la base de la tolva.

5. Vuelva a arrancar el motor.

NOTA: Si no puede tirar de la cuerda de

arranque por los desechos acumulados cerca

del propulsor, siga las instrucciones incluidas

bajo el título Limpieza de la Cámara de

Reducción en la sección "Mantenimiento de su

Trituradora Astilladora” en este manual.

Astillado

ADVERTENCIA: No utilice nunca la

trituradora astilladora sin haber bajado el

canal de la astilladora hasta la posición de

funcionamiento.

Se pueden introducir ramas de hasta dos pulgadas

(modelo serie CS2210) o de tres pulgadas (modelo

serie CS3310) de diámetro en el canal de la astilladora.

Respete las siguientes pautas cuando astille ramas:

• Mantenga ambas manos firmemente en la

rama a medida que la coloca dentro del canal

de la astilladora.

• No ponga nunca más de una rama dentro del

canal de la astilladora por vez.

• En el canal de la astilladora sólo se pueden

colocar ramas (de madera).

• Aplique presión intermitente (fuerza, en

impulsos cortos) cuando coloque ramas más

largas dentro del canal de la astilladora para

evitar ahogar o calar el motor.

IMPORTANTE: Nunca coloque ramas con un

diámetro superior a dos (2) pulgadas (modelo

serie CS2210) o tres (3) pulgadas (modelo

serie CS3310) en la tolva de la astilladora. De

hacerlo se puede dañar gravemente la cuchilla

astilladora, los agitadores o el propulsor de la

unidad.

NOTA: Para mejor rendimiento, opere siempre

la unidad con cuchillas astilladoras afiladas.

Si se produce una reducción apreciable en

el rendimiento mientras astilla ramas, debe

reemplazar las cuchillas astilladoras.

Vaciado de la bolsa

6. Pare el motor.

7. Oprima la hebilla de seguridad para soltar la

tira de extracción de la bolsa antes de soltarla

del deflector del canal. Vea la Figura 3-2.

Limpieza de la tolva

Si la tolva se tapa con desechos durante el

funcionamiento, proceda de la siguiente manera:

1. Tome la manija con las dos manos y agite

suavemente la trituradora astilladora para

ayudar a aflojar los desechos, atrayéndolos

hacia el propulsor.

Si no se elimina el atascamiento proceda de la

siguiente manera:

2. Pare el motor.

3. Use las manos para sacar los desechos que se

encuentran cerca de la parte superior de la

tolva.

6 Sección 3 — controleS y Funcionamiento

Figura 3-2

8. Vacíe la bolsa y vuelva a colocarla en la

abertura del deflector del canal. Consulte la

sección “Armado y Montaje” de este manual.

Page 17

Servicio

A

C

B

A

C

B

4

Servicio

Recomendaciones generales

• Respete siempre las normas de seguridad al

realizar tareas de mantenimiento.

• La garantía de esta trituradora astilladora no

cubre elementos que han estado sujetos al mal

uso o la negligencia del operador. Para recibir

el reembolso total de la garantía, el operador

deberá dar mantenimiento al equipo tal y

como se indica en este manual.

• El cambio de la velocidad controlada del motor

invalidará la garantía del motor.

• Todos los ajustes deben ser inspeccionados al

menos una vez por temporada.

• Revise periódicamente todos los sujetadores y

compruebe que estén bien ajustados.

ADVERTENCIA: Pare siempre el motor,

desconecte la bujía y haga tierra contra el

motor antes de limpiar, lubricar o hacer

cualquier tipo de mantenimiento en su

máquina.

Lubricación

1. Lubrique la bisagra del canal de la astilladora

con un aceite ligero una vez por temporada.

2. Lubrique los puntos pivotales del deflector

del canal con aceite liviano una vez por

temporada.

3. Siga las instrucciones para lubricar el motor del

manual del motor que acompaña a su unidad

en paquete aparte.

Cuidado del Equipo

• Limpie cuidadosamente la trituradora

astilladora después de cada uso.

• Lave la bolsa con agua periódicamente.

Permita que se seque bien a la sombra.

• Si la cámara de reducción se tapa, sáquela y

límpiela como se indica a continuación.

• Deje funcionar la unidad un rato hasta eliminar

todos los residuos antes de apagar y guardarla.

NOTA: No se recomienda limpiar con chorro

de agua a presión ya que el sistema de

combustible podría resultar contaminado.

Cuidado del Motor

Consulte la sección Mantenimiento del manual del

propietario/operador que acompaña a su unidad. Lea

y siga las instrucciones cuidadosamente.

• Verifique el nivel de aceite del motor antes

de cada uso como se indica en el manual del

motor que acompaña en paquete aparte.

• Limpie o reemplace el filtro de aire cada 25

horas en condiciones de uso normal. Limpie a

intervalos de pocas horas cuando haya mucho

polvo. Para realizar el mantenimiento del filtro

de aire, consulte el manual del motor.

• La bujía se debe limpiar y la separación se debe

reajustar una vez por temporada. Consulte

el manual del motor para ver el tipo de bujía

correcto y las especificaciones de la separación.

• Limpie periódicamente el motor con un trapo

o cepillo. Mantenga limpia la parte superior

del motor para permitir la circulación de aire

adecuada. Quite todo el césped, suciedad y

residuos combustibles del área del silenciador.

Limpieza del Canal de Reducción

ADVERTENCIA: Las cuchillas trituradoras

y astilladoras del motor están afiladas. Use

guantes de trabajo de cuero para

protegerse las manos cuando limpie la

cámara de reducción.

Si la cámara de reducción se tapa con residuos, la

pantalla de la trituradora se puede girar hacia arriba

para poder limpiar la zona circundante. Para ello,

proceda de la siguiente manera:

1. Pare el motor, desconecte la bujía y verifique

que la trituradora astilladora se ha detenido

por completo.

ADVERTENCIA: El silenciador y la zona

circundante están calientes si el motor ha

estado en funcionamiento. Sea precavido

y protéjase las manos si trabaja cerca del

silenciador.

2. Si está instalada, retire la bolsa de residuos.

Saque las dos perillas mariposa de ambos lados

del deflector del canal y gírelo hacia arriba. Vea

A en Figura 4-1.

Figura 4-1

3. Saque el broche de horquilla del pasador de

horquilla que se extiende a través de la caja del

motor y de la pantalla de la trituradora. Vea B

en Figura 4-1. Saque el pasador de horquilla.

4. Pivote hacia arriba la pantalla de la trituradora.

Vea C en Figura 4-1. Limpie los alrededores

barriendo los residuos.

5. Confirme que el cable de la bujía esté

desconectado y alejado de la bujía. Tire de la

cuerda del arrancador entre dos y tres veces

para purgar los residuos restantes de la cámara

de reducción

6. Una vez limpia la zona, gire la pantalla de la

trituradora y vuelva a afianzar con el pasador

de horquilla y el sujetador de horquillas que

retiró anteriormente.

7. Vuelva a colocar la bolsa de recolección de

residuos en el deflector del canal, si lo desea.

Cuidado de las Cuchillas Astilladoras

ADVERTENCIA: Las cuchillas astilladoras

del impulsor son filosas. Utilice guantes

de trabajo de cuero para protegerse las

manos.

1. Pare el motor, desconecte la bujía y verifique

que la trituradora astilladora se ha detenido

por completo.

2. Pivote la pantalla de la trituradora como se

indica bajo el título Limpieza de la cámara de

reducción.

3. Retire la traba que sujeta el canal de la

astilladora a la estructura. Para ello saque

los dos pernos hexagonales y las arandelas

cóncavas que la aseguran. Vea A en Figura 4-2.

Figura 4-2

4. Para sacar el canal de la astilladora saque las

tres tuercas hexagonales y las arandelas que

lo aseguran a la caja del motor. Vea B en Figura

4-2.

5. Gire el impulsor a mano hasta que una de las

dos cuchillas astilladoras sea visible a través de

la abertura de la caja del impulsor.

6. Para sacar la cuchilla saque los tornillos

hexagonales internos, las arandelas de

seguridad y las tuercas hexagonales que la

sujetan al motor. Vea C en Figura 4-2. Guarde

los accesorios.

NOTA: Use una llave hexagonal de 3/16”

(Allen) en el exterior de la cuchilla y una llave

de tubo de 1/2” (o cubo) en el interior del

motor. Sostenga la llave Allen firmemente y

gire la llave de tubo (o cubo) para aflojar la

tuerca.

7. Coloque una cuchilla de repuesto con los

accesorios extraídos anteriormente o afílela.

IMPORTANTE: Cuando afile la cuchilla,

protéjase las manos utilizando guantes. Siga

el ángulo original de afilado y asegúrese de

extraer una cantidad igual de cada cuchilla.

8. Para reemplazar la otra cuchilla, gire el motor

para exponer la segunda cuchilla y repita los

pasos anteriores.

7

Page 18

NOTA: Compruebe que las cuchillas estén

A

C

B

montadas nuevamente con el borde afilado

hacia afuera (hacia el canal de la astilladora).

Ajuste los accesorios con una presión de entre

20 pies/libras y 25 pies/libras.

Cuidado de la Cuchilla Trituradora

ADVERTENCIA: La cuchilla trituradora es

filosa. Utilice guantes de trabajo de cuero

para protegerse las manos.

1. Pare el motor, desconecte la bujía y verifique

que todas las piezas móviles se hayan detenido

por completo.

2. Saque las dos tuercas con reborde (y los pernos

hexagonales) que sujetan el soporte de la tolva

a la caja del motor. Guarde los accesorios. Vea

la Figura 4-3.

Figura 4-3

3. Pivote la pantalla de la trituradora como se

indica bajo el título Limpieza de la cámara de

reducción.

4. Saque las seis tuercas con reborde que sujetan

la guía de ingreso de la tolva a la caja del

motor. Vea A en Figura 4-4.

Figura 4-4

5. Separe con cuidado el montaje de la tolva de la

caja del motor y póngalo a un lado.

6. Coloque un trozo de madera dentro de la

abertura del deflector del canal para estabilizar