Page 1

Manual No. 62-254

Western Auto

OPERATION AND SERVICE INSTRUCTIONS

Wizard Front Tine Tiiier

STOCK NUMBER

94-2105-8

MODEL NUMBER

MTD2105A98

FACTORY NUMBER

219-355-098

Thank you for purchasing an American-built product.

Page 2

INDEX

Safe Operation Practices

Assembly.......................................................................4

Controls.......................................................................10

Operation.....................................................................10

How To Use Your Tiller...............................................10

Adjustments

Lubrication...................................................................14

Maintenance................................................................14

................................................................

...........................................

INSTRUCTIONS GIVEN WITH THIS SYM

BOL ARE FOR PERSONAL SAFETY. BE

A

SURE TO FOLLOW THEM,

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

This Wizard tiller will be repaired without charge by Western Auto Supply Company if it fails due

to defective materials or workmanship within one year of purchase date.

For repair service return tiller with proof of purchase date to any participating Western Auto Store.

Excluded from this warranty is any unit which has been altered, misused, abused, used for com

mercial or rental use. Repair by other than a Western Auto authorized service facility is also ex

cluded.

This warranty does not cover minor mechanical adjustments which are not due to defects in material

or workmanship. For assistance in making such adjustments, consult your owner’s manual.

Also excluded from Western Auto’s warranty is the engine used on Wizard tillers which is warranted

by the engine manufacturer. Repair service arrangements for the engine may be handled through

any participating Western Auto Store.

If difficulty is encountered in having this warranty honored, contact: Western Auto Supply Com

pany, Consumer Affairs Section, General Service Department, 2107 Grand Avenue, Kansas City.

Missouri 64108. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

WIZARD TILLER WARRANTY

MTD2002A98, MTD2105AdS, MTD3109A98 and MT04109A98

1 YEAR LIMITED WARRANTY

13

3

Off-Season Storage

Trouble Shooting Guide

Engine Operation and Maintenance

Instructions.........................................................17-20

Illustrated Parts for Tiller

Illustrated Parts for Engine

Parts Information

....................................................

..............................................

.......................................

....................................

.........................................

Back Cover

16

16

21-25

26-30

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

♦

J

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unim

proved forest-covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with

a spark arrester meeting applicable local or state laws (if any). If a spark arrester is used, it should be maintained

in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code).

Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available

through participating Western Auto Stores.

2

Page 3

WARNING \

To reduce the potential for any injury, comply with the following safety instructions. Failure to comply with

the instructions may result in personal injury.

SAFE OPERATION PRACTICES FOR TILLERS

1. It is suggested that this manual be read in its

entirety before attempting to assemble or

operate this unit. Keep this manual in a safe

place for future reference and tor ordering

replacement parts.

2. Your tiller is a precision piece of power equip*

ment, not a plaything. Therefore, exercise ex

treme caution at all times.

3. Read this Owner’s Manual carefully. Be

thoroughly familiar with the controls and the

proper use of the equipment.

4. Never allow children to operate a power tiller.

Only persons well acquainted with these rules

of safe operation should be allowed to use

your tiller.

5. No one should operate this un t while intoxi

cated or while taking medicaticn that impairs

the senses or reactions.

6. Keep the area of operation clear of all per

sons, particularly small children and pets.

14. Do not walk in front of the tiller white the

engine is running.

15. Check the fuel before starting the engine.

Gasoline is an extremely flammable fuel. Do

not fill gasoline tank indoors, when the engine

is running, or while the engine is still hot.

Wipe off any spilled gasoline before starting

the engine as it may cause a fire or explosion.

16. Do not run the engine while indoors. Exhaust

gases are deadly poisonous.

17. Be careful not to touch the muffler after the

engine has been running. It is hot.

18. Do not change the engine governor settings

or overspeed the engine. Excessive engine

speeds are dangerous.

19. Before any maintenance work is performed or

adjustments are made, remove the spark plug

wire and ground it on the engine block for

added safety.

7. Do not operate equipment when barefoot or

wearing open sandals. Always wear substan

tial footv/ear.

8. Do not wear loose fitting clothing that could

get caught on the tiller.

9. Do not start the engine unless the shift lever

is in the neutral (N) position.

10. Do not stand in front of the tiller while starting

the engine.

11. Do not place feet and hands on or near the

tines when starting the engine or while the

engine is running.

12. Never attempt to make a wheel or depth bar

adjustment while the engine is running.

13. Do not leave the tiller unattended with the

engine running.

20. Use caution when tilling near buildings and

fences. Rotating tines can cause damage or

injury.

21. Before attempting to remove rocks, bricks and

other objects from tines, stop the engine and

be sure the tines have stopped completely.

Disconnect the spark plug wire and ground to

prevent accidental starting.

22. Check the tine and engine mounting bolts at

frequent intervals for proper tightness.

23. Keep all nuts, bolts and screws tight to be

sure the equipment is in safe working condi

tion.

24. Never store the equipment with gasoline in

the tank inside of a building where fumes may

reach an open flame or spark. Allow the

engine to cool before storing in any

enclosure.

Page 4

NOTE

This unit is shipped WITHOUT GAS

OLINE or OIL. After assembly, see

separate engine section of this manual

for proper fuel and engine oil recom

mendations.

NOTE

Right and left hand is determined when

standing behind the titier in the operating

position.

D—I I 0^1

F

-----

» G—

B-

FIGURE 1.

ASSEMBLY INSTRUCTIONS

Tools Required for Assembly:

(2) M2" Wrenches or Sockets*

(2) 9/16" Wrenches or Sockets*

(1) Adjustable Wrench

(1) Phillips Screwdriver

(1) Flat Blade Screwdriver

‘The adjustable wrench may be used in piace of one

of the wrenches.

UNPACKING

Remove the tiller and loose parts from the carton. Make

certain all parts and literature have been removed

before the carton Is discarded.

Extend all control cables and place on the floor, Be

careful not to bend or kink control cables.

Parts in Carton:

Tiller

Handle Panel Assembly

Depth Stake

Tailpiece

Hardware Pack

‘Contents of Hardware Pack; (See Figure 1)

U-Clevis Pin

A (1)

B (4)

i

lO

Hairpin Clips

C

Clevis Pins

(3)

D

Hex Bolts 3/8-16 X 1" Long

(6)

E

Belleville Washers 3/8" I.D.

(2)

F

Lock Washers 3/8" I.D.

(6)

G

Hex Nuts 3/8-16 Thread

(6)

Phillips Head Self-Tapping Screw

J

(1)

K (1) Left Hand Cable Hold-Down (Black)

L (1) Right Hand Cable Hold-Down (Brown)

M (2) Self-Tapping Screws

N (3) Cable Ties

Loosen

Bolt

FIGURE 2.

Hairpin Clip (B)

Clevis

Pin (A)

Depth Stake

Spring

TAILPIECE INSTALLATION

Slide the tailpiece into the frame. If necessary, loosen

the two bolts on each side of the frame as shown in

figure 2 in order to insert the tailpiece. Secure with "U"-

devis pin (A) and hairpin clip (B). Tighten the bolts on

-the frame. See figure 2.

NOTE

The U-clevis pin which secures the

tailpiece can be set for two different

methods of operation. Refer to “Swinging

Tailpiece/Depth Stake” section on

page 11.

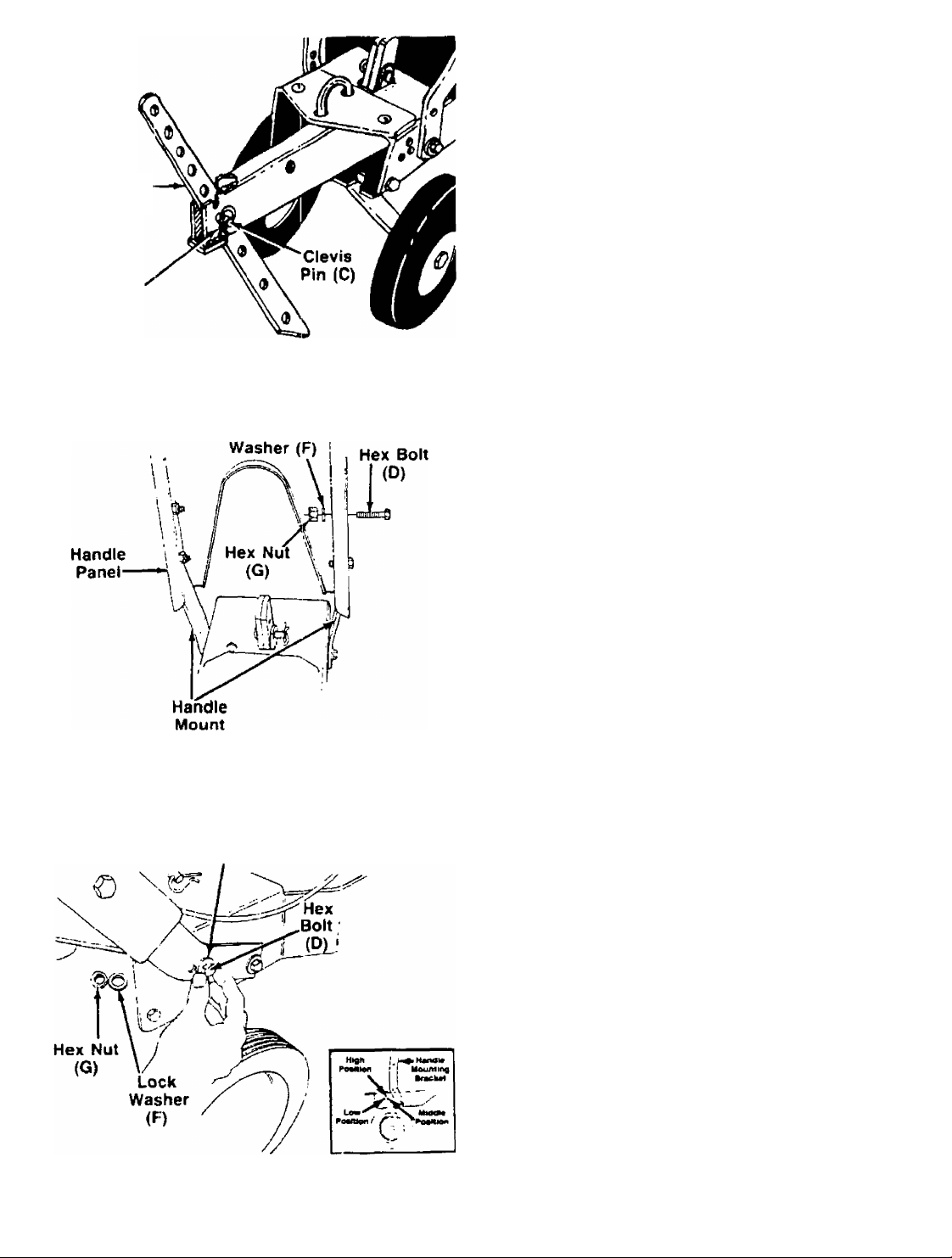

Page 5

Depth Stake

Hairpin

Clip (B)

FIGURE 3.

Lock

DEPTH STAKE INSTALLATION

Slide the depth stake into the tailpiece to desired depth.

Pointed end of depth stake should face forward as

■shown in figure 3. Secure with one clevis pin (C) and

hairpin clip (B).

HANDLE PANEL INSTALLATION

1.

---

The handle mounting brackets are in an upright

position for shipping purposes. Slide the handle

panel assembly down over the handle mounting

brackets. Secure with hex bolts (D), lock washers

------

(F) and hex nuts (G). See figure 4.

FIGURE 4.

FIGURE 5.

Brackets

Belleville

Washer (E)

2. There are three holes in the frame, which provide

three handle height positions. Pull the handle

assembly back and select position desired, align

ing one of the holes in handle mounting bracket

—with selected hole in the frame. See figure 5, inset.

3. Place bellevilte washers (E) onto hex bolts (D)

(crowned side of washer goes against head of bolt).

Place bolts through handle mounting brackets and

frame. Secure with lock washers (F) and hex nuts

(G). See figure 5. A 9/16" wrench and an ad

justable wrench is required.

4. Tighten securely all nuts and bolts used to assem

ble the handle, including handle pivot bolts.

Page 6

THROTTLE CONTROL ASSEMBLY

The throttle control is already attached to the engine.

Assemble the throttle control to the handle panel as

follows (be careful not to kink the cable).

1. Route the throttle control cable between the han

dle mounting brackets. Hold the throttle control

assembly beneath the handle panel. Turn the con

trol sideways and insert the lever up through the

wide portion of the slot on the handle panel. See

——figure 6A.

2. After the end of the lever is through the slot, turn

and then tip the control forward as shown in figure

6B.

■^NOTE

The lever must be all the way to the

back of the control housing as shown

in figure 6B.

3. Slide the control completely through the slot as

shown in figure 6C.

4. Push the control back into the slot in the handle

panel and press in place. See figure 6D. Be cer

tain the control is locked securely into the slot.

5. Secure the throttle control to the handle panel

using Phillips head self-tapping screw (J). See

figure 6E.

FIGURE 7.

Slot in

Cable Bracket

’Hold-Down

(K) (Black)

Cable

ATTACHING THE CLUTCH CONTROL CABLES

The clutch control cables, already attached to the idler

brackets, are labeled FORWARD and REVERSE. The

left hand cable hold-down is black and is marked with

an “L.” The right hand cable hold-down is brown and

-is marked with an “R.” See figure 8.

1. Attach the forward clutch cable to the left handle

as follows (be careful not to kink the cable),

a. Remove one hex nut and flat washer from the

end of the casing on the forward clutch cable.

Slip the wire through the slot on the cable

bracket on the left handle. Push the end of the

casing up through the cable bracket. Rethread

the hex nut on the end of the cable. Do not

tighten at this time. See figure 7.

b. Hook the barrel end of the cable into the left

hand cable hold-down (K) (black). Slide the

cable around in the slot as shown in figure 8.

FIGURE 8.

Page 7

c.---Pull the cable upwards to obtain slack, lift the

left hanc clutch grip and insert the left hand

cable hold-down into the clutch grip. Secure

-----

with self-tapping screw (M). See figure 9.

With the clutch lever released (in the “up" posi

tion), adjust the bottom nut at the cable bracket

so there is only a slight amount of slack in the

control wire. Tighten the upper nut against the

bracket. Squeeze the clutch lever against the

handle. The control wire should now be straight.

See figure 10.

NOTE

Do not overtighten control wire. Too

much tension may cause it to break.

Clutch

Grip

FIGURE 10.

Control Wire

is Straight

2. Attach the reverse clutch cable to the right handle

in the same manner, using the right hand cable

hold-down (L) (brown).

WARNING X

Ai

The forward and reverse clutch cable

adjustment must be checked before

the unit is operated as instructed in

the Final Adjustment section on page 8.

3. Secure the control cables to the handle panel as

follows.

a. Secure the forward and reverse clutch cables

to the holes in back of the handle panel (left

hand side) using two cable ties (N) as shown

---------

in figure 11. Leave ties fairly loose.

b. Secure the throttle control cable to one of the

holes in the inside of the handle panel (right

hand side) as shown in figure 11. Leave tie fairly

loose.

4. Frim excess ends of cable ties.

■» »

FIGURE 11.

Page 8

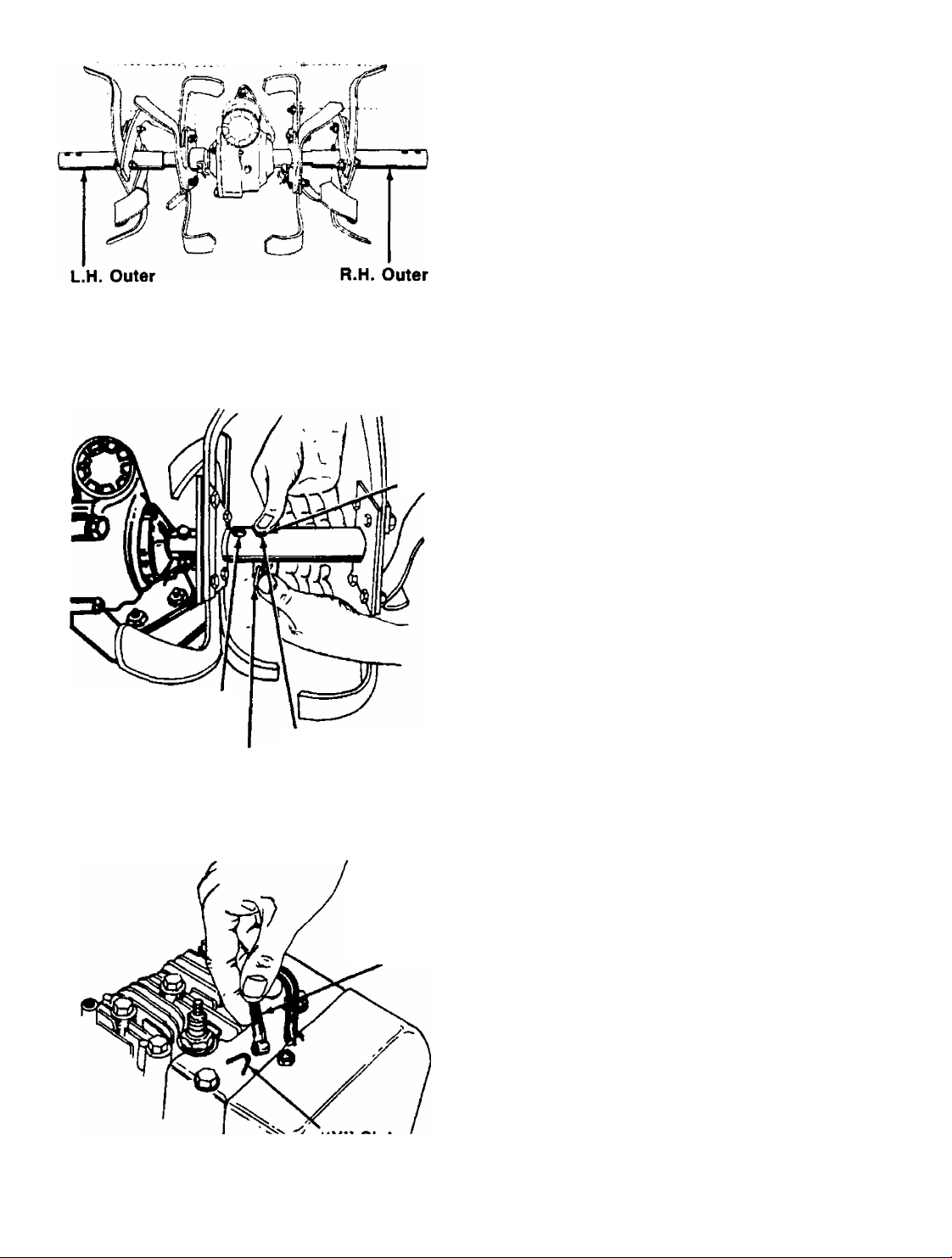

Tine Assembly

(Shipping

Position)

FiGURE 12.

FRONT

TINE INSTALLATION

The inner tine assemblies are installed in their correct

position at the factory. The outer tine assemblies have

been reversed for shipping purposes only. See figure

-12.

1. Remove both outer tine assemblies.

2. Place the left hand outer tine assembly (was

shipped on the right hand tine shaft) onto the left

hand shaft.

Tine Assembly

(Shipping

Position)

FIGURE 13.

FIGURE 14.

Hole for

28" Width

Hairpin

Clip (B)

Hole for

26" Width

-V*’ Slot

\\ on Engine

Clevis

Pin (C)

Spark Plug

Wire

3. Align one of the holes in the tine assembly with the

hole in the tine shaft. Using the end hole on the

tine assembly will give a tilling width of 28". Using

the second hole will give a tilling width of 26". See

—figure 13.

4. Secure with clevis pin (C) and hairpin clip (B).

5. Install the right hand outer tine assembly in the

same manner.

^ NOTE

Make certain tines are installed so

that the sharp edge of the tines will

enter the soil first when in forward

drive.

FINAL CLUTCH ADJUSTMENT

To check the forward and reverse clutch cable adjust

ment, proceed as follows.

1. Disconnect the spark plug wire from the spark plug

to prevent accidental starting. Secure the end of

spark plug wire in the “V” slot on the engine. See

------

figure 14.

2. With both clutch grips released (neutral position),

pull the starter rope several times. The tines

should not turn. If they turn forward, loosen the

hex nut below the cable bracket on the left han

dle a few turns. Tighten the hex nuts above the

bracket. If they turn in reverse, adjust the hex nuts

at the cable bracket on the right handle in the

same manner.

Page 9

L

Adjustable Wrench

FIGURE 15.

Front Plug

Add Lubricant

Here

CHECK GEAR CASE LUBRICANT

After the tiller is assembled and before gasoline and

oil are added to the engine, check the tiller gear case

for correct lubricant level.

1. Level the tiller by placing wheel yoke in the posi-

------

tion shown in figure 15, inset (clevis pin Is placed

in the second hole from the top).

2. Remove the front pipe plug from tiller gear case.

See figure 15.

3. If lubricant flows from the outlet, lubricant is at the

—correct level. See figure 16.

4. If lubricant fails to flow from the outlet, lubricant

should be added. USE PENNANT OIL EP #35000,

which is available in an 8 ounce squeeze tube.

Order part number 737-0136 from participating

Western Auto Stores.

CONTROLS

Reverse Drive

THROTTLE CONTROL

The throttle control lever is located in the center of the

handle panel. It controls the engine speed and stops

the engine. See figure 17.

FORWARD DRIVE CLUTCH LEVER

The forward drive clutch lever is located on the left han

dle. See figure 17. Squeezing the lever against the han

dle engages the forward tine drive. Release the lever

to stop the forward motion.

REVERSE DRIVE CLUTCH LEVER

The reverse drive clutch lever is located on the right

handle. See figure 17. Squeezing the lever against the

handle moves the tines in reverse. Release the lever

to stop the reverse drive.

NOTE

Never engage both the forward and

reverse drive at the same time, or the

engine will stall.

Page 10

DEPTH STAKE

The depth stake controls the tilling depth. Refer to

"How to Use Your Tiller" section on this page.

OPERATION

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as instructed

in the separate engine section of this manual. Read in

structions carefully.

NOTE

Your tiller is shipped without oil; how

ever, a small amount of oil may be

present from the factory.

TO START ENGINE

i WARNING i

ák

BE SURE NO ONE IS STANDING IN

FRONT OF THE TILLER WHILE THE

ENGINE IS RUNNING OR BEING

STARTED.

FIGURE 18.

7. Move throttle control to SLOW position for a few

minutes warm-up. Move choke lever to RUN posi

tion as engine warms up.

NOTE

In order to idle smoothly, a new engine

may require 3 to 5 minutes running

above slow idle speed. Idle speed has

been adjusted to be correct after this

break-in period.

TO STOP ENGINE

1. Move throttle control lever to STOP position. See

figure 17.

2. Disconnect spark plug wire from spark plug and

ground against the engine to prevent accidental

starting while equipment is unattended.

1. Attach spark plug wire to spark plug.

2. Move the throttle control lever forward to FAST or

START position. Make certain both clutch levers

are released. See figure 17.

3. Move choke lever to CHOKE position.

NOTE

A warm engine may not require choking.

4. Grasp starter handle (see figure 18) and pull rope

out slowly until engine reaches start of compres

sion cycle (rope will pull slightly harder at this

point). Let the rope rewind slowly.

5. Pull rope with a rapid, continuous, full arm stroke.

Keep a firm grip on start handle. Let rope rewind

slowly. Do not let starter handle snap back against

starter.

6. Repeat preceding instructions 4 and 5 until engine

fires. When engine starts, move choke lever on

engine halfway between CHOKE and RUN.

HOW TO USE YOUR TILLER

The tiller is a precision built machine designed for seed

bed preparation, cultivating, furrowing and mulching.

It is engineered to minimize the hardest work in the

vegetable or flower garden, to till the soil for planting

and cultivating, and to perform many other useful labor

saving tasks in the garden. With the proper amount of

care and maintenance, this machine will provide the

owner with many years of service.

WHEEL POSITION

The tiller is shipped with the wheels adjusted such that

the unit sits level. During digging as the tines enter the

ground and the front of the tiller lowers, the wheels must

be raised to level the unit. This is essential for proper

engine operation. This adjustment is made by remov

ing the clevis pin and hairpin clip from wheel yoke, rais

ing the wheels to the desired height, and replacing the

clevis pin and hairpin clip. See figure 19.

10

Page 11

Clevis Pin

\C

ii./

\ 1

SWINGING TAILPIECE/DEPTH STAKE

The entire tailpiece and depth stake can be either

locked in position or allowed to swing freely. The

tailpiece and depth stake are used in the unlocked posi

tion when it is necessary to maneuver in small areas.

To lock, line up the holes in the rear frame with the

holes in the tailpiece, and push in the short end of the

U-clevis pin. To allow the tailpiece and depth stake to

swing, pul! out the U-clevis pin and place it in the for

ward hole as shown in figure 20.

U-Clevis

Wheel Yoke in

this position

for deep digging

Wheel Yoke in this

position for shallow

digging, cultivating and

transport

FIGURE 21.

2. Depth Stake Adjustment: The depth stake acts

as a brake for the tiller and controls the depth and

speed at which the machine will operate. Remove

the clevis pin and hairpin clip to raise or lower

depth stake. See figure 19.

By increasing the depth of the depth stake, the for

ward speed of the machine is reduced, and the

working depth is increased. See figure 22. When

the depth stake is raised, the working depth of the

machine is reduced and the forward speed is in

creased. The working depth of the machine may

be predetermined by setting the depth stake and

wheels so that the wheels are about four inches

from the ground when the tines and depth stake

are resting on the ground. This setting will permit

a working depth of about four inches. When preset

ting the working depth, the handles should be ad

justed so the hand grips are a little above waist

height because the tiller will be lower when the

tines and depth stake penetrate the ground.

FIGURE 20.

CONTROLLING SPEED AND TILLING DEPTH:

1. Wheel Yoke Adjustment: Place wheel yoke so

that the wheels are forward (nearest point between

wheels and tines) for shallow tilling, cultivating and

transport. This will increase the forward speed.

Turn yoke around (farthest point between wheels

and tines) for deep tilling. Forward speed will

decrease. See figures 19 and 2i.

Wheel Setting

for Deep Digging ^

Transport

Depth

Stake^

Shallow'

Digging

Forward'

Deep Digging Wheels

Slow Forward

FIGURE 22,

11

Page 12

When tilling, leave approximately 8 inches of un

tilled soil between the first and second tilling paths,

then make the third path between the first and sec

ond as shown in figure 23. In some soils, the

desired depth is obtained the first time over the

garden. In other soils, the desired depth is obtained

by going over the garden two or three times. In the

latter case, the depth stake should be lowered

before each succeeding pass over the garden.

Passes should be made across the length and

width of the garden alternately. Rocks which are

turned up should be removed from the garden

area.

TRANSPORTING THE TILLER

To transport the tiller to or from the garden, pivot the

depth stake forward so it engages the tailpiece and

locks out of the way. See figure 22. With the throttle

control in SLOW position, the unit will move under its

own power, without damaging grass areas as long as

it is allowed to move freely. If the operator holds back,

it will start to dig.

CULTIVATING

For cultivating, a two to three inch depth is desirable.

Setting the wheels and depth stake so that the wheels

are about two inches above the ground while the tiller

is resting on the tines and depth stake will allow the

machine to work at cultivating depth. The throttle

should be set to control forward movement to a slow

walking speed. With outer tines installed, the working

width of the machine is 26 or 28 inches. See figures

24 and 26. For cultivation, this may be reduced to 14

inches by removing the outer tines. See figure 25.

FIGURE 23.

3. Handle Pressure: Further control of tilling depth

and travel speed can be obtained by variation of

pressure on the handles. A downward pressure on

the handles will reduce the working depth and in

crease the forward speed. An upward pressure on

the handles will increase the working depth and

reduce the forward speed. The type of soil and

working conditions will determine the actual set

ting of the depth stake and the handle pressure

required.

4. Throttle Control: The throttle control lever adjusts

the engine speed and stops the engine. With the

throttle control knob pushed completely forward,

the carburetor is in START or FAST position. Pull

ing the throttle back reduces the engine speed to

SLOW. Pull the throttle completely back to stop the

engine. See figure 17.

Use maximum engine speed for deep tilling. Move

the throttle control to SLOW when transporting the

tiller.

FIGURE 24.

Tilling width can be increased from 26 inches to 28

inches by removing the clevis pin and hairpin clip and

sliding the outer tines out one inch, and replacing the

clevis pin and hairpin clip. See figure 26.

12

Page 13

FIGURE 26.

When laying out plant rows, be sure to allow enough

width to permit cultivation between the rows. In grow

ing corn or similar crops, check-row planting will per

mit cross cultivation and practically eliminate hand

hoeing. See figure 27.

CULTIVATING

The U.S. Department of Agriculture and various state

and local agencies offer published booklets and expert

advice on alt phases of gardening. They should be con

sulted regarding soil information, planting dates,and the

most satisfactory varieties of crop for your particular

area.

ADJUSTMENTS

Ac WARNING I

Disconnect the spark plug wire and

ground against the engine before

performing any adjustments, re

pairs, or maintenance.

WHEEL ADJUSTMENTS

To adjust the wheel yoke and wheel position, refer to

"How To Use Your Tiller," on page 11.

DEPTH STAKE ADJUSTMENT

To adjust the depth stake, refer to "How To Use Your

Tiller" on page 11.

FIGURE 27.

The tiller has many uses other than tilling and

cultivating a garden. One of these is the preparation

of lawn area for seeding. The tiller will prepare a deep

seed bed which will be free of hard untitled spots, allow

ing a better stand of grass to grow. The tiller is very

useful for loosening hard soil for excavation with a

shovel. NO tedious hand pickwork will be necessary,

Your tiller may be used for mixing compost in the pile,

or for mixing it with the soil in your garden. This should

be done after the soil has been broken to the full work

ing depth. The compost should be worked in to a depth

of six to eighi inches. This may be done by working the

length of the garden, and then by making separate

passes across its width. The addition of decayed

organic matter will substantially increase the fertility of

your garden. For proper decaying action, fertilizer

should be applied and worked in with the mulch

materials. Breaking up leaves and straw and mixing it

with several inches of soil causes the soil to hold

moisture longer and allows proper aeration of the plant

root system. This also retards the growth of weeds.

TINE WIDTH ADJUSTMENT

To adjust the tine width, refer to "Cultivating" on page

12.

BELT TENSION ADJUSTMENT

Periodic adjustment of the belt tension may be required

due to normal stretch and wear on both the forward and

reverse belts. Adjustment is needed if the tines seem

to hesitate while tilling, but the engine maintains the

same speed.

To adjust, loosen the hex nut above the cable bracket

a few turns (refer to figure 10), Tighten the lower hex

nut against the bracket. Check the adjustment by

following the instruction in the "Final Clutch Adjust

ment" section of Assembly Instructions on page 8.

Test the operation of the tiller. Readjust as necessary.

NOTE

Do not overtighten control wire. Too

much tension may cause it to break.

CARBURETOR ADJUSTMENT

t WARNING i

If any adjustments are made to the

A

engine while the engine is running

(e.g. carburetor), disengage all clutches

and tines. Keep clear of all moving

parts. Be careful of heated surfaces

and muffler.

13

Page 14

Minor carburetor adjustment may be required to

compensate for differences in fuel, temperature,

altitude or load. If adjustments are needed, refer to

the engine section of this manual.

NOTE

A dirty air cleaner will cause engine to

run rough. Be certain air cleaner is

clean and attached to the carburetor

before adjusting carburetor. Do not make

unnecessary adjustments. Factory

settings are satisfactory for most appli

cations and conditions.

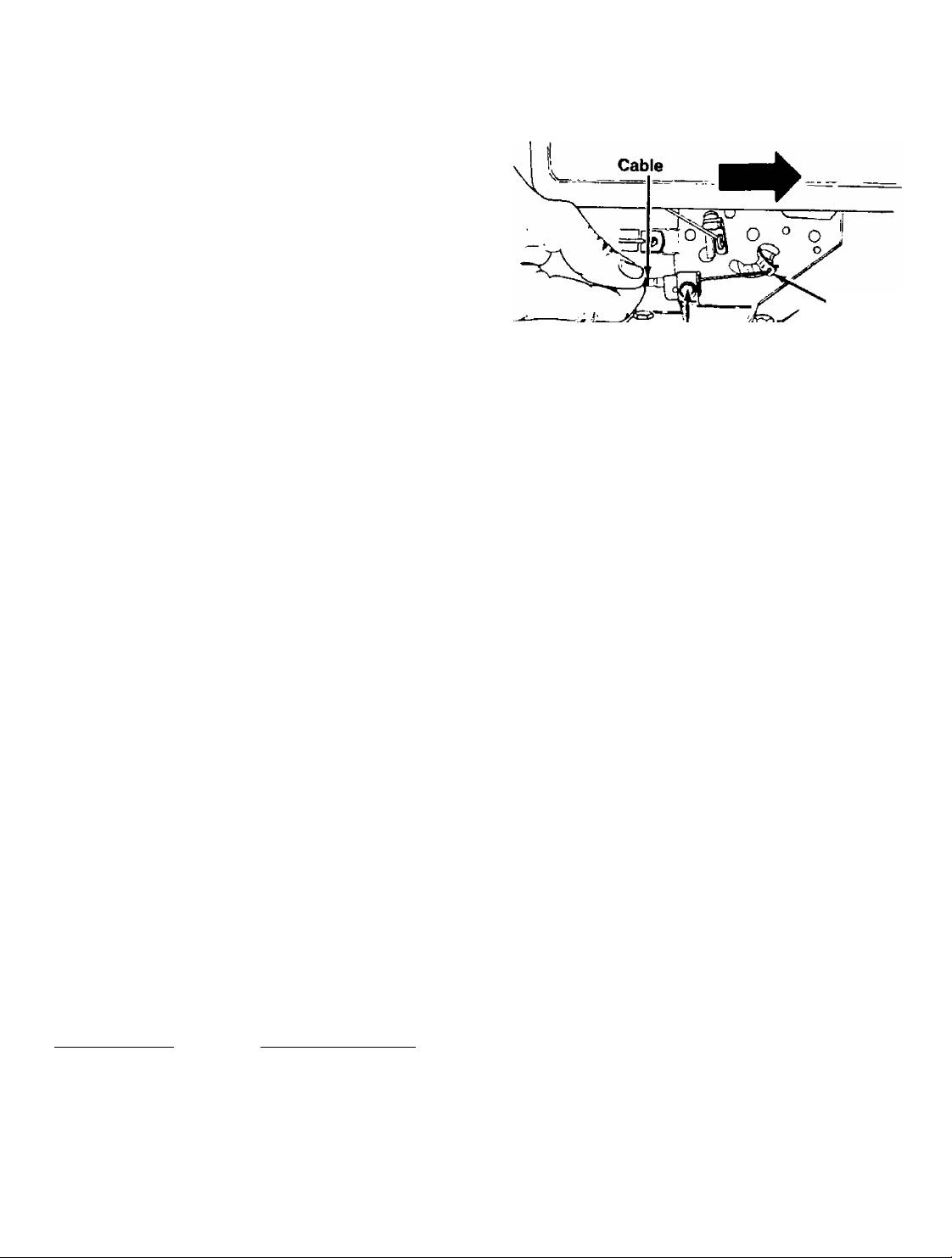

THROTTLE CONTROL ADJUSTMENT

To obtain satisfactory engine performance, the engine

throttle control must be adjusted properly. If it is

necessary to check the engine control adjustments,

proceed as follows.

1. Loosen the cable clamp screw. See figure 28.

2. With the throttle control in FAST position and the

cable connected to the adapter lever, push the

cable through the cable clamp in the direction

shown in figure 28 until the adapter lever is as far

up as it will go.

3. Tighten the cable clamp screw.

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not stop,

loosen cable clamp screw and readjust by pulling

cable backward slightly until engine stops.

Retighten cable clamp screw.

Pivot Points—Remove the belt cover and lubricate all

moving parts and pivot points at least once a season

using SAE 30 engine oil.

Transmission—Whenever disassembly of transmis

sion is required, transmission should be thoroughly

cleaned and lubricated with 6V2 ounces of PENNANT

OIL EP #35000 (available in an 8 ounces squeeze

tube). Order part no. 737-0136 through participating

Western Auto Stores. See figure 29.

Fill Plug

Check Plug ,5^ ^

FIGURE 29.

Breather Bolt

Oil Level

MAINTENANCE

NOTE

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance.

Cable Clamp

Screw

FIGURE 28.

LUBRICATION

; WARNING

A

Always stop engine and disconnect spark

plug wire before cleaning, lubricating

or doing any kind of work on tiller.

Adapter

Lever

TROUBLE SHOOTING

Refer to page 21 of this manual for trouble shooting

information.

ENGINE

Refer to the engine section of this manual for all

engine maintenance instructions.

CLEANING THE TINE AREA

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed off im

mediately instead of after it dries.

TRANSMISSION

After first two hours of operation and every five hours

thereafter, remove the cotter pin from the bearing ad

justment cap. Screw the cap in as far as possible us

ing the handle of a pair of pliers or similar tool. Then

back it off V2 turn. See figure 30. Replace the cotter pin.

Start the tiller and engage the tines. If the engine stalls

out. the bearing adjustment cap should be unscrewed

slightly.

14

Page 15

3. Remove the belt guard from the bottom of the

transmission pulley by removing one hex nut and

lock washer from the inside of the mounting plate

assembly. See figure 31.

4. Remove the belt from around the idler pulley. See

figure 32.

BELT REMOVAL AND REPLACEMENT

Your tiller has been engineered with belts made of

special material (Kevlar Tensile). They should not be

replaced with an off-the-shelf belt.

If belt replacement is required, order belt or belts by

part number through participating Western Auto Stores.

FORWARD DRIVE BELT— Part No. 754-0255

REVERSE DRIVE BELT— Part No. 754-0189

IMPORTANT

If either the forward or reverse drive

belt is replaced for any reason, make

certain to readjust the clutch cables to

the initial adjustment setting. Refer to

Assembly Instructions on pages 7 and 8

of this manual.

Reverse Belt (inside belt)

has wide side down, toward

Reverse

Forward Drive Belt (Refer to figure 32)

1. Remove the belt cover by removing three self

tapping screws, one located on top of the belt

cover, and one on each side at the bottom.

2. Remove the belt retainer, located at the transmis

sion pulley (bottom pulley), by removing two hex

bolts and nuts. See figure 31.

FIGURE 32.

5. Slip the belt off the engine pulley. Remove it from

the transmission pulley.

6. Reassemble the new belt, following instructions in

reverse order.

■^NOTE

Upon reassembly, make certain belt is

inside the belt guard pins as shown in

figure 32.

Reverse Drive Belt (See figure 32)

1. To remove the reverse drive belt, first remove the

forward drive belt as instructed in the previous

section.

2. Remove the hex nut which holds the reverse idler

pulley. See figure 33.

15

Page 16

OFF-SEASON STORAGE

If the tiller will not be used for a period longer than 30

days, the following steps should be taken to prepare

the tiller for storage.

1. Clean the exterior of engine and the entire tiller

thoroughly. Lubricate the tiller as described in the

lubrication instructions.

2. Refer to the engine section of this manual for cor

rect engine storage instructions.

3. Wipe tines with oiled rag to prevent rust.

4. Store tiller in a clean, dry area.

FIGURE 33.

3. Lift up on the idler bracket and remove the idler

pulley.

4. Unhook the reverse drive belt from the transmis

sion pulley and slide belt out.

5. Reassemble the new belt, following instructions in

reverse order.

NOTE

When storing any type of power

equipment in an unventilated or

metal storage shed, care should be

taken to rustproof the equipment.

Using a light oil or silicone, coat the

equipment, especially any springs,

bearings and cables.

16

Page 17

ENGINE OPERATING AND MAINTENANCE INSTRUCTIONS

FOR ENGINE MODEL 130202-3166-01

IMPORTANT

Do not start the engine before read

ing the following section of this

manual.

I WARNING I

A

Do not operate engine In an en

closed area. Exhaust gases contain

carbon monoxide, an odorless and

deadly poison.

Always disconnect spark plug wire from

spark plug before performing any repairs

or maintenance.

SECTION 1

BEFORE STARTING'

Fill Sump With Oil—Use a high quality detergent oil

classified “For Service SF, SE, SD or SC.” Nothing

should be added to the recommended oil.

Place engine level. Clean area around oil fill before

removing oil fill plug. Fill crankcase to the point of

overflowing. Pour slowly. Capacih/ approximately 1 Va

pints. Do not overfill. Oil fill plug must be securely

assembled in engine at all times when engine is

running.

Fill Fuel Tank—The engine will operate satisfactorily

on any gasoline intended for automotive use. DO NOT

MIX OIL WITH GASOLINE.

The use of clean, fresh, lead-free gasoline is recom

mended, Leaded gasoline may be used if lead-free is

not available. A minimum of 77 octane is recom

mended. The use of lead-free gasoline results in fewer

combustion deposits and longer valve life.

Do not fill fuel tank to point of overflowing. Allow tank

space for fuel expansion.

Recommended SAE Viscosity Grades

17

Page 18

SECTION 2

STARTING"

start, store and fuel engine in a level position.

WARNING: ALWAYS KEEP HANDS AND FEET

CLEAR OF TINES OR OTHER ROTATING

A

A

PARTS,

To Start Engine

1. Make certain both clutch levers are released.

2. Place the throttle control lever in FAST or START

position.

3. Move choke lever to CHOKE position.

Note: A warm engine may not require choking.

4. Stand at side of tiller. Grasp the starter handle and

pull out rapidly. Return it slowly to the engine.

Repeat as necessary.

5. After engine starts, move choke lever gradually to

RUN position.

SECTION 3

REGULAR MAINTENANCE'

WARNING: TO PREVENT ACCIDENTAL

STARTING when performing any main

tenance or repairs, always disconnect

spark plug wire from spark plug and ground

against the engine.

Check Oil Level after each five hours of operation. BE

SURE PROPER OIL LEVEL IS MAINTAINED.

Change Oil after first five hours of operation. Thereafter

change engine oil every 50 hours, under normal

operating conditions. Change engine oil every 25 hours

of operation if the engine is operated under heavy load,

or in high ambient temperatures. Change oil while

engine is warm.

Service Air Cleaner—Clean cartridge at three month

intervals or every 25 hours, whichever occurs first.

NOTE: Service more often under dusty conditions.

1. Loosen screw and tilt cover as illustrated.

2. Carefully remove pre-cleaner and cartridge.

3. Clean cartridge by tapping gently on a flat surface.

If very dirty, replace cartridge and pre-cleaner, or

clean as follows:

a. Wash in a low or non-sudsing detergent and

warm water solution. Caution: Do not use

petroleum solvents such as kerosene, to clean

cartridge.

b. Rinse thoroughly with flowing water from inside

out until water is clear.

c. Allow cartridge to stand and air dry thoroughly

before using. DO NOT OIL CARTRIDGE OR

PRE-CLEANER. DO NOT USE PRESSURIZED

AIR TO CLEAN OR DRY CARTRIDGE.

To Stop Engine—Move throttle control lever to STOP

position. Disconnect spark plug wire from the spark

plug and ground against the engine to prevent acciden

tal starting.

4. Install cartridge and pre-cleaner. Then close cover

and fasten screws securely.

18

Page 19

Clean Engine—Remove dirt and debris with a cloth or

brush. Cleaning with a forceful spray of water is not

recommended as water could contaminate the fuel

system.

WARNING; Periodically clean muffler area to

remove all dirt and combustible debris.

A

Clean Cooling System

Yearly or every 100 hours, whichever occurs first,

remove the blower housing and clean the area shown

to avoid overspeeding, overheating and engine

damage. Clean more often if necessary.

Remove Combustion Deposits every 100-300 hours

of operation. Remove cylinder head and cylinder head

shield. Scrape and wire brush the combustion deposits

from cylinder, cylinder head, top of piston and around

valves. Use a soft brush to remove deposits. Re

assemble gasket, cylinder head and cylinder head

shield. Turn screws down finger tight, with the three

longer screws around the exhaust valve. Torque

cylinder head screws in a staggered sequence to 140

inch pounds (15.82 Nm).

Spark Plug—Clean and reset gap at .030" every 100

hours of operation.

NOTE: Do not blast clean spark plug. Spark plug

should be cleaned by scraping or wire brushing and

washing with .a commercial solvent.

Clean Out

Chaff and Dirt

\

Caution: Sparking can occur if wire terminal does not

fit firmly on spark plug, or if stop switch vibrates against

spark plug. Reform terminal or repair switch if

necessary.

Spark Arrester Equipped Muffler—If engine muffler

is equipped with spark arrester screen assembly,

remove every 50 hours for cleaning and inspection.

Replace if damaged.

SECTION 4

ADJUSTMENTS'

CARBURETOR ADJUSTMENT

WARNING; If any adjustments are made to

the engine while the engine is running (e.g.

A

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load.

NOTE: The air cleaner must be assembled to car

buretor when running engine.

To Adjust Carburetor—Gently turn idle mixture valve

clockwise until it just closes. Valve may be damaged

by turning it in too far.

initial adjustment will permit the engine to be started

and warmed up (approximately 5 minutes) prior to final

adjustment.

SLOW position. Then rotate throttle counterclockwise

and hold against throttle stop while adjusting idle RPM

carburetor), keep clear of alt moving parts. Be

careful of heated surfaces and muffler.

Next, open the valve 1 turns counterclockwise. This

Final Adjustment—Place throttle control lever in

by turning idle speed adjusting screw to obtain 1750

RPM. Turn idle mixture valve in (clockwise—lean mix

ture) until engine just starts to slow. Then turn idle mix

ture valve out (counterclockwise—rich mixture) until

engine runs unevenly. Now turn idle mixture valve mid

way between rich and lean. Release throttle—engine

snould accelerate smoothly. If engine does not ac

celerate properly, the carburetor should be readjusted,

usually to a slightly richer mixture by turning idle mix

ture valve counterclockwise 1/8 turn more.

19

Page 20

CONTROL ADJUSTMENTS

The throttle control must be properly adjusted to stop,

start and operate the engine at maximum speed.

The acceptable operating speed range is 1800 to 3600

RPM. Idle speed is 1750 RPM. The manufacturer of

the equipment on which the engine is used, specifies

the top governed no load speed at which the engine

may be operated. DO NOT EXCEED this speed.

To Adjust Throttle Control;

1. Loosen the cable clamp screw. See illustration.

2. With the throttle control in FAST position and the

cable connected to the adapter lever, push the

cable through the cable clamp In the direction

shown until the adapter lever is as far up as it will

go.

3. Tighten the cable clamp screw.

SECTION 5

GENERAL INFORMATION'

4. Check that the engine stops when throttle control

is moved to STOP position. If engine does not stop,

loosen cable clamp screw and readjust by pulling

cable backward slightly until engine stops.

Retighten cable clamp screw.

Adapter

Lever

Cable Clamp

^ Screw

ENGINE DESIGN

This engine is single-cylinder L-head, air-cooled type.

MODEL SERIES 130202

Bore............................................................2-9/16" {65.09 mm)

Stroke.........................................................2-7/16" (61.91 mm)

Displacement

Horsepower Max..............................5.0 @ 3600 RPM

Torque (Ft.-Lbs.) Max

The horsepower ratings listed are established in

accordance with the Society of Automotive Engineers

Test Code-J607. For practical operation, the

horsepower loading should not exceed 85% of these

ratings. Engine power will decrease, 3'/2% for each

1,000 feet above sea level and 1 % for each 10® above

60® F.

In some areas, local law requires the use of a resistor

spark plug so as to suppress ignition signals. If an

engine was originally equipped with a resistor spark

plug, be sure to use the same type of spark plug for

replacement.

Major engine repairs should not be attempted unless

you have the proper tools and a thorough knowledge

of internal combustion engines.

TUNE-UP SPECIFICATIONS

Spark Plug Type

Short Plug CJ-8 235

Long Plug J-8C 295

Resistor Short Plug RCJ-8 245

Resistor Long Plug RJ-8C 306

Spark Plug Gap

Intake Valve Clearance

Exhaust Valve Clearance

..............................

.......................

_________

.......................................................

.................................

12.57 cu. in. (206 cc)

7.66 @ 2900 RPM

Champion Autolite

..............................

030"

005"-.007"

009"-.011"

STORAGE INSTRUCTIONS

Engines to be stored over 30 days should be completely

drained of fuel to prevent gum deposits forming on

essential carburetor parts, fuel filter and tank.

NOTE: The use of a fuel additive, such as STABIL, or

an equivalent, will minimize the formation of fuel gum

deposits during storage. Such an additive may be

added to the gasoline in the fuel tank of the engine,

or to the gasoline in a storage container.

a. All fuel should be removed from the tank. Run the

engine until it stops from lack of fuel.

b. While engine is still warm, drain oil from crankcase.

Refill with fresh oil.

c. Remove spark plug, pour approximately V2 ounce

(15 cc) of engine oil into cylinder and crank slowly

to distribute oil. Replace spark plug.

d. Clean dirt and chaff from cylinder, cylinder head

fins, blower housing, rotating screen and muffler

areas.

e. Store in a clean, dry area.

20

Page 21

Trouble Shooting Guide

Trouble Possible Cause(s)

Engine fails to start

Engine runs erratic

Engine overheats 1. Engine oil level low.

1. Fuel tank empty, or stale fuel,

2. Throttle control lever not in

starting position.

3. Blocked fuel tine.

4. Spark plug wire disconnected.

5. Faulty spark plug.

6. Engine flooded.

1. Unit running on CHOKE.

2. Spark plug wire loose.

3. Blocked fuel line or stale fuel.

4. Vent in gas cap plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Carburetor out of adjustment.

2. Air flow restricted.

3. Carburetor not adjusted

properly.

Corrective Action

1. Fill tank with clean, fresh gasoline.

2. Move throttle lever to start position.

3. Clean fuel line.

4. Connect wire to spark plug.

5. Clean, adjust gap or replace.!

6. Remove spark plug, dry the plug,

and crank engine with plug removed

and throttle in off position. Replace

spark plug, connect wire and resume

starting procedures.

1. Move choke lever to OFF position.

2. Connect and tighten spark plug wire.

3. Clean fuel line; fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel,

6. Clean air cleaner.!

7. Adjust carburetor.!

1. Fill crankcase with proper oil.!

2. Remove blower housing and clean.!

3. Adjust carburetor-!

Tines do not engage

tRefer to separate engine section of this manual.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest authorized servicer.

1. Foreign object lodged in tines.

2. Tine clevis pin(s) missing.

3. Control cable not adjusted

properly.

4. Belt worn and/or stretched.

1. Dislodge foreign object.

2. Replace tine clevis pin(s).

3. Adjust control cable (see assembly

instructions).

4. Replace belt.

21

Page 22

ILLUSTRATED PARTS FOR MODEL

MTD2105A98 FRONT TINE TILLER

\jT9kl

i ' i 8

'k. XjQ

•tav

^ Vt /

I 58

Welded to handle

¡0

^ r\

90 93

22

Page 23

PARTS LIST FOR MODEL MTD2105A98 FRONT TINE TILLER

HEF.

NO.

PART

NO.

04602

1

2

1545-029

3 710-0253

710-0779A

4

DESCRIPTION

U-Clevis Pin .5" Dia.

Clevis Pin 2" Lg.

Hex Bolt 3/8-16 X 1.0" Lg.*

Truss Mach. AB-Tao Scr.

#10 X .5" Lq.

5 710-0919 Hex B-Tap Set. #10 x .44" Lg.

7

712-0798 Hex Nut 3/8-16 The.* 40

8 714-0149B

725-0157

9

10

736-0105 Bell-Wash. 3/8" t.D

11 736-0169

12 746-0605

Internal Cotter Pin

Cable Tie

L-Wash. 3/8" l.D. 57

Barrel Cable Hold-Down—L.H.

13 746-0606 Barrel Cable Hold-Down—R.H,

031-O823A

14

15 746-0503

16

746-0619B

17 746-0620B

Throttle Control Box Ass’y.

Throttle Control Wire—35"

Clutch Control Cable—(Forward)

Clutch Control Cable—(Reverse) 62 784-0202

18 784-0250 Mounting Plate Ass'y.

20 04586

21

04697A-638

24 06805

U-Channel Plate

Tiller Frame Ass’yHandle Brkt.—L.H.

25 06806 Handle Brkt.—R.H.

06816

26

29 710-0152

U-Channel Brkt. Ass’y.

Hex Bolt 3/8-24 x 1 0"

30 710-0198 • Hex Sems Scr 5/16-18 x

.75 Lg.

31

710-0253

32 710-0451

33

710-0592

Hex Bolt 3/8-16 X 1 0" Lg. 92

Carr. Bolt 5/16-18 x .75 Lg.

Hex Bolt 1/2-20 x 1 0" Lg.

REF.

NO.

34 712-0214

35 712-0239

36

37

38

39

55

56 710-0151

PART

NO.

DESCRIPTION

Hex L-Nut 3/8-24 Thd.

Hex L-Nut 1/2-20 Thd.

712-0267 Hex Nut 5/16-18 Thd.'

Bell-Wash. 3/8" l.D.

L-Wash. 5/16" l.D.*

Extern. L-Wash. 3/8" l.D.

Extern. L-Wash. 1/2" l.D.

Tailpiece Ass’y.

50

736-0105

736-0119

736-0148

736-0190

06807-638

06811-638 Depth Stake

Hex Bolt 3/8-24 x 2.0" Lg.

710-0599 Hex TT-Tap Scr. 1/4-20 x

1/2" Lg.

58

712-0116

59 720-0180

Hex Ins. L-Nut 3/8-24 Thd.

Grip Handle

60 726-0247 Push Cap (For Handles)

61

732-0322

Depth Stake—Spring

Clutch Grip Ass’y.—L.H.

65

784-0243-638 Handle Ass'y.

69

784-0255 Clutch Grip Ass’y.—R.H.

80 06813

83 1545-029

84 712-0200A

734-0584

86

Wheel Yoke Ass'y.

Clevis Pin 2" Lg.

Hex Jam Nut 1/2-20 Thd.

Wheel Ass’y. 10 x 1.75

89 741-0116 Flange Brg. .631 l.D.

90

736-0187

F!-Wash. .640" x 1.24" x .06

91 736-0253 Bell-Wash. 1/2" l.D.

736-0921

L-Wash. 1/2" l.D.*

93 738-0318 Shoulder Bolt .625" Dia. x 2

94

736-0300 FI-Wash. 3/8" l.D.

2.75"

*For faster service obtain standard nuts, bolts, and washers local

ly. If these items cannot be obtained locally, order by part number

and size as shown on parts list.

NOTE

Specifications subject to change without notice or

obligation.

23

Page 24

ILLUSTRATED PARTS FOR MODEL

MTD2105A98 FRONT TINE TILLER

24

Page 25

PARTS LIST FOR MODEL MTD2105A98 FRONT TINE TILLER

REF.

NO.

PART

NO.

04648 Belt Guard

1

04657A Bracket

2

04704A

3

4

710-0118

5 710-0191

710-0198 Hex Sems Scr, 5/16-18 x

6

Belt Retainer 35

Hex Bolt 5/16-18 X 75" Lg.’ 36

Hex Bolt 3/8-24 x 1 25" Lg.*

DESCRIPTION

.75" Lg. 39

7 710-0342

Hex Bolt 3/8-16 X 1 25'' Lg.' 40

8 710-0380 Hex Bolt 5/16-18 X 1,75" 41

9 710-0451 Carr. Bolt 5/16-18 x .75" Lg.

710-0157

10

11

710-0599 Hex TT-Tap Scr. 1/4-20 x .5" 49

12

710-0642

Hex Boll 5/16-24 X .75" Lg.

Lg.

Hex TT-Tap Scr. 1/4-20 x

.75" Lg.

13 710-0643

14

710-0783

Hex L-Scr. 5/16-18 x 1.0" Lg.

Hex Wash. Hd. Slotted Scr.

#8-32 X .38" Lg.

15 712-0116

16 712-0185

17 712-0241

712-0267

18

19

712-0798

20 714-0105

21 714-0126

22 725-0157

23 726-0106

24 732-0562

25 736-0315

Hex Ins. L-Nut 3/8-24 Thd.

Speed Nut 1/4-20 Thd.

Hex Nut 3/8-24 Thd,

Hex Nut 5/16-18 Thd.'

Hex Nut 3/8-16 Thd •

Sq. Key 3/16^ 1,0"

#9 Hi-Pro Key 3/16 < 3/4"

Cable Tie

Cap Speed Nut 1/4 Rod

Extension Spring 3-5/8" Lg.

F^Wash. 3/4" I.D. x 1.5" O.D.

26 736-0119 L-Wash. 5/16" I.D.' 78

27

736-0119

736-0133 FI-Wash. .406" X 1.25" x 80 04676

28

L-Wash. 5/16" I.D.* 79

.10"

29

736-0142

FI-Wash. .281 I D. x .50 O.D.

x .063"

30

31

736-0169

736-0231

L-Wash. 3/8" I.D.'

FI-Wash. .344" X 1.125" X

.125"

32 738-0372 Shoulder Spacer

33 746-0619B Clutch Control Cable

(Forward)

34

PART

NO.

746-0620B

Clutch Control Cable

DESCRIPTION

(Reverse)

751-0233

5 H.P.

37

754-0189 V-Belt 44" Lg.

Muffler Deflector

Engine—B&S 130202-3166-01

38 754-0255 V-Belt 37" Lg.

756-0221

756-0223

Transmission Pulley

Engine Pulley

756-0225 Fl-ldier Pulley

42 784-0221

47

784-0226 Clutch Cable Bracket

48 784-0237

Tine Idler Brkt. Ass’y.

Idler Bracket Ass'y.

784-0240 Tine Shield

50 784-0241

51

784-0246A

Belt Guard

Brkt. Tine Shield

Reinforcement

784-0250

52

53 04697

54

717-0304 Transmission Ass'y. Comp.

Mounting Plate Ass’y-

Tiller Frame Ass’y.

(See Breakdown)

55

56

61

714-0149B

1545-029

710-0899A

Internal Cotter Pin

Clevis Pin

Hex Sems Scr. #10-32 x .62"

Lg.

751-0360A

62

70 04675

Casing Clamp

Inner Tine Adapter Ass'y.

Comp.—L.H.

71

75

76

04673

710-0191

712-0241

742-0107

742-0108

inner Tine Adapter Ass'y.

Hex Bolt 3/8-24 x 1.25" Lg.'

Hex Nut 3/8-24

Tine 14"—L.H.

Tine 14"—R.H.

Inner Tine Adapter Ass’y.

Comp.—R.H.

81 04695

Outer Tine Adapter Ass’y.

Comp.—L.H.

06797 Outer Tine Adapter Ass’y.

82

83 04696

Outer Tine Adapter Ass'y.

Comp.—R.H.

84

735-0639 Spark Plug Boot

'For faster service obtain standard nuts, bolts, and washers local

ly. If these items cannot be obtained locally, order by part number

and size as shown on parts list.

25

Page 26

ILLUSTRATED PARTS FOR MODEL

MTD2105A98 FRONT TINE TILLER

IMPORTANT

After every 5 hours of operation, screw

PARTS LIST FOR TRANSMISSION ASSEMBLY 717-0304

REF.

NO.

PART

NO.

OeSCRIPTtON

1 716-0119 Snap Ring .75" Dia. Shaft

2

721-0100

Oil Seal .75" Dia. Shaft

3 741-0197 Sleeve Brg. .752" x .878" x 16

1.0"

4 710-0599

736-0222

5

6

737-0103

7

741-0189 Range Brg. 1.0" I.D.

8

736-0259

Hex Wash. Self-Tap Scr.

External L-Wash. 1/4" I.D,

Sq. Hd. Pipe Plug 3/8" Thd.* 19

Fl-Wash. 1.0" X 1.62" X

.095"

9

714-0103

#91 Woodruff Key 1/4 x 3/4"

Dia.

10

711-0622

11

716-0102 Snap Ring—1.0" Dia. Shaft

12

717-0311

13

736-0119

14

721-0102 Oil Seal Double Up 1.0"

Tine Shaft 1.0" Dia.

Worm Wheel

L-Wash. 5/16" I.D.*

Shaft

REF.

NO.

15

PART

NO.

710-0371

DESCRIPTION

Hex Scr. 5/16-18 x .88" Lg.

(Plastic Insert)

736-0261 Wash.—Flat Toothed

(Special)

741-0188

17

18 735-0101

714-0474

20 10583

Bearing Cap with Bearing

0-Ring 3.62" X 3.88"

Cotter Pin 1/8" Dia. x .75"

Bearing Adjustment Cap

21 735-0100 0-Ring 2.12" X 2.28"

741-0107

22

23

24

716-0101

711-0469

Roller Bearing Ass’y- -75 I.D.

Snap Ring—.75" Dia. Shaft

Spacer .755 I.D. x 1.265 O.D.

25 714-0126 #9 Hi-Pro Key 3/16 X .75"

Dia.

717-0312

26

27

738-0170 Worm Shaft

719-0223 Transmission Case

28

737-0136 E.P. Oil #35000

—

Worm

26

Page 27

ILLUSTRATED PARTS FOR 130202-3166-01 ENGINE

FOR MODEL MTD2105A98 FRONT TINE TILLER

SEE REPAIR

INSTRUCTION

MANUAL.

27

Page 28

ILLUSTRATED PARTS FOR 130202-3166-01 ENGINE

FOR MODEL MTD2105A98 FRONT TINE TILLER

28

★SPKIALTDOLS RB3UIRED

TO wsmx.

SEE RERWR INSTRUCTION

MANUAL

________

358 GASKET SET

1019 Decal Kit

Page 29

ILLUSTRATED PARTS FOR 130202-3166-01 ENGINE

FOR MODEL MTD2105A98 FRONT TINE TILLER

124

29

Page 30

PARTS LIST FOR 130202-3166-01 ENGINE

FOR MODEL MTD2105A98 FRONT TINE TILLER

lEF.

NO.

1

2

3

5

7

8

9

10

11

12

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

PART

NO.

395990

297565

299819 Seal~~Oil

211542

*270383

294178

‘27549

93394 Screw—Breather Mtg. Sem

66578

*270080

*270125

‘270126

93368

93369

91249

397103

398078

297603

294606

66768

93032

297229

222698

298904 Piston Ass'y.—Standard

298905

298906

298907

298982

298983

298984

298985

26026

298909

298906

299430

221890

221876

92296

211119

261044 Valve—Intake

Cylinder Assembly

Bushing—Cylinder

Note: Requires special tools

for installation. 40

Head—Cylinder

Gasket—Cylinder Head 52

Breather—Valve Chamber

Gasket—Valve Cover

Grommet—Breather Tube

Gasket—Crankcase—.015"

Thick (Standard)

Gasket—Crankcase—.005" If longer rope is required,

Thick

G asket—C ran kcase—.009"

Thick

Screw—Cylinder Head

Screw—Cylinder Head

Plug—Pipe, 1/4" Std. Square

To Replace Crankshaft Gear

Pin, Order Part No. 230978

Crankshaft

Cover Ass’y—Crankcase

Bushing—Crankcase Cover

Note: Requires special tools

for installation.

Seal—Oil

Plug—Oil Filler

Screw—Crankcase Cover

Flywheel—Magneto

Key—Flywheel

Piston Ass’y —010"' O.S.

Piston Ass’y.—.020" O.S.

Piston Ass’y.—.030" O.S.

PISTON RING SETS:

Note: For Chrome Piston Ring

Set—Standard Size—Order

Part No. 299742.

Ring Set—Standard Piston

Ring Set—.010" O.S. Piston

Ring Set—.020" O.S. Piston

Ring Set—.030" O.S. Piston

Lock—Piston Pin

Pin Ass’y.—Piston—Standard

Pin Ass'y.—Piston—.005" O.S.

Rod Ass’y.—Connecting

Note; For Connecting Rod

with .020" undersize Crankpin

Bore—Order No. 390459.

Dipper—Connecting Rod

Lock—Conn. Rod Screw

Screw—Connecting Rod

Valve—Exhaust

DESCRIPTION

(2-3/32" Long)

(2-15/32" Long)

Head

Mounting Sem

REF.

NO.

35

36

37

45

46

55

56

57

58

59

60

65

66 399671 Clutch Ass’y.—Rewind Starter

67

68

70

71

73

74

75

81

90

95

96

97

108

118

124

127 220352

127A

127B 223472

149

152

154

163

180

181

190

191

200

201

202

203

204 222962

205

209

216

30

PART

NO.

260552

26478

222443

93312

260642 Tappet—Valve

212733

*271937

299431

295871

490179

66884

230228

66728

94128 Screw—Stamped Steel

394897 Housing—Starter Clutch

63770

298799 Ratchet—Rewind Starter

394506 Washer—Clutch Retainer

221923 Screen—Starter Pulley

93490

220865 Washer—Spring

222263

490533

93499 Screw—Throttle Valve to Shaft

223793

490048

491177

231533 Valve—Needle

93357

223789

26336 Spring—Needle Valve

260575

93527

271935

490554

490075

94094

‘271928

223886

262280

262270

280720

231520

262283

262359

Spring—Intake Valve

Spring—Exhaust Valve

Guard—Flywheel

Retainer—Valve Spring

Gear—Cam

Gasket—Carburetor Mounting

Housing—Rewind Starter

Pulley—Rewind Starter

Spring-Rewind Starter

Rope—Rewind Starter—63"

order rope No. 66894 and cut

to length.

Pin—Starter Grip

Grip—Starter Rope

Ball—Clutch

Screw—Sem

Lock—Screw (3/8" Dia.

Carburetor Assembly

Throttle—Carburetor

Shaft and Lever-Throttle

Valve Group—Choke

Screw—Hex. Head

Plug—Welch

Plug—Welch (Mixing Chamber;

Plug-Welch (Well)

Spring—Throttle Adjustment

Screw—Machine, Rd. Hd.—

Gasket—Air Cleaner Mounting

Tank Assembly—Fuel

Cap—Fuel Tank

Screw—Fuel Tank Mounting

Gasket—Fuel Tank Mounting

Guide—Air

Link—Governor

Link—Throttle

Crank—Bell

Bushing—Governor Lever

Screw—Shoulder

Spring—Governor

Link—Choke

DESCRIPTION

(2)

Long

Housing Mtg. Sem

Bolt Holes)

Sem

5-40 X 5/8"

Sem

(Fiat)

Page 31

PARTS LIST FOR 130202-3166-01 ENGINE

FOR MODEL MTD2105A98 FRONT TINE TILLER

(CONTINUED)

REF.

NO.

219

220

222

223

224

227

230

300

304

305

306 221511

307

308

333

335

337

346

356

358

363

373

383

392

394

432

433

434

435

467 280715

526

527

528

529

PART

NO. DESCRIPTION

391737

221551

490649

Gear—Governor

Washer—Thrust

Bracket—Control

223455 Lever—Governor Control

93491

490374

222450

393615

Rivet—Governor Control Lever

Lever Ass’y.—Governor 6' 1

Washer—Governor Lever

Muffler—Exhaust

490169 Housing—Blower 6-5

93158 Screw—Blower Housing 616

Shield—Cylinder

93490

221512

397358

93414

Screw—Cylinder Shield

Cover—Cylinder Head

Armature Assembly

Screw—Armature Mtg. Sem

298809 Plug—Spark \ Уг” High—

93705

398808

397145

19069

Screw—Sem,

Wire—Ground

Gasket Set

Flywheel Puller (Optional (Standard)

92987 Nut—Hex

89838

262328

270026

221377

93265

Wrench—Spark Plug

Spring—Fuel Pump Diaphragm

Diaphragm

Cap—Spring

Pin—Diaphragm Cover

210959 Cover—Diaphragm

93141 Screw—Diaphragm Cover

Knob—Control

93343

223786

231526

67838

Screw—Tank Bracket

Clamp—Breather Tube

Tube—Breather

Grommet—Breather Tube

•Included in Gasket Set—

Part No. 397145.

Mounting

Mounting

Mounting Sem

37-42 M.M.

Accessory)

Mounting Sem

REF.

NO.

535 271933

552 231079

PART

NO. DESCRIPTION

Element—Air Cleaner

Bushing—Governor Crank

(V4" l.D.)

5ii2 92613 Bolt—Governor Lever

592 231082

608 390463

Nut—Hex.—10-24

Starter Ass’y-—Rewind

391813 Fuel Pipe and Clip Assembly

6-3 93935 Screw—Hex. Hd. Shoulder

6M

621

634

6*3

93306 Cotter—Hairpin

93307

231077

Retainer—E-Ring

Crank—Governor (V4" Dia.)

396847 Switch—Stop

271853

Washer—Throttle Shaft (Foam)

280737 Retainer—Foam Element

6*3A 280726 Retainer—Air Filter

655 222598

676 393757

679

270382

Anchor Spring

Deflector—Exhaust

Washer Choke Shaft (Foam)

680 221839 Washer Choke Shaft (Brass)

741

851

669

261696

221798

211787

870 211172

Gear—Timing

Cable Terminal—Ignition

Seat—Intake Valve (Standard)

Seat—Exhaust Valve

Note: For Options see Repair

Manual.

871

231348

Guide—Exhaust Valve

Note: 63709 Guide—Intake

Valve. See Repair Instruction

Manual.

916

966

967

968 223765

969 490073

971

987

1016

1019

280321 Gear Rack—Governor

490074 Base—Air Cleaner

389959

Filter—Air

Cover—Air Cleaner

Screw—Cover Mtg.

94018

398970

490817

491100

___________

Screw—Air Cleaner

Seal—Throttle Shaft

Spacer

Decal (Label) Kit

J

31

Page 32

HOW AND WHERE TO ORDER REPLACEMENT PARTS

To eliminate error and to speed delivery of replacement

parts, always include the following information on your

order.

IMPORTANT

To correctly identify the merchandise

by model number for which a part is

needed, refer to the model number label

located on the tine shield.

1. Complete identification of the merchandise for

which the part is wanted.

(a) Name of Item—Front Tine Tiller

(b) Model No.—MTD2105A98

(c) Factory No.—219-355-098

2. Best possible identification of the part itself.

(a) Part Number—

(b) Part Name—

(c) If necessary return the old part as sample.

3. CUSTOMERS may order all replacement parts

from any participating Western Auto Store.

4. If it is not possible to order through a Western Auto

Store or Associate Store, replacement parts may

be ordered directly from the Western Auto National

Parts Distribution Center.

Western Auto National Parts Distribution Center

P.O. Box 183

Birmingham, Alabama 35283-0183

(205) 328-1501

FORM NO. 770-6843D

(R890327)

PRINTED IN U.S.A.

Loading...

Loading...