Page 1

OPERATOR’S MANUAL

SNOW THROWER

MODEL

31AE640F352

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spar k

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-9722.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A.

FORM NO

770-10167D.fm

.

(6/2002)

Page 2

TABLE OF CONTENTS

Content Page

Important Safe Operation Practices ........................................................................ 3

Loose Parts & Hardware Pack................................................................................. 5

Assembling Your Snow Thrower ............................................................................. 7

Know Your Snow Thrower....................................................................................... 10

Operating Your Snow Thrower ................................................................................ 11

Making Adjustments ................................................................................................ 13

Maintaining Your Snow Thrower ............................................................................. 14

Service .................................................................................................................... 15

Off-Season Storage................................................................................................. 17

Troubleshooting ...................................................................................................... 18

Parts List ................................................................................................................. 19

FINDING MODEL NUMBER

This Operator’s Manual is an important part of your new snow thrower. It will help you assemble, prepare and

maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. The information on the model plate is very

important if you need help from our Customer Support Department or an authorized dealer.

You can locate the model number by standing behind the unit in the operating position and looking down at the rear

frame below the engine. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

(Model Number)

www.mtdproducts.com

(Serial Number)

MTD LLC

P. O. BOX

CLEVELAND,OH

330-220-4683

800-800-7310

361131

Copy the model number here:

Copy the serial number here:

44136

ENGINE INFORMATION

The engine manufacturer is responsible for all engine-related issues with regard to performance, power-rating,

specifications, warranty and service. Please refer to the engine manufacturer’s Owner’s/Operator’s Manual packed

separately with your unit for more information.

CALLING CUSTOMER SUPPORT

Please do NOT return the unit to the retailer from which it was purchased, without first contacting Customer Support.

Should you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800) 800-7310 to reach a Customer Support representative.

Please have your unit’s model number and serial number ready when you call. See previous section to

locate this information. You will be asked to enter the serial number in order to process your call.

For more details about your unit, visit our website at www.mtdproducts.com

2

Page 3

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

This symbol points out important safety instructions, which if not followed, could endanger the personal

safety and/or property of yourself and others. Read and follow all instructions in this manual before

attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol—heed its warning.

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer, birth defects or

other reproductive harm

DANGER: This machine was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. This machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is to

be used. Remove all doormats, newspapers, sleds,

boards, wires and other foreign objects, which could be

tripped over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all clutch levers before starting the engine.

7. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator’s manual.

8. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

9. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes, which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than

½ inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

OPERATION

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or discharge chute. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller clutch lever is a safety device. Never

bypass its operation. Doing so makes the machine

unsafe and may cause personal injury.

3. The clutch levers must operate easily in both directions

and automatically return to the disengaged position when

released.

3

Page 4

4. Never operate with a missing or damaged discharge

chute. Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

6. Do not operate machine while under the influence of

alcohol or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operating on slopes.

10. Plan your snow-throwing pattern to avoid discharge

towards windows, walls, cars etc. Thus, avoiding

possible property damage or personal injury caused by a

ricochet.

11. Never direct discharge at children, bystanders and pets

or allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or

light. Always be sure of your footing and keep a firm hold

on the handles. Walk, never run.

14. Disengage power to the auger/impeller when

transporting or not in use.

15. Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when in reverse.

16. If the machine should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage.

Repair any damage before starting and operating.

17. Disengage all clutch levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the discharge chute, making any

adjustments, or inspections.

18. Never put your hand in the discharge or collector

openings. Always use the clean-out tool provided to

unclog the discharge opening. Do not unclog discharge

chute while engine is running. Shut off engine and remain

behind handles until all moving parts have stopped

before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. If situations occur which are not covered in this manual,

use care and good judgment.

Contact your dealer or telephone 1-800-800-7310 for

assistance and the name of your nearest servicing

dealer.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing or inspecting machine

disengage all clutch levers and stop engine. Wait until the

auger/impeller come to a complete stop. Disconnect the

spark plug wire and ground against the engine to prevent

unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer’s (OEM) parts only. “Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

6. Check clutch controls periodically to verify they engage

and disengage properly and adjust, if necessary. Refer to

the adjustment section in this operator’s manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator’s manual for proper

instructions on off-season storage.

WARNING — YOUR RESPONSIBILITY:

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine. The

safety labels are shown below for your reference.

4

Page 5

SECTION 2: ASSEMBLING YOUR SNOW THROWER

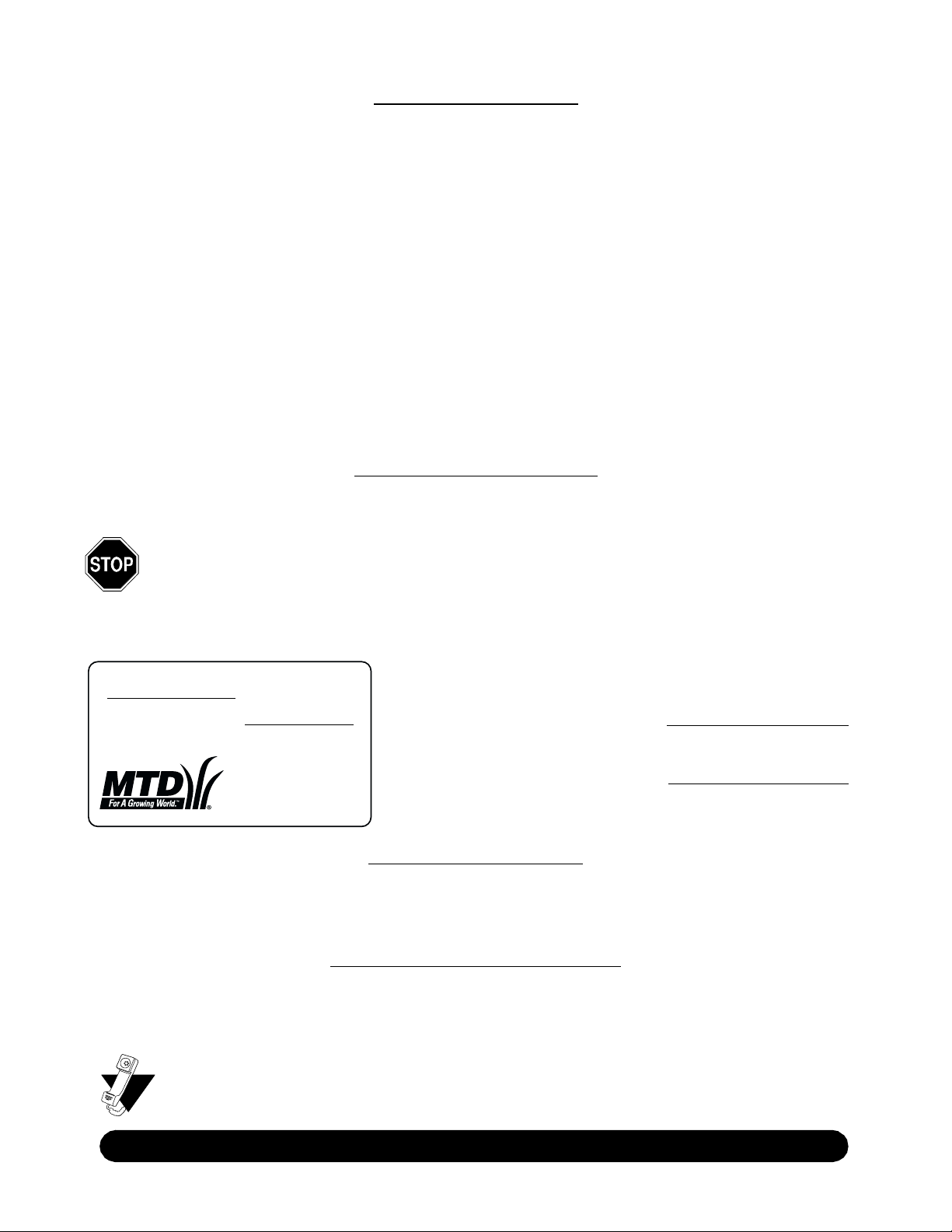

Loose Parts

Auger Shear Bolts (Spares)

Shear Bolts

(710-0890A)

NOTE: The augers are secured to the spiral shaft with

two shear bolts and hex lock nuts. If you hit a hard

foreign object or ice jam, the snow thrower is designed

so that the bolts may shear. Two replacement shear

bolts and nuts are provided for your convenience. Store

in a safe place until needed.

IMPORTANT:

standard hex bolts. Any damage to the auger gearbox

or other components as a result of doing so will NOT be

covered by your snow thrower’s warranty.

NEVER replace the auger shear bolts with

WARNING: Disconnect spark plug wire

and ground it against the engine to prevent

unintended starting.

Hex Lock Nuts

5/16” Thread

(712-0429)

Carriage

Bolt

Upper

Shift Rod

Hex Nut

Cupped

Washer

Upper

Handle

Wing

Nuts

Lower

Handle

Figure 1

Shift Rod

Connector

Assembly

NOTE: All references to right or left side of the snow

thrower are determined from behind the unit in the

operating position. The “operator’s position” is defined

as standing directly behind the snow thrower, facing the

handle panel.

WARNING: Disconnect the spark plug

wire and ground it against the engine to

prevent unintended starting.

• Remove the lower two plastic wing nuts, cupped

washers and carriage bolt (eyebolt on the left side)

from the lower handle. See Figure 1.

• Raise the upper handle assembly until it aligns with

lower handle.

• Be sure both cables are aligned with cable roller

guides located in the lower rear of snow thrower

frame.

• Secure the upper handle and lower handle with the

plastic wing nuts, cupped washers, and carriage

bolt (eyebolt on the left side) previously removed.

• Adjust the eyebolt on the chute directional control

so the control rod does not come into contact with

the engine by moving the hex nut against the

handle (if necessary).

Lower

Shift Rod

Eyebolt

Figure 2

• Retighten the wing nut to secure the chute

directional control in this position. See Figure 2.

• Slide the shift rod connector down over the end of

the lower shift rod. Tap the top of connector until it

locks on the lower shift rod.

NOTE: If the connector is not properly assembled, the

shift rod will pivot and you will not be able to shift gears

or change directions.

Lamp Wiring

• Wrap the wire from the lamp down the right handle

until the wire can be plugged into the alternator lead

wire located under the fuel tank. See Figure 3.

IMPORTANT:

controls or cables.

Lamp wire must not interfere with any

5

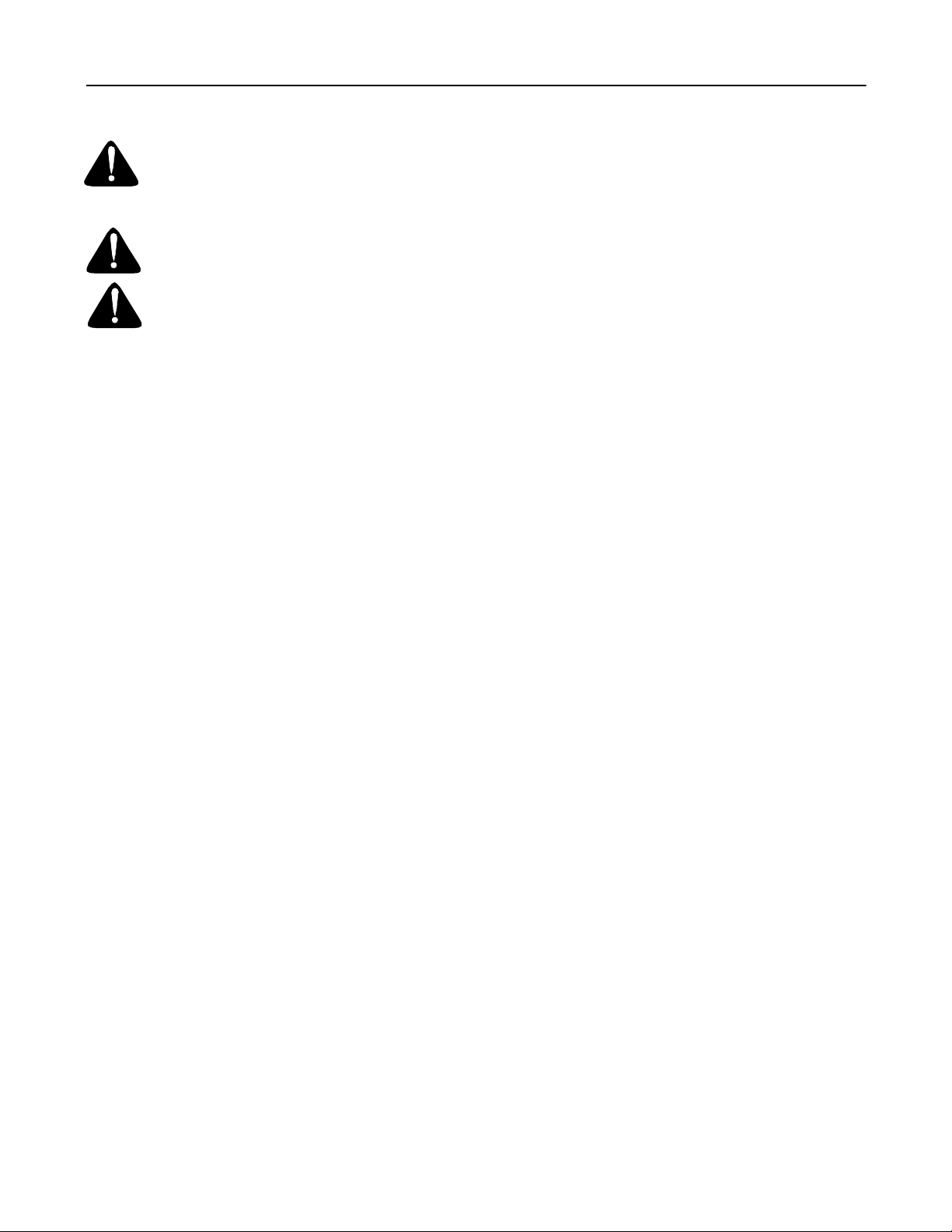

Page 6

Lower Handle

Lamp Wire

Alternator Lead

Figure 3

Gas and Oil

After assembly, service engine with gasoline, and

check oil level as instructed in the engine manual.

NOTE: Refer to Auger Control Test on page 8 prior to

operating your snow thrower. Read and follow all

instructions carefully and perform all adjustments to

verify your snow thrower is operating safely and

properly.

SECTION 3: KNOW YOUR SNOW THROWER

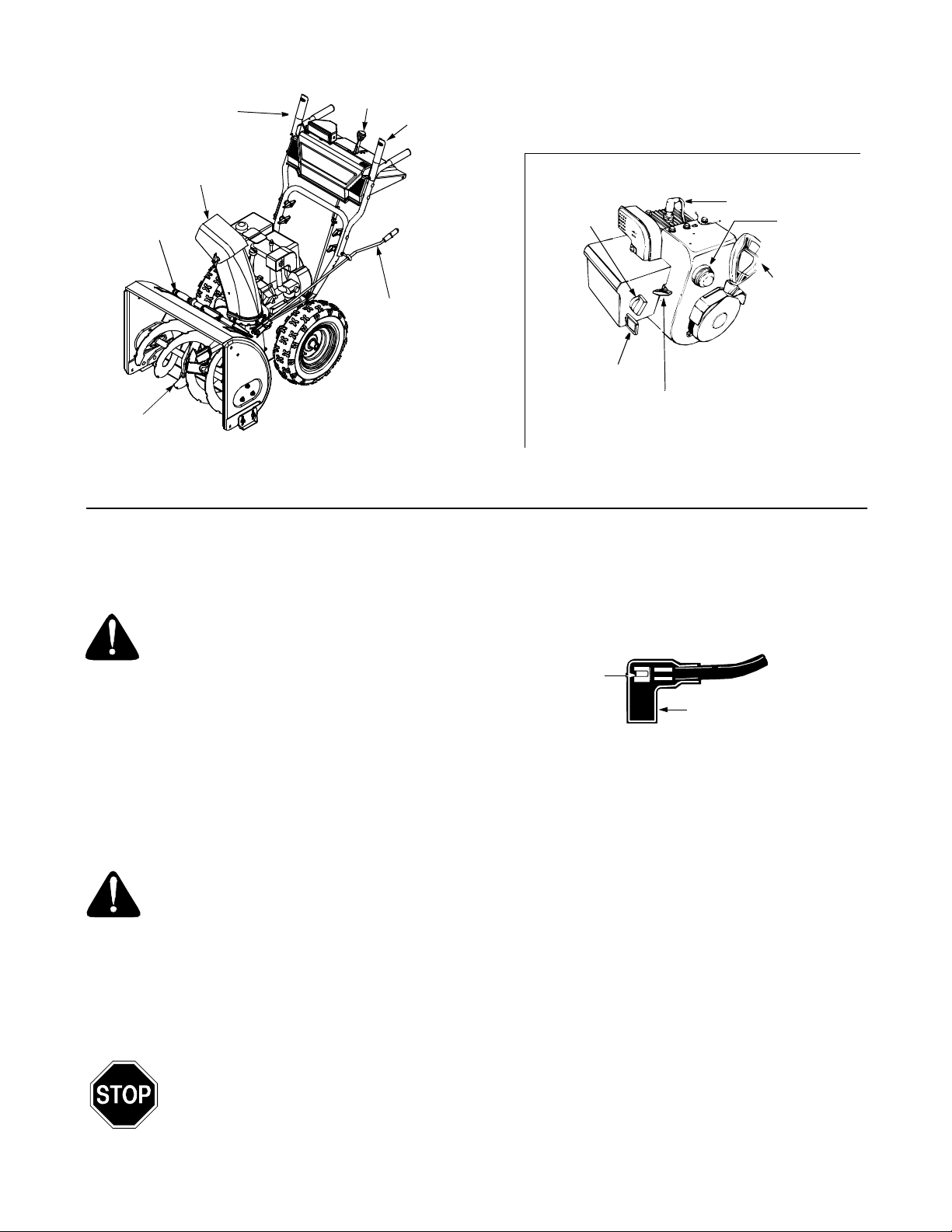

Operating Controls

WARNING: Be familiar with all controls and

their proper operation. Know how to stop the

machine and disengage them quickly.

Shift Lever

The shift lever is located in the center of the handle

panel. The shift lever may be moved into one of eight

positions. Run engine with throttle in the fast position.

Use the shift lever to determine ground speed.

Forward: There are six speeds. Position one (1) is the

slowest. Position six (6) is the fastest.

Reverse: There are two reverse (R) speeds R1 and R2.

The “R2” closest to the operator (all the way back) is the

faster of the two.

Auger Control

The auger control is located on the left handle. Squeeze

the control to engage the augers; release to stop the

augers. The traction control must also be released.

Traction / Auger Control Lock

The traction control is located on the right handle.

Squeeze the control to engage the wheel drive.

Release to stop.

This same control also locks the auger control so you

can turn the chute directional control without

interrupting the snow throwing process. If the auger

control is engaged with the traction control engaged,

the operator can release the auger control (on the left

handle) and the augers will remain engaged. Release

the traction control to stop both the augers and wheel

drive (auger control must also be released).

Chute Directional Control

The chute directional control is located on left hand side

of the snow thrower.To change the direction in which

snow is thrown, rotate chute directional control as

follows:

• Clockwise to discharge to the left.

• Counterclockwise to discharge to the right.

Chute Clean-out Tool

WARNING: Never use your hand to clear a

clogged discharge chute. Shut off engine and

remain behind handles until all moving parts

have stopped before unclogging.

The chute clean-out tool (see Figure 4) isdesigned to

clear a clogged discharge chute. Refer to Operating Your

Snow Thrower on page 9 for detailed instructions on how

toproperly use the chute clean-out tool.

Ignition Key

The ignition key must be inserted in the switch in order

for the engine to start. Remove the ignition key when

the snow thrower is not in use.

NOTE: Do NOT “turn” the ignition key in an attempt to

start the engine.

Throttle Control

The throttle control is located on the engine. It regulates

the speed of the engine. See Figure 4.

6

Page 7

Traction/Auger

Control Lock

Discharge Chute

Shift Lever

Auger Control

Chute

Clean-out Tool

Chute Directional Control

Auger

Figure 4

Choke

Ignition Key

SECTION 4: OPERATING YOUR SNOW THROWER

Before Starting

WARNING: Read, understand, and follow

all instructions and warnings on the machine

and in this manual before operating.

• The spark plug wire was disconnected for safety.

Attach spark plug wire to spark plug before starting.

• Attach spark plug wire to spark plug. Make certain

the metal loop on end of the spark plug wire (inside

the boot) is fastened securely over the metal tip on

the spark plug. See Figure 5.

Metal Loop

Spark Plug

Primer

Recoil Starter

Handle

Throttle Control

Rubber Boot

Gas And Oil Fill-up

• At the factory, a plastic cup is inserted inside the

fuel tank’s fill opening (beneath the fuel cap) to

prevent debris from entering the fuel tank during

assembly. Remove and discard this cup before

filling up the tank.

WARNING: Use extreme care when

handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

Never fuel machine indoor or while the

engine is hot or running. Extinguish

cigarettes, cigars, pipes and other sources of

ignition.

Starting Engine

IMPORTANT:

thrower, read, understand and follow ALL

instructions to perform adjustments found

under the heading Auger Control Test on

page 8 of this manual.

Prior to operating your snow

Figure 5

• Make certain the fuel shut-off valve, if so equipped,

is in the OPEN (vertical) position.

• Make certain the auger and traction controls are in

the disengaged (released) position.

• Move throttle control up to FAST position. Insert

ignition key into slot. Be certain it snaps into place.

Do not turn key. See Figure 4.

NOTE: Engine will not start unless ignition key is

inserted into ignition slot in carburetor cover. Do not

turn ignition key.

Recoil Starter:

• Rotate choke knob to FULL choke position (cold

engine start).

• If engine is warm, place choke in OFF position

instead of FULL.

• Push primer button three or four times for cold

engine start.

• If engine is warm, push primer button once only.

7

Page 8

NOTE: Always cover vent hole in primer button when

pushing. Additional priming may be necessary for first

start if temperature is below 15 degrees Fahrenheit.

• Grasp starter handle and pull rope out slowly, until it

pulls slightly harder. Let rope rewind slowly.

• Pull starter handle rapidly. Do not allow handle to

snap back. Allow it to rewind slowly while keeping a

firm hold on the starter handle.

• Repeat step above until engine starts.

• As engine warms up and begins to operate evenly,

rotate choke knob slowly to OFF position. If engine

falters, return to FULL choke, then slowly move to

OFF position.

Electric Starter

The electric starter is equipped with a grounded threewire power cord and plug, and is designed to operate

on 120 volt AC household current.

WARNING: The electric starter must be

used with a properly grounded three-prong

receptacle at all times to avoid possibility of

electric shock. Follow all instructions carefully

to operate the electric starter.

• Determine that your house wiring is a three-wire

grounded system. Ask a licensed electrician if you

are not certain.

• If your home wiring system is not a three-wire

grounded system, do not use this electric starter

under any conditions.

• If your home electrical system is grounded, but

a three-hole receptacle is not available, one should

be installed by a licensed electrician before using

the electric starter.

• If you have a grounded three-prong receptacle,

proceed as follows.

• Rotate choke knob to OFF position.

• Connect power cord to switch box on engine. Plug

the other end of power cord into a three-prong 120volt, grounded, AC receptacle.

• Push starter button to crank engine. As you crank

the engine, move choke knob to FULL choke

position.

• When engine starts, release starter button, and

move choke gradually to OFF. If engine falters,

move choke immediately to FULL and then

gradually to OFF.

• When disconnecting the power cord, always unplug

from the three-prong receptacle first, and then from

the snow thrower.

To Stop Engine

• To stop engine, remove the ignition key. Do not turn

key. Disconnect the spark plug wire from the spark

plug to prevent accidental starting while equipment

is unattended.

To prevent starter freeze-up:

• Run engine for a few minutes before stopping to

help dry off any moisture on the engine.

• Electric Starter: Connect power cord to switch box

on engine, then to 120 volt AC receptacle. With the

engine running, push starter button and spin the

starter for several seconds. The unusual sound

made by spinning the starter will not harm engine or

starter. Disconnect the power cord from receptacle

first, and then from switch box.

• Recoil Starter: With engine running, pull starter

rope with a rapid, continuous full arm stroke three

or four times. Pulling the starter rope will produce a

loud clattering sound, which is not harmful to the

engine or starter.

• Wipe all snow and moisture from the carburetor

cover in the area of the control levers. Also, move

control levers back and forth several times. Leave

throttle control lever in the STOP or OFF position.

Leave choke control in the FULL choke position.

• Remove ignition key and disconnect spark plug

wire. Do not turn key.

IMPORTANT:

safe place. Engine will not start without the ignition key.

Do not lose the ignition key. Keep it in a

To Engage Drive

• With the engine running near top speed, move shift

lever into one of the five FORWARD positions or

two REVERSE positions. Select a speed

appropriate for the snow conditions that exist. Use

the slower speeds until you are familiar with the

operation of the snow thrower.

• Squeeze the auger control and the augers will turn.

Release it and the augers will stop.

• Squeeze traction control and the snow thrower will

move. Release it and unit will stop. Never move

shift lever without releasing traction control.

To Engage Augers

• To engage augers and start throwing snow,

squeeze the auger control against the left handle.

Release to stop the augers.

Auger Control Test

IMPORTANT:

the snow thrower for the first time and at the start of

each winter season.

Check the adjustment of the auger control as follows:

• When the auger control is released and in the

disengaged “up” position, the cable should have

very little slack, but should NOT be tight.

Perform the following test before operating

WARNING: Do not over-tighten the cable.

Over-tightening may prevent the auger from

disengaging and compromise the safety of the

snow thrower.

8

Page 9

2. Stop the engine by removing the ignition key.

3. Remove the clean-out tool from the clip which

secures it to the rear of the auger housing.

4. Use the shovel-shaped end of the clean-out tool to

remove any snow and ice in the discharge chute.

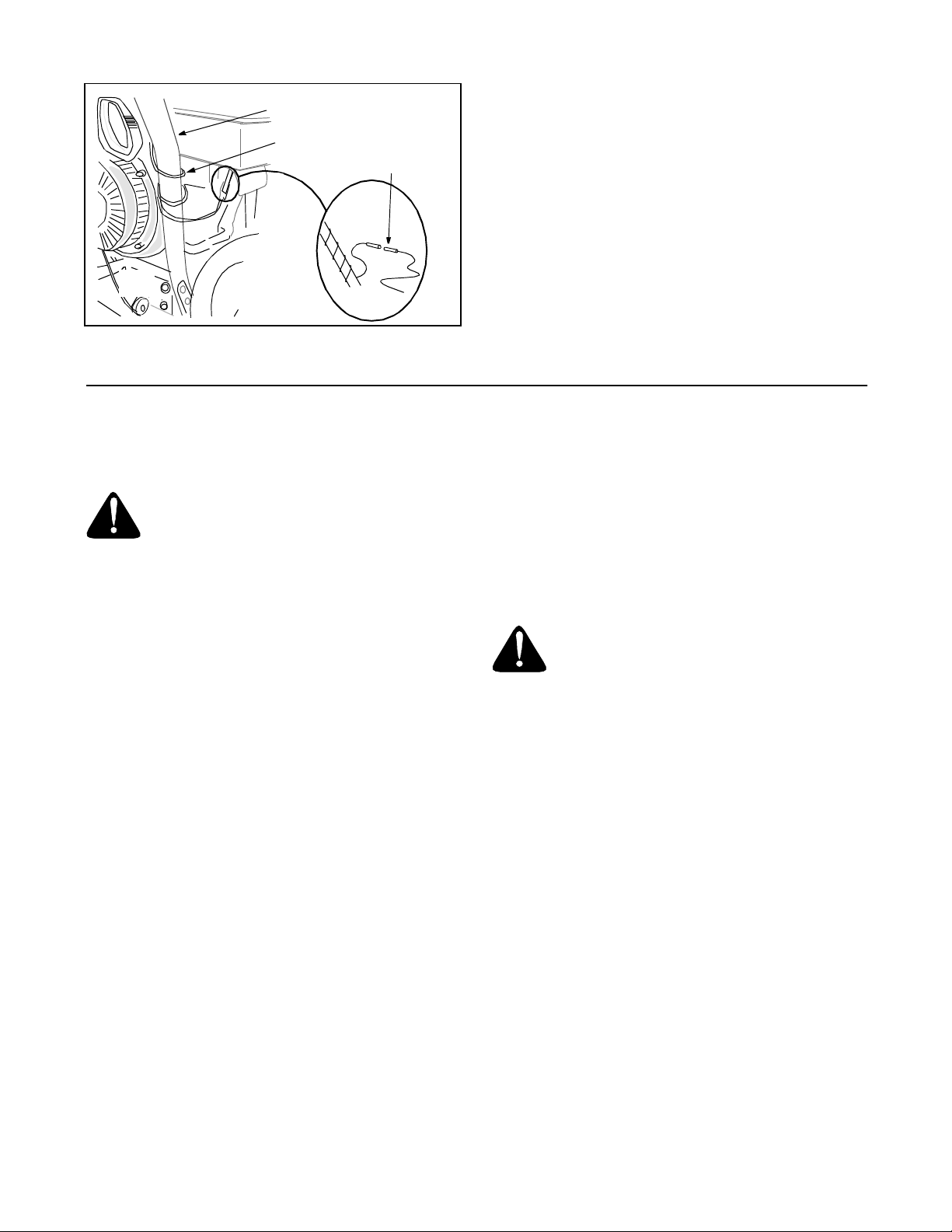

"Z" Fitting

Jam Nut

Make sure cable is straight

Figure 6

• In a well-ventilated area, start the snow thrower

engine as instructed earlier in this section under the

heading Starting Engine. Make sure the throttle is set

in the FAST position.

• While standing in the operator’s position (behind

the snow thrower) engage the auger.

• Allow the auger to remain engaged for

approximately ten (10) seconds before releasing

the auger control. Repeat this several times.

• With the engine running in the FAST position and

the auger control lever in the disengaged “up”

position, walk to the front of the machine.

• Confirm that the auger has completely stopped

rotating and shows NO signs of motion.

IMPORTANT:

immediately return to the operator’s position and shut

off the engine. Wait for all moving parts to stop before

readjusting the auger control cable.

• To readjust the control cable, loosen the hex jam

nut on the auger control cable “Z” fitting.

• Rotate the coupling end of the cable

counterclockwise to provide more slack.

• Retighten the hex jam nut. See Figure 6.

• Repeat Auger Control Test to verify proper

adjustment has been achieved.

If the auger shows ANY signs of rotating,

WARNING: Never use your hand to clear a

clogged discharge chute. Shut off engine and

remain behind handles until all moving parts

have stopped before unclogging.

5. Refasten the clean-out tool to the mounting clip on

the rear of the auger housing, re-start the engine.

6. While standing in the operator’s position (behind

the snow thrower), engage the auger clutch lever

for a few seconds to clear any remaining snow or

ice from the discharge chute before continuing to

clear snow.

Tire Chains (Optional Equipment)

Tire chains may be used whenever extra traction is

needed. Contact Customer Support as instructed on

page 2 for information regarding price and availability.

Snow Thrower Model Tire Chain Kit

31AE640F352 OEM-390-991

Drift Cutters (Optional Equipment)

Drift cutters should be used when operating the snow

thrower in heavy drift conditions. Contact Customer

Support as instructed on page 2 for information

regarding price and availability.

Snow Thrower Model Drift Cutter Kit

31AE640F352 OEM-390-679

Operating Tips

NOTE: Allow the engine to warm up for a few minutes

as the engine will not develop full power until it reaches

operating temperature.

WARNING: The muffler, engine and their

surrounding areas become hot and can cause

a burn. Do not touch.

Chute Clean-out Tool

The chute clean-out tool is conveniently fastened to the

rear of the auger housing with a mounting clip (Refer to

Figure 4). If the discharge chute becomes clogged

during operation, proceed as follows to safely clean the

chute and chute opening:

1. Release both the Auger Control Lever and the

Traction/Auger Control Lock Lever.

• Discharge snow downwind whenever possible.

Slightly overlap each previous path.

• Set the skid shoes 1/4" below the scraper bar for

normal usage. The skid shoes may be adjusted

upward for hard-packed snow. Adjust downward

when using on gravel or crushed rock.

• Avoid possible starter freeze-up. Clean the snow

thrower thoroughly after each use.

9

Page 10

SECTION 5: MAKING ADJUSTMENTS

WARNING: NEVER attempt to make any

adjustments while the engine is running,

except where specified in the operator’s

manual.

Auger Control

Refer to Auger Control Test on page 8 to adjust the auger

control.

Chute Assembly

The distance snow is thrown can be adjusted by

changing the angle of the chute assembly. To do so,

stop the engine by removing the ignition key and loosen

the plastic wing knobs found on either side of the

discharge chute. Pivot the chute upward or downward

before re-tightening the wing knobs.

Tire Pressure

• The tires are over-inflated for shipping purposes.

Before operating, check tire pressure and reduce, if

necessary, to between 15 psi and 20 psi.

NOTE: If the tire pressure is not equal in both tires, the

unit may pull to one side or the other.

WARNING: Drain the gasoline out of snow

thrower engine, place a piece of plastic film

under the gas cap to avoid spillage before

beginning the job.

To test further for correct adjustment, if necessary,

proceed as follows:

• Tip the snow thrower forward, allowing it to rest on

the auger housing.

• Remove the frame cover underneath the snow

thrower by removing six self-tapping screws.

• With the traction control released, there must be

clearance between the friction wheel and the drive

plate in all positions of the shift lever.

• With traction control engaged, the friction wheel

must contact the drive plate. See Figure 7.

Friction

Wheel

Gear Shaft

Traction Control and Shift Lever

• To check the adjustment of the traction control and

shift lever, proceed as follows:

• With the engine off, move the shift lever all the way

forward to sixth (6) position. With the traction

control released, push the snow thrower forward.

The unit should move forward freely. Then engage

the traction control grip. Wheels should stop

turning.

• Now release the traction control grip, and push the

unit again.

• Move the shift lever back to the fast reverse

position, then all the way forward again. There

should be no resistance in the shift lever, and

wheels should keep turning.

• If you feel resistance when moving the shift lever or

the wheels stop when they should not, loosen the

jam nut on the traction control cable and unthread

the cable one turn.

• If the wheels do not stop when you engage the

traction control grip, loosen the jam nut on the

traction control cable and thread the cable in one

turn. Recheck the adjustment and repeat as

necessary. Tighten the jam nut to secure the cable

when correct adjustment is reached.

Drive

Plate

Figure 7

If adjustment is necessary:

• Loosen the jam nut on the traction drive cable and

thread the cable in or out as necessary.

• Retighten the jam nut to secure the cable when

correct adjustment is reached.

• Reassemble the frame cover.

NOTE: If you placed plastic film under the gas cap, be

certain to remove it before operating the snow thrower.

Shift Rod

To adjust the shift rod, proceed as follows.

• Remove the hairpin clip and flat washer from the

shift handle under the handle panel.

• Place shift lever in sixth (6) position or the fastest

forward speed.

• Push shift arm assembly down as far as it will go

• Rotate the ferrule up or down on the shift rod as

necessary until the ferrule lines up with the upper

hole in the shift lever. See Figure 8.

10

Page 11

Shift

Lever

Upper

Shift Rod

Shift Rod

Connector

Lower

Shift Rod

Hairpin

Clip

Shift Arm

Assembly

Ferrule

Figure 8

• Insert ferrule into the upper hole in shift lever.

• Reinstall the hairpin clip and the washer.

IMPORTANT:

Check for correct adjustment of the shift

lever as instructed on page 10, before operating the

snow thrower.

Skid Shoes

The space between the shave plate and the ground can

be adjusted. For close snow removal, place skid shoes

in the low position. Use middle or high position when

area to be cleared is uneven.

• Adjust skid shoes by loosening the four hex nuts

and carriage bolts and moving skid shoes to

desired position. See WARNING:.

• Make certain the entire bottom surface of skid shoe

is against the ground to avoid uneven wear on the

skid shoes. Retighten nuts and bolts securely.

WARNING: Do not operate this snow

thrower on gravel as loose gravel can be

easily picked up and thrown by the auger

causing injury to the operator and/or damage

to the snow thrower.

Carriage Bolts

Hex Nuts

Skid Shoe

Figure 9

Inside Hole

in Axle

Click Pin

in Outside Hole

Figure 10

One Wheel Driving: Insert the click pin only

through the outside hole of the axle (not the rim) on

the right side of the snow thrower. This position

gives power drive to the left wheel only, making the

unit easier to maneuver.

Both Wheels Driving: Insert the click pin through

the hole in the hub of the rim and the inside hole on

the snow thrower’s right axle. This position is good

for heavy snow as there is power drive in both

wheels.

IMPORTANT:

Never operate the snow thrower with the

click pin inserted through both the rim and the outside

hole in the axle. Doing so can result in serious damage

to the drive system.

Drive Wheels

The wheels may be adjusted for two different methods

of operation. The adjustment is made by placing the

click pins in one of two different holes on the right side

of the unit. See Figure 10.

11

Page 12

SECTION 6: MAINTAINING YOUR SNOW THROWER

WARNING: Before servicing, repairing or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

Lubrication

Engine

• Refer to the engine manual for maintenance

procedures and instructions.

WARNING: When following instructions in

the engine manual for draining oil, be sure to

protect frame to avoid oil dripping onto

transmission parts.

Gear Shaft

• Lubricate the gear shaft with a good all-weather

multi-purpose light grease at least once a season or

after every 25 hours of operation.

Gear Case

• The auger gearbox has been filled with grease at

the factory. If disassembled for repairs, lubricate

with 1-1/2 ounces of grease (part no. 737-0168).

Bearings

Shear Bolts

Bearings

Figure 11

Klick Pin

IMPORTANT:

the seals could result. Be sure the vent plug is free of

grease in order to relieve pressure.

Do not overfill the gear case. Damage to

Auger Shaft

• At least once a season, remove shear bolts on

auger shaft. Oil or spray lubricant inside shaft. Also

lubricate the auger bearings at least once a season.

See Figure 11.

Chute Directional Control

• The worm gear on the chute directional control

should be greased with multipurpose automotive

grease.

IMPORTANT:

and drive plate.

Keep all grease and oil off friction wheel

Axle

Figure 12

Drive and Shifting Mechanism

• Remove rear cover. Oil any chains, sprockets,

gears, bearings, shafts, and shifting mechanism at

least once a season. Use engine oil or a spray

lubricant. Avoid getting oil on rubber friction wheel

and aluminum drive plate.

Wheels

• Oil or spray lubricant into bearings at least once a

season. Pull the klick pins and remove wheels,

clean and coat axles with a multipurpose

automotive grease. See Figure 12.

12

Page 13

SECTION 7: SERVICE

WARNING: Before servicing, repairing, or

inspecting, disengage all clutch levers and

stop engine. Wait until all moving parts have

come to a complete stop. Disconnect spark

plug wire and ground it against the engine to

prevent unintended starting.

Augers

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. If the snow thrower hits a

foreign object or ice jam, hex bolts will shear.

• If the augers will not turn, check to see if the bolts

have sheared. Two replacement shear bolts and

hex lock nuts have been provided in the snow

thrower’s hardware pack. For future use, order part

number 710-0890A (shear bolt 5/16-18 x 1.5") and

712-0429 (hex lock nut 5/16-18).

Shave Plate and Skid Shoes

The shave plate and skid shoes on the bottom of the

snow thrower are subject to wear. They should be

checked periodically and replaced when necessary.

• To remove skid shoes, remove the four carriage

bolts, bell washers and hex nuts which attach them

to the snow thrower. Reassemble new skid shoes

with the four carriage bolts, bell washers (cupped

side goes against skid shoes) and hex nuts. Make

certain the skid shoes are adjusted to be level.

• To remove shave plate, remove carriage bolts, bell

washers and hex nuts which attach it to the snow

thrower housing.

• Reassemble new shave plate, making sure heads

of the carriage bolts are to the inside of the housing.

Tighten securely.

Belt Replacement

WARNING: Disconnect the spark plug wire

from the spark plug and ground.

Auger Belts

NOTE: It is necessary to remove both auger belts in

order to change either one. If changing just one belt, be

certain to check the condition of the other belt.

• Remove the plastic belt cover on the front of the

engine by removing the two self-tapping screws.

See Figure 13.

• Drain the gasoline from the snow thrower, or place

a piece of plastic under the gas cap.

• Tip the snow thrower up and forward so that it rests

on the housing.

• Remove six self-tapping screws from the frame

cover underneath the snow thrower. See Figure 13

for the location of the hardware.

Belt

Cover

Self-Tapping

Screws

Figure 13

• Roll the front and rear auger belts off the engine

pulley. See Figure 14.

Rear Auger

Belt

Idler

Pulley

Engine

Pulley

• Unhook the idler spring from the hex bolt on the

auger housing. See Figure 15.

• Back out the stop bolt to allow the belts to slip

between the bolt and auger pulley. See Figure 16.

NOTE: It may be necessary to loosen the six hex nuts

that fasten the frame to the auger housing.

• Lift the rear auger belt from the auger pulley, and

slip belt between the support bracket and the auger

pulley. See Figure 15. Repeat this step for front

auger belt .

• Replace both auger drive belts by following

instructions in reverse order.

Idler

Pulley

Figure 14

Drive

Belt

Front Auger

Belt

Engine

Pulley

13

Page 14

Friction

Wheel

Support

Bracket

Rear Auger

Belt

Front Auger

Pulley

Auger

Pulley

Idler

Spring

Auger

Housing

Support

Bracket

Spring

Frame

Figure 15

Drive Belt

• Follow steps 1 through 4 of previous instructions.

• Pull idler pulley up, and lift belt off engine pulley and

friction wheel disc. See Figure 14.

• Back out the stop bolt until the support bracket rests

on the auger pulley. See Figure 16.

• Slip belt between friction wheel and friction wheel

disc. Remove and replace belt. Reassemble

following the instructions in reverse order.

NOTE: The support bracket must rest on the stop bolt

after the new belt has been assembled. See Figure 25.

Friction

Wheel

Disc

Stop

Bolt

Friction Wheel

Drive Belt

• Drain the gasoline from the snow thrower, or place

a piece of plastic under the gas cap.

• Tip the snow thrower up and forward, so that it rests

on the housing. See Figure 17.

Hex Nut and

Chute

Auger

Bell Washer

Note:

The unit is

shown resting on

its auger housing

Figure 17

• Remove the six self-tapping screws from the frame

cover underneath the snow thrower.

• Remove the klick pins which secure the wheels,

and remove the wheels from the axle.

• Using a wrench to hold the shaft, loosen, but do not

completely remove, the hex nut and bell washer on

left end of gear shaft. See Figure 17.

• Lightly tap the hex nut to dislodge the ball bearing

from the right side of frame. Remove the hex nut

and bell washer from left end of shaft.

• Slide the gear shaft to the right and slide the friction

wheel assembly from the shaft.

• Remove the four screws from the friction wheel

assembly. Remove the friction wheel rubber from

between the plates. See Figure 18.

Plates

Bearing

Screws

Hub

Support Bracket

Figure 16

Changing Friction Wheel Rubber

The rubber on the friction wheel is subject to wear and

should be checked after 25 hours of operation, and

periodically thereafter. Replace the friction wheel

rubber if any signs of wear or cracking are found.

Friction Wheel Rubber

Figure 18

• Reassemble new friction wheel rubber to the

friction wheel assembly, tightening the four screws

in rotation and with equal force.

• Position the friction wheel assembly up onto the pin

of the shift rod assembly, and slide the shaft

through the assembly. Reassemble the wheels and

the frame cover.

14

Page 15

SECTION 8: OFF-SEASON STORAGE

WARNING: Never store engine with fuel in

tank indoors or in enclosed, poorly ventilated

areas where fuel fumes may reach an open

flame, spark or pilot light as on a furnace,

water heater, clothes dryer, or other gas

appliance.

• If unit is to be stored over 30 days, prepare the

• Remove all dirt from exterior of engine and

equipment.

• Follow lubrication recommendations on page 12.

NOTE: When storing any type of power equipment in

an poorly ventilated or metal storage shed, care should

be taken to rustproof the equipment, especially springs,

cables and all moving parts.

engine for storage following instructions in the

engine manual.

SECTION 9: TROUBLE SHOOTING GUIDE

Trouble Possible Cause(s) Corrective Action

Engine fails to start Fuel tank empty, or stale fuel.

Blocked fuel line.

Choke not in ON position

Faulty spark plug.

Key not in switch on engine.

Spark plug wire

disconnected.

Primer button not depressed.

Fuel shut-off valve closed

(if so equipped).

Engine runs erratic Unit running on CHOKE.

Blocked fuel line or stale fuel.

Water or dirt in fuel system.

Carburetor out of adjustment.

Loss of power Spark plug wire loose.

Gas cap vent hole plugged.

Exhaust port plugged.

Engine overheats Carburetor not adjusted

properly.

Incorrect fuel mixture.

Excessive vibration Loose parts or damaged auger. Stop engine immediately and disconnect spark plug wire. Tighten all

Unit fails to propel

itself

Unit fails to

discharge snow

Incorrect adjustment of drive

cable.

Drive belt loose or damaged.

Discharge chute clogged.

Foreign object lodged in auger.

Incorrect adjustment of drive

cable.

Fill tank with clean, fresh gasoline. Fuel may not last over thirty days

unless a fuel stabilizer is used.

Clean fuel line.

Move switch to ON position

Clean, adjust gap or replace.

Insert key.

Connect spark plug wire.

Refer to the engine manual packed with your unit.

Open fuel shut-off valve.

Move choke lever to OFF position.

Clean fuel line; fill tank with clean fresh gasoline. Fuel may not last

over thirty days unless a fuel stabilizer is used.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit or have carburetor

adjusted by an authorized service dealer.

Connect and tighten spark plug wire.

Remove ice and snow from cap. Be certain vent hole is clear.

Clean-see Maintenance section of engine manual.

Refer to the engine manual packed with your unit or have carburetor

adjusted by an authorized service dealer.

Drain fuel tank. Refill with proper fuel mixture.

bolts and nuts. Make all necessary repairs. If vibration continues, have

unit serviced by an authorized service dealer.

Adjust drive cable. Refer to Adjustment section of this manual.

Replace drive belt. Refer to Belt Replacement on page 13.

Stop engine immediately and disconnect spark plug wire. Clean discharge chute and inside of auger housing.

Stop engine immediately and disconnect spark plug wire. Remove

object from auger.

Adjust drive cable. Refer to Adjustment section of this manual.

Drive belt loose or damaged.

Shear bolt(s) sheared

Replace drive belt. Refer to Belt Replacement on page 13.

Replace shear bolt(s)

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest authorized service dealer or

call 1-800-800-7310 for the Customer Support Center. Refer to separate engine manual packed with your snow

thrower for more engine related information.

15

Page 16

SECTION 10: MODEL 31AE640F352 PARTS LIST

33

54

63

25

51

32

24

17

21

31

29

34

35

16

36

23

20

57

3

26

26

62

61

15

27

19

18

13

14

1

12

10

3

4

6

3

7

5

2

11

1

17

39

1

18

30

20

22

37

38

2

9

8

28

53

54

55

59

60

56

52

54

57

58

45

50

26

27

44

41

48

49

42

43

47

40

26

16

Page 17

Model 31AE640F352

REF.

NO.

1 714-0507 Cotter Pin

2 747-0877 Rod

3 710-0599 Hex Washer Screw 1/4-20 x .5

4 784-5680 Handle Support Bracket — RH

5 784-5679 Handle Support Bracket — LH

6 748-0362 Cam Lock Handle

7 748-0363 Handle Lock Pawl

8 732-0145 Compression Spring

9 711-0653 Clevis Pin

10 720-0232 Knob

11 684-0037B Engagement Handle Assy — LH

12 784-5681 Handle Support Bracket — LH

13 784-5619A Shift Handle

14 784-5682 Handle Support Bracket — RH

15 732-0746 Torsion Spring

16 684-0036A Engagement Handle Assy — RH

17 735-0199A Rubber Bumper

18 736-0509 Washer

19 712-0271 Hex Nut 1/4-20 †

20 712-3010 Hex Nut 5/16-18

21 746-0778 Cable

22 684-0103 Panel

23 712-3068 Hex Lock Nut, 5/16-18

24 710-0449 Carriage Screw 5/16-18 x 2.25

25 712-0429 Hex Lock Nut, 5/16-18

26 714-0104 Cotter Pin

27 736-0275 Flat Washer 5/16

28 711-0677 Ferrule

29 710-0458 Carriage Screw 5/16-18 x 1.75

30 720-0274 Grip

31 749-0951 Lower Handle

32 710-1003 Hex Washer Screw

PART

NO. DESCRIPTION

REF.

NO.

33 731-1393 Handle Panel (for top-mount lamp)

34 736-0451 Saddle Washer

35 736-0242 Bell Washer .340 ID x .872 OD

36 747-0621 Lower Shift Rod

37 726-0100 Push Cap

38 720-0201A Chute Knob

39 749-0953A Upper Handle — LH

40 705-5204A Chute Crank

42 747-0697 Chute Crank Eyebolt

43 735-0234 Rubber Grommet

44 684-0008A Shift Arm Assembly

45 710-0788 Hex Washer Screw 1/4-20 x 1.0

46 784-5599 Handle Tab

47 736-0119 Lock Washer 5/16

48 710-0643 Hex Cap Screw 5/16-18 x 1

49 710-1880 Hex Cap Screw 5/16-18 x .75

50 736-0185 Flat Washer

51 731-0921 Upper Chute

52 731-1300B Lower Chute

53 712-3068 Hex Lock Nut 5/16-18

54 736-0159 5/16 Washer

55 710-0451 Carriage Bolt 5/16-18 x .75

56 710-04071 Carriage Screw 5/16-18 x 1.0

57 720-0284 Knob

58 712-3027 Hex Lock Nut 1/4-20

59 731-0851A Flange Keeper

60 710-3015 Hex Cap Screw 1/4-20 x .75

61 747-0620A Upper Shift Rod

62 750-0963 Rod Connector

63 625-0007 Halogen Light Assembly

PART

NO. DESCRIPTION

749-0952A Upper Handle — RH

† Used with lamp ground wire

17

Page 18

Model 31AE640F352

33

37

32

34

45

20

31

39

40

28

27

38

Drive Clutch Cable

13

14

26

36

8

35

15

7

16

25

29

24

22

21

25

23

42

43

5

6

41

4

17

18

20

Auger Clutch Cable

30

3

2

8

1

4

9

7

4

5

Auger Clutch Cable

19

10

44

11*

30

5

12

1

18

1

1

Page 19

Model 31AE640F352

REF.

NO.

1 710-1652 Self-tapping Screw, 1/4-20 x .625

2 784-5688 Drive Cable Guide Bracket

3 784-5687A Auger Clutch Cable Bracket

4 756-0625 Cable Roller

5 738-0924 Hex Screw 1/4-28

6 784-5630B Frame Assembly

7 741-0563 Ball Bearing

8 736-0105 Bell Washer

9 712-0116 Lock Jam Nut

10 741-04026 Hex Flange Bearing

11 736-0188 Flat Washer†

12 784-5689A Front Support Guide Bracket

13 710-0538 Lock Hex Screw

14 736-0242 Bell Washer .340 ID x .872 OD

15 714-0474 Cotter Pin

16 736-0160 Flat Washer .536 ID x .930 OD

17 710-0809 Self-tapping Screw, 1/4-20 x 1.25

18 784-5590 Frame Shift Bracket

19 784-5638 Frame Cover

20 710-1652 Hex Washer TT Screw 1/4-20

21 736-0351 Flat Washer .760 ID x .50 OD

22 717-1445 Gear

23 714-0126 Key

PA RT

NO. DESCRIPTION

REF.

NO.

24 717-1444 7-Tooth Shaft

25 715-0249 Roll Pin

26 714-0143 Klik Pin

27 684-0042B Friction Wheel Assembly

28 656-0012A Friction Disc Wheel

29 684-0013B Wheel Shift Rod Assembly

30 710-0599 Self-tapping Screw, 1/4-20 x .5

31 748-0190 Spacer

32 684-0021 Friction Wheel Bracket Assembly

33 732-0264 Extension Spring

34 712-0711 Jam Nut 3/8-24

35 746-0898B Drive Cable

36 738-0830 Axle 16” Wheels

37 790-00010 Friction Plate

38 735-0243B Friction Wheel Rubber

39 718-0301A Friction Wheel Hub

40 618-0063A Friction Wheel Bearing

41 711-1364 Clevis Pin, 1/4 x 1.3725

42 736-0142 Flat Washer, .281 x .5 x .063

43 714-0507 Cotter Pin, .75

44 712-0703A Insert Nut, 5/16-18

45 790-00011 Friction Plate (Exterior)

PA RT

NO. DESCRIPTION

† Use more than one washer on either side, only if necessary to reduce axle-play.

2

1

WHEEL CHART

MODEL

NUMBER

31AE640F352 16 x 4.8 731-04043 734-1709A 734-1530 734-0255 734-1708A 741-0401

WHEEL

SIZE

REF. NO. 1

SPACER

REF. NO. 2

WHEEL ASS’Y*

TIRE

ONLY

AIR

VALVE

RIM

ONLY

SLEEVE

BEARING (2)

* Wheel assembly includes one tire, one air valve, one painted rim and two sleeve bearings

19

Page 20

Model 31AE640F352

24

44

14

12

11

10

2

3

4

1

9

5

6

8

43

38

39

15

40

13

36

28

41

13

18

35

27

37

34

40

9

16

25

18

18

23

10

30

26

20

33

9

18

19

21

13

23

22

7

9

22

9

42

39

20

Page 21

Model 31AE640F352

REF.

NO.

1 712-0116 Lock Jam Nut 3/8-24

2 756-0178 Flat Idler

3 784-5632B Auger Idler Arm

4 710-0459A Hex Cap Screw 3/8-24 x 1.50

5 738-0281 Shoulder Screw

6 736-0167 Flat Washer, .565 x 1.25 x .02

7 732-0611 Extension Spring

8 712-3068 Hex Nut 5/16-18

9 712-3010 Hex Nut 5/16-18

10 736-0119 Lock Washer 5/16

11 05931A Housing

12 741-0309 Ball Bearing

13 710-0451 Carriage Bolt 5/16-18 x .75

14 705-5226 Reinforcement Chute

15 684-0040D 26” Housing Assembly

16 784-5618 Bearing Housing

18 736-0242 Bell Washer

19 741-0475 Bushing

20 784-5647 Chute Crank Bracket

21 731-1379C Chute Adapter

22 712-0324 Hex Lock Nut 1/4-20

23 736-0463 Flat Washer

24 731-2635 Mount, Chute Clean-out Tool

25 710-0703 Carriage Screw 1/4-20 x .75

26 710-0604A Hex Washer TT Screw 5/16-18

27 736-0169 Lock Washer 3/8

28 712-0798 Hex Nut 3/8-16

30 784-5580 Snow Shoe

31 731-2643 Chute Clean-out Tool

32 731-2635 Mount, Chute Clean-out Tool

33 784-5579A 26” Shave Plate

34 741-0245 Hex Flange Bearing

35 684-0065 Impeller Assembly

36 715-0114 Pin

37 712-0429 Lock Nut 5/16-18

38 605-5192A Spiral 26” RH

39 736-0188 Flat Washer

40 741-0493A Flange Bushing

41 605-5193A Spiral 26” LH

42 710-0890A Shear Bolt 5/16-18 x 1.5

43 746-0897 Drive Cable

44 731-2643 Chute Clean-out Tool

PART

NO. DESCRIPTION

21

Page 22

Model 31AE640F352

4

16

13

17

11

9

8

2

5

6

7

12

1

REF.

NO.

1 618-0123 RH Reducer Housing

2 618-0124 LH Reducer Housing

3 710-0642 Hex Screw 1/4-20 x .75

4 711-0909A Spiral Axle 26"

5 714-0161 Key

6 715-0143 Pin-Spiral

7 717-0528 Worm Gear, 20T

8 717-0526 Worm Shaft

9 718-0186 Thrust Collar

10 721-0325 Grease Plug

11 721-0327 Grease Seal

12 736-0351 Flat Washer .76 x 1.5 x .030

13 736-0369 Flat Washer .508 x 1.0 x .020

14 736-0445 Flat Washer .76 x 1.5 x .060

15 741-0662 Flange Bearing .75 x 1.0 x .59

16 741-0663 Flange Bearing .75 x 1.0 x .925

17 618-0121A Gearbox Ass’y. Complete 26"

PART

NO. DESCRIPTION

14

15

3

10

3

NOTE: NOTE: When rebuilding a gearbox assembly, include 1.5 oz. of Alvania EP Lead-Free Grease (Part No. 737-0168)

22

Page 23

IMPORTANT: For a proper working machine, use Factory Approved Parts.

V-BELTS are specially designed to engage and disengage safely. A substitute

(non OEM) V-Belt can be dangerous by not disengaging completely.

2

3

Model 31AE640F352

1

22

23

21

24

16

19

26

16

16

19

16

12

15

20

11

10

20

4

8

9

4

13

14

17

18

5

7

6

25

REF.

NO.

1 710-1652 Hex Washer Screw 1/4-20 x .625

2 731-1324 Belt Cover

3 732-0710 Extension Spring

4 710-0627 Hex Screw 5/16-24 x .75

5 710-3005 Hex Cap Screw 3/8-16 x 1.25

6 05896A Drive Clutch Idler Bracket

7 748-0234 Shoulder Spacer

8 756-0987 Pulley Half

9 754-0346 V-Belt

10 756-0986 Pulley Half

11 736-0270 Bell Washer

12 710-0230 Hex Cap Screw 1/4-28 x .50

13 756-0313 Flat Idler

PA RT

NO. DESCRIPTION

REF.

NO.

14 710-1245A Lock Hex Cap Screw 5/16-24

15 712-0181 Lock Jam Nut 3/8-16

16 756-0569 Pulley Half

17 736-0242 Bell Washer

18 736-0505 Flat Washer

19 754-0430A Belt

20 756-0967 Auger Pulley

21 736-0247 Flat Washer 3/8 x 1.25 OD

22 736-0331 Bell Washer

23 710-0696 Hex Cap Screw 3/8-24

24 748-0360 Pulley Adapter

25 710-0654A Hex Screw 3/8-16 x 1.0

26 629-0071 Extension Cord, Three-Prong

23

PA RT

NO. DESCRIPTION

Page 24

MANUFACTURER’S LIMITED WARRANTY FOR:

The limited warranty set forth below is given by MTD LLC with

respect to new merchandise purchased and used in the

United States, its possessions and territories.

MTD LLC warrants this product against defects for a period of

two (2) years commencing on the date of original purchase

and will, at its option, repair or replace, free of charge, any

part found to be defective in materials or workmanship. This

limited warranty shall only apply if this product has been operated and maintained in accordance with the Operator’s Man-

ual furnished with the product, and has not been subject to

misuse, abuse, commercial use, neglect, accident, improper

maintenance, alteration, vandalism, theft, fire, water, or damage because of other peril or natural disaster. Damage resulting from the installation or use of any accessory or

attachment not approved by MTD LLC for use with the product(s) covered by this manual will void your warranty as to

any resulting damage.

Normal wear parts or components thereof are subject to separate terms as follows: All normal wear parts or component

failures will be covered on the product for a period of 90 days

regardless of cause. After 90 days, but within the two year

period, normal wear part failures will be covered ONLY IF

caused by defects in materials or workmanship of OTHER

component parts. Normal wear parts and components

include, but are not limited to: batteries, belts, blades, blade

adapters, grass bags, rider deck wheels, seats, snow thrower

skid shoes, shave plates, auger spiral rubber, tires.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE, through your local authorized service dealer. To locate the dealer in your area, check

your Yellow Pages, or contact MTD LLC at P.O. Box 361131,

Cleveland, Ohio 44136-0019, 1-800-800-7310, 1-330-2204683 or log on to our Web site at www.mtdproducts.com.

This limited warranty does not provide coverage in the following cases:

a. The engine or component parts thereof. These items

carry a separate manufacturer’s warranty. Refer to the

applicable manufacturer’s warranty for terms and condi-

tions.

b. Log splitter pumps, valves, and cylinders have a sepa-

rate one year warranty.

c. Routine maintenance items such as lubricants, filters,

blade sharpening, tune-ups, brake adjustments, clutch

adjustments, deck adjustments, and normal deterioration

of the exterior finish due to use or exposure.

d. MTD LLC does not extend any warranty for products

sold or exported outside of the United States, its possessions and territories, except those sold through MTD

LLC’s authorized channels of export distribution.

e. Parts that are not genuine MTD parts are not covered by

this warranty.

f. Service completed by someone other than an authorized

service dealer is not covered by this warranty.

g. Transportation charges and service calls are not

covered.

No implied warranty, including any implied warranty of

merchantability of fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty, whether written or oral, except as mentioned above, given by any person or entity, including a

dealer or retailer, with respect to any product, shall bind

MTD LLC. During the period of the warranty, the exclusive remedy is repair or replacement of the product as

set forth above.

The provisions as set forth in this warranty provide the

sole and exclusive remedy arising from the sale. MTD

LLC shall not be liable for incidental or consequential

loss or damage including, without limitation, expenses

incurred for substitute or replacement lawn care services

or for rental expenses to temporarily replace a warranted

product.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or limitations on how long

an implied warranty lasts, so the above exclusions or limitations may not apply to you.

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of safety features of the product shall void this warranty.

You assume the risk and liability for loss, damage, or injury to

you and your property and/or to others and their property

arising out of the misuse or inability to use the product.

This limited warranty shall not extend to anyone other than

the original purchaser or to the person for whom it was purchased as a gift.

HOW STATE LAW RELATES TO THIS WARRANTY: This

limited warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 1-800-800-7310

Loading...

Loading...