Page 1

Service Manual

NOTE: These materials are for use by trained technicians who are experienced in the service and repair of outdoor power

equipment of the kind described in this publication, and are not intended for use by untrained or inexperienced individuals.

These materials are intended to provide supplemental information to assist the trained technician. Untrained or inexperienced

individuals should seek the assistance of an experienced and trained professional. Read, understand, and follow all instructions

and common sense when working on power equipment. This includes the contents of the product’s Operators Manual, supplied

with the equipment. No liability can be accepted for any inaccuracies or omission in this publication, although care has been

taken to make it as complete and accurate as possible at the time of publication. However, due to the variety of outdoor power

equipment and continuing product changes that occur over time, updates will be made to these instructions from time to time.

Therefore, it may be necessary to obtain the latest materials before servicing or repairing a product. The company reserves the

right to make changes at any time to this publication without prior notice and without incurring an obligation to make such

changes to previously published versions. Instructions, photographs and illustrations used in this publication are for reference

use only and may not depict actual model and component parts. © Copyright 2005 MTD Products Inc. All Rights Reserved.

31AE5MLG729 Two-Stage Snow Thrower

MTD Products LLC - Product Training and Education Department

FORM NUMBER 769-01418

9/2004

Page 2

Page 3

TABLE OF CONTENTS

General Information ....................................................................................................1

Tire Pressure .............................................................................................................2

Chute Installation ........................................................................................................2

Skid Shoe and Shave Plate Adjustment ....................................................................2

Shave Plate Adjustment .............................................................................................3

Drive Control Cable Adjustment .................................................................................3

Auger Control Testing and Adjustment ......................................................................4

Shift Rod Adjustment .................................................................................................5

Auger Belt Replacement ............................................................................................5

Drive Belt Replacement .............................................................................................6

Friction Wheel Removal ............................................................................................. 6

Planetary Gear Removal ............................................................................................8

Drive Shaft Removal ..................................................................................................9

Axlw Shaft Removal .................................................................................................10

Splitting the Unit .......................................................................................................11

FRiction Wheel Disc Disassembly ............................................................................13

Auger Pulley Removal ..............................................................................................14

Auger and Impeller Removal ....................................................................................14

Auger and Impeller Notes .........................................................................................15

Reducer Transmission .............................................................................................16

Reduction Transmission Disassembly .....................................................................16

Auger Idler Arm ........................................................................................................16

Page 4

Page 5

31AE5MLG729 Snow Thrower

31AE5MLG729

YARD MACHINES SNOW THROWER

Model 31AE5MLG729

• Serial Number 1G024B10168

• Two Stage – 4 Cycle HMSK80-110 – 10.5 HP

• 28” Xtreme Auger

GENERAL INFORMATION

The Owner’s Manual packet includes and engine manual, extra shear pins and cotter pins as well as a packet

containing a sample of Sta-Bill fuel stabilizer that will

treat up to 2 ½ gallons of regular gas.

CAUTION: When assembling the handle for the

first time, use caution when lifting the handle.

The shift lever rod can get caught on the lower

handle cross member and if forced into position

can bend the spring shift lever. If necessary,

move the shift rod in front of the cross member

as you raise the handle into position.

There are two Supplement Sheets dated July 19 2004

and July 20, 2004 – Subject: Connector Sleeve on Two

Stage Snow Thrower shift rod. (Styles: E, F, H, K, L, N,

O, P and Q.)

Vibration may cause the rod connector sleeve to slide

up out of position. The remedy is to slide the connecter

sleeve fully down. Secure it in place by placing a rubber bushing over the top of the lower shift rod OR the

upper shift rod.. (A small piece of gas line can be used

as a bushing.) This will prevent the sleeve from sliding

up the shaft. See Figure 1.

• 21” Intake Height

• Tecumseh Engine With Electric Start

• Power Steering

• 4 – Way Discharge Chute Control

• 6 Forward Speeds and 2 Reverse Speeds

• Built in Halogen Light

• Fully assembled with oil in engine

• The 4-way discharge chute control: for quick and

easy snow directional changes.

• Power Steering: For ultimate maneuverability

• XTREME Auger: Break down of ice and snow

before pushing the pieces into the impeller.

• Built-in Halogen Light: For use in early morning

or evening.

Rubber Bushing

Rod Connector Sleeve

Figure 1

Rubber bands hold the Auger and Drive control cables

in their respective nylon pulleys during shipping and

generally break during assembly of the handle.

Remove any pieces of rubber band after assembly.

1

Page 6

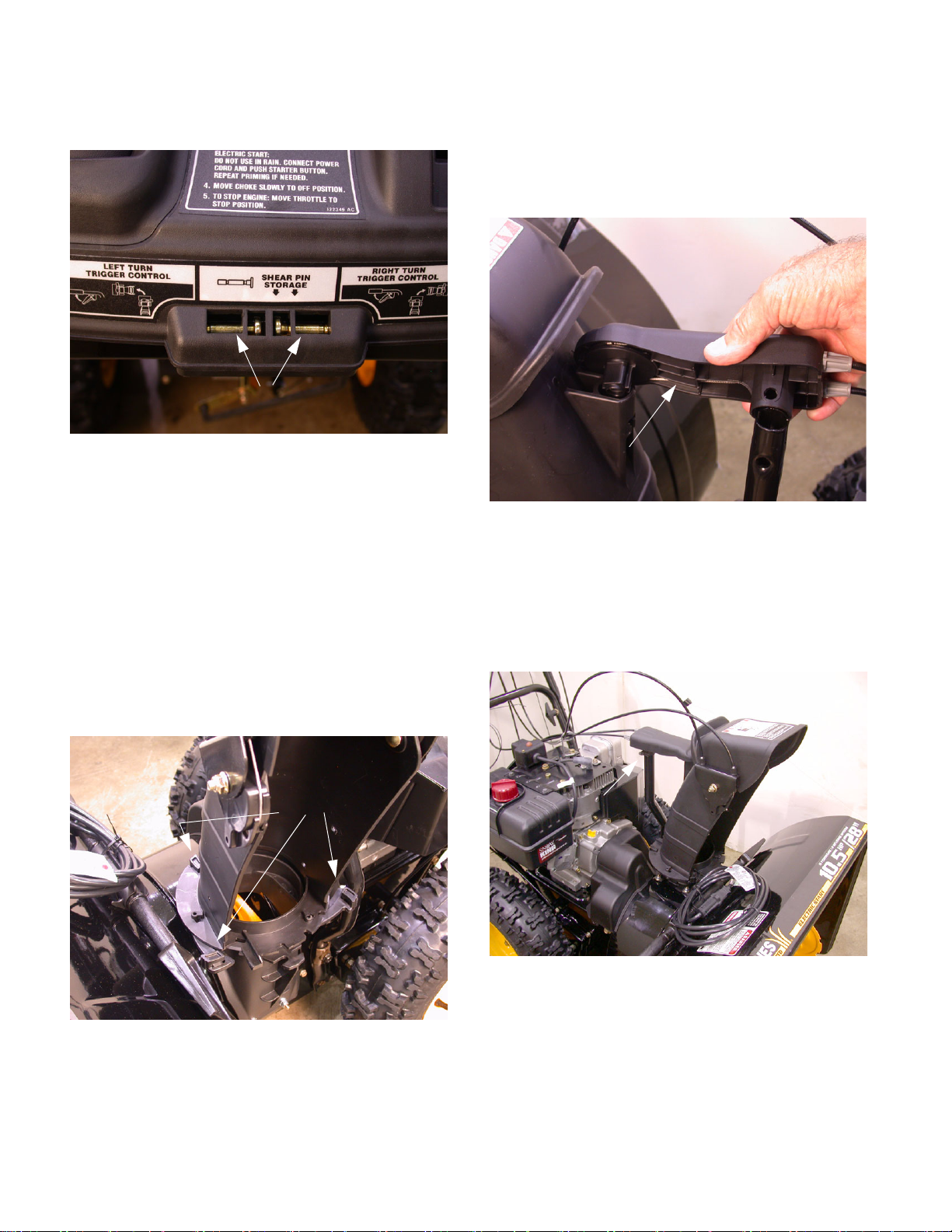

There is a storage area in the handle panel used for

holding the spare auger shear pins. See Figure 2.

Shear Pins Storage Area

2.3. Pull the hairpin clip out of the clevis pin on the

chute support rod. Save the hardware.

2.4. Insert the round end of the chute control box on

the short tube of the chute assembly. See Figure

4.

Figure 2

1. TIRE PRESSURE

Before operating, check tire pressure. Both tires should

be between 15 psi and 20 psi.

NOTE: If the tire pressure is not equal in both tires, the

unit may pull to one side or the other during operation.

2. CHUTE INSTALLATION

2.1. Apply a light lubricant to the rim/lip of the chute

base (and the underside of the chute assembly)

and position the chute over the base.

2.2. Close the flange keepers to secure the chute to

the base. See Figure 3.

Flange Keepers

Chute Control

Figure 4

2.5. Insert the other end of the chute control box into

the chute support tube.

2.6. Insert the clevis pin, removed earlier, through the

holes on the chute control box and the chute

support rod. Secure with the hairpin clip. See

Figure 5.

Clevis Pin

Figure 3

NOTE: If the flange keepers will not easily click

into place, use the palm of your hand to apply

swift, firm pressure to the back of each.

Figure 5

3. SKID SHOE AND SHAVE PLATE ADJUSTMENT

The space between the shave plate and the ground

can be adjusted.

For close snow removal on a smooth surface, raise

skid shoes higher on the auger housing to lower the

2

Page 7

shave plate.

Use a middle or lower position when the area to be

cleared is uneven, such as a gravel driveway.

CAUTION: Loose gravel can be picked up and

thrown by the auger, causing injury to the operator and bystanders and/or damage to the snow

thrower and surrounding property.

For initial adjustment we recommend placing the shave

plate on a piece of cardboard.

3.1. Loosen the four hex nuts (two on each side) and

carriage bolts attaching the skid shoes to the

auger housing. See Figure 6.

Hex Nuts

4.1. Remove the carriage bolts and hex nuts, which

attach it to the snow thrower housing. See Figure 7.

Carriage Bolts

Figure 7

4.2. Install a new shave plate, making sure the heads

of the carriage bolts are to the inside of housing.

4.3. Tighten nuts securely.

Skid Shoe

Figure 6

3.2. Move the skid shoes to the ground.

3.3. Tighten the hex nuts.

NOTE: Make certain the entire bottom surface of

skid shoe is against the ground to avoid uneven

wear on the skid shoes.

4. SHAVE PLATE REPLACEMENT

The shave plate will wear over time. It can be replaced

when worn excessively.

NOTE: You willl need to remove the skid shoes

prior to removing the shave plate.

5. DRIVE CONTROL CABLE ADJUSTMENT

When the drive control is released and in the disengaged, or "up" position, the cable should have very little

slack. It should NOT be tight.

Check the adjustment of the drive control as follows:

5.1. With the drive control released, push the snow

thrower gently forward. The unit should roll

freely.

5.2. Engage the drive control and gently attempt to

push the snow thrower forward. The wheels

should not turn. The unit should not roll freely.

5.3. With the drive control released, move the shift

lever back and forth between the R2 position

and the F6 position several times. There should

be no resistance in the shift lever.

If any of the above tests failed, the drive cable is in

need of adjustment.

3

Page 8

5.4. Loosen the hex jam nut on the auger control

cable "Z" fitting and rotate the coupling end of

the cable downward to provide more slack or

upward to take up slack. See Figure 8.

6.4. To readjust the control cable, loosen the hex jam

nut on the auger control cable "Z" fitting. Rotate

the coupling end of the cable counterclockwise

to provide more slack. Retighten the hex jam

nut. See Figure 9.

Hex Jam Nut

Figure 8

5.5. Retighten the hex jam nut and repeat all three

tests to verify proper adjustment has been

achieved.

6. AUGER CONTROL TESTING AND ADJUSTMENT

6.1. Start the engine and run it at full throttle.

6.2. While standing in the operator position, engage

the auger. Do this several times.

6.3. Release the auger control and walk to the front

of the unit. Confirm that the auger has completely stopped rotating and shows NO signs of

motion.

Hex Jam Nut

Figure 9

6.5. Repeat Auger Control Test to verify proper

adjustment has been achieved.

WARNING : Never attempt to make any adjustments while the engine is running, except where

specified in operator's manual.

The augers are secured to the spiral shaft with four

shear pins and cotter pins. If the auger should strike a

foreign object or ice jam, the snow thrower is designed

so that the pins may shear. See Figure 10.

Shear Pins

IMPORTANT: If the auger shows ANY signs of

rotating, immediately return to the operator's

position and shut off the engine. Wait for ALL

moving parts to stop before re-adjusting the

auger control.

Figure 10

If the augers will not turn, check to see if the pins have

sheared.

One set of replacement shear pins has been provided

with the snow thrower.

4

Page 9

When replacing pins, spray an oil lubricant into shaft

before inserting new pins.

7. SHIFT ROD ADJUSTMENT

If the full range of speeds (forward and reverse) cannot

be achieved, adjust the shift rod.

7.1. Place the shift lever in the fastest forward speed

position and remove the hairpin clip which

secures the ferrule to the shift lever. See Figure

11.

Hairpin Clip

Ferrule

8. AUGER BELT REPLACEMENT

8.1. Using a 3/8” socket and extension, remove the

two self-tapping screws securing the plastic belt

cover to the frame. See Figure 13.

Slf Tapping Screws

Figure 13

8.2. Roll the auger belt off the engine pulley. See Figure 14.

Figure 11

7.2. Rotate the shift arm down as far as it will go. See

Figure 12.

Shift Arm

Figure 12

7.3. Thread the ferrule up or down the shift rod until it

aligns with the hole in the shift lever.

Auger Belt

Engine Pulley

Figure 14

NOTE: Place a scewdriver under the belt as you

pull slowly on the starter cord to wind the belt off

the pulley

8.3. Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

8.4. Disconnect the spark plug wire from the spark

plug.

7.4. Re-secure the ferrule with the hairpin clip

removed earlier.

8.5. Carefully pivot the snow thrower up and forward

so that it rests on the auger housing.

5

Page 10

8.6. Using a 3/8” socket, remove the four self-tapping

screws which secure the frame cover to the

frame. See Figure 15.

Self Tapping Screws

Figure 15

To remove and replace your snow thrower's drive belt,

proceed as follows:

9.1. Follow steps 8.1 through 8.6 in the AUGER

BELT REMOVAL Section. Then continue with

the following steps.

9.2. Use a length of starter cord to pull the drive belt

idler pulley toward the right, away from the belt.

See Figure 17.

Starter Cord

8.7. Using a piece of starter cord, unhook the support

bracket spring from the frame. See Figure 16.

Starter Cord

8.8. Using a 9/16” socket and a ¾” wrench, loosen

and remove the shoulder screw which acts as a

belt keeper.

8.9. Remove the belt from around the auger pulley,

and slip the belt between the support bracket

and the auger pulley

Support Bracket Spring

Figure 16

Wood Block

Figure 17

9.3. Wedge a piece of wood under the pulley to hold

it in position.

9.4. Roll the drive belt off engine pulley.

9.5. Slip the drive belt off the pulley and between friction wheel and friction wheel disc. See Figure

18.

Friction Wheel Disc

Drive Belt

8.10. Reassemble auger belt by following instructions

in reverse order.

IMPORTANT: DO NOT forget to reinstall the

shoulder screw and reconnect the spring to the

frame after installing a replacement auger belt.

9. DRIVE BELT REPLACEMENT

Figure 18

9.6. Remove and replace belt in the reverse order.

6

Page 11

10. FRICTION WHEEL REMOVAL

If the snow thrower fails to drive with the drive control

engaged, and performing the drive control cable

adjustment fails to correct the problem, the friction

wheel may need to be replaced.

10.1. Examine the friction wheel for signs of wear or

cracking and replace if necessary.

10.2. Place the shift lever in second reverse (R2) position.

10.3. Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

10.4. Disconnect the spark plug wire from the spark

plug.

10.5. Carefully pivot the snow thrower up and forward

so that it rests on the auger housing.

10.7. Using a ½” socket remove the screws and bell

washers securing the wheels to the axles.

Remove both wheels. See Figure 20.

10.6. Using a 3/8” socket, remove the four self-tapping

screws that secure the frame cover to the frame.

See Figure 19.

Self Tapping Screws

Figure 19

Figure 20

10.8. Using a 3/8” socket, remove the four screws

securing the right drive cover to the frame.

Remove the drive cover. Repeat for the left drive

cover. See Figure 21.

Screws

Right Drive Cover

Figure 21

7

Page 12

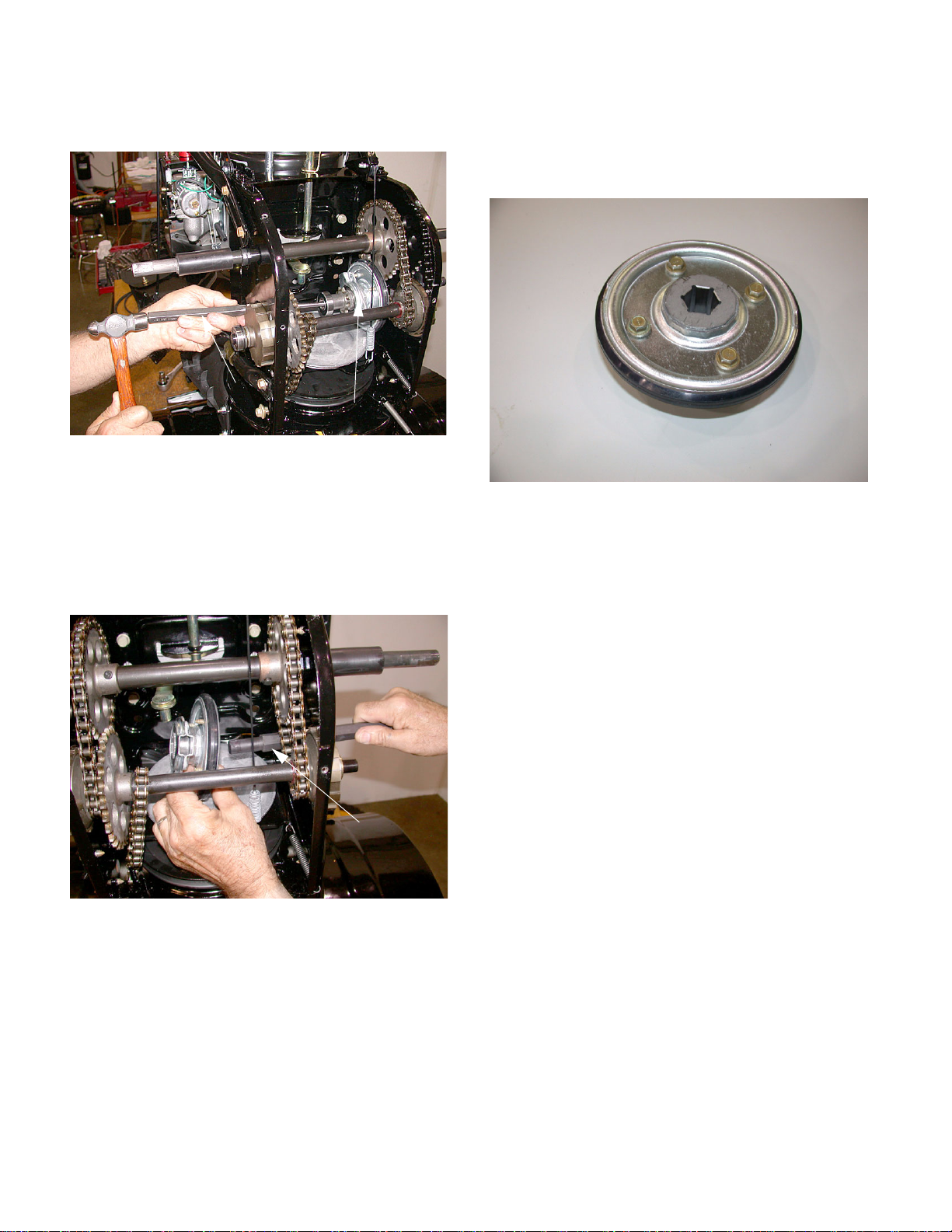

10.9. Holding the friction wheel assembly, slide the

hex gear shaft to the right. See Figure 22.

Drift Punch

Friction Wheel Assembly

Figure 22

If you're disassembling the friction wheel and replacing

only the rubber ring, proceed as follows:

10.13.Remove the four screws that secure the friction

wheel's side plates together. See Figure 24.

NOTE: It may be necessary to use a drift punch

on the left side of the shaft to drive it from the

bearing.

10.10.Lift the chain off the small sprocket.

10.11. Catch the bearing, sprocket and friction wheel as

they come off the shaft. See Figure 23.

Hex Shaft

Figure 23

Figure 24

10.14.Remove the rubber ring from between the

plates.

10.15.Reassemble the side plates with a replacement

rubber ring.

IMPORTANT: Tighten each screw only one rotation before turning the wheel clockwise and proceeding with the next screw. Repeat this process

several times to ensure the plates are secured

with equal force.

10.16.Slide the friction wheel assembly back onto the

hex shaft and follow the steps above in reverse

order to reassemble components.

11. PLANETARY GEAR REMOVAL

NOTE: It is not necessary to remove any belts to

service the planetary gears.

11.1. Remove the wheels on the side of the unit you

will be servicing.

NOTE: Maintain the correct order of parts during

disassembly.

10.12.Inspect the friction wheel for wear or damage.

NOTE: The friction wheel can be replaced as an

assembly or repaired.

If you're replacing the friction wheel assembly as a

whole, discard the worn assembly and slide the new

assembly onto the hex shaft. Follow the steps above in

reverse order to reassemble components.

8

Page 13

11.2. Using a 3/8” socket, remove the shaft retainer

cover. See Figure 25.

Shaft Retainer Cover

11.6. Remove the planetary ring gear. See Figure 27.

Planetary Ring Gear

Figure 25

11.3. Remove the ball bearing and flat washer.

11.4. Using snap ring pliers, remove the retaining ring.

See Figure 26.

Retaining Ring

Figure 26

11.5. Remove the three flat washer shims.

Figure 27

11.7. You can now remove and service the inner planetary gears.

NOTE: The procedure can be performed for

either planetary gear cluster.

12. DRIVE SHAFT REMOVAL

NOTE: It is not necessary to remove any belts to

service the Drive shaft.

12.1. Remove both planetary gear clusters as covered

in REMOVAL OF THE PLANETARY GEAR section.

12.2. Lift up on the right side of the drive shaft to allow

removal of the right chain. See Figure 28.

Drive Shaft

Figure 28

9

Page 14

12.3. Remove the right planetary gear cluster from the

drive shaft. See Figure 29.

Planetary Gear Cluster

Washer

Figure 29

12.4. Slide the drive shaft to the right while holding the

left planetary gear cluster in place. See Figure

30.

13.2. Remove both wheels.

13.3. Remove the frame cover.

13.4. Remove the spacers on each end of the axle.

See Figure 31.

Axle Spacer

Figure 31

13.5. Remove both cotter pins from the clevis pins

securing the sprockets to the wheel axle. See

Figure 32.

Slide

Drive Shaft

Figure 30

12.5. Remove the drive shaft and sprocket from the

unit.

12.6. Remove the drive chain from around the left

planetary gear cluster and remove the cluster

from the unit.

NOTE: During assembly, make sure the drive

clutch cable is routed on the inside of the drive

shaft.

13. AXLE SHAFT REMOVAL

NOTE: It is not necessary to remove the drive

shaft in order to service the wheel axle.

Cotter Pins &

Clevis Pins

Figure 32

13.6. Remove the clevis pins from the axle.

NOTE: This is a split axle.

13.1. Tip the unit up on the auger housing.

10

Page 15

13.7. Slide the right axle to the right and remove the

gear, shim washer and hex flange bearing from

the axle as you remove it. See Figure 33.

Right Axle

Axle Support Tube

Figure 33

13.8. Slide the left axle to the left and remove the axle

support tube, gear, shim washer and hex flange

bearing as you remove it. See Figure 34.

NOTE: Assembly Tip. Independently assemble

both the right and left side axle components

through their respective frame sides, leaving the

axles flush with each gear. Slide the axle support tube between the gears and slide the axles

together. Line up the gears with the holes in the

axle and replace the clevis pins and cotter pins.

See Figure 35.

Axle Support Tube

Left Axle

Figure 34

Figure 35

14. SPLITTING THE UNIT

Splitting the unit in two allows easy access to the friction disk and auger pulley.This is the preferred method

of servicing these parts.

14.1. Drain the gasoline from the snow thrower, or

place a piece of plastic under the gas cap.

14.2. Disconnect the spark plug wire from the spark

plug.

14.3. Remove the belt cover.

14.4. Remove the auger belt from around the engine

pulley.

11

Page 16

14.5. Use needle nose pliers to remove the hairpin clip

from the clevis pin securing the 4-way chute

control assembly to the chute support tube.

Remove the clevis pin. See Figure 36.

14.8. Using a ½” socket, remove the TT screw, handle

tab and washer securing the support tube to the

frame. Remove the support tube from the unit.

See Figure 38.

4-Way Chute Control

Hairpin Clip

Figure 36

14.6. Remove the control assembly and set it on the

engine.

14.7. Using a ½” socket, remove the AB screw securing the lower portion of the chute support tube to

the frame. See Figure 37.

Frame Screws

Support Tube

Figure 38

14.9. Using a 3/8” socket, remove the AB screw

securing the auger cable guide bracket to the

frame. See Figure 39.

AB screws

Figure 37

Auger Cable Bracket

Figure 39

14.10.Using a ½” socket, remove the 4 bolts (2 on

each side) securing the auger housing assembly

to the wheel drive frame.

12

Page 17

14.11. Separate the two halves of the unit. See Figure

40.

Figure 40

NOTE: As you separate the housing halves,

remove the extension spring from the auger idler

bracket.

CAUTION: After the unit is split, place wood

blocks at the rear of the wheel drive frame to

support it and keep it from tipping back.

15. FRICTION WHEEL DISC DISASSEMBLY

15.4. Using the engine pull start handle and a small

cotter pin removal tool, roll the drive belt off the

engine pulley. See Figure 42.

Drive Belt

Figure 42

15.5. Using a 9/16” socket and screwdriver, remove

the Jam nut and bell washer securing the friction

wheel disc to the friction wheel support bracket.

See Figure 43.

Hold screwdriver securely

while loosening jam nut

15.1. Disconnect the spark plug wire from the spark

plug.

15.2. Split the unit. Refer to the SPLITTING THE UNIT

Section.

15.3. Using a piece of starter cord, pull the drive clutch

idler bracket away from the belt and block it with

a piece of wood. See Figure 41.

Figure 41

Figure 43

15.6. Slip the belt off of the disc and remove the disc

from the unit.

15.7. Assemble in reverse order.

13

Page 18

NOTE: During reassembly note that there are

two mounting holes in the friciton wheel support

bracket. The friciton wheel disc must be installed

in the left hand hole as you face the friction

wheel support bracket. See Figure 44.

Assemble in left mounting hole

Figure 44

16.4. Inspect the pulley and adapter for any wear or

damage.

NOTE: During reassembly use Loctite 242 on

the screw.

NOTE: Torque to 160-200 inch pounds.

17. AUGER AND IMPELLER REMOVAL

17.1. Remove the Auger Pulley as covered in the

AUGER PULLEY REMOVAL Section..

17.2. Using a ½” socket, remove the two flange lock

nuts securing the bearing housing to the auger

housing. Remove the bearing housing and bearing and inspect for wear or damage. See Figure

46.

Flange Lock Nuts

16. AUGER PULLEY REMOVAL

16.1. Split the unit in two. Refer to the SPLITTING

THE UNIT Section.

16.2. Wedge a 2x4 between the spiral assembly and

the auger hosing to hold it in place. See Figure

45.

2x4

Auger Pulley Flat Washer Screw

Figure 45

Figure 46

NOTE: The two carriage bolts used to secure

the bearing housing are held in place by push-on

nuts.

17.3. Lay the auger housing on its face.

16.3. Using a 1/’2” socket, remove the screw and flat

washer securing the auger pulley to the impeller

assembly.

14

Page 19

17.4. Using a 1/2 “ socket, remove the four (two on

each side) hex screws securing the auger

assembly to the auger housing. See Figure 47.

Hex Screws

Figure 47

AUGER AND IMPELLER NOTES

• The impeller worm shaft is machined to match a

double D machining in the impeller. See Figure

49.

Double “D” Machining

17.5. Carefully tip back and remove the housing from

the auger assembly. See Figure 48.

Figure 48

Figure 49

• Hex flange bearings are used at the ends of the

auger axle.

• There a four shear pins used to attach the spiral

assemblies to the auger axle. Spare pins are

shipped with the unit.

• Spiral assemblies are marked left and right for

proper installation. See Figure 50.

Spiral Assembly

15

Figure 50

NOTE: During assembly, place the auger hous-

ing face up when installing the auger and impeller assembly.

Page 20

18. REDUCER TRANSMISSION

18.1. The reducer can be serviced. It can also be purchased as an assembly.

19.2. Separate the housing halves using a putty knife.

See Figure 53.

19.3. Inspect all internal parts for wear or damage.

NOTE: On the top of the gearbox is inspection

and access hole for adding grease when and if

required. Remove the rubber grommet from the

lubrication port. See Figure 51.

Rubber Grommet

Reducer Transmission

Figure 51

Ultra Gray

Figure 53

NOTE: before assembly, clean off all of the ultra-

gray sealant on both sides of the gearbox housing. Use ultra gray to reseal the housing before

assembly.

19. REDUCTION TRANSMISSION DISASSEMBLY

19.1. Using a 3/8” socket, remove the 5 TT screws

securing the reducer halves together. See Figure 52.

5 TT Screws

Figure 52

20. AUGER IDLER ARM

20.1. Split the unit. Refer to the SPLIT THE UNIT Section.

20.2. Remove the auger pulley. Refer to AUGER PULLEY REMOVAL Section.

16

Page 21

20.3. Align one of the holes in the impeller with the

idler arm nut on the front of the auger housing.

See Figure 54.

Alignment Hole

Figure 54

20.4. Using a 9/16’ socket on a long extension and a

15/16” socket on a ½’ socket wrench, remove

the nut and shoulder screw attaching the idler to

the auger housing. See Figure 55.

Idler Arm

Figure 55

20.5. Inspect the idler pulley for wear or damage.

NOTE: The idler pulley can be removed using a

9/16” socket and a 9/16” opened end wrench.

17

Loading...

Loading...