Page 1

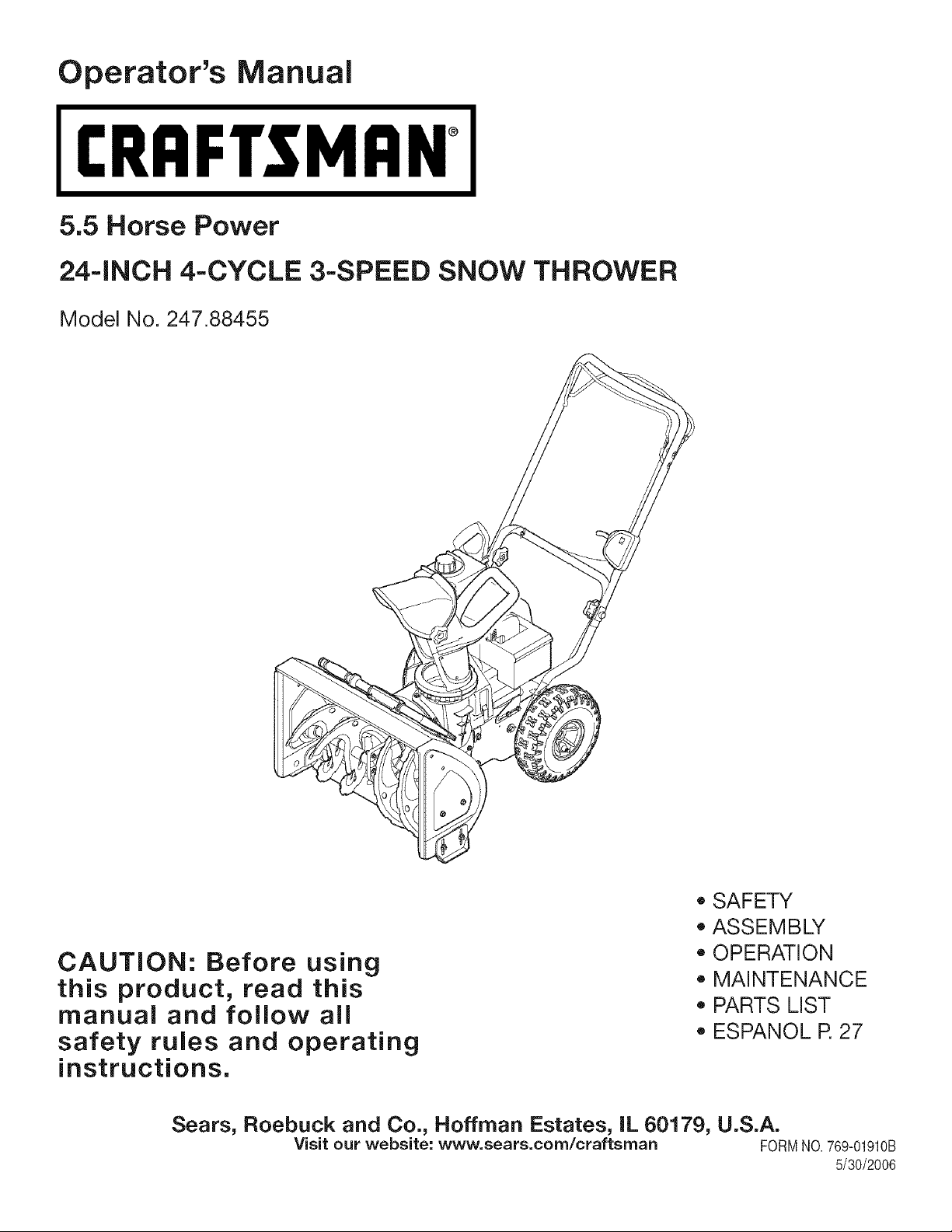

Operator's Manual

CRAFTSMAN°

5.5 Horse Power

24-iNCH 4-CYCLE 3-SPEED SNOW THROWER

Model No. 247.88455

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www, sears,corn/craftsrnan FORMNO.769-01910B

• SAFETY

• ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

ESPANOL R 27

5/30/2006

Page 2

Warranty Statement ................................................. Page 2 Maintenance and Service ................................. Pages 12-15

Safety Labels ........................................................... Page 3 Off Season Storage & Troubleshooting ............. Page 16-17

Rules of Safe Operation ..................................... Pages 4-5 Parts List .......................................................... Pages 18-25

Set Up &Adjustment .......................................... Pages 6-7 Espa_ol ................................................................... Page 27

Know Your Snow Thrower .................................. Pages 8-9 Service Numbers ............................................... Back Cover

Operation ........................................................ Pages 10-11

Two-YearWarrantyon Craftsman SnowThrower

Fortwoyearsfromthedate of purchase,whenthisCraftsmanSnowThrowerismaintained,lubricatedandtunedupaccordingto theinstructions

intheowner'smanual,Searswillrepair,freeof charge,anydefectin materialandworkmanship.IfthisCraftsmansnowthrowerisused for

commercialor rentalpurposes,thiswarrantyappliesforonly30daysfromthedateof purchase.

Thiswarrantydoesnotcover:

• Expendableitemswhichbecomewornduringnormaluse,suchasskidshoes,shaveplateandsparkplugs.

Repairsnecessarybecauseof operatorabuseor negligence,includingbentcrankshaftsandthefailureto maintaintheequipmentaccording

totheinstructionscontainedinthe owner'smanual.

WARRANTYSERVICEISAVAILABLEBYRETURNINGTHECRAFTSMANSNOWTHROWERTOTHE NEAREST

SEARSPARTS& REPAIRCENTERINTHEUNITEDSTATES.

This warrantyappliesonlywhilethisproductis in use intheUnitedStates.

TOLOCATETHENEARESTSEARSPARTS& REPAIRCENTERORTOSCHEDULESERVICE,

SIMPLYCONTACTSEARSAT1-800-4-MY-HOME®.

Thiswarrantygivesyouspecificlegalrightsandyoumayalso haveotherrightswhichmayvaryfromstateto state.

SEARS,ROEBUCKANDCO.,D/817WA,HOFFMANESTATES,IL 60179

Repair ProtectionAgreements

Congratulationson makingasmartpurchase.YournewCraftsman®

productisdesignedandmanufacturedforyearsofdependableopera-

tion.Butlikeallproducts,it mayrequirerepairfromtimetotime.That's

whenhavinga RepairProtectionAgreementcansaveyoumoneyand

aggravation.

Here'swhat'sincludedintheAgreement:

Expertserviceby our 12,000professionalrepairspecialists

Unlimitedserviceand nochargeforpartsand laboronall covered

repairs

Productreplacementif yourcoveredproductcan'tbe fixed

Discountof 10%fromregularpriceofserviceandservice-related

partsnotcoveredbytheagreement;also,10%off regularpriceof

preventivemaintenancecheck

Fasthelpbyphone- phonesupportfroma Searstechnicianon

productsrequiringin-homerepair,plusconvenientrepair

scheduling

Horse Power:

Engine Oil:

Fuel:

Spark Plug:

Engine:

5.5

SAE 5W-30

Unleaded Gasoline

Champion@ RJ19LM

Tecumseh LH195SP

PurchaseaRepairProtectionAgreementnowandprotectyourself

fromunexpectedhassleandexpense.

OnceyoupurchasetheAgreement,asimplephonecallis all thatit

takesfor youto scheduleservice.Youcancall anytimedayornight,or

schedulea serviceappointmentonline.

Searshasover12,000professionalrepairspecialists,whohave

accessto over4.5millionqualitypartsandaccessories.That'sthe

kindof

professionalismyoucancountonto helpprolongthelifeof yournew

purchaseforyearsto come.PurchaseyourRepairProtectionAgree-

menttoday!

Somelimitationsand exclusionsapply. For pricesandadditional

informationcall 1-800-827-6655.

SearsInstallation Service

ForSearsprofessionalinstallationofhomeappliances,garagedoor

openers,waterheaters,andother majorhomeitems,in the U.S.A.call

1-800-4-MY-HOME®

Model Number .............................................................

Serial Number ..............................................................

Date of Purchase ..........................................................

Record the model number, serial number

and date of purchase above

Page 3

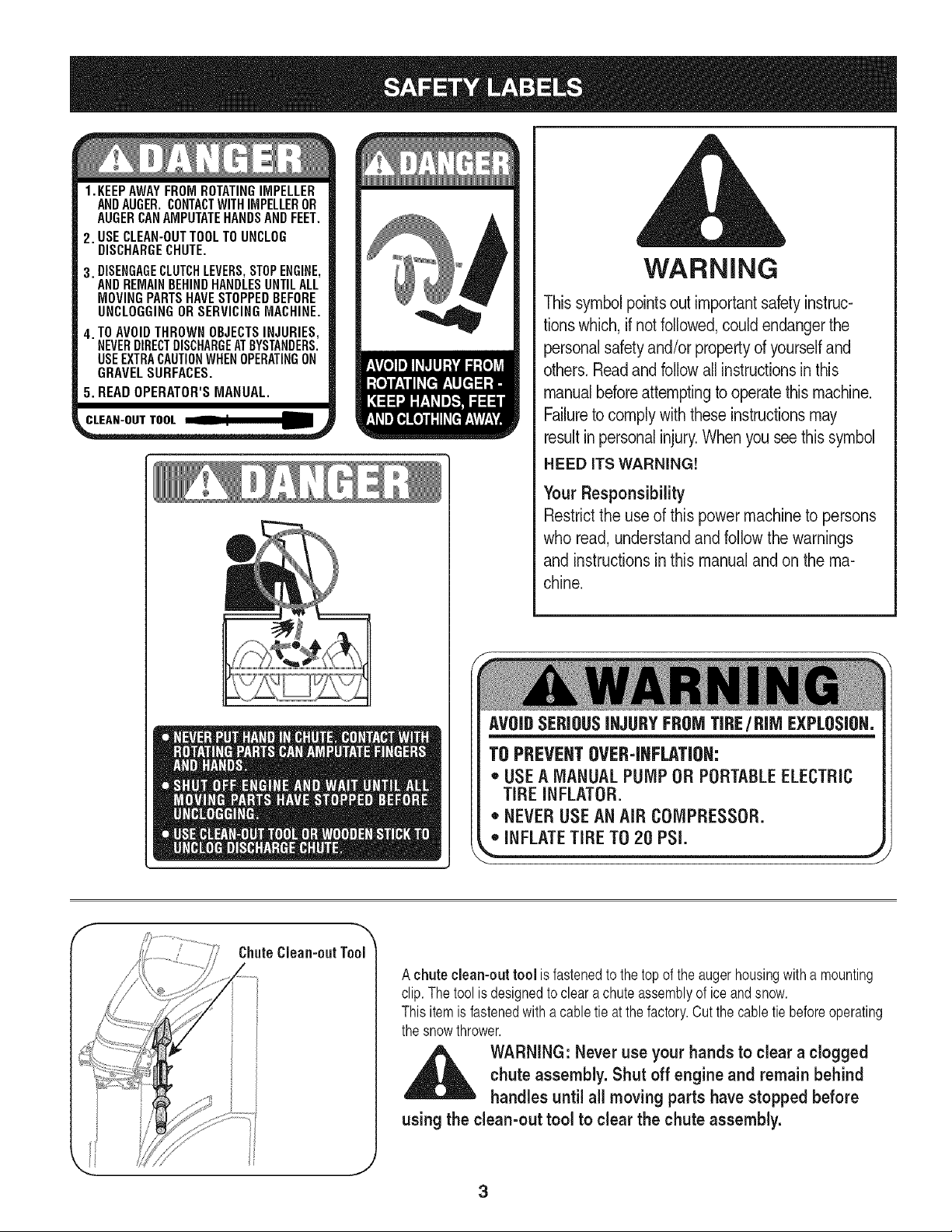

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET.

2. USECLEAN-OUTTOOLTOUNCLOG

DISCHARGECHUTE.

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGOR SERVICINGMACHINE.

4. TOAVOIDTHROWNOBJECTSINJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CLEAN-OUTTOOL

WARNING

Thissymbolpointsout importantsafetyinstruc-

tionswhich, ifnotfollowed,could endangerthe

personalsafetyand/or propertyd yourselfand

others.Readand followall instructionsinthis

manualbeforeattemptingto operatethismachine.

Failuretocomplywiththese instructionsmay

resultin personalinjury.When yousee thissymbol

HEED iTS WARNING!

Your Responsibility

Restrictthe useof this powermachineto persons

who read, understandand follow the warnings

and instructions in this manualand on the ma-

chine.

ChuteClean-outTool

AVOIDSERIOUSINJURYFROMTIRE/RIM EXPLOSION.

TO PREVENTOVER-INFLATION:

* USEA MANUAL PUMP OR PORTABLEELECTRIC

TIRE INFLATOR.

* NEVERUSEAN AiR COMPRESSOR.

,,"iNFLATETiRE702OPSi, j

A chute clean-out tool isfastenedtothetopofthe augerhousingwitha mounting

clip.Thetoolisdesignedtoclear achuteassemblyof iceandsnow.

Thisitemis fastenedwitha cabletieatthefactory.Cutthecabletiebeforeoperating

thesnowthrower.

chute assembly. Shut off engine and remain behind

WARNING: Never use your hands to clear a clogged

handles until all moving parts have stopped before

using the clean-out tool to clear the chute assembly.

Page 4

chemicalsknown to Stateof Californiato cause cancerand birth defects or other reproductiveharm.

WARNING: Engine Exhaust,some of its constituents,and certain vehiclecomponentscontain or emit

DANGER: Thismachine was builtto be operatedaccording to the rulesfor safe operation in this manual.As with any type

of power equipment,carelessnessor error on the part of the operator can result in seriousinjury.This machine is capable

of amputatinghandsand feet and throwing objects. Failureto observe the following safety instructionscould resultin

seriousinjury or death.

WARNING: This symbolpointsoutimportantsafetyinstructionswhich,if notfollowed,couldendangerthe

personalsafetyand/or propertyofyourselfand others.Readandfollowall instructionsin thismanualbefore

attemptingto operatethismachine.Failuretocomplywiththese instructionsmayresultin personalinjury.

Whenyou see this symbol.HEED ITSWARNING!

Your Responsibility: Restrictthe use of this power machineto personswho read,understandand followthe warnings

and instructionsin this manualand on the machine.

Training

1. Read,understand,andfollowallinstructionsontile machineandinthe

manual(s)beforeattemptingto assembleandoperate.Keepthismanualin

asafeplaceforfuture andregularreferenceandfor orderingreplacement

parts.

2. Be familiarwithallcontrolsandtheirproperoperation.Knowhowtostop

themachineanddisengagethemquickly.

3. Neverallowchildrenunder14yearsoldto operatethis machine.Children

14yearsoldandovershouldreadandunderstandthe operationinstruc-

tionsand safetyrulesinthis manualandshouldbe trainedandsupervised

bya parent.

4. Neverallowadultsto operatethismachinewithoutproperinstruction.

5. Thrownobjectscancauseseriouspersonalinjury.Planyoursnow-throwing

patterntoavoiddischargeofmaterialtowardroads,bystandersandthelike.

6. Keepbystanders,helpers,petsandchildrenatleast75feetfromthe

machinewhileit isin operation.Stopmachineif anyoneentersthe area.

7. Exercisecautionto avoidslippingor falling,especiallywhenoperatingin

reverse.

Preparation

1. Thoroughlyinspectthe areawherethe equipmentisto beused.Remove

all doormats,newspapers,sleds,boards,wiresandotherforeignobjects,

whichcould betrippedoveror thrownbythe auger/impeller.

2. Alwayswearsafetyglassesor eyeshieldsduringoperationandwhile

performingan adjustmentorrepairto protectyoureyes.Thrownobjects

whichricochetcancauseserious injuryto the eyes.

3. Donotoperatewithoutwearingadequatewinteroutergarments.Donot

wearjewelry,longscarvesor otherlooseclothing,whichcouldbecome

entangledinmovingparts.Wearfootwearwhichwill improvefootingon

slipperysurfaces.

4. Useagroundedthree-wireextensioncordand receptacleforall unitswith

electricstart engines.

5. Adjustcollector housingheightto clear gravelor crushedrocksurfaces.

6. Disengageallcontrolleversbeforestartingthe engine.

7. Neverattempttomake anyadjustmentswhileengineis running,except

wherespecificallyrecommendedinthe operator'smanual.

8. Letengineand machineadjusttooutdoortemperaturebeforestartingto

clearsnow.

9. To avoidpersonalinjuryor propertydamageuseextremecarein handling

gasoline.Gasolineis extremelyflammableandthe vaporsareexplosive.

Seriouspersonalinjurycan occurwhen gasolineisspilled onyourself

or yourclothes,which canignite.Washyourskin andchangeclothes

immediately.

a. Useonlyan approvedgasolinecontainer.

b. Extinguishall cigarettes,cigars,pipesand othersourcesofignition.

c. Neverfuel machineindoors.

d. Neverremovegascapor addfuelwhilethe engineishot or running.

e. Allowenginetocoolatleasttwo minutesbeforerefueling.

f. Neveroverfill fuel tank. Filltankto nomorethan_/zinchbelowbottom

offiller neckto providespacefor fuelexpansion.

g. Replacegasolinecapandtightensecurely.

h. Ifgasolineis spilled,wipeit offthe engineandequipment.Move

machinetoanotherarea. Wait5 minutesbeforestartingthe engine.

i. Neverstorethe machineorfuelcontainer insidewherethere isan open

flame,sparkor pilotlight (e.g.furnace,water heater,spaceheater,

clothesdryeretc.).

j. Allowmachineto cool at least5minutesbeforestoring.

4

Page 5

Operation

1. Do notputhands orfeet nearrotatingparts,intile auger/impellerhousing

orchuteassembly.Contactwith therotatingpartscan amputatehands

andfeet.

2. The auger/impellercontrolleveris a safetydevice.Neverbypassits

operation.Doingso makesthemachineunsafeand maycause personal

injury.

3. The controlleversmust operateeasily inbothdirectionsandautomatically

returntothe disengagedpositionwhenreleased.

4. Neveroperatewitha missingor damagedchuteassembly.Keepall safety

devicesin placeand working.

5. Neverrunan engineindoorsor in a poorlyventilatedarea.Engineexhaust

containscarbonmonoxide,anodorlessanddeadlygas.

6. Do notoperatemachinewhileunderthe influenceof alcoholor drugs.

7. Mufflerand enginebecomehotand cancausea burn. Donottouch.

8. Exerciseextremecautionwhenoperatingon orcrossinggravel surfaces.

Stayalert forhiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile operatingon slopes.

10.Planyoursnow-throwingpatterntoavoiddischargetowardswindows,

walls,carsetc.Thus, avoidingpossiblepropertydamageor personal

injurycausedby a ricochet.

11.Neverdirectdischargeatchildren,bystandersandpetsor allowanyonein

frontofthe machine.

12.Do notoverloadmachinecapacitybyattemptingto clearsnowat toofast

ofa rate.

13.Neveroperatethismachinewithoutgood visibilityor light. Alwaysbesure

ofyourfootingand keepafirm holdonthe handles.Walk,neverrun.

14.Disengagepowertothe auger/impellerwhentransportingor notin use.

15.Neveroperatemachineat hightransportspeedson slipperysurfaces.

Lookdownand behindand usecarewhenbackingup.

16.If the machineshouldstart tovibrateabnormally,stopthe engine,

disconnectthespark plugwireandgroundit againsttheengine.Inspect

thoroughlyfordamage.Repairanydamagebeforestartingand operating.

17.Disengageallcontrolleversandstop enginebeforeyou leavethe operat-

ingposition(behindthe handles).Waituntiltheauger/impellercomes

toa completestopbeforeuncloggingthechuteassembly,makingany

adjustments,or inspections.

18.Neverputyour handinthe dischargeor collectoropenings.Alwaysuse

theclean-outtool providedto unclogthedischargeopening.Do notunclog

chuteassemblywhileengineis running.Shutoff engineand remain

behindhandlesuntilallmovingpartshavestoppedbeforeunclogging.

19.Useonlyattachmentsandaccessoriesapprovedbythe manufacturer(e.g.

wheelweights,tirechains,cabsetc.).

20.If situationsoccurwhich are notcoveredin this manual,usecareand

goodjudgment.ContactyourSearsServiceCenterfor assistance.

Maintenance & Storage

1. Nevertamperwith safetydevices.Checktheirproperoperationregularly.

Referto the maintenanceand adjustmentsectionsofthis manual.

2. Beforecleaning,repairing,or inspectingmachinedisengageallcontrol

leversand stoptheengine.Waituntiltheauger/impellercometo a

completestop.Disconnectthe spark plugwireand groundagainstthe

enginetopreventunintendedstarting.

3. Check boltsandscrewsfor propertightnessatfrequentintervalstokeep

the machinein safeworkingcondition.Also,visuallyinspectmachinefor

anydamage.

4. Donotchangetheenginegovernorsettingor over-speedtheengine.The

governorcontrolsthe maximumsafeoperatingspeedof the engine.

5. Snowthrowershaveplatesandskid shoesaresubjecttowear and

damage.Foryoursafetyprotection,frequentlycheckallcomponentsand

replacewithoriginal equipmentmanufacturer's(OEM)partsonly."Useof

partswhich do notmeet the originalequipmentspecificationsmayleadto

improperperformanceandcompromisesafety!"

6. Checkcontrolsperiodicallyto verifythey engageanddisengageproperly

andadjust,if necessary.Refertothe adjustmentsectionin this operator's

manualfor instructions.

7. Maintainorreplacesafetyandinstructionlabels,asnecessary.

8. Observeproperdisposallawsandregulationsfor gas, oil,etc.to protect

the environment.

9. Priortostoring,runmachineafewminutestoclear snowfrommachine

andpreventfreezeup ofauger/impeller.

10.Neverstorethe machineorfuelcontainerinsidewherethere isanopen

flame,sparkor pilotlight suchas awater heater,furnace,clothesdryer

etc.

11.Alwaysreferto the operator'smanualfor properinstructionsonoff-season

storage.

Do not modify engine

Toavoidseriousinjuryor death,do notmodifyenginein anyway.Tampering

withthe governorsettingcanleadto a runawayengineandcauseitto operate

at unsafespeeds.Nevertamperwithfactorysettingofenginegovernor.

Notice regarding Emissions

Engineswhichare certifiedto complywith CaliforniaandfederalEPAemission

regulationsforSORE(SmallOffRoadEquipment)are certifiedtooperateon

regularunleadedgasoline,andmayincludethefollowingemissioncontrolsys-

tems:EngineModification(EM)andThreeWayCatalyst(TWO)ifso equipped.

Engine identification Decal

Thisdecalindicatestheengine'smodelnumber,specificationandthe dateof

manufacture.Pleaselookatthe decalontheengineofyour equipmentand

recordtheseinformationforfuturereference.

Theengineidentificationdecalalsoincludesenginelifespecificationsfor the

emissions-relatedusefullifeperiodof the engine.This periodrelatestothe

emissioncompliancelifeas certifiedbyEPAand/orCARB.Tofindthe lifeperiod

specificationofthe engine,pleasereadthe enginedecaland locatethe letter

(enclosedbyquotationmarks)betweenthewordsModerateandLifePeriod.

Matchone of thefollowingletterswiththeletterprintedonyourdecal.For

example,HMSK80modelsaredesignatedas:

"C"-- 250hours

"B"-- 500hours

"A"-- 1000hours

Page 6

IMPORTANT:This unitisshippedwiththeenginefull of oil. After

assembly,see page10forfuelandoildetails.

Removing From Carton

1. Cutthecornersof the cartonandlaythesidesflaton the ground.

Removeall packinginserts.

2. Theupperhandleis packagedunattachedtothesnowthrower,

thoughconnectedbycables.Movethesnowthrowerandupper

handleoutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

Before Assembly

R_emoveprotectivewrapp"_g

\

\

,_ WARNING:Disconnectthe spark plugwireand Ground

NOTE:Referenceto right,left,frontor rearof the unitis fromthe

operatingpositionunlessotherwisestated.

itagainstthe engineto prevent unintendedstarting.

Setting Up The Handle

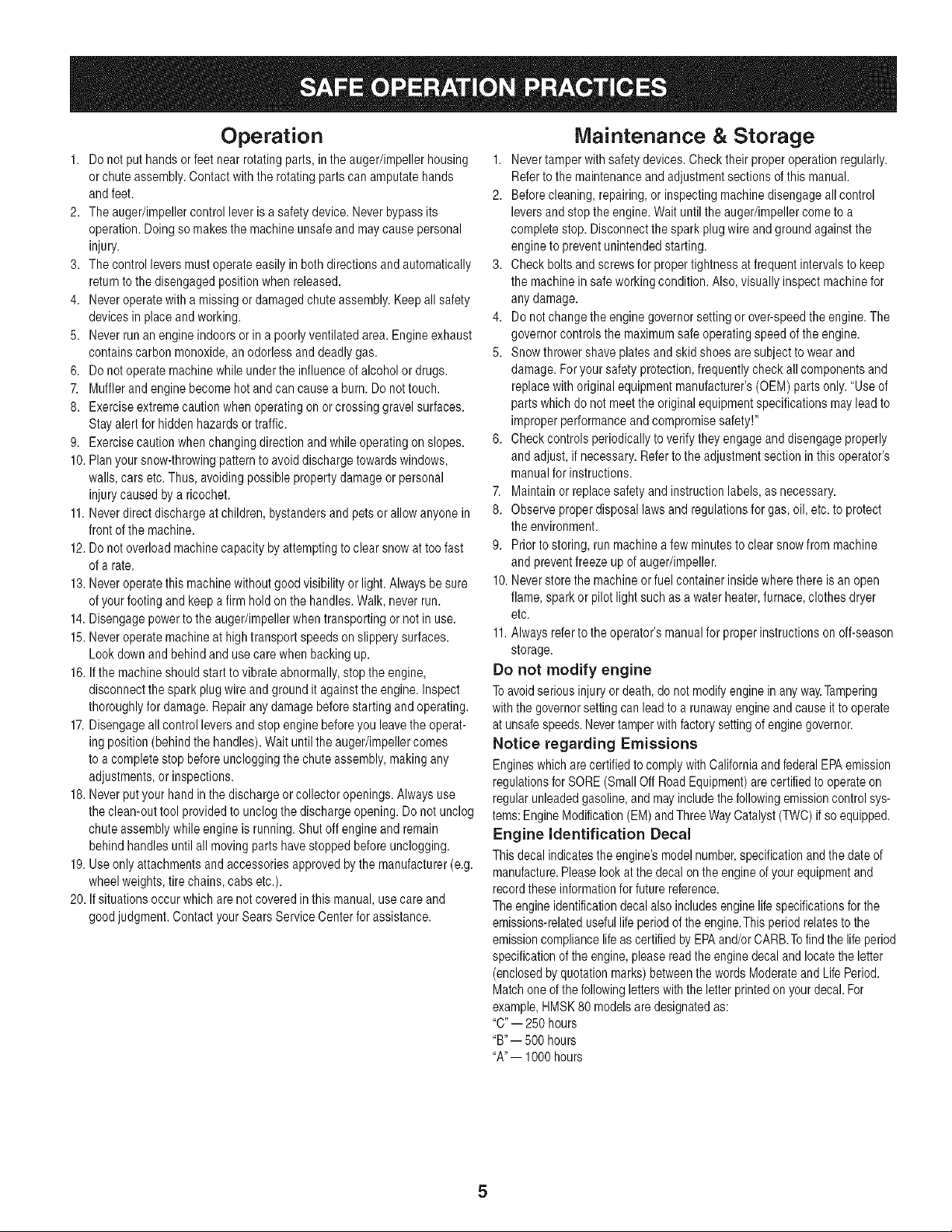

1. If applicable,removecabletie securingupperhandletolower

handleforshippingpurposes.Removeall protectiveplasticwrap-

pingfromhandlesasshownin Figure1.

NOTE: BecarefulNOTto removethethreelooselyfittedcableties

thatwillbeutilizedlaterto securecables.

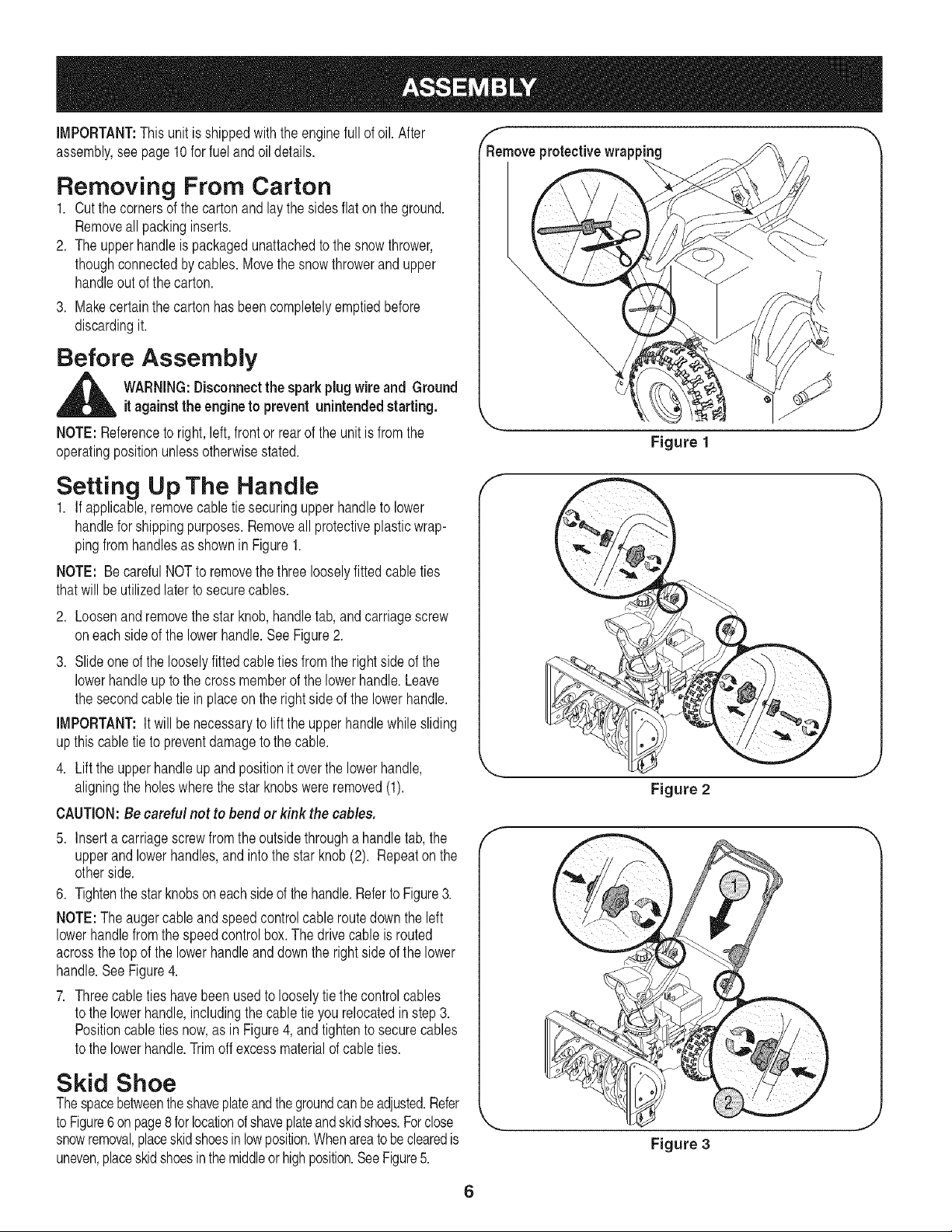

2. Loosenandremovethestarknob,handletab,andcarriagescrew

oneachsideofthelowerhandle.SeeFigure2.

3. Slideoneofthelooselyfittedcabletiesfromthe rightside of the

lowerhandleuptothecrossmemberofthelowerhandle.Leave

thesecondcabletie in placeonthe rightside of thelowerhandle.

IMPORTANT:It willbenecessaryto lifttheupperhandlewhilesliding

upthis cabletie topreventdamagetothecable.

4. Liftthe upperhandleupand positionit overthelowerhandle,

aligningtheholeswherethestarknobswereremoved(1).

CAUTION:Be careful not to bend or kink the cables,

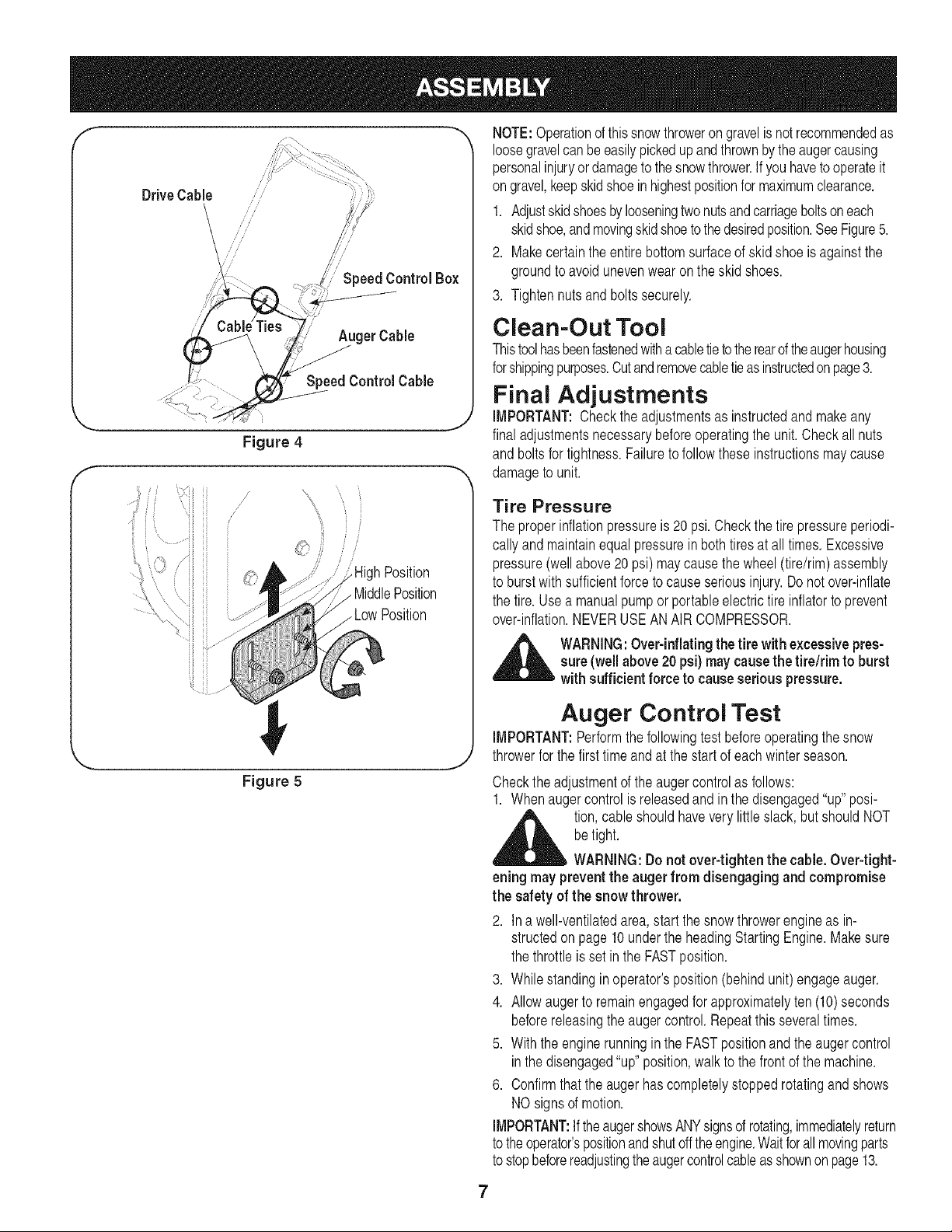

5. Inserta carriagescrewfromtheoutsidethrougha handletab,the

upperand lowerhandles,andintothestar knob(2). Repeatonthe

otherside.

6. Tightenthestarknobsoneachsideofthe handle.RefertoFigure3.

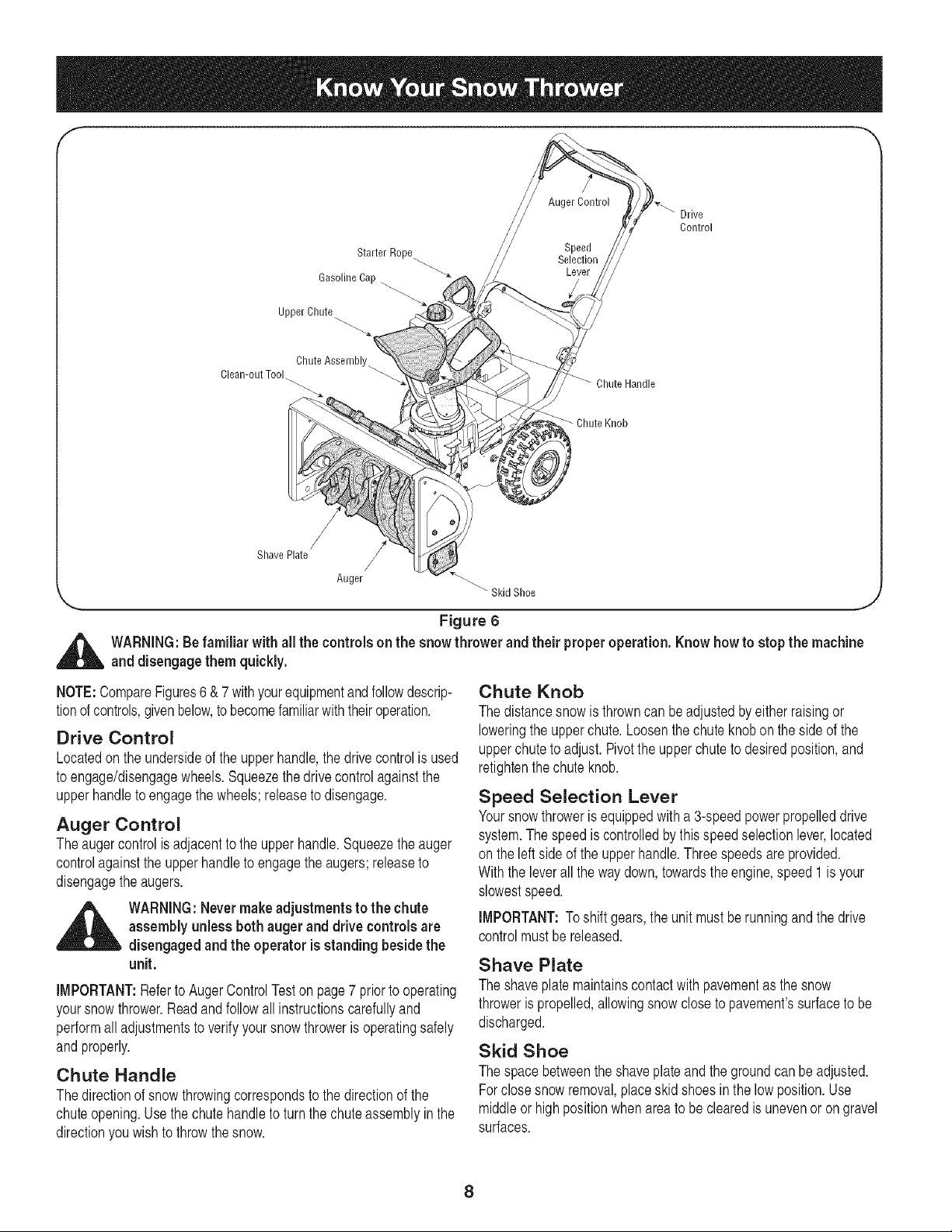

NOTE:The augercableandspeedcontrolcableroutedowntheleft

lowerhandlefromthe speedcontrolbox.The drivecableisrouted

acrossthetopofthe lowerhandleanddowntherightsideofthe lower

handle.SeeFigure4.

7. Threecabletieshavebeenusedtolooselytiethecontrolcables

tothelowerhandle,includingthecabletieyou relocatedinstep3.

Positioncabletiesnow,asin Figure4,and tightentosecurecables

tothelowerhandle.Trimoffexcessmaterialofcableties.

Figure 1

Figure 2

Skid Shoe

Thespacebetweentheshaveplateandthegroundcanbeadjusted.Refer

toFigure6onpage8forlocationofshaveplateandskidshoes.Forclose

snowremoval,placeskidshoesinlowposition.Whenareatobeclearedis

uneven,placeskidshoesinthemiddleor highposition.SeeFigure5.

Figure 3

6

Page 7

Drive Cable

NOTE:Operationofthissnowthrowerongravelisnot recommendedas

loosegravelcanbeeasilypickedupandthrownbytheaugercausing

personalinjuryordamagetothesnowthrower.Ifyou havetooperateit

on gravel,keepskidshoeinhighestpositionformaximumclearance.

/

Speed Control Box

1. Adjustskidshoesbylooseningtwonutsandcarriageboltsoneach

skidshoe,andmovingskidshoetothedesiredposition.SeeFigure5.

2. Makecertaintheentirebottomsurfaceofskidshoeisagainstthe

groundtoavoidunevenwearon theskid shoes.

3. Tightennutsandboltssecurely.

AugerCable

SpeedControl Cable

Clean-Out Tool

Thistoolhasbeenfastenedwitha cabletietotherearoftheaugerhousing

forshippingpurposes.Cutandremovecabletieasinstructedonpage3.

Final Adjustments

IMPORTANT:Checktheadjustmentsas instructedandmakeany

Figure 4

f

/

/

J

J

Position

MiddlePosition

finaladjustmentsnecessarybeforeoperatingtheunit.Checkall nuts

and boltsfor tightness.Failuretofollowtheseinstructionsmaycause

damageto unit.

Tire Pressure

Theproperinflationpressureis20 psi.Checkthetire pressureperiodi-

callyandmaintainequalpressureinbothtiresat alltimes.Excessive

pressure(wellabove20psi) maycausethewheel(tire/rim)assembly

to burstwithsufficientforceto causeseriousinjury.Donot over-inflate

thetire.Usea manualpumporportableelectrictire inflatorto prevent

over-inflation.NEVERUSEANAIRCOMPRESSOR.

,_ WARNING:Over-inflatingthe tire with excessivepres-

sure(well above20 psi)may causethe tire/rim to burst

with sufficient forceto cause serious pressure.

Auger Control Test

IMPORTANT:Performthe followingtestbeforeoperatingthesnow

throwerforthefirsttimeandat the startofeachwinterseason.

Figure 5

Checkthe adjustmentoftheaugercontrolasfollows:

1. Whenaugercontrolisreleasedandin thedisengaged"up"posi-

,_ tion,cableshouldhavevery littleslack,butshouldNOT

eningmay preventthe auger from disengaging and compromise

the safety of the snow thrower.

2. Ina well-ventilatedarea,startthe snowthrowerengineas in-

structedon page10underthe headingStartingEngine.Makesure

thethrottleis set intheFASTposition.

3. Whilestandinginoperator'sposition(behindunit)engageauger.

4. Allowaugertoremainengagedforapproximatelyten(10)seconds

beforereleasingtheaugercontrol.Repeatthisseveraltimes.

5. Withthe enginerunningin the FASTpositionandtheaugercontrol

inthedisengaged"up"position,walktothefrontof themachine.

6. Confirmthattheaugerhascompletelystoppedrotatingandshows

NOsignsofmotion.

IMPORTANT:IftheaugershowsANYsignsofrotating,immediatelyreturn

totheoperator'spositionandshutofftheengine.Waitforallmovingparts

tostopbeforereadjustingtheaugercontrolcableasshownonpage13.

betight.

WARNING:Donot over-tighten the cable.Over-tight-

7

Page 8

Gasoline Cap -_

Upper Chute

Drive

Control

Starter Rope

Shave Plate

Chute Assembly_

Chute Handle

Chute Knob

/

Anger "_ Skid Shoe

Clean-out Tool

'-.... ,J

Figure 6

_ ARNING:Be familiar with all the controls on the snow thrower and their properoperation. Know howto stop the machine

NOTE:CompareFigures6&7 withyourequipmentandfollowdescrip-

tionof controls,givenbelow,tobecomefamiliarwiththeiroperation.

Drive Control

Locatedonthe undersideof theupperhandle,thedrivecontrolis used

toengage/disengagewheels.Squeezethedrivecontrolagainstthe

upperhandletoengagethewheels;releasetodisengage.

Auger Control

Theaugercontrolisadjacenttotheupperhandle.Squeezethe auger

controlagainsttheupperhandletoengagetheaugers;releaseto

disengagethe augers.

_ ARNING:Nevermakeadjustments to the chute

iMPORTANT:RefertoAugerControlTeston page7 priorto operating

yoursnowthrower.Readandfollowall instructionscarefullyand

performalladjustmentstoverifyyoursnowthrowerisoperatingsafely

andproperly.

Chute Handle

Thedirectionof snowthrowingcorrespondsto thedirectionofthe

chuteopening.Usethe chutehandletoturnthechuteassemblyinthe

directionyouwishtothrowthesnow.

and disengage them quickly.

assembly unless both auger and drive controls are

disengaged and the operator is standing besidethe

unit.

Chute Knob

Thedistancesnowis throwncanbeadjustedbyeitherraisingor

loweringthe upperchute.Loosenthechuteknobonthesideof the

upperchutetoadjust.Pivotthe upperchutetodesiredposition,and

retightenthechuteknob.

Speed Selection Lever

Yoursnowthrowerisequippedwitha 3-speedpowerpropelleddrive

system.Thespeediscontrolledbythis speedselectionlever,located

on the leftsideofthe upperhandle.Threespeedsareprovided.

Withtheleverallthe waydown,towardstheengine,speed1isyour

slowestspeed.

iMPORTANT:Toshiftgears,theunit mustbe runningand thedrive

controlmustbereleased.

Shave Plate

Theshaveplatemaintainscontactwithpavementasthe snow

throwerispropelled,allowingsnowclosetopavement'ssurfacetobe

discharged.

Skid Shoe

Thespacebetweentheshaveplateandthegroundcanbe adjusted.

Forclosesnowremoval,placeskidshoesin thelowposition.Use

middleorhighpositionwhenareatobe clearedis unevenor on gravel

surfaces.

8

Page 9

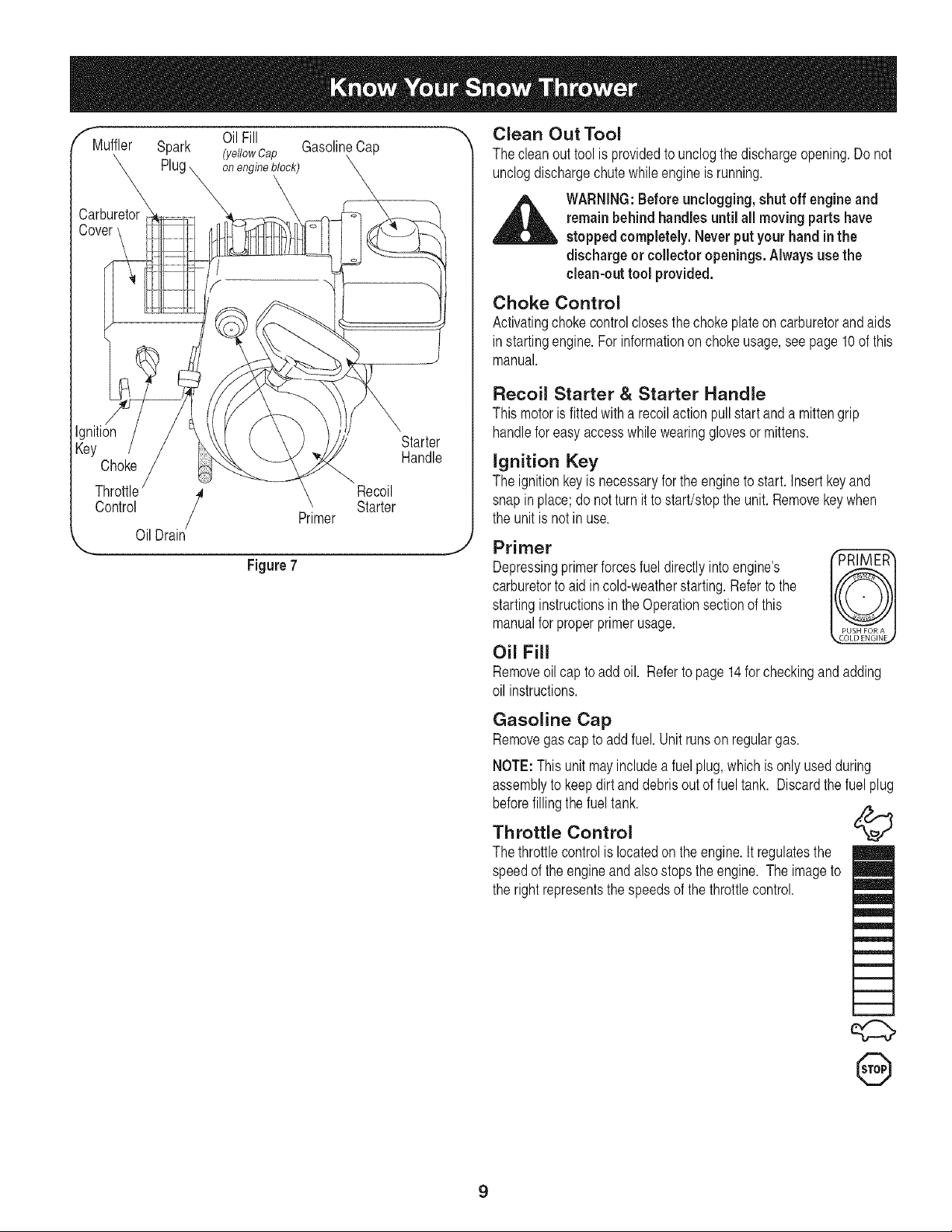

f"fMuffler Spark (ydlowCap GasolineCap

OilFill

onengineblock) \

x

X

Carburetor

Cow

Ignition

Key Starter

Choke

Control Primer Starter

Throttle / Recoil

OilDrain

,._ j

Figure7

Handle

"_ Clean Out Tool

Thecleanout toolisprovidedtounclogthedischargeopening.Do not

unclogdischargechutewhileengineisrunning.

_ ARNING:Before unclogging, shut off engineand

Choke Control

Activatingchokecontrolclosesthechokeplateoncarburetorandaids

instartingengine.Forinformationonchokeusage,seepage10ofthis

manual.

Recoil Starter & Starter Handle

Thismotoris fittedwitha recoilactionpullstartanda mittengrip

handleforeasyaccesswhilewearingglovesormittens.

Ignition Key

Theignitionkeyis necessaryfortheenginetostart.Insertkeyand

snapinplace;do notturnit to start/stopthe unit. Removekeywhen

theunitisnotin use.

Primer

Depressingprimerforcesfueldirectlyintoengine's Iv_KI

carburetortoaid incold-weatherstarting.Referto the

startinginstructionsintheOperationsectionofthis

manualforproperprimerusage.

remainbehind handles until all moving partshave

stopped completely. Never putyour hand inthe

discharge or collector openings. Always use the

clean-out tool provided.

Oil Fill

Removeoil captoaddoil. Refertopage14for checkingandadding

oil instructions.

Gasoline Cap

Removegas captoadd fuel.Unitrunsonregulargas.

NOTE:Thisunitmayincludeafuelplug,whichis only usedduring

assemblyto keepdirtanddebrisoutof fueltank. Discardthefuel plug

beforefillingthefueltank.

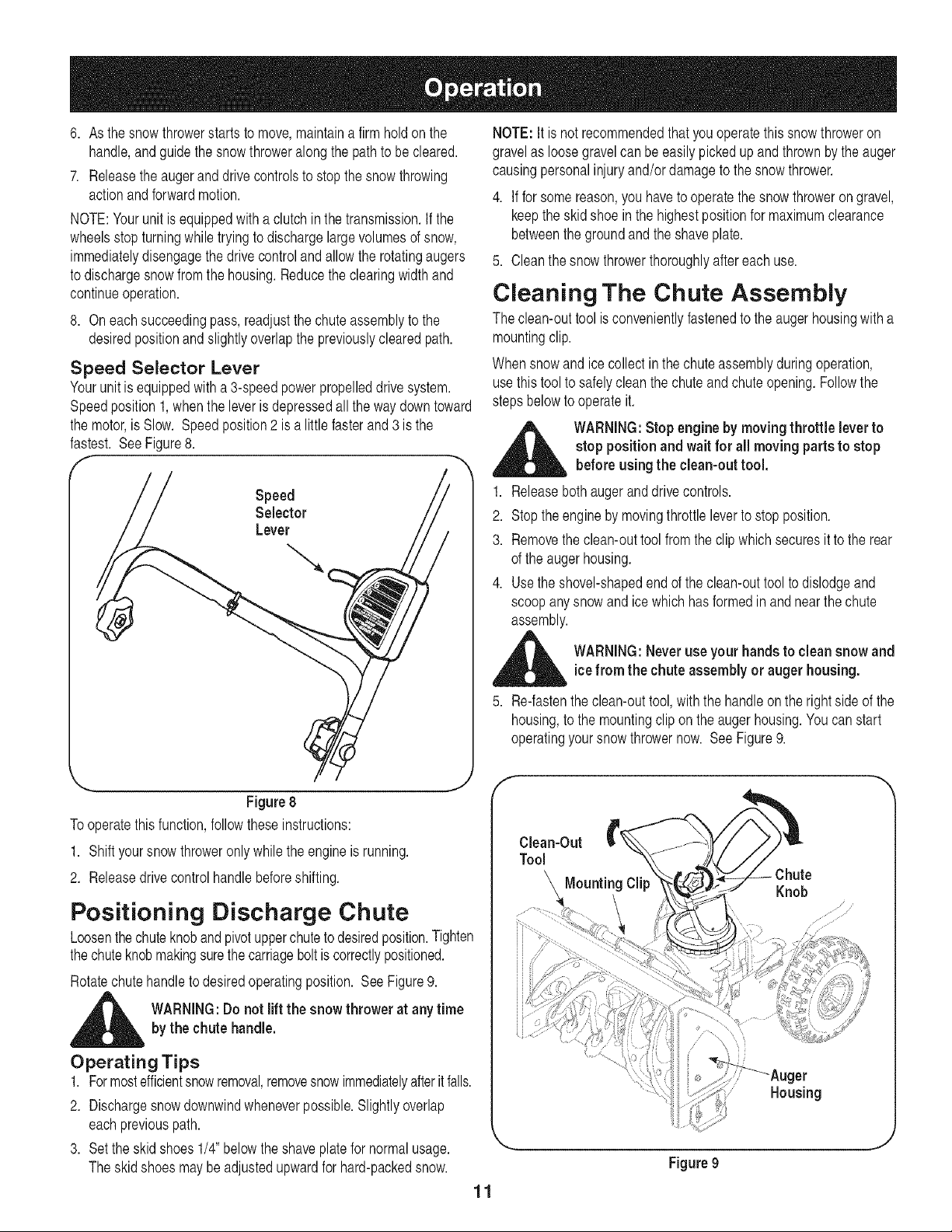

Throttle Control

Thethrottlecontrolis locatedontheengine.It regulatesthe

speedof the engineandalsostopstheengine.Theimageto

therightrepresentsthespeedsofthe throttlecontrol.

,:d:::>

@

9

Page 10

Before Starting Engine

Engine Oil

Theengineisshippedwithoil init.Checktheoil levelbeforefirstuse.

Forsubsequentfill-ups,usethegradeof engineoil specifiedon page

14.Toaddoil:

1. Removethedipstickfromtheoilfill. Pourfreshoilslowlythrough

theplug.Replacedipstick.

2. Checkandmakesurethatthe levelofoil isupto the FULLmarkon

thedipstick.

Gasoline

,_ WARNING:Gasolineisflammable and cautionmust

,_ WARNING:Keepyour snow thrower awayfrom any

1. Neverfillthe fueltankcompletely.Fillthetankto nomorethan1/2

inchbelowbottomoffillerneckto providespaceforexpansionof

fuel.

NOTE:Thisunitmayincludea fuel plug,whichisonly usedduring

assemblytokeepdirt anddebrisout offueltank. Discardthefuelplug

beforefillingthefueltank.

2. Alwaysuseclean,fresh,unleadedgradeautomotivegasoline.Fill

thefueltankoutdoorsandusea funnelor spoutto preventspilling.

Makesurethatthecontainerfromwhichyou pourthegasolineis

cleanandfreefromrustor otherforeignparticles.Makesureto

wipeoff anyspilledfuel beforestartingtheengine.

3. Atthe endofthejob,emptythe fueltank if the snowthroweris not

goingto beusedfor 30 daysor longer.Storegasolineinaclean

containerandkeepthecapin placeonthecontainer.

CAUTION:Never use engineor carburetor cleaner products in

the fuel tank.

be used when handlingor storingit. Donot fill fuel

tank while the snow thrower is running, whenit is

hot or when it is inan enclosed area.

open flame or an electricalspark and do not smoke

during fueling.

To Start Engine

6. Pushprimerbuttonwhilecoveringtheventhole.Removeyour

fingerfromtheprimerbetweenprimes.Donotprimeif temperature

is above500F;primetwo timesbetween500Fand 150F;and

primefour timesbelow150R

7. Graspstarterhandleandpull ropeoutslowlyuntilenginereaches

startofcompressioncycle(ropewillpullslightlyharderat this

point).Lettheroperewindslowly.

8. Pull ropewitha rapid,continuous,fullarmstroke.Keepingafirm

gripon thestarterhandle,lettheropereturnto thestarterslowly.

Repeatuntilenginestarts.

9. Asthe enginewarmsup,rotatethechokeknobslowlyto OFF

position.If theenginefalters,returnto FULLchoke,thenslowly

moveto OFFchokeposition.

10.Allowtheengineto warmupfor a fewminutesbecausetheengine

willnotdevelopfullpoweruntilit reachesoperatingtemperature.

11.Operatetheengineat fullthrottle(FAST)whenthrowingsnow.

For A Warm Start:

1. If restartingan engineafteratemporaryshut-down,rotatechoke

toOFFinsteadofFULLanddo notprime.Pullstarterhandleas

instructedbefore.

Before Stopping

1. Runenginefora fewminutestohelpdryoff anymoistureonengine.

2. Toavoidpossiblefreeze-upof thestarter,followthesesteps:

Recoil Starter

a. Withtheenginerunning,pullthestarterropewitha rapid,

continuousfullarmstrokethreeorfour times.

To Stop The Snow Thrower

1. Tostopthewheels,releasethedrivecontrol.

2. Tostopthrowingsnow,releasetheaugercontrol.

3. Tostopengine,pushthrottlecontrollevertoOFFandpullout the

key.Do notturnkey.

temperature

,_ WARNING:The of muffler and the

rounding areas mayexceed150° F.Avoid these areas

sur-

,_ WARNING:Besure no oneother than the operator

NOTE:Forlocationof alltheenginecontrolsreferredtointhis section,

referto Figure7.

isstanding nearthe snow thrower while starting or

operating. Do not operatethis snow thrower unless

the chute assembly has been properly installedand

issecured.

For A Cold Start

1. Makesurethataugeranddrivecontrolsarereleased.Attachspark

plugwiretosparkplug.

2. Turnfuelvalveon, ifsoequipped.

3. MovethrottlecontroltoFASTposition.

4. Pushkeyintotheignitionslotsothatitsnapsintoplace.Donotturnkey.

5. RotatechokecontroltoFULLchokeposition.

Clearing The Snow

CAUTION:Checkthe areato beclearedforforeignobjects.Remove

foreignobjects,if any.

1. Starttheenginefollowingstartinginstructions.

2. Allowtheenginetowarmupfora fewminutesastheenginewill

notdevelopfullpoweruntilit reachesoperatingtemperature.

3. Rotatethechuteassemblytothedesireddirection,awayfrom

bystandersand/orbuildings.

4. Makingcertainnobystandersorobstaclesareinfrontof the unit,

squeezetheaugercontrolcompletelyagainsttheupperhandleto

fullyengagetheaugers.

5. Whiletheaugercontrolis engaged,squeezethedrivecontrol

completelyagainsttheupperhandletoengagethewheels.Do not

"feather"thedrivecontrol.

10

Page 11

6. Asthesnowthrowerstartsto move,maintainafirm holdon the

handle,andguidethesnowthroweralongthepathto becleared.

7. Releasetheaugeranddrivecontrolstostopthesnowthrowing

actionandforwardmotion.

NOTE:Yourunitisequippedwithaclutchinthe transmission.If the

wheelsstopturningwhiletryingto dischargelargevolumesofsnow,

immediatelydisengagethedrivecontrolandallowtherotatingaugers

todischargesnowfromthehousing.Reducetheclearingwidthand

continueoperation.

8. Oneachsucceedingpass,readjustthechuteassemblytothe

desiredpositionandslightlyoverlapthepreviouslyclearedpath.

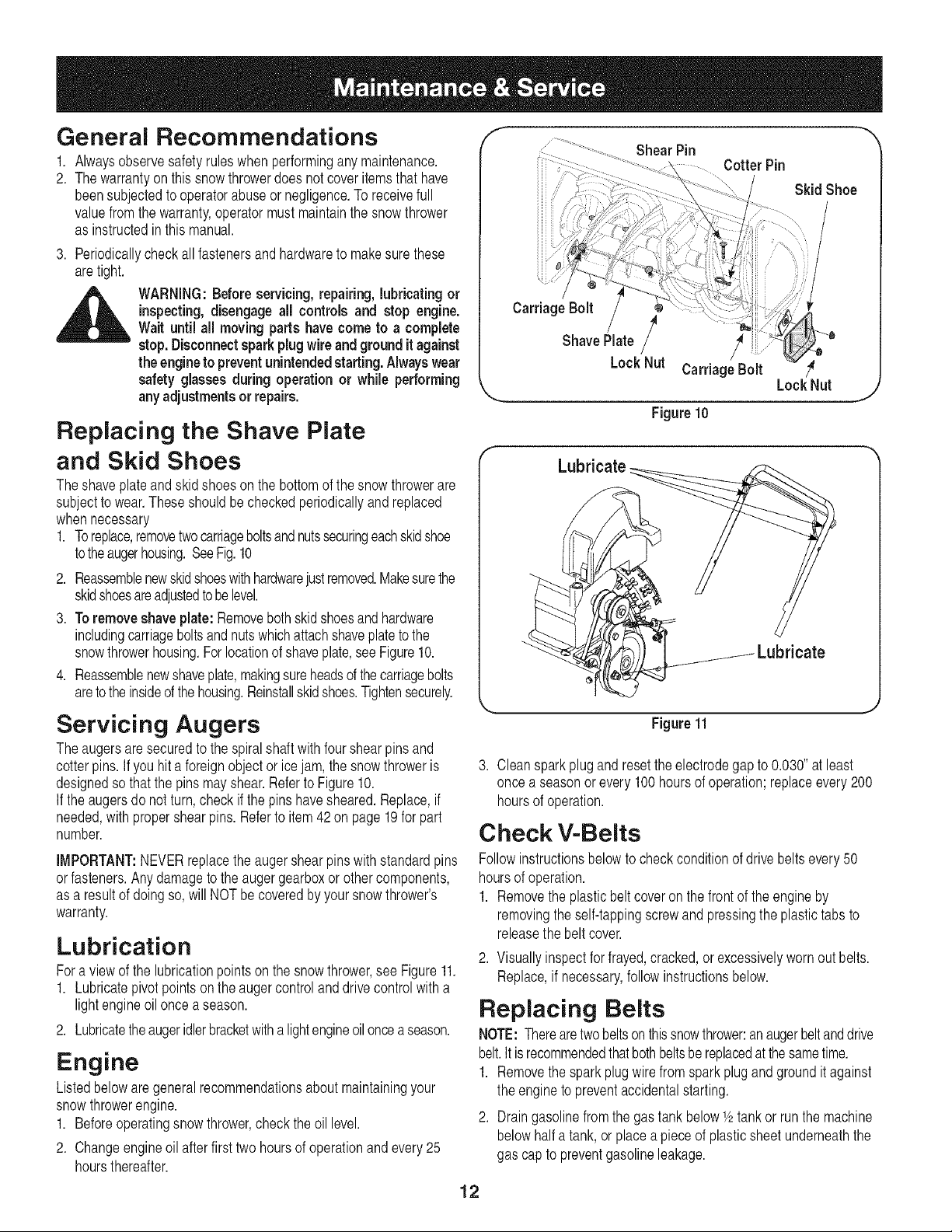

Speed Selector Lever

Yourunitisequippedwitha 3-speedpowerpropelleddrive system.

Speedposition1,whenthe leverisdepressedall thewaydowntoward

themotor,isSlow. Speedposition2 is a littlefasterand3 isthe

fastest. SeeFigure8.

Speed

Selector

Lever

NOTE:It isnot recommendedthatyouoperatethissnowthroweron

gravelas loosegravelcanbeeasilypickedup andthrownbythe auger

causingpersonalinjuryand/ordamagetothesnowthrower.

4. Ifforsomereason,youhavetooperatethesnowthrowerongravel,

keeptheskidshoe inthehighestpositionformaximumclearance

betweenthegroundandtheshaveplate.

5. Cleanthesnowthrowerthoroughlyaftereachuse.

Cleaning The Chute Assembly

Theclean-outtoolis convenientlyfastenedtothe augerhousingwitha

mountingclip.

Whensnowandicecollectinthe chuteassemblyduringoperation,

usethistooltosafelycleanthechuteandchuteopening.Followthe

stepsbelowtooperateit.

_ WARNING:Stopengineby moving throttle leverto

1. Releasebothaugeranddrivecontrols.

2. Stoptheenginebymovingthrottleleverto stopposition.

3. Removetheclean-outtoolfromthe clipwhichsecuresitto the rear

oftheaugerhousing.

4. Usetheshovel-shapedendofthe clean-outtooltodislodgeand

scoopanysnowandice whichhasformedin andnearthechute

assembly.

stoppositionand wait for all moving partsto stop

before usingthe clean-outtool.

Figure 8

Tooperatethisfunction,followtheseinstructions:

1. Shiftyoursnowthroweronlywhilethe engineis running.

2. Releasedrivecontrolhandlebeforeshifting.

Positioning Discharge Chute

Loosenthechuteknobandpivotupperchutetodesiredposition.Tighten

thechuteknobmakingsurethecarriageboltiscorrectlypositioned.

Rotatechutehandleto desiredoperatingposition. SeeFigure9.

,_ WARNING:Do not liftthe snowthrower at anytimebythe chutehandle.

Operating Tips

1. Formostefficientsnowremoval,removesnowimmediatelyafteritfalls.

2. Dischargesnowdownwindwheneverpossible.Slightlyoverlap

eachpreviouspath.

3. Settheskidshoes1/4"belowtheshaveplatefornormalusage.

Theskidshoesmaybeadjustedupwardfor hard-packedsnow.

_ ARNING:Neveruseyour handsto cleansnowand

5. Re-fastentheclean-outtool,withthe handleontherightsideofthe

housing,tothe mountingclipontheaugerhousing.Youcanstart

operatingyoursnowthrowernow. SeeFigure9.

icefrom the chuteassembly or auger housing.

f --,,,

Knob

_er

Housing

Figure9

11

J

Page 12

General Recommendations

1. Alwaysobservesafetyruleswhenperformingany maintenance.

2. Thewarrantyonthissnowthrowerdoesnotcoveritemsthat have

beensubjectedtooperatorabuseor negligence.Toreceivefull

valuefromthe warranty,operatormustmaintainthesnowthrower

asinstructedin thismanual.

3. Periodicallycheckallfastenersandhardwaretomakesurethese

aretight.

f

ShearPin

ill .

iii/

iiiii

iiiii

CotterPin

Skid Shoe

_ WARNING: Before servicing,repairing,lubricatingor

inspecting,disengageall controlsand stop engine.

Wait until all moving partshavecometo a complete

stop.Disconnectsparkplugwireandground itagainst

the engineto preventunintendedstarting.Alwayswear

safetyglassesduringoperation or while performing

anyadjustmentsor repairs.

Replacing the Shave Plate

and Skid Shoes

Theshaveplateandskidshoesonthe bottomofthe snowthrowerare

subjectto wear.Theseshouldbecheckedperiodicallyandreplaced

whennecessary

1. Toreplace,removetwocarriageboltsandnutssecuringeachskidshoe

totheaugerhousing.SeeFig.10

2. Reassemblenewskidshoeswithhardwarejustremoved.Makesurethe

skidshoesareadjustedtobelevel.

3. Toremoveshaveplate:Removebothskidshoesandhardware

includingcarriageboltsandnutswhichattachshaveplatetothe

snowthrowerhousing.Forlocationofshaveplate,seeFigure10.

4. Reassemblenewshaveplate,makingsureheadsof thecarriagebolts

aretothe insideofthehousing.Reinstallskidshoes.Tightensecurely.

Servicing Augers

Theaugersaresecuredto the spiralshaftwithfourshearpinsand

cotterpins.Ifyouhit a foreignobjector icejam,thesnowthroweris

designedsothatthe pinsmayshear.RefertoFigure10.

If the augersdonotturn,checkifthepinshavesheared.Replace,if

needed,withpropershearpins.Referto item42on page19forpart

number.

IMPORTANT:NEVERreplacetheaugershearpinswithstandardpins

orfasteners.Anydamagetothe augergearboxorothercomponents,

asa resultofdoingso,will NOTbe coveredbyyoursnowthrower's

warranty.

Lubrication

Fora viewofthelubricationpointson thesnowthrower,see Figure11.

1. Lubricatepivotpointsonthe augercontrolanddrivecontrolwitha

lightengineoiloncea season.

2. Lubricatetheaugeridlerbracketwithalightengineoilonceaseason.

Engine

Listedbelowaregeneralrecommendationsabout maintainingyour

snowthrowerengine.

1. Beforeoperatingsnowthrower,checktheoil level.

2. Changeengineoilafterfirst two hoursof operationandevery25

hoursthereafter.

Carriage Bolt

ShavePlate/

LockNut CarriageBolt

LockNut

Figure10

Lubricate

Figure11

3. Cleansparkplugand resettheelectrodegapto 0.030"atleast

oncea seasonorevery100hoursof operation;replaceevery200

hoursof operation.

Check V-Belts

Followinstructionsbelowtocheckconditionofdrivebeltsevery50

hoursofoperation.

1. Removetheplasticbeltcoveron the frontoftheengineby

removingtheself-tappingscrewandpressingtheplastictabsto

releasethe beltcover.

2. Visuallyinspectforfrayed,cracked,orexcessivelywornoutbelts.

Replace,if necessary,followinstructionsbelow.

Replacing Belts

NOTE:Therearetwobeltsonthissnowthrower:anaugerbeltanddrive

belt.Itisrecommendedthatbothbeltsbereplacedatthesametime.

1. Removethesparkplugwirefromsparkplugandgrounditagainst

theenginetopreventaccidentalstarting.

2. Draingasolinefromthe gastankbelowV2tankorrunthe machine

belowhalf a tank,or placeapieceof plasticsheetunderneaththe

gascaptopreventgasolineleakage.

12

J

Page 13

f

"-... HousingScrew ,j

Figure12

F ....

Figure13

AugerCabi_"_

Adjustment

Bracket

Wood Block

WARNING:Performbeltmaintenanceoutdoorsas

somegasmaypossiblyleakfromthecarburetoreven

thoughyou placedasheetofplasticunderneaththe

gascaptopreventthe gascapfrom leaking.

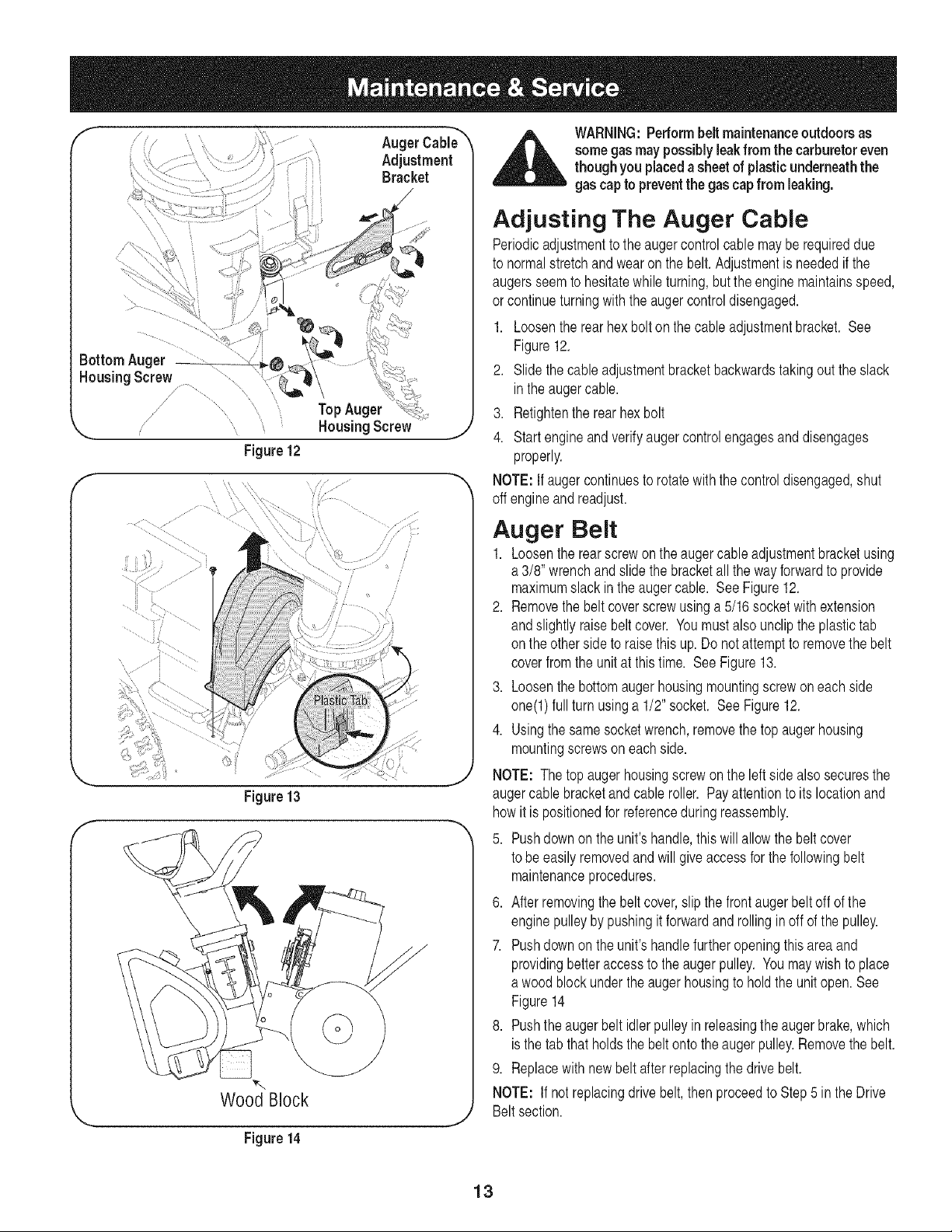

Adjusting The Auger Cable

Periodicadjustmentto the augercontrolcablemayberequireddue

to normalstretchandwearonthe belt.Adjustmentis neededifthe

augersseemto hesitatewhileturning,buttheenginemaintainsspeed,

or continueturningwiththeaugercontroldisengaged.

1. Loosentherearhex boltonthecableadjustmentbracket.See

Figure12.

2. Slidethecable adjustmentbracketbackwardstakingouttheslack

intheaugercable.

3. Retightentherearhexbolt

4. Startengineandverifyaugercontrolengagesanddisengages

properly.

NOTE:If augercontinuestorotatewiththecontroldisengaged,shut

off engineandreadjust.

Auger Belt

1. Loosentherearscrewonthe augercableadjustmentbracketusing

a 3/8' wrenchandslidethebracketallthewayforwardto provide

maximumslackintheaugercable. SeeFigure12.

2. Removethebelt coverscrewusinga5/16socketwithextension

andslightlyraisebeltcover. Youmustalsouncliptheplastictab

on theothersideto raisethis up.Donot attempttoremovethebelt

coverfromtheunitat thistime. SeeFigure13.

3. Loosenthebottomaugerhousingmountingscrewoneach side

one(l) fullturnusinga 1/2"socket. SeeFigure12.

4. Usingthesamesocketwrench,removethetopaugerhousing

mountingscrewsoneachside.

NOTE: Thetopaugerhousingscrewontheleftside alsosecuresthe

augercablebracketandcableroller. Payattentionto itslocationand

howit is positionedforreferenceduringreassembly.

5. Pushdownonthe unit'shandle,thiswillallowthe beltcover

tobe easilyremovedandwillgiveaccessforthe followingbelt

maintenanceprocedures.

6. Afterremovingthebeltcover,slipthefrontaugerbeltoff ofthe

enginepulleybypushingitforwardandrollingin offofthe pulley.

7. Pushdownonthe unit'shandlefurtheropeningthisareaand

providingbetteraccesstotheaugerpulley. Youmaywishtoplace

a woodblockunderthe augerhousingtoholdtheunitopen.See

Figure14

8. Pushtheaugerbeltidlerpulleyin releasingthe augerbrake,which

isthe tab that holdsthe beltontotheaugerpulley.Removethebelt.

9. Replacewithnewbelt afterreplacingthedrivebelt.

NOTE: If notreplacingdrivebelt,thenproceedto Step5 intheDrive

Beltsection.

Figure14

13

Page 14

Drive Belt

NOTE:ToreplacetheDriveBelt,you mustfirstfollowAugerBelt

instructions.Replacethedrivebeltbeforereassemblingthenewauger

belt.

1. Removehairpinclipand pivotrodfromunit. SeeFigure15.

2. Maneuvercontrolarmoutanddisconnectdrivecable.

3. Pullidlerpulleyonrighthandsideout, releasingtensionon drive

belt. Removedrivebeltfromidlerpulleyandtransmissionpulley.

SeeFigure16

4. Rotatecontrolarmin orderto maneuverbeltfromunit. Remove

beltand replacewithnewbelt.

NOTE: Besureto maintainpositionofthemulti-speedpulley

assemblysothatthebeltIocatorpinin thetop position.

5. Reassemblein theexactoppositeorder.

6. Afterreassemblyis completed,besuretoadjusttheaugercable.

Refertothe"AdjustingAugerCable"instructionson Page13ofthis

manual.

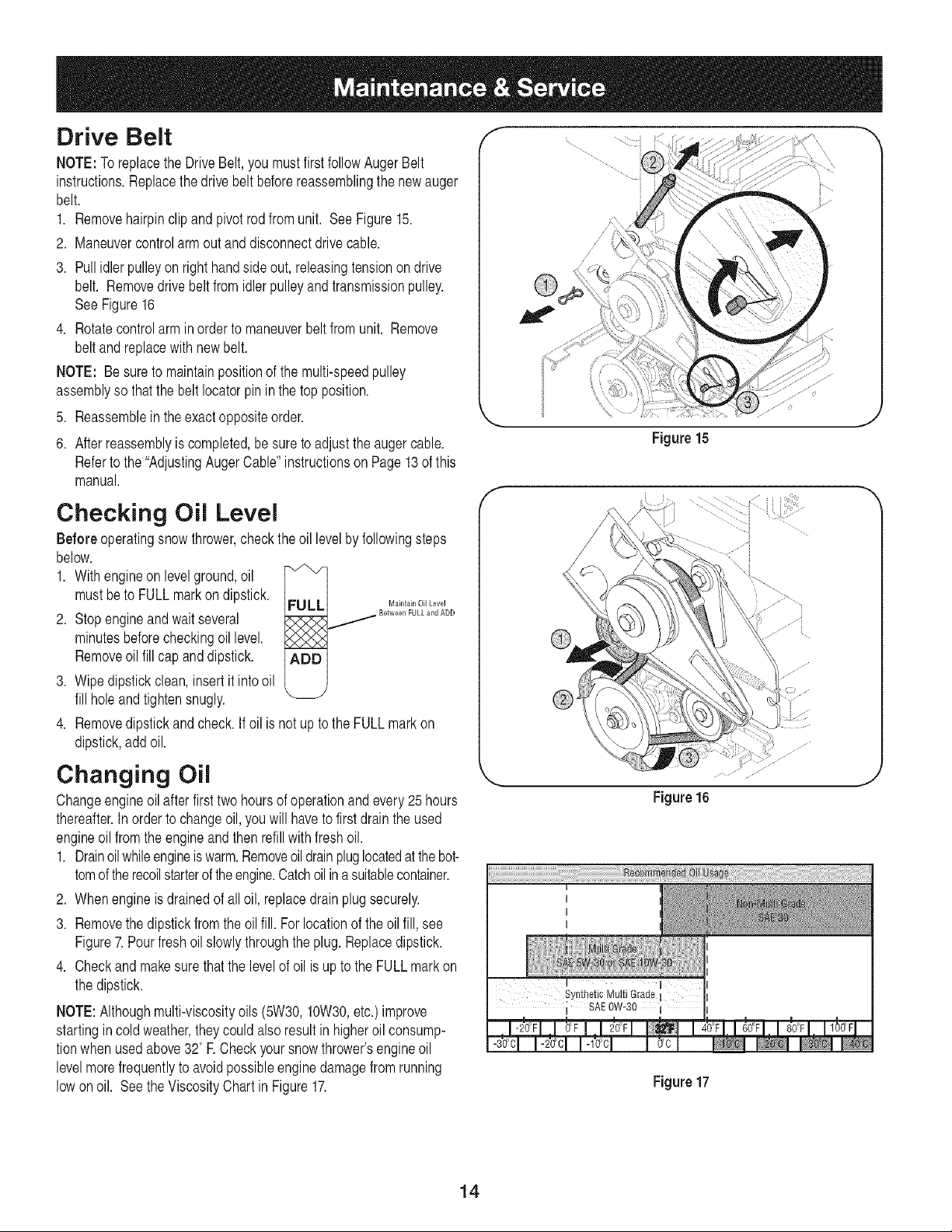

Checking Oil Level

Beforeoperatingsnowthrower,checkthe oil levelbyfollowingsteps

below.

1. Withengineonlevelground,oil

mustbeto FULLmarkon dipstick.

2. Stopengineandwaitseveral

minutesbeforecheckingoillevel.

Removeoil fillcap anddipstick.

3. Wipedipstickclean,insertit intooil

fillholeandtightensnugly.

4. Removedipstickandcheck.If oil isnotupto theFULLmarkon

dipstick,addoil.

FULLJ M_int_inOilLevel

_ Between FULL and ADD

ADD

Figure15

Changing Oil

Changeengineoilafterfirsttwo hoursofoperationandevery25hours

thereafter.Inorderto changeoil,youwill havetofirstdrainthe used

engineoil fromthe engineandthenrefillwithfreshoil.

1. Drainoilwhileengineiswarm.Removeoildrainpluglocatedatthebot-

tomoftherecoilstarterof theengine.Catchoilina suitablecontainer.

2. Whenengineisdrainedofalloil, replacedrainplugsecurely.

3. Removethedipstickfromtheoilfill. For locationof theoil fill,see

Figure7.Pourfreshoilslowlythroughtheplug.Replacedipstick.

4. Checkandmakesurethatthe levelofoil isupto the FULLmarkon

thedipstick.

NOTE:Althoughmulti-viscosityoils(5W30,10W30,etc.)improve

startingincoldweather,theycouldalsoresultin higheroilconsump-

tionwhen usedabove32°R Checkyoursnowthrower'sengineoil

levelmorefrequentlyto avoidpossibleenginedamagefromrunning

lowon oil. SeetheViscosityChartin Figure17.

14

Synthetic Multi Grade

; SAE0W-30

I

Figure16

1

Figure17

Page 15

Check Spark Plug

Cleansparkplugandresetthe electrodegapto 0.030"at leastonce

a seasonor every100hoursof operation;replaceevery200hoursof

operation.

1. Cleanareaaroundthesparkplugbase.

2. Removeandinspectthesparkplug. Checkgap,makesureit isset

at .030. SeeFigure18.

3. Replacethesparkplugif electrodesarepitted,burned,orthe

porcelainis cracked.

NOTE:Donotsandblastsparkplug.Sparkplugshouldbecleanedby

1..030 (.76ram)Gap

2. Electrodes

3. Porcelain

Figure18

Followthe maintenanceschedulegiven below. Some adjustmentswill haveto be made periodicallyto maintainyour unit

properly. Periodicallycheck all fastenersand makesure these aretight. Keeptrack of your scheduledservice by filling in

theService Dates field below.

scrapingor wirebrushingandwashingwitha commercialsolvent.

J

_ ARNING:Beforeservicing, repairing,lubricating or inspecting,disengageall controlsandstop engine.Wait untilall moving

partshavecometoacompletestop.Disconnectsparkplugwire andgroundit againstthe engineto preventunintendedstarting.

Alwayswearsafetyglassesduringoperationorwhileperforminganyadjustmentsor repairs.

Maintenance Schedule

TASKS SERVICEDATES

15

r--v1

Page 16

If the snowthrowerwill notbe usedfor 30daysor longer,orif itistheendof thesnowseasonwhenthe lastpossibilityofsnowisgone,the

equipmentneedstobestoredproperly.Followstorageinstructionsbelowto ensuretopperformancefromthesnowthrowerformanymoreyears.

Preparing Engine

Short-Term Storage

It is importanttopreventgumdepositsfromforminginessentialfuel

systempartsof the enginesuchasthecarburetor,fuelfilter,fuel hose,

ortankduringshort-termstorage(15-30days).Topreventthis,treat

thefuelsystemusingafuel stabalizer.

Fuelstabilizer(suchasSTA-BILTM or ULTRA-FRESHTM) isan accept-

ablealternativeinminimizingtheformationof fuelgumdepositsduring

storage.Addstabilizertogasolineinfueltankorstoragecontainer.

Alwaysfollowmixratiofoundonstabilizercontainer.Runengineat

least10minutesafteraddingstabilizertoallowitto reachthecarbure-

tor.

WARNING:Neverstoresnowthrower with fuel in

tank indoorsor inpoorlyventilatedareas,where

fuel fumes may reachan openflame, sparkor pilot

lightason afurnace, waterheater,clothesdryeror

gasappliance.

CAUTION:Alcohol blended fuels (called gasohol

or using ethanol or methanol) can attract moisture

which leadsto separation and formation of acids

during storage. Acidic gas can damagethe fuel

system of an engine whilein storage.

Preparing Snow Thrower

,, Whenstoringthesnowthrowerinanunventilatedormetalstorage

shed,careshouldbetakentorustprooftheequipment.Usinga

lightoilor silicone,coattheequipment,especiallyanychains,

springs,bearingsandcables.

,, Removealldirtfromexteriorof engineand equipment.

,, Followlubricationrecommendations.

,, Storeequipmentina clean,dryarea.

Long-Term Storage

Toavoidengineproblems,thefuelsystemshouldbeemptiedbefore

storagefor 30daysor longer.

,_ WARNING:Fuel left inengineduring warmweather

1. Runtheengineuntilthefueltankis emptyandit stopsduetolack

offuel.Donotattemptto pourfuel fromtheengine.

,_ WARNING:Neveruse engineor carburetorcleaning

2. Removethesparkplugandpourone (1)ounceof engineoil

throughthesparkplugholeintothecylinder.Coversparkplughole

witha ragandcranktheengineseveraltimesto distributetheoil.

Replacesparkplug.

deteriorates and willcauseserious starting prob-

lems.

productsinthe fuel tank or permanentdamagemay

occur,

16

Page 17

Problem Cause Remedy

Enginefails to start i. ChokenotinON position. !. MoveCheketo ONpositionl

2. Spaikp!ugwiredisconneoted. 2. Connectwireto sparkp!ug,

3, Fueltankernptyorstalefue!. 3. Fill tankwithclean,freshgasoline.

4, Enginenotprimed. 4 Prme engneas instruCtedin QpeiatingYoUr

5 Faiit sark lU 5 ceanadjustgaPorrepaee

• y p p g. : .

61 aloCkedfuellinel 6. €leanfue!!ine,

7.Safety keynot in ignitiononengine• 7. Insertkeyfullyintothe switch,

SnowThrower.

Enginerunserratic

1. UnitrunningonCHOKE.

2. Blockedfuellineor stalefuel.

3. Waterordirt in fuelsystem.

4. Carburetoroutof adjustment.

1. MovechokelevertoOFFposition.

2. Cleanfuelline;fill tankwithclean,freshgasoline.

3. Drainfueltank.Refillwithfreshfuel.

4. ContactSearsParts& RepairCenter.

Engineoverheats 1. Carburetornotadjustedproperly• 1. ContactSearsParts&ServiceCenter•

ExcessiveVibration 1. Loosepartsor damagedauger. 1. Stopengineimmediatelyanddisconnectspark

plugwire.Tightenallboltsandnuts.Ifvibration

continues,haveunitservicedbya SearsParts&

RepairCenter.

Loss of power i. spark p!ugWire!_ose:

2. Gascapventholeplugged• 2. Removeiceandsnowfromgas cap.Be certain

Unitfails to propel itself 1. Drivecontrolcableinneedofadjustment.

2. Drivebeltlooseordamaged.

i. connect andtightensparkp!ugWirel

3, ContactSearsParts& RepairCenter.

1. Adjustdrivecontrolcable.Referto Adjustments.

2. Replacedrivebelt.

Unitfailsto dischargeSnow 1, Chuteassemblyclogged. !. Stopengineimmediatelyanddisconnectspark

plugwire,O!ganchuteassemb!yandinsideof

augerhousingWith€lean-outtoolor a sticL

21 Foreigi objectiodged naugerl 2, stop engineimmediate!yanddisconnectspaik

plugwire.Removeobjectfromaugerwithclean-

outtoolora stick.

& Augeicablein needofadjustment• 3' Referto seivice &Adjustmentssecti°nl

& Augerbelt iooseordamaged. 4, Refeitoserviee&Adjustmentssectionl

5, Shearpin(s)sheared. 5. Replacewithnewshearpin(s),

NOTE:This section addressesminor service issues. For further details,contact Searsservice informationline by calling

1-800-4-MY-HOME.

17

Page 18

QI

18

Page 19

1 684-04037 ChuteAssembly 1 25 731-04218B Impeller 1

2 710-04071 CarriageBolt5/16-18x 1.0" 1 26 732-0611 ExtensionSpring 1

3 710-0451 CarriageBolt5/16-18 11 27 736-0174 WaveWasher 1

4 712-04063 FlangeLock Nut,5/16-18 1 28 738-0281 ShoulderScrew3/8-16 1

5 720-04072 StarKnob5/16-18 1 29 741-0245 HexFlangeBearing 2

6 731-04388A ChuteHandle 1 30 741-0309 BallBearing 1

7 731-04426A UpperChute 1 31 750-04191 Spacer 1

8 736-0159 FlatWasher.349x .879x .063 2 32 756-04249 FlatIdler 1

9 731-04127 LowerChute 1 33 784-0434 Auger IdlerBracket 1

10 731-04353 ChuteRing 1 34 790-00075 BearingHousing 1

11 731-2636A ChuteAdapter8" Dia. 1 35 618-04293 Auger GearboxAssembly 1

12 732-04111 ChuteAdjustmentSpring 1 36 684-04113 AugerAssembly- LH 2

13 712-04064 FlangeLock Nut 1/4-20 5 37 684-04114 AugerAssembly- RH 2

14 731-2643 Clean-outTool 1 38 684-04165 Auger Housing,24" 1

18 731-2635 Clean-outToolMount 1 39 714-04040 BowTie CotterPin 72 4

16 725-0157 CableTie 1 40 731-04870 Spacer,1.25x.75x 1.00 4

17 710-0134 CarriageScrew1/4-20x 0.62" 5 41 736-0351 FlatWasher 2

18 710-0520 HexBolt 3/8-16x 1.50" 1 42 738-04124A Shear Pin,.25x 1.50 4

19 710-0604A ABScrew5/16-18x .625 4 43 741-0493A FlangeBushing 8

20 712-04063 FlangeLock Nut,5/16-18 10 44 790-00087A HexBearingHousing 2

21 712-04065 FlangeLock Nut,3/8-16 1 45 790-00120 Shave Plate2.28 x 23.66LG 1

22 712-0266 JamLockNut 3/8-16 1 46 784-5580 Skid Shoe 2

23 715-04020 SpiralPin 2 47 746-04246 AugerCable 1

24 726-04012 PushOnNut 2

19

Page 20

®

[]

[] °'_

/

20

Page 21

1 710-0449 CarriageScrew5/16-18x2.25" 2 38 710-0664A TT SemsScrew3/8-16x 1.0" 4

2 710-0106 HexScrew1/4-20x 1.25" 2 39 710-0696 i HexBolt3/8-24x 0.875" 1

3 710-1260A Screw,5/16-18x .75" 4 40 710-1245B Lock Bolt5/16-24x 0.875" 1

4 712-04064 FlangeLockNut1/4-20 2 41 731-08364 BeltCover 1

5 720-04072 StarKnob 8/16-18 2 42 736-0247 FlatWasher,.4061Dx 1.250D 1

6 728-0157 CableTie 3 43 736-0508 FlatWasher,.341Dx 1.500D 1

7 746-04256 DriveCable 1 44 748-04067 i Pulley:Adapter,.75Dia. 1

8 746-04246 AugerCable 1 45 748-0234 ShoulderSpacer 1

9 711-04478 PivotRod 1 46 750-04568 i ShoulderSpacer 1

I

10 747-04405 DriveControl 1 47 784-04102 iV-Belt,3Lx 28.00 LG 1

11 749-04147 LowerHandle 1 48 784-04014 i V-Belt,3/8 x 26.680 Lg. 1

I

12 749-04236-0637 UpperHandle 1 49 786-04024 i Auger Pulley 1

13 790-00053 HandleTab 2 50 786-0869 i PulleyHalf 2

14 618-04296A TransmissionAssembly 1 51 710-0466 Screw,#10-16x.500 1

15 710-1260A Screw,5/16-18x .75" 4 52 790-00064 Heat Shield 1

16 710-1652 Screw,1/4-20x .625" 3 53 710-1667A Screw#10-16 2

17 711-1364 ClevisPin 1 54 731-08388A SpeedSelectorHousing- Lwr 1

18 714-0116 CotterPin, 1/8x 1.0 2 58 731-08389A SpeedSelectorHousing- Upr 1

19 714-04040 BowTieCotterPin 72 2 56 731-08360 i SpeedSelectorHousing-Lever 1

20 715-0249 RollPin 1 67 732-0627 I 6 SpeedShiftLeverSpring 1

21 717-04066A Pinion14T 1 68 746-04244 SpeedControlCable 1

22 717-04073A Gear70T 1 59 710-04329 Screw.169x.610 2

23 732-0409 ExtensionSpring 1 60 736-3092 FlatWasher.266x 1.0x .030 2

24 736-0192 FlatWasher 1 61 782-7596A i 6-SpeedControlArm 1

28 738-04184A ShoulderScrew1/4-20 1 62 790-00234A iActuatorMountingBracket 1

26 738-0924A CarriageScrew 1/4-28 1 63 790-00238A DriveWheelIdlerBracket 1

27 741-0246 HexFlangeBearing 2 64 686-0613 Multi-SpeedPulleyAssembly 1

28 741-04108 HexFlangeBearing 2 68 682-7827 i 6SpeedAssemblyCup 1

29 756-0625 CableRoller 1 66 741-0846 Ball Bearing 1

30 784-0419B DriveHousingFrame 1 67 756-0613 i PulleyHalf 1

31 790-00223 AugerCable Bracket 1 68 756-0612A DrivePulleyHalf 1

32 790-00224 AugerCable Adj.Bracket 1 69 684-04168 i Idler PulleyAssembly 2

33 634-02320 WheelAssemblySnowHogGray 2 70 747-04394A Auger ControlBail 1

34 710-0627 LockBolt8/16-24x0.75" 5 71 736-0232 lWaveWasher.631x .781x.013 1

35 736-0242 BellWasher 2 72 750-04871 ShoulderSpacer.60x .790x .838 2

36 738-1231 Axle 1

37 710-0224 HexScrew,#10-16x.800 1

21

Page 22

Tecumseh 5.5 H.P.Engine LH195SP- 67517D

i61

i24

i

3_

li81

20

3 _ _

J

287 390

90

262

_/355

E

_4

/

327

22

Page 23

Tecumseh 5.5 H.P.Engine LH195SP- 67517D

Ref.No. PartNo.

1 36469A

2 26727

5 30969

14 28277

15 31334

16 37729

17 31335

18 651018

19 31426

20 32600

25 36552

25A 35883

30 37842

40 36073

40 36074

40 36075

41 36070

41 36071

41 36072

42 36076

42 36077

42 36078

43 20381

45 32875A

46 32610A

48 37670

49 32654

50 37671

60 29745

64A 8345

65 30200

69 27677A

70 34674C

72 27642

75 27897

80 30574A

81 30590A

82 30591

83 30588A

86 650488

89 610961

90 611195

Description Qty Ref.No. PartNol Description Qty

Cylinder(Incl.2,20,72& 125) 1 92 650815 BellevilleWasher 1

DowelPin 2 93 650816 FlywheelNut 1

ExtensionCap(1/4-18NPT) 1 100 34443C SolidStateignition 1

Flatwasher 1 101 610118 SparkPlugCover 1

GovernorRod 1 102 651024 SolidStateMountingStud 2

GovernorLever 1 103 651007 Screw,T-15,10-24x 15/16" 2

GovernorLeverClamp 1 110 35182 GroundWire 1

Screw,T-15,8-32x 19/64" 1 110A 36874 GroundWire- Green,5.5" 1

ThrottleSpring 1 119 36443 *CylinderHeadGasket 1

Oil Seal 1 120 37675 CylinderHead(inc. 130A) 1

BlowerHousingBaffle(Incl.262) 1 125 36471 ExhaustValve(Std.)(Incl.151) 1

BaffleExtension 1 125 36472 ExhaustValve(1/320% (Incl.151) 1

Crankshaft 1 126 32644A intakeValve(Std.)(Incl. 151) 1

Piston,Pin&RingSet(Std.) 1 127 650691 Washer 1

Piston,Pin&RingSet(.0100% 1 130 6021A Screw,5/16-18x 1-1/2" 2

Piston,Pin&RingSet(.020OS) 1 130A 650694A Screw,5/16-18x2" 5

Piston& PinAss'y.(Std.)(Incl.43) 1 130B 650737 Screw,1/4-20x 1/2" 2

Piston& PinAss'y.(.010OS) (Incl.43) 1 130B 650818 Screw,5/16-18x 1-1/2" 1

Piston& PinAss'y.(.020OS)(Incl.43) 1 135 35395 ResistorSparkPlug(RJ19LM) 1

RingSet (Std.) 1 150 31672 ValveSpring 2

RingSet (.010OS) 1 151 31673 ValveSpringCap 2

RingSet (.020OS) 1 161 30063 Screw,T-30,1/4-20x 1/2" 1

PistonPin RetainingRing 2 161 30063 Screw,T-30,1/4-20x 1/2" 1

ConnectingRod Assy(Incl.46 & 49) 1 169 27234A *ValveCoverGasket 2

ConnectingRod Bolt 2 170 27666 BreatherBody 1

ValveLifter 2 171 31410 BreatherElement 1

Oil Dipper 1 172 34146 ValveCover 1

Camshaft(MCR) 1 173 35350 BreatherTube 1

BlowerHousingExtension 1 174 650128 Screw,10-24x1/2" 1

Washer 1 178 29752 Nut& LockWasher1/4-28 2

Screw,10-24x9/16" 1 181 650870 Screw,1/4-28x1-11/16" 1

•CylinderCoverGasket 1 182 6201 Screw,1/4-28x 7/8" 1

CylinderCover(Incl.75 thru83) 1 183 34583A Chokebracket 1

Oil DrainPlug(Sq.hd.,1/4-18) 2 184 26756 *CarburetorTointakePipeGasket 1

Oil Seal 1 185 33691 intakePipe 1

GovernorShaft 1 186 32698 GovernorLink 1

Washer 1 200 36677 ControlBracket(Incl.203thru 209A) 1

GovernorGearAssembly(Incl.81) 1 203 31342 CompressionSpring 1

GovernorSpool 1 204 651029 Screw,T-IO,5-40x 7/16" 1

Screw,1/4-20x 1-1/4" 7 206 610973 Terminal 1

FlywheelKey 1 206 610973 Terminal 1

Flywheel 1 215 35440 ControlKnob 1

23

Page 24

Tecumseh 5.5 H.P.Engine LH195SP- 67517D (Continuedfrompreviouspage)

Ref. No. Part No.

219 34582

220 35438

222 28820

223 650664

224 33673A

253 36701

254 36702

260 35656A

264A 650802

267 34212

274 33670A

275 35771A

277 792005

285 36467A

287 650926

287 650926

290 30705

292 26460

298 650665

300 35584

301 37845

309A 650783

310A 37868

311 37246

1-This enginemayhavebeenbuiltwiththe590707starter.

11(120V)StarterKit,18-wattflywheelw/ringgear,18-wattalternator,and

* Includedinthis GasketSet.

Description Qty

ChokeRod 1

ControlKnob 1

Screw,10-32x 1/2" 2

Screw,1/4-20x 1-19/32" 2

* IntakePipeGasket 1

CompressionReleaseWeight 1

CompressionReleaseSpring 1

BlowerHousing 1

Screw,1/4-20x5/8" 2

HoldDownBracket 1

* ExhaustGasket 1

Muffler(Incl.274) 1

Screw,1/4-20x2-1/2" 2

StarterCup 1

Screw,8-32x 21/64" 1

Screw,8-32x 21/64" 2

FuelLine 1

FuelLineClamp 2

Screw,1/4-15x3/4" 2

FuelTank(Incl.292 &301)(2 Quart) 1

FuelCap 1

Screw,10-24x3/4" 2

Dipstick 1

Dipstick 1

mounting

Ref.No. Part No. Description Qty

312 27625 Oil Fill Plug(Incl.312) 1

313 34080 Spacer 1

319 650735 Screw,10-24x3/8" 1

328 35062 IgnitionKey 2

329A 651060 Screw,8-32x23/64" 1

335 35072 CarburetorCover 1

338 650257 Screw,8-32x5/16" 2

340 36247 FuelTankBracket 1

342A 650675 Washer 2

345 33344 HeatBaffle 1

350 570682A PrimerAssembly 1

351 321800 PrimerLine 1

355 590574 StarterHandle(MittenGrip) 1

364 33333 CarburetorCoverBracket 1

364A 37673 LockingPlate 1

370 35282 Decal- SpeedControl&Choke 1

370 36501 Decal- Primer-InternationalSymbol 1

3701 37119 WarningDecal 1

380 640084B Carburetor(Incl.184) 1

390 590742 RewindStarter 1

396 33290E ElectricStarterMotor(110Volt) 0

396 730266 ElectricStarterKit(Optional)tt 0

400 36444 *GasketSet 1

600 651013 Washer 1

hardware.

Ref. No. Part No. - Description " Qty.

1 590742 RewindStarter 1

2 590645A Pulley& RewindSpringAss'y 1

3 590772 RepairKit 1

4 590574 MittenGrip Handle 1

5 590535 StarterRope(Length98") 1

0

3

24

Page 25

Tecumseh 5.5 H.P.Engine LH195SP- 67517D

17,

Ref. No. Part Nol

0 640084B

1 631615

2 631767

6 640070

7 650506

10 632108 ChokeShaft& LeverAssembly 1

14 631890 ChokeShutter 1

15 630735 ChokePositioningSpring 1

16 631807 FuelFitting 1

17 651025 ThrottleCrackScrew/IdleSpeedScrew 1

18 630766 TensionSpring 1

20 640027 IdleRestrictorScrew 1

20A 640053 IdleRestrictorScrewCap 1

27 631024 FloatShaft1 1

28 632802 Float(Plastic) 1

29 631028 FloatBowlO-Ring1 1

30 631021A InletNeedle,Seat& Clip (Incl.31) 1 1

31 631022 SpringClip 1

36 632745 MainNozzleTube 1

37 632547 O-Ring, MainNozzleTube1- 2

40 640131 HighSpeedBowlNut 1

44 27110A BowlNutWasher1 1

47 630748 WelchPlug,IdleMixtureWell1 1

48 631027 WelchPlug,AtmosphericVent1 1

60 632760B Repairkit(Incl.ItemsMarked1 in Notes) 1

Carburetor(Incl.184ofEnginePartsList) 1

ThrottleShaft& LeverAssembly 1

ThrottleReturnSpring 1

ThrottleShutter 1

ShutterScrew1 2

Description Qty.

Ref.No. ' Part No. I Description Qty.

1 590707 RecoilStarter 1

2 590709 Pulley& RewindSpringAss'y. 1

3 590774 RepairKit 1

4 590574 MittenGrip Handle 1

5 590535 StarterRope( Length98") 1

T_isi_l_st_t_on may no1dep_c_ac_aEeq_,e_t _nd ,s_orFefere_,__fpo_s only

1

Q

2

4

O

25

Page 26

26

Page 27

Manual dei operador

CRAFTSMAN°

5.5 caballos de fuerza

MAQUINA QUITANIEVE DE 24", 4 CICLOS Y 3

VELOCIDADES

NOmero de modelo 247.88455

PRECAUCION: antes de

utilizar este producto, lea

este manual y siga todas

las reglas de seguridad

y las instrucciones de

funcionamiento.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, EE.UU.

Visite nuestro sitio web: www.sears.corn/craftsrnan NOdeFORMULARIO769-01910B

• SEGURIDAD

MONTAJE

OPERACION

MANTENIMIENTO

LISTADO DE PIEZAS

ESPANOL

5/31/2006

Page 28

Declaraci6ndegarantia..........................PAgina28

Etiquetasdeseguridad...........................PAgina29

Reglasdeoperaci6nsegura..................PAginas30-31

Configuraci6nyajuste............................PAginas32-33

ConozcasumAquinaquitanieve...........PAgina34-35

Garanfiadedos aSos parala m_quina quitanieveCraftsman

Durantedosahosa partirde la fechade compra,siemprequea estamaquinaquitanievesele realiceel serviciode mantenimiento,lubricaci6n

ypuestaa puntodeacuerdoa las instruccionesdel manualdelpropietario,Searsrepararasincargocualquierdefectode materialeso manode

obra.Siesta m_.quinaquitanieveCraftsmanseutilizaparaprop6sitoscomercialesodealquiler,estagaranfiase aplicas61odurante30 diasa

partirde lafechadecompra. Estagaranfiano cubre:

• Elementosdesechablesquesedesgastanporel usonormal,incluyendoentreotros,zapatasantideslizantes,placade raspadoy bujias.

•Reparacionesnecesariasdebidoa abusoo negligenciadeloperador,incluyendoabolladuradelcig(]ehalyfallapornorealizarmantenimiento

delequipode acuerdoconlasinstruccionescontenidasenel manualdelpropietario.

EL SERVlCIODEGARANTiAEST#,DISPONIBLEPARALOSUSUARIOSQUELLEVENLAM#,QUINAQUITANIEVECRAFTSMANAL

CENTRODEPARTESy REPARACIONSEARSM#,SCERCANODENTRODELOSESTADOSUNIDOS.

EstagaranfiaesvalidaOnicamentemientraselproductose utilicedentrodelosEstadosUnidos.

PARAUBICARELCENTRODEPARTESY REPARACIONSEARSM#,SCERCANO0 PARAPROGRAMAREL SERVlCIOTECNICO,SIMPLE-

MENTECOMUNiQUESECONSEARSALTELEFONO1-800-4-MY-HOME@.

Estagaranfialeotorgaderechoslegalesespedficos;ustedtambienpuedetenerotrosderechos,loscualesvarbn de unestadoa otro.

SEARS,ROEBUCKANDCO.,D/817WA,HOFFMANESTATES,IL 60179

Operaci6n...............................................PAgina36-37

Mantenimientoy servicio......................P&gina38-41

Almacenamientofueradetemporadaysoluci6nde

problemas................................................P&gina42-43

NQmerodeservicio...........................Cubiertaposterior

Acuerdosde protecci6n sobre reparaciones

Felicitacionespor haberrealizadounaadquisici6ninteligente.El

productoCraftsman@queha adquiridoestadisehadoyfabricadopara

brindarmuchosahosde funcionamientoconfiable.

Perocomotodoslosproductosavecespuederequerirderepara-

clones.Esen esemomentocuandoeldisponerdeunacuerdode

protecci6nparareparacioneslepuedeahorrardineroy problemas.

A continuaci6nsedetallanlospuntosincluidosen elacuerdo:

• Servicioexpertoprestadopor nuestros12.000especialistasen

reparacionesprofesionales

Servicioilimitadosincargoparalas piezasy la manodeobraen

todaslasreparacionescubiertas

Reemplazodelproductosinoesposiblerepararelproductocubierto

Descuentode10%delprecionormaldelservicioyde laspiezas

relacionadasconel mismoquenoestencubiertasporel acuerdo;

adem_ts,10%de descuentodel precionormaldelaverificaci6nde

mantenimientopreventivo

Ayudarapidaportel_fono- asistenciatelef6nicaa cargode un

tecnicodeSearsparalosproductosquerequierenreparaci6na

domicilio,adem_tsdeunaprogramaci6nconvenienteparalarepara-

Caballos de fuerza : 5.5

Aceite del motor: SAE 5W=30

Combustible: Gasolina sin plomo

Bujias: Champion@ RJ19LM

Moto: Tecumseh LH195SP

ci6n.Adquieraahoraun acuerdodeprotecci6nparareparacionesy

protejasedeproblemasygastosinesperados

Unavezadquiridoel acuerdo,puedeprogramarelserviciocon

tans61orealizarunaIlamadatelef6nica.PuedeIlamarencualquier

momentodeldia o dela noche,o programarun servicioenlinea.

Searsdisponedemasde 12.000especialistasenreparaciones

profesionalesquetienenaccesoa m_.sde4,5millonesdepiezas

y accesoriosdegrancalidad.Esteesel tipo de profesionalismoen

el quepuedeconfiarparaquele ayudeaprolongarlavida_til del

productorecientementeadquiridoenlosahosporvenir,iAdquierahoy

suacuerdodeprotecci6nparareparaciones!

Se aplican determinadaslimitaciones y exclusiones.Paraobtener

precios e informaci6nadicional Ilameal 1-800-827-8655.

Servici0 de instalaci6ndeSears

Sideseasolicitarlainstalaci6nprofesionalde Searsde aparatos

domesticos,dispositivosparaabrirportones,calentadoresde aguay

otrosarticulosdom_sticosimportantes,enlosEstadosUnidosIlame

al 1-800-4-MY-HOME@

N_mero de modelo ......................................................

N_mero de serie ...........................................................

Fecha de compra .........................................................

Registre arriba el n_mero del modelo, el n_mero

de serie y la fecha de compra

28

Page 29

1.KEEPAWAYFROMROTATINGIMPELLER

ANDAUGER.CONTACTWITHIMPELLEROR

AUGERCANAMPUTATEHANDSANDFEET,

2. USECLEAN-OUTTOOLTO UNCLOG

DISCHARGECHUTE,

3. DISENGAGECLUTCHLEVERS,STOPENGINE,

ANDREMAINBEHINDHANDLESUNTILALL

MOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGOR SERVICINGMACHINE,

4. TOAVOIDTHROWNOBJECTSINJURIES,

NEVERDIRECTDISCHARGEATBYSTANDERS.

USEEXTRACAUTIONWHENOPERATINGON

GRAVELSURFACES.

5. READOPERATOR'SMANUAL.

CLEAN-OUT TOOL m_

ADVERTENCIA

Estesirnboloindicainstruccionesde seguridad

irnportantesque de no seguirse,se podrfa

ponerenpeligrola seguridadpersonaly/o la

propiedadsuyay de terceros.Leay sigatodas

las instruccioneseneste manualantesde iniciar

la operaci6nde estarn_.quina.Encaso de no

seguirestas instruccionespodriaprovocar

lesionespersonales.Cuandoveaeste sirnbolo.

SIGA LA ADVERTENCIA.

Su responsabilidad

Estarn_.quinaelectrica s61opueden usarlalas

personasque Jean,cornprendany respetenlas

advertenciase instruccionesque aparecen en

estemanual yen la rn_.quina.

Herramientade

npiezadel canal

AVOIDSERIOUSINJURYFROMTIRE/RIMEXPLOSION.

TO PREVENT0VER-INFLATION:

+ USE A MANUAL PUMP OR PORTABLEELECTRIC

TIRE INFLATOR.

+ NEVER USEAN AIR COMPRESSOR.

* INFLATETIRE TO 20 PSI.

HayunaherramientadelimpiezadeJcanalajustadaa lapartesuperior

delacajadelabarrenacon unpasadordeensamblado.Laherramienta

est,.disehadaparalimpiarelhieloy lanievedelmontajedeuncanal.

Esteproductosesujetamedianteunaunbn de cableen laf_.brica.

Cortela uni6ndecableantesdeoperarlam_tquinaquitanieve.

,_ ADVERTENCiA: nunca use sus manos

-- Apague el motor y permanezca detr_s de

J

para Jiberar un montaje de canal tapado.

las manijas hasta que todas Jaspartes

m6viJes se hayan detenido antes de utiJizar

la herramienta de limpieza para limpiar el

montaje del canal.

29

Page 30

ponentesdelvehiculocontienenoernitenproductosquirnicosqueelestadodeCaliforniaconsideraque

ADVERTENCIA:elescapedelmotordeesteproducto,algunosdesuscornponentesyalgunoscorn-

puedenproducircancer,defectosdenacirnientouotrosproblemasreproductivos.

PELIGRO:Estarn_.quinaest,.diseSadaparaserutilizadarespetandolasreglasdeseguridadcontenidasenestemanual.

AIigualqueconcualquiertipodeequipoelectrico,undescuidooerrordepartedeloperadorpuedeproducirlesiones

graves.Estarn_.quinaescapazdearnputarrnanosypiesydearrojarobjetoscongranfuerza.Denorespetarlasinstruc-

clonesdeseguridadsiguientessepuedenproducirlesionesgravesolarnuerte.

ADVERTENClA:estesirnboloindicainstruccionesdeseguridadirnportantesquedenoseguirse,se

podriaponerenpeligrolaseguridadpersonaly/olapropiedadsuyaydeterceros.Leaysigatodaslas

instruccionesenestemanualantesdeiniciarlaoperaci6ndeestarn_.quina.Encasodenoseguirestas

instruccionespodriaprovocarlesionespersonales.CuandoveaestesirnboloSlGALAADVERTENCIA.

Suresponsabilidad:estarn_.quinael_ctricas61opuedenusarlalaspersonasquelean,cornprendanyrespetenlasad-

vertenciase instruccionesqueaparecenenestemanualy enlarn_.quina.

Capacitaci6n

1. Lea,entiendaycumplatodaslas instruccionesincluidasenla ma.quinay

enlos manualesantes demontarlay utilizarla.Guardeestemanualen un

lugarseguroparaconsultasfuturasy regulares,asicomoparasolicitar

repuestos.

2. Familiaricesecontodosloscontrolesy sufuncionamientoapropiado.Sepa

comodetenerla maquinay camedesengranarloscontrolesrapidamente.

3. Nopermitanuncaque losnidosmenoresde14aSosutilicenestamaquina.

Losni5osde14a5osy masmayoresdebenleery comprenderlasinstruc-

clonesdefuncionamientoy las reglasdeseguridadcontenidaseneste

manual,ytambiendebensercapacitadosy estarsupervisadosporunode

lospadres.

4. Nuncapermitaquelosadultosutilicenestamaquinasinrecibirantesla

instrucci6napropiada.

5. Losobjetosarrojadosporla ma.quinapuedenproducirlesionesgraves.

Planifiqueelpatronenel queva air arrojandonieveparaevitarquela

descargade materialserealicehacialos caminos,losobservadores,etc.

6. Mantengaalosobservadores,ayudantes,mascotasy niSosporIomenosa

75pies dela maquinamientrasla mismaestaenfuncionamiento.Detenga

la maquinasialguienentraenla zona.

7. Seaprecavidoparaevitarpatinarseecaerseespecialmentecuandoopera

la maquinaen reversa.

Preparativos

1. Inspeccioneminuciosamenteel a.readondeutilizarAelequipo.Saquetodos

losfelpudos,periodicos,trineos,tablas,cablesy otrosobjetosextraSoscon

los quepedriatropezaroque podrianserarrojadosporla barrena/ motor.

2. Paraprotegerselosojosutilice siempreanteojoso antiparrasde

seguridadmientrasoperala mAquinao mientrasla ajustao repara.Los

objetosarrojadosque rebotanpuedenlesionargravementelavista.

3. Nooperela mAquinasinla vestimentaadecuadaparaestaral aire libreen

invierno.No utilicealhajas,bufandaslargasu otrasprendassueltasque

podrfanenredarseenlas partesm6viles.Utiliceuncalzadoespecialpara

superficiesresbaladizas.

4. Useunprolongadory untomacorrientedetres cablesconconexi6na

tierra paratodas las unidadescon motoresdeencendidoelectrico.

5. Ajuste laalturadela caja del tomacorrienteparalimpiarla gravao las

superficiescon piedrastrituradas.

6. Desengranetodas las palancasdecontrolantes dearrancarel motor.

7. Nuncaintenterealizarajustesmientrasel motorestAenmarchaexcepto

en loscasesespecificamenterecomendadosenel manualdel operador.

8. Dejequeel motory la maquinaseadaptena latemperaturaexteriorantes

de comenzarasacarla nieve.

9. ParaevitarlesionespersonalesodaSosmaterialesseasumamentecuidadosoal

manipularlagasolina.Lagasdinaesaltamenteinflamableysusvaporespuedencausar

explosiones.Sepuedelesionargravementesiderramagasolinasobreustedosobrela

ropayaquesepuedeprenderfuego.IAveselapielycambiesederopadeinmediato.

a. Utilicesale recipientesparagasolinaautorizados.

b.Apaguetodosloscigarrillos,cigarros,pipasy otrasfuentesdecombustion.

c. Nuncacarguecombustibleen la mAquinaen unespaciocerrado.

d. Nuncasaquelatapa delgas niagreguecombustiblemientrasel motor

estAcalienteoenmarcha.

e. Dejeque el motorseenfriepor Iomenosdosminutosantesdevolvera

cargarcombustible.

f. Nuncarecargueeltanque decombustible.Lleneeltanque noma.s

de 1/2 pulgadapordebajodela basedel cuellodelfiltro paradejar

espacioparala dilataciondel combustible.

g. Vuelvaa colocar latapa de lagasolinay ajustelabien.

h. Limpiela gasolinaderramadasobreel motory el equipo.Trasladela

maquinaa otrazona.Espere5 minutosantesdeencenderel motor.

i. Nuncaalmacenelama.quinao el recipientedecombustibleenun

espaciocerradodondehayafuego,chispaso luz piloto(porejemplo,

homes,calentadoresdeagua,calefactores,secadoresde ropa,etc.).

j. Dejequela maquinaseenfrieper Iomenos5 minutosantes de

guardarla.

30

Page 31

Operaci6n

1. No pongalasmanoso los piescercadelas piezasrotatorias,enla caja

dela barrena/ motoroen el montajedelcanalde descarga.Elcontacto

conlas piezasrotatoriaspuedeproducirla amputaciondemanosy pies.

2. Lapalancadecontroldela barrena/ motores undispositivodeseguri-

dad.Nuncapaseporalto sufuncionamiento.Dehacerlola operaci6nde

la maquinaes riesgosay puedeocasionarlesiones.

3. Laspalancasdecontroldebenfuncionarbienenambasdireccionesy

regresarautomaticamentea laposiciondedesengranecuandose lassuelta.

4. NuncaoperelamaquinasifaltaunmontajedelcanalosielmismoestAda_ado.

Mantengatodoslosdispositivosdeseguridadensulugaryenfuncionamiento.

5. Nuncaenciendaunmotorenespacioscerradosoen unazonaconpoca

ventilacion.Elescapedel motorcontienemonoxidodecarbono,ungas

inodoroy letal.

6. No utilicela mAquinabajola influenciadel alcoholo lasdrogas.

7. Elsilenciadory el motorse calientany puedenproducirquemaduras.No

lostoque.

8. Seasumamenteprecavidocuandooperela maquinasobreunasuperficie

congravao cuandolacruce.Mantengasealertaporsisepresentan

peligrosocultoso transito.

9. Tengacuidadocuandocambiededirecci6no cuandooperela maquina

enpendientes.

10.Planifiqueel patronenel que va air arrojandonieveparaevitar que

la descargadematerialseproduzcahacialasventanas,las paredes,

los automoviles,etc.yevitarasi posiblesdahosmaterialeso lesiones

producidasporlos rebotes.

11.Nuncadirijala descargahacialos ni_os,losobservadoresy lasmascotas

ni dejeque nadiese paredelantede la maquina.

12.No sobrecarguela capacidaddela maquinatratandode sacarla nieve

muyrApidamente.

13.Nuncaopereestamaquinasin buenavisibilidado iluminacion.Siempre

debeestarsegurode queestabien afirmadoy sostengabienlas manijas.

Camine,nuncacorra.

14.Cortelacorrientea la barrena/ motorcuandotransportelamaquinao

cuandola mismanoestaen uso.

15.Nuncaoperela maquinaaaltavelocidaddedesplazamientosobre

superficiesresbaladizas.Mirehaciaabajoy haciaatrasytengacuidado

cuandovayamarchaatrAs.

16.Si la mAquinacomenzaraavibrarde maneraanormal,detengael motor,

desconecteel cablede la bujiay pongalade maneraquehagamasa

contrael motor.Inspeccionelamaquinaminuciosamenteparaversiesta

da_ada.Reparetodoslos da_osantes deencendery operarla maquina.

17.Desengranetodaslaspalancasdecontroly detengael motorantesde

dejarla posici6nde operacion(detrasde las manijas).Esperea que la

barrena/ motorse detengaporcompletoantesdedestaparel montajedel

canalo realizarajustese inspecciones.

18.Nuncapongalas manosenlas aberturasdedescargaode recoleccion.

Utilicesiemprela herramientade limpiezaque se adjuntaparadestapar

la aberturade descarga.Nodestapeel montajedelcanal mientrasel

motorestaenfuncionamiento.Antesdedestaparlo,apagueel motory

permanezcadetrasde las manijashastaquetodaslas partesm6vilesse

hayandetenido.

19.Usesolounionesy accesoriosaprobadosporelfabricante(porejemplo,

pesasparalas ruedas,cadenasparalos neumaticos,cabinas,etc.).

20.Si se presentansituacionesquenoestanprevistasen estemanual,sea

cuidadosoyuseel sentidocomun.Contacteconsu centrodeservicio

Searsparaobtenerayuda.

IVlantenimiento y almacenamiento

1. Nuncamanipulelosdispositivosde seguridaddemaneraimprudente.

Controleperi6dicamenteque funcionende formaadecuada.Remitasea

las seccionesdemantenimientoy ajustedeestemanual.

2. Antesde realizarlalimpieza,repararo revisarla maquina,desengrane

todaslas palancasdecontroly detengael motor.Espereaque la barrena

/ motorse detengaporcompleto.Desconecteelcable dela bujfay

pongalode maneraque hagamasacontra el motorparaevitar quese

enciendade maneraaccidental.

3. Controlefrecuentementequetodos los pernosy tornillosestenbien

ajustadosparacomprobarquela maquinaseencuentraencondiciones

segurasdefuncionamiento.Asimismo,realiceuna inspecci6nvisualdela

maquinaparacontrolarsi la mismaestadahada.

4. Nocambiela configuraciondel reguladordelmotorni aceleredemasiado

el mismo.Elreguladorcontrolalavelocidadmaximaseguradeoperacion

delmotor.

5. Lasplacasderaspadoylaszapatasantideslizantesqueseusanconlamaquina

quitanievesedesgastany seda_an.Paraprotegersuseguridad,verifique

frecuentementetodosloscomponentesy reemplaceloss61oconpartesdelos

fabricantesdeequiposoriginales(OEM)."Lautilizaci6ndepiezasquenocumplan

conlasespecificacionesdeequiposoriginalespodrfatenercomoresultadoun

rendimientoincorrecto,yademaslaseguridadpodrfaestarcomprometida"

6. Reviseloscontrolesperiodicamenteparaverificarque engranenydesen-

granenadecuadamentey ajqstelossi esnecesario.Consultela seccion