MTD 31A-3BAD762, 31A-3BAD752 Owner’s Manual

Operator's Manual

Two-Stage

Snow Thrower

Model 3BA

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

Inthe State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

MTDLLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTED IN U.S.A.

FORM NO. 769-00747C

(7/29/2004)

TABLEOFCONTENTS

Content

Important Safe Operation Practices

Assembling Your Snow Thrower

Know Your Snow Thrower

Operating Your Snow Thrower

Making Adjustments

Page Content Page

3 Maintaining Your Snow Thrower 11

5 Servicing Your Snow Thrower 12

7 Trouble Shooting 14

8 Illustrated Parts 15

10 Warranty 20

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new snow thrower. Itwill help you assemble, prepare

and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. A sample model plate is

also given below. You can locate the model plate by standing at the operating position and

looking down at the rear of the snow thrower. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized

service dealer.

Copy the model number here:

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTretl/m theunit to theretailer from where it waspurchased,without first contactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, you can seek help from the experts. Choose from the options below:

Visit mtdproducts.com for many useful suggestions. Click on Customer Support button and

you will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

_fD:_ NSN__S

)-j_ ;, ,;_s'_>,>u<'" '_' !';U fl Y

:*fi _,

,_,rv L :_cE_tor

_sisl_ @ i(le to

D19 ©l _ ........................................................

g* ,_t I )I I)_ _> JOWl OQI

iii='.,".=,>4:,>.CLICKIIH]q!f)'<I

If you prefer to reach a Customer Support Representative, please call 1-800-800-7310.

Of 4,?0.1(. ;;_;:'

L_En ine

The engine manufacturer is responsible for all engine-related issues with regards to

aerformance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

_ ARNING: This symbol points out important safety instructions which, if not followed, could endangerthe personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol--heed its warning.

_ WARNING: Engine Exhaust, some of its constituents, and certain vehicle components contain

or emit chemicals known to State of California to cause cancer and birth defects or other

reproductive harm.

DANGER: This machine was built to be operated according to the rules for safe operation in this manual. As with

any type of power equipment, carelessness or error on the part of the operator can result in serious injury. This

machine is capable of amputating hands and feet and throwing objects. Failure to observe the following safety

instructions could result in serious injury or death,

Training 7.

1. Read, understand, and fellow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place 8.

for future and regular reference and for ordering

replacement parts. 9.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructions and safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without

proper instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Preparatien

1. Thoroughly inspect the area where the equipment is to

be used. Remove all doormats, newspapers, sleds,

boards, wires and other foreign objects, which could be

tripped over or thrown by the auger/impeller.

2. Always wear safety glasses or eye shields during j.

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can 0peratien

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer 1.

garments. Do not wear jewelry, long scarves or other

loose clothing, which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Use a grounded three-wire extension cord and

receptacle for all units with electric start engines.

5. Adjust collector housing height to clear gravel or crushed

rock surfaces.

6. Disengage all control levers before starting the engine.

Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual.

Let engine and machine adjust to outdoor temperature

before starting to clear snow.

To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes, which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than

1/zinch below bottom of filler neck to provide space

fer fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

Allow machine to cool at least 5 minutes before

storing.

Do not put hands or feet near rotating parts, in the auger/

impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine

unsafe and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged chute

assembly. Keep all safety devices in place and working.

5. Neverrunanengineindoorsorinapoorlyventilated

area.Engineexhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

6. Donotoperatemachinewhileundertheinfluenceof

alcoholordrugs.

7. Mufflerandenginebecomehotandcancauseaburn.Do

nottouch.

8. Exerciseextremecautionwhenoperatingonorcrossing

gravelsurfaces.Stayalertforhiddenhazardsortraffic.

9. Exercisecautionwhenchangingdirectionandwhile

operatingonslopes.

10.Planyoursnow-throwingpatterntoavoiddischarge

towardswindows,walls,carsetc.Thus,avoiding

possiblepropertydamageorpersonalinjurycausedbya

ricochet.

11.Neverdirectdischargeatchildren,bystandersandpets

orallowanyoneinfrontofthemachine.

12.Donotoverloadmachinecapacitybyattemptingtoclear

snowattoofastofarate.

13.Neveroperatethismachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfootingandkeepafirmhold

onthehandles.Walk,neverrun.

14.Disengagepowertotheauger/impellerwhen

transportingornotinuse.

15.Neveroperatemachineathightransportspeedson

slipperysurfaces.Lookdownandbehindandusecare

whenbackingup.

16.Ifthemachineshouldstarttovibrateabnormally,stopthe

engine,disconnectthesparkplugwireandgroundit

againsttheengine.Inspectthoroughlyfordamage.

Repairanydamagebeforestartingandoperating.

17.Disengageallcontrolleversandstopenginebeforeyou

leavetheoperatingposition(behindthehandles).Wait

untiltheauger/impellercomestoacompletestopbefore

uncloggingthechuteassembly,makinganyadjustments,

orinspections.

18.Neverputyourhandinthedischargeorcollector

openings.Alwaysusetheclean-outtoolprovidedto

unclogthedischargeopening.Donotunclogchute

assemblywhileengineisrunning.Shutoffengineand

remainbehindhandlesuntilallmovingpartshave

stoppedbeforeunclogging.

19.Useonlyattachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

20.Ifsituationsoccurwhicharenotcoveredinthismanual,

usecareandgoodjudgment.Contactyourdealerorcall

1-800-800-7310forassistanceandthenameofyour

nearestservicingdealer.

Maintenance& Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine

disengage all control levers and stop the engine. Wait

until the auger/impeller come to a complete stop.

Disconnect the spark plug wire and ground against the

engine to prevent unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original

equipment manufacturer's (HEM) parts only. "Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

6. Check controls periodically to verify they engage and

disengage properly and adjust, if necessary. Refer to the

adjustment section in this operator's manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas,

oil, etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

YourResponsibility

Restrict the use of this power machine to persons who

read, understand and follow the warnings and

instructions in this manual and on the machine.

Donotmodifyengine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a

runaway engine and cause it to operate at unsafe speeds.

Never tamper with factory setting of engine governor.

NoticeregardingEmissions

Engines which are certified to comply with California and

federal EPA emission regulations for SORE (Small Off Road

Equipment) are certified to operate on regular unleaded

gasoline, and may include the following emission control

systems: Engine Modification (EM) and Three Way Catalyst

(TWC) if so equipped.

1,K;EP AWAYFROMROTATINGIMPELLER

A_HHHOER.CON'ACTWITHIMPELLEROH

t_UGERCANAMPUTATEHANDSANDFEET.

SECTION2: ASSEMBLINGYOURSNOWTHROWER

IMPORTANT:This unit is shipped with the engine full of

oil. After assembly, see page 8 for fuel and oil details.

RemovingFromCarton

• Cut the corners of the carton and lay the sides flat

on the ground. Remove all packing inserts.

• Move the snow thrower out of the carton.

• Make certain the carton has been completely

emptied before discarding it.

BeforeAssembly

NOTE: Reference to right, left, front or rear of the unit is

from the operating position unless otherwise stated.

• Cut the cable tie that secures the upper handle to

the chute assembly for shipping purposes.

SettingUpTheHandle

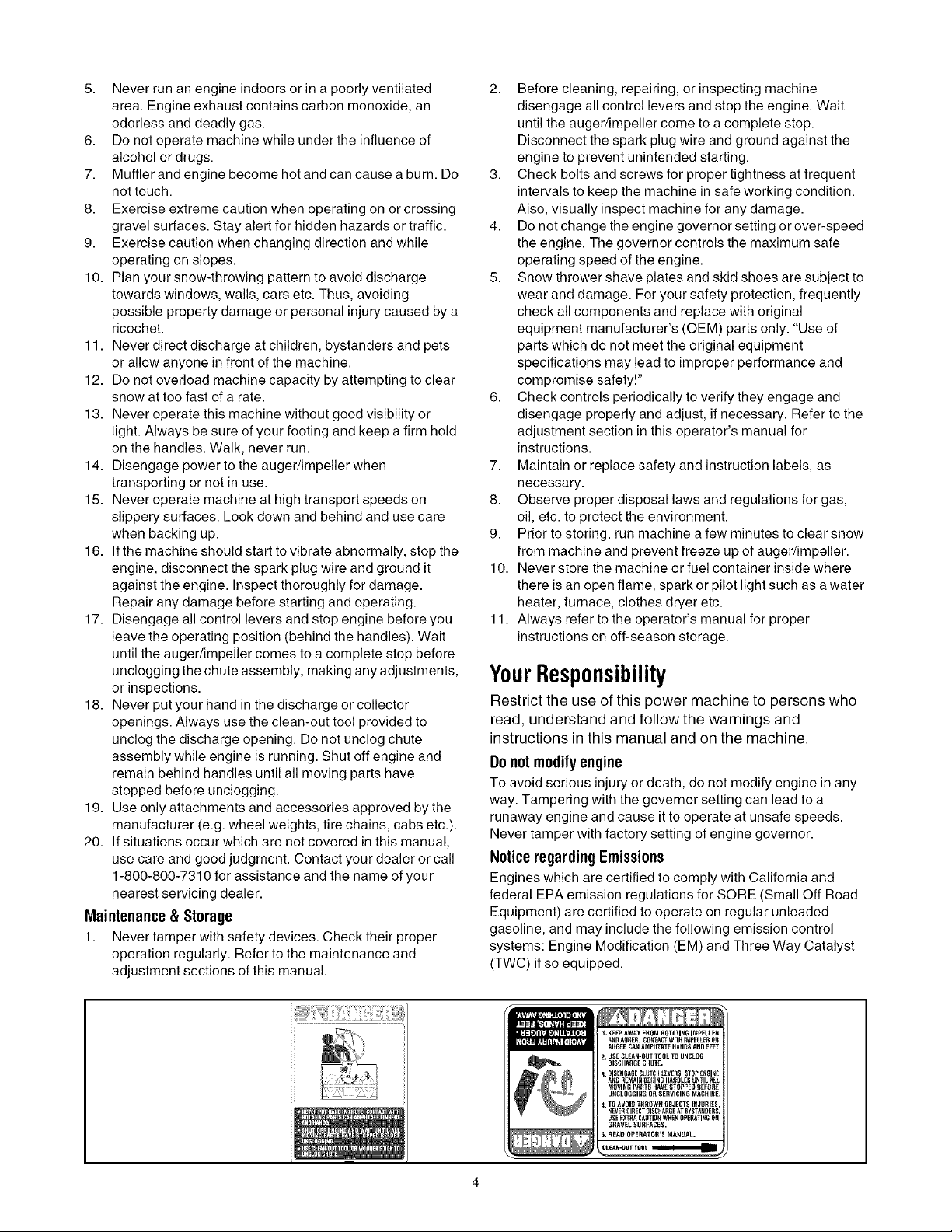

• Loosen the chute knob on the upper chute and

pivot the upper chute upwards as far as it will go.

Follow the direction of the arrow in Figure 1.

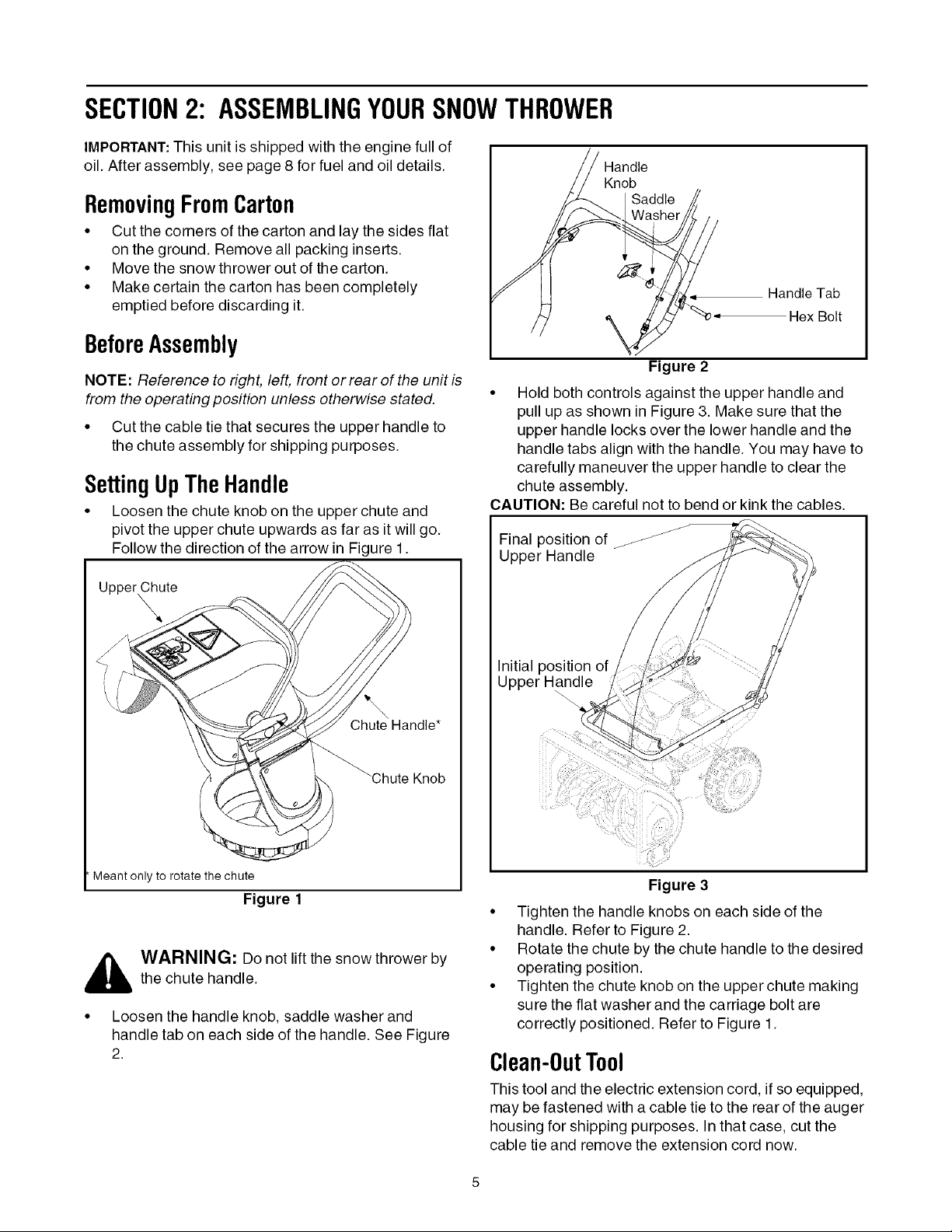

• Hold both controls against the upper handle and

pull up as shown in Figure 3. Make sure that the

upper handle locks over the lower handle and the

handle tabs align with the handle. You may have to

carefully maneuver the upper handle to clear the

chute assembly.

CAUTION: Be careful not to bend or kink the cables.

Final position of

Upper Handle

Handle

Knob

Saddle

Handle Tab

_ " Hex Bolt

Figure 2

Chute

Chute Handle*

Knob

Meant only to rotate the chute

Figure 1

_ ARNING: Do not lift the snow thrower by

• Loosen the handle knob, saddle washer and

the chute handle.

handle tab on each side of the handle. See Figure

2.

Initial position of

Upper Handle

Figure 3

• Tighten the handle knobs on each side of the

handle. Refer to Figure 2.

• Rotate the chute by the chute handle to the desired

operating position.

• Tighten the chute knob on the upper chute making

sure the flat washer and the carriage bolt are

correctly positioned. Refer to Figure 1.

Clean-OutTool

This tool and the electric extension cord, if so equipped,

may be fastened with a cable tie to the rear of the auger

housing for shipping purposes. In that case, cut the

cable tie and remove the extension cord now.

FinalAdjustments

IMPORTANT:Check the adjustments as instructed and

make any final adjustments necessary before operating

the unit. Check all nuts and bolts for tightness.Failure to

follow these instructions may cause damage to unit.

Tire Pressure (PneumaticTires)

The tires are over-inflated for shipping purposes. Check

tire pressure and reduce pressure, if needed, to 10-15

psi. Maintain equal pressure on both wheels of the

snow throwe r.

_ WARNING: Maximum tire pressure underany circumstance is 15 psi. Equal tire pressure

should be maintained at all times. Excessive

pressure (over 15 psi) when seating beads

may cause tire/rim assembly to burst with force

sufficient to cause serious injury

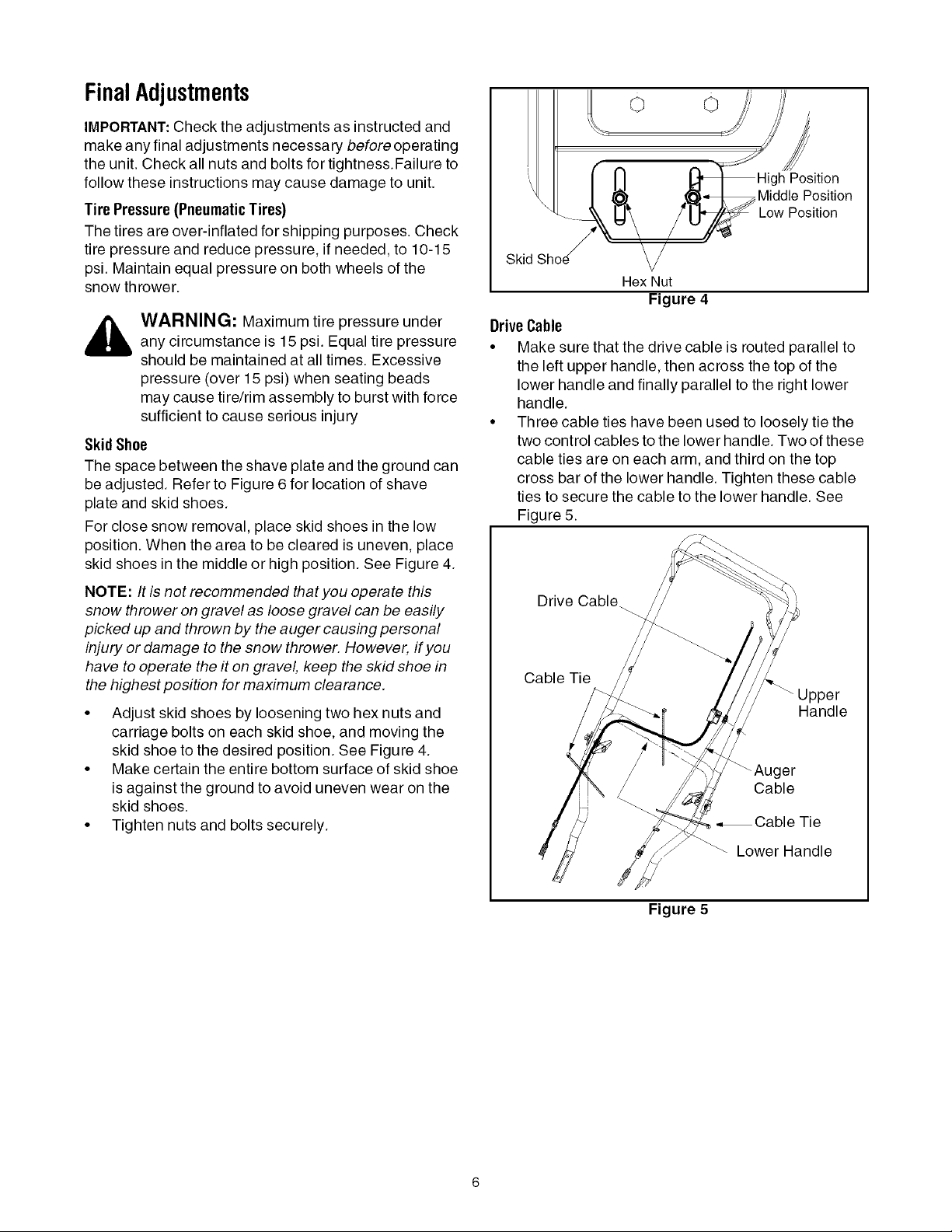

Skid Shoe

The space between the shave plate and the ground can

be adjusted. Refer to Figure 6 for location of shave

plate and skid shoes.

For close snow removal, place skid shoes in the low

position. When the area to be cleared is uneven, place

skid shoes in the middle or high position. See Figure 4.

o o

Position

Middle Position

Position

Hex Nut

Figure 4

DriveCable

• Make sure that the drive cable is routed parallel to

the left upper handle, then across the top of the

lower handle and finally parallel to the right lower

handle.

• Three cable ties have been used to loosely tie the

two control cables to the lower handle. Two of these

cable ties are on each arm, and third on the top

cross bar of the lower handle. Tighten these cable

ties to secure the cable to the lower handle. See

Figure 5.

NOTE: It is not recommended that you operate this

snow thrower on gravel as loose gravel can be easily

picked up and thrown by the auger causing personal

injury or damage to the snow thrower. However, if you

have to operate the it on gravel, keep the skid shoe in

the highest position for maximum clearance.

• Adjust skid shoes by loosening two hex nuts and

carriage bolts on each skid shoe, and moving the

skid shoe to the desired position. See Figure 4.

• Make certain the entire bottom surface of skid shoe

is against the ground to avoid uneven wear on the

skid shoes.

• Tighten nuts and bolts securely.

Drive Cable

Cable Tie

Handle

_Auger

Cable

_Cable Tie

Lower Handle

Figure 5

Loading...

Loading...