Page 1

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

OPER roR's

UAL

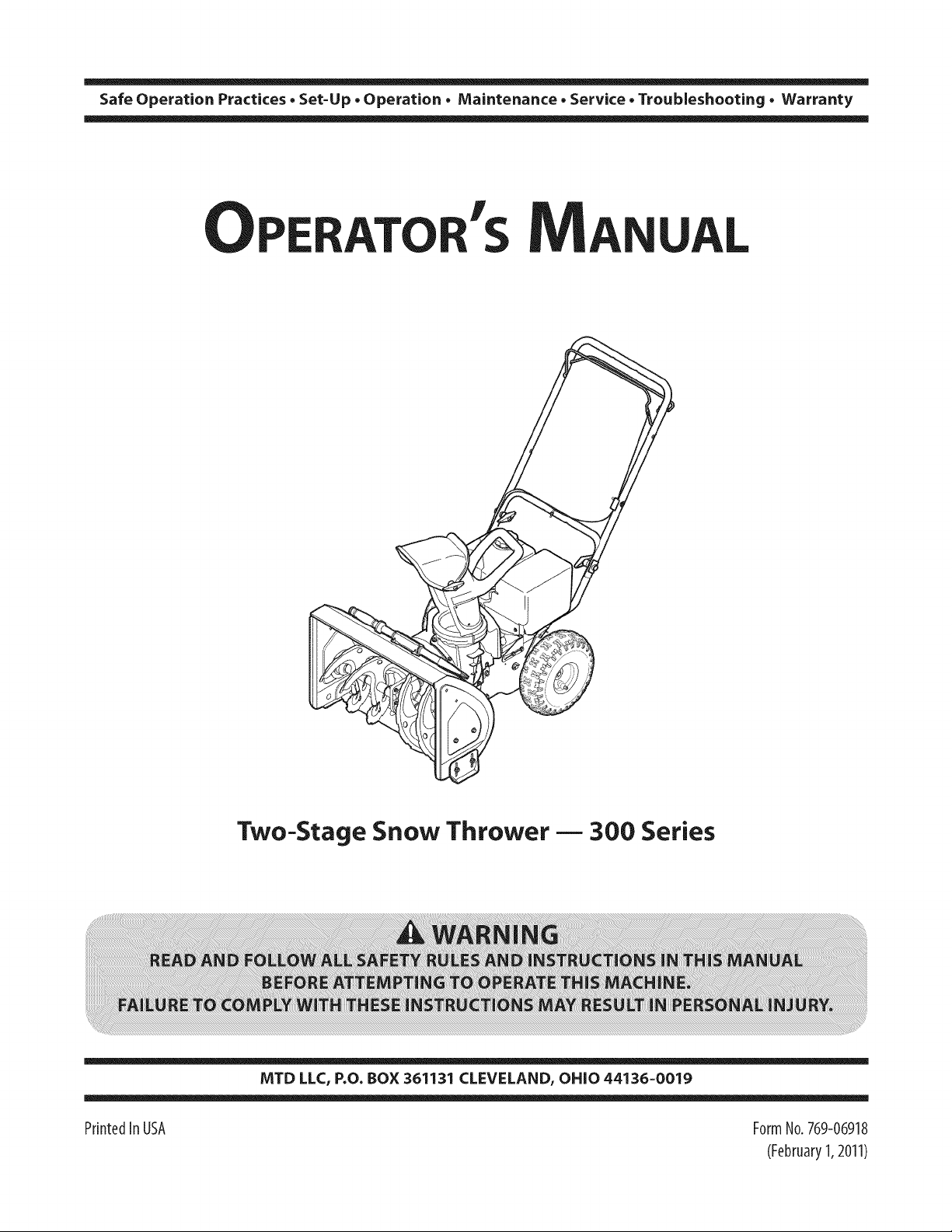

Two=Stage Snow Thrower m 300 Series

MTD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-06918

(February1,2011)

Page 2

ToTheOwner

ThankYou

1

Thank you for purchasing aSnowThrower manufactured by

MTD LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Pleasereadthis entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Pleasebesure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do socould

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the unit, its

features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD LLC

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Tableof Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 7

Controls and Features ............................................ 10

Operation ................................................................ 12

Maintenance and Adjustments ............................ 13

If you have any problems or questions concerning the unit,

phone your local authorized MTD service dealer or contact us

directly. MTD's Customer Support telephone numbers, web site

address and mailing address can be found on this page. We want

to ensure your complete satisfaction at all times.

Throughout this manual, all references to fight and left side of the

machine are observed from the operating position

Service ..................................................................... 15

Troubleshooting ..................................................... 17

Replacement Parts ................................................. 18

Warranty ................................................................. 21

Espanol ................................................................... 22

RecordProductinformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the operator's position and looking

down at the rear of the frame. Thisinformation will be necessary,

should you seek technical support via our web site, Customer

Support Department, or with alocal authorized service dealer.

MODEL NUMBER

D[3D[3D[3D[3D[3D

SERIAL NUMBER

FIFIFIFIFIFIFIFIFIFID

CustomerSupport

Please do NOT return the unit to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

0 Visit us on the web at www.mtdproducts.com

0 Call a Customer Support Representative at (800) 800-7310 or (330) 220-4683

0 Write us at MTD LLC • RO. Box 361131 • Cleveland, OH •44136-0019

Page 3

ImportantSafeOperationPractices

WARNING! This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING! Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

DANGER: This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing foreign objects. Failure to observe the following safety

instructions could result in serious injury or death.

2

Training Preparation

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow-throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, pets and children at least 75 feet from the

machine while it is in operation. Stop machine if anyone

enters the area.

Exercise caution to avoid slipping or falling, especially

when operating in reverse.

Thoroughly inspect the area where the equipment is to be used.

Remove all doormats, newspapers, sleds, boards, wires and other

foreign objects, which could be tripped over or thrown by the

auger/impeller.

1. Always wear safety glasses or eye shields during operation

and while performing an adjustment or repair to protect

your eyes. Thrown objects which ricochet can cause serious

injury to the eyes.

2. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other loose

clothing, which could become entangled in moving parts.

Wear footwear which will improve footing on slippery

surfaces.

3. Use a grounded three-wire extension cord and receptacle

for all machines with electric start engines.

4. Adjust auger housing height to clear gravel or crushed rock

surfaces.

5. Disengage all control levers before starting the engine.

6. Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual.

7. Let engine and machine adjust to outdoor temperature

before starting to clear snow.

Page 4

SafeHandling of 6asoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

Never fuel machine indoors.

C.

d.

Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to provide space for

fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

k. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic linen Always place

containers on the ground away from your vehicle

before filling.

I. If possible, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this

is not possible, then refuel such equipment on a

trailer with a portable container, rather than from a

gasoline dispenser nozzle.

m. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

Operation

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine unsafe

and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4.

Never operate with a missing or damaged chute assembly.

Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

6. Do not operate machine while under the influence of

alcohol or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch. Keep children away.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operating on slopes. Do not operate on steep slopes.

10. Plan your snow-throwing pattern to avoid discharge

towards windows, walls, cars etc. Thus, avoiding possible

property damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets or

allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13.

Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

14.

Disengage power to the auger/impeller when transporting

or not in use.

15.

Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when backing up.

16. If the machine should start to vibrate abnormally, stop

the engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage. Repair

any damage before starting and operating.

17. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the chute assembly, making any adjustments,

or inspections.

18. Never put your hand in the discharge or collector openings.

Always use the clean-out tool provided to unclog the

discharge opening. Do not unclog chute assembly while

engine is running. Shut off engine and remain behind

handles until all moving parts have stopped before

unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. When starting engine, pull cord slowly until resistance

is felt, then pull rapidly. Rapid retraction of starter cord

(kickback) will pull hand and arm toward engine faster than

you can let go. Broken bones, fractures, bruises or sprains

could result.

21.

If situations occur which are not covered in this manual, use

care and good judgment. Contact Customer Support for

assistance and the name of your nearest servicing dealer.

4 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

Page 5

ClearingaCloggedDischargeChute

Hand contact with the rotating impeller inside the discharge

chute is the most common cause of injury associated with snow

throwers. Never use your hand to clean out the discharge chute.

To clear the chute:

1. SHUTTHE ENGINE OFF!

2. Wait 10 seconds to be sure the impeller blades have

stopped rotating.

3. Always use a clean-out tool, not your hands.

Maintenance & Storage

1. Never tamper with safety devices. Check their proper

operation regularly. Refer to the maintenance and

adjustment sections of this manual.

2. Before cleaning, repairing, or inspecting machine

disengage all control levers and stop the engine. Wait until

the auger/impeller come to a complete stop. Disconnect

the spark plug wire and ground against the engine to

prevent unintended starting.

3. Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with original equipment

manufacturer's (OEM) parts only. "Use of parts which do

not meet the original equipment specifications may lead to

improper performance and compromise safety!"

6. Check control levers periodically to verify they engage

and disengage properly and adjust, if necessary. Refer

to the adjustment section in this operator's manual for

instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of auger/impeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

12. Check fuel line, tank, cap, and fittings frequently for cracks

or leaks. Replace if necessary.

13. Do not crank engine with spark plug removed.

14.

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 60 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Donotmodify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

internal combustion engine and should not be used

WARNING! This machine is equipped with an

on or near any unimproved forest-covered, brush

covered or grass-covered land unless the engine's

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

Ifa spark arrestor is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O.Box 361131 Cleveland, Ohio 44136-0019.

SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES S

Page 6

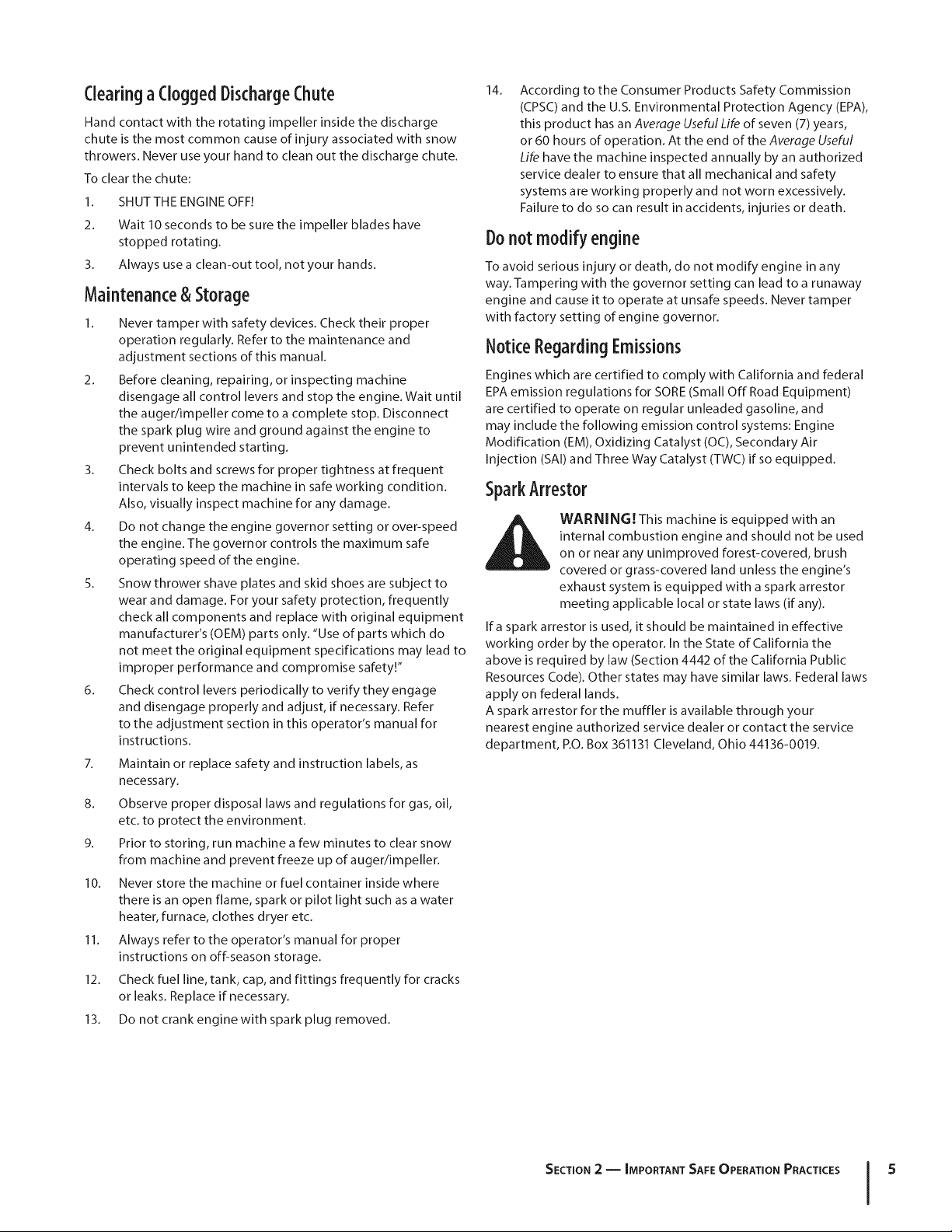

SafetySymbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating

blades inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating

blades inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute

assembly. Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine

and muffler to cool before touching.

WARNING! Your Responsibility--Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 I SECTION 2 -- IMPORTANT SAFE OPERATION PRACTICES

SAVETHESEINSTRUCTIONS!

Page 7

Assembly&Set-Up

Contents of Carton

One Snow Thrower

One Snow Thrower Operator's

Manual

Assembly

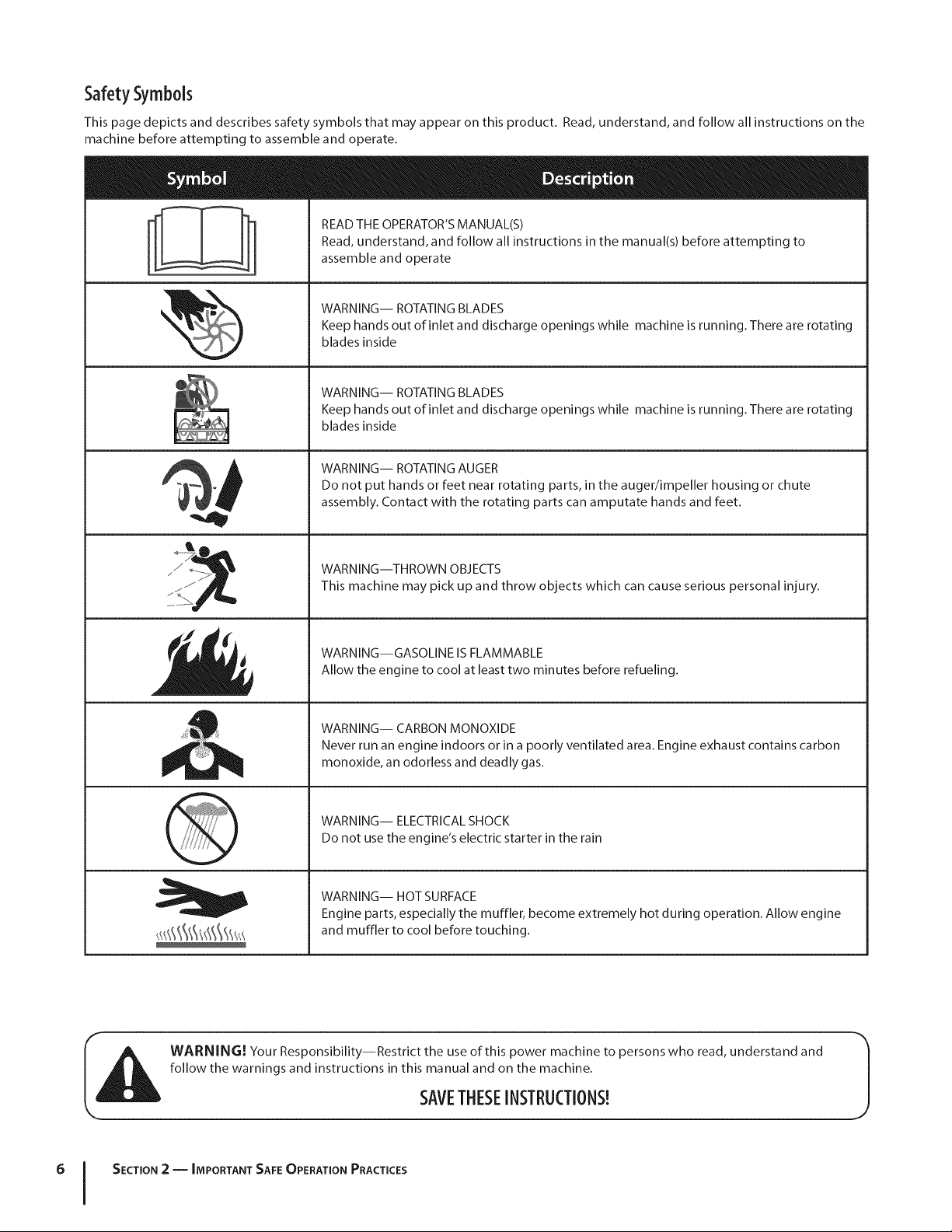

Setting UpTheHandle

1. Remove cable tie (if present) securing upper handle to

lower handle for shipping purposes. Remove all protective

plastic wrapping from handles.

NOTE: Be careful NOT to remove the two loosely fitted

cable ties that will be utilized later to secure cables.

2.

Loosen and remove the wing knob, saddle washer, handle

tab and carriage screw on each side of the lower handle.

See Fig. 3-1.

Two Replacement Auger Shear Pins

One Product Registration Card

3

One Engine Operator's Manual

Figure 34

3.

Slide one of the loosely fitted cable ties from the right side

of the lower handle up to the cross member of the lower

handle. Leave the second cable tie in place on the right side

of the lower handle. See Fig. 3-3 for reference.

IMPORTANT: It will be necessary to lift the upper handle while

sliding up this cable tie to prevent damage to the cable.

4. Lift the upper handle up and position it over the lower

handle, aligning the holes where the wing knobs were

removed (1).See Fig. 3-2.

CAUTION: Be careful not to bend or kink the cables.

5. Insert a carriage screw from the outside through a handle

tab, the upper and lower handles, a saddle washer and into

the wing knob (2). Repeat on the other side.

6. Tighten the wing knobs on each side of the handle. Refer

to Fig. 3-2.

Figure 3-2

NOTE:The auger cable routes down the left lower handle

and the drive cable is routed across the top of the lower

handle and down the right side of the lower handle. See

Fig. 3-3.

7.

Two cable ties have been used to loosely tie the control

cables to the lower handle, including the cable tie you

relocated in step 3. A push clip is also included on the

lower drive cable. Position cable ties now, as in Fig. 3-3, and

tighten to secure cables to the lower handle. Trim off excess

material of cable ties. If not already installed, push the clip

on the drive cable into the hole in the handle provided as

shown in the left inset below.

F

Drive Cable

Auger Cable

Figure 3=3

Page 8

Set-Up

TirePressure

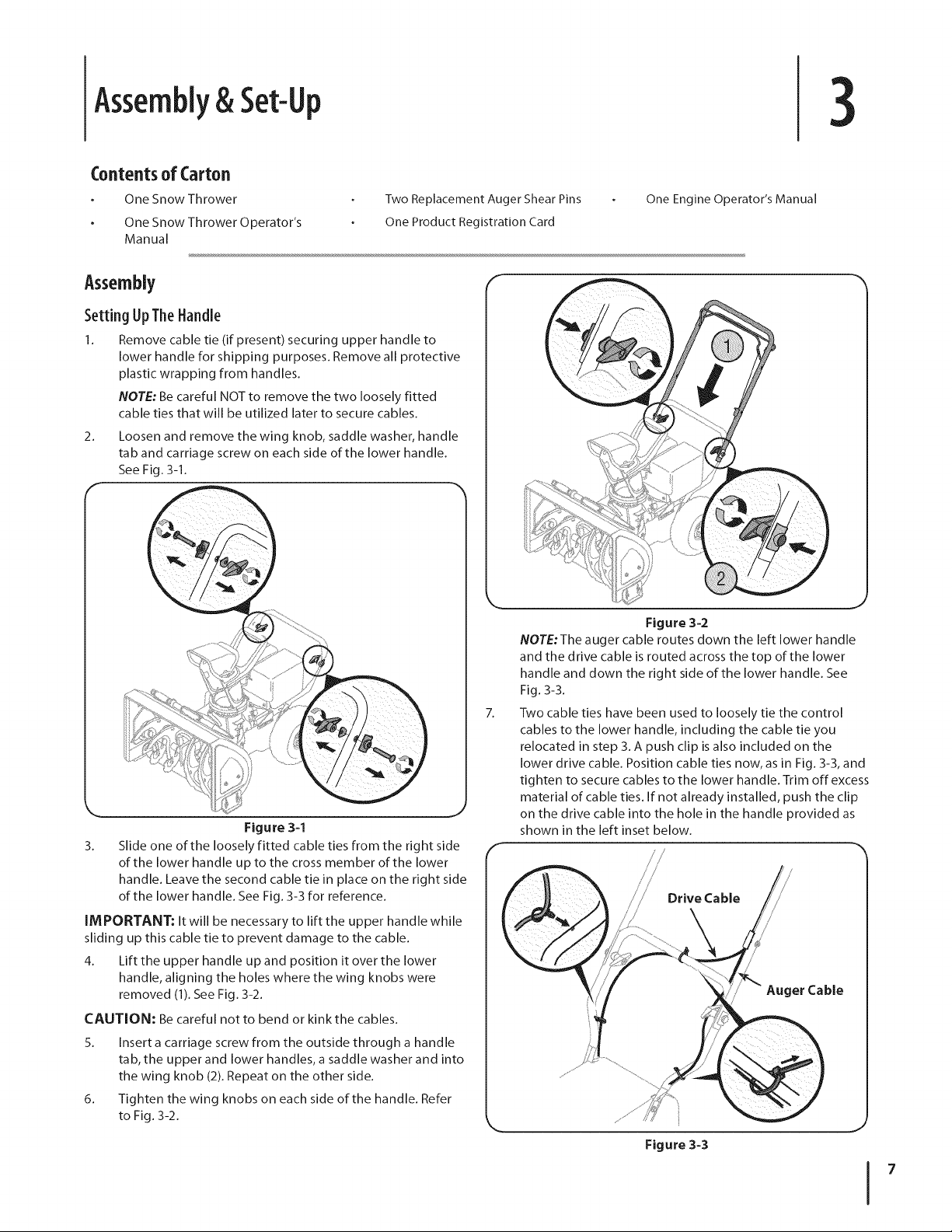

ShearPins

A pair of replacement auger shear pins and bow tie cotter pins

are included with your snow thrower. See Fig. 3-4. Store them in

a safe place until needed.

Figure 3-4

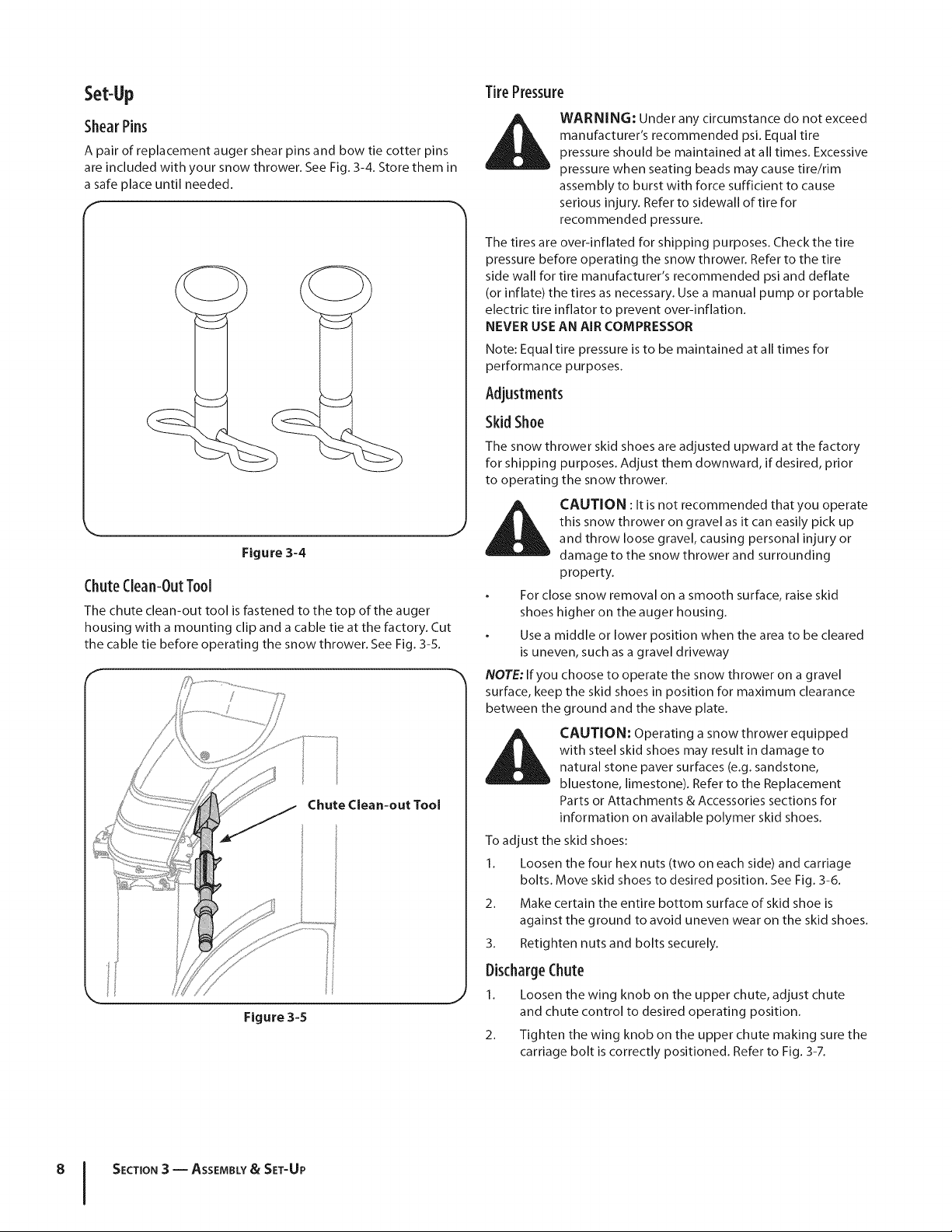

ChuteClean-OutT001

The chute clean-out tool is fastened to the top of the auger

housing with a mounting clip and a cable tie at the factory. Cut

the cable tie before operating the snow thrower. See Fig. 3-5.

manufacturer's recommended psi. Equal tire

WARNING: Under any circumstance do not exceed

pressure should be maintained at all times. Excessive

pressure when seating beads may cause tire/rim

assembly to burst with force sufficient to cause

serious injury. Refer to sidewall of tire for

recommended pressure.

The tires are over-inflated for shipping purposes. Check the tire

pressure before operating the snow thrower. Refer to the tire

side wall for tire manufacturer's recommended psi and deflate

(or inflate) the tires as necessary. Use a manual pump or portable

electric tire inflator to prevent over-inflation.

NEVER USE AN AIR COMPRESSOR

Note: Equal tire pressure is to be maintained at all times for

performance purposes.

Adjustments

SkidShoe

The snow thrower skid shoes are adjusted upward at the factory

for shipping purposes. Adjust them downward, if desired, prior

to operating the snow thrower.

this snow thrower on gravel as it can easily pick up

CAUTION :It is not recommended that you operate

and throw loose gravel, causing personal injury or

damage to the snow thrower and surrounding

property.

For close snow removal on a smooth surface, raise skid

shoes higher on the auger housing.

Use a middle or lower position when the area to be cleared

is uneven, such as a gravel driveway

NOTE: If you choose to operate the snow thrower on a gravel

surface, keep the skid shoes in position for maximum clearance

between the ground and the shave plate.

Figure 3-5

8 I SECTION3 -- ASSEMBLY& SET-UP

Chute Clean-out Tool

with steel skid shoes may result in damage to

CAUTION: Operating a snow thrower equipped

natural stone paver surfaces (e.g. sandstone,

-- bluestone, limestone). Refer to the Replacement

To adjust the skid shoes:

1. Loosen the four hex nuts (two on each side) and carriage

2. Make certain the entire bottom surface of skid shoe is

3. Retighten nuts and bolts securely.

Parts or Attachments & Accessories sections for

information on available polymer skid shoes.

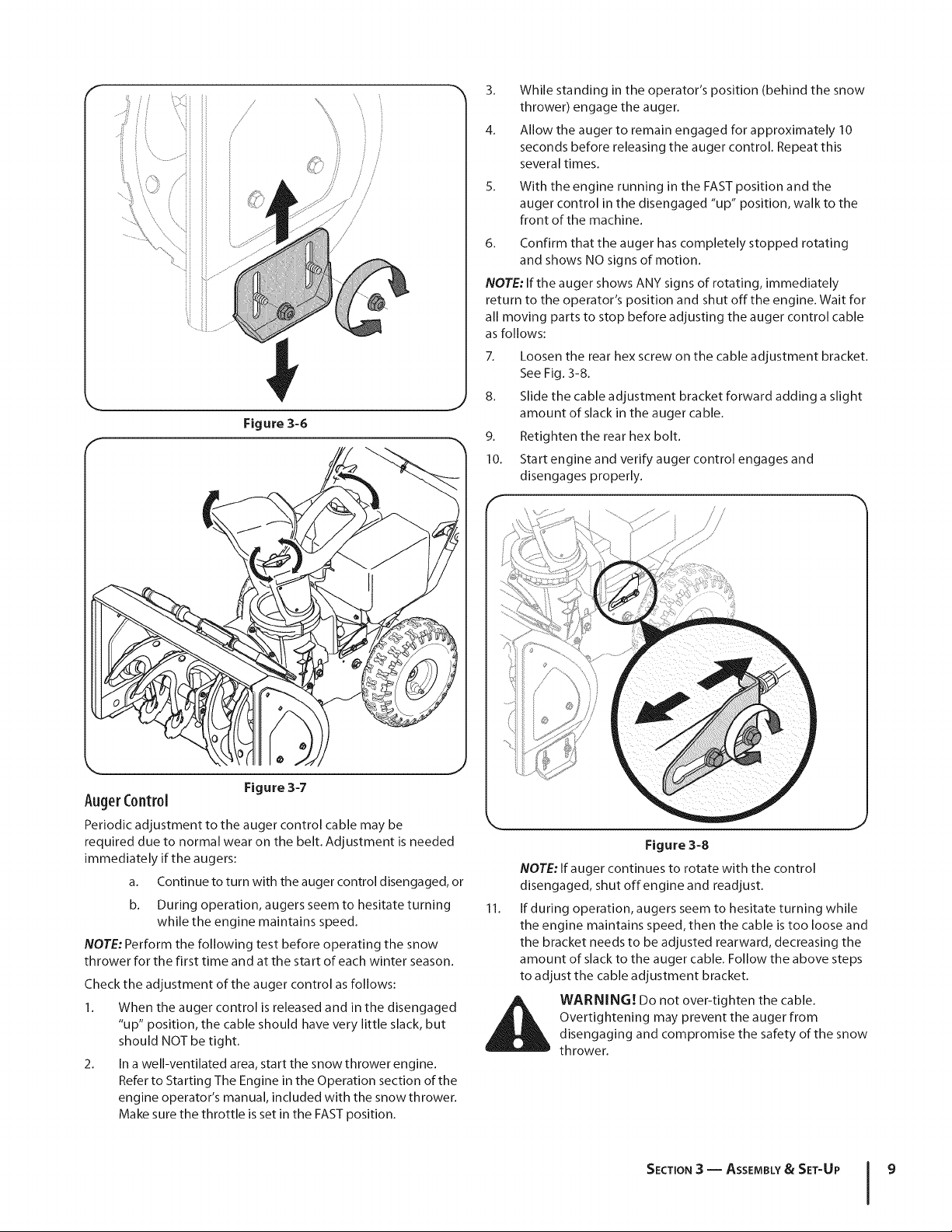

bolts. Move skid shoes to desired position. See Fig. 3-6.

against the ground to avoid uneven wear on the skid shoes.

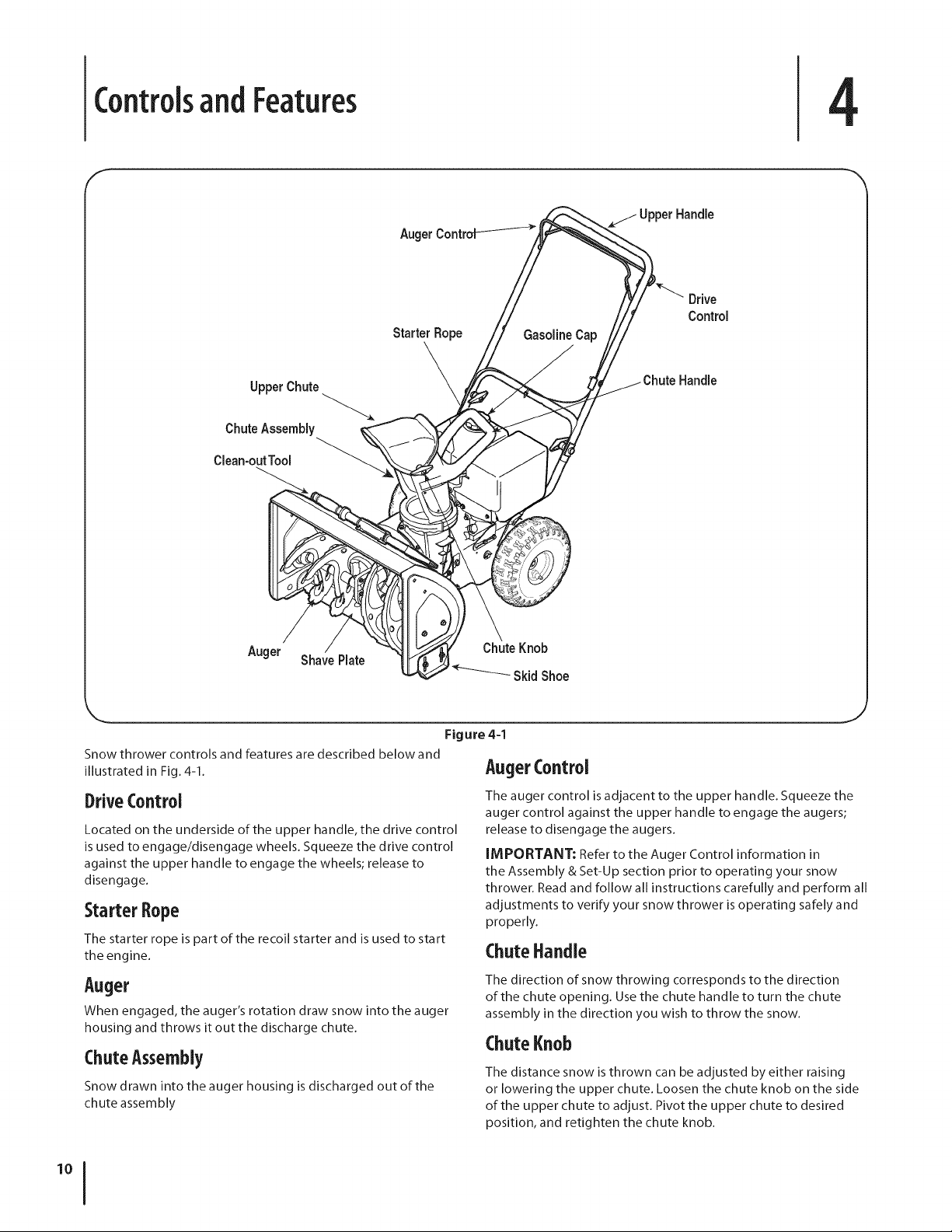

DischargeChute

I. Loosen the wing knob on the upper chute, adjust chute

and chute control to desired operating position.

2. Tighten the wing knob on the upper chute making sure the

carriage bolt is correctly positioned. Refer to Fig. 3-7.

Page 9

f

3. While standing in the operator's position (behind the snow

thrower) engage the auger.

4. Allow the auger to remain engaged for approximately 10

seconds before releasing the auger control. Repeat this

several times.

5,

With the engine running in the FASTposition and the

auger control in the disengaged "up" position, walk to the

front of the machine.

6. Confirm that the auger has completely stopped rotating

and shows NO signs of motion.

NOTE: If the auger shows ANY signs of rotating, immediately

return to the operator's position and shut off the engine. Wait for

all moving parts to stop before adjusting the auger control cable

as follows:

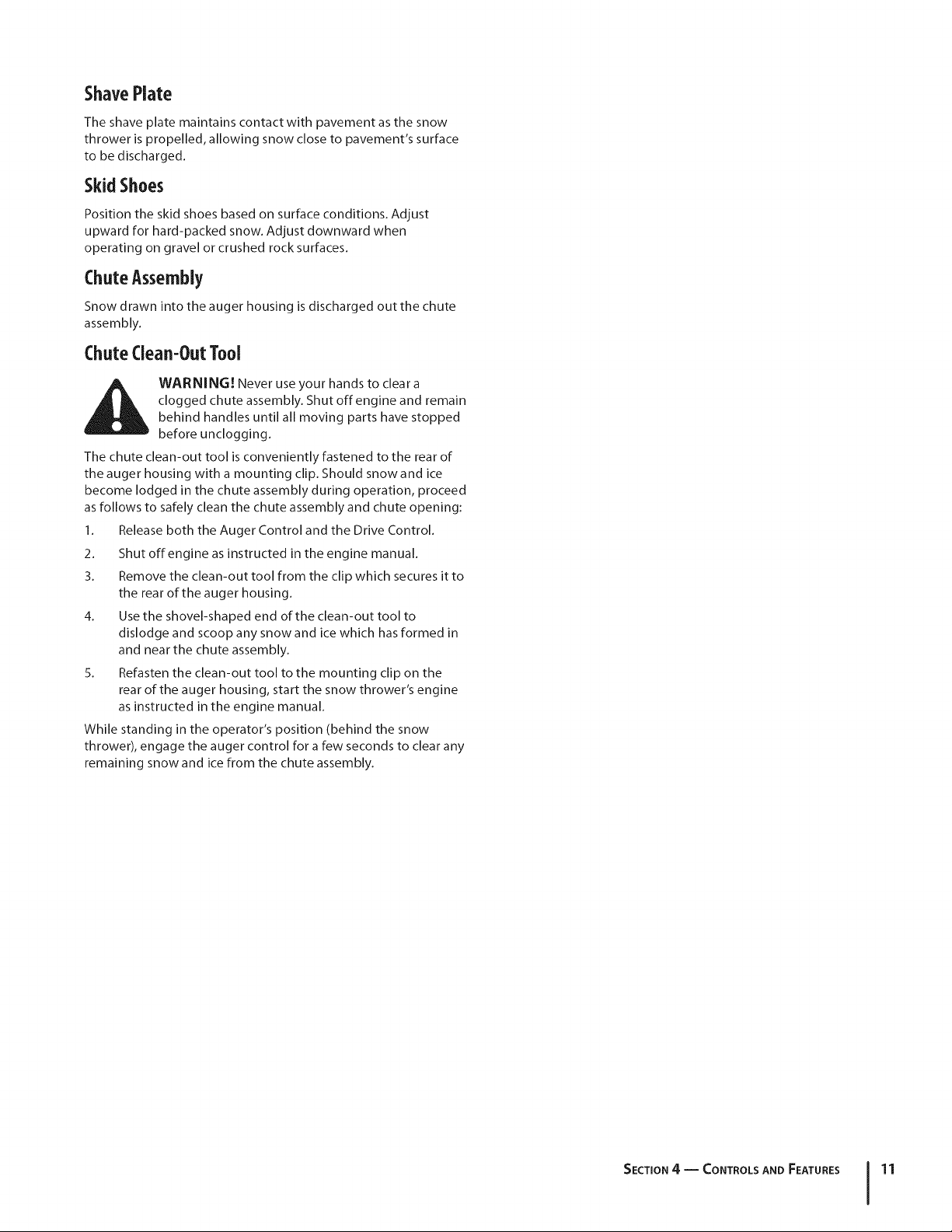

7. Loosen the rear hex screw on the cable adjustment bracket.

See Fig. 3-8.

8. Slide the cable adjustment bracket forward adding a slight

Figure 3=6

amount of slack in the auger cable.

9. Retighten the rear hex bolt.

10. Start engine and verify auger control engages and

disengages properly.

Figure 3-7

AugerControl

Periodic adjustment to the auger control cable may be

required due to normal wear on the belt. Adjustment is needed

immediately if the augers:

a. Continue to turn with the auger control disengaged, or

b. During operation, augers seem to hesitate turning

while the engine maintains speed.

NOTE: Perform the following test before operating the snow

thrower for the first time and at the sta rt of each winter season.

Check the adjustment of the auger control as follows:

1. When the auger control isreleased and in the disengaged

"up" position, the cable should have very little slack, but

should NOTbe tight.

2. Ina well-ventilated area,start the snow thrower engine.

Referto Starting The Engine in the Operation section of the

engine operator's manual, included with the snow thrower.

Make sure the throttle is set in the FASTposition.

Figure 3-8

NOTE: If auger continues to rotate with the control

disengaged, shut off engine and readjust.

11. If during operation, augers seem to hesitate turning while

the engine maintains speed, then the cable is too loose and

the bracket needs to be adjusted rearward, decreasing the

amount of slack to the auger cable. Follow the above steps

to adjust the cable adjustment bracket.

Overtightening may prevent the auger from

WARNING! Do not over-tighten the cable.

disengaging and compromise the safety of the snow

thrower.

SECTION 3 -- ASSEMBLY& SET-UP 9

Page 10

ControlsandFeatures

Auger

StarterRope

4

S UpperHandle

Drive

Control

Gasoline Cap

Upper Chute

Chute Assembly

Clean-outTool

Auger Shave Plate

Snow thrower controls and features are described below and

illustrated in Fig. 4-1.

Drive Control

Located on the underside of the upper handle, the drive control

is used to engage/disengage wheels. Squeeze the drive control

against the upper handle to engage the wheels; release to

disengage.

Starter Rope

The starter rope is part of the recoil starter and is used to start

the engine.

Auger

When engaged, the auger's rotation draw snow into the auger

housing and throws it out the discharge chute.

ChuteAssembly

Snow drawn into the auger housing is discharged out of the

chute assembly

Handle

ChuteKnob

SkidShoe

J

Figure 4-1

AugerControl

The auger control is adjacent to the upper handle. Squeeze the

auger control against the upper handle to engage the augers;

release to disengage the augers.

IMPORTANT: Refer to the Auger Control information in

the Assembly & Set-Up section prior to operating your snow

thrower. Read and follow all instructions carefully and perform all

adjustments to verify your snow thrower is operating safely and

properly.

ChuteHandle

The direction of snow throwing corresponds to the direction

of the chute opening. Use the chute handle to turn the chute

assembly in the direction you wish to throw the snow.

ChuteKnob

The distance snow is thrown can be adjusted by either raising

or lowering the upper chute. Loosen the chute knob on the side

of the upper chute to adjust. Pivot the upper chute to desired

position, and retighten the chute knob.

Page 11

ShavePlate

The shave plate maintains contact with pavement as the snow

thrower is propelled, allowing snow close to pavement's surface

to be discharged.

SkidShoes

Position the skid shoes based on surface conditions. Adjust

upward for hard-packed snow. Adjust downward when

operating on gravel or crushed rock surfaces.

ChuteAssembly

Snow drawn into the auger housing is discharged out the chute

assembly.

ChuteClean-OutTool

clogged chute assembly. Shut off engine and remain

WARNING! Never use your hands to clear a

behind handles until all moving parts have stopped

before unclogging.

The chute clean-out tool is conveniently fastened to the rear of

the auger housing with a mounting clip. Should snow and ice

become lodged in the chute assembly during operation, proceed

as follows to safely clean the chute assembly and chute opening:

1. Release both the Auger Control and the Drive Control.

2. Shut off engine as instructed in the engine manual.

3. Remove the clean-out tool from the clip which secures it to

the rear of the auger housing.

4. Use the shovel-shaped end of the clean-out tool to

dislodge and scoop any snow and ice which has formed in

and near the chute assembly.

5. Refasten the clean-out tool to the mounting clip on the

rear of the auger housing, start the snow thrower's engine

as instructed in the engine manual.

While standing in the operator's position (behind the snow

thrower), engage the auger control for a few seconds to clear any

remaining snow and ice from the chute assembly.

SECTION 4 -- CONTROLS AND FEATURES 11

Page 12

Operation

Starting TheEngine

Refer to the Operation section of the engine operator's manual

included with the snow thrower.

ToEngageDrive

Move the throttle control into the Fast (rabbit) position.

2.

To engage the drive, squeeze the drive control completely

against the upper handle to engage the wheels. To stop

the forward motion, release the drive control.

ToEngageAugers

1. To engage the augers, squeeze the auger control handle

completely against the upper handle. To stop the augers,

release handle.

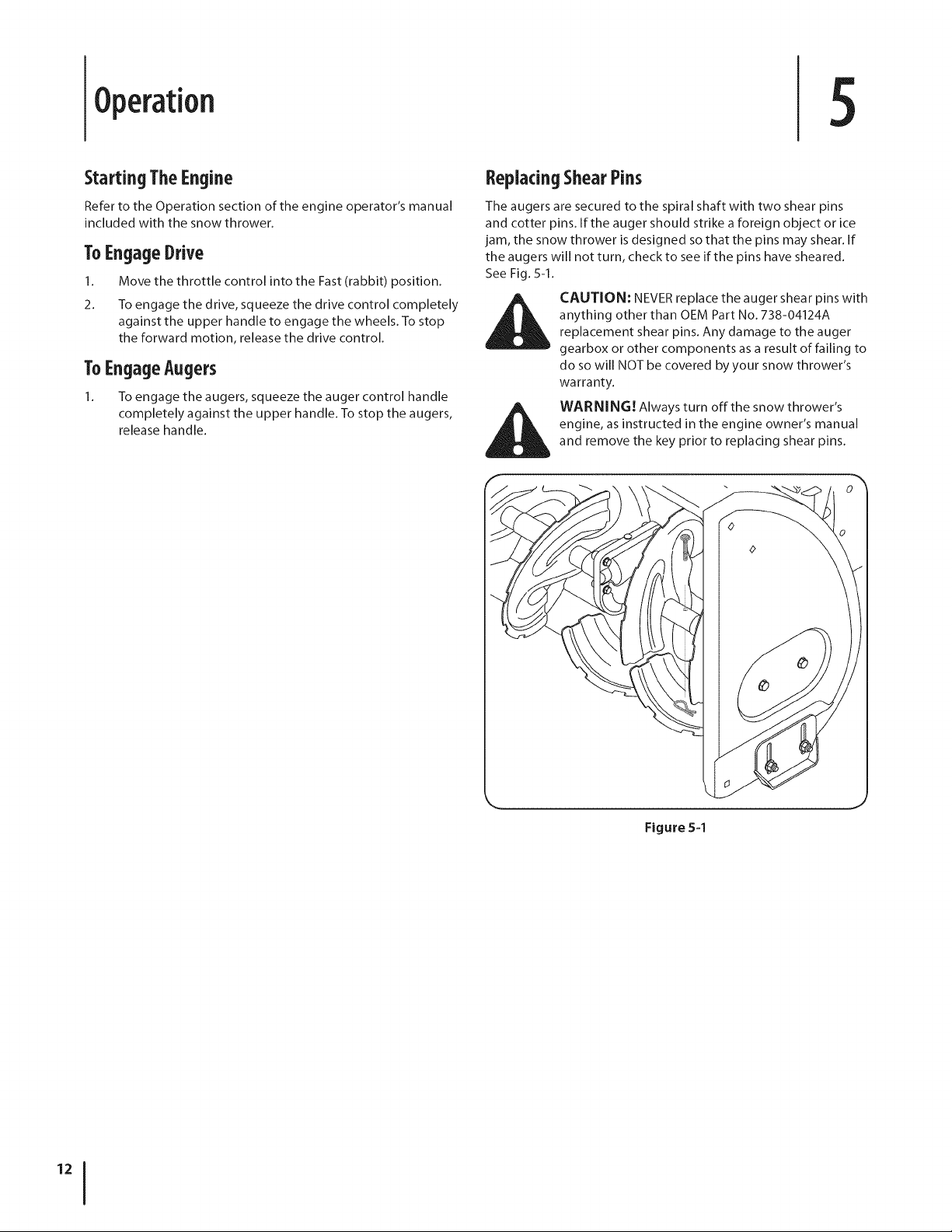

ReplacingShearPins

The augers are secured to the spiral shaft with two shear pins

and cotter pins. If the auger should strike a foreign object or ice

jam, the snow thrower is designed so that the pins may shear. If

the augers will not turn, check to see if the pins have sheared.

See Fig. 5-1.

anything other than OEM Part No. 738-04124A

CAUTION: NEVER replace the auger shear pins with

replacement shear pins. Any damage to the auger

gearbox or other components as a result of failing to

do so will NOT be covered by your snow thrower's

warranty.

engine, as instructed in the engine owner's manual

WARNING! Always turn off the snow thrower's

and remove the key prior to replacing shear pins.

Figure 54

Page 13

Maintenance&Adjustments

Maintenance

GeneralRecommendations

Always observe safety rules when performing any type of

maintenance.

The warranty on this snow thrower does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from the warranty, operator must

maintain the snow thrower as instructed in this manual.

Periodically check all fasteners and hardware to make sure

these are tight.

or inspecting, disengage all controls and stop

i_i WARNING! Before servicing, repairing, lubricating,

Engine

IMPORTANT: Refer to the engine operator's manual included

with the snow thrower for complete oil servicing instructions.

TirePressure

Refer to Setup in the Assembly and Setup section of this manual

for the pressure instructions.

If the tire pressure is not equal in both tires, the unit may pull to

one side or the other.

CheckV-Belts

Follow instructions below to check condition of drive belts every

50 hours of operation.

1. Remove the plastic belt cover on the front of the engine by

2_

engine. Wait until all moving parts have come to a

complete stop. Disconnect spark plug wire and

ground it against the engine to prevent unintended

starting. Always wear safety glasses during

operation or while performing any adjustments or

repairs.

removing the self-tapping screw and pressing the plastic

tabs to release the belt cover. See Fig. 7-1 in the Service

section of this manual.

Visually inspect for frayed, cracked, or excessively worn out

belts. Replace, if necessary, following instructions in the

Service section of this manual.

ShavePlateandSkidShoes

The shave plate and skid shoes on the bottom of the snow

thrower are subject to wear. These should be checked

periodically and replaced when necessary.

To replace skid shoes:

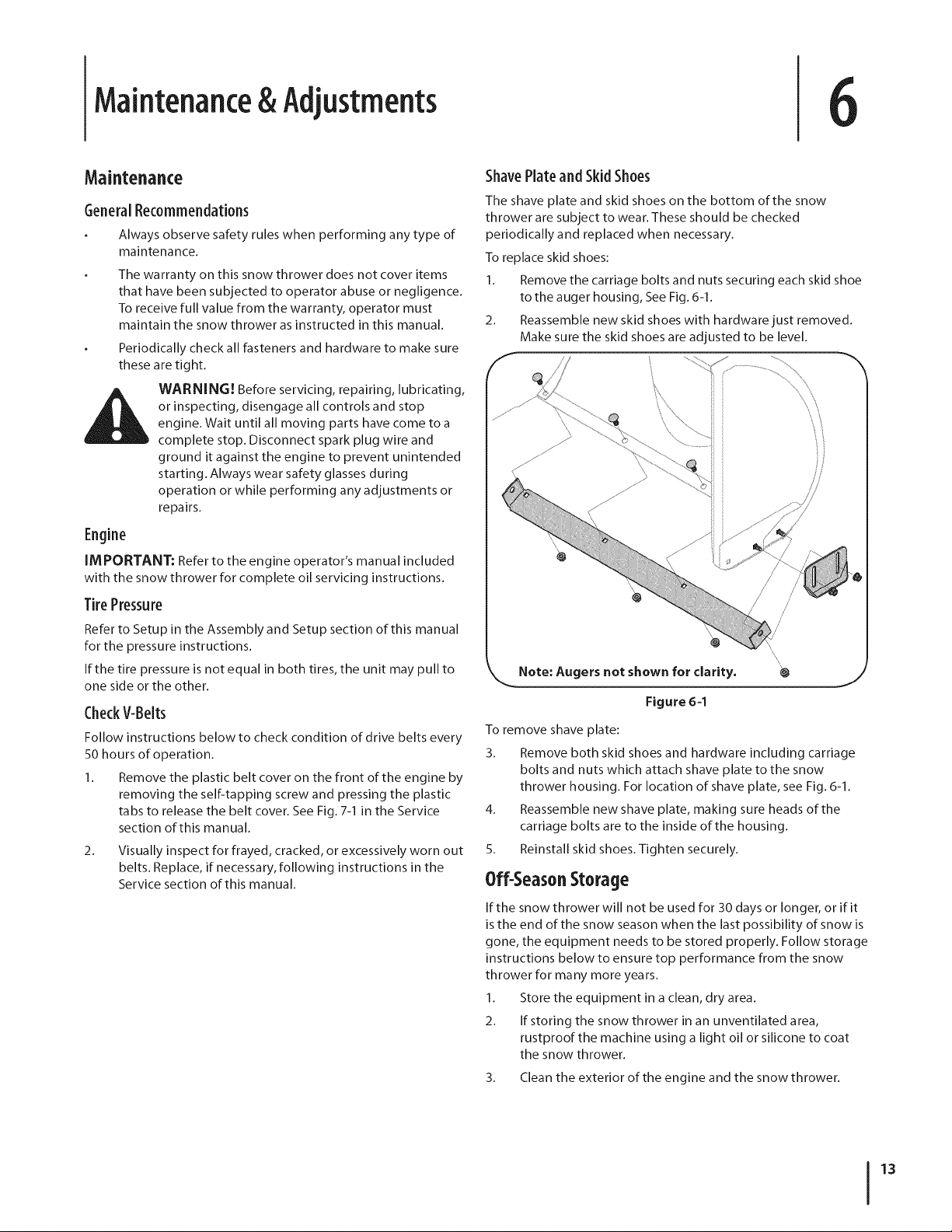

1. Remove the carriage bolts and nuts securing each skid shoe

to the auger housing, See Fig. 6-1.

2. Reassemble new skid shoes with hardware just removed.

Make sure the skid shoes are adjusted to be level.

F

jJJJ ii

\

/

/

/

/'

Note: Augers not shown for clarity. _ j

Figure 6-1

To remove shave plate:

3. Remove both skid shoes and hardware including carriage

bolts and nuts which attach shave plate to the snow

thrower housing. For location of shave plate, see Fig. 6-1.

4. Reassemble new shave plate, making sure heads of the

carriage bolts are to the inside of the housing.

5. Reinstall skid shoes. Tighten securely.

Off-SeasonStorage

If the snow thrower will not be used for 30 days or longer, or if it

is the end of the snow season when the last possibility of snow is

gone, the equipment needs to be stored properly. Follow storage

instructions below to ensure top performance from the snow

thrower for many more years.

1. Store the equipment in a clean, dry area.

2. If storing the snow thrower in an unventilated area,

rustproof the machine using a light oil or silicone to coat

the snow thrower.

3. Clean the exterior of the engine and the snow thrower.

13

Page 14

Preparing TheEngine

IMPORTANT: Refer to the engine operator's manual

included with the snow thrower for complete engine servicing

instructions.

WARNING! Never store the snow thrower with fuel

in the tank indoors or in poorly ventilated areas,

where fuel fumes may reach an open flame, spark or

pilot light ason a furnace, water heater, clothes

dryer orgas appliance.

PreparingTheSnowThrower

1. When storing the snow thrower in an unventilated or

metal storage shed,care should be taken to rustproof the

equipment. Using a light oil or silicone, coat the equipment,

especially any chains, springs, bearings and cables.

2. Remove all dirt from exterior of engine and equipment.

3. Follow lubrication recommendations in the Maintenance

section of this manual.

4. Store equipment in a clean, dry area.

Lubrication

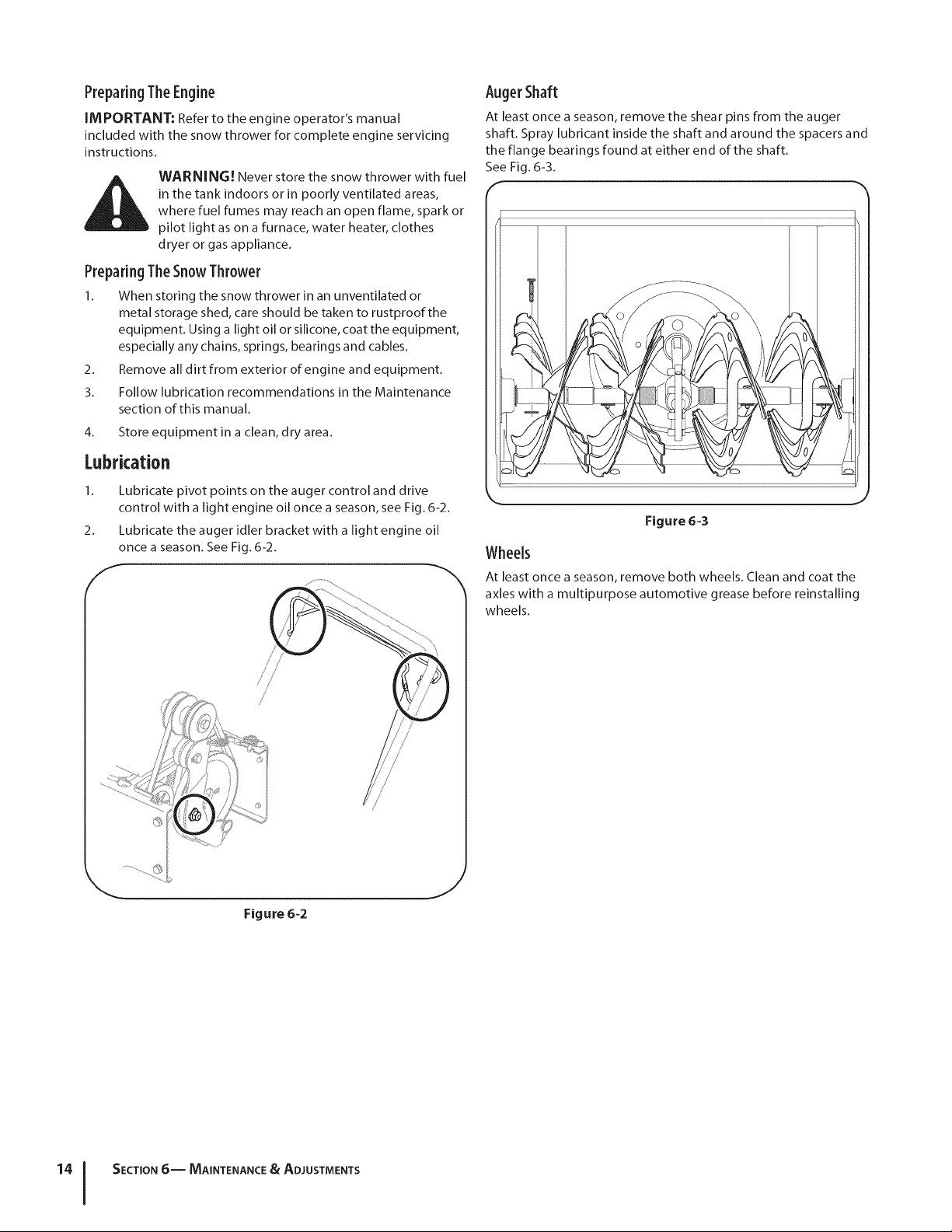

AugerShaft

At least once a season, remove the shear pins from the auger

shaft. Spray lubricant inside the shaft and around the spacers and

the flange bearings found at either end of the shaft.

See Fig. 6-3.

I O_ro _o S

I

1. Lubricate pivot points on the auger control and drive

control with a light engine oil once aseason, see Fig. 6-2.

2. Lubricate the auger idler bracket with a light engine oil

once a season. See Fig.6-2.

f

Figure 6-2

k

Figure 6-3

J

Wheels

At least once a season, remove both wheels. Clean and coat the

axles with a multipurpose automotive grease before reinstalling

wheels.

J

SECTION 6-- MAINTENANCE & ADJUSTMENTS

Page 15

Service

7

Augers

The augers are secured to the spiral shaft with four shear pins and

cotter pins. If you hit a foreign object or ice jam, the snow thrower

is designed so that the pins may shear. Refer to Fig. 5-1.

If the augers do not turn, check if the pins have sheared. Replace,

if needed, with proper shear pins. Refer to Parts List for correct

part number.

CAUTION: NEVER replace the auger shear pins with

standard pins or fasteners. Any damage to the auger

gearbox or other components, as a result of doing

so, will NOT be covered by your snow thrower's

warranty.

Replacing Belts

1. Allow the engine to run until it is out of fuel. Do not

attempt to pour fuel from the engine

2. Remove the key to prevent accidental starting.

3. Remove the self-tapping screw shown in Fig. 7-1, and press

the plastic tabs to release the belt cover. Pull the belt cover

up and out from around the engine and chute assembly.

Set it aside and save.

f .........

AugerBelt

1. Tip the snow thrower up and forward so that it rests on

the auger housing. Remove the belt keeper (Refer to Fig.

7-3). Return the snow thrower to its upright position to

complete the following steps.

2. Slip the front auger belt off of the engine pulley, pushing it

forward and rolling in off of the pulley. See Fig. 7-2.

Auger Belt

Figure 7-1

Figure 7-2

/

3. Squeeze the auger control handle to release the auger

brake, which is the tab that holds the belt onto the auger

pulley. Remove the belt.

4. Replace with new belt after replacing the drive belt.

J

15

Page 16

DriveBelt

NOTE: Replace the drive belt before reassembling the new auger

belt.

1.

Tip the snow thrower up and forward so that it rests on the

auger housing.

2.

Remove the spring that connects the transmission to a bolt

on the engine frame. See Fig. 7-3.

NOTE: It may be easier to first remove the flange lock nut,

then use needle-nosed pliers to firmly grip spring and

remove from bolt.

Spring

Belt Kee

Figure 7-3

3.

Pivot the transmission forward to release pressure on the

drive belt. Remove belt from transmission pulley.

4.

Remove the drive belt from around the engine pulley, and

away from the unit.

5.

Place the new drive belt on the engine pulley. See Fig. 7-2.

6.

Tilt the transmission forward and position the drive belt

onto the transmission pulley.

7.

Reconnect the spring to the bolt on the engine frame and

secure the transmission. Reinstall the flange lock nut.

8.

Install new auger belt.

9.

Reassemble the belt cover on the snow thrower

10.

Reassemble the belt keeper to the housing.

'°1

SECTION7-- SERVICE

Page 17

Troubleshooting

Problem Cause Remedy

Unit fails to self-propel

Unit fails to discharge snow

1. Drive belt loose or damaged.

2. Single speed transmission damaged.

1. Chute assembly clogged.

2. Shear pin(s) sheared.

3. Foreign object lodged in auger.

4. Auger control cable out of adjustment.

5. Auger belt loose or damaged.

1. Replace drive belt.

2. See an Authorized Service Dealer.

1. Stop engine and disconnect spark plug wire.

Clean chute and inside of auger housing with

clean-out tool or stick.

2. Replace shear pin(s).

3. Stop engine immediately and disconnect the

spark plug wire. Remove object from auger.

4. Adjust auger control cable.

5. Replace auger belt.

IMPORTANT: Refer to the engine operator's manual included with the snow thrower for engine troubleshooting instructions.

NOTE: For repairs beyond the minor adjustments listed above, contact your nearest authorized service representative or ca II1-800-800-7310

for the Customer Support Center. Refer to the engine manual packed separately with your snow thrower, for complete engine related

information.

17

Page 18

ReplacementParts

Component l Part Number and Description

9

954-04014 Auger Drive Belt

954-04013 Wheel Drive Belt

738-04124A

714-04040

784-5580

731-06439

931-2643

790-00117 Shave Plate, 22"

Shear Pin, 1.50

Bow-tie Cotter Pin

Skid Shoe, Standard (steel)

Skid Shoe, Standard (Polymer)

Chute Clean-out Tool

Phone (800) 800-7310 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready).

Parts Manual downloads are also available free of charge at www.mtdproducts.com.

Page 19

MTD CONSUMER GROUP INC (MTD), the California Air Resources Board (CARB)

and the United States Environment Protection Agency (U. S. EPA)

Emission Control System Warranty Statement

(Owner's Defect Warranty Rights and Obligations)

EMISSIONCONTROLSYSTEMCOVERAGEISAPPLICABLETOCERTIFIEDENGINESPURCHASEDINCALIFORNIAIN2005ANDTHERE-

AFTER,WHICHAREUSEDINCALIFORNIA,ANDTOCERTIFIEDMODELYEAR2005ANDLATERENGINESWHICHAREPURCHASEDAND

USEDELSEWHEREINTHEUNITEDSTATES.

Californiaandelsewherein theUnitedStatesEmissionControlDefectsWarrantyCoverage

TheCaliforniaAir ResourcesBoard(CARB),U.S. EPAandMTDarepleasedtoexplaintheemissionscontrolsystemwarrantyonyour modelyear

2006andlatersmalloff-roadengine.InCalifornia,newsmalloff-roadenginesmustbe designed,builtandequippedtomeettheStatesanti-smog

standards.ElsewhereintheUnitedStates,newnon-road,spark-ignitionenginescertifiedfor model2005andlater,mustmeetsimilarstandardsset

forthbytheU.S.EPA.MTDmustwarrantytheemissioncontrolsystemonyourengineforthe periodoftimelistedbelow,providedtherehasbeen

noabuse,neglectorimpropermaintenanceofyour smalloff-roadengine.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,theignitionsystem,andcatalyticconverter,fueltanks,

fuellines,fuelcaps,valves,canisters,filters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,MTDwillrepairyoursmalloff-roadengineat nocosttoyourincludingdiagnosis,partsandlabor.

MANUFACTURER'S WARRANTY COVERAGE:

Thisemissionscontrolsystemiswarrantedfor twoyears.If anyemission-relatedpartonyourengineisdefective,thepartwillberepairedor

replacedbyMTD.

OWNER'S WARRANTY RESPONSIBILITIES:

Asthesmalloff-roadengineowner,youareresponsibleforthe performanceofthe requiredmaintenancelistedinyourOwner'sManual.MTD

recommendsthatyouretainallyourreceiptscoveringmaintenanceson yoursmalloff-roadengine,butMTDcannotdenywarrantysolelyforthe

lackofreceiptsorforyour failureto ensuretheperformancetoallscheduledmaintenance.

Asthesmalloff-roadengineowner,youshouldhoweverbeawarethatMTDmaydenyyourwarrantycoverageif yoursmalloff-roadengineorpart

hasfailedduetoabuse,neglect,impropermaintenanceor unapprovedmodifications.

Youare responsibleforpresentingyoursmalloff-roadenginetoan AuthorizedMTDServiceDealerassoonasa problemexists.Thewarranted

repairsshouldbe completedina reasonableamountof time,nottoexceed30 days.

Ifyouhaveanyquestionsregardingyourwarrantyrightsandresponsibilities,you shouldcontacta MTDServiceRepresentativeat 1-800-800-7310

andaddressisMTDCONSUMERGROUP,RO.Box361131,ClevelandOH,44136-0019.

DEFECTS WARRANTY REQUIREMENTS FOR 1995 AND LATER SMALL OFF-ROAD ENGINES:

Thissectionappliesto 1995andlatersmalloff-roadengines.Thewarrantyperiodbeginsonthedatetheengineorequipmentisdeliveredtoan

ultimatepurchaser.

(a) GeneralEmissionsWarrantyCoverage

MTDmustwarranttotheultimatepurchaserandeachsubsequentpurchaserthattheengineis:

(1)Designed,built,andequippedsoas to conformwithallapplicableregulationsadoptedbytheAirResourcesBoardpursuantto itsauthorityin

Chapters1and2,Part5,Division26of theHealthandSafetyCode;and

(2) Freefromdefectsin materialsandworkmanshipthatcausethefailureofa warrantedpartto beidenticalinall materialrespectstothepartas

describedin theenginemanufacturer'sapplicationforcertificationfora periodof twoyears.

(b)Thewarrantyonemissions-relatedpartswillbe interpretedasfollows:

(1)Anywarrantedpartthatisnot scheduledforreplacementas requiredmaintenanceinthewritteninstructionsrequiredbySubsection(c)

mustbewarrantedforthe warrantyperioddefinedinSubsection(a)(2).Ifanysuchpartfailsduringtheperiodof warrantycoverage,it mustbe

repairedor replacedbyMTDaccordingtoSubsection(4)below.Anysuchpartrepairedor replacedunderthewarrantymustbewarrantedfor

theremainingwarrantyperiod.

(2)Anywarrantedpartthat is scheduledonlyfor regularinspectioninthewritteninstructionsrequiredbySubsection(c)mustbewarrantedfor

thewarrantyperioddefinedin Subsection(a)(2).A statementinsuchwritteninstructionstotheeffectof "repairorreplaceasnecessary"will

notreducetheperiodofwarrantycoverage.Anysuchpartrepairedorreplacedunderwarrantymustbewarrantedfortheremainingwarranty

period.

(3) Anywarrantedpartthat whichisscheduledfor replacementas requiredmaintenancein the writteninstructionsrequiredby Subsection(c)

mustbewarrantedforthe periodoftimepriortothefirstscheduledreplacementpointforthatpart.Ifthepartfailspriorto thefirstscheduled

replacement,thepartmustberepairedor replacedbyMTDaccordingtoSubsection(4) below.Anysuchpart repairedor replacedunder

warrantymustbewarrantedfortheremainderoftheperiodpriortothefirstscheduledreplacementpointfor thepart.

Page 20

(4)Repairorreplacementofanywarrantedpartunderthewarrantyprovisionsofthisarticlemustbeperformedatnochargetotheownerata

warrantystation.

(5)NotwithstandingtheprovisionsofSubsection(4)above,warrantyservicesorrepairsmustbeprovidedatallMTDdistributioncentersthat

arefranchisedtoservicethesubjectengines.

(6)Theownermustnotbechargedfordiagnosticlaborthatleadstothedeterminationthatawarrantedpartisinfactdefective,providedthat

suchdiagnosticworkisperformedatawarrantystation.

(7)Theenginemanufacturerisliablefordamagestootherenginecomponentsproximatelycausedbyafailureunderwarrantyofanywarranted

part.

(8)Throughouttheengine'swarrantyperioddefinedinSubsection(a)(2),MTDwillmaintainasupplyofwarrantedpartssufficienttomeetthe

expecteddemandforsuchparts.

(9)Anyreplacementpartmaybeusedintheperformanceofanywarrantymaintenanceorrepairsandmustbeprovidedwithoutchargetothe

owner.SuchusewillnotreducethewarrantyobligationsofMTD.

(10)Add-onormodifiedpartsthatarenotexemptedbytheAirResourcesBoardmaynotbeused.Theuseofanynon-exemptedadd-onor

modifiedpartsshallbegroundsfordisallowingawarrantyclaimmadeinaccordancewiththisarticle.Theenginemanufacturershallnotbe

liableunderthisarticletowarrantfailuresofwarrantedpartscausedbytheuseofnon-exemptedadd-onormodifiedpart.

(c)MTDwillincludea copyofthefollowingemissionwarrantypartslistwitheachnewengine,usingthoseportionsofthe listapplicabletothe

e__&gine.

(1)FuelMeteringSystem

•Coldstartenrichmentsystem(softchoke)

,,Carburetorandinternalparts

•Fuel Pump

•FuelTank

(2)AirInductionSystem

•Aircleaner

•Intakemanifold

(3) IgnitionSystem

•Sparkplug(s)

•MagnetoIgnitionSystem

(4)ExhaustSystem

Catalyticconverter

•SAI (Reedvalve)

(5) MiscellaneousItemsUsedin AboveSystem

Vacuum,temperature,position,timesensitivevalvesand switches

Connectorsandassemblies

(6) Evaporativecontrol

•Fuel HosecertifiedforARBevaporativeemissionof2006.

•Fuel HoseClamps

Tetheredfuelcap

Carboncanister

Vaporlines

GD0C-100174Rev.B

Page 21

MANUFACTURER'S LiMiTED WARRANTY FOR

The limited warranty set forth below is given by MTD LLCwith

respect to new merchandise purchased andused in the United States

and/or its territories and possessions, and by MTD Products Limited

with respectto new merchandise purchased and used in Canadaand/

or its territories and possessions (either entity respectively, "MTD").

"MTD" warrants this product (excluding its Normal WearParts and

Attachments as described below) against defects in material and

workmanship for a period of two (2) years commencing onthe date

of original purchase and will, at its option, repair or replace, free of

charge, any part found to be defective in materials or workmanship.

This limited warranty shall only apply if this product has been

operated and maintained in accordance with the Operator's Manual

furnished with the product, and has not beensubject to misuse,

abuse, commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water, or damage because of other

peril or natural disaster. Damage resulting from the installation or use

of any part, accessory or attachment not approved by MTD for use

with the product(s) covered by this manual will void your warranty as

to any resulting damage.

Normal WearPartsarewarranted to befree from defects in material

andworkmanship for a period of thirty (30) days from the date of

purchase. Normal wear parts include, but are not limited to items

such as: batteries, belts, blades, blade adapters, tines, grass bags,

wheels, rider deck wheels, seats, snow thrower skid shoes,friction

wheels, shaveplates, auger spiral rubber, engine oil, air filters, spark

plugs andtires.

Attachments-- MTD warrants attachments for this product against

defects in material and workmanship for a period of one (1) year,

commencing on the date of the attachment's original purchase or

lease.Attachments include, but are not limited to items such as:

grass collectors and mulch kits.

HOWTO OBTAINPARTSANDSERVICE:Warranty service is available,

WITH PROOFOFPURCHASE,through your localauthorized service

dealer.To locate the dealer in your area:

In the U.S.A.

Checkyour Yellow Pages,or contact MTD LLC at RO. Box 361131,

Cleveland, Ohio 44136-0019, or call 1-800-800-7310, 1-330-220-

4683 or log on to our Web site at www.mtdproducts.com.

In Canada

Contact MTD Products Limited, Kitchener, ON N2G4J1, or call 1-800-

668-1238 or log on to our Web site atwww.mtdcanada.com.

This limited warranty does not provide coverage in the following

cases:

a.

Log splitter pumps, valves, and cylinders havea separate one-

yearwarranty.

b.

Routine maintenance items such as lubricants, filters, blade

sharpening, tune-ups, brake adjustments, clutch adjustments,

deck adjustments, and normal deterioration of the exterior finish

dueto use or exposure.

c. Service completed by someone other than an authorized service

dealer.

d. MTD does not extend any warranty for products sold or exported

outside of the United States and/or Canada,andtheir respective

possessions and territories, except those sold through MTD's

authorized channels of export distribution.

e. Replacement parts that are not genuine MTD parts.

f. Transportation charges andservice calls.

g. MTD does not warrant this product for commercial use.

No implied warranty, includingany implied warranty of

merchantability or fitness for a particular purpose,applies after

the applicable periodof express written warranty above as to the

parts as identified. No other express warranty, whether written or

oral, except as mentioned above, given by any person or entity,

includinga dealer or retailer, with respect to any product,shall

bind MTD. Duringthe period of the warranty, the exclusive remedy

is repair or replacement of the product as set forth above.

The provisions as set forth inthis warranty providethe sole and

exclusive remedy arising from the sale. MTD shall not be liable

for incidental orconsequential loss or damage including, without

limitation, expenses incurred for substitute or replacement lawn

careservices or for rental expenses to temporarily replace a

warranted product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages,or limitations on how long an implied

warranty lasts, sothe above exclusions or limitations may not apply

to you.

In no event shall recovery of any kind begreater than the amount of

the purchase price of the product sold. Alteration of safety features of

the product shall void this warranty. You assume the risk and liability

for loss, damage, or injury to youand your property and/or to others

andtheir property arising out of the misuse or inability to use the

product.

This limited warranty shall not extend to anyone otherthan the

original purchaser or to the person for whom it was purchased as a

gift.

HOWSTATELAW RELATESTOTHISWARRANTY: This limited

warranty givesyou specific legal rights, and you may also haveother

rights which vary from state to state.

IMPORTANT:Owner must present Original Proof of Purchase to

obtain warranty coverage.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1=800=800=7310, 1=330=220-4683

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

GDOC-100016REV. C

Page 22

Medidas importantes de seguridad • Configuraci6n • Funcionamiento • Mantenimiento • Servicio •

Soluci6n de problemas • Garantia

ANUAL EL

M_quina quitanieve de dos etapas m Serie 300

lVITD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

ImpresoenEstadosUnidosdeAm_rka

Page 23

A!propietario

Gracias

Gracias por comprar una m_quina quitanieve fabricada por MTD

LLC. La misma ha sido diseffada cuidadosamente para brindar

excelente rendimiento si se la opera y mantiene correctamente.

Pot favor lea todo este manual antes de operar el equipo.

Le indica c6mo configurar, operar y mantener la m_quina

con seguridad y f_cilmente. Pot favor asegurese de seguir

cuidadosamente yen todo momento las pr_cticas de seguridad

recomendadas, y hac_rselas seguir a cualquier otra persona que

opere la m_quina. En caso de no hacerlo podrian producirse

lesiones personales o dahos materiales.

Toda la informaci6n contenida en este manual hace referencia

a la m_s reciente informaci6n de producto disponible en el

momento de la impresi6n. Revise el manual frecuentemente

para familiarizarse con la unidad, sus caracteristicas y

funcionamiento. Pot favor tenga en cuenta que este Manual

del Operador puede cubrir una gama de especificaciones de

productos de diferentes modelos. Las caracteristicas y funciones

incluidas y/o ilustradas en este manual pueden no set aplicables

a todos los modelos. MTD LLC se reserva el derecho de modificar

las especificaciones de los productos, los diseffos y el equipo

indice

Importante Medidas importantes de seguridad 24

Ensamblado y Conf_guraci6n ............................... 28

Controles y Caractefisticas .................................... 31

Funcionamiento .................................................... 33

Mantenimiento y Ajustes ...................................... 34

1

est_ndar sin previo aviso y sin generar responsabilidad pot

obligaciones de ning0n tipo.

Si tiene algun problema o duda respecto a la unidad, Ilame a un

distribuidor de servicio MTD autorizado o p6ngase en contacto

directamente con nosotros. Los n0meros de tel6fono, direcci6n

del sitio web y direcci6n postal de la Asistencia al Cliente de MTD

se encuentran en esta p_gina. Queremos garantizar su entera

satisfacci6n en todo momento.

En este manual, las referencias al lado derecho o izquierdo de la

m_quina se observan desde la posici6n del operador.

Servicio ................................................................... 36

Soluci6n de Problemas ......................................... 38

Repuestos ............................................................... 39

Garantia ......................................... Cubierta Trasera

Registrode informaci6ndeproducto

Antes de configurar y operar su equipo nuevo, pot favor Iocalice

la placa del modelo en el equipo y registre la informaci6n en

el _rea situada a la derecha. Para encontrar la placa de modelo,

col6quese detr_s de la unidad en la posici6n del operador y mire

hacia la parte inferior de la secci6n trasera del chasis. Si tiene

que solicitar soporte t_cnico a trav_s de nuestro sitio web, el

Departamento de Asistencia al Cliente, o de un distribuidor de

servicio autorizado local, necesitar_ esta informaci6n.

_OMERO DE MODELO

DDDDDDDDDDD

NOMERO DE SERIE

DDDDDDDDDDD

Asistendaai Ciiente

Por favor,NOdevuelva la unidad al minorista o distfibuidorsinponerse en contacto pfimero con elDepartamento de

Asistencia al Cliente.

En caso de tener problemas para montar este producto o de tener dudas con respecto a los controles, funcionamiento o

mantenimiento del mismo, puede solicitar la ayuda de expertos. Elija entre las opdones que se presentan a continuaci6n:

0 Visite nuestro sitio web en www.mtdproducts.com

0 Llame a un representante de Asistencia al CIiente al (800) 800-7310 6 (330) 220-4683

0 Escribanos a MTD LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

Page 24

Medidas importantes de

seguridad

iADVERTENCIA! La presencia de este s[mbolo indica que se trata de instrucciones

importantes de seguridad que se deben respetar para evitar poner en peligro su seguridad

personal y/o material y la de otras personas. Lea y siga todas las instrucciones de este manual

antes de poner en funcionamiento esta m_quina. Si no respeta estas instrucdones puede

provocar lesiones personales.

Cuando yea este s[mbolo, iTENGA EN CUENTAS LAS ADVERTENCIAS!

PROPOSICION 65 DE CALIFORNIA

,_ iADVERTENCIA! El escape del motor de este producto, algunos de sus componentes y

algunos componentes del vehkulo contienen o liberan sustancias qu[micas que el estado

de California considera que pueden producir c_ncer, defectos de nacimiento u otros

problemas reproductivos.

PELIGRO: Esta m_quina est_ dise_ada para ser utilizada respetando las normas de

seguridad contenidas en este manual. AI igual que con cualquier tipo de equipo motorizado,

un descuido o error por parte del operador puede producir lesiones graves. Esta m_quina es

capaz de amputar dedos, manos y pies y de arrojar objetos extra_os con gran fuerza. De no

respetar las instrucciones de seguridad siguientes se pueden producir lesiones graves o la

muerte.

Capacitaci6n 7.

1. Lea, entienda y cumpla todas las instrucciones incluidas en

la m_iquina yen los manuales antes de montarla y utilizarla.

Guarde este manual en un lugar seguro para consultas

futuras y peri6dicas, asi como para solicitar repuestos.

2. Familiaricese con todos los controles y con el uso adecuado

de los mismos. Sepa c6mo detener la m_iquina y desactivar

los controles r_ipidamente.

3. No permita nunca que los ni_os menores de 14 ahos

utilicen esta m_fiquina. Los ni_os de 14 ahos en adelante

deben leery entender las instrucciones de operaci6n y

normas de seguridad contenidas en este manual, yen la

m_fiquina ydeben set entrenados y supervisados pot un

adulto.

4.

Nunca permita que los adultos operen esta m_quina sin

recibir antes la instrucci6n apropiada.

5.

Los objetos arrojados por la m_quina pueden producir

lesiones graves. Planifique el patr6n en el que va air

arrojando nieve para evitar que la descarga de material se

realice hacia los caminos, los observadores, etc.

6.

Mantenga a los observadores, ayudantes, mascotas y ni_os

pot Io menos a 75 pies de la m_iquina mientras la misma

est,1 en funcionamiento. Detenga la m_fiquina si alguien se

acerca.

Sea precavido para evitar patinarse o caerse especialmente

cuando opera la m_fiquina en reversa.

Preparativos

Inspeccione minuciosamente el _irea donde utilizar_i el equipo.

Saque todos los felpudos, peri6dicos, trineos, tablas, cables y

otros objetos extrahos con los que podria tropezar o que podrian

set arrojados pot la barrena / impulsor.

1. Para protegerse los ojos utilice siempre anteojos o

antiparras de seguridad mientras opera la m_iquina o

mientras la ajusta o repara. Los objetos arrojados que

rebotan pueden producir lesiones oculares graves.

2. No opere la m_fiquina sin la vestimenta adecuada para

estar al aire libre en invierno. No utilice alhajas, bufandas

largas u otras prendas sueltas que podrian enredarse en las

partes m6viles. Utilice un calzado especial para superficies

resbaladizas.

3.

Use un prolongador y un tomacorriente de tres cables con

conexi6n a tierra para todas las m_fiquinas con motores de

encendido el6ctrico.

4. Ajuste la altura de la caja del tomacorriente para limpiar la

grava o las superficies con piedras trituradas.

5. Desengrane todas las palancas de control antes de arrancar

el motor.

Page 25

6. Nuncaintenterealizarajustesmientraselmotorest_

enmarchaexceptoenloscasosespecificamente

recomendadosenelmanualdeloperador.

7. Dejequeelmotorylam_quinaseadaptenala

temperaturaexteriorantesdecomenzarasacarlanieve.

Manejo seguro de la gasolina

Para evitar lesiones personales o daffos materiales tenga mucho

cuidado cuando trabaje con gasolina. La gasolina es sumamente

inflamable y sus vapores pueden causar explosiones. Si se

derrama gasolina encima o sobre la ropa se puede lesionar

gravemente ya que se puede incendiar. L_vese la piel y c_mbiese

de ropa de inmediato.

a. Utilice s61o los recipientes para gasolina autorizados.

b. Apague todos los cigarrillos, cigarros, pipas y otras

fuentes de combustidn.

c. Nunca cargue combustible en la m_quina en un

espacio cerrado.

d. Nunca saque la tapa del combustible ni agregue

combustible mientras el motor est_ caliente o en

ma rcha.

e. Deje que el motor seenfrie por Io menos dos

minutos antes de volver a cargar combustible.

f. Nunca Ilene en exceso el depdsito de combustible.

Llene el tanque a no m_s de 1/2pulgada por debajo

de la base del cuello de Ilenado dejando espacio

para la dilatacidn del combustible.

g. Vuelva a colocar la tapa de la gasolina y ajOstela

bien.

h. Limpie el combustible que se haya derramado sobre

el motor y el equipo. Traslade la m_quina a otra

zona. Espere 5 minutos antes de encender el motor.

i. Nunca almacene la m_quina o el recipiente de

combustible en un espacio cerrado donde haya

fuego, chispas o luz piloto (pot ejemplo, hornos,

calentadores de agua, calefactores, secadores de

ropa, etc.).

j. Deje que la m_quina se enfrie pot Io menos 5

minutos antes de guardarla.

k. Nunca Ilene los recipientes en el interior de

un vehiculo o cami6n o caja de remolque con

recubrimientos pl_sticos. Coloque siempre los

recipientes en el piso y lejos del vehiculo antes de

Ilenarlos.

I. Si es posible, retire el equipo a gasolina del cami6n o

remolque y II_nelo en el suelo. Si esto no es posible,

Ilene el equipo en un remolque con contenedor

port_til, en vez de desde una boquilla dispensadora

de gasolina.

m. Mantenga la boquilla dispensadora en contacto

con el borde del dep6sito de combustible o con la

abertura del recipiente en todo momento, hasta

terminar la carga. No utilice un dispositivo de

apertura/cierre de boquilla.

Funcionamiento

No ponga las manos o los pies cerca de las piezas

rotatorias, en la caja de la barrena / impulsor o en el

montaje del canal de descarga. Hacer contacto con piezas

giratorias puede resultar en la amputaci6n de manos o

pies.

2. La palanca de control de la barrena /impulsor es un

dispositivo de seguridad. Nunca evite su funcionamiento.

De hacerlo la operaci6n de la m_quina es riesgosa y puede

ocasionar lesiones.

3. Las palancas de control deben funcionar bien en ambas

direcciones y regresar autom_ticamente a la posici6n de

desengrane cuando se las suelta.

4. Nunca opere la m_quina si falta un montaje del canal o si

el mismo est_ daflado. Mantenga todos los dispositivos de

seguridad en su lugary en funcionamiento.

5. Nunca encienda el motor en espacios cerrados o en una

zona con poca ventilaci6n. El escape del motor contiene

mon6xido de carbono, un gas inodoro y letal.

6. No utilice la m_quina bajo la influencia del alcohol o las

drogas.

7. El silenciador y el motor se calientan y pueden causar

quemaduras. No los toque. Mantenga a los niflos alejados.

8. Sea sumamente precavido cuando opere la m_quina sobre

una superficie con grava o cuando la cruce. Mant6ngase

alerta pot si se presentan peligros ocultos o tr_nsito.

9. Tenga cuidado cuando cambie de direcci6n o cuando

opere la m_quina en pendientes. No use la m_quina en

pendientes pronunciadas.

10. Planifique el patr6n en el que va air arrojando nieve para

evitar que la descarga de material se produzca hacia las

ventanas, las paredes, los autom6viles, etc. y evitar asi

posibles daflos materiales o lesiones producidas pot los

rebotes.

11. Nunca dirija la descarga hacia los niflos, los observadores

o las mascotas ni deje que nadie se pare delante de la

m_quina.

12. No sobrecargue la capacidad de la m_quina tratando de

sacar la nieve muy r_pidamente.

13. Nunca opere esta m_quina sin buena visibilidad o

iluminaci6n. Siempre debe estar seguro de que est_ bien

afirmado y sujetando firmemente las manijas. Camine,

nunca corra.

14. Corte la corriente a la barrena / impulsor cuando transporte

la m_quina o cuando la misma noest_ en uso.

15. Nunca opere la m_quina a alta velocidad de

desplazamiento sobre superficies resbaladizas. Mire hacia

abajo y hacia atr_s y tenga cuidado cuando vaya marcha

atr_s.

16. Si la m_quina comenzara a vibrar de manera anormal,

detenga el motor, desconecte el cable de la bujia y p6ngala

de manera que haga masa contra el motor. Inspeccione la

m_quina minuciosamente para vet si est_ daflada. Repare

todos los daflos antes de encender y operar la m_quina.

17. Desengrane todas las palancas de control y detenga el

motor antes de dejar la posici6n de operaci6n (detr_s de las

manijas). Espere a que la barrena / impulsor se detenga pot

completo antes de destapar el montaje del canal o realizar

ajustes e inspecciones.

18. Nunca ponga las manos en las aberturas de descarga o

de recolecci6n. Utilice siempre la herramienta de limpieza

que se adjunta para destapar la abertura de descarga. No

destape el montaje del canal mientras el motor est_ en

funcionamiento. Antes de destaparlo, apague el motor

y permanezca detr_s de las manijas hasta que todas las

partes m6viles se hayan detenido.

19. Use s61o uniones y accesorios aprobados pot el fabricante

(pot ejemplo, pesas para las ruedas, cadenas para los

neum_ticos, cabinas, etc.).

SECTION 2 -- _V_EDIDAS IMPORTANTES DE SEGURIDAD 25

Page 26

20. Para encender el motor, jale de la cuerda lentamente hasta 12.

que sienta resistencia, luego jale r_ipidamente. El repliegue

r_ipido de la cuerda de arranque (tensi6n de retroceso)le

jalar_i la mano y el brazo hacia el motor m_is r_ipido de Io

que usted puede soltar. El resultado pueden ser huesos 13.

rotos, fracturas, hematomas o esguinces. 14.

21. Si se presentan situaciones que no est_in previstas en este

manual, sea cuidadoso y use el sentido comun. P6ngase en

contacto con Asistencia al Cliente para solicitar ayuda y el

nombre del distribuidor de servicio m_is cercano.

Mantenimiento y Almacenamiento

1.

Nunca altere los dispositivos de seguridad. Controle

peri6dicamente que funcionen correctamente. Remitase a

las secciones de mantenimiento y ajuste de este manual.

2.

Antes de realizar la limpieza, reparar o revisar la m_iquina,

desengrane todas las palancas de control y detenga el

motor. Espere a que la barrena /impulsor se detenga

pot completo. Desconecte el cable de la bujia y p6ngalo

haciendo masa contra el motor para evitar que se encienda

accidentalmente.

3.

Controle frecuentemente que todos los pernos y tornillos

est_n bien ajustados para comprobar que la m_quina se

encuentra en condiciones seguras de funcionamiento.

Adem_s, haga una inspeccidn visual de la m_quina para

verificar si est_ dahada.

4.

No cambie la configuraci6n del regulador del motor

ni acelere demasiado el mismo. El regulador del motor

controla la velocidad m_ixima segura de funcionamiento

del motor.

5. Las placas de raspado y las zapatas antideslizantes que se

usan con la m_iquina quitanieve se desgastan y se dahan.

Para proteger su seguridad, verifique frecuentemente

todos los componentes y reempl_icelos s61o con partes

de los fabricantes de equipos originales (OEM). "iEI uso de

piezas que no cumplen con las especificaciones del equipo

original puede resultar en rendimiento inadecuado adem_is

de poner en riesgo la seguridad!"

6. Revise las palancas de control peri6dicamente para

verificar que engranen y desengranen adecuadamente y

ajustelos si es necesario. Consulte la secci6n de ajustes de

este manual del operador para obtener instrucciones.

7. Mantenga o reemplace las etiquetas de seguridad e

instrucciones segun sea necesario.

8. Respete las normas referentes a la disposici6n correcta y las

reglamentaciones sobre gasolina, aceite, etc. para proteger

el medio ambiente.

9. Antes de almacenar la m_quina enci6ndala unos minutos

para sacar la nieve que haya quedado en la misma y para

evitar asi que se congele la barrena / impulsor.

10. Nunca almacene la m_quina o el recipiente de combustible

en un espacio cerrado donde haya fuego, chispas o luz

piloto como por ejemplo, calentadores de agua, hornos,

secadores de ropa, etc.

11. Consulte siempre el manual del operador para obtener

instrucciones adecuadas para el almacenamiento fuera de

temporada.

Nomodifique el motor

Para evitar lesiones graves o la muerte, no modifique el motor

bajo ninguna circunstancia. Si cambia la configuraci6n del

regulador el motor puede descontrolarse y operar a velocidades

inseguras. Nunca cambie la configuraci6n de f_ibrica del

regulador del motor.

Avisoreferido a emisiones

Los motores que est_n certificados y cumplen con las

regulaciones de emisiones federales EPAy de California para

SORE (Equipos peque_os todo terreno) est_n certificados para

operar con gasolina com0n sin plomo y pueden incluir los

siguientes sistemas de control de emisiones: Modificaci6n de

motor (EM) y catalizador de tres vias (TWC) si est_n equipados de

esa manera,

Guardachispas

Si se utiliza un amortiguador de chispas el operador Io debe

mantener en condiciones de uso adecuadas. En el Estado

de California las medidas anteriormente mencionadas son

exigidas pot ley (Articulo 4442 del Cddigo de Recursos P0blicos

de California). Es posible que existan leyes similares en otros

estados. Las leyes federales se aplican en territorios federales.

Puede conseguir el amortiguador de chispas para el silenciador

a trav_s de su distribuidor autorizado de motores o poni_ndose

en contacto con el departamento de servicios, RO. Box 361131

Cleveland, Ohio 44136-0019.

Verifique frecuentemente la linea de combustible, el

tanque, el tap6n, y los accesorios buscando rajaduras o

p_rdidas. Reemplace de set necesario.

No d_ arranque al motor si no est,1 la bujia de encendido.

Seg0n la Comisi6n de Seguridad de Productos para el

Consumidor de los Estados Unidos (CPSC) y la Agencia

de Protecci6n Ambiental de los Estados Unidos (EPA),

este producto tiene una vida dtilmedia de siete (7) ahos,

6 60 horas de funcionamiento. AI finalizar la vida dtil

media, adquiera una m_quina nueva o haga inspeccionar

anualmente 6sta por un distribuidor de servicio autorizado

para cerciorarse de que todos los sistemas mec_nicos y de

seguridad funcionan correctamente y no tienen excesivo

desgaste. Si no Io hace, pueden producirse accidentes,

lesiones o muerte

JADVERTENCIA! Esta m_iquina est,1 equipada con

un motor de combustidn interna y no debe ser

utilizada en o cerca de un terreno agreste cubierto

por bosque, malezas o hierba excepto si el sistema

de escape del motor est,1 equipado con un

amortiguador de chispas que cumpla con las leyes

locales o estatales correspondientes, en caso de

haberlas.

SECTION 2 -- _V_EDIDAS IMPORTANTES DE SEGURIDAD

Page 27

Sirnboios de Seguridad

Esta p_gina describe los simbolos y figuras de seguridad internacionales que pueden aparecer en este producto. Lea el manual del

operador para obtener la informaci6n terminada sobre seguridad, reunirse, operaci6n y mantenimiento y reparaci6n.

LEA ELMANUAL DEL OPERADOR (S)

Lea, entienda, y siga todas las instrucciones en el manual (es) antes de intentar reunirse y

funcionar.

LA ADVERTENClA -- PLATOS ROTATORIOS

Guarde manos de entrada y aperturas de la descarga mientras la m_quina corre. Alli ellos

hacen para girar platos dentro.

LA ADVERTENCIA- LAMINAS ROTATIVAS

Guarde manos de entrada y aperturas de descarga mientras la m_quina corre. Alli hacen girar

I_minas dentro.

LA ADVERTENCIA -- TALADRO ROTATIVO

No ponga manos o pies cerca del giro de partes, en el alojamiento de taladro/aspa o asamblea

de tolva. Contacto con las partes rotativas puede amputar manos y pies.

........!i........

OBJETOS LANZADOS POR ADVERTENClA

Esta m_quina puede recoger y lanzar objetos que pueden causar la herida personal seria.

GASOLINA DE ADVERTENClA ESINFLAMABLE

Permita que el motor se enfrie al menos dos minutos antes del reabastecimiento de

combustible.

ADVERTENCIA -- MONOXIDO DE CARBONO

Nunca dirijas un motor dentro o en un _rea real ventilada. Los gases de combusti6n de motor

contienen el mon6xido de carbono, un gas inodoro y mortal.

ADVERTENCIA -- ELECTROCHOQUE

No use eljuez de salida el_ctrico del motor en la Iluvia.

ADVERTENCIA -- SUPERFICIE CALIENTE

Las partes del motor, especialmente el silenciador, Ilega a set muy caliente durante la

operaci6n. Permita motor y silenciador para ponerse frio antes de tocar.

IADVERTENCIA. Su para Restringir responsabilidad el uso de esta m&quina de poder a personas que leyeron,

entienda y siga las advertencias e instrucciones en este manual yen la m_quina.

|

ISALVEi STOSINSTRUCCIONES!

SECTION 2 -- _V_EDIDAS IMPORTANTES DE SEGURIDAD 27

Page 28

MontajeyConfiguraci6n

Contenidode iacaja

Una m_quina quitanieve

de repuesto

Un Manual del Operador de la

M_quina Quitanieve

Montaje

Configuraci6nde la barra decontrol

1.

Extraiga la uni6n de cable (si la hay) que sujeta la barra

de control superior a la barra inferior para el envio. Saque

de las barras de control todos los envoltorios pl_sticos de

protecci6n.

NOTA:Asegurese de NO extraer las tres uniones de cable

flojas que se utilizar_n posteriormente para sujetar los cables.

2.

Afloje la perilla de aletas, la arandela c6ncava, la lengOeta de

la barra de control y el tornillo del carro que est_n a ambos