MTD 31A-2M1A799 Owner’s Manual

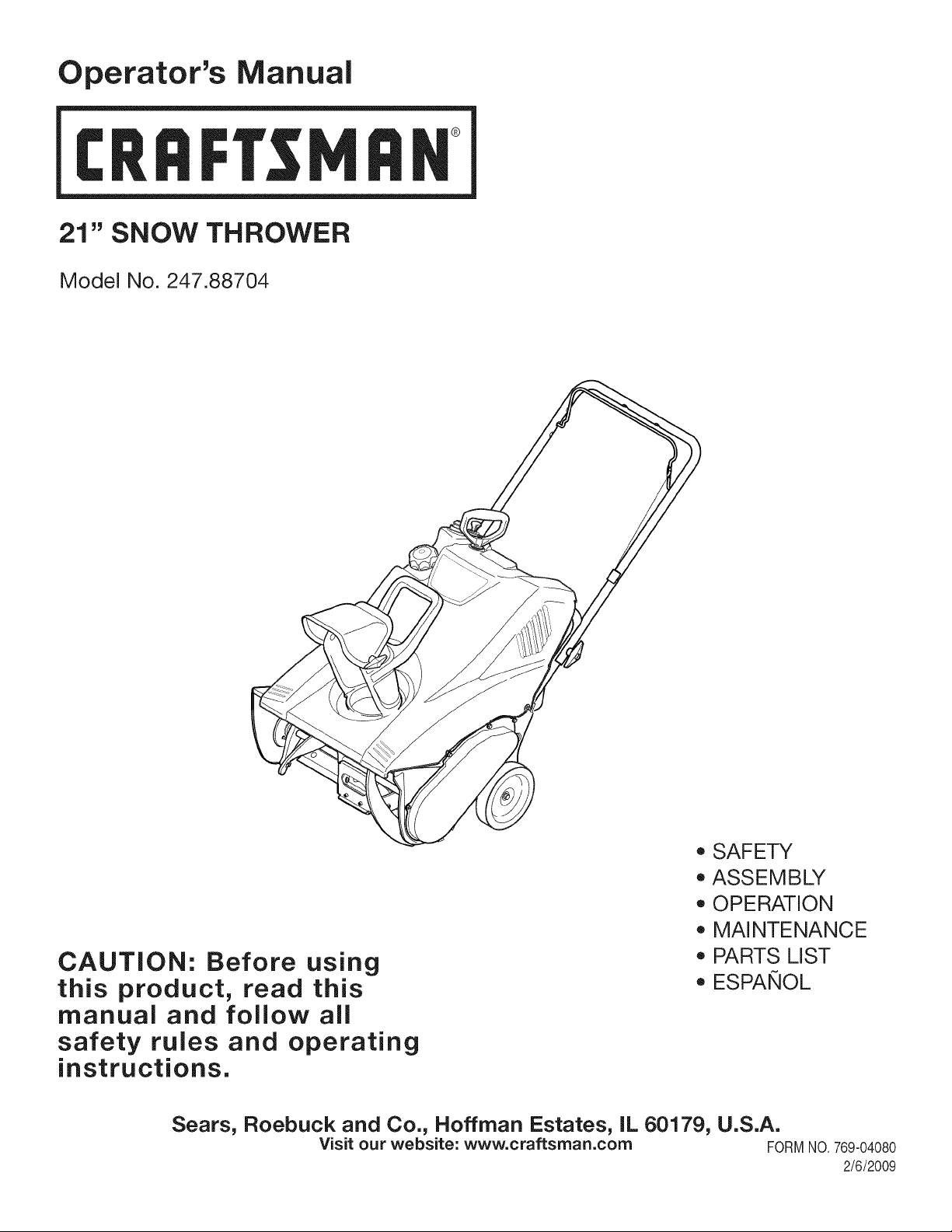

Operator's Manual

CRRFr MRN

21" SNOW THROWER

Model No. 247.88704

CAUTION: Before using

this product, read this

manual and follow all

safety rules and operating

instructions.

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

Visit our website: www.craftsman.com FORMNO.769-04080

o SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

o ESPANOL

2/6/2009

WarrantyStatement..................................Page2

SafeOperationPractices..........................Pages3-5

SafetyLabels............................................Page6

Assembly..................................................Pages7-8

Operation..................................................Pages10-12

ServiceandMaintenance.........................Pages13-17

CRAFTSMAN LiMiTED WARRANTY

Two Years on Snow Thrower

Whenoperatedand maintainedaccordingtoallsuppliedinstructions,ifthissnowthrowerfailsdueto a defectinmaterialorworkmanshipwithin

twoyearsfromthedateor purchase,call 1-800-4-MY-HOME®toarrangeforfree repair.

Thiswarrantyappliesforonly90daysfromthedateof purchaseifthissnowthroweriseverusedfor commercialor rentalpurposes.

Duringthefirstyearofpurchase,therewillbenochargefor warrantyserviceinyourhome.Foryourconvenience,in-homewarrantyservicewill

stillbeavailableafterthe firstyearof purchase,butatripchargewillapply.Thischargewillbe waivedif youtransportthesnowthrowertoan

authorizedCraftsmandrop-offlocation.Forthenearestauthorizedlocation,call 1-800-4-MY-HOME®.

Thiswarranty coversONLYdefects in material andworkmanship. Searswill NOTpayfor:

• Expendableitemsthatbecomewornduringnormaluse,includingbutnot limitedtoskidshoes,shaveplate,shearpins,sparkplug,air

cleaner,belts,andoil filter.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

Tirereplacementorrepaircausedbypuncturesfromoutsideobjects,suchas nails,thorns,stumps,or glass.

Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnot limitedtodamagecausedbyimpactingobjectsthatbendthe frameor

crankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountof engineoil,or failureto maintaintheequipmentaccordingtothe instructionscontained

intheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Off-SeasonStorage..................................Page18

TroubleShooting.......................................Page19

PartsList...................................................Page20-27

RepairProtectionAgreement...................Page31

Espa_ol.....................................................Page32

ServiceNumbers......................................BackCover

Thiswarrantyappliesonlywhilethisproductis usedinthe UnitedStates.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstatetostate.

EngineOilType: SAE5W-30

EngineOilCapacity: 20ounces

FuelCapacity: 2 Quarts

SparkPlug: TorchF6RTC

SparkPlugGap: .020"-.030"

©SearsBrands,LLC

Sears, Roebuckand Co.,Hoffman Estates, IL 60179

Model Number.................................................................

Serial Number .................................................................

Dateof Purchase.............................................................

Recordthemodelnumber,serialnumber

anddateof purchaseabove

2

Thissymbolpointsout importantsafetyinstructionswhich,ifnot

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowall instructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron thepartof theoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm,

TRAiNiNG

• Read,understand,andfollowall instructionsonthe machineand

in themanual(s)beforeattemptingtoassembleandoperate.

Failuretodo socan resultinseriousinjurytothe operatorand/

orbystanders.Keepthismanualin a safeplaceforfutureand

regularreferenceandfor orderingreplacementparts.Forques-

tionscall,1-800-659-5917.

• Befamiliarwithall controlsandtheir properoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsofageto operatethis

machine.Children14andover shouldreadandunderstandthe

instructionsandsafeoperationpracticesin thismanualandon

themachineandbe trainedandsupervisedbyanadult.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Thrownobjectscancauseseriouspersonalinjury.Planyour

snow-throwingpatterntoavoiddischargeof materialtoward

roads,bystandersandthe like.

• Keepbystanders,petsandchildrenat least75feetfromthe

machinewhileitisinoperation.Stopmachineifanyoneenters

thearea.

• Exercisecautiontoavoidslippingor falling,especiallywhen

operatinginreverse.

Your Responsibility--Restrict the useof this powermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandon themachine,

SAVE THESE INSTRUCTIONS!

PREPARATION

Thoroughlyinspecttheareawheretheequipmentis tobeused.

Removeall doormats,newspapers,sleds,boards,wiresandother

foreignobjects,whichcouldbe trippedoverorthrownbythe auger/

impeller.

Alwayswearsafetyglassesoreyeshieldsduringoperationand

whileperformingan adjustmentor repairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

Donot operatewithoutwearingadequatewinteroutergarments.

Donot wearjewelry,longscarvesorotherlooseclothing,which

couldbecomeentangledinmovingparts.Wearfootwearwhich

willimprovefootingonslipperysurfaces.

Usea groundedthree-wireextensioncordand receptacleforall

machineswithelectricstartengines.

Disengageall controlleversbeforestartingtheengine.

Neverattempttomakeanyadjustmentswhileengineis running,

exceptwherespecificallyrecommendedintheoperator'smanual.

Letengineandmachineadjustto outdoortemperaturebefore

startingtoclearsnow.

3

SafeHandling of Gasoline

Toavoidpersonalinjuryor propertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthe vaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineis spilled

onyourselforyourclotheswhichcan ignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

• Extinguishall cigarettes,cigars,pipesandothersources

ofignition.

• Neverfuelmachineindoors.

• Neverremovegascapor addfuelwhiletheengineis hot

or running.

• Allowenginetocoolat leasttwo minutesbeforerefueling.

• Neveroverfillfueltank.Filltanktono morethan1/2inch

belowbottomoffiller neckto providespaceforfuel

expansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeit offtheengineandequipment.

Movemachinetoanotherarea.Wait5 minutesbefore

startingtheengine.

• Neverstorethemachineor fuel containerinsidewhere

thereis anopenflame,sparkor pilotlight (e.g.furnace,

waterheater,spaceheater,clothesdryeretc.).

• Allowmachinetocoolat least5 minutesbeforestoring.

• Neverfillcontainersinsidea vehicleor ona truckor trailer

bedwitha plasticliner.Alwaysplacecontainersonthe

groundawayfromyourvehiclebeforefilling.

• If possible,removegas-poweredequipmentfromthetruck

ortrailerand refueliton theground.If thisisnotpossible,

thenrefuelsuchequipmentonatrailerwitha portable

container,ratherthanfromagasolinedispensernozzle.

• Keepthenozzleincontactwiththe rimofthe fueltankor

containeropeningatalltimesuntilfuelingiscomplete.Do

notuse a nozzlelock-opendevice.

OPERATION

• Donot puthandsorfeetnear rotatingparts,in theauger/impeller

housingorchuteassembly.Contactwiththe rotatingpartscan

amputatehandsandfeet.

• Theauger/impellercontrolleveris a safetydevice.Neverbypass

itsoperation.Doingsomakesthe machineunsafeandmaycause

personalinjury.

• Thecontrolleversmustoperateeasilyinbothdirectionsand

automaticallyreturntothedisengagedpositionwhenreleased.

• Neveroperatewitha missingor damagedchuteassembly.Keep

all safetydevicesinplaceandworking.

• Neverrunanengineindoorsorina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorlessanddeadlygas.

• Donotoperatemachinewhileundertheinfluenceofalcoholor

drugs.

• Mufflerandenginebecomehotandcancausea burn.Donot

touch.Keepchildrenaway.

• Exerciseextremecautionwhenoperatingonorcrossinggravel

surfaces.Stayalertforhiddenhazardsortraffic.

• Exercisecautionwhenchangingdirectionandwhileoperatingon

slopes.

• Planyoursnow-throwingpatternto avoiddischargetowards

windows,walls,carsetc.Thus,avoidingpossibleproperty

damageorpersonalinjurycausedby a ricochet.

• Neverdirectdischargeat children,bystandersand petsor allow

anyoneinfrontof themachine.

• Donotoverloadmachinecapacitybyattemptingtoclearsnowat

toofastof a rate.

• Neveroperatethismachinewithoutgoodvisibilityorlight.Always

be sureof yourfootingandkeepafirmholdon the handles.Walk,

neverrun.

• Disengagepowertotheauger/impellerwhentransportingor not

in use.

• Neveroperatemachineathightransportspeedsonslippery

surfaces.Lookdownand behindandusecarewhenbackingup.

• Ifthemachineshouldstartto vibrateabnormally,stoptheengine,

disconnectthe sparkplugwireandgrounditagainstthe engine.

Inspectthoroughlyfordamage.Repairanydamagebefore

startingandoperating.

• Disengageall controlleversandstopenginebeforeyouleave

theoperatingposition(behindthehandles).Waituntiltheauger/

impellercomestoa completestopbeforeuncloggingthechute

assembly,makinganyadjustments,or inspections.

• Neverputyourhandinthedischargeorcollectoropenings.Do

notunclogchuteassemblywhileengineis running.Shutoff

engineand remainbehindhandlesuntilall movingpartshave

stoppedbeforeunclogging.

• Useonlyattachmentsandaccessoriesapprovedbythemanufac-

turer(e.g.wheelweights,tirechains,cabsetc.).

• Whenstartingengine,pullcord slowlyuntilresistanceisfelt,then

pull rapidly.Rapidretractionofstartercord(kickback)willpull

handandarmtowardenginefasterthanyoucanlet go.Broken

bones,fractures,bruisesorsprainscouldresult.

• Ifsituationsoccurwhichare notcoveredinthis manual,use care

andgoodjudgment.ContactCustomerSupportforassistance

andthenameofyour nearestservicingdealer.

CLEARING A CLOGGED DISCHARGE CHUTE

Handcontactwiththe rotatingimpellerinsidethedischargechute

is the mostcommoncauseofinjuryassociatedwithsnowthrowers.

Neveruseyourhandtocleanoutthedischargechute.

Toclear thechute:

1. SHUTTHEENGINEOFF!

2. Wait 10secondstobe suretheimpellerbladeshavestopped

rotating.

3. Alwaysusea clean-outtool,notyourhands.

4

MAINTENANCE & STORAGE

• Nevertamperwithsafetydevices.Checktheirproperoperation

regularly.Refertothemaintenanceandadjustmentsectionsof

thismanual.

• Beforecleaning,repairing,or inspectingmachinedisengageall

controlleversandstoptheengine.Waituntilthe auger/impeller

cometoa completestop.Disconnectthe sparkplugwireand

groundagainsttheengineto preventunintendedstarting.

Checkboltsand screwsforpropertightnessatfrequentintervals

tokeepthemachineinsafeworkingcondition.Also,visually

inspectmachineforanydamage.

Donotchangetheenginegovernorsettingor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Snowthrowershaveplatesandskidshoesaresubjecttowear

anddamage.Foryoursafetyprotection,frequentlycheckall

componentsand replacewithoriginalequipmentmanufacturer's

(OEM)partsonly."Useofpartswhichdo notmeetthe original

equipmentspecificationsmayleadto improperperformanceand

compromisesafety!"

Checkcontrolleversperiodicallytoverifytheyengageanddisen-

gageproperlyandadjust,ifnecessary.Refertotheadjustment

sectioninthisoperator'smanualforinstructions.

Maintainorreplacesafetyandinstructionlabels,asnecessary.

• Observeproperdisposallawsand regulationsfor gas,oil,etc. to

protecttheenvironment.

Priorto storing,runmachineafew minutestoclearsnowfrom

machineandpreventfreezeupof auger/impeller.

Neverstorethemachineorfuel containerinsidewherethereisan

openflame,sparkorpilot lightsuchas a waterheater,furnace,

clothesdryeretc.

Alwaysrefertothe operator'smanualfor properinstructionson

off-seasonstorage.

Checkfuelline,tank, cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

Donotcrankenginewithsparkplugremoved.

AccordingtotheConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or60 hoursof

operation.At theendoftheAverageUsefulLifehavethemachine

inspectedannuallybyan authorizedservicedealerto ensurethat

allmechanicalandsafetysystemsareworkingproperlyand not

wornexcessively.Failureto do socanresultinaccidents,injuries

ordeath.

DO NOT MODIFY ENGINE

Toavoidseriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

EngineswhicharecertifiedtocomplywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOff RoadEquipment)are

certifiedto operateonregularunleadedgasoline,and mayinclude

thefollowingemissioncontrolsystems:EngineModification(EM),

OxidizingCatalyst(OC),SecondaryAirInjection(SAI)and ThreeWay

Catalyst(TWO)if soequipped.

SPARK ARRESTOR

Thismachineisequippedwithaninternalcombustionengineand

shouldnotbe usedonor nearanyunimprovedforest-covered,

brush-coveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestermeetingapplicablelocalor

statelaws(if any)

Ifa sparkattesterisused,itshouldbemaintainedin effectiveworking

orderbytheoperator.Inthe StateofCaliforniatheaboveis required

bylaw (Section4442ofthe CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws. Federallawsapplyonfederallands.

A sparkarresterforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthisproduct. Read,understand,andfollowallinstructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

i

i

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING BLADES

Keep hands out of inlet and discharge openings while machine is running. There are rotating blades

inside

WARNING-- ROTATING AUGER

Do not put hands or feet near rotating parts, in the auger/impeller housing or chute assembly.

Contact with the rotating parts can amputate hands and feet.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--GASOLINE ISFLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING-- ELECTRICAL SHOCK

Do not use the engine's electric starter in the rain

6

NOTE:Referencesto rightorleft sideofthesnowthrowerare

determinedfrombehindtheunitinthe operatingposition(standing

directlybehindthesnowthrower,facingthe handlepanel).

REMOVING FROM CARTON

1. Cutthecornersofthecartonandlaythesidesflaton theground.

Removeanddiscardallpackinginserts.

2. Movethesnowthroweroutofthecarton.

3. Makecertainthecartonhasbeencompletelyemptiedbefore

discardingit.

ASSEMBLY

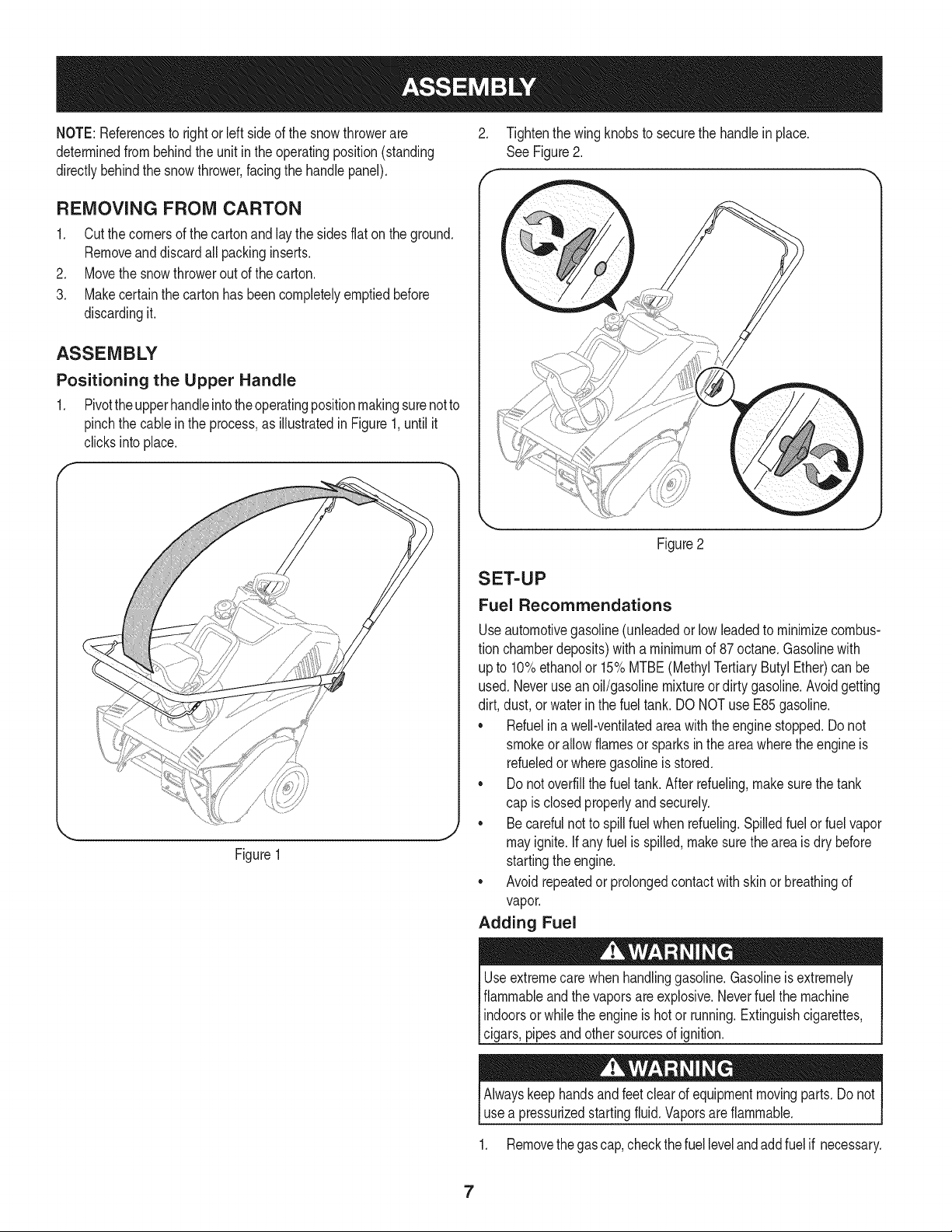

Positioning the Upper Handle

1. Pivottheupperhandleintotheoperatingpositionmakingsurenotto

pinchthe cableinthe process,asillustratedinFigure1,untilit

clicksintoplace.

J

Figure1

2. Tightenthewingknobstosecurethehandleinplace.

See Figure2.

f,

J

Figure2

SETUP

Fuel Recommendations

Useautomotivegasoline(unleadedor lowleadedtominimizecombus-

tionchamberdeposits)witha minimumof87 octane.Gasolinewith

up to 10%ethanolor15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,or waterinthefuel tank.DO NOTuseE85gasoline.

• Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksintheareawherethe engineis

refueledor wheregasolineisstored.

• Donotoverfillthefueltank.Afterrefueling,makesurethetank

capis closedproperlyandsecurely.

• Becarefulnotto spillfuelwhenrefueling.Spilledfuel orfuelvapor

mayignite.Ifanyfuelis spilled,makesuretheareaisdry before

startingthe engine.

• Avoidrepeatedorprolongedcontactwithskinor breathingof

vapor.

Adding Fuel

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelthe machine

indoorsorwhiletheengineis hotorrunning.Extinguishcigarettes,

cigars,pipesandothersourcesofignition.

Alwayskeephandsandfeetclear ofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsareflammable.

1. Removethegascap,checkthefuellevelandaddfuelif necessary.

7

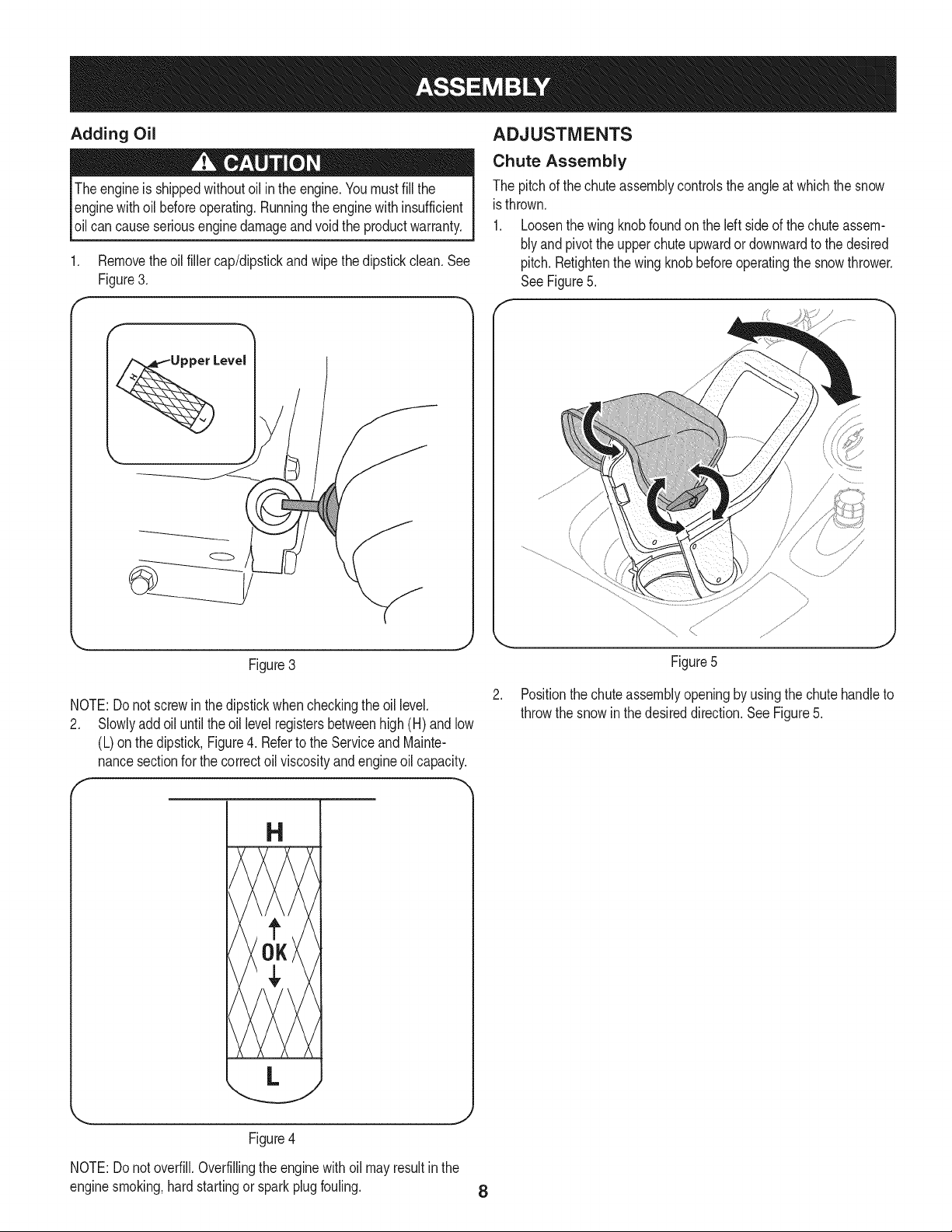

Adding Oil

Theengineis shippedwithoutoil intheengine.Youmustfillthe

enginewithoilbeforeoperating.Runningthe enginewithinsufficient

oilcancauseseriousenginedamageandvoidthe productwarranty.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.See

Figure3.

Level

ADJUSTMENTS

Chute Assembly

Thepitchof thechuteassemblycontrolstheangleat whichthesnow

isthrown.

1. Loosenthewingknobfoundonthe left sideofthe chuteassem-

blyandpivotthe upperchuteupwardordownwardtothedesired

pitch.Retightenthe wingknobbeforeoperatingthesnowthrower.

SeeFigure5.

f --,,

Figure3

NOTE:Donotscrewinthedipstickwhencheckingtheoil level.

2. Slowlyaddoil untiltheoillevelregistersbetweenhigh(H)andlow

(L)on thedipstick,Figure4. RefertotheServiceandMainte-

nancesectionforthe correctoilviscosityandengineoil capacity.

Figure5

Positionthechuteassemblyopeningbyusingthechutehandleto

throwthesnowinthedesireddirection.SeeFigure5.

,. j

Figure4

NOTE:Donotoverfill.Overfillingtheenginewithoil mayresultinthe

enginesmoking,hardstartingor sparkplugfouling.

8

This page left intentionallyblank.

9

RecoiJ Starter

Gas Ca

er ControJ

Chute Assernbl,

Shave Plate

Auger

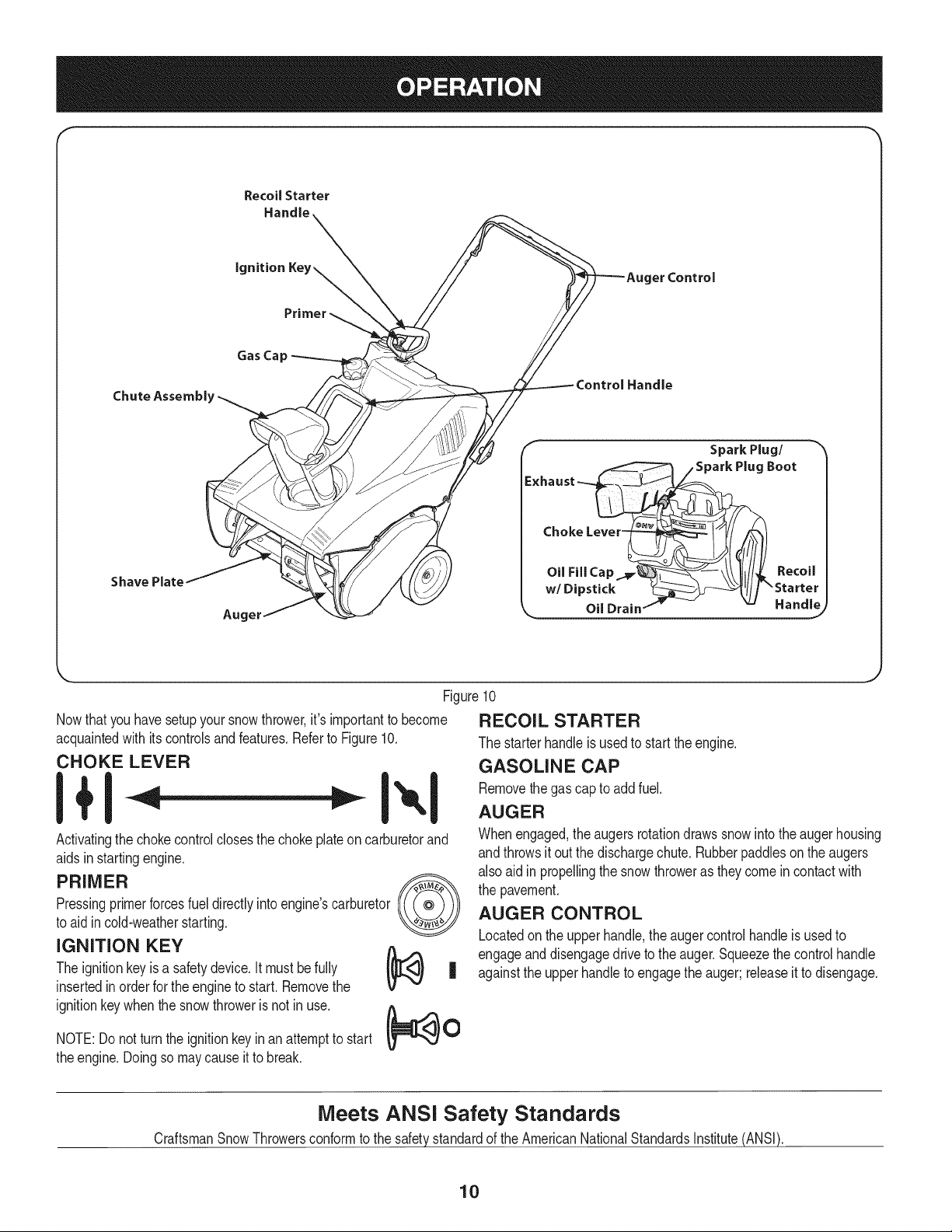

Nowthat youhavesetupyoursnowthrower,it's importanttobecome

acquaintedwith itscontrolsandfeatures.RefertoFigure10.

CHOKE LEVER

Activatingthechokecontrolclosesthechokeplateoncarburetorand

aidsinstartingengine.

Pressingprimerforcesfueldirectlyintoengine'scarburetor

PRIMER

toaidin cold-weatherstarting.

IGNITION KEY

Theignitionkeyisa safetydevice.It mustbefully

insertedinorderfortheengineto start.Removethe

ignitionkeywhenthesnowthrowerisnotin use.

HandJe

Figure10

f

Chok

Exhaust

Oil FillCap.._._

w/Dipstick

Oil Drain/

SparkPlug/ "_

Boot

_\/\_l//_ Recoil

J; %/'Starter

Hand_

RECOIL STARTER

Thestarterhandleisusedtostart theengine.

GASOLINE CAP

Removethegascaptoaddfuel.

AUGER

Whenengaged,theaugersrotationdrawssnowintotheaugerhousing

andthrowsit outthe dischargechute.Rubberpaddlesonthe augers

alsoaidin propellingthe snowthrowerastheycomeincontactwith

thepavement.

AUGER CONTROL

Locatedontheupperhandle,theaugercontrolhandleisusedto

engageanddisengagedrivetothe auger.Squeezethecontrolhandle

againsttheupperhandleto engagetheauger;releaseittodisengage.

NOTE:Donotturntheignitionkeyinan attemptto start

theengine.Doingso maycauseitto break.

Meets ANSI Safety Standards

CraftsmanSnowThrowersconformtothe safetystandardofthe AmericanNationalStandardsInstitute(ANSi).

10

CHUTE ASSEMBLY

Rotatethedischargechuteto theleftor rightusingthechutehandle.

Thepitchof thedischargechutecontrolstheangleat whichthesnow

isthrown.Loosenthewingknobontheside ofthedischargechute

beforepivotingthedischargechuteupwardordownward.Retighten

theknoboncethe desiredpositionhasbeenachieved.

SHAVE PLATE

Theshaveplate maintainscontactwiththepavementasthe snow

throwerispropelled,allowingsnowclosetothe pavement'ssurfaceto

bedischarged.

BEFORE STARTING THE ENGINE

machineandinthismanualbeforeo

1. Thesparkplugwirewasdisconnectedfor safety.Attachthespark

plugwireto thesparkplugbeforestarting.

STARTING THE ENGINE

)ressurizedstartin{ flammable.

5. Iftheengineiswarm,pushthe primerbuttononlyonce.

NOTE:Alwayscovertheventholeintheprimerbuttonwhenpushing.

Additionalprimingmaybe necessaryforthefirststartifthe tempera-

tureis below15° R

6. Graspthestarterhandleandpulltheropeoutslowly,until itpulls

slightlyharder.Letthe roperewindslowly.

7. Pullthestarterhandlerapidly.Donotallowthehandleto snap

back.Allowit to rewindslowlywhilekeepinga firmholdon the

handle.

8. Astheenginewarmsupandbeginstooperateevenly,slidethe

chokeleverslowlytothe 1/2chokeposition.Whentheengine

| a

beginsto runsmoothly,movethechoketothe OFF_ _position.

Iftheenginefails, returnto FULLI_1 choke,thenslowlymoveto

t÷II

1/2chokethentheOFF_ _position.

STOPPING THE ENGINE

1. Runthe enginefora fewminutesbeforestoppingto helpdryoff

anymoistureontheengine.

2. Tostoptheengineremovetheignitionkeyandstoreitin a safe

place.

3. Wipeallthesnowandmoistureawayfromtheenginecontrols

area.

Toavoidcarbonmonoxidepoisoning,makesuretheengineis

outdoorsina well-ventilatedarea.

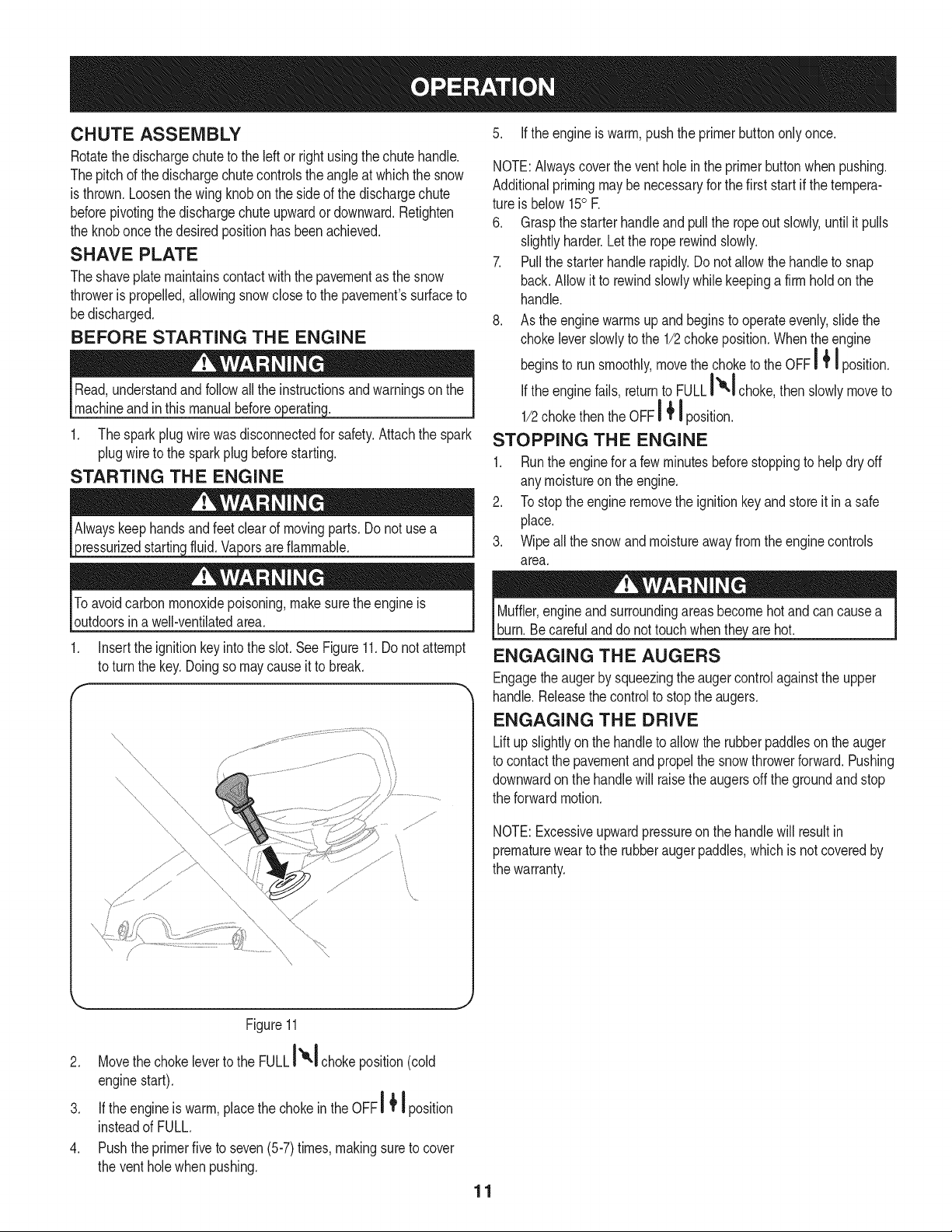

1. Insertthe ignitionkeyintotheslot.SeeFigure11.Donotattempt

toturnthekey.Doingso maycauseittobreak.

r

,%

Figure11

Muffler,engineandsurroundingareasbecomehotandcan causea

burn.Becarefulanddonot touchwhenthe,/are hot.

ENGAGING THE AUGERS

Engagethe augerbysqueezingtheaugercontrolagainsttheupper

handle.Releasethecontrolto stoptheaugers.

ENGAGING THE DRIVE

Liftup slightlyonthe handletoallowthe rubberpaddlesontheauger

tocontactthe pavementand propelthe snowthrowerforward.Pushing

downwardonthehandlewill raisetheaugersoffthe groundandstop

theforwardmotion.

NOTE:Excessiveupwardpressureonthe handlewillresultin

prematureweartotherubberaugerpaddles,whichisnotcoveredby

thewarranty.

2. MovethechokelevertotheFULLI_1 chokeposition(cold

enginestart).

I II

3. If theengineiswarm,placethechokeintheOFFi I position

insteadof FULL.

4. Pushthe primerfiveto seven(5-7)times,makingsuretocover

theventholewhenpushing.

11

Thispageleftintentionallyblank.

12

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsorrepairs.

Eachuse 1. Engineoillevel.

2. Snowthrowerandexhaust

1. Check

2. Clean

Followthemaintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.UsetheServiceLogcolumntokeeptrackof

completedmaintenancetasks.To locate the nearest SearsService

Centeror to scheduleservice,simplycontactSearsat

1-800-4-MY-HOME@.

= =

area.

1st5 hours 1. Engineoil. 1. Change.

Every5hours 1. Engineoil. 1. Check.

2. Exhaustarea. 2. Clean.

25 hours 1. Sparkplug. 2. Check.

Everyseason/50hours 1. Engineoil 1. Change

Everyseason/lO0hours 1. Sparkplug 1. Clean,replace,re-gap

Everyseason/Before 1. Pivotpoints 1. Lubricate

storage 2. Controlhandle 2. Lubricate

3. Extensionspring 3. Lubricate

ENGINE MAINTENANCE

.

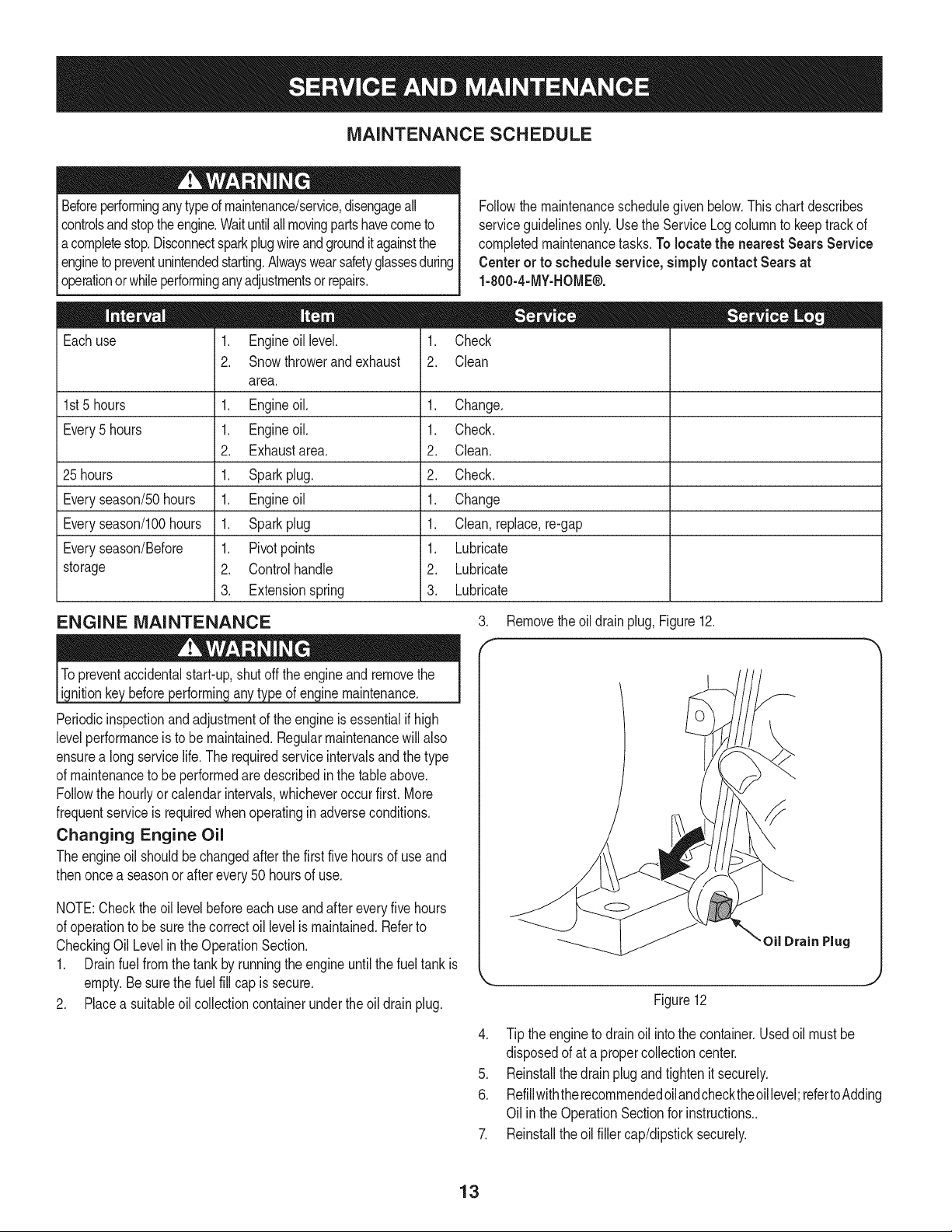

Removetheoildrainplug,Figure12.

f

ine maintenance.

Periodicinspectionandadjustmentof theengineisessentialifhigh

levelperformanceistobemaintained.Regularmaintenancewillalso

ensurealongservicelife.Therequiredserviceintervalsandthetype

ofmaintenanceto beperformedaredescribedinthetableabove.

Followthehourlyor calendarintervals,whicheveroccurfirst. More

frequentserviceisrequiredwhenoperatinginadverseconditions.

Changing Engine Oil

Theengineoil shouldbechangedafterthe firstfivehoursof useand

thenoncea seasonor afterevery50 hoursof use.

NOTE:Checktheoil levelbeforeeachuseandaftereveryfivehours

ofoperationtobesurethecorrectoil levelismaintained.Referto

CheckingOilLevelintheOperationSection.

1. Drainfuelfromthetankbyrunningtheengineuntilthefueltankis

empty.Besurethe fuelfill capissecure.

2. Placea suitableoilcollectioncontainerundertheoil drainplug.

Figure12

4. Tiptheenginetodrainoilintothe container.Usedoil mustbe

disposedofat a propercollectioncenter.

5. Reinstallthe drainplugandtightenitsecurely.

6. Refillwiththerecommendedoilandchecktheoillevel;refertoAdding

Oil intheOperationSectionforinstructions..

7. Reinstallthe oil fillercap/dipsticksecurely.

13

Thoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandlingusedoil.

NOTE:Pleasedisposeofusedmotoroil ina mannerthatisfriendlyto

theenvironment.Takeit toa recyclingcenteror othercollectioncenter.

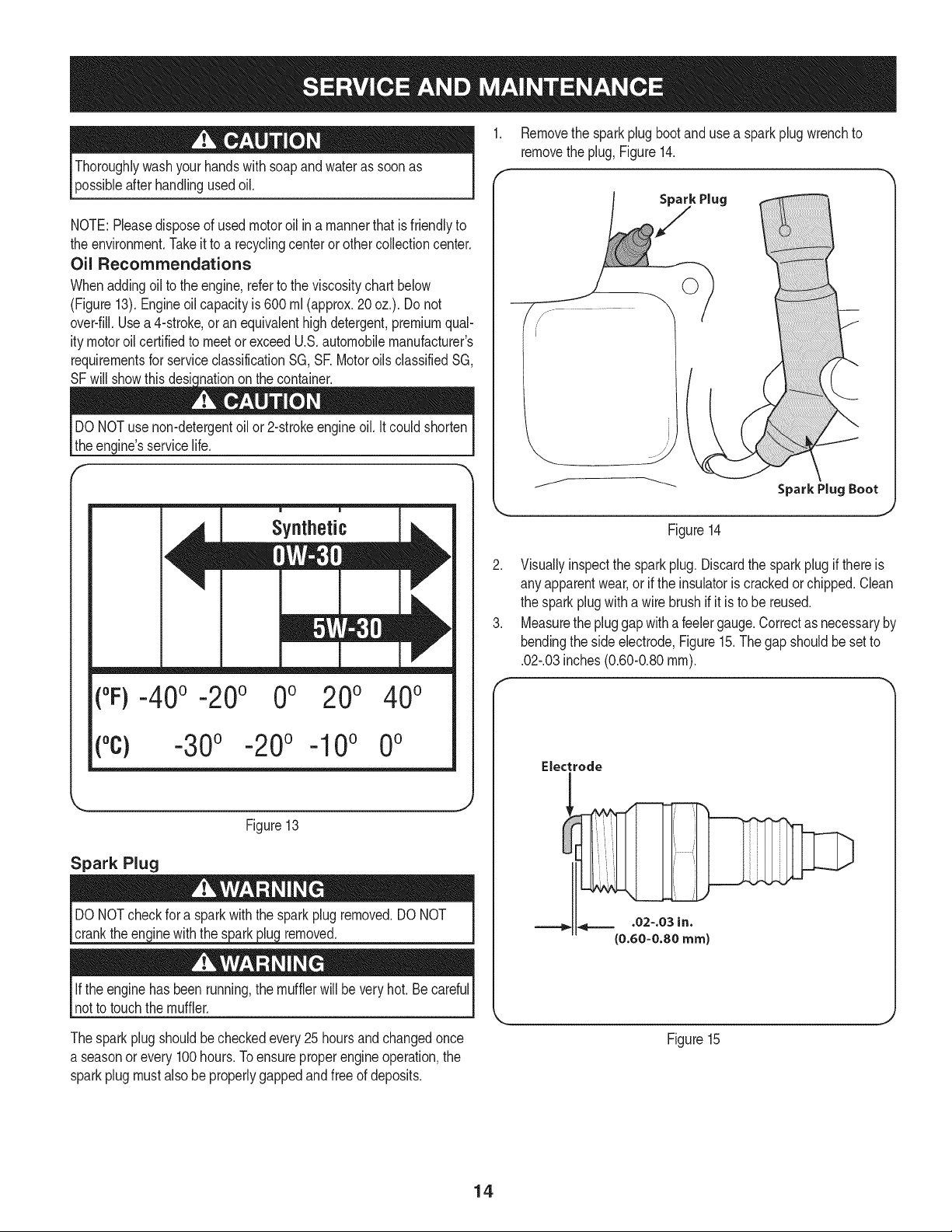

Oil Recommendations

Whenaddingoilto theengine,refertotheviscositychartbelow

(Figure13).Engineoilcapacityis600 rnl(approx.20 oz.). Donot

over-fill.Usea4-stroke,oranequivalenthighdetergent,premiumqual-

ity motoroilcertifiedto meetor exceedU.S.automobilemanufacturer's

requirementsfor serviceclassificationSG,SRMotoroils classifiedSG,

SFwill showthisdesicnationonthecontainer.

DONOTuse non-detergentoil or 2-strokeengineoil.Itcouldshorten

theengine'sservicelife.

f,

m m

Synthetic

Removethesparkplugbootand usea sparkplugwrenchto

removetheplug,Figure14.

©

Spark Plug Boot

Figure14

Visuallyinspectthe sparkplug.Discardthe sparkplugif thereis

anyapparentwear,oriftheinsulatoriscrackedorchipped.Clean

thesparkplugwitha wirebrushifit istobe reused.

Measurethepluggapwithafeelergauge.Correctasnecessaryby

bendingthe sideelectrode,Figure15.Thegapshouldbesetto

.02-.03inches(0.60-0.80ram).

(%-40 o -20o 0o 200 400

(oc) -30° -20° -10° 0°

Figure13

Spark Plug

cranktheen(inewiththe sark__ removed.

Iftheenginehasbeenrunning,themufflerwillbe veryhot.Becareful

notto touchthemuffler.

Thesparkplugshouldbecheckedevery25hoursandchangedonce

a seasonorevery100hours.Toensureproperengineoperation,the

sparkplugmustalso beproperlygappedandfree ofdeposits.

Electrode

_==== .02=.03in.

(0.60=0.80ram)

Figure15

14

4. Checkthatthesparkplugwasherisingoodconditionandthreadthe

sparkplugin byhandto preventcross-threading.

5. Afterthe sparkplugisseated,tightenwitha sparkplugwrenchto

compressthewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2-turnafterthe

sparkplugseatsto compressthewasher.Whenreinstallinga used

sparkplug,tighten1/8-to 1/4-turnafterthesparkplugseatsto

corn_ressthewasher.

becomever hotandcan damac me.

Cleaning the Engine

Iftheenginehasbeenrunning,allowitto coolforatleasthalfan hour

beforecleaning.Periodicallyremovedirtbuild-upfromengine.

Donot spraytheenginewithwaterto cleanitbecausethewater

couldcontaminatethefuel.Usinga gardenhoseor pressurewashing

Iequipmentcanalsoforcewaterintothemuffleropening.Waterthat

[passesthroughthe muffercan enterthecy nderandcausedamage,j

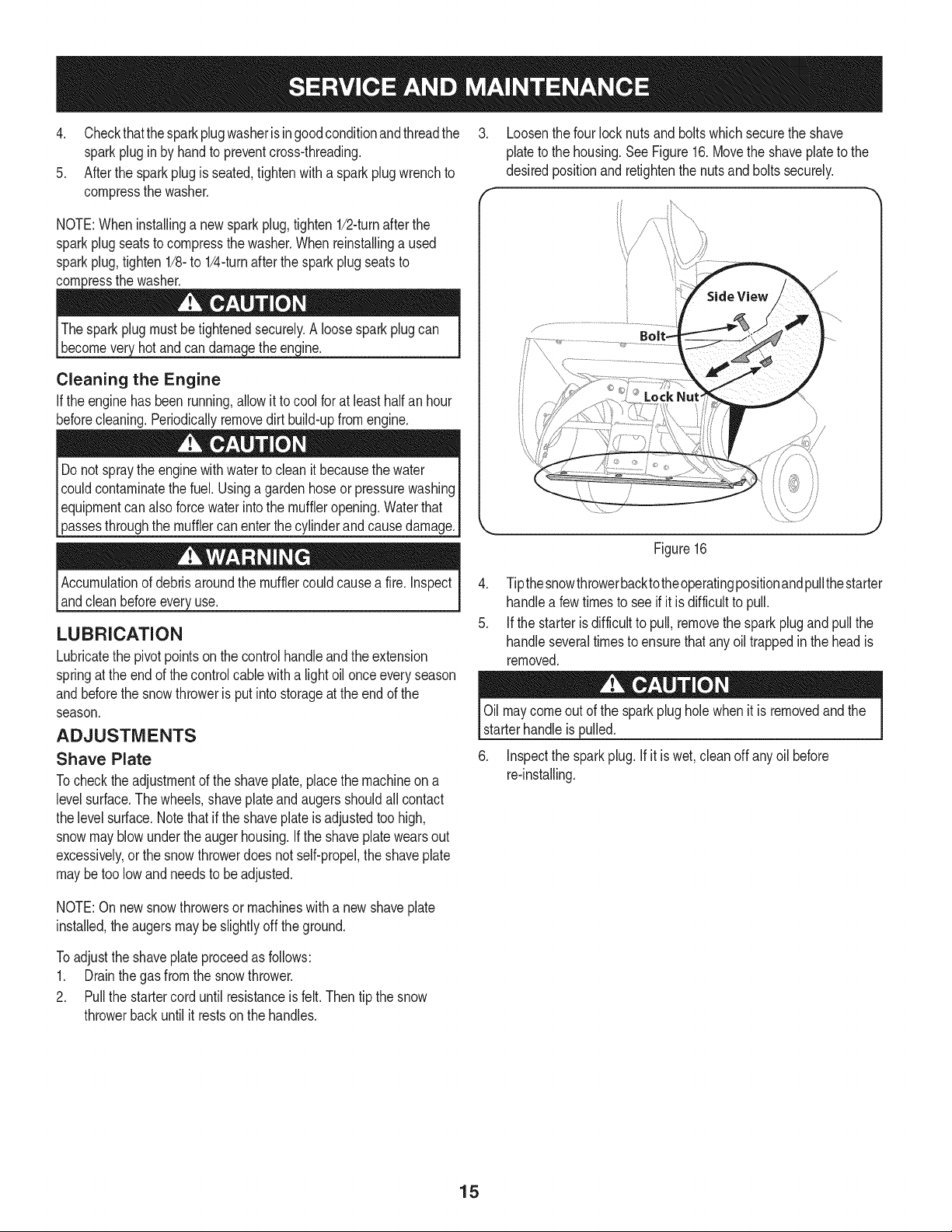

. Loosenthefourlocknutsandboltswhichsecuretheshave

plateto thehousing.SeeFigure16.Movethe shaveplatetothe

desiredpositionandretightenthenutsandboltssecurely.

Figure16

Accumulationofdebrisaroundthe mufflercouldcausea fire. Inspect

andcleanbeforeeveryuse.

LUBRICATION

Lubricatethepivotpointsonthecontrolhandleandtheextension

springat theendof thecontrolcablewitha lightoil onceeveryseason

andbeforethesnowthroweris putintostorageattheendof the

season.

ADJUSTMENTS

Shave Plate

Tochecktheadjustmentof theshaveplate,placethemachineona

levelsurface.Thewheels,shaveplateandaugersshouldallcontact

thelevelsurface.Notethatifthe shaveplateis adjustedtoohigh,

snowmayblowundertheaugerhousing.Iftheshaveplatewearsout

excessively,orthe snowthrowerdoesnot self-propel,theshaveplate

maybetoolowandneedsto beadjusted.

NOTE:Onnewsnowthrowersormachineswitha newshaveplate

installed,theaugersmaybeslightlyofftheground.

Toadjustthe shaveplateproceedasfollows:

1. Drainthegasfromthesnowthrower.

2. Pullthestartercorduntil resistanceisfelt. Thentip thesnow

throwerbackuntilit restson thehandles.

4. Tipthesnowthrowerbacktotheoperatingpositionandpullthestarter

handlea fewtimesto seeifit isdifficultto pull.

5. Ifthestarteris difficultto pull,removethesparkplugand pullthe

handleseveraltimestoensurethatanyoiltrappedinthe headis

removed.

Oilmaycomeoutof thesparkplugholewhenitis removedandthe

starterhandleis pulled.

6. Inspectthesparkplug.If itiswet,cleanoffanyoil before

re-installing.

15

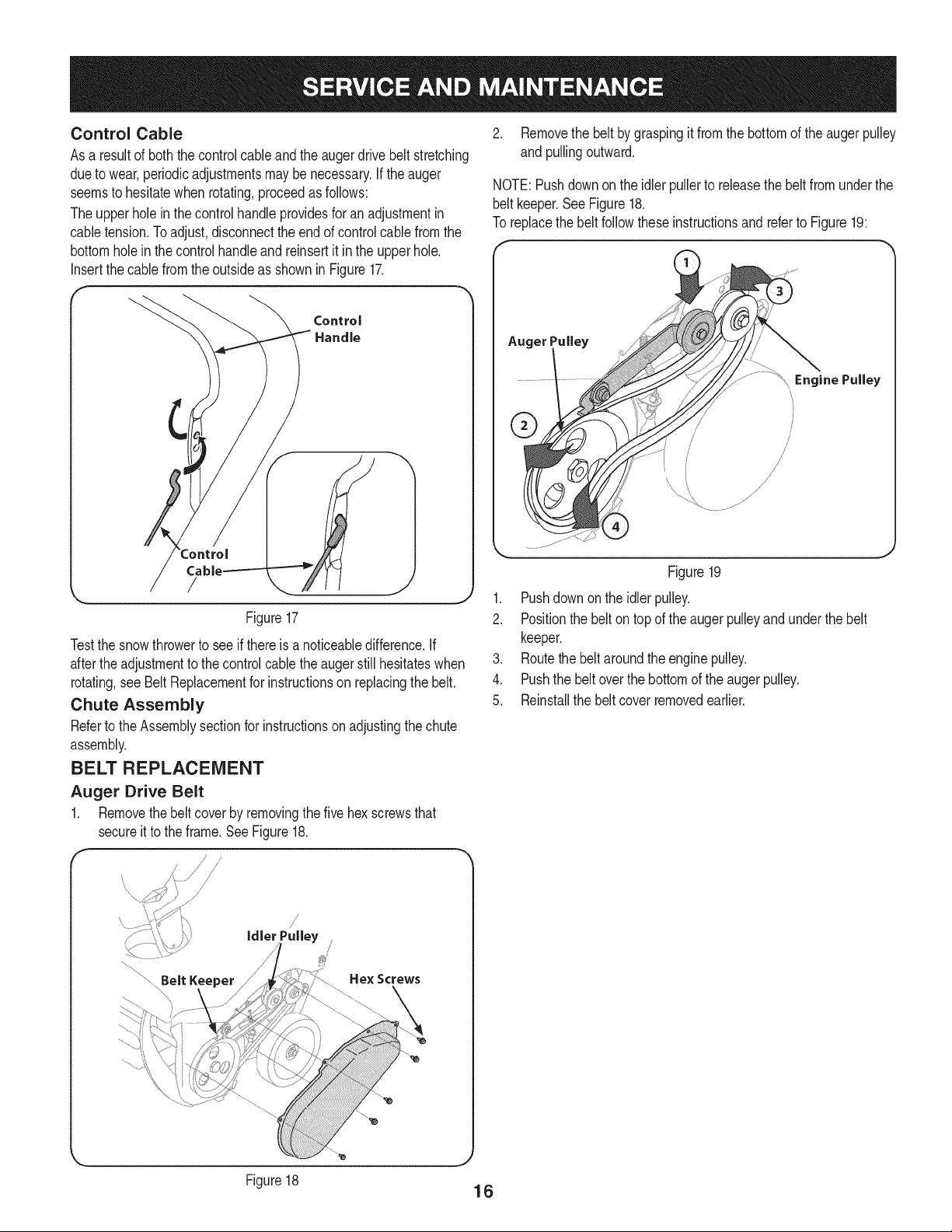

Control Cable

Asa resultof boththecontrolcableandtheaugerdrivebeltstretching

duetowear,periodicadjustmentsmaybenecessary.Iftheauger

seemsto hesitatewhenrotating,proceedasfollows:

Theupperholeinthe controlhandleprovidesforanadjustmentin

cabletension.Toadjust,disconnectthe endofcontrolcablefromthe

bottomholein the controlhandleand reinsertitintheupperhole.

Insertthe cablefromtheoutsideas shownin Figure17.

Control

Handle

2. Removethe beltbygraspingit fromthebottomoftheaugerpulley

and pullingoutward.

NOTE:Pushdownonthe idlerpullerto releasethebeltfromunderthe

beltkeeper.SeeFigure18.

Toreplacethebeltfollowtheseinstructionsand referto Figure19:

/

/

/

/

J

Figure17

Testthesnowthrowerto seeifthere isa noticeabledifference.If

aftertheadjustmenttothecontrolcabletheaugerstill hesitateswhen

rotating,seeBeltReplacementforinstructionsonreplacingthebelt.

Chute Assembly

Refertothe Assemblysectionforinstructionsonadjustingthechute

assembly.

BELT REPLACEMENT

Auger Drive Belt

1. Removethebeltcoverby removingthefivehex screwsthat

secureitto theframe.SeeFigure18.

................Belt Keeper

Figure19

1. Pushdownon theidlerpulley.

2. Positionthebelton topof theaugerpulleyandunderthe belt

keeper.

3. Routethebeltaroundtheenginepulley.

4. Pushthebeltoverthebottomoftheaugerpulley.

5. Reinstallthe beltcoverremovedearlier.

Figure18

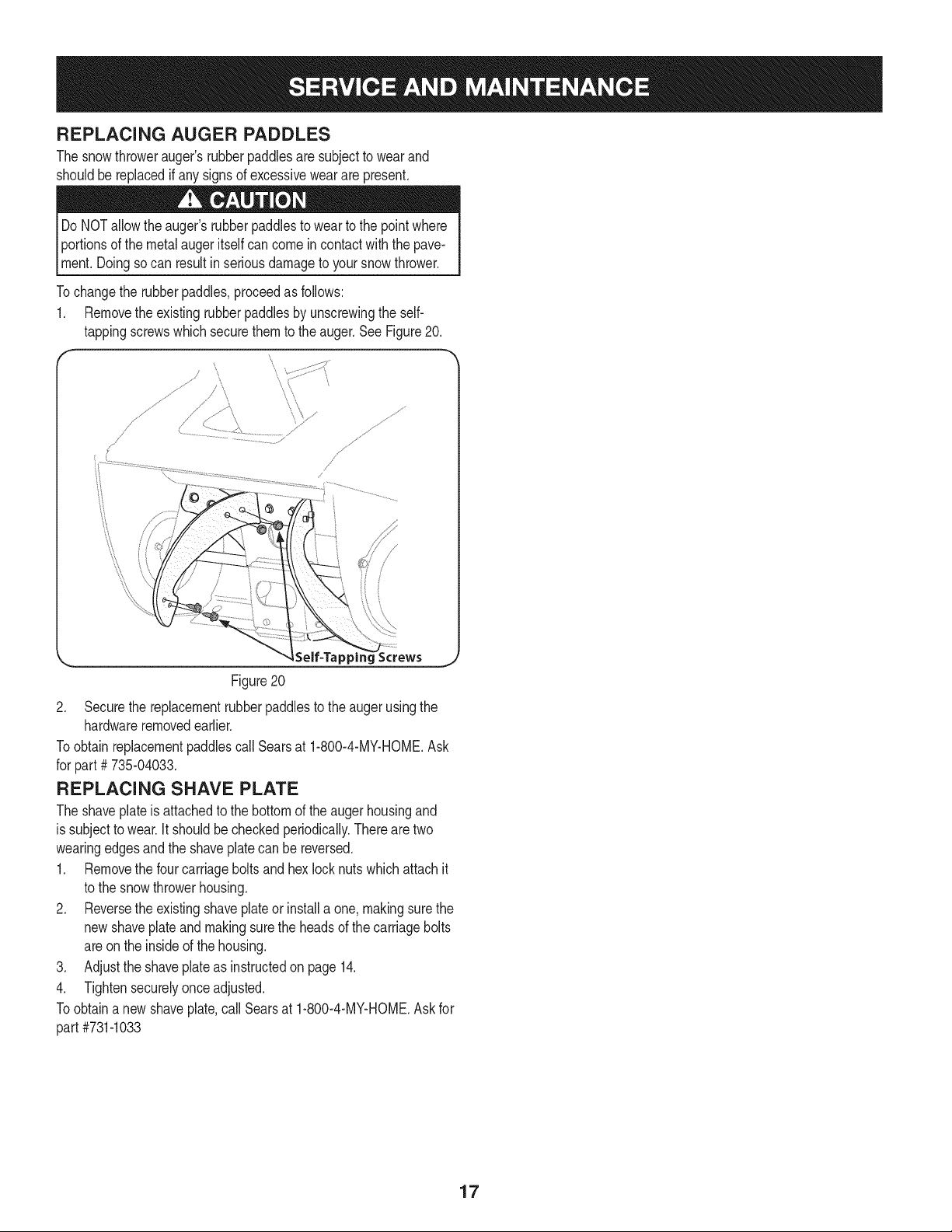

REPLACING AUGER PADDLES

Thesnowthrowerauger'srubberpaddlesaresubjecttowearand

shouldbereplacedifany signsof excessiveweararepresent.

DoNOTallowtheauger'srubberpaddlesto weartothepointwhere

Iportionsof themetalaugeritselfcancomein contactwiththepave-

lment.Doingsocan resultin seriousdamageto yoursnowthrower.

Tochangethe rubberpaddles,proceedasfollows:

1. Removetheexistingrubberpaddlesbyunscrewingthe self-

tappingscrewswhichsecurethemto theauger.SeeFigure20.

/

......." / +,

............i/." k _\I.........

f

Self-Tappir ..,,

Figure20

2. Securethereplacementrubberpaddlestotheaugerusingthe

hardwareremovedearlier.

ToobtainreplacementpaddlescallSearsat 1-800-4-MY-HOME.Ask

forpart# 735-04033.

REPLACING SHAVE PLATE

Theshaveplateisattachedtothe bottomoftheaugerhousingand

issubjecttowear.It shouldbe checkedperiodically.Therearetwo

wearingedgesandtheshaveplatecanbe reversed.

1. Removethefourcarriageboltsandhexlocknutswhichattachit

tothe snowthrowerhousing.

2. Reversetheexistingshaveplateor installa one,makingsurethe

newshaveplateand makingsuretheheadsof thecarriagebolts

areontheinsideofthehousing.

3. Adjusttheshaveplateasinstructedon page14.

4. Tightensecurelyonceadjusted.

Toobtaina newshaveplate,call Searsat 1-800-4-MY-HOME.Askfor

part#731-1033

17

Loading...

Loading...