MTD 31AS231-729, 31A-242-762, 31A-240-752, 31A-240-731 Owner’s Manual

Safe Operation Practices • Set-Up • Operation • Maintenance • Service • Troubleshooting • Warranty

's

L

Single=Stage Snowthrower m Two=Stroke

MTD LLC, P.O. BOX 361131 CLEVELAND, OHiO 44136-0019

PrintedIn USA FormNo.769-01283C

(JuLy9,2007)

ToTheOwner

ThankYou

1

Thank you for purchasing a Snow Thrower manufactured by

MTD LLC. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the unit, its

features and operation. Please be aware that this Operator's

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. MTD LLC

reserves the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 6

Controls & Features ................................................ 8

Operation ................................................................ 10

This product has met the rigid safety standards of the Outdoor

Power Equipment Institute and an independent testing

laboratory. If you have any problems or questions concerning the

unit, phone your local authorized MTD service dealer or contact

us directly. MTD's Customer Support telephone numbers,

website address and mailing address can be found on this page.

We want to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

The engine manufacturer is responsible for all engine-related

issues with regards to performance, power-rating, specifications,

warranty and service. Please refer to the engine manufacturer's

Owner's/Operator's Manual, packed separately with your unit, for

more information.

Maintenance & Adjustment ................................. 11

Service ..................................................................... 12

Troubleshooting ..................................................... 14

Replacement Parts ................................................. 15

RecordProductinformation

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the operator's position and looking

down at the rear of the deck. This information will be necessary,

should you seek technical support via our web site, Customer

Support Department, or with a local authorized service dealer.

MODEL NUMBER

EF1EF1EF1EF1EF1E

SERIALNUMBER

EF1EF1EF1EF1EF1E

CustomerSupport

Please do NOT return the unit to the retailer or dealer without first contacting our Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit us on the web at www.mtdproducts.com

Call a Customer Support Representative at (800) 800-7310 or (330) 220-4683

Write us at MTD LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

ImportantSafeOperationPractices

WARNING: This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING" Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

DANGER: This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing debris. Failure to observe the following safety instructions could

result in serious injury or death.

1

Training 8.

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place for

future and regular reference and for ordering replacement

parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 16 years of age to operate this

machine. Children 16 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and be trained and supervised by an

adult.

4. Never allow adults to operate this machine without proper

instruction.

5_

Keep bystanders, helpers, pets, and children at least 75 feet

from the machine while it is in operation. Stop machine if

anyone enters the area.

6_

Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

7_

Do not put hands and feet near rotating parts or in the

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.

Preparation

1. Thoroughly inspect the area where the equipment is to

2. Always wear safety glasses or safety goggles during

3. Wear sturdy, rough-soled work shoes and close-fitting

4. Before starting, check all bolts and screws for proper

5. Maintain or replace safety and instructions labels, as

Never attempt to unclog either the feed intake or

discharge opening, remove or empty bag, or inspect and

repair the machine while the engine is running. Shut the

engine off and wait until all moving parts have come to a

complete stop. Disconnect the spark plug wire and ground

it against the engine.

be used. Remove all rocks, bottles, cans, or other foreign

objects which could be picked up or thrown and cause

personal injury or damage to the machine.

operation and while performing an adjustment or repair,

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

slacks and shirts. Loose fitting clothes or jewelry can be

caught in movable parts. Never operate this machine

in bare feet or sandals. Wear leather work gloves when

feeding material in the chipper chute.

tightness to be sure the machine is in safe working

condition. Also, visually inspect machine for any damage at

frequent intervals.

necessary.

SafeHandling0f Gas01ine

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

c. When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

if this is not possible, then refuel such equipment on

a trailer with a portable container, rather than from a

gasoline dispenser nozzle.

d. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

e,

Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

f.

Never fuel machine indoors.

g.

Never remove gas cap or add fuel while the engine

is hot or running. Allow engine to cool at least two

minutes before refueling.

h. Never over fill fuel tank. Fill tank to no more than 1/2

inch below bottom of filler neck to allow space for

fuel expansion.

i. Replace gasoline cap and tighten securely.

j. If gasoline is spilled, wipe it off the engine and

equipment. Move unit to another area. Wait 5

minutes before starting the engine.

k. To reduce fire hazards, keep machine free of grass,

leaves, or other debris build-up. Clean up oil or fuel

spillage and remove any fuel soaked debris.

I. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

as on a water heater, space heater, furnace, clothes

dryer or other gas appliances.

Operation

1,

Do not put hands and feet near rotating parts or in the

feeding chambers and discharge opening. Contact with

the rotating impeller can amputate fingers, hands, and

feet.

2,

Before starting the machine, make sure the chipper chute,

feed intake, and cutting chamber are empty and free of all

debris.

3,

Thoroughly inspect all material to be shredded and

remove any metal, rocks, bottles, cans, or other foreign

objects which could cause personal injury or damage to

the machine.

4. If it becomes necessary to push material through the

shredder hopper, use a small diameter stick. Do not use

your hands or feet.

5. If the impeller strikes a foreign object or if your machine

should start making an unusual noise or vibration,

immediately shut the engine off. Allow the impeller to

come to a complete stop. Disconnect the spark plug wire,

ground it against the engine and perform the following

steps:

a. Inspect for damage.

b. Repair or replace any damaged parts.

c. Check for any loose parts and tighten to assure

continued safe operation.

6. Do not allow an accumulation of processed material to

build up in the discharge area. This can prevent proper

discharge and result in kickback of material through the

feed opening.

7. Do not attempt to shred or chip material larger than

specified on the machine or in this manual. Personal injury

or machine damage could result.

8. Never attempt to unclog either the feed intake or

discharge opening while the engine is running. Shut

the engine off, wait until all moving parts have stopped,

disconnect the spark plug wire and ground it against the

engine before clearing debris.

9. Never operate without the shredder hopper, chipper chute,

or chute deflector properly attached to the machine.

Never empty or change discharge bag while the engine is

running.

10. Keep all guards, deflectors and safety devices in place and

operating properly.

11. Keep your face and body back and to the side of the

chipper chute while feeding material into the machine to

avoid accidental kickback injuries.

12. Never operate this machine without good visibility or light.

13. Do not operate this machine on a paved, gravel or non-

level surface.

14. Do not operate this machine while under the influence of

alcohol or drugs.

15. Muffler and engine become hot and can cause a burn. Do

not touch.

16.

Never pick up or carry machine while the engine is running.

17.

If situations occur which are not covered in this manual, use

care and good judgement. Contact Customer Support for

assistance and the name of your nearest servicing dealer.

Maintenance&Storage

1,

Never tamper with safety devices. Check their proper

operation regularly.

2.

Check bolts and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage and repair,

if needed.

3. Before cleaning, repairing, or inspecting, stop the engine

4 J SECTION1 -- IMPORTANT SAFE OPERATION PRACTICES

and make certain the impeller and all moving parts have

stopped. Disconnect the spark plug wire and ground it

against the engine to prevent unintended starting.

4.

Do not change the engine governor settings or overspeed

the engine. The governor controls the maximum safe

operating speed of the engine.

5.

Maintain or replace safety and instruction labels, as

necessary.

6.

Follow this manual for safe loading, unloading,

transporting, and storage of this machine.

7.

Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer, etc.

8.

Always refer to the operator's manual for proper

instructions on off-season storage.

9.

If the fuel tank has to be drained, do this outdoors.

10.

Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

Donot modifyengine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

NoticeRegardingEmissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM) and Three Way Catalyst (TWC) if so equipped.

SparkArrestor

_ ARNING: This machine is equipped with an

If a spark arrester is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark attester for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, RO. Box 361131 Cleveland, Ohio 44136-0019.

internal combustion engine and should not be used

on or near any unimproved forest-covered,

brushcovered or grass-covered land unless the

engine's exhaust system is equipped with a spark

arrester meeting applicable local or state laws (if

any).

AverageUsefulLife

According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years, or 60

hours of operation. At the end of the Average Useful Life, buy

a new machine or have the machine inspected annually by an

authorized service dealer to ensure that all mechanical and

safety systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

WARNING: Your Responsibility--Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVETHESEiNSTRUCTiONS!

SECTION1 -- iMPORTANT SAFE OPERATION PRACTICES S

Assembly& Set-Up

Contents of Carton

3

Two Ignition Keys

One Snow Thrower Operator's

Manual

NOTE:This Operator's Manual covers several models. Snow

thrower features may vary by model. Not all features in this

manual are applicable to all snow thrower models.

One 2.6 oz. Bottle of Two Cycle Oil

One Tecumseh Engine Operator's

Manual

Assembly

Positioning the UpperHandle

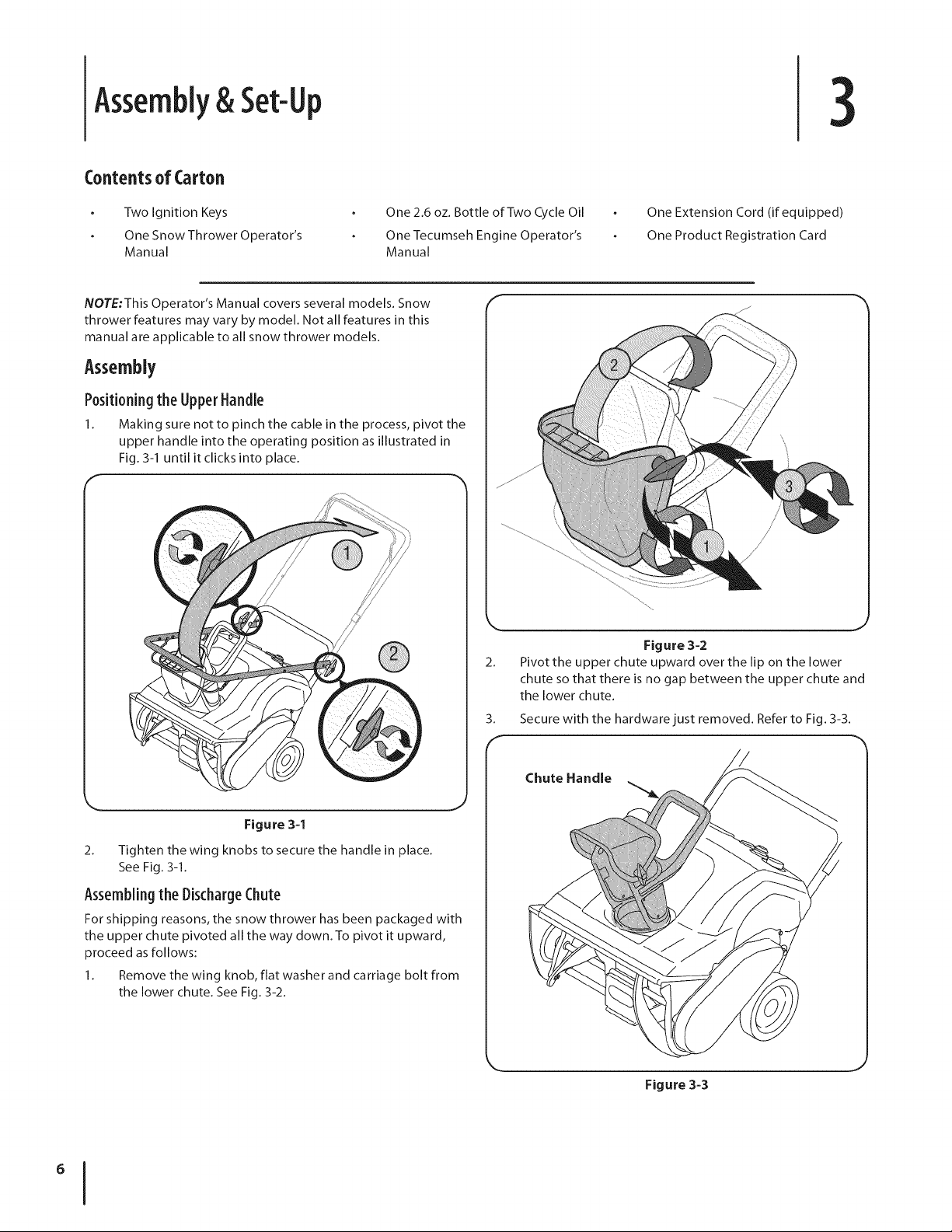

1. Making sure not to pinch the cable in the process, pivot the

upper handle into the operating position as illustrated in

Fig. 3-1 until it clicks into place.

One Extension Cord (if equipped)

One Product Registration Card

fs

/

/

2.

Pivot the upper chute upward over the lip on the lower

chute so that there is no gap between the upper chute and

the lower chute.

3.

Secure with the hardware just removed. Refer to Fig. 3-3.

Figure 3-2

r

Figure 3-1

2. Tighten the wing knobs to secure the handle in place.

See Fig. 3-1.

Assemblingthe DischargeChute

For shipping reasons, the snow thrower has been packaged with

the upper chute pivoted all the way down. To pivot it upward,

proceed as follows:

1. Remove the wing knob, flat washer and carriage bolt from

the lower chute. See Fig. 3-2.

Chute Handle

J

\

Figure 3-3

FuelAndOilMixture

Your snow thrower is equipped with a two-cycle engine that

requires a mixture of gasoline and two cycle oil at a ratio of 50:1.

Refer to the engine operator's manual for detailed instructions

regarding the mixture of oil and gasoline for your snow thrower's

engine.

FuelFill-Up

WARNING! Use extreme care when handling

gasoline. Gasoline is extremely flammable and the

vapors are explosive. Never fuel the machine

indoors or while the engine is hot or running.

Extinguish cigarettes, cigars, pipes and other

sources of ignition.

1. Check fuel level and add if necessary. Follow related

instructions in the separate engine manual packed with

your snow thrower.

NOTE:A plastic insert may have been placed into the fuel tank to

prevent dirt and debris from entering the tank during assembly.

Remove this insert before attempting to fill with fuel.

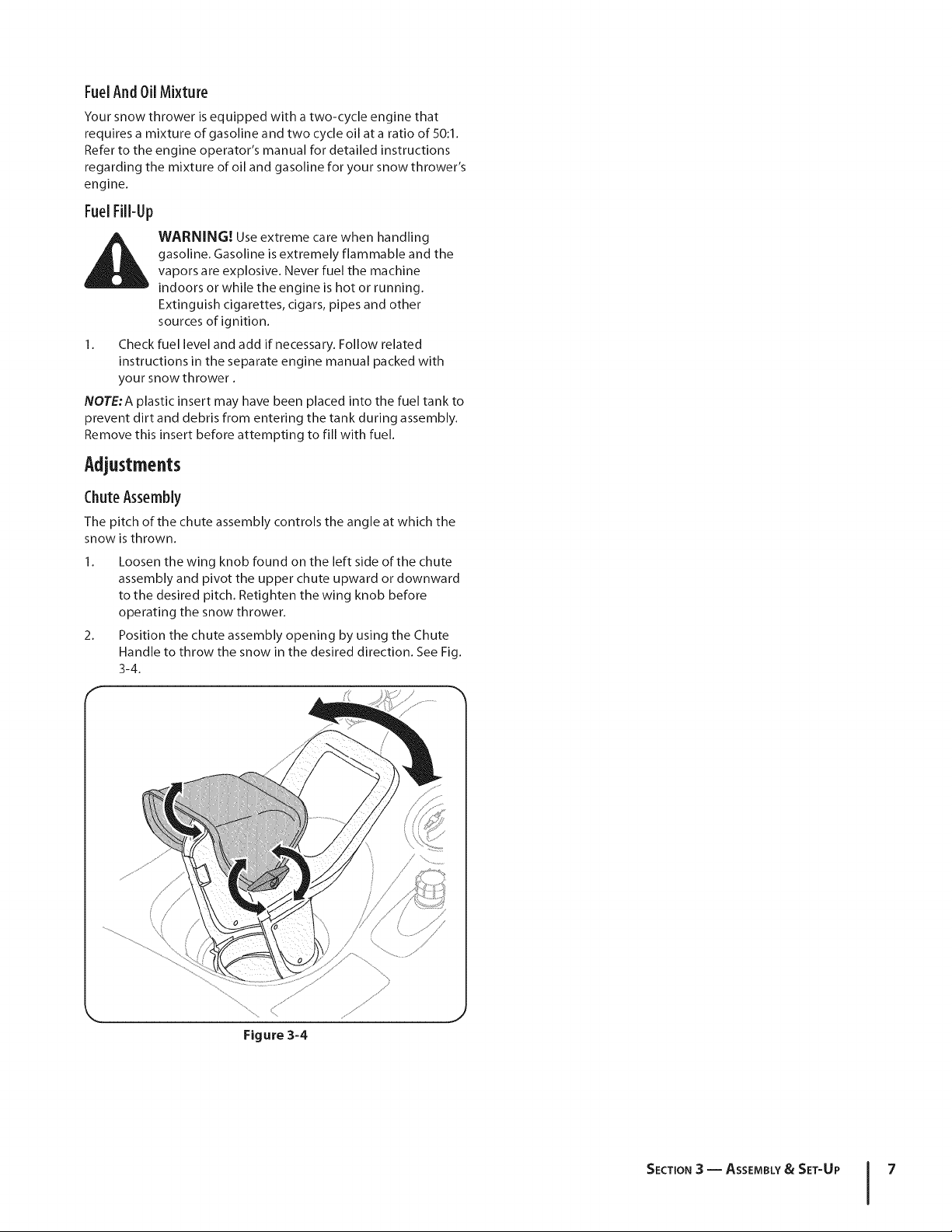

Adjustments

ChuteAssembly

The pitch of the chute assembly controls the angle at which the

snow is thrown.

1. Loosen the wing knob found on the left side of the chute

assembly and pivot the upper chute upward or downward

to the desired pitch. Retighten the wing knob before

operating the snow thrower.

2. Position the chute assembly opening by using the Chute

Handle to throw the snow in the desired direction. See Fig.

3-4.

Figure 3-4

!

SECTION3 -- ASSEMBLY& SET-UP 7

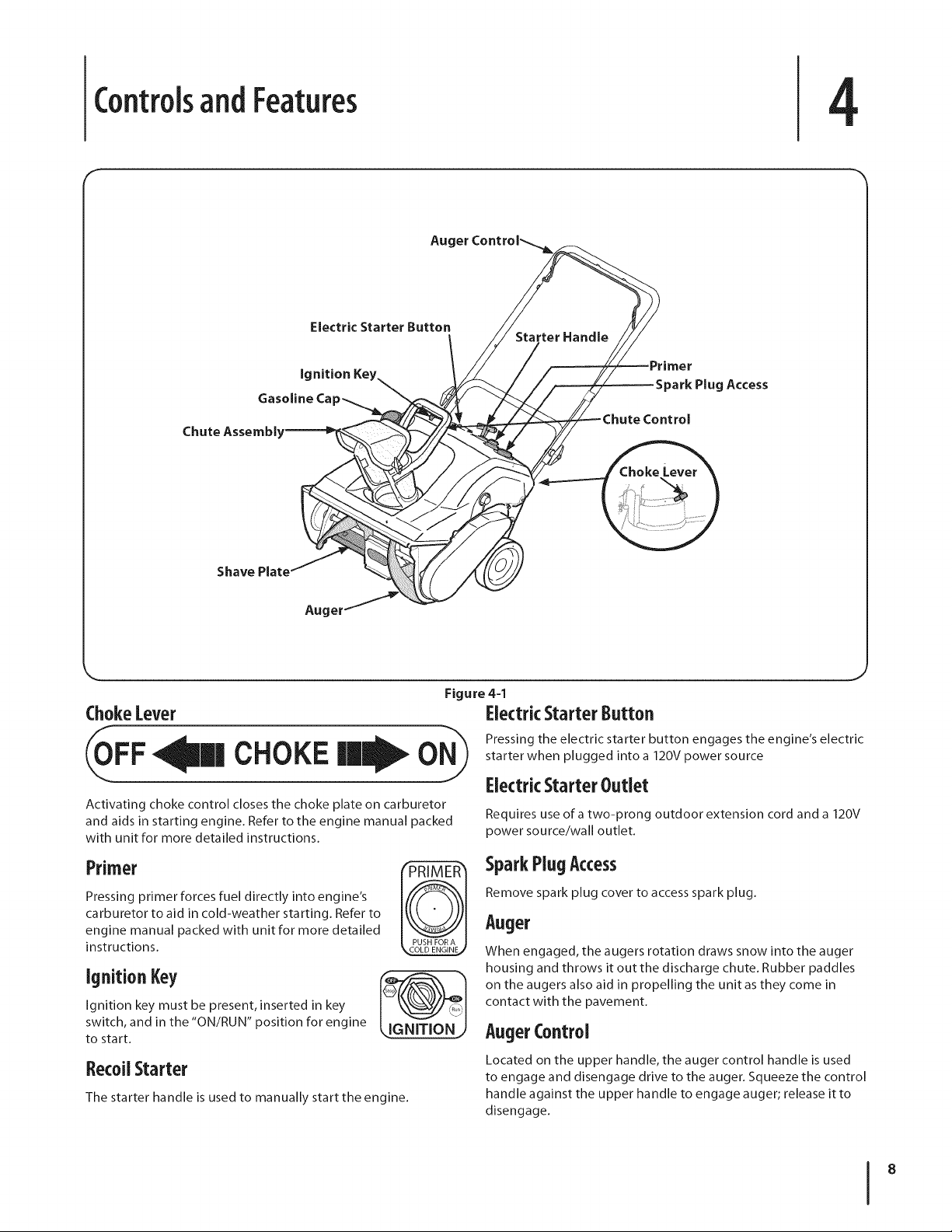

ControlsandFeatures

Electric Starter Button

4

Gasoline Ca

Chute Assernbl

Auger

CHOKE

Activating choke control closes the choke plate on carburetor

and aids in starting engine. Refer to the engine manual packed

with unit for more detailed instructions.

park Plug Access

Figure 4-1

ElectricStarterButton

Pressing the electric starter button engages the engine's electric

starter when plugged into a 120V power source

ElectricStarterOutlet

Requires use of a two-prong outdoor extension cord and a 120V

power source/wall outlet.

Primer

Pressing primer forces fuel directly into engine's

carburetor to aid in cold-weather starting. Refer to

engine manual packed with unit for more detailed

instructions.

Ignition Key

Ignition key must be present, inserted in key

switch, and in the "ON/RUN" position for engine

to start.

RecoilStarter

The starter handle is used to manually start the engine.

SparkPlugAccess

Remove spark plug cover to access spark plug.

Auger

When engaged, the augers rotation draws snow into the auger

housing and throws it out the discharge chute. Rubber paddles

on the augers also aid in propelling the unit as they come in

contact with the pavement.

AugerControl

Located on the upper handle, the auger control handle is used

to engage and disengage drive to the auger. Squeeze the control

handle against the upper handle to engage auger; release it to

disengage.

ChuteAssembly

Rotate the discharge chute to the left or right using the chute

handle.The pitch of the discharge chute controls angle at which

the snow is thrown. Loosen the wing knob on the side of the

discharge chute before pivoting the discharge chute upward or

downward. Retighten the knob once the desired position has

been achieved.

ShavePlate

The shave plate maintains contact with the pavement as

the snow thrower is propelled, allowing snow close to the

pavement's surface to be discharged.

GasolineCap

Remove the gas cap to add fuel. This machine runs on a mixture

of fuel and oil. Do NOT operate the snow thrower without first

reading the engine operator's manual for instructions regarding

proper fuel and engine oil.

SECTION4 -- CONTROLS AND FEATURES 9

Operation

5

BeforeStarting

i_ll WARNING! Read, understand and follow all

NOTE: For complete and detailed engine starting, stopping and

storing instructions, it is recommended that you read the engine

manual also included with this unit.

1. The spark plug wire was disconnected for safety. Attach

instructions and warnings on the machine and in

this manual before operating.

the spark plug wire to the spark plug before starting.

Starting the Engine

1. To avoid carbon monoxide poisoning, make sure the

engine is outdoors in a well-ventilated area.

2. Insert the ignition key into the slot. Turn key to ON position.

3. Now follow the instructions below as it pertains to your

machine.

ElectricStarter

WARNING! The electric starter must be used with

a properly grounded two-prong receptacle at all

times to avoid the possibility of electric shock.

Follow all instructions carefully prior to operating

the electric starter.

1.

The electric starter is equipped with a grounded two-wire

power cord and a plug. It is designed to operate on a 110

volt AC household current.

2. Move the Choke Control to the "Full" position.

3. Push the Primer three (3) times, making sure to cover the

vent hole when pushing.

4. Connect the power cord to the switch box on the dash

panel. Plug the other end of the power cord into a three-

prong 110-volt, grounded, AC receptacle.

5. Push the starter button to crank the engine.

6. When engine starts, release starter button, and move

choke gradually to 1/2Choke until engine runs smoothly.

Next move the Choke to OFF. If engine falters, move choke

immediately to FULL and then gradually to 1/2then to OFF.

7. Disconnect the power cord. Always unplug from the outlet

first, and then from the snow thrower.

Re(oilStarter

1.

Move the choke lever to FULL choke position (cold engine

start).

2.

If the engine is warm, place the choke in OFF position

instead of FULL.

3.

Push the Primer three (3) times, making sure to cover the

vent hole when pushing.

4.

If the engine is warm, push the primer button only once.

NOTE: Always cover the vent hole in the primer button

when pushing. Additional priming may be necessary for

first start if temperature is below 15 degrees Fahrenheit.

5.

Grasp the starter handle and pull the rope out slowly, until

it pulls slightly harder. Let the rope rewind slowly.

6.

Pull the starter handle rapidly. Do not allow the handle to

snap back. Allow it to rewind slowly while keeping a firm

hold on the starter handle.

7.

As the engine warms up and begins to operate evenly,

rotate the choke lever slowly to the 1/2Choke position.

When the engine begins to run smoothly, move the choke

to the OFF position. If the engine falters, return to FULL

choke, then slowly move to 1/2then OFF position.

Stopping the Engine

1. Run the engine for a few minutes before stopping to help

dry offany moisture on the engine.

2. To stop the engine, turn the ignition key to the OFF/STOP

position

3. Remove the ignition key and store it in a safe place.

4. Wipe all the snow and moisture from the area around the

engine.

NOTE: Excessive upward pressure on the handle will result

in premature wear on the rubber auger blades which

would not be covered by warranty.

_ WARNING! Muffler, engine and surrounding areas

become hot and can cause a burn. Be careful and do

not touch when hot.

Engagingthe Augers

1. Engage the auger by squeezing the auger control against

the upper handle. Release to stop the augers.

'°1

Engagingthe Drive

Lift up slightly on the handle to allow the rubber paddles

on the auger to contact the pavement and propel the snow

thrower forward. Pushing downward on the handle will

raise the augers offthe ground and stop forward motion.

Loading...

Loading...