Page 1

OPERATOR'S MANUAL

46"

SNOW

BLADE

Model Numbers

190-833-OEM

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 48829 (REV. 7/03)

Page 2

RULES FOR SAFE OPERATION

Any power equipment can cause injury if operated improperly or if the user does not understand how to operate

the equipment. Exercise caution at all times when operating equipment.

1. Read the tractor and snow blade owners manuals and know how to operate your tractor before using tractor with snow

blade attachment.

2. Never operate tractor and snow blade without wearing proper clothing suited to weather conditions and operation of

controls.

3. Never allow children to operate tractor and snow blade, and do not allow adults to operate without proper instructions.

4. Always begin with transmission in first (low) gear and gradually increase speed as required.

LOOK FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS. IT

MEANS -- ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED.

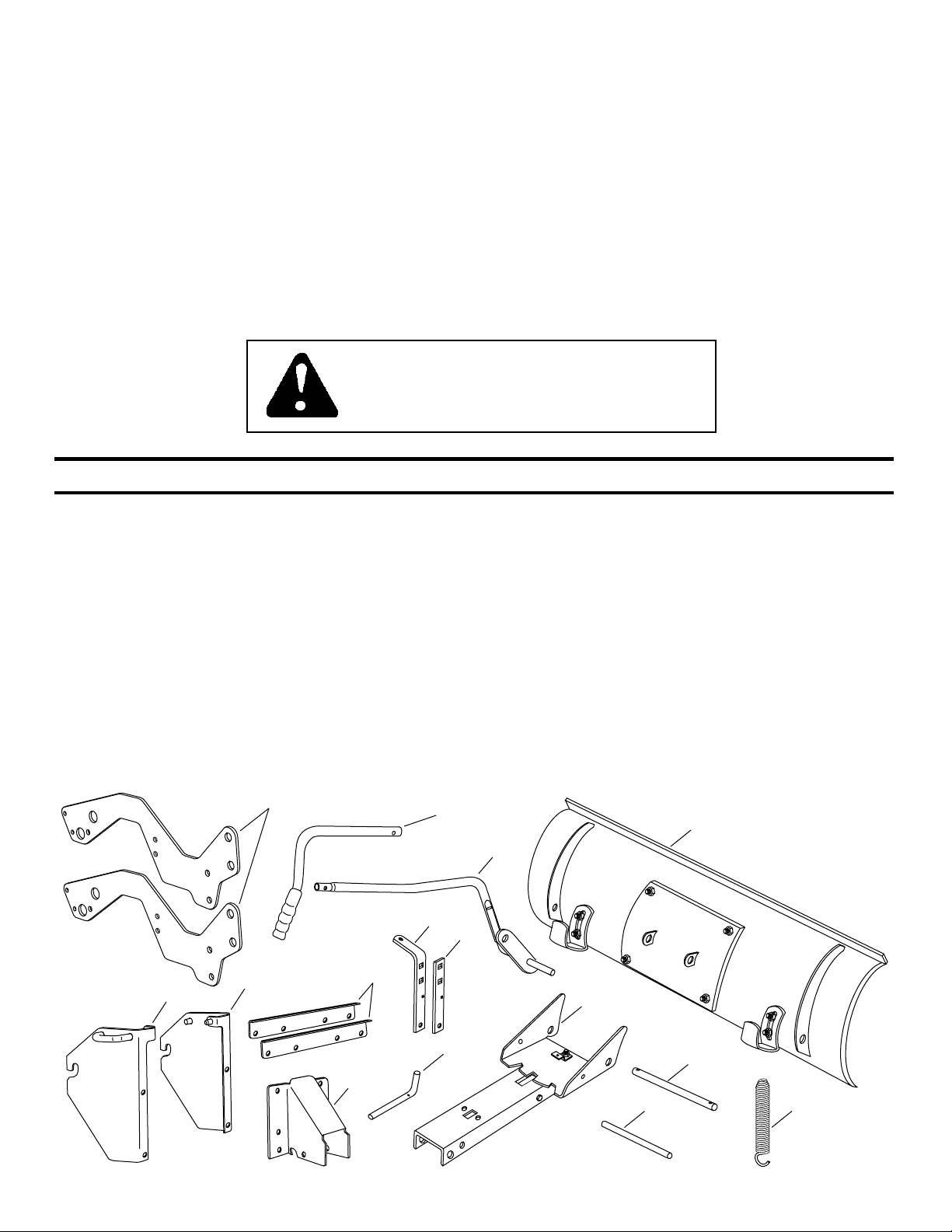

UNPACKING

Open carton. Remove parts and literature. Make

certain all parts and literature are removed before the

carton is discarded.

Lay out all parts according to the illustration below.

CARTON CONTENTS

A 2 Frame Brackets

B 1 Upper Lift Handle

C 1 Lower Lift Handle Assembly

D 1 Blade Assembly

E 1 R.H. Hitch Bracket

A

F

E

F 1 L.H. Hitch Bracket

G 2 Angle Brackets

H 1 Pivot Support Bracket

I 1 Channel Pivot Pin

J 1 Angle Lock Bar (Long)

G

K 1 Angle Lock Bar (Short)

L 1 Channel Assembly

M 1 Pivot Shaft

N 1 Spring Mount Rod

O 1 Blade Adjust Spring

B

D

C

J

K

L

I

H

2

M

N

O

Page 3

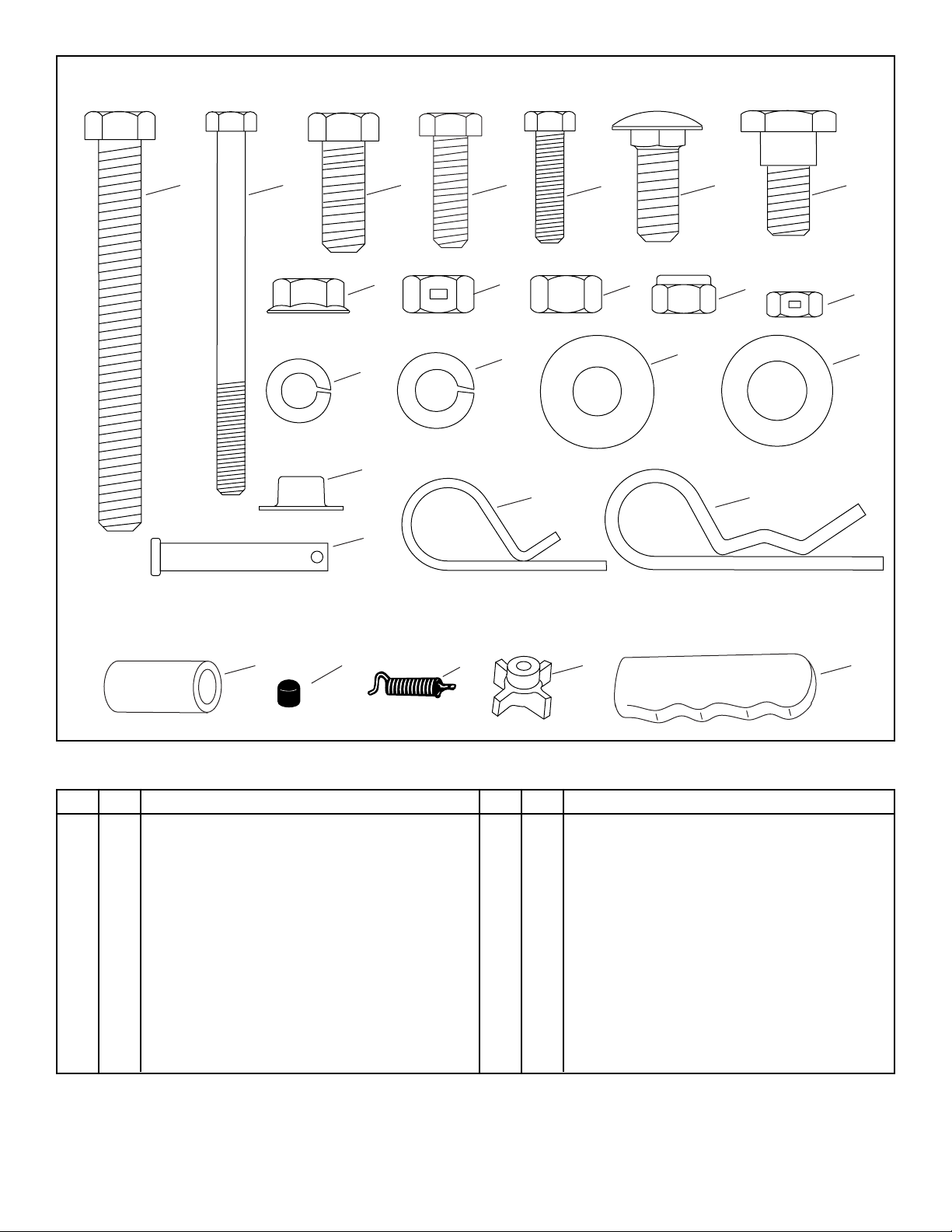

SHOWN FULL SIZE

A

B

C

L

M

S

T

DE

K

N

R

J

F

I

O P

Q

G

H

NOT SHOWN FULL SIZE

U V X Y

CONTENTS OF HARDWARE PACK

Key Qty Description

A 1 Hex Bolt, 3/8" x 3-1/2"

B 1 Hex Bolt, 1/4" x 3-1/4"

C 8 Hex Bolt, 3/8" x 1" Lg.

D 6 Hex Bolt, 5/16" x 1" Lg.

E 2 Hex Bolt, 1/4" x 1"

F 2 Carriage Bolt, 3/8" x 1" Lg.

G 2 Shoulder Bolt

H 3 Hex Lock Nut, 1/4"

I 6 Nylock Nut, 5/16"

J 1 Hex Nut, 3/8-16

K 4 Hex Lock Nut, 3/8"

L 8 Flange Nut, 3/8"

M 4 Lock Washer, 5/16"

W

Key Qty Description

N 2 Lock Washer, 3/8"

O 1 Flat Washer, 3/8"

P 1 Flat Washer, 1/2"

Q 2 Hairpin Cotter, 1/8" (large)

R 3 Hairpin Cotter, 3/32" (small)

S 2 Palnut, 3/8"

T 1 Clevis Pin, 1/4" x 1-1/2"

U 2 Spacer

V 1 Plastic Cap

W 1 Angle Lock Spring

X 1 Knob

Y 1 Handle Grip

3

Page 4

SECTION 1:

ASSEMBLY INSTRUCTIONS

NOTE: Right hand (R.H.) and left hand (L.H.) are deter-

mined from the operators position while seated

on the tractor.

TOOLS REQUIRED FOR ASSEMBLY

(2) 7/16" Wrenches

(2) 1/2" Wrenches

(2) 9/16" Wrenches

(1) 3/4" Wrench or Adjustable Wrench

REMOVING PARTS FROM CARTON

Remove all parts and hardware packages from the

carton. Lay out all parts and hardware and identify using

the illustrations on pages 2 and 3.

NOTE: Not all parts in the hardware pack will be needed

for any one tractor fit-up.

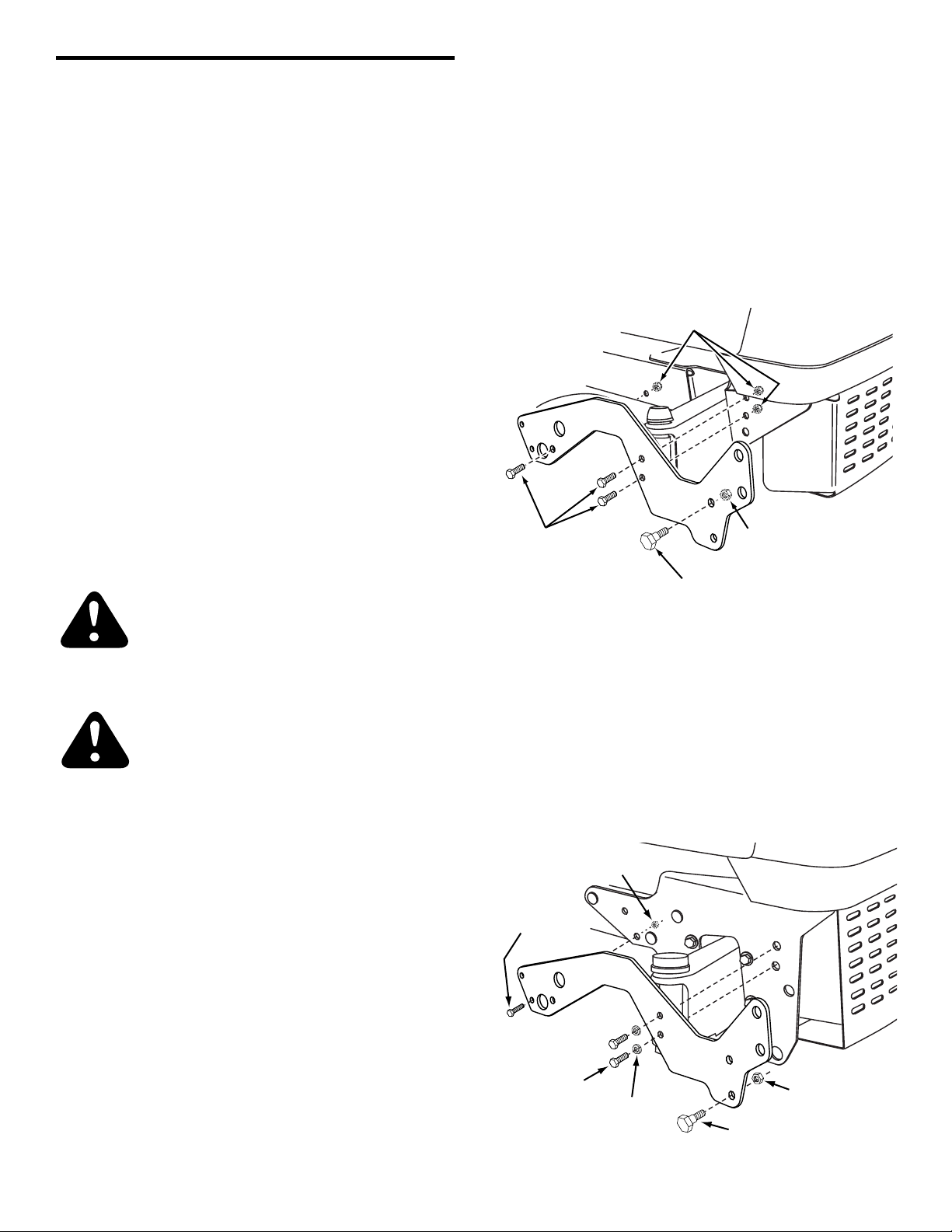

ASSEMBLING BRACKETS TO TRACTOR

FAST-ATTACH TRACTOR FRAMES

No bracket assembly required. Skip to ASSEMBLING

THE SNOW BLADE.

STANDARD TRACTOR FRAMES WITH 15" TIRES

6. Attach a frame bracket to each side of the tractor

frame. Assemble three 5/16" x 1" hex bolts and 5/16"

nylock nuts to the holes shown figure 1.

7. Assemble a shoulder bolt and a 3/8" hex lock nut to

the upper hole in each frame bracket as shown in

figure 1.

5/16" NYLOCK NUTS

PREPARING THE LAWN TRACTOR

CAUTION: Before beginning preparation,

select a firm and level surface which is large

enough to accommodate the snow blade

attachment and tractor. Engage brake lock.

WARNING: Stop engine and let muffler

cool before installing brackets.

1. Allow engine, muffler and exhaust deflector to cool

before beginning.

2. Disconnect the spark plug wire(s) from the spark

plug(s) and ground against the engine.

3. Remove the mowing deck as instructed in the belt

removal section of the owner's manual for the lawn

tractor.

REMOVING PARTS FROM TRACTOR

5/16" x 1"

HEX BOLTS

SHOULDER BOLT

Figure 1

STANDARD TRACTOR FRAMES WITH 16" TIRES

8. Attach a frame bracket to each side of the tractor frame.

Use two 5/16" x 1" hex bolts and 5/16" lock washers in

the holes shown in front of the axle. Use a 1/4" x 1" hex

bolt and 1/4" hex lock nut in the rear hole as shown.

Tighten carefully to avoid stripping threads in tractor

frame. See figure 2.

9. Assemble a shoulder bolt and a 3/8" hex lock nut to the

lower hole in each frame bracket as shown in figure 2.

1/4" HEX

LOCK NUT

1/4" x 1"

HEX BOLT

3/8" HEX

LOCK NUT

4. Remove any front mounted attachments which may

be installed on your tractor.

5. Mark and save all removed parts.

5/16" x 1"

HEX BOLTS

4

5/16" LOCK

WASHERS

3/8" HEX

LOCK NUT

SHOULDER BOLT

Figure 2

Page 5

3/8" PALNUT

PIVOT

PLATE

SPRING

MOUNT

ROD

3/8" PALNUT

3/8" x 3-1/2"

HEX BOLT

BLADE

ADJUST

SPRING

3/8" HEX NUT

ASSEMBLING THE SNOW BLADE

10. Assemble the long and short angle lock bars together

using two 3/8" x 1" carriage bolts, 3/8" lock washers

and 3/8" hex lock nuts. Make sure all holes are

aligned. See figure 3.

11. Insert the straight hook end the angle lock spring into

the middle hole in the angle lock bars. The curved

hook on the other end of the spring should be facing

up. See figure 3.

ANGLE LOCK BAR (LONG)

ANGLE LOCK BAR (SHORT)

3/8" LOCK WASHER

3/8" HEX LOCK NUT

3/8" x 1"

CARRIAGE BOLT

ANGLE LOCK SPRING

Figure 3

14.Using a hammer, assemble a 3/8" palnut onto one

end of the spring mount rod. Insert the other end of

the rod through the rear set of holes in the pivot

plate. Turn the pivot plate onto it's side on a block of

wood and hammer the remaining palnut onto the

other end of the rod. See figure 5.

Figure 5

12.Insert the curved hook of the angle lock spring up

through the hole in bracket (A). See figure 4.

13.Insert the angle lock bars down through the slot in the

channel. Underneath the channel place spacers on

both sides of the angle lock bars and insert a 1/4" x

3-1/4" hex bolt through the sides of the channel, the

spacers and the angle lock bars. Secure the bolt with

a 1/4" hex lock nut, tightening so that the angle lock

bars still pivot freely. See figure 4.

PIVOT

PLATE

CHANNEL

1/4" HEX

LOCK NUT

1" SPACERS (2)

BRACKET (A)

ANGLE

LOCK

SPRING

1/4" x 3-1/4"

HEX BOLT

15.Insert the 3/8" x 3-1/2" hex bolt through the angle lock

spring. Assemble a 3/8" hex nut about 1" onto the end

of the bolt. See figure 6.

Figure 6

Figure 4

5

Page 6

16.To attach the channel assembly to the blade, align

the pivot plate between the welded brackets on the

back of the blade. Insert the pivot shaft through the

holes in the pivot plate and the welded brackets.

Secure the pivot shaft with two 1/8" hair cotter pins.

See figure 7.

17.Hook the blade adjust spring over the spring mount

rod as shown. Insert the bolt through the hole at the

top of the blade and assemble the 3/8" flat washer

and the knob onto the bolt. Turn the knob until it is

tight. Place the plastic cap over the end of the bolt.

See figure 7.

NOTE: The blade is now set at the lowest spring tension.

To adjust the tension see the Adjustments section.

1/8" HAIR

COTTER

PIN

BLADE

ADJUST

SPRING

PLASTIC

CAP

KNOB

19.Assemble the R.H. and L.H. hitch brackets to the

angle support brackets using four 3/8" x 1" hex bolts

and 3/8" flanged nuts. See figure 9.

3/8" FLANGED NUT

3/8" x 1"

HEX BOLT

PIVOT

SHAFT

3/8"

HEX

NUT

SPRING

MOUNT

ROD

PIVOT PLATE

3/8" FLAT

WASHER

3/8" x 3-1/2"

HEX BOLT

BLADE

HAIRPIN CLIP

Figure 7

18.Arrange the angle support brackets as shown in

figure 8. Assemble the angle support brackets to the

pivot support bracket using four 3/8" x 1" hex bolts and

3/8" flanged nuts.

3/8" FLANGED NUT

Figure 9

20.Attach the channel assembly to the tractor by placing

the end of the channel inside the pivot support bracket.

Assemble the 1/2" flat washer onto the channel pivot

pin and insert the pin through the holes in the pivot

support bracket and the channel. Secure with a 3/32"

hair cotter pin. See figure 10.

PIVOT

SUPPORT

3/32" HAIR

COTTER PIN

CHANNEL

ASSEMBLY

BRACKET

3/8" x 1"

HEX BOLT

CHANNEL

PIVOT

PIN

WASHER

Figure 10

Figure 8

6

Page 7

21. Insert the end of the lower lift handle assembly through

the notch in the pivot support bracket and through the

holes in the channel. Align the lift link pin with the hole

in the welded bracket on the lower lift handle assembly. Insert the lift link pin through the hole in the

bracket and secure it with a 3/32" hair cotter pin. See

figure 11.

3/32" HAIR

COTTER PIN

ATTACHING SNOW BLADE TO TRACTOR

QUICK ATTACH TRACTOR FRAMES

24.Pull out on the hitch assembly's attachment pins and

swing the pins down away from the holes they were

in. See figure 13.

25.Hook the hitch assembly onto the shoulder bolts in the

tractor frame. See figure 13.

26.Align the holes in the hitch assembly with the holes in

the tractor frame. Insert the attachment pins to lock

the hitch assembly in place. See figure 13.

LIFT

LINK

PIN

WELDED

BRACKET

CHANNEL

LOWER LIFT

HANDLE ASSEMBLY

Figure 11

22.Assemble the handle grip onto the upper lift handle.

See figure 12.

23.Place the upper lift handle onto the lower lift handle

assembly. Align the holes and secure with the clevis

pin and a 3/32" hair cotter pin. See figure 12.

ATTACHMENT PIN

SHOULDER BOLT

Figure 13

STANDARD TRACTOR FRAMES

27.To attach the hitch assembly to the front of the tractor,

pull out on the attachment pins and swing the pins

down away from the holes they were in. See figure 14.

28.Hook the hitch assembly onto the shoulder bolts

assembled to the frame brackets. See figure 14.

29.Align the holes in the hitch assembly with the holes in

the frame brackets. Insert the attachment pins to lock

the hitch assembly in place. See figure 14.

PIN IN THIS HOLE

FOR 15" TIRES

UPPER LIFT HANDLE

CLEVIS PIN

COTTER PIN

LOWER LIFT HANDLE

ASSEMBLY

Figure 12

HANDLE GRIP

3/32" HAIR

SHOULDER BOLT

ATTACHMENT PIN

PIN IN THIS HOLE

FOR 16" TIRES

SHOULDER BOLT

ATTACHMENT PIN

Figure 14

7

Page 8

SECTION 2: OPERATING THE BLADE

CAUTION: Inspect the area to be worked

carefully before operating the snow blade.

Avoid pipes, roots, curbs or other heavy

obstructions.

The lift handle, located on the left side of the snow blade,

is used to raise and lower the blade. Pulling the lift handle

all the way back raises the snow blade. Move the lift

handle forward to lower the snow blade to the ground.

The angle of the blade can be adjusted to the right or left

by pulling back on the angle lock bar, shown in figure 15,

and repositioning the head of the blade to the right, left or

center.

ANGLE

LOCK

BAR

SECTION 3: ADJUSTMENTS

To Adjust Blade Spring

The blade adjust spring allows the blade to tilt forward to

bypass solid obstructions. The normal adjustment is for

the spring bolt to extend 1" through the top of the blade.

To increase the spring tension loosen the knob, screw

the nut farther down onto the bolt and then retighten the

knob.

To decrease the spring tension loosen the knob, screw

the nut farther out toward the end of the bolt and then

retighten the knob. Refer to figure 8 on page 6.

To Adjust Skid Shoes

The skid shoes at the ends of blade may be raised for

close work on smooth surfaces or lowered to raise the

blade to work on rough or uneven areas. Make sure both

shoes are set evenly and that the nuts are retightened

securely.

Figure 15

CAUTION: Know the terrain. Avoid

exceptionally sharp slopes or drop offs which

may be hidden by the snow. Never run the

snow blade into heavy material at high speed.

Always begin with the engine speed at the lowest possible setting, and gradually increase speed as required.

When working in a large area, do not attempt to move the

snow or dirt all in the same direction, causing an excessive buildup, which would become larger with each pass.

CAUTION: Always lower blade to ground

before leaving tractor.

8

Page 9

NOTES

9

Page 10

B

B

A

A

3

8

10

35

35

31

34

51

15

14

19

20

44

37

43

24

25

11

21

17

13

12

26

4

5

4

4

7

6

6

6

50

C

52

2

1

22

45

48

49

33

38

24

18

30

46

32

27

36

25

C

9

29

47

47

40

23

25

9

28

39

41

42

16

16

57

57

53

55

55

58

54

48

56

56

43

REPAIR PARTS LIST FOR MODELS 190-833-OEM 46" SNOW BLADE

10

Page 11

1 Washer

30 24023 1 Pivot Support Bracket

NO. NO.

REF. PART QTY. DESCRIPTION

31 23129 1 Angle Lock Bar (Long)

32 46553 1 Lift Handle, Upper

33 23151 1 Angle Lock Bar (Short)

34 23856 1 Spring Mount Rod

35 44917 2 Palnut, 3/8"

36 43010 1 Cotter Pin 1/8" x 1"

37 43348 1 Angle Lock Spring

38 47501 1 Knob

39 47553 2 Pin, Attachment

40 43362 1 Handle, Grip

41 732-3127 2 Spring, Compression

42 43659 2 Pin, Spring 3/16" x 1"

43 43013 3 Hex Lock Nut, 1/4-20 Thread

R19171616

44 43350 2 Carriage Bolt, 3/8-16 x 1"

45 46065 1 Channel Pivot Pin

46 63034 1 Lift Link Assembly

47 43001 8 Hex Bolt, 3/8-16 x 1"

48 43082 4 Hex Lock Nut, 3/8-16 Thread

51 46071 1 Hex Bolt, 1/4-20 x 3-1/4" Lg. Gr 5

49 43003 2 Lock Washer 3/8"

52 43349 1 1/4" x 1" Spring Pin

50

48829 1 Owners Manual

53 48106 2 Shoulder Bolt, 3/8-16 x 1/2"

54 43661 2 Hex Bolt, 1/4-20 x 1"

55 43063 6 Hex Bolt, 5/16-18 x 1"

56 47810 6 Hex Nut, 5/16-18 Nylock

57 24932 2 Frame Bracket

58 43086 4 Lock Washer, 5/16"

REPAIR PARTS LIST FOR MODEL 190-833-OEM 46" SNOW BLADE

1 63821 1 Blade - 46"

2 24524 1 Wear Plate - 46"

3 62980 1 Reinforcement Plate Assembly

4 43080 8 Bolt, Carriage 5/16-18 x 3/4"

5 44326 2 Bolt, Carriage 5/16-18 x 1"

6 43064 14 Hex Lock Nut, 5/16-18 Thread

7 43081 4 Washer, 5/16"

8 24690 2 Skid Shoe

9 24520 2 Bracket, Angle Support

10 24347 1 Push Channel

11 43262 1 Hex Lock Nut, 1/2-13 Thread

12 23131 1 Bolt, Special Pivot

13 1540-118 1 Washer, Flat 1/2"

14 23958 1 Plate, Pivot 7 Ga.

15 23130 1 Bracket, Spring Mt.

NO. NO.

REF. PART QTY. DESCRIPTION

16 47572 8 Flanged Lock Nut, 3/8-16 Thread

11

17 23122 1 Shaft, Pivot

18 43070 1 Washer, 3/8" STD.

19 9466R 1 Spring, Blade Adjust

20 44071 1 Hex Bolt, 3/8-16 x 3-1/2"

21 43015 1 Hex Nut, 3/8-16 Thread

22 44074 1 Plastic Cap

23 41-42 1 Pin, Clevis 1/4" x 1-1/2"

24 43343 2 Pin, Hair Cotter #4 (1/8")

25 43055 3 Pin, Hair Cotter #3 (3/32")

28 24518 1 Hitch Bracket, R.H.

26 46053 2 Spacer, .28 ID x 1"

27 63283 1 Lift Handle Assembly, Lower

29 24519 1 Hitch Bracket, L.H.

Page 12

If you are having difficulty assembling this product or if you have any

question regarding the controls, operation or maintenance of this unit,

please call the Customer Support Department. You can reach them by

calling:

1-800-800-7310

Loading...

Loading...