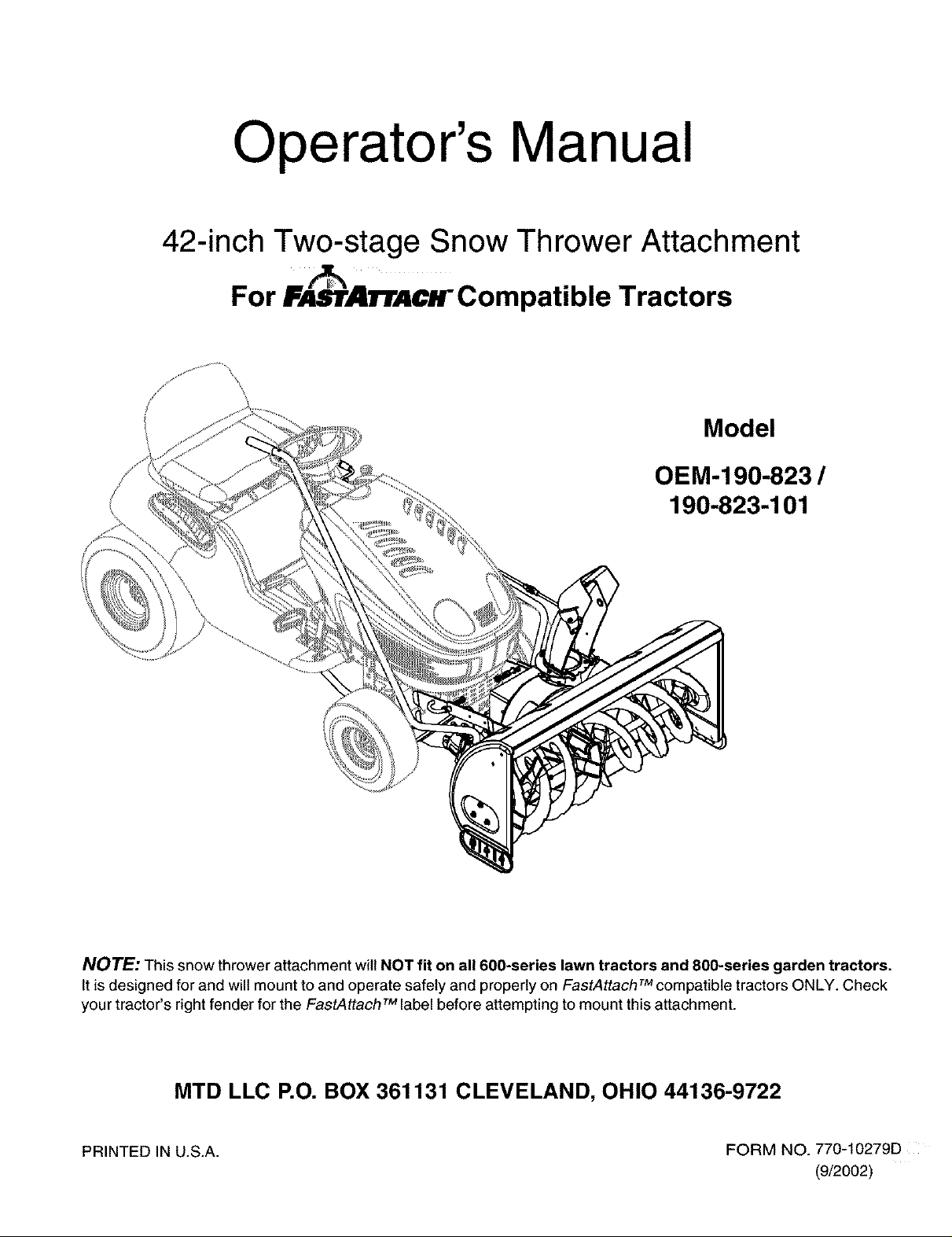

MTD OEM-190-823, 190-823-101 Owner’s Manual

Operator's Manual

42-inch Two-stage Snow Thrower Attachment

For FA_ATTACH" Compatible Tractors

Model

0EM-190-823 /

190-823-101

NOTE: This snow thrower attachment will NOT fit on all 600-series lawn tractors and 800-series garden tractors.

It is designed for and will mount to and operate safely and properly on FastAttach TM compatible tractors ONLY. Check

your tractor s right fender for the FastAttach label before attempting to mount this attachment.

MTD LLC P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-10279D

TM

(9/2002)

TABLEOFCONTENTS

Content Page

Important Safe Operation Practices ............................................................................... 3

To The Owner ............................................................................................................... 5

Contents of Crate ........................................................................................................... 5

Assembly ....................................................................................................................... 5

Controls ......................................................................................................................... 14

Operation ....................................................................................................................... 15

Making Adjustments ....................................................................................................... 16

Maintenance .................................................................................................................. 18

Model 823 Parts List ....................................................................................................... 20

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new snow thrower attachment. It will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the

equipment and copy the information from it in the space provided below. The information on the

model plate is very important if you need help from our Customer Support Department or an

authorized dealer.

You can locate the model number by looking it by looking on the rear, right portion of the snow thrower

impeller housing. A sample model plate is explained below. For future reference, please copy the model

number and the serial number of the equipment in the space below.

(Model Number) (Serial Number)

i BIR_I, _ MTD LLC

_l_ • _L_ |],_ P.O. BOX 361131

.... _" JH_H CLEVELAND,OH 44136

m,._F,,. , _ Ill® 330-220-4683

• www.mtdproducts.com 800-800-7310

Copy the model number here:

Copy the serial number here:

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or

maintenance of this unit, please call the Customer Support Department.

Call 1- (330) 220-4MTD (4683) or 1- (800)-800-7310 to reach a Customer Support representative.

Please have your unit's model number and serial number ready when you call. See previous section

to locate this information. You will be asked to enter the serial number in order to process your call.

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in per-

sonal injury. When you see this symbol--heed its warning.

cause cancer, birth defects or other reproductive harm. The battery and posts contain lead; wash hands

WARNING: The Battery and Engine Exhaust contains chemicals known to the State of California to

after handling.

DANGER: This machine was built to be operated according to the rules for safe operation in this man-

ual. As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

6.

TRAINING

1. Read, understand, and follow all instructions on the

machine and in the manual(s) before attempting to

assemble and operate. Keep this manual in a safe place

for future and regular reference and for ordering

replacement parts.

2. Be familiar with all controls and their proper operation.

Know how to stop the machine and disengage them

quickly.

3. Never allow children under 14 years old to operate this

machine. Children 14 years old and over should read and

understand the operation instructionsand safety rules in

this manual and should be trained and supervised by a

parent.

4. Never allow adults to operate this machine without proper

instruction.

5. Thrown objects can cause serious personal injury. Plan

your snow throwing pattern to avoid discharge of material

toward roads, bystanders and the like.

6. Keep bystanders, helpers, pets and children at least 75

feet from the machine while it is in operation. Stop

machine if anyone enters the area.

7. Exercise caution while operating tractor with this

attachment, especially when traveling in reverse.

PREPARATION

1. Thoroughly inspect the area where the equipment is to be

used. Remove all door mats, newspapers, sleds, boards,

wires and other foreign objects which could be thrown by

the augedimpeller.

2. Always wear safety glasses or eye shields during

operation and while performing an adjustment or repair to

protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

3. Do not operate without wearing adequate winter outer

garments. Do not wear jewelry, long scarves or other

loose clothing which could become entangled in moving

parts. Wear footwear which will improve footing on

slippery surfaces.

4. Adjust collector housing height to clear gravel or crushed

rock surfaces.

5. Disengage all clutches and shift into neutral before

starting the engine.

Never attempt to make any adjustments while engine is

running, except where specifically recommended in the

operator's manual(s).

7.

Let tractor engine and attachment adjust to outdoor

temperature before starting to clear snow.

8.

To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive. Serious

personal injury can occur when gasoline is spilled on

yourself or your clothes which can ignite. Wash your skin

and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the

engine is hot or running.

e. Allow engine to cool at least two minutes before

refueling.

f. Never over fill fuel tank. Fill tank to no more than Y2

inch below bottom of filler neck to provide space

for fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

OPERATION

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or discharge chute. Contact with the

rotating parts can amputate hands and feet.

2. Never operate with a missing or damaged discharge

chute. Keep all safety devices in place and working.

3. Never run an engine indoorsor in a poorly ventilated

area. Engine exhaust contains carbon monoxide, an

odorless and deadly gas.

4. Do not operate machine while under the influence of

alcohol or drugs.

5. Muffler and engine become hot and can cause a burn. Do

not touch.

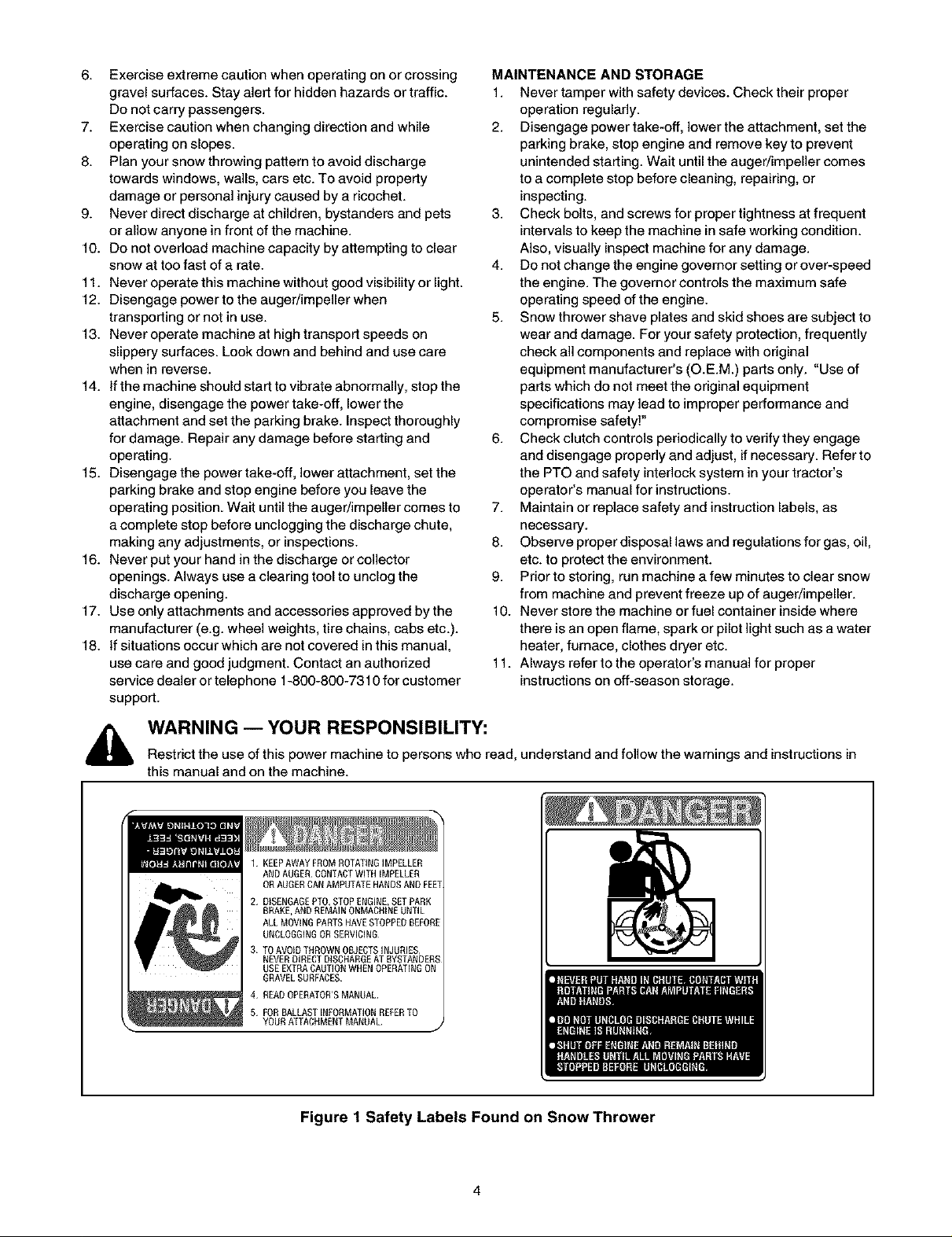

6. Exerciseextremecautionwhenoperatingonorcrossing

gravelsurfaces.Stayalertforhiddenhazardsortraffic.

Donotcarrypassengers.

7. Exercisecautionwhenchangingdirectionandwhile

operatingonslopes.

8. Planyoursnowthrowingpatterntoavoiddischarge

towardswindows,walls,carsetc.Toavoidproperty

damageorpersonalinjurycausedbyaricochet.

9. Neverdirectdischargeatchildren,bystandersandpets

orallowanyoneinfrontofthemachine.

10.Donotovedoadmachinecapecitybyattemptingtoclear

snowattoofastofarate.

11.Neveroperatethismachinewithoutgoodvisibilityorlight.

12.Disengagepowertotheauger/impellerwhen

transportingornotinuse.

13.Neveroperatemachineathightransportspeedson

slipperysurfaces.Lookdownandbehindandusecare

wheninreverse.

14.Ifthemachineshouldstarttovibrateabnormally,stopthe

engine,disengagethepowertake-off,lowerthe

attachmentandsettheparkingbrake.Inspectthoroughly

fordamage.Repairanydamagebeforestartingand

operating.

15.Disengagethepowertake-off,lowerattachment,setthe

parkingbrakeandstopenginebeforeyouleavethe

operatingposition.Waituntiltheauger/impenercomesto

acompletestopbeforeuncloggingthedischargechute,

makinganyadjustments,orinspections.

16.Neverputyourhandinthedischargeorcollector

openings.Alwaysuseaclearingtooltounclogthe

dischargeopening.

17.Useonlyattachmentsandaccessoriesapprovedbythe

manufacturer(e.g.wheelweights,tirechains,cabsetc.).

18.Ifsituationsoccurwhicharenotcoveredinthismanual

usecareandgoodjudgment.Contactanauthorized

servicedealerortelephone1-800-800-7310forcustomer

support.

MAINTENANCE AND STORAGE

1. Never tamper with safety devices. Check their proper

operation regularly.

2. Disengage power take-off, lower the attachment, set the

parking brake, stop engine and remove key to prevent

unintended starting. Wait until the augedimpeller comes

to a complete stop before cleaning, repairing, or

inspecting.

3. Check bolts, and screws for proper tightness at frequent

intervals to keep the machine in safe working condition.

Also, visually inspect machine for any damage.

4. Do not change the engine governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

5. Snow thrower shave plates and skid shoes are subject to

wear and damage. For your safety protection, frequently

check all components and replace with odgina]

equipment manufacturer's (O.EM.) parts only. "Use of

parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!"

6. Check clutch controls periodically to verify they engage

and disengage properly and adjust, if necessary. Refer to

the PTO and safety interlock system in your tractor's

operator's manual for instructions.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

9. Prior to storing, run machine a few minutes to clear snow

from machine and prevent freeze up of augedimpeller.

10. Never store the machine or fuel container inside where

there is an open flame, spark or pilot light such as a water

heater, furnace, clothes dryer etc.

11. Always refer to the operator's manual for proper

instructions on off-season storage.

_lb WARNING -- YOUR RESPONSIBILITY:

Restrict the use of this power machine to persons who read, understand and follow the warnings and instructions in

this manual and on the machine.

1 KEEPAWAYFROMROTAnNGiMPELLER

ANDAUGERCONTACTWiTHIMPELLER

ORAUGERCANAMPUTATEHANDSANDFEE1

2 DISENGAGEPTO,STOPENGINE,SFTPARR

BRAKE,ANDREMAINONMACRINEUNTIL

ALLMOVINGPARTSHAVESTOPPEDBEFORE

UNCLOGGINGORSERViCiNG¸

3 TOAVOIDTHROWNOBJECTSiNJURiES,

NEVERDIRECTD_SCRARG£ATBYSTANDERS

USEEXTRACAUTIONWRENOPERATINGON

GRAVELSURFACES¸

READ OPERATOR'S MANUAL

5

FOR BALLAST iNFORMATiON REFERTO

YOUR ATTACHMENT MANUAL¸

Figure 1 Safety Labels Found on Snow Thrower

SECTION2: TOTHEOWNER

Model 823 42-inch two-stage snow thrower is designed for use on FastAttach,. Compatible Lawn Tractors and

Garden Tractors ONLY. It will NOT fit nor operate properly or safely on ANY other tractor.

SECTION3: CONTENTSOFCRATE

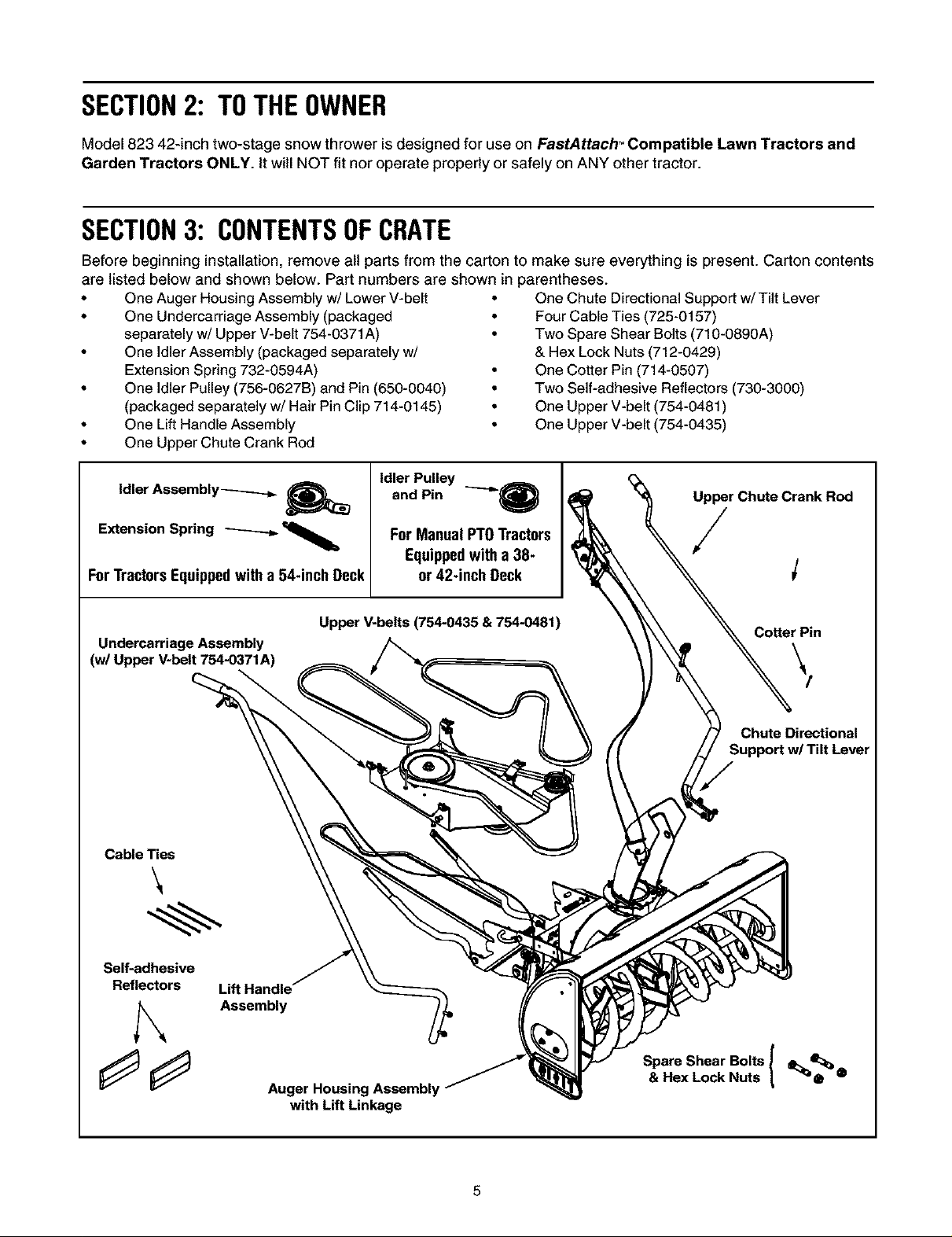

Before beginning installation, remove all parts from the carton to make sure everything is present. Carton contents

are listed below and shown below. Part numbers are shown in parentheses.

One Auger Housing Assembly w/Lower V-belt

One Undercarriage Assembly (packaged

separately w/Upper V-belt 754-0371A)

One Idler Assembly (packaged separately w/

Extension Spring 732-0594A)

One Idler Pulley (756-0627B) and Pin (650-0040)

(packaged separately w/Hair Pin Clip 714-0145)

One Lift Handle Assembly

One Upper Chute Crank Rod

Idler Pulley

and Pin "----'_O

One Chute Directional Support w/Tilt Lever

Four Cable Ties (725-0157)

Two Spare Shear Bolts (710-0890A)

& Hex Lock Nuts (712-0429)

One Cotter Pin (714-0507)

Two Self-adhesive Reflectors (730-3000)

One Upper V-belt (754-0481)

One Upper V-belt (754-0435)

Upper Chute Crank Rod

ForTractorsEquippedwith a 54-inch Deck

Upper V-belts (754-0435 & 754-0481)

Undercarriage Assembly

(w/Upper V-belt 754-0371A)

Cable Ties

\

Self-adhesive

Reflectors Lift Handle"

Assembly

ForManual PTOTractors

Equippedwith a 38-

or 42-inch Deck

/

Cotter Pin

Chute Directional

Support w/Tilt Lever

Auger Housing Assembly

with Lift Linkage

Spare Shear Bolts I

& Hex Lock Nuts L _:_O4_'®

SECTION4: ASSEMBLY

WARNING: Before installing attachment,

place tractor on afirm and level surface. Place

the PTO in the disengaged (OFF) position, set

the parking brake, shut engine off and remove

key to prevent unintended starting.

NOTE: References to LEFT and RIGHT indicate the

left and right sides of the tractor when facing forward in

the operator's position. Reference to the FRONT

indicates the grille end; to the REAR the drawbar end.

Your tractor's cutting deck, PTO belt and front deck

stabilizer bracket must be removed prior to mounting

the snow thrower attachment. If your tractor is equipped

with any front-end accessory (i.e. front bumper kit), it

must also be removed.

Idler Assembly

Shoulder

Spacer

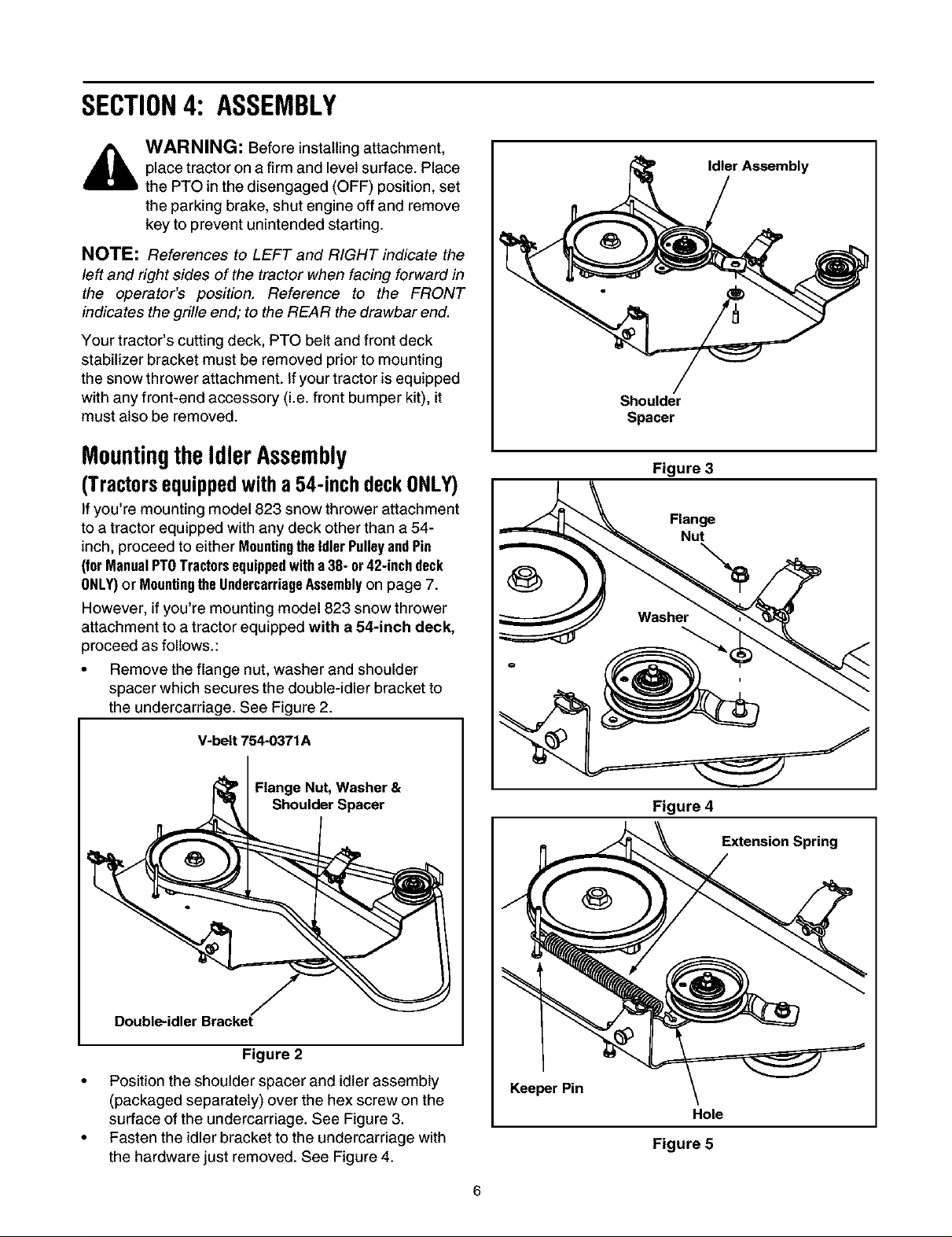

MountingtheIdlerAssembly

(Tractorsequippedwitha54-inchdeckONLY)

If you're mounting model 823 snow thrower attachment

to a tractor equipped with any deck other than a 54-

inch, proceed to either MountingtheIdlerPulleyandPin

(forManualPTOTractorsequippedwitha 38- or42-inchdeck

ONLY)or MountingtheUndercarriageAssemblyon page 7.

However, ifyou're mounting model 823 snow thrower

attachment to a tractor equipped with a 54-inch deck,

proceed as follows.:

• Remove the flange nut, washer and shoulder

spacer which secures the double-idler bracket to

the undercarriage. See Figure 2.

V-belt 754-0371A

Flange Nut, Washer &

Shoulder Spacer

Figure 3

Flange

Nut

Washer

Figure 4

Extension Spring

Double-idler Bracket

Figure 2

• Position the shoulder spacer and idler assembly

(packaged separately) over the hex screw on the

surface of the undercarriage. See Figure 3.

• Fasten the idler bracket to the undercarriage with

the hardware just removed. See Figure 4.

Keeper Pin

Hole

Figure 5

• Attach one end of the extension spring (732-

0594A) to the hole in the idler assembly just

mounted and the opposite end of the extension

spring to the keeper pin as illustrated in Figure 5.

• Position the upper v-belt as illustrated in Figure 6.

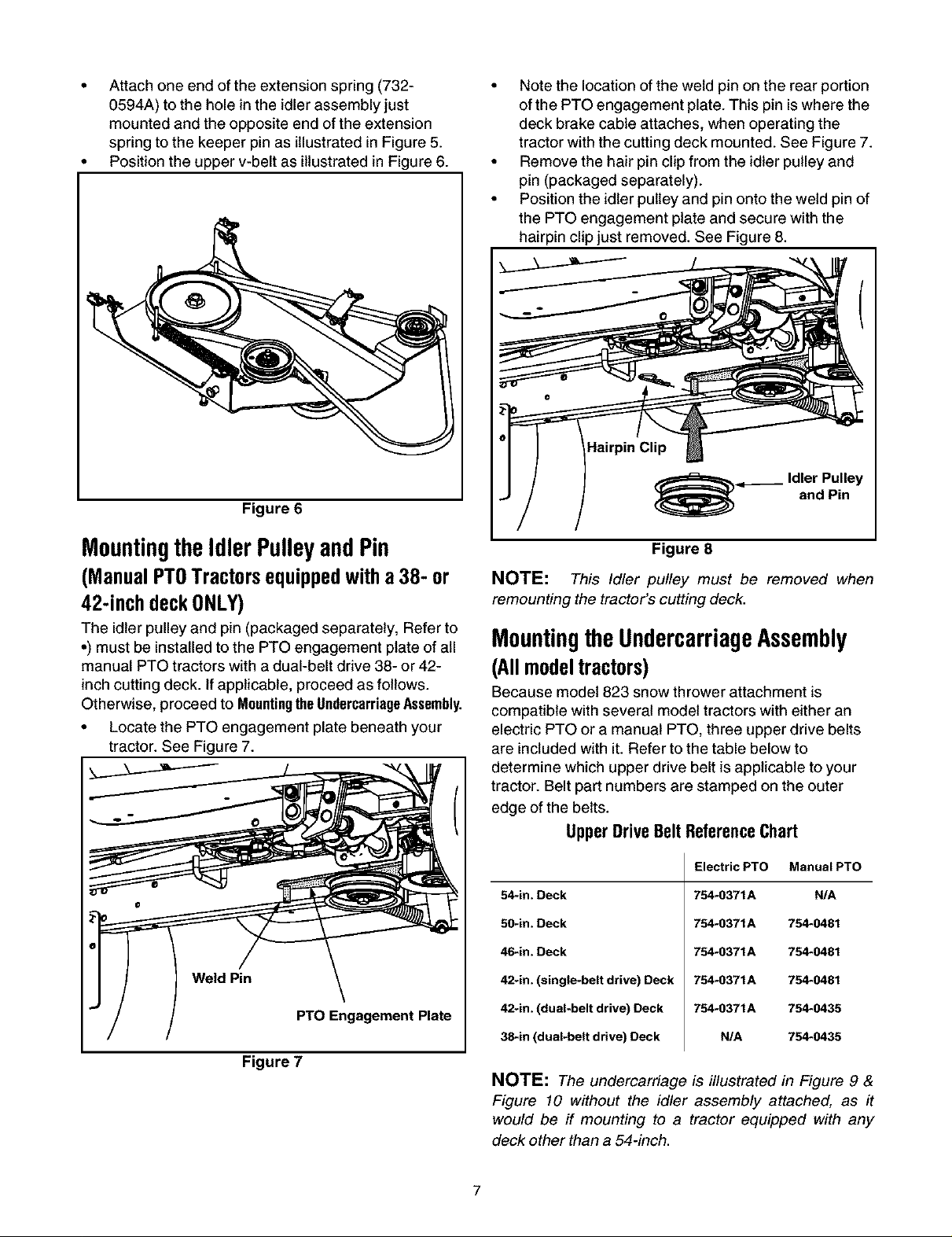

• Note the location of the weld pin on the rear portion

of the PTO engagement plate. This pin is where the

deck brake cable attaches, when operating the

tractor with the cutting deck mounted. See Figure 7.

• Remove the hair pin clip from the idler pulley and

pin (packaged separately).

• Position the idler pulley and pin onto the weld pin of

the PTO engagement plate and secure with the

hairpin clip just removed. See Figure 8.

Hairpin Clip

Figure 6

MountingtheIdler PulleyandPin

(ManualPTOTractorsequippedwitha38- or

42-inch deck ONLY)

The idler pulley and pin (packaged separately, Refer to

•) must be installed to the PTO engagement plate of all

manual PTO tractors with a dual-belt drive 38- or 42-

inch cutting deck. If applicable, proceed as follows.

Otherwise, proceed to MountingtheUndercarriageAssembly.

• Locate the PTO engagement plate beneath your

tractor. See Figure 7.

._...__ Idler Pulley

and Pin

Figure 8

NOTE: This /d/er pulley must be removed when

remounting the tractor's cutting deck.

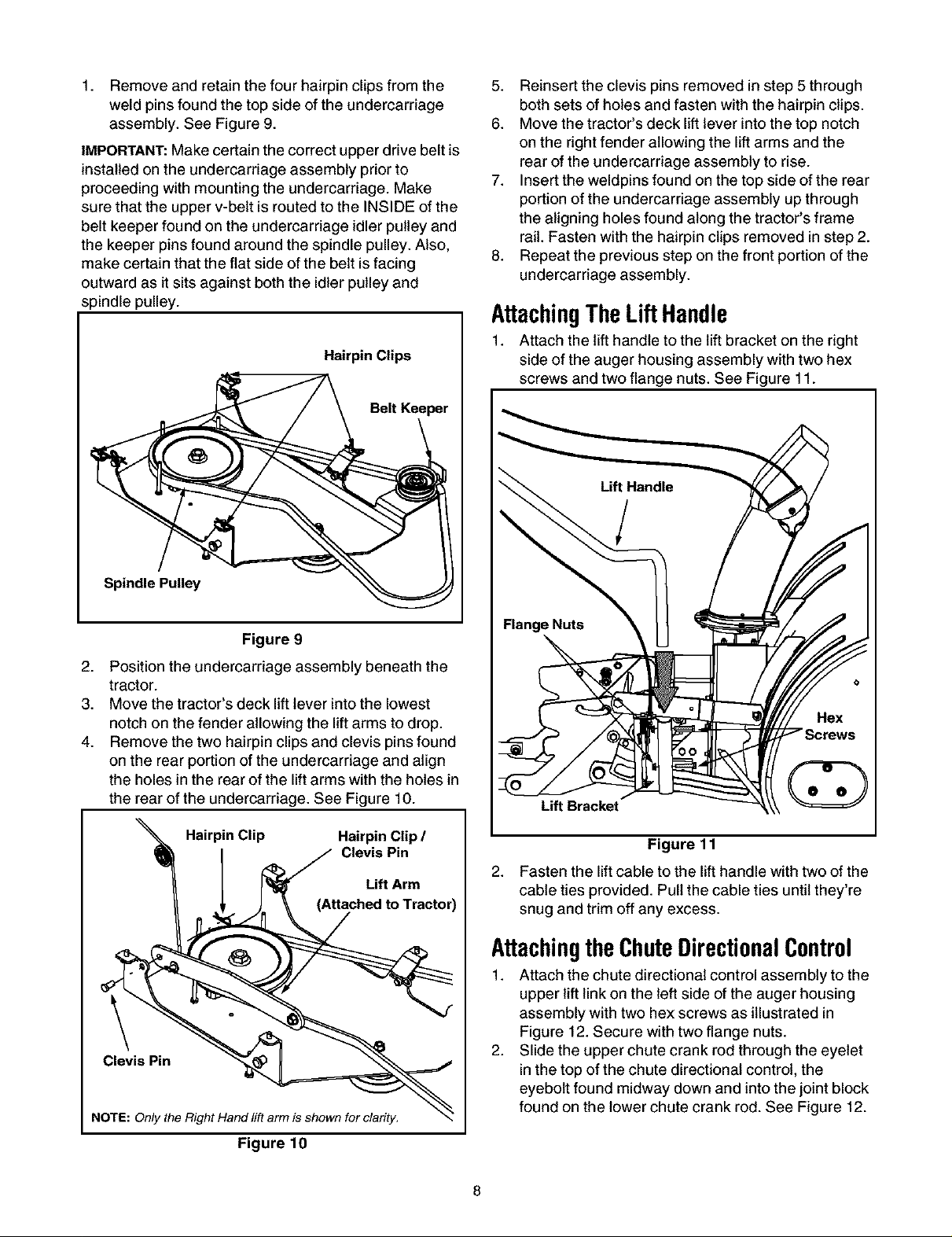

MountingtheUndercarriageAssembly

(Allmodeltractors)

Because model 823 snow thrower attachment is

compatible with several model tractors with either an

electric PTO or a manual PTO, three upper drive belts

are included with it. Refer to the table below to

determine which upper drive belt is applicable to your

tractor. Belt part numbers are stamped on the outer

edge of the belts.

UpperDriveBeltReferenceChart

Electric PTO Manual PTO

54-in. Deck

50-in. Deck

46-in. Deck

754-0371 A N/A

754-0371A 754-0481

754-037tA 754-0481

Weld Pin

Figure 7

PTO Engagement Plate

42-in. (single*belt drive) Deck

42-in. (dual-belt drive) Deck

38-in (dual-belt drive) Deck

754-0371A 754-0481

754-0371A 754-0435

N/A 754-0435

NOTE: The undercarriage is illustrated in Figure 9 &

Figure 10 without the idler assembly attached, as it

would be if mounting to a tractor equipped with any

deck other than a 54-inch.

1. Remove and retain the four hairpin clips from the

weld pins found the top side of the undercarriage

assembly. See Figure 9.

IMPORTANT: Make certain the correct upper drive belt is

installed on the undercarriage assembly prior to

proceeding with mounting the undercarriage. Make

sure that the upper v-belt is routed to the INSIDE of the

belt keeper found on the undercarriage idler pulley and

the keeper pins found around the spindle pulley. Also,

make certain that the flat side of the belt is facing

outward as it sits against both the idler pulley and

spindle pulley.

Hairpin Clips

5. Reinsert the clevis pins removed in step 5 through

both sets of holes and fasten with the hairpin clips.

6. Move the tractor's deck lift lever into the top notch

on the right fender allowing the lift arms and the

rear of the undercarriage assembly to rise.

7. Insert the weldpins found on the top side of the rear

portion of the undercarriage assembly up through

the aligning holes found along the tractor's frame

rail. Fasten with the hairpin clips removed instep 2.

8. Repeat the previous step on the front portion of the

undercarriage assembly.

AttachingTheLiftHandle

1. Attach the lift handle to the lift bracket on the right

side of the auger housing assembly with two hex

screws and two flange nuts. See Figure 11.

Belt Keeper

Spindle Pulley

Figure 9

2.

Position the undercarriage assembly beneath the

tractor.

3.

Move the tractor's deck lift lever intothe lowest

notch on the fender allowing the lift arms to drop.

4.

Remove the two hairpin clips and clevis pins found

on the rear portion of the undercarriage and align

the holes in the rear of the lift arms with the holes in

the rear of the undercarriage. See Figure 10.

"_ Hairpin Clip Hairpin Clip /

I _J Clevis Pin

| _ _' Lift Arm

._ _ched toTr=actor)

Clevis Pin

NOTE_s shown for clarit_ "%

Figure 10

I

Hex

Lift Bracket

Figure 11

2.

Fasten the lift cable to the lift handle with two of the

cable ties provided. Pull the cable ties until they're

snug and trim off any excess.

AttachingtheChuteDirectionalControl

1. Attach the chute directional control assembly to the

upper lift link on the left side of the auger housing

assembly with two hex screws as illustrated in

Figure 12. Secure with two flange nuts.

2. Slide the upper chute crank rod through the eyelet

in the top of the chute directional control, the

eyebolt found midway down and into the joint block

found on the lower chute crank rod. See Figure 12.

Loading...

Loading...