Page 1

OPERATOR’S MANUAL

8 HP TILLER

ATTACHMENT

Model Number

190-758

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning:

covered, brush-covered or grass-covered land unless the engine’s exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department, P.O. Box 368022 Cleveland, Ohio 44136-9722.

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

MTD PRODUCTS INC. P.O. BOX 368022 CLEVELAND, OHIO 44136-9722

PRINTED IN U.S.A. FORM NO. 770-8371A

Page 2

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES

WARNING: THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH, IF

NOT FOLLOWED, COULD ENDANGER THE PERSONAL SAFETY AND/OR PROPERTY OF

YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE YOUR UNIT. WHEN YOU SEE THIS SYMBOL- HEED ITS

WARNING.

Danger: This cutting machine is capable of amputating hands and feet and throwing objects.

Failure to observe the following safety instructions could result in serious injury or death.

1. GENERAL OPERATION

• Read, understand, and follow all instructions in the

manual before attempting to attach and operate

your tiller. Keep this manual in a safe place for

future reference and for ordering replacement

parts.

• Only allow responsible adults familiar with both the

tiller and tractor instructions to operate the

machine. Know controls and how to stop the

machine quickly.

• Do not put hands or feet under or near rotating

parts. Keep clear of tiller tines at all times.

• Clear the area of objects such as rocks, toys, wire,

etc. which could become caught in the tiller tines.

Always wear safety glasses or eye shields during

operation or while performing an adjustment or

repair, to protect eyes from foreign objects.

• Be sure the area is clear of other people and pets

before tilling. Stop machine if anyone enters area.

• Never carry passengers. Only the operator should

ride on the unit and only ride in the seat.

• Disengage tiller before shifting into reverse and

backing up. Always look down and behind before

and while backing.

• Slow down before turning. Operate the tractor

smoothly. Avoid erratic operation and excessive

speed.

• Never leave a running machine unattended.

Always disengage attachment, place transmission

in neutral, set park brake, stop engine and remove

key before dismounting.

• Raise and disengage tiller before making sharp

turns. Leaving tiller lowered and engage may

adversely offset steering/control of machine.

• Disengage tiller when not tilling.

• Stop engine and wait until tiller comes to a

complete stop before making any repairs,

adjusting or removing any rocks or debris.

• Till only in good daylight or good artificial light.

• Do not operate the machine while under the

influence of alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

• Use extra care when loading or unloading the

machine into a trailer or truck. This unit should not

be driven up or down a ramp onto a trailer or truck

under power, because the unit could tip over,

causing serious personal injury. The unit must be

pushed manually to load or unload properly.

• Wear sturdy, rough-soled work shoes and closefitting slacks and shirts. Do not wear loose fitting

clothes or jewelry. They can be caught in moving

parts. Never operate a unit in bare feet, sandals, or

sneakers.

• Check overhead clearance carefully before driving

under power lines, wires, bridges or low hanging

tree branches, before entering or leaving buildings,

or in any other situation where the operator may

be struck or pulled from the unit, which could result

in serious injury.

• Disengage all attachment clutches, thoroughly

depress the brake pedal, and shift into neutral

before attempting to start engine.

2. Slope Operation

• Slopes are a major factor related to loss of control

and tip-over accidents which can result in severe

injury or death. All slopes require extra caution. If

you cannot back up the slope or if you feel uneasy

on it, do not till on it.

DO:

• Till up and down slopes, not across.

• Remove obstacles such as rocks, limbs, etc.

• Watch for holes, ruts, bumps, and objects hidden

under the soil (e.g. rocks). Uneven terrain could

overturn the machine.

• Use slow speed. Choose a low enough gear so

that you will not have to stop or shift while on the

slope. Always keep tractor in gear when going

down slopes to take advantage of engine braking

action.

2

Page 3

• Keep all movement on the slopes slow and

gradual. Do not make sudden changes in speed or

direction. Rapid engagement or braking could

cause the front of the machine to lift.

• Avoid starting or stopping on a slope. If tires loose

traction, disengage tiller and proceed slowly

straight down the slope.

• For your safety, use the slope gauge included as

part of this manual to measure slopes before

operating this unit on a sloped or hilly area. If the

slope is greater than 15 degrees as shown on the

slope gauge, do not operate this unit on that area

or serious injury could result.

DO NOT:

• Do not turn on slopes unless necessary; then, turn

slowly and gradually downhill, if possible.

• Do not operate unit near drop-offs, ditches or

embankments. A wheel over the edge or an edge

caving in could cause sudden overturn.

• Do not operate tractor on wet grass. Reduced

traction could cause sliding.

• Do not try to stabilize the machine by putting your

foot on the ground.

3. Children

• Tragic accidents can occur if the operator is not

alert to the presence of children. Children are often

attracted to the machine and the tilling activity.

Never assume that children will remain where you

last saw them.

• Keep children out of the tilling area and in watchful

care of an adult other than the operator.

• Be alert and turn machine off if children enter the

area.

• Before and when backing, look behind and down

for small children.

• Never carry children. They may fall off and be

seriously injured or interfere with the safe machine

operation.

• Never allow children to operate the machine.

• Use extra care when approaching blind corners,

shrubs, trees or other objects that may obscure

vision.

4. Service

• Use extra care in handling gasoline and other

fuels. They are flammable and vapors are

explosive.

• Use only an approved container.

• Never remove gas cap or add fuel with the engine

running. Allow engine to cool at least two minutes

before refueling. Do not smoke.

• Never refuel the machine indoors.

• Never store the machine or fuel container inside

where there is an open flame, or spark, such as a

water heater, space heater, clothes dryer and the

like.

• Never run a machine inside a closed area.

• Check frequently and keep nuts and bolts tight and

keep equipment in safe working condition.

• Never tamper with safety devices. Check their

proper operation regularly. Use all guards as

instructed in this manual.

• To reduce fire hazard, keep machine free of grass,

leaves or other debris build-up. Clean up oil or fuel

spillage. Allow machine to cool before storing.

• Stop and inspect the equipment for damage if you

strike an object (e.g. rock). Repair, if necessary,

before re-starting and operating the machine.

• Never make adjustments or repairs with the engine

running.

• Check brake operation frequently. Adjust and

service as required.

• Muffler, engine, and belt guards become hot

during operation and can cause a burn. Allow to

cool down before touching.

• Do not change the engine governor settings or

overspeed the engine.

Danger: Your unit was built to be operated according to the rules for safe operation in this

manual. As with any type of power equipment, carelessness or error on the part of the operator can

result in serious injury. If you violate any of these rules, you may cause serious injury to yourself or

others.

3

Page 4

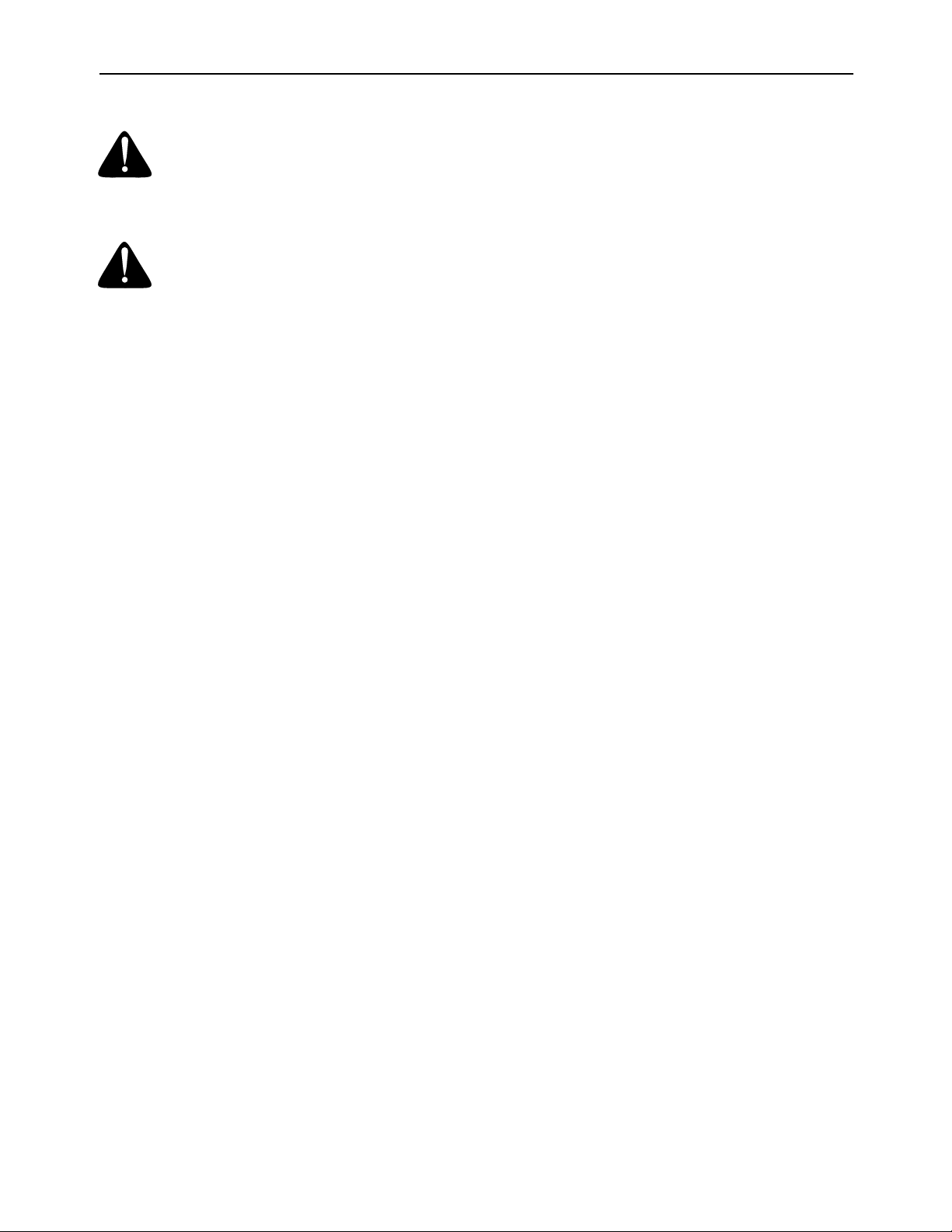

SECTION 1: UNPACKING

Extension

Spring

Swivel

Wheel

J

I

G

E

Link

Rod

Assembly

Figure 1

H

A

F

Assembly

B

D

Stabilizer

Hitch

Bar

E

Link

Remove the tiller, all loose parts and hardware pack

from the carton before discarding the carton.

Contents of Hardware Pack:

(See Figure 2)

A (1) Flat Washer 1/2" I.D. x 1" O.D.

B (1) Sleeve

C (1) Ferrule

D (2) Large Flat Washers

E (3) Hairpin Clips

F (1) Hairpin Clip

G (1) Hex Nut 5/16-18 Thread

H (1) Shoulder Bolt

I (1) Clevis Pin

J (1) Flat Washer 1/2" I.D. x 15/16" O.D.

K (1) Spacer (Not Shown)

L (1) Lock Washer (Not Shown)

C

M (1) Flat Wash 5/8 ID x 1 1/4 OD

N (1) Hairpin

For shipping purposes, the engine oil dipstick has

been placed between the engine and the gas tank.

Insert dipstick into oil fill tube before operating the

unit.

M

Figure 2

N

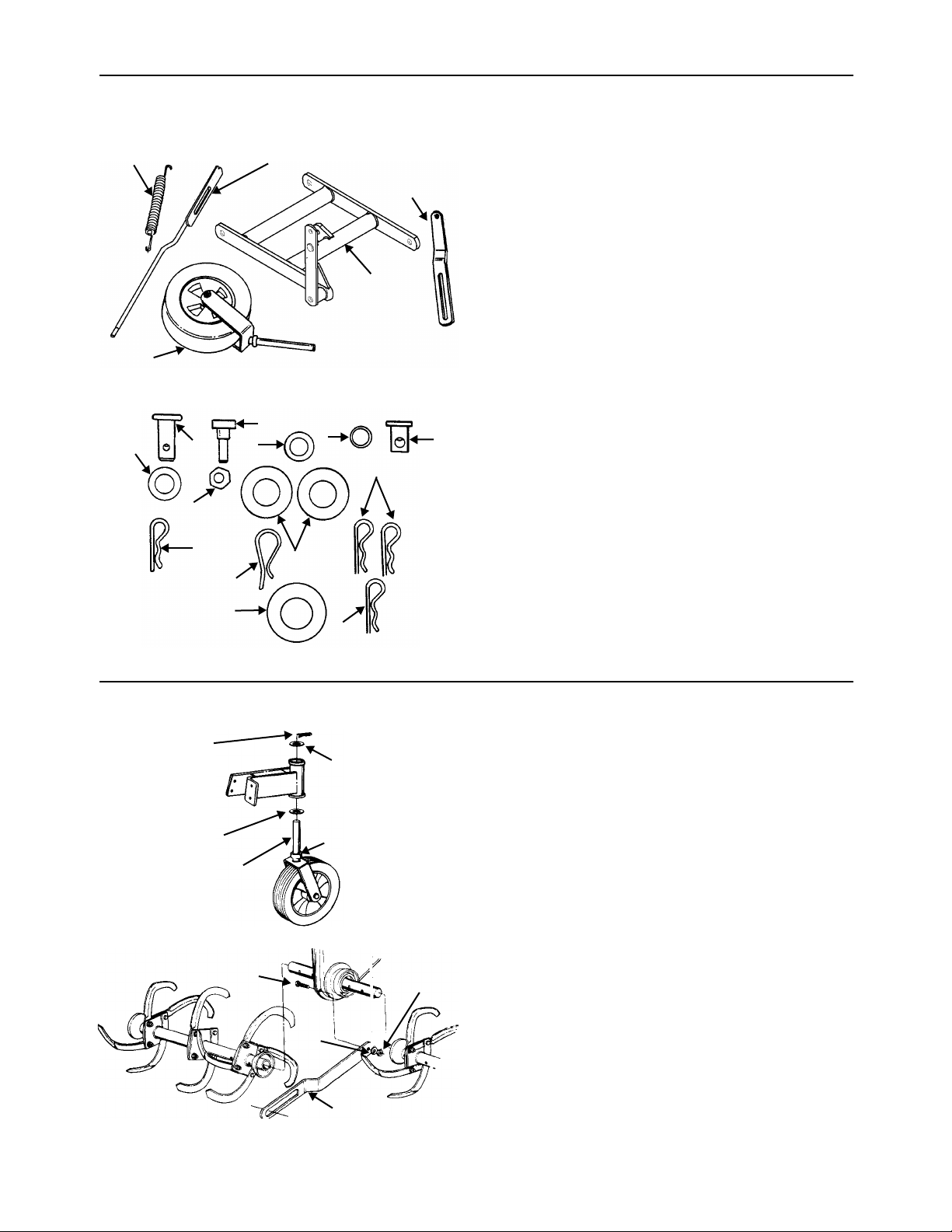

SECTION 2: ASSEMBLY INSTRUCTIONS

Hairpin

Clip (E)

Flat

Washer (D)

Swivel

Wheel

Shaft

Shoulder Bolt (H)

Flat

Washer (D)

Spacer (K)

Figure 3

Hex Nut

(G)

Lock

Washer (L)

IMPORTANT: This unit is shipped WITHOUT

GASOLINE or OIL. After assembly, service

engine with gasoline and oil as instructed in the

separate engine manual packed with your unit.

NOTE: Reference to right or left hand side of the

mower is observed from the operating position.

1. Place spacer (K), then one flat washer (D) over

2. Assemble the stabilizer link to front of chain

swivel wheel shaft. Place swivel wheel in

position on tiller. See Figure 3. Next, place

other flat washer (D) over swivel wheel shaft.

Secure with hairpin clip (E). See Figure 3.

case on tiller. Secure with shoulder bolt (H),

lock washer (L) and hex nut (G). See Figure 4.

Figure 4

Stabilizer

Link

4

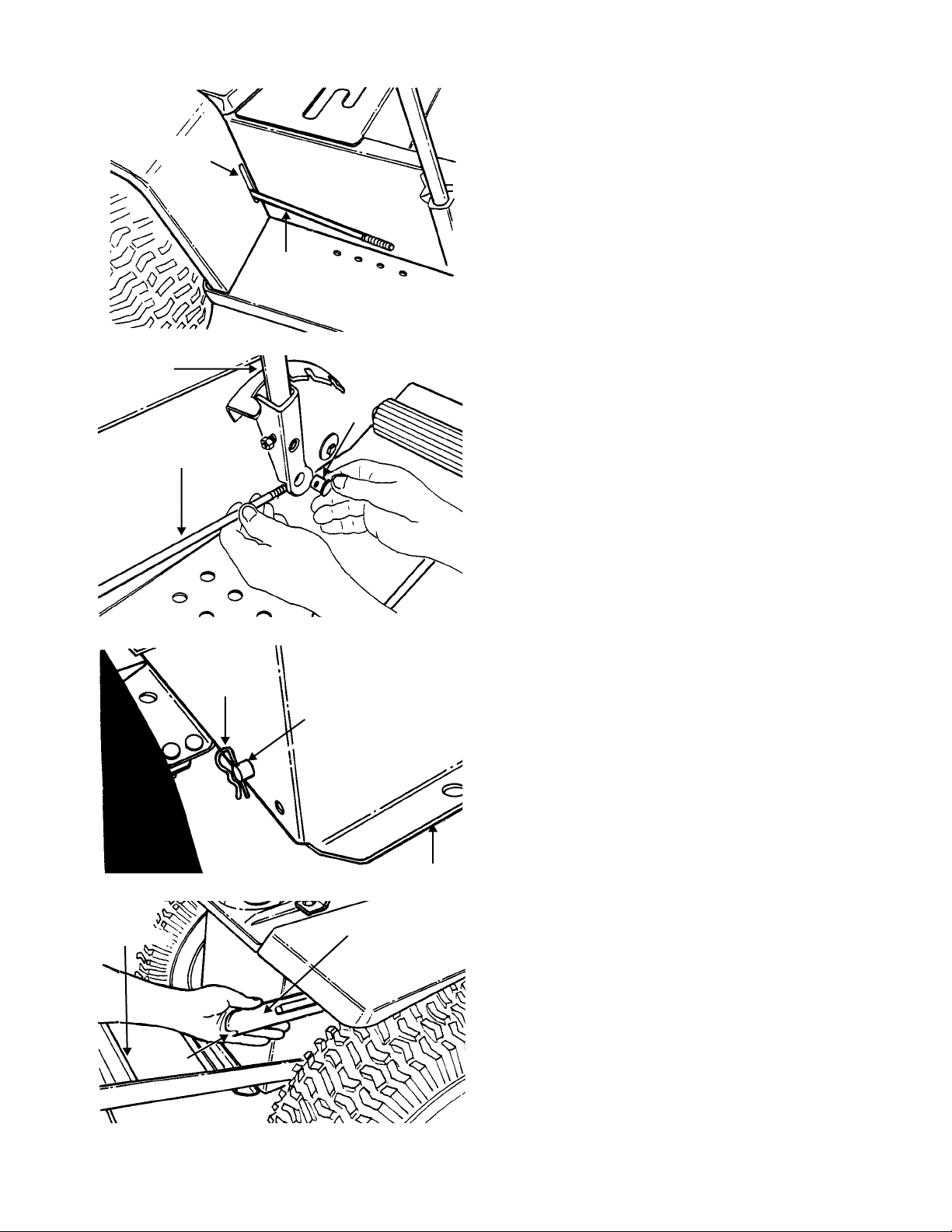

Page 5

5

Slot In

Tractor

Frame

Lift

Handle

Link Rod

Assembly

Link Rod

Assembly

Figure 5

Ferrule

3. Place the link rod assembly through the slot in

the tractor fender. See Figure 5.

4. Thread ferrule (C) onto link rod assembly until

approximately 1/4” of threads are showing. Place

ferrule (C) through hole in bottom of lift handle on

tractor. Slide washer (M) onto ferrule (C) and

secure with hairpin clip (N). See Figure 6.

Hitch

Bar

Assembly

Notch

Figure 6

Hairpin Clip

Figure 7

Hitch Rod

Rear of Tractor

Flat End

of Link Rod

Assembly

5. Remove the hitch rod from the rear of your

tractor by removing the two hairpin clips. See

Figure 7.

NOTE:

On 16 horsepower tractors, it is necessary

to hold up the gasoline tank when removing and

replacing the hitch rod.

6. Place new hitch rod (longer) in position on rear

of tractor. See Figure 7.

7. Place hitch bar assembly in position over ends

of hitch rod and secure with hairpin cotters

provided with tractor hitch bar. See Figure 8.

8. Turn flat end of link rod assembly so that the

notch is down. See Figure 8.

Figure 8

Page 6

Flat Washer (J)

Hairpin Clip (E)

6

Figure 9

Hairpin

Clip

Weld Pin

9. Lift hitch bar assembly up and place sleeve (B)

over weld stud on hitch bar. Next, place link rod

over sleeve and secure with one flat washer (J)

and hairpin clip (E). See Figure 9.

Hitch Rod

on Tractor

10. Back the tractor up to the tiller and hook the

hitch bar assembly to it. See Figure 10.

Hitch Bar

Assembly

Clevis Pin

(I)

Figure 10

Flat

Washer

(A)

Figure 11

Hairpin

Hairpin

Clip (E)

Hole in

Running

Board

Clip

NOTE:

Figure 10 is shown without the tractor for

clarity.

11. Remove one hairpin clip from hitch rod on tiller,

line up hitch bar assembly and install hitch rod.

Secure with hairpin clip. See Figure 10.

12. Secure the stabilizer link to the hitch bar

assembly with clevis pin (I), flat washer (A) and

hairpin clip (E), as shown in Figure 11.

13. Using a piece of wire, hook one end of

extension spring in the hole on the running

board and the other end of spring to the notch

in the linkage rod. See Figure 12. (On units with

a one piece fender, remove one bolt which

secures the bracket to the running board,

closest to the frame, in order to attach the

spring.)

Notch in

Linkage Arm

Figure 12

Extension Spring

NOTE:

Figure 12 is shown with the rear wheel

removed for clarity. It is not necessary to remove for

assembly.

Page 7

7

A

Ground

Wire

Wire

Lead

Adapter

Harness

Switch

Adapter

Harness

B

Wire Harness

on

Tractor

Tiller

Wire

Harness

Figure 13

14. There are two different types of seat safety

switches. Refer to Figure 13A and Figure 13B.

If the seat switch on your tractor is as shown in

Figure 13A , assemble the adapter harness as follows.

• On units with a one-piece fender, first remove

the fender from the unit by removing for selftapping screws from the top of the fender,

Seat

Wire

Lead

and four bolts, lock washers and nuts from

the fender and running boards.

• Unplug the wire lead from the switch located

on the right hand seat bracket. Plug the end

of the adapter harness into the switch on the

seat bracket.

• Plug the wire lead on the tractor into the

same end of the adapter harness.

• Attach the ground wire to a bolt on the tractor

frame.

• Plug the other end of the wire adapter into the

wire harness on the tiller.

NOTE:

adapter from your unit when the tiller is removed.

If your tractor is equipped with a plug on the

seat as shown in Figure 13B , connect the wire

harness on the tiller to the tractor as follows.

Disconnect the wire lead under the seat of the

tractor from the wire harness on the tractor.

Connect the plug on the tiller wire harness to the

wire lead on the seat. See Figure 13B.

15. Raise and lower the tractor lift lever a couple of

This tiller attachment is not designed to be raised off

the ground by the tractor lift lever. It is designed to

trail behind the tractor. The lift lever is only used to

raise the lower the tines.

It is not necessary to remove the wire

WARNING:

attachment, make certain to reconnect

the wire lead under the seat to the wire

harness on the tractor. Failure to do so

could result in serious personal injury.

The seat switch is a safety device,

designed for your protection. Never

attempt to bypass its operation.

times to make sure that the tiller tines are going

up and down.

When removing the tiller

SECTION 3: OPERATION

GAS AND OIL FILL-UP

Service the engine with gasoline and oil as

instructed in the separate engine manual packed

with your mower. Read instructions carefully.

WARNING:

indoors, with engine running or until

the engine has been allowed to cool for

at least two minutes after running.

TO START ENGINE

1. Attach spark plug wire to spark plug.

2. Place the tine clutch rod in the disengaged

position. See Figure 14.

Never fill fuel tank

Pull Forward

To Disengage

Push Back

To Engage

Tine Clutch Rod

Figure 14

Page 8

3. Push the CHOKE lever down all the way. Set

the throttle in the FAST position. See Figure 15.

NOTE:

4. Grasp the recoil starter handle and pull back

5. After engine starts, move choke lever gradually

A warm engine requires less choking.

rapidly, extending rope fully. Return it slowly to

the engine.

to OFF position.

Choke

Lever

Throttle

Control

Lever

Figure 15

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area)

clean to permit proper air circulation which is

essential to engine performance and life. Be certain

to remove all dirt and combustible debris from

muffler area.

CHAIN CASE LUBRICATION

The chain case is sealed at the factory and does not

require checking or changing.

If the chain case is disassembled for repair, replace

the grease with 12 ounces of plastilube “0” grade

grease (factory number 737-0133-14 ounce

container).

BELT REPLACEMENT

1. Remove the tine clutch rod by removing the

cotter pin in the hooked end of rod. See Figure

16.

Cotter Pin

TO STOP ENGINE

1. To stop the engine, move the throttle control

lever to the STOP position.

2. Disconnect the spark plug wire and ground it

against the engine to prevent accidental starting

while equipment is unattended.

SECTION 4: MAINTENANCE

WARNING:

and ground the spark plug wire before

performing any repairs or maintenance.

ENGINE

Refer to the separate engine manual for engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and

follow instructions carefully.

Service air cleaner every 25 hours under normal

conditions. Clean every few hours under extremely

dusty conditions. Poor engine performance and

flooding usually indicates that the air cleaner should

be serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

The spark plug should be cleaned and the gap

reset once a season. Spark plug replacement is

recommended at the start of each season; check

engine manual for correct plug type and gap

specifications.

Be sure to disconnect

Tine Clutch

Rod

Figure 16

2. Slide the tine clutch rod out of the belt cover.

3. Remove the belt cover by removing three hex

head self-tapping screws with a 3/8" wrench.

See Figure 17.

Belt Cover

Three Self-

Tapping Screws

Figure 17

8

Page 9

4. Move the idler bracket forward (disengaged

position) to remove the belt tension. Lift the belt

off the engine pulley and chain case pulley. See

Figure 18.

5. Using two 9/16" wrenches, remove the hex lock

nut holding the idler pulley and idler belt keeper.

NOTE:

pulley must be installed with the hub side towards

the chain case.

Upon reassembly of new belt, the idler

Idler

Bracket

Engine

Pulley

Idler Bracket

Disengaged

Chain

Case

Pulley

SECTION 5: OFF-SEASON

STORAGE

The following steps should be taken to prepare the

tiller for storage.

1. Clean tiller thoroughly.

2. Refer to engine manual for correct engine

storage instructions.

3. Coat tines with chassis grease to prevent

rusting.

4. Store tiller in a dry, clean area. Do not store

next to corrosive materials, such as fertilizer.

NOTE:

in an unventilated or metal storage shed, care

should be taken to rust-proof the equipment. Using

a light oil or silicone, coat the equipment, especially

cables and all moving parts.

When storing any type of power equipment

Idler Pulley

Figure 18

6. Reverse step 1 through step 5 to install the new

belt.

Hex Lock Nut

SECTION 6: OPTIONAL

EQUIPMENT

ACCESSORIES PART NUMBER

Agricultural Traction Tires OEM-190-859

OEM-190-865*

100 lb. Wheel Weights OEM-190-784

(2 per set / 50 lbs. each)

Electric Lift Kit OEM-190-749

*For use with 1997 or newer tractor.

9

Page 10

Model 758

PARTS LIST FOR CHAIN CASE ASSEMBLY COMPLETE 04991

Ref.

Part No. Code Description

No.

1 05034 Bearing Housing 1.375" Dia.

2 14895 Housing Assembly—R.H.

5 714-0136 #6 Hi-Pro Key 5/32" x .62" Lg.

6 14892 Input Shaft Assembly

7 14894 Housing Assembly—L.H.

8 741-0155 Ball Bearing .62" I.D. x 1.38"

O.D.

9 736-0329 L-Wash. 1/4" I.D.*

10 710-0258 Hex Bolt 1/4-20 x .62" Lg.*

14 736-0329 L-Wash. 1/4" I.D.

15 712-0287 Hex Cent. L-Nut 1/4-20 Thd.

16 04973 Dust Cap Cover

17 712-0158 Hex Cent. L-Nut 5/16-18 Thd.

18 736-0119 L-Wash. 5/16" I.D.*

19 04530 Cast Bearing Housing

20 721-0117 Oil Seal

21 748-0194 Flange Bearing 1.25" I.D. x

1.75" O.D.

Ref.

Part No. Code Description

No.

22 721-0119 Gasket

23 713-0150 Roller Chain #40-2 x 34.0" Lg.

24 711-0506 Tine Shaft

25 717-0189 Double Sprocket T24-2 Teeth

1/2" Pitch

26 715-0125 Spiral Pin 3/8" Dia. x 2.00" Lg.

27 710-0258 Hex Bolt 1/4-20 x .62" Lg.*

28 710-0118 Hex Bolt 5/16-18 x .75" Lg.

29 736-0119 L-Wash. 5/16" I.D.*

30 736-0195 Fl-Wash. 5/16" I.D.

31 711-0504 Sprocket Shaft

32 748-0855 Flange Bearing .62" I.D. x .75"

O.D.

33 04529 Double Sprocket Assembly

34 713-0149 Roller Chain #35-2 x 36.75"

Lg.

35 748-0192 Spacer 5/8" I.D. x 7/8" O.D.

10

Page 11

Model 758

Assembles to Lift

Handle on Tractor

100

101

Hooks in Running

Board on Tractor

11

Page 12

Model 758

Ref.

Part No. Description

No.

1 725-0713 Safety Switch

2 725-1290 Wire Harness

3 725-1393 Adapter Harness

5 714-0147 Internal Cotter Pin

6 736-0179 Fl-Wash. 1/2" I.D. x .93" O.D.

7 638-0016 Link Rod Assembly

8 732-0390 Extension Spring 1.25" O.D. x

12.75" Lg.

9 714-0114 Sq. Key 1/4" x 1/4" x 2.00" Lg.

10 689-0004 Hitch Bar Assembly

11 712-0138 Hex Nut 1/4-28 Thd.*

12 736-0329 L-Wash. 1/4" I.D.*

13 710-0195 Hex Bolt 1/4-28 x .62" Lg.

14 04966 Support Frame Assembly

15 710-0429 Hex Hd. “B”-Tap Scr. #10 x .62"

Lg.

16 727-0225 #2 Dog Chain x 20" Lg. (2 Req’d.)

17 710-0623 Hex Wash. Hd. Self-Tap Scr.

3/8-24 x .75" Lg.

18 736-0169 L-Wash. 3/8" I.D.*

19 04978 Swivel Wheel Support

20 736-0188 Fl-Wash. 3/4" I.D. x 1.50" O.D.

21 741-0382 Flange Bearing 3/4" I.D. x 1.00"

O.D.

22 04981 Swivel Wheel Caster

23 734-0979 Wheel Assembly 10.0 x 2.75

24 738-0476 Shoulder Bolt .623" I.D. x 3.62" Lg.

25 712-0290 Hex Cent. L-Nut 7/16-14 Thd.

26 04985 L.H. Shield Hinge Flap

04986 R.H. Shield Hinge Flap (Not

Shown)

27 714-0115 Cotter Pin 1/8" Dia. x 1.00" Lg.*

28 747-0340 L.H. Flap Rod

747-0339 R.H. Flap Rod (Not Shown)

29 710-0258 Hex Bolt 1/4-20 x .62" Lg.*

30 736-0173 Fl-Wash. 1/4" I.D.

31 14891 Brace—Tine Shield

32 712-0287 Hex Nut 1/4-20 Thd.*

33 710-0776A Hex Wash. Hd. Self-Tap Scr. 1/4"

x .62" Lg.

34 14890 Stabilizer Link

35 710-0342 Hex Bolt 3/8-16 x 1.25" Lg.*

36 711-0469 Spacer .752" I.D. x 1.25" O.D.

37 712-0158 Hex Cent. L-Nut 5/16-18 Thd.

38 04987 Clutch Lever

39 747-0379 Clutch Rod

40 738-0140 Shoulder Bolt 7/16" Dia. x 1.75"

41 04992 Idler Bracket

42 711-0310 Clevis Pin

43 747-0342 Clutch Link 3.62" Lg.

44 738-0155 Shoulder Bolt .435" Dia. x .160"

45 736-0273 Fl-Wash. .50" I.D. x 1.0" O.D. x .06

46 732-0384 Extension Spring .62" O.D. x

6.12" Lg.

47 712-0214 Hex Crown Nut 3/8-24 Thd.

Ref.

Part No. Description

No.

48 754-0253 “V”-Belt (Kevlar)

49 756-0351 1/2" “V”-Pulley 4.75" O.D. x .625"

Bore

50 736-0158 L-Wash. 5/8" I.D.*

51 712-0221 Hex Ins. L-Nut 5/18-16 Thd.

52 712-0375 Hex Cent. L-Nut 3/8-16 Thd.

53 736-0140 Fl-Wash. 3/8" I.D.

54 756-0293A Idler Pulley 4.0" O.D.

55 710-0314 Hex Bolt 7/16-20 x 1" Lg.

56 736-0171 L-Wash. 7/16" I.D.*

57 736-0319 Fl-Wash. 7/16" I.D. x 1.38"

58 756-0350 1/2" “V”-Pulley .475" O.D. x 1.00"

Bore

59 13819 Belt Guard

60 710-0520 Hex Bolt 3/8-16 x 1.50" Lg.*

61 712-0158 Hex Cent. L-Nut 5/16-18 Thd.

62 710-0780 Hex Bolt 7/16-14 x 2.00" Lg.

63 04970 Tine Adapter Assembly

64 742-0243 Tine—L.H.

65 731-0374 Flange Bearing 1.00" I.D.

66 748-0276 Spacer

67 736-0281 Thrust Wash. 1/2" I.D. x 1.55"

68 742-0244 Tine—R.H.

69 04995 Tine Assembly Comp.—L.H.

70 712-0241 Hex Nut 3/8-24 Thd.*

71 736-0119 L-Wash. 5/16" I.D.*

72 710-0459 Hex Bolt 3/8-24 x 1.5" Lg.*

73 712-0290 Hex Cent. L-Nut 7/16-14 Thd.

74 04991 Chain Case Ass’y. Comp.

75 04996 Tine Assembly Comp.—R.H.

76 710-0376 Hex Bolt 5/16-18 x 1.00" Lg.*

77 712-0267 Hex Nut 5/16-18 Thd.*

78 710-0237 Hex Bolt 5/16-24 x .62"

80 04988A Clutch Support Bracket

81 738-0296 Shld. Bolt .435" Dia. x .265"

5/16-18 Thd.

82 710-0412 Hex Bolt 1/4-28 x .75" Lg.

83 720-0142 Plastic Grip

84 738-0183 Shoulder Bolt .498" Dia. x .212"

Lg.

85 747-0378 Clutch Handle

86 14298 Clutch Support Shroud

87 04519 Engine Mounting Bracket

90 710-0201 Hex Bolt 3/8-16 x .62" Lg.

92 04975 L.H.—Side Plate

04976 R.H.—Side Plate (Not Shown)

93 04983 L.H.—Tine Shield

94 04984 R.H.—Tine Shield

95 710-0116 Hex Bolt 5/16-18 x 2.00" Lg.*

96 — 8 H.P. Engine

97 738-0992 Hitch Rod

98 750-0336 Push Bar Sleeve .503" I.D. x .624"

O.D.

99 711-0770 Ferrule

100 736-0187

101 714-0145 Hairpin clip

Flat Wash 5/8 ID x 1 1/4 OD

12

Page 13

SECTION 7: TROUBLE SHOOTING GUIDE

Trouble Possible Cause(s) Corrective Action

Engine fails to

start

Engine runs

erratic

Engine overheats

Tines do not

engage

Fuel tank empty, or stale fuel.

Throttle control lever not in correct

starting position (if so equipped).

Blocked fuel line.

Dirty aircleaner.

Choke not in ON position.

Spark plug wire disconnected.

Faulty spark plug.

Engine flooded.

Unit running on CHOKE.

Spark plug wire loose.

Blocked fuel line or stale fuel.

Vent in gas cap plugged.

Water or dirt in fuel system.

Dirty air cleaner.

Carburetor out of adjustment.

Engine oil level low.

Dirty air cleaner.

Air flow restricted.

Carburetor not adjusted properly.

Foreign object lodged in tines.

Tine clevis pin(s) missing.

Pulley and idler not in correct

adjustment.

Fill tank with clean, fresh gasoline. Fuel will not last over

thirty days unless a fuel stabilizer is used.

Move throttle lever to start position.

Clean fuel line.

Refer to the engine manual packed with your unit.

Move switch to ON position.

Connect wire to spark plug.

Clean, adjust gap or replace.

Refer to the engine manual packed with your unit.

Move choke lever to OFF position.

Connect and tighten spark plug wire.

Clean fuel line; fill tank with clean, fresh gasoline. Fuel will

not last over thirty days unless a fuel stabilizer is used.

Clear vent.

Drain fuel tank. Refill with fresh fuel.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Fill crankcase with proper oil.

Refer to the engine manual packed with your unit.

Refer to the engine manual packed with your unit.

Adjust carburetor as instructed in separate engine manual.

Dislodge foreign object.

Replace tine clevis pin(s).

Take unit to authorized service dealer.

Belt worn and/or stretched.

Replace belt.

Note: For repairs beyond the minor adjustments above, contact your local authorized service dealer.

13

Page 14

Page 15

Page 16

MANUFACTURER’S LIMITED WARRANTY FOR:

For TWO YEARS from the date of retail purchase

within the United States of America, its possessions

and territories, MTD PRODUCTS INC will, at its

option, repair or replace, for the original purchaser,

free of charge, any part or parts found to be

defective in material or workmanship. This warranty

covers units which have been operated and

maintained in accordance with the operating

instructions furnished with the unit, and which have

not been subject to misuse, abuse, commercial use,

neglect, accident, improper maintenance or

alteration.

Normal wear parts or components thereof are

subject to separate terms as noted below in the “No

Fault Ninety Day Consumer Warranty” clause.

All normal wear part failures will be covered on this

product for a period of 90 days regardless of cause.

After 90 days, but within the two year period, normal

wear parts failures will be covered ONLY IF caused

by defects in material or workmanship of OTHER

component parts. Normal wear parts are defined as

batteries*, belts, blades, blade adapters, grass

bags, rider deck wheels, seats, snow thrower skid

shoes, shave plates and tires.

How to obtain service: Warranty service is

available, with proof of purchase, through your local

authorized service dealer. To locate the dealer in

your area, please check the yellow pages or contact

the Customer Service Department of MTD

PRODUCTS INC, P. O. Box 368022, Cleveland,

Ohio 44136-9722. Phone 1 (800) 800-7310. The

return of a complete unit will not be accepted by the

factory unless prior written permission has been

extended by the Customer Service Department of

MTD PRODUCTS INC.

Transportation charges: Transportation charges

for the movement of any power equipment unit or

attachment are the responsibility of the purchaser.

Units exported out of the United States: MTD

PRODUCTS INC does not extend any warranty

for products sold or exported outside of the United

States of America, its possessions and territories,

except those sold through MTD PRODUCTS INC’s

authorized channels of export distribution.

Other Warranties:

1. The engine or component parts thereof carry

separate warranties from their manufacturers.

Please refer to the applicable manufacturer’s

warranty on these items.

2. *Batteries are covered by a 90-day replacement

warranty.

3. Log splitter pumps, valves and cylinders or

component parts thereof are covered by a one

year warranty.

4. All other warranties, express or implied,

including any implied warranty of

merchantability or fitness for a particular

purpose, are hereby expressly disclaimed in

their entirety.

5. The provisions as set forth in this warranty

provide the sole and exclusive remedy of MTD

PRODUCTS INC’s obligations arising from the

sales of its products. MTD PRODUCTS INC will

not be liable for incidental or consequential loss

or damage.

How state law relates to this warranty: This

limited warranty gives you specific legal rights, and

you may also have other rights which vary from

state to state. Certain disclaimers are not allowed in

some states and therefore they may not apply to

you under all circumstances.

NOTE: This warranty does not cover routine

maintenance items such as lubricants, filters, blade

sharpening and tune-ups, or adjustments such as

brake adjustments, clutch adjustments or deck

adjustments. Nor does this warranty cover normal

deterioration of the exterior finish due to use or

exposure.

Loading...

Loading...