Page 1

Safety • Assembly • Operation • Tips & Techniques • Maintenance • Troubleshooting • Parts Lists • Warranty

OPERATOR’S MANUAL

Model

OEM-190-032

190-032-101

PRINTED IN U.S.A.

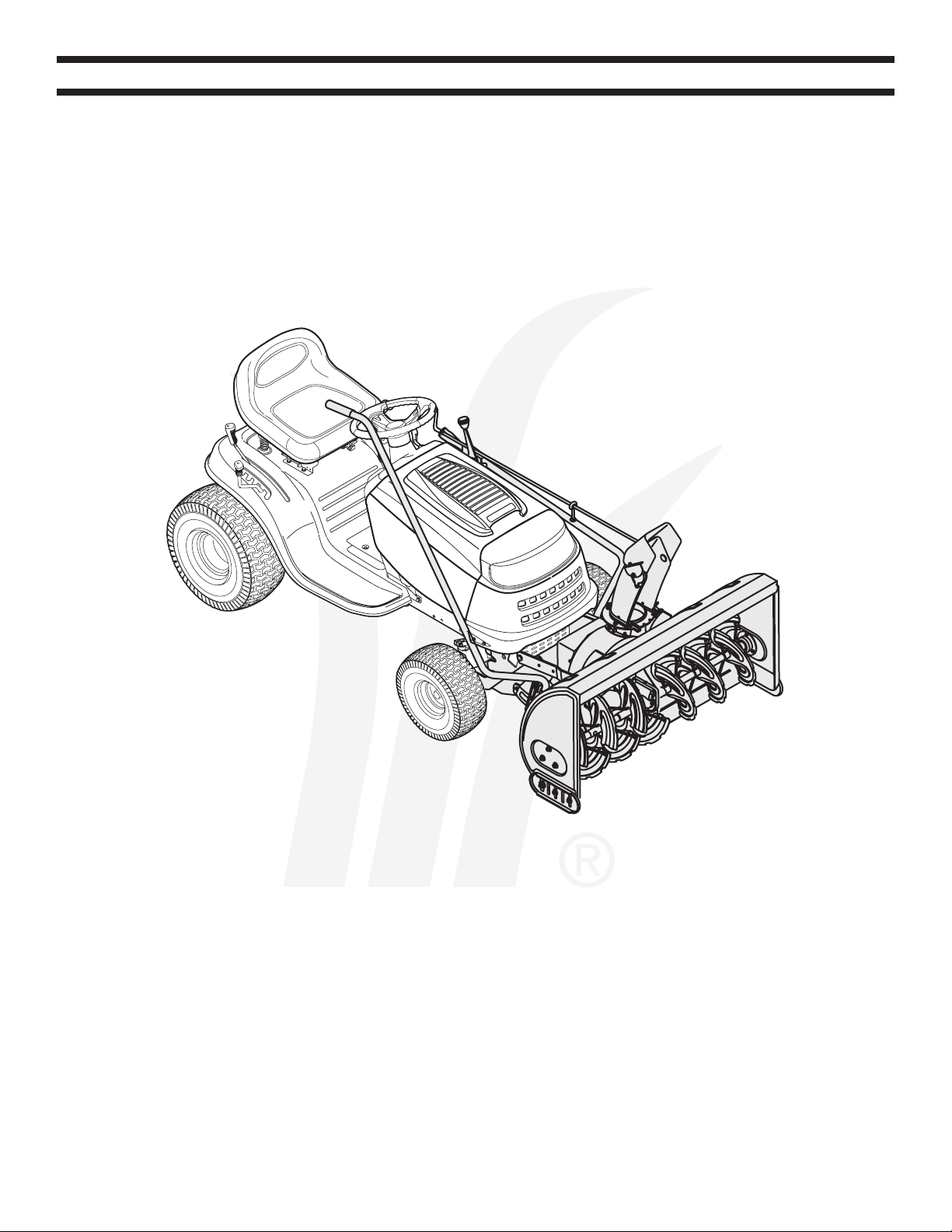

42-inch Two-Stage Snow Thrower Attachment

For FastAttach™ Compatible Lawn Tractors & Garden Tractors

FORM NO. 769-01933E

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

4/24/07

Page 2

This Operator’s Manual is an important part of your snow thrower attachment. It will help you assemble,

prepare and maintain the unit for best performance. Please read and understand what it says.

TABLE OF CONTENTS

1. Rider Model Identification ................................ Page 3

2. Snow Thrower Attachment Safety ................... Page 4-5

3. Carton Contents .............................................. Page 6-7

4. Assembly Models 600-649 & 800 Series ........ Page 8-13

5. Assembly All Model 700 Series ....................... Page 14-15

6. Attaching Controls ........................................... Page 16

7. Attaching Auger Housing ................................

8. Routing Upper & Lower Drive Belts ................. Page 18-19

Page 17

9. Controls ........................................................... Page 20

10.Operation ........................................................ Page 21

11. Adjustments ................................................... Page 22

12. Maintenance .................................................. Page 23

13. Parts List ........................................................ Page 24-29

13. Notes .............................................................Page 30-31

Warranty .......................................................... Page 32

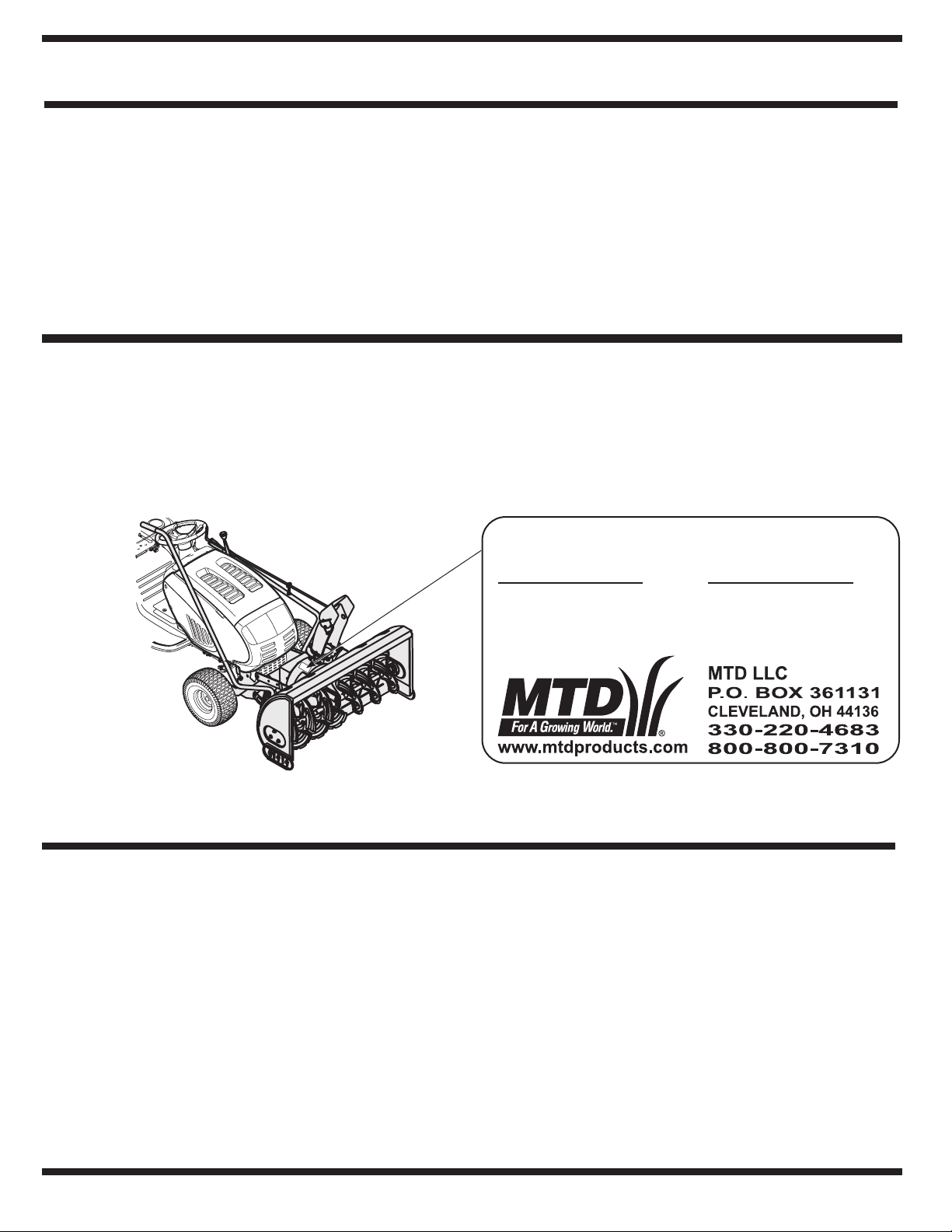

Finding and Recording Model Number

BEFORE YOU START ASSEMBLING YOUR NEW EQUIPMENT,

please locate the model plate and copy the information from it in this Operator’s Manual for future reference. The information on

the model plate is very important if you need help from our Customer Support Department or your authorized dealer. You can

locate it by looking on the top rear portion of the auger housing:

Model Number Serial Number

*Locate the model plate on your snow thrower attachment and copy the information from it in the space provided above for future reference.

Customer Support

Please do

purchased, without first contacting Customer Support.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of this

unit, you can seek help from the experts. Choose from the options below:

• Visit www.

• Phone a

• Please have your unit’s model number and serial number ready when you call. See above to locate this information. You will

be asked to enter the serial number in order to process your call.

mtdproducts.com. Click on the Service & Support menu option.

Customer Support Representative at 1-800-800-7310.

NOT

return the unit to the retailer from which it was

2

Page 3

Model Plate

Snow Thrower

Attachment

Figure 1

Sample Model Number

1 3 A M 7 9 0 G 0 0 0

Indicates Model Series 700

NOTE: This Operator’s Manual covers several models.

1

Snow thrower hook-up instructions vary by model. Not

1

6

3

0

3

13

8

1

1

4

6

4

1

3

4

6

H

7

-

-

O

3

C

,

0

0

L

D

X

2

N

L

0

O

A

2

8

B

L

-

-

E

D

.

V

0

T

0

O

E

3

.

L

0

M

P

C

3

8

m

s

t

o

c

c

.

u

d

o

r

p

d

t

m

w

.

w

w

all features discussed in this manual are applicable to all

snow thrower attachments. Assistance may be needed to

complete instalation.

Rider Model

Identification

To The Owner

Model OEM-190-032 two-stage snow thrower attachment is

designed for use on FastAttach™ Compatible Lawn Tractors

and Garden Tractors ONLY. It will NOT fit nor operate

properly or safely on ANY other tractor.

Determine The Model

of Your Rider

Since this manual is designed for installation of your new

snow thrower attachment on several different rider units,

it is important for you to determine which model of rider

you have. Therefore you will know which set of instructions in the following pages to follow.

To determine which model of rider you have, you will

need to locate the rider’s model plate, located under the

seat. Simply flip the seat up and locate the model plate,

which will consist of an 11 digit/letter model number

and a serial number. For ease in this installation and

for future use, copy your rider’s model number & serial

number below now:

and RIGHT indicate the

the tractor when facing

forward in the operator’s

position. Reference to

the FRONT indicates the

grille end; to the REAR,

the rear end of the rider.

NOTE:

References to LEFT

left and right sides of

Figure 2

Rider Model Number:__ __ __ __ __ __ __ __ __ __ __

Rider Serial Number:_____ _____ ____________ ___

The 5th, 6th & 7th numbers from the left in your model

number determine your rider’s model series. See Figure 2.

When you fill in your model number in the space above,

the actual model series number should fall into the gray

shaded area.

Now that you have determined what model rider you

are attaching this snow thrower attachment to, follow

the instructions in the following pages according to your

model of rider. You can locate which instructions apply to

your model of rider by the gray-shaded area in the border

of each page. For instance, an 809 or 80R would signify

that you should follow the instructions for Model Series

800.

3

Page 4

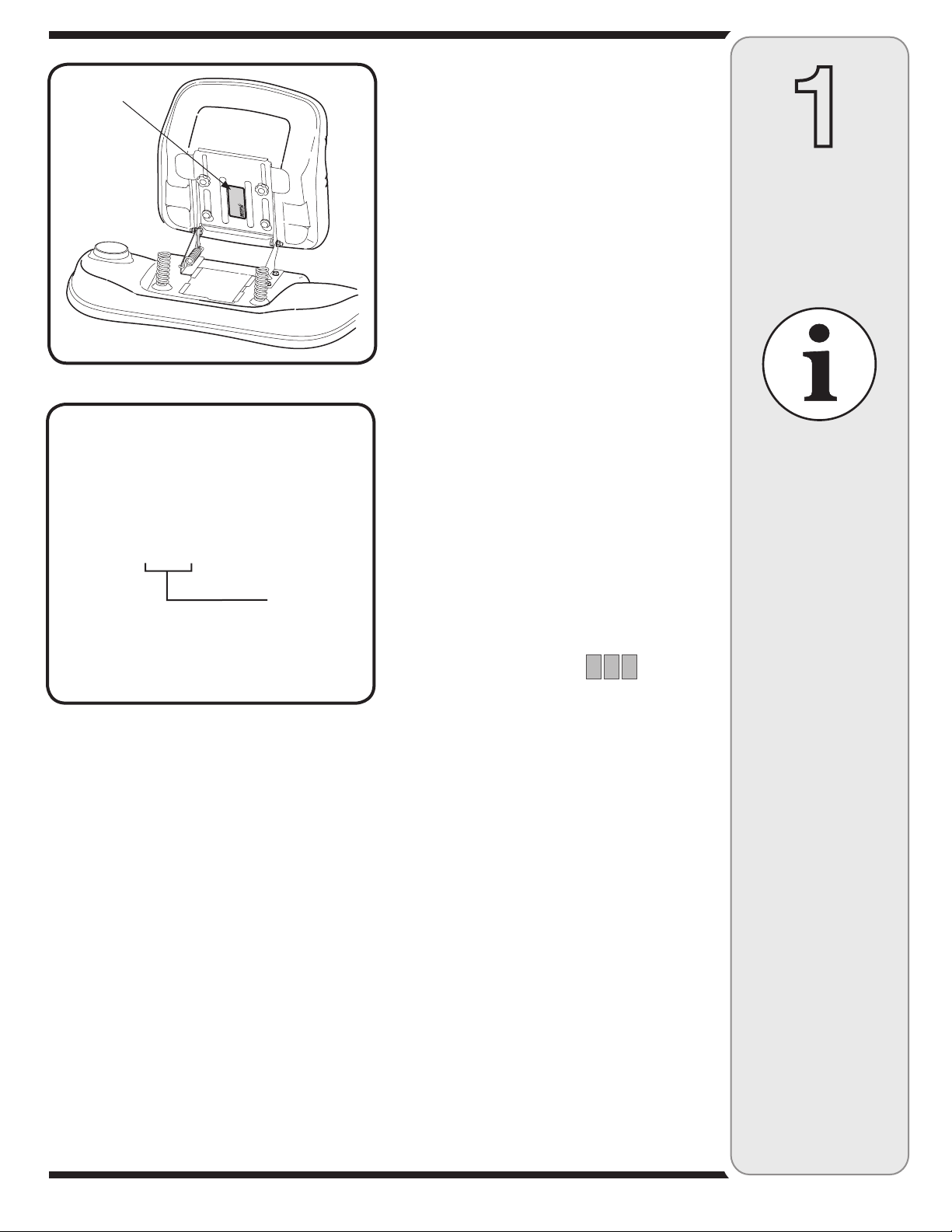

3

Carton

Contents

Undercarriage Assembly

Self-Adhesive

Reflectors

Cable Ties

If you are missing

any parts, please

do not contact the

retailer where you

purchased this unit,

call MTD directly at

1-330-220-4MTD or

toll free at

1-800-800-7310.

Extension Spring

Extension Spring

Lift Handle

Assembly

Upper Chute Crank Rod

Cotter Pin

Click Pins &

Clevis Pins

Auger Housing

Assembly w/

Linkage

Spare Shear Bolts

& Hex Lock Nuts

Figure 3

4

Page 5

CONTENTS OF CARTON

Before beginning installation, remove all parts from the carton to make sure everything is present. Carton

contents are listed below and shown in Figure 3. Hardware part numbers are shown in parentheses.

3

• One Auger Housing Assembly w/ Lower V-belt

• One Undercarriage Assembly w/ Upper V-belt

• One Lift Handle Assembly

• One Upper Chute Crank Rod

• Three Cable Ties (725-0157)

• Two Spare Shear Pins (738-04124) & Cotter Pins (714-04040)

• One Cotter Pin (714-0507)

• Two Self-adhesive Reflectors (730-3000)

• Extension Spring (732-04237)

• Extension Spring (732-04237)

• Clevis Pin (711-0332)

• Click Pin (714-0145)

Carton

Contents

If you are missing

any parts, please

do not contact the

retailer where you

purchased this unit,

call MTD directly at

1-330-220-4MTD or

toll free at

1-800-800-7310.

5

Page 6

4

Assembly

Model Series

600-649 &

All 800 series.

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

WARNING: Before installing attachment, place tractor on a firm and level surface. Place the

PTO in the disengaged (OFF) position, set the parking brake, shut engine off and remove key

to prevent unintended starting.

NOTE: References to LEFT and RIGHT indicate the left and right sides of the tractor when facing forward in the

operator’s position. Reference to the FRONT indicates the grille end; to the REAR the drawbar end.

IMPORTANT: You must first figure out which model of rider you are attaching this snow thrower to. Refer to Determine

Your Model of Rider on page 3 of this manual to determine what model rider you are attempting to install this attachment

to. Then proceed to the applicable instructions for your model of rider.

Your tractor’s cutting deck, PTO belt and front deck stabilizer bracket must be removed prior to mounting the snow

thrower attachment. Refer to your tractor’s Operator’s Manual for detailed instructions. If your tractor is equipped with

any front-end accessory (i.e. front bumper kit), it must also be removed.

Do you have an Electric PTO or Manual PTO?

If you engage your tractor’s cutting deck by using your left hand to pivot a lever forward, your tractor has a Manual

PTO. If you engage your tractor’s cutting deck by pulling outward on a small knob located on the tractor’s dash, your

tractor has an Electric PTO.

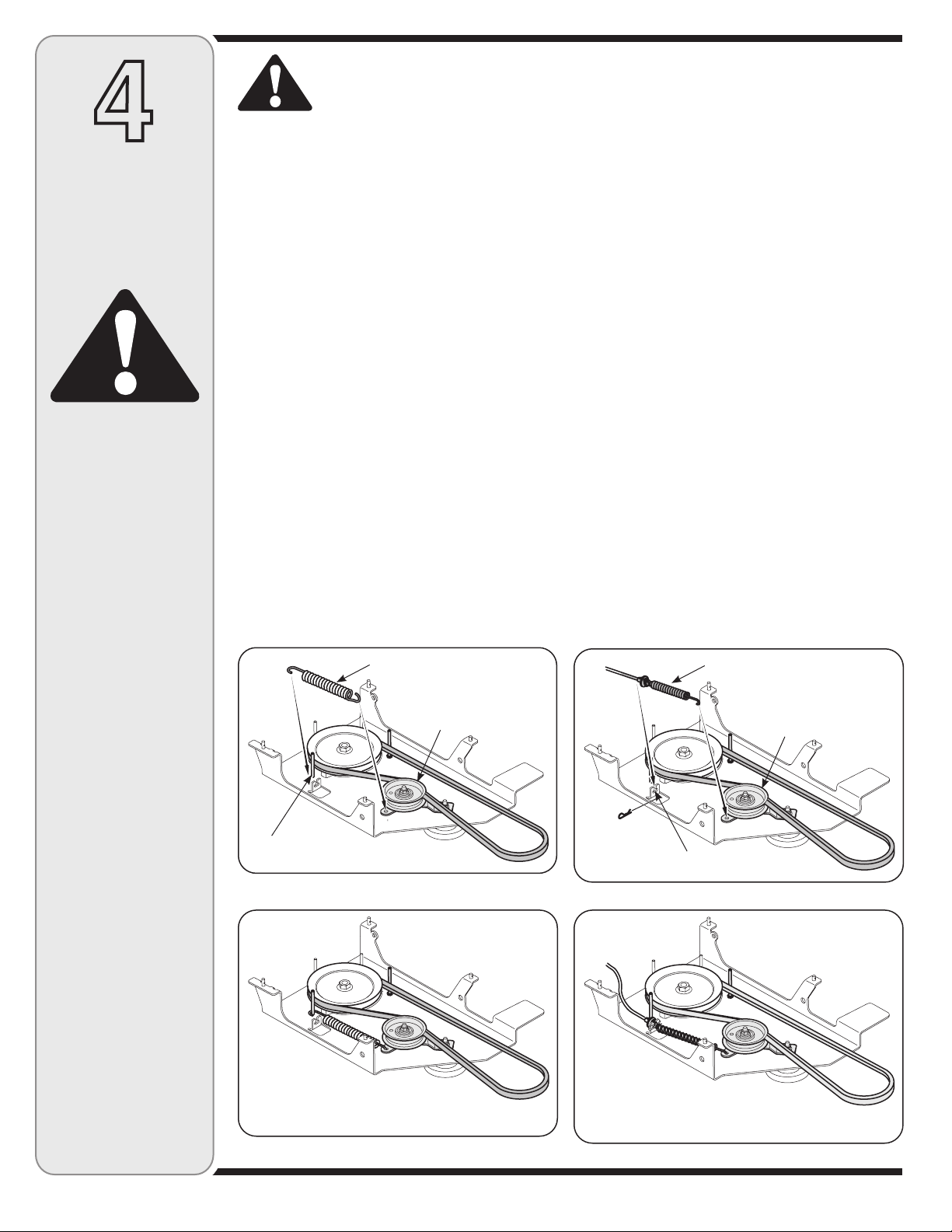

Mounting the Idler Assembly

Electric PTO Undercarriage

Assembly Setup

Proceed as follows when mounting this snow thrower

attachment to a tractor equipped with a 42, 46, 50 or

54-inch deck with electric PTO:

1. Attach one end of the extension spring (732-0594A)

to the hole in the idler assembly. Mount the opposite

end of the extension spring to the belt keeper pin as

illustrated in Figure 4–1.

2. Refer to Figure 4–2 for correct position.

Extension Spring

Idler Pulley &

Idler Bracket

Manual PTO Undercarriage

Assembly Setup

1. Attach the PTO cable to the idler bracket, then fit the

cable into the slotted fitting as seen in Figure 4–3.

NOTE: The PTO cable should be hanging down under

you tractor after you removed the mowing deck. You will

need to slide the undercarriage unit under your tractor in

position for which it will be mounted. The slanted side

should be pointed towards the front of your tractor.

2. Refer to Figure 4–4 for correct position.

PTO Cable

Idler Pulley &

Idler Bracket

Belt Keeper Pin

Figure 4–1

Figure 4–2

Slotted Fitting

Figure 4–3

Figure 4–4

6

Page 7

Mounting The

Undercarriage Assembly

1. Remove and retain the four hairpin clips from the

weld pins found on the top side of the undercarriage

assembly. Remove and retain the two clevis pins with

hairpin clips. This hardware is for later installation.

See Figure 4–5.

2. With the undercarriage assembly beneath the tractor,

see figure 4– 6, lift the undercarriage assembly up

against the frame of the tractor. The weldpins on the

top of the undercarriage assembly should go through

the aligning holes found along the tractor’s frame.

See Figure 4–7.

3. Fasten the undercarriage assembly to the frame with

the hairpin clips removed in step 1. See figure 4–8

4. Route the upper drive belt around the engine pulley.

See Figure 4–7.

NOTE: Proceed to the Assembling Controls section of

this manual if you have an Electric PTO.

5. Attach the extension spring to the idler pulley. See

figure 4–9. Connect the other end to tractor’s frame rail.

See Figure 4–10.

Figure 4–7

Figure 4–8

4

Assembly

Model Series

600-649 &

All 800 series.

WARNING

Before installing

attachment, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Figure 4–5

Figure 4–6

Figure 4–9

Figure 4–10

7

Page 8

Attaching Chute

Attaching

6

Assembling

Controls

NOTE:

All references to left

or right side of the

snow thrower is

from the operating

position only.

Directional Control

1. Attach the chute directional control assembly to the

upper lift link on the left side of the auger housing.

Assemble with two hex screws and washers as

illustrated in Figure 6–1. Secure with two flange nuts.

1. Secure the upper chute crank rod to the joint block

(A) on the lower chute crank rod with the cotter pin

(B) provided. See Figure 6–2.

3. Fasten chute tilt cables to chute directional control

with two of the cable ties provided. Pull cable ties

until snug and trim excess.

Upper Lift Link

Chute Directional

Control Assembly

Lift Handle

1. Attach lift handle to lift bracket on the right side of

auger housing assembly with two hex screws and two

flange nuts provided. See Figure 6–3.

2. Fasten the lift cable to the lift handle with two of the

cable ties provided. Pull the cable ties until snug and

trim excess.

Lift Handle

B

Figure 6–1

Auger Housing Assembly

Figure 6–3

Mounting Auger Assembly

WARNING: Before installing

attachment, place tractor on a firm

and level surface. Place PTO in the

disengaged (OFF) position, set the

parking brake, shut engine off and remove key to

prevent unintended starting.

IMPORTANT: If you are installing this snow thrower

attachment on any tractor model with a side discharge

muffler, See Figure 6– 4, then the heat shield on the

auger housing must be removed. See figure 6–5. To

A

Figure 6–2

Figure 6–4

8

Page 9

Attaching Reflectors

Peel off the backing from each of the reflectors to

expose the adhesive surface. Adhere the reflectors to

the rear of the tractor’s fender (one on the left and one

on the right) so that the reflectors simulate taillights.

7

Mounting

Auger

Heat Shield

Figure 6–5

remove the heat shield remove the four lock nuts and

bolts (two on either side of the unit) securing the heat

shield to the lift linkage. See figure 6–5.

IMPORTANT: It will be necessary to have a second

person assist you to complete the following steps.

1. Position the auger housing assembly in front of the tractor

as seen in Figure 6–6. Lay the belt and support tubes on

the installation surface.

2. Carefully move the tractor forward (by pushing, NOT

driving it) so that support tubes found on the rear of

the auger housing assembly are positioned between

the tractor’s front tires. Set the parking brake.

3. With the help of an assistant, lift up the auger housing

and move it so that it rests over the shoulder bolts found

on tractor See Figure 6–7.

4. Maneuver the auger housing until the mounting holes

line up. Insert the clevis pins from your hardware pack

and secure with a click pins. See Figure 6–8.

Figure 6–7

Housing

All Models

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place

the PTO in the disengaged (OFF) position,

set the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Attaching Support Tubes

1. Secure the left support tube to the front of the

undercarriage assembly with the clevis pin and hairpin

clip removed earlier. See Figure 6–9.

2. Repeat the previous step on the right side.

Belt

Support Tube

Figure 6–6

Clevis Pin

Figure 6–8

Figure 6–9

9

Page 10

Routing the Upper Drive Belt (Tractors Models with an Electric PTO)

8

Belt

Routing

Various Models

WARNING

Before installing

attachment, place

tractor on a firm and

level surface. Place

the PTO in the disengaged (OFF) position,

set the parking brake,

shut engine off and

remove key to prevent

unintended starting.

Spindle Pulley

Engine Pulley

All electric PTO

Decks 42, 46, 50, 54

PTO Idler Pulley

Figure 8–1

1. Attach and route upper drive belt around spindle pulley and idler pulley found on undercarriage, electric PTO

clutch and PTO idler pulley as illustrated in Figure 8–1. Make sure that the belt is routed to the INSIDE of the belt

keeper on the undercarriage idler pulley and the remaining keeper pins found around the spindle pulley.

IMPORTANT: Make certain that the flat side of the belt is facing outward as it sits against both the electric PTO

clutch and spindle pulley. This allows the “V” side of the belt to ride snugly in both pulleys.

Routing the Upper Drive Belt (Tractor Models with a Manual PTO)

Spindle Pulley Engine Pulley

All Manual PTO

Decks 38, 42, 46

PTO Idler Pulley

IMPORTANT:

Make certain that the

flat side of the belt is

facing outward. This

allows the “V” side of

the belt to ride snugly

in both pulleys.

Figure 8–2

1. Attach and route the upper drive belt around the engine pulley and spindle pulley, routed to the INSIDE of the

PTO idler pulley on the undercarriage. Make sure the belt is routed inside of the belt keeper pins found around

the spindle pulley and engine pulley. See Figure 8–2.

IMPORTANT: Be certain flat side of belt is facing outward. This allows “V” side of belt to ride snugly in both pulleys.

Routing the Lower Drive Belt (All Tractors Models)

Left Side

Spindle Pulley

Right Side

1. Attach and route the lower drive belt around the lower pulley on the spindle assembly, both pulleys on the doubleidler bracket found beneath the undercarriage, and the drive pulley found on the rear of the snow thrower housing

as illustrated in Figure 8–3.

2. Attach tension spring (found on undercarriage double-idler bracket) to the hex screw if it is not already attached.

Undercarriage

Double-Idler Bracket

Figure 8–3

Snow Thrower Drive Pulley

10

Page 11

WARNING: Be familiar with all controls

and their proper operation. Know how

to stop the machine and disengage

them quickly.

Engaging the Augers

and Impeller

Power to the snow thrower attachment is activated by

engaging the tractor’s PTO.

1. Place the tractor’s throttle control in the FAST (rabbit)

position and allow it to remain there for efficient snow

removal.

2. Move the PTO knob or PTO lever (on tractor’s so

equipped) into the “ON” position to engage the augers

and impeller.

3. Move the PTO knob or PTO lever (on tractor’s so

equipped) into the “OFF” position to disengage the

augers and impeller.

NOTE: The PTO knob (on units so equipped) cannot be

in the engaged (ON) position when the tractor is driving

in the reverse direction. The PTO knob must be in the

disengaged (OFF) position when the shift lever is placed

in REVERSE or the electric PTO clutch will automatically

shut off.

Refer to your tractor’s Operator’s Manual for more

information regarding your tractor’s PTO and safety

interlock system.

Trigger Control

Lift Handle

The lift handle is located on the right side of tractor and

is used to raise and lower snow thrower attachment.

1. To raise snow thrower attachment off of the ground,

pull rearward and down on the lift handle until

you feel the lift latch on the right side of the snow

thrower engage, locking the snow thrower in a raised

position See Figure 9 –1.

2. To lower the snow thrower, push downward on the

lift handle until there is enough slack in the lift cable

so that you may squeeze the trigger control. With

the trigger control squeezed, gently allow the snow

thrower to lower until it reaches the ground.

Chute Directional

Control

The chute directional control assembly is found on

the left side of the tractor and includes both the chute

tilt lever as well as the chute crank. Both affect the

direction that the discharged snow is thrown.

To pivot upper section of discharge chute, affecting the

distance and angle which the snow is thrown, move

the chute tilt lever forward or rearward into a desired

position.

The direction which snow is thrown can be changed

by rotating the discharge chute with the chute crank.

Turn the chute crank clockwise to rotate the chute and

discharge snow to the left. Crank it counterclockwise to

rotate the chute and discharge snow to the right.

9

Controls

WARNING

Be familiar with all

controls and their

proper operation.

Know how to stop

the machine and

disengage them

quickly.

Lift Handle

Chute Directional Control

NOTE:

The PTO knob (on

units so equipped)

cannot be in the

engaged (ON) position

when the tractor is

driving in the reverse

direction. The PTO

knob must be in the

disengaged (OFF)

position when the

shift lever is placed

in REVERSE or the

electric PTO clutch

will automatically

shut off.

Figure 9–1

11

Page 12

10

Operation

WARNING

Read, understand,

and follow all

instructions and

warnings on the

tractor, attachment,

and in the Operator’s

Manuals before

operating.

IMPORTANT:

The augers are secured

to the spiral shaft with

two shear bolts and hex

lock nuts. If you hit a

hard foreign object or

an ice jam, the snow

thrower is designed

so that the bolts may

shear. Two replacement

shear bolts and hex

lock nuts are provided

for your convenience.

Store in a safe place

until needed. NEVER

replace the auger shear

bolts with standard hex

bolts. Any damage to

the auger gearbox or

other components as a

result of doing so

will NOT be covered

by your snow

thrower’s warranty.

OPERATION

WARNING: Read, understand, and

follow all instructions and warnings

on the tractor, attachment, and in the

Operator’s Manuals before operating.

Your snow thrower attachment is capable of displacing

snow and clearing a path a width of 42 inches.

Observe the following operating instructions for efficient

snow removal.

1. Become familiar with and comfortable using all of

your tractor’s controls as instructed in your tractor’s

Operator’s Manual before operating it with the snow

thrower attachment.

2. Make certain the correct weight (and volume) of

motor oil in is your tractor’s engine as instructed in

the engine Owner’s Guide packed with the tractor’s

Operator’s Manual.

3. Always operate the snow thrower with the tractor’s

engine at maximum RPM (full throttle).

4. NEVER override any safety features on either your

tractor or the snow thrower attachment.

5. Make certain that all nuts, bolts, and hardware are

fastened securely and tight on both the tractor and

the snow thrower attachment prior to use.

6. Make certain snow thrower is assembled

properly and mounted to the tractor as instructed

in this manual.

8. Test all controls (tractor PTO, snow thrower lift

handle, chute tilt lever & chute crank) for smooth

operation prior to operating snow thrower in snow.

9. Make all adjustments (i.e. skid shoes, lift latch)

before operating your snow thrower attachment.

Follow instructions in the Adjustments section of this

manual when doing so.

10. Engage the tractor’s PTO to activate power to the

augers and impeller BEFORE driving the tractor

forward and into snow.

11. Keep your tractor’s ground-speed slow. The slower

your tractor is traveling, the more effectively the

snow thrower attachment can displace snow.

12. Adjust ground speed for snow conditions and

become familiar with different snow applications.

Your snow thrower attachment will operate differently

in wet heavy snow than it will it light, fluffy snow.

13. Overlap a previously cleared path when necessary

(deep snow) so as not to overload the auger housing

with snow.

14. NEVER drive the tractor into a snow bank. The

snow thrower attachment is not a dozer plow. The lift

linkage and/or the snow thrower drive system can

be damaged as a result of “plowing” with the snow

thrower attachment.

15. If the augers become jammed with a chunk of ice or a

foreign object, move the PTO into the disengaged (OFF)

position immediately and turn off the tractor’s engine

and remove the ignition key. Examine the auger area

thoroughly for damage and do NOT operate the snow

thrower attachment until any damage is repaired.

IMPORTANT: The augers are secured to the spiral

shaft with two shear bolts and hex lock nuts. If you hit

a hard foreign object or an ice jam, the snow thrower is

designed so that the bolts may shear. Two replacement

shear bolts and hex lock nuts are provided for your

convenience. Store in a safe place until needed. NEVER

replace the auger shear bolts with standard hex bolts.

Any damage to the auger gearbox or other components

as a result of doing so will NOT be covered by your snow

thrower’s warranty.

16. Whenever possible, discharge snow downwind.

17. Do NOT attempt to remove ice or hard-packed frozen snow.

18. When the tractor (with the snow thrower attachment

mounted) is not in service, use the lift lever to lower

the auger housing assembly to the ground to relieve

strain on the tractor’s front end between uses.

19. Always use tire chains and rear wheel weights on

your tractor where extra traction is needed. Refer to

the table to the right to determine which kits will fit

your tractor (tire dimensions are can be found on the

sidewalls of your tractor’s tires).

20. Use drift cutters to aid in displacing snow through

deep, drifted areas.

Tire Chain Kit Number

Garden Tractors

23” x 9.5” tires OEM-190-964

22” x 7.5” tires OEM-190-974

Lawn Tractors

20” x 10.0” tires OEM-190-916

20” x 8.0” tires OEM-190-658

18” x 9.5” tires OEM-190-657

18” x 8.5” tires OEM-190-754

18” x 6.5” tires OEM-190-664

Weight Kit Number

All Garden Tractors OEM-190-784

All Lawn Tractors OEM-190-215

Drift Cutter Kit Number

All Tractors OEM-390-679

NOTE: None of the kits in the table are included as

standard equipment with snow thrower attachment

OEM-190-032. Call our Customer Support Department

as instructed on page 2 of this manual for availability and

information regarding these kits.

12

Page 13

Making Adjustments

WARNING: Never attempt to make any

adjustments while the engine is running,

except where specified in the Operator’s

Manual. Place tractor on a firm and

level surface. Place the PTO in the disengaged (OFF)

position, set the parking brake, shut engine off, and

remove key to prevent unintended starting.

Lift Adjustment

If the lift index rod doesn’t latch securely or the pivot

release has too much slack in it, an adjustment can be

made as follows:

1. Loosen the upper hex nut a few turns, then tighten the

lower hex nut to shorten the cable length. See Figure 11–1.

2. Loosen the lower hex nut a few turns, then tighten the

upper hex nut to lengthen the cable. See Figure 11–1.

Lower Chute Crank

Support Bracket Adjustment

If the spiral at the base of the lower chute crank isn’t fully

engaging with the notches in the lower chute assembly,

the support bracket can be adjusted inward or outward as

follows:

1. Loosen, but do NOT remove the two hex nuts which

secure the support bracket to the snow thrower

housing. See Figure 11–2.

2. Adjust the support bracket inward or outward so that

the spiral is fully engaged in the notches on the chute

before retightening the hex nuts.

Skid Shoe Adjustment

The space between the shave plate and the ground can

be adjusted by repositioning the skid shoes found on

either side of the snow thrower’s auger housing. For close

snow removal, place skid shoes in the low position. Use

a middle or high position when the area to be cleared is

uneven.

IMPORTANT: It is NOT recommended that this snow

thrower be operated on a gravel surface, as loose stones

can be easily picked up and thrown by the machine. If

you must operate on a gravel surface, ALWAYS adjust the

skid shoes into the HIGH position to allow the shave plate

maximum clearance.

Adjust skid shoes as follows:

1. Loosen, but do NOT remove, the three hex nuts which

fasten the skid shoe to the auger housing.

See Figure 11–3.

2. Raise or lower the skid shoe to desired position.

NOTE: Make certain the entire base of both skid shoes

are against the ground to avoid uneven wear on the skid

shoes. When one side does wear out, the skid shoes are

reversible.

3. Retighten the hex nuts loosened earlier.

4. Repeat this adjustment on the skid shoe found on the

opposite side of the snow thrower.

Hex Nuts

Lift Index Rod

Hex Nuts

Figure 11–1

Figure 11–2

Figure 11–3

Lift Cable

Spiral

Support

Bracket

Skid Shoe

Hex Nut

11

Adjustments

WARNING

Never attempt

to make any

adjustments while

the engine is running,

except where

specified in the

Operator’s Manual.

Place tractor on a

firm and level

surface. Place

the PTO in the

disengaged (OFF)

position, set the

parking brake,

shut engine off,

and remove key

to prevent

unintended starting.

13

Page 14

12

Maintenance

Maintenance

WARNING: Before lubricating, repairing, or inspecting, place tractor on a

firm and level surface. Place the PTO

in the disengaged (OFF) position, set

the parking brake, shut engine off, and remove key

to prevent unintended starting.

Lubrication of

Chute Directional Control

The spiral on the end of the lower chute crank, the base

of the discharge chute itself and the joint blocks which

connect the lower and upper chute cranks should be

lubed with multi-purpose automotive grease once a

season. See Figure 12–1.

Lube Spiral

and Chute Base

Joint Block

WARNING

Before lubricating,

repairing, or

inspecting, place

tractor on a firm

and level surface.

Place the PTO in

the disengaged

(OFF) position, set

the parking brake,

shut engine off, and

remove key to prevent

unintended starting.

Auger Shaft

1. At least once a season, remove the shear bolts on

the auger shaft. Oil or spray lubricant inside and

on the plastic bearings on the shaft and near the

holes where the shear bolts were removed before

reattaching them. See Figure 12–2.

Shear Pin

Figure 12–1

Spacers

Figure 12–2

Bearing

14

Page 15

AA

19

BB

13

6

5

14

4

7

Part List:

Snow

Thrower

16

9

11

12

13

11

10

15

18

8

3

1

17

2

Attachment

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683.

www.mtdproducts.com

REF

NO.

1 736-3072 Flat Washer, .38 x .93 x .11

2 710-0151 Hex Cap Screw, 3/8-24 x 2

3 710-0521 Hex Cap Screw, 3/ 8-16 x 3

4 711-0242 Spacer

5 712-0241 Hex Nut, 3/8-24

6 732-0978 Extension Spring, .620 x 5.62

7 736-0169 Lock Washer, 3/ 8

8 756-0487 Idler pulley, 4” Diameter

9 784-5727 Idler Pivot Arm

10 712-0417 Flange Nut 5 /8-18

PART

NUMBER

DESCRIPTION

REF

NO.

11 741-0919 Ball Bearing

12 750-1096 Spacer

13 619-0044 Deck Spindle Housing

14 756-0999 Deck Pulley 7 ”

15 756-1173 Pulley 3.75”

16 738- 0976 Spindle Shaft

17 756-0627D Idler Pulley 3.50 dia.

18 738- 0347 Shoulder Spacer, .625 x .169

19 712-0417 Flange Nut 5/ 8-18

PART

NUMBER

DESCRIPTION

NOTE:

For painted parts, please

refer to the list of color

codes below. Please add

the applicable color code,

wherever needed, to the

part number to order a

replacement part.

For instance, if a part

numbered 700-xxxx is

painted powder black, the

part number to order would

be 700-xxxx-0637.

Yardman Green - 0665

Black - 0637

15

Page 16

1

16

2

52

55

62

57

58

61

26

53

60

54

29

50

51

42

48

17

4

3

4

4

9

74

12

11

C

B

59

21

56

87

22

88

22

6

5

8

10

7

4

4

15

14

13

67

98

89

78

85

20

19

18

AA

75

97

67

91

99

79

93

4

4

82

28

33

35

38

33

47

63

72

39

43

65

40

36

64

65

69

71

4

68

A

66

B

32

39

A

67

44

4

67

24

31

4

70

41

73

65

95

32

34

46

30

45

23

29

76

74

53

55

C

49

25

4

86

77

A

81

80

BB

A

67

91

90

92

27

81

x

37

16

Page 17

REF

PART No. DESCRIPTION

NO.

1 720-0232 Knob

2 784-5604 Chute Tilt Handle

3 731-1313C Chute Tilt Cable Guide

4 712-04063 Nylon Hex Lock Nut, 5/16-18

5 603-0302 Chute Tilt Bracket Assembly

6 710-0262 Carriage Bolt, 5/16-18 x 1.5

7 736-0451 Saddle Washer, .32 x .93

8 741-0475 Plastic Bushing

9 735-0234 Rubber Grommet , .44 x .94 x .5

10 747-0697 Eye Bolt

11 736-0242 Bell Washer, .340 x .872

12 750-04467 Support Chute Tube

13 714-0507 Cotter Pin, 3/32 x .75

14 784-5149 Joint Block Assembly

15 747-1201 Chute Crank Rod, .375 x 33

16 746-1108 Chute Cable, 62”

17 746-1109 Chute Cable w/ Clip, 62”

18 715-0138 Rolled Pin, 1/8 x .63

19 720-0201A Crank Knob

20 726-0100 Push Cap, 3/8 ID

21 747-04400 Rod, .375 x 11.375

22 715-0129 Spirol Pin, .125 x .82

23 611-0132A Rod Assembly

24 783-0880C RH Support Plate Assembly

25 783-0879C LH Support Plate Assembly

26 683-04150 Lift Bracket Assembly

27 710-0805 Hex Cap Screw, 5/16-18 x 1.50

28 710-0964A Hex Cap Screw, 5/8-18 x 1.31

29 710-3008 Hex Cap Screw, 5/16-18 x .75

30 711-0332 Clevis Pin, .5 x .78

31 712-0386A Slotted Hex Nut, 5/8-18

32 712-3000 Hex Lock Nut, 3/8-16

33 712-3022 Hex Lock Nut, 1/2-13

34 714-0470 Cotter Pin, 1/8 x 1.25

35 714-0474 Cotter Pin, .125 x .75

36 716-0102 Snap Ring

37 784-0402 Skid Plate

38 736-0272 Flat Washer, .51 x 1.0 x .060

39 736-0366 Flat Washer, .64 x 1.12 x .125

40 736-0452 Bell Washer, .396 x 1.14 x .095

41 783-1014A Drive Mounting Bracket

42 738-0234 Shoulder Screw, .5 x .29, 3/8-16

43 741-0170 Flange Bearing w/ Flats

44 756-1181A Drive Pulley, 7”

45 747-1192 Rod, 1/2 x 11.55

46 783-0876 Link, 5.875

47 783-0877 Link, 15.4

48 783-0878 Link, 13.35

49 783-1274B Heat Shield

50 790-00110 Snow Thrower Lift Bracket

51 710-1268 Hex Index Washer Screw #10-16

REF

PART No. DESCRIPTION

NO.

52 710-3143 Pan Phillips Screw, #10-24 x .75

53 710-3180 Hex Cap Screw, 5/16-18 x 1.75

54 715-0114 Heavy Duty Spirol Pin, 1/4 x 1.5

55 720-0274 Handle Grip

56 725-0157 Cable Tie

57 732-0306 Compression Spring

58 736-0140 Flat Washer, .385 x .62 x .063

59 736-0400 Flat Washer, .194 x .62 x .063

60 746-1103A Lift Cable, 42” w/ Trigger Control

61 747-1203 Lift Index Rod

62 750-1221 Lift Handle Tube

63 05931A Bearing Housing, 1.85 ID

64 703-2736 Belt Cover

65 710-0514 Hex Cap Screw, 3/8-16 x 1.0

66 710-3251 Socket Head Cap Screw

67 712-04065 Flange Lock Nut, 3/8-16

68 714-0122 Square Key, 3/16 x .75

69 714-0126 Hi-pro Key, 3/16 x .75

70 717-1714A Right Angle Drive

71 718-0691 Coupling

72 741-0309 Flange Ball Bearing, .75 x 1.85

73 747-1257 Belt Keeper Rod

74 712-3010 Flange Nut, 5/16

75

618-0411 Spindle Assembly (Incl. 38-44)

76

683-04210 Pulley Mounting Bracket

77

684-0149 Double Idler Bracket Assembly

78

710-0347 Hex Cap Screw, 3/8-16 x 1.75

79

710-04511 Pin 5/16-18

80

710-0260A Carriage Bolt, 5/16-18 x .62

81

711-0310 Clevis Pin, .5 x 1.18

82

711-1000 Belt Keeper Pin

83

712-04064 Nylon Hex Lock Nut, 1/4-20

84

712-04100 Wing Nut 5/16-18

85

714-0145 Click Pin, .092 x 1.64

86

714-0147 Internal Cotter Pin, .125 x 1.75

87

730-3000 Reflector

88

732-04237 Extension Spring .50 x 12.00

89

732-0594A Extension Spring .91 x 7.33

90

736-0192 Flat Washer, .531 x .93 x .09

91

736-3072 Flat Washer, .38 x .93 x .11

92

738-0145 Shoulder Screw, 3/8-16

93

738-0347 Shoulder Spacer, .625 x .169

94

749-1103 LH Support Tube

95

749-1104 RH Support Tube

96

754-0125A V-Belt

97

754-0498 V-Belt

98

756-0627D Idler Pulley 3.50 dia.

99

783-1291 Idler Bracket

13

Part List:

Snow

Thrower

Attachment

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683.

www.mtdproducts.com

17

Page 18

A

A

52

3

2

42

59

45

53

43

31

34

37

36

32

39

28

26

24

1

33

25

66

40

38

29

7

60

44

9

48

56

55

9

16

51

20

15

12

13

17

21

18

65

11

22

7

41

16

16

4

10

15

57

16

62

52

52

52

61

58 47

46

49

51

54

50

9

8

63

14

16

19

23

40

35

30

27

6

21

64

5

18

Page 19

13

REF

NO.

1 618-04315 Auger Gear Box (Incl. Ref. 23-41)

2 684-0158 Impeller Assembly, 12”

3 684-0148 Housing Assembly

4 703-2734 Housing Brace Bracket

5 684-04163 LH Spiral Auger

6 684-04164 RH Spiral Auger

7 710-0157 Hex Cap Screw, 5/16-24 x .75

8 710-0260A Carriage Bolt, 5/16-18 x .62

9 710-0276 Splined Carriage Screw

10 710-0726 Self Tapping Screw

11 714-04040 Bow-Tie Cotter Pin

12 712-3010 Hex Nut, 5/16-18

13 712-3057 Hex Nut, 5/16-24

14 715-0114 Spirol Pin, 1/4 x 1-1/2

15 736-0231 Flat Washer, .344 x 1.125 x .12

16 736-0242 Bell Washer, .340 x .872

17 741-0245 Hex Flange Bearing, .75 ID

18 741-0493A Flange Bushing, .80 x .91

19 784-0396A Skid Plate Bracket, 42”

20 784-5038B Slide Shoe

21 711-0469 Spacer, .75 x .125 x .5

22 784-5618 Hex Bearing Housing, 1.0

23 618-0123A RH Reducer Housing

24 618-0124A LH Reducer Housing

25 703-2733A Housing Brace Plate

26 710-0642 Self Tapping Screw, 1/4-20 x .75

27 711-04468 Spiral Axle, 41.5”

28 714-0161 Hi-Pro Key, 3/16 x 5/8

29 715-0143 Spring Spirol Pin, .25 x 1.25

30 717-0528A Worm Gear, 20-tooth

31 717-3320 Worm Shaft

32 718-0513 Thrust Collar

33 721-0325 Grease Plug

PART

NUMBER

DESCRIPTION

REF

NO.

34 721-0327 Grease Seal

35 736-0351 Flat Washer, .76 x 1.5 x .030

36 736-0369 Flat Washer, .508 x 1.0 x .020

37 736-0617 Thrust Washer, .75 x 1.25 x .0615

38 741-0150 Thrust Bearing, .75 x 1.25 x .078

39 748-0108 Flange Bearing, .503 x .75

40 741-0700 Flange Bearing, .75 x 1.0 x .59

41 721-0179 Grease Seal

42 684-0061 Chute Crank Assembly

43 703-2735A Chute Crank Bracket

44 705-5226 Chute Reinforcer

45 710-0276 Splined Carriage Screw

46 710-0262 Carriage Bolt, 5/16-18 x 1.5

47 710-04071 Carriage Screw, 5/16-18 x 1.0

48 710-0703 Screw, 1/4-20 x .75

49 710-0896 Hex Index Washer Screw

50 710-3015 Hex Cap Screw, 1/4-20 x .75

51 712-04064 Nylon Hex Lock Nut, 1/4-20

52 712-04063 Nylon Hex Lock Nut, 5 /16-18

53 715-0129 Spirol Pin, .125 x .82

54 731-0851A Chute Flange Keeper

55 731-1300B Lower Chute

56 731-1320 Upper Chute

57 731-1379C Adapter Chute

58 731-1313C Chute Tilt Cable Guide

59 741-0475 Plastic Bushing

60 784-5149 Joint Block Assembly

61 784-5594 Cable Bracket

62 784-5647 Chute Crank Bracket

63 712-3004A Flange Lock Nut, 5/16-18

64 731-04870 Spacer 1.25 x .75 x 1.00

65 731-1086A Sleeve .758 x 1.00 x 2.70

66 738-04124 Shear Pin, .25 x 1.50

PART

NUMBER

DESCRIPTION

Part List:

Snow

Thrower

Attachment

For parts and/or

accessories

please call

1-800-800-7310, or

1-330-220-4683.

www.mtdproducts.com

NOTE:

For painted parts, please

refer to the list of color

codes below. Please add

the applicable color code,

wherever needed, to the

part number to order a

replacement part.

For instance, if a part

numbered 700-xxxx is

painted powder black, the

part number to order would

be 700-xxxx-0637.

Yardman Green - 0665

Black - 0637

19

Loading...

Loading...