MTD 13A277SS299 Owner’s Manual

perator's

I:RnFrSMRN°

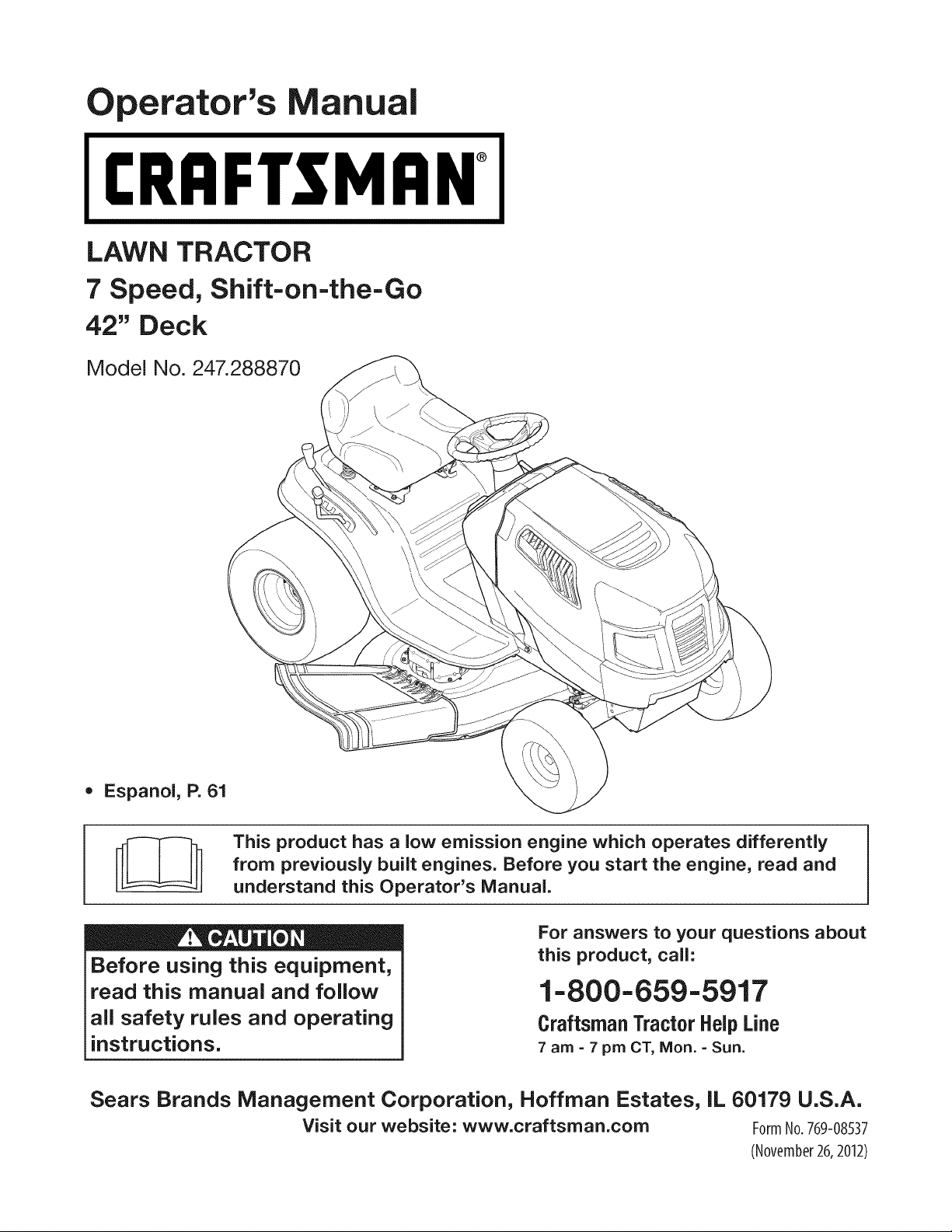

LAWN TRACTOR

7 Speed, Shift-on=the=Go

42" Deck

Model No. 247.288870

• Espanol, P. 61

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

For answers to your questions about

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-08537

this product, call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am =7 pm CT, Mort. =Sun.

(November26,2012)

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Slope Gauge ..................................................................... 8

Assembly ........................................................................... 9

Operation ........................................................................ 11

Service and Maintenance .............................................. 17

Off-Season Storage ........................................................ 27

Trou bleshooting .............................................................. 28

Labels ............................................................................. 29

Parts List ......................................................................... 30

Espafiol ............................................................................ 61

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthedateofpurchase,all non-expendablepartsofthis ridingequipmentarewarrantedagainstanydefectsin materialor

workmanship.Adefectivenon-expendablepartwill receivefreein-homerepairorreplacementif repairisunavailable.

BATTERYLIMITEDWARRANTY

FOR90 DAYSfromthe dateofpurchase,thebattery(an expendablepart)ofthis ridingequipmentiswarrantedagainstanydefectsinmaterialor

workmanship.Anewbatterywillbesuppliedfreeof charge.Youareresponsibleforthelaborcostof batteryinstallation.

ADDITIONALLIMITEDWARRANTIES

Inthe followingadditionalwarranties,youare responsibleforthe laborcostof partinstallationafterthe secondyearfromthedateof purchase.

FORFIVEYEARSfromthedateof purchase,theframeof this ridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.A

newframewill be suppliedfreeof charge.

FORTENYEARSfromthe dateofpurchase,thefrontaxleof thisridingequipmentiswarrantedagainstanydefectsin materialorworkmanship.

A newfrontaxlewill be suppliedfreeofcharge.

FORASLONGASIT ISUSEDbytheoriginalownerafterthetenthyearfromthedateofpurchase,thecastironfrontaxle(ifequipped)ofthisriding

equipmentiswarrantedagainstanydefectsinmaterialorworkmanship.Withproofofpurchase,a newcastironfrontaxlewillbesuppliedfreeofcharge.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfreerepairor replacement,call 1-800-659-5917orvisitthewebsite: www.craftsman.com

Inallcasesabove,if part repairor replacementis impossible,theridingequipmentwillbe replacedfree ofchargewiththesameor anequivalent

model.

Alloftheabovewarrantycoverageisvoidif thisridingequipmentis everusedwhileprovidingcommercialservicesorif rentedtoanotherperson.

ThiswarrantycoversONLYdefectsin materialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableparts(exceptbattery)thatcanwearoutfromnormalusewithinthe warrantyperiod,includingbutnotlimitedto blades,spark

plugs,air cleaners,belts,andoil filters.

Standardmaintenanceservicing,oilchanges,ortune-ups.

Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationor maintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnot limitedtodamagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendtheframe,axleassemblyorcrankshaft,or over-speedingtheengine.

• Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedbyimproper

storage,failureto usethepropergradeandamountofengineoil, failuretokeepthedeckclearofflammabledebris,orfailureto maintainthe

ridingequipmentaccordingto theinstructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyoumayalso haveotherrightswhichvaryfromstateto state.

Sears BrandsManagement Corporation, Hoffman Estates,IL 60179

Model Number:

EngineOil: SAE30 Serial Number:

Fuel: UnleadedGasoline Dateof Purchase:

SparkPlug: F6RTC(951-10292) Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

© SearsBrands,LLC 2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failuretocomplywith

theseinstructionsmayresultin personalinjury.Whenyou seethis

symbol,HEEDITSWARNING!

Thismachinewasbuilttobeoperatedaccordingtothe safeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partofthe operatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryor death.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknowntoStateof California

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingtoassembleandoperate.

Keepthis manualina safeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthemachineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldtooperatethismachine.

Children14yearsoldandovershouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbyaparent.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor athrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhile itisin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentisto be used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownby the blade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatternto avoiddischargeofmaterialtoward

roads,sidewalks,bystandersandthelike.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardthe operator.

Your Responsibility--Restricttheuse of thispowermachineto

personswhoread,understandandfollowthewarningsandinstruc-

tionsin thismanualandon the machine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtinmovable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointit at anyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherin its properplace.

Donot puthandsorfeetnearrotatingpartsor underthe cutting

deck.Contactwiththe blade(s)canamputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfor trafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublic roadway.

• Donot operatethemachinewhileundertheinfluenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backup slowly.

Alwayslookdownandbehindbeforeandwhilebackingtoavoida

back-overaccident.

3

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoa completestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthemachineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthemachine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthebrakepedal

completelybeforeattemptingto startengine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donot attemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpiles ofdryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfirehazard.

Useonlyaccessoriesandattachmentsapprovedfor this machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Fora list ofapprovedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilityto operatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor if youfeeluneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthis manual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Iftheslopeisgreaterthan15degreesasshownonthe Slope

Guide,do notoperatethis machineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,notacross.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchfor holes,ruts,bumps,rocks,orother hiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothaveto stopor shiftwhileon the slope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachineingearwhengoingdownslopes

totakeadvantageof enginebrakingaction.

• Followthe manufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersor otherattachments.These

canchangethestabilityofthe machine.

Keepallmovementontheslopesslowandgradual.Donotmake

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontofthe machinetolift andrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingona slope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdownthe slope.

DoNot:

• Donot turnon slopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donot mowneardrop-offs,ditchesor embankments.Themower

couldsuddenlyturnoverifa wheelis overtheedgeof a cliff,

ditch,or ifan edgecavesin.

• Donot try tostabilizethemachinebyputtingyourfooton the

ground.

• Donot usea grasscatcheronsteepslopes.

• Donot mowon wetgrass.Reducedtractioncouldcausesliding.

• Donot attempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolofthe machineresultinginseriousinjury

or death.

• Donot towheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendstopushthe tractorandmay

causeyouto loosecontrol(e.g.tractormayspeedup,brakingand

steeringabilityarereduced,attachmentmayjack-knifeandcause

tractorto overturn).

4

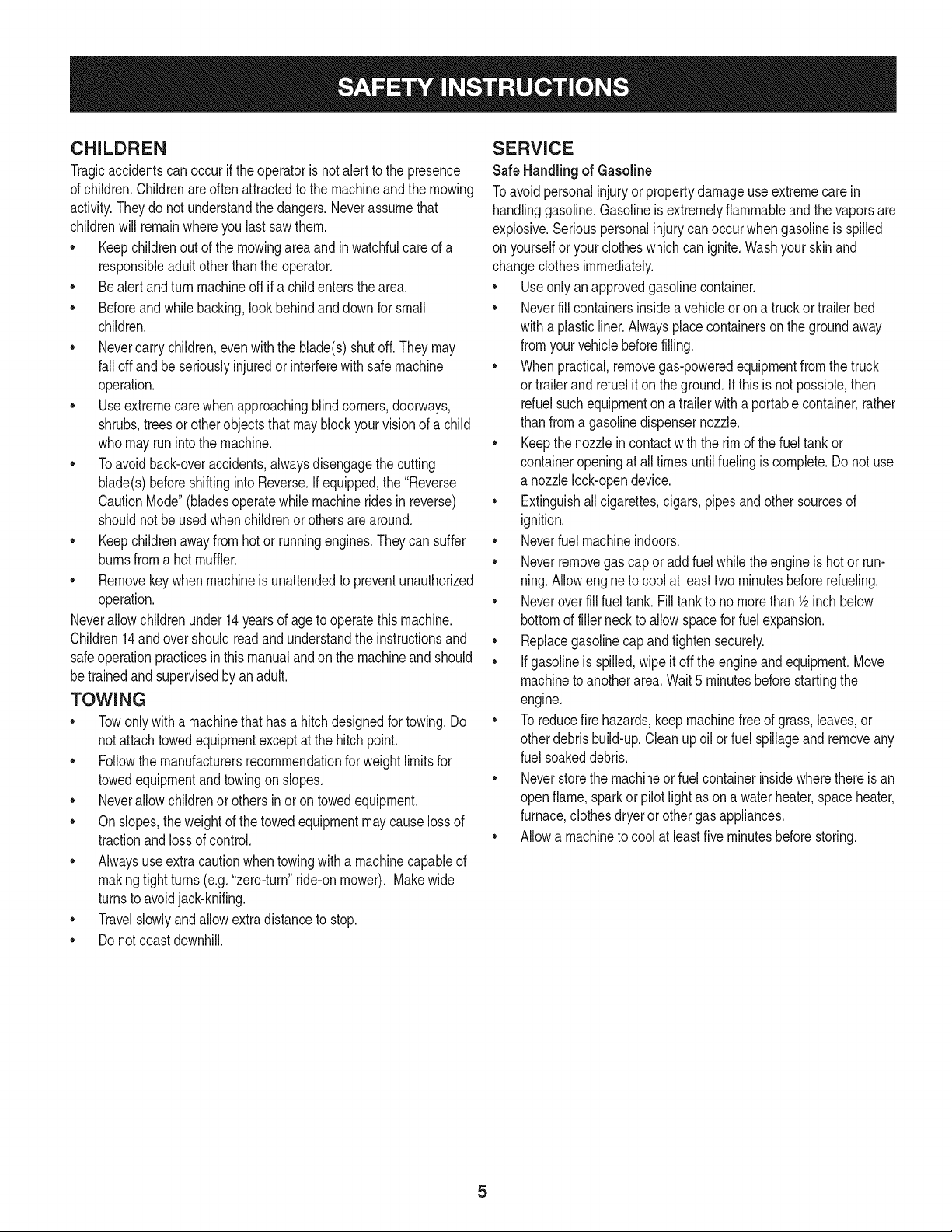

CHILDREN

Tragicaccidentscanoccuriftheoperatorisnotalerttothe presence

ofchildren.Childrenareoftenattractedtothemachineandthe mowing

activity.Theydo notunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthemowingareaand inwatchfulcare of a

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifa childentersthe area.

• Beforeandwhilebacking,lookbehindanddownforsmall

children.

Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionof a child

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethe cutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenor othersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofagetooperatethismachine.

Children14andovershouldreadandunderstandthe instructionsand

safeoperationpracticesinthismanualandon the machineandshould

betrainedandsupervisedbyanadult.

TOWING

Towonlywitha machinethathasahitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwithamachinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistancetostop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

Neverfill containersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefueliton theground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththerim ofthefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donot use

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

Neverremovegascapor addfuelwhilethe engineis hotorrun-

ning.Allowengineto coolat leasttwominutesbeforerefueling.

Neveroverfillfueltank. Filltanktono morethan1/2inchbelow

bottomoffillernecktoallowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefree ofgrass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight as ona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolatleastfiveminutesbeforestoring.

GeneralService

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andallmovingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

• Periodicallychecktomakesurethebladescometocomplete

stopwithinapproximately(5)fivesecondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

byaSearsorotherqualifiedservicedealer.

• Checkbrakeoperationfrequentlyasitissubjectedtowearduring

normaloperation.Adjustandserviceasrequired.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemor othersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothemachine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoverare subject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo not meettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donot changetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsfor gas,oil, etc.to

protecttheenvironment.

• Accordingto the ConsumerProductsSafetyCommission(CPSC)

andthe U.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasanAverageUsefulLifeofseven(7)years,or 270hours

ofoperation.AttheendoftheAverageUsefulLife,buy anew

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatall mechanicaland

safetysystemsareworkingproperlyandnot wornexcessively.

Failuretodosocanresultinaccidents,injuriesor death.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththe governorsettingcanleadtoa runawayengineand

causeittooperateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsfor SORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonor nearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,it shouldbemaintainedin effectiveworking

orderbytheoperator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthemuffleris availablethroughyournearestSears

PartsandRepairServiceCenter.

6

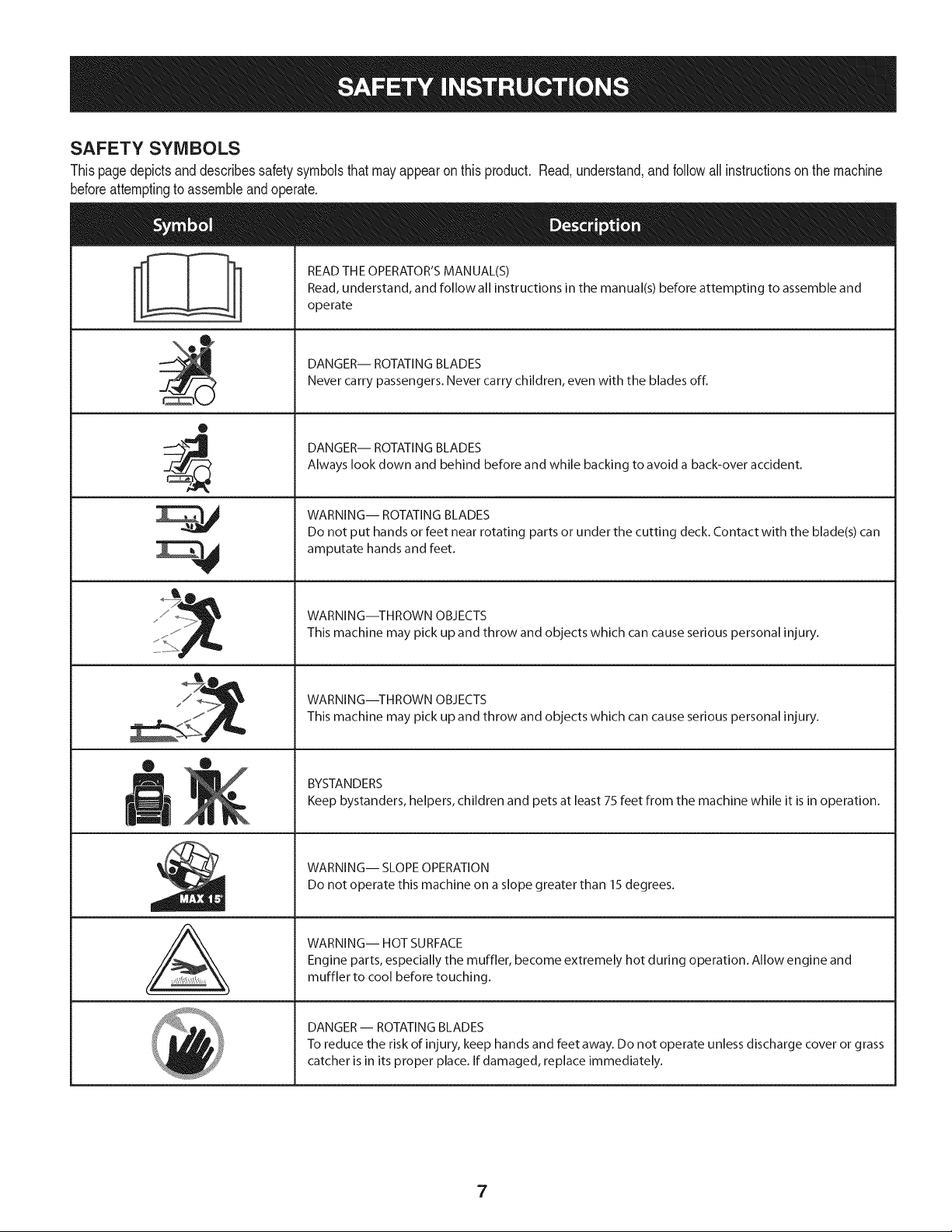

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthis product.Read,understand,andfollowallinstructionson the machine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

O

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s) can

amputate hands and feet.

A

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

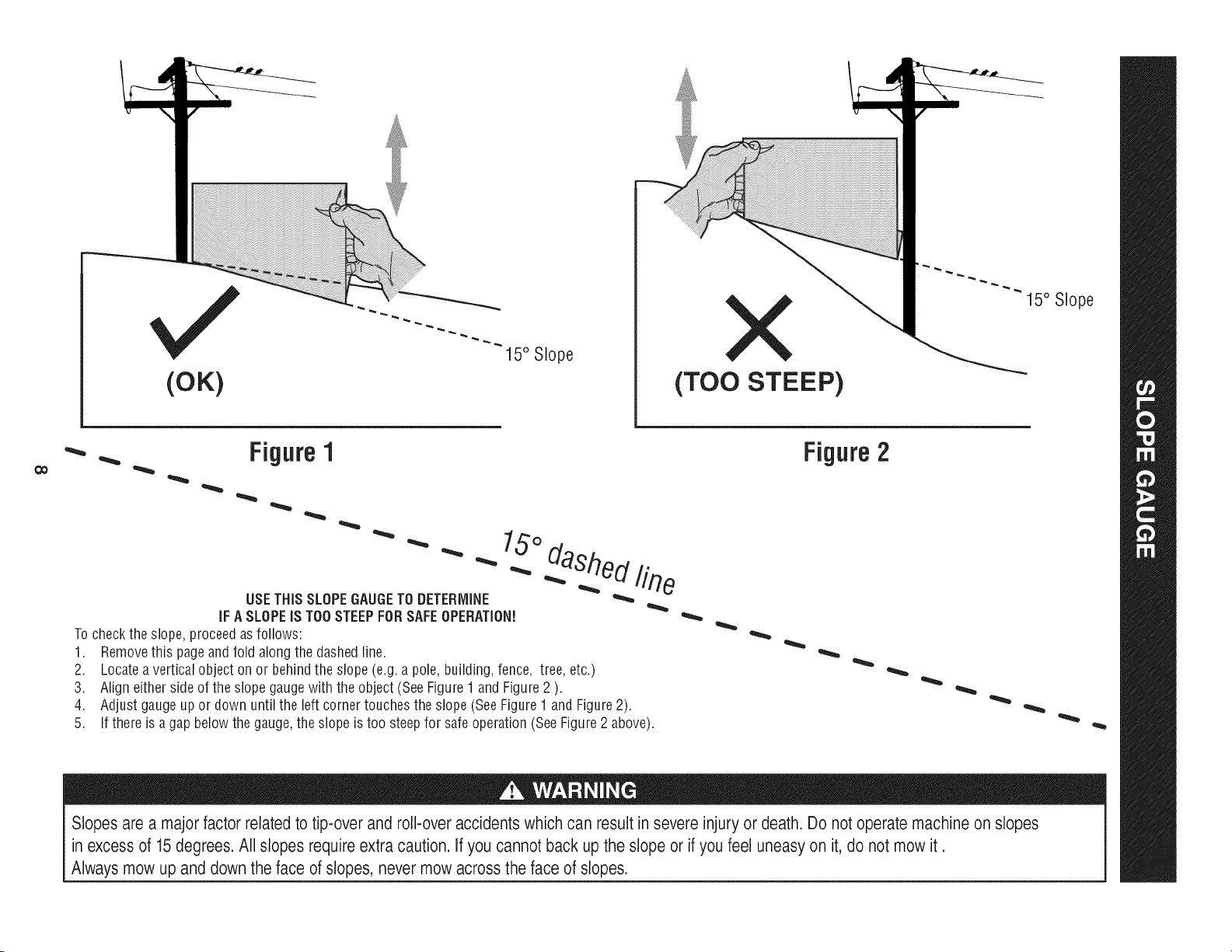

15° Slope

15° Slope

X

(OK)

'_. _ Figure1

(TOO STEEP)

Figure2

15°

dashedline

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEISTOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfold alongthe dashedline.

2. Locatea verticalobject onor behindthe slope (e.g.a pole,building,fence, tree,etc.)

3. Align eithersideof theslopegaugewith theobject(SeeFigure1and Figure2 ).

4. Adjust gaugeupor downuntil the left cornertouchestheslope (SeeFigure1and Figure2).

5.

If thereisagap belowthegauge,theslopeis too steepfor safeoperation(SeeFigure2 above).

Slopesare a majorfactor relatedto tip-over androll-over accidents whichcan resultin severe injuryor death.Do not operatemachine on slopes

in excess of 15degrees.All slopesrequire extra caution. Ifyou cannotback up theslope orif you feeluneasyon it, do not mow it.

Always mowup and down theface ofslopes, never mowacrossthe faceof slopes.

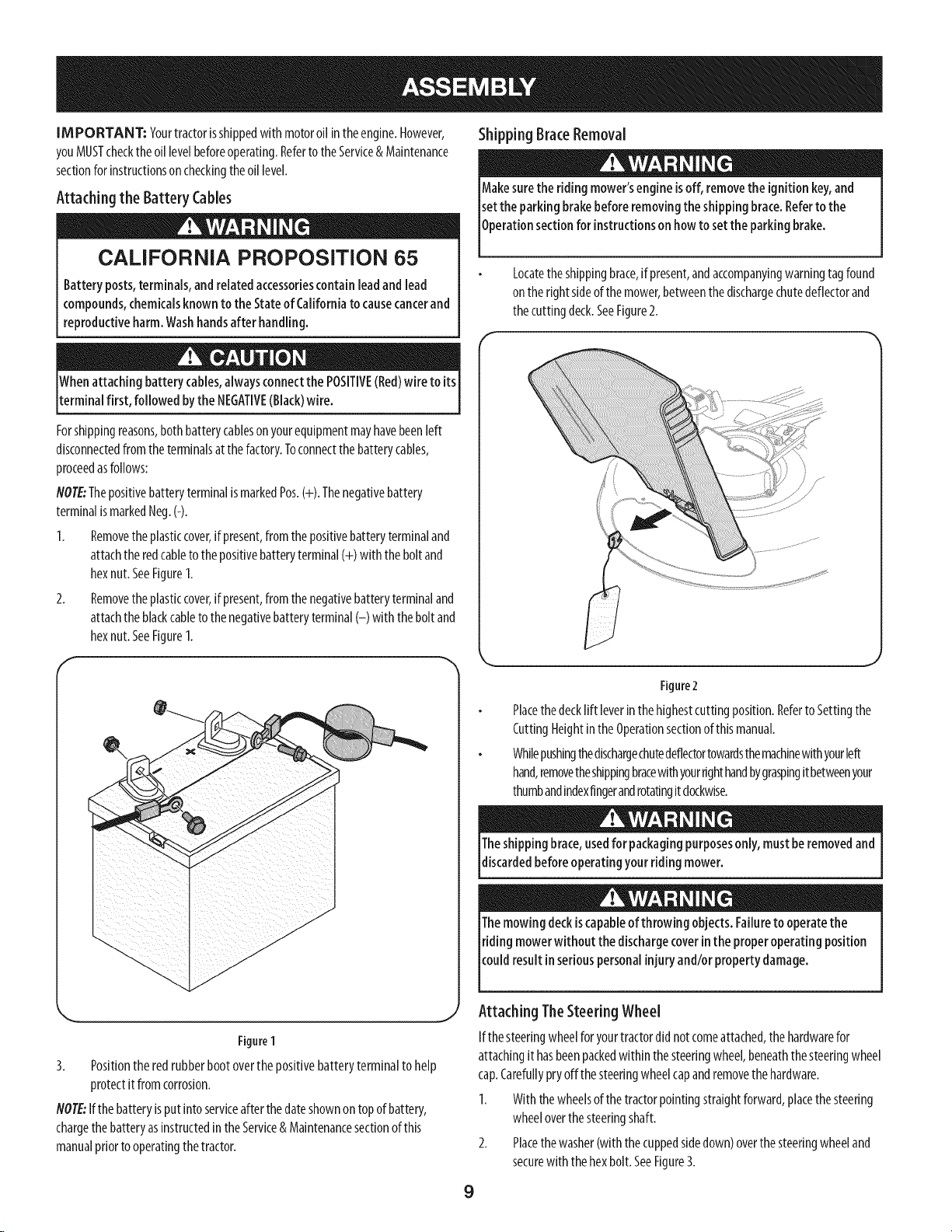

IM PORTANT: Yourtractorisshippedwith motoroil intheengine.However,

youMUSTchecktheoillevelbeforeoperating.Referto theService& Maintenance

sectionforinstructionsoncheckingtheoillevel.

Attaching the Battery Cables

Shipping BraceRemoval

Makesurethe ridingmower'sengineisoff, removethe ignition key,and

settheparkingbrakebefore removingtheshippingbrace.Referto the

CALIFORNIA PROPOSITION 65

Batteryposts,terminals, andrelatedaccessoriescontainleadandlead

compounds,chemicalsknown to the Stateof Californiato causecancerand

reproductiveharm.Washhandsafter handling.

Whenattachingbatterycables,alwaysconnectthe POSITIVE(Red)wire to its

terminalfirst, followed bythe NEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmentmayhavebeenleft

disconnectedfromtheterminalsat thefactory.Toconnectthe batterycables,

proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegativebattery

terminalismarkedNeg.(-).

I. Removetheplasticcover,ifpresent,fromthepositivebatteryterminaland

attachtheredcabletothepositivebatteryterminal(+) with theboltand

hexnut.SeeFigureI.

2. Removetheplasticcover,ifpresent,fromthenegativebatteryterminaland

attachtheblackcabletothenegativebatteryterminal(-) withtheboltand

hexnut.SeeFigure1.

f

Operatonsectonfor nstructonson howto setthe parkng brake.

Locatetheshippingbrace,if present,andaccompanyingwarningtagfound

ontherightsideofthemower,betweenthedischargechutedeflectorand

thecuttingdeck.SeeFigure2.

Figure2

Placethedecklift leverinthehighestcutting position.Referto Settingthe

CuttingHeightintheOperationsectionofthismanual.

Whilepushingthedischargechutedeflectortowardsthemachinewithyourleft

hand,removetheshippingbracewithyourrighthandbygraspingitbetweenyour

thumbandindexfingerandrotatingitclockwise.

/

7"

/"

J

/

Figure1

3. Positionthe redrubberbootoverthepositivebatteryterminalto help

protectitfromcorrosion.

NOTE:Ifthe batteryisput intoserviceafterthedateshownontopof battery,

chargethe batteryasinstructedin theService&MaintenancesectionoftNs

manualpriortooperatingthetractor.

Theshippingbrace,usedforpackagingpurposesonly,must beremovedand

discardedbeforeoperatingyourriding mower.

Themowingdeckiscapableof throwing objects.Failuretooperatethe

ridingmowerwithout the dischargecoverinthe properoperatingposition

coud resut n setous persona njuryand/or property damage.

Attaching TheSteeringWheel

J

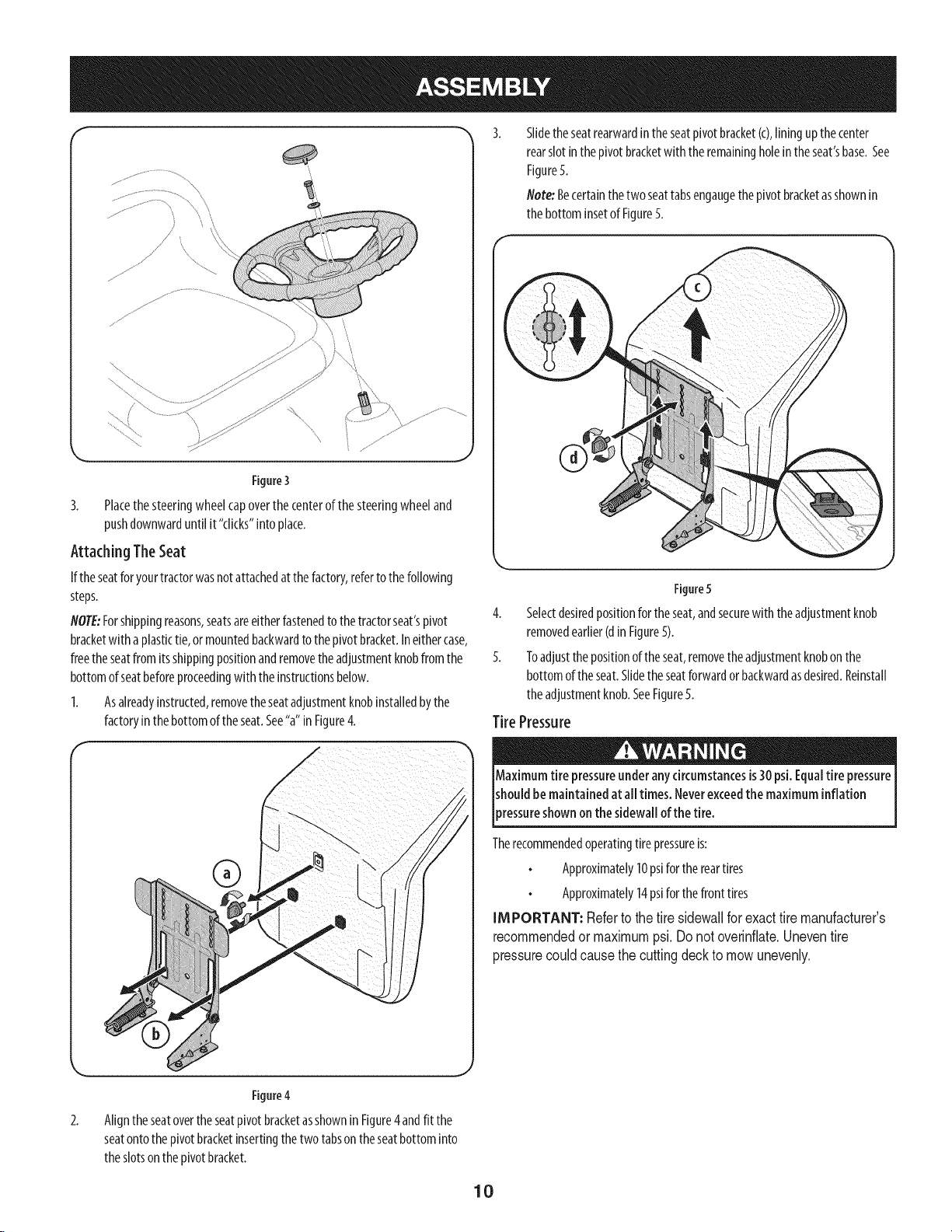

Ifthesteeringwheelforyourtractordidnotcomeattached,thehardwarefor

attachingithasbeenpackedwithinthesteeringwheel,beneaththesteeringwheel

cap.Carefullypryoffthe steeringwheelcapandremovethehardware.

I. Withthewheelsofthetractorpointingstraightforward,placethesteering

wheeloverthesteeringshaft.

2. Placethewasher(withthecuppedsidedown)overthesteeringwheeland

securewith thehexbolt.SeeFigure3.

9

F

\

Figure3

3.

Placethesteeringwheelcapoverthecenterofthesteeringwheeland

pushdownwarduntilit"clicks"intoplace.

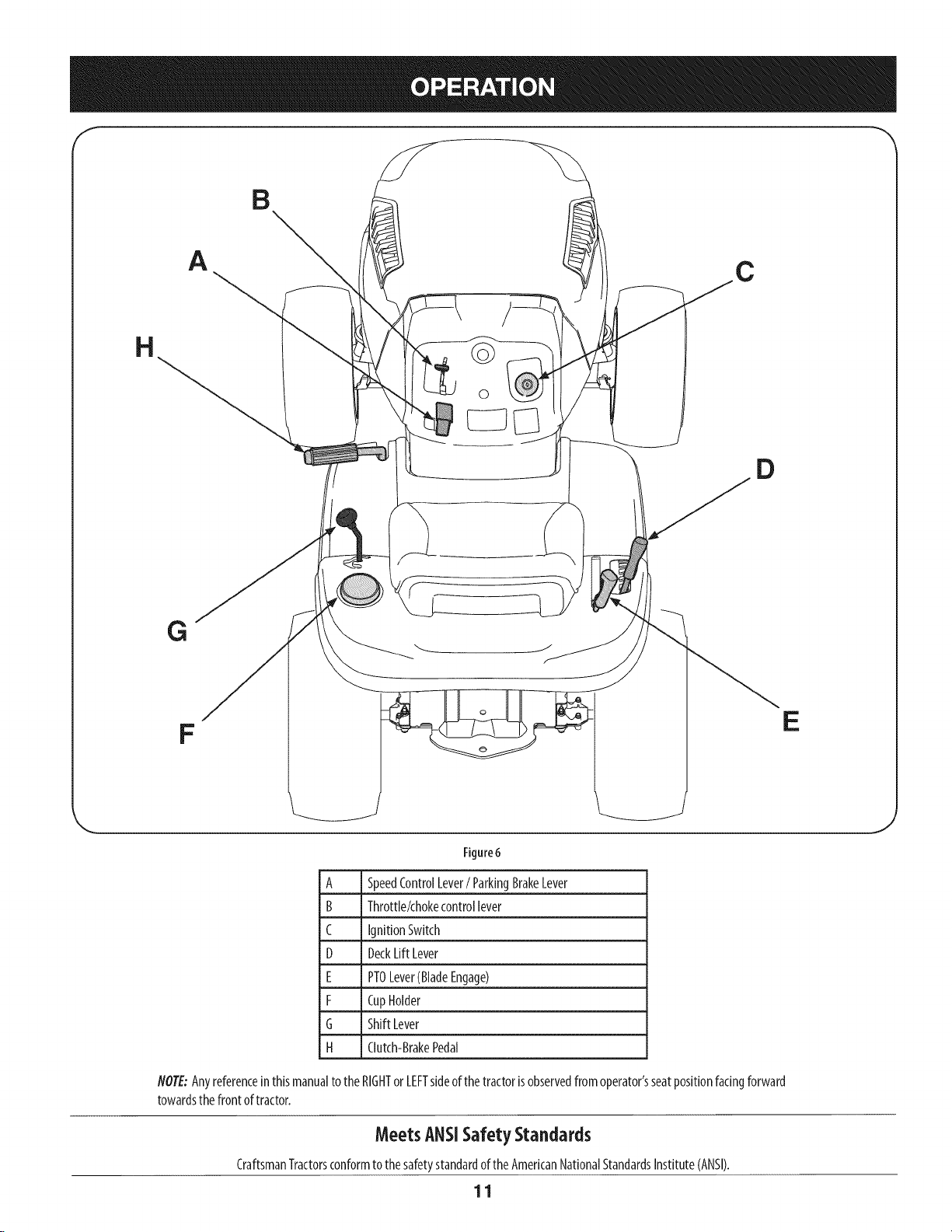

Attaching TheSeat

Iftheseatforyourtractorwasnotattachedat thefactory,refertothefollowing

steps.

NOTE:Forshippingreasons,seatsareeitherfastenedtothetractorseat'spivot

bracketwith a plastictie,ormountedbackwardtothepivotbracket.Ineithercase,

freetheseatfromitsshippingpositionandremovetheadjustmentknobfromthe

bottomofseatbeforeproceedingwith theinstructionsbelow.

1. Asalreadyinstructed,removetheseatadjustmentknobinstalledbythe

factoryin thebottomoftheseat.See"a"inFigure4.

Slidetheseatrearwardin theseatpivotbracket(c),liningupthecenter

rearslotinthepivotbracketwith theremainingholeintheseat'sbase.See

FigureS.

Note:Becertainthetwo seattabsengaugethepivotbracketasshownin

thebottominsetof Figure5.

Figure5

4. Selectdesiredpositionfortheseat,andsecurewith theadjustmentknob

removedearlier(dinFigure5).

5. Toadjustthepositionof theseat,removetheadjustmentknobonthe

bottomof theseat.Slidetheseatforwardor backwardasdesired.Reinstall

theadjustmentknob.SeeFigure5.

TirePressure

®

Figure4

2.

Aligntheseatovertheseatpivotbracketasshownin Figure4andfit the

seatontothepivotbracketinsertingthetwotabsontheseatbottominto

theslotsonthepivotbracket.

Maximumtire pressureunderanycircumstancesis30psi.Equaltire pressure

shouldbe maintainedatall times.Neverexceedthemaximum inflation

)ressureshownonthe sidewallof the tire.

Therecommendedoperatingtirepressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothetire sidewallforexacttire manufacturer's

recommendedormaximumpsi.Donot overinflate.Uneventire

pressurecouldcausethecuttingdeckto mowunevenly.

10

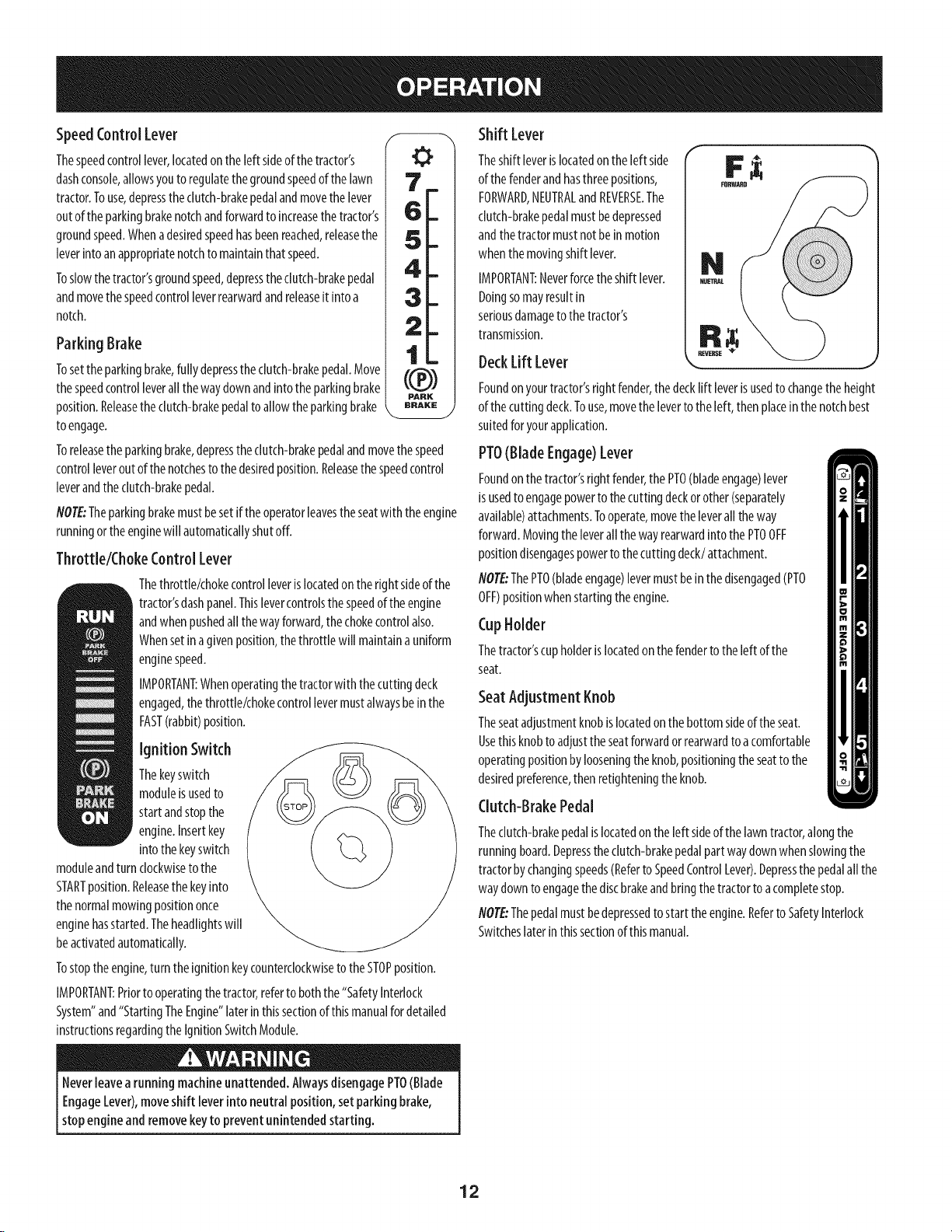

H

A

c)

D

(3

F

Figure6

A SpeedControlLever/ ParkingBrakeLever

B Throttle/chokecontrollever

C IgnitionSwitch

D DeckLiftLever

E PTOLever(BladeEngage)

F CupHolder

G ShiftLever

H Clutch-BrakePedal

NOTE:AnyreferenceinthismanualtotheRIGHTorLEFTsideofthetractorisobservedfromoperator'sseatpositionfacingforward

towardsthefrontof tractor.

MeetsANSISafety Standards

CraftsmanTractorsconformtothesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

E

SpeedControlLever

Thespeedcontrollever,locatedontheleftsideofthetractor's

dashconsole,allowsyoutoregulatethegroundspeedof thelawn

tractor.Touse,depressthedutch-brakepedalandmovethelever

outofthe parkingbrakenotchandforwardtoincreasethetractor's

groundspeed.Whenadesiredspeedhasbeenreached,releasethe

leverintoanappropriatenotchtomaintainthatspeed.

Toslowthetractor'sgroundspeed,depressthedutch-brakepedal

andmovethespeedcontrolleverrearwardandreleaseit intoa

notch.

Parking Brake

Tosettheparkingbrake,fully depresstheclutch-brakepedal.Move

thespeedcontrolleverallthewaydownandintothe parkingbrake

position.Releasetheclutch-brakepedaltoallowtheparkingbrake

toengage.

Toreleasetheparkingbrake,depressthedutch-brakepedalandmovethespeed

controlleveroutofthenotchesto thedesiredposition.Releasethespeedcontrol

leverandthedutch-brakepedal.

NOTE:Theparkingbrakemustbesetif theoperatorleavestheseatwith theengine

runningortheenginewill automaticallyshutoff.

0

7_

2-

1=

((D)

PARK

BRAKE

Throttle/Choke ControlLever

Thethrottle/chokecontrolleverislocatedon therightsideofthe

tractor'sdashpanel.This[evercontrolsthespeedoftheengine

andwhenpushedallthewayforward,thechokecontrolalso.

Whensetinagivenposition,thethrottlewill maintainauniform

enginespeed.

IMPORTANT:Whenoperatingthetractorwiththecuttingdeck

engaged,thethrottle/chokecontrollevermustalwaysbeinthe

FAST(rabbit)position.

Ignition Switch

Thekeyswitch

moduleisusedto

startandstopthe

engine.Insertkey

intothekeyswitch

moduleandturnclockwiseto the

STARTposition.Releasethekeyinto

thenormalmowingpositiononce

enginehasstarted.Theheadlightswill

beactivatedautomatically.

Tostoptheengine,turntheignitionkeycounterclockwisetotheSTOPposition.

IMPORTANT:Priortooperatingthetractor,refertoboththe"SafetyInterlock

System"and"StartingTheEngine"laterinthissectionof thismanualfordetailed

instructionsregardingthe IgnitionSwitchModule.

Shift Lever

Theshiftleverislocatedontheleftside

ofthefenderandhasthreepositions,

FORWARD,NEUTRALandREVERSE.The

clutch-brakepedalmustbedepressed

andthetractormustnotbeinmotion

whenthemovingshift lever.

IMPORTANT:Neverforcetheshiftlever.

Doingsomayresultin

seriousdamageto thetractor's

transmission.

DeckLift Lever

Foundonyourtractor'srightfender,thedecklift leverisusedto changetheheight

ofthecuttingdeck.Touse,movethelevertotheleft, thenplaceinthe notchbest

suitedforyourapplication.

PTO(Blade Engage)Lever

Foundonthetractor'srightfender,thePTO(bladeengage)lever

isusedto engagepowertothecuttingdeckorother(separately

available)attachments.Tooperate,movetheleveralltheway

forward.Movingthe leverallthewayrearwardintothe PTOOFF

positiondisengagespowertothecuttingdeck/attachment.

NOTE:ThePTO(bladeengage)levermustbein thedisengaged(PTO

OFF)positionwhenstartingtheengine.

CupHolder

Thetractor'scupholderislocatedonthefendertotheleftof the

seat.

SeatAdjustment Knob

Theseatadjustmentknobislocatedonthebottomsideoftheseat.

Usethisknobtoadjusttheseatforwardorrearwardto acomfortable

operatingpositionbylooseningtheknob,positioningtheseatto the

desiredpreference,thenretighteningtheknob.

Clutch-BrakePedal

Theclutch-brakepedalislocatedontheleftsideofthelawntractor,alongthe

runningboard.Depresstheclutch-brakepedalpartwaydownwhenslowingthe

tractorbychangingspeeds(Referto SpeedControlLever).Depressthe pedalallthe

waydowntoengagethediscbrakeandbringthetractortoacompletestop.

NOTE:Thepedalmustbedepressedtostart theengine.Referto SafetyInterlock

Switcheslaterin thissectionofthismanual.

Neverleavearunningmachineunattended.AlwaysdisengagePTO(Blade

EngageLever),moveshift leverinto neutral position,set parking brake,

stopengineandremovekeyto prevent unintendedstarting.

12

Gasand OilFill-up

Oil

IMPORTANT:Yourtractorisshippedwith motoroilintheengine.However,you

MUSTchecktheoillevelbeforeoperating.Becarefulnottooverfill.

Forinstructionsonhowtochecktheengineoil,refertoCheckingTheEngineOilin

theServiceandMaintenancesectionofthismanual.

Gasoline

Thegasolinetankislocatedunderthehood.Donotoverfill.

Useextremecarewhenhandling gasoline.Gasoline[sextremelyflammable

andthe vaporsareexplosive°Neverfuel machineindoorsorwhile the

engineishotor running. Extinguishcigarettes,cigars,pipes,andother

sourcesof gnt on.

NOTE:Purchasegasolineinsmallquantities.Donotusegasolineleftoverfromthe

previousseason,to minimizegumdepositsinthefuelsystem.

Thisengineiscertifiedtooperateonunleadedgasoline.Forbestresults,fill

thefueltankwith onlyclean,fresh,unleadedgasolinewith apumpsticker

octaneratingof 87orhigher.

Gasohol(upto 10%ethylalcohol,90%unleadedgasolinebyvolume)isan

approvedfuel.Othergasoline/alcoholblends,suchasE85,arenotapproved.

MethylTertiaryButylEther(MTBE)andunleadedgasolineblends(upto a

maximumof 15%MTBEbyvolume)areapprovedfuels.Othergasoline/ether

blendsarenotapproved.

Fillfueltankoutdoorsorinwell-ventilatedarea.

Donotoverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Neverremovegascaporaddfuelwhiletheengineishotor running.Allow

engineto coolatleasttwo minutesbeforerefueling.

Ifgasolineisspilled,wipeit off theengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

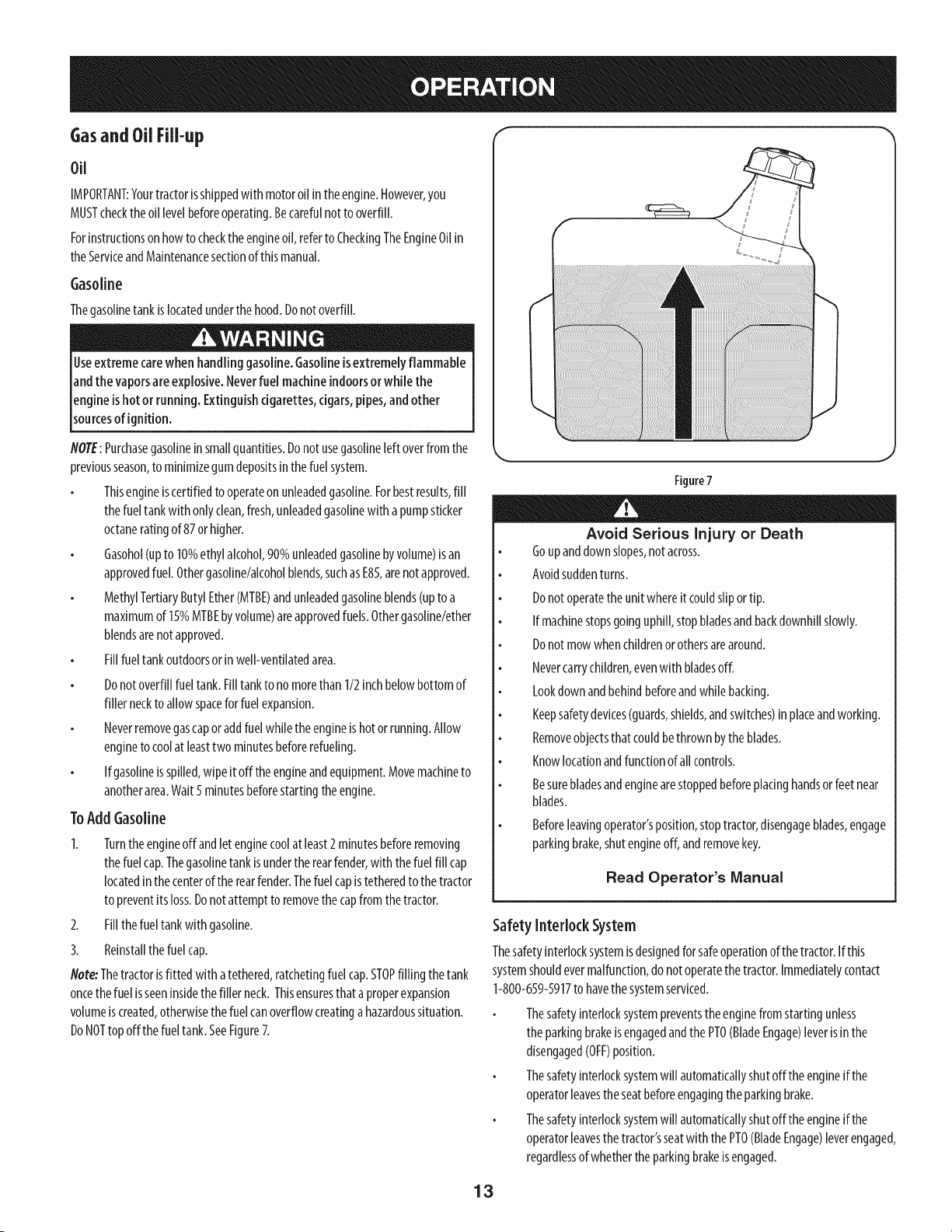

ToAddGasoline

1. Turntheengineoffandletenginecoolatleast2minutesbeforeremoving

thefuelcap.Thegasolinetankisundertherearfender,withthefuelfill cap

locatedin thecenteroftherearfender.Thefuelcapistetheredtothetractor

topreventitsloss.Donotattempttoremovethecapfromthetractor.

2. Fillthefueltankwithgasoline.

3. Reinstallthefuelcap.

Note:Thetractorisfitted with atethered,ratchetingfuelcap.STOPfilling thetank

oncethefuelisseeninsidethefillerneck.Thisensuresthataproperexpansion

volumeiscreated,otherwisethefuelcanoverflowcreatingahazardoussituation.

DoNOTtopoffthefueltank.SeeFigure7.

Figure7

Avoid Serious Injury or Death

Goupanddownslopes,notacross.

Avoidsuddenturns.

Donotoperatetheunitwhereit couldsliportip.

Ifmachinestopsgoinguphill,stopbladesandbackdownhillslowly.

Donotmowwhenchildrenorothersarearound.

Nevercarrychildren,evenwith bladesoff.

Lookdownandbehindbeforeandwhilebacking.

Keepsafetydevices(guards,shields,andswitches)inplaceandworking.

Removeobjectsthat couldbethrownbytheblades.

Knowlocationandfunctionofallcontrols.

Besurebladesandenginearestoppedbeforeplacinghandsorfeet near

blades.

Beforeleavingoperator'sposition,stoptractor,disengageblades,engage

parkingbrake,shutengineoff,andremovekey.

Read Operator's Manual

SafetyInterlock System

Thesafetyinterlocksystemisdesignedfor safeoperationofthetractor.Ifthis

systemshouldevermalfunction,donotoperatethetractor.Immediatelycontact

1-800-659-5917to havethesystemserviced.

Thesafetyinterlocksystempreventstheenginefromstartingunless

theparkingbrakeisengagedandthePTO(BladeEngage)leverisinthe

disengaged(OFF)position.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavestheseatbeforeengagingtheparkingbrake.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavesthetractor'sseatwiththe PTO(BladeEngage)leverengaged,

regardlessofwhethertheparkingbrakeisengaged.

13

Theenginewill automaticallyshutoffif thePTO(BladeEngage)leveris

movedintotheengaged(ON)positionwith theshift leverinReverse.

Ignition Switch

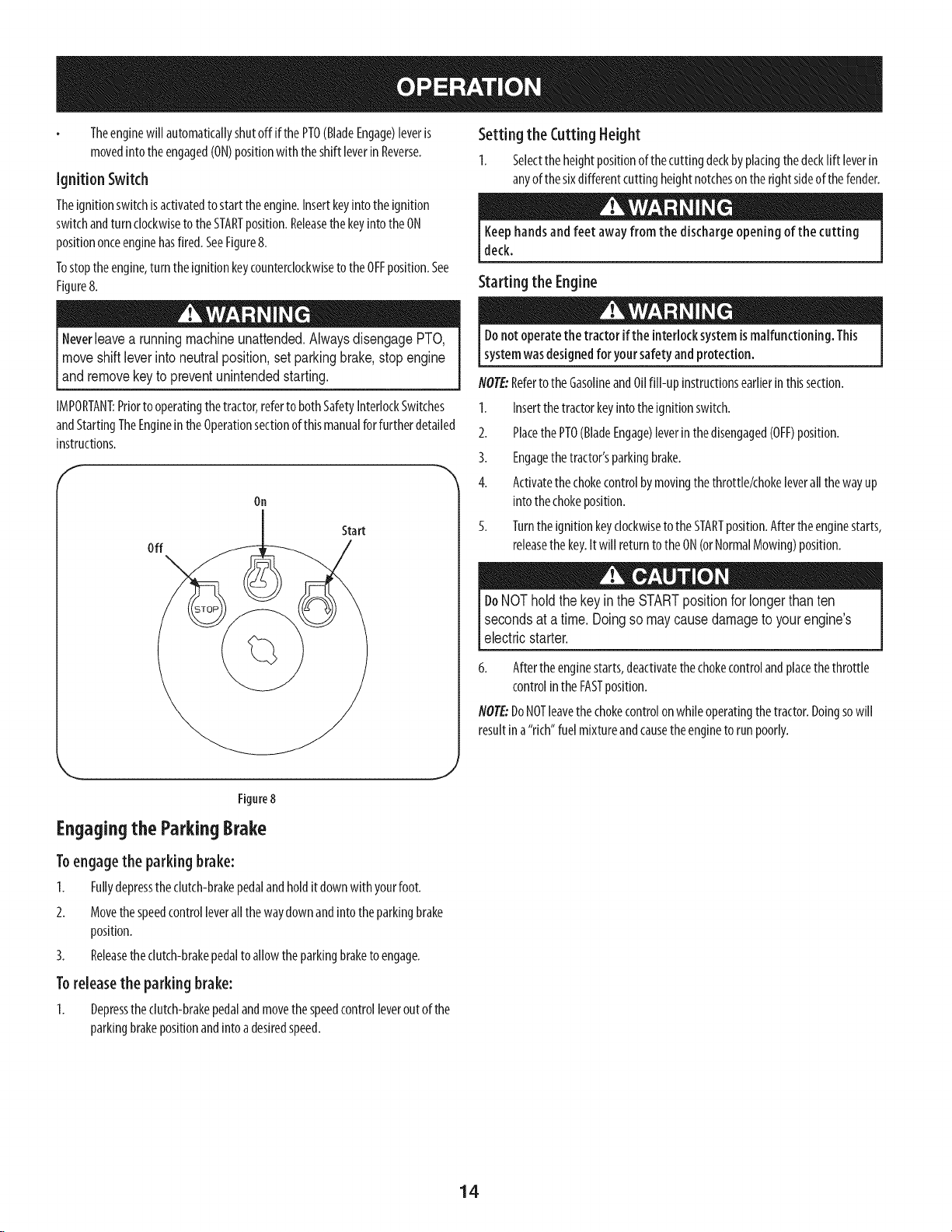

Theignitionswitchisactivatedto starttheengine.Insertkeyintotheignition

switchandturnclockwiseto theSTARTposition.ReleasethekeyintotheON

positiononceenginehasfired.SeeFigure8.

Tostoptheengine,turntheignitionkeycounterclockwiseto theOFFposition.See

Figure8.

Setting the CuttingHeight

1. Selecttheheightpositionofthecuttingdeckbyplacingthedecklift leverin

anyofthesixdifferentcuttingheightnotchesonthe rightsideofthefender.

Keephandsand feet away from the dischargeopening of the cutting

deck.

Starting the Engine

Neverleavea running machine unattended. Always disengage PTO,

move shift lever intoneutral position, set parking brake, stop engine

land remove key to prevent un ntended start ng.

IMPORTANT:Priortooperatingthetractor,refertobothSafetyInterlockSwitches

andStartingTheEngineintheOperationsectionof thismanualforfurtherdetailed

instructions.

On

Start

Off

J

Figure8

Donotoperatethe tractor if the interlock systemismalfunctioning. This

systemwasdesignedforyoursafetyand protection.

NOTE:RefertotheGasolineandOilfill-up instructionsearlierinthissection.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)position.

3. Engagethetractor'sparkingbrake.

4. Activatethechokecontrolbymovingthethrottle/chokeleverallthewayup

intothechokeposition.

5. TurntheignitionkeyclockwisetotheSTARTposition.Aftertheenginestarts,

releasethekey.Itwill returntotheON(orNormalMowing)position.

DoNOTholdthekeyintheSTARTpositionforlongerthanten

secondsat atime. Doingsomaycausedamagetoyourengine's

electricstarter.

6. Aftertheenginestarts,deactivatethechokecontrolandplacethethrottle

controlinthe FASTposition.

NOTE:DoNOTleavethechokecontrolonwhileoperatingthetractor.Doingsowill

resultina"rich"fuelmixtureandcausetheengineto run poorly.

Engaging the Parking Brake

Toengagethe parking brake:

I. Fullydepresstheclutch-brakepedalandholditdownwithyourfoot.

2. Movethespeedcontrolleverallthewaydownandintotheparkingbrake

position.

3. Releasethedutch-brakepedalto allowtheparkingbraketoengage.

Toreleasethe parking brake:

I. Depresstheclutch-brakepedalandmovethespeedcontrolleveroutofthe

parkingbrakepositionandintoadesiredspeed.

14

Stoppingthe Engine

Ifyoustrikeaforeignobject,stop theengine,disconnectthe sparkplug

wire(s)andgroundagainsttheengine.Thoroughlyinspectthe machinefor

anydamage.Repairthe damagebefore restarting andoperating

1. If thebladesareengaged,placethe PTO(BladeEngage)leverinthe

disengaged(OFF)position.

2. TurntheignitionkeycounterclockwisetotheSTOPposition.

3. Removethekeyfromtheignitionswitchto preventunintendedstarting.

DrivingTheTractor

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatofthe tractorwithout first placingthePTO(Blade

Engage)leverinthe disengaged(OFF)position,depressingthe brakepedal

andengagingthe parking brake.Ifleavingthe tractorunattended, also

turn the ignition keyoff andremovethe key.

Alwayslookdownand behindbeforeandwhile backingup to avoidaback-

overaccident.

1. Depresstheclutch-brakepedaltoreleasetheparkingbrakeandthenletthe

pedalup.

2. Movethethrottle leverintothe FAST(rabbit)position.

3. Placetheshift leverineithertheFORWARDorREVERSEposition.

IMPORTANT: DoNOTusetheshift levertochangethedirectionof travelwhen

thetractorisinmotion.Alwaysusetheclutch-brakepedalto bringthetractortoa

completestopbeforeshifting.

4. Releasetheparkingbrakebydepressingtheclutch-brakepedaland

positioningthespeedcontrolleverinthedesiredposition.

IMPORTANT: First-timeoperatorsshouldusespeedpositions1or2. Become

completelyfamiliarwith thetractor'soperationandcontrolsbeforeoperatingthe

tractorinhigherspeedpositions.

5. Releaseclutch-brakepedalslowlytoputunitintomotion.

6. Thelawntractorisbroughttoastopbydepressingtheclutch-brakepedal.

flOTE:Whenoperating the unit initially, therewill be little difference

between the highest two speeds until after the belts have seated

themselves into the pulleys during the break-in period.

Before leaving the operator's position for any reason, disengage the

blades, place the shift lever in neutral, engage the parking brake,

shut engine off and remove the key.

2. Engagetheparkingbrake.

3. Shutengineoffandremovethekey.Doingsowill minimizethepossibility

ofhavingyourlawn"browned"byhotexhaustfromyourtractor'srunning

engine.

Ifunitstallswithspeedcontrolinhighspeed,orif unitwill notoperatewith speed

controlleverinalowspeedposition,proceedasfollows:

1. Placeshift leverinNEUTRAL

2. Restartengine.

3. Placespeedcontrolleverinhighestspeedposition.

4. Releaseclutch-brakepedalfully.

5. Depressclutch-brakepedal.

6. Placespeedcontrolleverindesiredposition.

7. Placeshift leverineitherFORWARDorREVERSE,andfollownormaloperating

procedures.

Driving OnSlopes

Referto theSLOPEGAUGEin theSafetyInstructionssectionofthemanualtohelp

determineslopeswhereyoumayoperatethistractorsafely.

Donotmowoninclineswith aslopeinexcessof ISdegrees(ariseof

approximately2412feet every10feet). Thetractor couldoverturn and

causeseriousinjury.

Mowupanddownslopes,NEVERacross.

Exerciseextremecautionwhenchangingdirectiononslopes.

Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Avoidturnswhendrivingonaslope.Ifaturnmustbemade,turndownthe

slope.Turningupaslopegreatlyincreasesthechanceof a rollover.

Avoidstoppingwhendrivingupa slope.If itisnecessarytostopwhile

drivingupa slope,start upsmoothlyandcarefullyto reducethepossibility

offlippingthetractoroverbackward.

Engagingthe Blades

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeckorother

(separatelyavailable)attachments.Toengagetheblades,proceedasfollows:

1. Movethethrottle/chokecontrollevertotheFAST(rabbit)position.

2. Graspthe PTO(BladeEngage)leverandpivotitallthewayforwardintothe

engaged(ON)position.

3. Keepthethrottle leverintheFAST(rabbit)positionforthemostefficientuse

ofthecuttingdeckorother(separatelyavailable)attachments.

flOTE_Theenginewill automaticallyshutoff ifthe PTO(BladeEngage)leveris

movedintotheengaged(ON)positionwiththeshiftleverinReverse.

IMPORTANT: Whenstoppingthetractorforanyreasonwhileonagrass

surface,always:

1. Placetheshift leverinneutral.

15

Mulching

Amulchkitisavailableasanattachment.Mulchingisaprocessof redrculating

grassclippingsrepeatedlybeneaththecuttingdeck.Theultra-fineclippingsare

thenforcedbackintothe lawnwheretheyactasanaturalfertilizer.

Amulchkitcanbepurchased.Seethe ReplacementParts&Attachmentssectionof

thismanualformoreinformation.

Using the Deck Lift Lever

Toraisethecuttingdeck,movethedecklift leverto the left,then placeit inthe

notchbestsuitedfor yourapplication.RefertoSettingTheCuttingHeightearlierin

thisOperationsection.

MOWING

Tohelpavoidbladecontactora thrown object injury,keepbystanders,

[ helpers,childrenand petsat least75feet from the machinewhile itisin

[operation. Stopmachineifanyoneentersthe area.

Thefollowinginformationwill behelpfulwhenusingthecuttingdeckwithyour

tractor:

Planyourmowing pattern toavoiddischargeofmaterialstoward roads,

sidewalks,bystandersandthe like.Also,avoiddischargingmaterialagainst

awall orobstruction which maycausedischargedmaterial to ricochetback

towardthe operator.

Headlights

ThelampsareONwheneverthetractor'sengineisrunning.

Thelampsturn OFFwhentheignitionkeyismovedto theSTOPposition.

Donotmowathighgroundspeed,especiallyif amulchkit orgrasscollector

isinstalled.

Forbestresultsitisrecommendedthat thefirsttwo lapsbecutwith the

dischargethrowntowardsthecenter.Afterthefirsttwo laps,reversethe

directiontothrowthedischargetotheoutsideforthe balanceofcutting.

Thiswill giveabetterappearanceto thelawn.

Donotcutthegrasstooshort.Shortgrassinvitesweedgrowthandyellows

quicklyindryweather.

Mowingshouldalwaysbedonewiththeengineatfull throttle.

Underheavierconditionsitmaybenecessaryto gobackoverthecutareaa

secondtimetogetacleancut.

DoNOTattempttomowheavybrushandweedsandextremelytallgrass.

Yourtractorisdesignedto mowlawns,NOTclearbrush.

Keepthebladessharpandreplacethebladeswhenworn.RefertoCutting

BladesintheServicesectionofthismanualfor properbladesharpening

instructions.

16

MAINTENANCESCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageallcontrols

andstoptheengine.Waituntilallmovingpartshavecometoacomplete

stop.Disconnectsparkplugwireandgrounditagainsttheengineto prevent

unintendedstarting.Alwayswearsafetyglassesduringoperationorwhile

performinganyadjustmentsorrepairs.

BeforeEachUse 1. Engineoil level 1.

2. Mufflerareaandcontrols 2.

3. Fingerguard 3.

Inthe FirstFiveHours 1. EngineOil 1.

Every10Hours I. Hood/Dashairvents I.

2. Batteryterminals 2.

3. Deckspindlesandidlerbracket 3.

Every25hours 1. Airfilter'sprecleaner* 1.

2. Airfilter* 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings 4.

5. Frontdeckwheels 5.

Every50hours 1. Engineoil/Oil filter 1.

2. Muffler 2.

Annually 1. Airfilter 1.

2. Airfilter'spre-cleaner 2.

3. Sparkplug 3.

4. Aircoolingsystem* 4.

5. Fuelfilter 5.

6. SteeringGears 6.

7. RearWheels 7.

BeforeStorage 1. Hood/Dashairvents 1.

2. Batteryterminals 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings

5. Frontdeckwheels

6. Deckspindlesandidlerbracket

7. Pedalpivotpoints

*Servicemorefrequentlyunderdustyconditions.

Followthe maintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumnto keeptrackofcompleted

maintenancetasks.Tolocatethe nearest Parts& RepairServiceCenteror to

scheduleservice,simply contact1-800-659-5917.

Check

Clean

Clean

Change

Clean

Clean

Lubricate

Clean

Clean

Lubricate

Lubricate

Lubricate

Change/Replace

Check

Replace

Replace

Replace

Clean

Replace

Clean

Removeandgreaseaxles

Clean

Clean

Lubricate

4. Lubricate

5. Lubricate

6. Lubricate

7. Lubricate

Beforeperforminganymaintenanceorrepairs,disengagethePTO(Blade

EngageLever),engagethe parkingbrake,stopthe engineandremovethe

keyto preventunintendedstarting.

Ifthe enginehasbeenrecentlyrun,the engine,muffler and surrounding

metalsurfaceswill behot andcancauseburnsto the skin. Exercisecaution

to avoidburns.

17

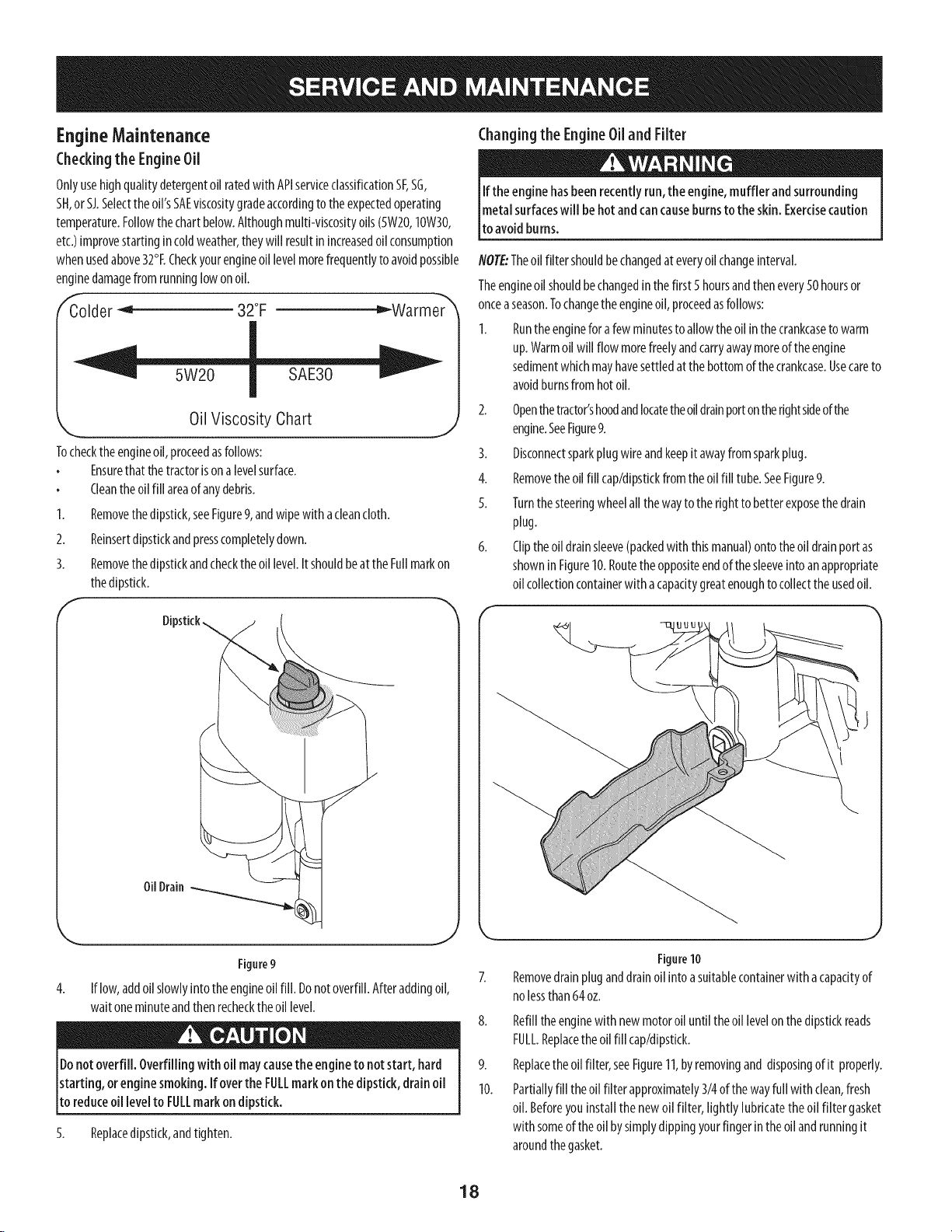

EngineMaintenance

Checkingthe Engine Oil

OnlyusehighqualitydetergentoilratedwithAPIserviceclassificationSF,SG,

SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingtotheexpectedoperating

temperature.Followthechartbelow.Althoughmulti-viscosityoils(5W20,10W30,

etc.)improvestartingin coldweather,theywill resultinincreasedoilconsumption

whenusedabove32°1:.Checkyourengineoillevelmorefrequentlytoavoidpossible

enginedamagefromrunninglowonoil.

E

Colder _ 32°F _Warmer

Changingthe EngineOiland Filter

Ifthe enginehasbeenrecentlyrun, the engine,muffler andsurrounding

metalsurfaceswill behot andcancauseburnsto theskin. Exercisecaution

toavoidburns.

g!OTE:Theoilfilter shouldbechangedat everyoilchangeinterval.

Theengineoilshouldbechangedin thefirst5hoursandthenevery50 hoursor

onceaseason.Tochangetheengineoil,proceedasfollows:

1. Runtheengineforafew minutestoallowtheoilinthecrankcaseto warm

up.Warmoilwill flow morefreelyandcarryawaymoreoftheengine

sedimentwhichmayhavesettledatthe bottomofthecrankcase.Usecareto

avoidburnsfromhotoil.

Oil Viscosity Chart

Tochecktheengineoil,proceedasfollows:

Ensurethat thetractorisonalevelsurface.

Cleantheoilfill areaofanydebris.

1.

Removethedipstick,seeFigure9,andwipewith acleancloth.

2.

Reinsertdipstickandpresscompletelydown.

3.

Removethedipstickandchecktheoillevel.ItshouldbeattheFullmarkon

thedipstick.

F

Dipstick

2. Openthetractor'shoodandlocatetheoildrainportontherightsideof the

J

engine.SeeFigure9.

3. Disconnectsparkplugwireandkeepitawayfromsparkplug.

4. Removetheoilfill cap/dipstkkfromtheoilfill tube.SeeFigure9.

5. Turnthesteeringwheelallthewaytothe righttobetterexposethedrain

plug.

6. Cliptheoildrainsleeve(packedwith thismanual)ontotheoil drainportas

showninFigure10.Routetheoppositeendofthesleeveintoanappropriate

oilcollectioncontainerwith acapacitygreatenoughto collectthe usedoil.

OilDrain

.. j

Figure9

4. If low,addoii slowlyintotheengineoiifill. Donotoverfill.Afteraddingoii,

waitoneminuteandthenrechecktheoillevel.

Donotoverfill. Overfilling with oii maycausethe engineto notstart, hard

starting, orenginesmoking.If overthe FULLmarkonthe dipstick,drain oil

to reduceoiilevelto FULLmarkondipstick.

5. Replacedipstick,andtighten.

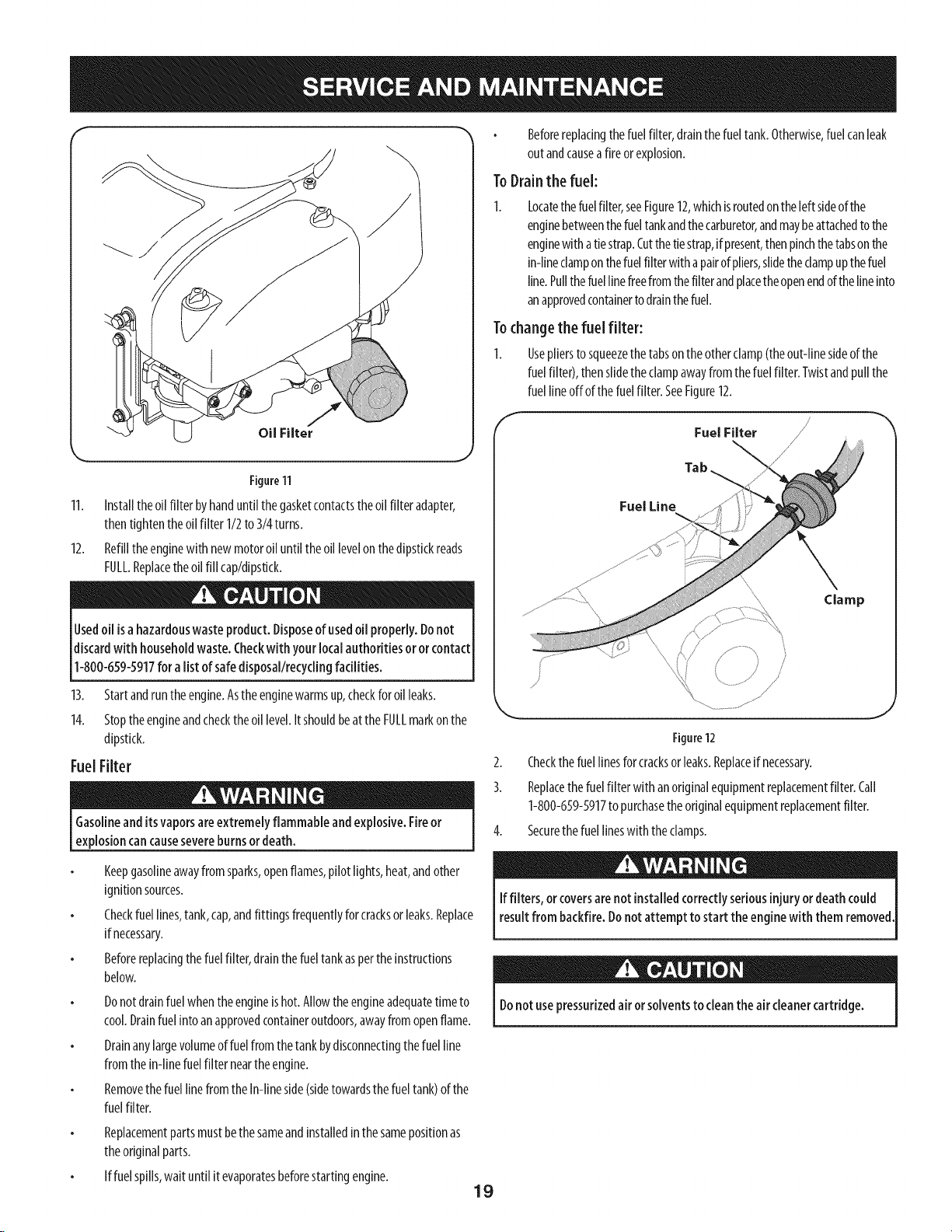

Figure10

Removedrainpluganddrainoilintoasuitablecontainerwith a capacityof

nolessthan64oz.

8. Refilltheenginewithnewmotoroiluntiltheoil levelonthedipstickreads

FULL.Replacetheoilfill cap/dipstick.

9. Replacetheoilfilter,seeFigure11,byremovingand disposingofit properly.

10. Partiallyfilltheoil filterapproximately3/4ofthewayfull with clean,fresh

oil. Beforeyouinstallthenewoil filter, lightlylubricatetheoil filter gasket

with someoftheoilbysimplydippingyourfingerintheoilandrunningit

aroundthegasket.

18

f

Oil Filter

Figure11

11. Installtheoil filter byhanduntilthegasketcontactstheoilfilter adapter,

thentightentheoilfilter 1/2to3/4turns.

12. Refilltheenginewithnewmotoroiluntil theoillevelonthedipstickreads

FULL.Replacetheoilfill cap/dipstkk.

Beforereplacingthefuelfilter,drainthefueltank.Otherwise,fuelcanleak

outandcauseafire orexplosion.

ToDrainthe fuel:

Locatethefuelfilter,seeFigure12,whichisroutedontheleft sideofthe

enginebetweenthefueltankandthecarburetor,andmaybeattachedto the

enginewithatiestrap.Cutthetiestrap,if present,thenpinchthetabsonthe

in-lineclamponthefuelfilterwithapairofpliers,slidetheclampupthefuel

line.Pullthefuellinefreefromthefilterandplacetheopenendofthelineinto

anapprovedcontainertodrainthefuel.

Tochangethe fuel filter:

1. Usepliersto squeezethetabsontheotherclamp(theout-linesideofthe

fuelfilter),thenslidetheclampawayfromthefuelfilter.Twistandpullthe

fuellineoffof thefuelfilter.SeeFigure12.

Fuel Line

Usedoilisahazardouswasteproduct.Disposeofusedoil properly.Donot

discardwith householdwaste.Checkwitbyour localauthoritiesor orcontact

1-800-659-5917for alistof safedisposal/recyclingfacilities.

13. Startandruntheengine.Astheenginewarmsup,checkforoilleaks.

14. Stoptheengineandchecktheoil level.ItshouldbeattheFULLmarkonthe

dipstick.

FuelFilter

Gasolineanditsvaporsareextremely flammableandexplosive.Fireor

explosioncancausesevereburnsordeath.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

ignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksor leaks.Replace

if necessary.

Beforereplacingthefuelfilter, drainthefueltankaspertheinstructions

below.

Donotdrainfuelwhentheengineishot.Allowtheengineadequatetimeto

cool.Drainfuelintoanapprovedcontaineroutdoors,awayfromopenflame.

Drainanylargevolumeoffuelfromthetankbydisconnectingthefuel line

fromthe in-linefuelfilter neartheengine.

Removethefuellinefromthe In-lineside(sidetowardsthefueltank)ofthe

fuelfilter.

Replacementpartsmustbethesameandinstalledinthesamepositionas

theoriginalparts.

Iffuelspills,wait untilit evaporatesbeforestartingengine.

Clamp

j/

Figure12

2. Checkthe fuellinesforcracksorleaks.Replaceifnecessary.

3. Replacethefuelfilter withanoriginalequipmentreplacementfilter.Call

1-800-659-5917to purchasetheoriginalequipmentreplacementfilter.

4. Securethefuellineswith theclamps.

Iffilters, orcoversarenot installedcorrectlyseriousinjuryordeathcould

resultfrom backfire.Donot attempt to startthe enginewith them removed.

Donotusepressurizedair orsolventsto cleanthe aircleanercartridge.

19

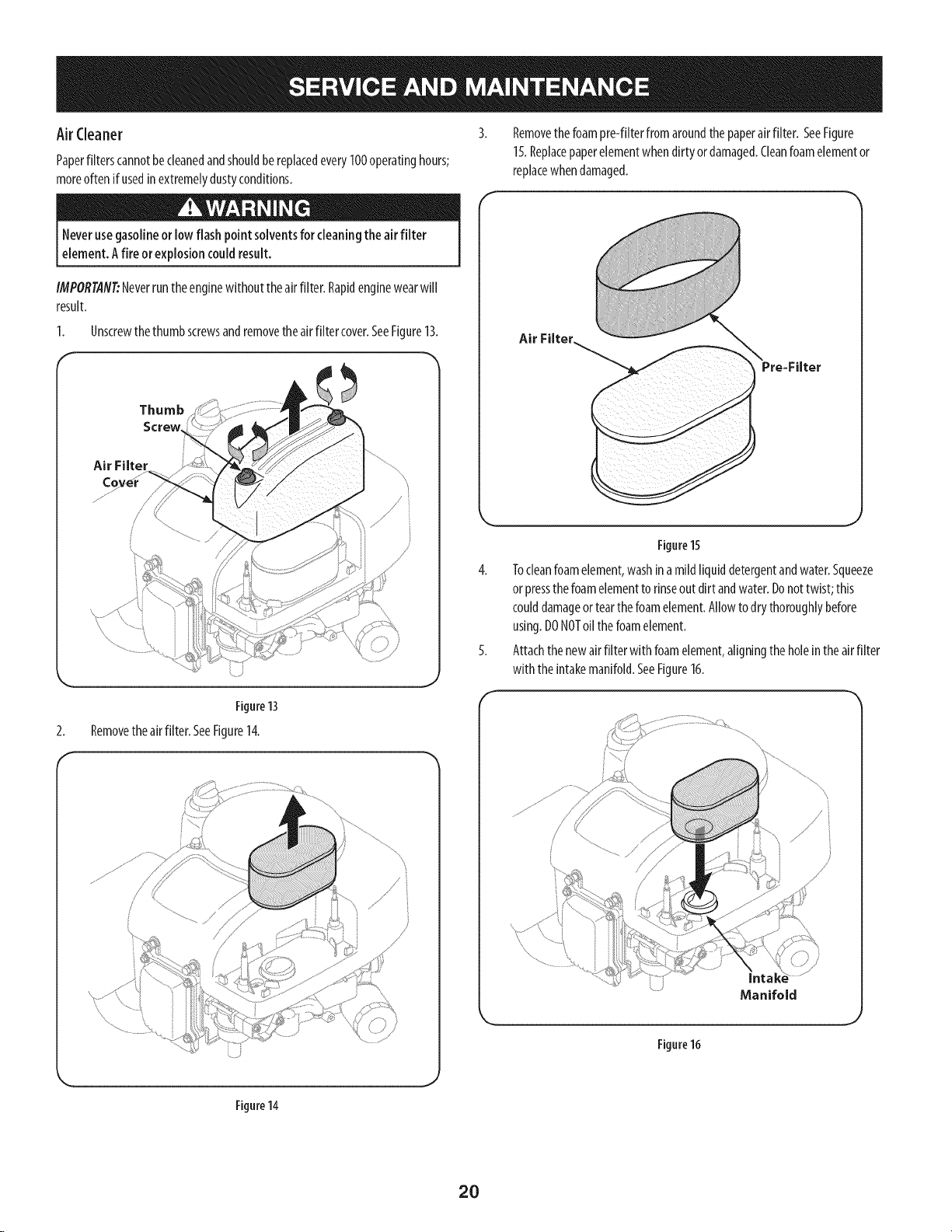

Air Cleaner

Paperfitterscannotbecleanedandshouldbereplacedevery100operatinghours;

moreoftenif usedin extremelydustyconditions.

Neverusegasolineor lowflash pointsolventsfor cleaningtheair filter

element.A fire orexplosioncouldresult.

IMPORTANT:Neverruntheenginewithout theairfilter. Rapidenginewearwill

result.

1. Unscrewthethumbscrewsandremovetheairfilter cover.SeeFigure13.

Thumb

Screw

Air Filter

Removethefoampre-fi[terfromaroundthepaperairfitter. SeeFigure

15.Replacepaperelementwhendirtyordamaged.Cleanfoamelementor

replacewhendamaged.

Air Filter

2.

Removetheairfilter. SeeFigure14.

Figure13

//

Figure15

4. Tocleanfoamelement,washinamildliquiddetergentandwater.Squeeze

orpressthefoamelementtorinseout dirtandwater.Donottwist;this

coulddamageortearthefoamelement.Allowtodrythoroughlybefore

using.DONOToil thefoamelement.

5. Attachthenewairfilterwith foamelement,aligningtheholeintheairfilter

with theintakemanifold.SeeFigure16.

Manifold

Figure14

Figure16

2O

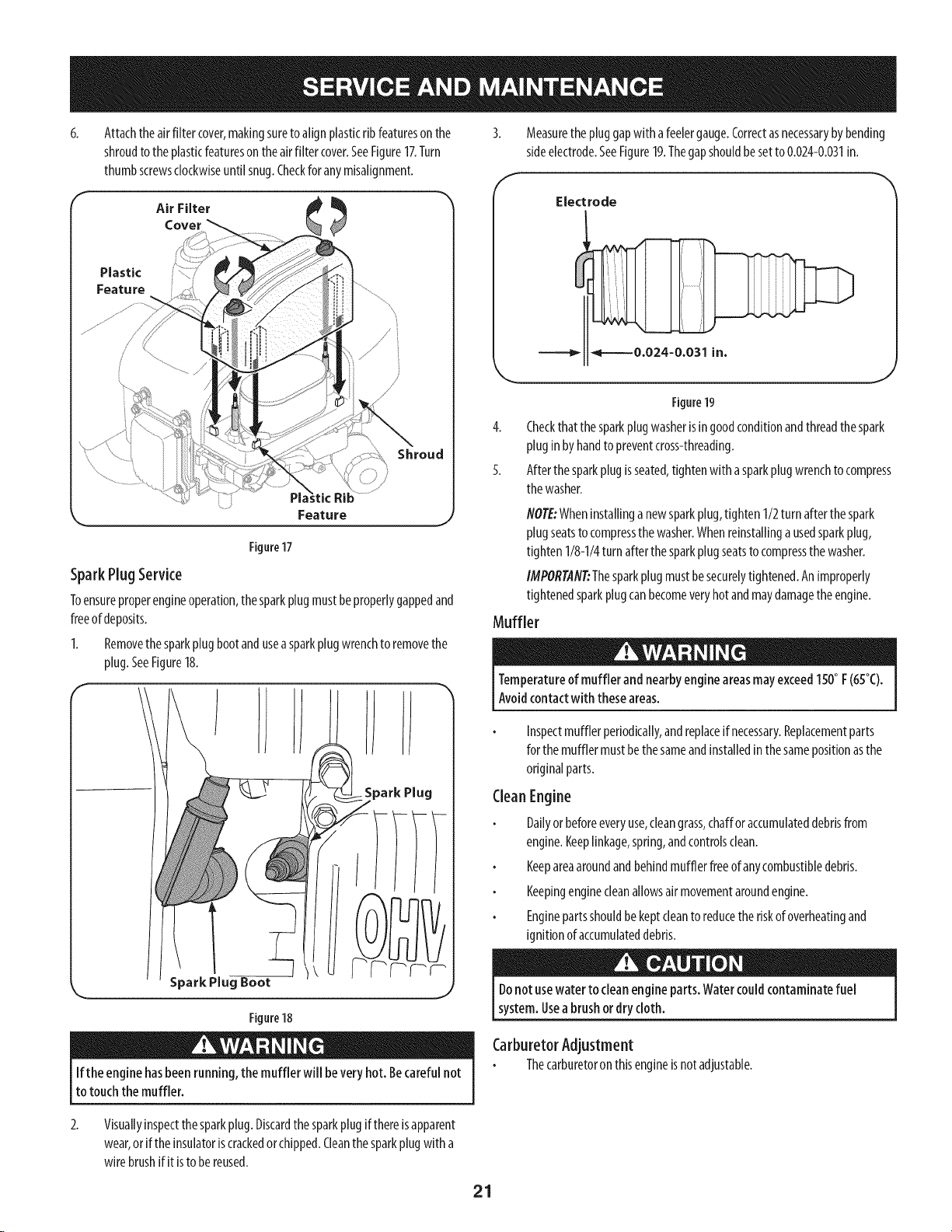

6.

Attachtheairfilter cover,makingsuretoalignplasticribfeaturesonthe

shroudtotheplasticfeaturesontheairfilter cover.SeeFigure17.Turn

thumbscrewsclockwiseuntilsnug.Checkfor anymisalignment.

Air Filter

Cover

Plastic

Feature

Shroud

Measurethepluggapwithafeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure19.Thegapshouldbesetto0.024-0.031in.

Electrode

J

Figure19

4. Checkthatthesparkplugwasherisingoodconditionandthreadthespark

pluginbyhandtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

k_ Feature

Figure17

SparkPlugService

Toensureproperengineoperation,thesparkplugmustbeproperlygappedand

freeofdeposits.

1. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug.SeeFigure18.

F

Spark Plug

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthespark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-1/4turnafterthesparkplugseatsto compressthewasher.

IMPORTANT:Thesparkplugmustbesecurelytightened.Animproperly

tightenedsparkplugcanbecomeveryhotandmaydamagetheengine.

Muffler

Temperatureofmuffler andnearbyengineareasmayexceed150° F(65°C).

Avoidcontactwith theseareas.

Inspectmufflerperiodically,andreplaceifnecessary.Replacementparts

forthe mufflermustbethesameandinstalledinthesamepositionasthe

originalparts.

CleanEngine

Dailyorbeforeeveryuse,cleangrass,chafforaccumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustibledebris.

Keepingenginecleanallowsairmovementaroundengine.

Enginepartsshouldbekeptcleantoreducetheriskofoverheatingand

ignitionofaccumulateddebris.

k_ Spark Plug Boot

J

Figure18

Ifthe enginehasbeenrunning,themuffler will beveryhot.Becarefulnot

to touchthe muffler.

2.

Visuallyinspectthesparkplug.Discardthesparkplugifthereisapparent

wear,oriftheinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifitistobereused.

Donotusewater to cleanengineparts.Watercouldcontaminatefuel

system.Usea brushordrycloth.

CarburetorAdjustment

Thecarburetoronthisengineisnotadjustable.

21

Lubrication

IMPORTANT: Theuseofa pressurewashertocleanyourtractorisNOT

recommended.It maycausedamageto electricalcomponents,spindles,pulleys,

bearingsortheengine.

Beforelubricating,repairing,orinspecting,alwaysdisengagePTO(Blade I

EngageLever),moveshift leverintoneutral position,setparkingbrake,stopI

engneandremovekeytopreventun ntendedstart ng. I

l

Pivot Points& Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift linkageat

leastonceaseasonwith lightoil.

RearWheels

Therearwheelsshouldberemovedfromtheaxlesonceaseason.Lubricatethe

axlesandtherimswellwith anall-purposegreasebeforere-installingthem.

Front Axles

Eachendofthetractor'sfrontpivotbarmaybeequippedwith agreasefitting.

Lubricatewith agreasegunafterevery25hoursoftractoroperation.

Battery

Thebatteryissealedandismaintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalscleanandfreeofcorrosive

build-up.

Aftercleaningthe batteryandterminals,applyalightcoatofpetroleumjelly

orgreaseto bothterminals.

Alwayskeeptherubberbootpositionedoverthepositiveterminaltoprevent

shorting.

IM PORTANT: Ifremovingthebatteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst,followedbythePOSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthe POSITIVE(Red)wireto itsterminal

first,followedbytheNEGATIVE(Black)wire.Becertainthatthewiresareconnected

tothecorrectterminals;reversingthemcouldchangethepolarityandresultin

damageto yourengine'salternatingsystem.

Adjustments

Neverattempt to makeanyadjustmentswhile the engineisrunning,except

wherespecifiedinthe operator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stirepressurebeforeperforminganydeckleveling

adjustments.RefertoTiresintheServicesectionofthismanualformore

informationregardingtirepressure.

FrontToRear

Thefrontofthecuttingdeckissupportedbyastabilizerbarthatcanbeadjustedto

levelthedeckfromfrontto rear.Thefrontof thedeckshouldbebetween1g-inch

and_8-inchlowerthantherearofthedeck.Adjustif necessaryasfollows:

1. Withthetractorparkedonafirm, levelsurface,placetheleverforliftingthe

platformon thesecondtothetopnotch(secondhighestposition)androtate

the bladeascloseaspossibleto thedischargechannelthatisparalleltothe

tractor.

2. Measurethedistancefromthefrontofthebladetipto thegroundandthe

rearofthebladetiptotheground.Thefirst measurementtakenshould

bebetweenlg"and_8"lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryforproperadjustmentandproceed,if

necessary,tothenextstep.

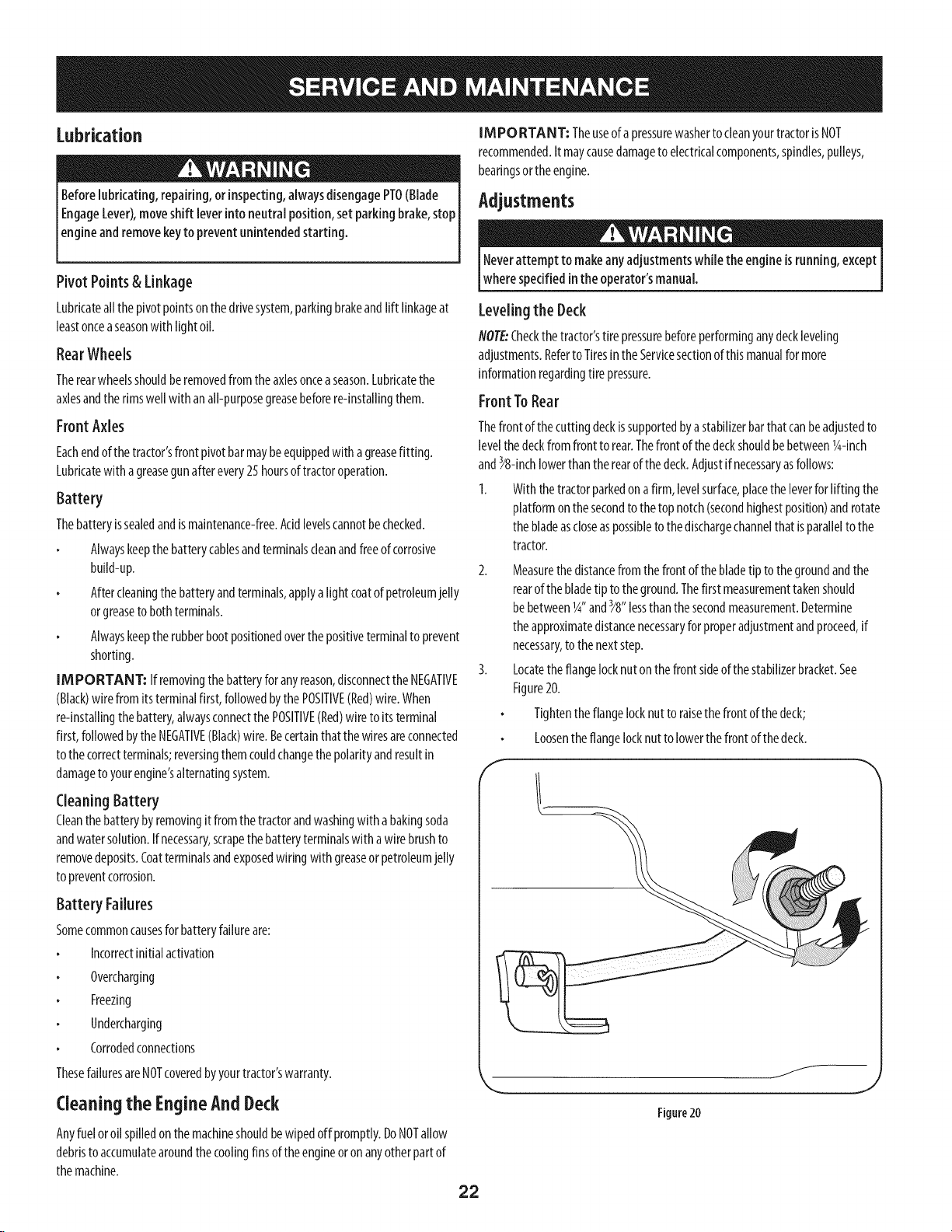

3. Locatetheflangelocknutonthefrontsideofthestabilizerbracket.See

Figure20.

Tightentheflangelocknutto raisethefrontof thedeck;

Loosentheflangelocknutto lowerthefrontofthedeck.

f

CleaningBattery

Cleanthebatterybyremovingit fromthetractorandwashingwith a bakingsoda

andwatersolution.Ifnecessary,scrapethebatteryterminalswitha wirebrushto

removedeposits.Coatterminalsandexposedwiringwith greaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesforbatteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Cleaningthe EngineAndDeck

Anyfueloroilspilledonthemachineshouldbewipedoff promptly.DoNOTallow

debristo accumulatearoundthecoolingfinsoftheengineoronanyotherpartof

themachine.

J

22

Sideto Side

Ifthecuttingdeckappearsto bemowingunevenly,asidetosideadjustmentcanbe

performed.Adjustifnecessaryasfollows:

1. Withthetractorparkedona firm,levelsurface,placethedecklift leverin

thesecondfromthetop notch(secondhighestposition)androtateboth

bladessothattheyareperpendicularwith thetractor.

2. Measurethedistancefromtheoutsideof theleft bladetiptotheground

andthedistancefromtheoutsideoftherightbladetipto theground.Both

measurementstakenshouldbeequal.Ifthey'renot,proceedtothenext

step.

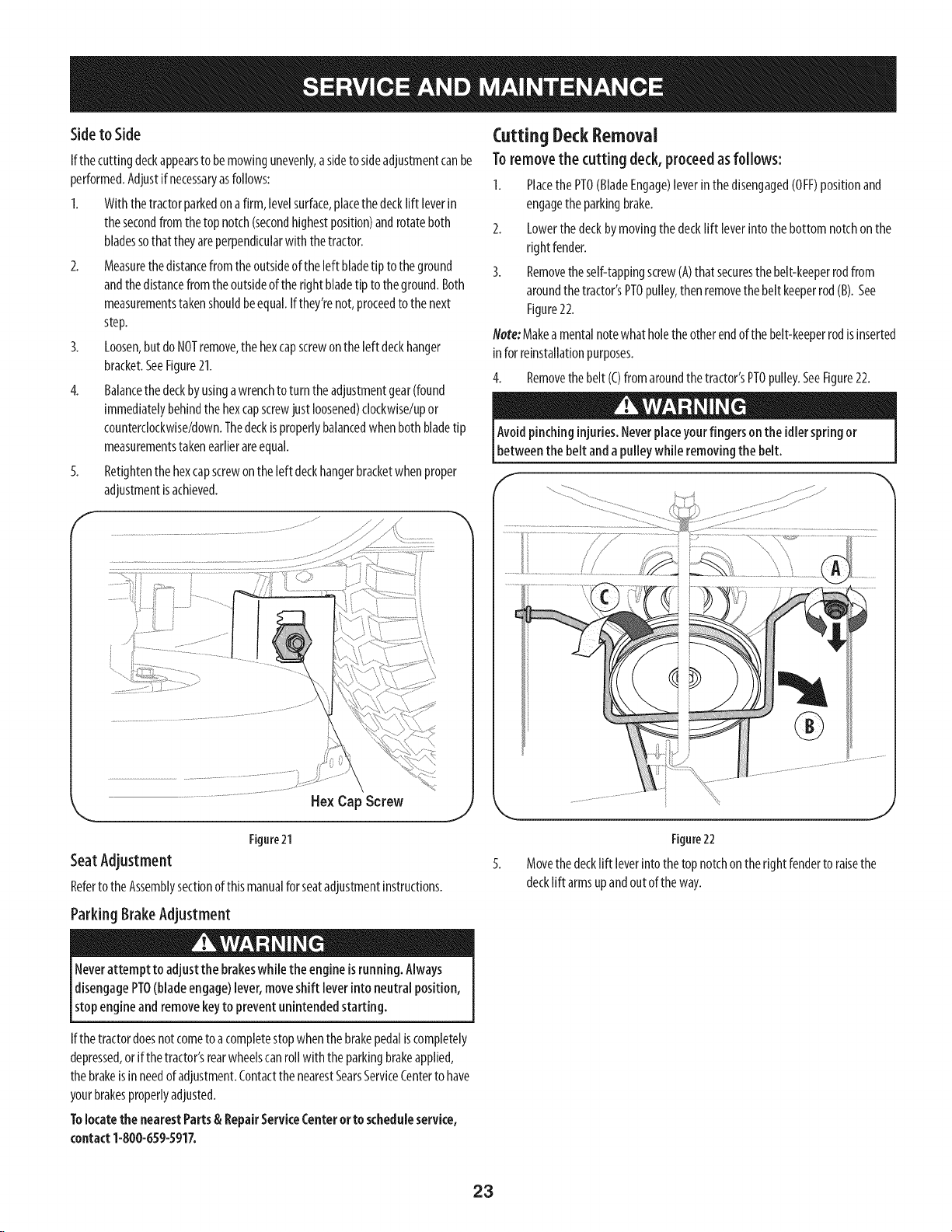

3. Loosen,butdoNOTremove,thehexcapscrewontheleftdeckhanger

bracket.SeeFigure21.

4. Balancethedeckbyusingawrenchtoturntheadjustmentgear(found

immediatelybehindthehexcapscrewjust loosened)clockwise/upor

counterclockwise/down.Thedeckisproperlybalancedwhenbothbladetip

measurementstakenearlierareequal.

5. Retightenthehexcapscrewontheleft deckhangerbracketwhenproper

adjustmentisachieved.

Cutting Deck Removal

Toremovethe cutting deck, proceedasfollows:

1. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)positionand

engagetheparkingbrake.

2. Lowerthedeckbymovingthedecklift leverintothebottom notchonthe

rightfender.

3. Removetheself-tappingscrewCA)that securesthebelt-keeperrodfrom

aroundthetractor'sPTOpulley,thenremovethebeltkeeperrod(B).See

Figure22.

Note:Makeamentalnotewhatholetheotherendofthe belt-keeperrodisinserted

inforreinstallationpurposes.

4. Removethebelt(C)fromaroundthetractor'sPTOpulley.SeeFigure22.

Avoidpinchinginjuries.Neverplaceyourfingersonthe idler springor

between the beltand apulleywhile removingthe belt.

f

HexCapScrew

Figure21

SeatAdjustment

RefertotheAssemblysectionofthis manualforseatadjustmentinstructions.

Parking BrakeAdjustment

Neverattempt to adjustthe brakeswhile theengineisrunning.Always

disengagePTO(bladeengage)lever,moveshift leverintoneutralposition,

stopengineandremovekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhenthe brakepedaliscompletely

depressed,orif thetractor'srearwheelscanrollwith theparkingbrakeapplied,

thebrakeisinneedofadjustment.ContactthenearestSearsServiceCenterto have

yourbrakesproperlyadjusted.

Tolocatethe nearestParts&RepairService(enter ortoscheduleservice,

contact1-800-659-5917.

J

Figure22

Movethedeckliftleverintothetopnotchontherightfendertoraisethe

decklift armsupandoutoftheway.

23

/_

//

/

/

/

PTOCable

Figure23

6.

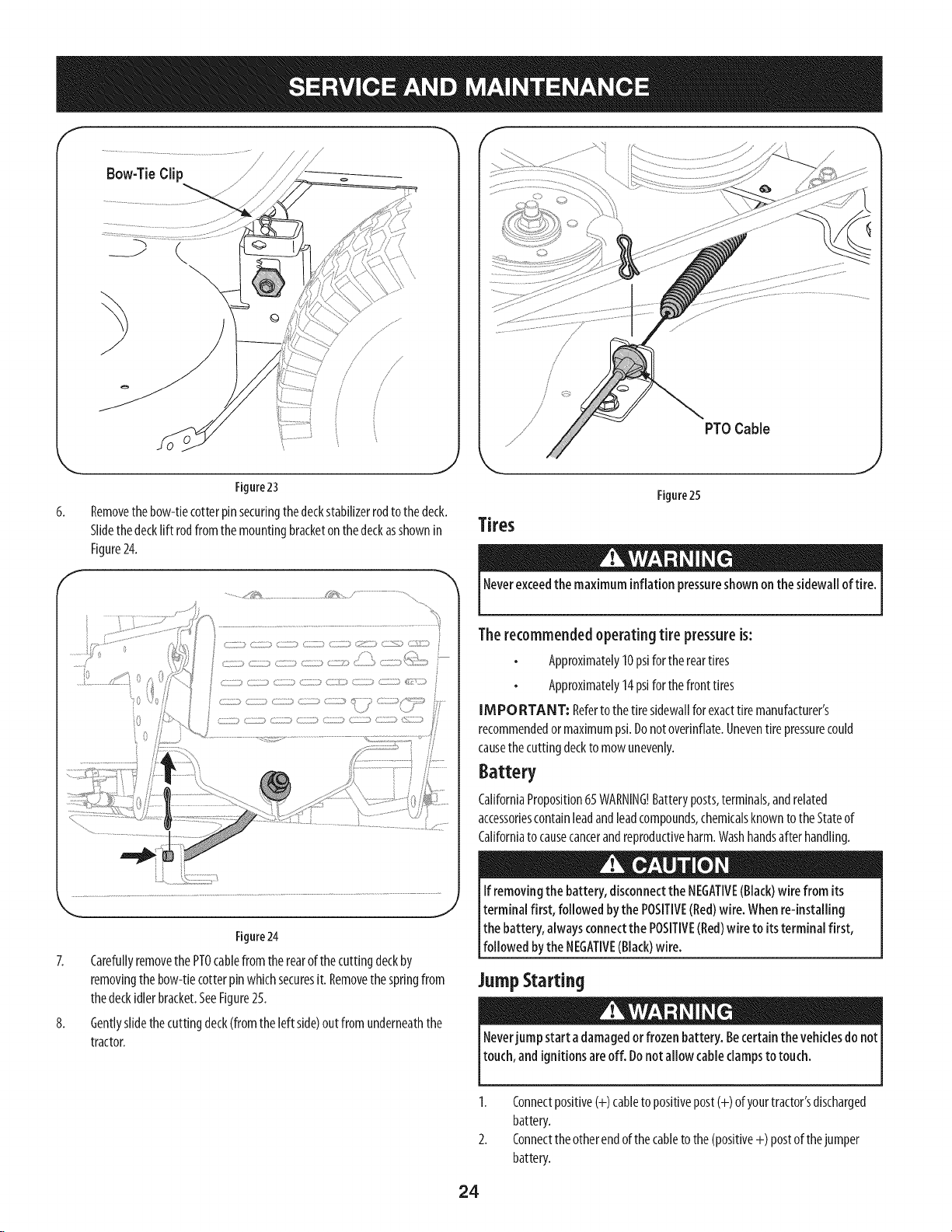

Removethebow-tiecotterpinsecuringthedeckstabilizerrodtothedeck.

Slidethedecklift rodfromthe mountingbracketonthedeckasshownin

Figure24.

f

,,__ /,__ ,........................

,.. j

Figure24

7. CarefullyremovethePTOcablefromtherearofthecuttingdeckby

removingthebow-tiecotterpinwhichsecuresit.Removethespringfrom

thedeckidlerbracket.SeeFigure25.

8. Gentlyslidethecuttingdeck(fromtheleft side)outfromunderneaththe

tractor.

Figure25

Tires

Neverexceedthemaximum inflation pressureshownonthe sidewalloftire.

Therecommended operating tire pressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothetire sidewallforexacttire manufacturer's

recommendedormaximumpsi.Donotoverinflate.Uneventirepressurecould

causethecuttingdecktomowunevenly.

Battery

CaliforniaProposition65WARNING!Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,chemicalsknowntotheStateof

Californiato causecancerandreproductiveharm.Washhandsafterhandling.

Ifremovingthe battery, disconnectthe NEGATIVE(Black)wire from its

terminal first, followed bythe POSITIVE(Red)wire.Whenre-installing

the battery,alwaysconnectthe POSITIVE(Red)wireto itsterminal first,

followed bythe NEGATIVE(Black)wire.

JumpStarting

Neverjumpstart adamagedor frozenbattery. Becertainthevehiclesdonot

touch,and ignitionsareoff. Donotallowcableclampstotouch.

1. Connectpositive(+)cabletopositivepost(+)of yourtractor'sdischarged

battery.

2. Connecttheotherendofthecabletothe(positive+)postofthejumper

battery.

24

3. Connectthesecondcable(negative-) to theotherpostofthejumper

battery.

4. Connecttheotherendofthenegativecableto theengineblockofthe

tractor,awayfromthebattery.Attachtoan unpaintedparttoassureagood

connection.

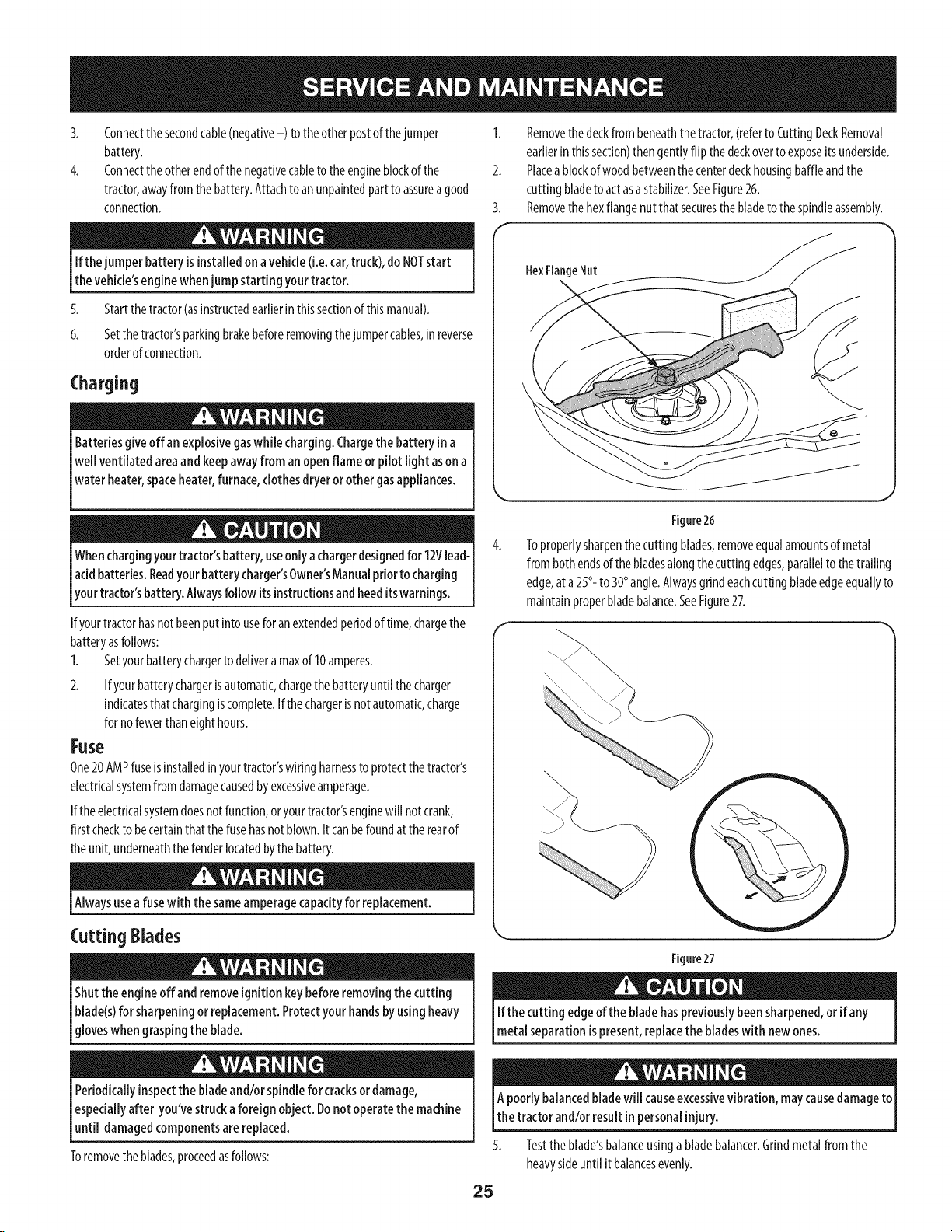

1. Removethedeckfrombeneaththetractor,(refertoCuttingDeckRemoval

earlierinthissection)thengentlyflipthedeckovertoexposeitsunderside.

2. Placeablockofwoodbetweenthecenterdeckhousingbaffleandthe

cuttingbladeto actasastabilizer.SeeFigure26.

3. Removethehexflangenutthatsecuresthebladetothespindleassembly.

Ifthejumper battery isinstalled onavehicle(i.e.car,truck),do NOTstart

thevehicle'senginewhenjumpstarting yourtractor.

5. Startthetractor(asinstructedearlierin thissectionofthismanual).

6. Setthetractor'sparkingbrakebeforeremovingthejumpercables,inreverse

orderofconnection.

Charging

Batteriesgive off anexplosivegaswhile charging.Chargethe battery ina

wellventilated areaandkeepawayfrom anopenflame or pilot light asona

waterheater,spaceheater,furnace,clothesdryerorother gasappliances.

Whenchargingyourtractor'sbattery,useonlyachargerdesignedfor 12Vlead-

acidbatteries.Readyourbatterycharger'sOwner'sManualpriortocharging [

yourtractor'sbattery.Alwaysfollow its instructionsandheeditswarnings, l

Ifyourtractorhasnotbeenputintouseforanextendedperiodof time,chargethe

batteryasfollows:

1. Setyourbatterychargerto deliveramaxof10amperes.

2. If yourbatterychargerisautomatic,chargethebatteryuntilthecharger

indicatesthatchargingiscomplete.Ifthechargerisnotautomatic,charge

forno fewerthaneighthours.

Fuse

One20AMPfuseisinstalledin yourtractor'swiringharnessto protectthetractor's

electricalsystemfromdamagecausedbyexcessiveamperage.

Iftheelectricalsystemdoesnotfunction,oryourtractor'senginewillnotcrank,

firstcheckto becertainthatthefusehasnotblown.Itcanbefoundatthe rearof

theunit,underneaththefenderlocatedbythebattery.

HexFlangeNut

Figure26

Toproperlysharpenthecuttingblades,removeequalamountsofmetal

frombothendsofthebladesalongthecuttingedges,parallelto thetrailing

edge,at a25°-to30°angle.Alwaysgrindeachcuttingbladeedgeequallyto

maintainproperbladebalance.SeeFigure27.

\4

Alwaysuseafusewith the sameamperagecapacityfor replacement.

Cutting Blades

Shutthe engineoff andremoveignition keybeforeremovingthe cutting

blade(s)for sharpeningor replacement.Protectyour handsbyusingheavy

gloveswhengraspingthe blade.

Periodicallyinspectthebladeandlor spindlefor cracksordamage,

especiallyafter you'vestruckaforeign object. Donot operatethe machine

until damagedcomponentsarereplaced.

Toremovetheblades,proceedasfollows:

Figure27

Ifthe cutting edgeofthe bladehaspreviouslybeensharpened,or if any

metal separationispresent,replacethebladeswith newones.

Apoorlybalancedbladewillcauseexcessivevibration, maycausedamageto

the tractor and/orresult in personalinjury.

Testtheblade'sbalanceusingabladebalancer.Grindmetalfromthe

heavysideuntil it balancesevenly.

25

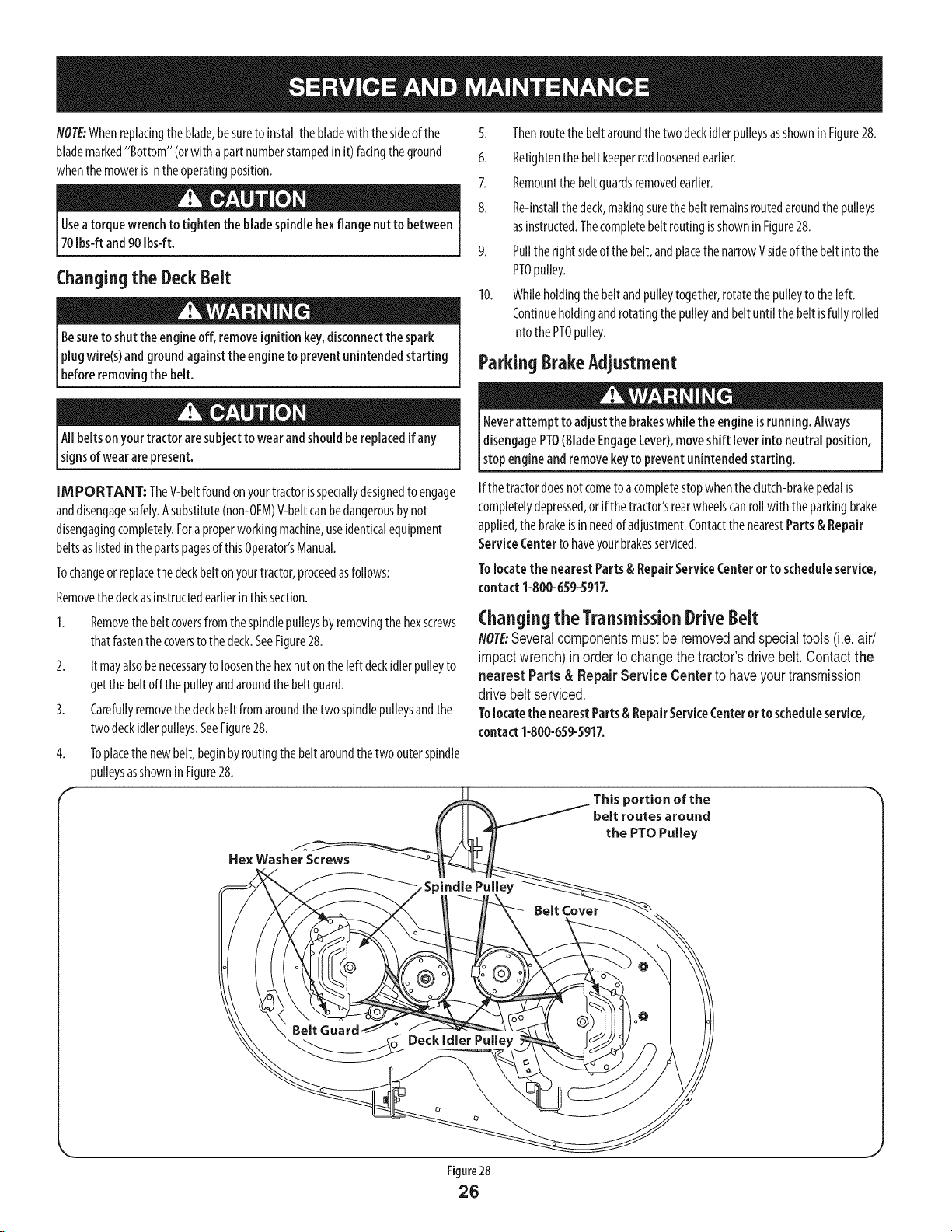

NOTE:Whenreplacingtheblade,besureto installthebladewiththesideofthe

blademarked"Bottom"(orwith a partnumberstampedin it)facingtheground

whenthemowerisintheoperatingposition.

Usea torquewrenchto tighten the bladespindlehe×flangenutto between

70[bs-ft and90[bs-ft.

Changingthe DeckBelt

Besureto shut theengineoff, removeignitionkey,disconnectthe spark

plugwire(s)andgroundagainstthe engineto preventunintendedstarting

[before removngthebe t.

5. Thenroutethe beltaroundthetwodeckidlerpulleysasshownin Figure28.

6. Retightenthe beltkeeperrodloosenedearlier.

7. Remountthe beltguardsremovedearlier.

8. Re-installthedeck,makingsurethebeltremainsroutedaroundthepulleys

asinstructed.Thecompletebeltroutingisshownin Figure28.

9. Pulltherightsideofthebelt,andplacethenarrowVsideofthebeltintothe

PTOpulley.

10. Whileholdingthebeltandpulleytogether,rotatethe pulleytotheleft.

Continueholdingandrotatingthepulleyandbeltuntilthebeltisfullyrolled

intothePTOpulley.

ParkingBrakeAdjustment

Ai[belts onyourtractoraresubjectto wearand shouldbereplacedifany

signsof weararepresent.

IM PORTANT: TheV-beltfoundonyourtractorisspeciallydesignedtoengage

anddisengagesafely.Asubstitute(non-OEM)V-beltcanbedangerousbynot

disengagingcompletely.Foraproperworkingmachine,useidenticalequipment

beltsaslistedinthepartspagesofthisOperator'sManual.

Tochangeor replacethedeckbeltonyourtractor,proceedasfollows:

Removethedeckasinstructedearlierinthissection.

1. Removethebelt coversfromthespindlepulleysbyremovingthehexscrews

thatfastenthecoverstothedeck.SeeFigure28.

2. It mayalsobenecessaryto loosenthehexnutontheleft deckidlerpulleyto

getthebeltoffthe pulleyandaroundthebeltguard.

3. Carefullyremovethedeckbeltfromaroundthetwospindlepulleysandthe

twodeckidlerpulleys.SeeFigure28.

4.

Toplacethenewbelt,beginbyroutingthebeltaroundthetwo outerspindle

pulleysasshowninFigure28.

f

Neverattempt to adjustthe brakeswhilethe engineisrunning.Always

[disengagePTO(BladeEngageLever),moveshift leverintoneutralposition,

[stopengineand removekeyto prevent unintendedstarting.

Ifthetractordoesnotcometoacompletestopwhentheclutch-brakepedalis

completelydepressed,orif thetractor'srearwheelscanrollwith theparkingbrake

applied,thebrakeisinneedofadjustment.ContactthenearestParts&Repair

ServiceCenterto haveyourbrakesserviced.

TolocatethenearestParts& RepairServiceCenterortoscheduleservice,

contact1-800-659-5917.

Changingthe TransmissionDrive Belt

NOTE"Several components must be removedand special tools (i.e. air/

impactwrench) inorder to change the tractor's drive belt, Contact the

nearest Parts & Repair Service Center to have your transmission

drive belt serviced.

Tolocatethe nearestParts& RepairServiceCenteror to scheduleservice,

contact1-800-659-5917.

J

Neverstorelawn tractor with fuel intank indoorsor in poorlyventilated

areaswhere fuelfumesmayreachanopenflame, spark,or pilot light ason

afurnace,water heater,clothesdryer,or gasappliance.

PreparingTheEngine

IMPORTANT: Fuelleft inthefueltankduringwarmweatherdeterioratesand

will causeseriousstartingproblems.

Topreventgumdepositsfromforminginsidetheengine'scarburetorandcausing

possiblemalfunctionoftheengine,thefuelsystemmustbeeithercompletely

emptied,orthegasolinemustbetreatedwithastabilizerto preventdeterioration.

I. Ifusinga fuelstabilizer:

a. Readtheproductmanufacturer'sinstructionsandrecommendations.

b. Addtoclean,freshgasolinethecorrectamountofstabilizerforthe

capacityofthefuelsystem.

c. Fillthefueltankwith treatedfuelandruntheenginefor 2-3minutesto

getstabilizedfuelintothecarburetor.

2. Ifemptylngthefuelsystem:

a. Donotdrainfuelwhentheengineishot.Allowtheengineadequate

timetocool.Drainfuelintoanapprovedcontaineroutdoors,awayfrom

openflame.

b. Drainanylargevolumeof fuelfromthetankbydisconnectingthe

fuellinefromthein-linefuelfilter neartheengine.Seethecomplete

instructionsforDrainingTheFuellaterin thissection.

Gasolineisextremelyflammableand canbeexplosiveundercertain

conditions. Draingasolinebeforestoring theequipmentforextended

periods.Drainfuel onlyinto anapprovedcontaineroutdoors,awayfrom

anopenflame. Allowengineto cool.Extinguishcigarettes,cigars,pipes,

andother sourcesof ignitionprior to drainingfuel.Storegasolineinan

approvedcontainerinsafelocation.

DrainingTheFuel

1. Locatethefuelfilter,whichislocatedonthe left sideoftheengine,andmay

beattachedtotheenginewitha tiestrap.

2. Cutthetiestrap,ifpresent,thenpinchthein-lineclamponthefuelfilter

with apairofpliers,slidetheclampupthefuelline.

3. Pullthefuellinefreefromthefilterandplacetheopenendofthe lineinto

anapprovedcontainertodrainthefuel.

PreparingThelawn tractor

Cleanandlubricatetractorthoroughlyasdescribedinthelubrication

instructions.

2. Donotuseapressurewasherorgardenhosetocleanyourunit.

3. Storemowerin adry,cleanarea.Donotstorenextto corrosivematerials,

suchasfertilizer.

c. Reconnectthefuellineandruntheengineuntilit startstofalter,then

usethechoketokeeptheenginerunninguntilallfuelin thecarburetor

hasbeenexhausted.

d. Disconnectthefuellineanddrainanyremaininggasolinefromthe

system.

Gasolineisa toxicsubstance.Disposeof gasolineproperly.Contactyour

localauthoritiesforapproveddisposalmethods.

3. Removethesparkplugandpourone(1)ounceofengineoilthroughthespark

plugholeintothecylinder.Cranktheengineseveraltimestodistributethe

oil. Replacethesparkplug.

27

Enginefailsto start

1. PTO/BladeEngageleverengaged.

2. Parkingbrakenotengaged.

3. Sparkplugwire(s)disconnected.

4. Throttle/Chokecontrollevernotincorrect

2. Engageparkingbrake.

3. Connectwire(s)to sparkplug(s).

4. PlaceThrottle/Chokeleverintothe FASTposition.

startingposition.

5. Chokenotactivated

6. Fueltankempty,or stalefuel.

7. BIockedfuelline.

8. Faultysparkplug(s).

9. Engineflooded.

5. MovetheThrottle/ChokeleverintotheChoke

6. Filltankwithclean,fresh(lessthan30 daysold) gas.

7. Replacethefuellineandreplacefuelfilter.

8. Clean,adjustgapor replaceplug(s).

9. Crankenginewiththrottlein FASTposition.

10. BlownFuse(s)

Enginerunserratically

1. UnitrunningwithCHOKEactivated.

2. Sparkplugwire(s)loose.

3. Blockedfuellineor stalefuel.

4. Ventingascapplugged.

5. Waterordirtinfuel system.

6. Dirtyaircleaner.

2. Connectsparkplugwire(s).

3. Replacethefuelline;fill tankwithclean,fresh

4. Clearventor replacecapif damaged.

5. Drainfueltank. Refillwithclean,freshgasoline.

6. Replaceaircleanerpaperelementor cleanfoam

Engineoverheats 1. Engineoillevellow. 1.

2. Airflowrestricted. 2.

Enginehesitatesat highRPM 1. Sparkpluggaptoo close. 1.

Engineidles rough 1. Sparkplugfouled,faultyor gaptoowide. 1.

2. Dirtyaircleaner. 2.

Excessivevibration

Mowerwill notmulchgrass

Unevencut

1. Cuttingbladelooseor unbalanced.

2. Damagedorbentcuttingblade.

1. Enginespeedtoolow.

2. Wetgrass.

3. Excessivelyhighgrass.

4. Dullblade.

1. Decknotleveledproperly.

2. Dullblade.

3. Uneventirepressure.

2. Replaceblade.

2. Do notmulchwhengrassis wet.

3. Mowonce ata highcuttingheight,thenmowagain

4. Sharpenorreplaceblade.

2. Sharpenorreplaceblade.

3. Checktire pressureinallfourtires.

1. Placeleverindisengaged(OFF)position.

position.

10. ReplaceFuse(s)See"Fuse"inServiceand

Maintenancesection.

1. DeactivatetheCHOKE.

gasolineandreplacefuelfilter.

pre-cleaner,ifequipped.

Fillcrankcasewithproperamountandweightof oil.

Cleangrassclippingsanddebrisfromaroundthe

engine'scoolingfinsandhousing.

Removesparkplugandresetthe gap.

Replacesparkplug.Set pluggap.

Replaceair cleanerelementand/orcleanpre-

cleaner.

1. Tightenbladeandspindle.

1. Placethrottlein FAST(rabbit)position.

at desiredheightor makea narrowercuttingswath.

1. Performside-to-sidedeckadjustment.

NEED MORE HELP?

%£{_ls_lfim_} t}*_e_:_x/,',{'w(sran<I moze on manag<'_ly[i£eo{o_, - fo[ f_e÷!

Find this and a[[ your other product manuals online.

Get answers from our team of home experts.