Page 1

perator's

I:RnFrSMRN°

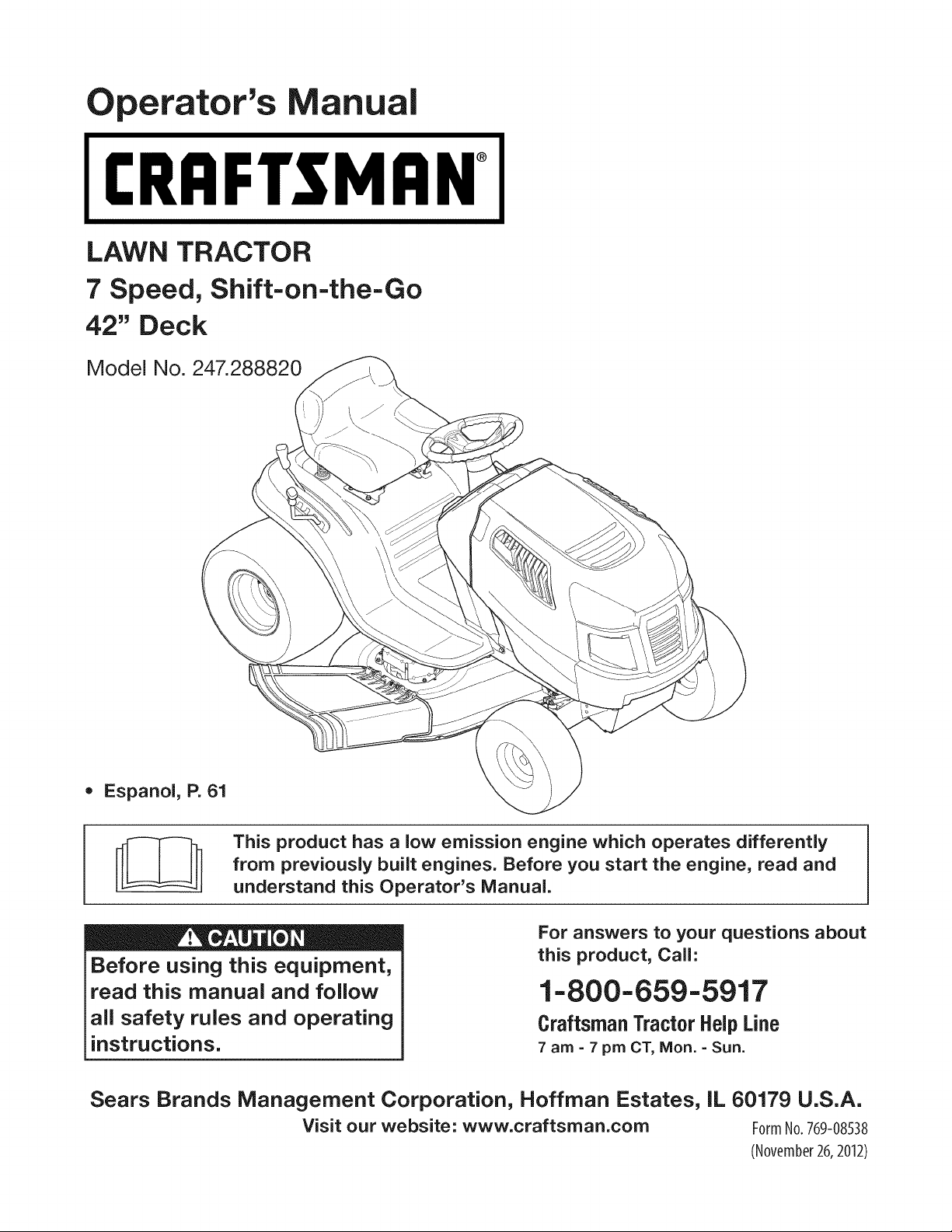

LAWN TRACTOR

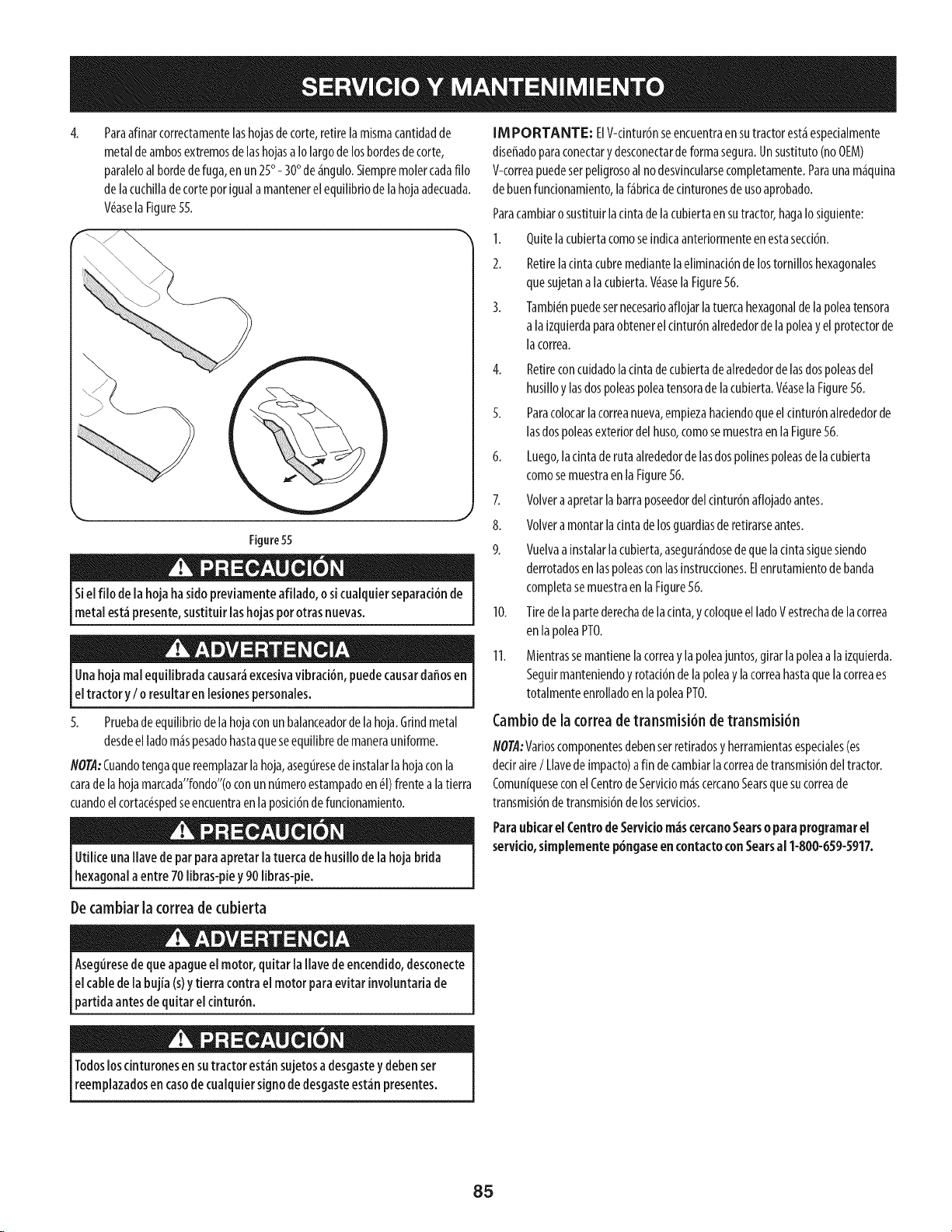

7 Speed, Shift-on=the=Go

42" Deck

Model No. 247.288820

• Espanol, P. 61

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

For answers to your questions about

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-08538

this product, Call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am =7 pm CT, Mort. =Sun.

(November26,2012)

Page 2

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Slope Gauge ..................................................................... 8

Assembly ........................................................................... 9

Operation ........................................................................ 11

Service and Maintenance .............................................. 17

Off-Season Storage ........................................................ 27

Troubleshooting .............................................................. 28

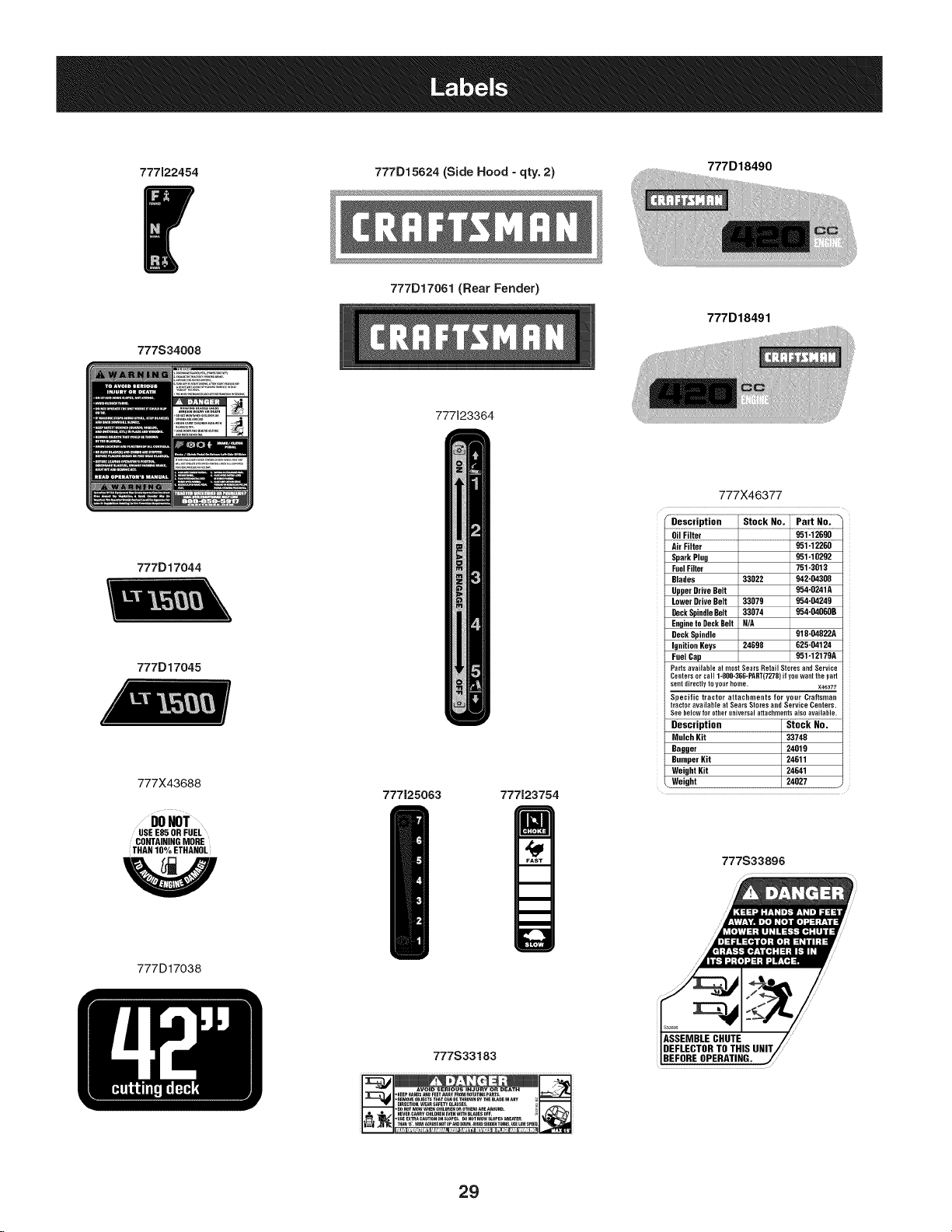

Labels ............................................................................. 29

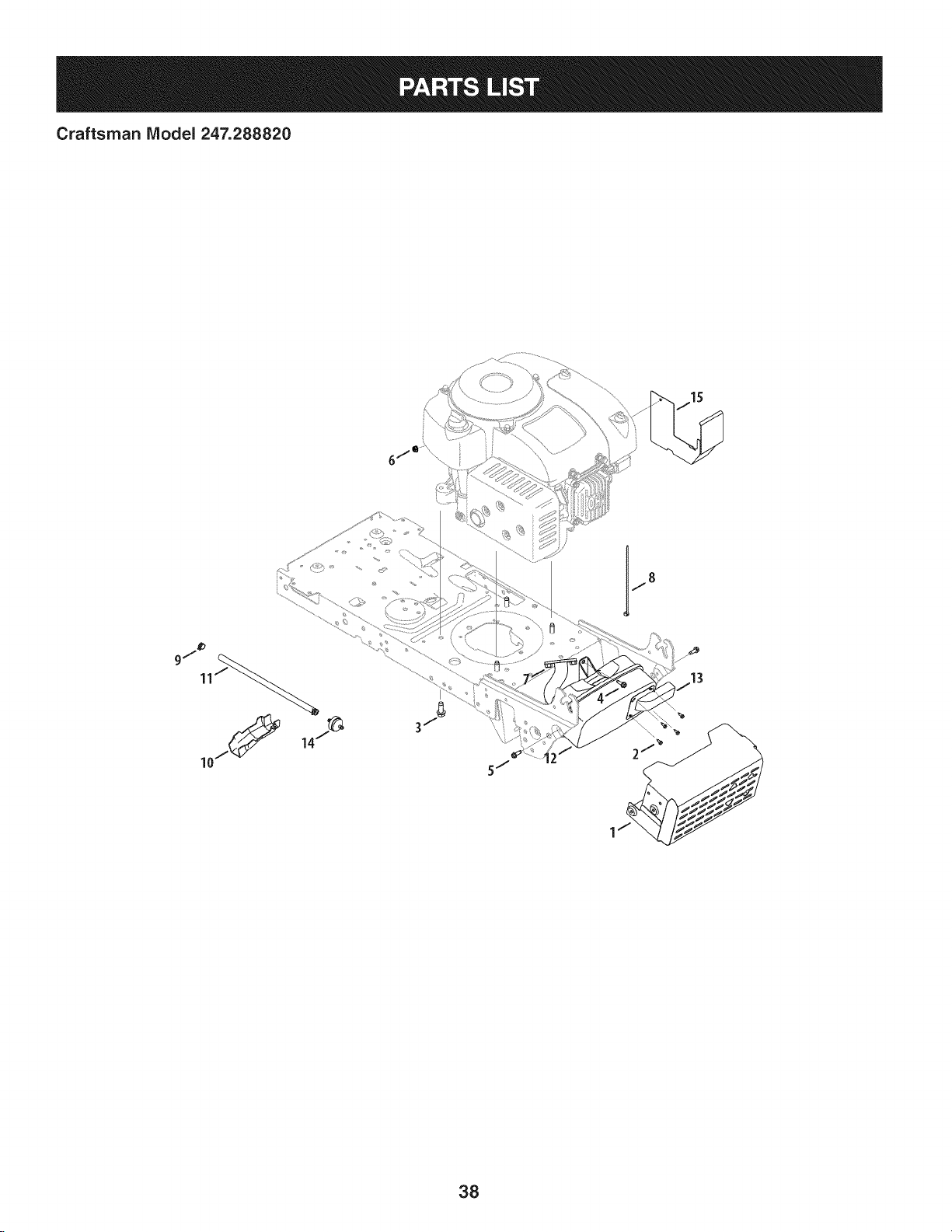

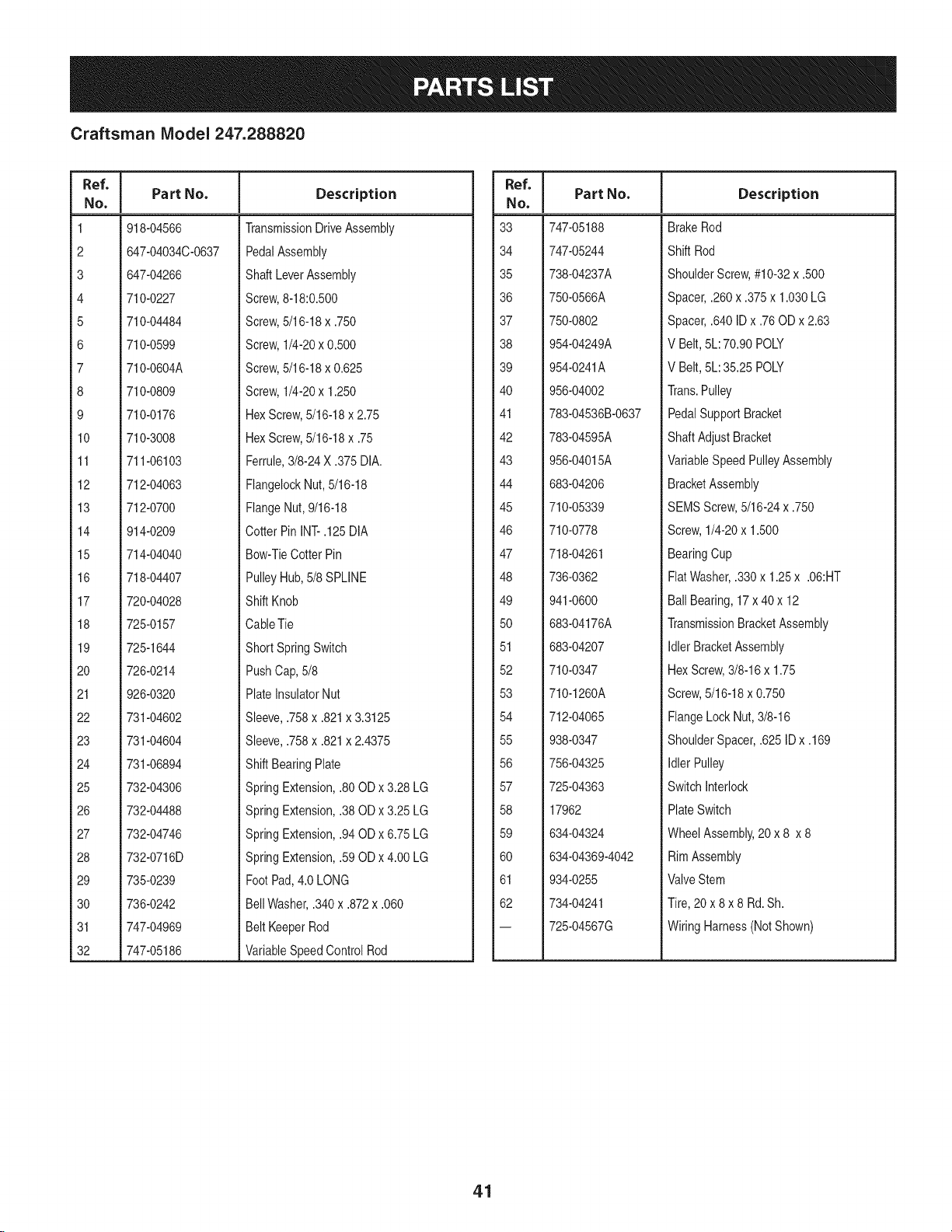

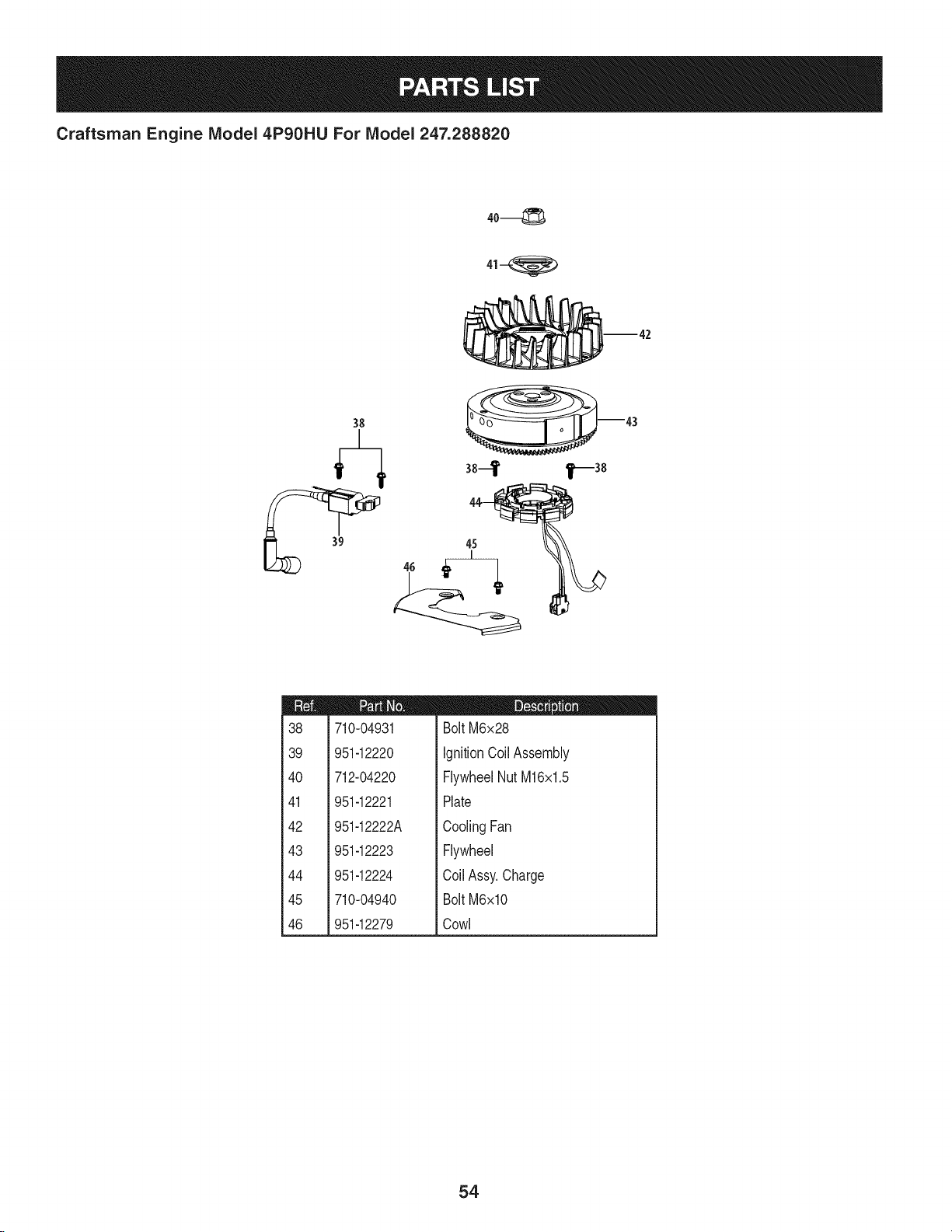

Parts List ......................................................................... 30

Espafiol ............................................................................ 61

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthedateofpurchase,all non-expendablepartsofthis ridingequipmentarewarrantedagainstanydefectsin materialor

workmanship.Adefectivenon-expendablepartwill receivefree in-homerepairorreplacementif repairisunavailable.

BATTERYLIMITEDWARRANTY

FOR90 DAYSfromthedateofpurchase,thebattery(anexpendablepart)of this ridingequipmentis warrantedagainstanydefectsinmaterialor

workmanship.Anewbatterywillbesuppliedfreeof charge.Youareresponsibleforthe laborcostof batteryinstallation.

ADDITIONALLIMITEDWARRANTIES

Inthe followingadditionalwarranties,youare responsibleforthe laborcost ofpartinstallationafterthe secondyearfromthedateof purchase.

FORFIVEYEARSfromthedateof purchase,the frameofthis ridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.A

newframewill be suppliedfreeof charge.

FORTENYEARSfromthe dateofpurchase,thefrontaxleof thisridingequipmentiswarrantedagainstany defectsin materialorworkmanship.

A newfrontaxlewillbe suppliedfreeof charge.

FORASLONGASIT ISUSEDbytheoriginalownerafterthetenthyearfromthedateofpurchase,thecastironfrontaxle(ifequipped)ofthisriding

equipmentiswarrantedagainstanydefectsinmaterialorworkmanship.Withproofofpurchase,anewcastironfrontaxlewillbesuppliedfreeofcharge.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfreerepairor replacement,call1-800-659-5917orvisitthewebsite: www.craftsman.com

Inallcasesabove,if partrepairor replacementisimpossible,theridingequipmentwillbe replacedfreeofchargewiththe sameor anequivalent

model.

Allofthe abovewarrantycoverageis void ifthisridingequipmentiseverusedwhileprovidingcommercialservicesor if rentedtoanotherperson.

ThiswarrantycoversONLYdefectsin materialandworkmanship.WarrantycoveragedoesNOTinclude:

• Expendableparts(exceptbattery)thatcanwearoutfromnormalusewithinthe warrantyperiod,includingbutnotlimitedto blades,spark

plugs,air cleaners,belts,andoil filters.

Standardmaintenanceservicing,oilchanges,ortune-ups.

Tirereplacementor repaircausedby puncturesfromoutsideobjects,suchas nails,thorns,stumps,or glass.

• Tireor wheelreplacementor repairresultingfromnormalwear,accident,orimproperoperationormaintenance.

Repairsnecessarybecauseof operatorabuse,includingbutnotlimitedtodamagecausedbytowingobjectsbeyondthecapabilityofthe

ridingequipment,impactingobjectsthatbendtheframe,axleassemblyorcrankshaft,or over-speedingtheengine.

Repairsnecessarybecauseof operatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby improper

storage,failureto usethepropergradeandamountof engineoil,failureto keepthedeckclearofflammabledebris,orfailuretomaintainthe

ridingequipmentaccordingto theinstructionscontainedin theoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfuel determinedto becontaminatedoroxidized(stale).In general,fuelshouldbeused

within30 daysof itspurchasedate.

• Normaldeteriorationandwearoftheexteriorfinishes,orproductlabelreplacement.

Thiswarrantygivesyouspecificlegalrights,andyou mayalsohaveotherrightswhichvaryfromstateto state.

Sears BrandsManagementCorporation, HoffmanEstates,IL 60179

Model Number:

EngineOil: SAE30 Serial Number:

Fuel: UnleadedGasoline Dateof Purchase:

SparkPlug: F6RTC(951-10292) Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

© SearsBrands,LLC 2

Page 3

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.As withanytypeof powerequipment,

carelessnessorerroron thepartoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionson themachineand

in themanual(s)beforeattemptingto assembleandoperate.

Keepthis manualinasafeplacefor futureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldtooperatethis machine.

Children14yearsoldandover shouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbya parent.

• Neverallowadultsto operatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhile itisin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentistobe used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbytheblade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatterntoavoiddischargeof materialtoward

roads,sidewalks,bystandersandthe like.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardtheoperator.

Your Responsibility--Restrict theuseof thispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepairtoprotectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointit at anyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherinits properplace.

Donot puthandsorfeetnearrotatingpartsor underthecutting

deck.Contactwiththe blade(s)canamputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfor trafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublicroadway.

• Donot operatethemachinewhileunderthe influenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backupslowly.

Alwayslookdownandbehindbeforeandwhilebackingto avoida

back-overaccident.

3

Page 4

• Slowdownbeforeturning.Operatethe machinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoa completestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthe machineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loador unloadproperly.

Mufflerandenginebecomehotandcancausea burn.Do not

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthemachine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthe brakepedal

completelybeforeattemptingto startengine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpilesof dryleaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfire hazard.

Useonlyaccessoriesandattachmentsapprovedforthis machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Fora list ofapprovedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin a largepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilitytooperatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossofcontrolandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor ifyoufeel uneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthis manual

to measureslopesbeforeoperatingthismachineona slopedor hilly

area.Ifthe slopeisgreaterthan15degreesasshownonthe Slope

Guide,do notoperatethis machineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,notacross.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchfor holes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothavetostopor shiftwhileon theslope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachineingearwhen goingdownslopes

totakeadvantageofenginebrakingaction.

• Followthe manufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersorotherattachments.These

canchangethestabilityof the machine.

Keepallmovementonthe slopesslowandgradual.Donotmake

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontof themachinetolift andrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingona slope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdowntheslope.

DoNot:

• Donot turnonslopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donot mowneardrop-offs,ditchesorembankments.The mower

couldsuddenlyturnoverif a wheelisovertheedgeof a cliff,

ditch,or ifan edgecavesin.

• Donot try tostabilizethemachinebyputtingyourfooton the

ground.

• Donot useagrasscatcheronsteepslopes.

• Donot mowon wetgrass.Reducedtractioncouldcausesliding.

• Donot attempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolof themachineresultinginseriousinjury

or death.

• Donot towheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendsto pushthetractorandmay

causeyouto loosecontrol(e.g.tractormayspeedup,brakingand

steeringabilityarereduced,attachmentmayjack-knifeandcause

tractorto overturn).

4

Page 5

CHILDREN

Tragicaccidentscanoccurifthe operatorisnotalerttothepresence

ofchildren.Childrenareoftenattractedto themachineandthemowing

activity.Theydo notunderstandthedangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthe mowingareaand inwatchfulcareofa

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifachildentersthearea.

• Beforeandwhilebacking,lookbehindanddownfor small

children.

Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionofa child

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethe cutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenorothersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofageto operatethismachine.

Children14andovershouldreadandunderstandtheinstructionsand

safeoperationpracticesinthismanualandon themachineandshould

betrainedandsupervisedbyan adult.

TOWING

Towonlywitha machinethathasa hitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwitha machinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistancetostop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

Neverfill containersinsidea vehicleoron a truckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthetruck

or trailerandrefuelitontheground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththe rimofthe fueltankor

containeropeningat all timesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuel machineindoors.

Neverremovegascapor addfuelwhiletheengineis hotorrun-

ning.Allowengineto coolat leasttwominutesbeforerefueling.

Neveroverfillfuel tank.Filltanktono morethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff theengineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefreeofgrass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuel spillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineorfuelcontainerinsidewherethereisan

openflame,sparkor pilotlight asona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolatleastfiveminutesbeforestoring.

Page 6

GeneralService

• Neverrunanengineindoorsorinapoorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertainthe

blade(s)andallmovingpartshavestopped.Disconnectthespark

plugwireandgroundagainsttheenginetopreventunintended

starting.

• Periodicallychecktomakesurethebladescometocomplete

stopwithinapproximately(5)fivesecondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

byaSearsorotherqualifiedservicedealer.

• Checkbrakeoperationfrequentlyasitissubjectedtowearduring

normaloperation.Adjustandserviceasrequired.

• Checktheblade(s)andenginemountingboltsatfrequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useofpartswhichdonot

meettheoriginalequipmentspecificationsmayleadtoimproper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepallnuts,bolts,andscrewstighttobesuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemorothersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stopthe engine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothemachine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoveraresubject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo notmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donot changetheenginegovernorsettingsorover-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsforgas,oil,etc.to

protecttheenvironment.

• Accordingto the ConsumerProductsSafetyCommission(CPSC)

andthe U.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasanAverageUsefulLifeofseven(7)years,or 270hours

ofoperation.Attheendof theAverageUsefulLife,buyanew

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatallmechanicaland

safetysystemsareworkingproperlyandnotwornexcessively.

Failuretodosocan resultinaccidents,injuriesor death.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if so equipped.

SPARK ARRESTOR

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonornearanyunimprovedforest-covered,

brushcoveredorgrass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

Ifa sparkarrestoris used,itshouldbe maintainedin effectiveworking

orderbythe operator.Inthe Stateof Californiatheaboveis required

bylaw (Section4442of theCaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

6

Page 7

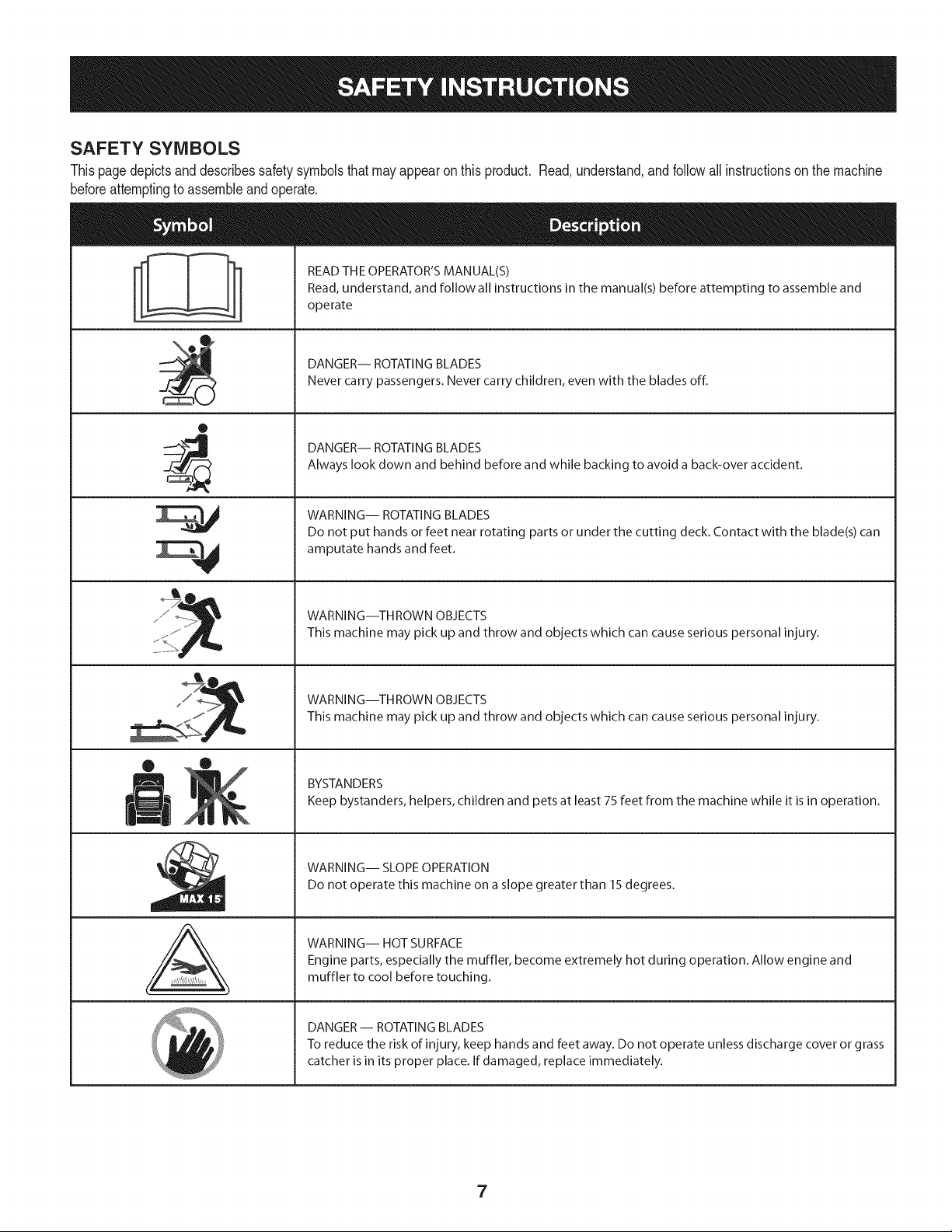

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthatmayappearonthis product.Read,understand,andfollowallinstructionson themachine

beforeattemptingtoassembleandoperate.

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

0

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s) can

amputate hands and feet.

A

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 15 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER-- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

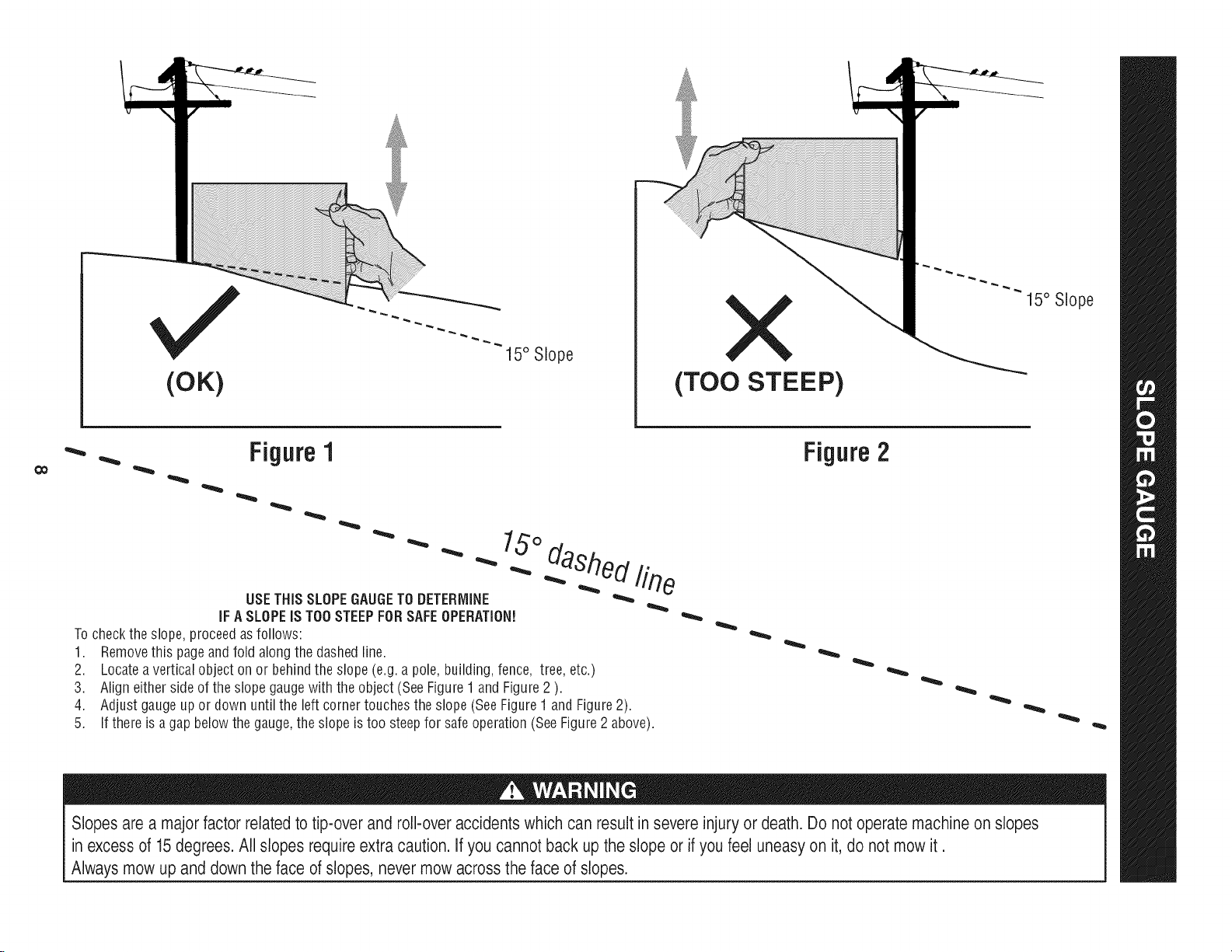

Page 8

15° Slope

15° Slope

X

(OK)

'_. _ Figure1

(TOO STEEP)

Figure2

15°

dashedline

USETHISSLOPEGAUGETODETERMINE

IFA SLOPEIS TOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfold alongthedashedline.

2. Locatea verticalobject onor behindthe slope(e.g.a pole, building,fence, tree,etc.)

3. Align eithersideoftheslope gaugewith theobject(SeeFigure1 and Figure2 ).

4. Adjust gaugeupor downuntilthe left cornertouchestheslope(SeeFigure1and Figure2).

5.

If thereisagap belowthegauge,theslopeistoo steepfor safeoperation(SeeFigure2 above).

Slopesare a majorfactor relatedtotip-over and roll-over accidents which can resultin severe injury or death. Do not operatemachine on slopes

in excess of 15degrees.All slopesrequireextra caution. Ifyou cannotbackup the slope orif you feeluneasyon it, do not mow it.

Always mowup and down theface ofslopes, never mowacrossthe face of slopes.

Page 9

IM PORTANT: Yourtractorisshippedwith motoroil intheengine.However,

youMUSTchecktheoillevelbeforeoperating.Referto theService& Maintenance

sectionforinstructionsoncheckingtheoillevel.

Attaching the Battery Cables

Shipping BraceRemoval

Makesurethe ridingmower'sengineisoff, removethe ignition key,and

setthe parkingbrakebeforeremovingthe shippingbrace.Refertothe

CALIFORNIA PROPOSITION 65

Batteryposts,terminals,and relatedaccessoriescontainleadand lead

compounds,chemicalsknown tothe Stateof Californiato causecancerand

reproductiveharm.Washhandsafter handling.

Whenattachingbattery cables,alwaysconnectthe POSITIVE(Red)wire to its

terminalfirst, followedbythe NEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmentmayhavebeenleft

disconnectedfromtheterminalsat thefactory.Toconnectthe batterycables,

proceedasfollows:

NOTE:ThepositivebatteryterminalismarkedPos.(+).Thenegativebattery

terminalismarkedNeg.(-).

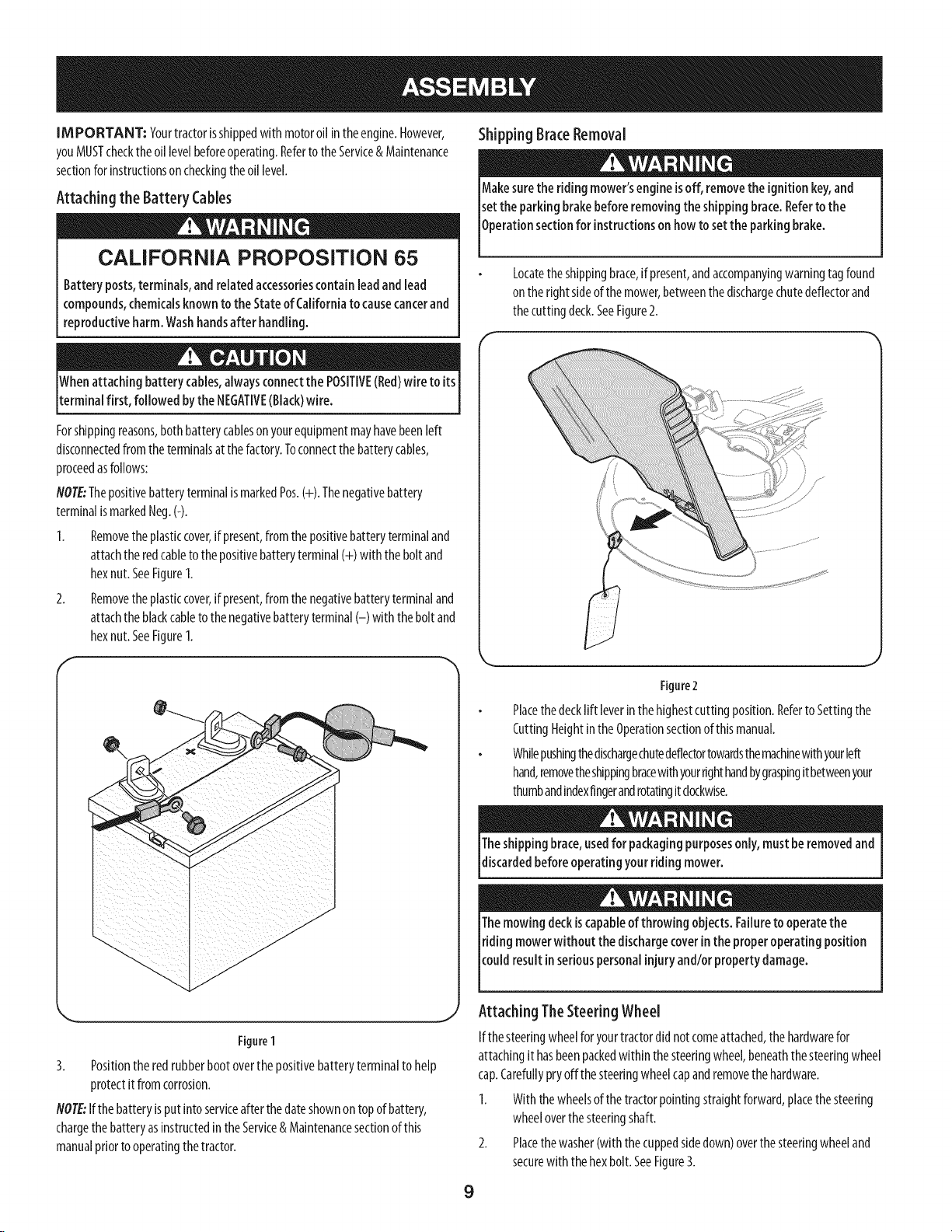

1. Removetheplasticcover,ifpresent,fromthepositivebatteryterminaland

attachtheredcabletothepositivebatteryterminal(+) with theboltand

hexnut.SeeFigure1.

2. Removetheplasticcover,ifpresent,fromthenegativebatteryterminaland

attachtheblackcableto thenegativebatteryterminal(-) with theboltand

hexnut.SeeFigure1.

f

Operatonsect onfor nstructonsonhowto setthe parkngbrake.

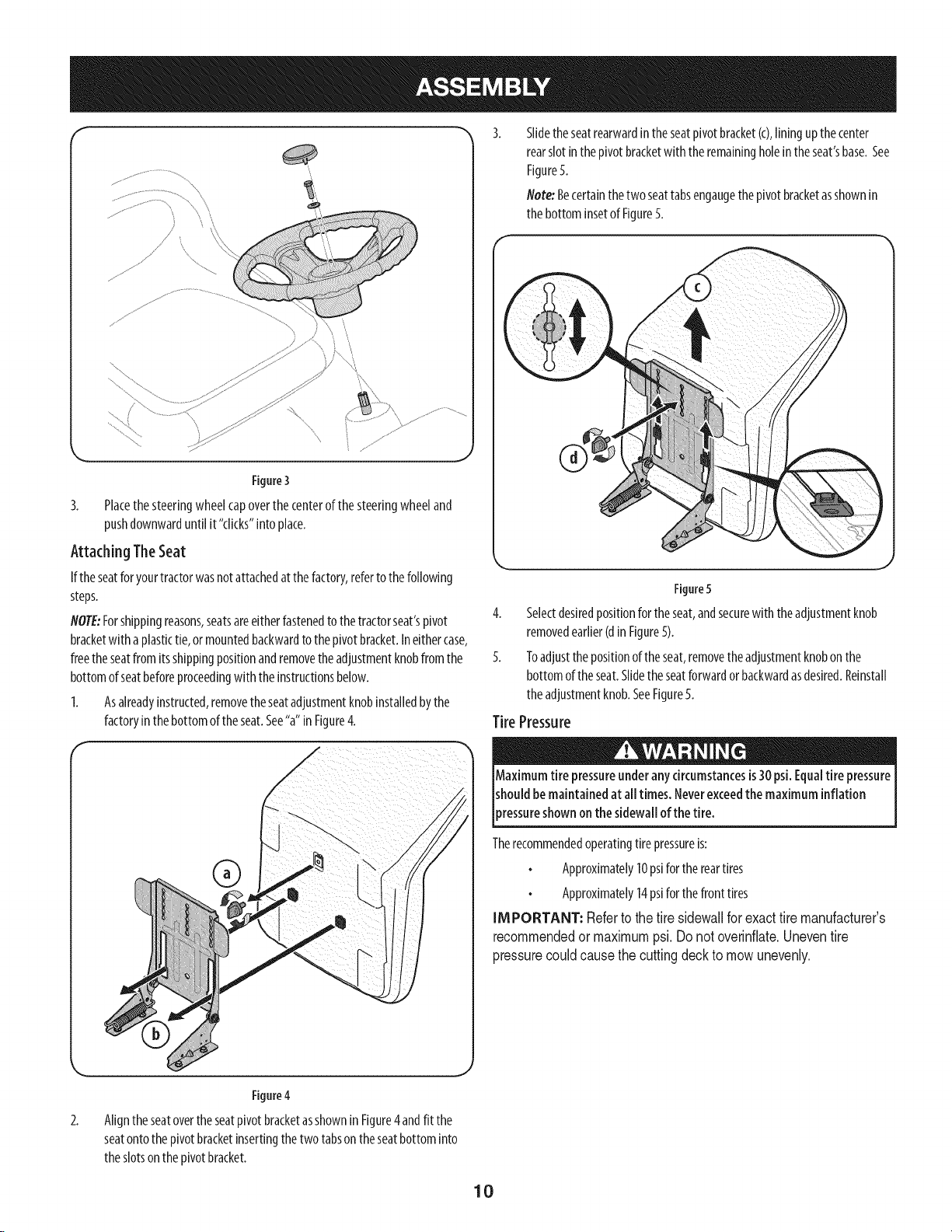

Locatetheshippingbrace,if present,andaccompanyingwarningtagfound

ontherightsideofthemower,betweenthedischargechutedeflectorand

thecuttingdeck.SeeFigure2.

Figure2

Placethedecklift leverin thehighestcutting position.RefertoSettingthe

CuttingHeightintheOperationsectionofthismanual.

Whilepushingthedischargechutedeflectortowardsthemachinewithyourleft

hand,removetheshippingbracewithyourrighthandbygraspingitbetweenyour

thumbandindexfingerandrotatingitclockwise.

/

/

/

/

/

Figure1

3. Positionthe redrubberbootoverthepositivebatteryterminaltohelp

protectitfromcorrosion.

NOTE:Ifthe batteryisput intoserviceafterthedateshownontopofbattery,

chargethe batteryasinstructedin theService& Maintenancesectionofthis

manualpriortooperatingthetractor.

Theshippingbrace,usedforpackagingpurposesonly,mustberemovedand

discardedbeforeoperatingyourridingmower.

Themowingdeckiscapableof throwing objects. Failuretooperatethe

ridingmowerwithout the dischargecoverinthe properoperating position

coudresut nsetouspersona njury and/orproperty damage.

Attaching TheSteeringWheel

J

Ifthesteeringwheelforyourtractordidnotcomeattached,thehardwarefor

attachingithasbeenpackedwithinthesteeringwheel,beneaththesteeringwheel

cap.Carefullypryoffthe steeringwheelcapandremovethehardware.

1. Withthewheelsof thetractorpointingstraightforward,placethesteering

wheeloverthesteeringshaft.

2. Placethewasher(withthecuppedsidedown)overthesteeringwheeland

securewith thehexbolt.SeeFigure3.

9

Page 10

F

\

Figure3

3.

Placethesteeringwheelcapoverthecenterofthesteeringwheeland

pushdownwarduntilit"clicks"intoplace.

Attaching TheSeat

Iftheseatforyourtractorwasnotattachedat thefactory,refertothefollowing

steps.

NOTE:Forshippingreasons,seatsareeitherfastenedtothetractorseat'spivot

bracketwith a plastictie, ormountedbackwardtothepivotbracket.Ineithercase,

freetheseatfromitsshippingpositionandremovetheadjustmentknobfromthe

bottomofseatbeforeproceedingwith theinstructionsbelow.

1. Asalreadyinstructed,removetheseatadjustmentknobinstalledbythe

factoryin thebottomoftheseat.See"a"inFigure4.

Slidetheseatrearwardin theseatpivotbracket(c),liningupthecenter

rearslotinthepivotbracketwith theremainingholeintheseat'sbase.See

FigureS.

Note:Becertainthetwo seattabsengaugethepivotbracketasshownin

thebottominsetof Figure5.

Figure5

4. Selectdesiredpositionfortheseat,andsecurewith theadjustmentknob

removedearlier(dinFigure5).

5. Toadjustthepositionof theseat,removetheadjustmentknobonthe

bottomof theseat.Slidetheseatforwardorbackwardasdesired.Reinstall

theadjustmentknob.SeeFigure5.

TirePressure

®

Figure4

2.

Aligntheseatovertheseatpivotbracketasshownin Figure4andfit the

seatontothepivotbracketinsertingthetwo tabsontheseatbottominto

theslotsonthepivotbracket.

Maximumtire pressureunderanycircumstancesis30psi.Equaltire pressure

shouldbemaintainedat alltimes. Neverexceedthe maximuminflation

)ressureshownonthe sidewallofthe tire.

Therecommendedoperatingtirepressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothe tire sidewallforexacttiremanufacturer's

recommendedormaximumpsi.Donotoverinflate.Uneventire

pressurecouldcausethecuttingdeckto mowunevenly.

10

Page 11

H

A

c)

D

(3

F

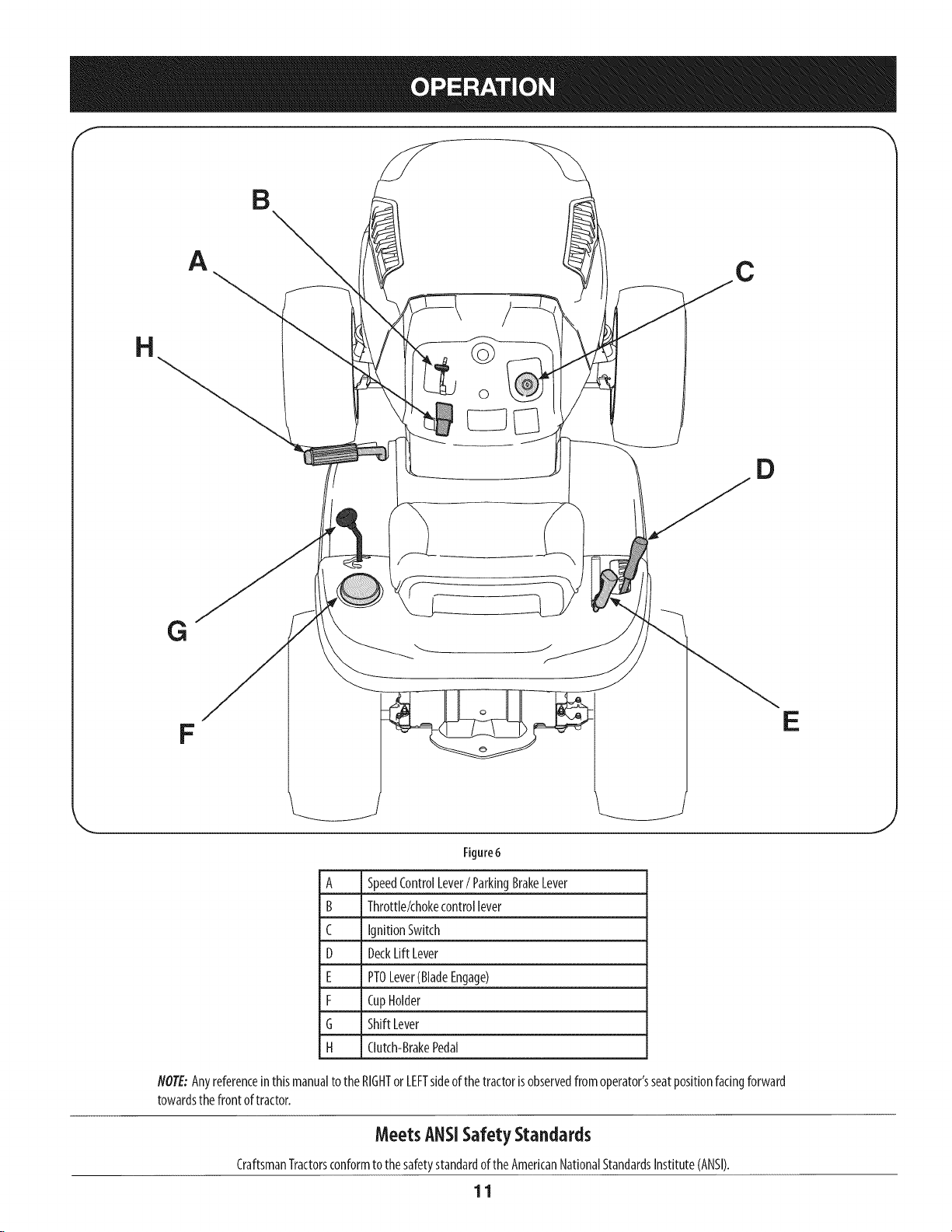

Figure6

A SpeedControlLever/ ParkingBrakeLever

B Throttle/chokecontrollever

C IgnitionSwitch

D DeckLiftLever

E PTOLever(BladeEngage)

F CupHolder

G ShiftLever

H Clutch-BrakePedal

NOTE:Anyreferenceinthis manualto theRIGHTorLEFTsideofthetractorisobservedfromoperator'sseatpositionfacingforward

towardsthefrontoftractor.

MeetsANSISafety Standards

CraftsmanTractorsconformto thesafetystandardoftheAmericanNationalStandardsInstitute(ANSI).

11

E

Page 12

SpeedControlLever

Thespeedcontrollever,Moatedontheleftsideofthetractor's

dashconsole,allowsyoutoregulatethegroundspeedofthelawn

tractor.Touse,depressthedutch-brakepedalandmovethelever

outofthe parkingbrakenotchandforwardtoincreasethetractor's

groundspeed.Whenadesiredspeedhasbeenreached,releasethe

leverintoanappropriatenotchtomaintainthat speed.

Toslowthetractor'sgroundspeed,depressthedutch-brakepedal

andmovethespeedcontrolleverrearwardandreleaseitintoa

notch.

ParkingBrake

Tosettheparkingbrake,fully depresstheclutch-brakepedal.Move

thespeedcontrolleverallthewaydownandintothe parkingbrake

position.Releasetheclutch-brakepedaltoallowtheparkingbrake

toengage.

Toreleasetheparkingbrake,depresstheclutch-brakepedalandmovethespeed

controlleveroutofthenotchesto thedesiredposition.Releasethespeedcontrol

leverandtheclutch-brakepedal.

NOTE:Theparkingbrakemustbesetif theoperatorleavestheseatwiththeengine

runningortheenginewill automaticallyshutoff.

7_

2-

1=

(Q)

PARK

BRAKE

Throttle/Choke ControlLever

Thethrottle/chokecontrolleverislocatedontherightsideofthe

tractor'sdashpanel.Thislevercontrolsthespeedof theengine

andwhenpushedallthewayforward,thechokecontrolalso.

Whensetinagivenposition,thethrottlewill maintainauniform

enginespeed.

IMPORTANT:Whenoperatingthetractorwiththecuttingdeck

engaged,thethrottle/chokecontrollevermustalwaysbeinthe

FAST(rabbit)position.

Ignition Switch

Thekeyswitch

moduleisusedto

startandstopthe

engine.Insertkey

intothekeyswitch

moduleandturnclockwisetothe

STARTposition.Releasethekeyinto

thenormalmowingpositiononce

enginehasstarted.Theheadlightswill

beactivatedautomatically.

Tostoptheengine,turntheignitionkeycounterclockwisetotheSTOPposition.

IMPORTANT:Priortooperatingthetractor,refertoboththe"SafetyInterlock

System"and"StartingTheEngine"laterinthissectionofthismanualfordetailed

instructionsregardingthe IgnitionSwitchModule.

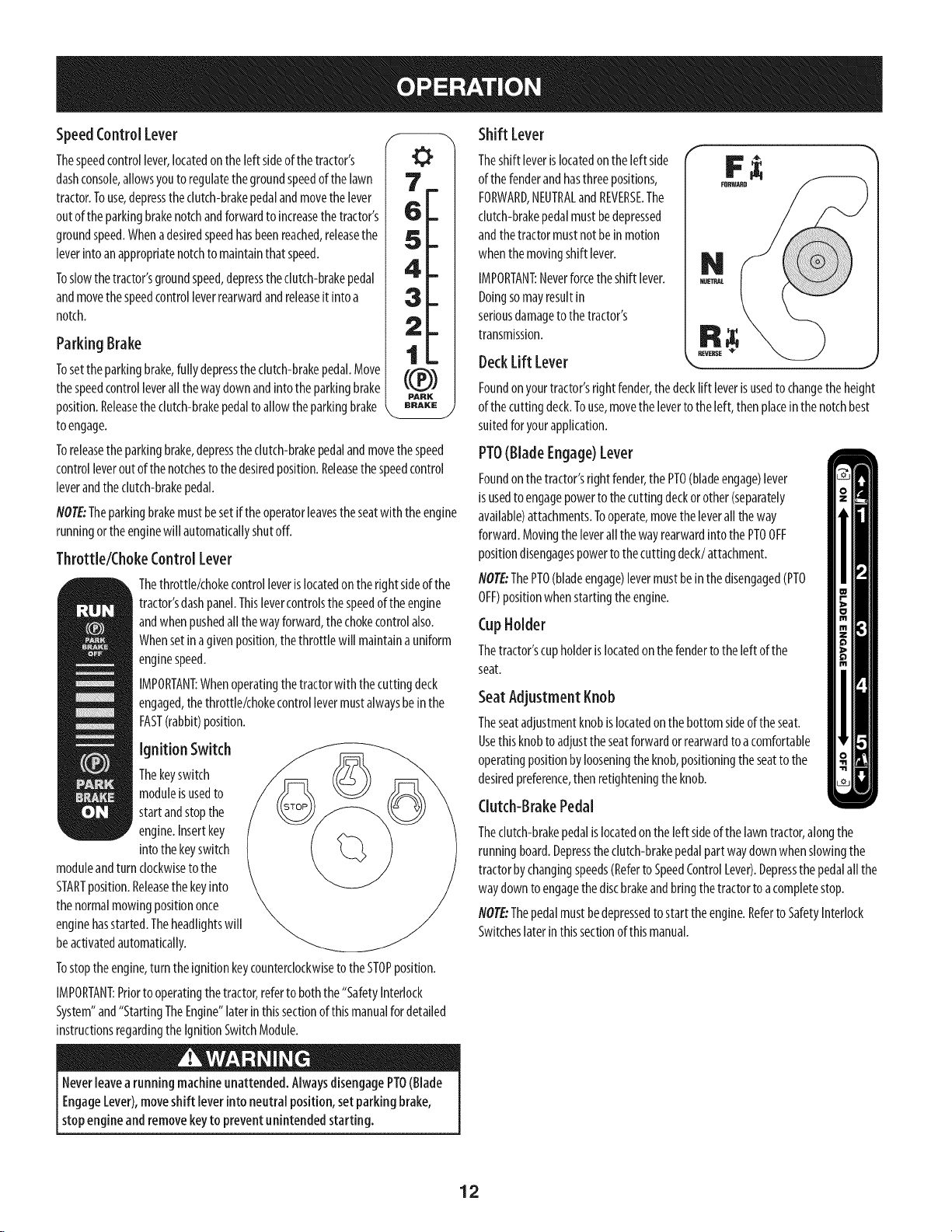

Shift Lever

Theshiftleverislocatedontheleftside

ofthefenderandhasthreepositions,

FORWARD,NEUTRALandREVERSE.The

clutch-brakepedalmustbedepressed

andthetractormustnotbein motion

whenthemovingshift lever.

IMPORTANT:Neverforcetheshift lever.

Doingsomayresultin

seriousdamagetothetractor's

transmission.

DeckLift Lever

Foundon yourtractor'srightfender,thedecklift leverisusedto changetheheight

ofthecuttingdeck.Touse,movethelevertotheleft,thenplaceinthe notchbest

suitedforyourapplication.

PTO(BladeEngage)Lever

Foundon thetractor'srightfender,thePTO(bladeengage)lever

isusedto engagepowertothecuttingdeckorother(separately

available)attachments.Tooperate,movetheleveralltheway

forward.Movingthe leverallthewayrearwardintothePTOOFF

positiondisengagespowertothecuttingdeck/attachment.

NOTE"ThePTO(bladeengage)levermustbein thedisengaged(PTO

OFF)positionwhenstartingtheengine.

CupHolder

Thetractor'scupholderislocatedonthefendertotheleftofthe

seat.

SeatAdjustment Knob

Theseatadjustmentknobislocatedonthebottomsideoftheseat.

Usethisknobtoadjusttheseatforwardorrearwardto a comfortable

operatingpositionbylooseningtheknob,positioningtheseatto the

desiredpreference,thenretighteningtheknob.

Clutch-BrakePedal

Thedutch-brakepedalislocatedontheleft sideofthelawntractor,alongthe

runningboard.Depressthedutch-brakepedalpartwaydownwhenslowingthe

tractorbychangingspeeds(Referto SpeedControlLever).Depressthe pedalallthe

waydowntoengagethediscbrakeandbringthetractortoacompletestop.

NOTE:Thepedalmustbedepressedtostarttheengine.Referto SafetyInterlock

Switcheslaterinthissectionofthismanual.

Neverleavearunningmachineunattended.AlwaysdisengagePTO(Blade

EngageLever),moveshift leverintoneutral position, setparkingbrake,

stopengineandremovekeyto preventunintendedstarting.

12

Page 13

Gasand Oil Fill-up

Oil

IMPORTANT:Yourtractorisshippedwith motoroilintheengine.However,you

MUSTchecktheoiilevelbeforeoperating.Becarefulnottooverfill.

Forinstructionsonhowtochecktheengineoil,refertoCheckingTheEngineOilin

theServiceandMaintenancesectionofthismanual.

Gasoline

Thegasolinetankislocatedunderthehood.Donotoverfill.

Useextremecarewhen handling gasoline.Gasolineisextremely flammable

andthe vaporsareexplosive.Neverfuelmachineindoorsorwhile the

engineishotorrunning. Extinguishcigarettes,cigars,pipes,andother

sourcesof gnt on.

NOTE:Purchasegasolinein smallquantities.Donotusegasolineleft overfromthe

previousseason,to minimizegumdepositsinthefuelsystem.

Thisengineiscertifiedtooperateonunleadedgasoline.Forbestresults,fill

thefueltankwithonlyclean,fresh,unleadedgasolinewith apumpsticker

octaneratingof 87orhigher.

Gasohol(upto 10%ethylalcohol,90%unleadedgasolinebyvolume)isan

approvedfuel.Othergasoline/alcoholblends,suchasE85,arenotapproved.

MethylTertiaryButylEther(MTBE)andunleadedgasolineblends(uptoa

maximumof 15%MTBEbyvolume)areapprovedfuels.Othergasoline/ether

blendsarenotapproved.

Fillfueltankoutdoorsorinwell-ventilatedarea.

Donotoverfillfueltank.Filltankto nomorethan1/2inchbelowbottomof

fillernecktoallowspaceforfuelexpansion.

Neverremovegascaporaddfuelwhiletheengineis hotor running.Allow

engineto coolatleasttwo minutesbeforerefueling.

Ifgasolineisspilled,wipeit off theengineandequipment.Movemachineto

anotherarea.Wait5minutesbeforestartingtheengine.

ToAddGasoline

1. Turntheengineoffandletenginecoolatleast2minutesbeforeremoving

thefuelcap.Thegasolinetankisundertherearfender,with thefuelfill cap

locatedin thecenteroftherearfender.Thefuelcapistetheredtothetractor

topreventitsloss.Donotattempttoremovethecapfromthetractor.

2. Fillthefueltankwithgasoline.

3. Reinstallthefuelcap.

Note:Thetractorisfitted with atethered,ratchetingfuelcap.STOPfilling thetank

oncethefuelisseeninsidethefiller neck.Thisensuresthataproperexpansion

volumeiscreated,otherwisethefuelcanoverflowcreatinga hazardoussituation.

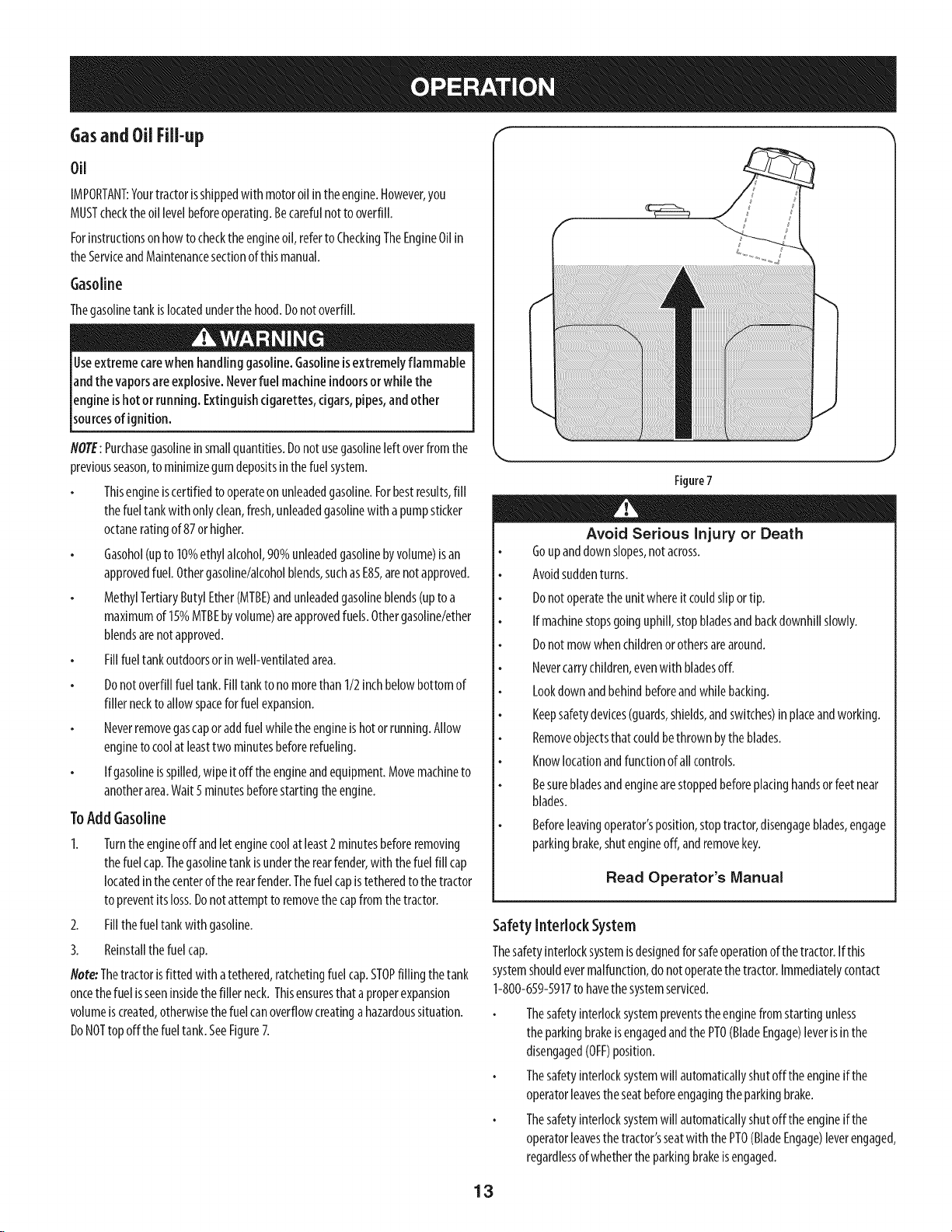

DoNOTtopoffthe fueltank.SeeFigure7.

Figure7

Avoid Serious Injury or Death

Goupanddownslopes,notacross.

Avoidsuddenturns.

Donotoperatetheunitwhereit couldsliportip.

Ifmachinestopsgoinguphill,stopbladesandbackdownhillslowly.

Donotmowwhenchildrenorothersarearound.

Nevercarrychildren,evenwithbladesoff.

Lookdownandbehindbeforeandwhilebacking.

Keepsafetydevices(guards,shields,andswitches)inplaceandworking.

Removeobjectsthat couldbethrownbytheblades.

Knowlocationandfunctionofallcontrols.

Besurebladesandenginearestoppedbeforeplacinghandsorfeet near

blades.

Beforeleavingoperator'sposition,stoptractor,disengageblades,engage

parkingbrake,shutengineoff,andremovekey.

Read Operator's Manual

SafetyInterlock System

Thesafetyinterlocksystemisdesignedfor safeoperationofthetractor.Ifthis

systemshouldevermalfunction,donotoperatethetractor.Immediatelycontact

1-800-659-5917to havethesystemserviced.

Thesafetyinterlocksystempreventstheenginefromstartingunless

theparkingbrakeisengagedandthePTO(BladeEngage)leverisinthe

disengaged(OFF)position.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavestheseatbeforeengagingtheparkingbrake.

Thesafetyinterlocksystemwill automaticallyshutofftheengineifthe

operatorleavesthetractor'sseatwiththe PTO(BladeEngage)leverengaged,

regardlessofwhethertheparkingbrakeisengaged.

13

Page 14

Theenginewill automaticallyshutoffif thePTO(BladeEngage)leveris

movedintotheengaged(ON)positionwith theshiftleverinReverse.

Ignition Switch

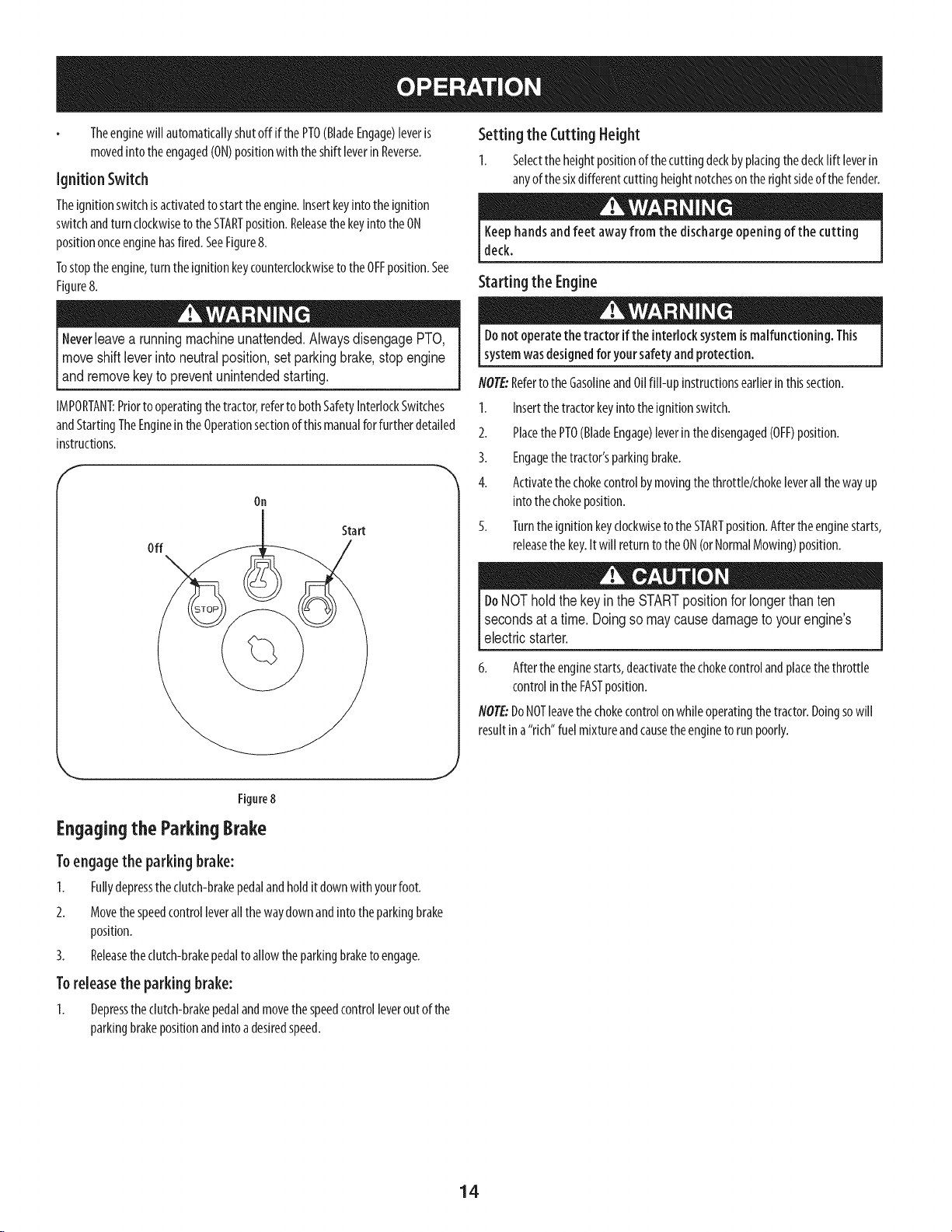

Theignitionswitchisactivatedtostarttheengine.Insertkeyintotheignition

switchandturnclockwisetotheSTARTposition.ReleasethekeyintotheON

positiononceenginehasfired.SeeFigure8.

Tostoptheengine,turntheignitionkeycounterclockwisetotheOFFposition.See

Figure8.

Setting the CuttingHeight

1. Selecttheheightpositionof thecuttingdeckbyplacingthedecklift leverin

anyofthesixdifferentcutting heightnotchesonthe rightsideofthefender.

Keephandsandfeet awayfrom the dischargeopening of the cutting

deck.

Starting the Engine

Neverleavea running machine unattended. Always disengage PTO,

move shift lever intoneutral position, set parking brake, stop engine

land remove key to prevent un ntended start ng.

IMPORTANT:Priortooperatingthetractor,refertobothSafetyInterlockSwitches

andStartingTheEngineintheOperationsectionof thismanualforfurtherdetailed

instructions.

On

Start

Off

J

Figure8

Donotoperatethe tractor if the interlocksystemismalfunctioning.This

systemwasdesignedforyour safetyandprotection.

NOTE:Referto theGasolineand0ii fill-up instructionsearlierinthissection.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(BladeEngage)leverinthedisengaged(OFF)position.

3. Engagethetractor'sparkingbrake.

4. Activatethechokecontrolbymovingthethrottle/chokeleverallthewayup

intothechokeposition.

5. TurntheignitionkeyclockwisetotheSTARTposition.Aftertheenginestarts,

releasethekey.Itwill returntotheON(orNormalMowing)position.

DoNOTholdthekeyinthe STARTpositionfor longerthanten

secondsat atime.Doingsomaycausedamagetoyourengine's

electricstarter.

6. Aftertheenginestarts,deactivatethechokecontrolandplacethethrottle

controlintheFASTposition.

NOTE:DoNOTleavethechokecontrolonwhileoperatingthetractor.Doingsowill

resultina"rich"fuelmixtureandcausetheenginetorunpoorly.

Engagingthe ParkingBrake

Toengagethe parking brake:

I. Fullydepresstheclutch-brakepedalandholditdownwithyourfoot.

2. Movethespeedcontrolleverallthewaydownandintotheparkingbrake

position.

3. Releasetheclutch-brakepedalto allowtheparkingbraketoengage.

Toreleasethe parking brake:

I. Depresstheclutch-brakepedalandmovethespeedcontrolleveroutofthe

parkingbrakepositionandintoadesiredspeed.

14

Page 15

Stoppingthe Engine

Ifyoustrikeaforeign object,stoptheengine,disconnectthe sparkplug

wire(s)andgroundagainstthe engine.Thoroughlyinspectthe machinefor

anydamage.Repairthe damagebeforerestarting and operating

1. If thebladesareengaged,placethe PTO(BladeEngage)leverinthe

disengaged(OFF)position.

2. TurntheignitionkeycounterclockwisetotheSTOPposition.

3. Removethekeyfromtheignitionswitchto preventunintendedstarting.

Driving TheTractor

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatofthe tractor without first placingthePTO(Blade

Engage)leverinthe disengaged(OFF)position,depressingthebrakepedal

andengagingtheparking brake.Ifleavingthetractor unattended,also

turn the ignition keyoff andremovethe key.

Alwayslookdownandbehind beforeandwhile backingupto avoidaback-

overaccident.

1. Depresstheclutch-brakepedaltoreleasetheparkingbrakeandthenlet the

pedalup.

2. Movethethrottle leverintothe FAST(rabbit)position.

3. PlacetheshiftleverineithertheFORWARDorREVERSEposition.

IMPORTANT: DoNOTusetheshift levertochangethedirectionof travelwhen

thetractorisinmotion.Alwaysusetheclutch-brakepedaltobringthetractorto a

completestopbeforeshifting.

4. Releasetheparkingbrakebydepressingtheclutch-brakepedaland

positioningthespeedcontrolleverinthedesiredposition.

IMPORTANT: First-timeoperatorsshouldusespeedpositions1or2.Become

completelyfamiliarwith thetractor'soperationandcontrolsbeforeoperatingthe

tractorinhigherspeedpositions.

5. Releaseclutch-brakepedalslowlytoputunitintomotion.

6. Thelawntractorisbroughttoastopbydepressingtheclutch-brakepedal.

NOTE:Whenoperating the unit initially, there will be little difference

between the highest two speeds until after the belts have seated

themselves into the pulleys during the break-in period.

Before leaving the operator's position for any reason, disengage the

blades, place the shift lever in neutral, engage the parking brake,

shut engine off and remove the key.

2. Engagetheparkingbrake.

3. Shutengineoffandremovethekey.Doingsowill minimizethepossibility

ofhavingyourlawn"browned"byhotexhaustfromyourtractor'srunning

engine.

Ifunitstallswith speedcontrolinhighspeed,orifunitwill notoperatewith speed

controlleverinalowspeedposition,proceedasfollows:

1. PlaceshiftleverinNEUTRAL

2. Restartengine.

3. Placespeedcontrolleverinhighestspeedposition.

4. Releaseclutch-brakepedalfully.

5. Depressclutch-brakepedal.

6. Placespeedcontrolleverindesiredposition.

7. PlaceshiftleverineitherFORWARDorREVERSE,andfollownormaloperating

procedures.

Driving OnSlopes

RefertotheSLOPEGAUGEin theSafetyInstructionssectionofthemanualtohelp

determineslopeswhereyoumayoperatethistractorsafely.

Donotmow oninclineswith aslopein excessof 15degrees(ariseof

approximately2-I12feetevery10feet). Thetractor couldoverturnand

causeseriousinjury.

Mowupanddownslopes,NEVERacross.

Exerciseextremecautionwhenchangingdirectiononslopes.

Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.Uneventerrain

couldoverturnthemachine.Tallgrasscanhideobstacles.

Avoidturnswhendrivingonaslope.Ifaturn mustbemade,turndownthe

slope.Turningupaslopegreatlyincreasesthechanceofa rollover.

Avoidstoppingwhendrivingupa slope.If it isnecessarytostopwhile

drivingupa slope,start upsmoothlyandcarefullyto reducethepossibility

offlippingthetractoroverbackward.

Engagingthe Blades

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeckorother

(separatelyavailable)attachments.Toengagetheblades,proceedasfollows:

1. Movethethrottle/chokecontrollevertotheFAST(rabbit)position.

2. GraspthePTO(BladeEngage)leverandpivotitallthewayforwardintothe

engaged(ON)position.

3. KeepthethrottleleverintheFAST(rabbit)positionforthemostefficientuse

ofthecuttingdeckorother(separatelyavailable)attachments.

NOTE:Theenginewill automaticallyshutoff ifthe PTO(BladeEngage)leveris

movedintotheengaged(ON)positionwiththeshift leverinReverse.

IMPORTANT: Whenstoppingthetractorforanyreasonwhileonagrass

surface,always:

1. Placetheshiftleverinneutral.

15

Page 16

Mulching

Amulchkitisavailableasanattachment.Mulchingisaprocessofredrculating

grassclippingsrepeatedlybeneaththecuttingdeck.Theultra-fineclippingsare

thenforcedbackintothelawnwheretheyactasanaturalfertilizer.

Amulchkitcanbepurchased.Seethe ReplacementParts&Attachmentssectionof

thismanualformoreinformation.

Usingthe DeckLift Lever

Toraisethecuttingdeck,movethedeckliftlevertothe left,thenplaceit inthe

notchbestsuitedfor yourapplication.RefertoSettingTheCuttingHeightearlierin

thisOperationsection.

MOWING

Tohelpavoidbladecontactorathrown objectinjury,keepbystanders,

[ helpers,childrenandpetsat least75feetfrom the machinewhile itisin

[ operation.Stopmachineifanyoneentersthe area.

Thefollowinginformationwill behelpfulwhenusingthecuttingdeckwithyour

tractor:

Planyourmowingpattern to avoiddischargeofmaterialstoward roads,

sidewalks,bystandersandthe like.Also,avoiddischargingmaterialagainst

awall orobstructionwhich maycausedischargedmaterialto ricochetback

towardthe operator.

Headlights

ThelampsareONwheneverthetractor'sengineisrunning.

Thelampsturn OFFwhentheignitionkeyismovedtotheSTOPposition.

Donotmowathighgroundspeed,especiallyifamulchkit orgrasscollector

isinstalled.

Forbestresultsitisrecommendedthatthefirsttwo lapsbecutwith the

dischargethrowntowardsthecenter.Afterthefirsttwolaps,reversethe

directiontothrowthedischargeto theoutsideforthe balanceofcutting.

Thiswill giveabetterappearanceto thelawn.

Donotcutthegrasstooshort.Shortgrassinvitesweedgrowthandyellows

quicklyindryweather.

Mowingshouldalwaysbedonewiththeengineatfull throttle.

Underheavierconditionsitmaybenecessarytogobackoverthecutareaa

secondtimeto getacleancut.

DoNOTattemptto mowheavybrushandweedsandextremelytallgrass.

Yourtractorisdesignedtomowlawns,NOTclearbrush.

Keepthebladessharpandreplacethebladeswhenworn.Referto Cutting

BladesintheServicesectionofthismanualfor properbladesharpening

instructions.

16

Page 17

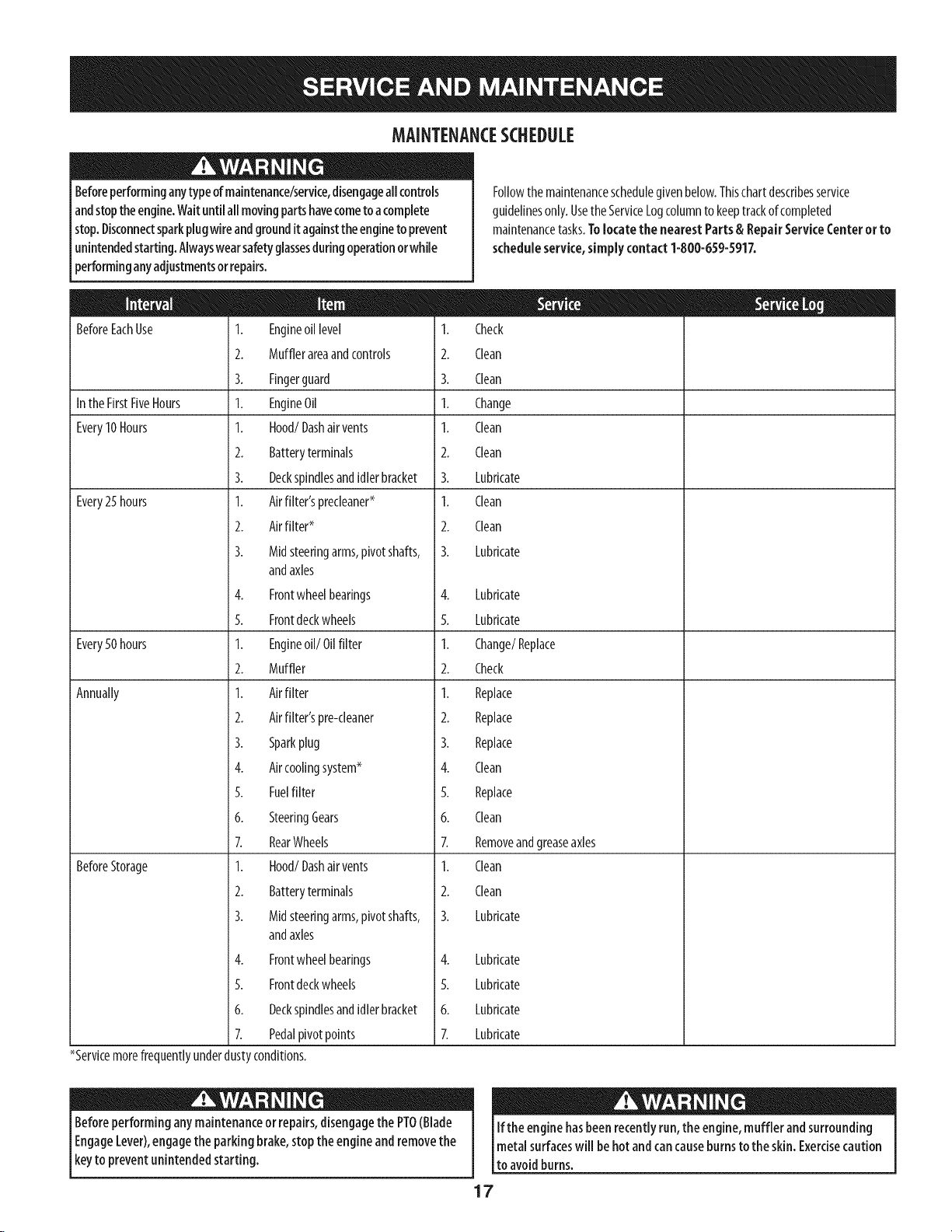

MAINTENANCESCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall controls

andstoptheengine.Waituntilallmovingpartshavecometoacomplete

stop.Disconnectsparkplugwireandgroundit againsttheengineto prevent

unintendedstarting.AlwayswearsafetyglassesduringoperationorwhUe

performinganyadjustmentsor repairs.

BeforeEachUse I. Engineoil level I.

2. Mufflerareaandcontrols 2.

3. Fingerguard 3.

Inthe FirstFiveHours I. EngineOil I.

Every10Hours I. Hood/Dashairvents I.

2. Batteryterminals 2.

3. Deckspindlesandidlerbracket 3.

Every25hours 1. Airfilter'sprecleaner* 1.

2. Airfilter* 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings 4.

5. Frontdeckwheels 5.

Every50hours 1. Engineoil/Oil filter 1.

2. Muffler 2.

Annually 1. Airfilter 1.

2. Airfilter'spre-cleaner 2.

3. Sparkplug 3.

4. Aircoolingsystem* 4.

5. Fuelfilter 5.

6. SteeringGears 6.

7. RearWheels 7.

BeforeStorage 1. Hood/Dashairvents 1.

2. Batteryterminals 2.

3. Midsteeringarms,pivotshafts, 3.

andaxles

4. Frontwheelbearings

5. Frontdeckwheels

6. Deckspindlesandidlerbracket

7. Pedalpivotpoints

*Servicemorefrequentlyunderdustyconditions.

Followthe maintenanceschedulegivenbelow.Thischartdescribesservice

guidelinesonly.UsetheServiceLogcolumnto keeptrackofcompleted

maintenancetasks.Tolocate the nearest Parts& RepairServiceCenteror to

scheduleservice,simplycontact 1-800-659-5917.

Check

Clean

Clean

Change

Clean

Clean

Lubricate

Clean

Clean

Lubricate

Lubricate

Lubricate

Change/Replace

Check

Replace

Replace

Replace

Clean

Replace

Clean

Removeandgreaseaxles

Clean

Clean

Lubricate

4. Lubricate

5. Lubricate

6. Lubricate

7. Lubricate

Beforeperforminganymaintenanceorrepairs,disengagethe PTO(Blade

EngageLever),engagethe parking brake,stopthe engineandremovethe

keyto preventunintendedstarting.

Ifthe enginehasbeenrecentlyrun,the engine,muffler andsurrounding

metalsurfaceswill behot andcancauseburnsto the skin.Exercisecaution

to avoidburns.

17

Page 18

Engine Maintenance

Checkingthe EngineOil

OnlyusehighqualitydetergentoilratedwithAPIserviceclassificationSF,SG,

SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingto theexpectedoperating

temperature.Followthechartbelow.Althoughmulti-viscosityoils(5W20,10W30,

etc.)improvestartingin coldweather,theywill resultinincreasedoilconsumption

whenusedabove32°1:.Checkyourengineoillevelmorefrequentlyto avoidpossible

enginedamagefromrunninglowonoil.

E

Colder _ 32°F _Warmer

Changingthe EngineOiland Filter

Ifthe enginehasbeenrecentlyrun,the engine,muffler andsurrounding

metalsurfaceswill behotand cancauseburnsto theskin.Exercisecaution

toavoidburns.

NOTE:Theoilfiltershouldbechangedateveryoilchangeinterval.

Theengineoilshouldbechangedinthefirst5hoursandthenevery50 hoursor

onceaseason.Tochangetheengineoil,proceedasfollows:

1. Runtheengineforafew minutesto allowtheoilinthecrankcasetowarm

up.Warmoilwill flow morefreelyandcarryawaymoreoftheengine

sedimentwhichmayhavesettledatthe bottomofthecrankcase.Usecareto

avoidburnsfromhotoil.

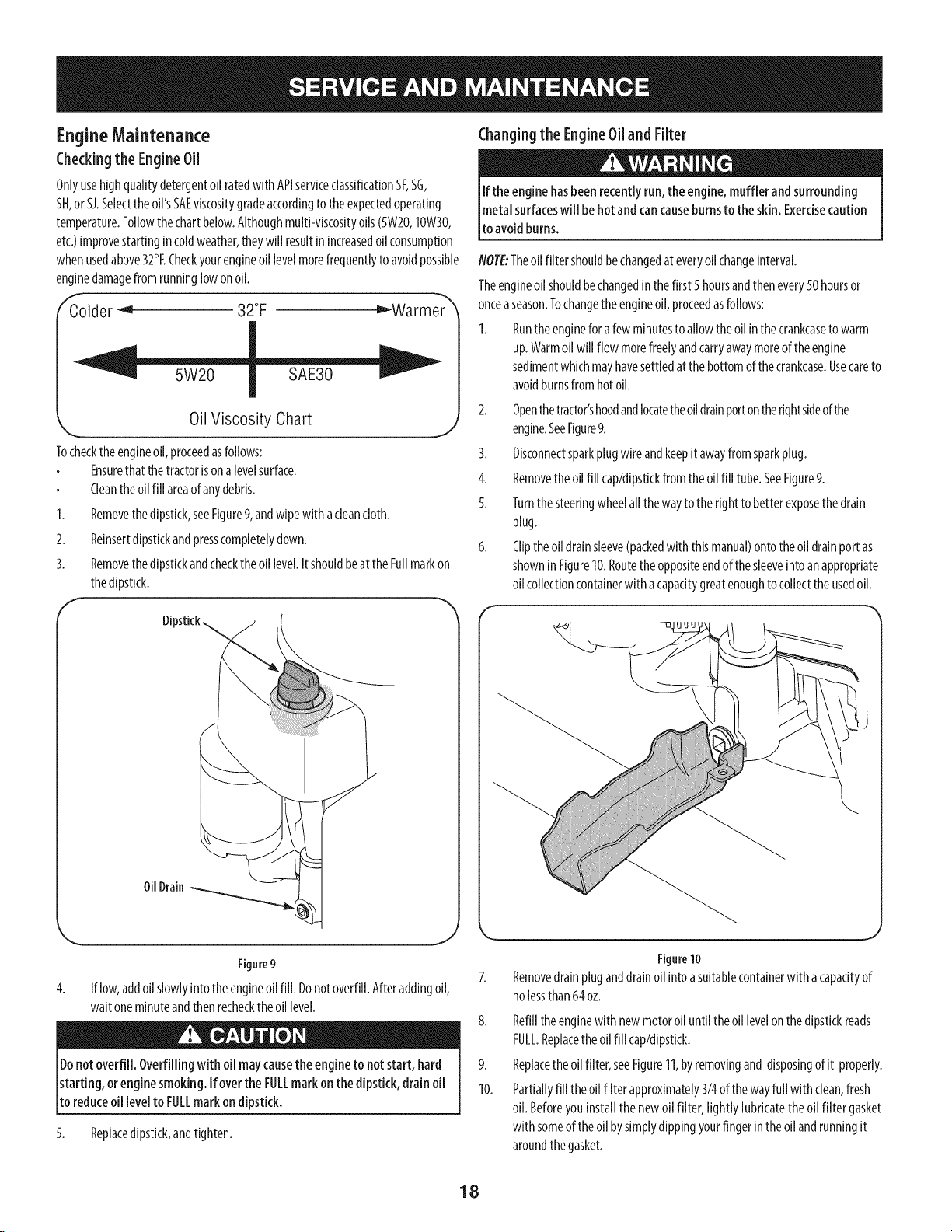

Oil Viscosity Chart

Tochecktheengineoil,proceedasfollows:

Ensurethatthetractorisonalevelsurface.

Cleantheoilfill areaofanydebris.

1.

Removethedipstick,seeFigure9,andwipewith acleancloth.

2.

Reinsertdipstickandpresscompletelydown.

3.

Removethedipstickandchecktheoillevel.ItshouldbeattheFullmarkon

thedipstick.

F

Dipstick

2. Openthetractor'shoodandlocatetheoildrainportontherightsideofthe

J

engine.SeeFigure9.

3. Disconnectsparkplugwireandkeepitawayfromsparkplug.

4. Removetheoilfill cap/dipstkkfromtheoilfill tube.SeeFigure9.

5. Turnthesteeringwheelallthewaytothe rightto betterexposethedrain

plug.

6. Cliptheoildrainsleeve(packedwith thismanual)ontotheoil drainportas

showninFigure10.Routetheoppositeendofthesleeveinto anappropriate

oilcollectioncontainerwith acapacitygreatenoughtocollectthe usedoil.

OilDrain

Figure9

4. If low,addoii slowlyintotheengineoiifill. Donotoverfill.Afteraddingoii,

waitoneminuteandthenrechecktheoillevel.

Donotoverfill. Overfillingwithoii maycausethe engineto notstart, hard

starting, orenginesmoking.Ifoverthe FULLmarkonthedipstick,drain oil

to reduceoillevelto FULLmarkondipstick.

5. Replacedipstick,andtighten.

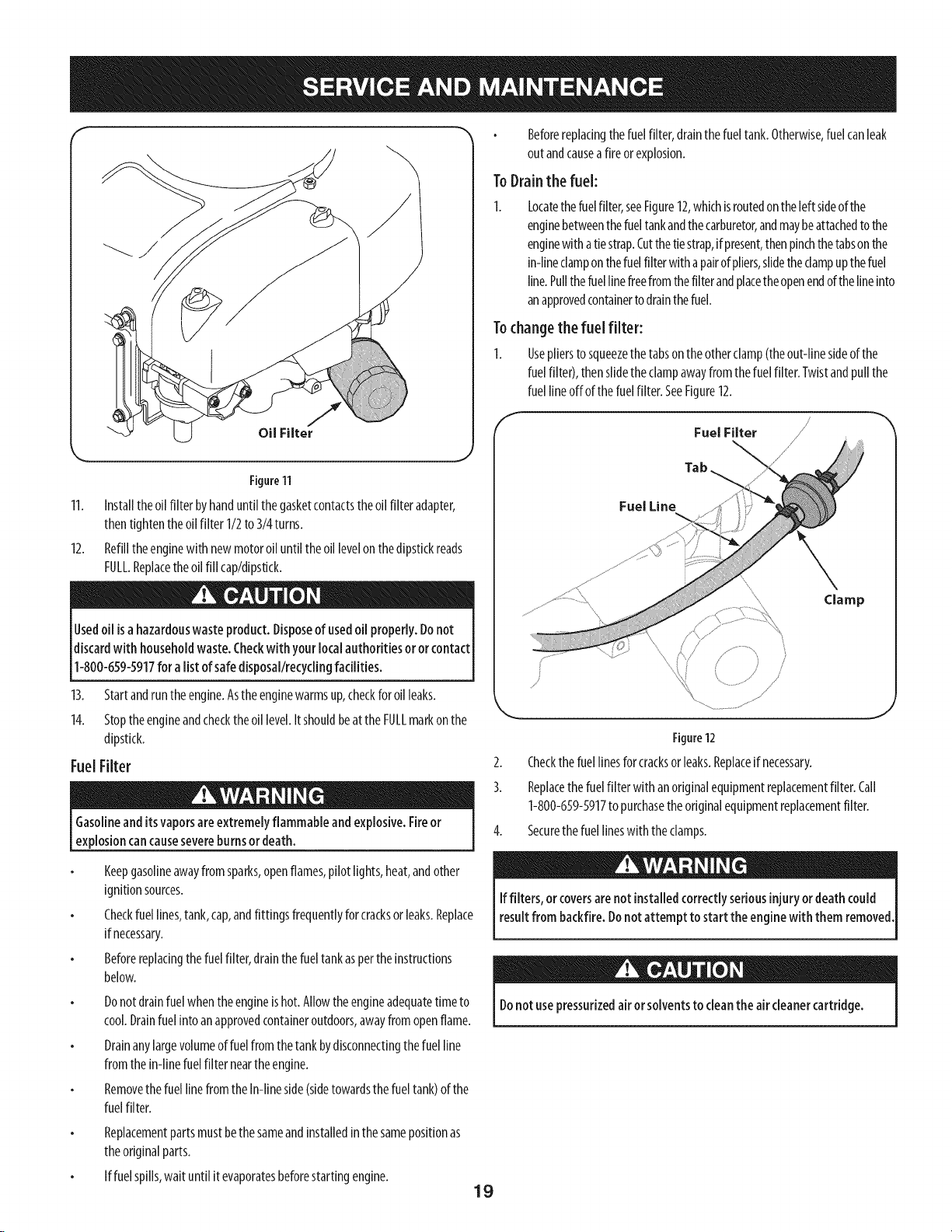

Figure10

Removedrainpluganddrainoilintoasuitablecontainerwith a capacityof

nolessthan64oz.

8. Refilltheenginewithnewmotoroil untiltheoil levelonthedipstickreads

FULL.Replacetheoilfill cap/dipstick.

9. Replacetheoilfilter,seeFigure11,byremovingand disposingofit properly.

10. Partiallyfilltheoil filterapproximately3/4ofthewayfullwith clean,fresh

oil. Beforeyouinstallthenewoil filter, lightly lubricatetheoil filter gasket

with someoftheoilbysimplydippingyourfingerintheoilandrunningit

aroundthegasket.

18

Page 19

f

Beforereplacingthefuelfilter,drainthefueltank.Otherwise,fuelcanleak

outandcauseafire orexplosion.

ToDrainthe fuel:

Locatethefuelfilter,seeFigure12,whichisroutedontheleftsideofthe

enginebetweenthefueltankandthecarburetor,andmaybeattachedtothe

enginewithatie strap.Cutthetiestrap,if present,thenpinchthetabsonthe

in-lineclamponthefuelfilterwithapairofpliers,slidetheclampupthefuel

line.Pullthefuellinefreefromthefilterandplacetheopenendofthelineinto

anapprovedcontainertodrainthefuel.

Tochangethe fuel filter:

1. Usepliersto squeezethetabsontheotherclamp(theout-linesideofthe

fuelfilter),thenslidetheclampawayfromthefuelfilter. Twistandpullthe

fuellineoffof thefuelfilter.SeeFigure12.

Oil Filter

Figure11

11. Installtheoil filter byhanduntilthegasketcontactstheoilfilter adapter,

thentightentheoilfilter 1/2to 3/4turns.

12. Refilltheenginewithnewmotoroiluntiltheoillevelonthedipstickreads

FULL.Replacetheoilfill cap/dipstkk.

Usedoil isahazardouswasteproduct.Disposeof usedoilproperly.Donot

discardwith householdwaste.Checkwith your local authoritiesororcontact

1-800-659-5917for a listof safedisposal/recyclingfacilities.

13. Startandruntheengine.Astheenginewarmsup,checkforoilleaks.

14. Stoptheengineandchecktheoil level.ItshouldbeattheFULLmarkonthe

dipstick.

FuelFilter

Gasolineanditsvaporsareextremelyflammable andexplosive.Fireor

explosioncancausesevereburnsordeath.

Keepgasolineawayfromsparks,openflames,pilotlights,heat,andother

ignitionsources.

Checkfuellines,tank,cap,andfittingsfrequentlyforcracksor leaks.Replace

if necessary.

Beforereplacingthefuelfilter,drainthefueltankaspertheinstructions

below.

Donotdrainfuelwhentheengineishot.Allowtheengineadequatetimeto

cool.Drainfuelintoanapprovedcontaineroutdoors,awayfromopenflame.

Drainanylargevolumeoffuelfromthetankbydisconnectingthefuelline

fromthe in-linefuelfilter neartheengine.

RemovethefuellinefromtheIn-lineside(sidetowardsthefueltank)ofthe

fuelfilter.

Replacementpartsmustbethesameandinstalledinthesamepositionas

theoriginalparts.

Iffuelspills,waituntil it evaporatesbeforestartingengine.

Fuel Filter

\

Tab

Fuel Line

j/

Figure12

2. Checkthe fuellinesforcracksorleaks.Replaceifnecessary.

3. Replacethefuelfilter withanoriginalequipmentreplacementfilter. Call

1-800-659-5917topurchasetheoriginalequipmentreplacementfilter.

4. Securethefuellineswith theclamps.

Iffilters, orcoversarenot installedcorrectlyseriousinjuryordeathcould

resultfrom backfire.Donot attempt to startthe enginewith themremoved,

Donotusepressurizedairor solventsto cleanthe aircleanercartridge.

19

Page 20

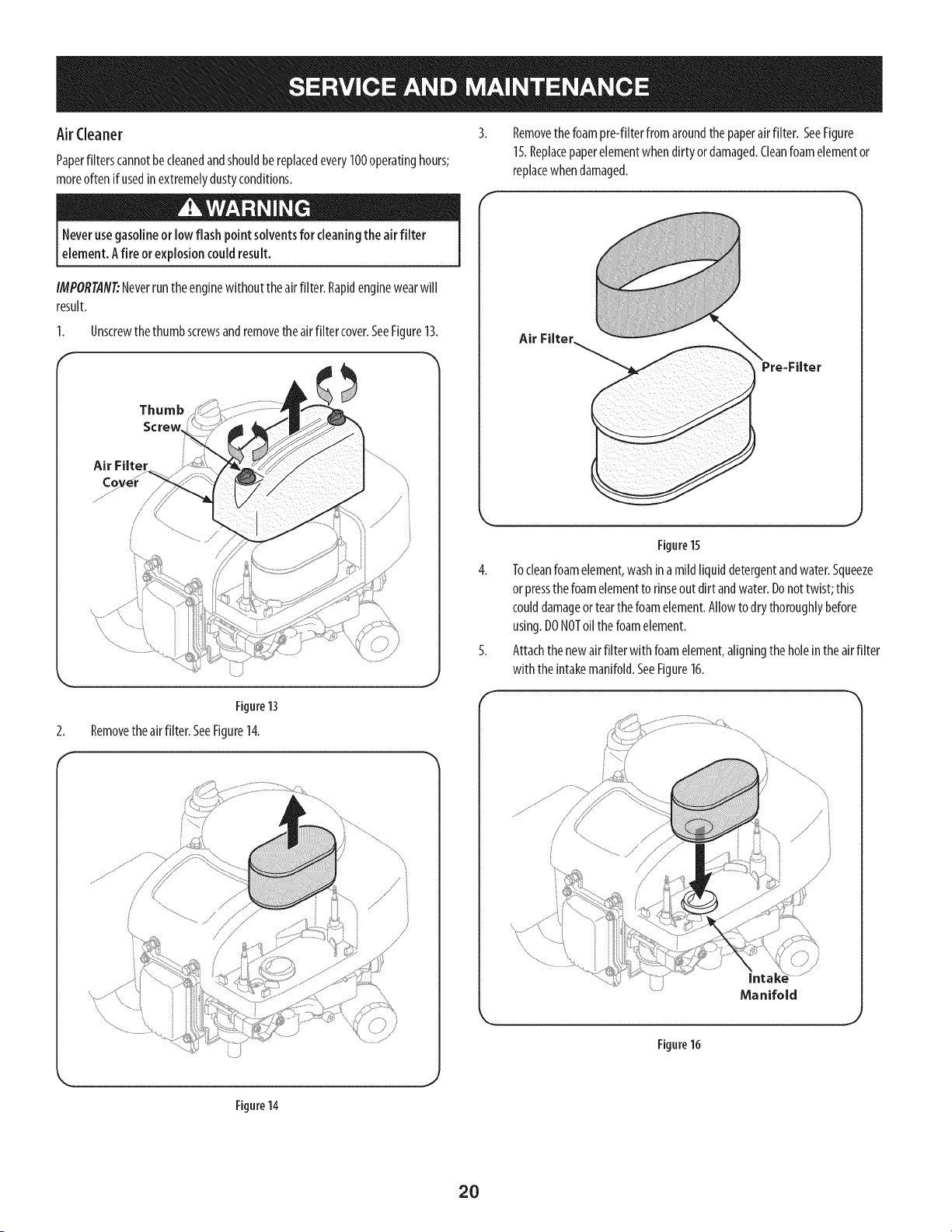

Air Cleaner

Paperfilterscannotbecleanedandshouldbereplacedevery100operatinghours;

moreoftenif usedin extremelydustyconditions.

Neverusegasolineor lowflash point solventsfor cleaningtheair filter

element.Afire orexplosioncouldresult.

IMPORTANT:Neverruntheenginewithout theairfilter. Rapidenginewearwill

result.

1. Unscrewthethumbscrewsandremovetheairfilter cover.SeeFigure13.

Thumb

Screw

Air FHter

Removethefoampre-fiIterfromaroundthepaperairfilter. SeeFigure

15.Replacepaperelementwhendirtyordamaged.Cleanfoamelementor

replacewhendamaged.

Air FHter

2.

Removetheairfilter. SeeFigure14.

Figure13

//

Figure15

4. Tocleanfoamelement,washinamildliquiddetergentandwater.Squeeze

orpressthefoamelementtorinseout dirtandwater.Donottwist;this

coulddamageortearthefoamelement.Allowtodrythoroughlybefore

using.DONOToil thefoamelement.

5. Attachthenewairfilterwith foamelement,aligningtheholeintheairfilter

with theintakemanifold.SeeFigure16.

/

/

Manifold

Figure14

Figure16

20

Page 21

6.

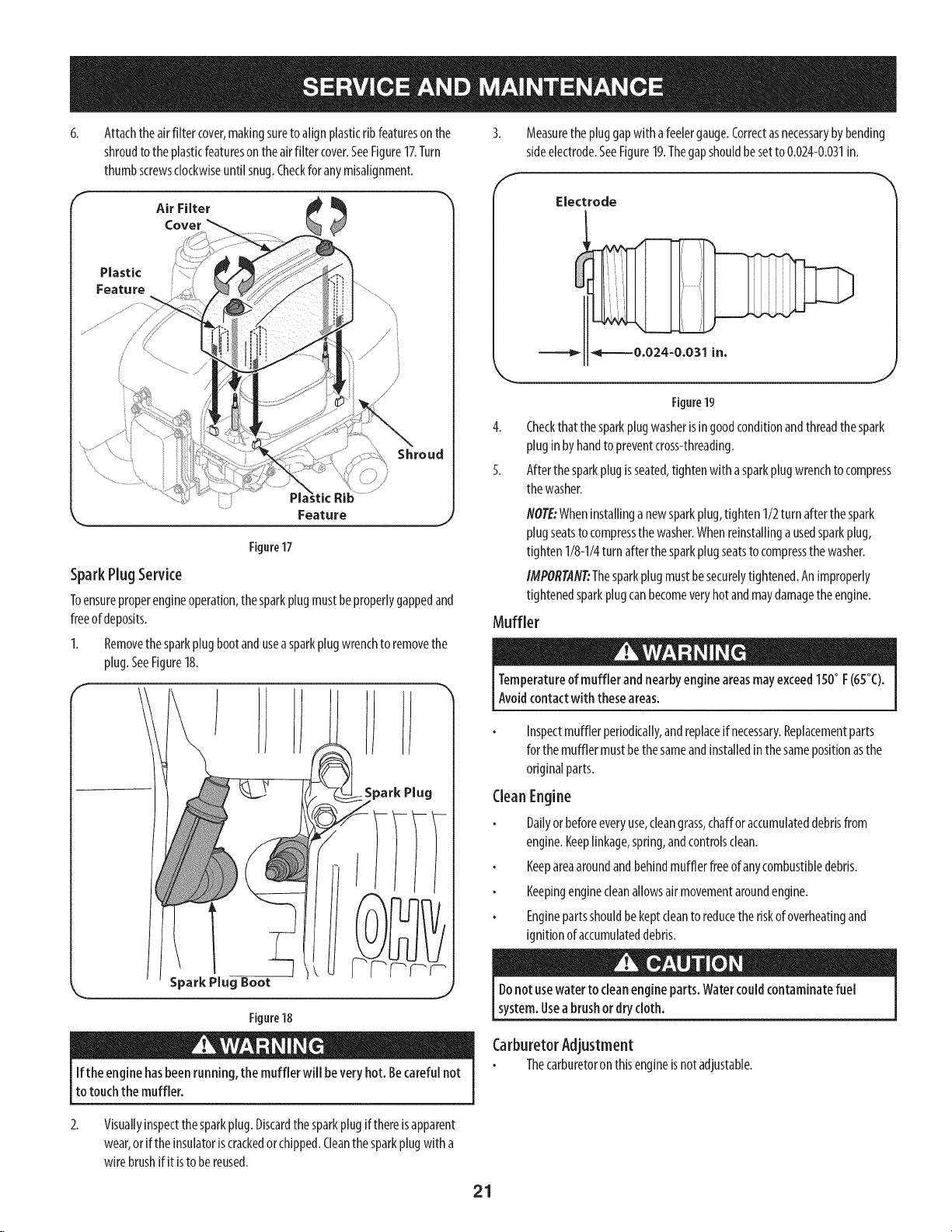

Attachtheairfilter cover,makingsuretoalignplasticribfeaturesonthe

shroudtotheplasticfeaturesontheairfilter cover.SeeFigure17.Turn

thumbscrewsclockwiseuntilsnug.Checkfor anymisalignment.

Air Filter

Cover

Plastic

Feature

Shroud

Feature

Figure17

SparePlug Service

Toensureproperengineoperation,thesparkplugmustbeproperlygappedand

freeofdeposits.

1. Removethesparkplugbootanduseasparkplugwrenchtoremovethe

plug.SeeFigure18.

f

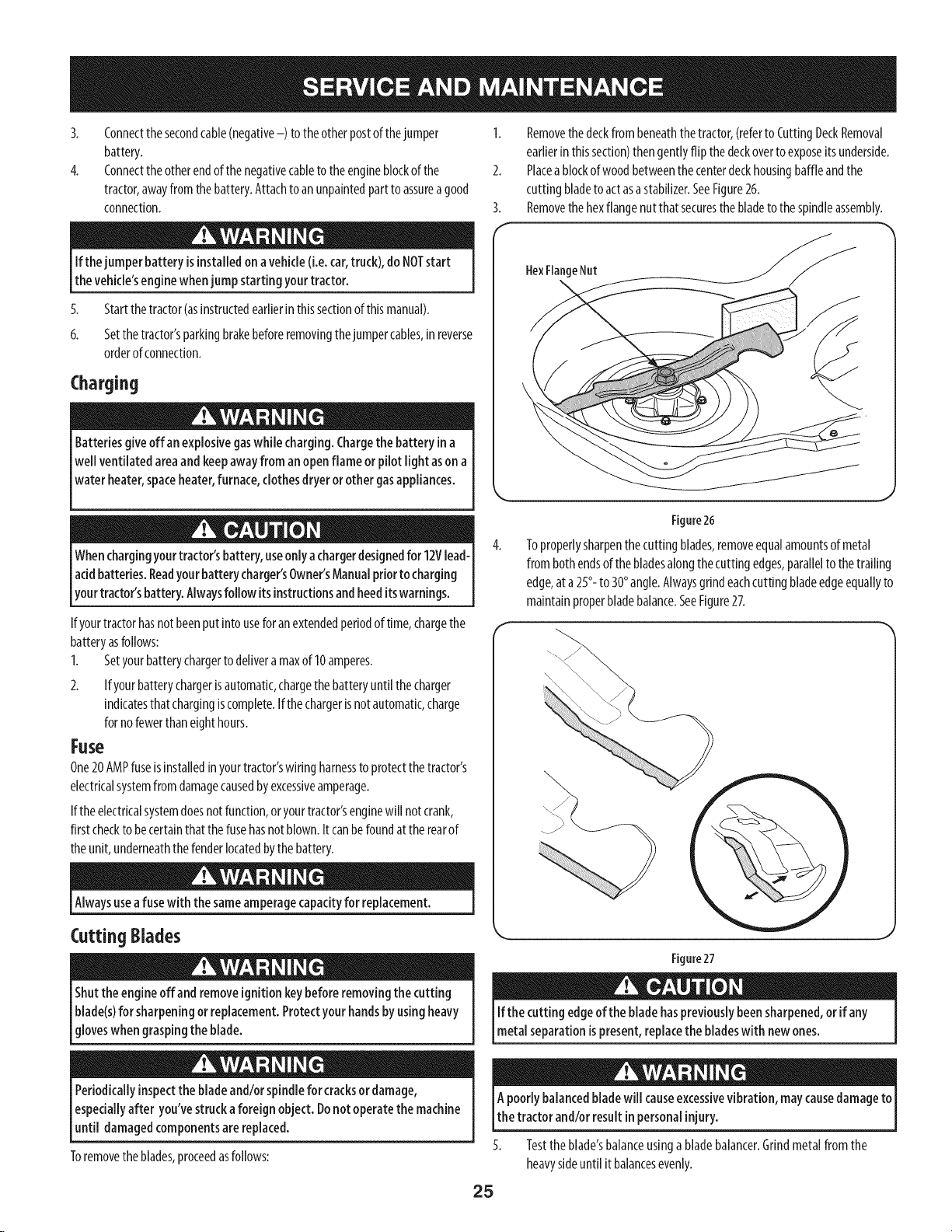

Measurethepluggapwithafeelergauge.Correctasnecessarybybending

sideelectrode.SeeFigure19.Thegapshouldbesetto0.024-0.031in.

Electrode

_=--_0.024-0.031 in,

J

Figure19

4. Checkthatthesparkplugwasherisingoodconditionandthreadthespark

pluginby handtopreventcross-threading.

5. Afterthesparkplugisseated,tightenwith asparkplugwrenchtocompress

thewasher.

NOTE:Wheninstallinga newsparkplug,tighten1/2turnafterthespark

plugseatstocompressthewasher.Whenreinstallinga usedsparkplug,

tighten1/8-1/4turn afterthesparkplugseatstocompressthewasher.

IMPORTANT:Thesparkplugmustbesecurelytightened.Animproperly

tightenedsparkplugcanbecomeveryhotandmaydamagetheengine.

Muffler

Temperatureof muffler and nearbyengineareasmayexceed150° F(65°C).

Avoidcontactwith theseareas.

Spark Plug

Ifthe enginehasbeenrunning,the muffler will beveryhot.Becareful not

to touchthe muffler.

2.

Visuallyinspectthesparkplug.Discardthesparkplugif thereisapparent

wear,orif theinsulatoriscrackedorchipped.Cleanthesparkplugwitha

wirebrushifit istobereused.

Inspectmufflerperiodically,andreplaceif necessary.Replacementparts

forthe mufflermustbethesameandinstalledinthesamepositionasthe

originalparts.

CleanEngine

Dailyorbeforeeveryuse,cleangrass,chafforaccumulateddebrisfrom

engine.Keeplinkage,spring,andcontrolsclean.

Keepareaaroundandbehindmufflerfreeofanycombustibledebris.

Keepingenginecleanallowsairmovementaroundengine.

Enginepartsshouldbe keptcleanto reducetheriskofoverheatingand

ignitionof accumulateddebris.

J

Donotusewater to cleanengineparts.Watercouldcontaminatefuel

system.Useabrushor drycloth.

CarburetorAdjustment

Thecarburetoronthisengineisnotadjustable.

21

Page 22

Lubrication

Beforelubricating,repairing,orinspecting,alwaysdisengagePTO(Blade

EngageLever),moveshift leverintoneutral position, setparkingbrake,stop

IMPORTANT: Theuseofa pressurewashertocleanyourtractorisNOT

recommended.It maycausedamageto electricalcomponents,spindles,pulleys,

bearingsortheengine.

Adjustments

engne andremovekeytopreventun ntendedstart rig.

Pivot Points& Linkage

Lubricateallthepivotpointsonthedrivesystem,parkingbrakeandlift linkageat

leastonceaseasonwith lightoil.

RearWheels

Therearwheelsshouldberemovedfromtheaxlesonceaseason.Lubricatethe

axlesandtherimswellwith anall-purposegreasebeforere-installingthem.

Front Axles

Eachendofthetractor'sfrontpivotbarmaybeequippedwith agreasefitting.

Lubricatewith agreasegunafterevery25hoursof tractoroperation.

Battery

Thebatteryissealedandismaintenance-free.Acidlevelscannotbechecked.

Alwayskeepthebatterycablesandterminalscleanandfreeofcorrosive

build-up.

Aftercleaningthe batteryandterminals,applyalightcoatof petroleumjelly

orgreasetobothterminals.

Alwayskeeptherubberbootpositionedoverthepositiveterminaltoprevent

shorting.

IM PORTANT: If removingthebatteryforanyreason,disconnecttheNEGATIVE

(Black)wirefromitsterminalfirst,followedbythePOSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthe POSITIVE(Red)wireto itsterminal

first,followedbytheNEGATIVE(Black)wire. Becertainthatthewiresareconnected

tothecorrectterminals;reversingthemcouldchangethepolarityandresultin

damageto yourengine'salternatingsystem.

Neverattempt to makeanyadjustmentswhile the engineisrunning,except

wherespecifiedintheoperator'smanual.

Levelingthe Deck

NOTE:Checkthetractor'stirepressurebeforeperforminganydeckleveling

adjustments.RefertoTiresintheServicesectionofthismanualformore

informationregardingtirepressure.

FrontTo Rear

Thefrontofthecuttingdeckissupportedbyastabilizerbarthatcanbeadjustedto

levelthedeckfromfrontto rear.Thefrontof thedeckshouldbebetween1g-inch

and_8-inchlowerthantherearofthedeck.Adjustif necessaryasfollows:

1. Withthetractorparkedonafirm,levelsurface,placetheleverfor liftingthe

platformon thesecondto thetopnotch(secondhighestposition)androtate

the bladeascloseaspossibleto thedischargechannelthatisparalleltothe

tractor.

2. Measurethedistancefromthefrontofthebladetiptothegroundandthe

rearofthebladetipto theground.Thefirst measurementtakenshould

bebetweenlg"and_8"lessthanthesecondmeasurement.Determine

theapproximatedistancenecessaryforproperadjustmentandproceed,if

necessary,tothenextstep.

3. Locatetheflangelocknutonthefrontsideofthestabilizerbracket.See

Figure20.

Tightentheflangelocknutto raisethefrontofthedeck;

Loosentheflangelocknutto lowerthefrontofthedeck.

f

CleaningBattery

Cleanthebatterybyremovingit fromthetractorandwashingwith a bakingsoda

andwatersolution.Ifnecessary,scrapethebatteryterminalswitha wirebrushto

removedeposits.Coatterminalsandexposedwiringwith greaseorpetroleumjelly

topreventcorrosion.

Battery Failures

Somecommoncausesforbatteryfailureare:

Incorrectinitialactivation

Overcharging

Freezing

Undercharging

Corrodedconnections

ThesefailuresareNOTcoveredbyyourtractor'swarranty.

Cleaningthe EngineAnd Deck

Anyfueloroilspilledonthemachineshouldbewipedoff promptly.DoNOTallow

debristo accumulatearoundthecoolingfinsoftheengineoronanyotherpartof

themachine.

J

22

Page 23

Sideto Side

Ifthecuttingdeckappearsto bemowingunevenly,asidetosideadjustmentcanbe

performed.Adjustifnecessaryasfollows:

1. Withthetractorparkedonafirm, levelsurface,placethedecklift leverin

thesecondfromthetop notch(secondhighestposition)androtateboth

bladessothattheyareperpendicularwith thetractor.

2. Measurethedistancefromtheoutsideof theleft bladetip to theground

andthedistancefromtheoutsideoftheright bladetipto theground.Both

measurementstakenshouldbeequal.Ifthey'renot,proceedto thenext

step.

3. Loosen,butdoNOTremove,thehexcapscrewontheleft deckhanger

bracket.SeeFigure21.

4. Balancethedeckby usingawrenchtoturntheadjustmentgear(found

immediatelybehindthehexcapscrewjustloosened)clockwise/upor

counterclockwise/down.Thedeckisproperlybalancedwhenbothbladetip

measurementstakenearlierareequal.

5. Retightenthehexcapscrewontheleftdeckhangerbracketwhenproper

adjustmentisachieved.

Cutting Deck Removal

Toremovethe cutting deck,proceedasfollows:

1. PlacethePTO(BladeEngage)leverin thedisengaged(OFF)positionand

engagetheparkingbrake.

2. Lowerthedeckbymovingthedecklift leverintothebottomnotchonthe

rightfender.

3. Removetheself-tappingscrewCA)that securesthebelt-keeperrodfrom

aroundthetractor'sPTOpulley,thenremovethebeltkeeperrod(B).See

Figure22.

Note:Makea mentalnotewhatholetheotherendofthe belt-keeperrodisinserted

inforreinstallationpurposes.

4. Removethebelt(C)fromaroundthetractor'sPTOpulley.SeeFigure22.

Avoidpinchinginjuries.Neverplaceyourfingers onthe idler springor

between the beltand apulleywhile removingthe belt.

f

Hex Cap Screw

Figure21

SeatAdjustment

RefertotheAssemblysectionofthis manualforseatadjustmentinstructions.

Parking BrakeAdjustment

Neverattempt toadjust the brakeswhile theengineisrunning.Always

disengagePTO(bladeengage)lever,moveshift leverinto neutral position,

stopengineandremovekeyto preventunintendedstarting.

Ifthetractordoesnotcometoacompletestopwhenthe brakepedaliscompletely

depressed,orif thetractor'srearwheelscanrollwith theparkingbrakeapplied,

thebrakeisin needofadjustment.ContactthenearestSearsServiceCenterto have

yourbrakesproperlyadjusted.

Tolocatethe nearestParts&RepairService(:enterortoscheduleservice,

contact1-800-659-5917.

23

\

Figure22

Movethedeckliftleverintothetopnotchontheright fendertoraisethe

decklift armsupandoutoftheway.

J

Page 24

/_

//

/

/

/

PTOCable

Figure23

6.

Removethebow-tiecotterpinsecuringthedeckstabilizerrodtothedeck.

Slidethedecklift rodfromthe mountingbracketonthedeckasshownin

Figure24.

f

,,__ /,__ ,........................

,.. j

Figure24

7. CarefullyremovethePTOcablefromtherearofthecuttingdeckby

removingthebow-tiecotterpinwhichsecuresit.Removethespringfrom

thedeckidlerbracket.SeeFigure25.

8. Gentlyslidethecuttingdeck(fromthe leftside)outfromunderneaththe

tractor.

Figure25

Tires

Neverexceedthemaximuminflationpressureshownonthesidewallof tire.

Therecommended operating tire pressureis:

Approximately10psiforthereartires

Approximately14psiforthefronttires

IMPORTANT: Refertothetire sidewallforexacttire manufacturer's

recommendedormaximumpsi.Donotoverinflate.Uneventirepressurecould

causethecuttingdecktomowunevenly.

Battery

CaliforniaProposition65WARNING!Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,chemicalsknowntotheStateof

Californiato causecancerandreproductiveharm.Washhandsafterhandling.

Ifremovingthe battery,disconnectthe NEGATIVE(Black)wire from its

terminal first, followed bythe POSITIVE(Red)wire. Whenre-installing

the battery,alwaysconnectthe POSITIVE(Red)wireto itsterminalfirst,

followed bytheNEGATIVE(Black)wire.

JumpStarting

Neverjumpstart adamagedorfrozen battery.Becertainthevehiclesdo not

touch,andignitionsareoff. Donotallow cableclampstotouch.

1. Connectpositive(+) cableto positivepost(+)of yourtractor'sdischarged

battery.

2. Connecttheotherendofthecabletothe(positive+) postofthejumper

battery.

24

Page 25

3. Connectthesecondcable(negative-) totheotherpostofthejumper

battery.

4. Connecttheotherendofthenegativecabletotheengineblockofthe

tractor,awayfromthebattery.Attachtoanunpaintedparttoassureagood

connection.

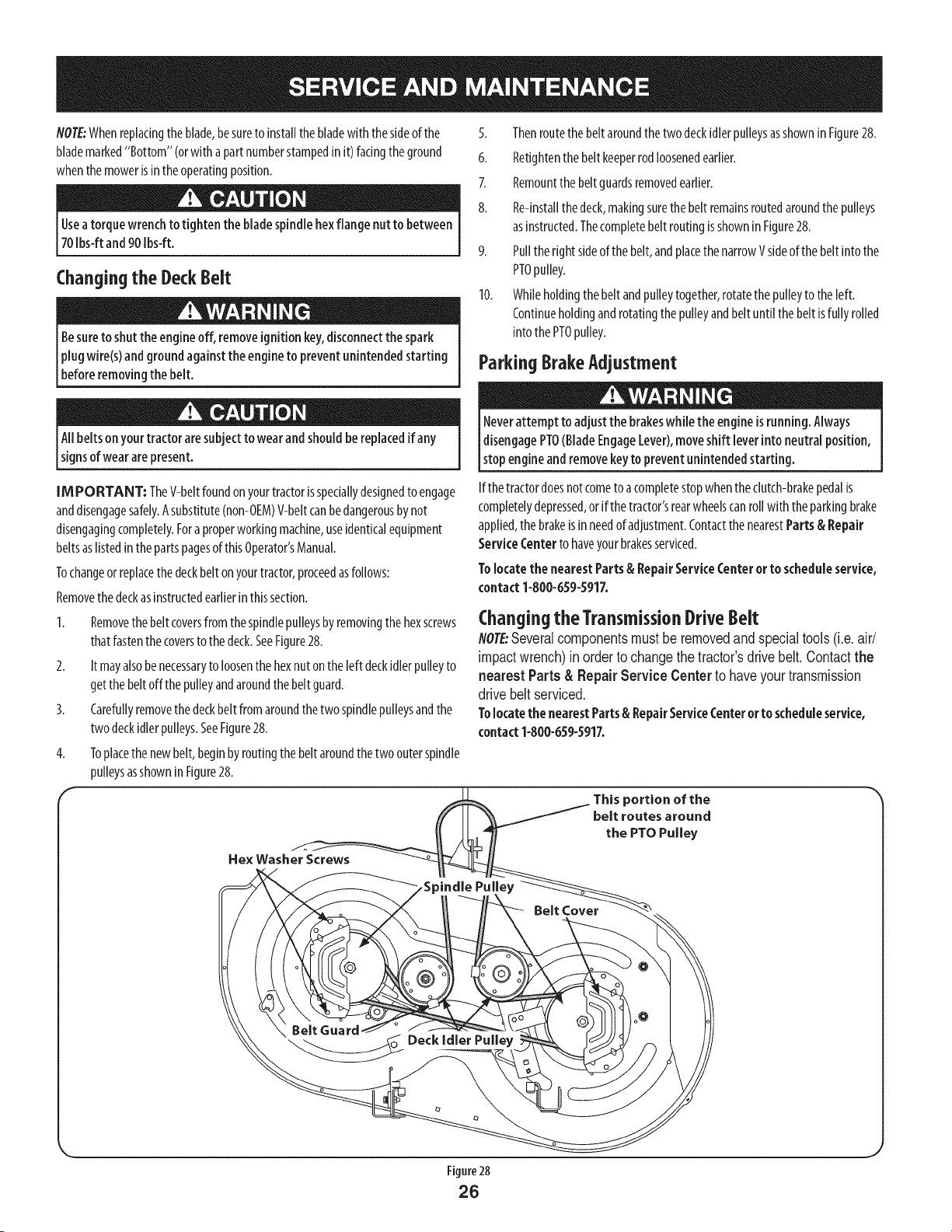

1. Removethedeckfrombeneaththetractor,(refertoCuttingDeckRemoval

earlierinthissection)thengentlyflip thedeckovertoexposeitsunderside.

2. Placeablockofwoodbetweenthecenterdeckhousingbaffleandthe

cuttingbladeto actasastabilizer.SeeFigure26.

3. Removethehexflangenutthatsecuresthebladetothespindleassembly.

Ifthejumperbatteryisinstalledonavehicle(i.e.car,truck),doNOTstart

thevehicle'senginewhenjumpstartingyourtractor.

5. Startthetractor(asinstructedearlierinthissectionofthismanual).

6. Setthetractor'sparkingbrakebeforeremovingthejumpercables,inreverse

orderofconnection.

Charging

Batteriesgive off anexplosivegaswhile charging.Chargethebattery ina

wellventilatedareaandkeepawayfrom anopenflame or pilotlight asona

waterheater,spaceheater,furnace,clothesdryeror other gasappliances.

Whenchargingyourtractor'sbattery,useonlya chargerdesignedfor 12Vlead-

acidbatteries.Readyourbatterycharger'sOwner'sManualpriortocharging

yourtractor'sbattery.Alwaysfollowitsinstructionsandheeditswarnings.

Ifyourtractorhasnotbeenputintouseforanextendedperiodoftime,chargethe

batteryasfollows:

1. Setyourbatterychargertodeliveramaxof10amperes.

2. If yourbatterychargerisautomatic,chargethebatteryuntilthecharger

indicatesthatchargingiscomplete.Ifthechargerisnotautomatic,charge

forno fewerthaneighthours.

Fuse

One20AMPfuseisinstalledin yourtractor'swiringharnessto protectthetractor's

electricalsystemfromdamagecausedbyexcessiveamperage.

Iftheelectricalsystemdoesnotfunction,oryourtractor'senginewillnotcrank,

firstcheckto becertainthatthefusehasnotblown.Itcanbefoundatthe rearof

theunit,underneaththefenderlocatedbythebattery.

HexFlangeNut

Figure26

Toproperlysharpenthecuttingblades,removeequalamountsofmetal

frombothendsof thebladesalongthecuttingedges,parallelto thetrailing

edge,at a25°-to 30°angle.Alwaysgrindeachcuttingbladeedgeequallyto

maintainproperbladebalance.SeeFigure27.

\4

Alwaysuseafusewith the sameamperagecapacityfor replacement.

Cutting Blades

Shutthe engineoffand removeignitionkeybeforeremovingthecutting

blade(s)for sharpeningorreplacement.Protectyourhandsbyusingheavy

gloveswhengraspingthe blade.

Periodicallyinspectthe bladeand/orspindlefor cracksordamage,

especiallyafter you'vestruckaforeign object.Donotoperatethe machine

until damagedcomponentsarereplaced.

Toremovetheblades,proceedasfollows:

Figure27

Ifthe cutting edgeofthe bladehaspreviouslybeensharpened,orif any

metal separationispresent,replacethebladeswith newones.

Apoorlybalancedbladewill causeexcessivevibration,maycausedamageto

the tractor and/orresult inpersonalinjury.

Testtheblade'sbalanceusinga bladebalancer.Grindmetalfromthe

heavysideuntil itbalancesevenly.

25

Page 26

NOTE:Whenreplacingtheblade,besureto installthebladewith thesideofthe

blademarked"Bottom"(orwith a partnumberstampedin it)facingtheground

whenthemowerisintheoperatingposition.

Usea torque wrenchto tighten the bladespindle he×flange nutto between

70[bs-ft and90[bs4t.

Changingthe DeckBelt

Besureto shut theengineoff, removeignitionkey,disconnectthe spark

plugwire(s)andgroundagainsttheengineto preventunintendedstarting

[before removngthe bet.

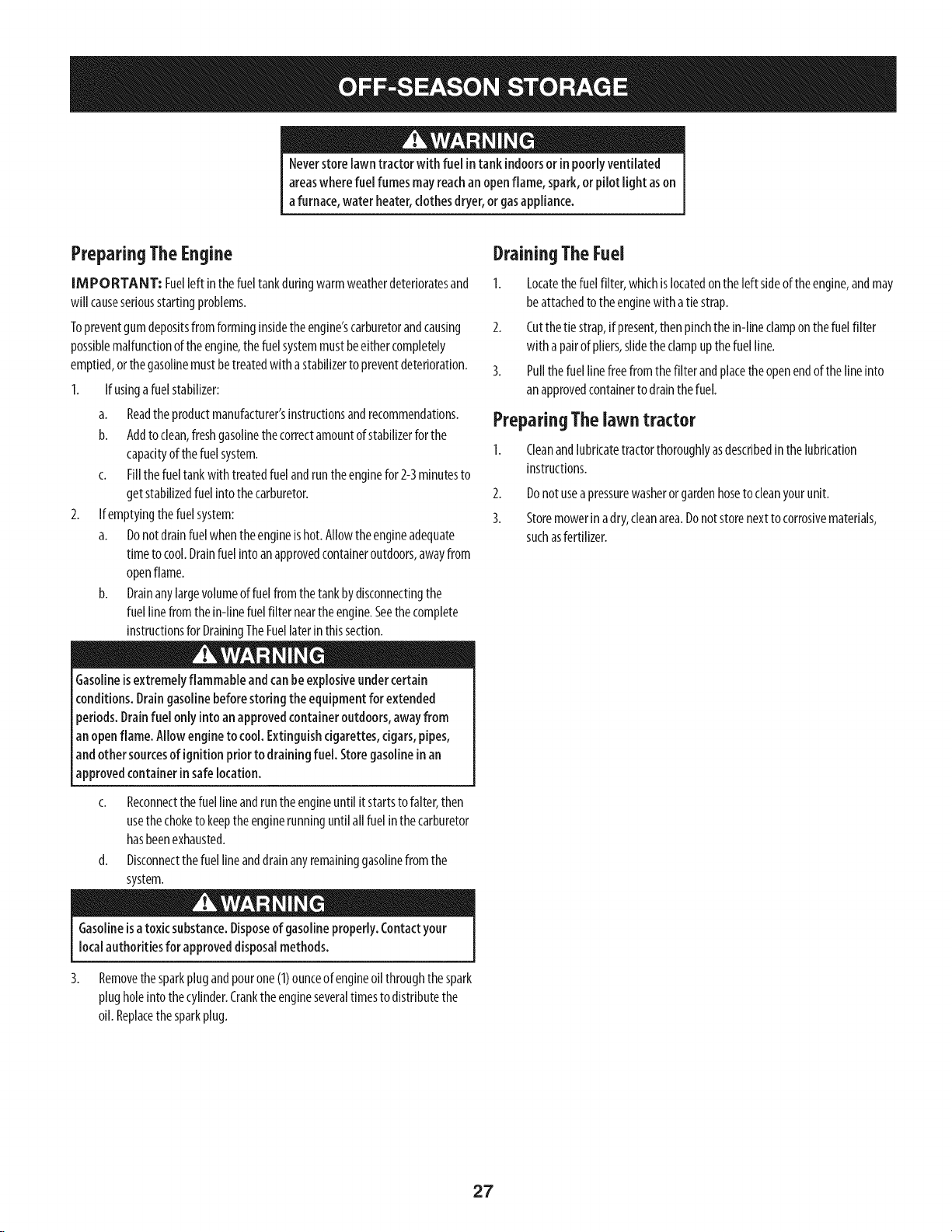

5. Thenroutethe beltaroundthetwodeckidlerpulleysasshowninFigure28.

6. Retightenthe beltkeeperrodloosenedearlier.

7. Remountthe beltguardsremovedearlier.

8. Re-installthedeck,makingsurethebeltremainsroutedaroundthepulleys

asinstructed.Thecompletebeltroutingisshownin Figure28.

9. Pulltherightsideofthebelt,andplacethenarrowVsideofthebeltintothe

PTOpulley.

10. Whileholdingthebeltandpulleytogether,rotatethepulleytotheleft.

Continueholdingandrotatingthepulleyandbeltuntilthebeltisfullyrolled

intothePTOpulley.

ParkingBrakeAdjustment

Allbeltsonyour tractorare subjectto wearand shouldbe replacedif any

signsof weararepresent.

IM PORTANT: TheV-beltfoundonyourtractorisspeciallydesignedto engage

anddisengagesafely.Asubstitute(non-OEM)V-beltcanbedangerousbynot

disengagingcompletely.Foraproperworkingmachine,useidenticalequipment

beltsaslistedinthepartspagesof thisOperator'sManual.

Tochangeor replacethedeckbeltonyourtractor,proceedasfollows:

Removethedeckasinstructedearlierinthissection.

1. Removethebeltcoversfromthespindlepulleysbyremovingthehexscrews

thatfastenthecoversto thedeck.SeeFigure28.

2. It mayalsobenecessarytoloosenthehexnutontheleftdeckidlerpulleyto

getthebeltoffthe pulleyandaroundthebeltguard.

3. Carefullyremovethedeckbeltfromaroundthetwospindlepulleysandthe

twodeckidlerpulleys.SeeFigure28.

4.

Toplacethenewbelt,beginbyroutingthebeltaroundthetwoouterspindle

pulleysasshowninFigure28.

Neverattempt to adjustthe brakeswhile theengineisrunning.Always

[disengagePTO(BladeEngageLever),moveshift leverintoneutralposition,

[stopengineand removekeyto preventunintendedstarting.

Ifthetractordoesnotcometo acompletestopwhentheclutch-brakepedalis

completelydepressed,orif thetractor'srearwheelscanrollwith theparkingbrake

applied,thebrakeisinneedofadjustment.ContactthenearestParts& Repair

ServiceCentertohaveyourbrakesserviced.

Tolocate the nearestParts& RepairServiceCenterorto scheduleservice,

contact1-800-659-5917.

Changingthe TransmissionDriveBelt

NOTE"Several components must be removed and special tools (i.e. air/

impactwrench) inorder to change the tractor's drive belt. Contact the

nearest Parts & Repair Service Center to have your transmission

drive belt serviced.

Tolocatethe nearestParts& RepairServiceCenterorto scheduleservice,

contact1-800-659-5917.

J

Page 27

Neverstorelawn tractorwith fuel intank indoorsor inpoorlyventilated

areaswhere fuelfumesmayreachan openflame,spark,or pilot light ason

afurnace,water heater,clothesdryer,orgasappliance.

PreparingTheEngine

IMPORTANT: Fuelleft inthefueltankduringwarmweatherdeterioratesand

will causeseriousstartingproblems.

Topreventgumdepositsfromforminginsidetheengine'scarburetorandcausing

possiblemalfunctionoftheengine,thefuelsystemmustbeeithercompletely

emptied,orthegasolinemustbetreatedwith astabilizerto preventdeterioration.

I. Ifusinga fuelstabilizer:

a. Readtheproductmanufacturer'sinstructionsandrecommendations.

b. Addtoclean,freshgasolinethecorrectamountofstabilizerforthe

capacityofthefuelsystem.

c. Fillthefueltankwith treatedfuelandruntheenginefor 2-3minutesto

getstabilizedfuelintothecarburetor.

2. Ifemptylngthefuelsystem:

a. Donotdrainfuelwhentheengineishot.Allowtheengineadequate

timetocool.Drainfuelinto anapprovedcontaineroutdoors,awayfrom

openflame.

b. Drainanylargevolumeof fuelfromthetankbydisconnectingthe

fuellinefromthein-linefuelfilter neartheengine.Seethecomplete

instructionsforDrainingTheFuellaterin thissection.

Gasolineisextremelyflammable and canbeexplosiveundercertain

conditions. Draingasolinebeforestoring theequipmentfor extended

periods.Drainfuel onlyinto anapprovedcontaineroutdoors,awayfrom

anopenflame.Allowengineto cool.Extinguishcigarettes,cigars,pipes,

andothersourcesofignition prior todraining fuel. Storegasolinein an

approvedcontainerinsafelocation.

DrainingTheFuel

1. Locatethefuelfilter,whichislocatedonthe leftsideoftheengine,andmay

beattachedtotheenginewithatiestrap.

2. Cutthetiestrap,if present,thenpinchthe in-lineclamponthefuel filter

with apairofpliers,slidetheclampupthefuelline.

3. Pullthefuellinefreefromthefilterandplacetheopenendofthelineinto

anapprovedcontainerto drainthefuel.

PreparingThelawn tractor

Cleanandlubricatetractorthoroughlyasdescribedinthelubrication

instructions.

2. Donotuseapressurewasherorgardenhosetocleanyourunit.

3. Storemowerin adry,cleanarea.Donotstorenexttocorrosivematerials,

suchasfertilizer.

c. Reconnectthefuellineandruntheengineuntil it startstofalter,then

usethechoketokeeptheenginerunninguntilallfuelin thecarburetor

hasbeenexhausted.

d. Disconnectthefuellineanddrainanyremaininggasolinefromthe

system.

Gasolineisa toxicsubstance.Disposeof gasolineproperly.Contactyour

localauthoritiesfor approveddisposalmethods.

3. Removethesparkplugandpourone(1)ounceofengineoilthroughthespark

plugholeintothecylinder.Cranktheengineseveraltimestodistributethe

oil. Replacethesparkplug.

27

Page 28

Enginefailsto start

1. PTO/BladeEngageleverengaged.

2. Parkingbrakenotengaged.

3. Sparkplugwire(s)disconnected.

4. Throttle/Chokecontrollevernotincorrect

2. Engageparkingbrake.

3. Connectwire(s)to sparkplug(s).

4. PlaceThrottle/Chokeleverintothe FASTposition.

startingposition.

5. Chokenotactivated

6. Fueltankempty,orstalefuel.

7. BIockedfuelline.

8. Faultysparkplug(s).

9. Engineflooded.

5. MovetheThrottle/Chokeleverintothe Choke

6. Filltankwithclean,fresh(lessthan30 daysold) gas.

7. Replacethefuellineandreplacefuelfilter.

8. Clean,adjustgapor replaceplug(s).

9. Crankenginewiththrottlein FASTposition.

10. BlownFuse(s)

Enginerunserratically

1. UnitrunningwithCHOKEactivated.

2. Sparkplugwire(s)loose.

3. Blockedfuellineor stalefuel.

4. Ventingascap plugged.

5. Waterordirtinfuel system.

6. Dirtyaircleaner.

2. Connectsparkplugwire(s).

3. Replacethefuelline;filltankwithclean,fresh

4. Clearventor replacecapifdamaged.

5. Drainfueltank. Refillwithclean,freshgasoline.

6. Replaceaircleanerpaperelementor cleanfoam

Engineoverheats 1. Engineoillevellow. 1.

2. Airflowrestricted. 2.

Enginehesitatesat highRPM 1. Sparkpluggaptoo close. 1.

Engineidles rough 1. Sparkplugfouled,faultyor gaptoowide. 1.

2. Dirtyaircleaner. 2.

Excessivevibration

Mowerwill notmulchgrass

Unevencut

1. Cuttingbladelooseor unbalanced.

2. Damagedor bentcuttingblade.

1. Enginespeedtoolow.

2. Wetgrass.

3. Excessivelyhighgrass.

4. Dullblade.

1. Decknotleveledproperly.

2. Dullblade.

3. Uneventirepressure.

2. Replaceblade.

2. Do notmulchwhengrassiswet.

3. Mowonce ata highcuttingheight,thenmowagain

4. Sharpenorreplaceblade.

2. Sharpenorreplaceblade.

3. Checktire pressureinallfour tires.

1. Placeleverindisengaged(OFF)position.

position.

10. ReplaceFuse(s)

1. DeactivatetheCHOKE.

gasolineandreplacefuelfilter.

pre-cleaner,ifequipped.

Fillcrankcasewithproperamountandweightof oil.

Cleangrassclippingsanddebrisfromaroundthe

engine'scoolingfinsandhousing.

Removesparkplugandresetthe gap.

Replacesparkplug.Set pluggap.

Replaceair cleanerelementand/orcleanpre-

cleaner.

1. Tightenbladeandspindle.

1. Placethrottlein FAST(rabbit)position.

at desiredheightor makea narrowercuttingswath.