MTD 13A226JD099 Owner’s Manual

perator's

£RnFrSMRN°

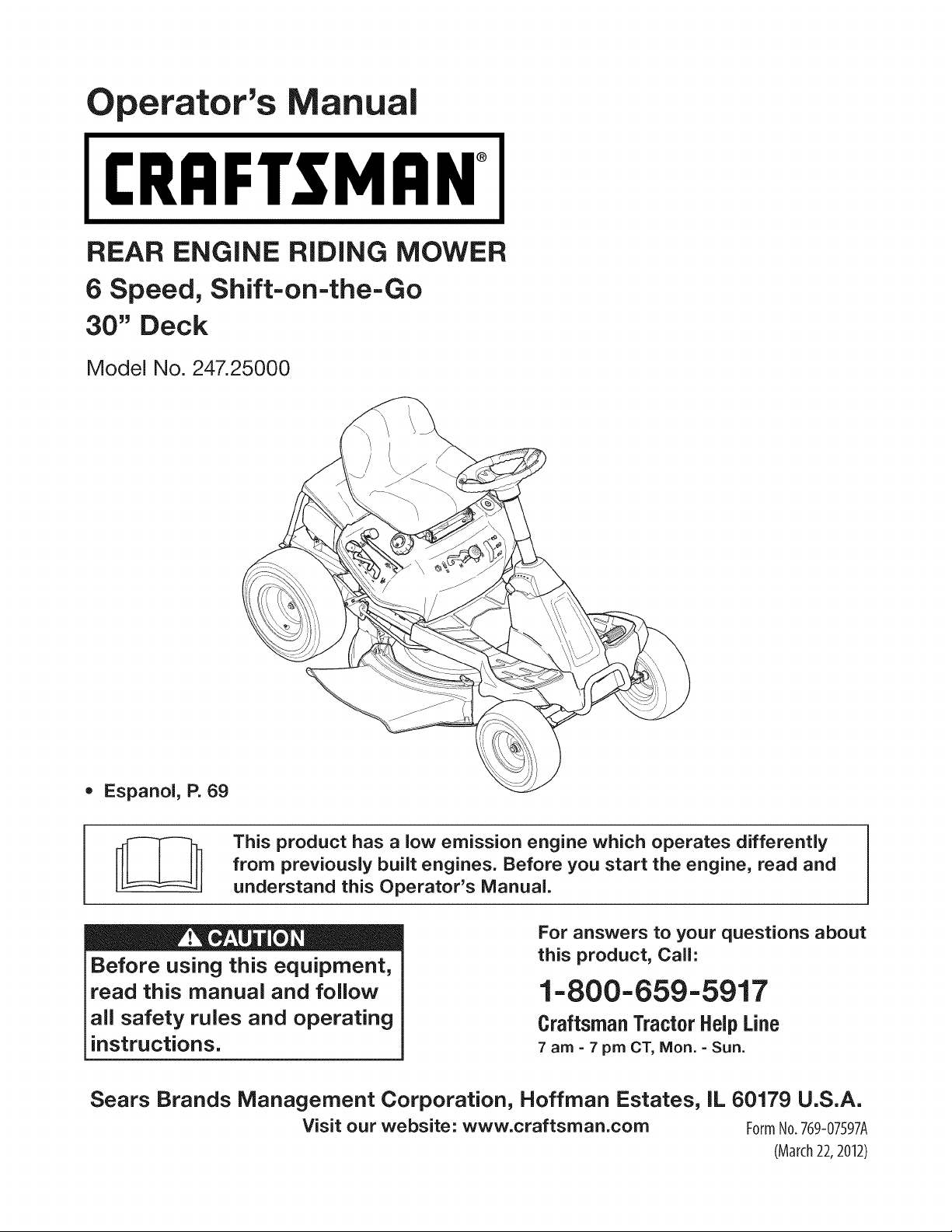

REAR ENGINE RiDiNG MOWER

6 Speed, Shift-on=the=Go

30" Deck

Model No. 247.25000

• Espanol, P. 69

This product has a low emission engine which operates differently

from previously built engines. Before you start the engine, read and

understand this Operator's Manual.

For answers to your questions about

Before using this equipment,

read this manual and follow

all safety rules and operating

instructions.

Sears Brands Management Corporation, Hoffman Estates, IL 60179 U.S.A.

Visit our website: www.craftsman.com FormNo.769-07597A

this product, Call:

1-800=659=5917

CraftsmanTractorHelpLine

7 am =7 pm CT, Mort. =Sun.

(March22,2012)

Warranty Statement .......................................................... 2

Safety Instructions ............................................................ 3

Slope Gauge ..................................................................... 9

Assembly ......................................................................... 10

Operation ........................................................................ 15

Service and Maintenance .............................................. 21

Off-Season Storage ........................................................ 32

Trou bleshooting .............................................................. 33

Labels ............................................................................. 34

Parts List ......................................................................... 35

Espa_ol ............................................................................ 69

Service Numbers ............................................. Back Cover

CRAFTSMAN FULL WARRANTY

FORTWOYEARSfromthedateofpurchase,all non-expendablepartsof thisridingequipmentarewarrantedagainstanydefectsinmaterial

or workmanship.A defectivenon-expendablepartwill receivefreein-homerepairor replacementif repairisimpossible.

FORFIVEYEARSfromthedateof purchase,the frameandfrontaxleof thisridingequipmentarewarrantedagainstanydefectsinmaterialor

workmanship.A defectiveframeorfrontaxle willreceivefreein-homerepairor replacementif repairisimpossible.

FOR90 DAYSfromthedateofpurchase,thebattery(anexpendablepart)of this ridingequipmentiswarrantedagainstanydefectsin material

or workmanship(ourtestingprovesthatit willnotholda charge).A defectivebatterywillreceivefreein-homereplacement.

ADDITIONALLIFETIMELIMITEDWARRANTYon CASTIRON FRONTAXLE(if equipped)

FORAS LONGASITISUSEDby theoriginalownerafterthefifthyearfromthedateof purchase,the castironfrontaxle (ffequipped)of

this ridingequipmentiswarrantedagainstanydefectsinmaterialorworkmanship.With proofof purchase,a defectivecastironfrontaxle will

receivefree in-homereplacement.

WARRANTYSERVICE

Forwarrantycoveragedetailsto obtainfreerepairor replacement,call 1-800-659-5917or visitthewebsite:www.craftsman.corn

Inallcasesabove,ifpartrepairor replacementisimpossible,theridingequipmentwillbereplacedfreeofchargewiththesameoranequivalentmodel.

All oftheabovewarrantycoverageis voidifthis ridingequipmentisever usedwhileprovidingcommercialservicesorifrentedtoanother

person.

This warrantycovers ONLYdefects inmaterial andworkmanship. Warrantycoverage does NOTinclude:

• Expendableparts(exceptbattery)thatcan wearoutfromnormalusewithinthe warrantyperiod,includingbutnotlimitedtoblades,

sparkplugs,air cleaners,belts,andoilfilters.

• Standardmaintenanceservicing,oilchanges,ortune-ups.

• Tirereplacementor repaircausedbypuncturesfromoutsideobjects,suchasnails,thorns,stumps,orglass.

• Tireorwheel replacementor repairresultingfromnormalwear,accident,or improperoperationormaintenance.

• Repairsnecessarybecauseofoperatorabuse,includingbutnotlimitedto damagecausedbytowingobjectsbeyondthecapabilityof

the ridingequipment,impactingobjectsthatbendtheframe,axleassemblyorcrankshaft,orover-speedingtheengine.

• Repairsnecessarybecauseofoperatornegligence,includingbutnotlimitedto,electricalandmechanicaldamagecausedby

improperstorage,failuretousethepropergradeandamountofengineoil, failureto keepthedeckclearof flammabledebris,or

failureto maintainthe ridingequipmentaccordingto the instructionscontainedintheoperator'smanual.

• Engine(fuelsystem)cleaningorrepairscausedbyfueldeterminedto becontaminatedoroxidized(stale).Ingeneral,fuelshouldbe

usedwithin30 daysofits purchasedate.

• Normaldeteriorationand wearofthe exteriorfinishes,or productlabelreplacement.

Thiswarrantygivesyou specificlegalrights,andyoumayalsohaveotherrightswhichvaryfromstatetostate.

Sears BrandsManagementCorporation, Hoffman Estates, IL60179

EngineOil: SAE30

Fuel: UnleadedGasoline

SparkPlug: F6RTC(951-10292)

© KCDIRLLC

Model Number:

Serial Number:

Dateof Purchase:

Recordthe modelnumber,serialnumber,

anddateof purchaseabove.

2

Thissymbolpointsout importantsafetyinstructionswhich,if not

followed,couldendangerthepersonalsafetyand/orpropertyof

yourselfandothers. Readandfollowallinstructionsin thismanual

beforeattemptingtooperatethismachine.Failureto complywith

theseinstructionsmayresultin personalinjury.Whenyouseethis

symbol,HEEDITSWARNING!

Thismachinewasbuiltto beoperatedaccordingtothesafeopera-

tionpracticesinthis manual.Aswithanytypeof powerequipment,

carelessnessorerroron the partoftheoperatorcanresultin serious

injury.Thismachineiscapableofamputatingfingers,hands,toes

andfeetandthrowingdebris.Failuretoobservethefollowingsafety

instructionscouldresultin seriousinjuryordeath.

CALIFORNIA PROPOSITION 65

EngineExhaust,someof itsconstituents,andcertainvehicle

componentscontainoremitchemicalsknownto StateofCalifornia

tocausecancerandbirthdefectsorotherreproductiveharm.

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

GENERAL OPERATION

• Read,understand,andfollowall instructionsonthemachineand

in themanual(s)beforeattemptingto assembleandoperate.

Keepthis manualinasafeplaceforfutureand regularreference

andfororderingreplacementparts.

• Befamiliarwithall controlsandtheirproperoperation.Knowhow

tostopthe machineanddisengagethemquickly.

• Neverallowchildrenunder14yearsoldtooperatethis machine.

Children14yearsoldandover shouldreadandunderstandthe

operationinstructionsandsafetyrulesinthismanualandshould

betrainedandsupervisedbya parent.

• Neverallowadultstooperatethismachinewithoutproper

instruction.

• Tohelpavoidbladecontactor a thrownobjectinjury,keep

bystanders,helpers,childrenandpetsatleast75feetfromthe

machinewhile itisin operation.Stopmachineifanyoneenters

thearea.

• Thoroughlyinspecttheareawheretheequipmentis to be used.

Removeallstones,sticks,wire,bones,toys,andotherforeign

objectswhichcouldbe pickedupandthrownbytheblade(s).

Thrownobjectscancauseseriouspersonalinjury.

• Planyourmowingpatternto avoiddischargeofmaterialtoward

roads,sidewalks,bystandersandthe like.Also,avoiddischarg-

ingmaterialagainstawallorobstructionwhichmaycause

dischargedmaterialto ricochetbacktowardthe operator.

Your Responsibility--Restrict theuseof thispowermachineto

personswhoread,understandandfollowthewarningsand instruc-

tionsin thismanualandonthemachine.

SAVE THESE INSTRUCTIONS!

• Alwayswearsafetyglassesorsafetygogglesduringoperation

andwhileperformingan adjustmentorrepairto protectyoureyes.

Thrownobjectswhichricochetcancauseseriousinjurytothe

eyes.

• Wearsturdy,rough-soledworkshoesandclose-fittingslacksand

shirts.Loosefittingclothesandjewelrycanbe caughtin movable

parts.Neveroperatethismachineinbarefeetorsandals.

• Beawareofthemowerandattachmentdischargedirectionand

do notpointit at anyone.Donotoperatethemowerwithoutthe

dischargecoverorentiregrasscatcherinits properplace.

Donot puthandsorfeetnearrotatingpartsor underthecutting

deck.Contactwiththe blade(s)canamputatehandsandfeet.

A missingordamageddischargecovercancausebladecontact

or thrownobjectinjuries.

• Stoptheblade(s)whencrossinggraveldrives,walks,orroads

andwhilenotcuttinggrass.

• Watchfortrafficwhenoperatingnearorcrossingroadways.This

machineis notintendedforuseonanypublicroadway.

• Donotoperatethemachinewhileunderthe influenceofalcohol

or drugs.

• Mowonlyindaylightorgoodartificiallight.

Nevercarrypassengers.

• Disengageblade(s)beforeshiftingintoreverse.Backup slowly.

Alwayslookdownandbehindbeforeandwhilebackingto avoida

back-overaccident.

3

• Slowdownbeforeturning.Operatethemachinesmoothly.Avoid

erraticoperationandexcessivespeed.

Disengageblade(s),setparkingbrake,stopengineandwaituntil

theblade(s)cometoa completestopbeforeremovinggrass

catcher,emptyinggrass,uncloggingchute,removinganygrassor

debris,or makinganyadjustments.

Neverleavea runningmachineunattended.Alwaysturnoff

blade(s),setparkingbrake,stopengineandremovekeybefore

dismounting.

Useextracarewhenloadingorunloadingthe machineintoa

trailerortruck.Thismachineshouldnotbedrivenupor down

ramp(s),becausethemachinecouldtip over,causingserious

personalinjury.Themachinemustbe pushedmanuallyon

ramp(s)to loadorunloadproperly.

Mufflerandenginebecomehotandcancausea burn.Donot

touch.

Checkoverheadclearancescarefullybeforedrivingunderlow

hangingtree branches,wires,dooropeningsetc.,wherethe

operatormaybestruckor pulledfromthe machine,whichcould

resultinseriousinjury.

Disengageallattachmentclutchesanddepressthe brakepedal

completelybeforeattemptingto startengine.

Yourmachineisdesignedto cutnormalresidentialgrassofa

heightnomorethan10".Donotattemptto mowthroughunusually

tall,drygrass(e.g.,pasture)orpilesof dry leaves.Drygrassor

leavesmaycontacttheengineexhaustand/orbuilduponthe

mowerdeckpresentinga potentialfire hazard.

Useonlyaccessoriesandattachmentsapprovedforthis machine

bythe machinemanufacturer.Read,understandandfollowall

instructionsprovidedwiththe approvedaccessoryorattachment.

Fora listof approvedaccessoriesandattachments,call 1-800-

659-5917.

Dataindicatesthatoperators,age60yearsandabove,are

involvedin alargepercentageofridingmower-relatedinjuries.

Theseoperatorsshouldevaluatetheirabilitytooperatetheriding

mowersafelyenoughto protectthemselvesandothersfrom

seriousinjury.

If situationsoccurwhicharenotcoveredinthismanual,usecare

andgoodjudgment.

SLOPE OPERATION

Slopesarea majorfactorrelatedtolossof controlandtip-over

accidentswhichcanresultinsevereinjuryor death.Allslopesrequire

extracaution.Ifyoucannotbackuptheslopeor if youfeeluneasyon

it, do notmowit.

Foryoursafety,usetheSlopeGuideincludedaspartofthis manual

to measureslopesbeforeoperatingthis machineona slopedor hilly

area.Ifthe slopeisgreaterthan12degreesasshownonthe Slope

Guide,do notoperatethismachineonthatareaor seriousinjurycould

result.

Do:

o

Mowupanddownslopes,notacross.Exerciseextremecaution

whenchangingdirectionon slopes.

• Watchforholes,ruts,bumps,rocks,orotherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

Useslowspeed.Choosea lowenoughspeedsettingsothat

youwill nothavetostopor shiftwhileon theslope.Tiresmay

losetractionon slopeseventhoughthe brakesarefunctioning

properly.Alwayskeepmachineingearwhen goingdownslopes

totakeadvantageofenginebrakingaction.

• Followthemanufacturer'srecommendationsforwheelweightsor

counterweightsto improvestability.

Useextracarewithgrasscatchersorotherattachments.These

canchangethestabilityof the machine.

Keepallmovementonthe slopesslowandgradual.Donot make

suddenchangesinspeedor direction.Rapidengagementor

brakingcouldcausethefrontof themachinetolift andrapidlyflip

overbackwardswhichcouldcauseseriousinjury.

• Avoidstartingorstoppingona slope.Iftireslosetraction,disen-

gagetheblade(s)andproceedslowlystraightdowntheslope.

DoNot:

• Donotturnonslopesunlessnecessary;then,turnslowlyand

graduallydownhill,ifpossible.

• Donotmowneardrop-offs,ditchesorembankments.Themower

couldsuddenlyturnoverif a wheelisovertheedgeofa cliff,

ditch,or ifan edgecavesin.

• Donottry to stabilizethemachinebyputtingyourfooton the

ground.

• Donotuseagrasscatcheronsteepslopes.

• Donotmowon wetgrass.Reducedtractioncouldcausesliding.

• Donotattempttocoastdownhill.Over-speedingmaycausethe

operatortolosecontrolof themachineresultingin seriousinjury

or death.

• Donottowheavypull behindattachments(e.g.loadeddumpcart,

lawnroller,etc.)on slopesgreaterthan5 degrees.Whengoing

downhill,theextraweighttendsto pushthetractorandmay

causeyouto loosecontrol(e.g.tractormayspeedup,brakingand

steeringabilityarereduced,attachmentmayjack-knifeandcause

tractorto overturn).

4

CHILDREN

Tragicaccidentscanoccurifthe operatorisnotalertto thepresence

ofchildren.Childrenareoftenattractedto themachineandthemowing

activity.Theydo notunderstandthe dangers.Neverassumethat

childrenwillremainwhereyoulastsawthem.

• Keepchildrenoutofthemowingareaand inwatchfulcareof a

responsibleadultotherthantheoperator.

• Bealertandturnmachineoff ifa childentersthearea.

• Beforeandwhilebacking,lookbehindanddownforsmall

children.

Nevercarrychildren,evenwiththeblade(s)shutoff.Theymay

falloffandbe seriouslyinjuredorinterferewithsafemachine

operation.

• Useextremecarewhenapproachingblindcorners,doorways,

shrubs,treesorotherobjectsthatmayblockyourvisionofa child

whomayrunintothe machine.

Toavoidback-overaccidents,alwaysdisengagethe cutting

blade(s)beforeshiftingintoReverse.Ifequipped,the"Reverse

CautionMode"(bladesoperatewhilemachineridesinreverse)

shouldnotbe usedwhenchildrenorothersarearound.

Keepchildrenawayfromhotor runningengines.Theycansuffer

burnsfroma hotmuffler.

• Removekeywhenmachineisunattendedtopreventunauthorized

operation.

Neverallowchildrenunder14yearsofageto operatethismachine.

Children14andovershouldreadandunderstandtheinstructionsand

safeoperationpracticesinthismanualandon themachineandshould

betrainedandsupervisedbyan adult.

TOWING

Towonlywitha machinethathasa hitchdesignedfortowing.Do

notattachtowedequipmentexceptatthehitchpoint.

Followthemanufacturersrecommendationforweightlimitsfor

towedequipmentandtowingonslopes.

Neverallowchildrenor othersinoron towedequipment.

Onslopes,theweightof thetowedequipmentmaycauselossof

tractionandlossof control.

Alwaysuseextracautionwhentowingwitha machinecapableof

makingtightturns(e.g."zero-turn"ride-onmower). Makewide

turnstoavoidjack-knifing.

Travelslowlyandallowextradistancetostop.

Donotcoastdownhill.

SERVICE

SafeHandlingof Gasoline

Toavoidpersonalinjuryorpropertydamageuseextremecarein

handlinggasoline.Gasolineisextremelyflammableandthevaporsare

explosive.Seriouspersonalinjurycanoccurwhengasolineisspilled

on yourselforyourclotheswhichcanignite.Washyourskinand

changeclothesimmediately.

• Useonlyanapprovedgasolinecontainer.

Neverfill containersinsidea vehicleoron atruckortrailerbed

witha plasticliner.Alwaysplacecontainerson thegroundaway

fromyourvehiclebeforefilling.

Whenpractical,removegas-poweredequipmentfromthe truck

or trailerandrefuelitontheground.Ifthis isnotpossible,then

refuelsuchequipmentona trailerwitha portablecontainer,rather

thanfroma gasolinedispensernozzle.

Keepthenozzleincontactwiththe rimofthefueltankor

containeropeningat all timesuntilfuelingiscomplete.Donotuse

a nozzlelock-opendevice.

Extinguishall cigarettes,cigars,pipesandothersourcesof

ignition.

• Neverfuelmachineindoors.

Neverremovegascapor addfuelwhilethe engineis hotorrun-

ning.Allowengineto coolatleasttwominutesbeforerefueling.

Neveroverfillfuel tank. Filltanktono morethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Replacegasolinecapandtightensecurely.

• Ifgasolineisspilled,wipeitoff the engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

• Toreducefirehazards,keepmachinefree of grass,leaves,or

otherdebrisbuild-up.Cleanup oilor fuelspillageandremoveany

fuelsoakeddebris.

• Neverstorethemachineor fuelcontainerinsidewherethereisan

openflame,sparkor pilotlight as ona waterheater,spaceheater,

furnace,clothesdryeror othergasappliances.

Allowa machineto coolat leastfiveminutesbeforestoring.

GeneralService

• Neverrunanengineindoorsor ina poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,anodorless,anddeadlygas.

• Beforecleaning,repairing,orinspecting,makecertaintheblade(s)

andall movingpartshavestopped.Disconnectthesparkplugwire

andgroundagainsttheenginetopreventunintendedstarting.

• Periodicallycheckto makesurethebladescometocomplete

stopwithinapproximately(5)five secondsafteroperatingthe

bladedisengagementcontrol.Ifthebladesdonotstopwithinthe

thistimeframe,yourmachineshouldbeservicedprofessionally

bya Searsorotherqualifiedservicedealer.

• Checkbrakeoperationfrequentlyas it is subjectedto wearduring

normaloperation.Adjustand serviceas required.

• Checkthe blade(s)andenginemountingboltsat frequent

intervalsforpropertightness.Also,visuallyinspectblade(s)

fordamage(e.g.,excessivewear,bent,cracked).Replacethe

blade(s)withtheoriginalequipmentmanufacturer's(O.E.M.)

blade(s)only,listedinthismanual.Useof partswhichdo not

meettheoriginalequipmentspecificationsmayleadto improper

performanceandcompromisesafety!

• Mowerbladesaresharp.Wrapthebladeorweargloves,anduse

extracautionwhenservicingthem.

• Keepall nuts,bolts,andscrewstightto besuretheequipmentis

insafeworkingcondition.

• Nevertamperwiththesafetyinterlocksystemor othersafety

devices.Checktheirproperoperationregularly.

• Afterstrikingaforeignobject,stoptheengine,disconnectthe

sparkplugwire(s)andgroundagainsttheengine.Thoroughly

inspectthemachineforanydamage.Repairthedamagebefore

startingandoperating.

• Neverattempttomakeadjustmentsor repairstothe machine

whilethe engineis running.

• Grasscatchercomponentsandthedischargecoveraresubject

towearanddamagewhichcouldexposemovingpartsor allow

objectsto bethrown.Forsafetyprotection,frequentlycheck

componentsand replaceimmediatelywithoriginalequipment

manufacturer's(O.E.M.)partsonly,listedinthis manual.Useof

partswhichdo notmeettheoriginalequipmentspecificationsmay

leadtoimproperperformanceandcompromisesafety!

• Donotchangetheenginegovernorsettingsor over-speedthe

engine.Thegovernorcontrolsthe maximumsafeoperatingspeed

ofthe engine.

• Maintainor replacesafetyandinstructionlabels,as necessary.

• Observeproperdisposallawsandregulationsforgas,oil, etc.to

protecttheenvironment.

• Accordingtothe ConsumerProductsSafetyCommission(CPSC)

andtheU.S.EnvironmentalProtectionAgency(EPA),thisproduct

hasan AverageUsefulLifeof seven(7)years,or270hours

ofoperation.Attheendof theAverageUsefulLife,buya new

machineor havethemachineinspectedannuallybya Searsor

otherqualifiedservicedealerto ensurethatallmechanicaland

safetysystemsare workingproperlyand notwornexcessively.

Failuretodo socanresultinaccidents,injuriesordeath.

DO NOT MODIFY ENGINE

Toavoid seriousinjuryor death,do notmodifyengineinanyway.

Tamperingwiththegovernorsettingcanleadto a runawayengineand

causeitto operateat unsafespeeds.Nevertamperwithfactorysetting

ofenginegovernor.

NOTICE REGARDING EMISSIONS

Engineswhicharecertifiedto complywithCaliforniaandfederal

EPAemissionregulationsforSORE(SmallOffRoadEquipment)are

certifiedto operateonregularunleadedgasoline,andmayinclude

thefollowingemissioncontrolsystems:EngineModification(EM)and

ThreeWayCatalyst(TWO)if soequipped.

SPARK ARRESTOR

Ifa sparkarrestoris used,it shouldbemaintainedin effectiveworking

orderbythe operator.IntheStateof Californiatheaboveis required

bylaw (Section4442of the CaliforniaPublicResourcesCode).Other

statesmayhavesimilarlaws.Federallawsapplyonfederallands.

A sparkarrestorforthemufflerisavailablethroughyournearestSears

PartsandRepairServiceCenter.

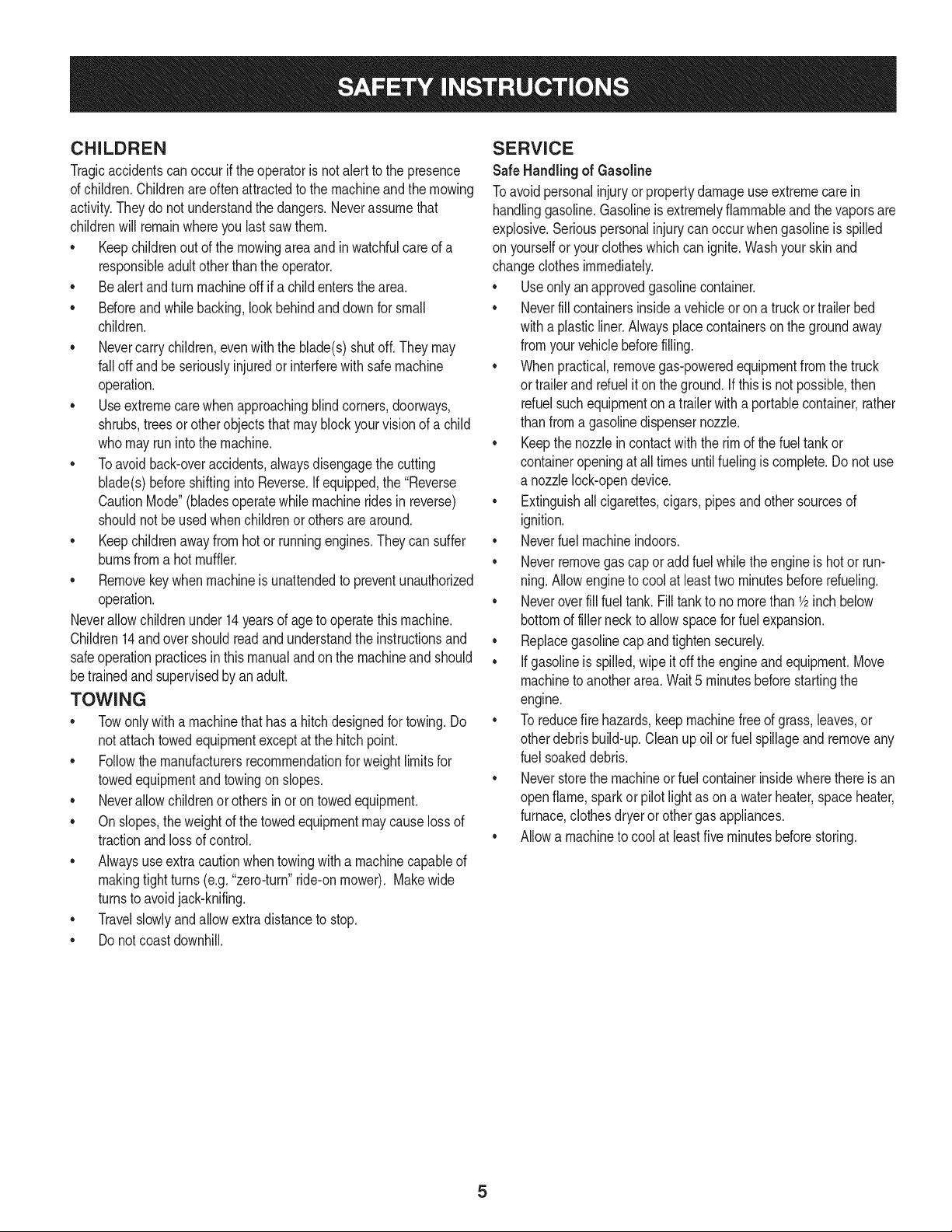

SAFETY SYMBOLS

Thispagedepictsanddescribessafetysymbolsthat mayappear

on thisproduct. Read,understand,andfollowall instructionson the

machinebeforeattemptingtoassembleandoperate.

Thismachineisequippedwithan internalcombustionengineand

shouldnot beusedonornearanyunimprovedforest-covered,

brushcoveredor grass-coveredlandunlesstheengine'sexhaust

systemisequippedwitha sparkarrestormeetingapplicablelocalor

statelaws(if any).

6

...._ •

s j/

READ THE OPERATOR'S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to assemble and

operate

DANGER-- ROTATING BLADES

Never carry passengers. Never carry children, even with the blades off.

DANGER-- ROTATING BLADES

To avoid a back-over accident, keep children away from the machine while it is in operation.

WARNING-- ROTATING BLADES

Do not put hands or feet near rotating parts or under the cutting deck. Contact with the blade(s)

can amputate hands and feet.

DANGER-- ROTATING BLADES

Always look down and behind before and while backing to avoid a back-over accident.

WARNING--THROWN OBJECTS

jZ

This machine may pick up and throw and objects which can cause serious personal injury.

WARNING--THROWN OBJECTS

This machine may pick up and throw and objects which can cause serious personal injury.

®

BYSTANDERS

Keep bystanders, helpers, children and pets at least 75 feet from the machine while it is in

operation.

WARNING-- SLOPE OPERATION

Do not operate this machine on a slope greater than 12 degrees.

WARNING-- HOT SURFACE

Engine parts, especially the muffler, become extremely hot during operation. Allow engine and

muffler to cool before touching.

DANGER-- ROTATING BLADES

To reduce the risk of injury, keep hands and feet away. Do not operate unless discharge cover or grass

catcher is in its proper place. If damaged, replace immediately.

7

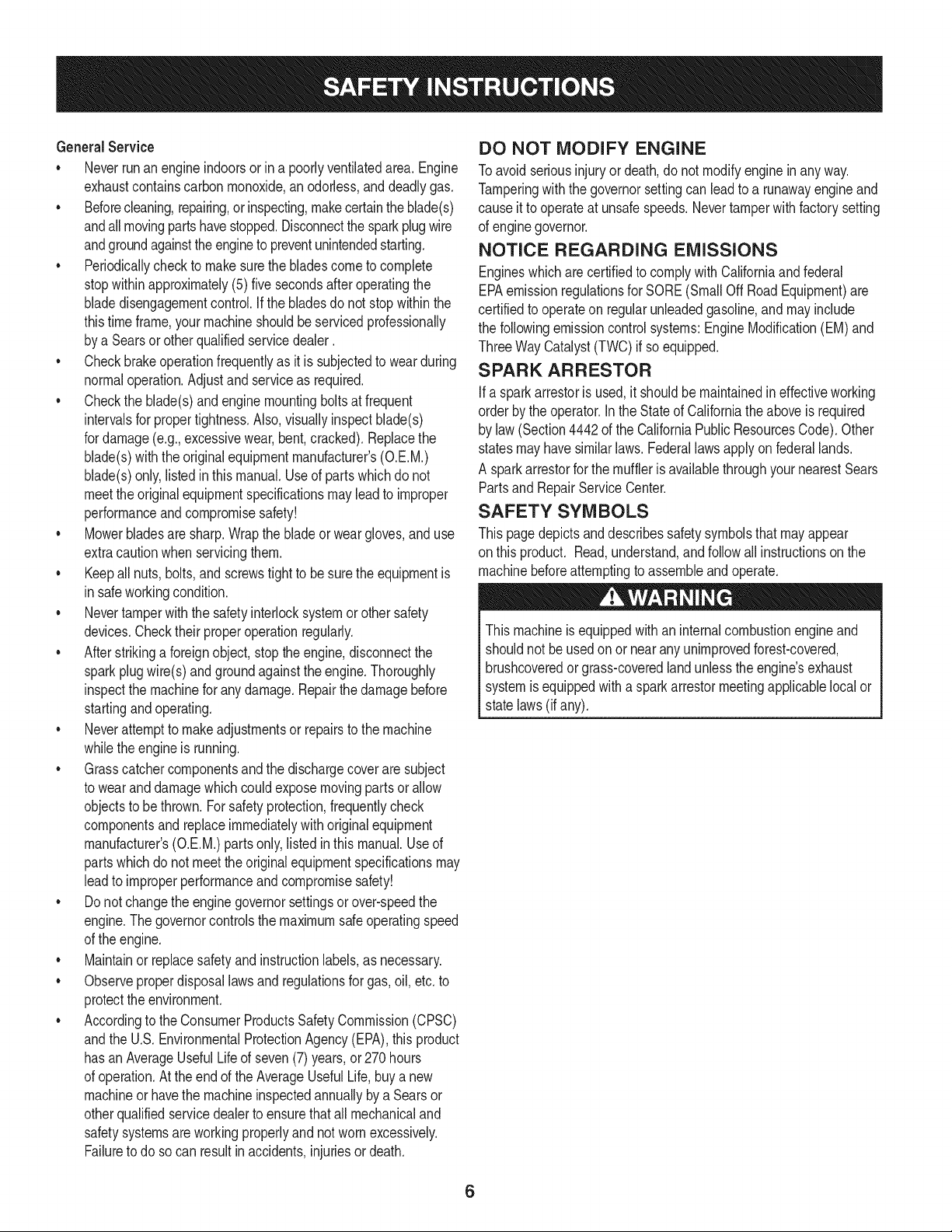

WARNING-- CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

DANGER-- ROTATING BLADES

Do not step on the cutting deck.

8

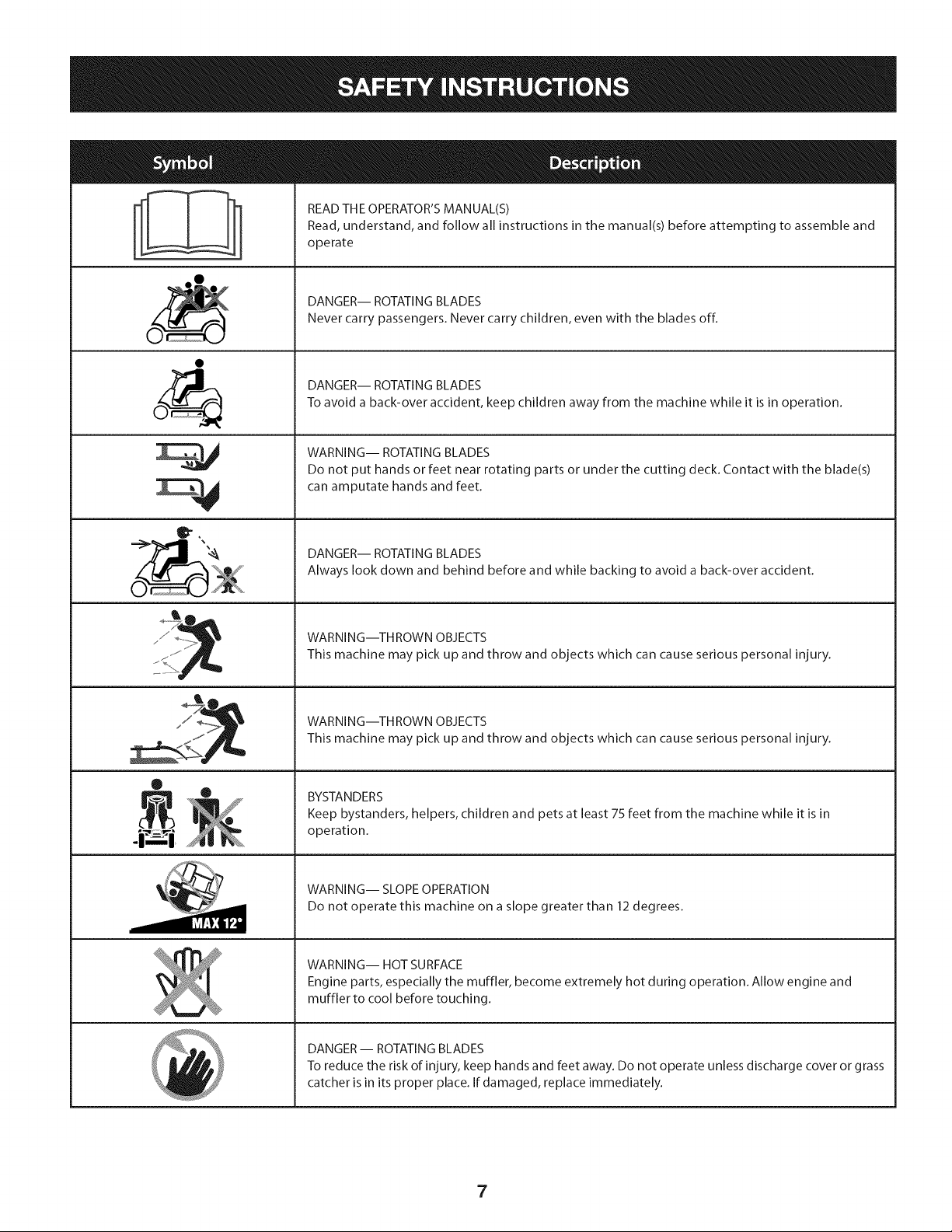

iiiii!i!i!i!i!i!i!i! ! ! ! !iiiiii!ii!!i

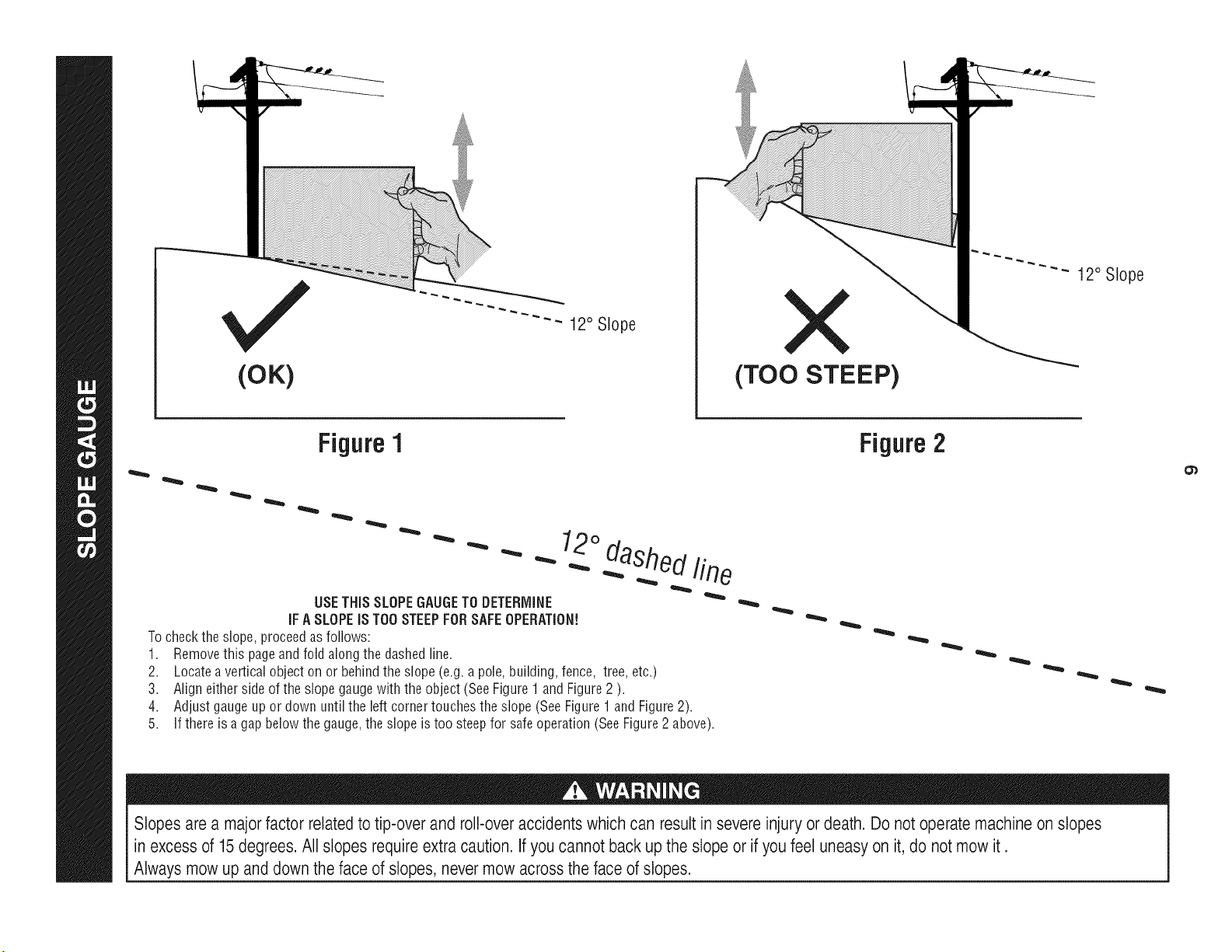

X

12° Slope

(OK)

Figure1

USETHiSSLOPEGAUGETODETERMINE

iFASLOPEiSTOOSTEEPFORSAFEOPERATION!

Tochecktheslope,proceedasfollows:

1. Removethis pageandfoldalongthedashedline.

2. Locateaverticalobjectonor behindtheslope(e.g.a pole,building,fence,tree,etc.)

3. Aligneithersideof theslopegaugewiththeobject(SeeFigure1andFigure2 ).

4. Adjustgaugeupor downuntilthe leftcornertouchestheslope(SeeFigure1andFigure2).

5.

If thereisa gapbelowthegauge,theslopeis toosteepfor safeoperation(SeeFigure2 above).

Slopes area majorfactor relatedtotip-over and roll-over accidentswhich can resultin severe injury or death. Do not operate machineon slopes

in excess of 15degrees.All slopes requireextra caution. If youcannot back up the slope or if you feel uneasy on it,do not mow it.

Always mowupand down the face of slopes, nevermow acrossthe face of slopes.

(TO0 STEEP)

Figure2

Contentsof Crate

• OneRidingMower

OneSteeringWheel/ShaftAssembly

OneRearHitchPlate

OneRidingMowerOperator'sManual

OneSeatAssembly

OneRearEngineCover

OneOilDrainSleeve

OneEngineOperator'sManual

CONTENTS OF HARDWARE PACK

Beforebeginninginstallation,removeallthe contentsfromthecrate

andallthehardwarefromthepackfromto makesureeverything

ispresent.Hardwareis listedbelow.Partnumbersare shownin

parentheses.

• Two5/16-18x 3/4"Screws-- HitchPlate(710-3008)

• Two5/16-18LockNuts-- HitchPlate(712-04063)

• Two1/4-15x 1"Screws-- EngineRearCover(710-1241)

• TwoShoulderBolts-- SeatPivotBracket(738-0140)

• Two5/16-18LockNuts-- SeatPivotBracket(712-04063)

• One1/4-20x 3/4" Screw-- SteeringPedestal(710-0924)

• One3/16HexKey-- SteeringShaft(710-05046)

RECOMMENDED TOOLS FOR ASSEMBLY

• 3/16"HexKey(includedinhardwarepack)

• 1/4"DriveRatchet

• 3/16"Wrench(oradjustablewrench)

• 3/8"Wrench(oradjustablewrench)

• 1/2"Wrench(oradjustablewrench)

• 5/8"Wrench(oradjustablewrench)

• 3/8"Socketwrench

• 1/2" Socketwrench

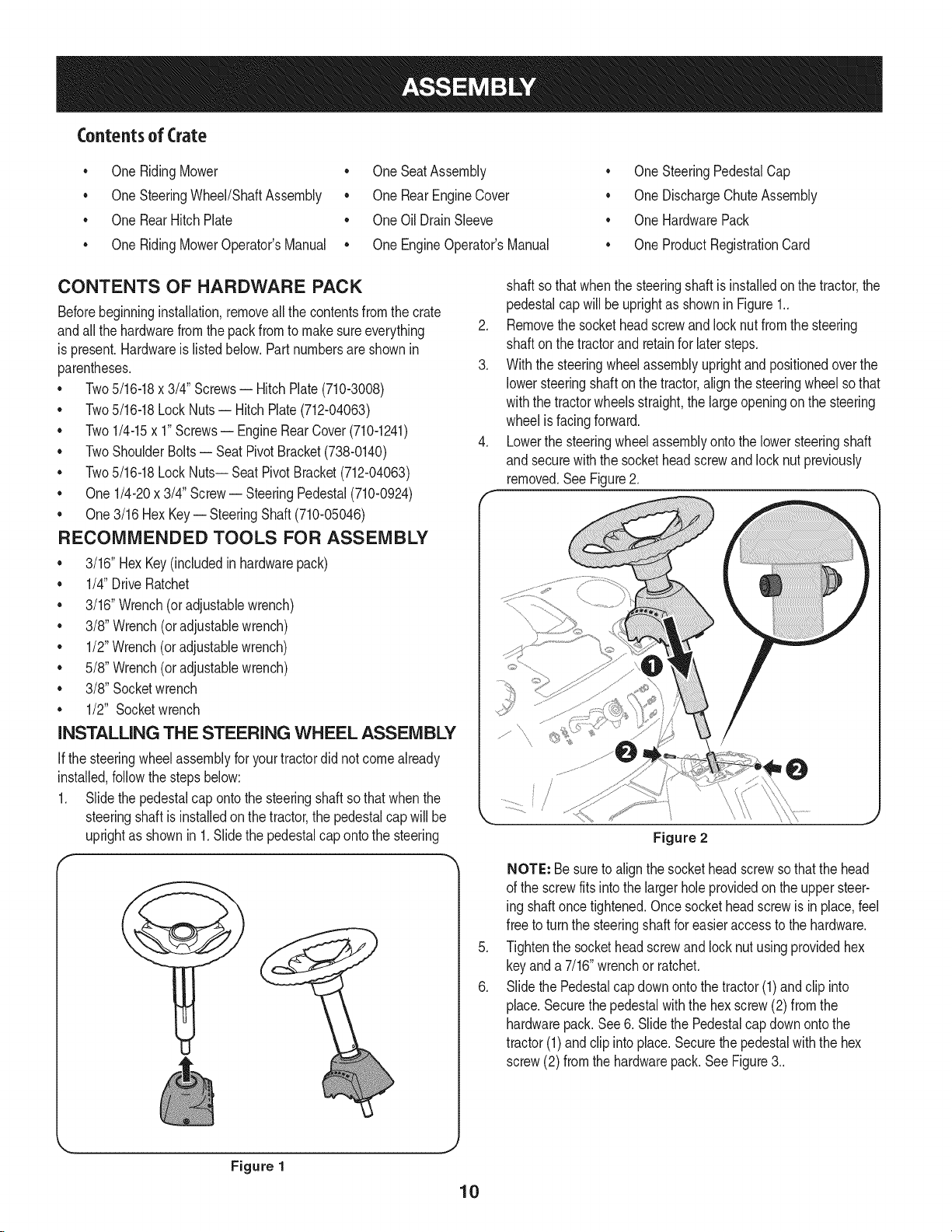

INSTALLING THE STEERING WHEEL ASSEMBLY

If thesteeringwheelassemblyforyourtractordidnotcomealready

installed,followthestepsbelow:

1. Slidethepedestalcapontothe steeringshaftsothatwhenthe

steeringshaftis installedonthetractor,the pedestalcap willbe

uprightas shownin 1.Slidethe pedestalcapontothesteering

OneSteeringPedestalCap

OneDischargeChuteAssembly

• OneHardwarePack

• OneProductRegistrationCard

shaftso thatwhenthesteeringshaft isinstalledon thetractor,the

pedestalcapwill beuprightas shownin Figure1..

2. Removethesocketheadscrewandlocknut fromthe steering

shaftonthe tractorandretainfor latersteps.

3. Withthesteeringwheelassemblyuprightandpositionedoverthe

lowersteeringshaftonthetractor,alignthe steeringwheelsothat

withthetractorwheelsstraight,thelargeopeningonthe steering

wheelis facingforward.

4. Lowerthesteeringwheelassemblyontothe lowersteeringshaft

and securewiththesocketheadscrewandlocknut previously

removed.SeeFigure2.

Figure 2

Figure 1

NOTE: Besureto alignthe socketheadscrewsothatthehead

ofthe screwfitsintothelargerholeprovidedon theuppersteer-

ing shaftoncetightened.Oncesocketheadscrewis in place,feel

freeto turnthesteeringshaftforeasieraccesstothe hardware.

.

Tightenthesocketheadscrewand locknutusingprovidedhex

keyanda 7/16"wrenchor ratchet.

6.

SlidethePedestalcapdownontothetractor(1)andclip into

place.Securethepedestalwiththehex screw(2)fromthe

hardwarepack.See6.Slidethe Pedestalcapdownontothe

tractor(1)andclip intoplace.Securethepedestalwiththe hex

screw(2) fromthehardwarepack.SeeFigure3..

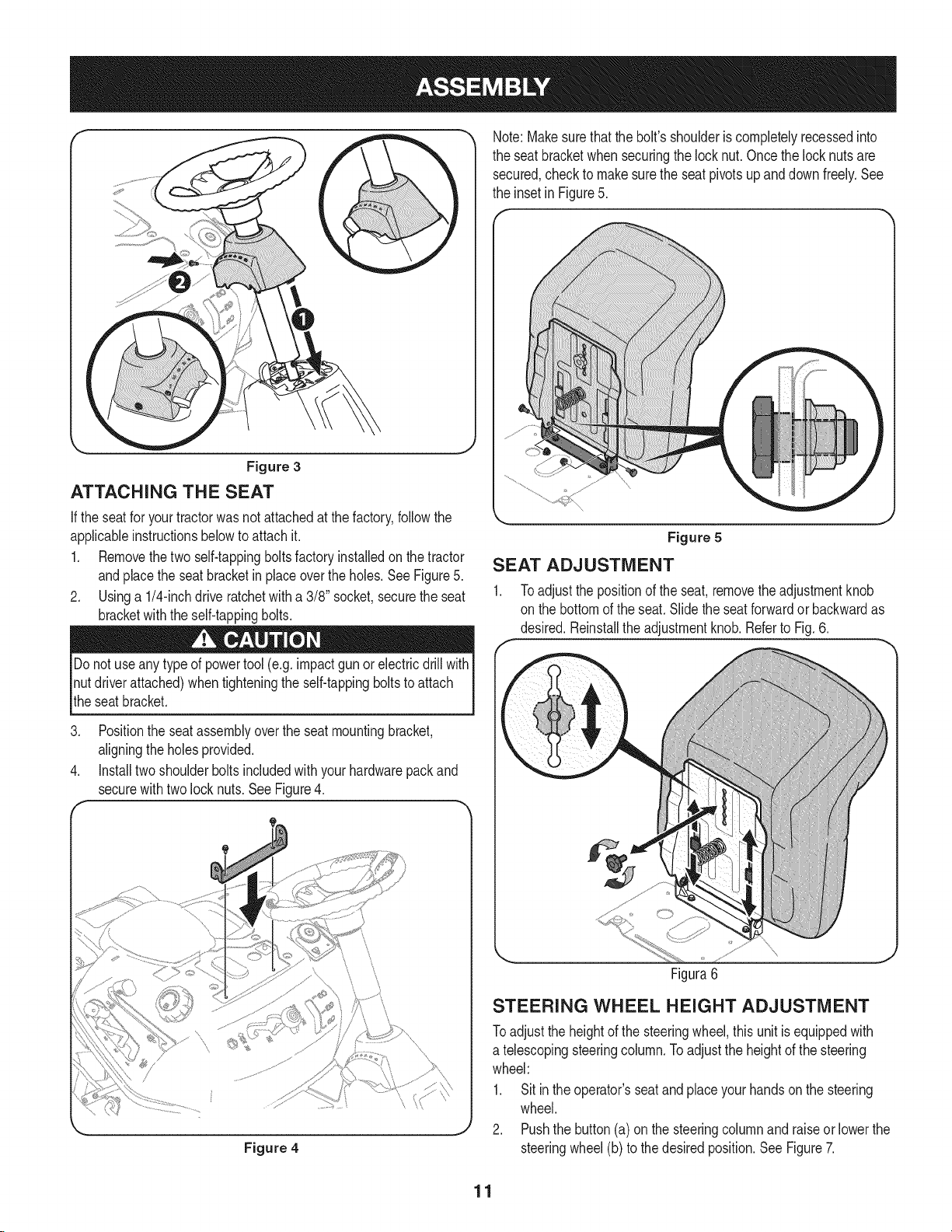

Figure 3

ATTACHING THE SEAT

If theseatforyourtractorwasnotattachedatthefactory,followthe

applicableinstructionsbelowtoattachit.

1. Removethetwo self-tappingboltsfactoryinstalledon the tractor

andplacethe seatbracketinplaceovertheholes.SeeFigure5.

2. Usinga 1/4-inchdrive ratchetwitha 3/8"socket,securetheseat

bracketwiththe self-tappingbolts.

Note:Makesurethatthebolt'sshoulderiscompletelyrecessedinto

theseatbracketwhensecuringthe locknut.Oncethelocknutsare

secured,checkto makesurethe seatpivotsupanddownfreely.See

theinsetin Figure5.

Figure 5

SEAT ADJUSTMENT

1. Toadjustthepositionof theseat,removetheadjustmentknob

on thebottomoftheseat.Slidethe seatforwardor backwardas

desired.Reinstalltheadjustmentknob.Referto Fig.6.

Donotuseanytypeof powertool(e.g.impactgunorelectricdrillwith

nutdriverattached)whentighteningthe self-tappingboltsto attach

theseatbracket.

3. Positionthe seatassemblyovertheseatmountingbracket,

aligningtheholesprovided.

4. Installtwoshoulderboltsincludedwithyourhardwarepackand

securewithtwolocknuts.SeeFigure4.

\\

Figure 4

\

Figura6

STEERING WHEEL HEIGHT ADJUSTMENT

Toadjustthe heightofthe steeringwheel,thisunit isequippedwith

a telescopingsteeringcolumn.Toadjusttheheightofthesteering

wheel:

1. Sitinthe operator'sseatandplaceyourhandsonthe steering

wheel.

2. Pushthebutton(a)on thesteeringcolumnandraiseor lowerthe

steeringwheel(b)to thedesiredposition.SeeFigure7.

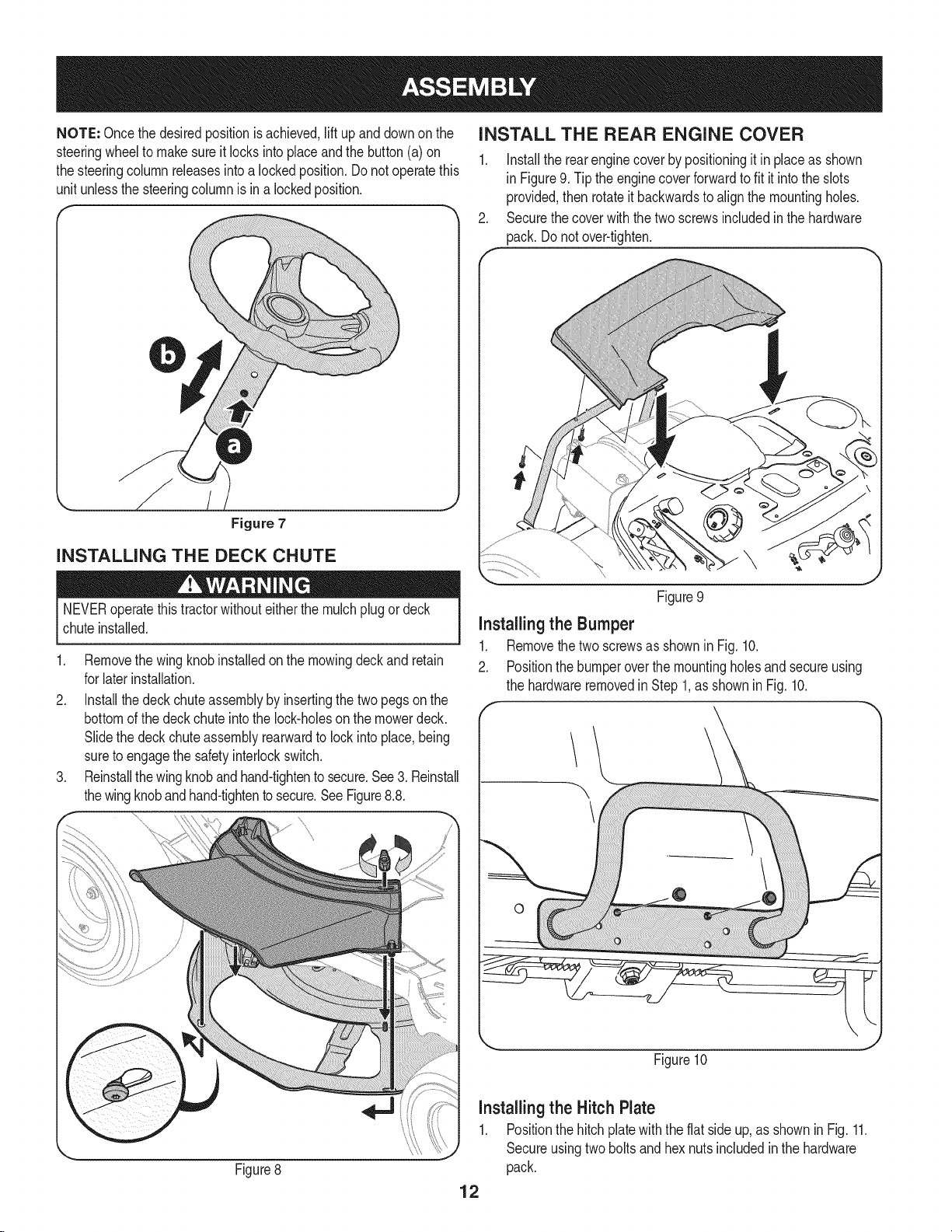

11

NOTE: Oncethe desiredpositionisachieved,lift upanddownonthe

steeringwheelto makesureit locksintoplaceandthebutton(a)on

thesteeringcolumnreleasesintoa lockedposition.Donotoperatethis

unitunlessthe steeringcolumnis ina lockedposition.

Figure 7

INSTALLING THE DECK CHUTE

INSTALL THE REAR ENGINE COVER

1. Installtherearenginecoverbypositioningit inplaceasshown

in Figure9.Tiptheenginecoverforwardtofit it intothe slots

provided,then rotateit backwardsto alignthemountingholes.

2. Securethecoverwiththetwo screwsincludedinthe hardware

pack.Donotover-tighten.

NEVERoperatethistractorwithouteitherthe mulchplugor deck

chuteinstalled.

1. Removethewing knobinstalledonthemowingdeckand retain

forlaterinstallation.

2. Installthedeckchuteassemblybyinsertingthetwo pegsonthe

bottomofthedeckchuteintothelock-holeson themowerdeck.

Slidethedeckchuteassemblyrearwardto lockinto place,being

sureto engagethesafetyinterlockswitch.

3. Reinstallthewingknobandhand-tightentosecure.See3.Reinstall

thewingknobandhand-tightento secure.SeeFigure8.8.

\

Figure9

Installingthe Bumper

1. Removethetwoscrewsasshownin Fig.10.

2. Positionthebumperoverthe mountingholesandsecureusing

thehardwareremovedin Step1,asshowninFig. 10.

Figure8

Figure10

installingthe Hitch Plate

1. Positionthe hitchplatewiththeflat sideup,asshownin Fig.11.

Secureusingtwoboltsandhexnutsincludedinthehardware

pack.

12

Figure11

CONNECTING THE BATTERY CABLES

CALiFORNiA PROPOSITION 65

Batteryposts,terminals,and relatedaccessoriescontainleadand

leadcompounds,chemicalsknowntotheStateof Californiato

causecancerandreproductiveharm.Washhandsafterhandling.

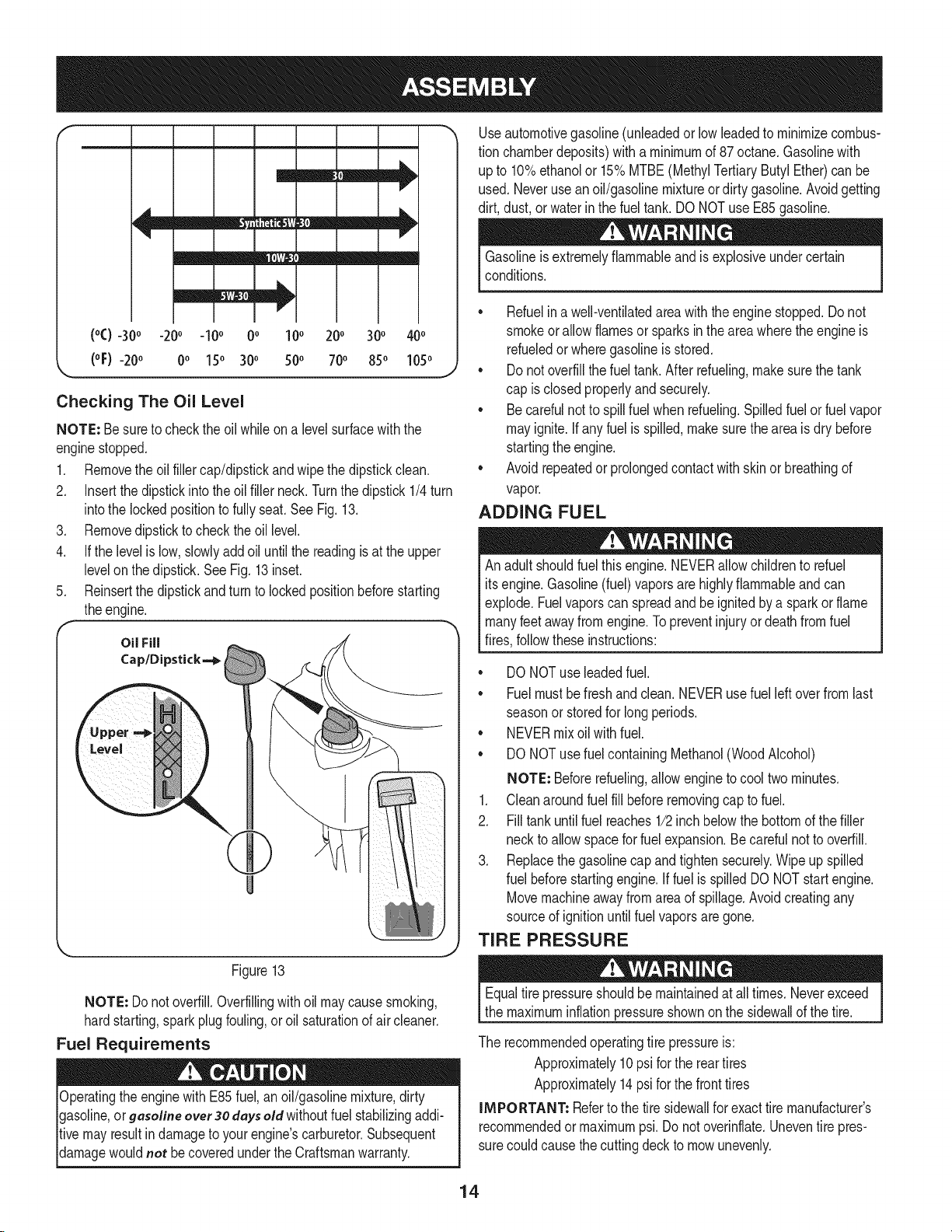

Figure12

GAS & OIL

NOTE: Theengineis shippedwithoutgasolineandwithmotoroil in

theengine.However,youMUSTchecktheoil levelbeforeoperating.

Becarefulnotto overfill.Runningtheenginewithinsufficientoilcan

causeseriousenginedamageandvoidthe enginewarranty.

Alwayskeephandsandfeetclearofequipmentmovingparts.Donot

usea pressurizedstartingfluid.Vaporsare flammable.

Whenattachingbatterycables,alwaysconnectthePOSITIVE(Red)

wireto its terminalfirst,followedby theNEGATIVE(Black)wire.

Forshippingreasons,bothbatterycablesonyourequipmentmay

havebeenleft disconnectedfromtheterminalsatthefactory.To

connectthebatterycables,proceedasfollows:

NOTE: ThepositivebatteryterminalismarkedPos.(+).Thenegative

batteryterminalis markedNeg.(-).

1. Removetheplasticcover,if present,fromthepositivebattery

terminalandattachthe redcabletothe positivebatteryterminal

(+)withthecarriageboltandhexnutusinga 7/16inchwrenchor

socketwrench.SeeFigure12.

2. Removetheplasticcover,if present,fromthenegativebattery

terminalandattachtheblackcabletothe negativebattery

terminal(-) withthecarriageboltandhex nutusinga7/16inch

wrenchor socketwrench.SeeFig.12.

3. Positionthe redrubberbootoverthepositivebatteryterminalto

helpprotectit fromcorrosion.

NOTE: Ifthe batteryisputintoserviceafterthedateshownontop/

sideof battery,chargethebatteryasinstructedinthe Maintenance

sectionof thisOperator'sManualpriorto operatingthetractor.

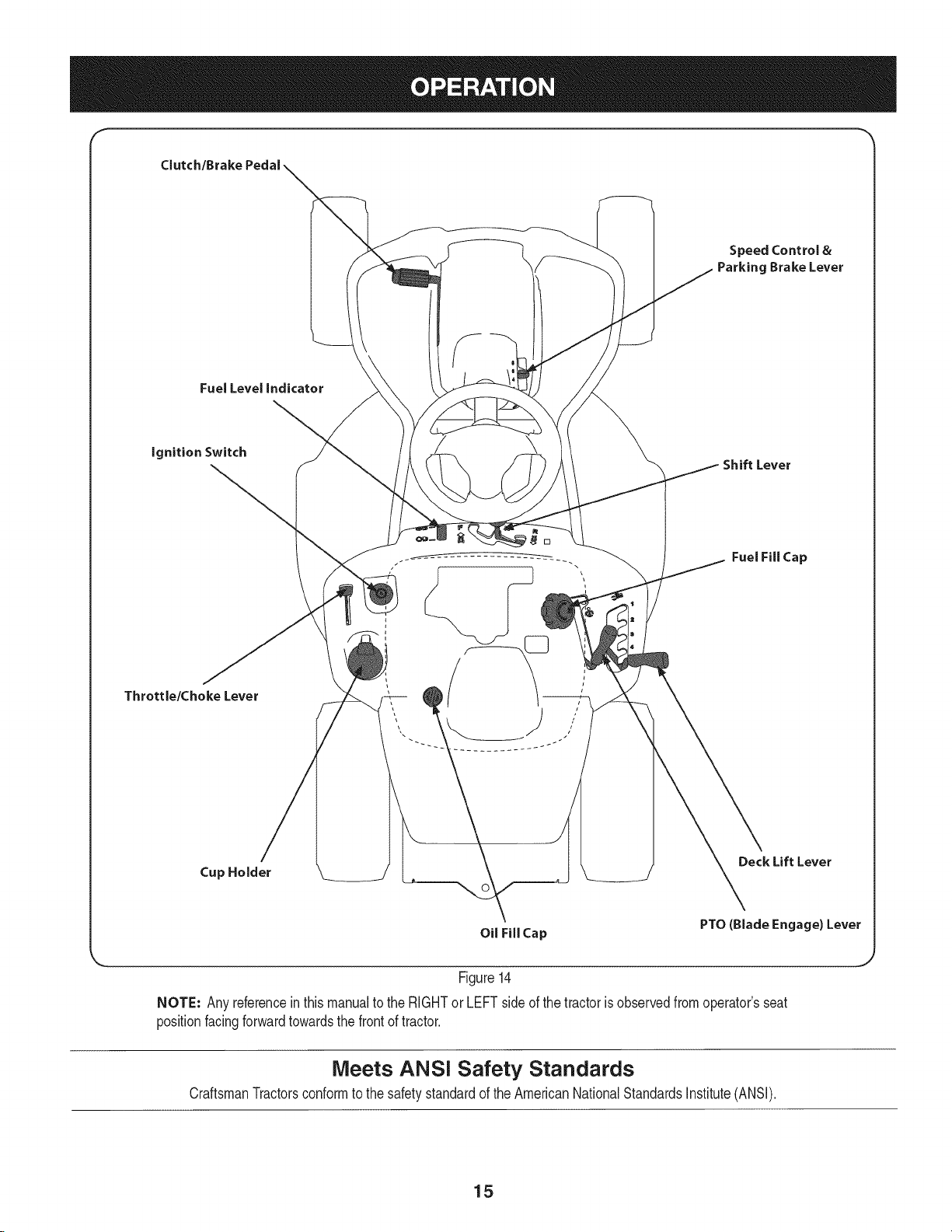

Oil Recommendations

Beforestartingengine,checkoil level;capacityis 1700ml/57.5ft.oz.

Referto viscositychartfor oil recommendations.Donotover-fill.Use

a syntheticornon-synthetic4-stroke,or anequivalenthighdetergent,

premiumqualitymotoroil certifiedto meetor exceedU.S.automobile

manufacturer'srequirementsforserviceclassificationSG,SEMotor

oilsclassifiedSG,SFwill showthisdesignationonthecontainer.

SAE10W-30isrecommendedforgeneral,alltemperatureuse.If

singleviscosityoilis used,selecttheappropriateviscosityon thenext

pagefortheaveragetemperaturein yourareafromthechartbelow.

Donot usenon-detergentoil or2-strokeengineoil. Itcouldshorten

theengine'sservicelife.

NOTE: A5w30syntheticoil maybeusedtoimprovestartabilityfor

coldweather(temperaturesbelow40 F).

13

mE/ml,

Useautomotivegasoline(unleadedor lowleadedto minimizecombus-

tionchamberdeposits)witha minimumof 87 octane.Gasolinewith

V

up to 10%ethanolor 15%MTBE(MethylTertiaryButylEther)canbe

used.Neverusean oil/gasolinemixtureordirty gasoline.Avoidgetting

dirt, dust,orwaterinthefueltank.DONOTuse E85gasoline.

mmmmm_

m mlb

(°C)-30o -20o -I0o 0o 100 200 300 400

(oF)-20o 0o 15o 300 500 700 850 1050

Checking The Oil Level

NOTE: Besuretochecktheoilwhileon a levelsurfacewiththe

enginestopped.

1. Removetheoil fillercap/dipstickandwipethedipstickclean.

2. Insertthe dipstickintothe oil fillerneck.Turnthedipstick1/4turn

intothelockedpositionto fullyseat.See Fig.13.

3. Removedipsticktochecktheoil level.

4. Ifthe levelislow,slowlyaddoiluntilthereadingisattheupper

levelonthe dipstick.SeeFig.13inset.

5. Reinsertthedipstickandturnto lockedpositionbeforestarting

theengine.

Oil Fill

Cap/Dipstick--_

Level

Figure13

NOTE: Donotoverfill.Overfillingwithoil maycausesmoking,

hardstarting,sparkplugfouling,oroil saturationofair cleaner.

Fuel Requirements

Operatingtheenginewith E85fuel,anoil/gasolinemixture,dirty

gasoline,or gasolineover 30daysold withoutfuelstabilizingaddi-

tivemayresultin damagetoyourengine'scarburetor.Subsequent

damagewouldnot becoveredundertheCraftsmanwarranty.

Gasolineisextremelyflammableand isexplosiveundercertain

conditions.

,, Refuelina well-ventilatedareawiththeenginestopped.Donot

smokeorallowflamesor sparksintheareawheretheengineis

refueledor wheregasolineisstored.

* Donot overfillthefueltank.After refueling,makesurethetank

J

capis closedproperlyandsecurely.

* Becarefulnotto spillfuelwhenrefueling.Spilledfuelorfuel vapor

mayignite.Ifanyfuelis spilled,makesuretheareaisdrybefore

startingthe engine.

* Avoidrepeatedorprolongedcontactwithskinor breathingof

vapor.

ADDING FUEL

Anadultshouldfuelthis engine.NEVERallowchildrentorefuel

itsengine.Gasoline(fuel)vaporsarehighlyflammableandcan

explode.Fuelvaporscanspreadandbeignitedbya sparkorflame

manyfeetawayfromengine.Topreventinjuryordeathfromfuel

fires,followtheseinstructions:

* DONOTuseleadedfuel.

* Fuelmustbefreshandclean.NEVERusefuel leftoverfromlast

seasonor storedforlongperiods.

* NEVERmixoilwithfuel.

* DONOTusefuelcontainingMethanol(WoodAlcohol)

NOTE: Beforerefueling,allowenginetocooltwo minutes.

1. Cleanaroundfuelfillbeforeremovingcap tofuel.

2. Filltankuntilfuel reaches1/2inchbelowthe bottomofthefiller

necktoallowspaceforfuel expansion.Becarefulnottooverfill.

3. Replacethegasolinecapand tightensecurely.Wipe upspilled

fuelbeforestartingengine.Iffuelis spilledDONOTstartengine.

Movemachineawayfromareaof spillage.Avoidcreatingany

sourceof ignitionuntilfuelvaporsaregone.

TIRE PRESSURE

,J

Equaltirepressureshouldbemaintainedat alltimes.Neverexceed

themaximuminflationpressureshownonthesidewallof thetire.

Therecommendedoperatingtirepressureis:

Approximately10psiforthe reartires

Approximately14psiforthefronttires

IMPORTANT: Refertothetiresidewallfor exacttiremanufacturer's

recommendedormaximumpsi.Donotoverinflate.Uneventire pres-

surecould causethecuttingdeckto mowunevenly.

14

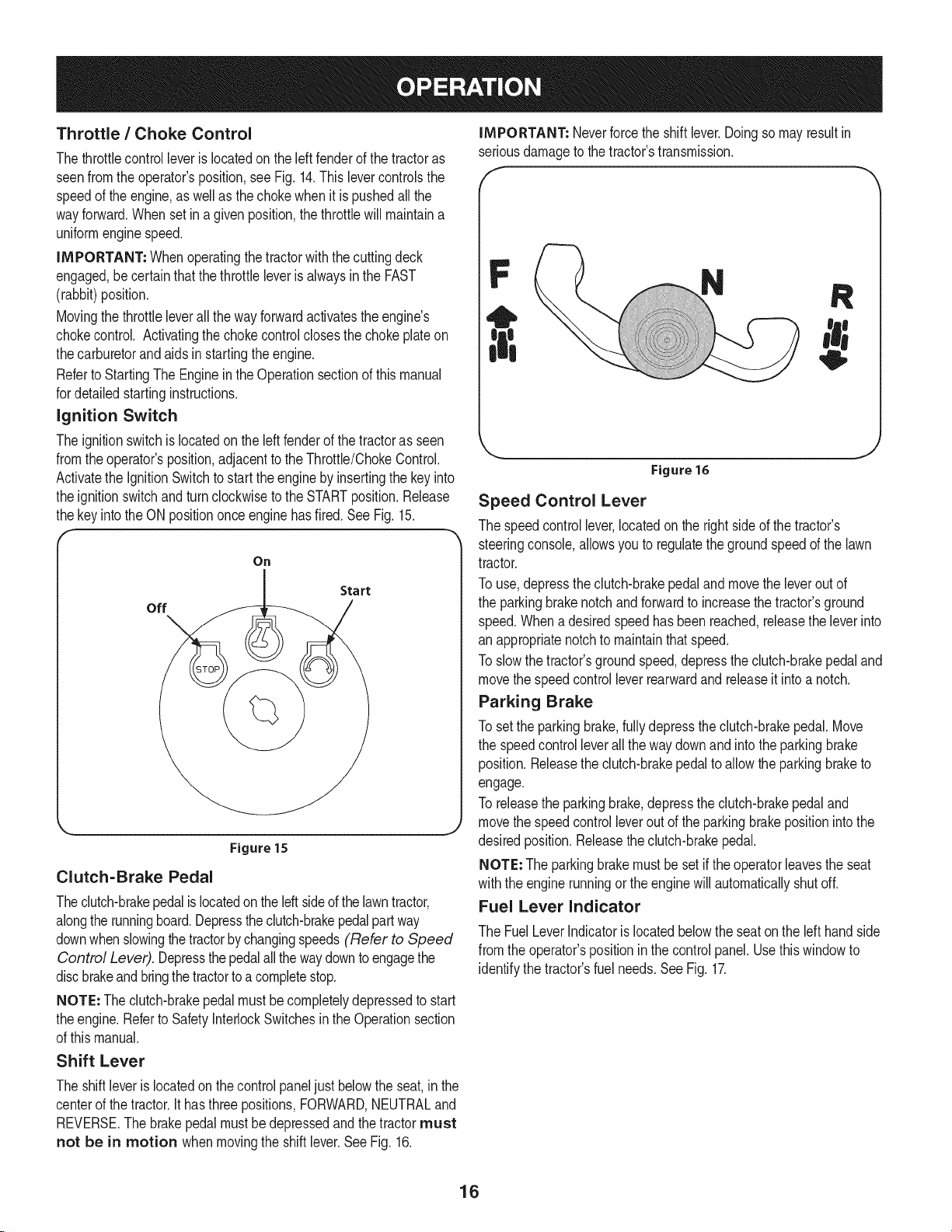

Clutch/Brake

Fuel Level indicator

Speed Control &

Parking Brake Lever

ignition Switch

Throttle/Choke Lever

Cup Holder

Shift Lever

[]

Fuel Fill Cap

Deck Lift Lever

Oil Fill Cap

PTO(Blade Engage) Lever

Figure14

NOTE: Anyreferenceinthismanualtothe RIGHTorLEFTside ofthetractorisobservedfromoperator'sseat

positionfacingforwardtowardsthe frontof tractor.

Meets ANSi Safety Standards

CraftsmanTractorsconformtothe safetystandardof theAmericanNationalStandardsInstitute(ANSI).

15

Throttle / Choke Control

Thethrottlecontrolleveris locatedon the leftfenderof the tractoras

seenfromthe operator'sposition,seeFig. 14.Thislevercontrolsthe

speedof theengine,aswellas the chokewhenitispushedallthe

wayforward.Whensetina givenposition,thethrottlewillmaintaina

uniformenginespeed.

iMPORTANT: Whenoperatingthetractorwiththe cuttingdeck

engaged,becertainthatthe throttleleverisalwaysintheFAST

(rabbit)position.

Movingthethrottleleverall thewayforwardactivatestheengine's

chokecontrol. Activatingthechokecontrolclosesthechokeplateon

thecarburetorandaids instartingtheengine.

RefertoStartingThe EngineintheOperationsectionofthis manual

fordetailedstartinginstructions.

ignition Switch

Theignitionswitchislocatedon theleftfenderofthetractorasseen

fromtheoperator'sposition,adjacenttothe Throttle/ChokeControl.

Activatethe ignitionSwitchtostarttheengineby insertingthekeyinto

theignitionswitchand turnclockwisetothe STARTposition.Release

thekeyintothe ONpositiononceenginehasfired.SeeFig.15.

On

Start

off

Figure 15

Clutch=Brake Pedal

Theclutch-brakepedalis locatedontheleftsideofthelawntractor,

alongtherunningboard.Depresstheclutch-brakepedalpartway

downwhenslowingthetractorbychangingspeeds(Refer to Speed

Control Lever). Depressthepedalallthewaydowntoengagethe

discbrakeandbringthetractortoa completestop.

NOTE: Theclutch-brakepedalmustbecompletelydepressedtostart

theengine.RefertoSafetyInterlockSwitchesinthe Operationsection

ofthismanual.

Shift Lever

iMPORTANT: Neverforcethe shiftlever.Doingsomayresultin

seriousdamagetothetractor'stransmission.

f

N

Figure 16

Speed Control Lever

Thespeedcontrollever,locatedon therightside ofthetractor's

steeringconsole,allowsyoutoregulatethegroundspeedofthe lawn

tractor.

Touse,depressthe clutch-brakepedalandmovetheleveroutof

theparkingbrakenotchandforwardto increasethetractor'sground

speed.Whena desiredspeedhasbeenreached,releasetheleverinto

an appropriatenotchto maintainthatspeed.

Toslowthe tractor'sgroundspeed,depresstheclutch-brakepedaland

movethespeedcontrolleverrearwardand releaseitintoanotch.

Parking Brake

Tosetthe parkingbrake,fullydepresstheclutch-brakepedal.Move

thespeedcontrolleverallthe waydownandintotheparkingbrake

position.Releasetheclutch-brakepedaltoallowthe parkingbraketo

engage.

Toreleasetheparkingbrake,depresstheclutch-brakepedaland

movethespeedcontrolleveroutofthe parkingbrakepositionintothe

desiredposition.Releasethe clutch-brakepedal.

NOTE:The parkingbrakemustbesetif theoperatorleavestheseat

withtheenginerunningortheenginewillautomaticallyshutoff.

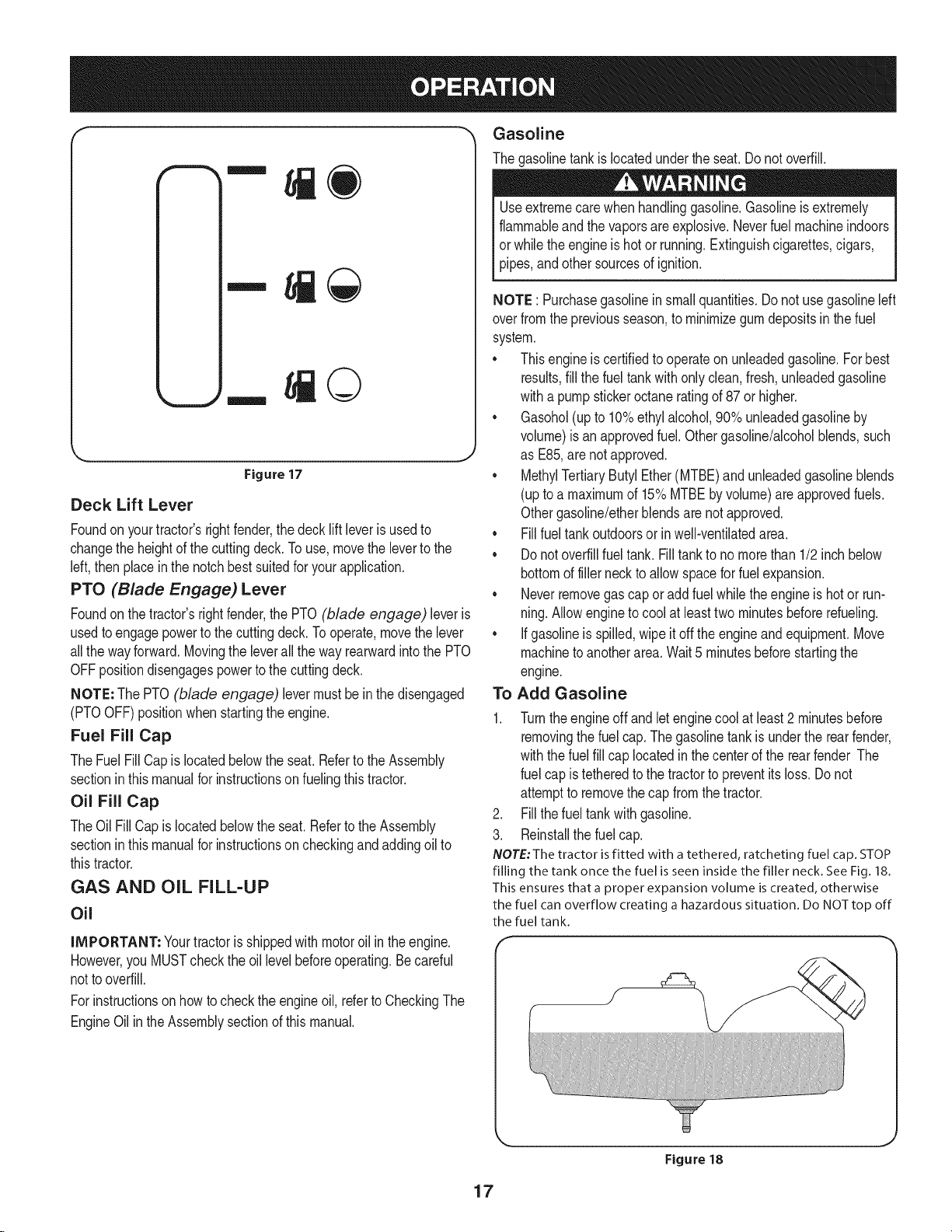

Fuel Lever Indicator

TheFuelLeverIndicatorislocatedbelowtheseatonthe left handside

fromtheoperator'spositioninthecontrolpanel.Usethiswindowto

identifythe tractor'sfuelneeds.SeeFig. 17.

Theshiftleveris locatedonthecontrolpaneljust belowtheseat,inthe

centerofthe tractor.Ithasthreepositions,FORWARD,NEUTRALand

REVERSE.The brakepedalmustbedepressedandthetractormust

not be in motion whenmovingtheshiftlever.SeeFig.16.

16

©

Figure 17

Deck Lift Lever

Foundonyourtractor'srightfender,thedecklift leverisusedto

changetheheightof thecuttingdeck.Touse,movethe levertothe

left,then placeinthenotchbestsuitedforyourapplication.

PTO (Blade Engage) Lever

Foundonthe tractor'srightfender,thePTO (blade engage) leveris

usedto engagepowerto thecuttingdeck.Tooperate,movethelever

allthewayforward.Movingtheleverall thewayrearwardintothe PTO

OFFpositiondisengagespowertothecuttingdeck.

NOTE: ThePTO(blade engage) levermust beinthedisengaged

(PTOOFF)positionwhenstartingtheengine.

Fuel Fill Cap

TheFuelFillCap islocatedbelowtheseat.RefertotheAssembly

sectioninthismanualforinstructionsonfuelingthistractor.

Oil Fill Cap

TheOil FillCapislocatedbelowthe seat.RefertotheAssembly

sectioninthismanualforinstructionsoncheckingandaddingoilto

thistractor.

GAS AND OIL FILL-UP

Oil

IMPORTANT: Yourtractorisshippedwith motoroilinthe engine.

However,youMUSTchecktheoil levelbeforeoperating.Becareful

nottooverfill.

Forinstructionsonhowtochecktheengineoil, refertoCheckingThe

EngineOilintheAssemblysectionof thismanual.

Gasoline

Thegasolinetankislocatedunderthe seat.Donot overfill.

Useextremecarewhenhandlinggasoline.Gasolineisextremely

flammableandthevaporsareexplosive.Neverfuelmachineindoors

orwhilethe engineis hotor running.Extinguishcigarettes,cigars,

pipes,andothersourcesof ignition.

NOTE : Purchasegasolineinsmallquantities.Donotusegasolineleft

overfromthe previousseason,to minimizegumdepositsinthe fuel

system.

• Thisengineiscertifiedtooperateonunleadedgasoline.Forbest

results,fill thefueltankwith onlyclean,fresh,unleadedgasoline

witha pumpstickeroctaneratingof87or higher.

• Gasohol(upto10%ethylalcohol,90%unleadedgasolineby

volume)isan approvedfuel.Othergasoline/alcoholblends,such

as E85,arenotapproved.

MethylTertiaryButylEther(MTBE)and unleadedgasolineblends

(uptoa maximumof 15%MTBEbyvolume)areapprovedfuels.

Othergasoline/etherblendsarenotapproved.

• Fillfueltankoutdoorsor inwell-ventilatedarea.

• Donotoverfillfueltank.Filltankto nomorethan1/2inchbelow

bottomoffillerneckto allowspaceforfuelexpansion.

• Neverremovegascap or addfuelwhiletheengineis hotor run-

ning.Allowengineto coolat leasttwominutesbeforerefueling.

• Ifgasolineisspilled,wipeitoff the engineandequipment.Move

machineto anotherarea.Wait5 minutesbeforestartingthe

engine.

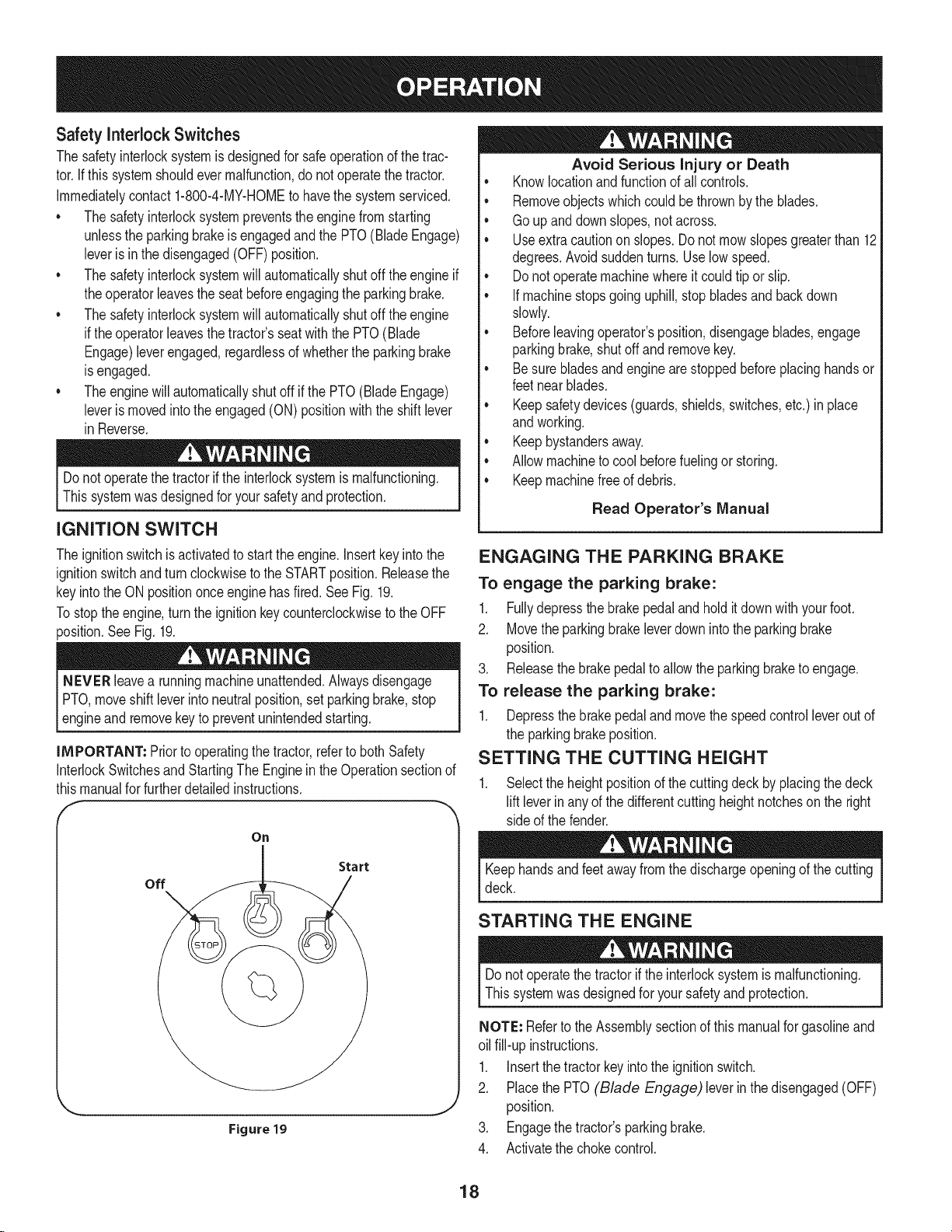

Add GasolineTo

1.

Turntheengineoffand letenginecoolatleast2 minutesbefore

removingthefuelcap.Thegasolinetankis undertherearfender,

withthefuel fillcaplocatedinthecenterof therearfender The

fuelcap istetheredtothe tractortopreventitsloss.Donot

attemptto removethecap fromthetractor.

2. Fillthefueltankwithgasoline.

3. Reinstallthefuelcap.

NOTE: The tractor is fitted with a tethered, ratcheting fuel cap. STOP

filling the tank once the fuel is seen inside the filler neck. See Fig. 18.

This ensures that a proper expansion volume is created, otherwise

the fuel can overflow creating a hazardous situation. Do NOTtop off

the fuel tank.

17

Figure 18

Safety interlockSwitches

Thesafetyinterlocksystemisdesignedforsafeoperationof thetrac-

tor.Ifthis systemshouldevermalfunction,donotoperatethetractor.

Immediatelycontact1-800i4iMY-HOMEto havethesystemserviced.

• Thesafetyinterlocksystempreventstheenginefromstarting

unlesstheparkingbrakeis engagedandthePTO(BladeEngage)

leveris inthedisengaged(OFF)position.

• Thesafetyinterlocksystemwillautomaticallyshutoff theengineif

theoperatorleavesthe seatbeforeengagingtheparkingbrake.

• Thesafetyinterlocksystemwill automaticallyshutoff theengine

ifthe operatorleavesthetractor'sseatwiththe PTO(Blade

Engage)leverengaged,regardlessofwhethertheparkingbrake

isengaged.

• Theenginewillautomaticallyshutoffif the PTO(BladeEngage)

leveris movedintotheengaged(ON)positionwiththeshiftlever

in Reverse.

Donot operatethetractoriftheinterlocksystemismalfunctioning.

Thissystemwasdesignedforyoursafetyand protection.

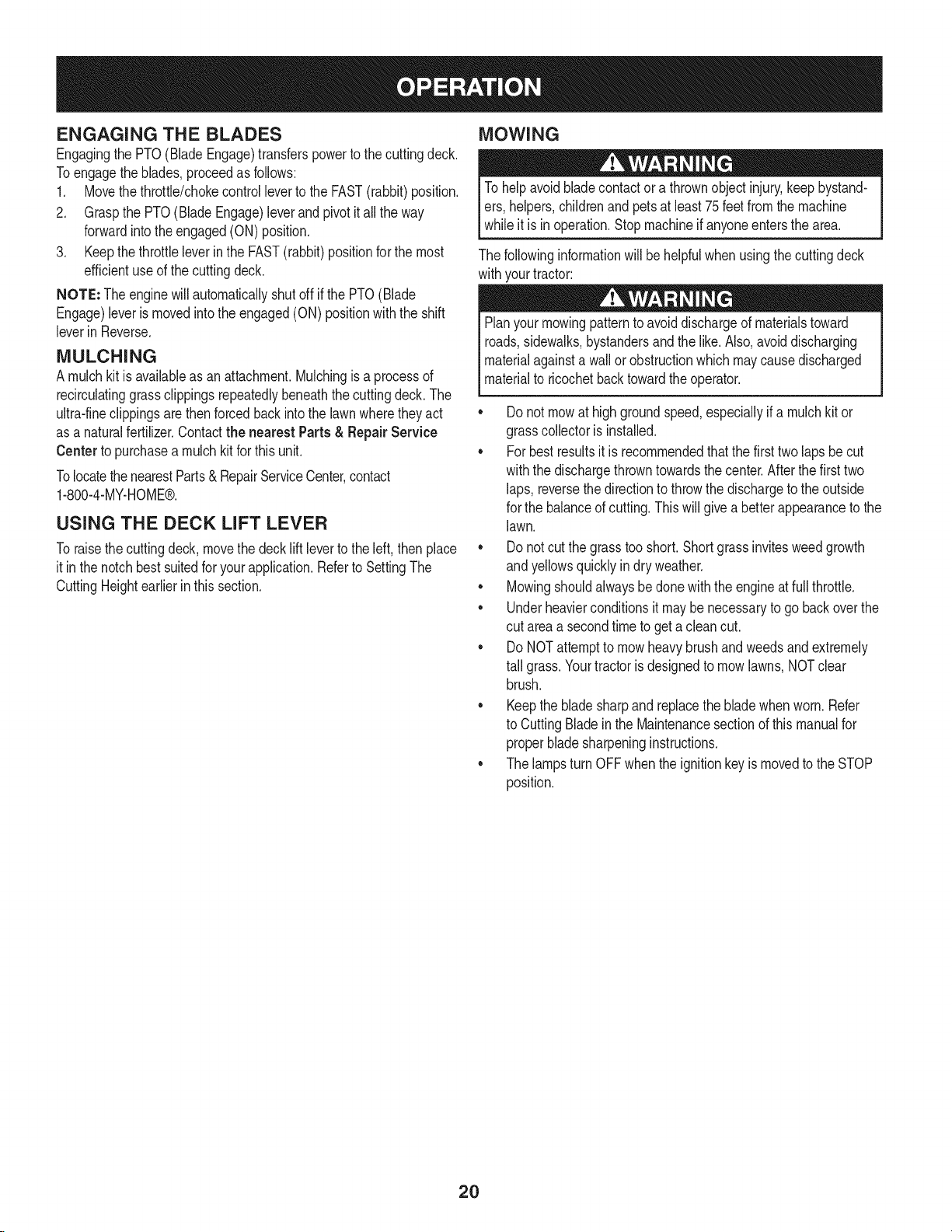

iGNiTiON SWITCH

Theignitionswitchisactivatedto starttheengine.Insertkeyintothe

ignitionswitchandturnclockwisetothe STARTposition.Releasethe

keyintothe ONpositiononceenginehasfired.SeeFig. 19.

Tostoptheengine,turntheignitionkeycounterclockwisetotheOFF

position.SeeFig. 19.

NEVER leavearunningmachineunattended.Alwaysdisengage

PTO,moveshiftleverintoneutralposition,setparkingbrake,stop

leng ne andremovekeyto preventunntendedstartng.

IMPORTANT: Priortooperatingthetractor,refertobothSafety

InterlockSwitchesandStartingThe EngineintheOperationsectionof

thismanualforfurtherdetailedinstructions.

On

Avoid Serious Injury or Death

• Knowlocationandfunctionofall controls.

• Removeobjectswhichcouldbe thrownbythe blades.

• Goup anddownslopes,notacross.

• Useextracautiononslopes.Donotmowslopesgreaterthan12

degrees.Avoidsuddenturns.Uselowspeed.

• Donotoperatemachinewhereitcouldtiporslip.

• Ifmachinestopsgoinguphill,stopbladesandbackdown

slowly.

• Beforeleavingoperator'sposition,disengageblades,engage

parkingbrake,shutoff andremovekey.

• Besurebladesandenginearestoppedbeforeplacinghandsor

feetnearblades.

• Keepsafetydevices(guards,shields,switches,etc.) in place

andworking.

• Keepbystandersaway.

• Allowmachineto coolbeforefuelingor storing.

• Keepmachinefreeof debris.

Read Operator's Manual

ENGAGING THE PARKING BRAKE

To engage the parking brake:

1. Fullydepressthebrakepedalandholditdownwithyourfoot.

2. Movetheparkingbrakeleverdownintothe parkingbrake

position.

3. Releasethebrakepedaltoallowtheparkingbraketoengage.

To release the parking brake:

1. Depressthebrakepedaland movethe speedcontrolleveroutof

theparkingbrakeposition.

SETTING THE CUTTING HEIGHT

1. Selecttheheightpositionofthecuttingdeckby placingthedeck

lift leverinanyofthedifferentcuttingheightnotchesonthe right

sideof thefender.

off

Figure 19

Start

Keephandsandfeetawayfromthedischargeopeningof thecutting

deck.

STARTING THE ENGINE

Donotoperatethetractorif theinterlocksystemismalfunctioning.

Thissystemwasdesignedfor yoursafetyandprotection.

NOTE: Refertothe Assemblysectionofthismanualforgasolineand

oil fill-upinstructions.

1. Insertthetractorkeyintotheignitionswitch.

2. PlacethePTO(Blade Engage) leverinthedisengaged(OFF)

J

position.

3. Engagethetractor'sparkingbrake.

4. Activatethechokecontrol.

18

5. Turntheignitionkeyclockwisetothe STARTposition.Afterthe

enginestarts,releasethekey.Itwill returntotheONposition.

IMPORTANT:DoNOTholdthekeyin theSTARTpositionforlonger

thanten secondsata time. Doingso maycausedamagetoyour

engine'selectricstarter.

6. Aftertheenginestarts,deactivatethe chokecontrolbyplacingthe

throttlecontrolintotheFASTposition.

NOTE: Do NOTleavethechokecontrolon whileoperatingthetractor.

Doingso willresultin a"rich"fuelmixtureandcausetheengineto run

poorly.

STOPPING THE ENGINE

Ifyoustrikea foreignobject,stoptheengine,disconnectthespark

plugwire(s)andgroundagainsttheengine.Thoroughlyinspectthe

machineforany damage.Repairthedamagebeforerestartingand

operating.

If thebladesareengaged,placethe PTO (Blade Engage)

leverinthe disengaged(OFF)position.

2. TurntheignitionkeycounterclockwisetotheSTOPposition.

3. Removethekeyfromtheignitionswitchto preventunintended

starting.

DRIVING THE TRACTOR

Avoidsuddenstarts,excessivespeedandsuddenstops.

Donotleavethe seatof thetractorwithoutfirstplacingthePTO

(BladeEngage)leverinthedisengaged(OFF)position,depressing

thebrakepedalandengagingthe parkingbrake.Ifleavingthetractor

unattended,alsoturn theignitionkeyoff andremovethekey.

Alwayslookdownandbehindbeforeandwhilebackingupto avoida

back-overaccident.

1. Depressthebrakepedalandmovethespeedcontrolleverout of

theparkingbrakeposition,thenletthe pedalrelease.

2. MovethethrottleleverintotheFAST(rabbit)position.

3. Placethe shiftleverin eitherthe FORWARDor REVERSE

position.

IMPORTANT: DoNOTusetheshiftlevertochangethedirection

oftravelwhenthetractorisinmotion.Alwaysusethebrakepedalto

bringthetractortoa completestopbeforeshifting.

4. Releasethe parkingbrakebydepressingthe clutch-brakepedal

andpositioningthe speedcontrolleverindesiredposition.

IMPORTANT= First-timeoperatorsshouldusespeedpositions1or

2.Becomecompletelyfamiliarwiththetractor'soperationandcontrols

beforeoperatingthe tractorinhigherspeedpositions.

5. Releaseclutch-brakepedalslowlytoput unit intomotion.

6. Thelawntractorisbroughttoa stopby depressingtheclutch-

brakepedal.

NOTE=Whenoperatingtheunitinitially,therewillbelittledifference

betweenthe highesttwospeedsuntilafterthebeltshaveseated

themselvesintothepulleysduringthe break-inperiod.

Beforeleavingthe operator'spositionforanyreason,disengagethe

blades,placethe shiftleverinneutral,engagetheparkingbrake,

shutengineoff andremovethekey.

IMPORTANT: Whenstoppingthe tractorforany reasonwhileon a

grasssurface,always:

1. Placetheshiftleverinneutral,

2. Engagetheparkingbrake,

3. Shutengineoffandremovethe key.Doingsowillminimizethe

possibilityof havingyourlawn"browned"byhot exhaustfrom

yourtractor'srunningengine.

Ifunitstallswithspeedcontrolinhighspeed,orif unitwill not operate

with speedcontrolleverina lowspeedposition,proceedasfollows:

1. PlaceshiftleverinNEUTRAL.

2. Restartengine.

3. Placespeedcontrolleverinhighestspeedposition.

4. Releaseclutch-brakepedalfully.

5. Depressclutch-brakepedal.

6. Placespeedcontrolleverindesiredposition.

7. Placeshiftleverineither FORWARDor REVERSE,andfollow

normaloperatingprocedures.

DRIVING ON SLOPES

Referto theSLOPEGAUGEinthe SafetyInstructionssectionofthe

manualtohelpdetermineslopeswhereyoumayoperatethistractor

safely.

Donot mowon inclineswitha slopeinexcessof 12degrees(arise

ofapproximately2 feetevery 10feet).The tractorcouldoverturnand

causeseriousinjury.

• Mowupanddownslopes,NEVERacross.

• Exerciseextremecautionwhenchangingdirectiononslopes.

• Watchforholes,ruts,bumps,rocks,or otherhiddenobjects.

Uneventerraincouldoverturnthe machine.Tallgrasscanhide

obstacles.

• Avoidturnswhendrivingona slope.If a turnmustbe made,turn

downthe slope.Turningupaslopegreatlyincreasesthe chance

ofa rollover.

• Avoidstoppingwhendrivingupa slope.If itisnecessaryto stop

whiledrivingup a slope,startupsmoothlyandcarefullyto reduce

thepossibilityof flippingthetractoroverbackward.

19

ENGAGING THE BLADES

Engagingthe PTO(BladeEngage)transferspowertothecuttingdeck.

Toengagethe blades,proceedasfollows:

1. Movethethrottle/chokecontrollevertothe FAST(rabbit)position.

2. Graspthe PTO(BladeEngage)leverandpivotit all the way

forwardintothe engaged(ON)position.

3. Keepthethrottleleverinthe FAST(rabbit)positionforthemost

efficientuseof thecuttingdeck.

NOTE: Theenginewillautomaticallyshutoff ifthe PTO(Blade

Engage)leveris movedintotheengaged(ON)positionwiththe shift

leverin Reverse.

MULCHING

A mulchkit isavailableas an attachment.Mulchingisa processof

recirculatinggrassclippingsrepeatedlybeneaththecuttingdeck.The

ultra-fineclippingsarethenforcedbackintothe lawnwheretheyact

asa naturalfertilizer.Contactthe nearest Parts & RepairService

Centerto purchasea mulchkit forthis unit.

TolocatethenearestParts& RepairServiceCenter,contact

1-800-4-MY-HOME®.

USING THE DECK LIFT LEVER

Toraisethecuttingdeck,movethe decklift leverto theleft,thenplace

itin thenotchbestsuitedforyourapplication.RefertoSettingThe

CuttingHeightearlierinthis section.

MOWING

Tohelpavoidbladecontactora thrownobjectinjury,keepbystand-

ers,helpers,childrenandpetsat least75feetfromthemachine

whileit isin operation.Stopmachineif anyoneentersthearea.

Thefollowinginformationwillbehelpfulwhenusingthecuttingdeck

withyourtractor:

Planyourmowingpatternto avoiddischargeofmaterialstoward

roads,sidewalks,bystandersandthelike.Also,avoiddischarging

materialagainstawallorobstructionwhichmaycausedischarged

materialtoricochetbacktowardtheoperator.

• Donotmowat highgroundspeed,especiallyif a mulchkitor

grasscollectoris installed.

• Forbestresultsit isrecommendedthatthefirst twolapsbecut

withthedischargethrowntowardsthe center.Afterthefirsttwo

laps, reversethedirectionto throwthe dischargeto theoutside

forthe balanceofcutting.Thiswillgiveabetterappearancetothe

lawn.

• Donotcutthegrasstooshort.Shortgrassinvitesweedgrowth

andyellowsquicklyin dryweather.

• Mowingshouldalwaysbedonewiththeengineat full throttle.

• Underheavierconditionsit maybe necessaryto go backoverthe

cut areaa secondtimetoget a cleancut.

• DoNOTattemptto mowheavybrushandweedsandextremely

tallgrass.Yourtractoris designedtomowlawns,NOTclear

brush.

• Keepthebladesharpandreplacethebladewhenworn.Refer

to CuttingBladeinthe Maintenancesectionofthis manualfor

properbladesharpeninginstructions.

• ThelampsturnOFFwhentheignitionkeyismovedtothe STOP

position.

2O

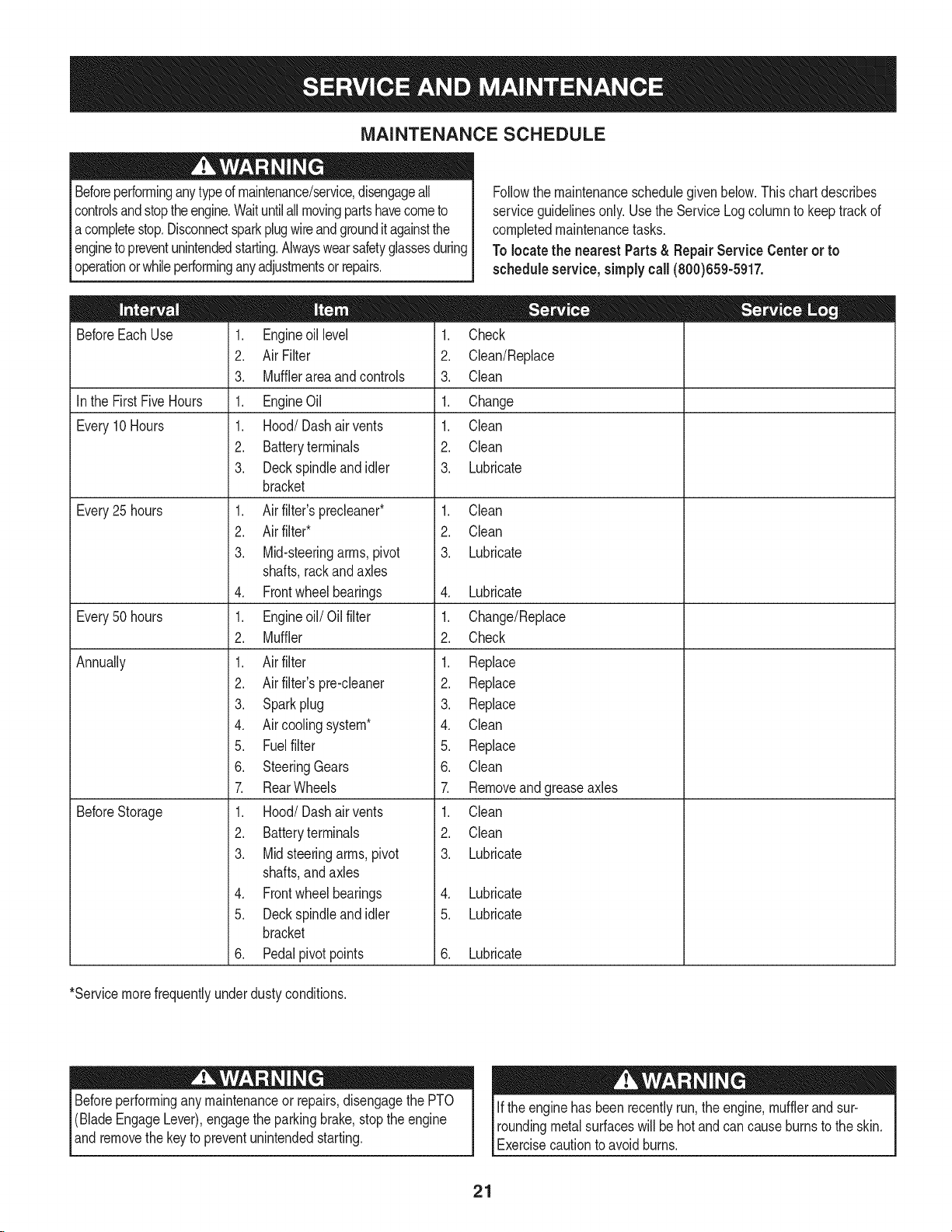

MAINTENANCE SCHEDULE

Beforeperforminganytypeofmaintenance/service,disengageall

controlsandstoptheengine.Waituntilallmovingpartshavecometo

acompletestop.Disconnectsparkplugwireandgrounditagainstthe

enginetopreventunintendedstarting.Alwayswearsafetyglassesduring

operationorwhileperforminganyadjustmentsor repairs.

BeforeEachUse

Inthe FirstFiveHours

Every10Hours

Every25 hours

Every50 hours

Annually

BeforeStorage

1. Engineoil level

2. Air Filter

3. Mufflerareaandcontrols

1. EngineOil

1. Hood/Dashairvents

2. Batteryterminals

3. Deckspindleandidler

bracket

1. Airfilter'sprecleaner*

2. Air filter*

3. Mid-steeringarms,pivot

shafts,rackandaxles

4. Frontwheelbearings

1. Engineoil/Oil filter

2. Muffler

1. Airfilter

2. Air filter'spre-cleaner

3. Sparkplug

4. Air coolingsystem*

5. Fuelfilter

6. SteeringGears

7. RearWheels

1. Hood/Dashairvents

2. Batteryterminals

3. Midsteeringarms,pivot

shafts,andaxles

4. Frontwheelbearings

5. Deckspindleandidler

bracket

6. Pedalpivotpoints

1. Check

2. Clean/Replace

3. Clean

1. Change

1. Clean

2. Clean

3. Lubricate

1. Clean

2. Clean

3. Lubricate

4. Lubricate

1. Change/Replace

2. Check

1. Replace

2. Replace

3. Replace

4. Clean

5. Replace

6. Clean

7. Removeandgreaseaxles

1. Clean

2. Clean

3. Lubricate

4. Lubricate

5. Lubricate

6. Lubricate

Followthe maintenanceschedulegivenbelow.Thischartdescribes

serviceguidelinesonly.Usethe ServiceLogcolumntokeeptrackof

completedmaintenancetasks.

Tolocate the nearest Parts& Repair Service Centeror to

scheduleservice,simplycall(800)659-5917.

*Servicemorefrequentlyunderdustyconditions.

Beforeperforminganymaintenanceor repairs,disengagethePTO

(BladeEngageLever),engagethe parkingbrake,stoptheengine

andremovethe keyto preventunintendedstarting.

If theenginehasbeenrecentlyrun,the engine,mufflerandsur-

roundingmetalsurfaceswillbehot andcancauseburnstotheskin.

Exercisecautiontoavoidburns.

21

ENGINE MAINTENANCE

Shutoffthe enginebeforeperforminganymaintenance.Toprevent

accidentalstart-up,disconnectthe sparkplugboot.

iMPORTANT: if enginemustbetippedtotransportequipmentorto

inspector removegrass,keepsparkplugsideof engineup.Transport-

ingortippingenginesparkplugdownmaycausesmoking,hard

starting,sparkplugfouling,oroil saturationofaircleaner.

Periodicinspectionandadjustmentoftheengineisessentialifhigh

levelperformanceistobe maintained.Regularmaintenancewillalso

ensurealongservicelife.Therequiredserviceintervalsandthe kind

ofmaintenanceto beperformedaredescribedinthe tableonthe

previouspage.Followthehourlyor calendarintervals,whicheveroccur

first.Morefrequentserviceisrequiredwhenoperatinginadverse

conditions.

Ifthe enginehasbeenrunning,themufflerwillbeveryhot. Becareful

notto touchthemuffler.

Servicing the Engine Oil

• Checktheoil levelregularly.

• Besurecorrectoil levelismaintained.Checktheoil everyfiveto

tenhoursof operation,beforestartingtheengine.SeeChecking

Oil LevelintheAssemblysection.

Onlyuse highqualitydetergentoil ratedwithAPIserviceclassification

SF,SG,SH,or SJ.Selecttheoil'sSAEviscositygradeaccordingto

theexpectedoperatingtemperature.Referto Gas& Oilinthe As-

semblysectionofthismanual.

Oil Drain

8. Removetheoildrainsleevefromtheoilsump.Returnthedipstick

tothe oilfilltubeandscrewtheoilfill capbackintoplace.

9. Refilltheenginewiththenewmotoroil.Referto Gas& Oilinthe

Assemblysectionof thismanualforinformationregardingthe

approvedoiltype.

iMPORTANT: Usedmotoroil maycauseskincancerif repeatedly

left incontactwiththeskinforprolongedperiods.Althoughthis is

unlikelyunlessyouhandleusedoil ona dailybasis,it isstilladvis-

abletothoroughlywashyourhandswithsoapandwaterassoonas

possibleafterhandlingusedoil.

NOTE: Pleasedisposeofusedmotoroilina mannerthatiscompat-

iblewiththeenvironment.Wesuggestyoutakeitina sealedcontainer

toyour localservicestationfor reclamation.Donotthrowitinthe

trash,pourit downadrainoron the ground.

iMPORTANT: Besuretocheckengineonalevelsurfacewiththe

enginestopped.Draintheoilwhiletheengineis stillwarmtoassure

rapidandcompletedraining.

Fordrainingoilfromthe engine'scrankcaseofselectmodeltractors,a

plasticoildrainsleeveispackedwiththisOperator'sManual.Todrain

theoil, proceedasfollows:

1. Unscrewthe oilfill capand removethedipstickfromtheoil fill

tube.

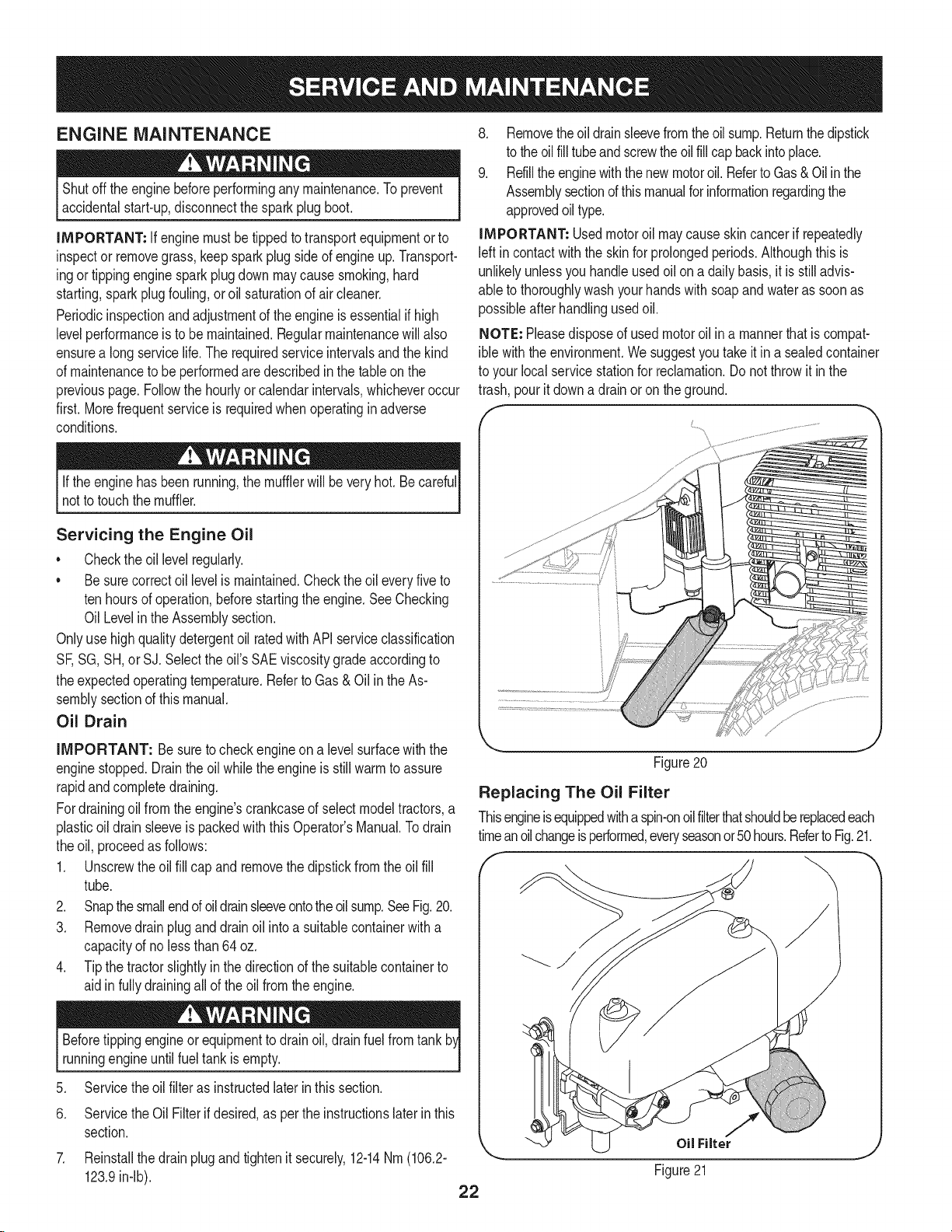

2. Snapthe smallendofoildrainsleeveontotheoilsump.SeeFig.20.

3. Removedrainpluganddrainoil intoa suitablecontainerwitha

capacityofno lessthan64oz.

4. Tipthe tractorslightlyinthe directionofthesuitablecontainerto

aidinfullydrainingall oftheoilfromtheengine.

Beforetippingengineor equipmentto drainoil,drainfuelfromtank

runningengineuntilfueltankisempty.

5. Servicetheoilfilteras instructedlater inthissection.

6. ServicetheOil Filterifdesired,aspertheinstructionslaterinthis

section.

7. Reinstallthedrainplugandtightenitsecurely,12-14Nm(106.2-

123.9in-lb).

Figure20

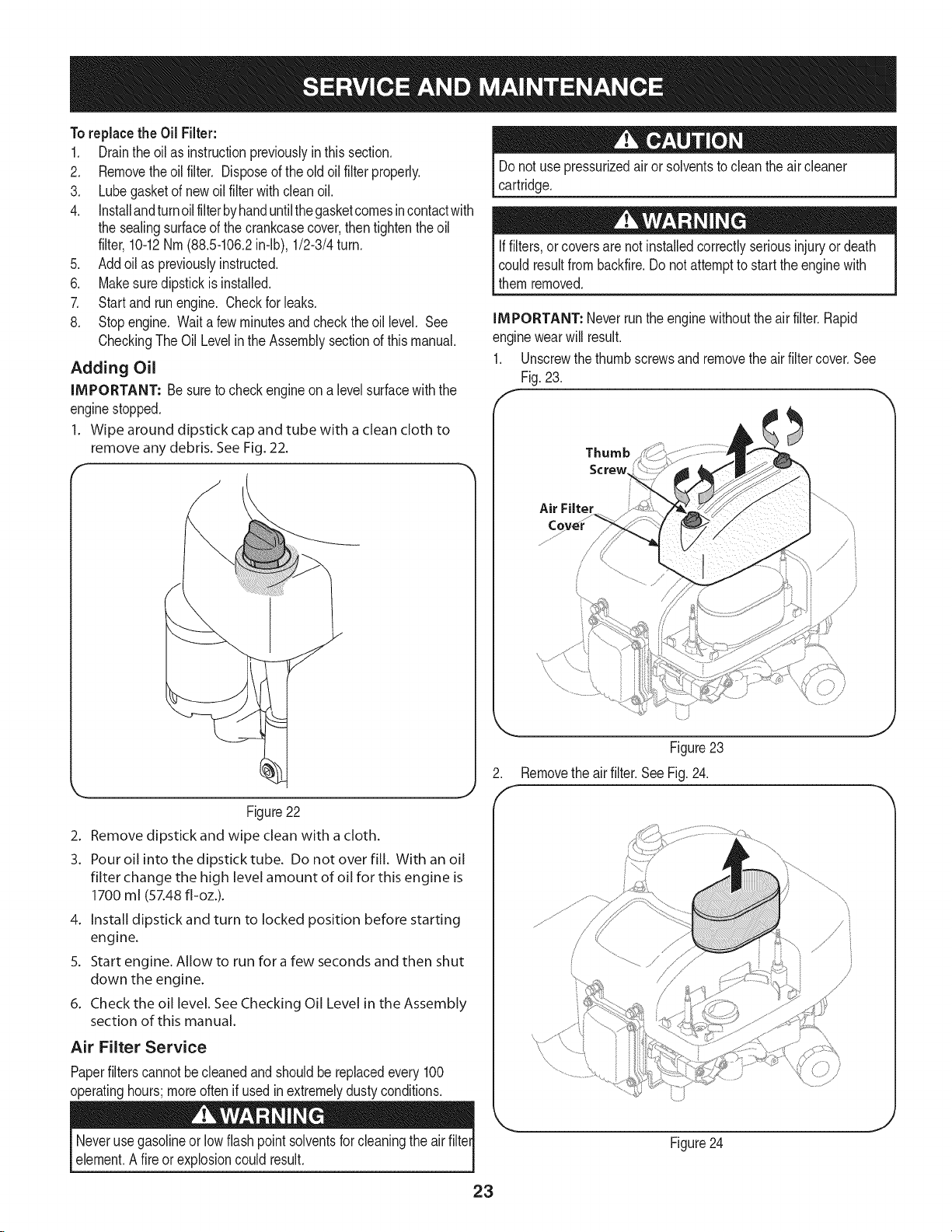

Replacing The Oil Filter

Thisengineisequippedwithaspin-onoilfilterthatshouldbereplacedeach

timeanoilchangeisperformed,everyseasonor50hours.RefertoFig.21.

_ 1/

OilFilter

Figure21

22

ToreplacetheOilFilter:

1. Draintheoilasinstructionpreviouslyinthis section.

2. Removetheoil filter. Disposeofthe oldoil filterproperly.

3. Lubegasketofnewoil filterwithcleanoil.

4. Installandturnoilfilterbyhanduntilthegasketcomesincontactwith

thesealingsurfaceof thecrankcasecover,thentightentheoil

filter,10-12Nm(88.5-106.2in-lb),1/2-3/4turn.

5. Addoilas previouslyinstructed.

6. Makesuredipstickisinstalled.

7. Startandrunengine. Checkforleaks.

8. Stopengine. Waita fewminutesandcheckthe oil level. See

CheckingTheOil LevelintheAssemblysectionofthismanual.

Adding Oil

iMPORTANT: Besuretocheckengineon alevelsurfacewiththe

enginestopped.

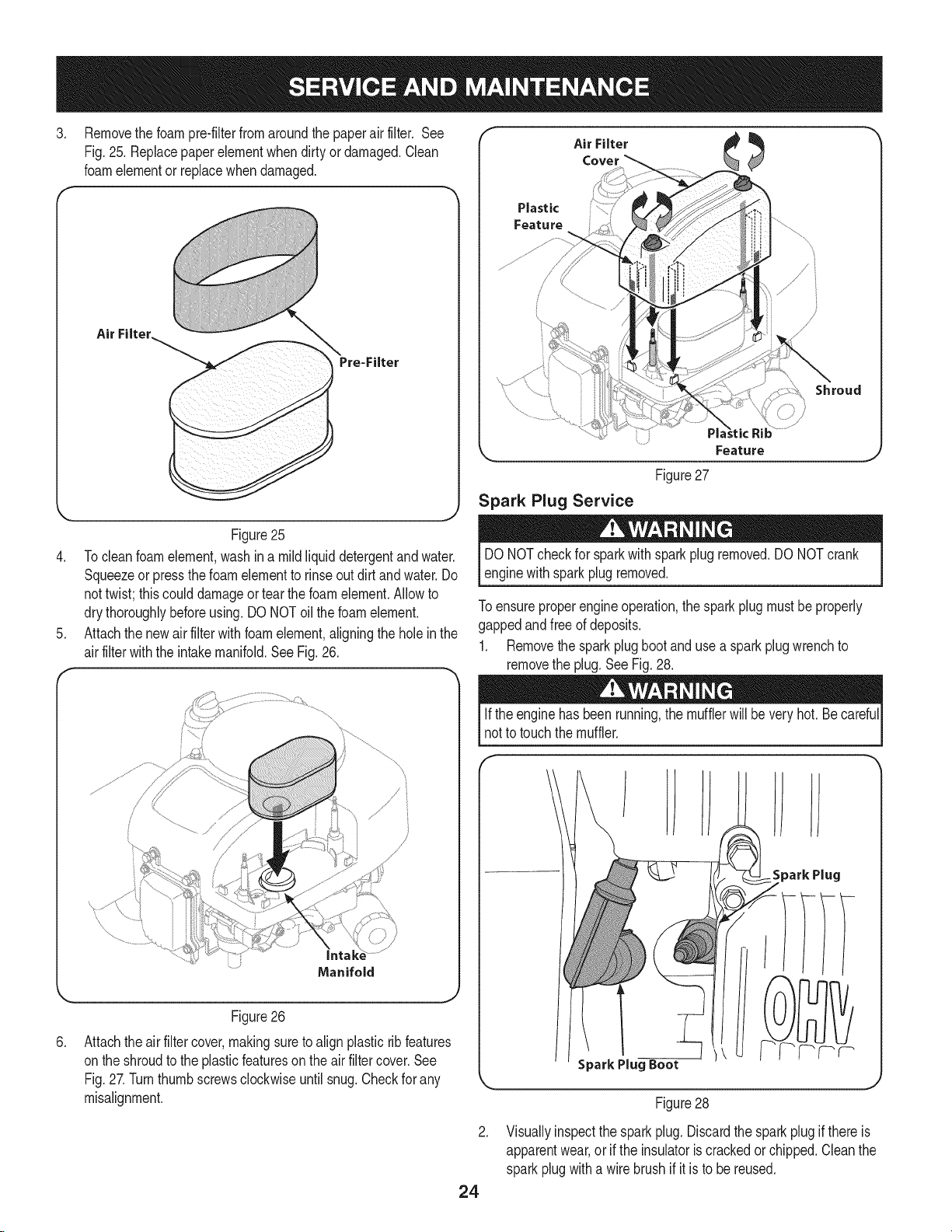

1. Wipe around dipstick cap and tube with a cleancloth to

remove any debris. SeeFig. 22.

Donot use _ressurizedairor solventstocleantheair cleaner

cartridge.

Iffilters,or coversarenotinstalledcorrectlyseriousinjuryordeath

couldresultfrombackfire.Donotattemptto starttheenginewith

themremoved.

IMPORTANT: Neverruntheenginewithouttheair filter.Rapid

enginewearwill result.

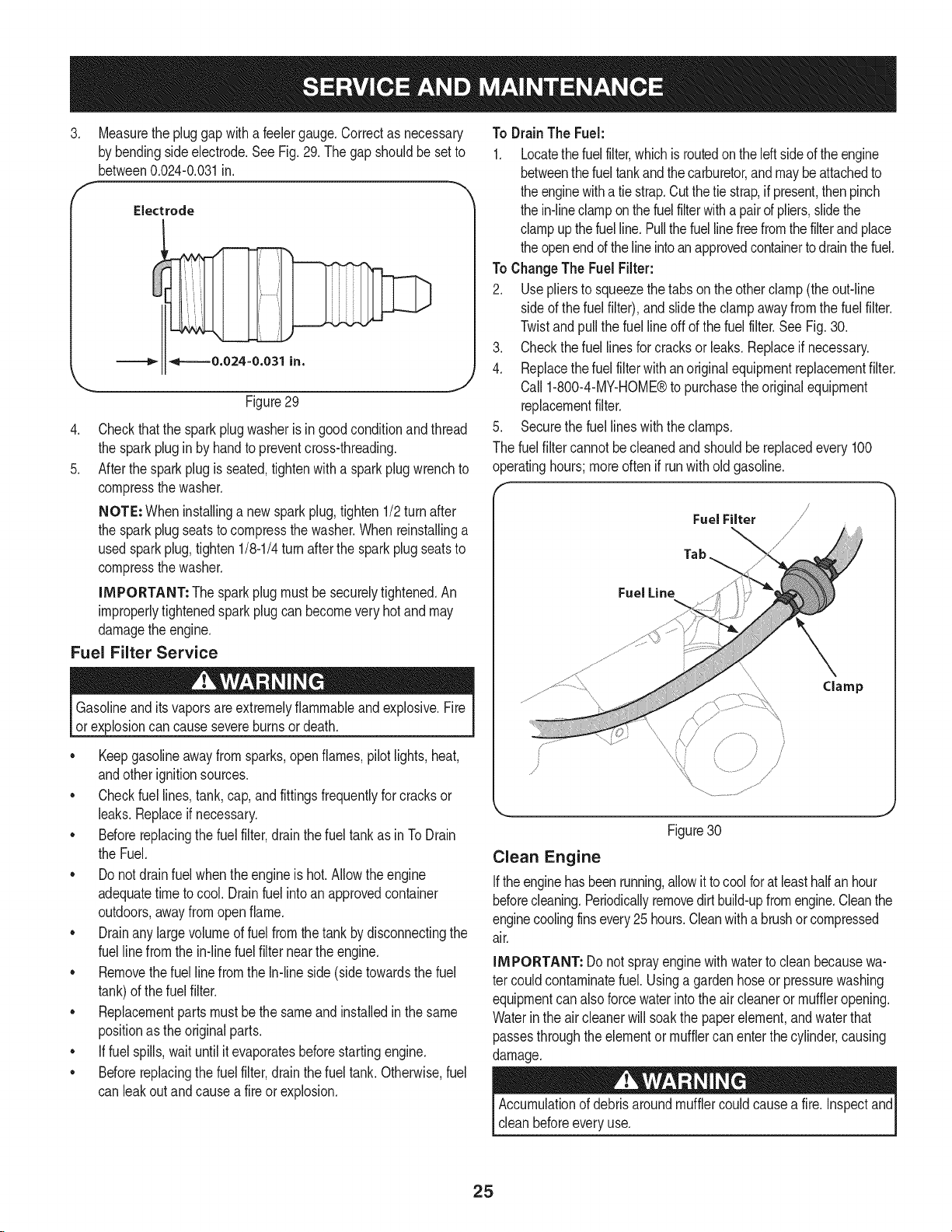

1. Unscrewthethumbscrewsand removetheairfiltercover.See

Fig.23.

Thumb

Screw

Air Filter

, '///

/

Figure 22

2. Remove dipstick and wipe clean with a cloth.

3. Pour oil into the dipstick tube. Do not over fill. With an oil

filter change the high level amount of oil for this engine is

1700 ml (57.48 fl-oz.).

4. Install dipstick and turn to locked position before starting

engine.

5. Start engine. Allow to run for afew seconds and then shut

down the engine.

6. Check the oil level. See Checking Oil Level in the Assembly

section of this manual.

Air Filter Service

Paperfilterscannotbecleanedandshouldbe replacedevery100

operatinghours;moreoftenif usedinextremelydustyconditions.

Neverusegasolineor lowflashpointsolventsforcleaningtheairfilter

element.Afire or explosioncould result.

23

Figure23

Removetheairfilter.SeeFig.24.

/

{ '_, ..................................../

Figure24

/ i

/

.

Removethefoampre-filterfromaroundthe paperair filter. See

Fig.25.Replacepaperelementwhendirtyor damaged.Clean

foamelementor replacewhendamaged.

Air Filter.

Figure25

4. Tocleanfoamelement,washina mildliquiddetergentandwater.

Squeezeor pressthefoamelementto rinseoutdirtandwater.Do

nottwist; thiscoulddamageortearthefoamelement.Allowto

drythoroughlybeforeusing.DO NOToilthe foamelement.

5. Attachthe newairfilterwithfoamelement,aligningtheholeinthe

airfilterwiththeintakemanifold.SeeFig.26.

Air Filter

Plastic

Feature

Shroud

)

Feature

Figure27

Spark Plug Service

DONOTcheckforsparkwith sparkplugremoved.DONOTcrank

enginewithsparkplugremoved.

Toensureproperengineoperation,the sparkplugmustbeproperly

gappedandfreeof deposits.

1. Removethesparkplugbootandusea sparkplugwrenchto

removethe plug.SeeFig.28.

Figure26

.

Attachtheair filtercover,makingsuretoalignplasticribfeatures

ontheshroudtothe plasticfeaturesontheair filtercover.See

Fig.27.Turnthumbscrewsclockwiseuntilsnug.Checkfor any

misalignment.

Iftheenginehas beenrunning,themufflerwillbeveryhot.Becareful

notto touchthemuffler.

SparkPlug

R.

Figure28

.

Visuallyinspectthe sparkplug.Discardthesparkplugifthereis

apparentwear,orif theinsulatoriscrackedorchipped.Cleanthe

sparkplugwitha wirebrushif it is tobe reused.

24

.

Measurethe pluggapwitha feelergauge.Correctas necessary

bybendingsideelectrode.SeeFig.29.Thegapshouldbesetto

between0.024-0.031in.

f

Electrode

Figure29

4.

Checkthatthe sparkplugwasheris ingoodconditionandthread

thesparkplugin byhandtopreventcross-threading.

5.

Afterthesparkplugis seated,tightenwithasparkplugwrenchto

compressthe washer.

NOTE: Wheninstallinga newsparkplug,tighten1/2turnafter

thesparkplugseatstocompressthewasher.Whenreinstallinga

usedsparkplug,tighten1/8-1/4turnafterthe sparkplugseatsto

compressthe washer.

IMPORTANT: The sparkplugmustbesecurelytightened.An

improperlytightenedsparkplugcan becomeveryhotandmay

damagetheengine.

Fuel Filter Service

To DrainThe Fuel:

1. Locatethefuelfilter,whichisroutedontheleftsideof theengine

betweenthefueltankandthecarburetor,andmaybeattachedto

theenginewithatie strap.Cutthetiestrap,ifpresent,thenpinch

thein-lineclamponthe fuelfilterwithapairofpliers,slidethe

clampupthefuelline.Pullthefuellinefreefromthefilterandplace

theopenendofthelineintoanapprovedcontainertodrainthefuel.

ToChangeThe FuelFilter:

2. Usepliersto squeezethetabson the otherclamp(theout-line

sideof thefuelfilter),and slidetheclampawayfromthefuelfilter.

Twistandpullthefuel lineoffof thefuelfilter.SeeFig.30.

3. Checkthefuellinesforcracksorleaks.Replaceifnecessary.

4. Replacethefuel filterwithanoriginalequipmentreplacementfilter.

Call1-800-4-MY-HOME®topurchasetheoriginalequipment

replacementfilter.

.

Securethefuellineswiththeclamps.

Thefuelfiltercannotbecleanedandshouldbe replacedevery100

operatinghours;moreoftenif runwitholdgasoline.

FuelFilter /

Tab

Fuel Line

Gasolineanditsvaporsareextremelyflammableandexplosive.Fire

or explosioncancausesevereburnsor death.

• Keepgasolineawayfromsparks,openflames,pilotlights,heat,

andotherignitionsources.

• Checkfuellines,tank,cap,andfittingsfrequentlyforcracksor

leaks.Replaceif necessary.

• Beforereplacingthe fuelfilter,drainthefueltankasinToDrain

theFuel.

• Donotdrainfuel whentheengineishot.Allowtheengine

adequatetimetocool. Drainfuelintoanapprovedcontainer

outdoors,awayfromopenflame.

• Drainanylargevolumeoffuelfromthe tankby disconnectingthe

fuellinefromthe in-linefuelfilterneartheengine.

• RemovethefuellinefromtheIn-lineside(sidetowardsthefuel

tank)ofthefuelfilter.

• Replacementpartsmustbethesameandinstalledinthesame

positionasthe originalparts.

• If fuelspills,waituntil itevaporatesbeforestartingengine.

• Beforereplacingthe fuelfilter,drainthefueltank.Otherwise,fuel

canleakoutand causea fireor explosion.

\

\

Figure30

Clean Engine

Iftheenginehasbeenrunning,allowit tocoolforatleasthalfanhour

beforecleaning.Periodicallyremovedirtbuild-upfromengine.Cleanthe

enginecoolingfinsevery25hours.Cleanwitha brushorcompressed

air.

IMPORTANT: Donotsprayenginewithwatertocleanbecausewa-

tercouldcontaminatefuel. Usinga gardenhoseorpressurewashing

equipmentcan alsoforcewaterintotheair cleanerormuffleropening.

Waterin theaircleanerwillsoakthepaperelement,andwaterthat

passesthroughthe elementormufflercanenterthecylinder,causing

damage.

Accumulationofdebrisaroundmufflercouldcausea fire.Inspectand

cleanbeforeeveryuse.

25

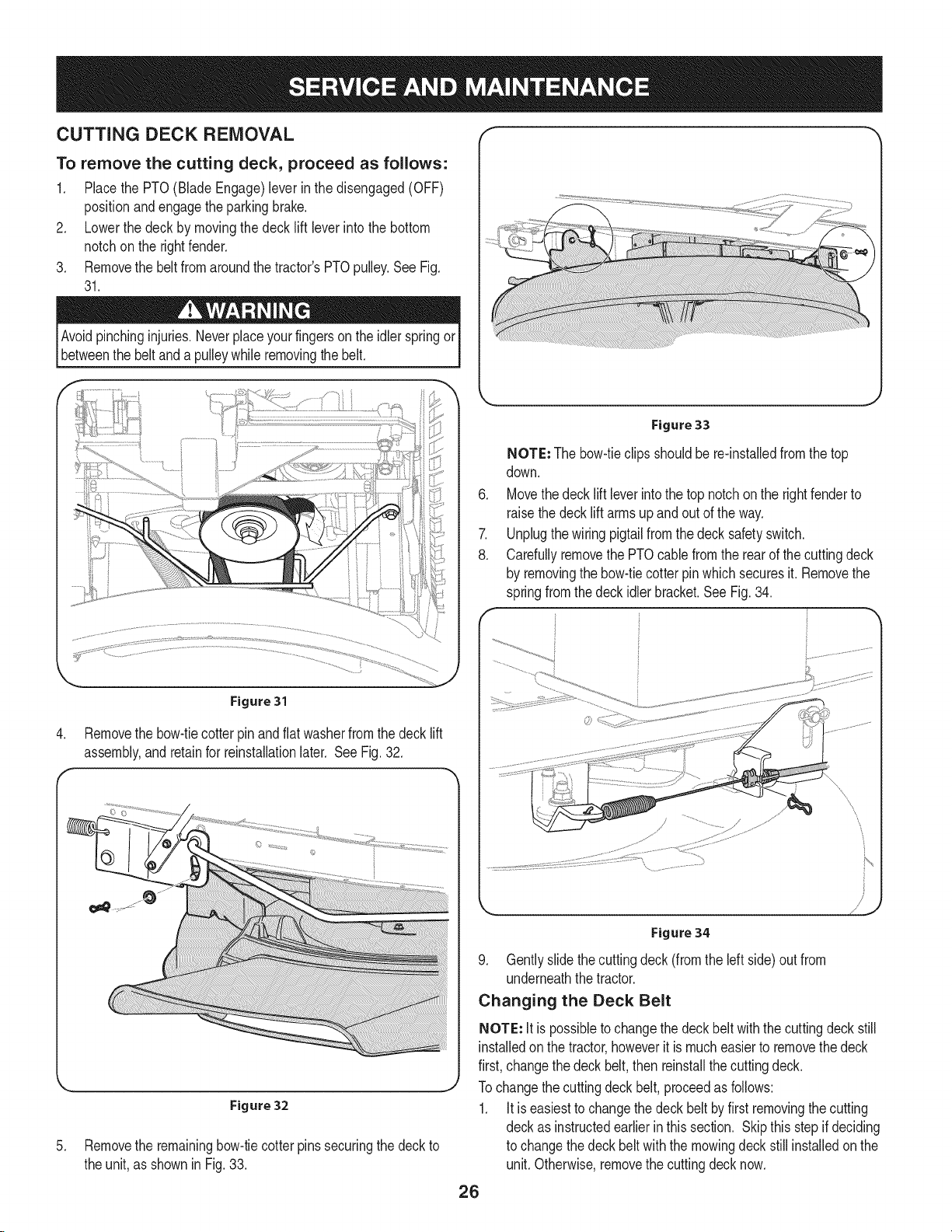

CUTTING DECK REMOVAL

To remove the cutting deck, proceed as follows:

1. Placethe PTO(BladeEngage)leverin the disengaged(OFF)

positionandengagetheparkingbrake.

2. Lowerthe deck bymovingthe deck lift lever intothe bottom

notchon therightfender.

3. Removethe beltfromaroundthetractor'sPTOpulley.SeeFig.

31.

Avoidpinchinginjuries.Neverplaceyourfingersontheidlerspringor

betweenthe beltanda pulleywhileremovingthebelt.

k,__ j

Figure 33

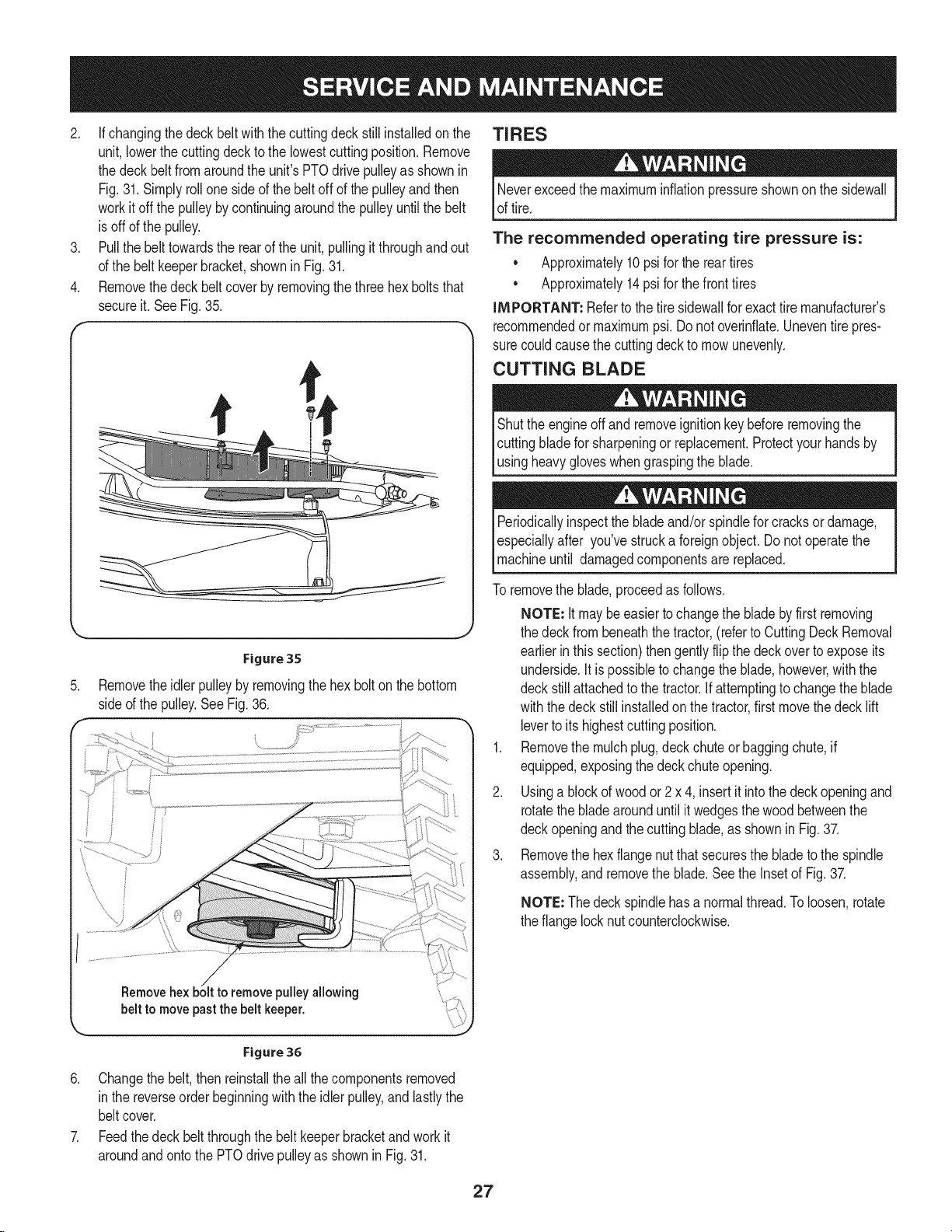

NOTE: Thebow-tieclipsshouldbe re-installedfromthetop

down.

.

Movethedecklift leverintothetopnotchon therightfenderto

raisethedecklift armsupandout oftheway.

7.

Unplugthewiringpigtailfromthedecksafetyswitch.

8.

CarefullyremovethePTOcablefromtherearof thecuttingdeck

by removingthe bow-tiecotterpinwhichsecuresit.Removethe

springfromthe deckidlerbracket.SeeFig.34.

F

Figure 31

4. Removethe bow-tiecotterpin andflat washerfromthe decklift

assembly,andretainfor reinstallationlater. SeeFig.32.

,._ j

Figure 32

5. Removethe remainingbow-tiecotterpinssecuringthedeckto

theunit,as shownin Fig.33.

Figure 34

9. Gentlyslidethecuttingdeck (fromtheleftside)outfrom

underneaththetractor.

Changing the Deck Belt

NOTE: Itispossibleto changethedeckbeltwiththecuttingdeckstill

installedonthetractor,howeveritis mucheasiertoremovethedeck

first,changethedeck belt,thenreinstallthecuttingdeck.

Tochangethecuttingdeckbelt,proceedasfollows:

1. Itiseasiesttochangethedeckbeltby firstremovingthe cutting

deckasinstructedearlierinthis section. Skipthisstepifdeciding

tochangethedeckbeltwiththemowingdeckstillinstalledonthe

unit.Otherwise,removethe cuttingdecknow.

26

2. If changingthedeckbelt withthecuttingdeckstillinstalledonthe

unit,lowerthecuttingdeckto thelowestcuttingposition.Remove

thedeckbeltfromaroundtheunit'sPTOdrivepulleyasshownin

Fig.31.Simplyrollone sideofthebeltoff ofthepulleyandthen

workitoffthe pulleybycontinuingaroundthepulleyuntilthebelt

isoff ofthepulley.

3. Pullthebelttowardstherearoftheunit,pullingit throughandout

ofthe beltkeeperbracket,shownin Fig.31.

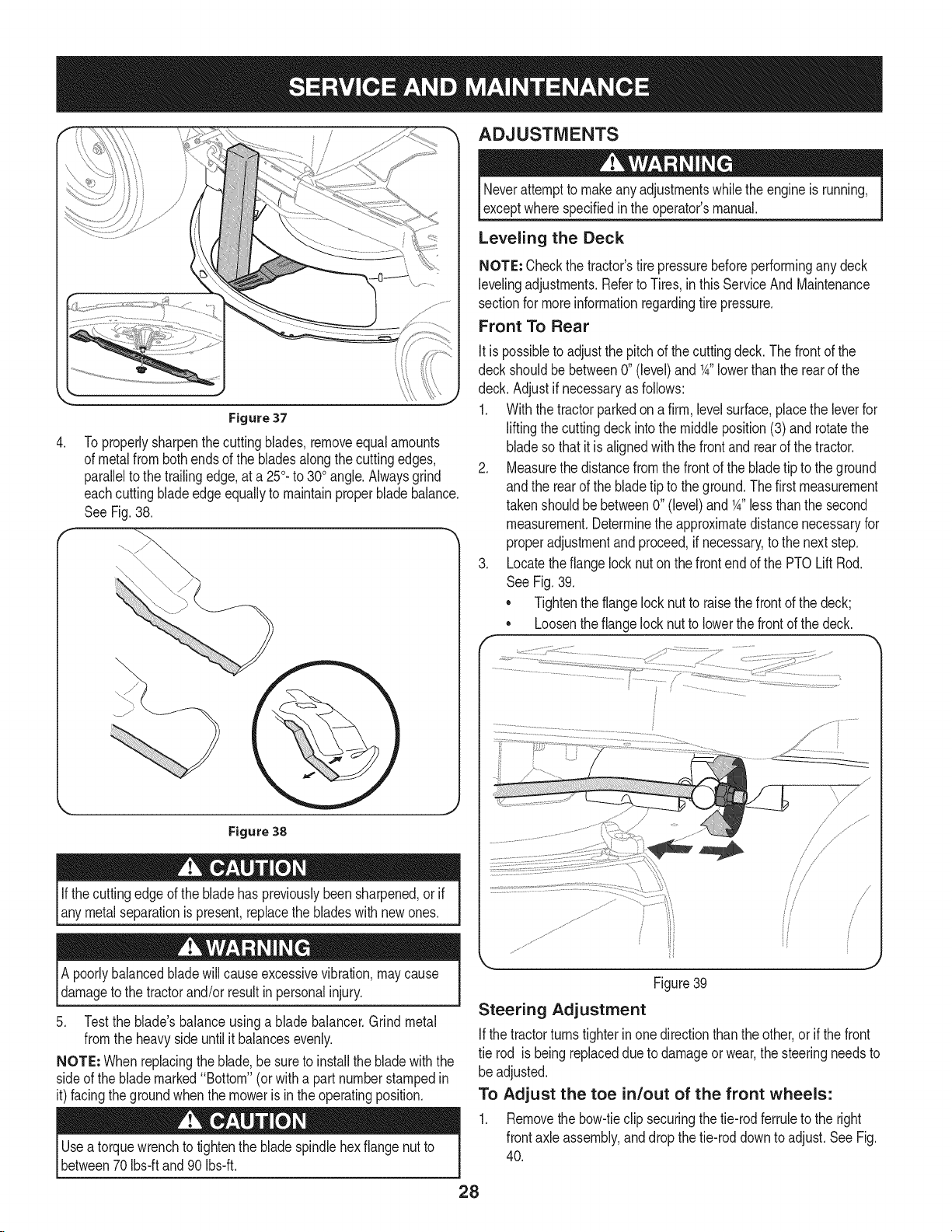

4. Removethedeckbeltcoverby removingthethreehexboltsthat

secureit. SeeFig.35.

f

TIRES

Neverexceedthe maximuminflationpressureshownonthesidewall

oftire.

The recommended operating tire pressure is:

• Approximately10psiforthe reartires

• Approximately14psi forthefronttires

IMPORTANT: Refertothetiresidewallfor exacttiremanufacturer's

recommendedormaximumpsi.Donotoverinfiate.Uneventirepres-

surecouldcausethecuttingdeckto mowunevenly.

CUTTING BLADE

Shutthe engineoff and removeignitionkeybeforeremovingthe

cuttingbladefor sharpeningor replacement.Protectyourhandsby

_usngheavygoveswhengraspngthe bade.

Periodicallyinspectthebladeand/orspindleforcracksor damage,

especiallyafter you'vestrucka foreignobject.Donotoperatethe

machineuntil damagedcomponentsarereplaced.

Figure 35

.

Removetheidlerpulleyby removingthehex boltonthebottom

sideof thepulley.SeeFig.36.

/

pulleyallowing

belt to move pastthe belt keeper.

Toremovetheblade,proceedasfollows.

NOTE: It maybeeasiertochangethebladebyfirstremoving

thedeckfrombeneaththetractor,(refertoCuttingDeckRemoval

earlierinthis section)thengentlyflipthedeckovertoexposeits

underside.Itispossibleto changetheblade,however,withthe

deckstillattachedto thetractor.Ifattemptingtochangetheblade

withthedeckstillinstalledonthetractor,firstmovethe decklift

levertoitshighestcuttingposition.

1. Removethemulchplug,deckchuteorbaggingchute,if

equipped,exposingthedeckchuteopening.

2. Usinga blockof woodor 2 x 4, insertit intothedeckopeningand

rotatethebladearounduntilit wedgesthewoodbetweenthe

deckopeningandthecuttingblade,as showninFig.37.

3. Removethehexflangenutthatsecuresthebladetothe spindle

assembly,and removetheblade.Seethe Insetof Fig.37.

NOTE: Thedeckspindlehasa normalthread.Toloosen,rotate

theflangelocknutcounterclockwise.

Figure 36

6. Changethebelt,thenreinstallthe allthe componentsremoved

in thereverseorderbeginningwith theidlerpulley,andlastlythe

beltcover.

7. Feedthedeck beltthroughthebeltkeeperbracketandworkit

aroundandontothe PTOdrivepulleyasshownin Fig.31.

27

Figure 37

.

Toproperlysharpenthecuttingblades,removeequalamounts

ofmetalfrombothendsof thebladesalongthecuttingedges,

paralleltothe trailingedge,ata 250.to300angle.Alwaysgrind

eachcuttingbladeedgeequallyto maintainproperbladebalance.

SeeFig.38.

\

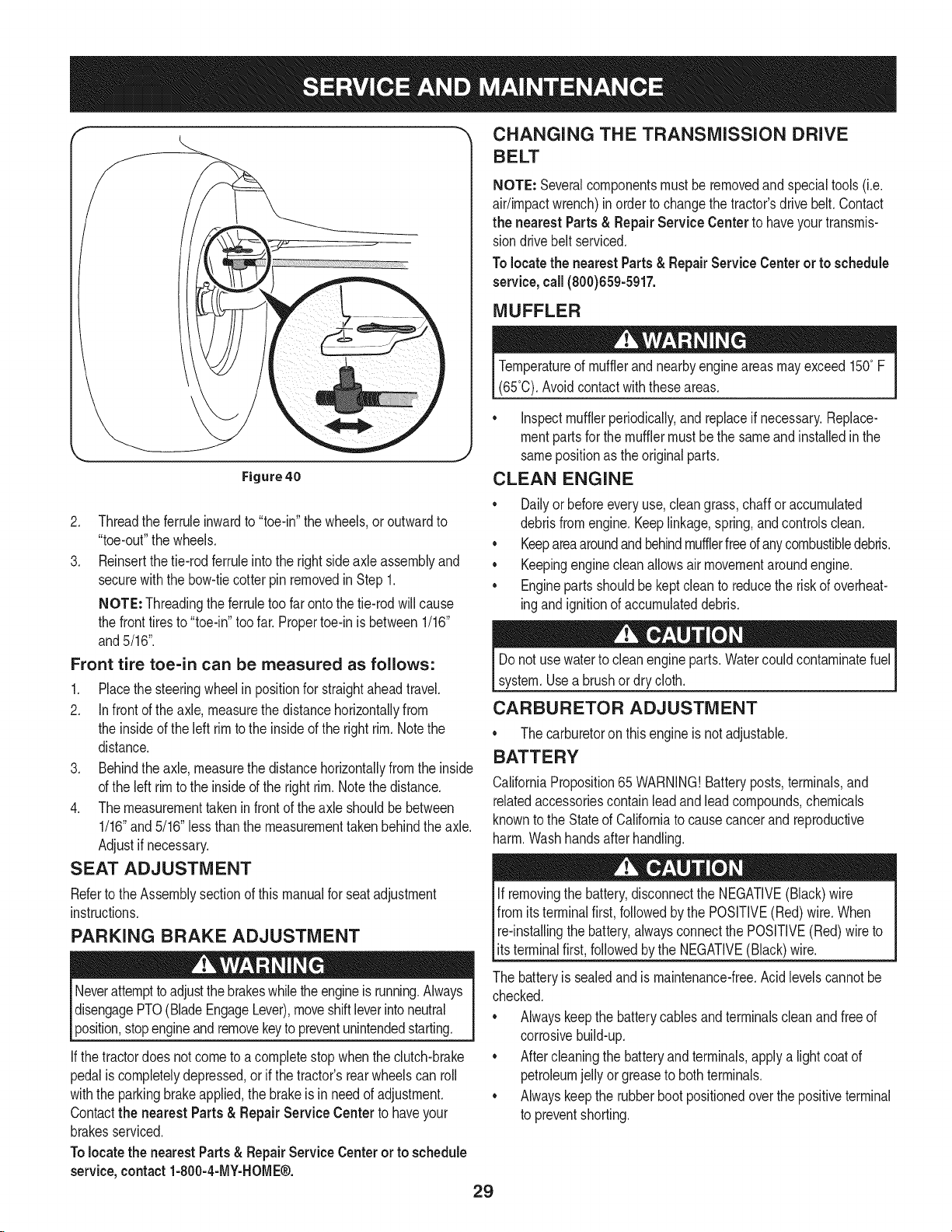

ADJUSTMENTS

Neverattemptto makeanyadjustmentswhilethe engineisrunning,

exceptwherespecifiedinthe operator'smanual.

Leveling the Deck

NOTE: Checkthetractor'stire pressurebeforeperforminganydeck

levelingadjustments.RefertoTires,inthis ServiceAndMaintenance

sectionfor moreinformationregardingtirepressure.

Front To Rear

Itis possibletoadjustthepitchofthe cuttingdeck.Thefrontof the

deckshouldbe between0"(level)andK" lowerthantherearof the

deck.Adjustif necessaryasfollows:

1. Withthetractorparkedona firm,levelsurface,placetheleverfor

liftingthecuttingdeckintothe middleposition(3)and rotatethe

bladesothatit is alignedwiththe frontand rearofthe tractor.

2. Measurethedistancefromthefrontof thebladetiptothe ground

andthe rearofthebladetip to theground.Thefirstmeasurement

takenshouldbebetween0"(level)andK" lessthanthesecond

measurement.Determinethe approximatedistancenecessaryfor

properadjustmentandproceed,if necessary,tothenextstep.

3. Locatetheflangelocknutonthe frontendof thePTOLift Rod.

See Fig.39.

• Tightentheflangelocknut toraisethefrontofthedeck;

• Loosentheflangelocknutto lowerthefrontof thedeck.

J

Figure 38

If thecuttingedgeofthebladehaspreviouslybeensharpened,or if

anymetalseparationispresent,replacethe bladeswithnewones.

A poorlybalancedbladewillcauseexcessivevibration,maycause

damagetothetractorand/orresultinpersonalinjury.

5. Testthe blade'sbalanceusinga bladebalancer.Grindmetal

fromtheheavysideuntilit balancesevenly.

NOTE: Whenreplacingtheblade,besureto installthe bladewiththe

sideof theblademarked"Bottom"(orwitha partnumberstampedin

it)facingthe groundwhenthemowerisin theoperatingposition.

Useatorquewrenchto tightenthebladespindlehexflangenutto

between70 Ibsiftand90 Ibsift.

/ J

/< j

//

Figure39

Steering Adjustment

Ifthetractorturnstighterinonedirectionthanthe other,or ifthe front

tie rod isbeingreplaceddueto damageorwear,thesteeringneedsto

be adjusted.

To Adjust the toe in/out of the front wheels:

1. Removethebow-tieclip securingthetie-rodferruletothe right

frontaxleassembly,anddropthetie-roddowntoadjust.See Fig.

40.

28

s//

i

Figure 40

2. Threadtheferruleinwardto"toe-in"thewheels,oroutwardto

"toe-out"thewheels.

3. Reinsertthetie-rodferruleintothe rightsideaxleassemblyand

securewiththebow-tiecotterpinremovedin Step1.

NOTE: Threadingtheferruletoo farontothetie-rodwillcause

thefronttiresto "toe-in"too far.Propertoe-inis between1/16"

and5/16".

Front tire toe-in can be measured as follows:

1. Placethesteeringwheelin positionfor straightaheadtravel.

2. Infrontof the axle,measurethedistancehorizontallyfrom

theinsideofthe leftrim totheinsideofthe rightrim.Notethe

distance.

3. Behindtheaxle,measurethedistancehorizontallyfromthe inside

ofthe left rimto theinsideoftherightrim.Notethe distance.

4. Themeasurementtakeninfrontoftheaxle shouldbebetween

1/16"and5/16"lessthanthemeasurementtakenbehindthe axle.

Adjustif necessary.

SEAT ADJUSTMENT

Refertothe Assemblysectionofthismanualforseatadjustment

instructions.

PARKING BRAKE ADJUSTMENT

Neverattempttoadjustthe brakeswhiletheengineisrunning.Always

disengagePTO(BladeEngageLever),moveshiftleverintoneutral

position,stopengineandremovekeytopreventunintendedstarting.

If thetractordoesnotcometoacompletestopwhenthe clutch-brake

pedaliscompletelydepressed,orif thetractor'srearwheelscanroll

withtheparkingbrakeapplied,thebrakeisin needofadjustment.

Contactthe nearest Parts & Repair Service Center tohaveyour

brakesserviced.

Tolocate thenearest Parts&RepairServiceCenterortoschedule

service,contact1-800-4-MY-HOME®.

CHANGING THE TRANSMISSION DRIVE

BELT

NOTE: Severalcomponentsmustbe removedandspecialtools(i.e.

air/impactwrench)in ordertochangethetractor'sdrivebelt.Contact

the nearest Parts& RepairService Centertohaveyourtransmis-

siondrivebeltserviced.

Tolocatethe nearestParts& RepairServiceCenterorto schedule

service, call(800)659-5917.

MUFFLER

Temperatureof mufflerandnearbyengineareasmayexceed150°F

(65°0).Avoidcontactwiththeseareas.

• Inspectmufflerperiodically,andreplaceif necessary.Replace-

mentpartsforthe mufflermustbe thesameandinstalledinthe

samepositionastheoriginalparts.

CLEAN ENGINE

• Dailyor beforeeveryuse,cleangrass,chafforaccumulated

debrisfromengine.Keeplinkage,spring,andcontrolsclean.

• Keepareaaroundandbehindmufflerfreeofanycombustibledebris.

• Keepingenginecleanallowsair movementaroundengine.

• Enginepartsshouldbekeptcleanto reducetheriskofoverheat-

ingandignitionofaccumulateddebris.

Donot usewatertocleanengineparts.Watercouldcontaminatefuel

system.Usea brushordrycloth.

CARBURETOR ADJUSTMENT

• Thecarburetoron thisengineis notadjustable.

BATTERY

CaliforniaProposition65WARNING!Batteryposts,terminals,and

relatedaccessoriescontainleadandleadcompounds,chemicals

knownto the Stateof Californiatocausecancerandreproductive

harm.Washhandsafterhandling.

If removingthe battery,disconnecttheNEGATIVE(Black)wire

fromitsterminalfirst,followedbythe POSITIVE(Red)wire.When

re-installingthebattery,alwaysconnectthePOSITIVE(Red)wireto

[ts termna f rst,fo owedbytheNEGATVE (Back) wre.

Thebatteryissealedandismaintenance-free.Acidlevelscannotbe

checked.

• Alwayskeepthebatterycablesandterminalscleanandfreeof

corrosivebuild-up.

• Aftercleaningthebatteryandterminals,applyalightcoatof

petroleumjellyorgreasetobothterminals.

• Alwayskeepthe rubberbootpositionedoverthepositiveterminal