MSI CRANE SCALE Maintance Manual

MSI

CRANE SCALE

SAFETY

AND

PERIODIC

MAINTENANCE

MANUAL

Safe Rigging, Loading and Operation

Including Suggested Inspection

and Maintenance Procedures

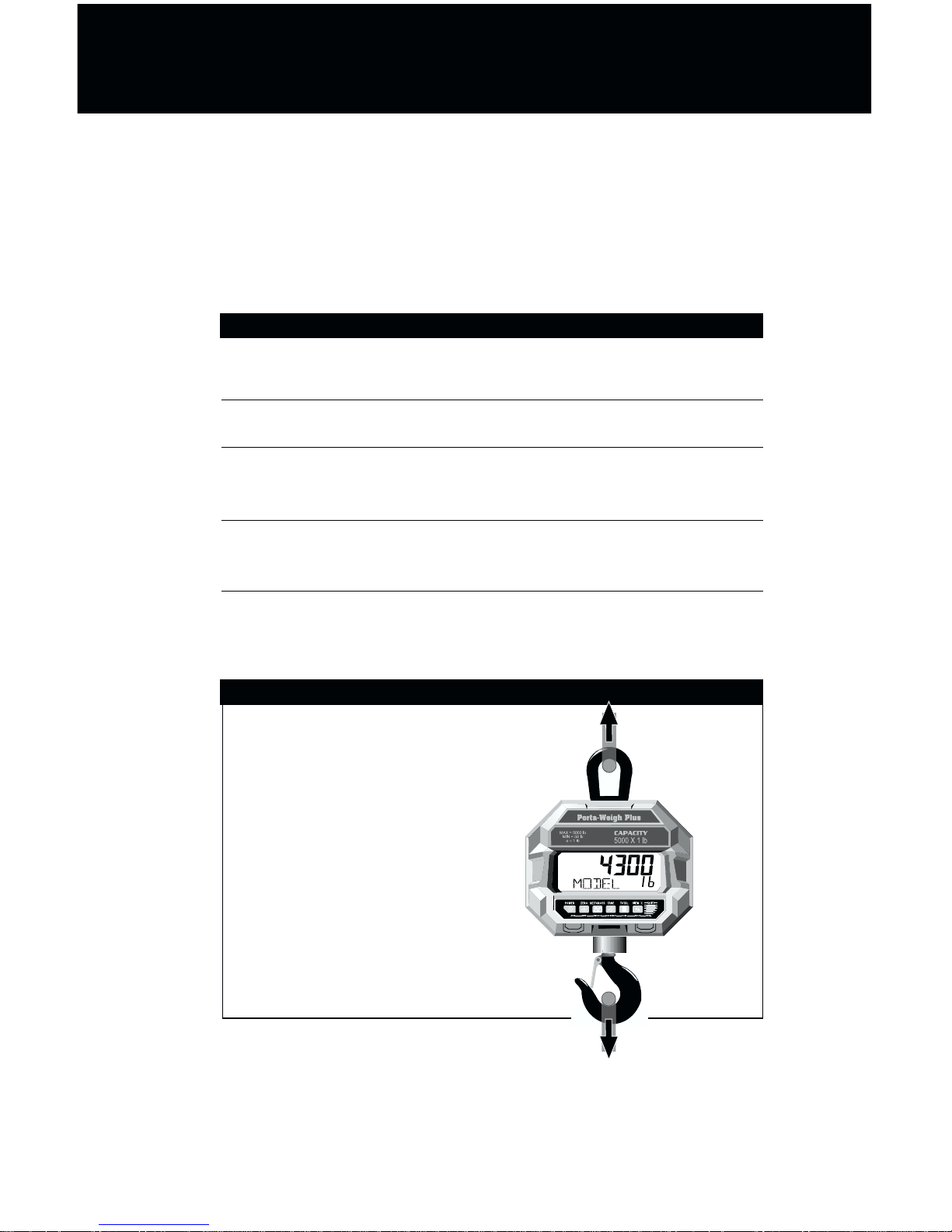

MODEL

SERIAL NUMBER

Measurement Systems International

www.msiscales.com

2

M E A S U R E M E N T S Y S T E M S I N T E R N A T I O N A L

S A F E T Y M A N U A L

M S I C R A N E S C A L E

S A F E T Y M A N U A L

M S I C R A N E S C A L E

3

M E A S U R E M E N T S Y S T E M S I N T E R N A T I O N A L

S A F E T Y M A N U A L

M S I C R A N E S C A L E

Table of Contents

Forward ................................................................................ 3

Safe Operating Guidelines ....................................................4

Operating suggestions .......................................................4

Handling hoist motion ........................................................4

Safe Loading and Rigging Guidelines....................................5

Loading Procedure "Do's" & "Don'ts" - Illustrations .......... 6-8

Recommended Inspection Procedures .................................8

Load Train Visual Inspection Suggestions .............................9

Visual Inspection of Shackles ................................................9

Shackle Field Inspection Areas .......................................... 10

Shackles with Excessive Wear ............................................ 10

Improper Replacement of Pins in Shackle.......................... 11

Overloaded Shackle ............................................................ 11

Shackle Eye with Twist ........................................................11

Scale Hook Inspection .................................................. 11-12

Field Inspection and Repair .................................................12

Recommended Preventive Maintenance ....................... 13-14

Notes ................................................................................. 15

Forward

This manual has been prepared to provide information and

suggestions for safe operation, rigging, inspection, and

maintenance of Measurement Systems International (MSI)

Crane Scales.

It is not intended that the suggestions in this manual take

precedence over existing plant safety rules and regulations,

OSHA regulations, or instructions issued by the crane manu-

facturer. However, a thorough study of the following information should provide a better understanding of operation and

afford a greater margin of safety for personnel and machinery.

It must be recognized that this is a manual of suggestions for

the crane scale operator’s use. It is the responsibility of the

owner to make personnel aware of all federal, state and local

rules and codes and to make certain that operators are

properly trained.

4

M E A S U R E M E N T S Y S T E M S I N T E R N A T I O N A L

S A F E T Y M A N U A L

M S I C R A N E S C A L E

Safe Operating Guidelines

Before operating a MSI crane scale, the scale operator should

carefully read and study the appropriate Operation Manual

supplied by

MSI and note any special instructions.

Operating suggestions

1. Do not make lifts beyond rated load capacity of the

crane scale, sling chains, rope slings, etc.

2. Do not operate the crane scale if ropes, slings, cables,

chains, etc. show any sign of defects or excessive wear.

3. Before moving the load, make certain that load slings,

load chains or other lifting devices are fully seated in the

saddle of the crane scale hook with hook latch closed.

4. At no time should a load be left suspended from the

crane scale unless the operator is at the master

switch or push buttons with the power on; and under

this condition keep the load as close to the floor as

possible to minimize the possibility of an injury, should

the load drop. When the crane scale is holding a load,

the crane operator should remain at the master switch or

push buttons.

5. When a hitcher is used, it should be the joint responsibility of the crane operator and the hitcher to see that

hitches are secure and that all loose material has been

removed from the load before starting a lift.

6. Do not lift loads with ropes, slings, cables, chains, etc.

hanging loose.

7. All ropes, slings, cables, chains, etc. should be removed

from the crane scale when not in use. (A dangling cable

can inadvertently snag other objects when the crane is

moving.)

8. Operators should not maneuver a loaded crane scale

over personnel.

Handling hoist motion

After the crane scale hook has been positioned over the load,

lower it until the load can be attached to the scale hook. As

the scale hook approaches this level, reduce the speed so

that the lowering can be stopped smoothly and quickly.

S A F E T Y M A N U A L

M S I C R A N E S C A L E

5

M E A S U R E M E N T S Y S T E M S I N T E R N A T I O N A L

S A F E T Y M A N U A L

M S I C R A N E S C A L E

If load slings are used to handle the load, the slings should be

fully seated in the saddle of the scale hook. With the scale

hook latch closed, the scale hook should be started upward

slowly until all slack has been taken out of the slings. Then

ensure the load is properly balanced and the slings are

properly positioned.

WARNING!

Loads may disengage from crane scale hook and shackle or

lifting eye if proper procedures are not followed.

A falling load may cause serious injury or death.

The crane scale hook must always support the load. The load

must never be supported by the latch.

Never lift more than the crane scale's assigned Working Load

Limit (WLL) rating.

Read and understand the instructions in this manual before

using the crane scale.

In-line Loading

• CAPACITY RATINGS ON THE

CRANE SCALE ARE FOR IN-LINE

LOADING.

• USE HARDWARE THAT CREATES

SINGLE POINT ATTACHMENTS

AND ALLOWS THE SCALE

FREEDOM OF ALIGNMENT.

Safe Loading and Rigging Guidelines

Loading...

Loading...