Page 1

MSI-9300 Series

Porta-Weigh+

Crane Scale

MSI-9300 Crane Scales

MSI-9300HT Hi-Torque Crane Scales

User

Guide

Measurement Systems International

Page 2

MSI-9300 Porta-Weigh+ Crane Scale

TABLE OF CONTENTS

SECTION 1 – INTRODUCTION & INSTALLATION .........................................................................................3

Introduction ...................................................................................................................................................3

Installation .....................................................................................................................................................3

Battery Removal & Replacement ..................................................................................................................4

Battery Life ....................................................................................................................................................5

Battery Charger ..............................................................................................................................................5

FCC Statement ...............................................................................................................................................6

MSI-9300 Porta-Weigh Plus Display ............................................................................................................

Keyboard Operations .....................................................................................................................................7

SECTION 2 – SCALE OPERATION .............................................................................................................8

POWER .........................................................................................................................................................8

Multiple scale channels .................................................................................................................................8

ZERO .............................................................................................................................................................8

TARE .............................................................................................................................................................

Special TARE Modes ..................................................................................................................................

NET/GROSS ...............................................................................................................................................10

UNITS .........................................................................................................................................................10

TEST ............................................................................................................................................................11

Internal Temperature Display ......................................................................................................................

RF List .........................................................................................................................................................11

SECTION 3 – MSI-9300 SETUP MENU .................................................................................................12

Key Functions during Setup ........................................................................................................................12

Setup Menu Structure ..................................................................................................................................12

User Key Function .......................................................................................................................................13

Automatic Off ..............................................................................................................................................13

Units ............................................................................................................................................................14

Total .............................................................................................................................................................

Automatic Temperature Display ..................................................................................................................16

RF LIST Scrolling .......................................................................................................................................16

7

9

10

11

15

SECTION 4 – RF REMOTE CONTROL ..................................................................................................... 18

Description ..................................................................................................................................................18

Functions .....................................................................................................................................................18

Setting the Transmitter Address ...................................................................................................................

Contention Considerations ..........................................................................................................................19

Battery Replacement ...................................................................................................................................19

RF Remote Control FCC Statement ............................................................................................................19

18

SECTION 4 – THE EMBEDDED CELLSCALE ............................................................................................20

Accessing The CellScale .............................................................................................................................20

Connection Procedure .................................................................................................................................20

Comm port Cable ........................................................................................................................................20

Set Points .....................................................................................................................................................21

Password Protection ....................................................................................................................................21

Scale Calibration .........................................................................................................................................21

Calibration Procedure ..................................................................................................................................22

CellScale Settings for MSI-9300 .................................................................................................................26

RF System Setup .........................................................................................................................................27

Legal Standard .............................................................................................................................................27

Setting the Legal Standard Mode ................................................................................................................27

Legal-For-Trade Control Device .................................................................................................................28

Sealing MSI-9300 Crane Scales ..................................................................................................................29

APPENDIX – SPECIFICATIONS & DIMENSIONS .........................................................................................31

Hardware Overview .....................................................................................................................................31

General Features ..........................................................................................................................................31

General Specifications .................................................................................................................................32

Dimensions and Load Train Specifications, Standard MSI-9300 ...............................................................33

Dimensions and Load Train Specifications, MSI-9300HT ......................................................................33

Options and Accessories ..............................................................................................................................

The MSI Limited Warranty .........................................................................................................................

34

34

Page 2 MSI-9300 Crane Scale™ • User Guide

Page 3

MEASUREMENT SYSTEMS INTERNATIONAL

DO

USE HARDWARE THAT CREATES SINGLE

POINT ATTACHMENTS AND ALLOWS THE

SCALE FREEDOM OF ALIGNMENT.

DO NOT

DO NOT USE MULTIPLE ATTACHMENTS.

DO NOT

1. DO NOT PUSH OR PULL ON LOADED

SCALE. 2. DO NOT PULL LATERALLY ON

HOOK WITH SCALE LOADED.

DO NOT

DO NOT INTERFACE HARDWARE

(SHACKLES, HOOKS ETC.) THAT ARE

OVERSIZED AND RESTRICT

SINGLE POINT

LOADING AND SELF-ALIGNMENT WHICH

CAN RESULT IN OFF-AXIS LOADING.

SECTION 1 – INTRODUCTION & INSTALLATION

INTRODUCTION

The Measurement Systems International MSI-9300 Series Porta-Weigh Plus Crane Scales are designed to

provide a rugged weight indicator and data system for any type and size of crane used in industry. Two basic

styles are available: MSI-9300 and MSI-9300HT. This guide is used for both versions as they have identical

electronics.

The standard MSI-9300 is supplied with rotating hooks or shackle interfaces. The MSI-9300HT Hi-Torque

version features a fixed load train that does not rotate and a new load cell design that withstands the induced

torque associated with power assisted rotating loads. With options available for both top and bottom interfaces, the MSI-9300HT easily integrates with existing powered rotators to provide safe material handling and

increased operational efficiency. The MSI-9300 Series combines CellScale technology with MSI’s advanced

Crane Scale architecture providing both a local and remote display capability. Combined with CellScale accessory components, they become advanced data gathering networks suitable for process control, safety monitoring, and weight related data collection.

The circuitry is fully shock-mounted and water proof making a robust

overhead weighing system for use indoors and out. The large 1.2” (30mm)

ultra bright LED readable at distances up to 50’ (15m). Display brightness can be set to automatically adjust to ambient lighting conditions for

optimum viewing and battery conservation.

The MSI-9300 Series crane scales can communicate with CellScale family

indicators and modems at distances up to 1000’ (300m) outdoors (even

further with gain antennas). Both fixed and handheld indicators are available, as well as Modems for direct connection to computers. A remote

4-20mA interface is available for direct connection to PLCs and other

process control equipment. CellScale Virtual Monitor (CVM) software is

available to enable your PC to act as a full-featured digital scale indicator

with data logging capabilities.

INSTALLATION

The MSI-9300 installs easily by hanging it on the crane, using properly

sized shackles. Follow proper loading procedures to ensure that side loading is eliminated. Please refer to MSI’s brochure, “Crane Safety” when

installing model MSI-9300.

One of the most common installation problems is using an oversize

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 3

Page 4

MSI-9300 Porta-Weigh+ Crane Scale

shackle or too large a hook to interface with the MSI-9300. This can cause off center loading and stress points

that will reduce the life of the MSI-9300 lifting eye or hook. Use the appropriate interface hardware for the

capacity of the scale. If your interface hardware does not fi t properly, MSI can supply the MSI-9300 with

oversize lifting eyes or shackle interfaces. If the crane hook is too large to fi t in the lifting eye with single point

interface, then install the scale using adaptive rigging.

If multiple attachments are needed, use a shackle or ring to attach the multiple lines to thus keeping a single

point attachment to the scale. Single point attachments are necessary to ensure the safety and accuracy of the

scale system.

Regular maintenance inspections of the lifting system should be performed to ensure safety. Pay particular

attention for signs of stress on any element in the load train.

BATTERY REMOVAL & REPLACEMENT

1) Turn the crane scale Off.

2) With one hand, hold the battery access to prevent it from falling.

3) Rotate the two cam-latch knobs counter-clockwise until the plate latches disengage.

4) Carefully back the plate out of the battery well.

5) Release the battery retaining strap.

Battery Access Plate

Cam-Latch Knobs

12V Sealed Lead Acid Battery

MSI P/N D00599-0004

The Battery Access Plate and

the Sealed Lead Acid Battery are

potential falling hazards. When

opening the battery access, be

sure to hold the battery to prevent

it from falling. This battery contains

Lead and should be recycled when

it has reached its end of life.

Page 4 MSI-9300 Crane Scale™ • User Guide

Page 5

MEASUREMENT SYSTEMS INTERNATIONAL

6) Remove the battery by pulling straight back.

7) Install a fully charged battery by plugging it in to the exposed battery jacks. The crane scale will turn on

briefly then turn itself off.

8) Reattach the battery retaining strap.

9) Reseat the access panel.

10) Put pressure on the plate to partly compress the gasket. While applying pressure, turn the cam-latch knobs

clockwise until the plate is reseated. Make sure the plate is firmly in place.

BATTERY LIFE

The MSI-9300 battery life depends on a number of factors: Brightness of the LED and number of segments lit,

the amount of RF activity, and the age and condition of the SLA (sealed lead acid) battery. The MSI-9300 will

automatically turn the scale off when the SLA battery drops to approximately 10.5V. You must recharge the

battery when this happens. Leaving a discharged battery in the scale, which has a maintenance battery drain,

can result in a deep discharged battery which will shorten its service life.

SLA batteries do not suffer from memory effects and actually benefit from frequent rechargings. Recharge

the battery whenever it is convenient even when it still has available life. Due to the maintenance discharge

imposed on the battery by the MSI-9300 electronics, do not store the MSI-9300 more than 7 days with the

battery inside. Remove the battery.

Battery Use Guidelines

1) Recharge whenever convenient. Do not wait for the scale to shut itself off if your work situation permits.

2) If you need the scale continuously, keep a fully charged spare battery. Replace the drained battery as close

as possible to the low battery warning, or earlier.

3) SLA Batteries that have not been deep discharged should withstand 500 to 1500 charging cycles.

4) The low battery warning will indicate about 2-4 hours of additional use before the MSI-9300 turns itself

off.

5) If the MSI-9300 is not going to used again soon, remove the SLA battery to prevent deep discharge while

the unit is in storage.

BATTERY CHARGER

Each MSI-9300 Series crane scale is shipped with a battery charger (MSI P/N 502221-0001) designed to

charge and maintain the battery. Exact charging time will depend on the degree of discharge of the battery. A

battery removed when the low battery warning first appears should take about 4-6 hours to fully charge. A deep

discharged battery might take 24 hours to recover.

Using the Charger

1) Remove the Battery from the 9300. See previous page for removal instructions.

2) Connect the charger assembly to the AC supply (86-260VAC). The Power Status light should be green. If

the power status light fails to illuminate, check your AC power connection and make sure the VAC jack is

fully seated.

3) Plug in the polarized connector to the jacks on the battery.

4) The Charge Status light should turn ORANGE indicating fast charge.

If the status light remains Green when the battery is first plugged in, the battery may be defective.

5) Charge until the status light turns GREEN.

Deep discharged batteries may require a couple days to recover full charge.

When the charge cycle is complete you can (and should) leave the battery on the charger until it is needed. The

charger keeps a maintenance float charge on the battery to ensure the best possible operation times. For scales

that are in high usage, MSI recommends obtaining a spare battery so one can always be on the charger.

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 5

Page 6

MSI-9300 Porta-Weigh+ Crane Scale

Charge Indicator Light

Amber = Charging

Green = Float

The charger is a universal input type and is rated for 100-240VAC, 50-60Hz. AC power cords suitable for any

world location are available from MSI.

FCC STATEMENT

FCC ID: HSW-2450M

Note: This unit has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at their

expense.

Page 6 MSI-9300 Crane Scale™ • User Guide

Page 7

MEASUREMENT SYSTEMS INTERNATIONAL

Ttl

0

MOTION

RF

2

BAT

LOW

Net Grs

kg lb

Tare

8.8.8.8.8.8

1

2

3

T

0

ZERO NET/GROSS TAREPOWER TEST

1 2 3 4 5

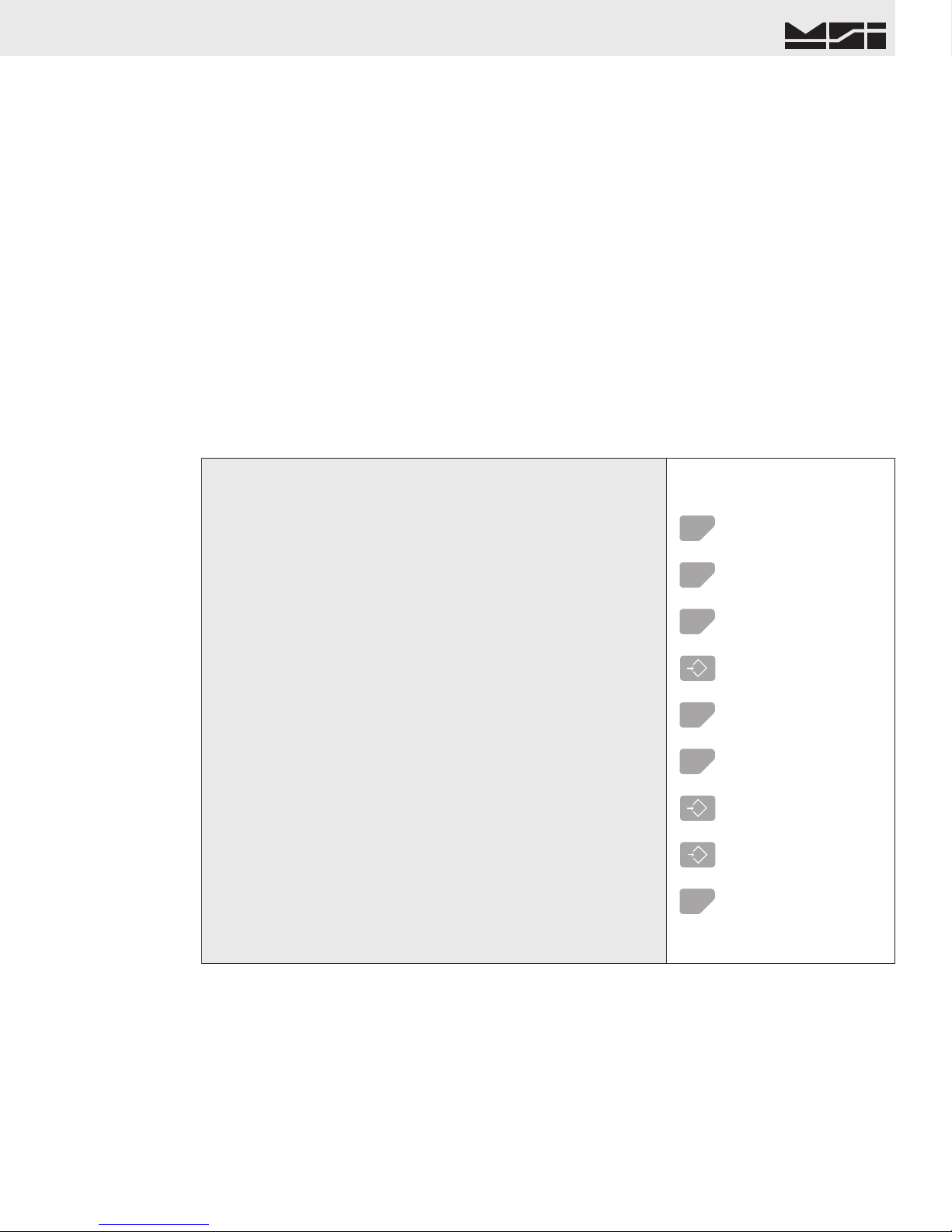

MSI-9300 PORTA-WEIGH PLUS DISPLAY

The MSI-9300 has six 1.2” (30.5mm) ultrabright LED Digits along with annunciators. The brightness of the

display is automatically adjusted to the lighting conditions. When the ambient light is dim, the LEDs are lower

in intensity. When ambient light is bright, the LED intensity level is increased to allow sunlight readability.

Light

6 Digit Weight and Data Display

Minus Sign

Only used when

six digits are displayed

Middle segment used

for ≤5 displayed digits

Center of Zero

Indicator

Sensor

Set Points

1-3

RF Comm

KEYBOARD OPERATIONS

1) POWER – Push to turn the scale on or off.

2) ZERO – Used to zero the scale. The zero range is usually 100% of full scale unless prohibited by legal-for

trade settings.

3) NET/GROSS – Switches scale between NET and GROSS weight readings (assuming a Tare value has

been stored).

4) TARE – When in GROSS mode, pushing TARE will zero any weight on the scale and cause the scale to go

Rev 1 7/27/02 for SW Ver 1-1

into the NET mode. When in NET mode, pushing TARE will display the TARE value for 2 seconds, then

revert back to the NET weight display. In NET mode, pushing TARE twice will set a new Tare. Pushing

TARE followed immediately by ZERO will clear the Tare value and revert the scale to Gross Mode

5) TEST/USER Key – When pushed, this causes a display segment check, and provides battery and RF

Network information. Also programmable for USER desired functions. See SETUP USER KEY. User Key

Functions Available: Units (kg/lb) • Total • Scan List Increment (multi-channel systems) • °F/°C • Change

Network (SW V3-33 and above) • Test (default)

Low Battery

Indicator

Warning

Weight in

Motion

Displaying

Tare Wt

Displaying

Total Wt

Displaying

Net Wt

Displaying

Gross Wt

MSI-9300 Crane Scale™ • User Guide Page 7

Wt Unit is

kilograms

Wt Unit is

pounds

Page 8

MSI-9300 Porta-Weigh+ Crane Scale

POWER

0

ZERO

SECTION 2 – SCALE OPERATION

POWER

To Turn On the Power

1) Push POWER. The system performs a display

check: All segments and annuciators illuminate

for 3 seconds.

2) The LED displays the firmware Rev number.

3) Next, the display shows the Network address

followed by the ID address. This is the operating network address for any slave device to log

onto.

The network and ID Address are usually but not always the

same. Numbers for Network range from 0 to 31 and for address

from 0-254. Initially the MSI-9300 display will not know the Network address and will skip this step.

4) The display begins a numeric test while the

CellScale component is establishing Network

and Comm Port connections. The count up pattern will continue for 10-20 seconds and will

sometimes restart. This is normal.

1

2 E00-25

3 nt 2

3 id 2

4 000000

4 11111

8.8.8.8.8.8

5) Once the RF Network is established and the

Comm Port connection to the display is set the

display will indicate “ConEct” [sic]. The scale is

now ready for operation.

MULTIPLE SCALE CHANNELS

MSI-9300 Series crane scales are capable of hosting multiple independent scale inputs. These are connected

via RF using MSI-6260CS and/or MSI-9300 Series crane scales setup as Network Slaves, or by special order,

additional inputs can be hard-wired directly. In addition, the CellScale Math channels can be used for manipulating the scale data. To directly access additional channels, the TEST/USER key can be programmed to “S

List” to scroll through the available scale channels. See “USER KEY FUNCTION” in this manual. See the

CellScale User Guide for the procedure to add additional channels. The crane scale’s keypad operates on the

displayed channel only.

ZERO

Sets the zero reading of the scale. Use the zero key to take out small deviations in zero when the scale is

unloaded. (See “TARE” for zeroing (Taring) package or pallet weights)

To Zero

Push ZERO. The weight reading must be stable within

±1 division for the zero function to work.

The backup memory stores the zero reading, and can restore it even if

power fails.

The numeric digits display “0” (or 0.0 or 0.00, etc.).

4 222222

5

C

onect

0.0

Rules for Use:

1) Works in GROSS mode or NET mode. Zeroing while in Net mode will zero the gross weight causing the

display to show the negative Tare value.

2) The scale must be stable. The scale will not zero if the motion detect annunciator is on.

3) The scale will accept a zero setting over the full Range of the scale (NTEP and other Legal-for-trade

models may have a limited zero range). Zero settings above 4% of full scale will subtract from the overall

capacity of the scale. For example if you zero out 100 lb. on a 1000 lb. scale the overall capacity of the

scale will reduce to 900 lb. plus the allowed over-range amount.

Page 8 MSI-9300 Crane Scale™ • User Guide

Page 9

MEASUREMENT SYSTEMS INTERNATIONAL

T

TARE

T

TARE

T

TARE

T

TARE

T

TARE

T

TARE

TARE

Tare is typically used to zero out a known weight such as a packing container or pallet and display the load in

NET weight. A Tare value is entered in one of three ways:

1) AUTO TARE – When the TARE key is pushed twice, the current weight is zeroed and Net Weight is dis

played. This is the only Tare function available from the MSI-9300 keypad.

2) KEYBOARD TARE – Available from a 3750CS or 9750A Indicator only. Using the numeric keys, the

operator keys in the desired Tare Weight then pushes the ENTER Key. See the 3750CS or 9750A User

Guides.

3) TARE UP/DOWN – Available from a 3750CS Indicator only. Using the Scroll Keys, the Tare value is

changed one scale division at a time. TARE UP/DOWN is useful for increasing or decreasing the cur

rent Tare value slightly. The Keyboard Tare and Tare Up/Down modes can be disabled through the use

of SETUP TARE. In the “AUTO” mode a single push of the TARE key will enact AUTO TARE. See the

3750CS User Guide.

To Auto Tare (in Gross Mode)

1) From Gross Mode, push TARE. The current weight is

stored in the Tare register, the display mode changes

to Net, and the display reads 0. All following readings are deviations from the set Tare value.

1

0

Net

-

-

To Read the Current Tare Value

1) From Net Mode, push TARE. The current weight

stored in the Tare register is displayed for 2 seconds.

Then the display mode reverts to Net Weight.

To Auto Tare (in Net Mode)

1) From Net Mode, push TARE. The current Tare value

is displayed.

2) Within 2 seconds, push TARE again. Assuming no

motion, the current Gross weight is stored to the Tare

register, and the mode is set to Net weight with the

new tare value. All following readings are deviations

from the set Tare value.

1

1234

Tare

2 4444

Net

1

1234

Tare

2

0

Net

To Clear Tare and Revert to Gross Mode

Use the Net/Gross to return to Gross Mode without clearing the Tare value.

1) From Net Mode, push TARE. The current Tare value

is displayed.

2) Within 2 seconds, push ZERO. The current Tare

weight is cleared from the Tare register, and the mode

is set to Gross weight.

Rev 1 7/27/02 for SW Ver 1-1

1

1234

Tare

2

5565

Gross

MSI-9300 Crane Scale™ • User Guide Page 9

Page 10

MSI-9300 Porta-Weigh+ Crane Scale

NET/GROSS

NET/GROSS

TEST

TEST

Tare - Rules for Use:

1) Only positive gross weight readings can be tared. Weight can be tared in both the NET and GROSS

modes. When in the NET mode, the TARE is not cumulative, all the weight is zeroed.

2) The motion annunciator must be off. The weight reading must be stable.

3) Setting or changing the tare has no effect on the Gross zero setting.

4) Taring will reduce the apparent over range of the scale. For example, taring a 10 lb. container on a 60

lb. scale, the scale will overload at a net weight of 50 lb. (60-10) plus any additional allowed overload

(usually ~4% or 9d).

5) The scale stores the Tare value in the current ID Code memory until cleared. Each available ID Code

can store independent Tare values.

Multiple Tare Memories

MSI-9300 Series crane scales are capable of storing Tare values through the use of the ID Codes. Each ID code

stores an independent Tare. ID Codes are accessible through the MSI-3750CS, MSI-9750A or MSI-9850, or

through a MSI-9020 CellModem using Host Commands.

SPECIAL TARE MODES

The Tare function has two special modes. These modes are configured through the Comm Port. See the MSI9000 CellScale User Manual for information on configuring the Tare Mode.

UNIV TAR

The Universal Tare feature allows a single Tare value to be shared by all ID Codes. With UNIV TAR enabled

the individual Tares stored with each ID Code are ignored (but not erased). Disabling UNIV TAR will restore

the original Tare values. UNIV TAR is intended for those applications where a common carrier or pallet is

used, but multiple ID Codes are necessary for data collection.

NET/GROSS

UNITS

AUTO CLR

Enabling “AUTO CLR” causes the MSI-9300 to clear the Tare Value after each lift greater than 0 NET. The

Tare Value is cleared and the display mode reverts to Gross Weight once the load is removed (the weight goes

below 0 NET). The “ON TOTAL” setting clears the Tare Value after the load is totaled. The default for the

“AUTO CLR” function is “DISABLED” . When disabled, the Tare Value can only be cleared manually (see

“To Clear Tare and return to Gross Mode”.)

Switches the display between Net and Gross modes. Net Weight is defined as Gross Weight minus a Tare

Weight.

To Switch Between Net Mode and Gross Mode

Switching back to Gross mode from Net mode will not clear the Tare value. This allows the operator to use the Gross Mode temporarily without having to reestablish the Tare value. Only manually clearing the Tare or setting a new Tare will change the tare value held before switching into Gross Mode.

OIML Legal-for-trade units only: The NET/GROSS key is temporary action only. The Gross weight is displayed for 2 seconds and then the display

returns to the Net Mode. The only way to return to permanent Gross readings is to clear the Tare (see Clear Tare procedure).

1) Starting in the NET weight mode, push NET/GROSS.

The weight mode will change to Gross weight.

If you are in Gross Mode and a Tare value has not been established, the

Net/Gross key has no effect.

1

GRS

2) Pushing NET/GROSS again will revert the display to the

NET mode.

2

Allows easy weight units conversions. Although the CellScale offers up to 8 units, the MSI-9300 will only

display pounds or kilograms.

This operation requires that the Test/User Key function is set to Units. See “Setup USER key Function ”.

To Change the UNITS

NET

Push the TEST/USER key (programmed as UNITS). The

weight display will toggle between kg and lb.

Page 10 MSI-9300 Crane Scale™ • User Guide

1

kg

lb

Page 11

MEASUREMENT SYSTEMS INTERNATIONAL

TEST

TEST

TEST

Provides a functional system test, and an on-demand display check without disturbing the current weighment.

The Test function can be interrupted by pushing any key during the test.

To start the Test

Push the TEST/USER key (programmed as TEST). The

display will do the following steps:

1) All LEDs are illuminated for 1 second.

1

8.8.8.8.8.8

2) The battery condition in approximate per cent of remaining life is displayed.

3) The Network Address is displayed.

Numbered from 0-31

4) The Network ID is displayed.

Numbered from 0 to 254

5) The display digits count up from 0 to 9.

6) Returns to normal weight mode.

INTERNAL TEMPERATURE DISPLAY

The MSI-9300 can monitor its internal temperature. This feature is for use in Foundry applications or any other

Crane use around high temperature sources. The temperature display can be set to display automatically at 20

second intervals (see page 15) and will display in degrees C or degrees F. The purpose of monitoring the internal temperature is to ensure that the scale is not damaged by overlong exposure to high temperatures. The MSI9300 offers a heat shield option for foundry use that increases the dwell time possible when lifting melt pots.

MSI-9300 Series Crane Scales must be immediately removed from the high heat source when the internal temperature reaches 158°F or 70°C.

To Manually Display the MSI-9300 Internal Temperature

USER key Function set to “ °F °C ”. Temperature units are set in the Setup Menus.

2 b= 80.5

3 nt 17

4 id 17

5 000000

111111

999999

Push the TEST/USER key. The current internal tempera-

ture will display for 2 seconds.

RF LIST

When the scale is used in multiple RF Networks, the RF List function allows the user to easily switch between

several networks. These networks must be setup in the embedded CellScale (See MSI-9000 User Guide).t

This operation requires that the Test/User Key function is set to RFList. See “Setup USER key Function ”.

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 11

71.2°C

Page 12

MSI-9300 Porta-Weigh+ Crane Scale

T

0

ZERO NET/GROSS TAREPOWER TEST

123

TEST

POWER

TEST

°F

°C

OFF

ENABLE

OFF

AU

TOLD

AU

TONR

AU

TOPE

PRESS

TOTAL MODE

MENU

kg

lb

OFF

0.16 hr

0.5 hr

1 hour

TEST

UNIT

S LIST

°F °C

rFList

OFF

TOT

AL

USER KEY

FUNCTION

MENU

MAIN

SETUP MENU

AUTO OFF

MENU

F

unc

Hold Down

w/ Power Off

Let Go of Test

>1 s after Display

turns on.

A-OFF

U

nit

tot

AL

° A

uto

° U

nit

TEST

TEST

TEST

TEST

TEST

TEST

TEST

POWER

SECTION 3 – MSI-9300 SETUP MENU

KEY FUNCTIONS DURING SETUP

1) The Test key is used to scroll through menu selections.

2) The Tare key is used to select the displayed menu choice.

3) The Zero key is used to exit out of the current menu. At the root level the Zero key turns off the Setup

mode and returns the MSI-9300 to weight display.

To Start the Setup Menu

1) If the MSI-9300 is on, turn it off with the POWER key.

2) Press and hold the TEST key.

3) While still holding the TEST key, turn on the MSI-9300

with the POWER key.

4) Release the TEST key after the segment test screen is finished.

5) After a few seconds, the display will show the first Setup

Menu item, “FUNC”.

SETUP MENU STRUCTURE

hold

8.8.8.8.8.8

release

Func

Page 12 MSI-9300 Crane Scale™ • User Guide

Page 13

MEASUREMENT SYSTEMS INTERNATIONAL

T

TARE

TEST

TEST

TEST

TEST

TEST

TEST

T

TARE

0

ZERO

TEST

USER KEY FUNCTION

The TEST/USER key can be programmed to 1 of 6 functions:

1) TEST – Default function. Provides segment test of the display, battery level, and RF Network information.

2) UNIT – Switch between pounds (lb) and kilograms (kg).

3) S LIST – (Scan List) Change displayed channel to the next channel in the CellScale Scan List. Applicable

to multichannel systems only.

4) °F °C – Displays the internal MSI-9300 temperature for 2 seconds.

5) OFF – No function

6) TOTAL – If manual total is enabled, pushing the TEST/USER key will add the current weight to the

Total register. Subsequent pushes will display the totaled weight until Total is reset by returning to zero

(below the total threshold, see the CellScale User Guide for more information on total threshold). If in any

Auto-Total mode, the USER key functions as View Total, displaying the Total Weight for two seconds.

To Set the User Key Function

1) Start the Setup Mode using the procedure on the previous

page.

2) With the display reading “Func” press the TARE (Select)

key. The currently programmed USER key mode will dis

play flashing.

The example assumes the dejault function TEST is the current USER key

function.

1

2

-

3

3

F

unc

test

U

nit

S L

ist

AUTOMATIC OFF

The MSI-9300 can be set to turn itself off in periods of inactivity by enabling the Automatic Off feature. The

Auto Off timer is reset whenever a button is pushed or weight changes. There are 4 settings:

1) OFF – Feature disabled

3) Use the TEST (Scroll) key to scroll through the choices.

In this example the TEST key function will be changed to TOTAL.

4) When the desired choice is shown, Press TARE (Select)

to select it.

Pushing TARE (Select) places the displayed function as the USER key function, and exits the FUNC menu.

5) The next Main Menu item, “A-OFF” will appear. Either

select another Setup procedure with the TEST (Select) key,

or return to weighing mode by pushing ZERO (Exit).

3

°F °C

3

rFLiSt

3

OFF

3

tota

4

A-OFF

5

to exit

5

to select other Main

Setup Menu items.

L

2) 0.16 hr – MSI-9300 will turn off in approximately 10 minutes

3) 0.5 hr – MSI-9300 will turn off in ~30 minutes

4) 1 hour – MSI-9300 will turn off in ~1 hour.

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 13

Page 14

MSI-9300 Porta-Weigh+ Crane Scale

TEST

T

TARE

TEST

TEST

TEST

T

TARE

0

ZERO

TEST

TEST

TEST

T

TARE

TEST

T

TARE

0

ZERO

TEST

To Setup Automatic Off

1) Start the Setup Mode using the procedure on page 12.

1

F

unc

UNITS

2) Use the TEST (Scroll) key to scroll to “A-OFF”.

3) With the display reading “A-OFF” press the TARE

(Select) key. The currently programmed Auto-Off setting

will display flashing.

The example assumes the Auto-Off function was OFF.

4) Use the TEST (Scroll) key to scroll through the choices.

In this example the Auto-Off function will be set to 1 hour.

5) When the desired choice is shown, Press TARE (Select)

to select it.

Pushing TARE (Select) places the displayed setting as the Auto-Off mode,

and exits back to the Main Setup Menu.

6) The next Main Menu item, “Unit” will appear. Either

select another Setup procedure with the TEST (Select)

key, or return to weighing mode by pushing ZERO

(Exit).

The MSI-9300 will display and convert weight in pounds or kilograms. The TEST/USER key can be set to

switch between lb and kg if desired. If only 1 weight unit is needed, use this procedure to set the desired unit.

To Setup the Weight Unit

2

a-Off

3

4

4

4

5

6

6

Setup Menu items.

OFF

0.16 hr

0.50 hr

1 hour

U

to exit

to select other Main

nit

1) Start the Setup Mode using the procedure on page 12.

2) Use the TEST (Scroll) key to scroll to “Unit”.

3) With the display reading “Unit” press the TARE (Select)

key. The currently programmed Unit setting will display

flashing.

4) Use the TEST (Scroll) key to switch between kg and lb.

In this example the unit will be changed to kg.

5) When the desired choice is shown, Press TARE (Select)

to select it.

Pushing TARE (Select) sets the weight unit, and exits back to the Main Setup

Menu.

6) The next Main Menu item, “Total” will appear. Either

select another Setup procedure with the TEST (Select) key,

or return to weighing mode by pushing ZERO (Exit).

1

2

2

3

lb

4

kg

5

6

6

Setup Menu items.

F

unc

a-Off

U

tota

to exit

to select other Main

nit

U

nit

U

nit

L

Page 14 MSI-9300 Crane Scale™ • User Guide

Page 15

MEASUREMENT SYSTEMS INTERNATIONAL

TEST

TEST

TEST

T

TARE

TEST

TEST

T

TARE

0

ZERO

TEST

TOTAL

The MSI-9300 CellScale feature set provides Total and Statistics capabilities. The MSI-9300 keypad allows the

enabling and display of some of these features. More extensive total and statistics capability is provided when

a 9750A or 3750CS meter is part of the network. However, the MSI-9300 allows the setting of the following

Total features:

1) OFF – Total feature turned off

2) Autoload – The autoload feature provides an algorithm for totaling that requires a 3750CS equipped with

an auxiliary push button. Intended for commodity loading into containers. See the CellScale User Guide

for a complete description of the Autoload feature.

3) Autonorm – The Autonorm Total will automatically total all steady weights above the auto total threshold.

Once totaled, the weight must return to near zero before the scale will autototal again. The autonorm

total totals the last settled weight before the scale went back to zero, so be sure the weight is removed

rapidly from the scale.

4) Autopeak – Similar to Autonorm except the weight totaled will be the highest settled weight before the

weight returns to near zero.

5) Press – Indicates that a manual total key must be pressed to cause a total to occur. This can be the USER

key programmed to total, or total keys found on the 3750CS or 9750A indicators.

To Set the Total Mode

1) Start the Setup Mode using the procedure on page 12.

1

F

unc

2) Use the TEST (Scroll) key to scroll to “Total”.

3) With the display reading “Total” press the TARE (Select)

key. The currently programmed Total setting will display

flashing.

4) Use the TEST (Scroll) key to scroll through the total

modes.

In this example the mode will be changed to “AutoNorm” (AutoNr).

5) When the desired choice is shown, Press TARE (Select)

to select it.

Pushing TARE (Select) sets the Total mode, and exits back to the Main

Setup Menu.

6) The next Main Menu item, “° Auto” will appear. Either

select another Setup procedure with the TEST (Select)

key, or return to weighing mode by pushing ZERO

(Exit).

2

a-Off

2

2

3

4

4

5

6

6

U

nit

tota

OFF

autoLd

auto

° Auto

to exit

to select other Main

Setup Menu items.

L

Nr

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 15

Page 16

MSI-9300 Porta-Weigh+ Crane Scale

TEST

TEST

TEST

TEST

T

TARE

TEST

T

TARE

T

TARE

TEST

T

TARE

0

ZERO

TEST

TEST

TEST

TEST

TEST

AUTOMATIC TEMPERATURE DISPLAY

The MSI-9300 will display its internal temperature once every 20 seconds if enabled with the following procedure.

To Enable Auto Temp Display (° Auto) & Set Temperature Units

1) Start the Setup Mode using the procedure on page 12.

F

unc

a-Off

U

nit

2) Use the TEST (Scroll) key to scroll to “° Auto”.

3) With the display reading “° Auto” press the TARE (Select)

key. The currently programmed Auto-Temperature setting will display flashing.

1

2

2

4) Use the TEST (Scroll) key to Enable the Auto-Temperature mode.

5) When the desired choice is shown, Press TARE (Select)

to select it.

Pushing TARE (Select) sets the Auto-Temp mode either OFF or Enable, and

exits back to the Main Setup Menu.

6) The next Main Menu item, “° Unit” will appear. Push

TARE (Select) to setup the desired temperature unit (°F

or °C).

7) Use the TEST (Scroll) key to select °C or °F.

8) Push TARE (Select) to set the temperature unit.

9) The next Main Menu item, “Func” will appear. Either

select another Setup procedure with the TEST (Select)

key, or return to weighing mode by pushing ZERO

(Exit).

2

tota

2

° Auto

3

4

5

6

7

8

9

9

Setup Menu items.

OFF

EnAbL

° Unit

°F

°C

F

to exit

to select other Main

unc

L

e

RF LIST SCROLLING

The internal RF modem can be preconfigured with up to 8 RF Network assignments. This allows the scale to

move from network to network without having to hook up a computer to change the network assignments. The

RF List must be originally configured in the embedded CellScale using the Terminal Access Mode. Once the

RF List is programmed, the user can change networks with the following procedure.

1) Program the USER key to “rFLiSt” using the procedure

on page 12.

2) Press the TEST/USER key to display the current network

setting. The first two digits are the Network, the second 3

digits are the new “My ID”.

3) Press the TEST key to scroll through the Network choices.

Up to 8 networks can be configured.

To exit without changing the Network Settings, press the ZERO key at any time.

4) When the desired Network setting is shown, press TARE

Page 16 MSI-9300 Crane Scale™ • User Guide

1

2

3

3

3

F

unc

1- 21

2- 21

12- 56

14-232

Page 17

MEASUREMENT SYSTEMS INTERNATIONAL

T

TARE

0

ZERO

(Select) to select it.

Pushing TARE (Select) reconfigures the Modem to new network settings.

5) The display will go into test mode while the network settings are being altered. When the modem is successfully

changed, the display will return to the weight mode.

To Change Current RF Network

This feature is intended for use in large installations where, for service or work load purposes, the crane scale

must be used on a new network. When the crane scale is a remote (slave) device, the Master CellScale must be

configured with a matching channel 5 scanlist to allow seamless Network migration. In other words, the “MY

ID” must be identical to the unit it is replacing. Make sure two remote devices with the same “My ID” are

never on at the same time in the same Network.

When the crane scale is a Host (Master) device, only the network number can be changed, the master “My ID”

will not change. All remote devices on the previous network will lose communciation.

4

5

5 222222

000000

111111

to cancel and exit

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 17

Page 18

MSI-9300 Porta-Weigh+ Crane Scale

Scale Remote Controller

Measurement Systems International

NET

GROSS

F2

ZERO

F1

TARE

TOTAL

VIEW ∑

F3

F4

SECTION 4 – RF REMOTE CONTROL

DESCRIPTION

MSI-9300 Series crane scales can be equipped with an RF Remote Control (RFRC). This differs from using

the MSI-9750A or MSI-3750CS Indicators to control the scale. The RFRC is a transmit only device that can be

used to perform basic scale functions. It does not have the range of the Spread Spectrum modems built into the

RF versions of MSI-9300 Series crane scales and is intended for local control only. Range will vary from 25’ to

100’ depending on room conditions and line of sight to the display. The remote receiving antenna is behind the

red lens of the crane scale and best range will occur when the display is visible to the operator using the RFRC.

One big advantage the RFRC provides is the ability to turn the unit on remotely. The RFRC can also be used in

systems that do not have the RF Modem.

The RFRC is available in three versions differing only in transmit frequency. The standard version operates at

418MHz. Available alternative frequencies are 315MHz and 433MHz.

FUNCTIONS

The RF Remote control duplicates the functions of the front panel keys on

MSI-9300 Series crane scales. The POWER, ZERO, NET/GROSS, and TARE

key function identically. In addition, the RFRC adds direct control of TOTAL

and VIEW TOTAL without the use of the USER key. The TOTAL still needs to

be enabled and configured in the embedded CellScale before these features will

function properly. See page 14 for the procedure to set up the Total mode.

The F1 key functions the same as the TEST/USER key on the front panel. The

exact function of this key depends on the USER key setup procedure. See page

12 for the procedure to configure the USER key which will also configure the

F1 key on the remote. Since the RFRC has a dedicated key for Total, there is no

need to program the USER key to Total, and it can be used for other purposes.

The F2 key is programmed to trigger a remote print. When F2 is pressed, the

crane scale will transmit the data string programmed in the virtual Comm Port

3 of the embedded CellScale. This data string can be used in a variety of ways.

For example, a remote printer can be connected to the MSI-9020 CellModem.

When F2 is pressed, the remote printer could print the weight along with time,

date, total weight, or any other data parameter available from the embedded

CellScale. Another common use is to send the weight data to a computer configured to data log the information to a database.

For information on Data Strings and the use of Virtual CommPort 3, refer to the

MSI-9000 CellScale Users Guide. F3 and F4 are not supported by MSI-9300

Series crane scales. These keys function as TOTAL and VIEW TOTAL (∑).

SETTING THE TRANSMITTER ADDRESS

In order to allow the formation of up to 1024 unique

Transmitter-Receiver relationships, the transmitter’s

address may be selected using internal DIP switches as

shown. The switches are accessed by removing the DIPswitch access cover.

If the switch is on, the address line is connected to ground, otherwise it is floating. The receiver’s address must match in order for the units to communicate.

MSI supplies the transmitter and receiver as a matched

set with the DIP switches already configured. A replacement RFRC will only need to have the transmitter DIP

Page 18 MSI-9300 Crane Scale™ • User Guide

switch set. To change the DIP switch in the receiver

requires disassembly of the crane scale front casting.

Due to differing DIP switch styles, the receiver DIP switch appears opposite to that

of the transmitter. On the receiver, the OFF position is on the right, and the ON

position is on the left.

Page 19

MEASUREMENT SYSTEMS INTERNATIONAL

CONTENTION CONSIDERATIONS

It is important to understand that only one transmitter at a time can be activated within a reception area. While

the transmitted signal consists of encoded digital data, only one carrier of any frequency can occupy airspace

without contention at any given time.

BATTERY REPLACEMENT

The remote unit utilizes a CR-2032 Button Lithium Cell. In normal use it will provide

1-2 years of operation. Access for replacement is accomplished by removing the battery

access cover by pressing down firmly on the label area and sliding it off. Once the unit is

open, remove the battery by sliding it from beneath the holder. Replace the cell with the

same type while observing the polarity shown.

RF REMOTE CONTROL FCC STATEMENT

INSTRUCTION TO THE USER

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures: Reorient or relocate the receiving antenna. Increase the separation between the equipment

and receiver. Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. Consult the dealer or an experienced radio/TV technician for help.

This equipment has been certified to comply with the limits for a Class B computing device, pursuant to FCC

Rules. In order to maintain compliance with FCC regulations, shielded cables must be used with this equipment. Operation with non-approved equipment or unshielded cables is likely to result in interference to radio

and TV reception. The user is cautioned that changes and modifications made to the equipment without the

approval of manufacturer could void the user’s authority to operate this equipment

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 19

Page 20

MSI-9300 Porta-Weigh+ Crane Scale

1

2

3

4

5

6

7

8

(NC) 9

Brown (TD)

Black (RD)

Blue (GND)

Grey (CTS)

White (RTS)

Ju

mper 1-6-4

RS-232 DCE

9-Pin Female ‘D’

Solder Cup

View

Standard wiring for direct

9000 to Computer connection

SECTION 4 – THE EMBEDDED CELLSCALE

For a complete guide to all the features of the embedded CellScale, refer to the MSI-9000 User Guide.

ACCESSING THE CELLSCALE

MSI-9300 Series crane scales are a shell interface to an embedded CellScale. To access the advanced features

of the CellScale, a Comm Port is provided on the front casting of the crane scale. This Comm Port is only used

for interfacing to the embedded CellScale and cannot be used as an output of any kind.

The CellScale offers Set Points, ID Codes, and other advanced features which are controlled either through a

remote Indicators such as the MSI-3750CS, the MSI-9850, or the MSI-9750A Handheld. These features are

also accessed by connecting a terminal program in a PC to the Comm Port. Tested terminal programs that

function well with the CellScale include ProComm Plus, Qmodem, HyperTerm (shipped with many versions

of Windows), WinTerm, and ZTerm (for Macintosh). Usually a VT102 emulation is used. All commands are

single key except when entering data.

Settings for your terminal program are: 9600 baud, 8 bit, 1 start bit, 1 stop bit, no parity, Handshaking usually

not required, but you can turn on Xon/Xoff if you desire.

While the Comm Port is in use, the display of the MSI-9300 Series crane scale is in standby with the message

“C-Port” or “H-Port” displayed. The only key that will function in this mode is the Power key.

The CellScale Terminal Access Mode is used to set Network parameters, Scale parameters, Set Points, and

other various setup conditions. Refer to the MSI-9000 CellScale User Guide for detailed information. The Terminal Access Mode is used for calibration on MSI-9300 Series crane scales that do not have the RF modem.

CONNECTION PROCEDURE

The MSI-9300 must be on and finished with its startup sequence before connecting the

terminal cable to a PC.

1) Without connecting the PC or Terminal to the MSI-9300, turn the MSI-9300 on. Wait for the startup

sequence to complete (usually about 10-15 seconds). When weight is displayed, the MSI-9300 is ready.

2) Press and Hold the

3) Connect the PC to the MSI-9300 through the Comm Port. Start your terminal emulation program with set

tings 9600-N-8-1

4) You can now access the Terminal menus in the CellScale. Push any key to refresh the menu.

5) Once in the Terminal Access Mode menus, commands are usually a single number or letter. Refer to the

9000 CellScale User Guide for further information.

COMM PORT CABLE

The MSI-9300 comes standard with one Comm port cable wired for RS-232 (MSI P/N 501705-0001) following the AT standard for 9 pin serial cables (DCE). An unterminated cable is available (MSI P/N 12023) if you

wish to wire your own serial cable for RS-232.

Comm Port Cable Color Code RS-232

Brown – Transmit output from CellScale, connect to

receive of DTE.

Black – Receive input to CellScale, connect to trans-

mit of DTE.

NET/GROSS key and then push TEST. The display should change to “H-PORT”.

-

Grey – CTS Input to CellScale. Connect to RTS or

Page 20 MSI-9300 Crane Scale™ • User Guide

RTR output of DTE.

White – RTS/RTR output from CellScale. Connect to

CTS input of DTE.

Blue – Signal Ground

Drain Wire – Connect to metal shell.

Page 21

MEASUREMENT SYSTEMS INTERNATIONAL

SET POINTS

The Internal CellScale can monitor up to 32 Set Points. Set Points are used for safety warnings and process

control. The MSI-9300 has LED annunciators for Set Points 1 through 3. Set Points are programmed from a

3750CS, a 9750A, or through the Terminal Access Mode. On special order MSI can supply audible alarms,

sirens, or other warning devices for Set Point outputs.

PASSWORD PROTECTION

The calibration and setup features in the MSI-9300 Series crane scales can be protected from tampering

through the use of passwords. Passwords can be up to 20 characters long. Be sure to record your password(s).

The default password is just a return. You can lock features without passwords to prevent accidental feature

changes. Password protection of calibration is not required for LFT scales as they are protected with a seal

switch.

Main CellScale Menu ➔ (4) Feature Locks / Passwords

***** Feature Locks/Passwords Setup *****

(1) Calibration

(2) Channel menu

(3) Communications

(4) NTEP

(5) Product ID menu

(6) Radio menu

(7) Set Points menu

(8) Strings menu

(9) Individual Features

(ESC) Exit

Main CellScale Menu ➔ (4) Feature Locks / Passwords ➔ (1) Calibration

***** Calibration Lock *****

(1) Calibration password is: None

(2) Calibration is: Un-Locked

(ESC) Exit

This menu is typical of all the lock menus. You can assign a separate password to any major feature. To lock

a feature or menu, press 2 change from “Un-locked” to “Locked”. When a feature is locked, entering into the

menu will require the password before proceeding. To lock all channel related setups, MSI recommends locking the Channel menu (choice 2). This prevents tampering of calibration and all parameters related to scale

performance.

SCALE CALIBRATION

MSI-9300 Series crane scales are best calibrated using a remote indicator such as the MSI-3750CS, MSI-9850,

or the MSI-9750A Handheld. Calibration procedures using these devices are covered in their respective User

Guides. If the crane scale is not RF equipped, the only way to calibrate it is through the Comm Port using the

Terminal Access Mode.

MSI recommends having test weights of at least 50% capacity to properly calibrate the Crane Scale. The calibration procedures will operate with as little as 12.5% of capacity, though rated accuracy cannot be guaranteed.

Very large capacity scales are often calibrated using transfer techniques. Weigh something on a truck scale,

then pick it up on the Crane scale and match the weight during the calibration procedure. The CellScale software permits multi-point calibration (up to 9 span points + Zero). MSI Crane Scales are very linear from zero

to capacity, and therefore, usually do not require Multi-Point calibration. The need for Multi-Point calibration

is left up to the Scale Technician.

Legal-for-Trade Units

To calibrate LFT units, you must first press the pushbutton found behind the seal screw on the front panel (see

figure 4-1). Sealing instructions are found on page 29.

Calibration Tips

1) Make sure that the scale and load are stable (not swinging or vibrating) for every calibration step.

2) Prevent off-center loading during calibration. The scale must be perpendicular to the earth to prevent

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 21

Page 22

MSI-9300 Porta-Weigh+ Crane Scale

cosine theta errors. Adjust the rigging as necessary so that the pull is straight through the center of the

scale.

3) Calibration always starts with the zero load. Remove all rigging that is not always present on the scale.

However, it is sometimes best to calibrate zero with the rigging necessary for picking up the test weights

attached to the scale. It’s effect on dead load can be zeroed out later.

4) If rigging has not been zeroed out, make sure you add its weight to the test weight when entering the cali

bration weight.

5) Multi-point calibration can be done in any random order, as long as the zero step is first.

CALIBRATION PROCEDURE

The following procedure assumes the scale can be unloaded to perform a zero reading.

1) Connect a terminal (or computer with a terminal program) to the crane scale’s Comm port. Settings for

your terminal program are: 9600 baud, 8 bit, 1 start bit, 1 stop bit, no parity, Handshaking is usually not

required, but you can turn on Xon/Xoff if you desire.

2) The crane scale display should read “C-Port”. If not proceed anyway. Step 3 will reconfigure the Comm

Port.

3) Press and Hold NET/GROSS then press USER. The LED should read “H-Port”. Press [RETURN] on your

terminal program. The CellScale main menu should appear.

---------- MSI 9000 - CellScale ----------

- (c) 2005 Measurement Systems International -

----------------------------------------------

13:48:06 10/02/05

(1) Channels/Calibration

(2) Communications

(3) Display

(4) Feature Locks/Passwords

(5) Product IDs

(6) Set Points

(7) System

(8) About...

-

Enter choice :

4) Select “Channels / Calibration” by pressing the terminal’s [1] key. The Channel Setup menu appears or a

dialog box asks you to press the sealed calibration keys (Standard set for NTEP or OIML mode).

***** Channel Setup *****

(1) Channel Calibration

(2) Data backup

(3) Filter (software)

(4) Channel Scanlist functions

(5) Motion Compensation (Accelerometer option required)

(6) Motion Detection

(7) Tare

(8) Total

(9) Units Lock

(a) Zero

(b) Standard Mode: Industry

(c) 4 to 20mA

(ESC) Exit

5) Start the Calibration procedure by pressing [1]. The “Choose Channel to Calibrate” menu appears. This

menu allows you to select which channel is to be calibrated. It uses the Scan List to identify which channels are available for calibration.

For multiple channel systems, the channel list must be set up before starting the calibration procedure. See Section 4 in the MSI-9000 CellScale User Guide.

Page 22 MSI-9300 Crane Scale™ • User Guide

Page 23

MEASUREMENT SYSTEMS INTERNATIONAL

***** Choose Channel Parameters *****

(1) Continue. These settings are correct

(2) Choose the channel to calibrate: 1-1

(3) Calibration timeout: 10 minutes

(ESC) Exit

6) If the desired channel is already displayed, press [1] to continue to the next step. The channel number is

changed by pressing [2] until the desired channel to calibrate is displayed. This is typically 1-1 on MSI9300 Series crane scales. Dual load cell systems might have a channel 2-1 for the second load cell. Once

the correct channel is shown, press [1] “Continue ...”.

NOTE: Channel default is the first active channel. In this case, 1-1. It is also recommended to change the calibration timeout to NONE, by pressing [ 3 ], until

menu item 3 indicates: NONE.

7) The Channel Calibration menu appears. If the CellScale channel has never been calibrated, then you must

select [1]. If this is a recalibration for the same capacity, count-by (d) and calibration units, then you can

skip to step 10 by pressing [2]. Press [2] only if the settings at the bottom of the screen match the capacity

and resolution requirements.

***** Channel Calibration *****

(1) Perform a completely new calibration

(2) Re-do the current calibration

(3) Manually adjust current cal points

(4) Reset all cal parameters to defaults

(ESC) Exit

Calibrate channel #: 1-1

The channel name is: Fred2...............

Calibration Capacity: 1000.0

Calibration Countby: 0.2

Calibration Units: Pounds

8) The CellScale prompts for the calibration unit. Chose the desired unit. In this example we will choose kilograms (2). MSI-9300 Series crane scales only have annunciators for pounds and kilograms.

Your choice of calibration unit does not prevent you from displaying the weight in any other unit. Select the unit matching your test weights.

***** Choose Calibration Units *****

(1) Pounds

(2) Kilograms

(3) Tons

(4) Metric Tons

(5) Ounces

(6) Grams

(7) Deka-Newtons

Type a key...

9) The CellScale next prompts for the capacity. With the numeric keys, enter the capacity of the scale. In our

example we’ll enter 10,000 kg.

The capacity represents the highest operating value of the crane scale. Do not enter a higher number than the scale is rated for. The actual overload point is a

few scale divisions above the entered capacity depending on the legal-for-trade settings.

Type in the new capacity: kg

10) The CellScale next prompts for the count by (d). The list presented is calculated by the processor according to the type of transducer as set up in the channel list. In this example we’ll select [b] to provide 5000

counts.

This list is for a type ‘A’ scale with up to 10000 counts resolution. This is the standard default. MSI recommends all MSI-9300 Series crane scales calibrated at

5000 divisions or less. Too many divisions will compromise stability and settling time. Use the largest division size suitable for your application.

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 23

Page 24

MSI-9300 Porta-Weigh+ Crane Scale

***** Select a countby *****

(a) 1. Kilograms

(b) 2. Kilograms

(c) 5. Kilograms

(d) 10. Kilograms

(e) 20. Kilograms

(f) 50. Kilograms

(g) 100. Kilograms

11) The first actual calibration step is zero. Unload the scale, make sure it is stable, and press Y. The scale

performs its zeroing step, removing all dead load. This process takes up to 4 seconds.

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Test2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Unload the scale.

Press (Y) when scale is unloaded and steady

Press (B) to backup

Press (ESC) to exit calibration

Raw A/D counts: 1900709

The number presented at the bottom of the screen is direct A/D counts. This is for troubleshooting only. This number will never be steady as it represents 24

bits. If the deviation is less than ±750 counts the load is stable enough for a 5000 count scale. The calibration step needs the scale platform to remain steady and

unloaded during this step.

12) Next, the CellScale prompts for the value of the first test weight. This step defaults to capacity. If this is

what you want push ‘Y’ otherwise push ‘N’ to input the actual cal weight. In our example, we will use a

5000 kg test weight first.

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Test2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Test weight # 1 in Kilograms : 10000.

Press (Y) if this is correct

Press (N) to change

Press (B) to backup

Press (ESC) to exit calibration

It does not matter if you cal from high to low, or low to high, or any order at all. The CellScale calibration routine works in any order.

13) Press [n]. Type in the test weight value and enter it using the return key. In this example we will use 5000

kg as the first test weight.

Type in the new test weight value: 5000 Kilograms

Page 24 MSI-9300 Crane Scale™ • User Guide

Page 25

MEASUREMENT SYSTEMS INTERNATIONAL

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Fred2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Test weight # 1 in Kilograms : 5000.

Load the scale with test weight # 1

Press (Y) when scale is loaded and steady

Press (B) to backup

Press (ESC) to exit calibration

Raw A/D counts: 1675807

14) Load the scale platform with the indicated test weight (5000 kg for our example). When the scale is stable

push ‘Y’.

15) The CellScale calibrates with the first test weight, and then presents the following menu. The upper half of

the screen indicates the two cal steps taken so far, zero and a 5000 kg test weight. If this two point calibra

tion is adequate for the application (in most well designed scale systems, it is), the ESC key can be pressed

to end calibration, and store all the calibration constants. However if additional test weights are applied,

repeat steps 11 and 12 until finished. Up to 9 span points can be calibrated. Any time it is deemed that

enough points have been entered, pushing the ESC key will end the calibration and store the constants in

calibration memory.

-

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Fred2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Test weight # 1 in Kilograms : 5000.

Test weight # 2 in Kilograms : 2001.

Press (Y) if this is correct

Press (N) to change

Press (B) to backup

Press (ESC) to complete and store calibration

For clarity we’ll add a second cal’ point at 2000 kg in this example calibration. Load the scale with the

2000 kg weight. If the display shows the exact right number, this cal point is not needed. In our example,

the display showed 2001 ( a 1/2 ‘d’ error). We can pull this in with a second point calibration, even though

this error probably would not show in a system with a 2kg ‘d’.

16) Type [n] to bring up the weight entry screen. Type in the correct value for the 2nd test weight. Push return

to enter the value.

Type in the new test weight value: 2000 Kilograms

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 25

Page 26

MSI-9300 Porta-Weigh+ Crane Scale

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Fred2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Test weight # 1 in Kilograms : 5000.

Test weight # 2 in Kilograms : 2000.

Load the scale with test weight # 2

Press (Y) when scale is loaded and steady

Press (B) to backup

Press (ESC) to complete and store calibration

Raw A/D counts: 4528050

17) Ensure the 2nd test weight is on the scale and steady. When it is, press [Y].

***** Channel Calibration *****

Calibrating Ch # 1-1, named: Fred2...............

Precision in Kilograms : 10000. x 2.

Test weight # 0 in Kilograms : 0.

Test weight # 1 in Kilograms : 2000.

Test weight # 2 in Kilograms : 5000.

Test weight # 3 in Kilograms : 2000.

Press (Y) if this is correct

Press (N) to change

Press (B) to backup

Press (ESC) to complete and store calibration

18) After the second span point calibration, the CellScale rearranges the test weights in ascending order. The

following menu appears for cal point 3. This is the end of our example calibration. Push [ESC] to end cal,

store constants, and return to the main menu. If more span points are desired, repeat steps 16 and 17 up to

a maximum of 9 span points.

CELLSCALE SETTINGS FOR MSI-9300

Certain Terminal Access Settings are required for compatibility with the MSI-9300 display board. These settings should not be changed. The default settings should be:

MAIN > SYSTEM > POWER: Set to AC (Display board checks battery, do not set to 12V SLA).

MAIN > SYSTEM > LEDs: Turn all off and turn Power to Low. (LEDs can’t be seen anyway, saves power to

turn them off).

Do not modify Comm Port 1 baud rate settings. This could interfere with communications with the display

board.

RF SYSTEM SETUP

MSI-9300 Series crane scales use an embedded CellScale to communicate through an advanced 2.4GHz

Spread Spectrum modem. Details of the RF Network setup is covered in the MSI-9000 CellScale User Guide.

LEGAL STANDARD

The MSI-9300 Series scales must be configured properly for use in Legal -for-Trade transactions. For most

industrial applications, LFT settings are not required. The Industrial and Metric settings have the same accuracy performance as the NTEP and OIML settings. Unless you are required by law to use the scale in LFT

Page 26 MSI-9300 Crane Scale™ • User Guide

Page 27

MEASUREMENT SYSTEMS INTERNATIONAL

mode, leave the system in Industry or Metric modes.

Descriptions of standard modes:

[1] Industry – All functions and units are available. This is the default mode of the scale.

[2] NTEP – Choosing NTEP has the following effect: 1) The sealed switch must be pressed to modify any

metrologically significant setting. 2) Multiple remote RF display devices are allowed, but only one device

is allowed to zero, tare, or any other control function. This device is determined in the Communications

Menu (page 28). See “Sealing the MSI-9000” on the following page for details on sealing the settings and

calibrations.

[3] OIML – R76 sealed mode. Features not allowed by OIML R76 testing are locked out. R76 feature set

is TBD. This setting is not yet operational.

[4] Metric – All features are enabled, except only Metric units are available (g, kg, Metric Tons).

SETTING THE LEGAL STANDARD MODE

1) From the Channels/Calibration Menu, push [b].

***** Channel Setup *****

(1) Channel Calibration

(2) Data backup

(3) Filter (software)

(4) Channel Scanlist functions

(5) Motion Compensation (Accelerometer option required)

(6) Motion Detection

(7) Tare

(8) Total

(9) Units Lock

(a) Zero

(b) Standard Mode: Industry

(c) 4 to 20mA

(ESC) Exit

***** Scale Standard Setup *****

(1) Industry

(2) NTEP

(3) OIML

(4) Metric (g, kg, metric tons)

(ESC) Exit

2) Select the desired scale standard.

3) Selecting NTEP or OIML for the first time will bring up the following screen:

********** Notice **********

* You must push the sealed *

* calibration switch on the*

* CellScale to continue. *

* Push now or *

* *

* *

* (ESC) to exit *

****************************

Remove the seal screw (see figure 4-1). Using a non-metallic tool, gently press the pushbutton located

behind the hole. This enables menu access and calibration of all the metrologically significant parameters.

Pressing the button stays in effect until the power is cycled.

Rev 1 7/27/02 for SW Ver 1-1

MSI-9300 Crane Scale™ • User Guide Page 27

Page 28

MSI-9300 Porta-Weigh+ Crane Scale

LEGAL-FOR-TRADE CONTROL DEVICE

When the MSI-9300 is configured for NTEP or OIML Legal-For-Trade (LFT) only one remote device is

allowed to have control over the CellScale. The control device is the only RF connected device that can

zero, tare, calibrate, and any other controls that are considered metrologically significant. This control can be

assigned to a 3750CS Remote Display, a 9750A Handheld Display, or to a 9020 CellModem connected to a

computer using the MSI Host commands. 9850 Indicator approval is pending.

Additional RF connected devices are allowed, but they can only function as displays with no controls. Thus

you can assign, for example, a 9750A as the control device, but you can still operate a scoreboard display connected to a CellModem (MSI-9020). Additional 9750A’s can monitor the weight, but they would not be able to

zero or tare the weight, or change the weight mode.

The assigned Control Device RF ID must be known before entering this menu. The number needed is refered

to as “My ID” in a 3750CS, or “My address” in the 9750A. These can be read from the Modem settings in

each device. Of course, the main Network numbers much match between the MSI-9300 and the assigned LFT

control device.

Main CellScale Menu ➔ (2) Communications➔ (9) Assigned Legal-For-Trade Control Device