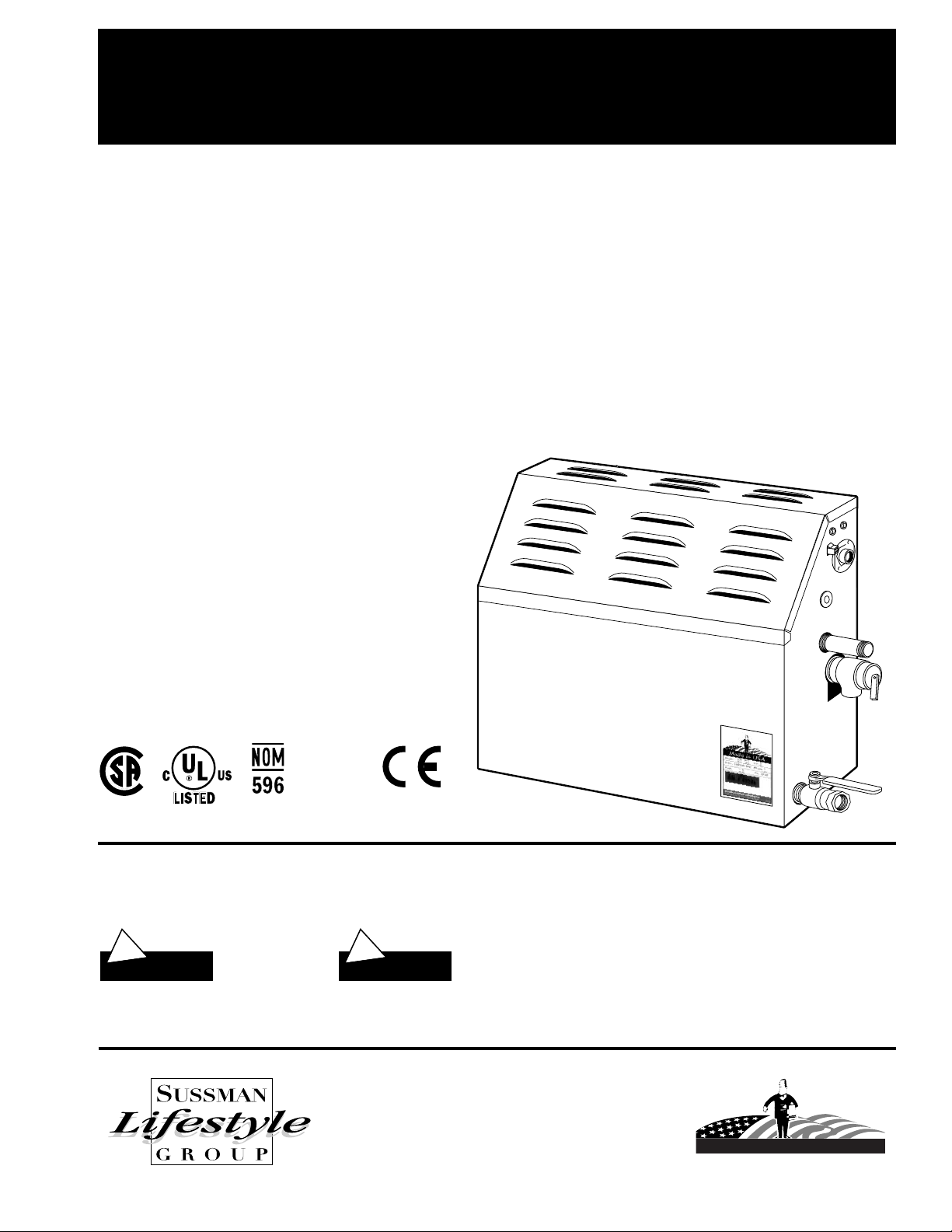

MrSteam MS-65, MS-90MS-150, MS-225, MS-300, MS-400 Maintenance Manual

MODELS:

_________

MS-65

MS-90

MS-150

MS-225

MS-300

MS-400

IMPORTANT NOTE

:

As you follow these instructions, you will notice warning and caution symbols. This blocked information is important for the

safe and efficient installation and operation of this generator.

These are two types of potential hazards that may occur during this installation and operation:

!

WARNING

!

CAUTION

Table of Contents: . . . . . . Page

Before Installing. . . . . . . . . . . . . . . . . . . . . 1

Steam Room Requirements . . . . . . . . . . . . 1

Locating the Steam Generator Unit. . . . . . 2

Typical Installation . . . . . . . . . . . . . . . . . . . 2

MS Super 4, 5, 6 Typical Installation. . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plumbing

Water Supply

Generator Dimensions . . . . . . . . . . . . . . . . 5

Electrical Specifications . . . . . . . . . . . . . . . 6

Input Power Wiring . . . . . . . . . . . . . . . . . . 7

Wiring Diagrams . . . . . . . . . . . . . . . . . . 8- 10

Optional Autoflush Feature . . . . . . . . . . . 11

Check Out & Operation . . . . . . . . . . . . . . 12

Major Electrical Systems Test . . . . . . . . . . 12

Trouble Shooting . . . . . . . . . . . . . . . . 13- 15

Five Easy Steps to Properly Size . . . . . . . . 16

Replacement Parts Diagram . . . . . . . . . . . 17

Replacement Parts List . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 19

states a hazard may cause serious

injury or death if precautions are

not followed.

signals a situation where minor

injury or product damage may occur

if you do not follow instructions.

IMPORTANT NOTE:

This highlights information that is especially

relevant to a problem-free installation.

PUR 101289 Rev. 4/01

MrSteam

®

Residential Steambath Generator Systems

Installation,Operation & Maintenance Manual

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101 • (718) 937-4500

1-800-767- 8326 • Fax: (718) 472-3256 • www.mrsteam.com

Western Regional Offices

9410 S. La Cienega Blvd., Inglewood CA 90301

1-800 72 STEAM (1-800 727-8326) • Fax: (310) 216-2944

Steam Outlet

Steam Head

Made in USA

Listed Steam Bath

Generator 777D

ANSI

Drain

Safety Valve

MS-SUPER 1

MS-SUPER 2

MS-SUPER 3

MS-Super 4

MS-Super 5

MS-Super 6

MODEL____________ Serial No._________________

M

rSteam

MrSteam

Installation, Operation & Maintenance Manual

Read these instructions before installation or service. Although this MS steambath generator has been fully qualified for shipment by MR. STEAM, the following must be reviewed for proper, safe and enjoyable steam bathing.

Verify that the model and accessories are correct, including incoming line voltage.

Insure steambath generator has been correctly sized for the steambath room. Pay particular attention to room

volume and construction. If any questions, please refer to MR. STEAM sizing guide enclosed.

(see page 16)

Marble or glass walls or ceilings, or exterior walls “ENLARGE” the room’s size, requiring a generator larger

than one based only on the room’s cubic foot (L x H x W) volume.

The physical size of the unit, clearance for plumbing servicing, and its distance from the steam room must all

be considered before final installation.

IMPORTANT

MR. STEAM units are intended to be operated with a MR. STEAM timer and/or temperature control only,

and are to be installed strictly in accordance with the specific instructions supplied with these optional

accessories and the information contained in this manual.

Mr. Steam steam generators are connected to 240V line voltage and contain live electrical components. All installation and service to be performed by qualified electricians and plumbers only. Installation or service by unqualified persons may void the warranty.

1.

Steam room must be completely enclosed, with full walls, door, floor and ceiling.

2.

It is recommended that a gasketed door is used for heat sealing and steam containment.

3.

If tile-type flooring is used, install anti-skid strips or equivalent, for safety.

4.

Walls and ceilings must be covered with water-resistant, non-corrosive surface,

such as tile, molded acrylic, fiberglass, etc.

5.

Provide a floor drain.

6.

No heating, venting or air conditioning devices should be installed inside the steam room.

Before Installing

1

Steam Room Requirements

!

WARNING

MrSteam

Installation, Operation & Maintenance Manual

Select a location as near as possible to the steam room.

Typical locations include: closet, vanity cabinet, heated attic or basement.

1.

Locate steambath generator within 25 feet of steam room.

2.

Do not install steambath generator inside steam room.

3.

Do not install steambath generator outdoors.

4.

Do not install steambath generator in unheated attic or any locations where water could freeze.

5.

Do not install steambath generator near combustible or corrosive materials and chemicals.

6.

Install steambath generator on a solid and level surface.

7.

Install steambath generator in an upright position only.

8.

Install anti-water hammer device as required.

9.

Provide access to both ends of steambath generator for servicing. See page 5.

10.

Steam line, safety valve and drain valve become hot during operation. Provide appropriate protection.

11.

MR. STEAM CONTROLS can be located inside the steam room or on the outside of the steam room.

See separate CONTROL INSTALLATION AND OPERATION INSTRUCTIONS for specific details.

If the SMART/TWO or SMART/PLUS controls are located outside the steamroom, a remote sensor (part

number MSNC) is required.

NOTE: The SMART/ONE, SMART/REMOTE, SMART/TWO and SMART/PLUS controls are

UL Approved for installation and operation in a wet location

Locating the Steam Generator Unit

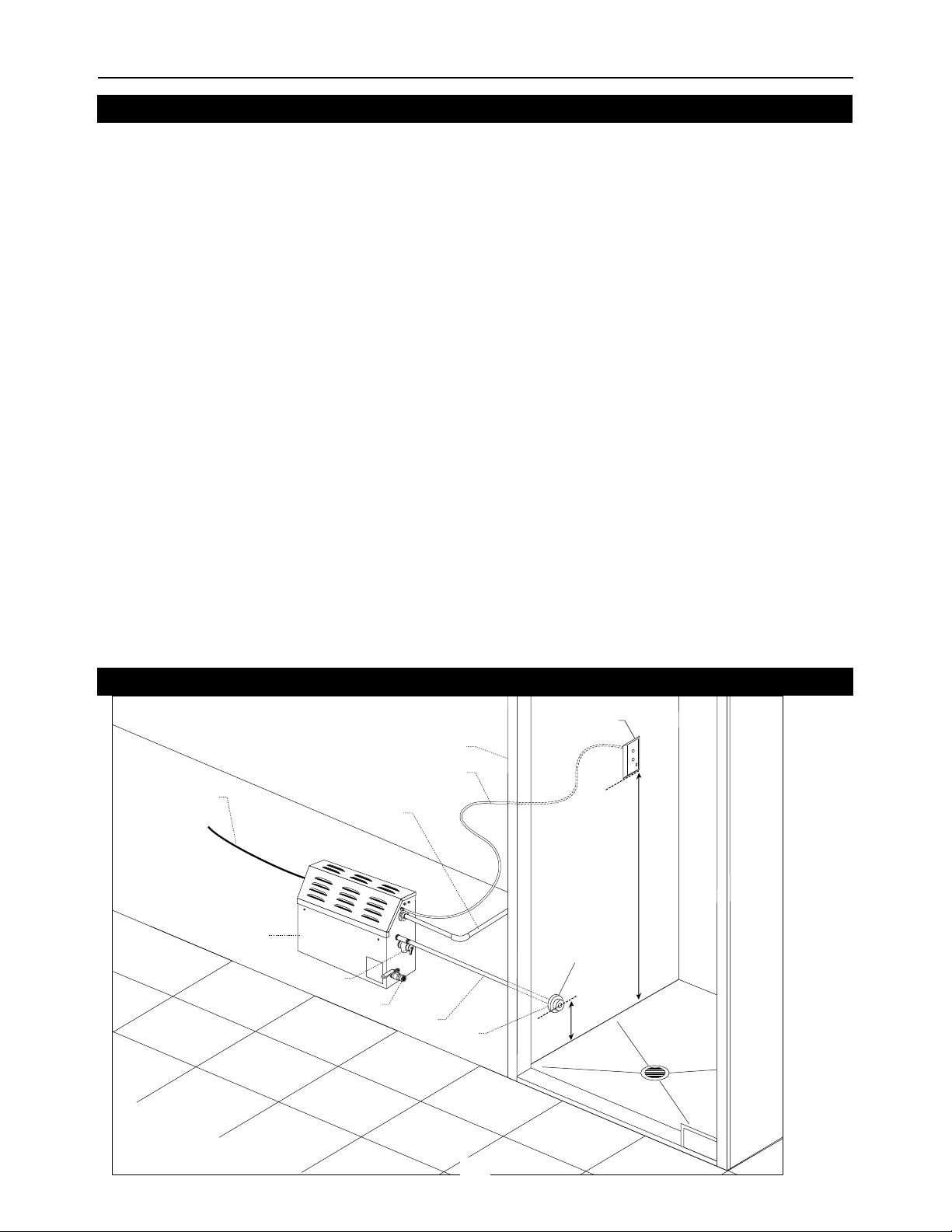

Typical MrSteam Installation

2

Locate control

4 to 5 feet above floor

Steam room enclosure

Control cable

Power supply

steam generator

Mr. Steam

Safety valve

Water feed

Drain

Steam line

Steam head

Locate steamhead

6"-12" above floor

MrSteam

Installation, Operation & Maintenance Manual

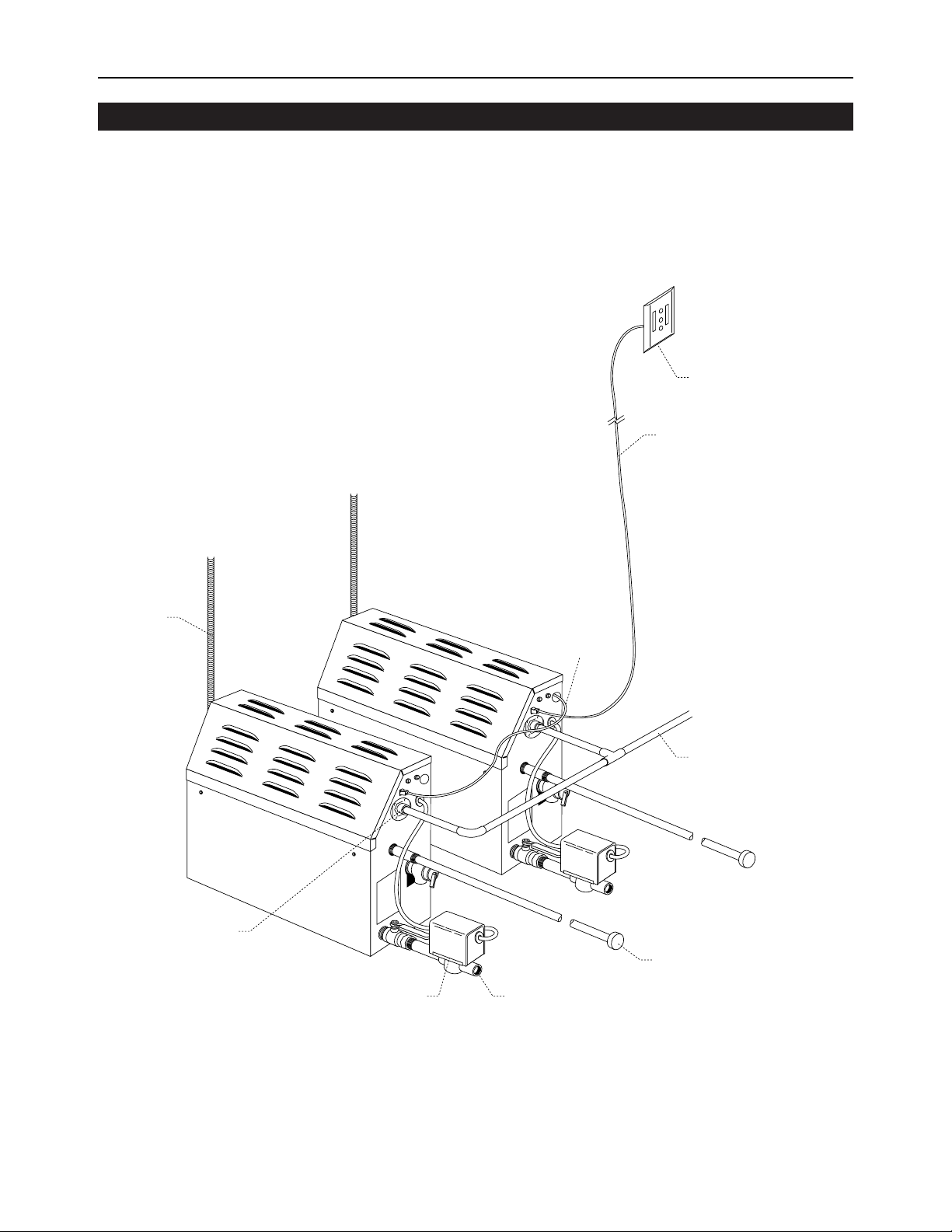

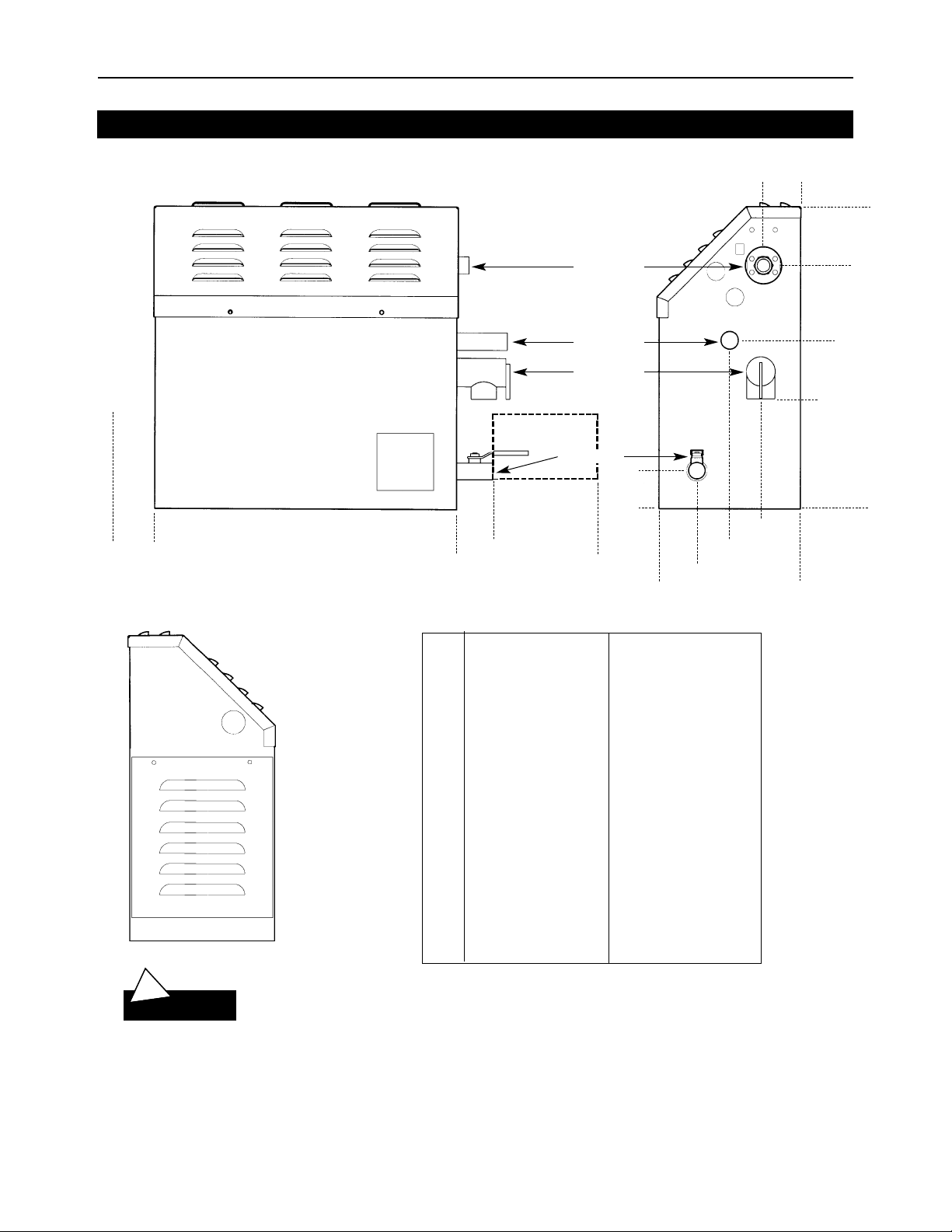

MS Super 4, 5, 6 Typical Configuration

3

MS Super 4, 5, 6 typical installation

shown with optional autoflush

Installation Instructions for Models:

MS-Super 4, MS-Super 5 and MS-Super 6

1.

Install each unit as in a single installation.

2.

Connect the SMART/PLUS control to either unit per instructions supplied with the SMART/PLUS control.

3.

Using the interconnecting cable provided (PN 103608) connect the Black plug to the Liquid Level Control

Board Terminal marked TANDEM in the same unit connected to the SMART/PLUS

control. Connect the White plug to the second unit, to the White receptacle

located above the water inlet.

4.

Connect separate plumbing and power supplies for each unit.

Smart/Plus Control

Smart/Plus

Control cable

Power supply

Interconnecting cable

(supplied)

Water supply line

Water inlet

Steam head

Autoflush assmebly Connect to drain line

MrSteam

Installation, Operation & Maintenance Manual

Plumbing

All plumbing shall be performed by a qualified plumber and in accordance with applicable national and local codes.

• Use unions on all pipe connections.

• Use only brass piping or copper tubing

• Do not use black, galvanized or PVC pipe.

Water Supply (3/8” NPT)

1.

Connect hot or cold water line. Hot water line is preferable. Hot water should not exceed 160° F.

2.

Provide a shut off valve in the supply line.

3.

Do not overheat inlet solenoid valve with solder connections. Overheating will damage parts.

4.

Flush inlet water line thoroughly before making connection to unit.

5.

Strainer is required if there are solid particles in the water.

6.

For best performance water pressure should be 15 to 20 psig.

7.

Provide anti-water hammer device as required.

Steam Outlet ( 1/2” NPT)

1.

Do not install a valve in steam line. Flow of steam must be unobstructed.

2.

Use 1/2-inch brass or copper pipe from unit to steam head.

3.

Insulate steam line using pipe insulation rated 250° F or higher.

4.

Pitch steam line to avoid valleys and trapping of condensate.

5.

Pitch steam line 1/4” per foot towards steam head or steam generator.

Steam Head

1.

Locate steam head 6 to 12 inches from floor, except:

• For tub/shower enclosures, install steam head 6 inches above tub top ledge.

• When used in shower stall with acrylic or other non-heat resistant floors,

install steam head 20-30 inches from floor or use a steam shield MS-103412.

2.

If steam room is provided with seat(s), locate steam head as far away from seat as possible.

3.

Install steam head with steam emission slot facing downward.

4. NOTE:

To preserve steam head finish, do not use wrench or other tools to tighten.

Hand tightening is sufficient when Teflon or equal pipe thread sealing compound is used.

5.

Locate steamhead as required to prevent accidental contact with steam.

Drain (1/2” NPT)

NOTE:

A drain valve is provided to facilitate servicing.

Where local codes permit, provide a drain line connection from steambath generator drain valve. Check local

plumbing code for receptor, trap and vent requirements. Unit drains by gravity.

Safety Valve (3/4” NPT)

Where permitted by local codes, provide a connection for safety valve.

To insure proper and automatic safety valve operation,

DO NOT connect a shut off valve or a plug at safety valve outlet.

Installation

4

!

WARNING

MrSteam

Installation, Operation & Maintenance Manual

MS65-MS400 MS SUPER 1-6

_______________________________________

A 5-1/2 (140) 7-1/4 (184)

_______________________________________

B 8-1/4 (210) 10 (254)

_______________________________________

C 11-7/8 (302) 12-1/2 (310)

_______________________________________

D 14-3/4 (375) 18-3/4 (466)

_______________________________________

E 1-3/4 (45) 6 (152)

_______________________________________

F 1-7/8 (48) 2-1/2 (64)

_______________________________________

G 3-1/2 (89) 4 (102)

_______________________________________

H5 (127) 6 (152)

_______________________________________

I 6-3/4 (171) 7-7/8 (200)

_______________________________________

J 1-3/4 (45) 1-3/8 (35)

_______________________________________

K 14-1/2 (368) 19-3/4 (502)

_______________________________________

L 2-1/2 (64) 2-3/8 (60)

_______________________________________

M6 (152) 6-3/8 (162)

Generator Diagram

5

NOTES:

1. M=AutoFlush

2. All units in inches (MM)

3. MS Super4 includes (2) MS Super 1 units

4. MS Super5 includes (2) MS Super 2 units

5. MS Super6 includes (2) MS Super 3 units

/---- E-----\

/----- F----\

/-----

L----\/--- 12”---\

/--------------------------

M-----------------------\

/------------------------------------------------------------

K-----------------------------------------------------------\

/

---------------------------------

\

/----------- G ---------\

/

------------------

H

----------------

\

/

------------------------------------- I------------------------------------

\

A

/

-----------

\

J

/

-----------------------------------------------------

\

B

/

------------------------------------------------------------------------------

\

C

/

--------------------------------------------------------------------------------------------------

\

D

Water Inlet

Steam Outlet

Safety Valve

Drain Valve

AutoFlush

Clearance for

Element Service

Side View Showing

Element Access Panel

TO AVOID EQUIPMENT

DAMAGE DO NOT CONNECT

POWER SUPPLY

DIRECTLY TO ELEMENTS !!!

__________________________

!

CAUTION

Loading...

Loading...