MPC ATD-313186 User Manual

®

ATD Actuator

Automatic Door Drive

Model 50 ATD-313186

Operating and Installation Instructions

Milwaukee Protective Covers

2300 South Calhoun Road

New Berlin, WI 53151

Phone: 414-906-4000

Fax: 414-906-4100

© 1998 Milwaukee Protective Covers

V2.0

www.MPCovers.com

ATD 50 Actuator® Operating Instructions

Contents

1 Explanation of symbols .................................................4

2 General Safety Instructions ..........................................4

2.1 Correct Use .....................................................................5

2.2 Design and Installation Personnel Requirements.....5

2.3 General Information and MPC™ Liability...................5

3 Theory of Operation.......................................................6

4 Design Information.........................................................7

4.1 Mechanical ......................................................................7

4.1.1 The Door..........................................................................7

4.1.2 Installation Position........................................................7

4.1.3 Installation.......................................................................8

4.2 Electrical..........................................................................9

4.2.1 Main Power Connection................................................9

4.2.2 Control Connection ..................................................... 10

5 Start-up Procedure...................................................... 10

5.1 Preparation................................................................... 10

5.2 Start-up ......................................................................... 11

6 Check List for Functional Tests................................. 11

7 Error Diagnosis............................................................ 13

8 Hardware Error Displays ............................................ 14

9 Standard Input Functions ........................................... 15

10 Standard Output Functions ........................................ 17

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 2

ATD 50 Actuator® Operating Instructions

11 Operation...................................................................... 19

11.1 Calibration Run............................................................ 19

11.2 Door Movements......................................................... 20

11.3 Reversing Motion........................................................ 20

12 Memory and System Layout...................................... 21

13 Technical Data.............................................................. 22

14 Electrical Wiring Diagram........................................... 24

15 Physical Dimensions................................................... 25

16 Trouble Shooting Guide......................................... 26

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 3

1 Explanation of symbols

This symbol warns of general hazards and of possible damage to the equipment.

This symbol warns of dangerous electrical voltages or current

2 General Safety Instructions

ATD 50 Actuator® Operating Instructions

Before beginning installation or start-up, read and follow these

instructions. Damage to the unit and personal injury may result

from not following these instructions.

Keep fingers away from all moving parts. Be especially careful to install guards or shield

to protect personnel from the moving drive belt and pulleys.

• Be sure the electrical power is disconnected and locked-out when working

on the ATD 50 Actuator

• Install the electrical cables and power only after the mechanical installation of the

unit.

• Turn on the power to the ATD 50 Actuator® only after all internal cables are

connected. Do not connect cables while the unit is powered.

• Always use the correct tools for installation and repair.

®

.

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 4

2.1 Correct Use

The ATD 50 Actuator® is designed for operating automatic doors on machine tools

and industrial equipment. It is intended to automatically open and close doors,

detect obstructions, and hold the door when closed. Vertical doors must be

installed using a counter-weight system since the ATD 50 Actuator® is not intended

to lift or hold the weight of a door.

Any other use for the ATD 50 Actuator® is the judgement and risk of the installer.

The brake on the ATD 50 Actuator® is intended to help prevent

accidental opening of the door. The brake is not an absolute

positive lock and can be overcome by a strong pull of the door.

The machine designer and/or installer must decide if additional

positive latches are required to insure proper machine safety.

ATD 50 Actuator® Operating Instructions

Use the ATD 50 Actuator® system only when it is operating properly and as

designed. Any problems or malfunctions should be repaired immediately. The

safety systems of the ATD 50 Actuator® unit depend upon correct operation.

2.2 Design and Installation Personnel Requirements

The design and installation of the guard door system, including the ATD 50

Actuator® must be completed by qualified personnel with training and experience in

the area of power-operated doors. The personnel must be familiar with relevant

work safety regulations, accident prevention guidelines, and generally accepted

technical practices.

2.3 General Information

The operating, maintenance, and installation instructions provided by Milwaukee

Protective Covers must be observed. The drive must be maintained and repaired

only by qualified technicians who are familiar with the ATD 50 Actuator® and have

been instructed about the possible dangers.

2.3 continued on next page

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 5

2.3 General Information (cont.)

The purchaser, designer, and/or installer is responsible to insure the correct and

safe application of the ATD 50 Actuator®. These personnel must insure that all

Federal, State, and Local laws and regulations regarding workplace safety are

observed. OSHA and other safety regulations must be observed when completing

an installation.

Milwaukee Protective Covers is not responsible for incidental and/or consequential

damages resulting from the use or application of the ATD 50 Actuator®. Our

maximum liability under warranty is for only the cost of the product sold. Milwaukee

Protective Covers makes no claims for merchantability or fitness of use for specific

machine guarding applications. The purchaser, designer, and/or installer of the

ATD 50 Actuator® must decide if the drive is applicable to a given machine

application. In addition, Milwaukee Protective Covers specifically declines any

responsibility for damage or injury resulting from unauthorized changes to the drive,

including software parameter changes. No employee of Milwaukee Protective

Covers is authorized to modify this warranty without the specific written approval of

a company officer.

ATD 50 Actuator® Operating Instructions

3 Theory of Operation

The ATD 50 Actuator® is controlled using a built-in microprocessor computer. The

microprocessor is programmed to provide optimum motion control and safe

response to obstructions. Internal parameters can be changed by authorized

service personnel to customize the installation. The software can be modified for

each installation.

®

The ATD 50 Actuator

automatically adjusts to the opening width of the machine. During the OPEN and

CLOSE motion, the unit finds the end-stop positions of the door. Therefore, the

door width is not limited in any way.

The internal drive motor is operated by a variable frequency converter which

provides the optimal speed and torque for each movement. The motor speed and

torque are continuously monitored thereby providing a sensitive and accurate

electronic reversing feature ( see Section 11.3).

is completely self-calibrating. Upon power-up, the unit

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 6

4 Design Information

4.1 Mechanical

All components in the system must be designed and installed to withstand the

forces produced by the system. This includes the door itself, all mounting brackets,

the idler pulley, the connector between the door and belt, and the door end stops.

Maximum tensile force of the belt 30 lbs (130 N)

Weight of the ATD 50 Actuator® unit 31 lbs (14Kg)

4.1.1 The Door

The door must have fixed positive stops at each end of travel. The stops must be

able to withstand the maximum pressure of the driving force (30 lbs /130 N).

ATD 50 Actuator® Operating Instructions

Smooth door movement is the most important criteria to insure correct operation.

The door should have a consistent drag force over its complete travel. The door

guides should provide as low a drag resistance as possible. This will insure

trouble-free operation and will increase the drives’ sensitivity to any obstructions.

4.1.2 Installation Position

The ATD 50 Actuator® can be installed in any position and any orientation

according to the specific application. The drive belt, idler pulley, and ATD 50

Actuator® should be installed so that the moving parts do not touch or rub on any

other part of the machine. Also, the drive pulley and idler must be properly aligned

to insure correct belt travel. Failure to align the drive belt properly will result in

excessive belt wear and shortened belt life.

The ATD 50 Actuator® unit and the drive belt should be installed outside the area of

contamination. If the unit must be installed inside the area of contamination, the

drive belt must be protected from chips, coolants, or other debris.

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 7

ATD 50 Actuator® Operating Instructions

4.1.3 Installation

The ATD 50 Actuator® internal frame is mounted into the metal enclosure with 6

screws. (There are two screws on the back of the unit and four button-head cap

screws on the top.) For installation, only the four screws on the top OR the two

screws on the back should be used.

Never loosen all 6 screws at the same time! Otherwise the internal frame will be

loose inside the metal housing. If the internal frame is allowed to move inside the

metal housing, the drive shaft can be damaged by scraping against the sealing

elements.

Under no circumstances should the large hexagonal screw on the drive pulley

be loosened!

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 8

4.2 Electrical

ATD 50 Actuator® Operating Instructions

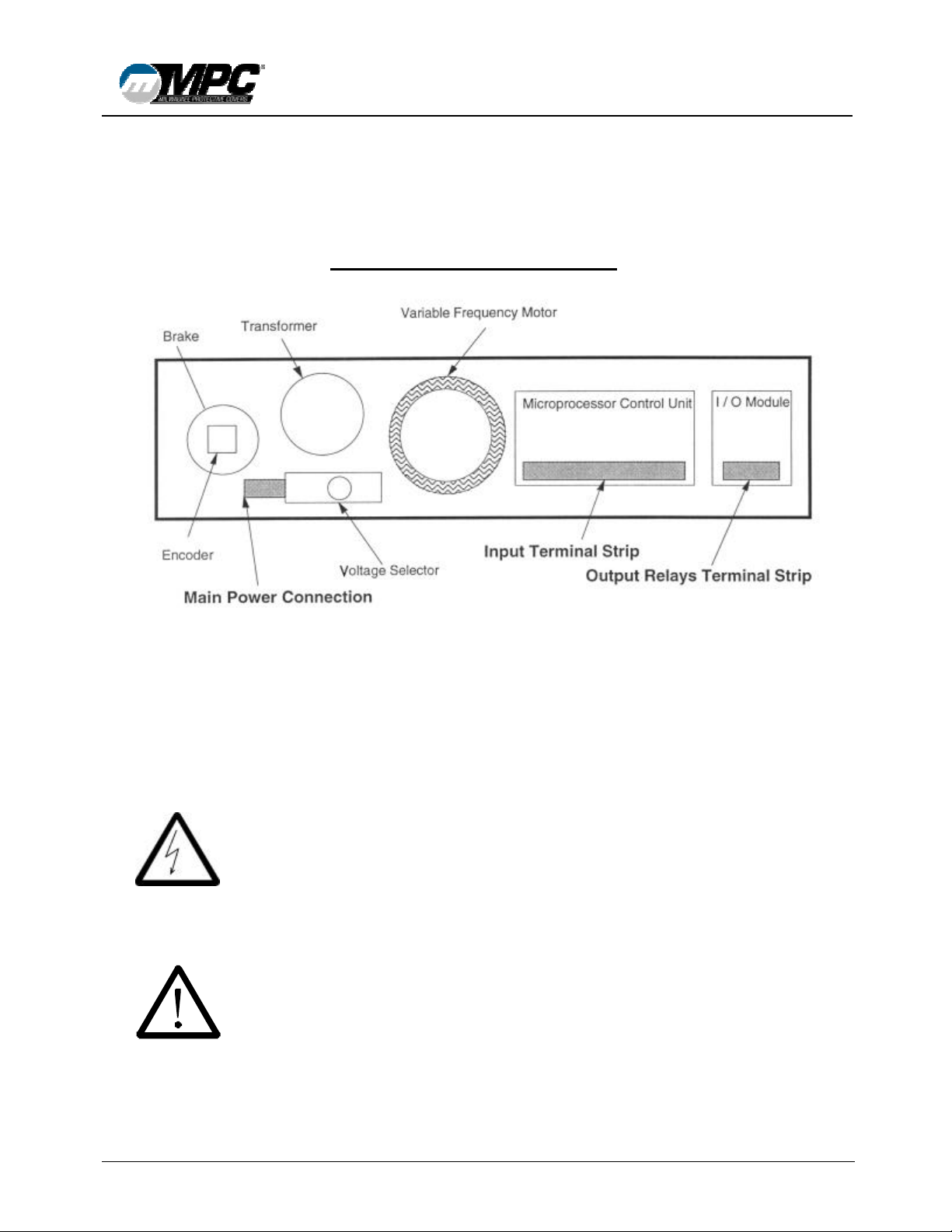

Internal View of ATD 50 Actuator¨

4.2.1 Main Power Connection

The main power supply can be switched between 115 volts and 230 volts and with 50

or 60 Hz AC power. There is an internal switch on the main power connection to

select 115V or 230V.

The main power must be externally protected with a 10 amp fast-blow fuse and

a system disconnect.

Verify that the power selection switch is set to the correct voltage before start-up!

3811 N. Holton Street • Milwaukee, WI • 53212 •USA • Phone • 414-906-4000 • Fax 414-906-4100 • www.MPCovers.com

Page 9

Loading...

Loading...