Mountain Off Road SB7686-1 User Manual

MOUNTAIN OFF ROAD ENTERPRISES LLC.

P O BOX 690 DELTA, COLORADO 81416

970-625-0500

E-MAIL: info@mountainoffroad.com

www.mountainoffroad.com

INSTRUCTIONS FOR M.O.R.E.™ SB7686-1 Steering Box Bracket H.D.

Please read Terms/Policies on page 2 before installing

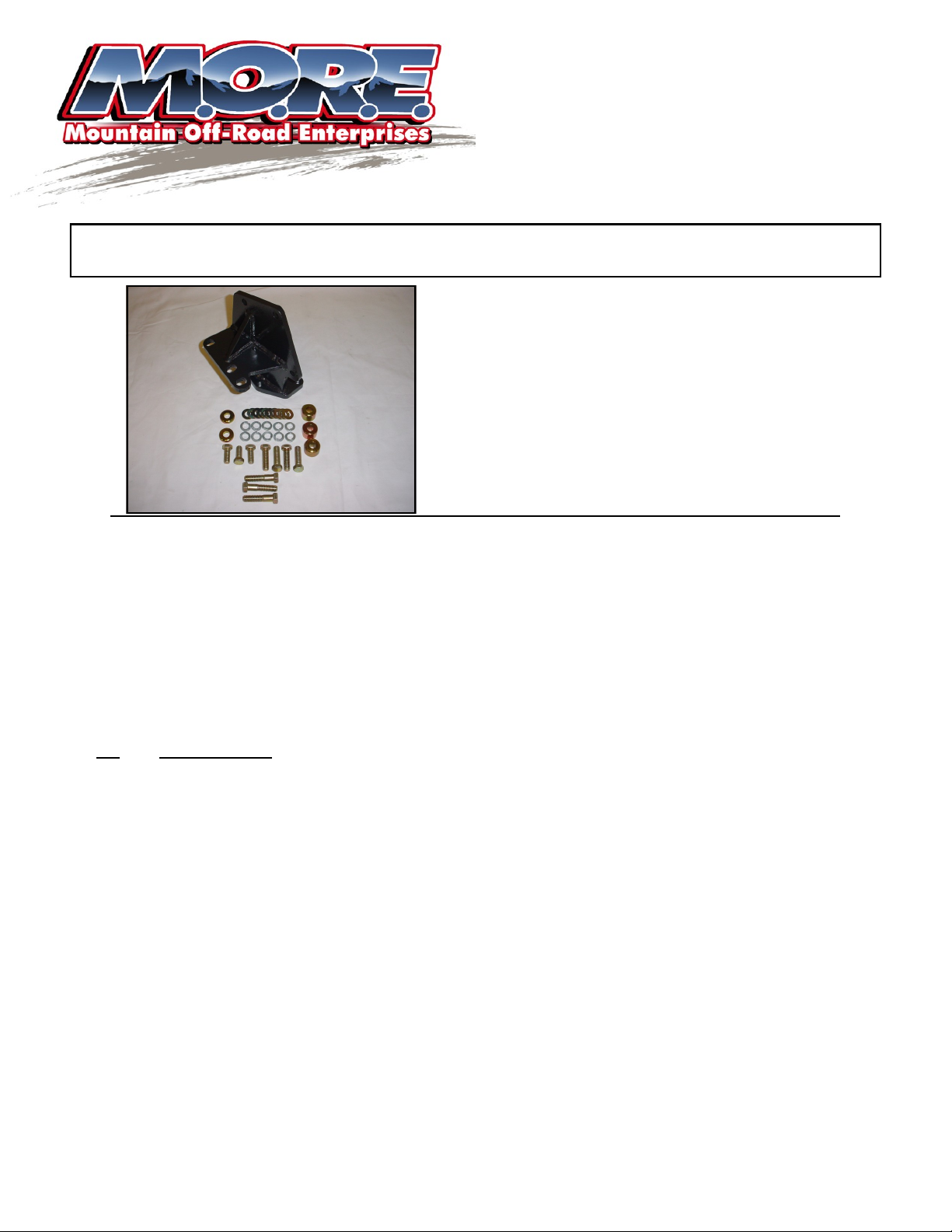

CONTENTS of KIT:

Qty: Description:

1 Bracket-Steering Box H.D.

3 Bracket to Box Spacers (3/4” thick)

1 Bracket to Box Spacer (1/4” thick)

1 Frame to Bracket Spacer (1/4” thick)

3 7/16” x 2” Bolts

4 7/16” x 1-1/2” Bolts

3 7/16” x 1” Bolts

10 7/16” Flat Washers

10 7/16” Lock Washers

Please read all instructions before installing.

This Steering Box Bracket H.D. (Heavy Duty) is designed to fit 1976-1986 Jeep® CJ-5, CJ-7, CJ-8 vehicles and

will move the steering gear forward 1 1/4”. Depending on the type of steering shaft your Jeep has , it may

be necessary to replace or modify the steering shaft ( see figure 7). Please read and understand all in-

structions before installing. Due to the fact that this bracket is over 300% stronger than the stamped steel factory bracket, the stress loads of large tires will be transferred directly to the frame. Because of the strength of

this bracket, your frame should be checked often for signs of cracking and stress. For this reason we recommend using the optional third crossmember mounting hole. See STEP 2 for instructions on using this hole.

(Hardware has been provided in your kit for the use of this hole.) You may also consider Frame Plates

(#FP300), to help add more strength to the Jeep® CJ frame.

FIT and TOLERANCES: This kit is the result of countless hours of research, testing, fitting and refining.

Jeep® frames have a wide tolerance on bolt hole centers from frame to frame. In addition to the factory tolerances, most people install other then factory equipment (i.e.: steering gear boxes, bumpers, springs, winches,

shackle reversal systems, etc.) M.O.R.E.™ has done the best job we can to insure that this part fits with sev-

eral of the possibilities. However, you may find it necessary to modify (i.e.: grind, elongate, bend, or force)

the parts in this kit, or other parts on your Jeep®, to fit on your rig. Please use common sense when installing these parts and understand that once you modify this part in any way, shape or form, it is not returnable.

STEP 1: Remove steering box and bracket from frame. It is not necessary to disconnect the steering

box from the pitman arm (or pitman arm from the drag link), or to disconnect the power steering hoses. Only

remove all bracket to frame bolts and, box to bracket bolts. Support the box with a floor jack or blocks. Be

careful not to damage the hoses! The old stamped steel brackets can now be discarded.

STEP 2: For extra strength the Steering Box Bracket has been designed to use a third bracket-to-

crossmember bolt. This hole must be drilled in the crossmember using the bracket as a template. To do this,

set the bracket on TOP of the crossmember with the third hole toward the driver side frame rail. (See Figure

4 for location of third hole in the bracket). Align the two existing holes and loosely thread two of the 7/16 bolts

in the bracket from the bottom. Now with the bracket held in position by the two bolts, mark the location for

the third hole. Remove the bracket, center-punch the location and drill with a ½" drill. Deburr the hole top and

bottom.

PAGE 1 of 2

STEP 3: The steering shaft will need to be extended to reach the steering box after the box has been

moved forward. The shaft is telescoping from the factory (so it can collapse in case of a collision). To make it gain

length or extend the two halves must have the plastic locking device removed. The plastic must be melted out by

heating the shafts. If you choose this method, remove the entire shaft from the Jeep. Use a torch and slightly heat

the two halves until the plastic is melted out and the two shafts will slide apart. Do this in a well ventilated area

cause the melting plastic produces toxic fumes. Clean them with a wire brush, and paint them. Do not reinstall the

steering shaft at this time. ( SEE Note for Figure 7)

STEP 4: The inside lip on the crossmember will need to have a section removed to allow the steering box

to be moved forward.( see figure 1& 2). The brake line for the PS caliper is located behind this crossmember so

move it out of the way before you begin cutting. Be very careful that you do not damage the brake line or radiator

when cutting. After the crossmember has been cut we recommend cleaning the edges so there are no sharp

edges. We opted to weld in a piece of cold roll material to strengthen the crossmember after it had been cut. ( see

figure 3 )

STEP 5 : Locate the ¼" bracket to box spacer, 1-½" bolt, flat washer and lock washer. Put the lockwasher,

and flat washer onto this bolt and insert through the hole on the bracket that is labeled #1 in (figure 5), with the

flat edge of the spacer facing the bracket. See figure 6 . (Note that the spacer goes on the opposite side of the

bracket from the washers). We recommend a dab of thread locking compound (Lock-Tight) be placed on all of the

mounting bolts. Now loosely thread the bolt into the hole of the steering box. Now all remaining box to bracket

bolts and spacers can be assembled in the same manner. Pay careful attention to assure that the flat side of the

spacers are facing the bracket. Once all four bolts are in, torque to approximately 45 ft/lbs.

STEP 6 : This step will be much easier with someone to assist in holding up the bracket while the bolts are

started. Lift assembly into position and align top two holes on the bracket with the existing holes in crossmember.

Loosely start both 1" bolts with flat and lock washers from the top. Tighten these bolts down to finger tight only

(these should not be tightened until all other bolts and spacers are in place.) Place remaining spacer (bracket to

frame) between frame and bracket aligned with the rearmost hole. Front two holes of bracket should be aligned

over the shackle mount (or Shackle Reversal System front pivot bracket). Insert 1-½" bolts using flat and lock

washers through all three holes and finger tighten. Tighten bolts through crossmember first and then bolts through

the frame. Torque bolts on crossmember to 45 ft/lbs. and bolts on frame to 35 ft/lbs. Reinstall the steering shaft.

Final Notes: Start vehicle and turn wheels lock to lock several times to check for any signs of binding or unusual noises. Torque on all bolts should be checked after the first few hours of use and then periodically after that.

Figure 1 Figure 2 Figure 3

PAGE 2 of 3

Loading...

Loading...