Mountain Off Road SB7686 User Manual

MOUNTAIN OFF ROAD ENTERPRISES LLC.

P.O. BOX 690, DELTA, COLORADO, 81416

970-625-0500 970-625-3747 Fax

info@mountainoffroad.com

www.mountainoffroad.com

INSTRUCTIONS FOR M.O.R.E.™ SB7686 Steering Box Bracket H.D.

Please read Terms/Policies on page 2 before installing

CONTENTS of KIT:

Qty: Description:

1 Bracket-Steering Box H.D.

3 Bracket to Box Spacers (3/4” thick)

1 Bracket to Box Spacer (1/4” thick)

1 Frame to Bracket Spacer (1/4” thick)

3 7/16” x 2” Bolts

4 7/16” x 1-1/2” Bolts

3 7/16” x 1” Bolts

10 7/16” Flat Washers

10 7/16” Lock Washers

Please read all instructions before installing.

This Steering Box Bracket H.D. (Heavy Duty) is designed to fit 1976-1986 Jeep® CJ-5, CJ-7, CJ-8 vehicles.

Please read and understand all instructions before installing. Due to the fact that this bracket is over 300%

stronger than the stamped steel factory bracket, the stress loads of large tires will be transferred directly to

the frame. Because of the strength of this bracket, your frame should be checked often for signs of cracking

and stress. For this reason we recommend using the optional third crossmember mounting hole. See STEP 2

for instructions on using this hole. (Hardware has been provided in your kit for the use of this hole.) You may

also consider our Steering Box Brace (#SB9037) and our Frame Plates (#FP300), to help transfer the load to

the passenger side frame rail, and add more strength to the Jeep® CJ frame.

FIT and TOLERANCES: This kit is the result of countless hours of research, testing, fitting and refining.

Jeep® frames have a wide tolerance on bolt hole centers from frame to frame. In addition to the factory tolerances, most people install other then factory equipment (i.e.: steering gear boxes, bumpers, springs, winches,

shackle reversal systems, etc.) M.O.R.E.™ has done the best job we can to insure that this part fits with sev-

eral of the possibilities. However, you may find it necessary to modify (i.e.: grind, elongate, bend, or force)

the parts in this kit, or other parts on your Jeep®, to fit on your rig. Please use common sense when installing these parts and understand that once you modify this part in any way, shape or form, it is not returnable.

STEP 1: Remove steering box and bracket from frame. It is not necessary to disconnect the steering

box from the pitman arm (or pitman arm from the drag link), or to disconnect the power steering hoses. Only

remove all bracket to frame bolts and, box to bracket bolts. Support the box with a floor jack or blocks. Be

careful not to damage the hoses! The old stamped steel brackets can now be discarded.

STEP 2: For extra strength the Steering Box Bracket has been designed to use a third bracket-to-

crossmember bolt. This hole must be drilled in the crossmember using the bracket as a template. To do this,

set the bracket on TOP of the crossmember with the third hole toward the driver side frame rail. ( See Figure

1 for location of third hole in the bracket). Align the two existing holes and loosely thread two of the 7/16 bolts

in the bracket from the bottom. Now with the bracket held in position by the two bolts, mark the location for

the third hole. Remove the bracket, center-punch the location and drill with a ½" drill. Deburr the hole top and

bottom.

PAGE 1 of 2

STEP 3: Locate the ¼" bracket to box spacer, 1-½" bolt, flat washer and lock washer. Put the lockwasher then the flat washer onto the bolt and insert through the hole on the bracket that is labeled #1 in figure

2, with the flat edge of the spacer facing the bracket. See figure 2. (Note that the spacer goes on the opposite

side of the bracket from the washers). We recommend a dab of thread locking compound (Lock-Tight) be

placed on all of the mounting bolts. Now loosely thread the bolt into the hole of the steering box. Now all remaining box to bracket bolts and spacers can be assembled in the same manner. Pay careful attention to assure that

the flat side of the spacers are facing the bracket. Once all four bolts are in, torque to approximately 45 ft/lbs.

STEP 4: This step will be much easier with someone to assist in holding up the bracket while the bolts

are started. Lift assembly into position and align top two holes on the bracket with the existing holes in crossmember. Loosely start both 1" bolts with flat and lock washers from the top. Tighten these bolts down to finger

tight only (these should not be tightened until all other bolts and spacers are in place.) Place remaining spacer

(bracket to frame) between frame and bracket aligned with the rearmost hole. Front two holes of bracket should

be aligned over the shackle mount (or Shackle Reversal System front pivot bracket). Insert 1-½" bolts using flat

and lock washers through all three holes and finger tighten. Tighten bolts through crossmember first and then

bolts through the frame. Torque bolts on crossmember to 45 ft/lbs. and bolts on frame to 35 ft/lbs.

Final Notes: Start vehicle and turn wheels lock to lock several times to check for any signs of binding or unusual noises. Torque on all bolts should be checked after the first few hours of use and then periodically after

that.

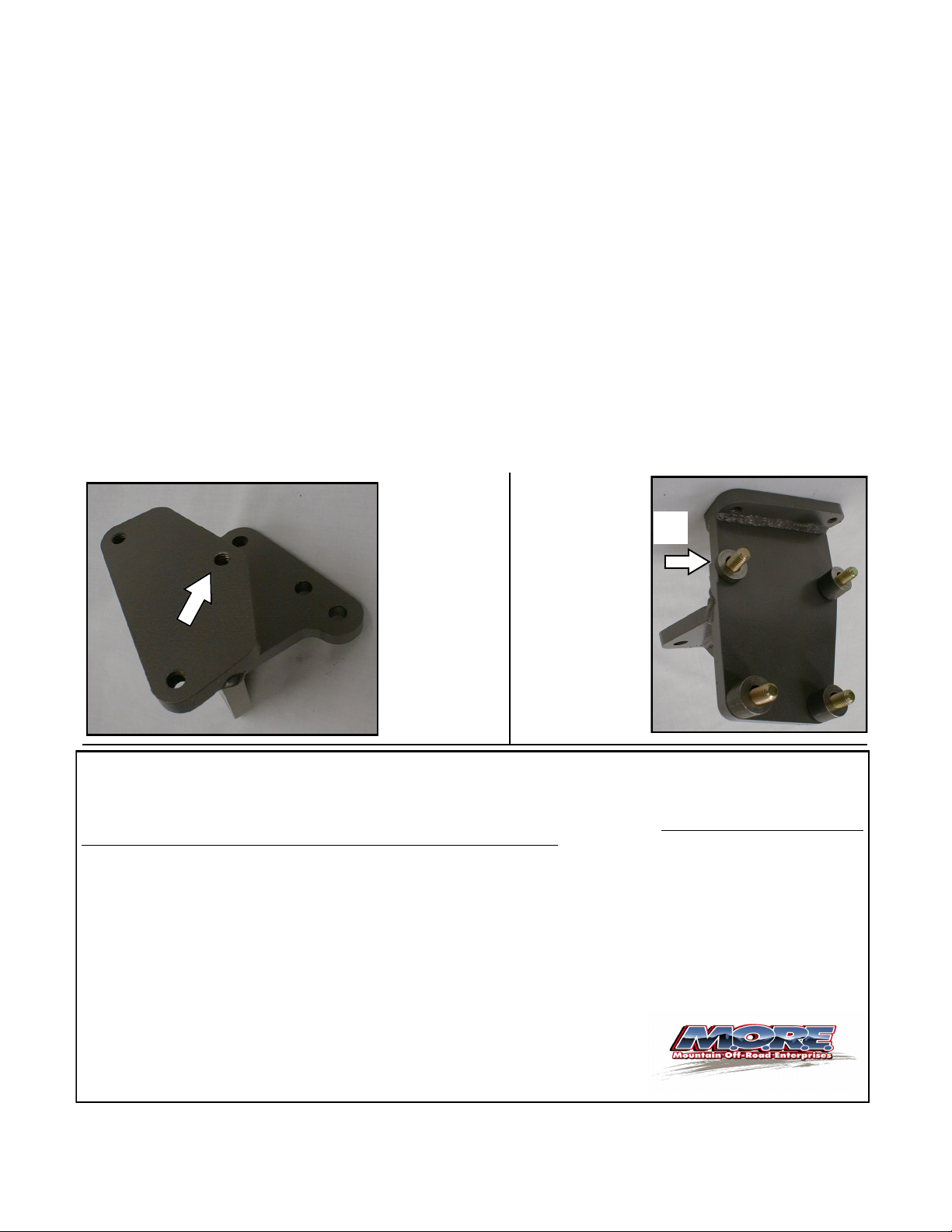

FIGURE 1

This picture shows

the optional 3rd

mounting location

that you must drill

a hole in the

crossmember for.

FIGURE 2

This picture shows

the H.D. Bracket

as it would be

installed in the

Jeep. The thin

spacer is placed

on the upper left

mounting bolt.

(#1).

#1

TERMS/POLICIES:

RETURNS: No returns will be accepted without prior permission from M.O.R.E.™ LLC. You must call for a Return Goods Authorization (RGA)

number. Merchandise must be returned prepaid and insured. A claim must be made with in 30 days from receipt of merchandise. The original

invoice or a copy with the RGA number written on must accompany all returns. A 20% restocking fee will be charged on all parts returned for

credit or refund unless merchandise is proven to be defective or was shipped wrong by M.O.R.E.™ LLC. No merchandise will be issued credit

or refund if it has been installed, modified, used in any way or is in unsalable condition.

WARRANTY: All merchandise is warranted to be free from defects in materials and workmanship prior to installation. Any alteration or improper use will void this warranty. Because all parts we sell are intended for use in heavy-duty applications it is not possible to warrantee or

guarantee the performance of any items. M.O.R.E.™ LLC. products and the products manufactured by others, which we sell may be subject

to an infinite variety of conditions due to the manner in which they are used, serviced and/or installed. Purchasers and users of such products

rely upon their own judgment as to the suitable use selection, service and installation of such products.

PRODUCT DISCLAIMER: Modification of your vehicle to enhance performance with parts sold by M.O.R.E.™ LLC. may create a dangerous

condition which could cause serious bodily injury, and the buyer hereby expressly assumes all risks associated with any such modifications.

All parts sold by M.O.R.E.™ LLC. are for racing or off road use only. Mountain Off Road Enterprises LLC. will not accept responsibility for

personal injury or property damage arising from the failure of any parts manufactured or sold by M.O.R.E.™ LLC.

Specifications are subject to change without notice.

These instructions, and the M.O.R.E.™ logo are copyright©, 2008.

PAGE 2 of 2

Loading...

Loading...