Page 1

control – motion – interface

IV 251

Signal Converter

SSI => Analogue and SSI => Serial

ELEKTRO-TRADING sp. z o.o

Tel. +48 (0-32) 734-55-72

Tel/Fax +48 (0-32) 734-55-70

E-Mail et@elektro-trading.com.pl

http://www.elektro-trading.com.pl

• Suitable for operation with all sensors and encoders using SSI interface

• Scalable analogue outputs +/- 10 volts, 0-20 mA and 4-20 mA proportional to the

sensor signal

• Serial RS232 and RS485 interface for serial readout of the encoder data

• Easy to set up by Teach function or by PC

• Linearisation facilities by freely programmable input-output curves

• Additional facilities as bit-blanking, round-loop-operation etc.

• 18–30 volts DC power supply, auxiliary voltage output 5 V DC for sensor supply

Operating Instructions

IV25101A_e.DOC / Feb-08 Page 1 / 25

Page 2

Safety Instructions

• This manual is an essential part of the unit and contains important hints about

function, correct handling and commissioning. Non-observance can result in

damage to the unit or the machine or even in injury to persons using the

equipment!

• The unit must only be installed, connected and activated by a qualified electrician

• It is a must to observe all general and also all country-specific and application-

specific safety standards

• When this unit is used with applications where failure or maloperation could cause

damage to a machine or hazard to the operating staff, it is indispensable to meet

effective precautions in order to avoid such consequences

• Regarding installation, wiring, environmental conditions, screening of cables and

earthing, you must follow the general standards of industrial automation industry

• - Errors and omissions excepted –

Notice of Compatibility

:

The IV251 converter described in this manual is a follow-up model of the obsolete WD251

converter. It provides an extended range of functions with use of a few more parameters, but

is otherwise practically 100% compatible to WD251 units for use with SSI absolute encoders.

For applications using incremental encoders, please refer to our converter type ZU252.

Version: Description:

IV25101a/af/kk/hk/Feb.08 Version A5-motrona

IV25101A_e.DOC / Feb-08 Page 2 / 25

Page 3

Table of Contents

1. Introduction....................................................................................................4

2. Terminal Assignments and Connections........................................................ 5

2.1. Encoder connections with Master operation........................................................5

2.2. Encoder connections with Slave operation...........................................................6

2.3. Analogue outputs ..................................................................................................6

2.4. Serial interface......................................................................................................7

3. DIL switch settings.........................................................................................8

4. Commissioning...............................................................................................9

4.1. Self Test: ...............................................................................................................9

4.2. SSI signal test: ......................................................................................................9

4.3. Scaling of the analogue output with use of the Teach function:..........................9

4.4. The Set Input: ......................................................................................................10

5. Serial Readout of the Actual Encoder Position............................................ 11

6. PC setup using the operator software OS32................................................ 12

7. Parameter Settings ...................................................................................... 13

7.1. Display Settings: .................................................................................................13

7.2. General Settings:.................................................................................................13

7.3. SSI Specific Settings:..........................................................................................16

7.4. SSI Error Settings: ...............................................................................................19

7.5. Linearisation Settings in %:................................................................................19

7.6. Set-up Settings:...................................................................................................19

7.7. RS 232 / RS 485 Settings:...................................................................................19

8. Free Programmable Linearization.................................................................21

9. Testing Functions......................................................................................... 23

10. Dimensions and Specifications....................................................................24

11. Parameter-List..............................................................................................25

IV25101A_e.DOC / Feb-08 Page 3 / 25

Page 4

1. Introduction

IV251 is a small and low-cost, but highly performing converter for industrial applications, where

the information of a sensor or encoder with SSI interface needs to be converted to an analogue

signal or to a serial RS232/485 data format.

The unit has been designed as a compact module with 12 screw terminals and a 9-position

SUB-D connector (female). The housing is suitable for standard DIN rail mounting.

Applicable encoders and sensors:

Single-turn or multi-turn absolute encoders and all similar sensors using a standard SSI

interface (6 to 25 bits of resolution with binary or Gray code). The unit can operate in either

master mode (clock signal generated by the IV251 unit), or in slave mode (clock signal

generated by a remote device)

Remark to the encoder resolution:

The unit provides settings for the standard resolutions of 13 bits, 21 bits and 25 bits. In

general, for sensors with other resolutions you can use the next higher setting (i.e. set the

unit to 21 bits with a sensor of 16 bits).

Depending on brand and specification of the encoder, in some cases it may be necessary to

blank out the surplus bits by using the bit blanking function described later. In general

however, the unit should work perfectly also without special bit blanking.

IV25101A_e.DOC / Feb-08 Page 4 / 25

Page 5

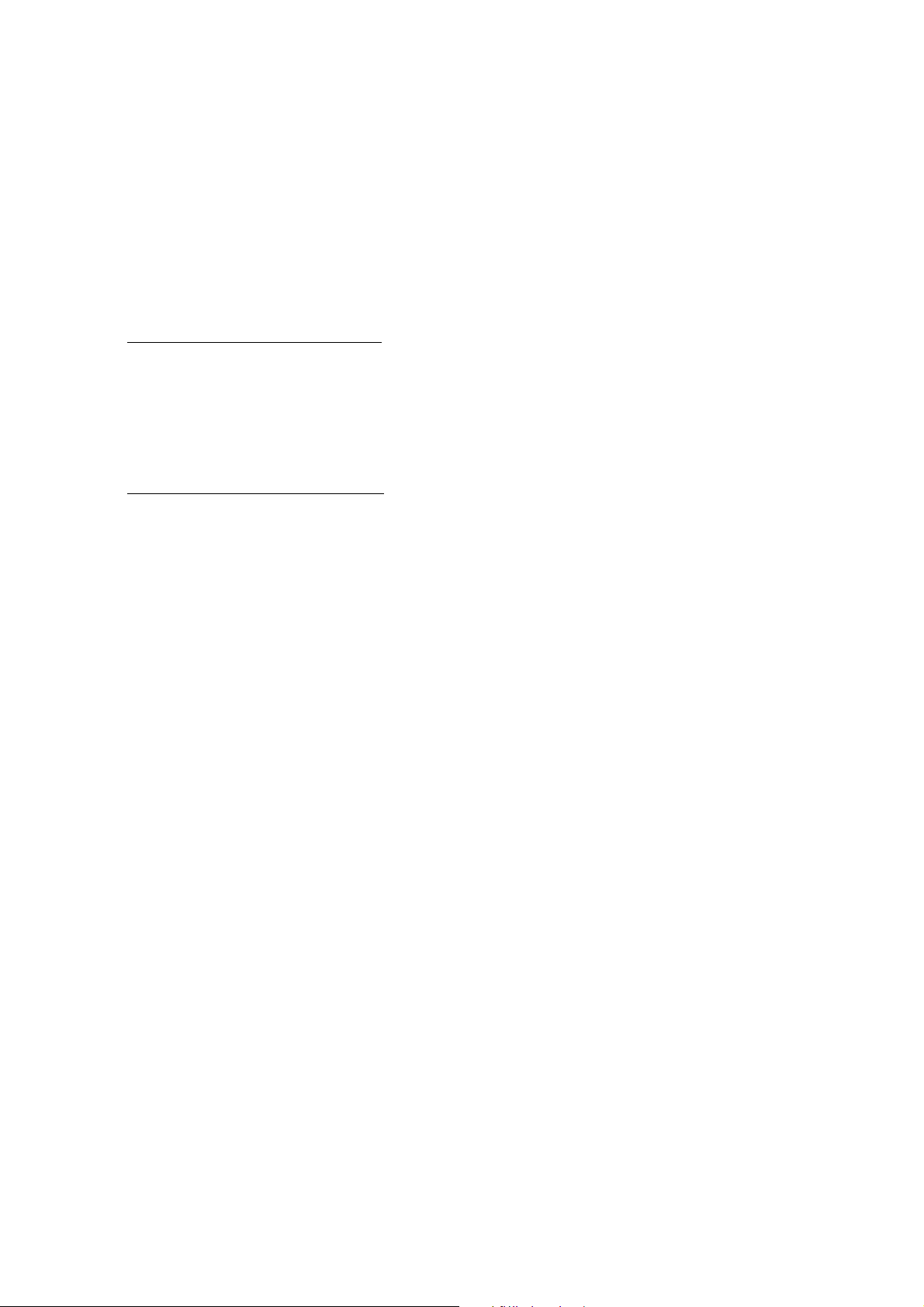

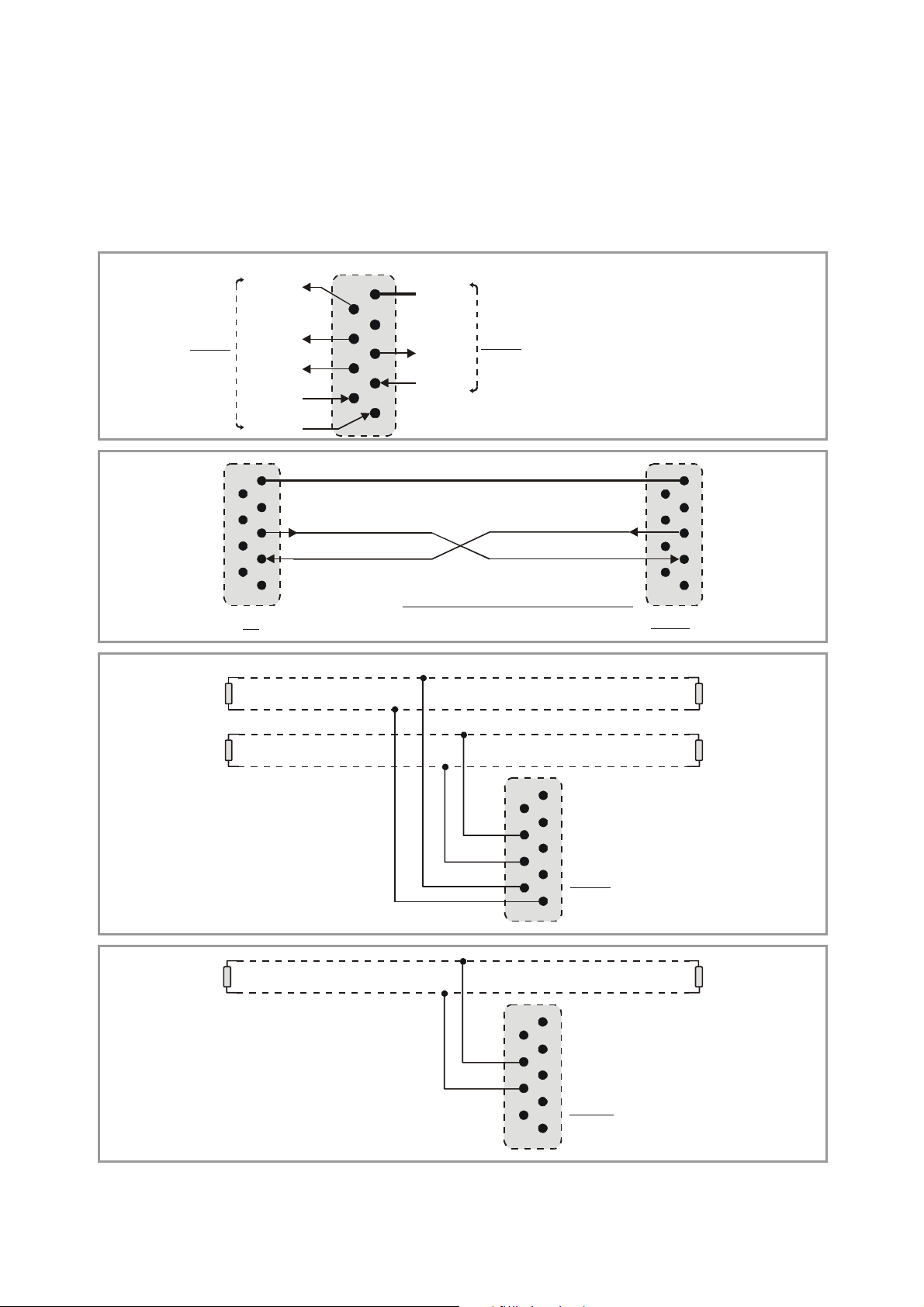

2. Terminal Assignments and Connections

The subsequent diagram shows the assignment of the screw terminals.

We recommend to connect the Minus wire of the power supply to earth potential. GND

terminals 4, 6 and 12 are connected internally. Depending on input voltage and load of the

auxiliary voltage output, the total power consumption of the unit is about 200 mA.

0-20mA / 4-20mA out

Aux. 5.5V ou t (m ax . 150 m A)

SS I D ata (-)

SS I D ata (+)

Set

7

8

9

1

0

1

1

1

2

P

O

W

E

R

1

2

3

4

5

6

Analo gue out +/-10V

SSI- Clock (-)

SSI- Clock (+)

Analogue GND ( - )

+18...30 VD C ( typ. 20 0 m A)

GND ( - )GND ( - )

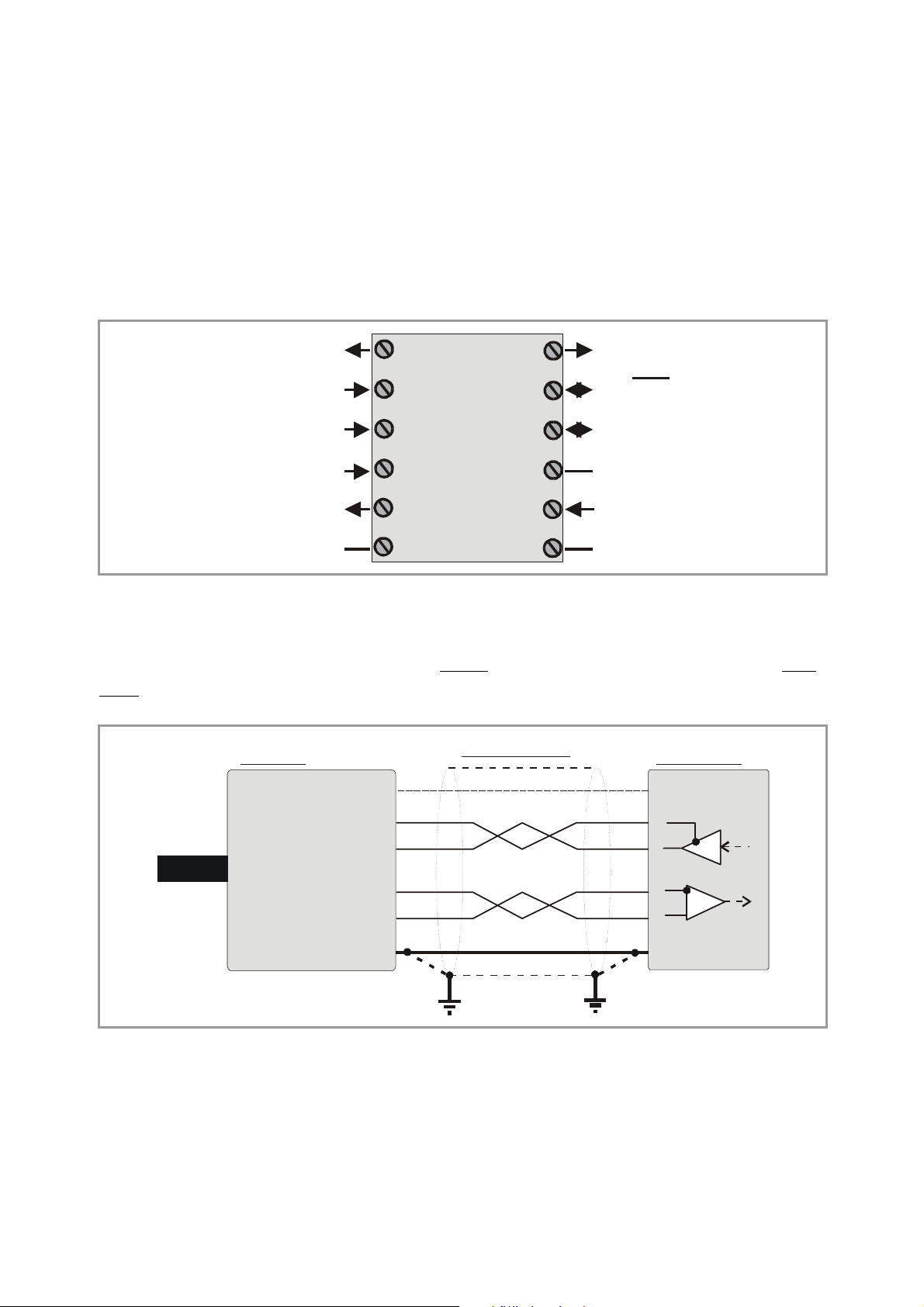

2.1. Encoder connections with Master operation

We recommend to connect the screen to the Minus wire of the encoder supply voltage on both

sides.

SSI encoder

(+5,5V)

Clock-

Clock+

DataData+

GND

Master mode

(optional)

IV251 converter

11 (+5.5V)

2

3

8

9

12 (GND)

IV25101A_e.DOC / Feb-08 Page 5 / 25

Page 6

2.2. Encoder connections with Slave operation

With this mode, the IV251 converter operates in parallel to another unit, acting as a „listener“

to the existing data communication.

Quite according to need, the common potential of the master can be connected to terminal 12

(GND), or remain open for fully differential operation.

Master

Slave mode

ClockClock+

IV251 converter

11 (+5.5V)

2

3

+

-

+

k

k

c

c

o

o

l

l

C

C

+-

Encoder

-

a

a

t

t

a

a

D

D

DataData+

8

9

12 (GND)

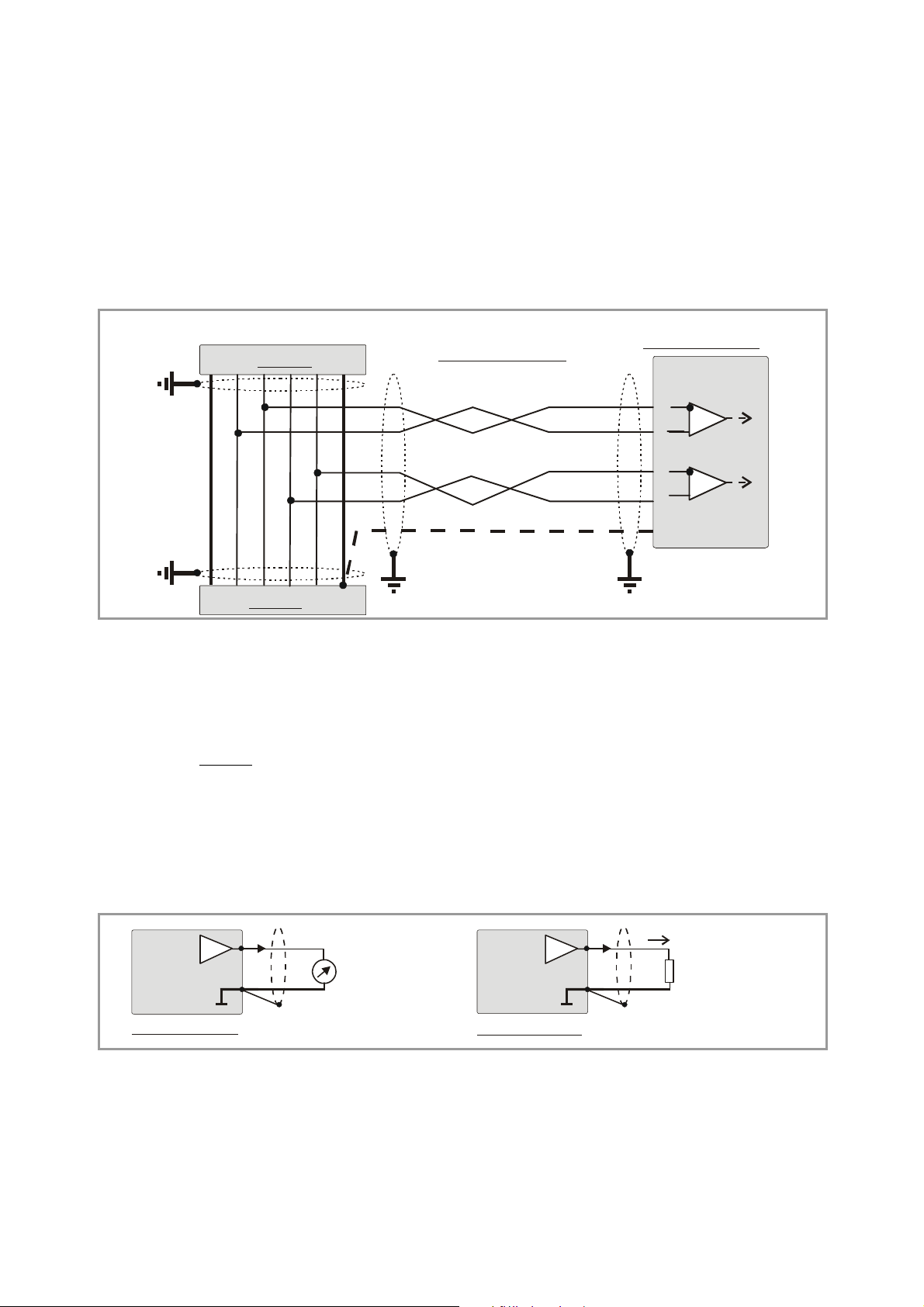

2.3. Analogue outputs

The unit provides one +/-10V voltage output and one 0-20 mA / 4-20 mA current output at a

resolution of 14 Bits

The nominal load of the voltage output is 2 mA; the current output accepts loads between

0 and 270 Ohms.

There is a separate analogue ground terminal, which internally is connected to the GND

potential of the power supply

Vout

GND

(i.e. the voltage output operates in steps of 1.25 mV).

1

4

+/- 10V

(max. 2 mA)

Iout

GND

7

4

0/4 - 20 mA

(R = 0 ... 270 Ohms)

Voltage output

Current output

IV25101A_e.DOC / Feb-08 Page 6 / 25

Page 7

2.4. Serial interface

The unit provides a RS232 interface and a RS485 interface, however only one of the two can be

used at a time. Serial communication allows to read out the encoder position and to set

parameters and variables by PC, according to need.

+5V

5

9

4

RS485

T+

T-

8

3

7

2

R+

6

1

R-

4

4

2

2

GND

TxD

RxD

RS232:

T+

Please connect only pins 2, 3 and 5 !

5

5

9

9

8

8

3

3

7

7

6

6

1

1

PC

GND int.

TxD

RxD

RS232

Sub-D-9 (female on unit site)

5

5

9

9

4

4

8

8

3

3

7

7

2

2

6

6

1

1

IV 251

120 Ohms 120 Ohms

120 Ohms 120 Ohms

RS485- Bus

( 4- wire )

120 Ohms

RS485- Bus

( 2- wire )

TR+

R-

5

5

9

9

4

T+

T-

R+

R-

T+

T-

4

8

8

3

3

7

7

2

2

1

1

IV 251

6

6

120 Ohms

5

5

9

9

4

4

8

8

3

3

7

7

2

2

1

1

IV 251

6

6

IV25101A_e.DOC / Feb-08 Page 7 / 25

Page 8

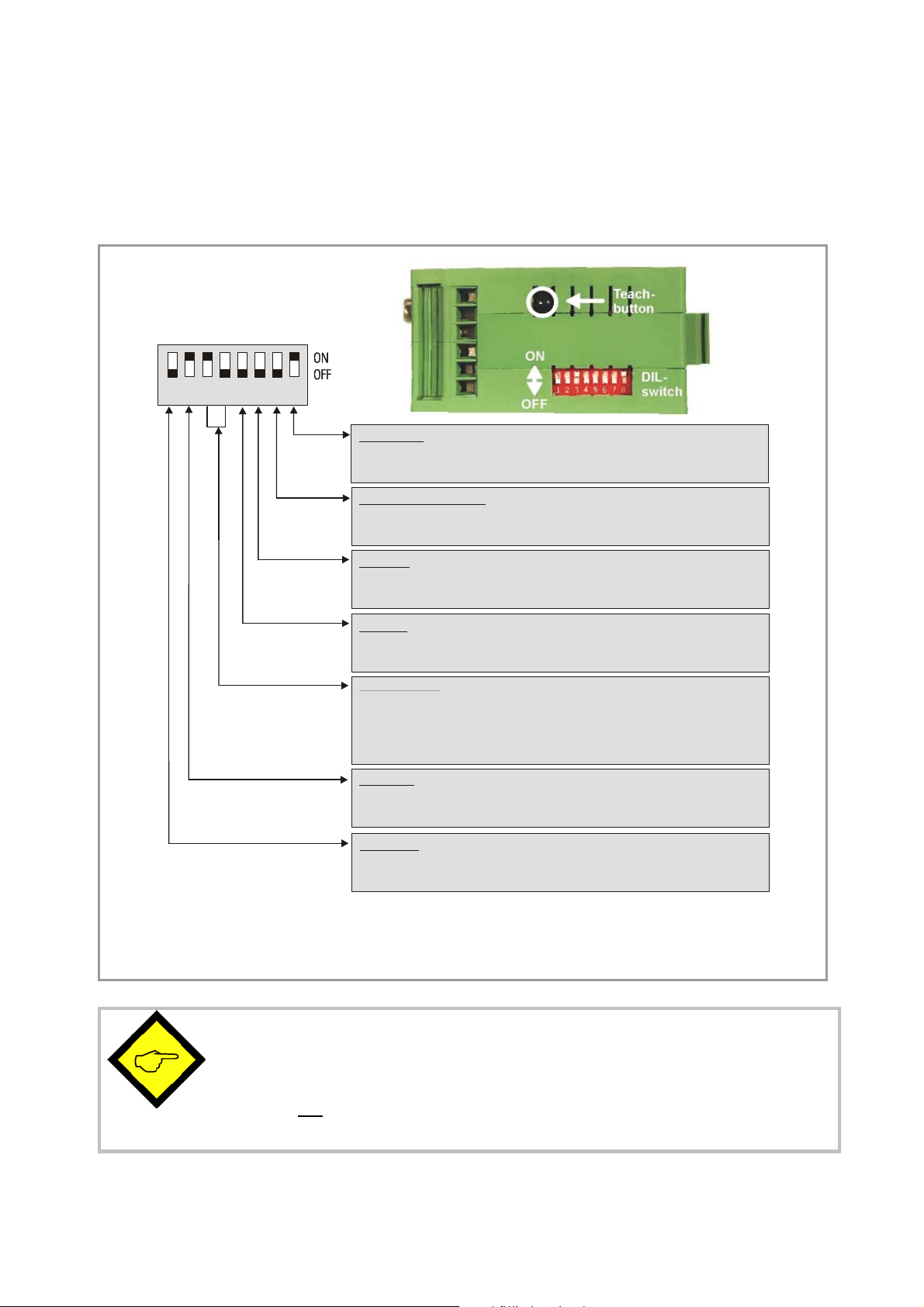

3. DIL switch settings

The DIL switch located on the top site of the unit provides customer-specific settings of desired

operation modes.

1 2345678

Set Default:

OFF:Unit loads default settings with every power-up cycle

ON : No loading of default settings upon power-up.

Analogue Update Mode

OFF:Update of analogue output in a fixed preset time pattern

ON: Update of analogue output after every SSI telegram

SSI- Test:

OFF: Normal LED operation, Teach function enabled

ON: Verifies correct status of clock and data lines, Teach function disabled

SSI Code

OFF: Gray Code

ON: Binary Code

SSI Resolution:

3 OFF, 4 OFF : not valid

3 ON, 4 OFF : 25 Bit

3 OFF, 4 ON : 21 Bit

3 ON, 4 ON : 13 Bit

SSI Mode:

OFF: Slave Mode

ON : Master Mode

Serial Port:

OFF : RS 232- Format

ON : RS 485- Format

The switch settings shown above are suitable for Master operation of a 25 bit SSI encoder with Gray

coded output. The analogue output operates with equidistant update time and the serial link is set to

RS232 communication.

• Changes of the switch settings will become active only after the

next power-up cycle!

• After setup and commissioning, please set DIL switch position 6

to ON

. If set to OFF, any inadvertently touch of the „Teach“ button would

•

overwrite your previous scaling input!

IV25101A_e.DOC / Feb-08 Page 8 / 25

Page 9

4. Commissioning

With basic applications, you can use the Teach procedure for commissioning of the unit.

Extended functions need a PC for setup and are described later.

4.1. Self Test:

Set all DIL switches according to your application and connect encoder and power supply to the

unit. Set switch position No. 6 to ON first (test mode) and power the unit up. The green LED

(power) and the yellow LED (status) must light both. After a successful self-test, the yellow LED

must switch off again (approx. 1 sec.)

4.2. SSI signal test:

Push the Teach button one time now. This will verify the SSI Data lines. The yellow LED must

switch on. Where it remains off, you need to cross the input lines “Data+” (9) and “Data-“ (8).

The second actuation of the Teach button will test the SSI Clock lines in the same manner.

Again, the LED must be lit, otherwise you need to cross the lines “Clock+” (3) and “Clock-“ (2).*)

The third actuation of the Teach button will switch the LED off and conclude the test cycle.

Where you find your status LED lit after the first and the second actuation of the button, your

wiring of the encoder is o.k. Please power the unit down and set DIL position 6 to OFF for Teach

operation. With use of a PC and the OS32 operator software, you can check the status also

from the indicator boxes „Status SSI clock“ and „Status SSI data“ (red = status o.k.)

4.3. Scaling of the analogue output with use of the Teach function:

Power the unit up again, with DIL position 6 set to OFF. Press the Teach button one time.

The status LED will blink in a slow sequence now while the unit waits for the zero position.

Move your encoder to where you like zero output and press the button again.

This stores your zero definition and the LED will blink in a fast sequence now while the unit

waits for the full scale position. Move your encoder to where you desire full scale output and

press the button once more.

This stores your full scale definition and the LED will switch off. Your analogue output is now

set to the desired operating range, as selected by the output mode setting.

*) Testing the clock lines is primarily useful with Slave operation. Though the test works also in Master

mode, the result says only that the internal generation of the clock works fine. However, with Master

mode, this test cannot indicate faulty clock drivers or bad wiring of the clock lines.

IV25101A_e.DOC / Feb-08 Page 9 / 25

Page 10

• Your full scale position is allowed to be higher or lower than the zero position

• More scaling facilities and linearization functions are available with PC setup

• Teach min“ always refers to the initial output value defined by „Output

mode“, i.e. 0 volts or 0 mA or 4 mA

• When, after setting of the full scale position, the status LED does not switch

off, this indicates an overflow error where the mechanical zero position of

your encoder lies between your two teach settings. In this case you need to

change the zero position of the encoder (mechanically or by corresponding

programming of the encoder). With PC setup, the converter itself provides

also an electronic suppression of the overflow jump

• The only way to reset an overflow error state is to cycle the power supply

• The LED overflow check may fail with encoders providing a resolution

lower than 13 bits

Overflow error

Teach min.

Encoder zero

Teach max.

4.4. The Set Input:

With a HIGH signal on the Set input (terminal 10), the unit temporary substitutes the SSI

encoder data by a set value as entered to the “SSI Set Value” register, and the analogue output

as well as the serial readout will follow correspondingly. This means, independent of the actual

mechanical position of the encoder, the unit internally uses the register data instead of the

encoder SSI data. It turns back to normal encoder reading as soon as the Set signal goes LOW

again.

This function can be very useful for testing and commissioning purpose.

The Set input uses PNP / HTL characteristics (LOW = open or 0 – 3 V, HIGH = 10 – 30 V)

IV25101A_e.DOC / Feb-08 Page 10 / 25

Page 11

5. Serial Readout of the Actual Encoder Position

You can read out the actual SSI position of the encoder at any time from the serial link. For

setting of communication parameters, a PC is required.

IV251 uses the DRIVECOM communication standard according to ISO 1745.

Details about this protocol can be found in our file Serpro1a.doc

download on the

The serial access code for the actual encoder position is „ :8

(ASCII characters, colon and 8)

motrona

homepage.

which is available for

„

IV25101A_e.DOC / Feb-08 Page 11 / 25

Page 12

6. PC setup using the operator software OS32

You can apply the full set of functions when using a PC and our operator software OS32 for

setup of the unit. You can download this software and full instructions, free of charge, from our

homepage

www.motrona.de

• Connect your PC to the converter, using a serial RS232 cable like shown in section 2.4 of

this manual. Make sure, the cable only connects pins 2, 3 and 5.

• Run the OS3.x software and you will find the following screen:

• In case your text and color fields remain empty and the headline says „OFFLINE“, you must

verify your serial settings. To do this, select „Comms“ from the menu bar. Ex factory, all

motrona

units use the following serial standard settings:

Unit No. 11, Baud rate 9600, 1 start/ 7 data/ parity even/ 1 stop bit

• If the serial settings of the unit should be unknown, you can run the „SCAN“ function from

the „TOOLS“ menu to find out.

IV25101A_e.DOC / Feb-08 Page 12 / 25

Page 13

7. Parameter Settings

7.1. Display Settings:

X Operand, / Operand, +/-Operand:

These operands serve for conversion of the position information transmitted by the encoder into

other engineering units like millimeters or inches etc. This conversion only refers to the numeric

readout value by serial link, but does not affect the scaling of the analogue output.

With the settings x Operand = 1.0000

/ Operand = 1.0000 and

+/- Operand = 0.0000

the serial readout value equals to the encoder value.

Serial Readout SSI encoder data = x

[

xOperand

]

/Operand

+ +/-Operand

7.2. General Settings:

Teach Minimum, Teach Maximum:

These two settings define the range of the encoder where the analogue output should move

between minimum and maximum output. At any time you can use the Teach button of the unit

or the soft keys on the screen to set these registers*), but you are free to enter your settings

directly by keyboard, without using the Teach function.

Round Loop:

In general, this setting should be 00000. Any other settings will substitute the real encoder

position by a repeating cycle count.

Example

range between 0 and 2047. When we underpass zero with reverse direction, again 2047 will

appear. When we exceed 2047 with forward direction, we restart at 0 again.

The zero position of the round-loop counter can be set by register “SSI-Offset” which allows

settings between 0 and the Round-Loop value. Register “Direction” allows to set the counting

direction of the round loop counter (0 = up, 1 = down).

Within this new definition of a round-loop range, you are free to set the zero and full scale

thresholds of your analogue output again by means of Teach-Min. and Teach-Max. parameters.

*) Click to Teach-Min (on) and again (off), then click to Teach-Max (on) and again (off).

To activate your Teach results, click to “Activate Data”, to read out and see your Teach results on the

screen, click the “Read” key.

All settings will be finally stored to the unit after clicking the “Store EEprom” key.

: when we set this register to 2048, the internal position register will only move in a

IV25101A_e.DOC / Feb-08 Page 13 / 25

Page 14

The following drawings explain the coherence between original encoder data, Round-Loop

setting, SSI-Offset and Direction register.

8192

Original encoder signal

Encoder 13Bit

Direction = 0

SSI-Offset = 1024

Round-Loop = 2048

2048

1024

0 360

Volt

8192

T-Max

T-Min

Round-Loop= 2048SSI-Offset= 1024

Round-Loop signal

180

Analogue Output (Output Mode = 1)

Original encoder signal

degrees

Encoder 13Bit

Direction = 1

SSI-Offset = 1024

Round-Loop = 2048

Round-Loop signal

2048

1024

T-Max

T-Min

0 360

Volt

180

Round-Loop= 2048SSI-Offset= 1024

Analogue Output (Output Mode = 1)

degrees

The Round-Loop function is also suitable to suppress the encoder overflow, when the

mechanical zero position of your encoder lies between your Teach-Min and Teach-Max values

and you do not like to change the mechanical situation. As shown in the subsequent picture,

you need to set the Round-Loop register to the full encoder resolution and then shift the zero

transition by setting the SSI Offset correspondingly.

IV25101A_e.DOC / Feb-08 Page 14 / 25

Page 15

• Every change of the Round-Loop setting requires new entry of Teach-Min,

Teach-Max and Offset values

• With use of the Round-Loop function it is also possible to change the

counting direction of the encoder, by setting the Direction bit correspondingly

• After any action concerning the round-loop and direction settings, new entry

of Teach-Min, Teach-Max and Offset becomes necessary.

8192

Encoder 13Bit

Direction = 0

SSI-Offset = 2048

Round-Loop = 8192

Original encoder signal

T-Min

T-Max

2048

0

Volt

Analogue Output (Output Mode = 1)

Round-Loop signal

360180 degrees

Output Mode:

Selects the output format of the analogue outputs like shown:

V

Min. Max.

Output Mode = 0

-10V ... 0 ... +10V

Encoder

V

Min.

Max.

Output Mode = 1

0 ... +10V

Encoder

mA

Min.

Max.

Output Mode = 2

4 ... 20 mA

Encoder

mA

Min.

Max.

Output Mode = 3

0 ... 20 mA

Encoder

Linearisation Mode:

Sets the mode of linearization

0: Linearisation off, registers P1 to P16 do not affect the output characteristics.

1: Linearisation in a range of 0 – 100%

2: Linearisation over full range –100% to +100%

(See examples under the section „Linearisation”)

IV25101A_e.DOC / Feb-08 Page 15 / 25

Page 16

t

7.3. SSI Specific Settings:

SSI Low Bit:

Defines the lowest bit (LSB) for evaluation, when the bit blanking function is used.

Must be set to “01” for evaluation of the full encoder range.

SSI High Bit:

Defines the highest bit (MSB) for evaluation, when the bit blanking function is used.

Must be set to the total number of encoder bits for evaluation of the full encoder range.

The following example uses a 13 bit encoder where High Bit is set to 12 and Low Bit is set to

03, resulting in evaluation of bits 03 to 12 only and blanking out positions 01, 02 and 13.

High order bit Low order bi

(Hi_bit = 12, Lo_bit = 03)

13 12 11 10 09 08 07 06 05 04 03 02 01

Evaluated encoder bits

(LSB)(MSB)

Hint for the use of the bit blanking function:

Bit blanking results in a different evaluation of the encoder information, and you should be fully

aware of what happens with the resolution and the number of registered turns when you use

this function.

The subsequent example uses a 13-bit single-turn encoder to explain two different results

when blanking out one bit:

• Without blanking, a 13 bit encoder would provide a 0 – 8191 information with a 0 - 360º

turn of the encoder shaft.

This would assume a setting of “High Bit = 13” and “Low Bit = 01”.

It is easy to understand that there are two different ways how to use only 12 of the 13 bits

available:

•

When we set High Bit to 12 while Low Bit remains 01, we have blanked the high order bit.

The result corresponds to an encoder providing information 0 – 4095 while we turn from

0 - 180º, and again the same 0 – 4095 information while we continue from 180º to 360º.

The resolution remains unchanged with respect of the number of steps per revolution.

• We can also leave High Bit to 13 and set Low Bit to 02 instead. This means we blank the

low order bit now. As a result, within one turn of 0 - 360º, we receive the encoder

information 0 – 4095 one time only, but the total number of steps per revolution has been

halved.

IV25101A_e.DOC / Feb-08 Page 16 / 25

Page 17

SSI Baud Rate:

Sets the communication speed of the SSI interface with SSI encoders.

Setting range: 100 Hz to 1MHz.

You are free to set any desired frequency between 0.1 kHz and 1000.0 kHz. For technical

reasons however, in the upper frequency range with Master operation, the unit will only

generate one of the following frequencies accurately:

1 000,0 kHz 888,0 kHz 800,0 kHz 727,0 kHz 666,0 kHz

615,0 kHz 571,0 kHz 533,0 kHz 500,0 kHz 470,0 kHz

444,0 kHz 421,0 kHz 400,0 kHz 380,0 kHz 363,0 kHz

347,0 kHz 333,0 kHz 320,0 kHz 307,0 kHz 296,0 kHz

With Master operation, other settings will result in generation of the next upper or lower value

according to above list. With all settings < 250.0 kHz the error between set rate and generated

rate becomes negligible.

285,0 kHz 275,0 kHz 266,0 kHz 258,0 kHz 250,0 kHz

It is mandatory to set the Baud rate also with Slave operation. In this case, however, the

setting serves only to determine the pause time for correct synchronization (pause is detected

after 4 clock cycles). The unit automatically synchronizes with every remote clock signal within

the specified Baud rate range.

SSI Wait Time:

This register sets the waiting time between two SSI telegrams in a range from 0.001 to 99.999

sec. In normal operation, due to processor cycle times, the real time may vary by 512 μsec. with

respect to the preset time: The fastest sequence possible is 1.3 μsec with a setting of 0.000.

With Slave operation mode, the distance of the SSI protocols depends on the remote Master

and the SSI Wait Time specifies the distance of evaluation data strings. Setting to 100 msec

results in evaluation of one telegram only every 100 msec, even though the Master may have

transmitted many telegrams more.

Especially with applications of closed-loop control loops, it may be of advantage to have

equidistant updating of the analogue output (DIL switch 7 = OFF). This is possible with Master

mode only, and the Wait Time setting (must be >0) directly corresponds to the time pattern of

updates.

The subsequent drawing explains the timing with use of equidistant update mode with a SSI

Wait Time setting of 3 msec.

IV25101A_e.DOC / Feb-08 Page 17 / 25

Page 18

Analogue

Update

Analogue

Update

TM1

SSI-Telegram

0msec

1msec 2msec 3msec

SSI Wait Time = 3 msec

TM2

Auswertung

Calculations

SSI-Telegram

• The shortest possible time for equidistant updating is 1.3 msec, due to

internal processing times (SSI Wait Time set to 0.001)

• The time marks TM1 and TM2 shown in above diagram can be displayed with

the Monitor function of the PC operator software. It is easy to understand

that the sum of both times must be equal to the Wait Time setting; otherwise you must increase the Baud rate or choose a longer update cycle.

(The serial access codes are :3 for TM1 and :5 for TM2)

• In critical cases you can reduce the internal processing times of the unit, by

omitting the conversion of serial RS232 encoder data. For this, just set

parameter “/Operand” to 00000

SSI Offset:

Defines the electrical zero position of the encoder with respect to the mechanical zero position.

When the Round-Loop function is not active (Round-Loop = 0), the SSI Offset is subtracted from

the SSI position reading, which can also cause negative results. When the Round-Loop is

active, SSI Offset displaces the mechanical zero position, but always with only positive results.

SSI Set Value:

Applying a remote Set signal to the Set input (terminal 10) results in a temporary substitution of

the SSI position value by the SSI Set Value entered here. This function allows easy testing and

simulation of fixed analogue output values while commissioning.

IV25101A_e.DOC / Feb-08 Page 18 / 25

Page 19

7.4. SSI Error Settings:

SSI Error Bit:

Defines the position of the error bit, if available with the encoder you use. Errors indicated by

the encoder can be read out via serial code ;9

(semicolon nine, error indication = 2000hex). In

case of an error, on your PC screen, the “Error Bit active” box will appear red and the front LED

will blink at a 1:4 On/Off ratio.

00: no error bit available

13: bit 13 represents the error bit

25: bit 25 represents the error bit etc.

SSI Error Bit Polarity:

Defines the polarity of the Error Bit

0: Bit is LOW in case of error

1: Bit is HIGH in case of error

7.5. Linearisation Settings in %:

P01 (x), P01 (y) etc:

Linearisation registers as shown in section 8.

7.6. Set-up Settings:

Analogue Offset:

This register can adjust the analogue zero output in a range of approx. +/- 100mV

(respectively +/- 200 μA), if necessary.

Analogue Gain:

Sets the maximum output swing of the analogue output.

Setting of 1000 results in a 10 volts respectively 20 milliamps output swing.

Direction:

This parameter changes the internal direction of counting (0 or 1), provided the unit operates in

the Round Loop mode.

Any changes of the Round Loop or Direction registers require a new Teach procedure.

7.7. RS 232 / RS 485 Settings:

Unit Number:

It is necessary to attach a specific address to each unit, since up to 32 units can be connected

to the same bus with RS485 systems. You can choose any address number between 11 and 99.

Factory setting = 11

The address must not contain any “0“ because such numbers are reserved for collective

addressing of several units or groups.

IV25101A_e.DOC / Feb-08 Page 19 / 25

Page 20

Serial Baud Rate:

Setting Baud

0* 9600

1 4800

2 2400

3 1200

4 600

5 19 200

6 38 400

Serial Format:

Setting Data bits Parity Stop bits

0* 7 even 1

1 7 even 2

2 7 odd 1

3 7 odd 2

4 7 none 1

5 7 none 2

6 8 even 1

7 8 odd 1

8 8 none 1

9 8 none 2

* = Factory setting

* = Factory setting

IV25101A_e.DOC / Feb-08 Page 20 / 25

Page 21

8. Free Programmable Linearization

This programmable feature allows the user to convert a linear motion to a non-linear analogue

output and vice-versa. There are 16 programmable interpolation points available, which can be

set in any desired distance over the full conversion range. Between two points, the unit uses

linear interpolation. Therefore it is advisable to use more points in a range with strong curves

and only a few points where the curvature is less.

To specify your desired linearization curve, you must first set the „Linearisation Mode“ register

to either 1 or 2.

Use registers P1(x) to P16(x) to specify the coordinates on the x-axis. These are the analogue

output values that the unit normally would generate according to the actual encoder position.

These settings must be in % of full scale.

Now enter the attached values to registers P1(y) to P16(y). These are the values that the

analogue output will generate instead of the x- values.

As an example, the value of P2(y) will substitute the encoder value P2(x) etc.

*) Output mode = 0

• x-registers must use continuously increasing settings, i.e. P1(x) must have

the lowest setting and P16(x) must have the highest setting

• All entries use a percentage format of xx.xxx% full scale. Setting 0.000%

means zero output and setting 100.000% means full scale output.

• With Linearisation Mode set to 1, it is a must to set P1(x) to 0% and P16(x)

to 100%. Linearization is defined in the positive range only and the negative

range will be a mirror image of the positive range with reference to zero

• With Linearisation Mode set to 2

, it is a must to set P1(x) to –100% and

P16(x) to +100%. This enables the user to set curves which are not

symmetric to the zero position.

y

P1(x)= -100%

P1(y)= 95%

y

P16(x)=100%

P8(y)= 80%

P16(y)= 80%

P8(x)= 0%

x

P1(x)= 0%

*)

Linearisation Mode = 1

P1(y)=10%

Linearisation Mode = 2

x

P16(x)=+100%

P16(y)= -60%

IV25101A_e.DOC / Feb-08 Page 21 / 25

Page 22

You can visualize your curve on the PC screen or by means of an external oscilloscope. For this,

select TOOLS, then TEST and there „Analogue Voltage Function“. The unit will now simulate a

repeating motion of the encoder over the full range and generate the analogue signal

accordingly. When you use the Scope function of the operator software, you must set the serial

code „ :1

„ to record the analogue output.

IV25101A_e.DOC / Feb-08 Page 22 / 25

Page 23

9. Testing Functions

When you select TEST from the TOOLS menu, you are able to verify the following data, by

clicking to the corresponding field:

• Actual encoder position

• DIL switch settings

• Internal supply voltages

• Analogue output state

Furthermore, the following registers can be recorded by using the monitor function:

IV25101A_e.DOC / Feb-08 Page 23 / 25

Page 24

10. Dimensions and Specifications

40 mm

( 1.575’’ )

)

’

’

0

1

1

.

3

(

m

m

9

7

91 mm ( 3.583’’ )

74 mm ( 2.913’’ )

Front view Side view

Top v i ew

Power Supply : 18...30 VDC

Power consumption : about 170 mA at 18V (+5.5V not connected)

about 120 mA at 30V

Inputs (SSI) : TTL differential, RS-422 standard (1.0 MHz)

SSI Format : 13, 21 or 25 Bit (Master / Slave / Gray / Bin)

SSI break time : min. 4 clock cycles

Set Input (HTL) : High > 10V , Low < 3V (Ri = 5k)

Active High; minimum pulse duration 10 msec.

Encoder supply : +5.5V +/- 5% (max. Load: 150 mA)

Analogue outputs : +/- 10V (> 5 kOhm), 0-20 mA / 4-20 mA (<270 Ohms)

Resolution : 14 Bits

Stabilization time : 2 msec.

Accuracy : +/- 0.1%

Temperature-Range : Operation: 0° ... +45°C (+32 … +113°F)

Storage: -25° … +70°C (-13 … +158 °F)

Weight : approx. 190 g

Conformity and Standards : EMC 89/336/EEC: EN 61000-6-2

EN 61000-6-3

LV73/23/EEC: EN 61010-1

IV25101A_e.DOC / Feb-08 Page 24 / 25

Page 25

11. Parameter-List

Parameter Min. value Max. value Default Positions Char. Serial

Code

X Operand -10.0000 +10.0000 1.0000 +/- 6 4 00

/ Operand 0 10.0000 1.0000 6 4 01

+/- Operand -99999999 99999999 0 +/- 8 0 02

Teach Minimum -99999999 +99999999 0 +/- 8 0 03

Teach Maximum -99999999 +99999999 10000 +/- 8 0 04

Round Loop 0 99999999 0 8 0 05

Output Mode 0 3 0 1 0 06

Linearisation Mode 0 2 0 1 0 07

SSI Low Bit 0 25 1 2 0 08

SSI High Bit 1 25 25 2 0 09

SSI Baud rate 100 1000000 100000 7 0 10

SSI Wait Time 0 10.000 0 5 3 11

SSI Offset 0 99999999 0 8 0 12

SSI Reset Value 0 99999999 0 8 0 13

SSI Error Bit 0 25 0 2 0 14

SSI Error Bit Polarity 0 1 0 1 0 15

P1(x) -100.000 +100.000 100000 +/- 6 3 A0

P1(y)….. -100.000 +100.000 100000 +/- 6 3 A1

P16(x) -100.000 +100.000 100000 +/- 6 3 D0

P16(y) -100.000 +100.000 100000 +/- 6 3 D1

Direction 0 1 0 1 0 46

Analog Offset -99 +99 0 +/-2 0 47

Analog Gain 0 10000 1000 5 0 48

Unit Number 0 99 11 2 0 90

Serial Baud Rate 0 6 0 1 0 91

Serial Format 0 9 0 1 0 92

IV25101A_e.DOC / Feb-08 Page 25 / 25

Loading...

Loading...