Page 1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MT Series

Installation manual

Retain for future use

Variable speed drives

for AC motors

75 HP (55 kW) ... 100 HP (75 kW) / 200 - 240V

125 HP (90 kW) ... 400 HP (250 kW) / 380 - 480V

Page 2

Content

s

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Contents____________________________________________________________________________________________________ 3

Before you begin______________________________________________________________________________________________ 4

Steps for setting up the drive ____________________________________________________________________________________ 5

Preliminary recommendations ___________________________________________________________________________________ 6

Drive ratings _________________________________________________________________________________________________ 8

Dimensions and weights_______________________________________________________________________________________ 10

Installing the DC choke________________________________________________________________________________________ 12

Connecting the DC choke______________________________________________________________________________________ 13

Derating as a function of temperature and switching frequency_________________________________________________________ 14

Mounting in a wall-mounted or floor-standing enclosure ______________________________________________________________ 16

Installing the kit for IP31/NEMA type 1 conformity ___________________________________________________________________ 19

Position of the charging LED ___________________________________________________________________________________ 21

Installing option cards_________________________________________________________________________________________ 22

Wiring recommendations ______________________________________________________________________________________ 24

Power terminals _____________________________________________________________________________________________ 26

Control terminals_____________________________________________________________________________________________ 38

Option terminals _____________________________________________________________________________________________ 40

Connection diagrams _____________ ____________________________________________________________________________ 45

Operation on an IT system_____________________________________________________________________________________ 58

Electromagnetic compatibility, wiring _____________________________________________________________________________ 61

3

Page 3

Bef

ore you begin

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Read and understand these instructions before performing any procedure on this drive.

HAZARDOUS VOLTAGE

• Read and understand this manual before installing or operating the MT Series driv e.

Installation, adjustment, repair and maintenance must be performed by qualified

personnel.

• The user is responsible for compliance with all international and national electrical

standards in force concerning protective grounding of al l equipment.

• Many parts of this variable speed drive, including the printed circuit boards, operate

at the line voltage. DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with

voltage present.

• DO NOT short across terminals PA/+ and PC/- or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and st opping the

drive.

• Before servicing the variable speed drive:

- Disconnect all power.

- Place a “DO NOT TURN ON” label on the variable speed drive disconnect.

- Lock the disconnect in the open position.

• Disconnect all power including external control power that may be present before

servicing the drive. Wait for the charging LED to go off. Then follow the DC bus voltage

measurement procedure given on page 21

45 V. The drive LEDs are not accurate indicators of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

DANGER

to verify that the DC voltage is less than

CAUTION

IMPROPER DRIVE OPERATION

• If the drive is not turned on for a long period, the performance of its electrol ytic

capacitors will be reduced.

• If it is stopped for a prolonged period, turn the drive on every two years for at least

5 hours to restore the performance of the capacitors, then check its operation. It is

recommended that the drive is not connected directly to the line vo ltage. The vol tage

should be increased gradually using an adjustable AC source.

Failure to follow these instructions can result in equipment damage.

4

Page 4

Steps for setting up the drive

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

INSTALLATION

b 1 Take delivery of the drive

v Check that the catalog number printed on the label is the same

as that on the purchase order

v Remove the MT Series from its packaging and check that it has

not been damaged in transit

b 2 Check the line voltage

v Check that the line voltage is compatible with the

voltage range of the drive (see pages 8 and 9)

Steps 1 to 4 must

be performed with

the power off

b 3 Mount the drive

v Mount the drive in accordance with the instructions

in this document

v Install and connect the DC choke (see page 11)

v Install any internal and external options

b 4 Wire the drive

v Connect the motor, ensuring that its

connections correspond to the voltage

v Connect the line supply, after making sure that

it is turned off

v Connect the control

v Connect the speed reference

PROGRAMMING

v 1 Please refer to the

Programming Manual

5

Page 5

Prelimi

MT

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

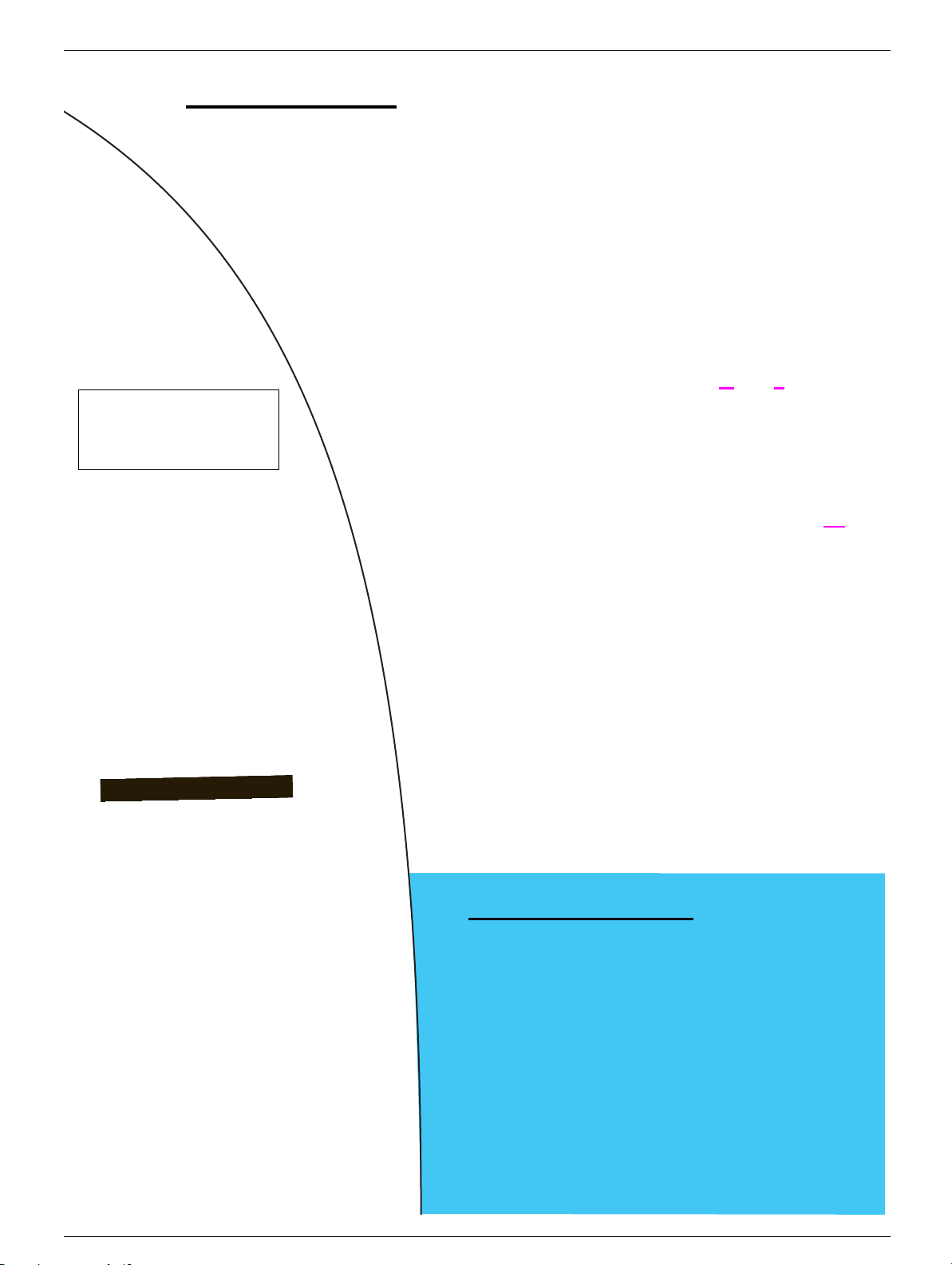

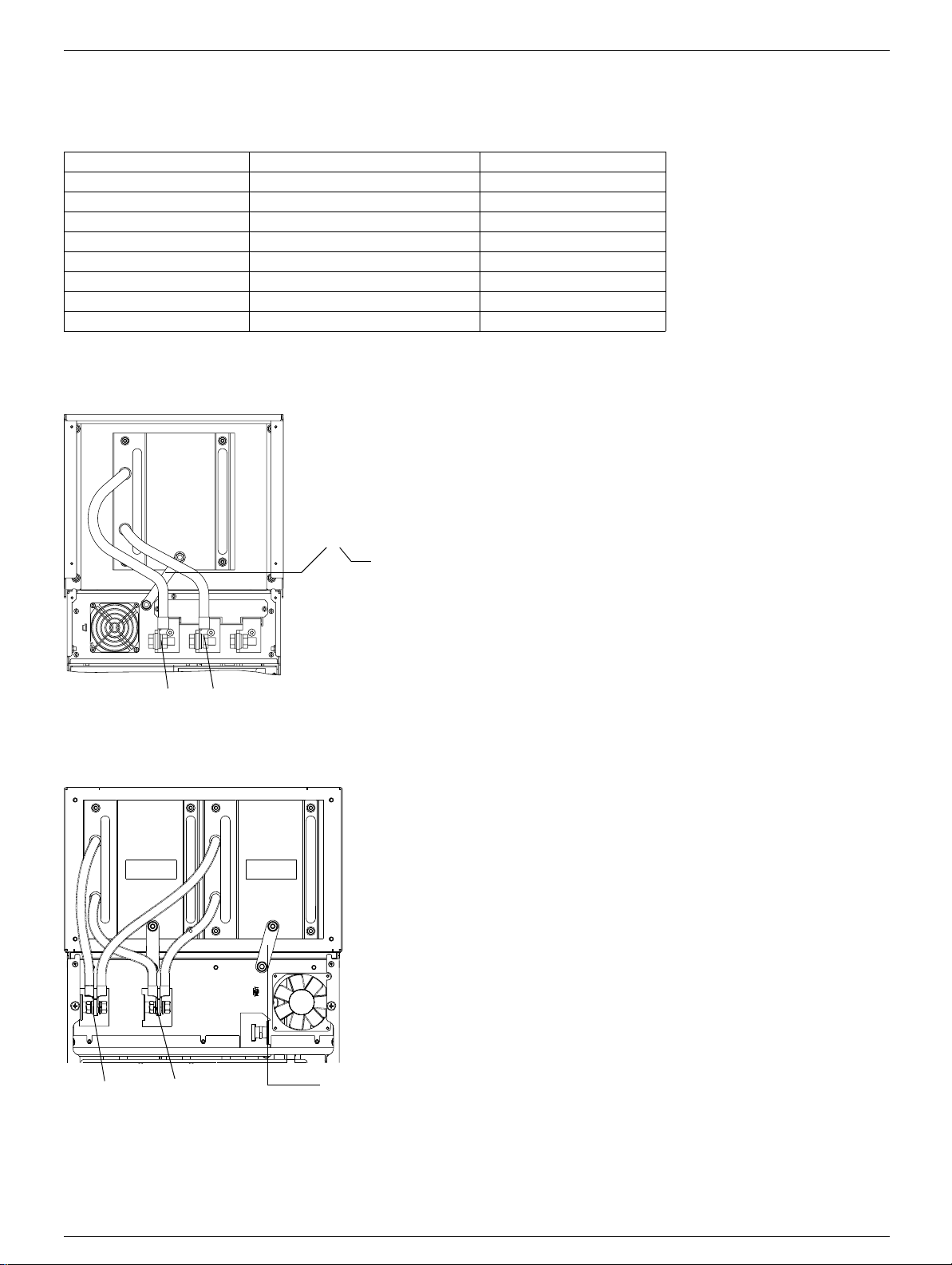

Figure 1

nary recommendations

Receiving

DC choke

The packaging contains two items:

- The drive

-A DC choke (figure 1)

Handling/storage

To protect the drive prior to installation, handle and store the device in its packaging.

Ensure that the ambient conditions are acceptable.

WARNING

DAMAGED PACKAGING

If the packaging appears damaged, it can be dangerous to open and handle it.

Take precautions against all risks when performing this operation.

Failure to follow these instructions can result in death or serious injury.

WARNING

Figure 2

60°

max.

Figure 3

DAMAGED EQUIPMENT

Do not install or operate any drive that appears damaged.

Failure to follow this instruction can resu lt in dea th or se rio us inj ury .

Unpacking/handling

The drive and DC choke (if applicable) are attac hed to a palle t usi ng screws (figure 1).

When there is a DC choke, it is supplied assembled for ease of transport.

The equipment must be unpacked in the following order:

Dismantle the DC choke (figure 2) so that it can subsequently be installed,

1

and remove the choke using a hoi

Remove the screws attaching the choke support to the pallet (figure 3).

2

st (figure 3).

WARNING

RISK OF INJURY

The screws used to attach the choke support to the pallet are difficult to access,

involving a risk of injury. Take every precaution to avoid this risk, and use

protective gloves.

Failure to follow this instruction can res u lt in s eriou s inju ry .

3 Remove the screws attaching the drive to the pallet and handle the drive using a hoist.

The drive has handl

ing lugs for this purpose (figure 4).

WARNING

RISK OF TIPPING

Never stand the drive upright (figure 5) without supporting it, as it will tip over.

Failure to follow this instru ction can result in death or serious inju

equipment damage.

ry and

Figure 4 Figure 5

6

Page 6

Prelimi

nary recommendations

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Installing the drive

- Mount the drive on a wall or in the ba ck of the enclosure, in accordance with the recommendations describ ed in this document, before

installing the DC choke.

Installing the DC choke

MT275 to MT2100 and MT4125 to MT4400 drives are supplied with a DC choke that must be installed on the top of the drive and wired

in accordance with the recommendations described in this document. This choke must be used for connecting drives to the 3-phase line

supply.

- Mount the DC choke on the back of the enclosure or on the wall on top of the drive, and connect it. The instructions for instal

connecti

- Check that the seal between the drive and the choke chassis is performing its role correctly.

ng the choke are given on page

11.

Recommendations

Read and understand the instructions in the Programming Manual.

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure t hat the line voltage is comp atible with the supply volt age range shown

on the drive nameplate. The drive may be damaged if the line vol tage is not compatible.

Failure to follow this instruction can result in equipment damage.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Before turning on and configuring the MT Series, check that the PWR (POWER REMOVAL) input is deactivated

(programmedto 0) in order to prevent unintended operation. Do not forget to reactivate the Power Removal input to start

the motor.

• Before turning on or on exiting the configuration menus, check that t he inputs assigned to the run command are

deactivated (programmed to 0) since they can cause the motor to start immediately.

Failure to follow these instructions will result in death or serious injury.

ling and

If the safety of personnel requires the prohibition of unwanted or unintended operation, electronic locking is performed by the MT

Series “Power Removal” function.

This function requires the use of connection diagrams conformin

level 2 according to IEC/EN 61508.

The Power Removal function takes priority over any run command.

g to category 3 of st

andard EN 954-1 and safety integrity

7

Page 7

Dri

ve ratings

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

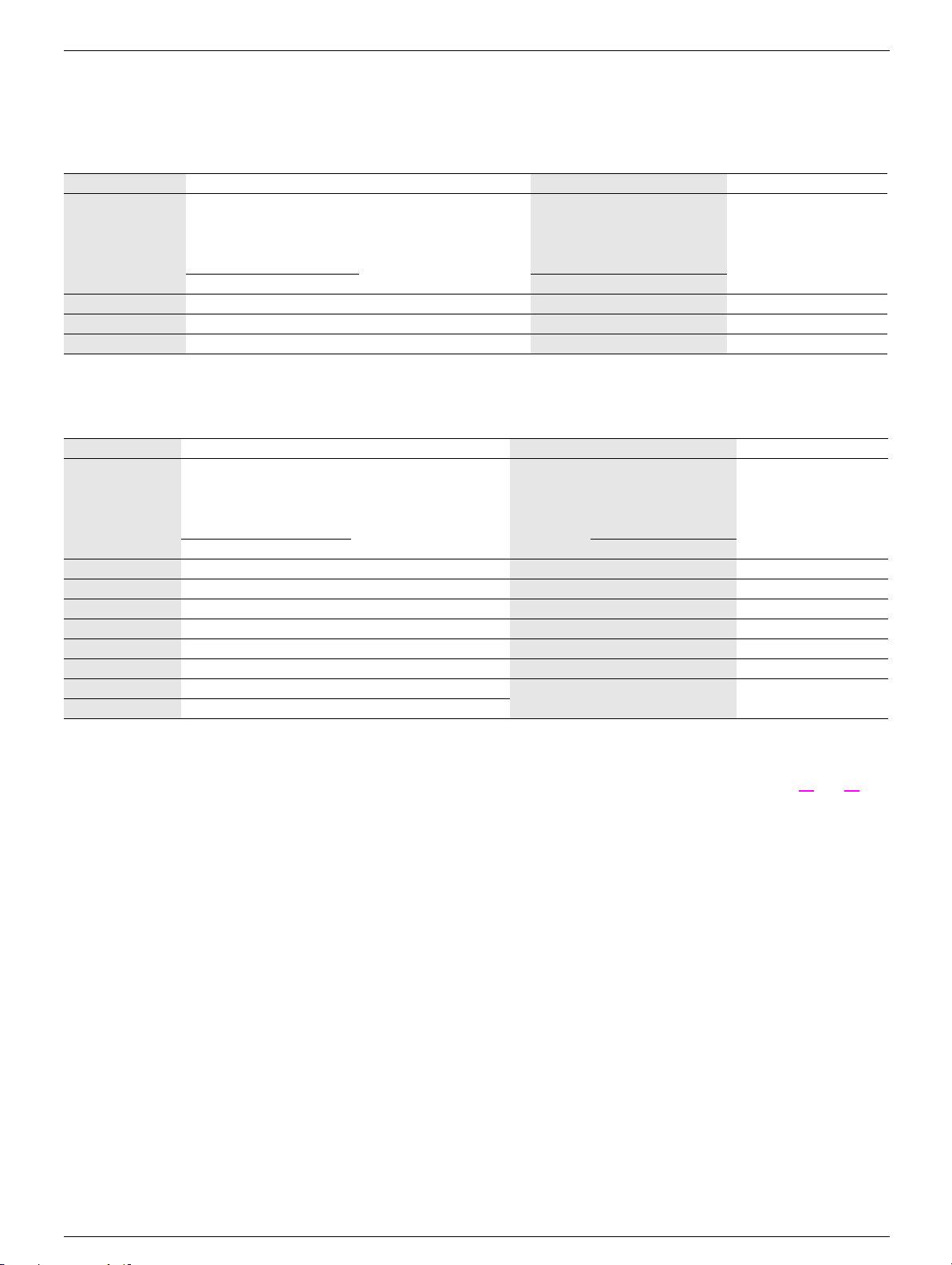

Power ratings in kW

3-phase supply voltage: 200…240 V 50/60 Hz

3-phase motor 200...240 V

Motor Line supply (input) Drive (output) MT Series

Power

indicated on

nameplate (1)

kW A A kA kVA A A A

55 202 171 35 71 221 332 365 MT275

75 274 231 35 95 285 428 470 MT2100

Line current (2) Max.

at 200 V

at 240 V 60 s 2 s

pros

line Isc (4)

pective

3-phase supply voltage: 380…480 V 50/60 Hz

3-phase motor 380...480 V

Motor Line supply (input) Drive (output) MT Series

Power

indicated on

nameplate (1)

kW A A kA kVA A A A

90 166 134 35 109 179 268 295 MT4125

110 202 163 35 133 215 322 354 MT4150

132 239 192 35 157 259 388 427 MT4200

160 289 233 50 190 314 471 518 MT4250

200 357 286 50 235 387 580 638 MT4300

220 396 320 50 261 481 721 793 MT4400

250 444 357 50 292

Line current (2) Max.

at 380 V

at 480 V 60 s 2 s

ospective

pr

line Isc (4)

Apparent

power

Apparent

power

Max.

available

nominal

current In

(1)

Max.

available

nominal

current In

(1)

Max. transient

current (1) for

Max. transient current

(1) for

Catalog number (3)

Catalog number (3)

(1)These power ratings and currents are given for an ambient temperature of 50°C (122°F) at the factory-set switchi ng frequency of 2.5 kHz,

used in cont

Above 2.5 kHz, the drive will reduce the switching frequency auto matically in the event of excesive temperature rise. For contin

operation above 2.5

(2)Typical value for the indicated motor power rating, with a standard 4-pol e motor on a supply with the indicate d “Max. prospective line Isc”.

(3)Th

e drives are supplied as standard with a DC choke, which must be used for connecting the drive on a 3-phase line supply.

For connections to the DC bus, the drive can be controlled without a choke. (contact factory for details)

(4)If the drive is installed on a line supply with a prospective short circui t current t hat is higher than t he value given in this column, use line

chokes.

inuous operation.

kHz, derating must be applied to the drive nominal current in accordance with t he curves on pages

uous

13 and 14.

8

Page 8

Dri

ve ratings

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

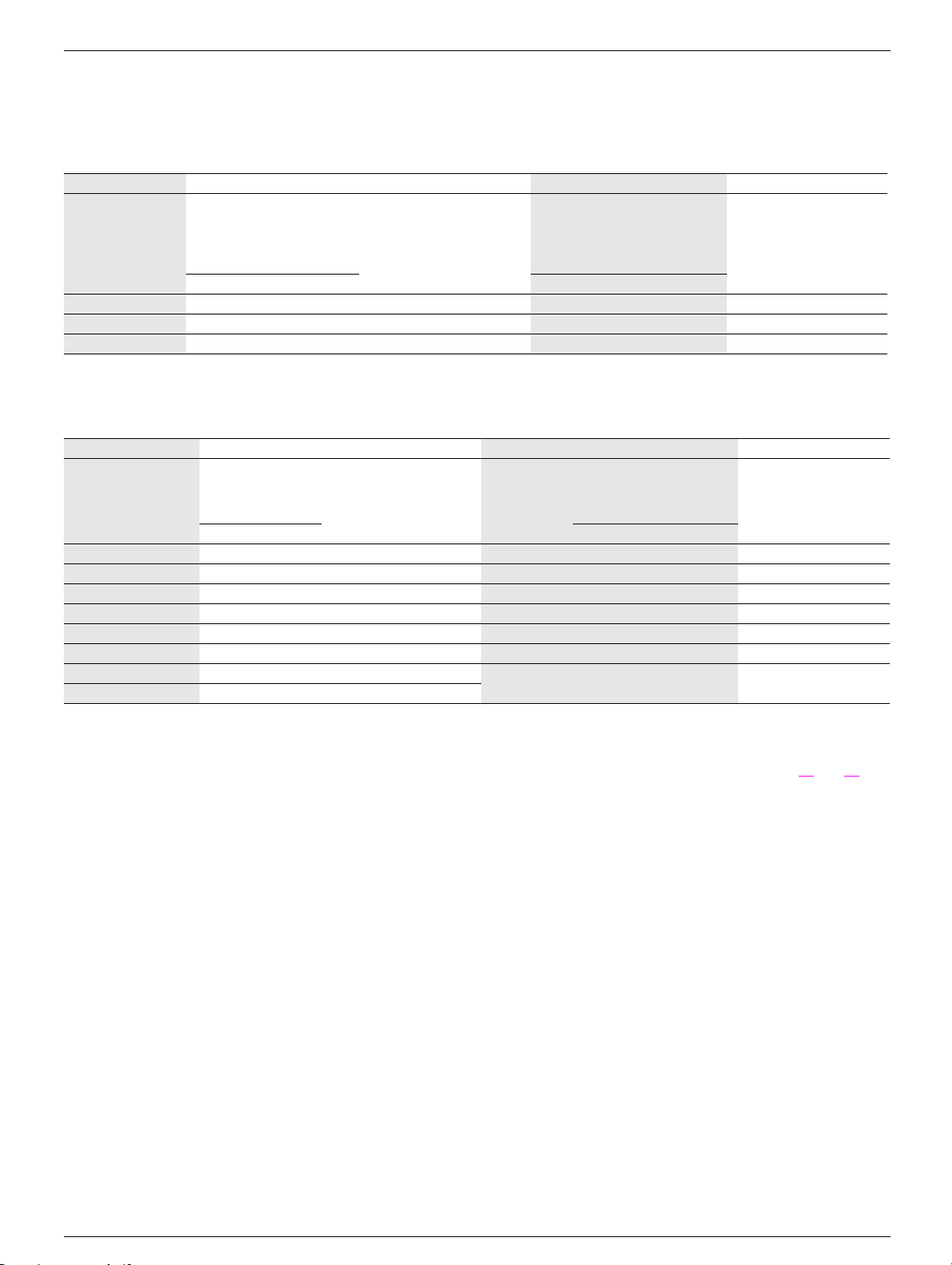

Power ratings in HP

3-phase supply voltage: 200…240 V 50/60 Hz

3-phase motor 200...240 V

Motor Line supply (input) Drive (output) MT Series

Power

indicated on

name plate (1)

HP A A kA kVA A A A

75 206 180 35 71 221 332 365 MT275

100 274 237 35 95 285 428 470 MT2100

Line current (2) Max.

at 200 V

at 240 V 60 s 2 s

pros

line Isc (4)

pective

3-phase supply voltage: 460...480 V 50/60 Hz

3-phase motor 460 V

Motor Line supply (input) Drive (output) MT Series

Power

indicated on

name plate (1)

HP A kA kVA A A A

125 143 35 114 179 268 295 MT4125

150 173 35 138 215 322 354 MT4150

200 225 35 179 259 388 427 MT4200

250 281 50 224 314 471 518 MT4250

300 333 50 265 387 580 638 MT4300

350 394 50 314 481 721 793 MT4400

400 442 50 352

Line current (2) Max.

at 460 V 60 s 2 s

rospective

p

line Isc (4)

Apparent

power

Apparent

power

Max.

available

nominal

current In

(1)

Max.

available

nominal

current In (1)

Max. transient

current (1) for

Max. transient current (1)

for

Catalog number (3)

Catalog number (3)

(1)These power ratings and currents are given for an ambient temperature of 50°C (122°F) at the factory-set switchi ng frequency of 2.5 kHz,

used in cont

Above 2.5 kHz, the drive will reduce the switching frequency auto matically in the event of excesive temperature rise. For contin

operation above 2.5

(2)Typical value for the indicated motor power rating, with a standard 4-pol e motor on a supply with the indicate d “Max. prospective line Isc”.

(3)Th

e drives are supplied as standard with a DC choke, which must be used for connecting the drive on a 3-phase line supply.

For connections to the DC bus, the drive can be controlled without a choke. (contact the factory for details)

(4) If the drive is installed on a line s uppl y with a p ros pecti ve s hort circ uit cu rre nt that is hi gher tha n t he value g ive n i n th

chokes.

inuous operation.

kHz, derating must be applied to the drive nominal current in accordance with t he curves on pages

13 and 14.

is colum

uous

n, use line

9

Page 9

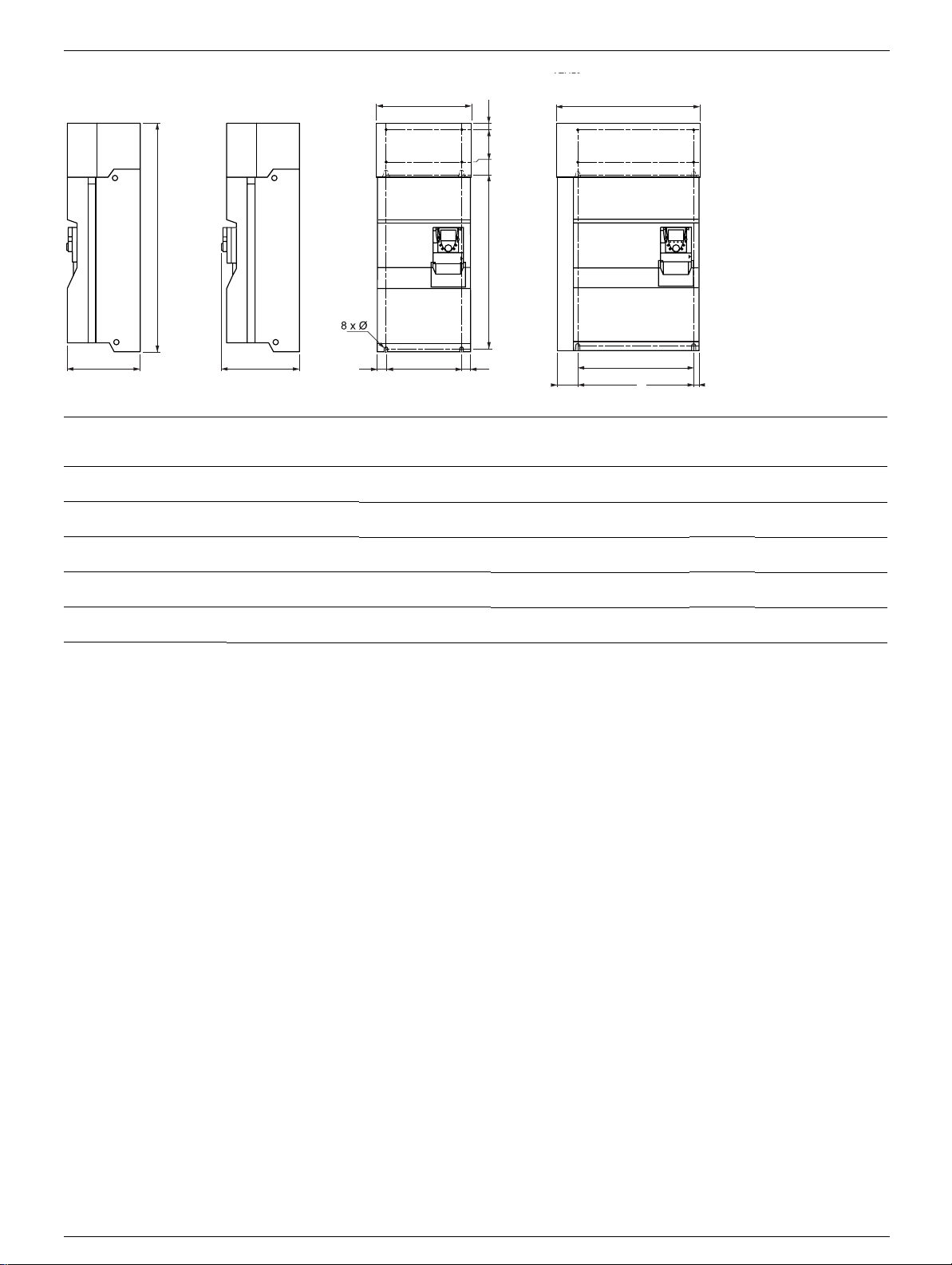

Di

mensions and weights

MT275,MT2100,MT4125

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

With 2 option cards (1)With 0 or 1 option card (1) ATV71H MT4300 to MT4400 with braking unit

b

377 mm

(14.77 in)

392 mm

(15.43 in)

MT a

275,4125

(12.60)

4150,2100

(14.17)

4200

(13.39)

4250

(17.32)

4300,4400,4450

(23.43)

mm

(in.

320

360

340

440

595

to MT4400

a

==G

b

mm

)

(in.

)

920

(36.22)

1022

(40.23)

1,190

(46.62)

1,190

(46.62)

1,190

(46.62)

G

mm

(in.)

250

(9.84)

298

(11.73)

285

(11.22)

350

(13.78)

540

(21.26)

mm

(in.)

650

(25.59)

758

(29.84)

920

(36.22)

920

(36.22)

920

(36.22)

HK1KK2

H

670 (26.37)

540 mm (21,26 in)

102,5 mm

(4.03 in)

K

mm

(in.

15

)

0

K1

mm

(in.

)

(5.91)75(2.95)30(1.18)

150

91)72(2.83)30(1.18)

(5.

0

15

(5.91)75(2.95)30(1.18)

0

15

(5.91)75(2.95)30(1.18)

0

15

(5.91)75(2.95)30(1.18)

27,5 mm

(1.08 in)

K2

mm

(in.)

Ø

mm

n.)

(i

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

For

Weight

screws

M10 92

M10 108

M10 116

M10 163

M10 207

kg

(lb.

(132)

(163)

(255)

(358)

(455)

)

ATV71

10

Page 10

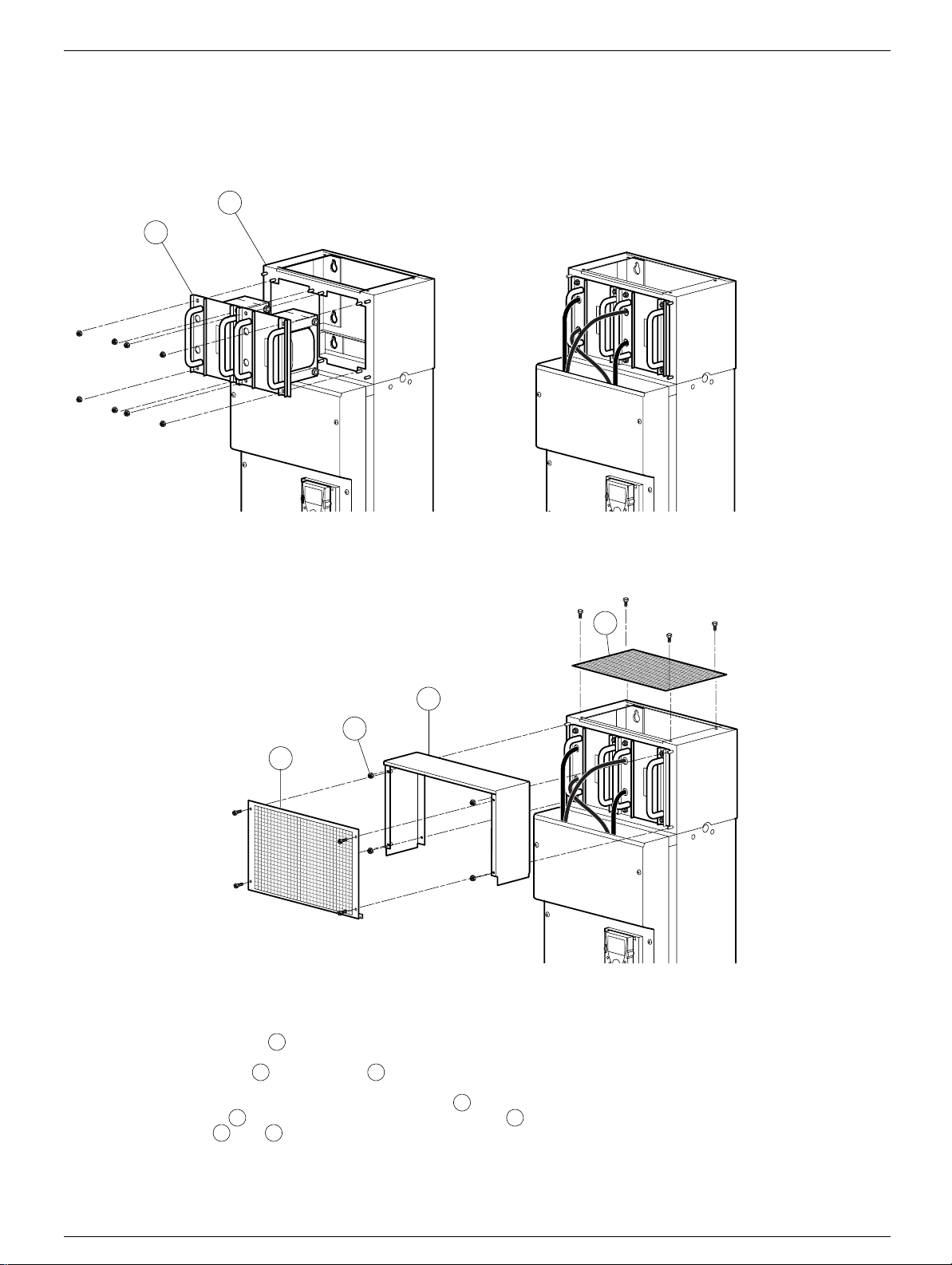

Installi

ng the

DC chok

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

This should be performed after mounting the drive and before wiring it. If a MT-VW3 A7 101 braking module is used, install the module on

the drive before installing the DC choke.

During installation, ensure that no liquid, dust or conductive objects fall into the drive.

e

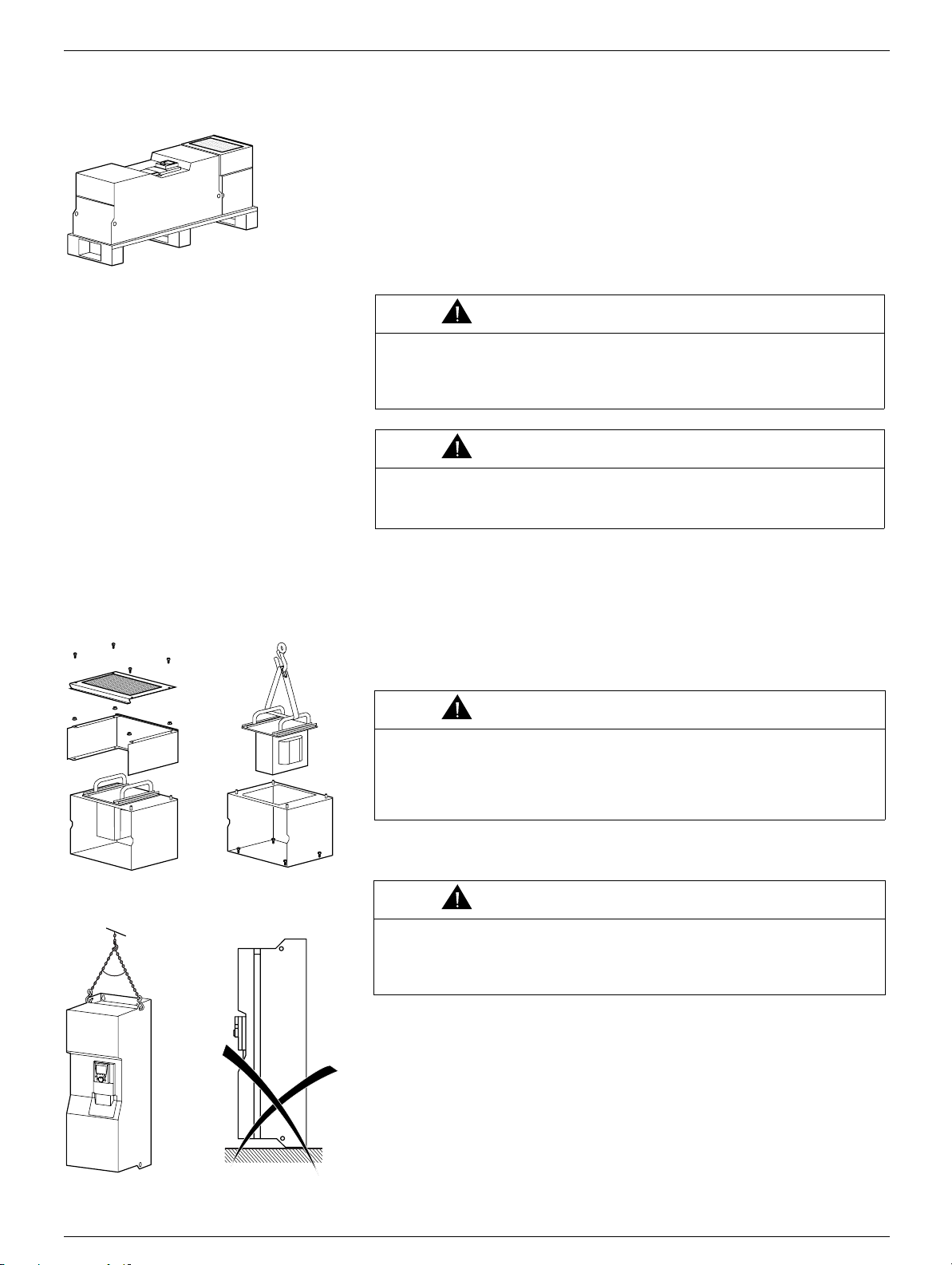

Example of installing DC chokes on an MT4250

1

2

6

3

4

5

- Mount the DC choke chassis on the wall, on top of the drive. Ensure that the chassis is tightl y secured to the drive to maintain the

IP54 seal of the ventilation duct.

- Then install the DC choke on the chassis using the nuts provided.

- Connect the choke between the PO and PA/+ terminals on the drive (see next page and note below).

- Connect the grounding strip between the DC choke chassis and the drive.

- Then mount the cover on the chassis and secure it with the nuts provided.

- Then mount panels and using the sc rews provided.

5 6

1

2 1

1

3 4

Once the choke has been installed, the degree of protection of the top of the drive is IP31.

The number of DC chokes supplied with the drive varies according to the drive rating.

Note:

11

Page 11

C

onnecting the

DC chok

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1 to 4 chokes can be connected in parallel as described in the examples below.

e

Table showing possible drive/choke combinations

Drive Number of chokes in parallel Choke model

MT275 1 DC-CHOKE 5

MT2100 1 DC-CHOKE 6

MT4125 1 DC-CHOKE 1

MT4150 1 DC-CHOKE 2

MT4200 1 DC-CHOKE 4

MT4250 2 DC-CHOKE 1

MT4300 2 DC-CHOKE 3

MT4400 2 DC-CHOKE 4

Example 1:

MT275... MT2100,

MT4125... MT4200

Grounding

strip

PO PA/+

Example 2:MT4250... MT4400

Example 3:

ATV71HC31N4

PO.1 PA/+ PO.2

PO PA/+

12

Grounding

strip

Page 12

D

erating as a function of temperature and switching frequency

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

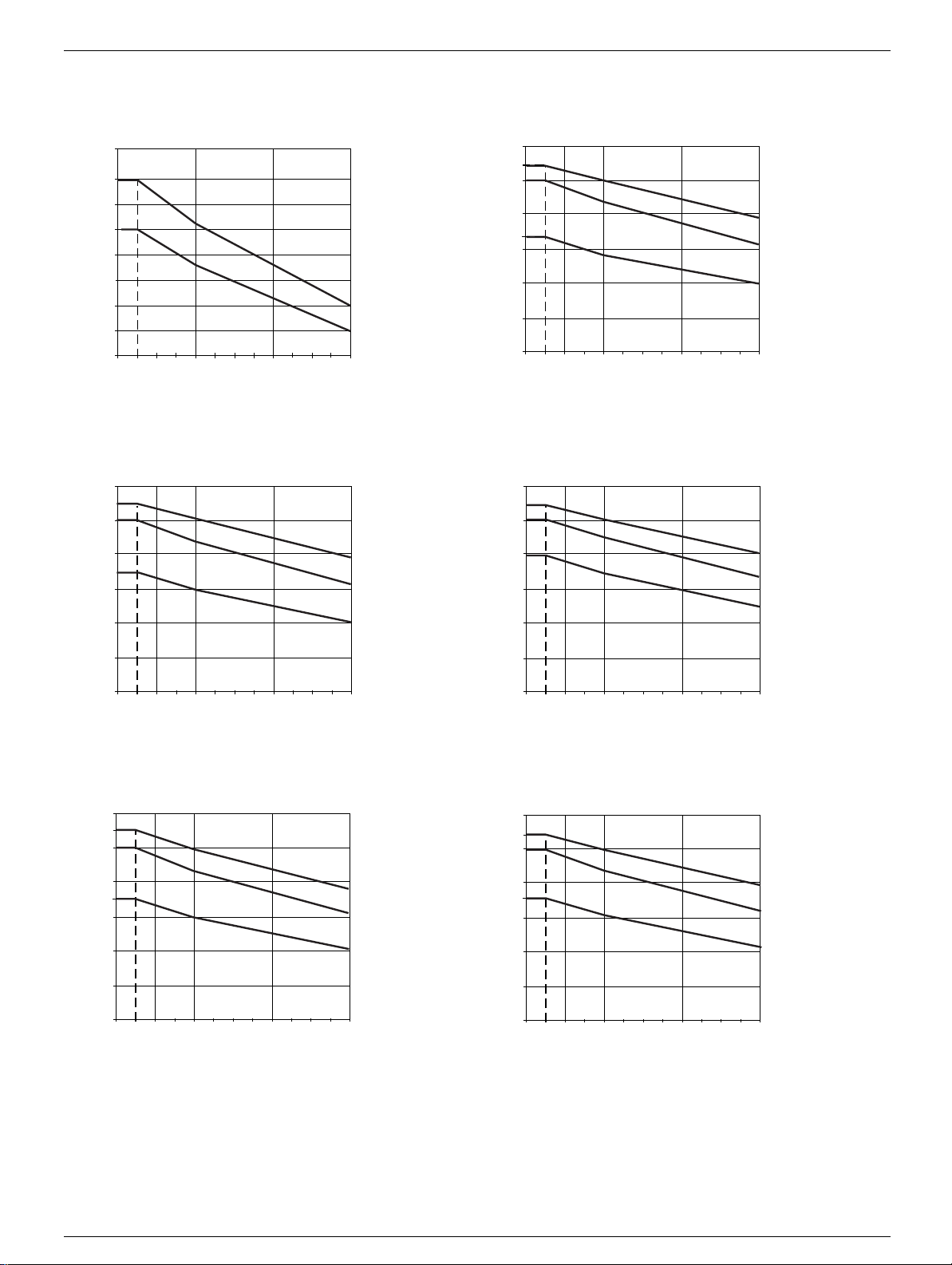

Derating curves for the drive current In as a function of the temperature and s witching frequency.

MT275 , MT2100 MT4125

120

In = 100

90

80

70

60

50

40

30

%

50°C (122°F)

60°C (140°F)

2,5 kHz 4 kHz 6 kHz 8 kHz

120

110

In = 100

%

80

67

60

40

20

0

Switching frequency

MT4150 MT4200

120

109

In = 100

80

70

60

40

%

40°C (104°F)

50°C (122°F)

60°C (140°F)

120

107

In = 100

%

78

60

40

40°C (104°F)

50°C (122°F)

60°C (140°F)

2,5 kHz 4 kHz 6 kHz 8 kHz

Switching frequency

40°C (104°F)

50°C (122°F)

60°C (140°F)

20

0

2,5 kHz 4 kHz 6 kHz 8 kHz

20

0

2,5 kHz 4 kHz 6 kHz 8 kHz

Switching frequency

MT4250 MT4300

120

111

In = 100

%

80

71

60

40

20

0

2,5 kHz 4 kHz 6 kHz 8 kHz

40°C (104°F)

50°C (122°F)

60°C (140°F)

120

109

In = 100

%

80

72

60

40

20

0

2,5 kHz 4 kHz 6 kHz 8 kHz

Switching frequency

For intermediate temperatures (e.g. 55°C (131°F)), interpolate bet ween 2 curves.

Switching frequency

40°C (104°F)

50°C (122°F)

60°C (140°F)

Switching frequency

13

Page 13

D

erating as a function of the temperature and the switching frequency

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

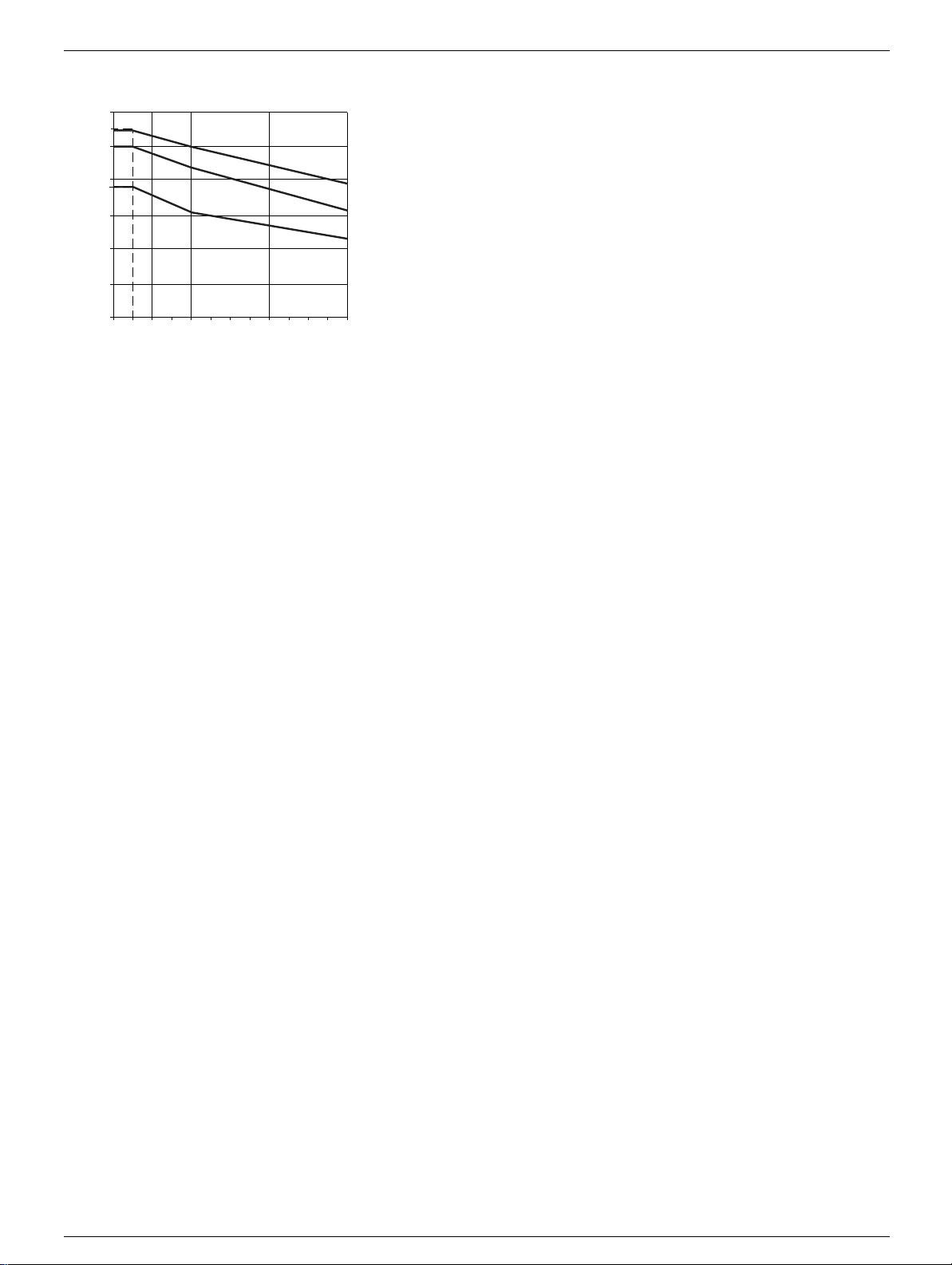

MT4400

%

120

108

In = 100

77

40°C (104°F)

50°C (122°F)

60

40

20

0

2,5 kHz 4 kHz 6 kHz 8 kHz

60°C (140°F)

Switching frequency

For intermediate temperatures (e.g. 55°C (131°F)), interpolate bet ween 2 curves.

14

Page 14

M

ounting in a wall-mounted or floor-standing enclosure

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

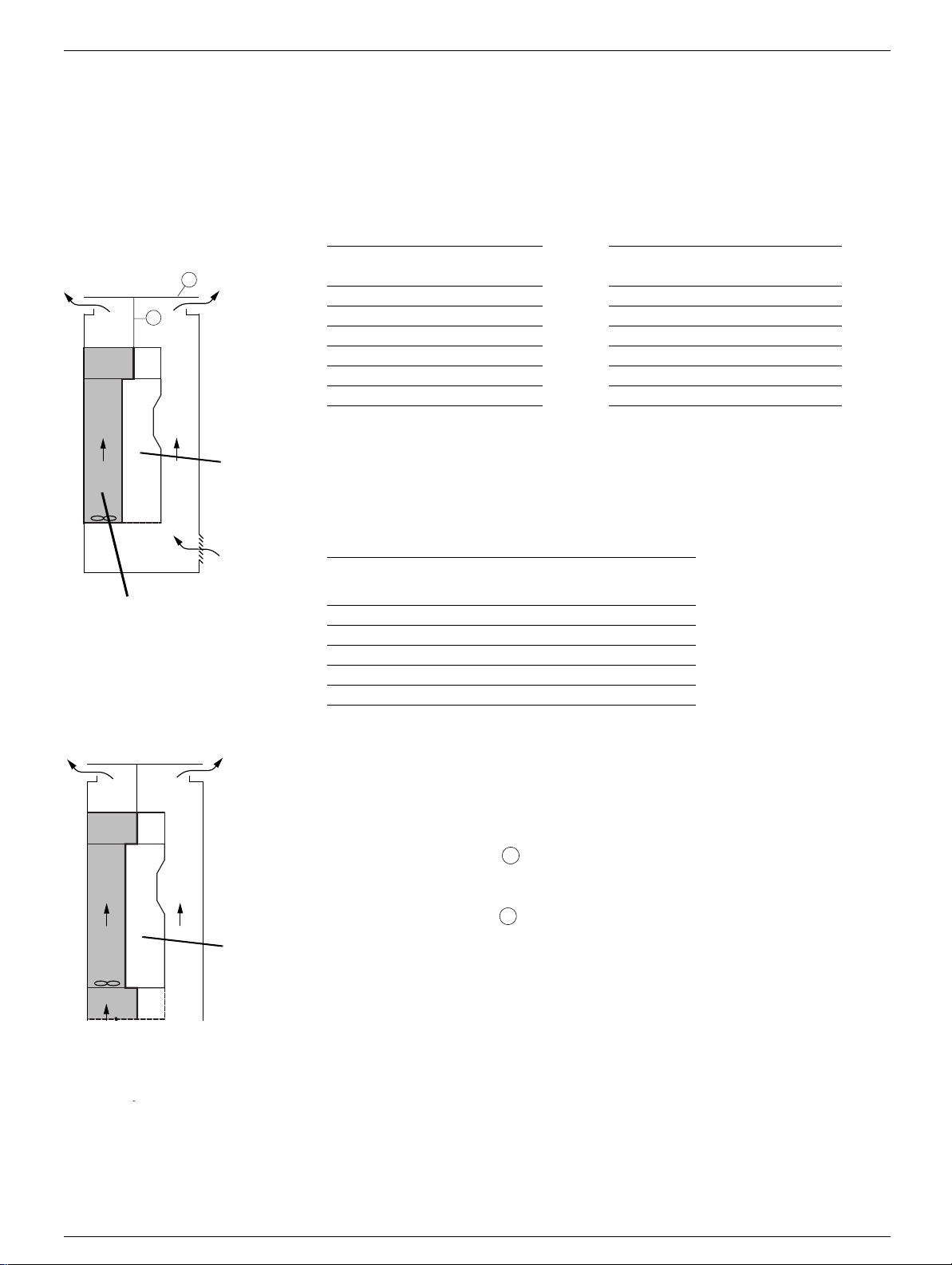

Install the drive vertically at ± 10°. Do not place it close to heating elements.

Installing the heatsink inside the enclosure

The power dissipated by the drive power components is given in the table below.

Dissipated power

These levels of power dissipation are given for operation at nominal load and for a switching

frequency of 2.5 Hz.

Figure 1

2

1

MT

MT Dissipated power MT Dissipated power

W W

275 1,715 4300 4,930

2100 2,204 4400 5,873

4125 2,403

4150 2,593

4200 2,726

4250 3,812

The drive has a fan for cooling the power components. The air is circul ated f rom the bottom t o

the top of the uni

is isolated from the control section by IP54 protection. The DC choke extends this duct while

maintaining IP54 protection.

The drive dissipates a great deal of power, which must be evacuated to the outside of the

closure.

en

Air inlets and out

ual to the v

eq

t via a duct (the duct is shown shaded gray on the diagram opposite). This duct

lets must be provided to ensure that the flow of air in the enclosure is at least

alue given in the table below for each drive.

Figure 2

Cooling duct for power

components.

IP54 protection(nema 12)

MT

MT

275,4125 402 236

2100,4150 774 455

4200 745 438

4250 860 506

4300,4400 1,260 742

Several methods of evacuation are possible. The followi ng is a propos ed met hod fo r IP23 a nd

IP54 mounting.

Flow rate

3

m

/hour ft3/min

IP23 mounting (standard operating conditions):

Figure 1

Install the drive on an enclosure baseplate.

Install the DC choke in accordance with the mounting recommendations.

The simplest mounting is to extend the IP54 duct between the upper outlet of the DC choke

d the top o

an

DC choke.

The hot air is thus evacuated to the outside and does not contribute towards increasing the

nternal temper

i

It is advisable to add a plate approximately 150 mm from the top of the encl osure over t he

air outlet opening to prevent foreign bodies falling into the drive cooling duct.

The air inlet can be via a grille on the bottom front panel of the enclosure door, in accordance

h the required flow

wit

Figure 2

It is advisable to use a kit for IP31/NEMA type 1 conformity (to be ordered as an option) for

taching the powe

at

DC choke, and has an IP54 duct to help guide the incoming air.

f the enclosure . Fixing points are provided for this purpose on the top of the

ature of the enclosure.

r cables. The design of the IP31 kit is based on the same principle as the

1

2

rates given in the above table.

Note:

- If the air in the power circuit is totally evacuated to the outsi de, very li t tle power is di ssi pated

nside the enclosure.

Kit for IP31 or NEMA

type 1 conformity

i

flange mounting (see the next page).

- Connect all the additional metal parts to ground.

In this case, use the dissipated power table for dust and damp proof

15

Page 15

M

ounting in a wall-mounted or floor-standing enclosure

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Mounting the heatsink inside the enclosure (continued)

IP54 mounting (standard operating conditions):

1

The drive must be mounted in an IP54 enclosure in certain environmental conditions: dust,

corrosive gases, high humidity with risk of condensation and dripping water, splashing liquid, etc.

MT

2

4

3

The simplest way of obtaining an enclosure with IP54 protection is to follow the mounting

recommendations for IP

1 Do not make an air outlet hole for the control section. Do not make an air inlet hole in the

enclosure door. Th

via a plinth added for the purpose.

2 Add the IP31 or NEMA type 1 conformity kit in accordance with the mounting instructi ons.

3 Add an enclosure baseplate designed to provide IP54 protection around the power cables.

4 Add an air evacuation duct between the baseplate and the duct of the IP31 or NEMA

pe 1 conformity kit.

ty

be mounted. Drill a hole in the base of the enclosure to allow air t o enter. Place seals around

the duct that has been added to maintain IP54 protection.

5 Add a 200 mm plinth at the bottom of the enclosure with grilles to allow air to ent er.

6 Use the dissipated power table below to calculate the size of the enclos ure.

Note: Connect all the additional metal parts to ground.

23 protection with the following 5 additional points:

e air for the power section will enter through the bottom of the enclosure

The IP31 or NEMA type 1 conformity kit en

ables an extension duct to

Power dissipated inside the enclosure by the control section

5

(for calculating the size of the enclosure)

These power ratings are given for operation at nominal load and for the factory-set switching

frequency.

MT Dissipated power (1) MT Dissipated power (1)

W W

275 154 4300 493

2100 154 4400 586

4125 237

4150 261

4200 296

4250 350

(1)Add 7W to this value for each option card added

Dust and damp proof flange mounting (heatsink outside

the enclosure)

This mounting is used to reduce the dissipated power in the enclosure by locating the power

section outside the enclosure.

This requires the use of the dust and damp proof flange mounting kit MT-VW3A9509.

ease refer to the

(pl

The degree of protection for the drive mounted in this way becomes IP54.(nema 12)

To mount the kit on the drive, please refer to the manual supplied with th e kit.

Use the dissipated power table above to calculate the size of the enclosure.

In this case the DC choke can be mounted directly on the back of the enclosure.

catalog).

16

Page 16

M

ounting in a wall-mounted or floor-standing enclosure

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

If the hot air exiting the drive is not ducte d and evacuated to the ou tside, it may be sucked back in again, which would render th e ventilati on

ineffective. To prevent this, leave sufficient free space around the drive, as shown below.

The wall-mounted or floor-standing enclosure must be cooled in order to evacuate the dissipated heat.

u h1

u h2

MT h1 h2

mm in. mm in.

275,2100,4125 100 3.94 100 3.94

4150,4200,4250 150 5.90 150 5.90

4300,4400 200 7.87 150 5.90

Free space in front of the drive: 10 mm (0.39 in.) minimum

17

Page 17

Installi

ng the

kit f

IP31/NEMA t

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

On MT275 to MT2100 and MT4125 to MT4400 drives, the cable shielding can be attached and connected to ground using one of the

following two kits:

• Kit for IP31 conformity (MT-VW3 A9 109)

• Kit for NEMA Type 1 conformity (MT-VW3 A9 209 )

or

ype 1 conformity

This kit is not supplied with the drive. It must be ordered separately (please refer to the

2

3

6

4

catalog). It is mounted under the drive as shown below.

5

1

- Mount the chassis on the wall or in the back of the enclosure under the drive. Ensure that the chassis is tight ly secured to the drive

to maintain the IP54 seal of the ventilation duct. Use the 2 clamps which fit into the drive’s carrying holes for this purpose .

- Mount the nema 1 box on the kit chassis using the screws provided.

- Mount the clamp to ensure emc plate is securely grounded.

- Mount the conduit cover on the nema 1 box using the screws provided.

- Then mount the top cover cover on the box plate using the screws provided.

1

5

2

3

4

6

Note:

This kit can be used to help guide the incoming air. It is supplied with a seal to ensure IP54 protection between the duct and the drive.

Close the carrying holes on the drive with the plastic plugs provided for the purpose.

5

18

Page 18

Installi

ng the

kit f

IP31/NEMA t

ity

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

or

ype 1 conform

MT-VW3 A9 209 ... 216 MT-VW3 A9 209 ... 213,

b

c

MT-VW3 a

A9 209 320

A9 210 360

A9 211 340

A9 212 440

A9 213 595

A9 214

A9 215 (890)

A9 216 1,120

mm

(in.)

(12.6)

(14.17)

(13.39)

(17.32)

(23.43)

670

(23.43)

(35.04

(44.09

215

H3

H1

GG1 G2

==

aa a

b

mm

(in.

220

(8.66)

300

(11.81)

315

(12.4)

375

(14.76)

375

(14.76)

375

(14.76)

475

(18.7)

475

(18.7)

mm

)

(in.)

367

(14.45)

367

(14.45)

369

(14.53)

424

(16.69)

472

(18.58)

472

(18.58)

474

(18.66)

474

(18.66)

H2

c

G

mm

(in.)

250

(9.84)

298

(11.73)

285

(11.22)

350

(13.78)

540

(21.26)

540

(21.26)

835

(32.87)

495

(19.49)

MT-VW3 A9 214 MT-VW3 A9 216

G1

mm

(in.

-

-

-

-

-

-

-

-

-

-

102.5

(4.03)

-

-

-

-

G

G2

mm

)

n.)

(i

-

-

-

-

-

-

-

-

-

-

27.5

(1.08)

-

-

-

-

G3

mm

(in.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

70

(2.76)

)

=

H1

mm

n.)

(i

95

(3.74)65(2.56)75(2.95)

172

(6.77)65(2.56)75(2.95)

240

(9.40)35(1.37)55(2.15)

250

(9.84)65(2.56)75(2.95)

250

(9.84)65(2.56)75(2.95)

250

(9.84)65(2.56)75(2.95)

350

(13.78)65(2.56)75(2.95)

350

(13.78)65(2.56)75(2.95)

G

H2

mm

(in.

G3

H3

mm

)

(in.)

G

Ø

mm

(in.)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

11.5

(0.45)

sc

=

For

rews

M10

M10

M10

M10

M10

M10

M10

M10

19

Page 19

L

ocation of the charging

LED

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Before working on the drive, turn it off, wait until the red capacitor charging LED has gone out, then measure the DC bus voltage.

Location of the capacitor charging LED

Red LED indicating that the DC bus is powered up

Procedure for measuring the

DC bus voltage

DANGER

HAZARDOUS VOLTAGE

Read and understand the instructions on page 4 before performing this procedure.

Failure to follow this instruction will re su lt in dea th or se rio us injury.

The DC bus voltage can exceed 1,000 VDC. Use a properly rated voltage s ensing dev ice when p erforming t his pro cedure. To measure t he

DC bus voltage:

1 Disconnect the drive power supply.

2 Wait for the capacitor chargi ng LE D to go off.

3 Measure the voltage of the DC bus between the PA/+ and PC/- terminals to check whether the voltage is less than 45 VDC. Refer to

4 If the DC bus capacitors have not discharged completely, contact Motortronics agent (do not repair or operate the drive).

25 for the layout of the power terminals.

e

pag

20

Page 20

Installi

ng option cards

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

These should ideally be installed once the drive is mounted and before wiring it.

Check that the red capacitor charging LED has gone out. Measure the DC bus voltage in accordance with the procedure indicated on

20.

page

The option cards are installed under the drive control front panel. Remove the graphic keypad then take off the control front panel as

d below.

indicate

Remove the control front panel

1

• Using a screwdriver, press down on

the catch and pull to release the lefthand part of the control front panel

2

• Do the same on the

right-hand side

3

Removing the empty option card support

MT275 to MT2100 and MT4125 to MT4400 drives are supplied with an empty option card support. If adding an

I/O or communication option card or a “Controller Inside” programmable card, remove the support

This card support serves no purpose if one or more option cards are used.

• Pivot the control front panel

and remove it

following the instructions below.

1

2

1

Open the empty option card support

2

Release the support from its hooks and remove it

21

Page 21

Installi

ng option cards

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Installing an encoder interface card

There is a special slot on the drive for adding an encoder interface card.

• First remove the empty option card support if it is still in place, as

shown on the previous page, so that you can access the slot for the

encoder feedback card.

• If an I/O or communication option card has already been installed,

remove it so you can access the slot for the encoder feedback card.

• After installing the encoder interface card, replace the empty card

support or the option card(s).

Installing an I/O extension card or a communication card

2

1

1

2

Replacing the control front panel

3

3

Replace the control front panel over the option card (same procedure as for installing

the option card, see and )

1 2

Position the option card on the clasps

Pivot the card until it clicks into place

22

Page 22

Wiri

ng recommendations

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Power

The drive must be connected to the protective ground. To comply with local regulations concerning high leakage currents (above 3.5 mA),

use at least a 10 mm² (AWG 6) protective conductor or 2 protective conduct ors with the same cross-section as the power supply conductors.

DANGER

HAZARDOUS VOLTAGE

Ground equipment using the ground connecting point provided as shown i n the figure below. The drive panel must be

properly grounded before power is applied.

Failure to follow these instructions will result in death or serious injury.

Drive

Drive

Drive

• Check whether the resistance to the protective ground is one ohm or less.

• If several drives are to be connected to the protective ground, each drive must be connected

directly to this

ground as shown opposite.

WARNING

IMPROPER WIRING PRACTICES

• The MT drive will be damaged if input line voltage is applied to the output terminals (U/T1,V/T2,W/T3).

• Check the power connections before powering up the MT drive.

• If replacing another drive, verify that all wiring connections to the MT drive comply with all wiring instructions in this

al.

manu

Failure to

When upstream protection by means of a “residual current device” is required by t he installation sta ndards, a type A device sh ou

for single phas

• HF current filtering

• A time delay which prevents tripping caused by the load from st

devices. In this case, choose devices with immunity against nuisance tripping, for example “residual current devices” with reinforced

immunity from the

follow these instructions can result in death or serious injury.

e drives and type B for 3-phase drives. Choose a suitable model integrating:

ray capacitance on power-up. The t

s.i range.

ld be used

ime delay is not possible for 30 mA

If the installation includes several drives, provide one “residual current device” per drive.

WARNING

INADEQUATE OVERCURRENT PROTECTION

• Overcurrent protective devices must be properly coordinated.

• The Canadian Electricity Code and the National Electrical Code require branch circuit protect

recommended on the drive nameplate to achieve published short-circuit current ratings.

• Do not connect the drive to a power feeder whose short-circuit

in the tables on pages

Failure to follow these instructions can result in de

8 and 9.

ath or serious injury.

capacity exceeds the driv

ion. Use the fuses

e short-circuit current indicated

23

Page 23

Wiri

ng recommendations

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Keep the power cables separate from circuits in t he installation with low-level signal s (detectors, PLCs, measuring apparatus, v ideo, phone).

The motor cables must be at least 0.5 m (20 in.) long.

Do not immerse the motor cables in water.

Do not use surge arresters or power factor correction capacitors on the variable speed drive output.

CAUTION

IMPROPER USE OF A BRAKING RESISTOR

• Only use the braking resistor values recommended in our catalogs.

• Wire a thermal overload relay in the sequence or configure the braking resistor protection (please refer to the

Programming Manual) so that the drive p

Failure to follow these instructions can re

Control

Keep the control circuits away from the power circuits. For control and speed reference circuits, we recommend using shielded twisted

cables with a pitch of between 25 and 50 mm (0.98 and 1.97 in.) and connecting the s hielding to ground at each end.

ower section AC supply is disconnected in the event of a fault.

sult in equi

pment damage.

If using conduit, do not lay the motor, power supply and control cables in the same conduit. Keep the metal conduit containing the power

supply cables

containing the power supply cables at least 31 cm (12 in.) away from the metal conduits contai ni ng th e contro l cabl es. If it is necessary for

control and power cables to cross each other, be sure they cross at right angles.

at least 8 cm (3 in.) away from the metal conduit containing the control cables. Keep the non-metal conduits or cable ducts

Length of motor cables

0 ... 50 m

(0 ... 164 ft)

Shielded

MT275 to MT2100

MT4125 to MT4400

Note: On old generation motors or those with poor insulation it is advisable to use a motor choke with 5 m (16.4 ft) of cable.

Choice of associated components:

Please refer to the catalog.

cable

Unshielded

cable

50 ... 100 m

(164 ... 328 ft)

100 ... 200 m

(328 ... 656 ft)

Motor

hoke

c

Motor choke 2 motor chokes in series

200 ... 300 m

(656 ... 984 ft)

300 ... 400 m

(984 ... 1,312 ft)

2 motor chokes in

400 ... 600 m

(1,312 ... 1,968 ft)

series

24

Page 24

P

ower terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Access to the power terminals

To access the power terminals, unscrew the front panel and remove the protective cover

Terminals for

DC choke

Fan power

supply

DC bus power supply

• Power section AC supply

• Output to the motor

• Connections to ground

• Output to braking resistor (up

to MT4250 rating only)

Characteristics and functions of the power terminals

Terminal Function MT

3 x t Protective ground connection terminals All ratings

R/L1, S/L2, T/L3 (1) Power supply All ratings

PO DC choke connection

PA/+ DC bus + polarity and DC choke connection All ratings

PC/- DC bus - polarity All ratings

PA Output to braking resistor MT275 , MT2100

PB Output to braking resistor

U/T1, V/T2, W/T3 Output to the motor All ratings

RO, SO, TO

Separate power supply for the fan when the drive is

powered by t

he DC bus only

BU+, BU- + and - polarities to be connected to the braking unit MT4300 to MT4400

X20, X92, X3 Braking unit control cable connection

(1) From the MT4300 upwards, there are no braking resistor connection terminals on the drive as the braking uni t is optional (please refer

to the catalog). The braking resistor is then connected to the braking unit.

MT275 , MT2100

MT4125 to MT4400

MT4125 to MT4250 (2)

MT2100

MT4150

to MT4400

Refer to the braking unit User’s Manual.

25

Page 25

P

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

ower terminals

MT275 , MT4125

Front view

320 (12.54)

View from above

View from below

70 (2.74) 60 (2.35)

115 (4.50)

M12

5 (0.2)

PC/-PA/+PO

M10

M8

295 (11.55)

230 (9.01)

172 (6.74)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

225 (8.81)

100 (3.92)

65 (2.55)

14 (0.55)

M10

85(3.33)

105(4.11)

M10

60(2.35)

50 (1.96)

Max. wire size/terminal tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB

2

2 x 100 mm

2 x 250 MCM / 212 lb.in 2 x 250 MCM / 360 lb.in 250 MCM / 106 lb.in

/ 24 Nm 2 x 100 mm2 / 41 Nm 60 mm2 / 12 Nm

38 (1.49)57(2.23)

32 (1.25)

26

Page 26

P

ower terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MT2100 , MT4150

Front view

View from above

320 (12.54)

125 (4.90)

149(5.84)

67 (2.62)

M12

5 (0.2)

PC/-PA/+PO

View from below

Fan terminals (1)

70 (2.74)

265 (10.38)

250 (9.80)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

328 (4.02)

260 (10.18)

200 (7.83)

155 (6.07)

27 (1.06)

55,5 (2.17)

34 (1.33)

58 (2.27)

M10

79,5 (3.11)

217 (8.50)

M10

60 (2.35)

M10

38 (1.49)

M8

62 (2.43)

Max. wire size/terminal tightening torque

Drive terminals L1/R, L2/S , L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 100 mm

/ 24 Nm 2 x 150 mm2 / 41 Nm 60 mm2 / 12 Nm 5.5 mm2 / 1.4 Nm

2 x 250 MCM / 212 lb.in 2 x 250 MCM / 360 lb.in 250 MCM / 106 lb.in AWG 10 / 12 lb.in

(1)

137 (5.37)

(1)Power supply for the fans, compulsory if the drive is powered by the DC bus only. Do not use if the drive has a 3-phase AC supply via

L1/R, L2/S, L3/T.

27

Page 27

P

ower terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MT4200

View from above

Front view

80 (3.13) 56 (2.19) 58 (2.28)

317 (12.43)

PA/+

View from below

115 (4.50)

M12

PC/-PO

Fan terminals (1)

321 (12.58)

322 (12.62)

281 (11.01)

252 (9.87)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

252 (9.87)

99 (3.88)

80 (3.13)

76 (2.98)

18 (0.71)

43 (1.68)

72 (2.83)

80 (3.13)

M10

75 (2.94)

M10

75 (2.94)

257 (10.07)

M10

M8

68 (2.66)

38 (1.49)

Max. wire size/terminal tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 120 mm

/ 24 Nm 2 x 120 mm2 / 41 Nm 120 mm2 / 24 Nm 5.5 mm2 / 1.4 Nm

2 x 250 MCM / 212 lb.in 2 x 250 MCM / 360 lb.in 250 MCM / 212 lb.in AWG 10 / 12 lb.in

(1)Power supply for the fans, compulsory if the drive is powered by the DC bus only. Do not use if the drive has a 3-phase AC supply via

L1/R, L2/S, L3/T.

28

(1)

Page 28

P

ower terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MT4250

View from above

47 (1.84)

Front view

100 (3.92) 150 (5.88)

319,50 (12.52)

PO PA/+ PC/-

View from below

319,50 (12.52)

112 (4.39)

40 (1.57)

M12

Fan terminals (1)

286 (11.20)

321 (12.58)

270 (10.58)

251 (9.83)

U/T1 V/T2

R/L1

S/L2 T/L3

W/T3

PA PB

260 (10.18)

104 (4.07)

80 (3.13)

74 (2.90)

114 (4.47) 102 (4.00)

21 (0.82) 104 (4.07) 102 (4.00)

102 (4.00)74 (2.90)

357 (13.99)

M12

M12

M12

M8

38 (1.49)

Max. wire size/terminal tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ PA, PB RO, SO, TO

2

2 x 150 mm

/ 41 Nm 2 x 150 mm2 / 41 Nm 120 mm2 / 24 Nm 5.5 mm2 / 1.4 Nm

2 x 350 MCM / 360 lb.in 2 x 350 MCM / 360 lb.in 250 MCM / 212 lb.in AWG 10 / 12 lb.in

(1)Power supply for the fans, compulsory if the drive is powered by the DC bus only. Do not use if the drive has a 3-phase AC supply via

L1/R, L2/S, L3/T.

(1)

68 (2.66)

29

Page 29

P

ower terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

MT4300 , MT4400

Front view

View from above

PO PA/+ PC/-

View from below

319,50 (12.52)

102 (4.00)

145 (5.68)

87 (3.41)

100 (3.92) 112 (4.39)

2 x M12

Fan terminals (1)

67 (2.62)

70 (2.74)

98 (3.84)

271 (10.61)

251 (9.83)

R/L1

U/T1 V/T2

S/L2 T/L3

W/T3

322 (12.62)

36 (1.41)

43 (1.67)

113,5 (4.45) 175 (6.85)

173,5 (68.01)

130 (5.09)

M12

176,5 (69.19)

175 (6.85)175 (6.85)

M12

M12

Max. wire size/terminal tightening torque

Drive terminals L1/R, L2/S, L3/T, U/T1, V/T2, W/T3 PC/-, PO, PA/+ RO, SO, TO

2

4 x 185 mm

/ 41 Nm 4 x 185 mm2 / 41 Nm 5.5 mm2 / 1.4 Nm

3 x 350 MCM / 360 lb.in 3 x 350 MCM / 360 lb.in AWG 10 / 12 lb.in

(1)Power supply for the fans, compulsory if the drive is powered by the DC bus only. Do not use if the drive has a 3-phase AC supply via

L1/R, L2/S, L3/T.

(1)

30

Page 30

Control t

erminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Access to the control terminals

Removing the terminal card

To access the control terminals,

open the cover on the control front panel.

1

2

Arrangement of the control terminals

SW1

SW2

R1A

R1B

R1C

R2A

R2C

+10

AI1+

AI1-

COM

AI2

AO1

COM

To make it easier to wire the drive control section,

the control terminal card can be removed.

• Undo the screw until the spring is fully extended.

• Remove the card by sliding it downwards.

IMPROPERLY SECURED TERMINAL CARD

When replacing the control terminal card, it is essential to

fully tighten the captive screw.

Failure to follow this instruction can result in

eq

Logic input switch

Source

Int

Sink

Ext

LI6 input switch

PTC LI

Factory setting: Source

Factory setting: LI

uipment damag

CAUTION

e.

Maximum wire size:

2.5 mm² – AWG 14

LI2

LI3

LI4

LI5

0V

P24

LI1

Note: The

MT is supplied with a link between the PWR and +24 terminals.

LI6

+24

PWR

RJ45

RJ45 connector

Max. tightening torque:

0.6 Nm – 5.3 lb.in

31

Page 31

Control t

erminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Characteristics and functions of the control terminals

Terminal Function Electrical characteristics

R1A

R1B

R1C

R2A

R2C

Common point C/O contact (R1C) of

programmab

N/O contact of programmable relay R2

le relay R1

• Minimum swi

• Maximum switching capacity on resistive load:

5 A for 250 VAC or 3

• Maximum switching curren

2 A for 2

• Reaction ti

• Service life: 100,000 operations at max. switching power

tching capacity: 3 mA for 24 VDC

50 VAC or 30 VDC

me: 7 ms ± 0.5 ms

0 VDC

t on inductive load (cos ϕ = 0.4 L/R = 7 ms):

+10 + 10 VDC power supply for reference

AI1+

AI1-

COM Analog I/O common 0V

AI2 Depending on software configuration:

COM Analog I/O

AO1 Depending on software configuration:

P24 Input for external +24 VDC control

0V Logic input common and 0V of P24

1

LI

LI2

LI3

LI4

LI5

LI6 Depending on the position of the SW2

+24 Logic input power supply SW1 switch in Source or Sink Int position

entiometer

pot

1 to 10 k

Differential analog input AI1 • -10 to +10 VDC (max. safe voltage 24 V)

Analog voltage input

or

Analog current input

Analog voltage output

or

Analog current output

power s

external power supply

Programmable logic inputs • +24 VDC (max. 30 V)

swi

or

Ω

common 0V

upply

tch:

- Programmable lo

- Input for PTC probes

gic input

• + 10 VDC (10.5 V ± 0.5V)

• 10 mA max.

• Reaction time: 2 ms ± 0.5 ms, 11-bit resolution + 1 sign bit

• Accuracy ± 0.6% for ∆θ = 60°C (140°F), linearity ± 0.15% of max. value

• Analog input 0 to +10 VDC (max. safe voltage 24 V),

impedance 30 kΩ

or

• Analog input X – Y mA, X and Y can be programmed from 0 to 20 mA,

• Impedance 250 Ω

• Reaction time: 2 ms ± 0.5 ms

• 11-bit resolution, accuracy ± 0.6% for ∆θ = 60°C (140°F), linearity ± 0.15% of max.

ue

val

• Analog output 0 to +10 VDC, load impedance greater than 50 kΩ

or

• Analog output X – Y mA, X and Y can be programmed from 0 to 20 mA

• Max. load impedance 500 Ω

• 10-bit resolution, reaction time: 2 ms ± 0.5 ms

• Accuracy ± 1% for ∆θ = 60°C (140°F), linearity ± 0.2% of max. value

• +24

VDC (min. 19 V, max. 30 V)

• Power 30 Watts

0V

• Impedance 3.5 kΩ

• Reaction time: 2 ms ± 0.5 ms

SW2 switch on LI (factory setting)

• Same characteristics as logic inputs LI1 to LI5

or

SW2 switch on PTC

• Trip threshold 3 kΩ, reset threshold 1.8 kΩ

• Short-circuit detection threshold < 50 Ω

• +24 VDC power supply (min. 21 V, max. 2 7 V), pro tec ted aga ins t short -c ircui ts and

verloads

o

•

Max. current available for customers 200 mA

SW1 switch State 0 State 1

Source (factory setting) < 5 VDC > 11 VDC

Sink Int or Sink Ext > 16 VDC < 10 VDC

SW1 switch in Sink Ext position

• Input for external +24 VDC power supply for the logic inputs

PWR Power Removal safety function input

32

When PWR is not connected to the

24 V, the motor cannot be started

ompliance with functiona

(c

standard EN 954-1 and IEC/EN 61508)

l safety

• 24 VDC power supply (max. 30 V)

• Impedance 1.5 kΩ

• State 0 if < 2V, state 1 if > 17V

• Reaction time: 10 ms

Page 32

Opti

on terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Logic I/O option card terminals (MT-VW3 A3 201)

Logic input switch SW3

SW3

Source

Sink

Ext

Int

Factory setting: Source

Maximum wire size:

1.5 mm² – AWG 16

R3A

R3C

R3B0V-10

+24

LI7

LI8

LI9

LI10

TH1+

TH1-

L01

L02

CLO

0V

Characteristics and functions of the terminals

Terminal Function Electrical characteristics

R3A

R3B

Common point C/O contact R3C of

programmab

le relay R3

R3C

-10 -10 VDC power supply for reference

entiometer 1 to

pot

10 k

Ω

+24 Logic input power supply SW3 switch in Source or Sink Int position

LI7

Programmable logic inputs • +24 VDC power supply (max. 30 V)

LI8

LI9

LI10

• Minimum switchi

ng capacity: 3 mA for 24 VDC

• Maximum switching capacity on resistive load:

5 A for 250 VAC or 30 VDC

• Maximum switching capacity on inductive load (cos ϕ

2 A for 250

VAC or 30 VDC

• Reaction time: 7 ms ± 0.5 ms

• Service life: 100,000 operations

•- 10 VDC (-10.5 V ± 0.5V)

• 10 mA max.

• +24 VDC power supp

ly (min. 21 V, max. 27 V),

overloads

• Max. current available for customers 200 mA (This current correspon ds to the total

consu

mption on t

he control card +24 and the option cards +24)

SW3 switch in Sink Ext position

• Input for external +24 VDC power supply for the logic inputs

• Impedance 3.5 kΩ

• Reaction time 2 ms ± 0.5 ms

Max. tightening torque:

0.25 Nm – 2.21 lb.in

= 0.4 L/R = 7 ms):

protected against short-circuits and

Switch SW3 State 0 State 1

Source (factory setting) < 5 VDC > 11 VDC

Sink Int or Sink Ext > 16 VDC < 10 VDC

0 V 0 V 0 V

TH1+ PTC probe input • T ri p th re s ho l d 3 kΩ, reset threshold 1.8 kΩ

TH1LO1

LO2

Open collector programmable logic

puts

out

• Short-circuit detection threshold < 50 Ω

• +24 VDC (max. 30

V)

• Max. current 200 mA for internal power supply and 200 mA for external power supply

• Reaction time: 2 ms ± 0.5 ms

CLO Logic output common

0V 0 V 0 V

33

Page 33

Opti

on terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Extended I/O option card terminals (MT-VW3 A3 202)

Logic input switch SW4

Source

Ext

Sink

SW4

Int

Factory setting: Source

0V

CLO

LO4

LO3

RP

TH2TH2+

R4A

R4B

R4C

-10

AI3+

AI3-

AI4

COM

AO2

Characteristics and functions of the terminals

Terminal Function Electrical characteristics

R4A

R4B

R4C

Common point C/O contact R4C of

programmab

le relay R4

• Minimum switchi

ng capacity: 3 mA for 24 VDC

• Maximum switching capacity on resistive load:

5 A for 250 VAC or 30 VDC

• Maximum switching capacity on inductive load (cos ϕ

A for 250 VAC

1.5

• Reaction time 10 m s ± 1 ms

• Service life: 100,000 operations

AO3

+24

LI11

LI12

or 30 VDC

LI13

Maximum wire size:

1.5 mm² – AWG 16

Max. tightening torque:

0.25 Nm – 2.21 lb.in

0V

LI14

= 0.4 L/R = 7 ms):

-10 -10 VDC power supply for reference

Ω

potentiometer 1 to

10 k

AI3+ + polarity of the current differential

analog input AI3

AI3- - polarity of the current differential

og input AI3

anal

AI4 Dependi

ng on software configuration:

Analog current input

or

Analog voltage input

COM Analog I/O

AO2

AO3

Depending on software configuration:

Analog voltage outputs

common 0 V

or

Analog current outputs

•-10 VDC (-10.5 V ± 0.5V)

• 10 mA max.

nalog input X – Y mA, X and Y can be programmed from 0 to 20 mA,

• A

impedance 250 Ω

• Reaction time: 5 ms ± 1 ms

• 11-bit resolution + 1 sign bit, accuracy ± 0.6% for ∆θ = 60°C (140°F)

• Linearity ± 0.15% of max. value

• Analog input 0 to +10 VDC (max. safe voltage 24 V),

impedance 30 kΩ

or

• Analog input X – Y mA, X and Y can be programmed from 0 to 20 mA

Impedance 250 Ω

• Reaction time: 5 ms ± 1 ms

• 11-bit resolution, accuracy ± 0.6% for ∆θ = 60°C (140°F), linearity ± 0.15% of max.

ue

val

• 0 – 10 VDC or -10/+10 VDC bi

polar analog output dependi

ng on software

configuration, load impedance greater than 50 kΩ

or

• Analog current output X-Y mA, X and Y can be programmed from 0 to 20 mA, ma x.

d impedance 500 Ω

loa

t resolution

• 10-bi

• Reaction time 5 ms ± 1 ms, accuracy ± 1% for ∆θ = 60°C (140°F), linearity ± 0.2%

34

Page 34

Opti

on terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Terminal Function Electrical characteristics

+24 Logic input power supply SW4 switch in Source or Sink Int position

LI11

LI12

LI13

LI14

0V Logic input common 0 V

Programmable logic inputs • +24 VDC (max. 30 V)

• +24 VDC output (min. 21 V, max. 27 V), protected against short-circuits and overload s

• Max. current available for customers 200 mA (This current corresponds to the total

sumption on the c

con

SW4 switch in Sink Ext position

• Input for external +24 VDC power supply for the logic inputs

• Impedance 3.5 kΩ

• Reaction time: 5 ms ± 1 ms

ontrol card +24 and the option cards +24)

SW4 switch State 0 State 1

Source (factory setting) < 5 VDC > 11 VDC

Sink Int or Sink Ext > 16 VDC < 10 VDC

TH2+

TH2-

RP Frequency input • Frequency range: 0…30 kHz

LO3

LO4

CLO Logic output common

0V 0 V 0 V

PTC probe input • Trip threshold 3 kΩ, reset threshold 1.8 kΩ

Open collector programmable logic

puts

out

• Short-circuit detection threshold < 50 Ω

• Cyclic ratio: 50% ± 10%

• Maximum sampling time: 5 ms ± 1 ms

• Maximum input voltage 30 V, 15 mA

• Add a resistor if the input voltage is greater than 5 V (510 Ω for 12 V, 910 Ω for 15 V,

1.3 kΩ for 24 V)

• State 0 if < 1.2 V, state 1 if > 3.5 V

• +24 VDC

• Max. current 20 mA for internal power supply and 200 mA for external power supply

• Reaction time 5 ms ± 1 ms

(max. 30 V)

35

Page 35

Opti

on terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Encoder interface card terminals

VW3 A3 401...407

MT VW3 A3 401..407

0Vs

+Vs

B

B

A

A

Characteristics and functions of the terminals

Encoder interface cards with RS422-compatible differential outputs

Terminal Functi

+Vs Encoder power

0Vs

A, /A

B, /B

on Electr

s

upply

Incremental

ogic inputs

l

Maximum wire size:

1.5 mm² – AWG 16

Max. tightening torque:

0.25 Nm – 2.21 lb.in

ical characteristics

MT-VW3 A3 401 MT-VW3 A3 402

• 5VDC (max. 5.

and overloads

• Max. current 200 mA

• Max.

resolution: 5,000 points/rev

• Max. frequency: 300 kHz

5V) protected against short-circuits

• 15 VDC (max. 16 V) protected against short-ci rcuits

d overloads

an

• Max. current 175 mA

Encoder interface cards with open collector outputs

Terminal Function Electrical characteristics

MT-VW3 A3 403 MT-VW3 A3 404

+Vs Encoder power

0Vs

A, /A

B, /B

Encoder interface cards with push-pull outputs

Terminal Function Electrical characteristics

+Vs Encoder power

0Vs

A, /A

B, /B

supply

Incremental

ogic inputs

l

supply

State 0 If <1.5 V

State 1 If > 7.7 V and < 13 V If > 7.7 V and < 16 V If > 11.5 V and < 25 V

Incremental

ogic inputs

l

• 12 VDC (max. 13 V) pro

and overloads

• Max. current 175 mA

• Max.

resolution: 5,000 points/rev

• Max. frequency: 300 kHz

MT-VW3 A3 405 MT-VW3 A3 406 MT-VW3 A3 407

• 12 VDC (max. 13

against short-circuits and

overloads

• Max. current 175 mA

• Max.

resolution: 5,000 points/rev

• Max. frequency: 300 kHz

V) protected

tected against short-circuits

• 15 VDC (max. 16 V) protected

nst short-circuits and

agai

overloads

• Max. current 175 mA

• 15 VDC (max. 16 V) protected against short-ci rcuits

d overloads

an

• Max. current 175 mA

• 24 VDC (min. 20V, max. 30V)

cted against short-circuits

prote

and overloads

• Max. current 100 mA

36

Page 36

Opti

on terminals

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Selecting the encoder

The 7 encoder interface cards available as options with the MT Series enable three different encoder technologies to be used.

• Optical incremental encoder with differential outputs compatible with the RS422 standard

• Optical incremental encoder with open collector outputs

• Optical incremental encoder with push pull-outputs

The encoder must comply with the following two limits:

• Maximum encoder frequency 300 kHz

• Maximum resolution 5,000 points/revolution

Choose the max. standard resolution within these limits to obtai n optimum accuracy.

Wiring the encoder

Use a shielded cable containing 3 twis ted pairs with a pitch o f between 25 and 50 mm (0 .98 in. and 1.97 in.). Conne ct the shielding to ground

at both ends.

The minimum cross-section of the conductors must comply with the table below to limit line voltage drop:

Max. length of

encoder cable

10 m

8 ft

32.

50 m

164 ft

100 m

328 ft

200 m

6 ft

65

300 m

984 ft

MT-VW3 A3 401...40

Max. consumption

current of encoder

100 mA 0.2 mm² AWG 24 100 mA 0.2 mm² AW

200 mA 0.2 mm² AWG 24 200 mA 0.2 mm² AWG 24

100 mA 0.5 mm² AWG 20 100 mA 0.5 mm² AWG 20

200 mA 0.7

100 mA 0.75 mm² AWG 18 100 mA 0.75 mm² AWG 18

200 mA 1.

- - - 100 mA 0.5 mm² AWG 20

- - - 200 mA 1.5 mm² AW

- - - 100 mA 0.75 mm² AWG 18

- - - 200 mA 1.5 mm² AW

Mini

2 MT-VW3 A3 403...407

mum cross-section of

conductors

5 mm² AWG 18 200 mA 0.75 mm² AWG 18

5 mm² AWG 15 200 mA 1.5 mm² AWG 16

Max. consumption

current of encoder

Minimum cross-section of

conductors

G 24

G 15

G 15

37

Page 37

C

onnection diagrams

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Connection diagrams conforming to standards EN 954-1 category 1 and

IEC/EN 61508 capacity SIL1, stopping category 0 in accordance with standard

IEC/EN 60204-1(if required)

Diagram with line contactor

- Q2

- Q2

- KM1

(1)

R1A

(2)

R1C

A1

(3) (3) (3)

S / L2

R / L1

U / T1

V / T2

V1

U1

M

3 a

T / L3

W / T3

W1

Diagram with disconnect switch

- T1

R1B

R2A

- Q3

R2C

- S2

A1

PWR

R1CR1A

+24

- S1

- KM1

- KM1

A2A1

(1)

R1A

(2)

R1C

R1B

R2A

R2C

PWR

+24

Q1

(3) (3) (3)

S / L2

R / L1

U / T1

V / T2

V1

U1

M

3 a

T / L3

W / T3

W1

A1

(1) Line choke (if used)

(2) Fault relay contacts, for remote signaling of drive status.

Note: Install interference suppressors on all inductive circuits near the drive or connected to the same circuit (relays, contactors, solenoid

valv

es, etc).

Choice of associated components:

Please refer to the catalog.

38

Page 38

C

onnection diagrams

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Connection diagrams conforming to standards EN 954-1 category 3 and

IEC/EN 61508 capacity SIL2, stopping category 0 in accordance with standard

IEC/EN 60204-1(if required)

This connection diagram is suitable for use with machines with a short freewheel stop time (with low inertia or high resistive torque).

When the emergency stop is activated, the drive power supply is turned off immediately and the motor stops in accordance with

category 0 of standard

This diagram must be used for hoisting a pplications.

A contact on the safety relay must be inserted in the brake control circuit to engage it safely when the Power Removal safety function is

activ

ated.

IEC/EN 60204-1.

N(-)

L1(+)

F1

S1

A2 23 33Y2 13

XPS AC

48 V, 115 V, 230 V

A2

S2

ESC

Y1

T

PE

Logic

K2K1

K1

K2

14 24 34

Y43

Y44

(1)

A1

(4) (4) (4)

S / L2

R / L1

U / T1

V / T2

V1

U1

M

3 a

W1

T / L3

W / T3

R1A

(2)

R1C

R1B

LI1

LI2

LI6

(3)

+24

PWR

(1)Line choke, if used.

(2)Fault relay contacts, for remote signaling of drive status

(3)It is essential to connect the shielding on the cable connected to the Power Removal input to ground.

- Standard EN 954-1 category 3 requires the use of a stop button with double contact (S1).

- S1 is used to activate the Power Removal safety function.

- S2 is used to initialize the safety relay when powering up or after an emergency stop. ESC enables the use of other initializati

conditions for

the module.

- One Preventa module can be used for the Power Removal safety function on several MT drives.

- A logic input on the safety relay can be used to indicate safely that the drive is operating in safe conditions.

Note:

For preventive maintenance, the Power Removal function must be activated at least once a year.

The drive power supply must be turned off and then on again before carrying out this preventive maintenance.

The drive logic output signals cannot be considered as safety-type signals.

Fit interference suppressors to all inductive circuits near the drive or coupled to the same circuit (relays, contactors, soleno

id valves, etc).

on

Choice

of associated components:

Please refer to the catalog.

39

Page 39

C

onnection diagrams

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Connection diagram conforming to standards EN 954-1 category 3 and

IEC/EN 61508 capacity SIL2, stopping category 1 in accordance with standard

IEC/EN 60204-1(if required)

This connection diagram is suitable for use with machines with a long freewheel stop time (machines with high inertia or low resistive torque).

This diagram must not be used for hoisting applications.

When the emergency stop is activated, deceleration of the motor controlled by the drive is requested first. Then, after a time delay

corresponding to t

Example:

- 2-wire control

- LI1 assigned to forward

- LI2 assigned to reverse

he deceleration time, the Power Removal safety function is activated.

N(-)

L1(-)

F1

S1

A1

(5) (5) (5)

S / L2

R / L1

U / T1

V / T2

V1

U1

M

3 a

W1

(1)

T / L3

W / T3

R1A

A2

XPS AT

115 V

230 V

A2 PE Y1

(2)

R1B

R1C

-+

T

(3)

LI1

LI2

S21 S11

S33

S2

(4)

LI6

B1 S12 S22

K1 K2

K1 K2K3

PWR

+24

Logic

2

1

K1

K2

K4

K3

K4

Y2 Y3

ESC

13

K1

K2

14 34 42 6858

Y4 Y5

23

33 41 57 67

K3

K4

24

(1)Line choke, if used.

(2)Fault relay contacts, for remote signaling of drive status

(3)In this example, the logic inputs Lix are wired as “Source” but ca

n be wired as “Si

nk Int” or “Sink Ext” (please refer to page 42).

(4)It is essential to connect the shielding on the cable connected to the Power Removal input to ground.

- Standard EN 954-1 category 3 requires the use of an emergency stop with double contact (S1).

- S1 is used to activate the Power Removal safety function.

- S2 is used to initialize the braking module when powering up or aft

er an emergency stop. ESC enables

the use of other initialization

conditions for the module.

- One Preventa module can be used for the Power Removal saf ety function on several MT Seri es drives. In this case the time d elay mu

be set t

o the longest stopping time.

- A logic input on the safety relay can be used to indicate safely that the drive is operating in safe conditions.

For preventive maintenance, the Power Removal function must be activated at least once a year.

Note:

The drive

power supply must be turned off and then on again before carrying out this preventive maintenance.

The drive logic output signals cannot be considered as safety-type signals.

Install interference suppressors on all inductive circuits near the drive or coupled to the same circuit (relays, contactors, so

lenoid valves, etc

Choice of associated components:

Please refer to the catalog.

40

st

).

Page 40

C

onnection diagrams

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Braking resistor connection diagram

MT275 to MT2100

MT4125 to MT4250

Up to 160 kW power (MT4250), braking resistors are connected directly to the terminals at the base o

f the drive (terminals PA and PB).

A1

(1)Thermal overload relay

MT 4300 to MT4400

From 200 kW upwards (MT 4300), the braking resistor is connected to the external

ATV71

MT Series

PB

PA

braking resistor

TH

(1)

braking unit. Refer to the braking unit

User’s Manual.

41

Page 41

C

onnection diagrams

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Control connection diagrams

Control card connection diagram

A1

PWR

ATV71Hppppp

+24

LI1

MT......

LI2

LI3

LI4

LI5

LI6

0V

+10

AI1+

Reference

potentiometer

AI1-

AI2

0 ± 10 V

or

X-Y mA

COM

AO1

COM

Logic input switch (SW1)

The logic input switch (SW1) is used to adapt the operation of the logic inputs to the technology of the programmable controller outputs.

• Set the switch to Source (factory setting) if using PLC output

• Set the switch to Sink Int or Sink Ext if using PLC outputs with NPN transistors.

• SW1 switch set to “Source” position • SW1 switch set to “Source” position and use of an external power

SW1

Source

Sink

Int

Ext

A1

+24

ATV71Hppppp

MT......

LI1

LI2

LI3

LI4

LI5

LI6

s with PNP transistors.

SW1

0V

supply for the LIs

Source

Int

Sink

Ext

A1

+24

ATV71Hppppp

MT......

LI1

LI2

LI3

LI4

LI5

LI6

0V

24 VDC source

+24 V

0 V

1 switch set to “Sink Int” position • SW1 switch set to “Sink Ext” position

• SW

SW1

Source

Sink

Int

Ext

A1

+24

ATV71Hppppp

MT......

LI1

LI2

LI3

LI4

LI5

LI6

0V

SW1

Source

Int

Sink

Ext

24 VDC source

+24 V

0 V

A1

+24

ATV71Hppppp

MT......

LI1

LI2

LI3

WARNING

Unintended Equipment Operation

• When the SW1 switch is set to “Sink Int” or “Sink Ext”, the common must never be connected to ground or the protect ive

ground, as there is then a risk of unintended starting on the first insulat ion fault.

Failure to follow these instructions can result in death or serious injury.

LI4

LI5

LI6

0V

42