Motortronics ME2 installation Guide

ME2 Series

Micro AC Drives

INSTALLATION & START-UP

MANUAL

REV3

9081101MN

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Motortronics

ME2 Series

Micro AC Drives

Thank you for purchasing this Motortronics ME2 Series variable frequency AC drive. When properly installed, operated and maintained, the ME2 will provide a lifetime of reliable operation. It is mandatory that the person who operates, inspects, and maintains this equipment thoroughly reads and understands this manual. This will insure safe and reliable operation of the controller.

This unit has been put through demanding tests at the factory prior to shipment. Before unpacking check the following:

•Verify that the model number on the box matches your purchase order.

•Inspect for possible shipping damage (if damaged, notify the freight carrier and file a claim within 15 days of receipt).

After unpacking, please check the following:

•Verify that the label specifications match your application requirement.

•Check all electrical connections and screws. Verify that there is no visible damage to any of the components.

Warning! Do not service equipment with voltage applied! Unit can be a source of fatal electrical shock! To avoid shock hazard, disconnect main power and wait until the LED on the main control board goes out before working on the control. Warning labels (not supplied) must be attached to terminals, enclosure and control panel.

Unit does not provide overspeed protection or incorporate current limiting control.

To obtain optimum operation from your ME2 Series drive, it is strongly recommended that this manual is read and understood.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Table of Contents |

|

Chapter 1 General Information ................................................ |

1 |

1.1Introduction

1.2Specifications

1.3Mounting Dimensions/ Terminal Block Location

Chapter 2 Power and Control Wiring ..................................... |

5 |

2.1Power and Control Wiring

2.2Wiring Diagram

2.2.1Power Terminal Block ( TM1 )

2.2.2Control Terminal Block ( TM2)

2.2.3External Control Signal Selection ( SW1 )

Chapter 3 Keypad Operation and Programming ................... |

10 |

3.1Keypad Operation

3.2Easy Programming

3.3List of Parameters

3.4Parameter Function Description

Chapter 4 Fault Codes .............................................................. |

25 |

4.1Failure or Trip which cannot be reset by Reset Key

4.2Failure or Trip which can be reset by Reset Key but cannot be Auto Reset

4.3Failure or Trip which can be Auto Reset or reset by Reset Key

4.4Operational Stop Indications

4.5Operation Error Indications

Chapter 5 Other Information .................................................... |

29 |

5.1Selecting AC Line/Load Reactors

5.2Record of Drive Settings

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Me2 Series |

Installation Manual |

Chapter 1 - General Information 1.1- Introduction

The Motortronics ME2 Series is a high performance generalpurpose micro AC drive that incorporates a high efficiency Pulse Width Modulated (PWM) design and IPM technology.

The output closely approximates a sinusoidal current waveform to allow variable speed control of any conventional squirrel cage AC induction motor.

1.2 - Specifications

|

1P2 thru 101: Single phase |

|

|

|

|

|||||

Input Voltage |

110 ~ 120V (-15% ±10%) |

|

|

|

|

|||||

50/60 Hz (±5%) |

2P2 thru 203: Single phase |

|

|

|

|

|||||

|

200 ~ 240V (+10%/-15%) |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

Output Voltage |

401 thru 403: Three phase 380 ~ 460V |

|

||||||||

Control Method |

Sinusoidal wave PWM control (PNP type 12 |

|||||||||

- 24V) |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

Ratings |

|

Model Number (ME2-XXX-M) |

|

|||||||

1P2 |

1P5 |

101 |

2P2 |

2P5 |

|

201 |

202 |

|

203 |

|

|

|

|

||||||||

Motor KW |

0.2 |

0.4 |

0.75 |

0.2 |

0.4 |

|

0.75 |

1.5 |

|

2.2 |

Motor HP |

1/4 |

1/2 |

1 |

1/4 |

1/2 |

|

1 |

2 |

|

3 |

Current A |

1.4 |

2.3 |

4.2 |

1.4 |

2.3 |

|

4.2 |

7.5 |

|

10.5 |

Capacity KVA |

0.53 |

0.88 |

1.6 |

0.53 |

0.88 |

|

1.6 |

2.9 |

|

4.0 |

Weight lbs |

1.5 |

1.5 |

1.5 |

1.6 |

1.7 |

|

1.8 |

3.8 |

|

3.8 |

Ratings |

|

Model Number (ME2-XXX-M) |

|

|||||||

|

401 |

402 |

403 |

|

|

|

|

|

|

|

Motor KW |

0.75 |

1.5 |

2.2 |

|

|

|

|

|

|

|

Motor HP |

1 |

2 |

3 |

|

|

|

|

|

|

|

Current A |

2.3 |

3.8 |

5.2 |

|

|

|

|

|

|

|

Capacity KVA |

1.7 |

2.9 |

4 |

|

|

|

|

|

|

|

Weight lbs |

3.5 |

3.5 |

3.6 |

|

|

|

|

|

|

|

Me2 Series

-1-

1.2 - Specifications

Approvals |

UL, cUL, CE |

|

Mounting |

Direct or optional DIN rail mount (for <1 HP |

|

drives) |

||

|

||

Digital Display |

Indicates, frequency, parameter |

|

selection, fault record |

||

|

1.2.1 - Frequency Control

|

Range |

1 - 200 Hz |

|

Control |

|

Digital: 0.1 Hz (0-99.9Hz) |

|

Resolution |

1 Hz (100 -120 Hz) |

||

|

|||

|

|

Analog: 1 Hz (60Hz) |

|

Frequency |

Setting |

Digital Keypad; 0-10VDC, |

|

Signal |

0-20mA, 10K Pot |

||

|

|||

|

|

|

|

|

Limit |

Frequency upper/lower limit |

|

|

Carrier |

4 ~ 16 kHz |

|

|

Frequency |

||

|

|

||

|

|

|

1.2.2 - Control Characteristics

Me2 Series

-2-

1.2.3 - Protective Functions

|

Overload |

150% for 1 minute |

|

|

Over-voltage |

DC-bus voltage > 410 V |

|

|

Under-voltage |

DC-bus voltage < 200 V |

|

|

Momentary Power |

0-2 seconds (can be restarted |

|

Function |

Loss |

via speed search) |

|

|

|

||

Stall prevention |

During accel/decel/constant |

||

|

|

||

Protective |

|

speed |

|

|

|

||

Output short circuit |

Provided by electronic circuit |

||

|

|||

|

|

|

|

|

Ground fault |

Provided by electronic circuit |

|

|

during start-up and run |

||

|

|

||

|

|

|

|

|

Other protection |

Heatsink fin overtemp, current |

|

|

limit |

||

|

|

||

|

|

|

1.2.4 - Environmental Specifications

Ambient Temperature |

- 10 to + 40° C |

|

(14° to 104° F) |

||

|

||

Humidity |

≤ 95% relative, non- |

|

condensing |

||

|

||

Vibration |

Under 1G |

|

|

Class A filter standard in all |

|

EMC |

200 volt units |

|

rated 1/4 thru 1 HP; |

||

|

Optional Class B for all other |

|

|

units |

|

Enclosure |

Panel Mount / IP20 |

Me2 Series

-3-

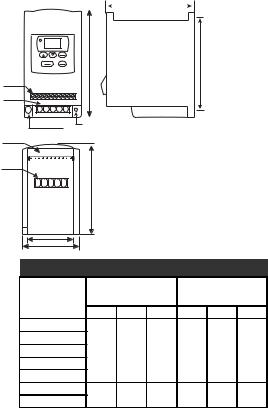

1.3 - Mounting Dimensions

C

|

DATA |

|

|

|

|

D |

|

|

RESET |

ENT |

|

|

|

|

|

||

RUN |

DSP |

A |

|

|

|

|

|

|

STOP |

FUN |

|

|

|

|

|

|

|

TM2 |

|

|

|

|

|

|

|

|

TM1 |

|

|

|

|

|

|

|

|

GROUND |

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

TM2 FRONT VIEW |

|

SIDE VIEW |

|

|

|

|||

TM1 |

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

|

|

|

BOTTOM VIEW |

|

|

|

|||

E |

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

ME2 Dimensions |

|

|

||||

|

|

|

Overall |

|

|

Mounting |

|

|

Model |

Dimensions |

Dimensions |

||||||

|

|

A |

B |

C |

D |

E |

F |

|

ME2-1P2-M |

|

|

|

|

|

|

||

ME2-1P5-M |

|

|

|

|

|

|

||

ME2-2P2-M 5.2 |

2.8 |

4.6 |

4.6 |

2.4 |

0.18 |

|||

ME2-2P5-M |

|

|

|

|

|

|

||

ME2-201-M |

|

|

|

|

|

|

||

ME2-202-M |

5.63 |

4.65 |

6.76 |

5.0 |

4.25 |

0.18 |

||

ME2-203-M |

||||||||

|

|

|

|

|

|

|||

|

|

|

Me2 Series |

|

|

|

||

|

|

|

-4- |

|

|

|

|

|

Me2 Series |

Installation Manual |

Chapter 2 - Power and Control Wiring

2.1 - Power and Control Wiring

This chapter deals with recommended power wiring practices for the ME2 Series AC drive. Remember, you must always conform to the National Electrical Code (NEC) and any applicable local codes. Always make sure the keypad is off, the LEDs are off, and the DC bus is discharged before adding or changing any wiring.

Warning! This section involves working with potentially lethal voltage levels! Caution must be used to prevent personal harm. Do not service equipment with voltage applied! To avoid shock hazard, disconnect main power and wait until the LED on the main control board goes out before working on the control. Warning labels (not supplied) must be attached to terminals, enclosure and control panel.

• DO NOT touch any circuit components while AC power is on or immediately after the main AC power is disconnected from the unit. Wait until the LED on the control board goes out.

• DO NOT make any connections to the drive before the unit is disconnected from the AC power. Failure to adhere to this warning could result in serious or lethal injury.

• Only use in a pollution degree 2 macro-- environment or equivalent.

Me2 Series

-5-

•Never connect the input power wiring to the drive terminals T1, T2, or T3.

•Always use UL/CSA approved wire and ring lugs.

•Always make a positive ground termination to the Earth terminal of the drive.

•Use copper conductors only and size field wiring based upon 75º wire only.

Model |

Maximum |

Maximum Input |

Power |

Control |

Copper |

|

Input Fuse |

Circuit Breaker |

Ground |

||||

Number |

Wiring |

Wiring |

||||

(Time Delay) |

(Amps) |

Wiring |

||||

|

|

|

||||

|

|

|

|

|

|

|

ME2-1P2 |

8 |

10 |

|

|

|

|

ME2-1P5 |

12 |

20 |

|

|

|

|

|

|

|

|

|

14 AWG |

|

ME2-2P2 |

4.5 |

10 |

14-12 AWG |

|

||

|

|

|

22-18 AWG |

|

||

ME2-2P5 |

8 |

10 |

|

|||

|

|

|||||

|

|

|

|

|

|

|

ME2-201 |

12 |

20 |

|

|

|

|

ME2-202 |

20 |

30 |

|

|

12 AWG |

|

ME2-203 |

30 |

40 |

12-10 AWG |

|

10 AWG |

Notes:

1.240 VAC units are suitable for use on a circuit capable of delivering not more than 5000 RMS symmetrical amperes, 240 Volts maximum.

2.Always ensure that values used conform to NEC and all applicable local codes.

Note: Keypad operator cannot be removed.

Me2 Series

-6-

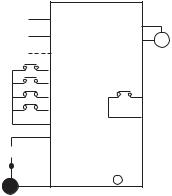

2.2 - Me2 Wiring Diagram

|

|

|

|

|

|

|

|

|

|

Braking Resistor |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

(Optional) |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

R |

|

|

|

|||||||

|

|

|

|

L1 (R) |

|

|

(U) T1 |

|

|

|

||||||

Incoming |

|

|

|

|

|

|

|

|

|

|||||||

|

L2 (S) |

|

|

(V) T2 |

|

M |

||||||||||

Power |

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

L3 (T) |

|

|

(W) T3 |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

3 |

FWD |

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

4 |

REV |

|

|

|

|

|

|

|

|

|

|

||

Multi-function |

|

1 |

|

|

|

|

||||||||||

6 |

SP1 |

|

|

|

|

|||||||||||

Input |

|

|

|

|

|

|

|

|

|

|

||||||

7 |

|

|

|

|

|

|

|

|

Multi-function |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

RST |

2 |

|

|

Output |

|||||||||

|

|

|

|

|

|

|||||||||||

|

|

|

5 |

12V (Internally Supplied) |

|

|

|

|||||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

8 |

+10V |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

10K Ω |

|

|

9 |

MVI |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

(0~10V/0~20mA, 4-20mA) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

10 |

0V (FM-) |

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

0~10V |

11 |

FM+ |

|

|

|

|

|

|

|

|

|

|

||

Frequency |

|

|

|

|

|

|

|

|

|

|

|

Grounding |

||||

Meter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

*NOTE: L3(T) is only used on ME-202 and ME-203

2.2.1- Power Terminal Block (TM1)

Notes:

1.Tightening torque for TM1 is 1 lbs-ft or 12 lbs-in.

2.Use copper conductors only. Size field wiring based on 75ºC wire only.

3.Wire voltage rating must be a minimum of 300V.

4.Ratings of the terminal block (TM1) are 300V, 15A

Symbol |

Function Description |

L1 (R) |

|

L2 (S) |

AC power source input |

L3 (T) |

|

P |

External braking resistor |

|

(only for Me2- |

|

|

R |

202/203/401/402/403 |

|

|

T1 (U) |

|

T2 (V) |

Drive output to the motor |

T3 (W) |

|

Me2 Series

-7-

Loading...

Loading...