Page 1

ME2 Series

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Micro AC Drives

INST ALLA TION & ST ART -UP

MANUAL

REV3

9081101MN

Page 2

Motortronics

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

ME2 Series

Micro AC Drives

Thank you for purchasing this Motortronics ME2 Series variable

frequency AC drive. When properly installed, operated and maintained,

the ME2 will provide a lifetime of reliable operation. It is mandatory

that the person who operates, inspects, and maintains this equipment

thoroughly reads and understands this manual. This will insure safe

and reliable operation of the controller.

This unit has been put through demanding tests at the factory prior to

shipment. Before unpacking check the following:

• Verify that the model number on the box matches your

purchase order.

• Inspect for possible shipping damage (if damaged, notify

the freight carrier and file a claim within 15 days of receipt).

After unpacking, please check the following:

• Verify that the label specifications match your application

requirement.

• Check all electrical connections and screws. Verify that

there is no visible damage to any of the components.

Warning! Do not service equipment with voltage applied!

Unit can be a source of fatal electrical shock! T o avoid

shock hazard, disconnect main power and wait until the

LED on the main control board goes out before working

on the control. Warning labels (not supplied) must be

attached to terminals, enclosure and control panel.

Unit does not provide overspeed protection or incorporate

current limiting control.

To obtain optimum operation from your ME2 Series drive, it is

strongly recommended that this manual is read and

understood.

Page 3

Table of Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Chapter 1 General Information ................................................ 1

1.1 Introduction

1.2 Specifications

1.3 Mounting Dimensions/ Terminal Block Location

Chapter 2 Power and Control Wiring ..................................... 5

2.1 Power and Control Wiring

2.2 Wiring Diagram

2.2.1 Power T erminal Block ( TM1 )

2.2.2 Control Terminal Block ( TM2)

2.2.3 External Control Signal Selection ( SW1 )

Chapter 3 Keypad Operation and Programming ................... 10

3.1 Keypad Operation

3.2 Easy Programming

3.3 List of Parameters

3.4 Parameter Function Description

Chapter 4 Fault Codes .............................................................. 25

4.1 Failure or Trip which cannot be reset by Reset Key

4.2 Failure or Trip which can be reset by Reset Key but cannot

be Auto Reset

4.3 Failure or Trip which can be Auto Reset or reset by Reset

Key

4.4 Operational Stop Indications

4.5 Operation Error Indications

Chapter 5 Other Information .................................................... 29

5.1 Selecting AC Line/Load Reactors

5.2 Record of Drive Settings

Page 4

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 5

Me2 Series Installation Manual

p

Chapter 1 - General Information

1.1- Introduction

The Motortronics ME2 Series is a high performance general-

purpose micro AC drive that incorporates a high efficiency

Pulse Width Modulated (PWM) design and IPM technology.

The output closely approximates a sinusoidal current

waveform to allow variable speed control of any conventional

squirrel cage AC induction motor.

1.2 - Specifications

1P2 thru 101: Single phase

Input Voltage

50/60 Hz (±5%)

Output Volt age

Control Method

Ratings

Motor KW

Motor HP

Current A

Capacity KVA

W eight lbs

Ratings

Motor KW

Motor HP

Current A

Capacity KVA

W eight lbs

110 ~ 120V (-15% ±10%)

2P2 thru 203: Single phase

200 ~ 240V (+10%/-15%)

401 thru 403: Three phase 380 ~ 460V

Sinusoidal wave PWM control (PNP type 12

- 24V)

Model Number (ME2-XXX-M)

1P2 1P5 101 2P2 2P5 201 202 203

0.2 0.4 0.75 0.2 0.4 0.75 1.5 2.2

1/4 1/2 1 1/4 1/2 1 2 3

1.42.34.21.42.34.27.510.5

0.53 0.88 1.6 0.53 0.88 1.6 2.9 4.0

1.51.51.51.61.71.83.83.8

Model Number (ME2-XXX-M)

401 402 403

0.75 1.5 2.2

123

2.3 3.8 5.2

1.7 2.9 4

3.5 3.5 3.6

Me2 Series

-1-

Page 6

1.2 - Specifications

Approvals

Mounting

Digital Display

UL, cUL, CE

Direct or optional DIN rail mount (for <

drives)

Indicates, frequency, parameter

selection, fault record

1.2.1 - Frequency Control

1 - 200 Hz

Digital: 0.1 Hz (0-99.9Hz)

1 Hz (100 -120 Hz)

Analog: 1 Hz (60Hz)

Digital Keypad; 0-10VDC,

0-20mA, 10K Pot

Frequency upper/lower limit

4 ~ 16 kHz

Frequency Control

Range

Resolution

Setting

Signal

Limit

Carrier

Frequency

1.2.2 - Control Characteristics

1 HP

Me2 Series

-2-

Page 7

1.2.3 - Protective Functions

Overload 150% for 1 minute

Over-voltage DC-bus voltage > 410 V

Under-voltage DC-bus voltage < 200 V

Momentary Power

Loss

0-2 seconds (can be restarted

via speed search)

Stall prevention

Output short circuit Provided by electronic circuit

Protective Func tio n

Ground fault

Other protection

During accel/decel/c onst ant

speed

Provided by electronic circuit

during start-up and run

Heatsink fin overtemp, current

limit

1.2.4 - Environmental Specifications

Ambient Temperat ure

Humidity

Vibration

EMC

Enclosure

- 10 to + 40° C

(14° to 104° F)

≤ 95% relative, noncondensing

Under 1G

Class A filter standard in all

200 volt units

rated 1/4 thru 1 HP;

Optional Class B for all other

units

Panel Mount / IP20

Me2 Series

-3-

Page 8

1.3 - Mounting Dimensions

C

DATA

ENT

RESET

RUN

DSP

FUN

STOP

TM2

TM1

A

D

GROUND

FRONT VIEW SIDE VIEW

TM2

TM1

F

C

BOTTOM VIEW

E

B

ME2 Dimensions

Model

ME2-1P2-M

ME2-1P5-M

ME2-2P2-M

ME2-2P5-M

ME2-201-M

ME2-202-M

ME2-203-M

ABCDEF

5.2 2.8 4.6 4.6

Overall

Dimensions

Me2 Series

-4-

Mounting

Dimensions

2.4 0.18

4.25 0.186.765.63 4.65 5.0

Page 9

Me2 Series Installation Manual

Chapter 2 - Power and Control Wiring

2.1 - Power and Control Wiring

This chapter deals with recommended power wiring practices

for the ME2 Series AC drive. Remember, you must always

conform to the National Electrical Code (NEC) and any

applicable local codes. Always make sure the keypad is off,

the LEDs are off, and the DC bus is discharged before adding

or changing any wiring.

Warning! This section involves working with potentially

lethal voltage levels! Caution must be used to

prevent personal harm. Do not service

equipment with voltage applied! T o avoid shock

hazard, disconnect main power and wait until

the LED on the main control board goes out

before working on the control. Warning labels

(not supplied) must be attached to terminals,

enclosure and control panel.

• DO NOT touch any circuit components while AC

power is on or immediately after the main AC

power is disconnected from the unit. Wait until

the LED on the control board goes out.

• DO NOT make any connections to the drive

before the unit is disconnected from the AC

power. Failure to adhere to this warning could

result in serious or lethal injury.

• Only use in a pollution degree 2 macro--

environment or equivalent.

Me2 Series

-5-

Page 10

• Never connect the input power wiring to the

drive terminals T1, T2, or T3.

• Always use UL/CSA approved wire and ring lugs.

• Always make a positive ground termination to

the Earth terminal of the drive.

• Use copper conductors only and size field wiring

based upon 75º wire only.

Model

Number

ME2-1P2 8 10

ME2-1P5 12 20

ME2-2P2 4.5 10

ME2-2P5 8 10

ME2-201 12 20

ME2-202 20 30 12 AWG

ME2-203 30 40 12-10 AWG 10 AWG

Maximum

Input Fuse

(Time Delay)

Maximum Input

Circuit Breaker

(Amps)

Power

Wiring

14-12 AWG

Control

Wiring

22-18 AWG

Copper

Ground

Wiring

14 AWG

Notes:

1. 240 VAC units are suitable for use on a circuit capable

of delivering not more than 5000 RMS symmetrical

amperes, 240 Volts maximum.

2. Always ensure that values used conform to NEC and

all applicable local codes.

Note: Keypad operator cannot be removed.

Me2 Series

-6-

Page 11

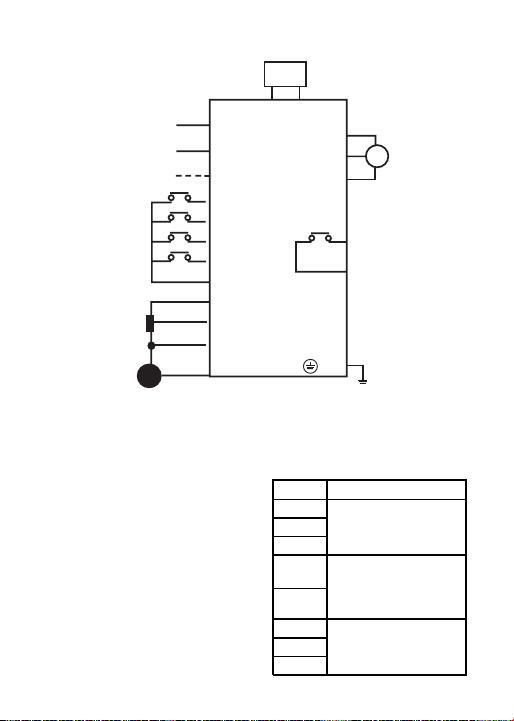

2.2 - Me2 Wiring Diagram

Braking Resistor

(Optional)

P

R

(U) T1

(V) T2

(W) T3

(Internally Supplied)

1

2

M

Multi-function

Output

Grounding

Multi-function

Input

10K Ω

Frequency

Meter

Incoming

Power

0~10V

3

4

6

7

5

8

9

10

11

L1 (R)

L2 (S)

L3 (T)

FWD

REV

SP1

RST

12V

+10V

MVI

(0~10V/0~20mA, 4-20mA)

0V (FM-)

FM+

*NOTE: L3(T) is only used on ME-202 and ME-203

2.2.1- Power Terminal Block (TM1)

Notes:

1. Tightening torque for TM1

is 1 lbs-ft or 12 lbs-in.

2. Use copper conductors

only. Size field wiring

based on 75ºC wire only.

3. Wire voltage rating must

be a minimum of 300V.

4. Ratings of the terminal

block (TM1) are 300V, 15A

Symbol Function Description

L1 (R)

AC power source input

L2 (S)

L3 (T)

P

External braking resistor

202/203/401/402/403

R

T1 (U)

Drive output to the motor

T2 (V)

T3 (W)

Me2 Series

-7-

(only for Me2-

Page 12

2.2.2- Control Terminal Block ( TM2 )

Function Description

1

Programmable output (Fn21)

Rated 250VAC/30VDC, 1A

2

3FWD

4REV

5 +12V

6SP1

7 RESET

Operation control terminals (refer to Fn03)

Common point of terminals 3 / 4 / 6 / 7

Multifunction input terminals (refer to Fn20)

Multifunction input terminal 2 (Fn20)

8+10V

0V

9 Analog input point

(FM-)

10

11 FM+

Analog common

point

Analog output

positive connection

point

Power terminal of potentiometer

(High side of potentiometer)

Analog frequency signal input

terminal (wiper of potentiometer

or positive terminal of 0~10V /

4~20mA/ 0~20mA)

Analog signal common point

(Low side of potentiometer or

negative terminal of 0~10V /

4~20mA / 0~20mA)

Multifunction analog output

terminal

Output terminal signal is

0~10VDC

Notes:

1. Tightening torque for TM2 is 0.42 lbs-ft or 5.03 lbs-in.

2. Use copper conductors only. Size field wiring based

on 75ºC wire only.

3. Wire voltage rating must be a minimum of 300V.

4. Control wiring should not run in the same conduit or

raceway with power or motor wiring.

Me2 Series

-8-

Page 13

2.2.3- External Control Signal ( SW1 )

SW1 is located in a compartment on the side of the AC

drive.

Switch External Signal Type

0~20mA analog signal ( When Fn11 is set to 1 )

I

V

I

V

1

2

3

4-20mA analog signal ( When Fn11 is set to 2 )

1

2

0~10 VDC analog signal ( When Fn11 is set to 1 )

3

Remove cover to reveal switch

Me2 Series

-9-

Page 14

Me2 Series Installation Manual

Chapter 3 - Keypad Operation and Programming

3.1 - Keypad Operation

Refer to this section if the

keypad will be used to control

the drive and if no external

control connections are

required. This section can also

be used when testing the drive

without control connections.

Note: Keypad operator cannot be

removed.

3.2 - Easy Programming

The ME2 Series has two basic loops:

Operation Loop- changes frequency to increase/decrease

motor speed

Programming Loop- changes function settings

Me2 Series

-10-

Page 15

Programming

Loop

Change

Function?

Press this key to

DSP

display function

FUN

number (FXX)

Press this key to

∧∧

∧

∧∧

∧∧

∧

∧∧

reach function

to be changed

Press this key to

DATA

read existing

ENT

function setting

Press this key to

∧∧

∧

∧∧

∧∧

∧

∧∧

go to new setting

Press this key to

DATA

enter new

ENT

function setting

Press this key to return to

DSP

frequency display or skip this

FUN

key to continue changing functions.

POWER ON

Displays

Frequency

Note:

DSP

FUN

∧∧

∧

∧∧

∧∧

∧

∧∧

RUN

STOP

This key allows

you to switch

from one loop to

the other

Operation

Loop

Change

Frequency?

Press this key to

reach function to

be changed

Press this key to

start/stop the

motor

Me2 Series

-11-

Page 16

3.3- List of Parameters

Function FN Function Description Unit Range

0 Factory Adjustment 000

Accel/Decel time

Operation mode 3

Motor rotation

direction

V/F patt er n 5

Frequency

upper/lower limit

SP1 frequency 8 SP1 frequency [Note: 2] 10 Hz

JOG frequency 9 JOG frequency [Note: 2] 6 Hz

Operation

Control

Frequency

Control

Notes:

1. Can be changed during running mode.

2. If the setting is between 0.1 and 1, the display

3. Refer to Fn25.

4. Factory set default settings depend on Fn25

1 Acceleration time [Notes: 1, 2] 0.1 sec 0.1~999 S 5.0 S

2 Deceleration time [Notes: 1, 2] 0.1 sec 0.1~999 S 5.0 S

0: Forward / Stop, Stop / Reverse

1: Run / Stop, Reverse / Forward

0: Forward

4

1: Reverse

[Note:1]

V/F pattern setting

[Notes: 3, 4]

Frequncy upper limit

6

[Notes: 2, 3, 4]

7 Frequency lower limit [Note: 2] 000

0: Keypad

10

1: External control

0: Keypad

1: 0 ~ 10V, 4 ~ 20mA, 10K pot

(no offset)

11

2: 2 ~ 10V, 4 ~ 20mA

(with 20% offset)

1 0~1 000

1 0~1 000

11~64

0.1Hz 0 . 0 ~ 2 0 0 Hz

1 0~1 000

1 0~2 000

increments in 0.1 units. If the setting is equal to or

greater than 1, the display increments in units of 1.

programming.

Me2 Series

-12-

Factory

Setting

60 Hz

Page 17

3.3- List of Parameters (continued)

Function FN Function Description Range

Carrier frequency 12 Carrier frequency setting 1~10 5

Torque

compensation

Stopping mode 14

DC

Braking

Setting

Electronic

Thermal

Overload

Torque

13

compensation gain

[Note: 1]

0:Decelerate to stop

1: Coast to stop

15 DC braking time 0.0~25.5 S 0.5 S

DC braking injection

16

frequency

17 DC braking level 0.0~20.0% 8.0%

Based on drive rated

18

current

Unit

1

0.1%

1

0.1 sec

0.1 Hz

0.10%

1%

0.0~10.0% 000

0~1 000

1~10 Hz 1.5 Hz

0-200% 100%

Factory

Setting

1: Jog

2: SP1

3: Emergency Stop

4: External Base Block

5: Reset

6: SP2

Programmable

Inputs

19 Multifun ction Input (TM1) 2

20 Multifun ction Input (TM2) 5

Notes:

1. Can be changed during running mode.

2. If the setting is between 0.1 and 1, the display

increments in 0.1 units. If the setting is equal to or

greater than 1, the display increments in units of 1.

3. Refer to Fn25.

4. Factory set default settings depend on Fn25

programming.

Me2 Series

-13-

Page 18

3.3- List of Parameters (continued)

Function FN Function Description Unit Rang e

Programmable

Output

Reverse Mode

Lockout

Momentary

Power

Loss Restart

Auto Restart 24 Number of auto-restart times 1 0~5 000

Factory Setting 25

SP2 Frequency 26 SP2 Frequency [Note: 2] 0.1 Hz 0.0~200 20

SP3 Frequency 27 SP3 Frequency [Note: 2] 0.1 Hz 0.0~200 30

Software

version

Fault History 30 Last 3 faults in memory

21 Multifunction Output 3

0: REV run enabled

22

1: REV disabled

0: Enabled

23

1: Disabled

010: Constants initialized

to 50 Hz system

020: Constants initialized

to 60 Hz system

28 Reserved for future use

29 CPU program version 1.8

Notes:

1. Can be adjusted during running mode.

2. If the setting is between 0.1 and 1, the display

increments in 0.1 units. If the setting is equal to or

greater than 1, the display increments in units of 1.

3. Refer to Fn25.

4. Factory set default settings depend on Fn25

programming.

1: Running

2: At set speed

3: Fault

1 0~1 000

1 0~1 000

Factory

Setting

000

Me2 Series

-14-

Page 19

3.4 - Parameter Function Description

3

5

p

p

Com

3

5

p

Com

3

1

0

Fn00 Factory set. Do not change.

Fn01 - Acceleration time

Factory Setting = 5 seconds; Range = 0.1 ~ 999 sec

Fn02 - Deceleration time

Factory Setting = 5 seconds; Range = 0.1 ~ 999 sec

1. Acceleration/deceleration time calculation formula:

Acceleration time = Fn01 x Setting Frequency

Deceleration time = Fn02 x Setting Frequency

Fn03 - Operation mode selection - Factory Setting = 000

Range = 0 : Forward / Stop , Reverse / Stop

= 1 : Run / Stop , Forward / Reverse

60Hz

60Hz

FN03 =

TM2 PIN

TM2 PIN4

Fn3 = 0

Fn3 = 1

4

Forward

Forward

FWD/Sto

REV/Sto

Reverse

4

Reverse

(note)

*

*

Note: Fn03 active only when Fn10 = 1 (external control)

*Reverse command is ignored when Fn22 = 1

Me2 Series

-15-

Run/Sto

FWD/REV

FN03 =

Page 20

Fn04 - Motor rotation direction

Factory Setting = 0

Range = 0 : forward

= 1 : reverse

Note: When Fn22 = 1 : (Reverse disabled),

Fn04 cannot = 1. Keypad indication will display “LOC”.

Fn05 - V/F pattern

Factory Setting = 4; Range = 1- 6

Select one of six fixed V/F patterns :

Application

Fn5 Setting

60 Hz

V/F pattern

General Application High starting torque

4

100

V (%)

B

C

1

3.0

60 120

V (%)

100

B

C

Hz

1

5

3.060120

Hz

Variable torque

V (%)

100

B

C

1

3060120

6

Hz

Application

Fn5 Setting

50 Hz

V/F pattern

General Application High starting torque

1

100

V (%)

B

C

2.5

1

V (%)

100

B

C

Hz

50

120

1

Me2 Series

-16-

2.5

2

Variable torque

3

V (%)

100

B

C

Hz

1

120

50

25 50 120

Hz

Page 21

Fn06 - Frequency upper limit

Factory Setting = 60Hz; Range = 0.0 ~ 200Hz

Fn07 - Frequency lower limit

Factory Setting = 0.0; Range = 0 ~ 200 Hz

Notes: 1. If Fn07 = 0 Hz, and the frequency is equal to 0Hz,

the drive will stop at 0 speed.

2. If Fn07 > 0 Hz, and the frequency is less than or

equal to Fn07, the drive output will = Fn07.

Fn08 - SP1 frequency

Factory Setting = 10 Hz; Range = 0 ~ 200 Hz

Fn09 - Jog frequency

Factory Setting = 6 Hz; Range = 0 ~ 200 Hz

1. When Fn19 or Fn20 = 2 and multifunction input

terminal is on, the drive will operate at SP1 frequency

(Fn08)

2. When Fn19 or Fn20 = 1 and multifunction input

terminal is on, the drive will operate at Jog frequency

(Fn09)

3. The priority of using frequency reference is : Jog >

SP1 > Keypad setting or external control signal

Fn10 - Operation Control

Factory Setting = 0

Range = 0 : Keypad operated

= 1 : External control operated (emergency stop on

the keypad is still active)

Me2 Series

-17-

Page 22

Fn11 - Frequency control

Factory Setting = 0

Range = 0 :Frequency reference is set

via the keypad

= 1 :Frequency reference is set via

the potentiometer or analog

signal on TM2 with no offset

Fn6

0mA0V4mA

Fn11=1

Fn11=2

20mA

10V

( 0 ~ 10V / 0 - 20mA )

= 2 :Frequency reference is set via the

potentiometer or analog signal on TM2

with 20% offset (4-20mA )

Note: When Jog frequency or SP1 frequency is switched

on, the frequency is set via the Jog or SP1 speed. The

arrow buttons on the keypad are disabled during

acceleration /deceleration modes and when the multifunction terminal is active. Original settings will be restored

after Jog or SP1 connection is OFF. Ensure correct

selection of SW1 (refer to 2.2.3).

Fn12 - Carrier frequency

Factory Setting = 5; Range = 1 ~ 10 (4 ~ 16 kHz)

Although IGBT type drives can provide low noise under

normal operation, it is possible that the high carrier

frequency may interfere with external electronic

components (or other drives) or even cause vibration in the

motor. Adjusting the carrier frequency can eliminate these

problems.

FN12 Carrier Frequency FN12 Carrier Fre quenc y

1 4 kHz 6 10 kHz

2 5 kHz 7 12 kHz

3 6 kHz 8 14.4 kHz

4 7.2 kHz 9 15 kHz

5 8 kHz 10 16 kHz

Me2 Series

-18-

Page 23

Fn13 - Torque compensation gain

Factory Setting = 0; Range = 0 ~ 10 %

Drive output will be the B and C voltage points on the V/F

pattern (refer to Fn05) plus the Fn13 setting. This setting

will enhance the output torque. Note: When Fn13 = 0, the

torque boost function is disabled.

Fn14 - Stopping mode

Factory Setting = 0

Range = 0 : Deceleration to stop

= 1 : Coast to stop

If Fn14 = 0

When the drive receives the stop command, it decelerates

to the frequency set point of Fn16. The DC braking will

start at the level set in Fn17. After the time duration (set in

Fn15), the drive will stop.

If Fn14 = 1

The drive output stops immediately after receiving a stop

command. The motor will enter a free running state and

coast to a stop.

Fn15 - DC braking time

Factory Setting = 0.5; Range = 0 ~ 25.5 seconds

Fn16 - DC braking starting frequency

Factory Setting = 1.5; Range = 1 ~ 10 Hz

Fn17 - DC braking level

Factory Setting = 8.0; Range = 0 ~ 20 %

Me2 Series

-19-

Page 24

Fn18 - Electronic Thermal Overload

Factory Setting = 100; Range = 0 ~ 200 %

1. Function of the electronic thermal overload

protecting the motor

1. Motor rated current = Drive rated current x Fn18 or

Fn18 = Motor rated current / drive rated current

Derating

Fn5 = 4,5,6

60 Hz standard motor

%

100

90

60

20 60

Fn5 = 1, 2, 3

50 Hz standard motor

%

Derating

100

90

60

Hz

20 50

Hz

2. When the load is within 100% of the motor rated current,

the drive will operate continuously. When the load

reaches 150% of the motor rated current, the drive will

trip within 1 minute.

3. After the electronic thermal overload is activated, the

drive output is shut off immediately. OL1 will flash on

the keypad. To resume operation, push the RESET

button or activate the external reset terminal.

4. When operating at low speeds, the motor’s heat

dissipation capability is reduced. The electronic thermal

overload activation level is also reduced. To ensure

proper motor protection, choose an appropriate Fn05

setting.

2. Function of the electronic thermal overload

protecting the drive

1. When the load is within 103% of the drive rated current, the

drive will operate continuously. When the load reaches 150%

of the rated current of the drive, the drive will trip within 1

minute.

Me2 Series

-20-

Page 25

2. After activation of the drive’s

electronic thermal overload, the

drive output shuts off immediately .

OL2 will flash on the keypad. To

resume operation, push the

Minute

(1)

(2)

1.0

150

100

RESET button on the keypad or

activate the external reset terminal.

Fn19 - Multifunction input (TM2 - Pin 6)

Factory Setting = 2; Range = 1 ~ 6

Fn20 - Multifunction input (TM2 - Pin 7)

Factory Setting = 5; Range = 1 ~ 6

1. Fn19, Fn20 = 1 : JOG

2. Fn19, Fn20 = 2 or 6 : Preset Speed Control

Fn Setting

Fn 19 = 2

Fn 20 = 6

Fn 19 = 6

Fn 20 = 2

SP1

Terminal

ON OFF FN 08 (SP1)

OFF ON Fn 26 (SP2)

ON ON Fn 27 (SP3)

ON OFF F n 26 (SP2)

OFF ON FN 08 (SP1)

ON ON Fn 27 (SP3)

Reset

Terminal

Output

Frequency

3. Fn19, Fn20 = 3 : External emergency stop signal

When the external emergency stop signal is activated, the

drive decelerates to a stop (ignoring the setting in Fn14).

Keypad flashes E.S. after stop. When the emergency stop

signal is deactivated, turn the RUN switch OFF and then ON

again (if Fn10 = 1) or push the RUN key (if Fn10 = 0). The

drive will resume operation and restart. If the emergency

stop signal is removed before the drive stops, it will still execute

emergency stop.

4. Fn19, Fn20 = 4 : External Base Block (immediate

shut off)

When the external base block signal is activated, the

Me2 Series

-21-

Percentage of

Current

Page 26

drive output immediately shuts off (ignoring the setting

in Fn14). Keypad will flash b.b. after stop. After the base

block signal is deactivated, turn the RUN switch OFF

and then ON again (if Fn10 = 1) or push the RUN key (if

Fn10 = 0). The drive will restart from the starting

frequency.

5. Fn19, Fn20 = 5 : Reset when drive is in fault

condition

Fn21 - Multi-function output

Factory Setting = 3

Range= 1 : Run mode signal

= 2 : At frequency signal

= 3 : Fault signal

Fn22 - Reverse mode lockout

Factory Setting = 0

Range= 0 : REV command enabled

= 1 : REV command disabled

Note: When Fn04 is set to 1 (reverse), Fn22 cannot be set

to 1. Keypad will display “LOC”. Fn04 must be changed to

0 setting (forward) before Fn22 can be set to 1.

Fn23 - Restart after momentary power loss

Factory Setting = 0

Range= 0 : Restart enabled

= 1 : Restart disabled

1. When AC power temporarily drops below the low volt age

protection level the drive will stop immediately. If the power

source returns within 2 seconds, the drive can restart via

speed search (start searching from the previous operating

frequency) or fault, displaying “LV-C”.

2. When Fn23 = 0, if the temporary power loss is less than

2 seconds, the drive will resume operation via speed

search 0.5 seconds after power returns. Fn24 does not

Me2 Series

-22-

Page 27

limit the number of restarts. If the temporary power loss

is longer than 2 seconds, automatic restart will be

determined by the setting of Fn24.

3. When Fn23 = 1, the drive will stop immediately after the

temporary power loss and display “LV -C” on the keyp ad.

The drive will not restart automatically. (Not controlled

by Fn24)

Fn24 - Number of Auto-restart times

Factory Setting = 0; Range = 0 ~ 5

1. When Fn24 = 0, the drive will not automatically restart

if the power loss period is longer than 2 seconds.

2. When Fn24 > 0, the drive will resume operation via

speed search 0.5 secs after power returns. The drive

will accelerate or decelerate to the frequency setting.

3. When the drive is set to decelerate to stop (Fn14) or

DC braking (Fn17) the transient restart procedure is not

performed.

4. When either of the following occur, the auto-restart

counter will be reset:

1. No additional faults (during operation or stop)

occur within 10 minutes of restart.

2. RESET is pressed or external RESET is

activated.

Fn25 - Factory setting - Factory Setting = 000

Range= 010 : Constants set for 50Hz system

= 020 : Constants set for 60Hz system

1. When Fn25 is set to 010, all parameters are restored to

settings for 50Hz operation. The settings of Fn05 and

Fn06 are reset to 1 and 50 respectively. Fn25 is restored

back to 000 after the reset process is complete.

2. When Fn25 is set to 020, all parameters are restored to

the original factory settings for 60Hz operation. The

Me2 Series

-23-

Page 28

settings of Fn05 and Fn06 are reset to 4 and 60

respectively. Fn25 is restored back to 000 af ter the reset

process is complete.

Fn26 - SP2 Frequency

Factory Setting = 20 Hz; Range = 0.0 ~ 200 Hz

1. Fn26 establishes the second of three preset command

frequencies. Used to configure a specific speed for multistep applications.

Fn27 - SP3 Frequency

Factory Setting = 30 Hz; Range = 0.0 ~ 200 Hz

1. Fn27 establishes the third of three preset command

frequencies. Used to configure a specific speed for multistep applications.

Fn28 : Reserved

Fn29 - Software (program) version

- Factory Setting = 1.8

Fn30 : Fault trace

1. Keypad will indicate the sequence of the occurrence

of faults by location of the decimal point:

x.xx = the most recent fault

xx.x = the previous fault

xxx. = the earliest fault in the record

2. When entering the Fn30 function, the x.xx record will

be displayed first. Pressing the /\ button will read out

xx.x then xxx. then x.xx consecutively.

3. When entering Fn30 function, if the RESET button is

pressed, the fault record will be cleared. Indication

display will show -.--, --.- and ---.

4. Example: When the content of fault memory indicates

O.CC, the latest fault was OC-C (over current during

constant speed).

Me2 Series

-24-

Page 29

Me2 Series Installation Manual

Chapter 4 - Fault Codes

4.1 - Failure or Trip which cannot be reset by Reset Key

FAULT CODE CONTENT PROBABLE CAUSE WHAT TO DO

Program Error High electronic noise

CPF

EEPROM error EEPROM defective Replace Drive

EPR

Install RC type suppressor on

all contactor/brake coils

OV

LV

OH

Over voltage

in stop mode

Low voltage

in stop mode

Heatsink overheat

during stop mode

Detection circuit is

damaged

1. Input voltage too low

2. Detection circuit is

damaged

1. Ambient temperature is

high or ventilation is poor

2.Detection circuit is

damaged

Me2 Series

-25-

Replace Drive

1. Correct Input voltage

2. Replace Drive

1. Replace Drive

2. Improve Ventilation

Page 30

4.2 - Failure or Trip which can be reset by Reset Key

but cannot be Auto Reset

FAULT CODE CONTENT PROBABLE CAUSE WHAT TO DO

Over-current

OC

during stop mode

OL1 Motor over-load

OL2 Drive over-l oad

Detection circuit failure Replace Drive

1. Excessive load

2. Incorrect V/f pattern

3. Improper Fn18 setting

1. Excessive load

2. Incorrect V/f pattern

1. Select a larger HP unit

2. Select correct V/f pattern

3. Adjust Fn18 according to

instructions

1. Select a larger HP unit

2. Select correct V/f pattern

Me2 Series

-26-

Page 31

4.3 - Failure or Trip which can be Auto Reset or reset

by Reset Key

FAULT CODE CONTENT PROBABLE CAUSE WHAT TO DO

Over-current

OCS

during start

Over-current

during

OCA

acceleration

Over-current

OCC

during constant

speed

Over-current

OCd

during

deceleration

Over-current

OCb

during braking

Over-voltage

during constant

OVC

speed operation

Low Voltage

during constant

LVC

speed

Overheat during

OHC

constant speed

1. Motor is shorted

2. Motor is grounded

3. Transistor module

damaged

1. Acceleration time setting

too short

2. Wrong V/f pattern

3. Motor exceeds unit rating

1. Transient loading

2. Input voltage fluctuations

1. Deceleration setting

too short

DC braking frequency,

braking voltage, or braking

time setting too high

1. Deceleration time is set

too short or load inertia is

too high

2. Input voltage fluctuations

1. Input voltage too low

2. Input voltage fluctuations

1. Load is too great

2. Ambient temperature too

high or poor ventilation

1. Inspect/repair motor

2. Remove grounding point

3. Replace Drive

1. Extend acceleration time

2. Select correct V/f pattern

3. Select larger HP unit

1. Check load condition

2. Install a reactor between the

power supply and the Drive

1. Extend deceleration time

Reduce settings of Fn15,

Fn16, or Fn17

1. Extend deceleration time

2. Correct line voltage problem

1. Correct input voltage

2. Correct line voltage

1. Check load

2. Limit ambient temperature

or improve ventilation

Me2 Series

-27-

Page 32

4.4 - Operation Stop Indications

FAULT CODE CONTENT

SP0

Zero speed stop

Keypad

SP2

emergency stop

External

E.S.

emergency stop

External BASE

b.b.

BLOCK

An SP0 fault code can only occur when Fn7 is set to 0.

If an SP0 fault code occurs and Fn11=0, use the keypad to

increase the speed above 1 Hz.

If an SPO fault code occurs and Fn11=1, increase the

value of the external analog signal.

If Fn10 = 1 and the STOP key on the keypad

is pressed during operation, the drive will

stop according to the setting in Fn 14 and stop.

Keypad will flash E.S. aft er stop.

(Refer to instruction fo r F n19 for details.)

When the external emergency stop si gnal is activated

via the multi-function input terminal, the drive wi ll

decelerate and stop. Keypad will flash E.S. after stop.

(Refer to instruction fo r F n19 for details.)

When the external BASE BLOCK signal is activated

via the multi-function terminal, the drive output will

stop immediately and flash b.b. for indication.

(Refer to instruction fo r F n19 for details.)

WHAT TO DO

4.5 - Operation Error Indications

FAULT CODE CONTENT PROBABLE CAUSE WHAT TO DO

Motor directi on

LOC

Keypad operation

ER1

Parameter setting

ER2

1. Attempted to reverse

direcion when Fn22 = 1

locked

2. Attempted to set Fn2 2 to

1 when Fn04 = 1

1. Press UP or DOWN arrow

keys when Fn11 = 1 or

under SP1 operation

2. Attempted to to change

Fn29

error

3. Attempted to change

parameter that cannot be

changed during run mode.

(Refer to parameter list)

1. Fn6 < or = Fn7 1. Change so Fn6 > Fn7

error

1. Change Fn22 to 0

2. Change Fn04 to 0

1. Use UP or DOWN

arrow keys to adjust

frequency setting after

changing Fn11 = 0

2. Do not change Fn29

3. Change function during

stop mode

Me2 Series

-28-

Page 33

Me2 Series Installation Manual

Chapter 5 - Other Information

5.1 - Selecting AC Line/Load Reactors

Model

ME2-2P2-M 3.0 7.0

ME2-2P5-M 5.2 4.2

ME2-201-M 9.4 2.1

ME2-202-M 19.0 1.1

ME2-203-M 25.0 0.71

Current Value ( A ) Inductance ( m H )

Reactor

Me2 Series

-29-

Page 34

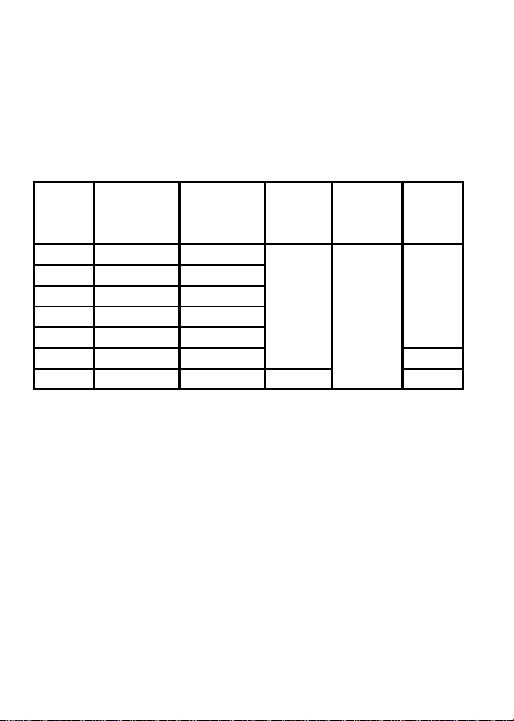

5.2 - Record of Settings

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Customer

Application

Address

Fn## Fn## Fn##

Fn00 Fn11 Fn22

Fn01 Fn12 Fn23

Fn02 Fn13 Fn24

Fn03 Fn14 Fn25

Fn04 Fn15 Fn26

Fn05 Fn16 Fn27

Fn06 Fn17 Fn28

Fn07 Fn18 Fn29

Fn08 Fn19

Fn09 Fn20

Fn10 Fn21

Model

Telephone

Value ValueValue

Fn30

Loading...

Loading...