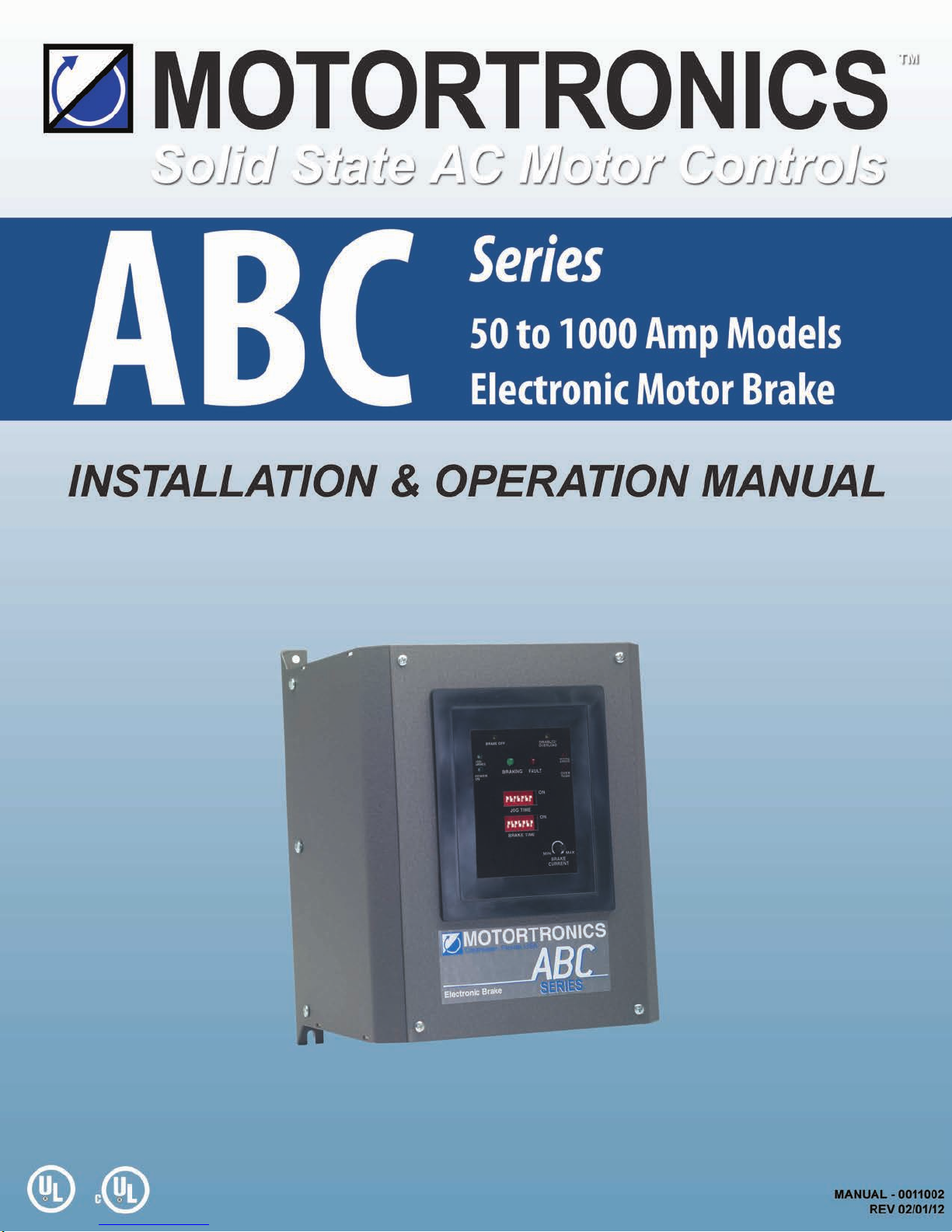

Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Page 2

Motortronics

Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1 Introduction ............................................................................................................................................... 2

1.1 General ............................................................................................................................................... 3

1.2 Theory of Operation ............................................................................................................................ 3

1.3 Braking Sizing and Selection .............................................................................................................. 3

1.4 Applications ........................................................................................................................................ 4

1.5 Where Mechanical Brakes Should be Used ....................................................................................... 5

1.6 ABC Model Numbers, Ratings and Dimensions ................................................................................. 6

2 Operation ................................................................................................................................................ 12

2.1 Sequence of Operation ..................................................................................................................... 12

2.2 Fault Conditions ................................................................................................................................ 14

2.3 Mechanical Brake Control ................................................................................................................ 15

3 Installation ............................................................................................................................................... 16

3.1 Fault History ...................................................................................................................................... 16

3.2 Fault Code Table .............................................................................................................................. 16

3.3 Event Records .................................................................................................................................. 16

4 Wiring ...................................................................................................................................................... 17

4.1 Introduction ....................................................................................................................................... 17

4.2 Line and Load Connections .............................................................................................................. 17

4.3 Control Connections ......................................................................................................................... 20

5 Adjustements ......................................................................................................................................... 23

5.1 Time Adjustment Procedures ........................................................................................................... 23

5.2 Jog Time Adjustment ........................................................................................................................ 23

5.3 Brake Time Adjustment .................................................................................................................... 24

5.4 Brake Current Adjustment ................................................................................................................ 24

Table of contents

6 Start-Up................................................................................................................................................... 26

6.1 Start-up Check List ........................................................................................................................... 26

6.2 Equipment ......................................................................................................................................... 26

6.3 Setup Sequence ............................................................................................................................... 26

6.4 Check Normal Sequence of Operation ............................................................................................. 26

APPENDIX A: TECHNICAL SPECIFICATIONS ........................................................................... 27

WARRANTY INFORMATION ....................................................................................................... 29

Page 3

Motortronics

Page 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Your Role in Product Safety

This equipment is designed and manufactured to the highest standards to provide safe and reliable operation

for its intended use. Only qualified personnel should install, maintain, and service this equipment, and only after

reading and fully understanding all of the information in this manual. All instructions should be strictly followed.

All Warnings, Cautions, and Notes must be taken into account for your particular installation. Users should

consult Motortronics or a Motortronics distributor/service centre if there are any questions.

All installation instructions may be superseded by applicable local, regional, or national electrical codes.

Drawings, application information, and technical representations included in this manual are for typical

installations, and should not in any way be considered specific to your application or conditions. Consult

Motortronics for supplemental information if necessary.

Contents of this manual are believed to be correct at the time of printing. In following with our on-going

commitment to meeting customer needs and developing our products to suit them, Motortronics reserves the

right to change specifications of this product and/or the contents of this manual without notice. As a result,

supplemental data sheets and/or drawings may be associated with this equipment. Please contact Motortronics

and have the unit serial number available if you notice conflicts with what is depicted in the manual and what is

installed in the field.

Phasetronics (dba Motortronics) accepts no liability for any consequences resulting from inappropriate, negligent,

or incorrect installation, application, adjustment, or maintenance of this equipment.

Notice Label

Explanation:

W

ARNING!

Warning labels such as this denotes specific

area of the

manual.

These

statements

are

intended

concerns

to be

for

life/

safety/damage

followed without exception.

issues associated with this

CAUTION!

Caution labels are

under

circumstances as described.

responsible

intended

for

identifying

to alert the user to

These items are

the

applicable installa

specific

critical

tion

issues.

issues that MAY cause damage or

in some

installations

but

not

personnel

all. The user is

risks

NOTE: Notice labels are

to the proper use and

intended

long

term

to alert the user to issues that require particular

reliability

of the

equipment.

attention

with regard

Page 4

Motortronics

Page 3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1 About the Motortronics ABC Series

1.1 General

The ABC Series is a solid state DC injection brake for stopping three- phase AC induction motors. This full-wave

DC brake design offers smooth, low peak level braking for quiet, steady operation and optimal performance.

Designed to handle even high inertia loads, the ABC Series eliminates costly and potentially dangerous "coastto- stop" times. A built-in microprocessor provides system supervision that includes digital timing control for

jogging and braking.

The integral Operator Interface Module provides LED indication of the unit's operating status and easy

adjustments for quick setup. Standard features include interlocks and mechanical brake release relays, a brake

disable input and zero speed sensing with override.

1.2 Theory of Operation

Incoming AC power is fed to terminals L1 and L2 directly from the line side of the motor starter terminals and is

converted to DC within the ABC Series. Once the motor starter has been turned off (opened) and the residual

energy in the motor has dissipated, the DC current from the ABC Series is applied (injected) to starter terminals

T1 and T2 respectively. This creates a stationary magnetic field in the AC motor stator windings.

The braking torque will increase in proportion to the amount of current allowed to flow. (The DC injection level

can be adjusted using the Brake Current Potentiometer on the operator interface module. This modulates the

applied voltage based upon an "RMS" closed loop current feedback signal from the integral sensors.) The rotor

then pulls into alignment with this stationary field and brings the load to a stop faster than if it coasted to a stop.

1.3 Brake Sizing and Selection

ABC Series brakes are suitable for use in most AC motor applications where coast-to-stop times are undesirable

or unacceptable. The ABC Series is a current controlling brake, so various sizes of brake units can be applied to

various motor sizes. Because DC injection means applying power to the AC motor after turning it "Off", motor

heating (although minimal) will continue during the braking cycle and should be considered when selecting the

motor. AC motor manufacturers recommend that each braking cycle over 100% FLA be considered as an

additional starting cycle when calculating the starts- per-hour ratings for the selected motor.

If the selected ABC

start cycles for these calculations (and 300% FLA = 3

exceed 400% of the motor nameplate FLA without first consulting the motor manufacturer. Additional guidelines

for applying ABC Series brakes follow:

Series

is sized to deliver 200% of motor rated current, consider each brake cycle to be 2

"starts"

per brake). Never size any DC injection brake to

Page 5

Motortronics

Page 4

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.3.1 Standard Duty Sizing

Applying an ABC Series brake that is rated for <115% of the

maximum length of braking time without exceeding the thermal capacity of the stator windings. Since current is

controlled by the ABC

impedance decreases with speed. Braking torque will be highest at the beginning of the cycle, and can be as

much as 100% of the FLT (Full Load Torque) when set to motor FLA.

As the motor slows, the braking torque slowly decreases, reducing the mechanical stresses as much as

possible. Sizing a brake in this manner is typically good for machine tools, saws, conveyors, lumber machinery,

and most chippers where the coast-to-stop time does not exceed 5 minutes. Stop times vary greatly with load

and friction, but can be expected to be 1/2 of the coast-to-stop time or less. Keep in mind that the maximum

brake time is setting is 127 seconds. In heavily loaded, high inertia machines and long coast-to-stop times, the

Standard Duty model may not stop the load. Consider using the Extra Duty rating instead.

Series

throughout the braking cycle, braking torque will vary as the motor circuit

FLA

(Full Load Amp) rating of the motor allows

1.3.2 Extra Duty Sizing

For heavier machine loads such as large chippers, punch presses and other flywheel based machines, selecting

an ABC Series brake based on 200-250% of the motor nameplate FLA allows faster braking. The maximum

developed braking torque can be as much as

200% of the motor rated Full Load Torque. In this case, the load can typically stop in twice the Across-the-Line

starting time. Duty cycling of the motor is a much more important consideration in applications since additional

thermal stresses due to higher current levels are applied to the motor.

1.3.3 Custom Sizing

Extreme loads (such as overhauling conveyors or large centrifuges), or short stop times (approaching the

across-the-line starting time of the motor) may require sizing the ABC Series for 300% of the motor FLA or

greater, and should be done with careful consideration of motor heating, duty cycle, and limitations of

mechanical stress on the drive train components.

1.3.4 Emergency Stopping

An ABC Series brake used in conjunction with a mechanical brake should be considered if the stop times must

be equal to or shorter than the across-the-line start time, consider using and ABC

with a mechanical brake.

Series

brake in conjunction

Page 6

Motortronics

Page 5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.4 Applications

The ABC Series electronic brake is ideal for machine and process equipment control applications for efficiency,

increased safety, and reduced equipment maintenance costs. Among the benefits:

Efficiency

batch loading, or maintenance shutdowns. Productive time increases as overall operating costs decrease

because the load stops more quickly. The ABC Series eliminates the common practice of jamming the load to a

stop which seriously reduces the life and effectiveness of saw blades, molding heads, and knives.

Increase Safety by eliminating the need to "jam-stop" equipment. This will prevent any personnel injuries

caused by kickbacks and broken blades. Use the ABC Series in conjunction with safety inter- lock devices to

stop the motor as quickly as possible, reducing the risk of contact with dangerous rotating elements of

machinery. Prevent premature wear or component failure and eliminate the need for hasty repairs that can put

maintenance personnel in potentially dangerous situations. ABC Series brakes can be used as part of a system

to facilitate OS H A General

exposed to hazardous moving parts. They can also be utilized to satisfy braking requirements of the British

Columbia Workers Compensation

as planers, chippers, and hogs.

Reduce maintenance costs by using the ABC Series. Eliminate the need to plug-reverse a load and reduce

the associated damage to gear boxes and other power train components. The ABC

or slow down the load in one direction before reversing to the other. On machines where mechanical brakes are

used to stop or hold a load, use the ABC Series to stop it first, then set the mechanical brake as a "parking

brake". This eliminates the normal wear and tear to the brake pads or shoes. On loads such as vibrating

feeders, screens, or separators, damage from mechanical harmonics that occur during coast-down can be

eliminated by using an ABC Series. It allows the motor/load to quickly pass through any dangerous speeds and

come to a stop.

is improved because you no longer have to wait through long coast-to-stop times for blade changes,

Industry Standards (

Amendment Act

29 CFR1910 Subpart O) requiring that workers not be

(Book 3 Part 27.42) for rotating knife machinery such

Series

can be used to stop

1.5 Where Mechanical Brakes should be used

Power loss

the braking cycle. If the incoming line power is lost from the utility, an upstream circuit protective device trips, or

an emergency shutdown routine is initiated, no braking will take place. If braking is still necessary for safety

reasons (even in the event of a power failure), consider using mechanical brakes as a backup device. Under

normal operation conditions, the ABC Series stops the load and the mechanical brake holds it.

during braking

- The ABC Series, like all DC injection brakes, requires power to be applied during

Holding

motor comes to a complete stop and therefore CANNOT BE USED AS HOLDING BRAKE. If braking must be

applied continuously while the load is at rest, mechanical "Parking Brakes" are required. The ABC Series

includes a Mechanical Brake Release Relay to facilitate proper coordination of the mechanical brake in these

applications.

Stop times

energy to dissipate from the windings before DC current can be applied (otherwise damage to the brake or

circuit devices may occur). The length of this "wait state" depends on the motor's residual magnetism and the

motor frame size, but can be as much as 5 seconds. This, combined with the limits on braking torque, makes DC

injection braking ineffective if braking time must be shorter than the starting time (Across-the-Line).

the load after it comes to a stop - All DC injection brakes inherently lose braking torque when the

shorter

than start times - Like all DC injection brakes, the ABC Series waits for the residual motor

W

ARNING!

DC

Injection

Mechanical Brake

use in these

brakes cannot be used for

Release Relay that can be used to

applications.

holding

a load after

coordinate

it

comes to a stop. The ABC Series

the

operation

of a

mechanical

includes

brake for

a

Page 7

Motortronics

Page 6

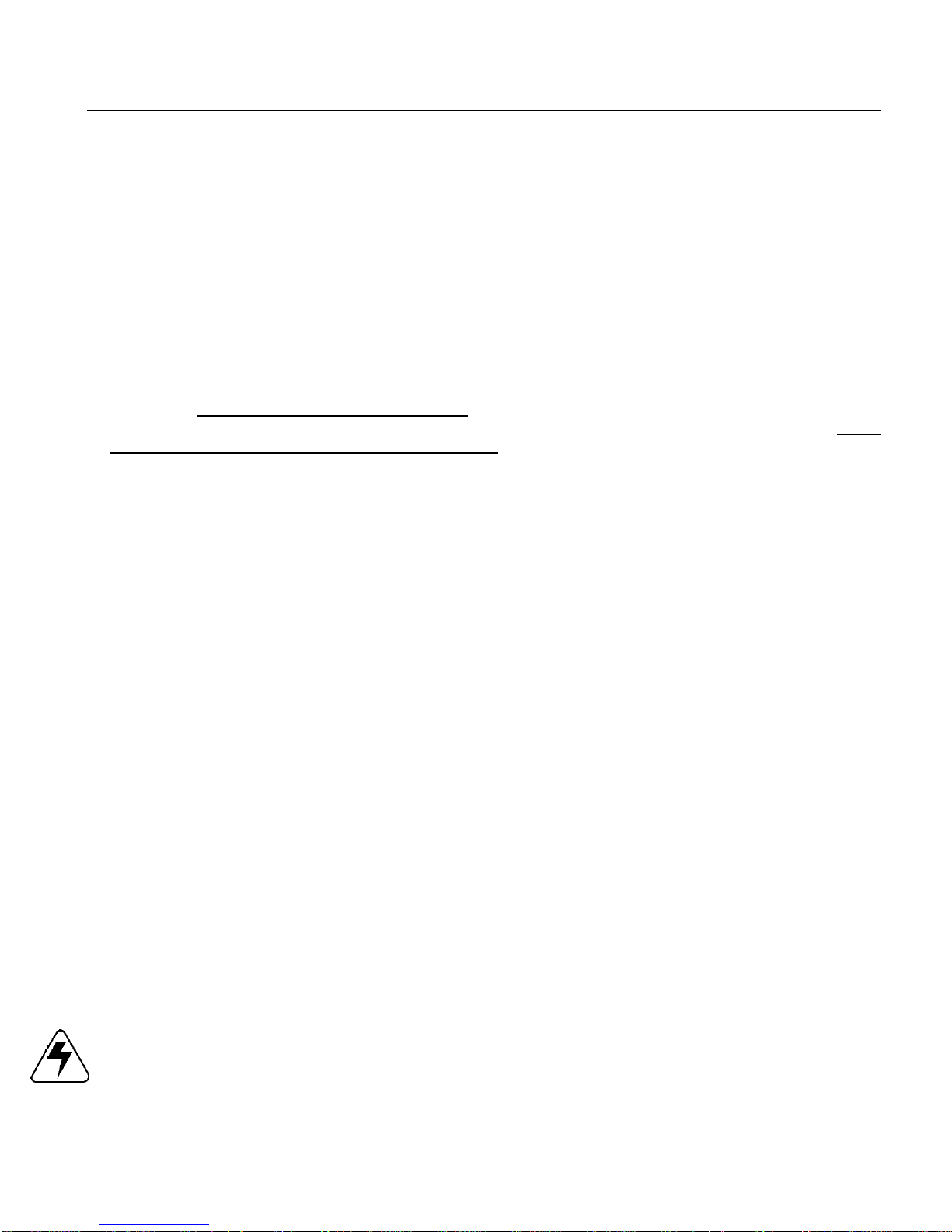

ABC - 200 - - E

Voltage

240 = 208 – 240V, 400 = 380 – 415V

480 = 440 – 480V, 600 = 575 – 600V

Enclosure

P = Panel Mount

E = NEMA 4/12 Sealed

Max. Brake Amps

50 – 1000 A.

ABC SERIES

Model

Number*

Max

Amps

Typical Horsepower Usage

Dimensions

208 V

240V

480V

600V

Panel

Dim Ref.#

NEMA 4/12

Dim Ref. #

Std.

Duty

Extra

Duty

Std.

Duty

Extra

Duty

Std.

Duty

Extra

Duty

Std.

Duty

Extra

Duty

ABC-50

50

15

7.5

20

10

40

25

50

30 2 7

ABC -100

100

30

20

40

25

75

50

100

60 2 7

ABC-200

200

75

40

75

50

150

100

200

125 3 8

ABC-300

300

100

60

125

75

250

150

300

200 4 9

ABC-400

400

150

75

150

100

350

200

400

250 4 9

ABC-550

550

250

125

200

150

500

300

600

350 5 10

ABC -800

800

350

200

350

200

700

450

900

500 5 10

ABC-1000

1000

400

250

400

300

900

500

1000

600 5 10

Dim

Ref. #

Dimensions (Inches)

A B C D E

F

2

10.5

7.9

7.2

10

6.8

0.21

3

16.5

10

10

15.9

9

0.28 4 16

16

10

15

15

0.5 5 21

26

10.4

20

25

0.5 6 16

12 9 14.5

10.5

0.5 7 20

16 9 18.5

14.5

0.5 8 24

20

16

22.5

18.5

0.5

9

36

24

16

34.5

22.5

0.5

10

36

30

16

34.5

28.5

0.5

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

1.6 ABC Series Model Number, Rating and Dimensions

NOTES:

1. Never exceed the Full Load Amp rating of the motor without checking the motor manufacturer's data

with regards to appropriateness of the application and duty cycle.

2. If duty cycle is not known, Motortronics recommends using the Extra Duty Brake since braking current

can be adjusted down to meet the actual load requirements.

Page 8

Motortronics

Page 7

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

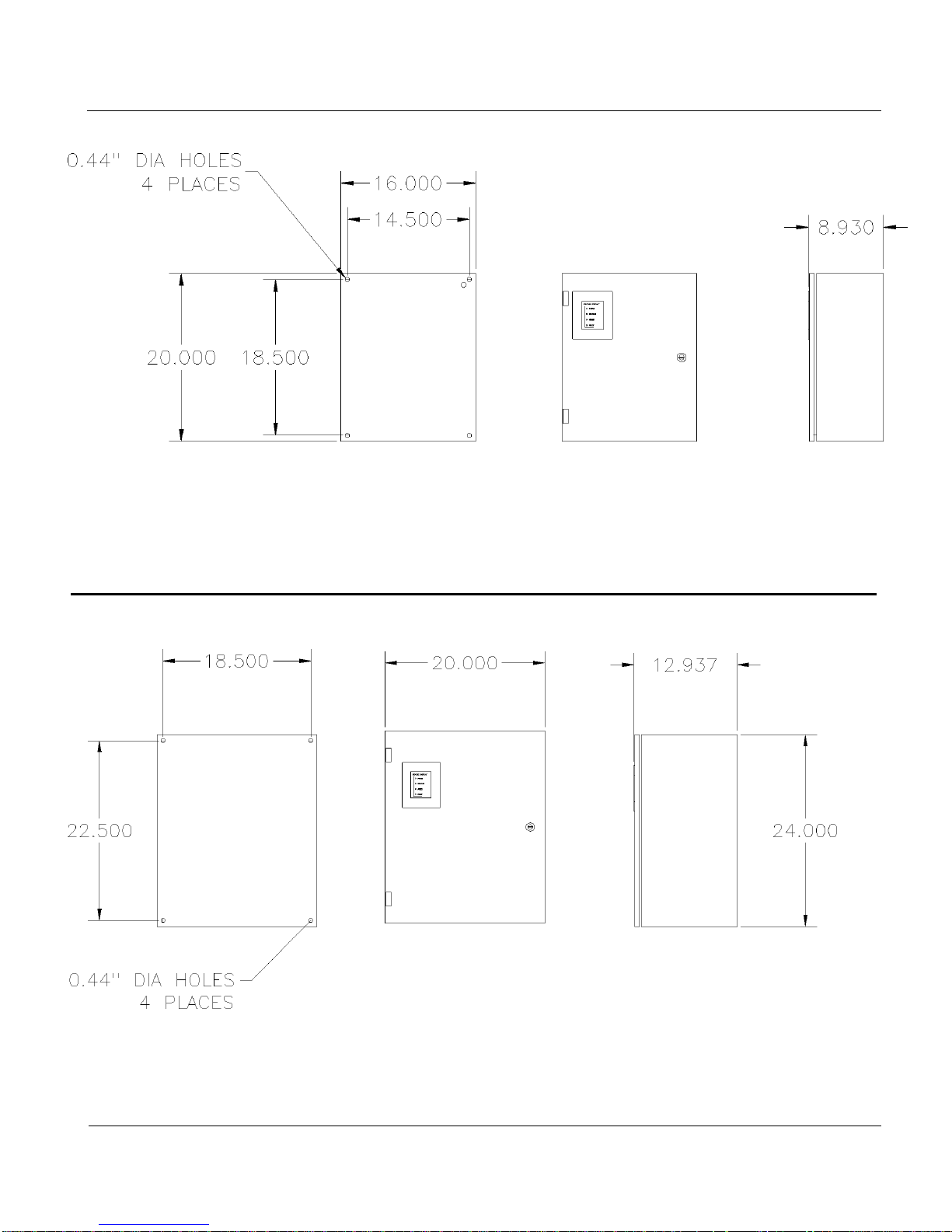

N4/12 Outline: ABC-50/100-E

N4/12 Outline: ABC-200-E

Page 9

Motortronics

Page 8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

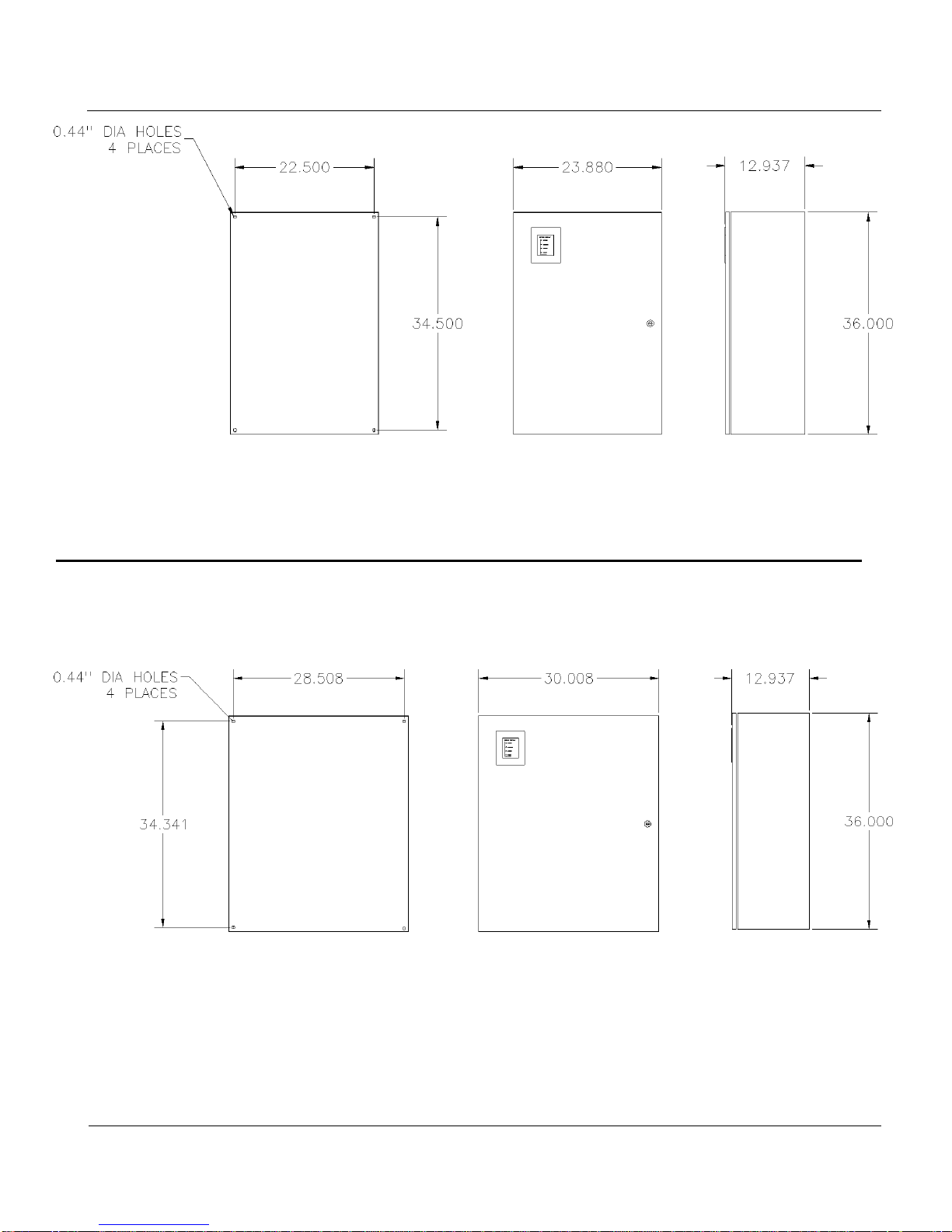

N4/12 Outline: ABC-300/400-E

N4/12 Outline: ABC-550/800-E

Page 10

Motortronics

Page 9

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Panels Outline: ABC-50/100

Panels Outline: ABC-200

Page 11

Motortronics

Page 10

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Panels Outline: ABC-300/400

Panels Outline: ABC-550/800

Page 12

Motortronics

Page 11

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Panels Outline: ABC-1000

Page 13

Motortronics

Page 12

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2 Operation

2.1 Sequence of Operation

The ABC Series brake becomes "Armed" when the motor starter turns "On” and then braking occurs when the

starter is turned "Off". An Operator Interface Module has two large LEDs to indicate "Braking" or "Fault"

condition, plus six smaller LEDs to indicate the following modes of operation:

2.1.1 “Power On”

The ABC Series brake is self-powered from the available motor branch circuit as derived from Terminals L1 and

L2. If fuses are used, this LED will indicate a blown fuse condition in either of these circuits by being off when

power is applied to the starter (see section 4.2.1). This LED does NOT indicate motor starter or ABC Series

brake unit operational status.

2.1.2 Jog / Armed

The ABC Series receives a Brake Command from an input wired to the motor starter which indicates the starter

status (see section 4.3.1). The ABC Series can be programmed to wait a period of time before going into the

"Armed"

time with- out the braking cycle interfering. (The "Jog" time is set via the "Jog Time" dip switches.) This LED will

flash once per second until the end of the jog time. If the Motor Starter is turned off again while the ABC Series

is still in the "Jog" mode, the brake will NOT arm and DC injection will not take place (setting this time to zero

will turn off this feature). After the "Jog Time" expires, the ABC Series will enter the "Armed" mode (indicated

when the JOG/ARMED LED illuminates in a steady state). The ABC Series is now ready to begin DC injection

braking the next time the motor starter is turned off. The "Armed" mode has no time limit and will be

maintained for the duration of the motor run time.

condition using the "Jog" feature. This feature allows for user setup and testing of systems during the jog

Page 14

Motortronics

Page 13

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.1.3 “Braking”

The ABC Series will enter the braking mode when the motor is given a stop command after being "Armed" (see

"JOG / ARMED" above). To prevent damaging current spikes, a factory programmed delay allows the existing

motor magnetic field to decay before DC is applied (see section 5.1). During the "BRAKING" mode, a set of N.C.

interlock contacts change state and disable the motor starter control circuit during the braking cycle (see section

4.2.2).

The ABC

Interlock Relay and monitors the Zero Speed Sense Circuit. Braking will continue until the first one of three

events occurs: 1) the Zero Speed Sense circuit determines the motor has stopped, 2) the "Brake Time" expires,

or 3) the unit receives a "Brake Disable" signal input. When braking is complete, the

Interlock Relay and is ready for another cycle.

Series

begins injecting a regulated DC braking current and simultaneously digitally times, controls the

ABC

Series releases the

2.1.4 Brake OFF

This LED illuminates whenever the ABC Series is not actively braking (either because the motor is on or the

previous braking cycle has been completed). The ABC Series provides a built-in, closed-loop sensing circuit that

accurately determines when the motor has stopped based on the subtle signals received from the unused motor

winding. If the Zero Speed Sensing circuit determines that the motor has come to a stop before the Brake Time

has expired, it will override the brake time setting and shut the ABC Series off. The "BRAKE OFF" LED will then

illuminate. NOTE: Since the Brake Time may expire prior to the Zero Speed override coming into play, this

circuit should not be used as a true Zero Speed indicator.

W

ARNING!

The ABC Series DC

will result in the

to a stop is

pro

vided as a backup system. The ABC Series brake offers a Me

for this

critical regardless

purpose.

loss

Injection

of

Brake

braking ability,

requires

of the

AC power for

which can be

avail

ability

hazardous

of

brak

electrical

chanical

ing. Power loss before or

to

personnel and/or equipment.

power,

mechanical braking should

Brake Release Relay

during braking

If

braking

be

specifically

Page 15

Motortronics

Page 14

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.2 Fault Conditions

The “FAULT” LED will illuminate when any of the following conditions occur:

2.2.1 “Disabled”

The "DISABLED" mode is activated when the ABC Series receives a command on the Brake Disable input (a

N.O. dry contact at TB1) (see section 4.3.2). This mode can be used to remove the electronic brake from the

system, and is useful in applications that only require braking at certain times during the process and during

system setup. Note: The ABC Series is a "smart brake" and will sense a running motor and automatically arm

itself if released from the "DISABLED" mode. Under these circumstances, the ABC Series will go through the

"JOG" and

normal ready state.

"ARMED"

sequence again. If the unit has determined the motor is stopped, the brake will return to the

NOTE: The ABC Series

brake unit is

disabled

Mechanical

during

the

Brake Release Relay will

braking mode.

set

the

mechanical

brake if the ABC Series

2.2.2 “Wiring Error”

The ABC Series unit will recognize when the interface connections or monitored signals are not correct with

respect to the proper operation sequence. If the brake detects a miswire or an improper sequence of events, it

will "self-disable" to prevent any conflicts with the existing systems and indicate "WIRING ERROR". If this

occurs, the "Fault" LED and "Wiring Error" LEDs will illuminate. Once the miswire or wrong sequence is

corrected, the brake will automatically enable itself and resume normal operation.

2.2.3 “Over Temp”

The ABC Series has thermal sensors built into the heat sink assembly. If the heat sink approaches temperatures

too high for the SCRs, the sensors will cause a Fault and illuminate the "Fault" and "Over Temp" LEDs.

Page 16

Motortronics

Page 15

OPERATION

RELAY STATUS

Power On

No Change (de-energized)

Jog / Armed

Energizes (follows motor starter coil)

Braking

Remains energized

Braking Time Completed /

Zero Speed Override

De-energizes

Disabled – Before or During Jog / Armed

Remains Energized (follows motor starter coil)

Disabled – During Braking

De-energizes

Fault

De-energizes

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

2.3 Mechanical Brake Control

The ABC Series includes a Mechanical Brake Release Relay that can be utilized to control an electromechanical brake coil. This relay has a Form “A” contact (1 N.O.) that changes state as follows (see section

4.3.4):

Page 17

Motortronics

Page 16

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

3 Installation

3.1 Receiving and Unpacking

Upon receipt of the product you should immediately do the following:

• Carefully unpack the unit from the shipping carton and inspect it for shipping damage.

• Verify that the model number on the unit matches your purchase order.

• Check all electrical terminals to be sure screws are tight.

3.2 Initial Unit Inspection

Complete a visual check of the unit for damage which may have occurred during shipping and handling. Report

any damage immediately and file a claim with the freight carrier within 15 days of receipt. Do not attempt to

continue installation.

CAUTION!

Do not operate or

may result in

install

per

sonnel injury or

the ABC Series Brake if it appears to be damaged or

equipment damage.

visually

defective. Doing so

3.3 Location

Proper location of the ABC Series is necessary to achieve specified performance and normal operation lifetime.

The unit should always be installed in an area where the following conditions exist:

• Ambient operating temperature:

Chassis unit: 0 to 50°C (32 to 122°F)

Enclosed unit: 0 to 40°C (32 to 104°F)

• Humidity: 5 to 95% non-condensing

• Free from metallic particles, conductive dust and corrosive gas

• Free from excessive vibration (below 0.5G)

• Open panel units must be mounted in the appropriate type of en- closure. Enclosure size and type must be

suitable to dissipate heat generated by the unit. Contact factory for details.

3.4 Mounting and Cleaning

The unit is air cooled and must be properly mounted to allow for unrestricted airflow across the heat sink. The unit

should be mounted with the heat sink fins in a vertical plane, with a minimum of five (5) inches (127mm) of free

space around the unit for adequate ventilation. The ambient air should be free of any contaminants which can

clog louvers or coat the unit. As with all electrical equipment, the unit must be protected from water and

condensing humidity to prevent damage to the unit. In damp or cold environments, space heaters may be

required.

W

ARNING!

Remove All Sources of Power Before Cleaning the

should be cleaned on a regular basis to ensure proper cooling. Do not use any chemicals to clean the

unit. To remove surface dust, use 80 to 100 psi clean, dry compressed air only. A three inch, high

quality, dry paint brush is helpful to loosen up the dust prior to using compressed air on the unit.

Unit.

In dirty or contaminated atmospheres the unit

Page 18

Motortronics

Page 17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4 Wiring

4.1 Introduction

• Installation of the brake unit should be done by properly qualified personnel.

• Check local and other applicable codes to ensure that all installation requirements are met prior to operation.

• Prior to beginning the installation, verify that the motor and brake unit have the same voltage ratings.

• Check the unit to verify that it is rated for the appropriate current (approximately equal to the motor FLA if

sized for Standard Duty - see section 1.3).

W

ARNING!

Do not service

shock hazard,

terminals, enclosure

equipment

disconnect

and

with voltage a

main power before

control

panel

to meet local

pplied!

working

Unit can

codes.

be

source of fatal

on the unit. Warning labels must be attached to

electrical shocks!

To avoid

4.2 Line and Load Connections

Power conductors for the Line and Load connections should be, at a minimum, sized at 125% of the current

rating. Brake sizing and duty cycling should be considered when determining if conductors should be oversized

for your application. For example, high torque, fast stop applications with maximum duty cycle may require

conductors sized for the maximum output capability of the ABC Series, and motor lead wires should match.

Page 19

Motortronics

Page 18

UNIT RATING

SCPD

SCPD SIZED AS % OF ABC

UNIT RATING

10 – 100 Amps

Class RK5 Fuse

Class J Fuse

Circuit breaker

No greater than 250%

No greater than 400%

No allowable (fuses required)

200 – 1000 Amps

Class RK5 Fuse

Class J Fuse

No greater than 250%

No greater than 400%

Circuit breaker

No greater than 250%

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.2.1 Line Power Connections

Connect the line leads to the input terminals L1 and L2 provided on the unit. The line power must be supplied

from a source with suitable Short Circuit Protective Devices (SCPD) conforming to local and national electric

codes. Additional fusing is necessary only when the motor circuit is fused at a level too low to protect the ABC

Series per code. Recommendations for commonly available SCPDs are as follows:

W

ARNING!

Many motor safety

disconnect

switch

disconnect switches

with one that is rated for DC voltage at the motor line

alternative, disconnect incoming line

motor

precaution

circuit during braking,

may result

in

damage to the

and post

are not rated to

power before

warning

disconnect

labels at all affected devices. Failure to observe this

and /or

inter

opening

bodily injury

rupt DC

current.

any load side

Replace any load side safety

voltage

rating or greater. As an

disconnect switches

in

the

Page 20

Motortronics

Page 19

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.2.2 Load Power Connections

Connect the motor leads to the output terminals T1 and T2 provided on the unit. The unit will operate on either a

Wye or a Delta connected motor. An additional control wire must be run from motor lead T3 of the starter to the

voltage sensing circuit of the ABC

Series. The terminal for this is marked "T3". This terminal carries very little

current so #20 wire (or higher) can be used. Fuse protection ad- equate for the field wiring used must be

provided per code.

NOTE: If the ABC Series brake is being used with 2-speed, Wye- Delta or Reduced Voltage starter,

factory

for

additional

load

connection information.

consult

CAUTION!

Power Factor

used with an

include

Correction Capacitors should

ABC

Series brake. PFC

a separate

isolation

contactor

NOT be

connected

Capacitors should

.

to the load side of the motor starter when

only be

connected

to

the

line side and must

Page 21

Motortronics

Page 20

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.3 Control Connections

Control wire should be run in a separate conduit from power lines (twisted, shielded cable should be adequate).

Whenever possible, conduits containing control and power conductors should cross at right angles to each

other. Control connections are made to terminal blocks mounted on the printed circuit boards inside the unit

case. TB1 is on the Logic Board (see page 11) with the terminals for Starter Monitor (Brake Command) and Brake

Disable. TB2 is located on the Power Board, and contains terminals for the Interlock Contacts and Mechanical

Brake Relay.

W

ARNING!

The motor starter must never be operated

damage to the

unit

may

result.

manually

when

the

brake unit is

connected.

Blown fuses and/or

4.3.1 Starter Monitor Input

Provides a brake command signal from the motor starter (refer to section 2.1.3). Connect either the normally

open, or normally closed (user preference) dry auxiliary contact on the motor starter to TB1, terminals 1 and 2 on

the logic board. To utilize a normally closed contact select Jumper X1 (factory default). For normally open contact, move the Jumper to X2. For reversing starters, use 2 N.O. contacts in parallel or 2 N.C. contacts (1 from

each contactor) in series to this input. Circuit voltage potential: 15VDC maximum.

Page 22

Motortronics

Page 21

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.3.2 Brake Disable Input

Disables electronic braking functions before, during, or after operation (refer to section 2.2.1). To utilize this

feature, wire a N.O. dry contact to TB1 terminals 3 and 4 on the logic board. The disable feature will activate as

long as the contact is closed, and will resume operation sequence only when the disable command is released

(i.e. the contact is opened). Once the ABC Series has resumed operation, it will evaluate the status of the motor

and re-enter the "JOG" mode if conditions are

correct.

Circuit voltage potential: 15VDC maximum.

Note: The Brake Disable can and

thermal

overload

by

wiring

will prevent the brake from

should

be used to disable the

normally

operating

open

contacts

if a motor

from the

over-

ABC

load trip

Series brake in the event of a motor

overload

relay to these

termi

nals. This

condition occurs.

Page 23

Motortronics

Page 22

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

4.3.3 Interlock Contacts

The ABC Series unit must be interlocked with the motor starter coil circuit to disable the motor starter during the

braking cycle for proper operation (refer to 2.1.3). Two sets of "FORM C" contacts are provided on TB2 on

power board to interlock the motor starter with the brake. Terminals 1, 2, and 3 are the first set and terminals 4,

5, and 6 are the second. Use both sets for reversing starters, each in one of the contactor coil circuits. The

second set may be used as a status indicator in non-reversing starter applications. Never connect the interlock

contacts parallel to the contactor coil or across the power line. Circuit voltage potential: same as starter control

circuit, 240VAC maximum.

W

ARNING!

If this

the unit may be

wiring

is done

voided.

incorrectly

or not at all, severe damage

to

the unit may occur and the

warranty

on

4.3.4 Mechanical Brake Release Relay

The ABC Series brake unit can work in conjunction with a mechanical brake by interfacing with the motor and

allowing for mechanical brake control. The ABC Series brake can be used for stopping, and the mechanical

brake can be used for holding. The Mechanical Brake Release contacts are N.O. relay contacts rated for 5A,

250VAC and are located at terminals 7 and 8 of TB2 on the Power Board (see section 2.3 for additional

operating details).

The unit will detect the motor start command and release the mechanical brake. When the stop command is

given, the ABC

injection braking sequence, then engage the mechanical brake at the end of the braking cycle. If the disable

feature is engaged while in "BRAKING" mode, the ABC Series will automatically set the mechanical brake.

Series

brake unit will continue to keep the mechanical brake released, proceed with the DC

Page 24

Motortronics

Page 23

On

1 2 3 4 5 6 7

Switch Positions

Jog Time

1 2 4 8 16 32 64

Time (sec.)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5 Adjustments

5.1 Time Adjustment Procedures

Time settings for "Jog Time" and "Brake Time" are adjusted by use of dip switches on the front mounted Operator

Interface Module. Time settings are in seconds (set in binary code). Each switch denotes a binary digit from1- 7

positions, totalling 127 seconds maximum when all are switched to the "On" position.

Operator Interface

Module

5.2 Jog Time Setting

Factory Setting: 7

The jog time is adjustable from 0-127 seconds and is made using the 7 position dip switch SW2, labeled "Jog

Time". Set the switches according to the jog time required. Setting all the switches to the "Off" position (Jog

Time = 0) will disable this function.

Example:

Setting dip

= 7

seconds

CAUTION!

Damage to the motor,

correct.

normal

the DC

accelerate the load on start (

Setting this

operations.

injection

seconds

switch positions

total jog

brake. The jog time

time.

equipment,

switch

Setting the jog time too

1, 2, and 3 to “ON” = 1+2+4

brake and/or

to less than the

should typically

across-

the-line) plus

long

electrical

factory setting

may result in

approximately

circuit

may

be set to equal

may occur if this

involve

equipment operating without

two

risk to the

the

seconds.

time it takes the motor to

adjustment

equip

ment and affect

the benefit of

is not

Page 25

Motortronics

Page 24

On

1 2 3 4 5 6 7

Switch Positions

Brake Time

1 2 4 8 16 32 64

Time (sec.)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

5.3 Brake Time Setting

Factory Setting: 7

The brake time is programmable from 1 to 127 seconds. Set the switches marked "Brake Time" to the brake

time required. Typical brake time settings should be 1/2 of the load's coast-to-stop time or less, as necessary.

Each dip switch represents a binary time value. Add the times together for the final brake time setting

Example:

Setting dip

= 7

NOTE: Stop times

accurately

seconds) to insure

seconds

seconds

switch positions

total brake

shorter

sense

that

proper stopping.

time.

the motor has

1, 2, and 3 to

than 4 seconds will not allow

"ON"

stopped.

= 1+2+4

Brake Time must be used to turn the ABC Series off (t-2

enough

time for the Zero Speed Sensing

circuit

to

5.4 Brake Current Setting

Factory Setting: 50% of Unit

It is strongly recommended that you try the factory settings first be- fore making any adjustments. If adjustments

are necessary, a "true" RMS AC clamp-on ammeter should be used to check the current supplied to the motor

while braking. Place the meter on one of the ABC Series' input power lines. Start the motor by energizing the

motor starter contactor. Allow the motor to come up to full speed with the normal load. Engage the brake by deenergizing (stopping) the motor starter contactor. Then, increase the brake current, if necessary, by slowly

adjusting the brake torque potentiometer (P1)(located in the Operation Interface Module) in a clockwise direction.

The braking torque should be adjusted so that the braking time expires at the same time the motor stops. Adjust

the brake current and/or brake time until acceptable. Start and stop the motor several times to verify proper

operation.

W

ARNING!

Never exceed the RMS full load current rating of the motor without first checking with the motor manufacturer for

the maximum allowable amount of DC current that can be supplied to the motor during braking application.

Rating

Page 26

Motortronics

Page 25

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Application Specific Adjustments

These settings are factory preset to provide optimum performance in a wide variety of applications, and should

not be changed unless the user is specifically aware of the risks and consequences (contact factory for details).

Brake On Delay (Switch SW1)

This DIP switch controls the amount of time that the ABC Series brake waits prior to applying DC current to the

motor windings in order to allow the magnetic field to decay. The rate of decay varies with motor frame size, so

this SHOULD NOT BE CHANGED. Changing this setting could result in damage to the ABC Series

components and circuit protective devices. If your application requires a specific delay time, please contact the

factory for assistance.

Zero Speed Sensing Disable (Jumper X3)

If for some reason you need to disable the Zero Speed Sensing, remove this jumper. The ABC Series will then

continue braking for the entire Brake Time setting, even if the motor has already come to a complete stop.

Disconnecting the sensing lead to the "T3" terminal, will cause a "Wiring Error" fault, and therefore should not be

used as a means of disabling the Zero Speed Sense circuit.

50 Hz

Operation

(Power Board Jumper X1)

Remove this jumper on units ordered as 60 Hz, but required to operate at 50 Hz. Units ordered as 50 Hz will not

have this jumper, so it must be installed for testing on 60 Hz systems.

CAUTION!

Some

be field

include

your

warranty

adjustments

adjusted without specific instructions

: P1

and P2

.

and devices

visible

potentiometers,

on the ABC Series boards are preset at

from

and push

factory

button PB1.

authorized

Tampering or

the

service

altering

factory

personnel.

and

should

These devices

these devices may void

NOT

Page 27

Motortronics

Page 26

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

6 Start-up

6.1 Start-up Check List

• Verify that the supply voltage matches the supply voltage of the ABC Series brake.

• Confirm that the power lines are attached to the input terminals.

• Verify that the output leads are connected to the output terminals.

• Complete the appropriate control and interlock connections.

• Clear the area of people and extra parts before start up.

NOTE: For 50 Hz

operation,

be sure that jumper

X1

on the

Power Board is

6.2 Equipment

The following equipment will be needed for start-up:

• A "true" RMS AC clamp-on ammeter to check braking current.

• A small screw driver to adjust braking torque (if necessary).

• A digital volt meter

• Stop watch or other means of measuring time.

.

removed.

6.3 Setup Sequence

• Start the motor by energizing the motor starter.

• Allow the programmed jog time to expire. (Factory set for 7 sec.)

• De-energize the motor starter to initiate brake mode.

• Monitor the input current to the ABC Series unit on any one of

clamp-on ammeter.

• Adjust the brake current if necessary.

• If the brake times out before the motor stops, increase the value of the brake time switch, or increase the

brake current (Note: Never exceed the RMS rating of the motor without checking with the motor

manufacturer).

• If the Zero Speed Sense option engages and turns off the brake before the programmed brake time

expires, adjust the brake time dip switch for approximately two (2) seconds longer than the actual stop

time.

its

input leads with the "true" RMS AC

6.4 Check Normal Sequence of Operations

Apply power to the system. The "Power On" LED should indicate that the line power is correct. Both the

"Power On" and the "Brake Off" LED should be illuminated.

• Start the motor. The "Jog / Armed" LED should flash once per second to indicate programmed Jog Time.

• Allow the motor to run. The "Jog / Armed" LED should light solid.

• Initiate the motor stop command. The "Brake Off" LED should go out and the "Brake On" LED should

illuminate. The unit should continue braking until the motor comes to a stop or the programmed brake time

expires.

Page 28

Motortronics

Page 27

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

APPENDIX A: Technical Specifications

Voltage Rating: Models rated from 208 – 600 +/- 10%

Line Frequency: Selectable for 50 / 60 Hz + 2Hz

Current Ratings: 50 – 1000A

50, 100, 200, 300, 400, 550, 800, 1000A

Output Capacity: 25% duty cycle at 100% unit rating

Power Circuit: Fu wave bridge, 4 SCRs, designed for use without isolation

contactors.

Transient Protection: RC snubber dv/dt circuit on each SCR device.

Fusing: Approved for use with existing motor starter fusing when unit is

sized for motor FLA. Consult NEC for any other fusing requirements.

Control Circuit: Self-powered directly from line terminals. No separate control

voltage required.

Control Method: Microprocessor unit control sequencing, I/O monitoring and status

annunciation. Braking current is adjustable via true RMS regulated

control using phase angle firing of SCRs.

Operator Adjustments: Brake Time and Jog Time = 7 position binary dip-switch.

Brake Current = potentiometer

Adjustment Ranges: Brake Jog Time = 0 – 127 seconds in 1 sec. increments.

Brake Current = Up to 100% of unit rating.

Inputs: Starter Monitor = Dry input for auxiliary contact from motor starter.

Jumper selectable for N.O. or N.C. contact.

Inputs: Brake Disable = Dry input for N.O. contact to disable braking before

or during operation. Can be wired to the starter thermal overload

N.O. auxiliary contact to prevent braking of overloaded motor.

Jumper selectable for N.O. or N.C. contact.

Motor Power Sensor (T3) = Voltage input used for sensing motor

power presence in sequencing / status circuit and for zero speed

sensing during braking.

Page 29

Motortronics

Page 28

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Outputs: Starter Coil Interlock = Two sets of FORM “C” relay contacts for us

Mechanical brake Release = N.O. relay contact for use in controlling

in interlocking the starter coil and/or other devices to prevent

energizing as the braking power is applied.

electro-mechanical brake as a holding brake. When the ABC Series

is “disabled”, this circuit controls the mechanical brake normally as if

it is the only brake in the system.

Aux. Contact Ratings: 5 Amps, 250 VAC max.

LED Status Indicators: Large LEDs: braking = green; Fault = Red

Small LEDs: Power On, Jog/Armed, Brake Off, Disabled, Over

Temp and Wiring Error.

Operating Design Temperature: 32ºF – 122ºF / 0ºC to 50ºC

Storage Temperature: -4ºF – 176ºF / -20ºC to 80ºC

Ambient Conditions: 5% to 95% relative humidity

0 – 3300ft (1000m) elevation

Approval: UL, cUL Listed

Page 30

Motortronics

Page 29

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Warranty information

Motortronics warrants its products to be free from defects in material and/or workmanship for a period of one

year from the date of installation, to a maximum of 18 months from the date of shipment as indicated by the

unit's date code. The Company reserves the right to repair or replace any mal- functioning units under warranty

at their option. All warranty repairs must be performed by the Company factory or on site by factory authorized

service firms or personnel approved by the Company.

Solid state controls have different operating characteristics from those of electromechanical equipment. Because

of these differences and the wide variety of applications for solid state controls, each application designer must

verify that the solid state equipment is acceptable for his application. In no event will Motortronics be liable or

responsible for indirect or consequential damages resulting from the use or application of this equipment. The

diagrams and illustrations in this document are included solely for illustrative purposes. Because of the number

of different applications, Motortronics cannot be responsible or liable for actual use based on the examples or

diagrams.

Loading...

Loading...