Motortech MIC500 Operating Manual

3

5

MIC500 –

IGNITION CONTROLLER

OPERATING MANUAL

MOTORTECH Ignition Controllers

P/N 01.10.0

0-EN | Rev. 01/201

Copyright

© Copyright 2015 MOTORTECH GmbH. All rights reserved.

Distribution and reproduction of this publication or parts thereof, regardless of the specific

purpose and form, are not permissible without express written approval by MOTORTECH.

Information contained in this publication may be changed without prior notice.

Trademarks

All trademarks and logos displayed or used in this publication are the property of the respective

entitled person.

S

TABLE OF CONTENT

1 General Information ..................................................................................................... 7

1.1 What Is the Purpose of this Operating Manual? ......................................................... 7

1.2 Who Is this Operating Manual Targeted to? ............................................................... 7

1.3 Which Symbols Are Used in the Operating Manual? ................................................... 7

1.4 Which Abbreviations/Acronyms Are Used in the Operating Manual? ........................... 8

2 Safety Instructions .................................................................................................... 10

2.1 General Safety Instructions ................................................................................... 10

2.2 Electrostatic Discharge Hazards ............................................................................. 11

2.3 Special Safety Instructions for the Device ............................................................... 11

2.4 Proper Disposal .................................................................................................... 13

3 Intended Use ............................................................................................................. 14

3.1 Functional Description .......................................................................................... 14

3.2 Applications ......................................................................................................... 14

4 Product Description ................................................................................................... 15

4.1 Product Overview .................................................................................................. 15

4.2 Technical Data...................................................................................................... 16

4.2.1 Certifications ..................................................................................................... 16

4.2.2 Mechanical Data ................................................................................................ 20

4.2.3 Warning Notices on the Device ........................................................................... 20

4.2.4 Product Identification – Labeling on the Device ................................................... 20

4.2.5 Electrical Data ................................................................................................... 21

4.2.6 Interfaces ......................................................................................................... 22

4.2.7 Requirements for External Equipment ................................................................. 22

4.2.8 Overview Drawings ............................................................................................ 23

5 Installation Instructions ............................................................................................ 26

5.1 Unpacking ............................................................................................................ 26

5.2 Determine the Installation Location of the Pickup and the Trigger Disc ..................... 26

5.3 Installation of the Ignition Controller ..................................................................... 27

6 Wiring of the Device .................................................................................................. 28

6.1 Input and Output Wiring on the Controller .............................................................. 28

6.1.1 Input and Output Connector – P/N 06.00.507, P/N 06.00.508 ............................... 29

6.1.2 Input and Output Connector – P/N 06.00.510 ....................................................... 30

6.1.3 Input and Output Connector – P/N 06.00.511 ....................................................... 32

6.1.4 Input and Output Connector – P/N 06.00.513 ....................................................... 34

6.1.5 Input and Output Connector – P/N 06.00.514 ....................................................... 36

Rev. 01/2015 3

TABLE OF CONTENTS

6.1.6 Input and Output Connector – P/N 06.00.515-6 and -8 ......................................... 38

6.1.7 Input and Output Connector – P/N 06.00.516 ....................................................... 40

6.1.8 Input and Output Connector – P/N 06.00.517 ....................................................... 42

6.1.9 Input and Output Connector – P/N 06.00.520 ...................................................... 44

6.1.10 Input and Output Connector – P/N 06.00.525 ..................................................... 46

6.1.11 Input and Output Connector – P/N 06.00.530 ..................................................... 48

6.1.12 Input and Output Connector – P/N 06.00.550 ..................................................... 50

6.1.13 Input Wiring – Power Supply ............................................................................. 52

6.1.14 Input Wiring – 4-20 mA Input ............................................................................ 53

6.1.15 Input Wiring – Pickup ....................................................................................... 54

6.1.16 Wiring – Digital Input, Go/NoGo ........................................................................ 56

7 Functions ................................................................................................................... 57

7.1 Monitoring of Pickup Signal ................................................................................... 57

7.2 Go/NoGo ............................................................................................................. 57

7.3 Remote-Controlled Ignition Release ....................................................................... 58

7.4 Schedules A/B ..................................................................................................... 59

7.5 Timing Correction ................................................................................................. 60

7.5.1 Manual Timing Correction ................................................................................... 61

7.5.2 Analog Current Input – 4-20 mA .......................................................................... 62

7.5.3 Speed Curve ...................................................................................................... 62

7.5.4 Cylinder-to-Cylinder Alignment ........................................................................... 62

7.6 Misfire Detection .................................................................................................. 62

7.7 Ignition Energy ..................................................................................................... 63

8 Adjustments .............................................................................................................. 64

8.1 Ignition Control .................................................................................................... 64

8.1.1 System Requirements Ignition Control ................................................................. 64

8.1.2 Installing Ignition Control ................................................................................... 64

8.1.3 Starting Ignition Control ..................................................................................... 67

8.1.4 Menu Bar and Buttons ........................................................................................ 68

8.2 Hand-Held Programmer ........................................................................................ 69

8.2.1 RS232 Interface Adjustments ............................................................................. 69

8.2.2 Switching on the Hand-Held Programmer ............................................................ 70

8.2.3 Keys of the Control Panel .................................................................................... 71

8.3 Conventions Used in the Following ........................................................................ 72

8.4 Main View ............................................................................................................ 73

8.5 Parameterization Level ......................................................................................... 75

8.5.1 General Operation of the Parameterization Level ................................................. 75

4 Rev. 01/2015

8.5.2 Brief Overview of Parameters ............................................................................. 78

8.5.3 Set Sequence Number ....................................................................................... 80

8.5.4 Set Reset Position ............................................................................................. 84

8.5.5 Set Overspeed ................................................................................................... 84

8.5.6 Set Security Speed ............................................................................................ 85

8.5.7 Set Misfire Rate ................................................................................................. 86

8.5.8 Activate Cylinder-to-Cylinder Alignment .............................................................. 87

8.5.9 Select Function for Digital Input .......................................................................... 87

8.5.10 Activate Potentiometer ..................................................................................... 88

8.5.11 Activate Functions for Schedules A and B ........................................................... 89

8.5.12 Set Potentiometer Limits .................................................................................. 91

8.5.13 Set Ignition Timing Limits ................................................................................. 93

8.5.14 Set Timing Offset for Schedule B ....................................................................... 95

8.5.15 Set Limits for 4-20 mA Input .............................................................................. 95

8.5.16 Set Speed Curve .............................................................................................. 97

8.5.17 Configuration Example ................................................................................... 100

8.6 Additional Functions .......................................................................................... 102

8.6.1 Set Ignition Energy .......................................................................................... 102

8.6.2 Information View ............................................................................................. 103

8.6.3 Cylinder-to-Cylinder Alignment ........................................................................ 103

8.6.4 Self Test ......................................................................................................... 105

8.6.5 Misfire Detection ............................................................................................. 107

8.7 Programming Overview ....................................................................................... 107

9 Operation ................................................................................................................ 110

9.1 Start-up .............................................................................................................. 110

9.2 Shutdown ........................................................................................................... 110

10 Errors ...................................................................................................................... 111

10.1 Possible Faults ................................................................................................... 111

10.2 Causes of Faults................................................................................................. 111

10.2.1 Overspeed ...................................................................................................... 111

10.2.2 Misfire Detection (Primary) .............................................................................. 111

10.2.3 Pickup Input Errors .......................................................................................... 112

10.2.4 Insufficient Power Supply ................................................................................ 112

10.2.5 Exiting Error Status ......................................................................................... 112

10.3 Troubleshooting and Eliminating Errors ............................................................... 113

10.3.1 Message and Error Overview ............................................................................ 113

10.3.2 Testing Supply Voltage .................................................................................... 114

Rev. 01/2015 5

TABLE OF CONTENTS

10.3.3 Testing Pickup Signal ...................................................................................... 114

10.3.4 Running a Self Test ......................................................................................... 116

10.3.5 Customer Service Information .......................................................................... 117

10.3.6 Returning Equipment for Repair / Inspection .................................................... 117

10.3.7 Instructions for Packaging the Equipment ......................................................... 118

11 Maintenance ........................................................................................................... 119

11.1 Maintenance Instructions .................................................................................... 119

11.2 Spare Parts and Accessories ............................................................................... 119

12 Index ..................................................................................................................... 120

6 Rev. 01/2015

1 GENERAL INFORMATION

Read through this operating manual carefully before use and become familiar with the machine.

Installation and start-up should not be carried out before reading and understanding this

document. Keep this manual readily available so that you can reference it as needed.

1.1 What Is the Purpose of this Operating Manual?

This manual serves as an aid for the installation and operation of the product and supports the

technical staff with all operating and maintenance tasks to be performed. Furthermore, this

manual is aimed at preventing dangers to life and health of the user and third parties.

1.2 Who Is this Operating Manual Targeted to?

The operating manual provides a code of conduct for personnel tasked with the set-up,

operation, maintenance, and repair of gas engines. A certain level of technical knowledge with

respect to the operation of gas engines and basic knowledge of electronic ignition systems are

necessary. Persons who are only authorized to operate the gas engine shall be trained by the

operating company and shall be expressly instructed concerning potential hazards.

1.3 Which Symbols Are Used in the Operating Manual?

The following symbols are used in this manual and must be observed:

Example

This symbol indicates examples, which point out necessary handling steps

and techniques. In addition, you receive additional information from the

examples, which will increase your knowledge.

Notice

This symbol indicates important notices for the user. Follow these. In

addition, this symbol is used for overviews that give you a summary of the

necessary work steps.

Warning

This symbol indicates warnings for possible risks of property damage or

risks to health. Read these warning notices carefully and take the

mentioned precautionary measures.

Rev. 01/2015 7

1 GENERAL INFORMATION

Danger

This symbol indicates warnings for danger to life, especially due to high

voltage. Read these warning notices carefully and take the mentioned

precautionary measures.

1.4 Which Abbreviations/Acronyms Are Used in the Operating Manual?

In the manual or the user interface, the following abbreviations / acronyms are used:

Abb. Term Description Explanation

ADV Advance Advanced with respect

to top dead center

ATDC After Top Dead Center After top dead center

BTDC Before Top Dead

Center

CE Conformité

Européenne

°crank-

Degree crankshaft Unit for the rotation angle of

Before top dead

center

Conformity with EU

directives

shaft

CSA Canadian Standards

Association

DC Direct Current Direct current

EMC Electromagnetic

Compatibility

LED Light Emitting Diode Light emitting diode Light emitting electronic semi-

POT Potentiometer Continuously adjustable

PWR Power Output / current Operating voltage

RET Retard Retarded with respect

to the top dead center

Indicates the direction for

timing

Mark based on EU legislation

for certain products in

conjunction with product safety

the crankshaft

Organization that defines

standards, inspects products

for safety compliance, and

issues pertinent certifications.

Compatibility of electrical or

electronic equipment items

with their surroundings

conductor

potential divider

Indicates the direction for

timing

8 Rev. 01/2015

Abb. Term Description Explanation

RPM Revolutions Per

Minute

Revolutions per

minute

Unit for speed

TDC Top Dead Center

Rev. 01/2015 9

2 SAFETY INSTRUCTIONS

2.1 General Safety Instructions

The following safety instructions must be followed in the area in which the device is operated.

High voltage! Danger to life!

While the engine is running, the area around the ignition system especially

holds the risk of danger due to high voltage. The following parts should

therefore not be touched or removed unless explicitly stated otherwise:

– Ignition coils and caps

– Wires of the high voltage circuit

– In- and output wiring of the ignition controller

– Pickups and their wiring

Danger to persons with pacemakers!

Electromagnetic impulses in the wiring of the ignition system may exceed

the permissible limits of pacemakers. Persons with pacemakers must

MOTORTECH equipment is manufactured as state of the art and therefore safe and reliable to

operate. Nevertheless the equipment can cause risks or damages can occur, if the following

instructions are not complied with:

– The gas engine must only be operated by trained and authorized personnel.

– Operate the equipment only within the parameters specified in the technical data.

– Use the equipment correctly and for its intended use only.

– Never apply force.

– For all work, such as installation, conversion, adaptation, maintenance, and repair, all

equipment must be disconnected from the power supply and secured against unintentional

restarting.

– Perform only such maintenance and repair work as is described in this operating manual,

and follow the instructions given while working. For maintenance of the equipment, only use

spare parts supplied by MOTORTECH. Further work must only be performed by personnel

authorized by MOTORTECH. Non-compliance with the instructions will void any warranties

for the proper function of the equipment as well as the responsibility for the validity of the

certifications.

– Safety devices must not be dismounted or disabled.

– Avoid all activities that can impair the function of the equipment.

therefore not be present in the vicinity of the ignition system being

operated. Mark the operating location of the ignition system with the

corresponding standardized warning symbol.

10 Rev. 01/2015

– Operate the equipment only while it is in proper condition.

– Investigate all changes detected while operating the gas engine or ignition system.

– Ensure compliance with all laws, directives and regulations applicable to the operation of

your system, including such not expressly stated herein.

– If the system is not entirely tight and sealed, gas may escape and lead to an explosion

hazard. Upon completion of all assembly works, always check the system's tightness.

– Always ensure adequate ventilation of the engine compartment.

– Ensure a safe position at the gas engine.

2.2 Electrostatic Discharge Hazards

Electronic equipment is sensitive to static electricity. To protect these components from damage

caused by static electricity, special precautions must be taken to minimize or prevent

electrostatic discharge.

Observe these safety precautions while you work with the equipment or in its vicinity.

– Before performing maintenance or repair work, ensure that the static electricity inherent to

your body is discharged.

– Do not wear clothing made from synthetic materials to prevent static electricity from

building up. Your clothing should therefore be made of cotton or cotton mix materials.

– Keep plastics such as vinyl and Styrofoam materials as far away from the control system, the

modules, and the work environment as possible.

– Do not remove the circuit boards from the housing of the device.

2.3 Special Safety Instructions for the Device

Danger to life! Hazardous residual voltage!

A dangerous level of residual voltage is present in the ignition system for up

to three minutes after stopping the ignition. Do not touch any components

of the ignition kit during this time.

Explosion hazard!

When the system is powered up, do not remove any connectors unless the

system is not located in a potentially explosive atmosphere.

Rev. 01/2015 11

2 SAFETY INSTRUCTIONS

Explosion hazard!

The replacement of parts or assemblies can impair compliance with CSA

Class I, Division 2 (Group C, D), T4.

Explosion hazard!

Never remove the equipment while the device is connected to a power

source unless the system is not located in an explosive environment.

Risk of burning!

The surfaces of the system may heat up to high temperatures.

Operational safety!

All connector screws and screw joints must be adequately tightened.

Compliance with the following tightening torques is mandatory:

– RS232 connection: 1 Nm (0.7 lb-ft)

– Connection plug 6-pole, 7-pole, 10-pole: 2.6 Nm (1.9 lb-ft)

– Connection plug 14-pole, 19-pole: 5 Nm (3.7 lb-ft)

Explosion hazard!

Never remove the cover for timing adjustment and the RS232 interface,

unless the system is not located in an explosive environment.

12 Rev. 01/2015

Risk of damage!

Magnetic fields and heat occur when welding, which may damage or

destroy the MIC500. Therefore, pay attention to the following when

welding:

– Disconnect all electrical connections to the MIC500 prior to welding.

– Protect the MIC500 against direct contact with the welding unit and

magnetic fields, sparks and liquid metal.

2.4 Proper Disposal

After the expiration of its service life, MOTORTECH equipment can be disposed of with other

commercial waste, or it may be returned to MOTORTECH. We will ensure its environmentally

friendly disposal.

Rev. 01/2015 13

3

INTENDED USE

3.1 Functional Description

The devices of the MIC500 series are microprocessor-controlled condenser discharge ignition

systems, which provide the ignition energy for gas engines with up to 16 cylinders.

Please note that the manufacturer is not required to implement configurations of the ignition

controller for specific engines, and that devices may be delivered without pertinent

configuration.

The ignition controllers of the MIC500 series use information supplied by the pickup to precisely

determine the correct timing for the respective outputs. An event type N+1 trigger disc serves as

transmitter.

The timing is influenced by various inputs made either automatically or manually. This can be

implemented with the installed manual potentiometer, an analog input signal (4-20 mA) or a

configurable speed curve.

By checking the information received, the ignition controllers continuously monitor the system

status of the pickup and the correct operation of the primary ignition circuit during operation.

Depending on the severity of an error that is detected, the devices will shut down immediately or

warn the operator by a flashing LED.

To protect the engine, the ignition controllers additionally have an adjustable overspeed shutoff.

3.2 Applications

Depending on the device type, the ignition controllers of the MIC500 series are designed for

specific 2- or 4-stroke gas engines. Depending on the device type, there are between 2 to max.

16 ignition outputs available.

The ignition controllers supply the energy output required for the corresponding ignition coils of

the gas engines and can supply signals for peripheral devices. Any use other than the one

described in the operating manual shall be considered improper use and will result in the

voiding of all warranties.

14 Rev. 01/2015

4

PRODUCT DESCRIPTION

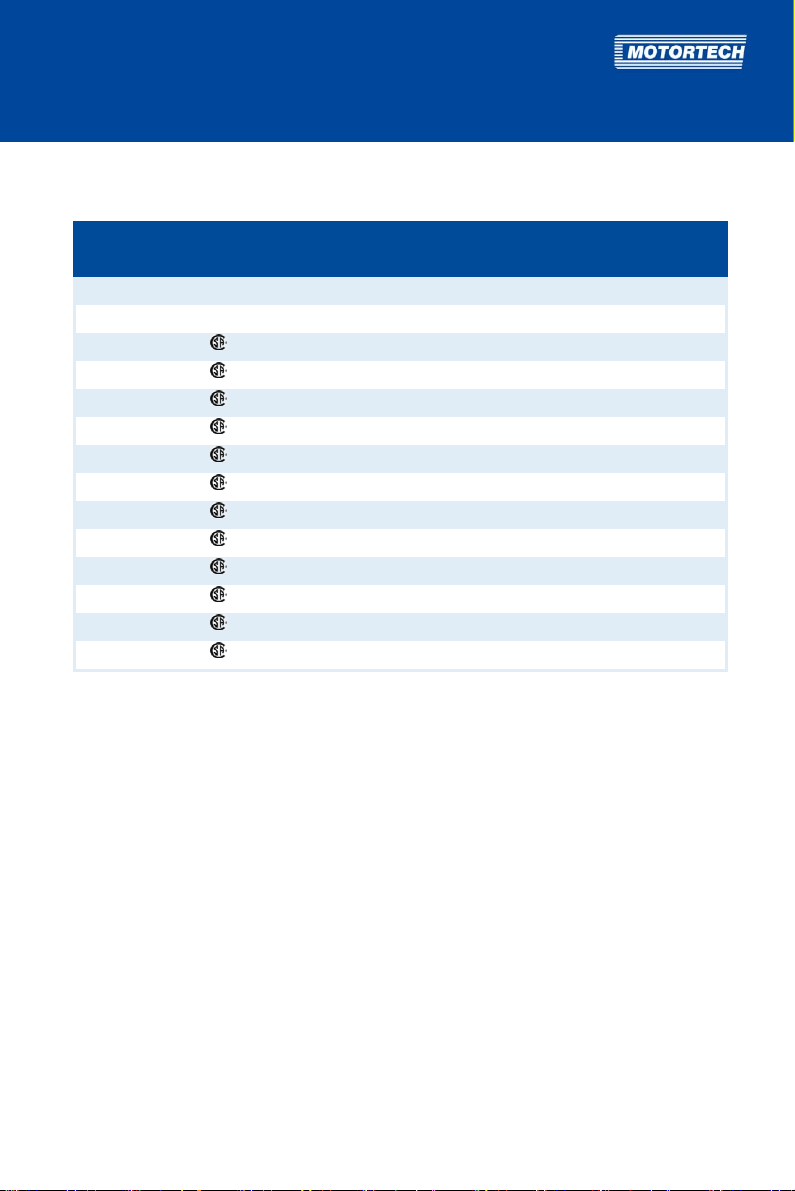

4.1 Product Overview

The following properties of the devices from the MIC500 series differ as follows:

Device type

P/N 06.00.507 8 30 V DC 24VDC

P/N 06.00.508 8 30 V DC 24 V DC

P/N 06.00.510 16 30 V DC 24VDC

P/N 06.00.511 16 30V DC 24VDC

P/N 06.00.513 8 300 V DC 8V DC

P/N 06.00.514 16 30 V DC 8 V DC

P/N 06.00.515-6 8 (programmed on 6) 300 V DC 8VDC

P/N 06.00.515-8 8 300 V DC 8 V DC

P/N 06.00.516 16 (programmed on 12) 300 V DC 8VDC

P/N 06.00.517 16 300 V DC 8 V DC

P/N 06.00.520 8 300 V DC 24VDC

P/N 06.00.525 12 300 V DC 24 V DC

P/N 06.00.530 16 300 V DC 24VDC

P/N 06.00.550 8 30V DC 24VDC

Number of outputs

Test port /

monitor voltage

Voltage for pickup

Rev. 01/2015 15

4 PRODUCT DESCRIPTION

4.2 Technical Data

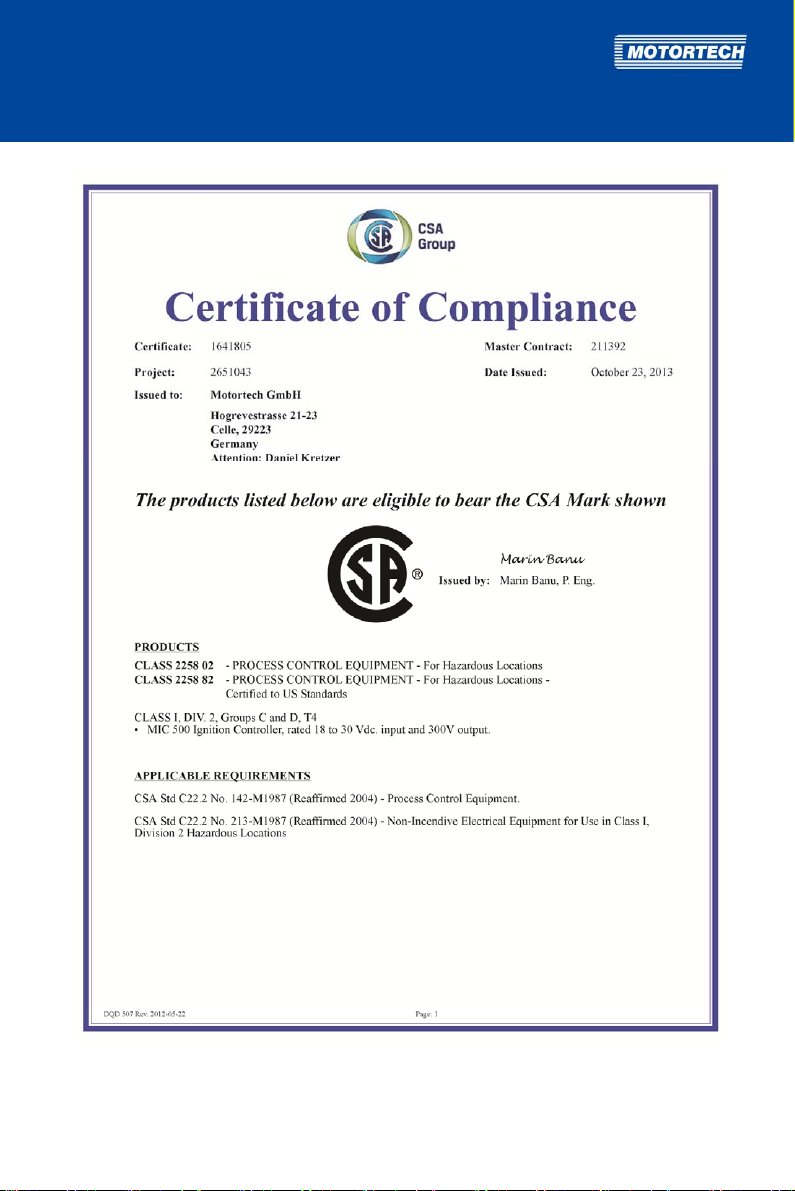

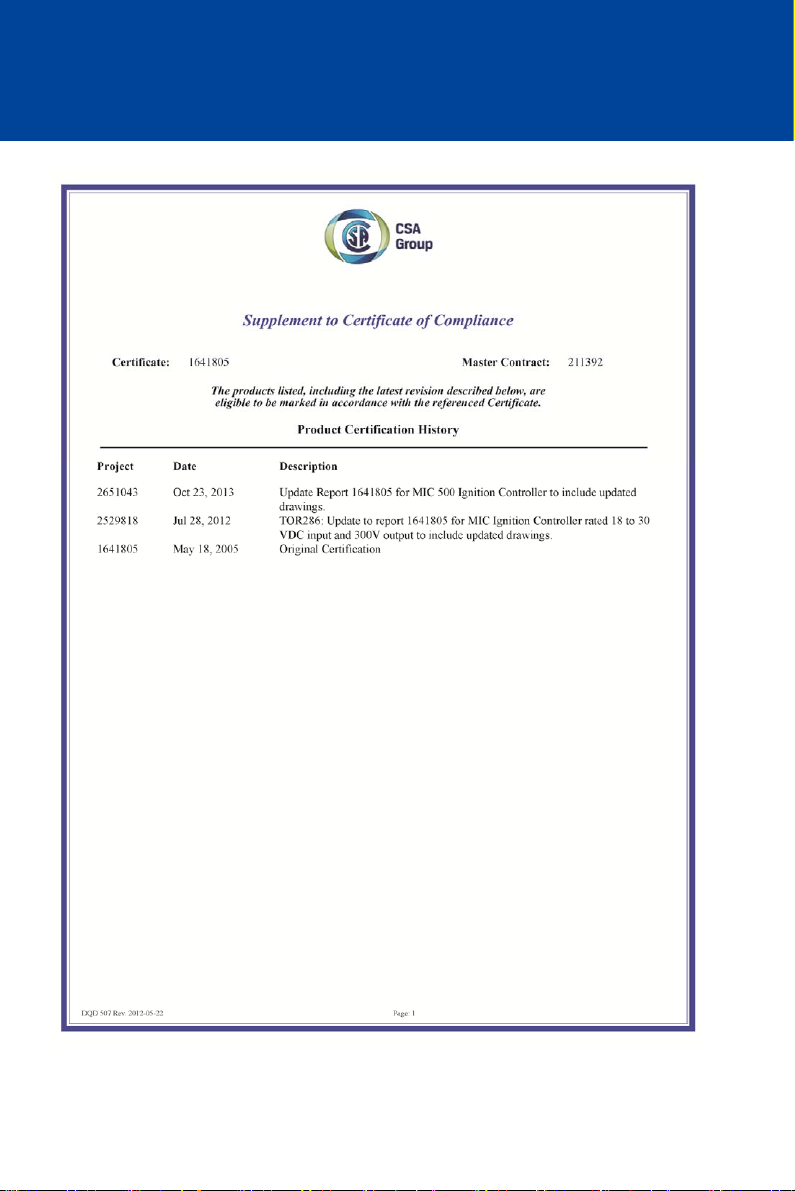

4.2.1 Certifications

The ignition controllers of the MIC500 series with the test mark are certified as per the

following CSA standards:

CSA

– Class I, Division 2, Group C and D, T4

– CSA Std C22.2 No. 142-M1987 (Reaffirmed 2004)

– CSA Std C22.2 No. 213-M1987 (Reaffirmed 2004)

The ignition controllers of the MIC500 series are additionally certified as per the following

directives/regulations:

CE

– EMC Directive 2004/108/EC

– Limits as per DIN EN 55011:2011

– Immunity for industrial environments as per DIN EN 61000-6-2:2006-03

– Emission standard for industrial environments as per DIN EN 61000-6-4:2007-09

– Low Voltage Directive 2006/95/EC

– Low voltage switchgear – General rules as per DIN EN 60947-1:2007

16 Rev. 01/2015

Rev. 01/2015 17

4 PRODUCT DESCRIPTION

18 Rev. 01/2015

x

DECLARATION OF CONFORMITY

The Company:

declares that the products: Ignition controller MIC500

Intended purpose: to be used on gas-Otto-engines

complies with the provisions of the following EC Directives:

under consideration of following standards:

The marking of the product is: P/N 06.00.5x

This declaration is submitted by:

Name: Florian Virchow

MOTORTECH GmbH

Hogrevestrasse 21 - 23

29223 Celle

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

DIN EN 55011-2011

DIN EN 61000-6-2-2006:03

DIN EN 61000-6-4-2007:09

DIN EN 60947-1 : 2007

Professional status: Managing Director

Celle, 13.07.2011

City, date

Rev. 01/2015 19

legally binding signature

4 PRODUCT DESCRIPTION

4.2.2 Mechanical Data

The devices of the MIC500 series have the following mechanical characteristics:

Feature Value

Dimensions see chapter Overview Drawings on page 23

Weight 2.1 kg (4.7 lbs)

Shape of device see chapter Overview Drawings on page 23

Climatic environmental

conditions

4.2.3 Warning Notices on the Device

EXPLOSION HAZARD! Do not open cover for timing adjustment and RS232 interface unless area is

known to be non-hazardous.

WARNING! Read and understand the installation and operating manual prior to installing or

making any adjustments.

EXPLOSION HAZARD! Do not disconnect while circuit is live unless area is known to be nonhazardous. For wiring details please refer to the operating manual.

CAUTION! Do not pressure wash this ignition module. Damage to electronic components may

result.

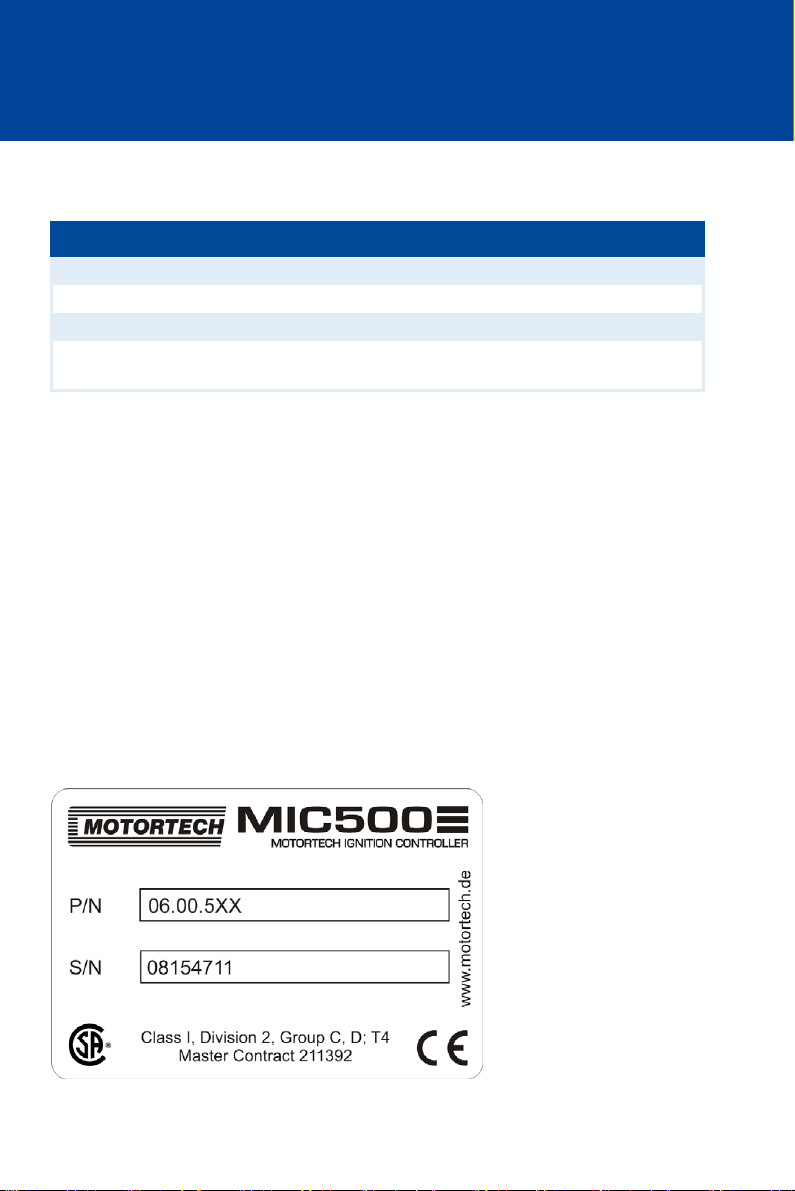

4.2.4 Product Identification – Labeling on the Device

The necessary numbers for unique product identification are on the device:

– P/N: Product number of the ignition controller

– S/N: Serial number of the ignition controller

-40°C to +70°C (-40°F to +158°F)

20 Rev. 01/2015

4.2.5 Electrical Data

The devices of the MIC500 series have the following electrical characteristics:

Feature Value

Power consumption 60 W with 24 V

Power supply 18 V DC to 30 V DC

Required current Peak current 20 A

External fuse 6 A, slow blow

Number of ignition

outputs

Output voltage and

output energy

Output connector Depending on device type (see Input and Output Wiring on the

Electrical Data for Inputs and Outputs

The inputs and outputs of the MIC500 ignition controllers have the following electrical data:

Inputs and outputs Values

4-20 mA input Auxiliary voltage: Corresponds to supply voltage of the MIC500

Digital input Impedance: 10 kΩ

Go/NoGo output Switching capacity: 100 mA

Signal LED An LED to display operating mode and errors

Pickup input Impedance: 10 k

Continuous current 5 A

Depending on device type 8, 12 or 16 outputs (see Product

Overview on page 15)

Max. 180 mJ with 300 V

The output energy is adjustable from 15 % to 100 %.

Controller on page 28)

Open: 0 V to 0.8 V

Closed: 2.8 V to 30 V

Open collector output

Darlington-Transistor design

Voltage applied: 18 V DC to 30 V DC

Peak/steady current: max. 0.45 A DC

Output power: max. 2.4 W

Power supply for inductive pickups is based on the input voltage

e. g. 24 V DC with an input voltage of 24 V DC (see Product

Overview on page 15).

Rev. 01/2015 21

4 PRODUCT DESCRIPTION

Inputs and outputs Values

Ignition coil outputs Output voltage: Max. 300 V

Output energy: Max. 180 mJ

Test ports /

monitor voltage

4.2.6 Interfaces

RS232

– VT100-Terminal

– Baud rate: 9,600, data bits: 8, stop bit: 1, parity: none

– Plug connection: D-SUB, 9-pole

– Maximum lead length: 5 m

4.2.7 Requirements for External Equipment

External equipment shall fulfill the input and output specifications of the MIC500.

Depending on device type (see Product Overviewon page 15)

22 Rev. 01/2015

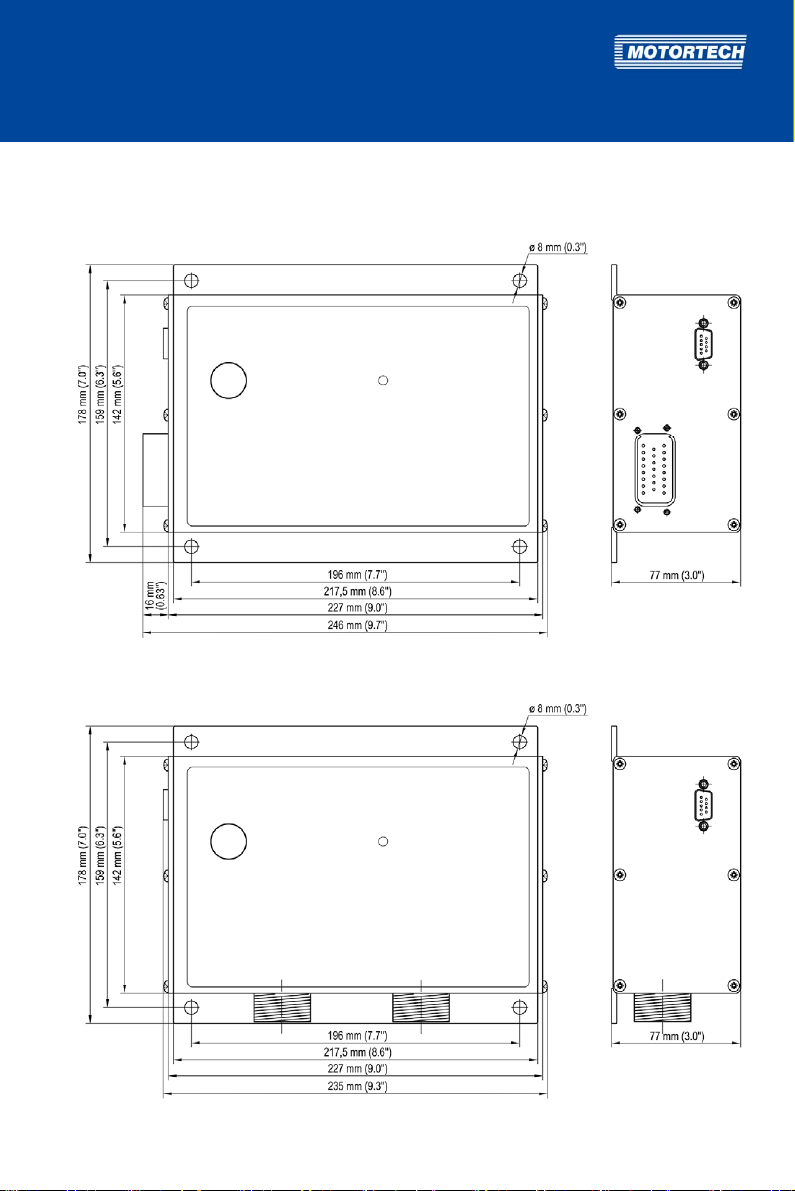

4.2.8 Overview Drawings

P/N 06.00.507, P/N 06.00.508:

P/N 06.00.511, P/N 06.00.520, P/N 06.00.525, P/N 06.00.530, P/N 06.00.550:

Rev. 01/2015 23

4 PRODUCT DESCRIPTION

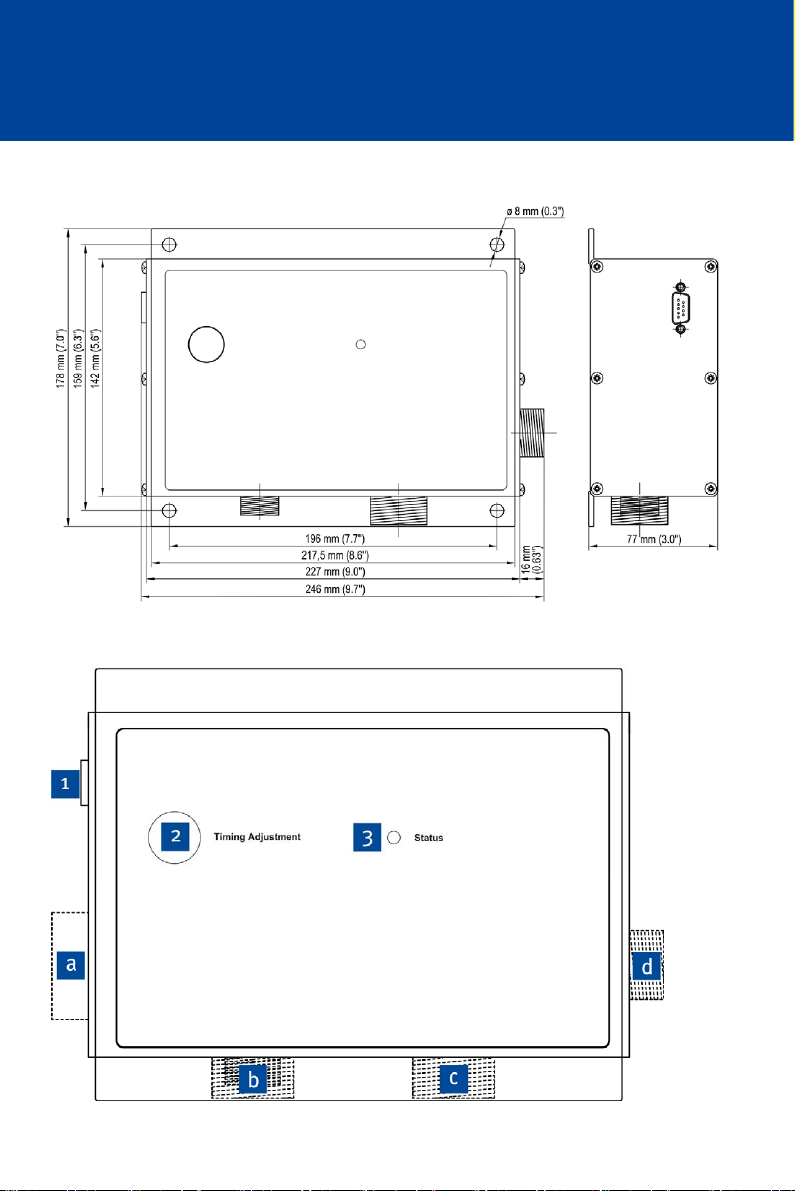

P/N 06.00.513, P/N 06.00.514, P/N 06.00.515-6 and -8, P/N 06.00.516, P/N 06.00.517:

All device types:

24 Rev. 01/2015

Device Components

Pos. Labeling Description Function

Timing adjustment potentiometer Potentiometer for manual timing

Status Status LED LED for displaying operating mode and

Inputs and Outputs Based on Device Type

The connections for the input and output wiring vary between the device types. For detailed

information, see section Input and Output Wiring on the Controller on page 28.

Pos. Connection position Function

Left side of device Input and output connection, 23-pole (depending on device

Left front Input and output connection, 6-, 7-, or 10-pole (depending on

Right front Input and output connection, 10-, 14-, or 19-pole (depending

Right side of device Input connection, 10-pole (depending on device type)

RS232 connection Connection of the ignition controller to a

computer or a hand-held programmer for

configuration and status monitoring (see

Adjustments on page 64).

adjustment (see Manual Timing Correction

on page 61).

error conditions (see Message and Error

Overview on page 113)

type)

device type)

on device type)

Rev. 01/2015 25

5

INSTALLATION INSTRUCTIONS

5.1 Unpacking

Unpack the device, taking care not to damage it, and ensure that the operating manual is always

stored with the ignition controller and is easily accessible. Check the contents for completeness

and verify that the device type meets your application requirements.

Scope of Supply

The scope of supply of the MIC500 ignition controllers consists of the following components:

– Ignition controller MIC500

– Installation set incl. four vibration dampers

– Ground strap

– Storage device (USB flash drive or CD-ROM) with software for configuring the ignition

controller

– RS232 interface cable for connecting the ignition controller with a PC/laptop or hand-held

programmer

– Operating manual

5.2 Determine the Installation Location of the Pickup and the Trigger Disc

Depending on engine type and application, the position of the pickup must be specified. All

angle reference information is based on:

TDC 1st cylinder / Compression cycle

The installation location for the pickup must have adequate mechanical strength and must not

exceed the specified temperature ranges. The pickup is designed for its appropriate use only,

multiple use of the pickup signal is not permissible. The N+1 triggering can be carried out via the

crankshaft or the camshaft. Ensure good accessibility to facilitate the calibration of the pickup.

Comply with the pertinent regulations for the wire routing.

The precise position of the pickup is shown in the example in chapter Input Wiring – Pickup on

page 54.

26 Rev. 01/2015

5.3 Installation of the Ignition Controller

Risk of damage!

The device must not be installed directly on or at the engine, as vibration

and heat may cause damage to electronic components.

The installation of the MIC500 ignition controller is implemented on a fixed bracket or a wall

near the engine. Always use the included vibration dampers and the ground strap. The

installation location of the device must be selected so that the distance to the pickup installed

on the engine ensures a reliable signal transmission to the ignition controller, and so that there

is adequate space for maintenance and repair work. Also ensure adequate space for the

connection wiring. The mechanical specifications must be complied with. The ground strap

serves to ground the ignition controller and must be used accordingly. Ensure a flawless

electrical connection for this purpose.

Installation locations where strong vibrations or ambient temperatures of below -40 °C (-40 °F)

or above +70 °C (+158 °F) are present are not permissible and result in the warranty being

voided.

Rev. 01/2015 27

6 WIRING OF THE DEVICE

6.1 Input and Output Wiring on the Controller

Operational safety!

All connector screws and screw joints must be adequately tightened.

Compliance with the following tightening torques is mandatory:

– RS232 connection: 1 Nm (0.7 lb-ft)

– Connection plug 6-pole, 7-pole, 10-pole: 2.6 Nm (1.9 lb-ft)

– Connection plug 14-pole, 19-pole: 5 Nm (3.7 lb-ft)

Operational safety!

Never connect more than one output to each ignition coil, as the output

boards can otherwise be damaged!

Assignment of the wire colors

Take the assignment of the wire colors of the wiring harness for the input

and output wiring from the wiring plan enclosed with the wiring harness.

Protection when using wiring rails

Every wiring rail on the engine block should be grounded to avoid

disruptions in the device caused by secondary current in the ignition coils.

28 Rev. 01/2015

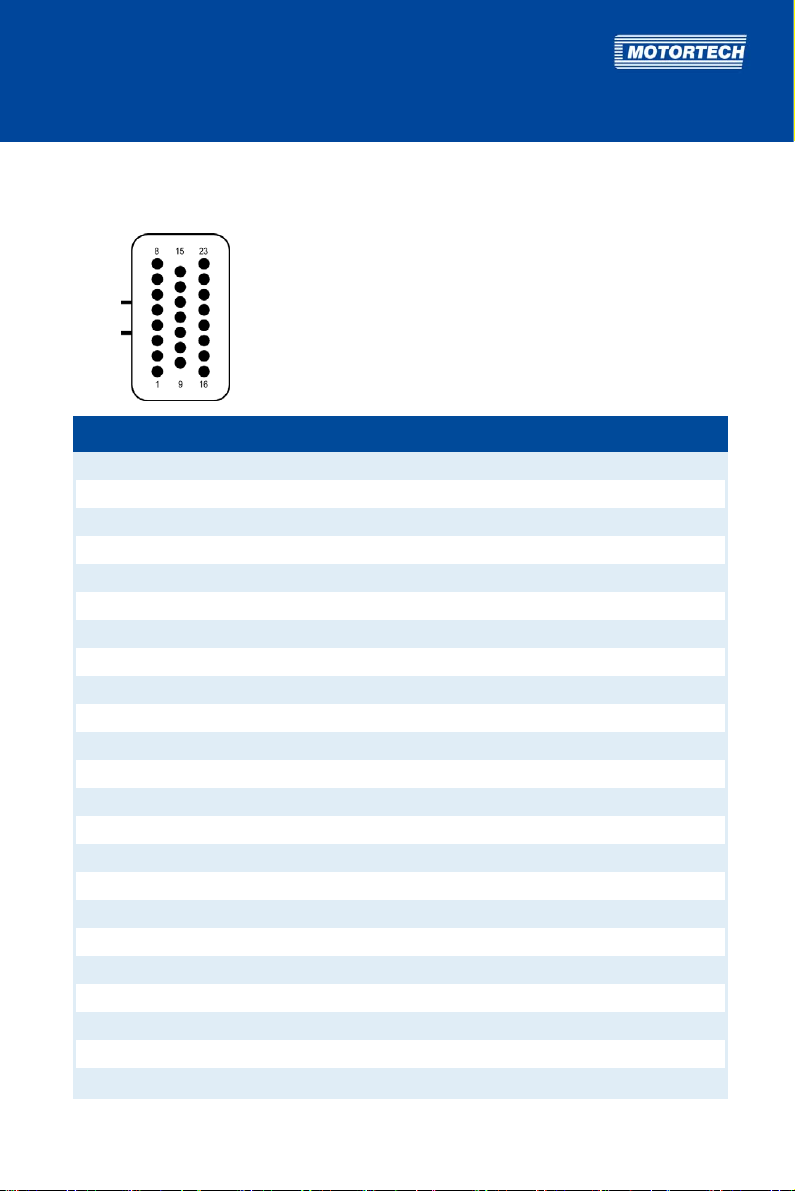

6.1.1 Input and Output Connector – P/N 06.00.507, P/N 06.00.508

Input and output connector: left side of device, 23-pole, connector

Pin Pin assignment

1 Ignition output D

2 Ignition output C

3 Ignition output B

4 Ignition output A

5 Switch Go/NoGo

6 Not used

7 (+) 4-20 mA

8 Pickup signal

9 Ignition output E

10 Ground

11 Measuring lead (1:10)

12 (-) Supply voltage

13 (+) Supply voltage

14 Supply voltage pickup (24 V DC)

15 (-) 4-20 mA

16 Ignition output F

17 Ignition output K

18 Ignition output L

19 Digital input (Switch A/B or Switch Start/Stop)

20 Not used

21 Not used

22 4-20 mA PWR

23 Pickup ground

Rev. 01/2015 29

6 WIRING OF THE DEVICE

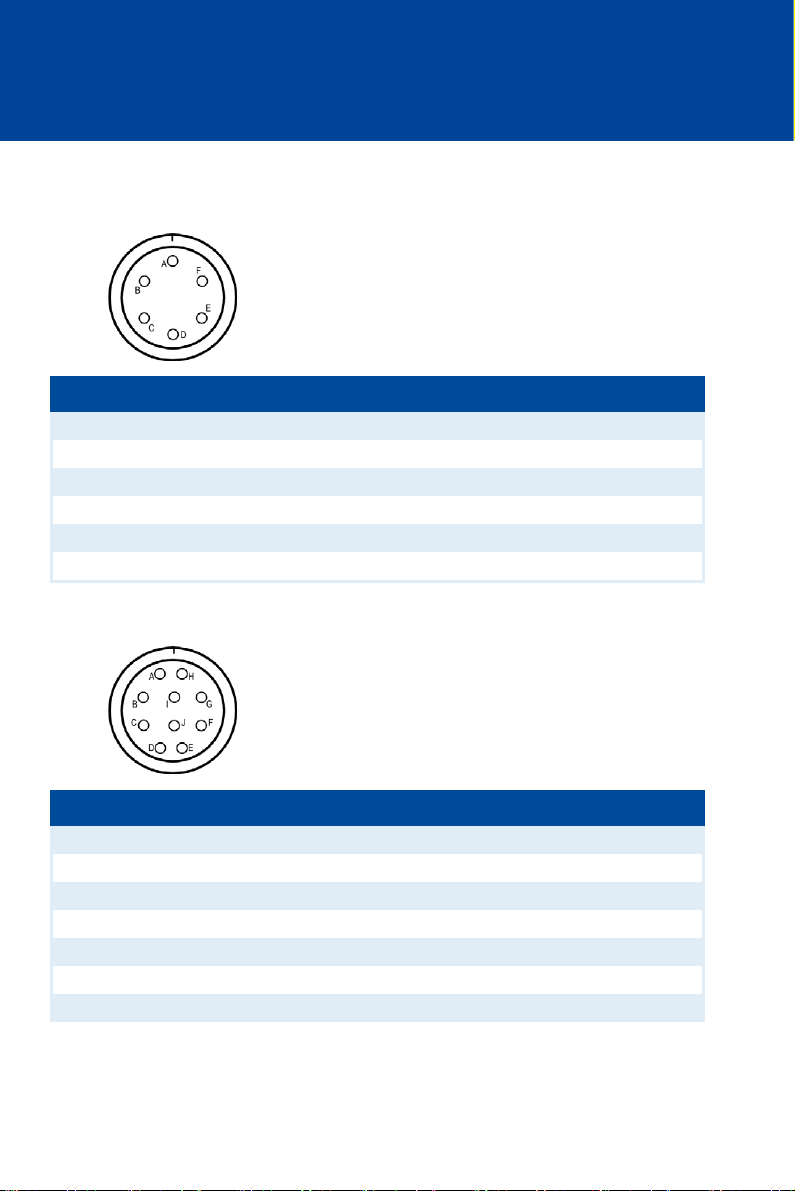

6.1.2 Input and Output Connector – P/N 06.00.510

Input connector: left front, 6-pole, socket

Pole Pole assignment

A Pickup signal

B Supply voltage pickup (24 V DC)

C Pickup ground

D Switch Go/NoGo

E (+) Supply voltage

F (-) Supply voltage

right side of device, 10-pole, socket

Pole Pole assignment

A Not used

B Not used

C (+) 4-20 mA

D Digital input (Switch A/B or Switch Start/Stop)

E (-) 4-20 mA

F 4-20 mA PWR

G Not used

30 Rev. 01/2015

Loading...

Loading...