Page 1

SSE™ 5000

UHF Range 2

(450–488 MHz)

Portable Radio

Service Manual

Page 2

Page 3

Title Page

SSE™ 5000

UHF Range 2 (450–488 MHz)

Portable Radio

Service Manual

Motorola, Inc.

8000 West Sunrise Boulevard

Fort Lauderdale, Florida 33322

6881094C12-A

Page 4

Foreword

C

n

This manual includes all the information necessary to maintain peak product performance and maximum working time of

the SSE 5000 portable radio, using Level 1, 2, and 3 service procedures. (For a description of the different levels of service,

see Section 3.1: “Levels of Service” on page 3-1.) Therefore, the manual contains sections on radio specifications for UHF

Range 2 (450–488 MHz), a general description of the SSE 5000 radio, radio alignment procedures, test equipment, service

aids, general maintenance recommendations, procedures for assembly and disassembly, schematics, board overlays,

parts lists, and service procedures down to the component level

For information on user operation of the radio, refer to the applicable publications available separately (see “Related

Publications” on page vii).

Product Safety and RF Exposure Compliance

Before using this product, read the operating instructions

!

a u t i o

This radio is restricted to occupational use only to satisfy FCC RF energy exposure requirements.

Before using this product, read the RF energy awareness information and operating instructions in the

Product Safety and RF Exposure booklet enclosed with your radio (Motorola Publication part number

6881095C98) to ensure compliance with RF energy exposure limits.

for safe usage contained in the Product Safety and RF

Exposure booklet enclosed with your radio.

ATTENTION!

.

Manual Revisions

Changes which occur after this manual is printed are described in FMRs (Florida Manual Revisions). These FMRs provide

complete replacement pages for all added, changed, and deleted items. To obtain FMRs, contact the Radio Products

Services Division (refer to Appendix B: “Replacement Parts Ordering”).

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer programs stored in

semiconductor memories or other media. Laws in the United States and other countries preserve for Motorola certain

exclusive rights for copyrighted computer programs, including, but not limited to, the exclusive right to copy or reproduce in

any form the copyrighted computer program. Accordingly, any copyrighted Motorola computer programs contained in the

Motorola products described in this manual may not be copied, reproduced, modified, reverse-engineered, or distributed in

any manner without the express written permission of Motorola. Furthermore, the purchase of Motorola products shall not

be deemed to grant either directly or by implication, estoppel, or otherwise, any license under the copyrights, patents or

patent applications of Motorola, except for the normal non-exclusive license to use that arises by operation of law in the

sale of a product.

Document Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the express written permission

of Motorola. No part of this manual may be reproduced, distributed, or transmitted in any form or by any means, electronic

or mechanical, for any purpose without the express written permission of Motorola.

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable. However, no responsibility is

assumed for inaccuracies. Furthermore, Motorola reserves the right to make changes to any products herein to improve

readability, function, or design. Motorola does not assume any liability arising out of the applications or use of any product

or circuit described herein; nor does it cover any license under its patent rights nor the rights of others.

Trademarks

MOTOROLA, the Stylized M logo, and FLASHport are registered in the US Patent & Trademark Office. All other products or

service names are the property of their respective owners.

© Motorola, Inc. 2005.

Page 5

Table of Contents iii

Table of Contents

Foreword.........................................................................................................ii

Product Safety and RF Exposure Compliance ............................................................................................ii

Manual Revisions ........................................................................................................................................ ii

Computer Software Copyrights ...................................................................................................................ii

Document Copyrights .................................................................................................................................. ii

Disclaimer....................................................................................................................................................ii

Trademarks ................................................................................................................................................. ii

Commercial Warranty ...................................................................................xi

Special Note on NYPD Warranty Agreement .............................................................................................xi

Limited Warranty ........................................................................................................................................ xi

MOTOROLA COMMUNICATION PRODUCTS ................................................................................ xi

I. What This Warranty Covers And For How Long .....................................................................xi

II. General Provisions ................................................................................................................ xii

III. State Law Rights .................................................................................................................. xii

IV. How To Get Warranty Service ............................................................................................. xii

V. What This Warranty Does Not Cover.................................................................................... xii

VI. Patent And Software Provisions ......................................................................................... xiii

VII. Governing Law................................................................................................................... xiii

Chapter 1 Radio Description ............................................................... 1-1

1.1 Physical Features of the Radio...................................................................................................... 1-1

1.2 FLASHport

1.3 Portable Radio Model Numbering System..................................................................................... 1-2

1.4 SSE 5000 UHF Range 2 (450–488 MHz) Model Chart ................................................................. 1-3

1.5 Specifications for UHF Range 2 (450–488 MHz) Radios .............................................................. 1-4

1.6 Notations Used in This Manual...................................................................................................... 1-5

®

................................................................................................................................... 1-1

Chapter 2 Theory of Operation............................................................ 2-1

2.1 Major Assemblies .......................................................................................................................... 2-1

2.2 Mode of Operation ......................................................................................................................... 2-2

2.2.1 Receiving .......................................................................................................................... 2-2

2.2.2 Transmitting ...................................................................................................................... 2-3

2.3 Power Distribution.......................................................................................................................... 2-4

2.3.1 DC Power Routing—Transceiver Board ........................................................................... 2-5

2.3.2 DC Power Routing—VOCON Board................................................................................. 2-5

2.4 Transceiver Board ......................................................................................................................... 2-7

2.4.1 Interconnections ............................................................................................................... 2-7

2.4.1.1 Battery Connector J3............................................................................................... 2-7

2.4.1.2 VOCON Connector P1............................................................................................. 2-7

2.4.1.3 Antenna Ports.......................................................................................................... 2-8

2.4.1.4 Serial EEPROM....................................................................................................... 2-8

2.4.1.5 Power Conditioning Components ............................................................................ 2-9

6881094C12-A November 11, 2004

Page 6

iv Table of Contents

2.4.2 Receiver............................................................................................................................ 2-9

2.4.2.1 Receiver Front-End.................................................................................................. 2-9

2.4.2.2 Receiver Back-End ................................................................................................ 2-10

2.4.3 Transmitter...................................................................................................................... 2-11

2.4.3.1 Power Distribution.................................................................................................. 2-12

2.4.3.2 Driver Amplifier ...................................................................................................... 2-12

2.4.3.3 Power Amplifier Transistor Q107........................................................................... 2-12

2.4.3.4 Directional Coupler ................................................................................................ 2-13

2.4.3.5 Antenna Switch...................................................................................................... 2-13

2.4.3.6 Harmonic Filter....................................................................................................... 2-13

2.4.3.7 RF Detector D101.................................................................................................. 2-14

2.4.3.8 Power-Control IC (PCIC) U104.............................................................................. 2-14

2.4.4 Frequency Generation Unit (FGU).................................................................................. 2-16

2.4.4.1 Reference Oscillator Y200..................................................................................... 2-16

2.4.4.2 Fractional-N Frequency Synthesizer (FracN) IC U202 .......................................... 2-16

2.4.4.3 Loop Filter..............................................................................................................2-17

2.4.4.4 VCO Buffer IC (VCOBIC)....................................................................................... 2-17

2.5 VOCON Board ............................................................................................................................. 2-17

2.5.1 Interconnections.............................................................................................................. 2-18

2.5.1.1 Transceiver Board Connector P201....................................................................... 2-18

2.5.1.2 Universal Flex Connector J102.............................................................................. 2-18

2.5.1.3 Internal Speaker and Microphone Flex Connector M102 ...................................... 2-19

2.5.1.4 Control Top Flex Connector J707.......................................................................... 2-19

2.5.1.5 Encryption Module Connector J701....................................................................... 2-19

2.5.1.6 Display Module Connector J301............................................................................ 2-19

2.5.2 Functional Blocks............................................................................................................ 2-19

2.5.2.1 Controller and Memory .......................................................................................... 2-19

2.5.2.2 Audio and Power.................................................................................................... 2-23

2.5.2.3 Interface Support ................................................................................................... 2-26

2.5.3 Display Module ............................................................................................................... 2-31

2.5.4 Controls and Control Top Flex ........................................................................................ 2-31

2.5.5 VOCON Audio Paths ...................................................................................................... 2-32

2.5.5.1 Transmit Audio Path .............................................................................................. 2-32

2.5.5.2 Receive Audio Path ............................................................................................... 2-33

2.5.6 Radio Power-Up/Power-Down Sequence ....................................................................... 2-34

Chapter 3 Test Equipment and Service Aids ..................................... 3-1

3.1 Levels of Service............................................................................................................................ 3-1

3.2 Test Equipment.............................................................................................................................. 3-1

3.3 Service Aids ................................................................................................................................... 3-3

3.4 Field Programming......................................................................................................................... 3-6

Chapter 4 Performance Checks .......................................................... 4-1

4.1 Test Equipment Setup ................................................................................................................... 4-1

4.2 Radio Test Mode............................................................................................................................ 4-2

4.2.1 Access the Test Mode ...................................................................................................... 4-2

4.2.2 RF Test Mode ................................................................................................................... 4-4

4.2.3 Control Top Test Mode ..................................................................................................... 4-5

4.3 Receiver Performance Checks ...................................................................................................... 4-6

4.4 Transmitter Performance Checks .................................................................................................. 4-7

November 11, 2004 6881094C12-A

Page 7

Table of Contents v

Chapter 5 Radio Alignment Procedures............................................. 5-1

5.1 Radio Alignment Test Setup .......................................................................................................... 5-1

5.2 Reading the Radio ......................................................................................................................... 5-2

5.3 Tuner Menu ................................................................................................................................... 5-2

5.4 Radio Information .......................................................................................................................... 5-2

5.5 Transmitter Alignments.................................................................................................................. 5-3

5.5.1 Softpot .............................................................................................................................. 5-3

5.5.2 Reference Oscillator Alignment ........................................................................................ 5-3

5.5.3 Transmit Power Alignment................................................................................................ 5-4

5.5.4 Transmit Deviation Balance Alignment ............................................................................. 5-7

5.5.5 Transmit Deviation Limit Alignment .................................................................................. 5-8

5.6 Performance Testing ..................................................................................................................... 5-9

5.6.1 Transmitter Test Pattern ...................................................................................................5-9

5.6.2 Battery Reading Calibration .............................................................................................. 5-9

Chapter 6 Encryption ........................................................................... 6-1

6.1 Load an Encryption Key................................................................................................................. 6-1

6.2 Multikey Feature ............................................................................................................................ 6-1

Chapter 7 Disassembly/Reassembly Procedures ............................. 7-1

7.1 General Maintenance .................................................................................................................... 7-1

7.1.1 Inspection ......................................................................................................................... 7-1

7.1.2 Cleaning............................................................................................................................ 7-1

7.2 Handling Precautions..................................................................................................................... 7-2

7.3 SSE 5000 Exploded View.............................................................................................................. 7-3

7.4 Disassembly/Reassembly Procedures for Accessories................................................................. 7-6

7.4.1 Antenna ............................................................................................................................ 7-6

7.4.1.1 Attach the Antenna .................................................................................................. 7-6

7.4.1.2 Remove the Antenna............................................................................................... 7-6

7.4.2 Battery .............................................................................................................................. 7-6

7.4.2.1 Attach the Battery .................................................................................................... 7-7

7.4.2.2 Remove the Battery ................................................................................................. 7-7

7.4.3 Belt Clip ............................................................................................................................ 7-7

7.4.3.1 Attach the Belt Clip .................................................................................................. 7-7

7.4.3.2 Remove the Belt Clip ............................................................................................... 7-8

7.4.4 Carry Case........................................................................................................................ 7-9

7.4.5 Universal Connector Dust Cover .................................................................................... 7-10

7.4.5.1 Remove the Universal Connector Dust Cover....................................................... 7-10

7.4.5.2 Attach the Universal Connector Dust Cover .......................................................... 7-10

7.5 Disassembly/Reassembly Procedures for Radio Knobs ............................................................. 7-10

7.5.1 Channel Select Knob ...................................................................................................... 7-11

7.5.1.1 Remove the Channel Select Knob......................................................................... 7-11

7.5.1.2 Install the Channel Select Knob............................................................................. 7-11

7.5.2 Volume Knob .................................................................................................................. 7-11

7.5.2.1 Remove the Volume Knob..................................................................................... 7-11

7.5.2.2 Install the Volume Knob......................................................................................... 7-12

7.6 Disassembly Procedures for SSE 5000 Radio ............................................................................ 7-12

7.6.1 Separate the Chassis and Housing Assemblies ............................................................. 7-12

7.6.2 Disassemble the Chassis Assembly ............................................................................... 7-12

6881094C12-A November 11, 2004

Page 8

vi Table of Contents

7.6.3 Disassemble the Control Top.......................................................................................... 7-13

7.6.4 Disassemble the Housing Baseplate .............................................................................. 7-14

7.7 Reassembly Procedures for SSE 5000 Radio ............................................................................. 7-15

7.7.1 Reassemble the Control Top .......................................................................................... 7-15

7.7.2 Reassemble the Chassis Assembly................................................................................ 7-16

7.7.3 Join the Chassis and Housing Assemblies ..................................................................... 7-16

7.7.4 Reassemble the Housing Baseplate............................................................................... 7-17

Chapter 8 Troubleshooting.................................................................. 8-1

8.1 Voltage Measurement and Signal Tracing..................................................................................... 8-1

8.2 Standard Bias Table ...................................................................................................................... 8-1

8.3 Power-Up Error Codes................................................................................................................... 8-2

8.4 Operational Error Codes ................................................................................................................ 8-3

8.5 Receiver Troubleshooting .............................................................................................................. 8-3

8.6 Transmitter Troubleshooting .......................................................................................................... 8-4

8.7 Encryption Troubleshooting ........................................................................................................... 8-4

Chapter 9 Troubleshooting Charts ..................................................... 9-1

9.1 List of Troubleshooting Charts ....................................................................................................... 9-1

9.2 Main Troubleshooting Flowchart.................................................................................................... 9-2

9.6 Volume Set Error ......................................................................................................................... 9-11

9.7 Channel Select Error.................................................................................................................... 9-12

9.8 Button Test................................................................................................................................... 9-13

9.9 Top/Side Button Test ................................................................................................................... 9-14

9.10 VCO TX/RX Unlock...................................................................................................................... 9-15

9.15 Keyload Failure ............................................................................................................................ 9-28

9.16 Secure Hardware Failure ............................................................................................................. 9-29

Chapter 10 Troubleshooting Tables ................................................... 10-1

10.1 List of Board and IC Signals ........................................................................................................ 10-1

Chapter 11 Troubleshooting Waveforms ........................................... 11-1

11.1 List of Waveforms ........................................................................................................................ 11-1

11.2 13 MHz Clock............................................................................................................................... 11-2

11.3 16.8 MHz Buffer Input and Output ............................................................................................... 11-3

11.4 32.768 kHz Clock Outputs ........................................................................................................... 11-4

11.5 SPI B Data ................................................................................................................................... 11-5

11.6 Receive Serial Audio Port (SAP) ................................................................................................. 11-6

11.7 Receive Baseband Interface Port (RX BBP)................................................................................ 11-7

11.8 Transmit Baseband Interface Port (TX BBP) ............................................................................... 11-8

Chapter 12 Schematics, Board Layouts, and Parts Lists ................. 12-1

12.1 Transceiver (RF) Board ............................................................................................................... 12-2

12.2 VOCON Board ........................................................................................................................... 12-17

November 11, 2004 6881094C12-A

Page 9

Table of Contents vii

12.3 Control Flex ............................................................................................................................... 12-33

12.4 Universal Flex ............................................................................................................................ 12-35

12.5 UCM........................................................................................................................................... 12-37

Appendix A Accessories .........................................................................A-1

A.1 Antennas........................................................................................................................................A-1

A.2 Batteries.........................................................................................................................................A-1

A.3 Carrying Accessories..................................................................................................................... A-1

A.4 Chargers and Charger Accessories...............................................................................................A-1

A.5 Dust Cover..................................................................................................................................... A-1

A.6 Keyload Accessories .....................................................................................................................A-2

A.7 Microphones and Microphone Accessories ................................................................................... A-2

A.8 Programming Cables .....................................................................................................................A-2

A.9 Surveillance Accessories............................................................................................................... A-2

Appendix B Replacement Parts Ordering..............................................B-1

B.1 Basic Ordering Information ............................................................................................................B-1

B.2 Transceiver Board and VOCON Board Ordering Information........................................................ B-1

B.3 Motorola Online .............................................................................................................................B-1

B.4 Mail Orders ....................................................................................................................................B-1

B.5 Telephone Orders.......................................................................................................................... B-1

B.6 Fax Orders.....................................................................................................................................B-2

B.7 Parts Identification .........................................................................................................................B-2

B.8 Product Customer Service............................................................................................................. B-2

Glossary.........................................................................................Glossary-1

Index.....................................................................................................Index-1

Related Publications

SSE 5000 Portable Radio User Guide....................................................................................... 6881094C11

SSE 5000 Portable Radio User Guide (on CD) ......................................................................... 9985086F04

SSE 5000 Product Listing (Factory Mutual Approval) ............................................................... 6881094C14

SSE 5000 Portable Radio Quick Guide ..................................................................................... 6881094C16

SSE 5000 Interactive End-User Training (on CD) ..................................................................... 6881094C17

SSE 5000 Portable Radio Service Manual (on CD) .................................................................. 9985086F05

FLASHport User Guide.............................................................................................................. 6881094C35

CPS Installation guide ............................................................................................................... 6881095C44

6881094C12-A November 11, 2004

Page 10

viii

Notes

November 11, 2004 6881094C12-A

Page 11

List of Figures ix

List of Figures

Figure 1-1. Physical Features of the SSE 5000 Radio............................................................................ 1-1

Figure 2-1. SSE 5000 Overall Block Diagram ......................................................................................... 2-1

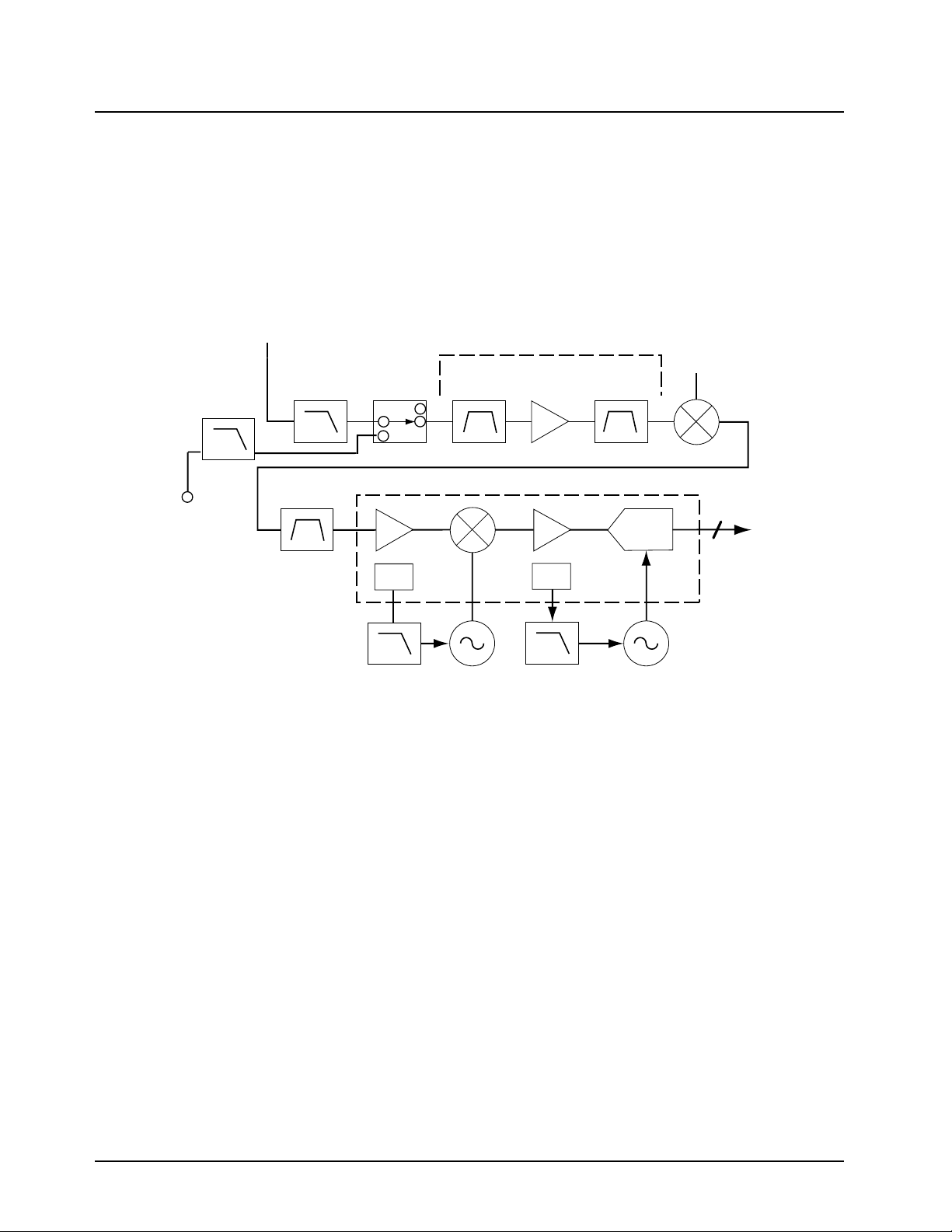

Figure 2-2. Receiver Block Diagram ....................................................................................................... 2-2

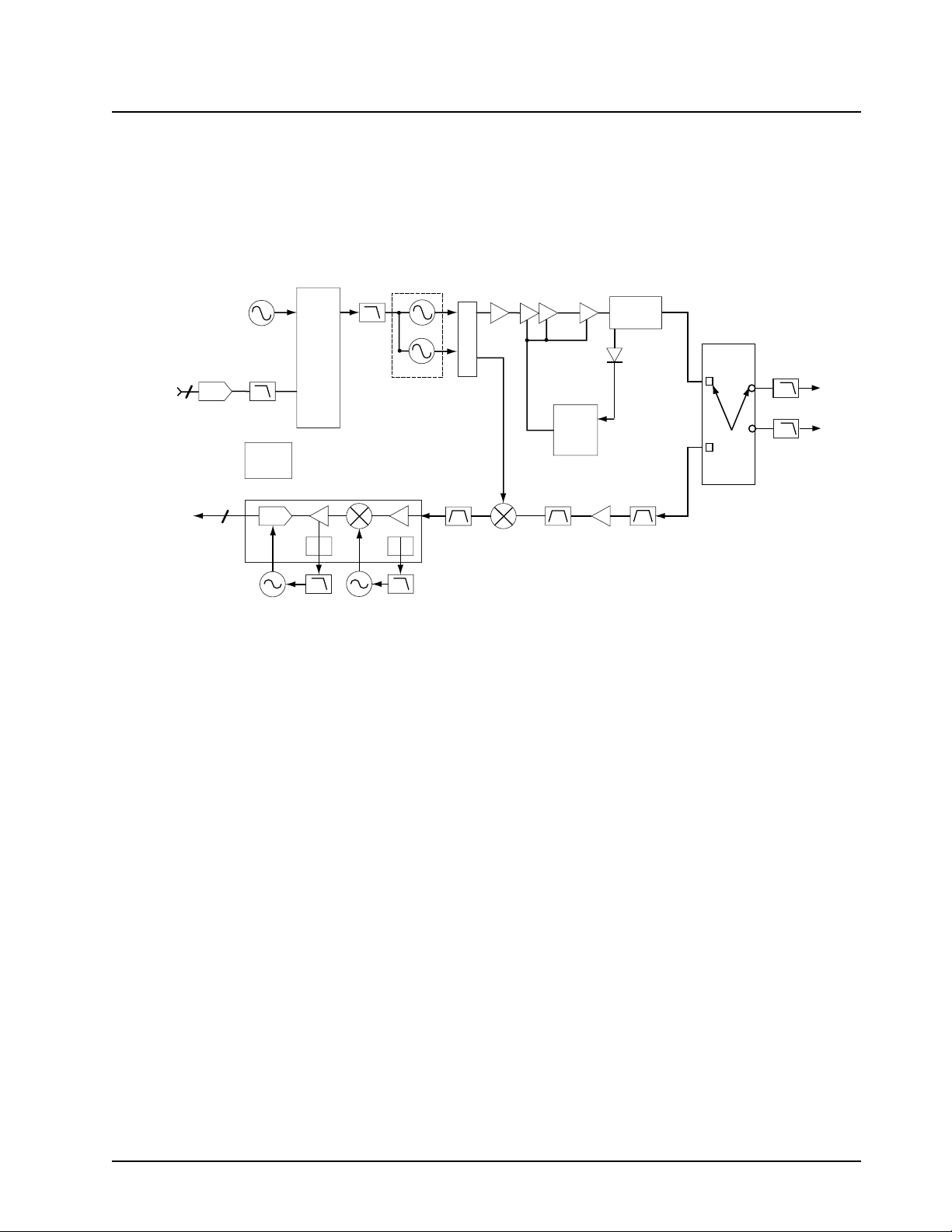

Figure 2-3. Transceiver (UHF Range) Block Diagram (Power and Control Omitted).............................. 2-3

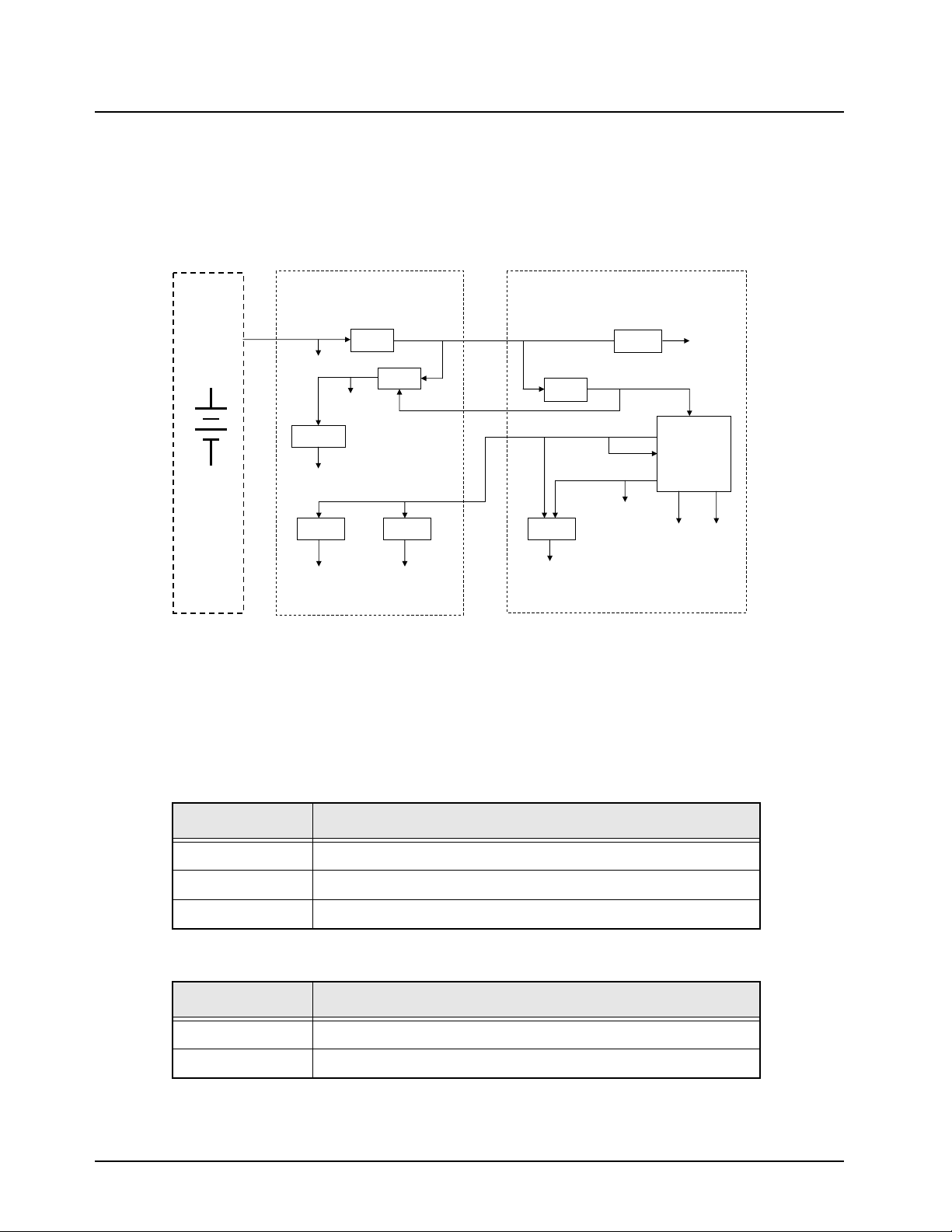

Figure 2-4. DC Power Distribution—UHF Radios ................................................................................... 2-4

Figure 2-5. Abacus III (AD9874) Functional Block Diagram.................................................................. 2-11

Figure 2-6. Transmitter Block Diagram ................................................................................................. 2-12

Figure 2-7. VOCON Board Block Diagram............................................................................................2-18

Figure 2-8. Dual-Core Processor EIM and Memory Block Diagram...................................................... 2-23

Figure 2-9. Universal Side Connector ................................................................................................... 2-29

Figure 2-10. VOCON Board Connector J102..........................................................................................2-30

Figure 2-11. VOCON Transmit Audio Path ............................................................................................. 2-33

Figure 2-12. VOCON Receive Audio Path .............................................................................................. 2-34

Figure 4-1. Performance Checks Test Setup .......................................................................................... 4-1

Figure 5-1. Radio Alignment Test Setup.................................................................................................. 5-1

Figure 5-2. Tuner Software Main Menu................................................................................................... 5-2

Figure 5-3. Radio Information Screen ..................................................................................................... 5-2

Figure 5-4. Typical Softpot Screen .......................................................................................................... 5-3

Figure 5-5. Reference Oscillator Alignment Screen ................................................................................5-4

Figure 5-6. Transmit Power Alignment Screen (High Power) ................................................................. 5-6

Figure 5-7. Transmit Power Alignment Screen (Low Power) .................................................................. 5-6

Figure 5-8. Transmit Deviation Balance Alignment Screen..................................................................... 5-7

Figure 5-9. Transmit Deviation Limit Alignment Screen .......................................................................... 5-8

Figure 5-10. Transmitter Test Pattern Screen ........................................................................................... 5-9

Figure 5-11. Battery Reading Calibration Screen.................................................................................... 5-10

Figure 7-1. SSE 5000 Exploded View..................................................................................................... 7-3

Figure 7-2. Attaching/Removing the Antenna ......................................................................................... 7-6

Figure 7-3. Attaching/Removing the Battery ........................................................................................... 7-7

Figure 7-4. Attaching the Belt Clip........................................................................................................... 7-8

Figure 7-5. Removing the Belt Clip ......................................................................................................... 7-8

Figure 7-6. Assembling the Carry Case .................................................................................................. 7-9

Figure 7-7. Attaching the Universal Connector Dust Cover .................................................................. 7-10

Figure 11-1. 13 MHz Clock Waveform .................................................................................................... 11-2

Figure 11-2. 16.8 MHz Buffer Input and Output Waveforms ................................................................... 11-3

Figure 11-3. 32.768 kHz Clock Outputs Waveforms............................................................................... 11-4

Figure 11-4. SPI B Data Waveforms ....................................................................................................... 11-5

Figure 11-5. Receive Serial Audio Port (SAP) Waveforms ..................................................................... 11-6

Figure 11-6. Receive Baseband Interface Port (RX BBP) Waveforms ................................................... 11-7

Figure 11-7. Transmit Baseband Interface Port (TX BBP) Waveforms ................................................... 11-8

6881094C12-A November 11, 2004

Page 12

x List of Tables

List of Tables

Table 2-1. Conventional Batteries .......................................................................................................... 2-4

Table 2-2. Smart Batteries ..................................................................................................................... 2-4

Table 2-3. Transceiver Voltage Regulators............................................................................................ 2-5

Table 2-4. VOCON Board DC Power Distribution .................................................................................. 2-6

Table 2-5. Battery Connector J3 ............................................................................................................ 2-7

Table 2-6. VOCON Connector P1 .......................................................................................................... 2-7

Table 2-7. Local Oscillator and First IF Frequencies .............................................................................2-9

Table 2-8. Power Control IC (U104) Pin Descriptions.......................................................................... 2-14

Table 2-9. Audio PA Status .................................................................................................................. 2-26

Table 2-10. Pin Assignments for Universal Side Connector .................................................................. 2-30

Table 2-11. Option Select Functions...................................................................................................... 2-31

Table 3-1. Test Equipment ..................................................................................................................... 3-1

Table 3-2. Service Aids .......................................................................................................................... 3-3

Table 4-1. Initial Equipment Control Settings ......................................................................................... 4-2

Table 4-2. Test-Mode Displays............................................................................................................... 4-3

Table 4-3. Test Frequencies (MHz) ........................................................................................................ 4-4

Table 4-4. Test Environments................................................................................................................. 4-4

Table 4-5. Receiver Performance Checks .............................................................................................4-6

Table 4-6. Transmitter Performance Checks ......................................................................................... 4-7

Table 5-1. Reference Oscillator Alignment ............................................................................................ 5-4

Table 5-2. Transmit Power Settings ....................................................................................................... 5-5

Table 7-1. SSE 5000 Exploded View Parts List ..................................................................................... 7-4

Table 7-2. Tools Used for Disassembly/Reassembly ........................................................................... 7-10

Table 8-1. Standard Operating Bias....................................................................................................... 8-1

Table 8-2. Power-Up Error Code Displays ............................................................................................. 8-2

Table 8-3. Operational Error Code Displays .......................................................................................... 8-3

Table 8-4. Receiver Troubleshooting Chart ........................................................................................... 8-3

Table 8-5. Transmitter Troubleshooting Chart........................................................................................ 8-4

Table 8-6. Encryption Troubleshooting Chart......................................................................................... 8-4

Table 9-1. Troubleshooting Charts List .................................................................................................. 9-1

Table 10-1. List of Tables of Board and IC Signals ................................................................................ 10-1

Table 10-2. J102 VOCON Board to Universal Flex................................................................................ 10-2

Table 10-3. J707 VOCON Board to Controls Flex Assembly................................................................. 10-2

Table 10-4. J701 VOCON Board to Encryption Module......................................................................... 10-3

Table 10-5. U402 FLASH Pinouts.......................................................................................................... 10-4

Table 10-6. U403 SRAM Pinouts ........................................................................................................... 10-6

Table 10-7. U401 MCU/DSP IC Pinouts ................................................................................................ 10-8

Table 10-8. U301 Digital-Support IC Pinouts ....................................................................................... 10-17

Table 10-9. U501 GCAP II IC Pinouts.................................................................................................. 10-19

Table 11-1. List of Waveforms ............................................................................................................... 11-1

Table 12-1. List of Transceiver Schematics, Board Layouts and Parts Lists ......................................... 12-1

Table 12-2. List of VOCON Schematics, Board Layouts and Parts Lists............................................... 12-1

Table 12-3. List of Control Flex Schematics and Board Layouts ........................................................... 12-1

Table 12-4. List of Universal Flex Schematics and Board Layouts........................................................ 12-1

Table 12-5. List of UCM Schematics and Board Layouts....................................................................... 12-1

November 11, 2004 6881094C12-A

Page 13

Commercial Warranty

Special Note on NYPD Warranty Agreement

The three-year warranty on the NYPD SSE 5000 portable radio units represents the combination of the

standard one-year product warranty (detailed in this section) and the two-year Motorola Express Service Plus

(ESP) option. ESP is an extended service coverage plan, which provides for the repair of this product for an

additional period of two years beyond the expiration date of the standard warranty. For more information about

ESP, contact the Motorola Radio Support Center at 2200 Galvin Drive, Elgin IL 60123, (800) 422-4210 (U.S.

and Canada) / (847) 538-8023 (international).

Limited Warranty

MOTOROLA COMMUNICATION PRODUCTS

I. What This Warranty Covers And For How Long

MOTOROLA INC. (“MOTOROLA”) warrants the MOTOROLA manufactured Communication

Products listed below (“Product”) against defects in material and workmanship under normal use and

service for a period of time from the date of purchase as scheduled below:

SSE 5000 Portable Units Three (3) Years

Product Accessories One (1) Year

Motorola, at its option, will at no charge either repair the Product (with new or reconditioned parts),

replace it (with a new or reconditioned Product), or refund the purchase price of the Product during

the warranty period provided it is returned in accordance with the terms of this warranty. Replaced

parts or boards are warranted for the balance of the original applicable warranty period. All replaced

parts of Product shall become the property of MOTOROLA.

This express limited warranty is extended by MOTOROLA to the original end user purchaser only

and is not assignable or transferable to any other party. This is the complete warranty for the Product

manufactured by MOTOROLA. MOTOROLA assumes no obligations or liability for additions or

modifications to this warranty unless made in writing and signed by an officer of MOTOROLA.

Unless made in a separate agreement between MOTOROLA and the original end user purchaser,

MOTOROLA does not warrant the installation, maintenance or service of the Product.

MOTOROLA cannot be responsible in any way for any ancillary equipment not furnished by

MOTOROLA which is attached to or used in connection with the Product, or for operation of the

Product with any ancillary equipment, and all such equipment is expressly excluded from this

warranty. Because each system which may use the Product is unique, MOTOROLA disclaims

liability for range, coverage, or operation of the system as a whole under this warranty.

Page 14

xii Commercial Warranty

II. General Provisions

This warranty sets forth the full extent of MOTOROLA’S responsibilities regarding the Product.

Repair, replacement or refund of the purchase price, at MOTOROLA’s option, is the exclusive

remedy. THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER EXPRESS WARRANTIES. IMPLIED

WARRANTIES, INCLUDING WITHOUT LIMITATION, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO THE

DURATION OF THIS LIMITED WARRANTY. IN NO EVENT SHALL MOTOROLA BE LIABLE FOR

DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE PRODUCT, FOR ANY LOSS OF

USE, LOSS OF TIME, INCONVENIENCE, COMMERCIAL LOSS, LOST PROFITS OR SAVINGS

OR OTHER INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF THE

USE OR INABILITY TO USE SUCH PRODUCT, TO THE FULL EXTENT SUCH MAY BE

DISCLAIMED BY LAW.

III. State Law Rights

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LIMITATION ON HOW LONG AN IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION OR EXCLUSIONS MAY NOT APPLY.

This warranty gives specific legal rights, and there may be other rights which may vary from state to

state.

IV. How To Get Warranty Service

You must provide proof of purchase (bearing the date of purchase and Product item serial number)

in order to receive warranty service and, also, deliver or send the Product item, transportation and

insurance prepaid, to an authorized warranty service location. Warranty service will be provided by

Motorola through one of its authorized warranty service locations. If you first contact the company

which sold you the Product, it can facilitate your obtaining warranty service. You can also call

Motorola at 1-888-567-7347 US/Canada.

V. What This Warranty Does Not Cover

A. Defects or damage resulting from use of the Product in other than its normal and customary

manner.

B. Defects or damage from misuse, accident, water, or neglect.

C. Defects or damage from improper testing, operation, maintenance, installation, alteration,

modification, or adjustment.

D. Breakage or damage to antennas unless caused directly by defects in material workmanship.

E. A Product subjected to unauthorized Product modifications, disassemblies or repairs

(including, without limitation, the addition to the Product of non-Motorola supplied equipment)

which adversely affect performance of the Product or interfere with Motorola's normal

warranty inspection and testing of the Product to verify any warranty claim.

F. Product which has had the serial number removed or made illegible.

G. Rechargeable batteries if:

- any of the seals on the battery enclosure of cells are broken or show evidence of

tampering.

- the damage or defect is caused by charging or using the battery in equipment or service

other than the Product for which it is specified.

H. Freight costs to the repair depot.

November 11, 2004 6881094C12-A

Page 15

Commercial Warranty xiii

I. A Product which, due to illegal or unauthorized alteration of the software/firmware in the

Product, does not function in accordance with MOTOROLA’s published specifications or the

FCC type acceptance labeling in effect for the Product at the time the Product was initially

distributed from MOTOROLA.

J. Scratches or other cosmetic damage to Product surfaces that does not affect the operation of

the Product.

K. Normal and customary wear and tear.

VI. Patent And Software Provisions

MOTOROLA will defend, at its own expense, any suit brought against the end user purchaser to the

extent that it is based on a claim that the Product or parts infringe a United States patent, and

MOTOROLA will pay those costs and damages finally awarded against the end user purchaser in

any such suit which are attributable to any such claim, but such defense and payments are

conditioned on the following:

A. that MOTOROLA will be notified promptly in writing by such purchaser of any notice of such

claim;

B. that MOTOROLA will have sole control of the defense of such suit and all negotiations for its

settlement or compromise; and

C. should the Product or parts become, or in MOTOROLA’s opinion be likely to become, the

subject of a claim of infringement of a United States patent, that such purchaser will permit

MOTOROLA, at its option and expense, either to procure for such purchaser the right to

continue using the Product or parts or to replace or modify the same so that it becomes

noninfringing or to grant such purchaser a credit for the Product or parts as depreciated and

accept its return. The depreciation will be an equal amount per year over the lifetime of the

Product or parts as established by MOTOROLA.

MOTOROLA will have no liability with respect to any claim of patent infringement which is based

upon the combination of the Product or parts furnished hereunder with software, apparatus or

devices not furnished by MOTOROLA, nor will MOTOROLA have any liability for the use of ancillary

equipment or software not furnished by MOTOROLA which is attached to or used in connection with

the Product. The foregoing states the entire liability of MOTOROLA with respect to infringement of

patents by the Product or any parts thereof.

Laws in the United States and other countries preserve for MOTOROLA certain exclusive rights for

copyrighted MOTOROLA software such as the exclusive rights to reproduce in copies and distribute

copies of such Motorola software. MOTOROLA software may be used in only the Product in which

the software was originally embodied and such software in such Product may not be replaced,

copied, distributed, modified in any way, or used to produce any derivative thereof. No other use

including, without limitation, alteration, modification, reproduction, distribution, or reverse

engineering of such MOTOROLA software or exercise of rights in such MOTOROLA software is

permitted. No license is granted by implication, estoppel or otherwise under MOTOROLA patent

rights or copyrights.

VII. Governing Law

This Warranty is governed by the laws of the State of Illinois, USA.

6881094C12-A November 11, 2004

Page 16

xiv Commercial Warranty

Notes

November 11, 2004 6881094C12-A

Page 17

Chapter 1 Radio Description

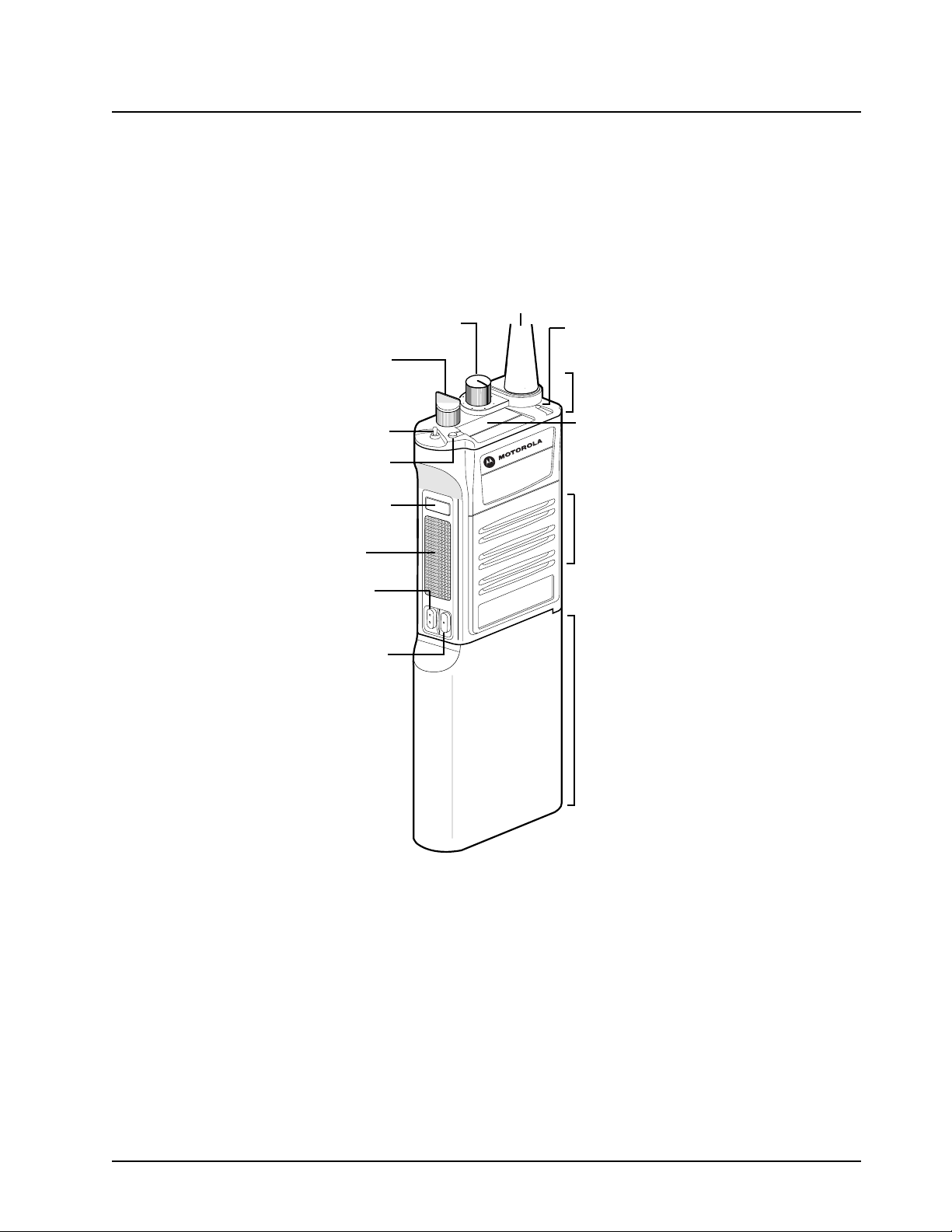

1.1 Physical Features of the Radio

Figure 1-1 shows the physical features of the SSE 5000 portable radio.

On/Off/

Volume

Knob

Channel

Bank Select

Switch

Display

Button

Monitor

Button

PTT

Channel

Bank

Button

Secure

Button

Channel

Select

Knob

7

5

3

Antenna

5

1

1

P

Y

N

0

5

E

S

S

D

Transm it/

Receive

Indicator

(LED)

Control

Top

Display (1 line x 8 char,

bitmapped LCD)

0

0

Speaker/

Mic

Battery

The SSE 5000 portable radio operates in the UHF Range 2 (450–488 MHz) frequency band. It can

be programmed with up to 96 channels. Earlier versions of the radio, which could be programmed

with up to 48 channels, can be upgraded to 96-channel capability via FLASHport

1.2 FLASHport

The SSE 5000 radio utilizes Motorola’s FLASHport technology. FLASHport allows you to add

software that drives the radio’s capabilities, both at the time of purchase and afterwards. Previously,

changing a radio’s features and capabilities meant significant modifications, or buying a new radio.

Now the radio’s features and capabilities can be upgraded with FLASHport software, similar to how a

computer can be loaded with different software. For information on upgrading the radio’s features

using FLASHport, see the FLASHport User Guide (Motorola publication part number 6881094C35).

Figure 1-1. Physical Features of the SSE 5000 Radio

®

®

.

Page 18

1-2 Radio Description: Portable Radio Model Numbering System

1.3 Portable Radio Model Numbering System

SSE5000ModelNumber:

Position:

Position1-TypeofUnit

H=Hand-HeldPortable

Positions2&3-ModelSeries

10=SSE5000

Position4-FrequencyBand

Lessthan29.7MHz

A

=

29.7to35.99MHz

B

=

36to41.99MHz

C

=

42to50MHz

D

=

66to80MHz

F

=

74to90MHz

G

=

ProductSpecific

H

=

136to162MHz

J

=

146to178MHz

K

=

174to210MHz

L

=

190to235MHz

M

=

Valuesgivenrepresentrangeonly;theyare

notabsolute.

Position5-PowerLevel

0to0.7Watts

A

=

0.7to0.9Watts

B

=

1.0to3.9Watts

C

=

4.0to5.0Watts

D

=

5.1to6.0Watts

E

=

6.1to10Watts

F

=

Position6-PhysicalPackages

RFModemOperation

A

=

ReceiverOnly

B

=

StandardControl;NoDisplay

C

=

StandardControl;WithDisplay

D

=

LimitedKeypad;NoDisplay

E

=

LimitedKeypad;WithDisplay

F

=

FullKeypad;NoDisplay

G

=

FullKeypad;WithDisplay

H

=

LimitedControls;NoDisplay

J

=

LimitedControls;BasicDisplay

K

=

LimitedControls;LimitedDisplay

L

=

RotaryControls;StandardDisplay

M

=

EnhancedControls;EnhancedDisplay

N

=

LowProfile;NoDisplay

P

=

LowProfile;BasicDisplay

Q

=

LowProfile;BasicDisplay,FullKeypad

R

=

Position7-ChannelSpacing

1=5kHz

2=6.25kHz

3=10kHz

4=12.5kHz

H10 S DD 9 P W 6 A N S P 0 1

123 4 56 7 8 910111213141516

P

=

Q

=

R

=

S

=

T

=

U

=

V

=

W

=

Y

=

Z

=

5=15kHz

6=20/25kHz

7=30kHz

9=Variable/Programmable

336to410MHz

403to437MHz

438to482MHz

470to520MHz

ProductSpecific

764to870MHz

825to870MHz

896to941MHz

1.0to1.6GHz

1.5to2.0GHz

Positions13-16

SPModelSuffix

Position12-

UniqueModelVariations

C=Cenelec

N=StandardPackage

Position11-Version

VersionLetter(Alpha)-MajorChange

Position10-FeatureLevel

1=Basic

2=LimitedPackage

3=LimitedPlus

4=Intermediate

5=StandardPackage

Position9-PrimarySystemType

A

=

Conventional

B

=

PrivacyPlus

C

=

ClearSMARTNET

D

=

AdvancedConventionalStat-Alert

E

=

EnhancedPrivacyPlus

F

=

Nauganet888Series

G

=

JapanSpecializedMobileRadio(JSMR)

H

=

Multi-ChannelAccess(MCA)

J

=

CoveragePLUS

K

=

MPT1327*-Public

L

=

MPT1327*-Private

M

=

Radiocom

N

=

ToneSignalling

P

=

BinarySignalling

Q

=

Phonenet

W

=

Programmable

X

=

SecureConventional

Y

=

SecureSMARTNET

6=StandardPlus

7=ExpandedPackage

8=ExpandedPlus

9=FullFeature/

Programmable

*MPT=MinistryofPostsandTelecommunications

Position8-PrimaryOperation

A

=

Conventional/Simplex

B

=

Conventional/Duplex

C

=

TrunkedTwinType

D

=

DualModeTrunked

E

=

DualModeTrunked/Duplex

F

=

TrunkedTypeI

G

=

TrunkedTypeII

H

=

FDMA*DigitalDualMode

J

=

TDMA**DigitalDualMode

K

=

SingleSideband

L

=

GlobalPositioningSatelliteCapable

M

=

AmplitudeCompandedSideband(ACSB)

P

=

Programmable

*FDMA=FrequencyDivisionMultipleAccess

**TDMA=TimeDivisionMultipleAccess

MAEPF-27326-A

November 11, 2004 6881094C12-A

Page 19

Radio Description: SSE 5000 UHF Range 2 (450–488 MHz) Model Chart 1-3

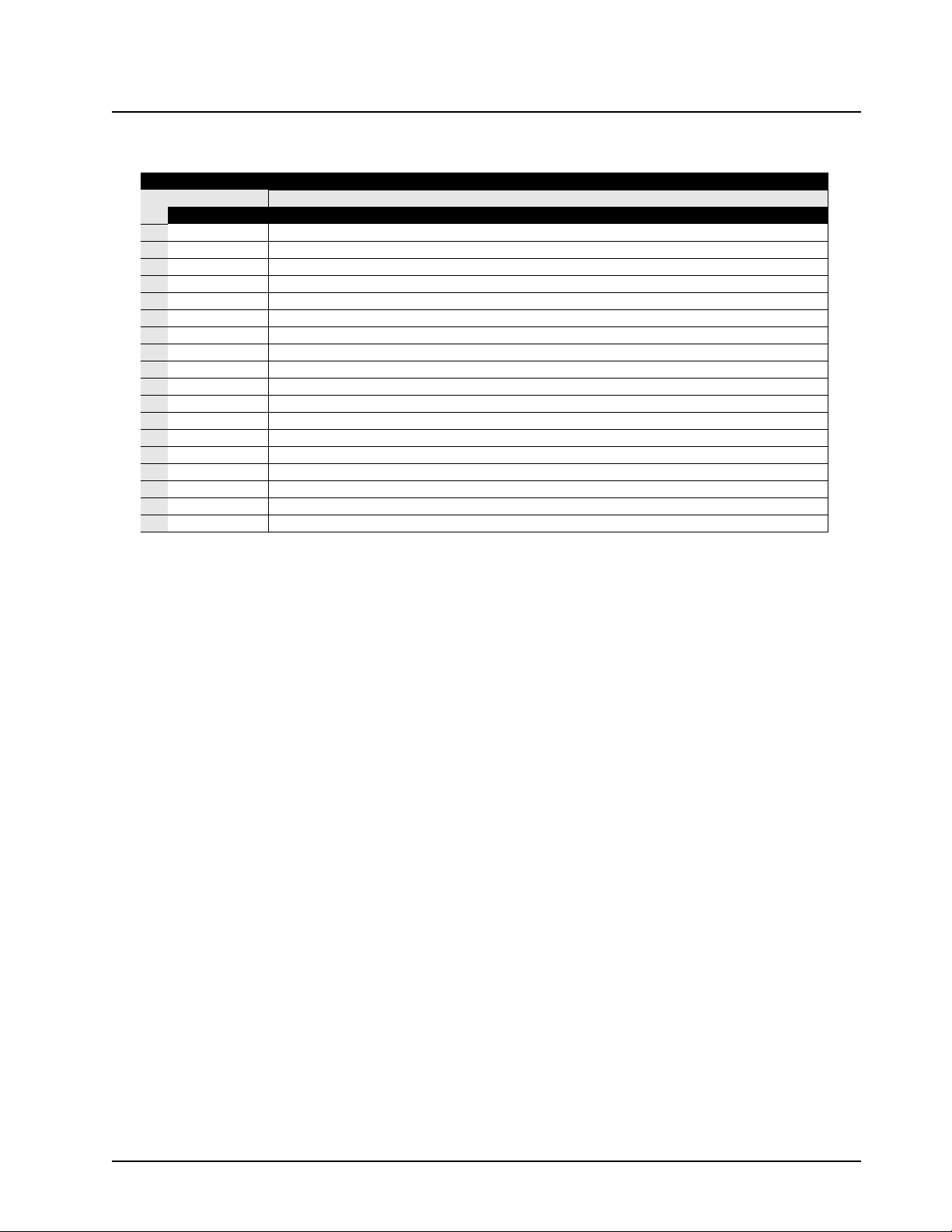

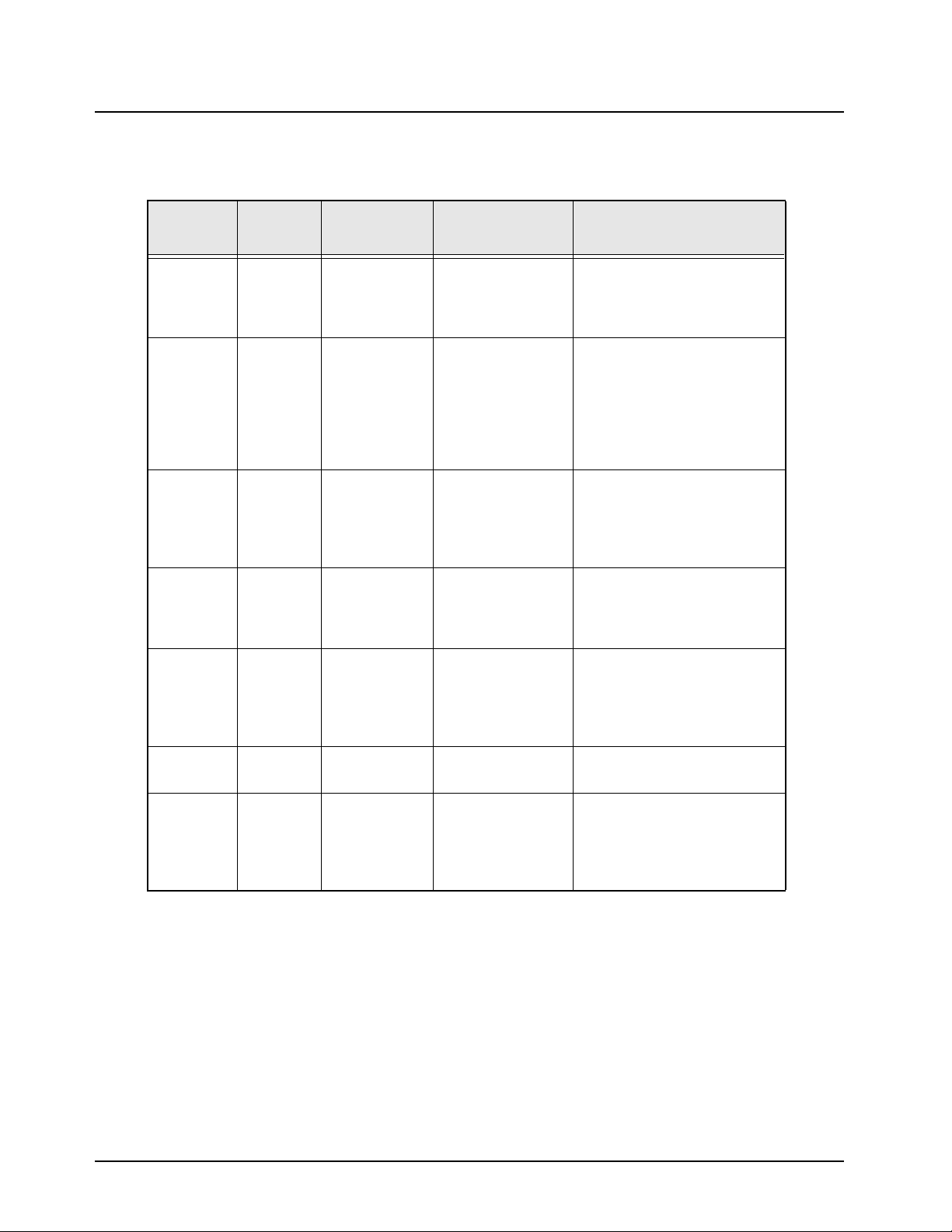

1.4 SSE 5000 UHF Range 2 (450–488 MHz) Model Chart

MODEL NUMBER DESCRIPTION

H10SDD9PW6AN UHF Range 2 (450–488 MHz), 2–5 Watts, SSE 5000

ITEM NUMBER DESCRIPTION

X — Antenna, UHF (Refer to Section A.1: “Antennas” on page A-1)

X — Battery (Refer to Section A.2: “Batteries” on page A-1)

X NUE7337_ Board, Transceiver, UHF Range 2 (450–488 MHz)

X NCN6186_ Board, VOCON *

X — Cable, Programming (Refer to Section A.8: “Programming Cables” on page A-2)

X — Case, Carrying (Refer to Section A.3: “Carrying Accessories” on page A-1)

X — Charger (Refer to Section A.4: “Chargers and Charger Accessories” on page A-1)

X NTN7061_ Cover, Accessory Connector

X NNTN4709_ Kit, Belt Clip

X NNTN4825_ Kit, Chassis, Back

X NNTN4826_ Kit, Chassis, Front

X 8485687E01 Kit, Control Flex

X NNTN4468_ Kit, Hardware

X NNTN4467_ Kit, Housing

X 8485791E01 Kit, Speaker Mic Flex

X — Mic Accessories (Refer to Section A.7: “Microphones and Microphone Accessories” on page A-2)

X NNTN4006_ Module, Encryption, DES, DES-XL, DES-PFB

X — Surveillance Accessories (Refer to Section A.9: “Surveillance Accessories” on page A-2)

X

Notes:

X = Item Included

* = When ordering a VOCON board, you will be asked to provide the radio's model number, FLASHcode, host

code, and DSP code. You can find this information as follows:

• For the radio model number and FLASHcode, place the radio in test mode (see Section 4.2: “Radio Test

Mode” on page 4-2) and view the scrolling displays.

• For the host code and DSP code, read the radio using the programming cable (RKN4121_ or RKN4122_)

and view the information in the CPS.

6881094C12-A November 11, 2004

Page 20

1-4 Radio Description: Specifications for UHF Range 2 (450–488 MHz) Radios

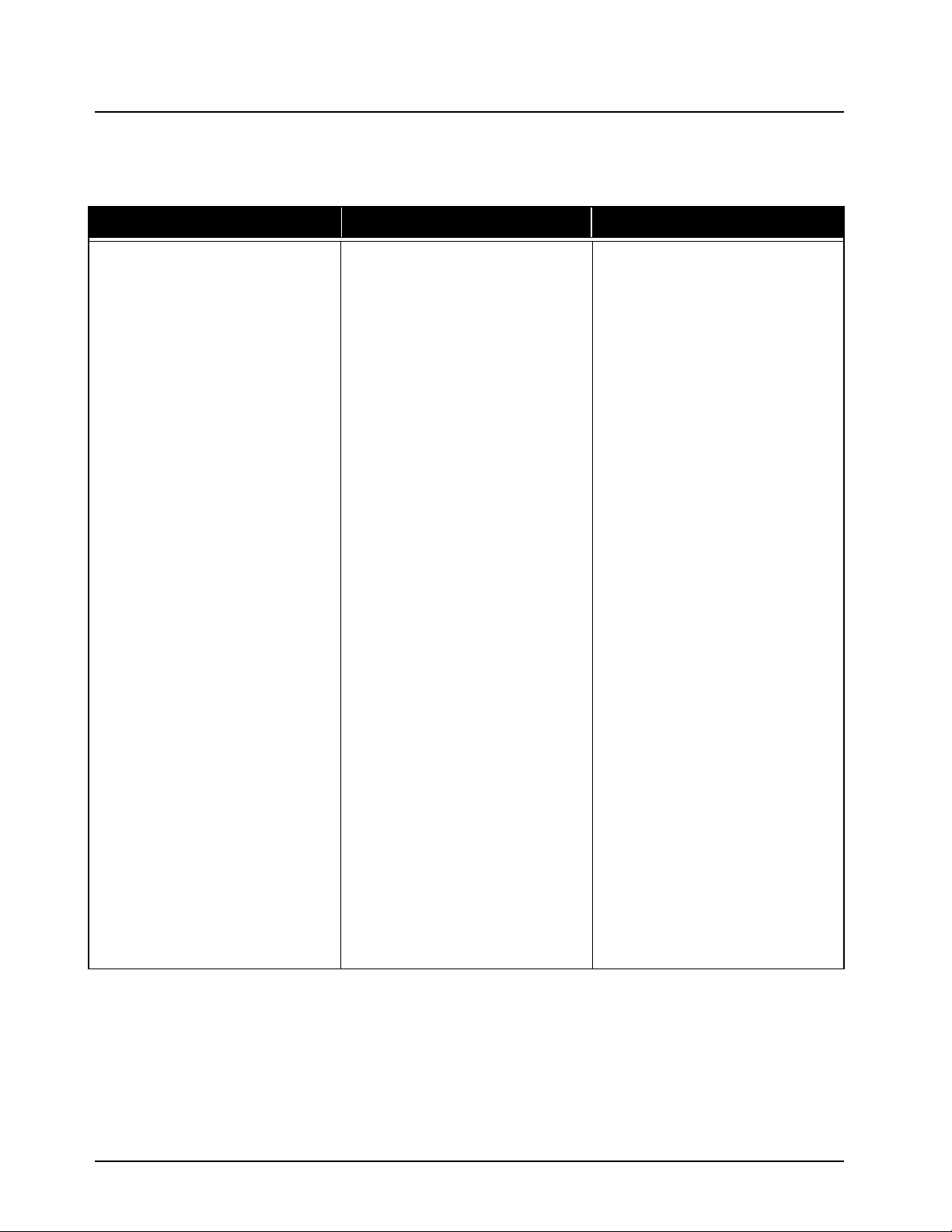

1.5 Specifications for UHF Range 2 (450–488 MHz) Radios

All specifications are per Telecommunications Industry Association TIA/EIA-603 unless otherwise

noted.

GENERAL RECEIVER TRANSMITTER

FCC Designation: AZ489FT4861

Temperature Range:

Operating: –30°C to +60°C

Storage: –40°C to +85°C

Power Supply: Nickel-Cadmium Battery (NiCd)

Battery Voltage:

Nominal: 7.5 Vdc

Range: 6 to 9 Vdc

Transmit Current Drain (typical)*:

5W RF Power: 1800 mA

2W RF Power: 1100 mA

Receive Current Drain at Rated Audio

(typical)*: 240 mA

Standby Current Drain (typical)*: 80 mA

Recommended Battery:

NiCd: NTN4595

or NiCd Smart: HNN9033

Optional FM (Factory Mutual) Battery:

NiCd FM: NTN4596*

or NiCd FM (HazMat): NTN4992*

or NiCd Smart FM: HNN9034*

* FM Intrinsically Safe.

Dimensions (H x W x D):

Without Battery (Radio Only):

H W

(no antenna) (at cntl top) (at cntl top)

4.7 in. 2.92 in. 1.37 in.

119.5 mm 74.2 mm 34.9 mm

(no antenna) (at bottom) (at PTT)

4.7 in. 2.66 in. 1.27 in.

119.5 mm 67.6 mm 32.2 mm

With Battery:

H W

(no antenna) (at cntl top) (at cntl top)

8.5 in. 2.92 in. 1.37 in.

215.9 mm 74.2 mm 34.9 mm

(no antenna) (at bottom) (at PTT)

8.5 in. 2.66 in. 1.27 in.

215.9 mm 67.6 mm 32.2 mm

D

D

Frequency Range: 450–488 MHz

Bandwidth: 38 MHz

Reference Sensitivity (12 dB SINAD) (typical):

0.25 µV

Intermodulation Rejection (typical): 75 dB

Adjacent Channel Rejection (typical):

25/30 kHz 78 dB

12.5 kHz 68 dB

Spurious Response Rejection (typical): 80 dB

Rated Audio Frequency Output Power:

500 mW

Hum and Noise Ratio (typical):

25 kHz 50 dB

12.5 kHz 43 dB

Audio Distortion (typical): 1.0%

Channel Spacing: 12.5/25 kHz

Frequency Range: 450–488 MHz

Conducted Carrier Output Power Rating:

450–488 MHz: 2–5 Watts

Carrier Frequency Stability (typical)

(–30 to +60°C; 25°C ref.): ±0.0002%

Conducted Spurious Emissions (typical):

70 dBc

FM Hum and Noise Ratio (typical)

(Companion Receiver): 25 kHz 50 dB

12.5 kHz 40 dB

Audio Distortion (typical): 1.5%

Modulation Limiting: 25 kHz ±5.0 kHz

12.5 kHz ±2.5 kHz

Adjacent Channel Power Ratio (ACPR)

(typical): 25 kHz 77 dBc

12.5 kHz 62 dBc

Emissions Designators:

20K0F1E, 16K0F3E, 11K0F3E, 8K10F1D, and

8K10F1E

Weight: (w/ Antenna):

Less Battery: 11.2 oz (316.9 gm)

With NiCd Smart: 15.9 oz (449.4 gm)

With NiCd: 13.7 oz (387.8 gm)

* Test box will add 25 mA.

Specifications subject to change without notice.

November 11, 2004 6881094C12-A

Page 21

Radio Description: Notations Used in This Manual 1-5

C

n

W

G

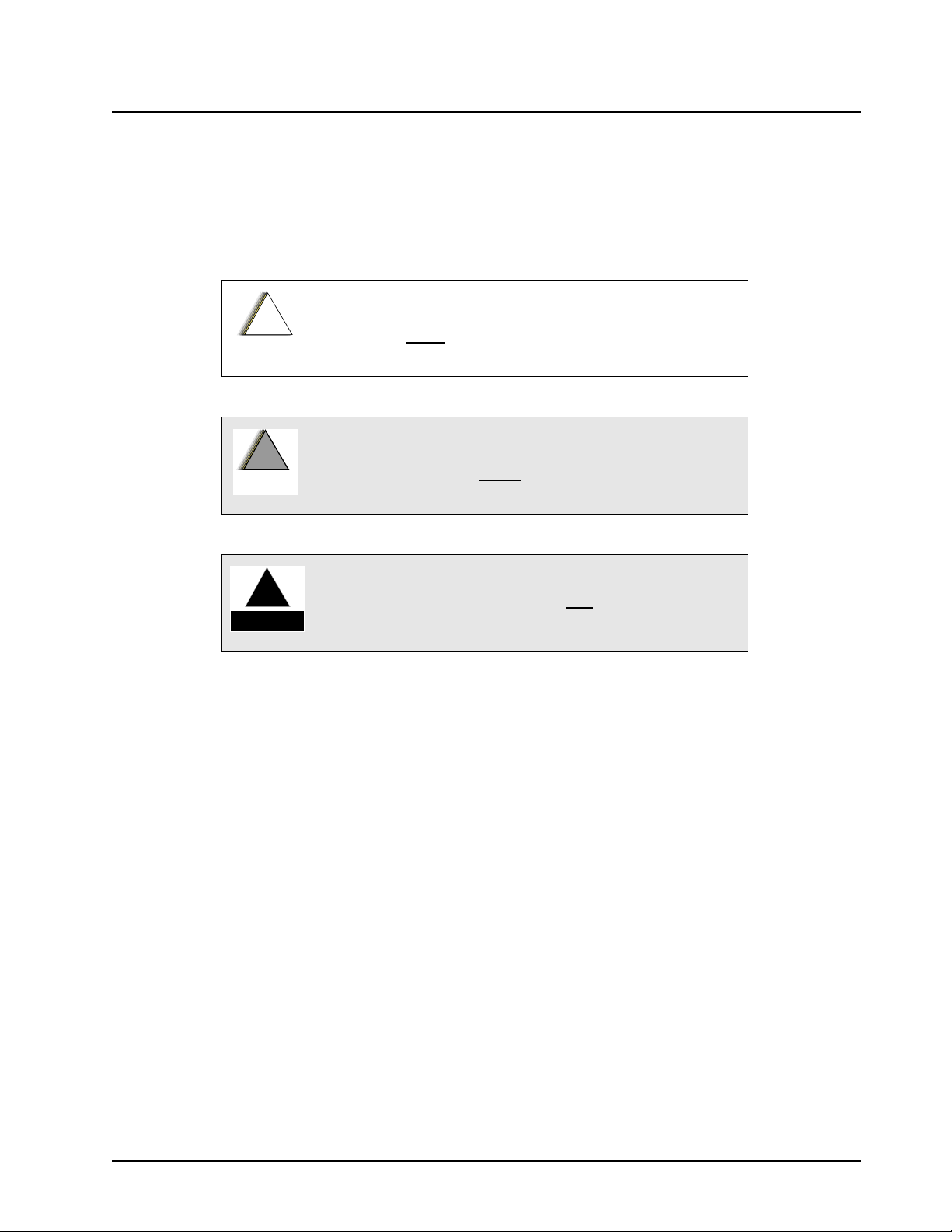

1.6 Notations Used in This Manual

Throughout the text in this publication, you will notice the use of note, caution, warning, and danger

notations. These notations are used to emphasize that safety hazards exist, and due care must be

taken and observed.

NOTE: An operational procedure, practice, or condition that is essential to emphasize.

!

a u t i o

!

!

A R N I N

!

D A N G E R

CAUTION indicates a potentially hazardous situation which, if

not avoided, might

WARNING indicates a potentially hazardous situation

which, if not avoided, could

DANGER indicates an imminently hazardous

situation which, if not avoided, will

injury.

result in equipment damage.

result in death or injury.

result in death or

6881094C12-A November 11, 2004

Page 22

1-6 Radio Description: Notations Used in This Manual

Notes

November 11, 2004 6881094C12-A

Page 23

Chapter 2 Theory of Operation

This chapter provides a detailed circuit description of the SSE 5000 transceiver and VOCON boards.

When reading the theory of operation, refer to the appropriate schematic and component location

diagrams located in the back of this manual. This detailed theory of operation can help isolate the

problem to a particular component.

The SSE 5000 radio is a dual-mode (digital/analog), microcontroller-based transceiver incorporating

a digital signal processor (DSP). The microcontroller handles the general radio control, monitors

status, and processes commands input from the keypad or other user controls. The DSP processes

the typical analog signals, and generates the standard signaling digitally to provide compatibility with

existing analog systems. In addition, the DSP provides digital modulation techniques, utilizing voice

encoding techniques with error correction schemes. This provides the user with enhanced range and

audio quality, all in a reduced bandwidth channel requirement. It allows embedded signaling, which

can mix system information and data with digital voice to support a multitude of system features.

The SSE 5000 radio operates within the UHF range (450 to 488 MHz).

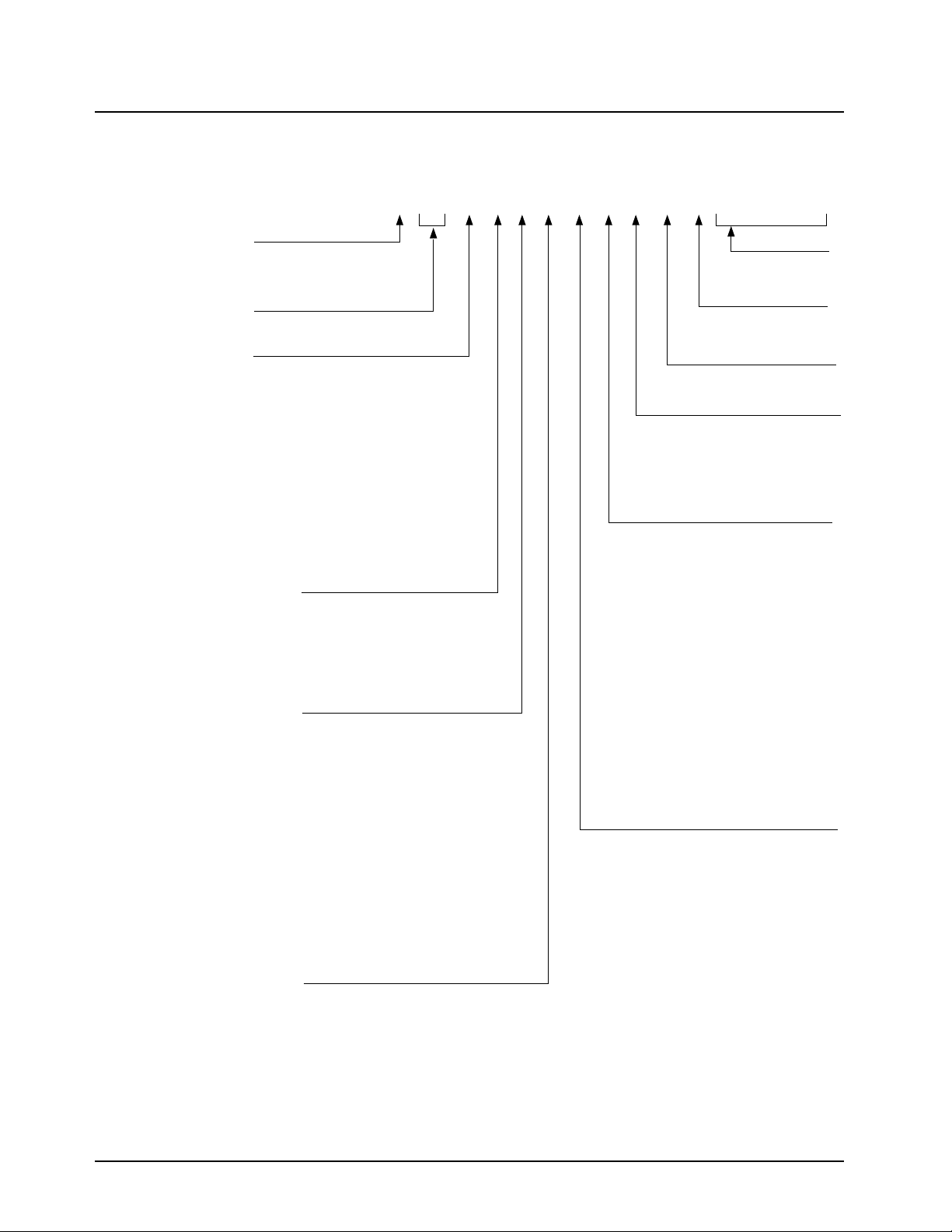

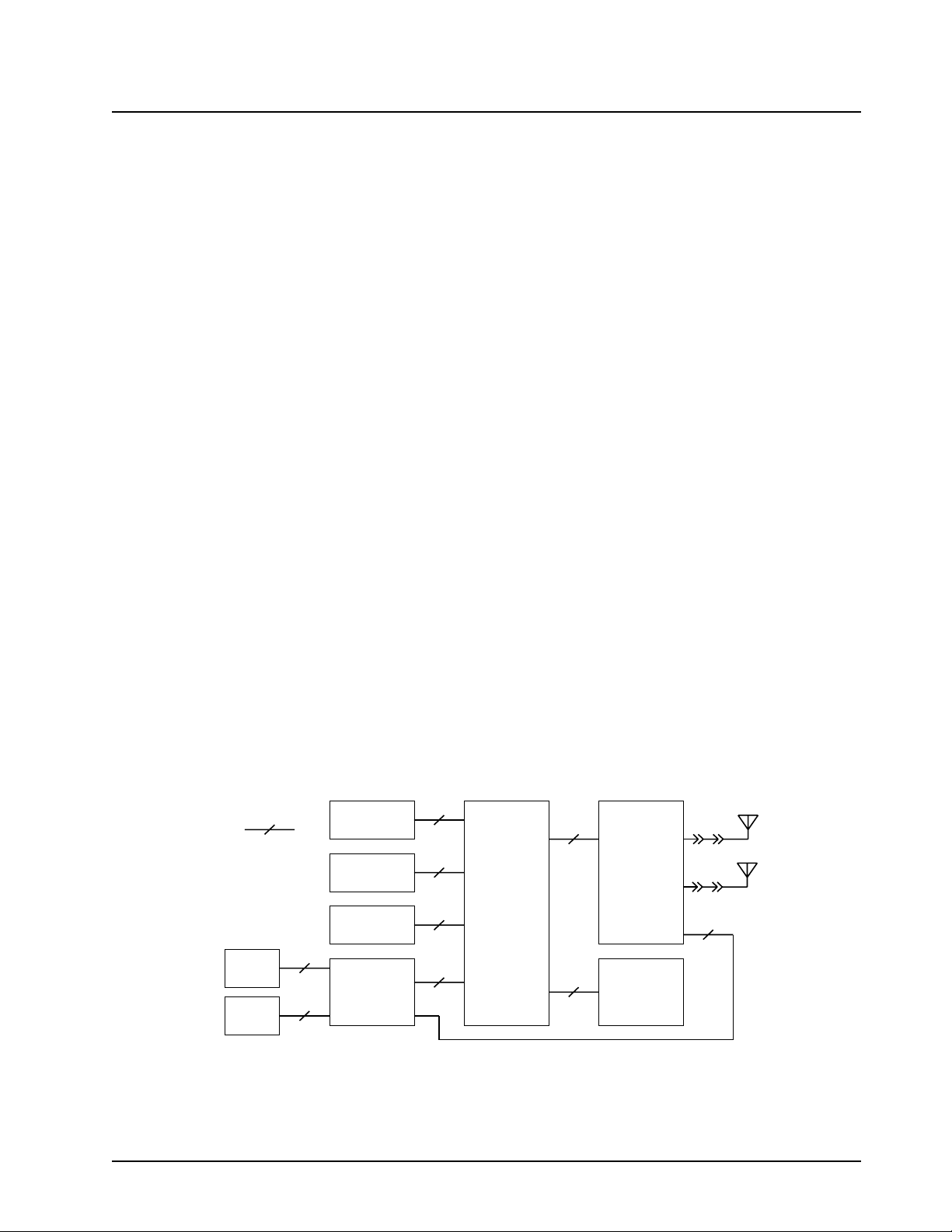

2.1 Major Assemblies

The SSE 5000 radio includes the following major assemblies (see Figure 2-1):

• VOCON Board — contains a dual-core processor which includes both the microcontroller unit

(MCU) and a digital signal processor (DSP) core, the processor’s memory devices, an audio

and power supply support integrated circuit (IC), a digital-support IC, and the audio power

amplifier.

• Transceiver (XCVR) Board — contains all transmit, receive, and frequency generation

circuitry, including the digital receiver back-end IC and the reference oscillator.

• Controls/Universal Flex — contains on/off/volume switch, channel select switch, push-to-talk

(PTT) switch, monitor button, several function-selectable switches, universal connector,

speaker, and microphone.

• Display — 112 pixels x 32 pixels bit-mapped, liquid-crystal display (LCD).

Note:

Indicates12

wires

External

Accessory

Connector

7.5V

Battery

J101

J102

J1

Standard

Antenna

Remote

Antenna

3

MAEPF-27277-B

4

M102

20

J707

VOCON

20

14

Board

J301

J102

26

P201 P1

40

J701

Transceiver

Board

Encryption

Module

(Optional)

12

3

InternalSpeaker

& MicFlex

Control

Top

Display

Universal

Flex

12

Figure 2-1. SSE 5000 Overall Block Diagram

Page 24

2-2 Theory of Operation: Mode of Operation

2.2 Mode of Operation

This section provides an overview of the radio’s receive and transmit operation in the analog mode.

2.2.1 Receiving

When the radio is receiving (see Figure 2-2), the signal travels from the antenna connector to the

transceiver board, passing through the antenna switch and the receiver front-end. The signal is then

filtered, amplified, and mixed with the first local-oscillator signal, generated by the voltage-controlled

oscillator (VCO).

RXFrontEnd

LNA

CKO

Preselector

Filter

ADC

1stLO

1st

Mixer

3

MAEPF-27278-B

RX_SSI_DATA

toVOCONBoard

Remote

Port

Harmonic

Filter

RFInput

Harmonic

XTAL

Filter

Filter

Antenna

Switch

LO

Preselector

Filter

ABACUSIII-RXBackEnd

Figure 2-2. Receiver Block Diagram

The resulting intermediate frequency (IF) signal is fed to the IF circuitry, where it is again filtered and

passed to the Abacus III digital back-end IC. In the digital back-end IC, the IF signal is mixed with the

second local oscillator to create the second IF at 2.25 MHz. In the back-end IC, a bandpass, sigmadelta, analog-to-digital converter then decodes the second IF signal, and outputs, on the radio’s

serial synchronous interface (SSI) bus, digital audio to the VOCON board.

On the VOCON board, the dual-core processor’s digital-signal processor (DSP) digitally filters the

PCM audio. The DSP decodes the information in the signal and identifies the appropriate destination

for it.

• For a voice signal, the DSP will route the digital voice data to the CODEC inside the audio and

power supply support IC, for conversion to an analog signal. The CODEC will then present the

signal to the receive audio pre-amplifier, then to the audio power amplifier, which drives the

speaker.

• For signaling information, the DSP will decode the message and pass it internally to the

microcontrol unit of the dual-core processor.

November 11, 2004 6881094C12-A

Page 25

Theory of Operation: Mode of Operation 2-3

2.2.2 Transmitting

When the radio is transmitting, microphone audio is passed through gain stages to the CODEC,

where the signal is digitized (see Figure 2-3). The CODEC passes digital data to the DSP, where preemphasis and low-pass (splatter) filtering are done. The DSP passes this signal to a digital/analog

converter (DAC), where it is reconverted into an analog signal and scaled for application to the

voltage-controlled oscillator as a modulation signal.

TX_SSIfrom

VOCONBoard

RX_SSIto

VOCONBoard

PCIC

U104

Preselector

Filter

Power

Module

Q107

D101

RXLNA

Directional

Coupler

U101

Preselector

Filter

Dual

Antenna

Switch

Harmonic

MAEPF-27530-A

Filter

To

Remote

Port

To

Antenna

Reference

Oscillator

Y200

FracN

3

DAC

U203

FL200

SerialEE

3

LPF

PROM

U4

Sample

Clk

MOD

IN

ABACUSIIIU500

Loop

Filter

Note:

ThisUHFrangehas2VCOs

(1TX,1RX)

2ND

LO

VCO1

VCO2

Crystal

VCOBIC

Filter

TX

Buffer

Mixer

Amplifier

U102

TXDriver

Figure 2-3. Transceiver (UHF Range) Block Diagram (Power and Control Omitted)

Transmitted signaling information is applied to the DSP from the microcontrol unit, where it is coded,

and passed to the DAC, which handles it the same as a voice signal. The DAC output connects to

the synthesizer modulation input. A modulated carrier is provided to the transmitter power amplifier,

which transmits the signal under dynamic power control.

6881094C12-A November 11, 2004

Page 26

2-4 Theory of Operation: Power Distribution

2.3 Power Distribution

This section provides a detailed circuit description of the power distribution of the SSE 5000 radio.

In the SSE 5000 radio, power (B+) is distributed to two boards: the transceiver (RF) board and the

VOCON board (see Figure 2-4). In the case of a secure radio, B+ is also supplied to the encryption

module.

FET

1.55V

VOCONBoard

VCC5

SW_B+

3.8V(VSW1)

1.875Volts

(VSW2)

(VREF)

5Volts

GCAPII

2.893

2.893

Volts Volts

(V2)

MAEPF-27419-A

Battery

7.5Volts

(Nominal)

RFBoard

J1

BATT FB+

RAWB+

Fuse

FET

XB+

(controlsignal)

V5A

5Volts

V3A V3D

3Volts

AnalogCircuits

3Volts

DigitalCircuits

P1

UNSW_B+

P201

1.55Volts

(VSW_1.55)

Figure 2-4. DC Power Distribution—UHF Radios

Power for the radio is provided through a battery supplying a nominal 7.5 Vdc directly to the

transceiver. The following battery types and capacities are available:

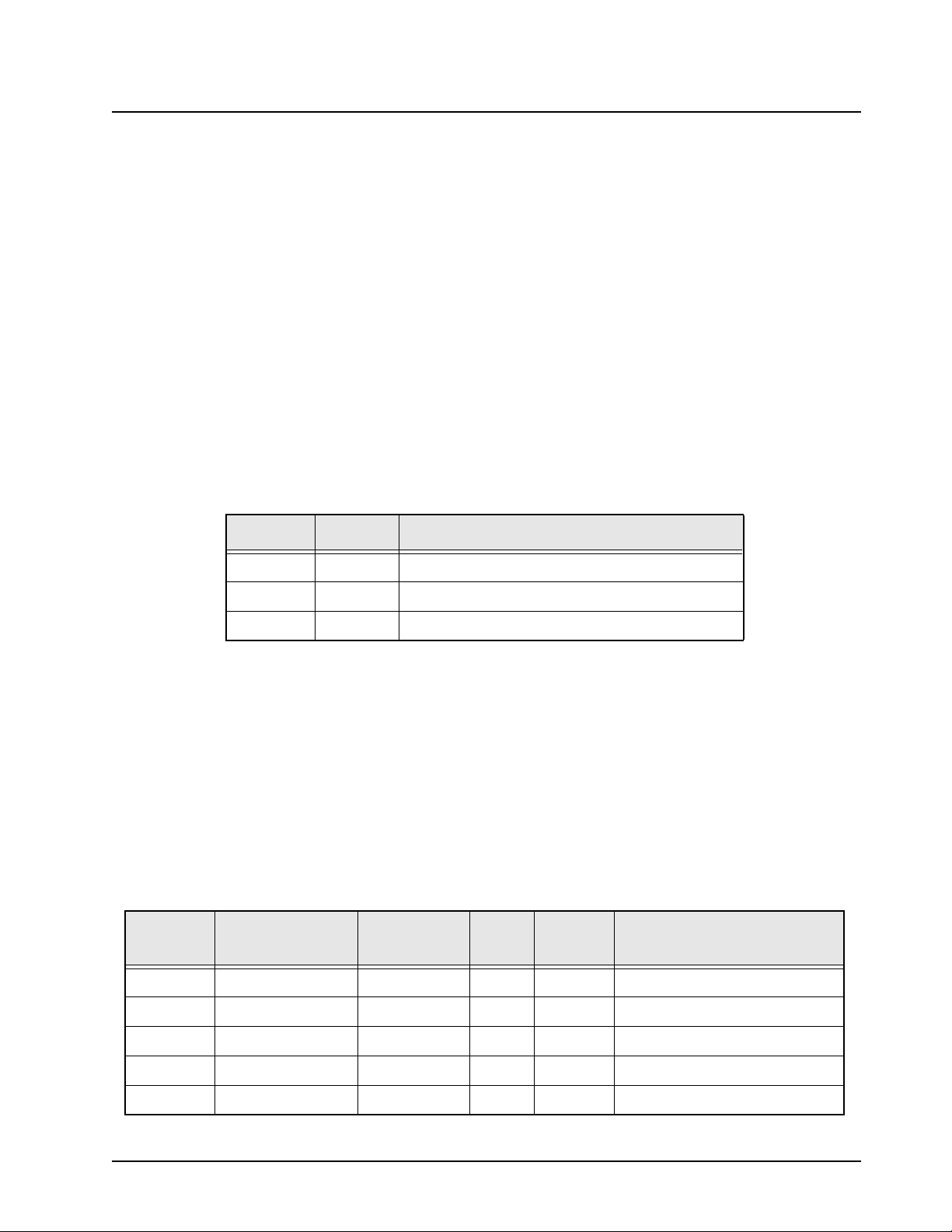

Table 2-1. Conventional Batteries

Part Number Description

NTN4595 Premium NiCd (1800 mAh, 7.5 V)

NTN4596 Premium NiCd FM (1800 mAh, 7.5 V)

NTN4992 Premium NiCd FM (1800 mAh, 7.5 V) (HazMat)

Table 2-2. Smart Batteries

Part Number Description

HNN9033 impres™ NiCd (2000 mAh)

HNN9034 impres™ NiCd FM (2000 mAh)

B+ from the battery is electrically switched to most of the radio, rather than routed through the On/

Off/Volume knob. The electrical switching of B+ supports a keep-alive mode. Under software control,

November 11, 2004 6881094C12-A

Page 27

Theory of Operation: Power Distribution 2-5

even when the On/Off/Volume knob has been turned to the off position, power remains on until the

microcontroller unit (MCU) completes its power-down, at which time the radio is physically powered

down.

2.3.1 DC Power Routing—Transceiver Board

Connector J1, the B+ assembly, connects the battery to the transceiver board. Two capacitors

provide protection against momentary breaks at the B+ connector due to contact bounce when the

radio is dropped.

An RF bead forms a power-line filter for signal RAWB+, which supplies battery voltage to the

transmitter PA.

A transistor, controlled by signal SWB+ from the VOCON board, turns on XB+, which supplies the

5-V linear regulator, TX_ALC block and SW_FL.

Fuse F901 and a filter supply fused B-plus to the VOCON board. In turn, the VOCON board supplies

VSW1, regulated 3.8 Vdc, from the Global Control Audio and Power (GCAP) switching regulator to

the XCVR. A switch, controlled by SWB+, turns on V38 to the XCVR 3-V linear regulators. The

XCVR regulated power supplies are summarized in Table 2-3.

Table 2-3. Transceiver Voltage Regulators

IC

Name

LP2989 V5A Regulated 5.0 Vdc

LP3985 V3D Regulated 3.0 Vdc digital

LP3985 V3A Regulated 3.0 Vdc analog for the RX FE

Output

Signal Name

Description

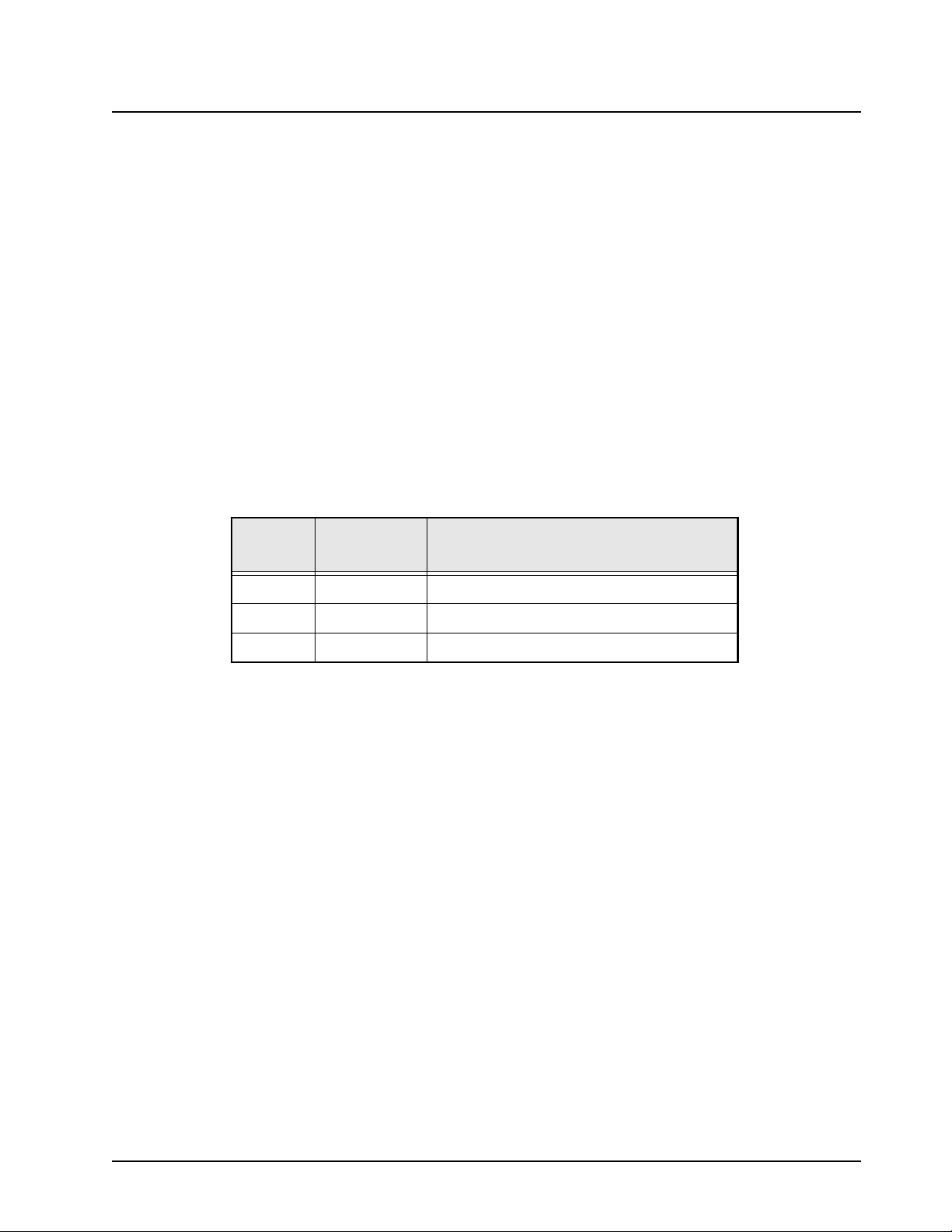

2.3.2 DC Power Routing—VOCON Board

Raw B+, or unswitched B+, (UNSW_B+) is routed to connector J1 on the transceiver board, and then

on to P201 on the VOCON board. Here the UNSW B+ is forwarded to the radio’s control top

On/Off/Volume knob through connector J707 and a flex circuit, as well as to regulator U505 (VCC5).

The On/Off/Volume knob controls B+SENSE to a BJT switch, which in turn controls a power

MOSFET. The MOSFET is a solid-state power switch that provides SW B+ to the VOCON board, the

audio PA, the GCAP II IC (via GCAP_B+), and back to the transceiver board.

In the case of a secure radio model, SW B+ and UNSW B+ are also supplied to the encryption

module through connector J701.

The BJT switch is also under the control of the MCU via Vref from the GCAP II IC (U501). This allows

the MCU to follow an orderly power-down sequence when it senses that B+SENSE is off. This sense

is provided through MECH_SW_BAR (inverted B+SENSE).

The digital circuits in the VOCON board are powered from regulators located in the GCAP II IC

(U501), an external 5 Vdc regulator (VCC5, U505), and an external 1.55 Vdc regulator (VSW_1.55).

The GCAP II IC provides three supplies: VSW1, VSW2, and V2. These regulators are software

programmable.

6881094C12-A November 11, 2004

Page 28

2-6 Theory of Operation: Power Distribution

Table 2-4 lists the supply voltages and the circuits that use these voltages.

Table 2-4. VOCON Board DC Power Distribution

Supply

Name

UNSW_B+ 9 to 6 Vdc

SW_B+ 9 to 6 Vdc

VCC5 5Vdc Linear regula-

VSW1 3.8 Vdc Switching

VSW2 1.8 Vdc Switching

Output

Voltage

7.5 Vdc

nominal

7.5 Vdc

nominal

Supply Type

Battery N/A VCC5 input

Battery N/A VSW1 input (GCAP)

tor

regulator

software programmable

regulator

software programmable

Unprogrammed

Output Voltage

N/A Smart battery circuitry

3.2 Vdc 3-V regulators (RF)

2.2 Vdc Dual-core processor’s external

Circuits Supplied

Mechanical switch

Power switch (FET)

Secure module

Audio power amplifier

Side connector

SW_B+ to transceiver board

GCAP IC

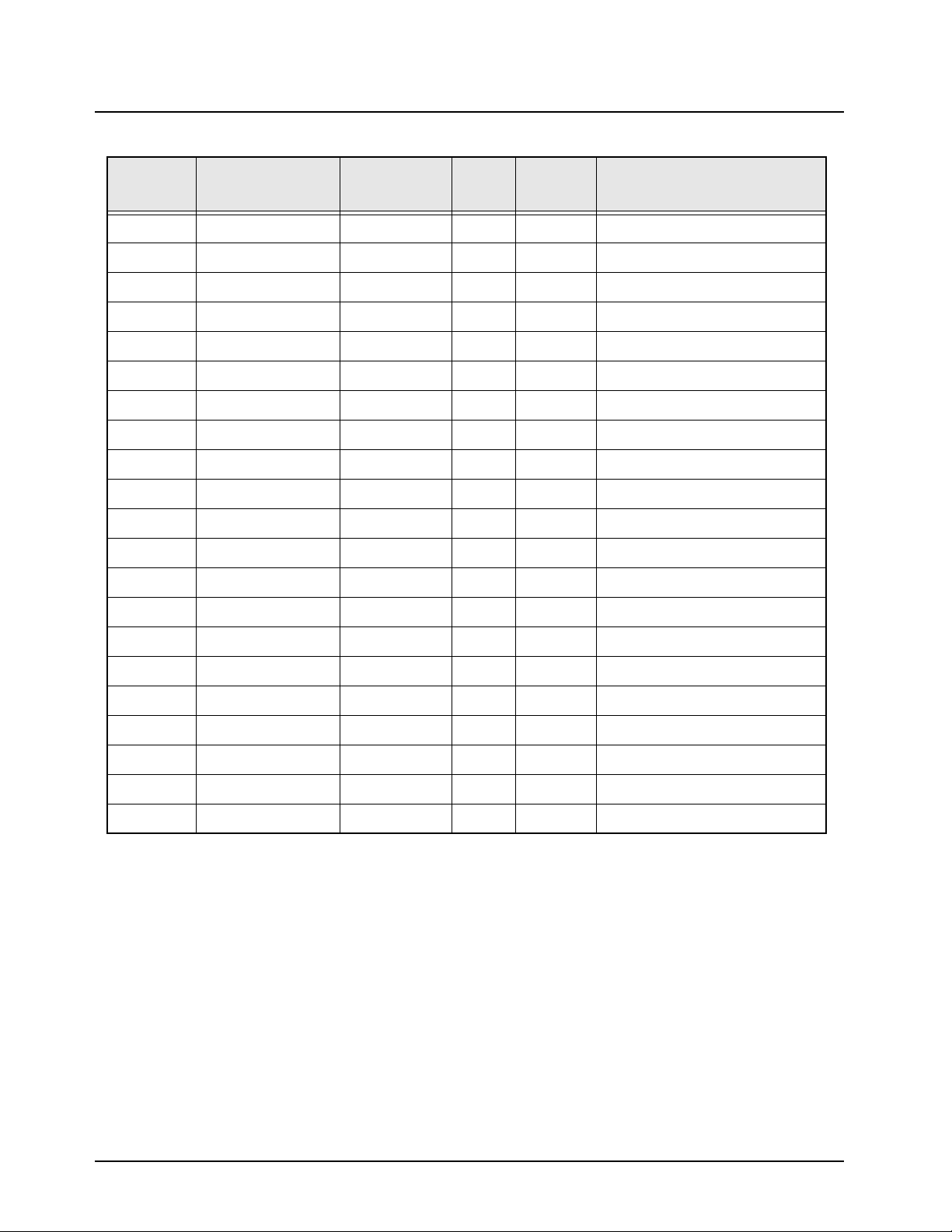

Secure module