Page 1

STARLINE

®

SG 2000

Telecommunications Optical Node

Installation and Operation Manual

4

2

6

IN

7

Page 2

Caution

Caution

CautionCaution

These servicing instructions are for use by qualified personnel only. To reduce the risk of electrical shock, do not perform any servicing other than that

contained in the Installation and Troubles hoot ing I ns t ruct ions unless you a r e qua lified t o do s o. Refer all servicing to qualified service personnel.

Special Symbols that Might Appear on the Equipment

Special Symbols that Might Appear on the Equipment

Special Symbols that Might Appear on the EquipmentSpecial Symbols that Might Appear on the Equipment

This is a class 1 product that contains a class IIIb laser and is intended for operation in a closed environment with fiber

attached. Do not look into the optical connector of the transmitter with power applied. Laser output is invisible, and eye

damage result. Do not defeat safety features that prevent looking into optical connector.

This product contains a class IIIb laser and is intended for operation in a closed environment with fiber attached. Do not look

into the optical connector of the transmitter with power applied. Laser output is invisible, and eye damage can result. Do not

defeat safety features that prevent looking into optical connector.

This symbol indicates that dangerous voltage levels are present within the equipment. These volt a ges ar e not insula t ed a nd

may be of sufficient strength to cause serious bodily injury when touched. The symbol may also appear on schematics.

The exclamation point, within an equilateral triangle, is intended to alert the user to the presence of important installation,

servicing, and operating instructions in t he document s a c co mpa nying t he equip ment .

For continued protection against fire, replace all fuses only with fuses having the same electrical ratings marked at the

location of the fuse.

Copyright © 2001 by Motorola Inc.

All rights reserved. No part of this publication may be reproduced in any form or by any means or used to make any derivative work (such as translation,

transformation or adaptation) without written permission from Motorola, Inc.

Motorola, Inc. reserves the right to revise this publication and to make changes in content from time to time without obligation on the part Motorola, Inc.

to provide notification of such revision or change. Motorola Inc. provides this guide without warranty of any kind, either implied or expressed, including,

but not limited, to the implied warranties of merchantability and fitness for a particular purpose. Motorola, Inc. may make improvements or changes in

the product(s) described in this manual at any time.

________________________________________________________________________________________________________________________________

MOTOROLA, the stylized M logo, and STARLINE are registered trademarks, and LIFELINE is a trademark of Motorola, Inc.

All other product or service names are the property of their respective owners.

Page 3

Contents

Section 1

Introduction

Using this Manual ..........................................................................................................................................1-3

Related Documentation ..................................................................................................................................1-3

Document Conventions ..................................................................................................................................1-4

If You Need Help...........................................................................................................................................1-4

Calling for Repairs .........................................................................................................................................1-5

Section 2

Overview

Housing ........................................................................................................................................................2-1

Mounting Holes ......................................................................................................................................2-1

Port Locations................................................................................................................. .......................2-2

Gaskets.................................................................................................................................................2-3

Power Supply................................................................................................................................................2-4

Network Monitoring ........................................................................................................................................2-5

Configuration ................................................................................................................................................2-5

Forward Path.................................................................................................................................................2-7

SG2-LR Receiver ................................................................................................................................... 2-9

Analog Return Path ..................................................................................................................................... 2-10

Analog Return Transmitt ers ..................................................................................................................2-10

Digital Return Path ......................................................................................................................................2-12

DS-SG2-DRT/A .................................................................................................................................... 2-12

DS-SG2-DRT-2X/A ............................................................................................................................... 2-13

Level Control.................................................................................................................. .............................2-14

Options and Accessories.............................................................................................................................. 2-14

Gain Selection...................................................................................................................................... 2-16

Tilt Selection ........................................................................................................................................2-18

Section 3

Bench Setup

Powering the Node ........................................................................................................................................3-3

Power Supply Settings.......................................................................................................... .........................3-5

Single Power Supply o r Commonly Po wered Redunda nt Supplie s.............................................................3-7

Individually Powered Supplies ................................................................................................................. 3-7

SG 2000 Instal lation and Opera tion Manual

Page 4

ii Contents

Quick Checks - Functional Testi ng.................................................................................................................3-8

Forward Path ......................................................................................................................................... 3-8

Manual Gain Control .......................................................................................................................3-9

Thermal Control, Model TCU ...........................................................................................................3-9

Automatic Level Control, Model ADU................................................................................................ 3-9

Analog Return Path .............................................................................................................................. 3-10

Digital Return Path...............................................................................................................................3-10

Forward Path Padding .................................................................................................................................3-11

Launch Amplifier Outpu t Stage Paddi ng........................................................................................................3-14

Link Performance ........................................................................................................................................ 3-15

Installing the DS-SG2-DRRB Bo ard Option ...................................................................................................3-1 8

Installing the Status Monito r Option .............................................................................................................. 3-2 2

SG 2000 Activation Worksh eet.....................................................................................................................3-23

Section 4

Installation

Splicing Fiber................................................................................................................................................ 4-1

Strand Wire Mounting....................................................................................................................................4-3

Coaxial Cables................................................................................................................. .............................4-5

Fiber Cables ................................................................................................................................................. 4-5

Section 5

Operation

Forward Path RF Configurati on......................................................................................................................5-1

Single Receiver Mode.............................................................................................................................5-1

Redundant Receiver M ode ......................................................................................................................5-2

Broadband/Narrowcast Mode ..................................................................................................................5-2

AB Override Functionali ty.......................................................................................................................5-3

B Override......................................................................................................................................5-3

A Override......................................................................................................................................5-4

Status Monitor/Manual Co ntrol Operation .........................................................................................5-4

Analog Return Path RF Configuration.............................................................................................................5-5

Digital Return Path RF Configu ration .............................................................................................................. 5-7

SG 2000 Optical Modules ..............................................................................................................................5-9

Installing SG 2000 Optical Modules......................................................................................................... 5-9

Removing SG 2000 Optic al Modules ....................................................................................................... 5-9

Cleaning the Optical Connector................................................................................................. ............5-10

SG2-LR Optical Receiv er.............................................................................................................................5-1 0

Wavelength Selection Jumpe r......................................................................................................................5-13

SG2-IFPT Optical Transmitt er......................................................................................................................5-14

SG2-FPT Optical Trans mitter.......................................................................................................................5-15

SG2-DFBT Optical Transmitt er .....................................................................................................................5-16

SG 2000 Instal lation and Opera tion Manual

Page 5

Contents iii

SG2-DFBT/3 Optical Trans mitter..................................................................................................................5-18

SG2-EIFPT Optical Transmitt er....................................................................................................................5-19

DS-SG2-DRT/A Digital Return T ransmitter....................................................................................................5-20

DS-SG2-DRT-2X/A Digi tal Return T ransmitter............................................................................................... 5-22

SG2-PS Power Supply..........................................................................................................................5-25

Status Monitoring ........................................................................................................................................ 5-26

Manual Control Board..................................................................................................................................5-27

Ingress Control............................................................................................................................................ 5-29

Appendix A

Specifications

Appendix B

Torque Specifications

Abbreviations and Acronyms

Figures

Figure 1-1 SG 2000 — closed ............................................................................................ 1-1

Figure 1-2 SG 2000 — open..............................................................................................1-2

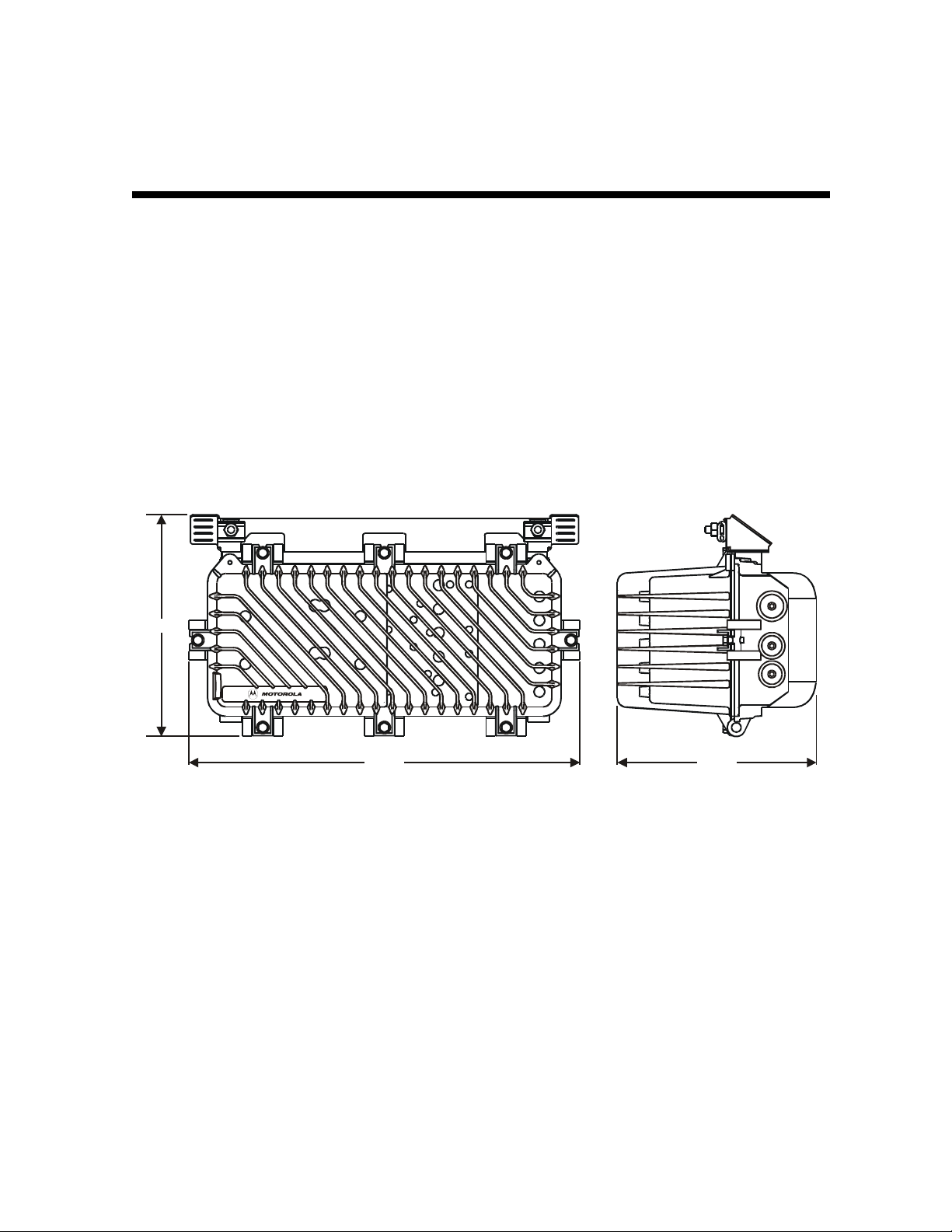

Figure 2-1 SG 2000 housing dimensions - front and side view............................................. 2-1

Figure 2-2 Port locations...................................................................................................2-2

Figure 2-3 Housing gaskets............................................................................................... 2-3

Figure 2-4 SG2-PS2 power supply.....................................................................................2-4

Figure 2-5 Configuration notation....................................................................................... 2-6

Figure 2-6 Signal flow diagram .......................................................................................... 2-7

Figure 2-7 SG2-LR receiver functional diagram ..................................................................2-9

Figure 2-8 SG2 transmitter block diagram ........................................................................ 2-11

Figure 2-9 Optical input versus 750 MHz gain...................................................................2-16

Figure 2-10 Optical input versus 870 MHz gain................................................................. 2-17

Figure 2-11 Relative level dB versus 750 MHz slope 77 channels...................................... 2-18

Figure 2-12 Relative level dB versus 870 MHz slope 94 channels...................................... 2-19

Figure 2-13 Relative level dB versus 870 MHz slope 110 channels....................................2-20

Figure 3-1 SG 2000 lid showing major components.............................................................3-1

Figure 3-2 SG 2000 RF chassis.........................................................................................3-2

Figure 3-3 Fuse configuration............................................................................................ 3-3

Figure 3-4 Fuse locations.................................................................................................. 3-5

Figure 3-5 SG2-PS2 power supply.....................................................................................3-6

SG 2000 Instal lation and Opera tion Manual

Page 6

iv Contents

Figure 3-6 JP1 common-powered single or redundant power configuration .......................... 3-7

Figure 3-7 JP1 split-powered redundant power supply configuration ................................... 3-7

Figure 3-8 SG2-75 low-gain output-stage pad-effects chart .............................................. 3-14

Figure 3-9 SG2-87 low-gain output-stage pad-effects chart .............................................. 3-15

Figure 3-10 SG2-* link c/n performance, 77 channels....................................................... 3-16

Figure 3-11 SG2-* link c/n performance, 110 channels ..................................................... 3-17

Figure 3-12 DS-SG2-DRRB board ................................................................................... 3-18

Figure 3-13 DS-SG2-DRRB board installed...................................................................... 3-19

Figure 3-14 Location of JXPs on E-pack.......................................................................... 3-20

Figure 3-15 SG2 lid configured with the DS-SG2-DRRB board .......................................... 3-21

Figure 4-1 Service cable connection and compression fitting .............................................. 4-1

Figure 4-2 Mounting bracket-front view.............................................................................. 4-3

Figure 4-3 Mounting bracket-rear and side views............................................................... 4-4

Figure 4-4 Center conductor length................................................................................... 4-5

Figure 4-5 Housing lid and fiber spool tray......................................................................... 4-6

Figure 4-6 Fiber spool tray................................................................................................ 4-6

Figure 5-1 Single receiver................................................................................................. 5-1

Figure 5-2 Redundant receiver .......................................................................................... 5-2

Figure 5-3 Broadband/narrowcast...................................................................................... 5-2

Figure 5-4 B override........................................................................................................ 5-3

Figure 5-5 A override........................................................................................................ 5-4

Figure 5-6 Status monitor/MCB operation .......................................................................... 5-4

Figure 5-7 Redundant return.............................................................................................5-5

Figure 5-8 Split return....................................................................................................... 5-5

Figure 5-9 RF chassis and location of the SG2-RPM/C or SG2-RPM/S board...................... 5-6

Figure 5-10 DS-SG2-DRT/A redundant return .................................................................... 5-7

Figure 5-11 DS-SG2-DRT-2X/A split return........................................................................ 5-8

Figure 5-12 DS-SG2-DRT-2X/A redundant return...............................................................5-8

Figure 5-13 SG2-LR ....................................................................................................... 5-10

Figure 5-14 Test-point voltage versus optical power......................................................... 5-12

Figure 5-15 Wavelength selection jumper........................................................................ 5-13

Figure 5-16 SG2-IFPT .................................................................................................... 5-14

Figure 5-17 SG2-FPT ..................................................................................................... 5-15

Figure 5-18 SG2-DFBT................................................................................................... 5-16

Figure 5-19 SG2-DFBT/3 ................................................................................................ 5-18

Figure 5-20 SG2-EIFPT .................................................................................................. 5-19

Figure 5-21 DS-SG2-DRT/A............................................................................................ 5-20

Figure 5-22 DS-SG2-DRT/A............................................................................................ 5-20

SG 2000 Instal lation and Opera tion Manual

Page 7

Contents v

Figure 5-23 DS-SG2-DRT-2X/A........................................................................................5-22

Figure 5-24 DS-SG2-DRT-2X/A........................................................................................5-22

Figure 5-25 DS-SG2-DRT-2X/A cable connector ...............................................................5-24

Figure 5-26 DS-SG2-DRT-2X/A installed in SG 2000 ........................................................5-24

Figure 5-27 DS-SG2-DRT-2X/A second RF input cable connection ....................................5-25

Figure 5-28 SG2-PS power supply................................................................................... 5-25

Figure 5-29 MCB board ................................................................................................... 5-28

Tables

Table 2-1 Analog return transmitters................................................................................2-10

Table 2-2 Digital return transmitters .................................................................................2-12

Table 2-3 Options and accessories..................................................................................2-14

Table 3-1 AC fuses ........................................................................................................... 3-4

Table 3-2 SG 2000 pad chart-standard gain ..................................................................... 3-12

Table 3-3 SG 2000 pad chart-high gain ............................................................................3-13

Table 3-4 Common problems...........................................................................................3-22

Table 5-1 SG2-LR features ..............................................................................................5-11

Table 5-2 SG2-LR minimum output levels.........................................................................5-11

Table 5-3 SG2-IFPT features ...........................................................................................5-14

Table 5-4 SG2-FPT features ............................................................................................5-15

Table 5-5 SG2-DFBT features.......................................................................................... 5-16

Table 5-6 SG2-DFBT/3 features.......................................................................................5-18

Table 5-7 SG2-EIFPT features.........................................................................................5-19

Table 5-8 DS-SG2-DRT/A features................................................................................... 5-21

Table 5-9 DS-SG2-DRT-2X/A features .............................................................................5-23

Table 5-10 Reporting and control provisions..................................................................... 5-26

Table 5-11 MCB user-interface settings............................................................................ 5-27

Table A-1 SG 2000 optical characteristics ......................................................................... A-1

Table A-2 Station RF characteristics................................................................................. A-1

Table A-3 SG 2000 General characteristics ....................................................................... A-2

Table A-4 SG2-LR specifications ...................................................................................... A-2

Table A-5 SG2-IFPT RF specifications.............................................................................. A-3

Table A-6 SG2-FPT RF specifications............................................................................... A-3

Table A-7 SG2-DFBT RF specifications............................................................................. A-4

Table A-8 SG2-DFBT/3 RF specifications .......................................................................... A-4

Table A-9 SG2-EIFPT RF specifications ............................................................................ A-5

Table A-10 SG2-DRT/A RF specifications ......................................................................... A-5

Table A-11 SG2-DRT-2X/A RF specifications .................................................................... A-6

Table A-12 Optical output power vs. wavelength for DS-SG2-DRT*/A transmitters .............. A-6

SG 2000 Instal lation and Opera tion Manual

Page 8

vi Contents

Table A-13 Current requirements ......................................................................................A-7

Table A-14 SG2-75 performance, with 77 channels............................................................ A-8

Table A-15 SG2-87 performance, with 94 channels............................................................ A-8

Table A-16 SG2-87 performance, with 110 channels.......................................................... A-8

SG 2000 Instal lation and Opera tion Manual

Page 9

Section 1

Introduction

Motorola’s SG 2000 telecommunications optical node performs light wave-to-RF and RF-to-light

wave signal conversions in an optical transmission link. This product is designed to support a wide

variety of advanced hybrid-fiber/coaxial network topologies.

As broadband communication systems continue to evolve, the demand increases for optical links that

carry the signal further into the transport system. These systems require additional features and

functionality such as digital compression and alternate access at significantly lower costs. Fully

configured, the SG 2000 supports these next-generation telecommunication networks. It also

supports a variety of single and two-way broadband network applications such as broadcast video,

interactive video, telephony, and data.

Figure 1-1 illustrates a closed SG 2000 telecommunications optical node:

Figure 1-1

SG 2000 — closed

6

7 8

3

2

1

4

5

SG 2000 Instal lation and Opera tion Manual

Page 10

1-2 Introduction

A

A

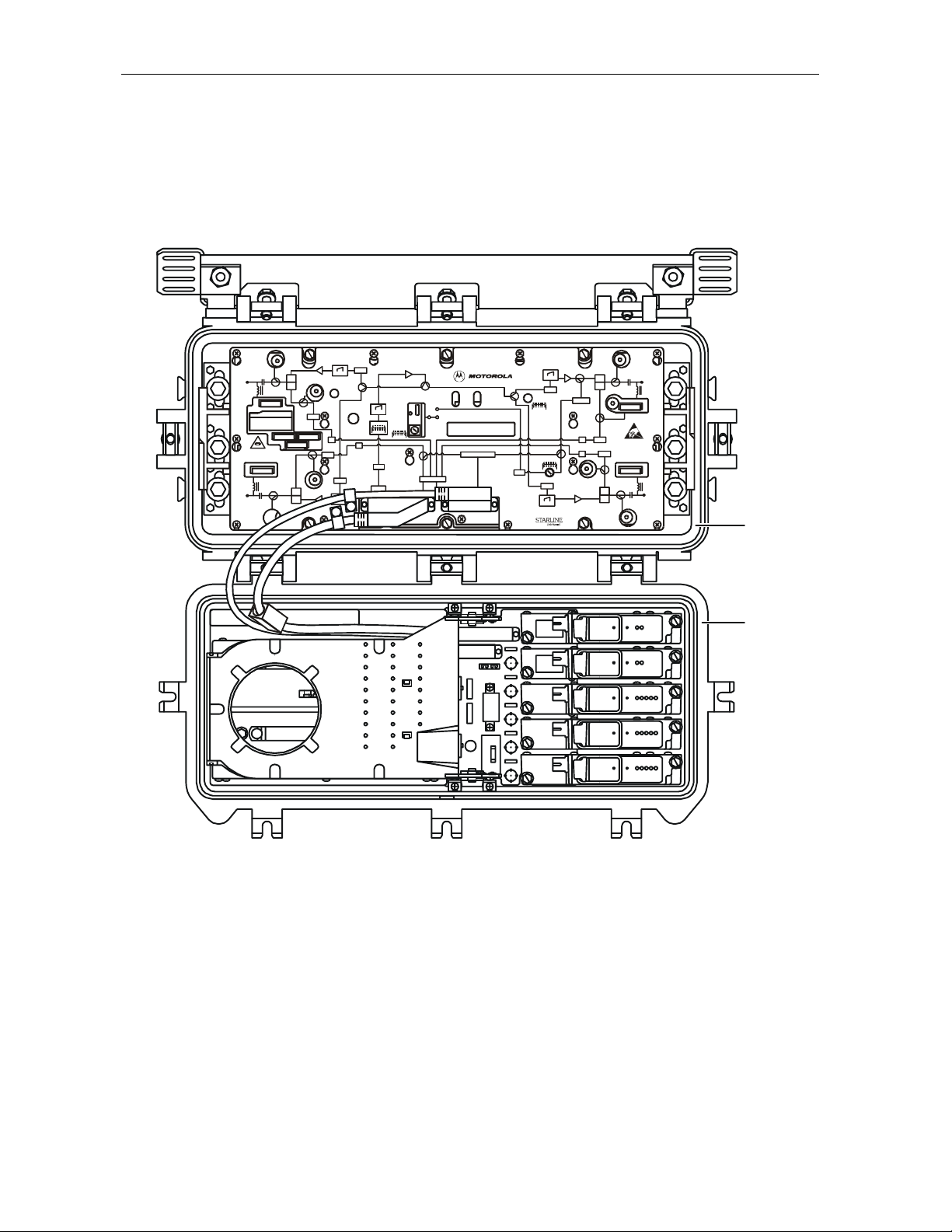

Figure 1-2 illustrates an open SG 2000 telecommunications optical node:

Figure 1-2

SG 2000 — open

H

L

JXP 2

JXP 4

L

H

SSEMBLED IN MEXICO

-20dB

-20dB

CAUTION:

CONTAINS PARTS

ND ASSEM B LI E S

SUSCEPTIBLE TO

DAMAGE BY

ELECTROSTATIC

DISCHARGE (ESD)

-20dB

-20dB

REFER TO

MANUA L F OR

FUSE VALUES

-20dB

H

L

JXP 1

L

H

PORT 1 PORT 2

FTEC

PORT 3

JXP 1

FWD EQ

ON

-20dB

+24 V DC

IS

IS

JXP 3

JXP 3

-20dB

FWD EQ

MDR

VARILOSSE R

RCVR

INPUT

ADU

ON

OFF

MAN

SG2-

FRB

STATUS MO NI TOR

RPM/*

SG 2000

Optical Node

FWD EQ

JXP 2

TCU

JXPADU

IS

IS

ADU

ADU

FWD EQ

-20dB

JXP 4

PORT 4

Base

Lid

Features include:

! 52 through 870 MHz forward passband, 5 through 40 MHz return standard (other splits are

available, see Appendix A, “Specifications”)

! Optical receivers - up to three

! Optical transmitters - up to two

! Four independent RF outputs

! Ingress switching capability through manual or headend control

! Redundant powering capability

! 15 A power passing

SG 2000 Instal lation and Opera tion Manual

Page 11

Introduction 1-3

! Optional LIFELINE

! User-friendly fiber management

! 60/90 volt powering

! Digital return redundancy capability

! Modular plug-in diplex filters and equalizers

! Custom configuration for unique system requirements

™

status monitoring

Using this Manual

The following sections provide information and instructions to install, configure, and operate the

SG 2000:

Section 1 Introduction provides a brief description of the product, identifies the information

Section 2 Overv iew describes the SG 2000 node and includes details regarding your options

Section 3 Bench Setup provides full configuration, set-up of options, and bench testing

Section 4 Installation provides instructions for installing the SG 2000 in a distribution

contained in this manual, and gives the help line telephone number and repair

return information.

and their functions.

procedures that are recommended before installation.

system.

Section 5 Operation provides information governing the use of various options and

applications required by your system.

Appendix A Specifications provides technical specifications for the SG 2000 node and major

options.

Appendix B Torque Specifications provides the appropriate torque specifications for the

screws, clamps, connectors, and bolts used in the SG 2000.

Abbreviations

and Acronyms

The Abbreviations and Acronyms list contains the full spelling of the short forms

used in this manual.

Related Documentation

Although these documents provide information that may be of interest to you, they are not required

to install or operate the SG 2000.

# LL-CU LIFELINE Control Unit Installation and Operation Manual

# LIFELINE for Windows Site Preparation Guide

# LIFELINE for Windows Software Operations Manual

# Return Path Level Selection, Setup, and Alignment Procedure Reference Guide

SG 2000 Instal lation and Opera tion Manual

Page 12

1-4 Introduction

Document Conventions

Before you begin to use the SG 2000, familiarize yourself with the stylistic conventions used in this

manual:

Bold type

SMALL CAPS

*

(Asterisk)

Italic type

Indicates text that you must type exactly as it appears or indicates a default value

Denotes silk screening on the equipment, typically representing front and rear-

panel controls, I/O connections and indicators (LEDs).

Indicates that there are several versions of the same model number and the

information applies to all models. When the information applies to a specific model,

the complete model number is given.

Denotes a displayed variable, a variable that you must type, or is used for

emphasis

If You Need Help

If you need assistance while working with the SG 2000, contact the Motorola Technical Response

Center (TRC):

# Inside the U.S.: 1-888-944-HELP (1-888-944-4357 )

# Outside the U.S.: 215-323-0044

# Online: http://www.motorola.com/broadband

Support, then click Web Support.

The TRC is open from 8:00 a.m. to 7:00 p.m. Eastern Time, Monday through Friday and 10 AM to

6 PM Eastern Time, Saturday. When the TRC is closed, emergency service only is available on a

call-back basis. Web Support offers a searchable solutions database, technical documentation, and

low priority issue creation/tracking 24 hours per day, 7 days per week.

, click HTML/Modem Version, click Customer

SG 2000 Instal lation and Opera tion Manual

Page 13

Introduction 1-5

Calling for Repairs

If repair is necessary, call the Motorola Repair Facility at 1-800-642-0442 for a Return for Service

Authorization (RSA) number before sending the unit. The RSA number must be prominently

displayed on all equipment cartons. The Repair Facility is open from 7 AM to 4 PM Pacific Time,

Monday through Friday.

When calling from outside the United States, use the appropriate international access code and then

call 526-314-1000, extension 3194, to contact the Repair Facility.

When shipping equipment for repair, follow these steps:

1 Pack the unit securely.

2 Enclose a note describing the exact problem.

3 Enclose a copy of the invoice that verifies the warranty status.

4 Ship the unit PREPAID to the following add ress:

Motorola BCS

c/o Exel

Attn: RSA #___________

6908 East Century Park Dr.

Tucson, AZ 85706

SG 2000 Instal lation and Opera tion Manual

Page 14

Section 2

Overview

Designed to be flexible, you can configure the SG 2000 with up to three optical receivers, four

independent high-level RF outputs, and two return-path optical transmitters. Multiple receiver and

transmitter combinations are available to satisfy split-band or redundancy requirements. The forward

passband is extended to 870 MHz to increase channel capacity and support advanced interactive

services and global applications.

Housing

The aluminum housing protects the electronics from weather damage and dissipates internally

generated heat. Figure 2-1 illustrates the housing dimensions of the SG 2000 optical node:

Figure 2-1

SG 2000 housing di mensions - front and s ide view

12.25

6

7 8

3

2

1

21.60 10.99

4

5

34 OUT

For strand mounting, the optional bracket must be used. If the node is configured for strand

mounting, the bracket is installed on the node at the factory. The bracket provides two clamps,

located 16-7/8 inches apart, that secure the strand with 5/16 × 20 stainless steel bolts.

Coaxial cable connections to the housing are made using conventional 5/8 inch × 24 threads per inch,

stinger-type connectors.

Mounting Holes

Two threaded holes are located on the horizontal centerline on the back of the housing. These

5/16 × 18 × ¾ holes are separated by 11 inches center-to-center and can be used for pedestal or

surface mounting.

SG 2000 Instal lation and Opera tion Manual

Page 15

2-2 Overview

Port Locations

The five housing ports, shown in Figure 2-2, provide connection for coaxial cables. Note that the

housing ports are not labeled the same as the ports on the RF chassis. Side-by-side connector fittings

are limited to .750 inches at ports 1 and 2 and/or ports 3 and 4. These ports are protected by factory

inserted threaded plugs or plastic cap plugs which are discarded when the cable connectors are

installed. Port 2 is used only for connection to an external 60 Vac or 90 Vac power supply. Port 4 is

unused.

Figure 2-2 illustrates a front and end view of the housing and port locations:

Figure 2-2

Port locatio ns

6

7 8

3

2

1

4

5

Port 1 Port 2

AC port Unused

Port 3 Port 4

12IN

Lid

34 OUT

SG 2000 Instal lation and Opera tion Manual

Page 16

Overview 2-3

A

A

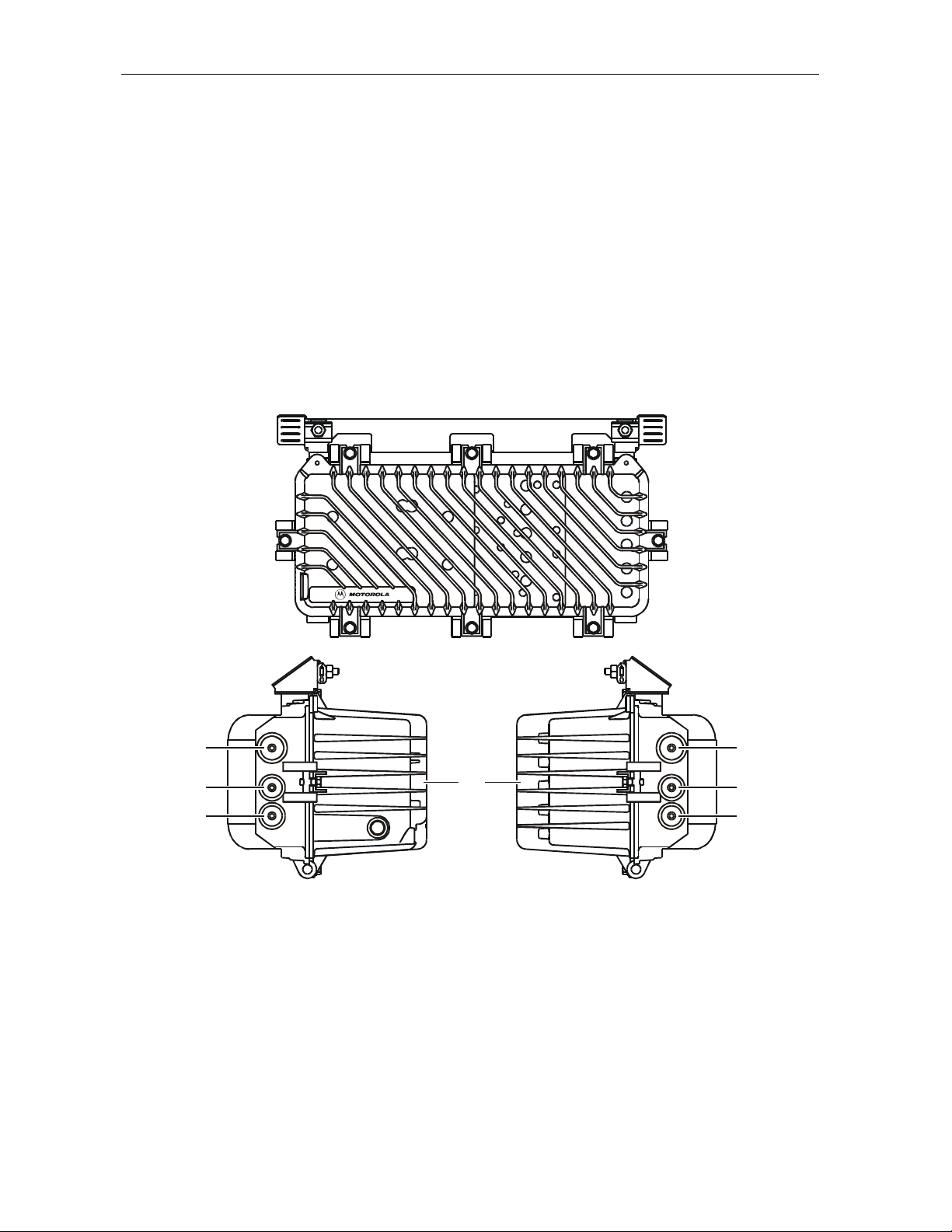

Gaskets

Each housing is equipped with a woven-wire gasket and a silicone-rubber weather gasket between

the housing base and lid as shown in Figure 2-3:

Figure 2-3

Housing ga skets

Weather ga ske t

(silicone rubber)

H

L

JXP 2

JXP 4

L

H

SSEMBLED IN MEXICO

-20dB

-20dB

CAUTION:

CONTAINS PARTS

ND ASSEMBLIES

SUSCEPTIBLE TO

DAMAGE B Y

ELECTROSTATIC

DISCHAR GE (E SD)

-20dB

-20dB

REFER TO

MANUAL FO R

FUSE VALUES

-20dB

H

L

JXP 1

L

H

PORT 1 PORT 2

FTEC

PORT 3

JXP 1

FWD EQ

ON

-20dB

+24 V DC

IS

IS

JXP 3

JXP 3

-20dB

FWD EQ

MDR

VARILOSSE R

RCVR

INPUT

ADU

ON

OFF

MAN

SG2-

FRB

STATUS MO NI TOR

RPM/*

SG 2000

Optical Node

FWD EQ

JXP 2

TCU

JXPADU

IS

IS

ADU

ADU

FWD EQ

-20dB

JXP 4

PORT 4

RF gasket

(woven wire)

The gaskets provide efficient ground continuity, RF shielding and weather protection. Both gaskets

must be in place and in good condition to ensure proper operation and protection of the node. The

silicone rubber gasket should be lightly covered with silicone grease each time the node is opened.

Replace the gasket if it is damaged or deformed.

SG 2000 Instal lation and Opera tion Manual

Page 17

2-4 Overview

Power Supply

The SG 2000 power supply (SG2-PS2) is located in the housing lid to optimize heat transfer and to

balance the thermal load between the base and the lid . F or high rel iab il ity or redun dancy

applications, two power supplies can be used. An umbilical cord connects the SG2-PS2 to the lid

motherboard (LIDB).

A flexible power-distribution design enables you to power the node from any of the four RF ports.

Using fuses and shunts you can configure the node to distribute power to the remaining active ports.

You can also power the node locally through the ac only port (port 2) while a second cable-plant

power supply loops through the other two main RF ports.

The power supply includes a heavy-duty, gas discharge tube surge protector located on the amplifier

module. You can replace this surge protector with the optional FTEC surge protector. The FTEC

triggers at approximately 230 V and presents a short circuit to the line during periods of over

voltage. After the ac input voltage returns to normal, the FTEC returns to its open-circuit state. This

provides the node with a level of protection against surge currents on the ac line. The same protector

is used for both supplies unless the split ac-feed option is implemented; then, the secondary or

redundant power supply is protected by a conventional heavy-duty gas discharge tube.

The 20-ampere fuses are installed at the factory to provide power passing to additional amplifiers.

Section 3, “Bench Setup,” discusses fusing options that are also diagrammed in Figure 3-1.

Figure 3-2 illustrates the location of the fuses.

The SG 2000 optical node can be powered from either 60 Vac or 90 Vac system power supplies. The

unit is shipped from the factory set for 60 Vac powering. For systems equipped with 90 Vac

powering, the suitcase jumper on the dc power supply can be repositioned to optimize the supply

start-up voltage for the higher input range. Section 3, “Bench Setup” provides a description of this

procedure.

Figure 2-4 illustrates the SG2-PS2 power supply:

Figure 2-4

SG2-PS2 power supply

SG2-PS2

NO USER SERVICEABLE PARTS INSIDE

CAUTION

VOLTAGES IN EXCESS OF

300 VOLTS ARE PRESENT

UNDER COVER AND MAY

BE PRESENT AFTER POW ER

IS REMOVED

SEE INSTALLAT ION MANUAL FOR SERVICE

LO HI

ASSEMBLED IN MEXICO

24V 5V

ADJ

TEST

POINT

TEST

POINT

The optional SG2-PS power supply is required to support DS-SG2-DRT-2X/A transmitters in a

redundant configuration. The SG2-PS2 and SG2-PS power supplies are interchangeable.

SG 2000 Instal lation and Opera tion Manual

Page 18

Overview 2-5

Network Monitoring

The optional LIFELINE Status Monitoring System (LL-SG2) enables you to monitor the SG 2000

from a headend or a remote location. The transponder consists of a plug-in module mounted on the

main RF board. If you do not employ status monitoring and use redundant receivers and/or

transmitters, a manual control board (MCB) occupies the same position on the main RF board.

The entire LIFELINE system includes:

LL-CU control units

Are connected to the system at the headend and interrogate each

SG 2000 field transponder with FM outbound and inbound

transmissions. A variety of outbound and inbound frequencies can be

selected depending on the configuration of the system. The control unit

reports this information to the status monitor computer.

Status Monitor

Computer and

Software

LL-SG2-* Field

Installed

Transponders

Includes an IBM

unit (CU) through an RS-232 link. LIFELINE software enables the

operator to view measurements taken by the transponders.

Installed in individual field components, this unit interfaces with the CU at

the headend. It reports such parameters as: forward amplifier dc current

draw, ac and dc voltage, temperature, automatic drive unit (ADU-*) drive

-compatible computer that is connected to the control

voltage, management and control of RF ingress switching, and tamper

status.

Configuration

To accommodate unique system criteria, the SG 2000 is shipped as a configured product. Hundreds

of variations are available with configurations designed to address numerous system requirements

that include:

! Varying RF output configurations

! Forward bandwidth to 750 MHz or 870 MHz

! Forward slope options L, M, H, and U

! Band splits S, J, A, K, E, and M

! Silicon or GaAs technology

! Forward and return path redundancy

# High and low gain options

# Network monitoring

# RF output level control - thermal or automatic

# Multiple return options

Optional hardware features include:

! Analog and digital return transmitter options

! Service cable

# Surge protection

# Chromate or epoxy housing finish

# SC/APC or FC/APC optical connectors

# Ingress switching

SG 2000 Instal lation and Opera tion Manual

Page 19

2-6 Overview

You can order the SG 2000 in a number of configurations to suit system requirements. The shipped

configuration is noted in a label on the lower portion of the RF chassis cover.

Figure 2-5 illustrates a sample model using the configuration notation:

Figure 2-5

Configuration notation

Return Path Configurations (Analog Return)Key

No Transmitter

SG2-DFBT/*

Dual SG2-DFBT/* w/split return

Dual SG2-DFBT/* w/redundancy

E

F

N

D

Return Path Configurations (Digital Return) ***

DS-SG2-DRT/A-1310-DFB/SC w/redundancy

DS-SG2-DRT/A-1550-DFB/SC w/redundancy

DS-SG2-DRT/A-1510c-DFB/SC w/redundancy

DS-SG2-DRT/A-1530c-DFB/SC w/redundancy

23242526272829

Key

SG2-DFBT3/* (2mw)

I

DS-SG2-DRT/A-1550c-DFB/SC w/redundancy

SG2-FPT/*

Dual SG2-FPT/* w/split return

Dual SG2-FPT/* w/redundancy

SG2-EIFPT/*

Dual SG2-EIFP T/* w/split return

Dual SG2-DFBT3/* w/split return

Dual SG2-DFBT3/* w/redundancy

J

K

M

O

DS-SG2-DRT/A-1570c-DFB/SC w/redundancy

DS-SG2-DR T-2x /A-1470c-DF B/SC w/ s pl it return

DS-SG2-DR T-2x /A-1490c-DF B/SC w/ s pl it return

DS-SG2-DRT-2x/A-1590c-DFB/SC w/split return

30

31323334353637383940414243

Dual SG2-EIFPT/* w/redundancy

T

R

S

P

DS-SG2-DRT-2x/A-1610c-DFB/SC w/split return

DS-SG2-DRT/A-1470c-DFB/SC

DS-SG2-DRT/A-1490c-DFB/SC

DS-SG2-DRT/A-1590c-DFB/SC

DS-SG2-DRT/A-1610c-DFB/SC

Finish

Key

DS-SG2-DRT-2x/A-1470 c -DF B/ SC w/r e dun dancy split return

Mounting

None

Chromate

Pedestal

Strand

N

C

X

Y

Key

Ingress switch

None

Ingress switches

N

S

Key

Status Monitoring

None

AMC/Frequency agile

TollG/Frequency agile

J

N

H

NLT

SC/APC

S

MN MCB w/SIC

Power Supply

Single

Dual

Redundant w/SIC

SDR*

Key

Service Cable

6 FiberSer Cable

None

C

N

Key

FC/APC

Surge Protection

F

Surge Arre sto r

FTEC BTA Crowbar

F

N

Key

Forward Receivers

Freq

Vendor

DS-SG2-DRT-2x/A-1490 c -DF B/ SC w/r e dun dancy split return

DS-SG2-DRT-2x/A-1590 c -DF B/ SC w/r e dun dancy split return

DS-SG2-DRT-2x/A-1610 c -DF B/ SC w/r e dun dancy split return

DS-SG2-DRT/A-1470c-DFB/SC w/redundancy

DS-SG2-DRT/A-1490c-DFB/SC w/redundancy

DS-SG2-DRT/A-1570c-DFB/SC w/redundancy

DS-SG2-DRT/A-1610c-DFB/SC w/redundancy

44

Connectorization **

Key

Control

TCU

ADU 499.25/S

ADU 439.25/S

ADU 549.00/S

ADU 403.25/S

ADU 445.25/S

ADU 325.25/S

SG2-LR Single

Dual SG2-LR One Narrowcast/One Broadcast

Dual SG2-LR/Dual Receivers w/Redundancy

Dual SG2-LR/Narrowcast w/Redundancy/One Broadcast

None

Return Path Configurations (Digital Return) ***

DS-SG2-DRT-2x/A-1310-FP/SC w/split return

DS-SG2-DRT -2 x / A-1 3 10-DFB/SC w/split return

DS-SG2-DRT -2 x / A-1 5 50-DFB/SC w/split return

1

2345678

Key

Bandpass Split

5-40 MHz/52-870 MHz

5-55 MHz/70-870 MHz

5-65 MHz/85-870 MHz

SJAKE

Key

I

T

A

DEH

Key

DS-SG2-DRT-2x/A-1510c-DFB/SC w/split return

DS-SG2-DRT-2x/A-1530c-DFB/SC w/split return

DS-SG2-DRT-2x/A-1550c-DFB/SC w/split return

DS-SG2-DRT-2x/A-1570c-DFB/SC w/split return

DS-SG2-DRT/A-1310-FP/SC

DS-SG2-DRT/A-1310-DFB/SC

DS-SG2-DRT/A-1550-DFB/SC

DS-SG2-DRT/A-1510c-DFB/SC

DS-SG2-DRT/A-1530c-DFB/SC

DS-SG2-DRT/A-1550c-DFB/SC

DS-SG2-DRT/A-1570c-DFB/SC

DS-SG2-DRT-2x/A-1310-FP/SC w/redundancy split return

DS-SG2-DRT-2x/A-1310-DFB/SC w/redundancy split return

DS-SG2-DRT-2x/A-1550-DFB/SC w/redundancy split return

DS-SG2-DRT-2x/A-1510c-DFB/SC w/redundancy split return

DS-SG2-DRT-2x/A-1530c-DFB/SC w/redundancy split return

DS-SG2-DRT-2x/A-1550c-DFB/SC w/redundancy split return

DS-SG2-DRT-2x/A-1570c-DFB/SC w/redundancy split return

Bandpass

Key

DS-SG2-DRT/A-1310-FP/SC w/redundancy

Low/2 8 dB S ilicon

High/34 dB Silicon

Low/2 8 dB GaAs

Gain/Hybrid Technology

Key

RF Configurations

2 Bridger

Key

3 Bridger

BCD

750 MHz

870 MHz

75

SG2 87 S S D P T N S A 11 N S N N N N X

87

High/34 dB GaAs

S

T

P

R

4 Bridger

1 Trunk; 2 Bridger

2 Trunk; 2 Bridger

2 Trunk; 1 Bridger

F

E

G

9

10111213141516171819202122

5-42 MHz/54-870 MHz

5-30 MHz/47-870 MHz

5-80 MHz/108-870 MHz

M

Tilt

6 dB

Key

10 dB

8 dB

12.5 dB

14 dB

L

BASHU

16 dB

J

ABCDN

Key

SG 2000 Instal lation and Opera tion Manual

Page 20

Overview 2-7

A

A

A

A

A

A

Refer to the current Motorola catalog for option and feature availability.

Forward Path

The multiple receiver functionality of the platform accommodates split-band and/or redundancy

applications. A typical split-band configuration has analog signals in the 52 MHz through 550 MHz

band feeding one receiver (C location in Figure 2-6). Digital transmissions or narrowcast signals are

carried between 450/550 MHz and 870 MHz on another fiber and processed by the second receiver

(A location). You can use the optional third receiver (B location) as a back up in the event that the

narrowcast receiver loses optical signal input. Automatic path switchover occurs through either the

optional status monitoring or manual control-board modules.

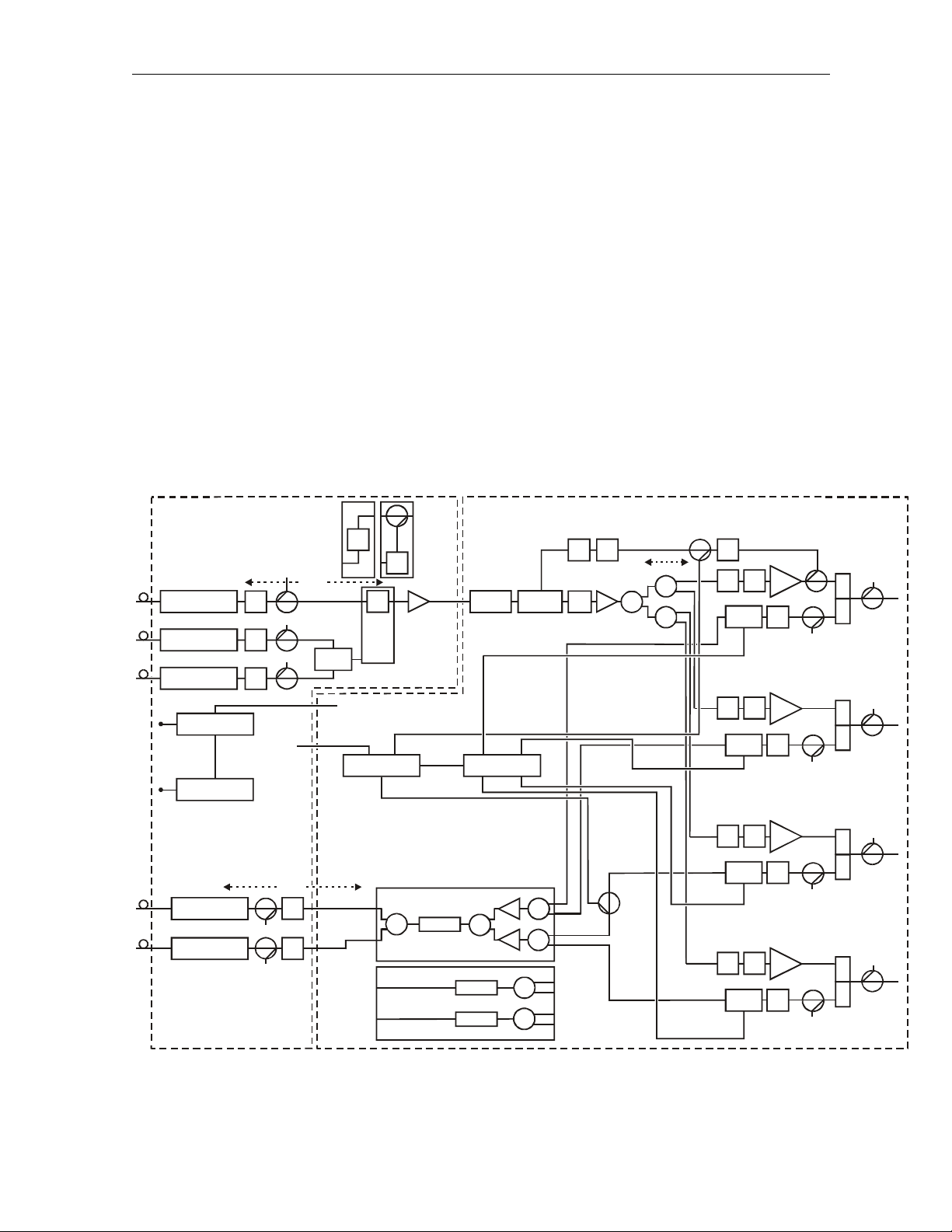

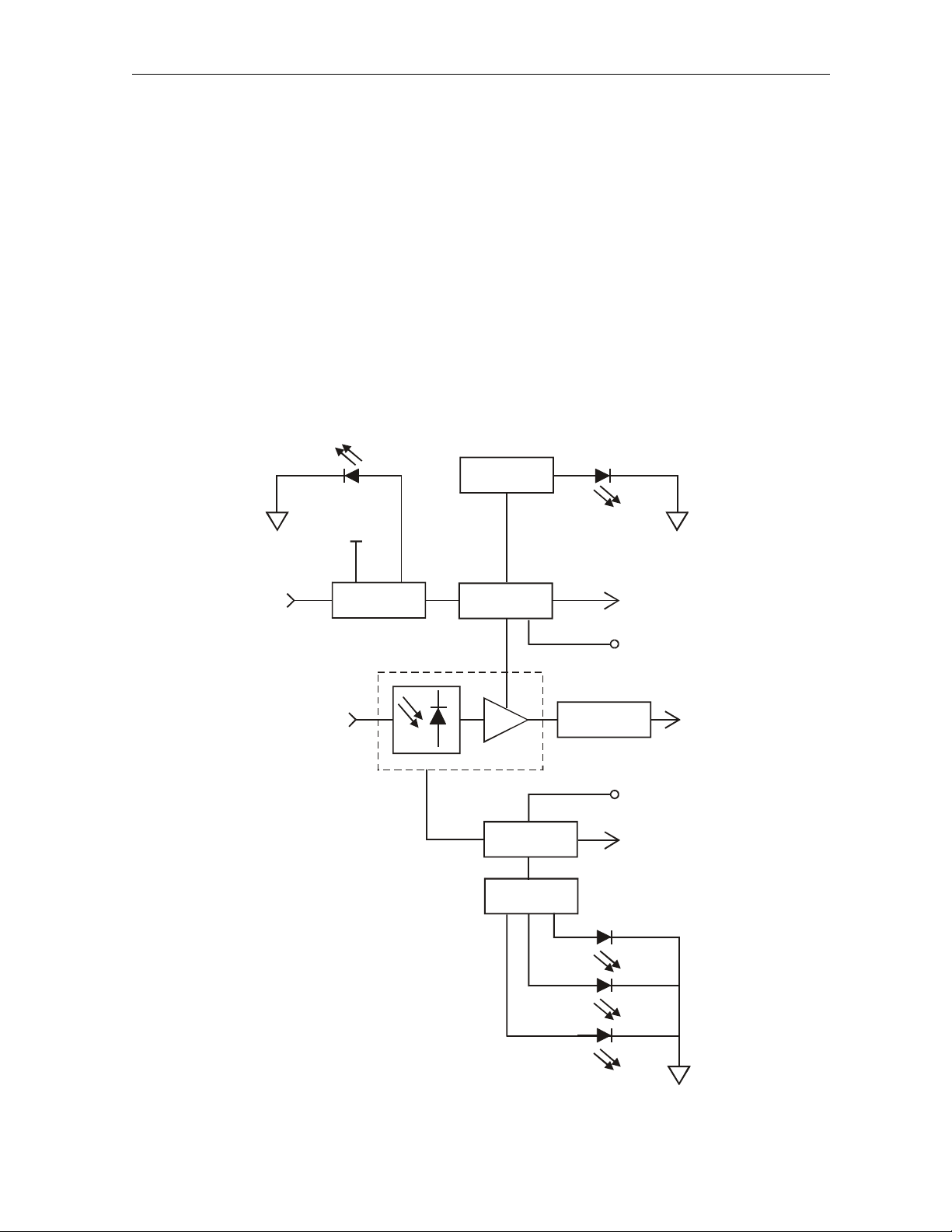

Figure 2-6 provides a diagram of the signal flow-path through the SG 2000:

Figure 2-6

Signal flow diagram

SG2 lid

Receiver C

Receiver B

Receiver A

Power supply

Power supply

Optical transmitter

Optical transmitter

JXP

JXP

JXP

Data lines

TP

TP

SG2-ABJ/P

forward

A/B

jumper

TP

TP

TP

-1.0

JXP

*

JXP

**

-1.5

Switch

JXP

JXP

+24 VDC

+5 VDC

ACV

Status monitor

SG2-FBS

forward

band

split

HP

filter

+15 Lo

+21.5 Hi

SG2-FJB/P

forward

jumper

board

-3.5 -3.5

SG2-RPLPF

SG2 RF chassis

SG2-RPM/C

-2.0

LP filter

SG2-RPM/S

LP filter

LP filter

SG2-RPLPF

-2.0 -1.5

AttenuatorSG2-FRB

-2.0

@ Min atten

Ingress control

-3.5+8.5

-3.5

-2.0

All forward and return path test points (TP) are -20dB

5dB

*

With second transmitter pad = 5dB; withou t second transmitter pad = 15dB

**

POT

DU JXP

MDR

+ 18.5

mplifier

Splitter

-0.5

-8.0

Splitter

Splitter

-1.0

EQ

JXP

Ingress

-2.0

EQ

JXP

Ingress

EQ

JXP

Ingress

JXP EQ

Ingress

mplifier

+18.5

JXP

mplifier

JXP

mplifier

JXP

mplifier

JXP

-0.5

TP

TP

TP

TP

-1.0

-1.0

Diplex

filter

H

L

-0.5

Diplex

filter

H

L

Diplex

filter

H

L

Diplex

filter

H

L

TP

-0.5

TP

TP

TP

SG 2000 Instal lation and Opera tion Manual

Page 21

2-8 Overview

To assess fiber link status, the optical-power monitor circuit is active at all times (even when the

receiver is disabled). An integrated optical bulkhead connector and module link status indicators

enhance fiber management and reduce troubleshooting time. The receiver module is fully compatible

with the status monitor transponder for remote monitoring of key module and link performance

parameters.

Several plug-in boards are available to configure the SG 2000 lid board for single, redundant, or

narrowcast receiver arrangements. A low-noise pre-amplifier hybrid amplifies the signal to a level

suitable for connection to the RF chassis.

An SG2-FRB flatness board, at the input to the RF chassis, compensates for hybrid and accessory

response signatures. A variable attenuator circuit enables fine adjustment of the output level, and is

driven either by the standard thermal control unit (TCU) or optional ADU pilot automatic gain

control (AGC) module to compensate for tempera tur e and input lev el var ia tion s.

The MDR-*/* circuit board provides a fixed linear equalizer for either 750 MHz or 870 MHz. This

equalizer comes in numerous values to support various levels of output tilt. The MDR board also

compensates for the low frequency roll-off inherent in plug-in diplexers.

A driver-hybrid amplifies the signal to a sufficiently high level to feed up to four power-doubling

output stages. These output hybrids can be either conventional silicon or premium gallium arsenide

types for even higher station output at low distortion. Plug-in facilities are available ahead of each

output stage for individual equalizer boards. These can be installed to customize the tilt for the

various ports. At one output, a minus 16 dB directional coupler provides signal to the optional ADU

and status-monitor modules. This signal is used only when either or both of these options is installed.

It is not necessary to terminate the coupler output when neither option is present.

Minus 20 dB directional test points are available at various points in the signal paths of the node.

Because these test points are 75-ohm source impedance, special test probes are not required.

Model JXP-* attenuator pads are used for adjusting signal levels within the signal path. The unit is

shipped with JXP-ZX versions installed.

SG 2000 Instal lation and Opera tion Manual

Page 22

Overview 2-9

SG2-LR Receiver

The receiver module (SG2-LR) is designed specifically for high performance in the SG 2000. The

SG2-LR receiver uses an integrated optical-hybrid photo-detector for improved RF performance over

the entire 40 MHz through 870 MHz passband. It is enabled and disabled in response to a signal

from the status monitor transponder or manual control board (MCB). This provides excellent

isolation, improved reliability, and reduced power consumption when the receiver is used in

redundant applications.

Figure 2-7 illustrates a functional block diagram of the SG2-LR receiver:

Figure 2-7

SG2-LR receiver function al diagram

Module

enabled

Threshold

comparators

Module

enable

Optical

input

+24V

Module enable

logic

Optical receiver hybrid

Hybrid current

monitor

Optical power

monitor

Threshold

comparators

Module

fault

Matching

network

Hybrid current

sense signal

(10V/A)

Hybrid current

test point

(1.0 V/A)

RF

output

Optical power

test point

(1 V/mW)

Optical power

sense signal

(1 V/mW)

Low

Normal

High

SG 2000 Instal lation and Opera tion Manual

Page 23

2-10 Overview

Analog Return Path

Similar to the multiple optical receivers, the dual return-path optical transmitters also have

split-return or redundant functionality. In split-return applications two of the four RF return signals

are fed to one optical transmitter while the remaining two return signals are fed to the second

transmitter.

Signal levels are adjusted in each return path using model JXP-* attenuator pads. Units are shipped

with a JXP-5 (5 dB) attenuator pad at the input position of each installed transmitter. If only one

transmitter is in the unit, there will be a 15 dB pad at the second transmitter input position to serve as

a termination. Ingress switching is also an available option. If ingress switches are not used, JXP-2

pads are installed.

When configured for redundancy, both return lasers are active and transmit the combined RF return

signals simultaneously. Or, they can be activated independently using the status monitor transponder

or the MCB. In the event of path failure, return path redundancy is accomplished at the headend or

the receive site by switching to the alternate or active return fiber.

Analog Return Transmitters

Five optical analog return transmitters are available to meet the needs of most return applications.

Table 2-1 identifies and describes the five analog return transmitters:

Table 2-1

Analog return transmitters

Model Description

SG2-IFPT/*

SG2-FPT/*

SG2-DFBT/*

SG2-DFBT/3

SG2-EIFPT/*

Uses an isolated, uncooled, Fabry-Perot laser operating at 400 µW. It carries a

full 35 MHz of digital data or up to two video channels.

Uses a non-isolated, uncooled, Fabry-Perot laser operating at 400 µW. It carries a

full 35 MHz of digital data or up to two video channels.

Uses an uncooled, isolated DFB laser operating at 1 mW for improved link

performance. It carries a full 35 MHz of digital data or up to two video channels.

Uses an uncooled, isolated DFB laser operating at 2 mW for improved link

performance. It carries a full 35 MHz of digital data or up to two video channels.

Uses an uncooled, enhanced, and isolated Fabry-Perot laser operating at 1 mW

for improved link performance. It carries a full 35 MHz of digital data or up to two

video channels.

The transmitters include thermal compensation circuitry to minimize the change in received optical

and RF signal level at the headend as the node temperature varies. To reduce power consumption and

enhance reliability, the transmitters can be enabled and disabled in response to a signal from the

status monitor transponder or the MCB. An integrated optical bulkhead connector and module status

indicators enhance fiber management and reduce troubleshooting time. For remote monitoring of key

module performance parameters, the return modules are fully compatible with the status-monitor

transponder.

SG 2000 Instal lation and Opera tion Manual

Page 24

Overview 2-11

Figure 2-8 illustrates a functional block diagram of the SG2 transmitter:

Figure 2-8

SG2 transm itter block d iagram

Hybrid

current

test

RF

input

Thermal

compensation

Optical

power

test

JXP

factory calibration

only

Laser

bias

control

Laser

diode

module

Fiber

output

Laser

current

test

SG 2000 Instal lation and Opera tion Manual

Page 25

2-12 Overview

Digital Return Path

The digital return transmitter series (DS-SG2-DRT*) converts a broadband analog RF return-path

signal into digital optical signals with 10-bit resolution.

The transmitters used for digital return applications are divided into two families: DS-SG2-DRT/A

and DS-SG2-DRT-2X/A.

Seven digital return transmitters per family are available to meet the needs of most digital return

applications.

Table 2-2 identifies the fourteen opti cal dig it al re turn transmitters:

Table 2-2

Digital return transmitters

DS-SG2-DRT/A DS-SG2-DRT-2X/A

DS-SG2-DRT/A-1310 FP DS-SG2-DRT-2X

DS-SG2-DRT/A-1310 DFB DS-SG2-DRT-2X/A-1310 D FB

DS-SG2-DRT/A-1470 DFB DS-SG2-DRT-2X/A-1470 D FB

(1)

/A-1310 FP

DS-SG2-DRT/A-1490 DFB DS-SG2-DRT-2X/A-1490 D FB

DS-SG2-DRT/A-1550 DFB DS-SG2-DRT-2X/A-1550 D FB

DS-SG2-DRT/A-1510c

DS-SG2-DRT/A-1530c DFB DS-SG2-DRT-2X/A-1530c DFB

DS-SG2-DRT/A-1550c DFB DS-SG2-DRT-2X/A-1550c DFB

DS-SG2-DRT/A-1570c DFB DS-SG2-DRT-2X/A-1570c DFB

DS-SG2-DRT/A-1590 DFB DS-SG2-DRT-2X/A-1590 D FB

DS-SG2-DRT/A-1610 DFB DS-SG2-DRT-2X/A-1610 D FB

(1) 2X in the model number denotes time division multiplexing (TDM)

(2) c in the model number denotes coarse wave division multiplexing (CWDM)

(2)

DFB DS-SG2-DRT-2X/A-1510c DFB

To prepare for an anticipated increa se in retu rn tra ff ic, provisi oning fo r CWDM is buil t into the

transmitters. The CWD M optio n con sis ts of las ers at predef ined wavelengths. This option is

available to support multiplexing in the optical domain, using eight-wavelength wave division

multiplexing (WDM) in the DS-SG2-DRT/A-15XX DFB and DS-SG2-DRT-2X/A-15XX DFB

windows.

DS-SG2-DRT/A

The DS-SG2-DRT/A digitizes a single analog 5-42 MHz return path signal to produce a 1.6 Gbps

data stream. This data stream is then routed to a digital laser for transmission to a corresponding

digital return receiver. The node can be configured with one or two DS-SG2-DRT/A transmitters,

with dual transmitters providing redundancy. In conjunction with these transmitters, the node must

also be configured with the SG2 Return Path Module/Combined (SG2-RPM/C). The return signals

from all four ports are combined and fed to the optical transmitters.

SG 2000 Instal lation and Opera tion Manual

Page 26

Overview 2-13

When configured for redundancy , both return transm it t ers are normally active and transmit th e

combined RF return signal simultaneously. In the event of path failure, continuity of service is

accomplished at the headend or the receiver site by switching to the alternate or active return fiber.

Signal levels are adjusted in each return path using Model JXP-* attenuator pads. Units are shipped

with a JXP-5 (5 dB) attenuator pad at the input position of each installed transmitter. If only one

transmitter is installed, there will be a 15 dB pad at the second transmitter input position to serve as a

termination.

DS-SG2-DRT-2X/A

The DS-SG2-DRT-2X/A has two separate RF inputs. The transmitter digitizes these two independent

analog 5-42 MHz return-path signals to produce two 1.25 Gbps data streams. These two data streams

are then multiplexed to create a single 2.5 Gbps data stream that is then routed to a digital laser for

transmission to a corresponding digital return receiver. In conjunction with these transmitters, the

node must also be configured with the SG2 Return Path Module/Split (SG2-RPM/S). Return signals

from two of the four node ports are fed to one RF input of the transmitter while the remaining two

return signals are fed to the second RF input. The signal paths for both inputs are explained in more

detail in Section 5, “Operation”.

Signal levels are adjusted in each return path using Model JXP-* attenuator pads. The transmitter

gets one of its RF signals automatically when the unit is plugged into its appropriate slot. The second

RF signal comes through a special adapter from the adjacent connector, which is normally available

for installing a redundant transmitter. Therefore, the units are shipped with two JXP-5 attenuator

pads at the input positions.

Ingress control switching is an available option with any return transmitter configuration. If ingress

switches are not used, JXP-2 pads are installed in each ingress switch position on the main RF board.

The node can be configured with one or two DS-SG2-DRT-2X/A transmitters, with dual transmitters

providing redundancy. The redundancy configuration is explained in more detail in Section 5,

“Operation”.

Section 5, “Operation,” also provides detailed information and block diagrams for each series of

digital transmitters.

SG 2000 Instal lation and Opera tion Manual

Page 27

2-14 Overview

Level Control

The gain of hybrid IC amplifiers varies with temperature. In addition, changes in system channel

loading and/or splices in the fiber link can change the level of the received signal.

The standard TCU board compensates for anticipated hybrid gain changes by sensing housing

temperature and signaling needed changes to the RF attenuator.

The ADU board, an optional plug-in module, monitors the amplitude of a selected pilot frequency.

The pilot frequency is an available analog television channel not scrambled by the sync suppression

method. Any changes in amplitude are fed back to the RF attenuator that makes appropriate

corrections.

The input to the ADU contains a JXP-* pad. The factory-installed value of this pad is 6 dB (JXP-6)

for bridger level outputs and 0 dB (JXP-ZX) for trunk level outputs. Under normal conditions, it

should not be changed.

Options and Accessories

Table 2-3 provides a list of options and accessories for the SG 2000:

Table 2-3

Options and accessories

Model Description Function

ADU-*

TCU

JXP-*A

JXP-ZX

FTEC

LL-SG2

Automatic drive

unit

Thermal control

unit

Fixed

attenuator

0 dB attenuator This attenuator is used in place of JXP-*A pads when no

Crowbar

overvoltage

protection

LIFELINE

module

This option automatically adjusts gain by monitoring changes

in the level of the selected pilot carrier. E ither an ADU or T CU

must be installed.

The TCU controls amplifier gain for changes in hybrid gain at

the sensed temperature.

Attenuator pads are used to adjust amplifier levels and are

available in 1 dB steps from 1 through 24 dB. The appropriate

value must be installed.

attenuation is needed.

The FTEC is an electronic crowbar/surge protector that can be

used to replace the existing 230-volt gas discharge surge

protector.

This module enables the system operator to monitor the SG2

from a remote location. See Section 5, “Operation” for

parameters monitored. Several frequencies are available. See

the product catalog for additional information.

GFAL

F/JXP

SG 2000 Instal lation and Opera tion Manual

Test probe This probe is used to evaluate node performance.

Injection probe This probe is used to inject a signal for test purposes.

Page 28

Overview 2-15

Model Description Function

SG2-MCB

SG2-SB/*

SG2-PS

SG2-PS2

SG2-

SERCAB/*

SG2-FE-

*/750

SG2-FE*/870

SG2-IS

SG2-LR

DS-SG2-DRRB

Manual control

board

This board locally controls the ingress switch and

receiver/transmitter A/B redundant switching if the node is not

equipped with status monitoring.

Strand bracket Bracket for hanging a strand mounted node.

Power supply

Provides the +24 V and +5 V dc supply to the station. It has an

extended voltage range and is power-factor corrected.

Power supply

Provides the +24 V and +5 V dc supply to the station.

Service cable A 6-fiber service cable that is available with SC/APC or

FC/APC connectors.

Forward

equalizers

Used to increase output tilt at one or more ports in a 750 MHz

system. They are available in 1 dB increments from 2 dB

through 6 dB.

Forward

equalizers

Used to increase output tilt at one or more ports in an 870

MHz system. They are available in 1 dB increments from 2 dB

through 6 dB.

Ingress switch This switch enables the operator to troubleshoot without

shutting down the return path. It requires the use of either the

LL-SG2/* or the SG2-MCB.

Lightwave

receiver

Digital return

redundancy

board

This receiver converts the received optical signal to

broadband RF.

This board provides the redundant input to a

DS-SG2-DRT/A-2X digital return transmitter. One DRRB is

used for each -2X transmitter.

SG2-*

DS-SG2-DRT*

Analog return

transmitters

Digital return

transmitters

Table 2-1 identifies and describes the five optical analog

return-path transmitters.

Table 2-2 identifies all models of the optical digital return-path

transmitters. Section 5, “Operation,” provides detailed

information and block diagrams for each series of digital

transmitters.

SG 2000 Instal lation and Opera tion Manual

Page 29

2-16 Overview

O

B

Gain Selection

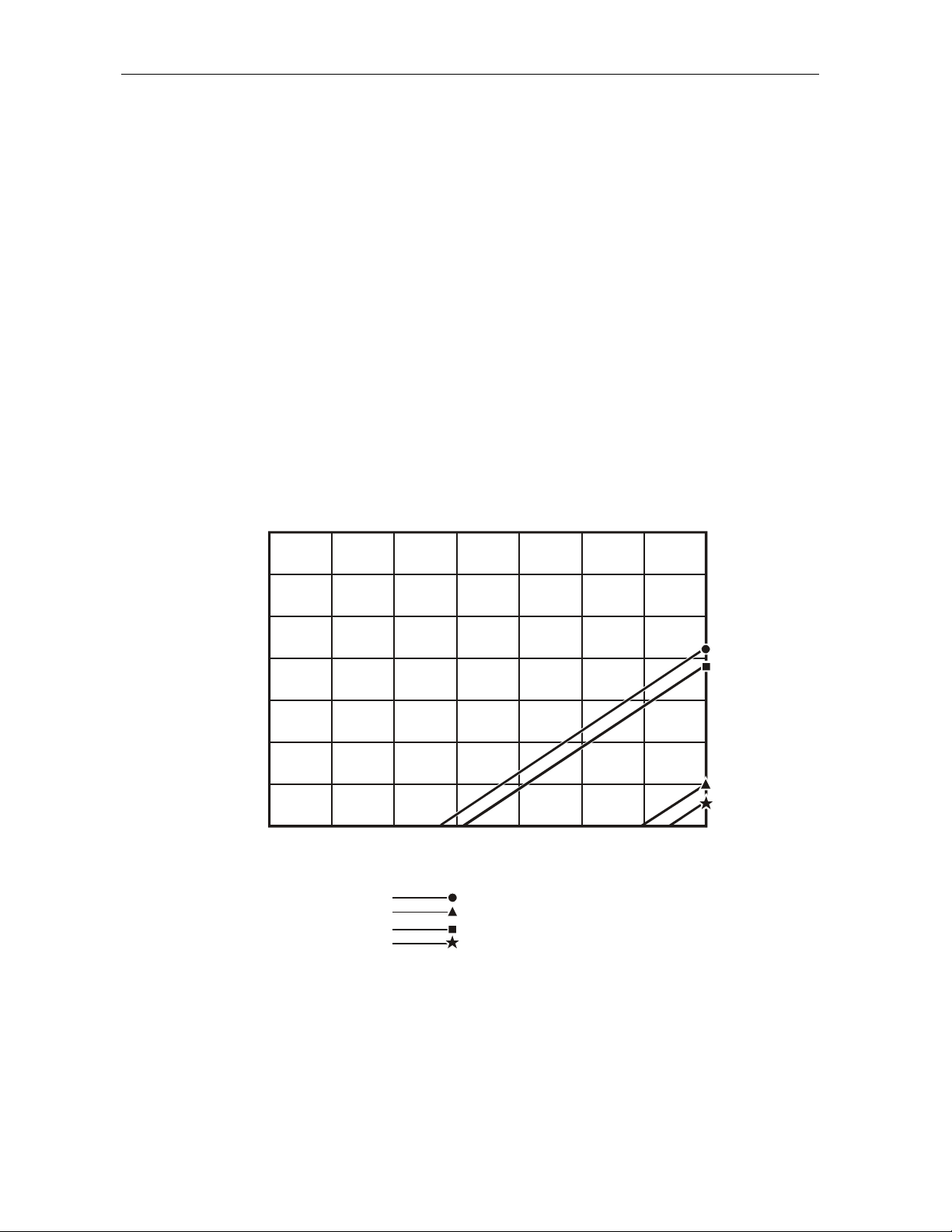

Figures 2-9 through 2-13 illustrate SG 2000 gain and tilt selection charts based on frequency and

channel load options.

To use the gain option selection charts, Figures 2-9 and 2-10, first find the point on the left hand axis

that corresponds to the expected optical input power at the node. Move across this horizontal line to

the right until it intersects a vertical line corresponding to the desired RF output level.

If this intersection is above and to the left of the diagonal “lo gain limit” line for the channel loading

under consideration, the low-gain option will give optimum performance with minimum padding. If

the intersection lies between the “lo gain limit” and “hi gain limit” lines, then choose the high-gain

option. Operation at a combination of input and output levels below and to the right of the “hi gain

limit” line is not possible.

Figure 2-9 illustrates the gain option selection chart for 750 MHz:

Figure 2-9

Optical inp ut versus 750 MHz gain

2

1

0

m)

-1

-2

ptical input (d

-3

-4

-5

38 40

Lo gain limit, 94 ch

Hi gain limit, 94 ch

Lo gain limit, 77 ch

Hi gain limit, 77 ch

750 MHz Gain Selection

42

Bridger output level (dBmV), 750 MHz equivalent

(Trunk output level is 10 dB lower)

44 46 48 50 52

Figure 2-9 gives the output level at 750 MHz. For a system loaded with analog channels to

550 MHz, the actual level at 550 MHz is 3.5 dB lower with the standard overall tilt of 12.5 dB. For

the low tilt of 10 dB, the reduction at 550 MHz is 3.0 dB. For the high tilt of 14 dB, the 550 MHz

level is 4.0 dB lower than at 750 MHz.

SG 2000 Instal lation and Opera tion Manual

Page 30

Overview 2-17

O

B

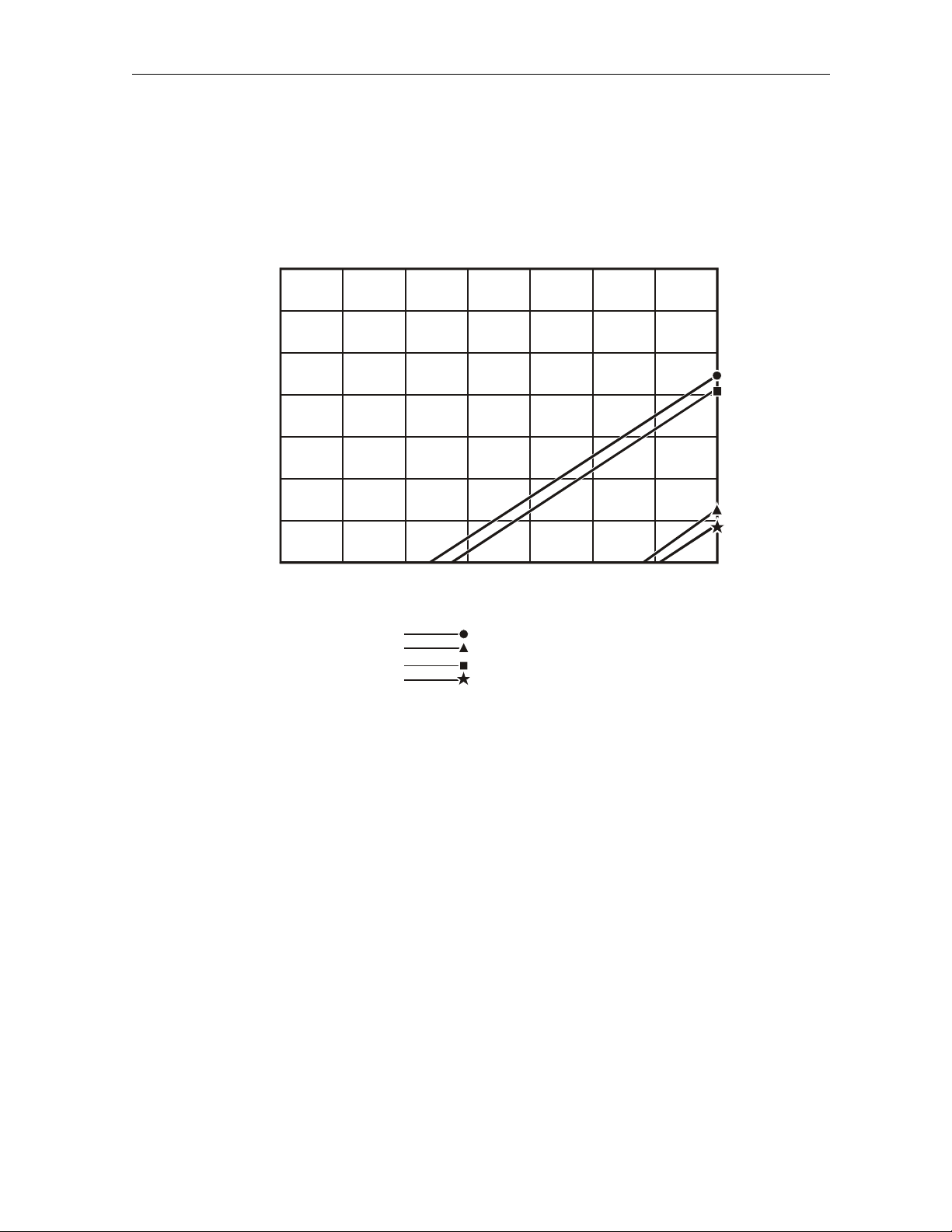

Figure 2-10 illustrates the gain option selection chart for 870 MHz:

Figure 2-10

Optical inp ut versus 870 MHz gain

2

1

0

m)

-1

-2

ptical input (d

-3

-4

-5

38 40

Lo gain limit, 110 ch

Hi gain limit, 110 ch

Lo gain limit, 94 ch

Hi gain limit, 94 ch

870 MHz Gain Selection

42

Bridger output level (dBmV), 870 MHz equivalent

(Trunk output level is 10 dB lower)

44 46 48 50 52

Figure 2-10 gives the output level at 870 MHz. For a system loaded with analog channels to

750 MHz, the actual level at 750 MHz is 1.7 dB lower with the standard overall tilt of 11.5 dB. For

the low tilt of 9.0 dB, the reduction at 750 MHz is 13 dB. For the high tilt of 14 dB, the 750 MHz

level is 2.1 dB lower than at 870 MHz.

For a system loaded with analog channels to 650 MHz, the actual level at 650 MHz is 3.1 dB lower

than the given 870 MHz level with the standard overall tilt of 11.5 dB. For the low tilt of 9.0 dB, the

reduction at 650 MHz is 2.4 dB. For the high tilt of 14 dB, the 650 MHz level is 3.8 dB lower than at

870 MHz.

SG 2000 Instal lation and Opera tion Manual

Page 31

2-18 Overview

R

B

Tilt Selection

To use the tilt selection charts, first determine the system operating bandwidth, either 750 MHz or

870 MHz. Next, determine the desired system channel load either 77, 94, or 110 channels. Use the

corresponding bandwidth and channel loading chart to determine the preferred tilt, either low,

standard, or high.

Figure 2-11 illustrates the tilt select ion cha rt for 750 M Hz bandwidth and 77-chan nel load:

Figure 2-11

Relative level dB versus 750 MHz slope 77 channels

SG2 750 MHz Slope Chart

77 Analog Channel s, 200 MH z Digital

14

13

12

11

10

9

8

7

6

5

4

elative level, d

3

2

1

0

-1

-2

-3

50

Low

Standar d

High

150 250 350 450 550 650 750

Frequency, MHz

SG 2000 Instal lation and Opera tion Manual

Page 32

Overview 2-19

R

B

Figure 2-12 illustrates the tilt select ion cha rt for 870 M Hz bandwidth and 94-chan nel load :

Figure 2-12

Relative level dB versus 870 MHz slope 94 channels

SG2 870 MHz Slope Chart

94 Analog Channel s, 220 MH z Digital

14

13

12

11

10

9

8

7

6

5

4

3

2

elative level, d

1

0

-1

-2

-3

-4

50

High

Standar d

Low

150 250 350 450 550 650 750

Frequency, MHz

870

SG 2000 Instal lation and Opera tion Manual

Page 33

2-20 Overview

R

B

Figure 2-13 illustrates the tilt select ion cha rt for 870 M Hz bandwidth and 110-cha nnel load :

Figure 2-13

Relative level dB versus 870 MHz slope 110 channels

SG2 870 MHz Slope Chart

110 Analog Channels, 120 MHz Digital

14

13

12

11

10

9

8

7

6

5

4

elative level, d

3

2

1

0

-1

-2

-3

50 150 250 350 450 550 650 750 870

Frequency, MHz

High

Standar d

Low

SG 2000 Instal lation and Opera tion Manual

Page 34

Section 3

Bench Setup

Before you install the SG 2000 you must set it up to meet the power and configuration requirements

for the node location. Bench set-up and quick check procedures are recommended to ensure proper

functioning of all components and simplify field installation. The last two pages of this section

provide an SG 2000 activation worksheet for you to record all pertinent setup information.

To facilitate on-line replacement, “hot-plugging” — inserting and removing optical modules and

power supplies — on SG 2000s equipped with redundant supplies, is possible with the node powered

and operational.

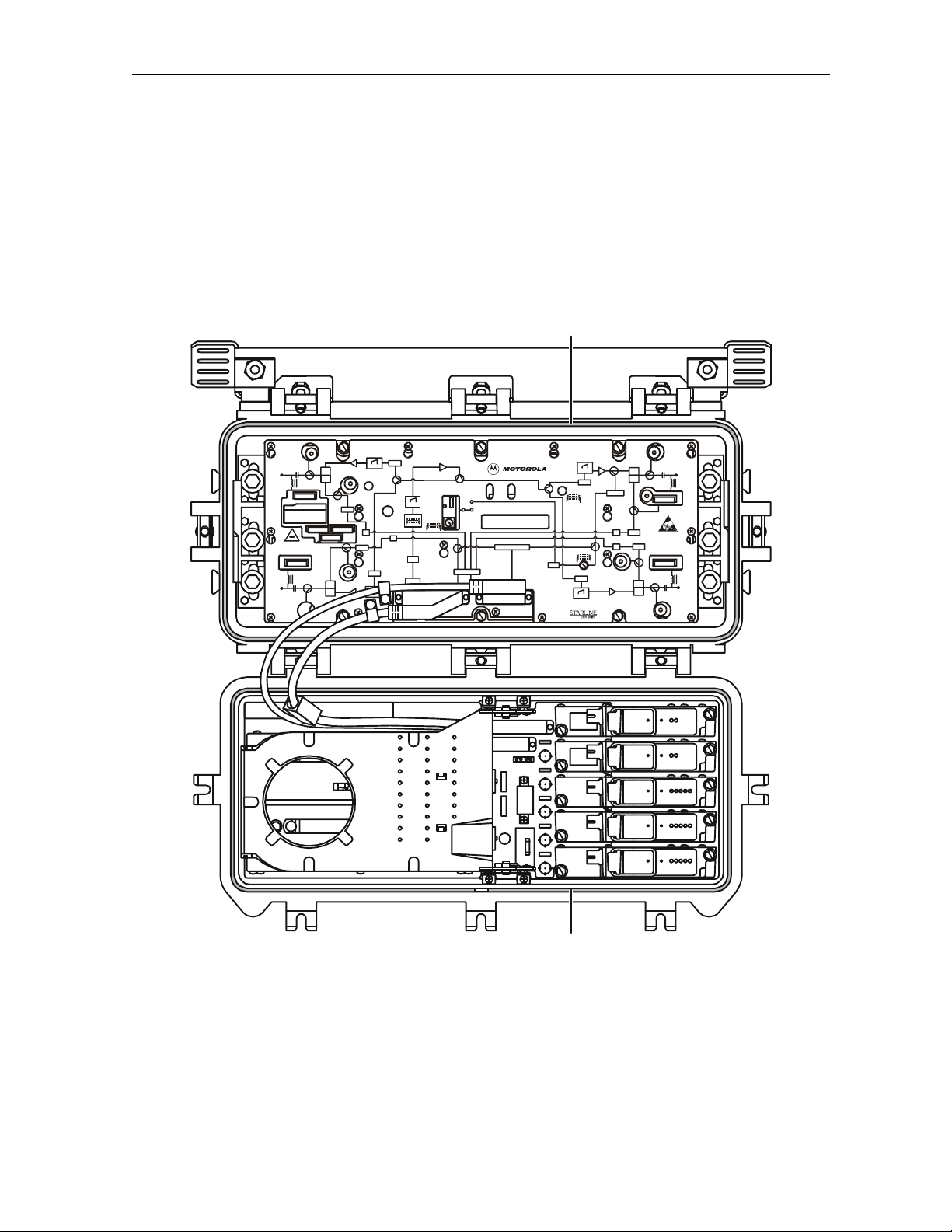

Figure 3-1 illustrates the upper-half housing or lid of the SG 2000 and identifies the location of all

major components:

Figure 3-1

SG 2000 lid showing major components

Pad - optical transmitter B

Test point - optical transmitter B

Pad - optical transmitter A

JP1

Test point - optical transmitter A

Power

supply 2

Power

supply 1

JP2

Optical

transmitter B

Optical

transmitter A

Optical

receiver C

Optical

receiver B

Optical

receiver A

Pad - optical receiver C

Test point - optical receiver C

Pad - optical receiver B

Test point - optical receiver B

Pad - optical receiver A

Test point - optical receiver A

SG 2000 Installation and Operation Manual

Page 35

3-2 Bench Setup

Figure 3-2 illustrates the RF chassis with the cover removed indicating the location of major

components:

Figure 3-2

SG 2000 RF chassis

Drive unit selector (AUTO/MAN)

Gain control (MAN ADJ)

Driver hybrid

MDR board

Forward pad

SG2-FE*

Output hybrid port 1

Ingress switch or JXP2A

Return pad

Diplex filter

Status monitor or MCB

ADU or TCU

Forward pad

SG2-FE*

Output hybrid port 2

SM & ADU pad

Ingress switches or JXP2A's

Diplex filter

Return pad

Diplex filter

Ingress switch or JXP2A

Output hybrid port 3

Forward pad

SG2-FE*

Flatness board

SG 2000 Installation and Operation Manual

Return pads

Diplex filter

Output hybrid port 4

ADU level control (ADU ADJ)

SG2-FE*

Forward pad

Optics to RF

cable interfaces

Page 36

Bench Setup 3-3

y

Powering the Node

You can conveniently power the SG 2000 by applying 60 Vac or 90 Vac to housing port 2. This port

is not used for RF purposes. All ports are rated at 15 amperes maximum and are fused with common,

blade-type 20-ampere automotive f uses. The 10-ampere fuse protects the dc power supply wiring

and can also be used to disconnect ac power from the power supply.

In addition to providing overcurrent protection, fuse locations also determine the paths for ac

bypassing through the housing.

Figure 3-3 diagrams fuse configurations for ac and dc powering:

Figure 3-3

Fuse configuration

Housing

Port 2

IN

Port 1

AC port

Port 3Port 1

F3

20 Amp

F2

20 Amp

F4

10 Amp

F1

20 Amp

SG2-PIC SG2-SIC

RF chassis

JP1

DC power

Pos 2

supply 1

SG2 lid assembly

Pos 1

F7

Jumper

F5

20 Amp

F6

20 Amp

DC power

suppl

Port 2

Unused

OUT

Port 4

Port 4 Port 3

2

SG 2000 Installation and Operation Manual

Page 37

3-4 Bench Setup

Table 3-1 identifies and describes the ac fuse options:

Table 3-1

AC fuses

Fuse Function Rating Type

F1

F2

F3

F4

F5

F6

F7