Page 1

PrPMC800/800ET Processor PMC

Module

Installation and Use

PRPMC800A/IH5

June 2006 Edition

Page 2

© Copyright 2001, 2002, 2003, 2006 Motorola, Inc.

All Rights Reserved.

Printed in the United States of America.

Motorola and the Motorola symbol are registered trademarks of Motorola, Inc.

CompactPCI is a registered trademark of PCI Industrial Computer Manufacturers Group.

All other products mentioned in this document are trademarks or registered trademarks of their

respective holders.

Page 3

Safety Summary

The following general safety precautions must be observed during all phases of operation,

service, and repair of this equipment. Failure to comply with these precautions or with specific

warnings elsewhere in this manual could result in personal injury or damage to the

equipment.

The safety precautions listed below represent warnings of certain dangers of which Motorola

is aware. You, as the user of the product, should follow these warnings and all other safety

precautions necessary for the safe operation of the equipment in your operating environment.

Ground the Instrument.

To minimize shock hazard, the equipment chassis and enclosure must be connected to an

electrical ground. If the equipment is supplied with a three-conductor AC power cable, the

power cable must be plugged into an approved three-contact electrical outlet, with the

grounding wire (green/yellow) reliably connected to an electrical ground (safety ground) at the

power outlet. The power jack and mating plug of the power cable meet International

Electrotechnical Commission (IEC) safety standards and local electrical regulatory codes.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in any explosive atmosphere such as in the presence of

flammable gases or fumes. Operation of any electrical equipment in such an environment

could result in an explosion and cause injury or damage.

Keep Away From Live Circuits Inside the Equipment.

Operating personnel must not remove equipment covers. Only Factory Authorized Service

Personnel or other qualified service personnel may remove equipment covers for internal

subassembly or component replacement or any internal adjustment. Service personnel

should not replace components with power cable connected. Under certain conditions,

dangerous voltages may exist even with the power cable removed. To avoid injuries, such

personnel should always disconnect power and discharge circuits before touching

components.

Use Caution When Exposing or Handling a CRT.

Breakage of a Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments

(implosion). To prevent CRT implosion, do not handle the CRT and avoid rough handling or

jarring of the equipment. Handling of a CRT should be done only by qualified service

personnel using approved safety mask and gloves.

Do Not Substitute Parts or Modify Equipment.

Do not install substitute parts or perform any unauthorized modification of the equipment.

Contact your local Motorola representative for service and repair to ensure that all safety

features are maintained.

Observe Warnings in Manual.

Warnings, such as the example below, precede potentially dangerous procedures throughout

this manual. Instructions contained in the warnings must be followed. You should also employ

all other safety precautions which you deem necessary for the operation of the equipment in

your operating environment.

Page 4

To prevent serious injury or death from dangerous voltages, use extreme

caution when handling, testing, and adjusting this equipment and its

Warning

components.

Flammability

All Motorola PWBs (printed wiring boards) are manufactured with a flammability rating of 94V0 by UL-recognized manufacturers.

EMI Caution

This equipment generates, uses and can radiate electromagnetic energy. It

!

Caution

may cause or be susceptible to electromagnetic interference (EMI) if not

installed and used with adequate EMI protection.

CE Notice (European Community)

!

Warning

This is a Class A product. In a domestic environment, this product may cause

radio interference, in which case the user may be required to take adequate

measures.

Motorola products with the CE marking comply with the EMC Directive (89/336/EEC).

Compliance with this directive implies conformity to the following European Norms:

EN55022 “Limits and Methods of Measurement of Radio Interference Characteristics of

Information Technology Equipment”; this product tested to Equipment Class A

EN 300 386 V.1.2.1 “Electromagnetic compatibility and radio spectrum matters (ERM);

Telecommunication network equipment; Electromagnetic compatibility (EMC)

requirements”

Board products are tested in a representative system to show compliance with the above

mentioned requirements. A proper installation in a CE-marked system will maintain the required

EMC performance.

In accordance with European Community directives, a “Declaration of Conformity” has been

made and is available on request. Please contact your sales representative.

Page 5

Notice

While reasonable efforts have been made to assure the accuracy of this document, Motorola,

Inc. assumes no liability resulting from any omissions in this document, or from the use of the

information obtained therein. Motorola reserves the right to revise this document and to make

changes from time to time in the content hereof without obligation of Motorola to notify any

person of such revision or changes.

Electronic versions of this material may be read online, downloaded for personal use, or

referenced in another document as a URL to the Motorola website. The text itself may not be

published commercially in print or electronic form, edited, translated, or otherwise altered

without the permission of Motorola, Inc.

It is possible that this publication may contain reference to or information about Motorola

products (machines and programs), programming, or services that are not available in your

country. Such references or information must not be construed to mean that Motorola intends

to announce such Motorola products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government,

the following notice shall apply unless otherwise agreed to in writing by Motorola, Inc.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in

subparagraph (b)(3) of the Rights in Technical Data clause at DFARS 252.227-7013 (Nov.

1995) and of the Rights in Noncommercial Computer Software and Documentation clause at

DFARS 252.227-7014 (Jun. 1995).

Motorola, Inc.

Embedded Communications Computing

2900 South Diablo Way

Tempe, Arizona 85282

Page 6

Page 7

Contents

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Preparation and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

PrPMC800/800ET Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Monarch and Non-Monarch PrPMCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Carrier Board Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview of Start-Up Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Preparing the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PrPMC800/800ET Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Harrier Power-Up Configuration Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ESD Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation of PrPMC800/800ET on a VME or CompactPCI Board . . . . . . . . . . . . . . . . . . . . . . . 7

2 Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Status LEDs and Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Debug Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ethernet Port Adapter Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

L2 Cache . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Harrier System Memory Controller / PCI Host Bridge ASIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Harrier Power-Up Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Arbitration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flash Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Onboard Bank A Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Optional Bank B Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

vii

Page 8

Contents

ECC Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Onboard SDRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10BaseT/100BaseTX Ethernet Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Miscellaneous Control and Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

32-Bit Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Watchdog Timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Interrupt Routing and Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Asynchronous Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Clock Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

PrPMC800/800ET Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Module Reset Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

PCI Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

PRESENT# Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

MONARCH# Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

INTA#-INTD# Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

IDSELB, REQB#, and GNTB# Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

M66EN Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RESETOUT_L Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EREADY Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

PCI Signaling Voltage Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Debug Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

ABORT# and RESET# Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Harrier Power-Up Configuration Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

On-Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Memory Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PCI Mezzanine Card (PMC) Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ethernet Adapter Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Debug Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Harrier Power-Up Configuration Header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Debug Serial Port Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5 PPCBug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PPCBug Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Memory Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

PPCBug Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

MPU, Hardware, and Firmware Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Using PPCBug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Debugger Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

viii

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 9

Contents

6 Modifying the Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

CNFG – Configure Board Information Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

ENV – Set Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuring the PPCBug Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

A Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Mechanical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Environmental Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

EMC Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

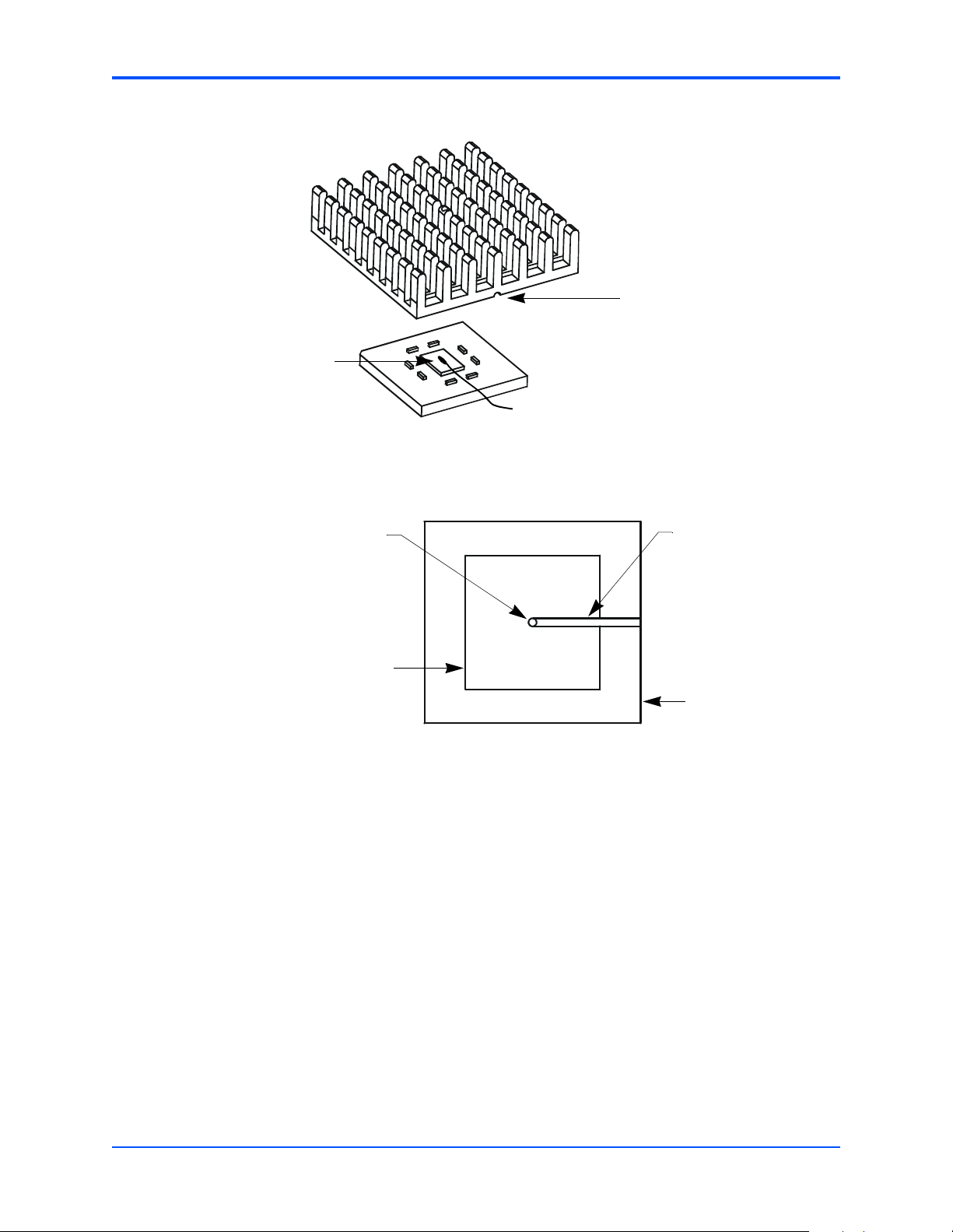

B Thermal Validation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Thermally Significant Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Component Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Measuring Junction Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Measuring Case Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Measuring Local Air Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

C Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Embedded Communications Computing Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Manufacturers’ Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

ix

Page 10

Contents

x

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 11

List of Figures

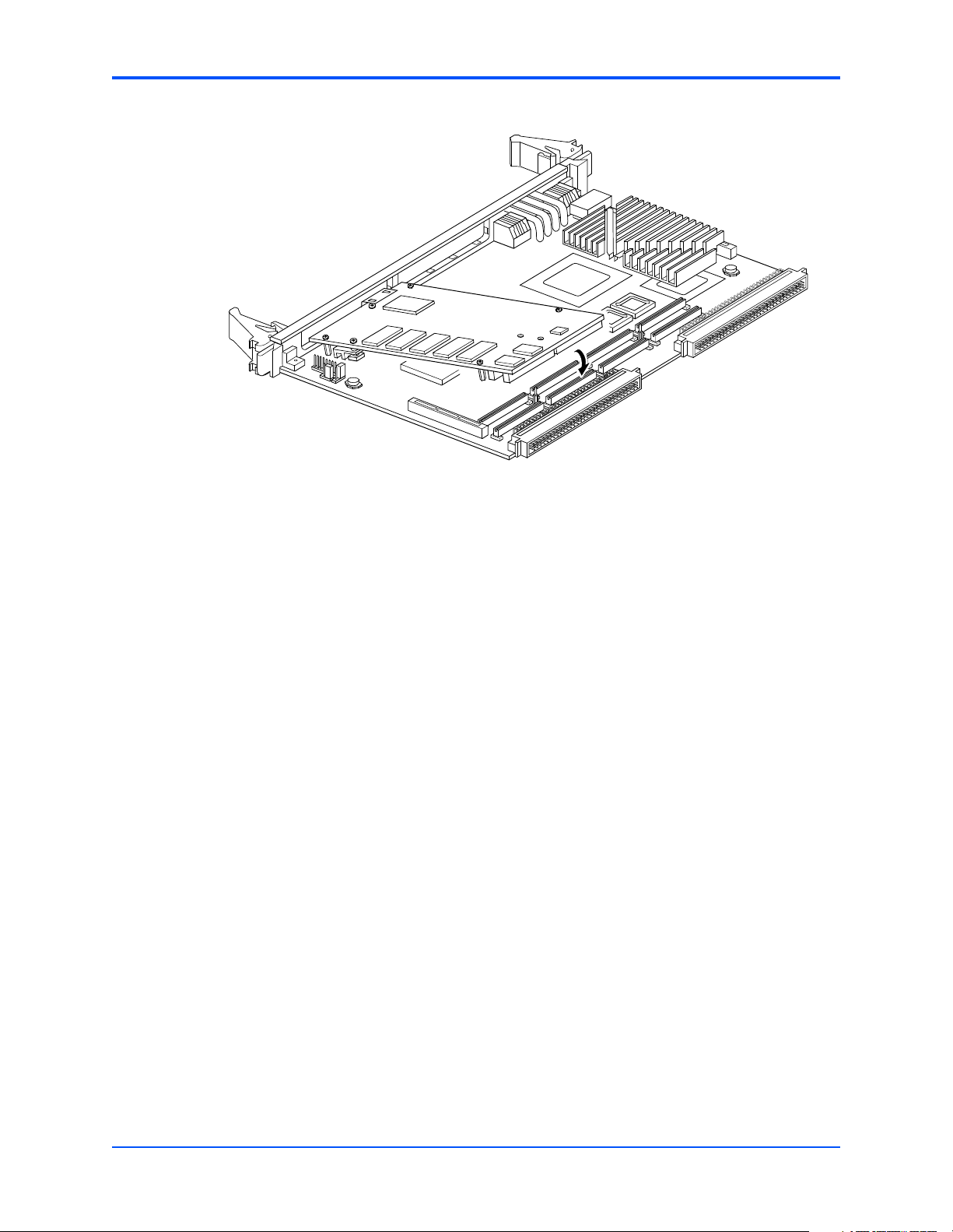

Figure 1-1. PrPMC800/800ET Headers, Connectors and Components . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 1-2. Installing a PrPMC800/800ET on a VMEmodule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2-3. PrPMC800/800ET Debug Serial Port Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 3-1. PrPMC800/800ET Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 3-2. PrPMC800/800ET Reset Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure B-1. Thermally Significant Components (Primary Side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure B-2. Thermally Significant Components (Secondary Side) . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Figure B-3. Measuring Local Air Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure B-4. Mounting a Thermocouple Under a Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

xi

Page 12

List of Figures

xii

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 13

List of Tables

Table 2-1. PrPMC800/800ET Models/Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Table 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvii

Table 1-3. Start-Up Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Table 1-4. J2 Harrier Power-Up Configuration Header Pin Assignments . . . . . . . . . . . . . . . . . . . . . . 5

Table 3-1. PrPMC800/800ET Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 3-2. Harrier Power-Up Configuration Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 3-3. PPC to PCI Clock Ratios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 3-4. Reset Source Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Table 4-1. PMC Connector P11 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 4-2. PMC Connector P12 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 4-3. PMC Connector P13 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 4-4. PMC Connector P14 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 4-5. J3 Ethernet Adapter Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4-6. J1 Debug Header Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 4-7. J2 Harrier Power-Up Configuration Header Pin Assignments . . . . . . . . . . . . . . . . . . . . . 37

Table 4-8. PrPMC Cable-001 Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 5-1. Debugger Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 5-2. Diagnostic Test Groups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table A-1. Power Requirements for PrPMC800/800ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table B-1. Thermally Significant Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table C-1. Embedded Communications Computing Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Table C-2. Manufacturers’ Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Table C-3. Related Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

xiii

Page 14

List of Tables

xiv

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 15

About This Manual

PrPMC800/800ET Processor PMC Module Installation and Use provides information for

installation and configuration of the PrPMC800/800ET, including jumper settings and

installation procedures. It also includes descriptions of various components’ functions,

connector pinout information, and a general description of the PPCBug firmware used with the

board.

Information in this manual applies to Motorola boards that are compatible with the PowerPC

™

instruction set architecture and that use PPCBug as their resident debugger program. The

majority of these boards, including most Processor PMC, VME, CompactPCI

®

and ATX form

factors, are equipped with PPCBug.

This document is limited to the installation and use instructions. For programming information,

refer to the Harrier ASIC Programmer’s Reference Guide and the PrPMC800/800ET Processor

PMC Module Programmer’s Reference Guide.

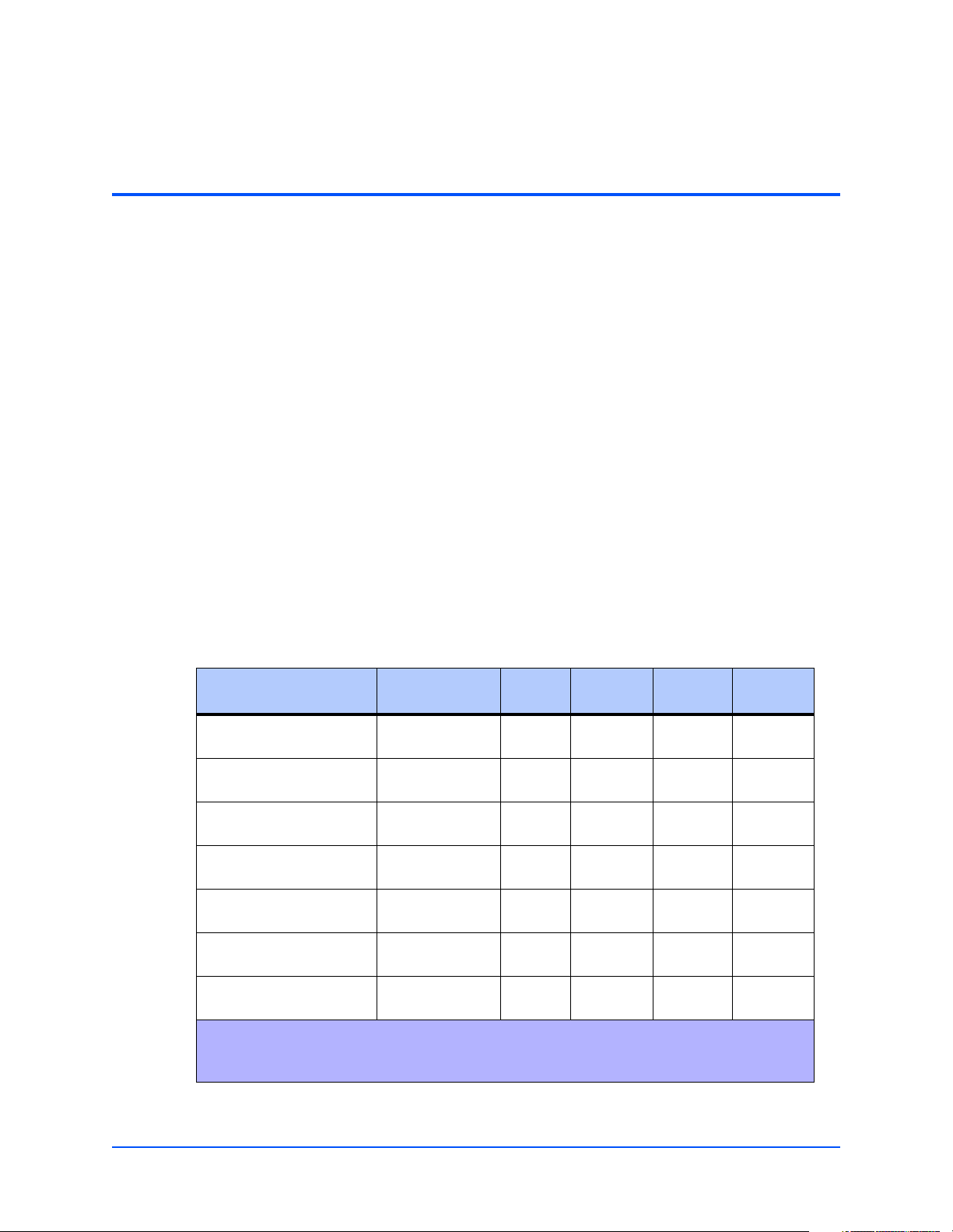

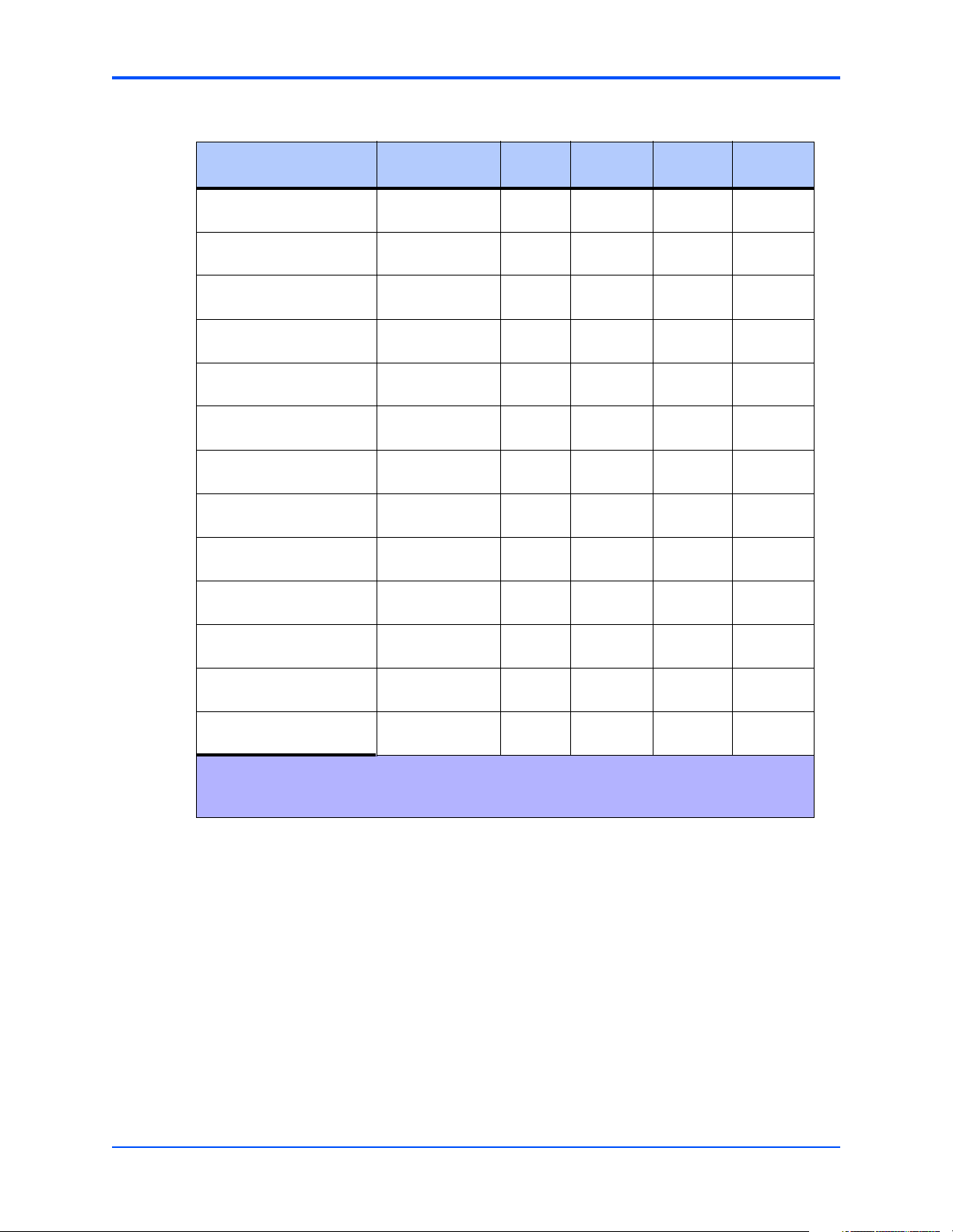

The following table lists the various model numbers and configurations for the

PrPMC800/800ET. Note that some of the models listed below qualify as Class B devices. If you

require a Class B device, contact your Motorola sales representative for specific models and

configurations that meet those requirements.

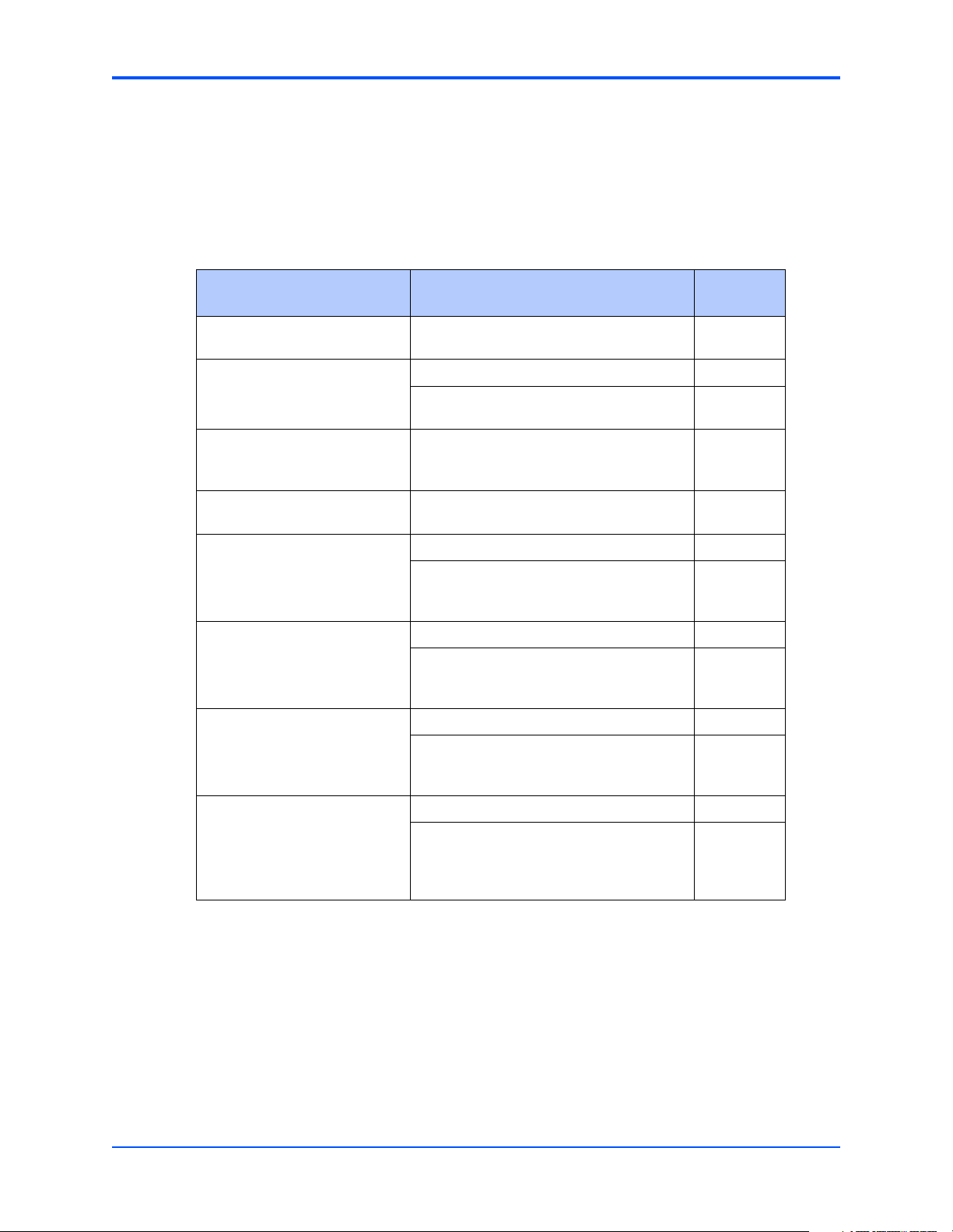

Table 2-1. PrPMC800/800ET Models/Configurations

Model Number

PrPMC800

PrPMC800-5251 MPC750 Class/

PrPMC800-5261 MPC750 Class/

Processor /

Speed

450 MHz

450 MHz

L2

Cache

1MB 128MB Front 33 MHz

1MB 256MB Front 33 MHz

Memory Ethernet PCI Bus

Speed

PrPMC800-5271 MPC750 Class/

450 MHz

PrPMC800-1261 MPC7410/

450 MHz

PrPMC800-1271 MPC7410/

450 MHz

PrPMC800-5259 MPC750 Class/

450 MHz

PrPMC800-5269 MPC750 Class/

450 MHz

* Industrial temperature models

For RoHS compliant models of these boards, please contact your local Motorola sales

representative.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

1MB 512MB Front 33 MHz

2MB 256MB Front 33 MHz

2MB 512MB Front 33 MHz

1MB 128MB Rear 33 MHz

1MB 256MB Rear 33 MHz

xv

Page 16

About This Manual

Table 2-1. PrPMC800/800ET Models/Configurations (continued)

Model Number

PrPMC800

PrPMC800-5279 MPC750 Class/

PrPMC800-1259 MPC7410/

PrPMC800-1269 MPC7410/

PrPMC800-1279 MPC7410/

PrPMC800-1251 MPC7410/

PrPMC800-2251 MPC7410/

PrPMC800-6251 MPC750 Class/

PrPMC800-6271 MPC750 Class/

PrPMC800-2261 MPC7410/

PrPMC800-2271 MPC7410/

Processor /

Speed

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

450 MHz

L2

Cache

1MB 512MB Rear 33 MHz

2MB 128MB Rear 33 MHz

2MB 256MB Rear 33 MHz

2MB 512MB Rear 33 MHz

2MB 128MB Front 33 MHz

2MB 128MB None 66 MHz

1MB 128MB None 66 MHz

1MB 512MB None 66 MHz

2MB 256MB None 66 MHz

2MB 512MB None 66 MHz

Memory Ethernet PCI Bus

Speed

Capable

Capable

Capable

Capable

Capable

PrPMC800-1361* MPC7410/500MHz2MB 256MB Front 33MHz

Capable

PrPMC800-1369* MPC7410/500MHz2MB 256MB Rear 33MHz

Capable

PrPMC800-2361* MPC7410/500MHz2MB 256MB None 66MHz

Capable

* Industrial temperature models

For RoHS compliant models of these boards, please contact your local Motorola sales

representative.

xvi

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 17

About This Manual

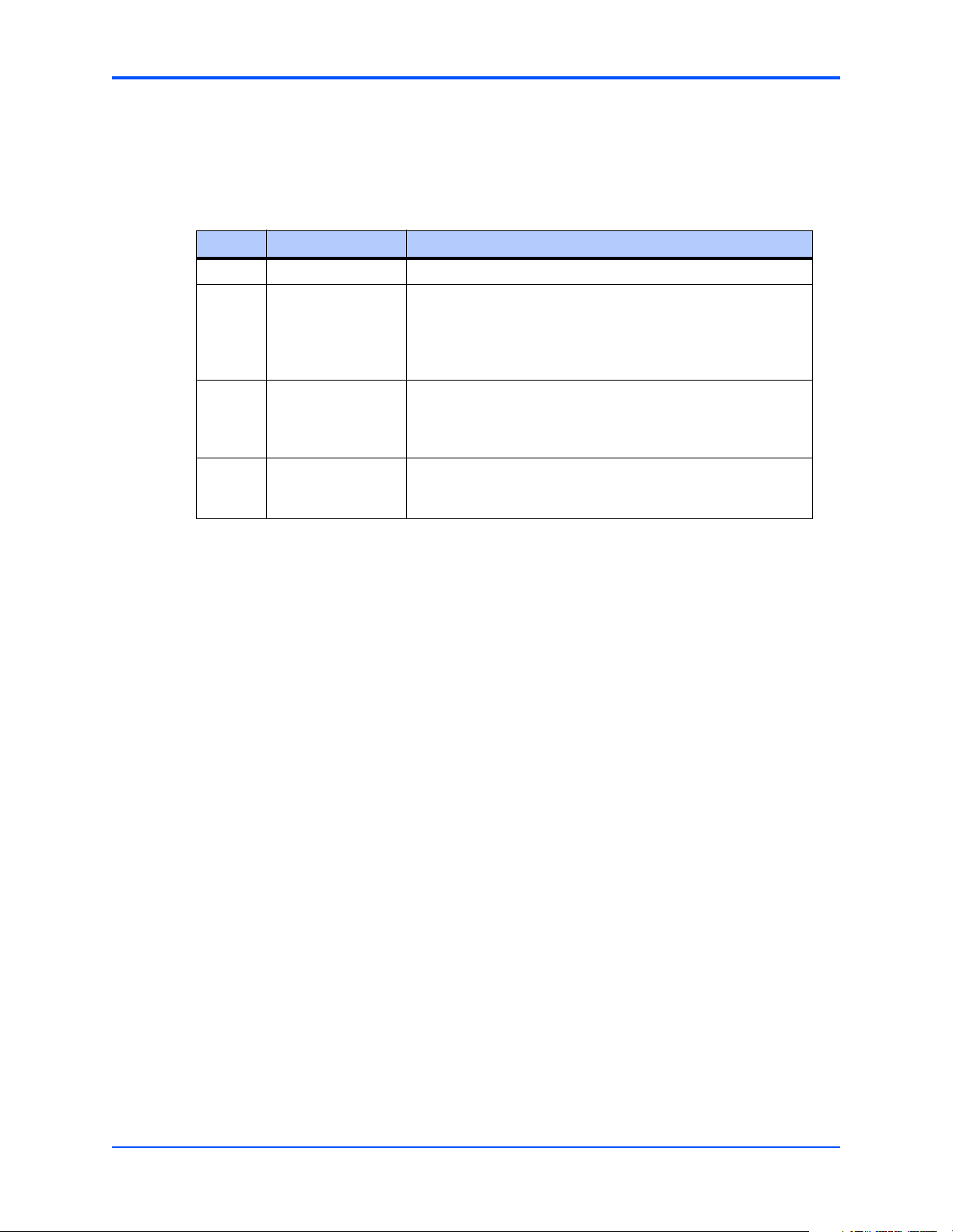

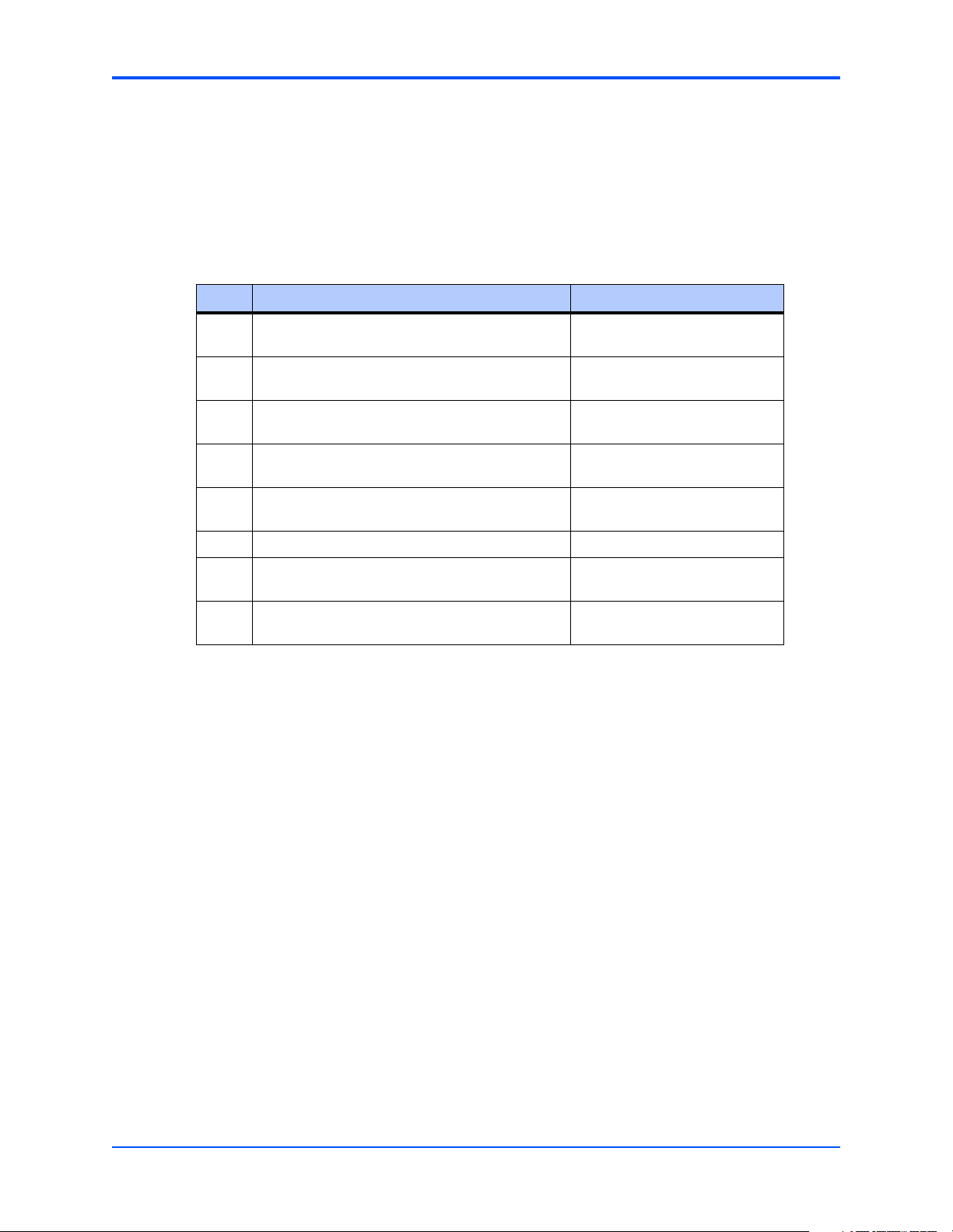

Summary of Changes

The following changes have been made to this manual.

Table 2-2.

Date Doc. Rev. Changes

6/2006 PRPMC800A/IH5 Updated Model and Configuration Table per EOL product list.

9/2003 PRPMC800A/IH4 Updates include processor core frequencies, Ethernet chip to

include 82551IT, board temperature specifications. New model

numbers were added to the Models/Configurations table to

reflect the availability of industrial temperature board

configurations.

01/2002 PRPMC800A/IH3 New model numbers were added to the Models/Configurations

table preceding this section to reflect the availability of lowpower board configurations. The Functional Description

(Chapter 3) and Specifications (Appendix B) were updated.

09/2001 PRPMC800A/IH2 New model numbers were added to the Models/Configurations

table preceding this section to reflect the 512MB memory

upgrade.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

xvii

Page 18

About This Manual

Overview of Contents

Chapter 1, Preparation and Installation, provides a general description of the PrPMC800/800ET

including a summary of the basic features and architecture. It also includes a brief discussion

of the monarch and non-monarch use of this board, and the carrier board requirements when

the PrPMC800/800ET is being used as a monarch. The remainder of the chapter includes an

overview of the start-up procedures, general information on unpacking and hardware

preparation, and installation instructions.

Chapter 2, Operating Instructions, contains a section on applying power, a brief description of

status LEDs and debug serial ports.

Chapter 3, Functional Description, provides a list of the main features of the PrPMC800/800ET.

It also provides a general description of the board, a block diagram, and subsections on all of

the major components on the board, including configuration settings for the Harrier ASIC. In

addition, it also describes various key functions such as arbitration, setting flash memory,

memory size settings and system registers.

Chapter 4, Connector Pin Assignments, includes tables of pin assignments for all connectors

and headers on the board.

Chapter 5, PPCBug, includes a general discussion of PPCBug, the initialization process and

steps, and a brief summary of the use of PPCBug with a list of current commands. A list of the

current Diagnostic Test Groups is also included.

Chapter 6, Modifying the Environment, provides a general overview of how to change various

parameters within PPCBug firmware. It discusses two main commands: ENV and CNFG.

Appendix A, Specifications, provides basic mechanical, electrical and environmental

specifications for the PrPMC800/800ET, as well as a section on Thermal Validation offering

information on thermally significant components and an overview of how to measure various

junction and case temperatures.

Appendix B, Thermal Validation, provides systems integrators with information which can be

used to conduct thermal evaluations of the board in their specific system configuration.

Appendix C, Related Documentation, provides a list of other Motorola Embedded

Communications Computing related documents, applicable Manufacturer’s (vendor)

documents, and a list of related specifications.Comments and Suggestions

Motorola welcomes and appreciates your comments on its documentation. We want to know

what you think about our manuals and how we can make them better. Mail comments to:

Embedded Communications Computing

Reader Comments DW164

2900 S. Diablo Way

Tempe, Arizona 85282

xviii

You can also submit comments to the following e-mail address: eccrc@motorola.com.

In all your correspondence, please list your name, position, and company. Be sure to include

the title and part number of the manual and tell how you used it. Then tell us your feelings about

its strengths and weaknesses and any recommendations for improvements.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 19

Conventions Used in This Manual

The following typographical conventions are used in this document:

bold

is used for user input that you type just as it appears. Bold is also used for commands,

options and arguments to commands, and names of programs, directories and files.

italic

is used for names of variables to which you assign values. Italic is also used for

comments in screen displays and examples, and to introduce new terms.

courier

is used for system output (for example, screen displays, reports), examples, and

system prompts.

<Enter>, <Return> or <CR>

<CR> represents the carriage return or Enter key.

About This Manual

CTRL

represents the Control key. Execute control characters by pressing the Ctrl key and the

letter simultaneously, for example, Ctrl-d.

|

separates two or more items from which to choose (one only)

[ ]

encloses an optional item that may not occur at all, or may occur once.

{ }

encloses an optional item that may not occur at all, or may occur one or more times.

A character precedes a data or address parameter to specify the numeric format, as follows (if

not specified, the format is hexadecimal):

$dollar

a hexadecimal character

0x Zero-x

% percent a binary number

& ampersand a decimal number

Data and address sizes are defined as follows:

A byte is eight bits, numbered 0 through 7, with bit 0 being the least significant.

A half-word is 16 bits, numbered 0 through 15, with bit 0 being the least significant.

A word is 32 bits, numbered 0 through 31, with bit 0 being the least significant.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

xix

Page 20

About This Manual

The MPU on the board is programmed to big-endian byte ordering. Any attempt to use little-

endian byte ordering will immediately render the debugger unusable.

Note

All references to processor bus support via the Harrier ASIC relate specifically

to the MPC60x-class bus mode. They do not imply support of any other

PowerPC-architecture bus mode.

xx

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 21

1 Preparation and Installation

Introduction

This chapter provides a brief description of the PrPMC800/800ET Processor PMC Module, and

instructions for preparing and installing the hardware.

In this manual, the name PrPMC800/800ET refers to all models of the PrPMC800/800ET series

boards, unless otherwise specified. These are add-on modules intended for use with any host

carrier board that accepts a PMC or PrPMC module.

PrPMC800/800ET Description

The PrPMC800/800ET is a single-width, standard-length and standard-height Processor PCI

Mezzanine Card (PrPMC) board. It is compatible with the PowerPlus III architecture and

consists of an MPC750-class or MPC7410 processor and the Harrier PCI-Host bridge/system

memory controller ASIC. The PrPMC800/800ET features 1MB or 2MB of L2 cache (depending

upon the configuration/version being used), 32MB of flash memory (a second bank of flash can

be located on the baseboard and accessed through the PMC P14 connector), one bank of

SDRAM (64MB to 512MB) onboard, a 10BaseT/100BaseTX Ethernet channel based on the

Intel 82559ER/82551IT device and an RS-232 transceiver providing debug capabilities through

one of the Harrier UART channels.

1

Four 64-pin PMC connectors on the PrPMC800/800ET are used to connect the

PrPMC800/800ET to the host board. One right-angle 20-pin connector located on the primary

side of the PrPMC800/800ET provides an interface to the asynchronous serial port and the

processor JTAG/COP port, along with the RESET# and ABORT# signals used for debug

support. The serial port and JTAG/COP interfaces, along with the ABORT_L signal, are also

routed to the PMC P14 connector for host board access.

Connectivity to the Ethernet channel is provided either by a front panel connector or by rear I/O

via the P14 connector. The build option determines the connection method. Models of this

board configured for Ethernet routing via the Pn4 do not have a front bezel.

The PrPMC800/800ET module can operate as a monarch (master) for the baseboard, or as a

slave processor PMC, depending on the state of the MONARCH# signal from the PMC P12

connector. When configured as the monarch, the PrPMC800/800ET enumerates the PCI bus,

and monitors and services the four PCI interrupts. If configured to operate in the non-monarch

mode, the PrPMC800/800ET module does not enumerate the bus or service interrupts, but it

may generate a PCI interrupt. The following section describes these modes of operation in

greater detail.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

1

Page 22

1 Preparation and Installation

Monarch and Non-Monarch PrPMCs

The traditional concept of host/master and slave/target processors changes with the inception

of the PrPMC because of the arbiter and clock source. Traditionally located on the host board,

these functions are not part of the PrPMC800/800ET. The VITA 32 specification defines the

terms monarch and non-monarch to refer to these two modes of operation for PrPMCs. A

monarch PrPMC is defined as the main PCI bus PrPMC (or CPU) that performs PCI bus

enumeration at power-up or reset and acts as the PCI interrupt handler. The non-monarch is a

slave/target processor that does not perform bus enumeration and does not service PCI

interrupts but may generate a PCI interrupt to the host processor.

A system may have one monarch PrPMC800/800ET and/or one or more non-monarch

PrPMC800/800ETs, creating a loosely coupled multiprocessing system. A PrPMC800/800ET

operating as a monarch may be mated to a carrier board with slave processors, PCI, and other

I/O devices. A PrPMC800/800ET operating as a non-monarch may be installed on a carrier with

a host processor and other PCI devices, such as an MVME2400 or an MCPN765 board.

PPCBug does not support all of the operating characteristics of a PrPMC800/800ET operating

as a non-monarch. Consequently, another operating system, such as a Real-Time Operating

System, may be required.

The PrPMC800/800ET firmware PPCBug is configured to operate as either a monarch or non-

monarch by reading the state of the MONARCH# pin on the PrPMC800/800ET. This pin is

either grounded or left open on the carrier board to enable the desired mode of operation. Refer

to the MONARCH# signal explanation on page 25 of this manual for more information.

Carrier Board Requirements

A carrier board must provide the standard PCI interface, including 3.3V and 5V power (the

PrPMC800/800ET only requires 3.3V), PCI address/control, a PCI clock, and two PCI arbiter

REQ/GNT pairs (refer to the VITA-32-199x specification for more information). The carrier

board must also ground the MONARCH# pin to enable the monarch operating mode. Leaving

the MONARCH# pin open enables the non-monarch mode. Additionally, board models

PrPMC800-2151, -2161, -2241, -2251, -2261, -2361, -2271, -6241, -6251, -6261, and -6271

may be configured for 66 MHz PCI operation. To enable this mode, the M66EN pin must be

pulled up on the baseboard.

System Enclosure

The system enclosure requirements are determined by the configuration and architecture of the

baseboard (either VME, CompactPCI, or custom). Only a single slot is necessary for both the

baseboard and the attached PrPMC800/800ET in a VME or CompactPCI chassis.

2

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 23

Overview of Start-Up Procedures

The following table lists the things you need to do before you can use this board and tells where

to find the information you need to perform each step. Be sure to read this entire chapter,

including all Cautions and Warnings, before you begin.

Table 1-3. Start-Up Overview

What you need to do ... Refer to ... On page

1 Preparation and Installation

...

Unpack the hardware. Unpacking the PrPMC800/800ET

Hardware

Make any settings or

adjustments on the

PrPMC800/800ET module.

Prepare any other optional

devices or equipment you will

be using.

Install the PrPMC800/800ET on

the baseboard.

Connect any other optional

devices or equipment you will

be using.

Power up the system. Status Indicators 10

Examine the environmental

parameters and make any

changes needed.

Program the PrPMC800/800ET

module and PMCs as needed

for your applications.

Preparing the PrPMC800/800ET Hardware 4

PrPMC800/800ET Configuration

Considerations

For more information on optional devices

and equipment, refer to the documentation

provided with that equipment.

Installation of a PrPMC800/800ET on a

VME or CompactPCI board

Connector Pin Assignments 29

For more information on optional devices

and equipment, refer to the documentation

provided with that equipment.

You may also wish to obtain the PPCBug

Diagnostics Manual, listed in Appendix C,

Related Documentation.

ENV - Set Environment 50

You may also wish to obtain the PPCBug

Firmware Package User’s Manual, listed in

Appendix C, Related Documentation.

Preparing the PrPMC800/800ET Hardware 4

You may also wish to obtain the

PrPMC800/800ET Processor PMC Module

Programmer’s Reference Guide, listed in

Appendix C, Related Documentation.

4

4

7

65

65

65

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

3

Page 24

1 Preparation and Installation

Unpacking the Hardware

Note

Unpack the equipment from the shipping carton(s). Refer to the packing list(s) and verify that

all items are present. Save the packing material for storing and reshipping of equipment.

Caution

If the shipping carton(s) is/are damaged upon receipt, request that the carrier’s

agent be present during the unpacking and inspection of the equipment.

Avoid touching areas of integrated circuitry; static discharge can damage

circuits.

Preparing the Hardware

To produce the desired configuration and ensure proper operation of the PrPMC800/800ET, you

may need to carry out certain modifications before and after installing the modules.

The following paragraphs discuss the preparation of the PrPMC800/800ET hardware

components prior to installing them into a chassis and connecting them.

PrPMC800/800ET Configuration

The PrPMC800/800ET provides software control over most options. By setting bits in control

registers, after installing the PrPMC800/800ET in a system, you can modify its configuration.

Refer to Table 1-4 on page 5 for information on the Harrier Power-Up Configuration header,

which provides access for configuration control. The PrPMC800/800ET control registers are

described in detail in the PrPMC800/800ET Processor PMC Module Programmer’s Reference

Guide and the Harrier ASIC Programmer’s Reference Guide as listed in Appendix C, Related

Documentation.

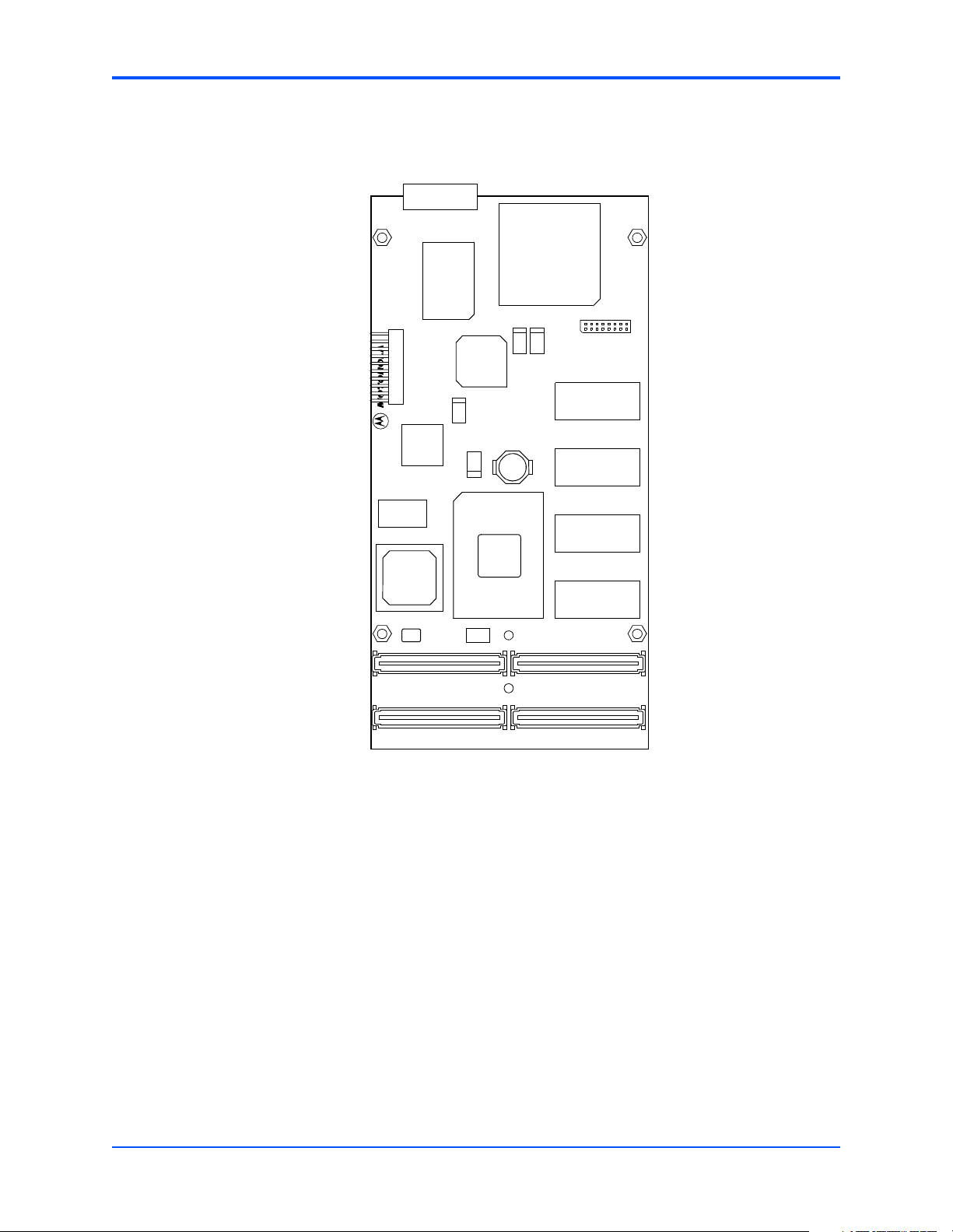

Figure 1-1 on page 6 shows the placement of headers, connectors, and components on the

PrPMC800/800ET. The PrPMC800/800ET was factory tested and is shipped with the

configurations described in the following sections. It contains a factory-installed debug monitor,

PPCBug, which operates with those factory settings.

4

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 25

Harrier Power-Up Configuration Header

A 2mm, 16-pin low profile header located on side 1 of the PrPMC800/800ET provides the

means to change some of the Harrier power-up configuration settings. The pin assignments for

this header, along with the power-up setting with the jumper on or off, are as follows (boards are

shipped with all jumpers off):

Table 1-4. J2 Harrier Power-Up Configuration Header Pin Assignments

J2 Jumper On Jumper Off

1 Preparation and Installation

1-2 PUST0 = 0

Harrier PUST Bit 0 in GCSR Register.

3-4 PUST1 = 0

Harrier PUST Bit 1 in GCSR Register

5-6 PUST2 = 0

Harrier PUST Bit 2 in GCSR Register

7-8 PUST3 = 0

Harrier PUST Bit 2 in GCSR Register

9-10 Hold off Configuration Space access Configuration Space access

11-12 Processor held in reset at power-up Processor enabled at power-up

13-14 Class Code set for I2O Controller” Class Code set for “Bridge

15-16 Xport 1uses normal data byte ordering Xport 1 uses Hawk data byte

PUST0 = 1

PUST1 = 1

PUST2 = 1

PUST3 = 1

enabled

Device”

ordering

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

5

Page 26

1 Preparation and Installation

19120

J3

115

U2

U6

2

2

J1

L3

U1

L5

16

1

15

J2

U10

U10

U9

T1

U8

U5

U4

U7

1

2

1

2

P11

P12

1263

64

1263

64

P13

P14

63

64

63

64

Figure 1-1. PrPMC800/800ET Headers, Connectors and Components

6

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 27

Installation

The following instructions tell how to install the PrPMC800/800ET on a typical VME or

CompactPCI single board computer. The PrPMC800/800ET can also be installed on an ATX

form factor carrier board that is equipped with industry standard PMC slots.

ESD Precautions

1 Preparation and Installation

Use ESD

Wrist Strap

If an ESD station is not available, you can avoid damage resulting from ESD by wearing an

antistatic wrist strap (available at electronics stores) that is attached to an active electrical

ground. Note that a system chassis may not be grounded if it is unplugged.

Caution

Motorola strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system. Electronic

components, such as disk drives, computer boards, and memory modules,

can be extremely sensitive to ESD. After removing the component from the

system or its protective wrapper, place the component flat on a grounded,

static-free surface (and, in the case of a board, component side up). Do not

slide the component over any surface.

Avoid touching areas of integrated circuitry; static discharge can damage

circuits.

Installation of PrPMC800/800ET on a VME or CompactPCI Board

To install a PrPMC800/800ET mezzanine on an VMEmodule or CompactPCI board, refer to

Figure 1-2 and perform the following steps:

1. Attach an ESD strap to your wrist. Attach the other end of the ESD strap to an electrical

ground. (Note that the system chassis may not be grounded if it is unplugged) The ESD

strap must be secured to your wrist and to ground throughout the procedure.

2. Perform an operating system shutdown. Turn the AC or DC power off and remove the

AC cord or DC power lines from the system. Remove the chassis or system cover(s) as

necessary to gain access to the VMEmodule or CompactPCI board.

3. Carefully remove the VMEmodule or CompactPCI board from its card slot and place it

on a clean and adequately protected working surface (preferably an ESD mat) with the

backplane connectors facing you.

4. Place the PrPMC800/800ET mezzanine module on top of the VMEmodule, or

CompactPCI board, with the four PMC connectors on the PrPMC800/800ET aligned with

the four corresponding connectors on the baseboard. Connectors P11, P12, P13, and

P14 at the bottom edge of the PrPMC800/800ET should connect smoothly with the

corresponding connectors on the VMEmodule or CompactPCI board.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

7

Page 28

1 Preparation and Installation

Figure 1-2. Installing a PrPMC800/800ET on a VMEmodule

5. Align the standoffs on the PrPMC800/800ET mezzanine with the VMEmodule or

CompactPCI board. Install the Phillips-head screws through the holes in the baseboard

and the spacers. Tighten the screws.

6. Install the VME or CompactPCI assembly in its proper card slot. Ensure the module is

seated properly in the backplane connectors. Do not damage or bend connector pins.

7. Replace the chassis or system cover(s) and connect the system to the AC or DC power

source. Turn the equipment power on.

8

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 29

2 Operating Instructions

Introduction

This chapter provides information about powering up the PrPMC800/800ET system, and

functionality of the status indicators, and I/O ports on the PrPMC800/800ET module.

Applying Power

After you have verified that all necessary hardware preparation has been done, that all

connections have been made correctly, and that the installation is complete, you can power up

the system. The MPU, hardware and firmware initialization process is performed by the

PPCBug firmware at power-up or system reset. The firmware initializes the devices on the

PrPMC800/800ET module in preparation for booting the operating system.

2

The firmware, PPCBug, is shipped from the factory with an appropriate set of defaults. In most

cases there is no need to modify the firmware configuration before you boot the operating

system. However, if you choose to do so, refer to Chapter 6, Modifying the Environment for

further information about modifying these defaults.

The following flowchart shows the basic initialization process that takes place during

PrPMC800/800ET system start-up.

For further information on PPCBug, refer to Chapter 5, PPCBug, or to the PPCBug

documentation listed in Appendix C, Related Documentation.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

9

Page 30

2 Operating Instructions

STARTUP

INITIALIZATION

POST

BOOTING

MONITOR

Power-up/reset initialization

Initialize devices on the PrPMC800/800ET

module/system

Power On Self Test diagnostics

Firmware-configured boot mechanism,

if so configured. Default is no boot.

Interactive, command-driven on-line PowerPC

debugger, when terminal connected.

Status LEDs and Port Connections

The PrPMC800/800ET’s status indicators (LEDs), Debug Serial port and Ethernet Port adapter

cable are described in the following subsections.

Status Indicators

There are two LED (light-emitting diode) status indicators located on the secondary side of

thePrPMC800/800ET, BDFL and CPU.

BDFL

The yellow fail LED is lit when the Harrier Board fail bit (BDFL) in the Miscellaneous Control and

Status register is active (software controlled). This LED is illuminated at reset and then turned

off after PPCBug has successfully completed initialization.

CPU

The green CPU LED is lit when the DBB# (Data Bus Busy) signal line on the processor bus is

active (hardware controlled).

10

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 31

Debug Serial Port

A three-wire debug serial RS-232 port (TXD, RXD, GND) is available on the 2mm, 20-pin rightangle header (J1) located on the primary side of the PrPMC800/800ET. Refer to Figure 2-3 for

pin definitions. An optional J1-to-DB9 adapter cable is available from Motorola. Contact your

local Motorola Sales Office or Distributor for more information or to order cable part number:

PrPMC-CABLE-001. The pinout description for this cable is defined in Debug Serial Port Cable

on page 38.

The debug port may be used for connecting a terminal to the PrPMC800/800ET to serve as the

firmware console for the factory installed debugger, PPCBug. The port is configured as follows:

❏ 8 bits per character

❏ 1 stop bit per character

❏ Parity disabled (no parity)

❏ Baud rate = 9600 baud (default baud rate at power-up)

After power-up, the baud rate of the debug port can be reconfigured by using the debugger’s

Por t Format (PF) command. Refer to Chapter 5, PPCBug and Chapter 6, Modifying the

Environment for information about PPCBug.

2 Operating Instructions

SOUT0

SIN0

Harrier

PrPMC800/800ET

Figure 2-3. PrPMC800/800ET Debug Serial Port Configuration

Ethernet Port Adapter Cable

An Ethernet port adapter cable is available for those models with front panel Ethernet. The

cable provides the capability to adapt the low profile Ethernet connector (J3) to a standard RJ45

receptacle. Contact your local Motorola Sales Office to order cable part number: PRPMCCable-003.

19

20

14

Debug

Header J1

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

11

Page 32

Page 33

3 Functional Description

Introduction

This chapter describes the PrPMC800/800ET Processor PMC Module on a block diagram level.

The General Description provides an overview of the PrPMC800/800ET, followed by a detailed

description of several blocks of circuitry. Figure 3-1 on page 15 shows a block diagram of the

overall board architecture.

Detailed descriptions of other PrPMC800/800ET blocks, including programmable registers in

the ASIC and peripheral chips, can be found in the PrPMC800/800ET Processor PMC Module

Programmer’s Reference Guide and the Harrier ASIC Programmer’s Reference Guide, listed in

Appendix C, Related Documentation. Refer to those documents for a more comprehensive set

of functional descriptions.

3

Features

The following table summarizes the features of the PrPMC800/800ET processor module.

Table 3-1. PrPMC800/800ET Features

Feature Description

Processor Single MPC750-class or MPC7410 processor

L2 Cache Backside L2 Cache using pipeline burst-mode SRAMS:

Flash Memory Bank A: 32MB soldered on-board using two 128 Mbit devices.

SDRAM Double-Bit-Error detect, Single-Bit-Error correct across 72 bits

Memory Controller Harrier’s SMC (System Memory Controller).

Core frequencies of 450 MHz for MPC750-class, 450Mhz and

500Mhz for MPC7410, 400Mhz for MPC7410(N)

Bus clock frequency of 100 MHz.

Address and data bus parity

1MB for MPC750-class and MPC7410 (N), 2MB for the MPC7410

Data bus parity

Bank B: Second bank of flash can be located on host board and

accessed through the PMC P14 connector.

Single bank of 16-bit wide devices onboard provide 64MB, 128MB,

256MB, or 512MB SDRAM.

PCI Host Bridge Harrier’s PHB (PCI Host Bridge).

Interrupt Controller Harrier’s MPIC (Multi-Processor Interrupt Controller).

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

13

Page 34

3 Functional Description

Table 3-1. PrPMC800/800ET Features (continued)

Feature Description

PCI Interface 32/64-bit Data

Ethernet Interface 10BaseT/100BaseTX interface based on the Intel 82559ER/82551IT

SROM Two 8K byte dual-address I

Debug Support Two 16550-compatible async serial ports (in Harrier) with RS-232

33 MHz minimum, 66 MHz capable on certain models

3.3V/5V universal signaling compatible interface

P11, P12, P13 and P14 PMC connectors

Address/data parity per PCI specification

device

AT93C46 SROM for 82559ER/82551IT configuration

2

C serial EEPROM devices for Vital

Product Data, user configuration data

One 256 byte standard I

interface

Processor JTAG/COP Interface

RESET and ABORT signals

Signals routed to 2mm header and PMC connector P14

2

C serial EEPROM for memory SPD

Input Power

Requirements

Form Factor Single-width, standard-length PMC (74mm x 149mm) with 10mm

3.3V +

board-to-board stacking height.

Standard (3.5mm) side 2 height

General Description

The PrPMC800/800ET is a Motorola processor PMC module compatible with the PowerPlus III

architecture. It consists of an MPC750-class, MPC7410, or MPC7410 (N) processor and:

❏ L2 backside cache

❏ Harrier System Memory Controller/PCI Host Bridge ASIC

❏ 32MB of flash memory

❏ 64MB to 512MB of ECC-protected SDRAM on board with memory expansion capability

❏ 10BaseT/100BaseTX Ethernet controller

❏ Debug serial port

The PrPMC800/800ET module interfaces to the host board PCI bus via the PMC P11, P12 and

P13 connectors. These provide a 64-bit PCI interface (that is, 33 MHz/66 MHz capable)

between the host board and the PrPMC800/800ET. The PrPMC module draws +3.3V through

the PMC connectors. The onboard Processor Core Power Supply derives the core voltage from

the +3.3V power. The clock generator derives all of the required onboard clocks from the PCI

clock input on P11.

5%

14

The PrPMC800/800ET module has a 2mm header onboard to support module debug

operations. This header provides the interface to the debug serial RS-232 port and an interface

to the processor JTAG/COP port.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 35

The PrPMC800/800ET module can function as a system controller (monarch mode) for the host

board or as a slave processor (non-monarch) PMC, depending on the state of the MONARCH#

signal from the PMC connector. When configured as the monarch, the PrPMC800/800ET’s

PPCBug enumerates the PCI bus as well as monitor and service the four PCI interrupts.

Block Diagram

The following figure is a block diagram of the PrPMC800/800ET’s overall architecture

3.3V

Processor Core

Power Supply

3 Functional Description

Bank A

Onboard SDRAM

64MB - 256MB

3.3V

Clock

Generator

2.5V Core

Power Supply

A T93C46

82559ER/82551IT

10/100 Ethernet

PMC P11/P12/P13 Connectors

1MB/2MB

SROM

Front

Connector

L2 Cache

Processor

MPC750 Type/

MPC7410

MPC60x Processor

PPC60x Processor

Harrier ASIC

System Memory Controller (SMC)

Bus

32/64-bit PCI

Bus

Bus

and PCI Host Bridge (PHB)

SROM

A T24Cxx

PMC P14 Connector

Flash Bank B (Xport 1)

Xport 0

Debug

Header

RS-232

TXCVR

OSC

1.84 MHZ

Flash Bank A

32MB

Figure 3-1. PrPMC800/800ET Block Diagram

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

15

Page 36

3 Functional Description

Processor

The PrPMC800/800ET board can be ordered with one of the following low-power/low care

voltage processor chips: 450 MHz MPC750-class, 450MHz or 500MHz MCP7410, or a 400

MHz MPC7410 (N).

L2 Cache

The PrPMC800/800ET utilizes a backside L2 cache structure via the MPC750-class or

MPC7410 processor chip families. The L2 cache is implemented with an on-chip, 2-way setassociative tag memory and external direct-mapped synchronous SRAMs for data storage. The

external SRAMs are accessed through a dedicated 72-bit wide (64 bits of data and 8 bits of

parity) L2 cache port. The MPC750-class processors support up to 1MB of L2 cache SRAMs.

The MPC7410 processor can support up to 2MB. The L2 cache can operate in copyback or

write-through modes and supports system cache coherency through snooping. Data parity

generation and checking can be disabled by programming the processor’s L2 cache control

register accordingly. The MPC7410 processor also supports direct mapping of the SRAM

memory, in conjunction with normal L2 cache operation. In this mode, a portion of the SRAM

memory space may be mapped to appear as a private memory space in the memory map.

Refer to the processor data sheet for additional information.

The L2 cache data SRAM for the PrPMC800/800ET is implemented using two 128K x 36 or

256K x 36 synchronous pipelined burst SRAMs providing a total of 1MB or 2MB of L2 cache,

depending on the board version.

Harrier System Memory Controller / PCI Host Bridge ASIC

The Harrier ASIC provides the bridge function between the PPC60x bus, the system memory,

and the PCI Local Bus. The Harrier ASIC incorporates the following key features:

– 100 MHz PowerPC-compatible bus interface

– SDRAM interface supporting up to eight banks of 512MB each, with ECC

– 32/64-bit REV2.1 compliant PCI bus interface capable of running up to 66 MHz

– Single channel DMA controller

– Message passing unit supporting I2O and generic functions

– Two internal 16550-type UARTs

–Two I

– MPIC compliant interrupt controller

– Four Xport channels for interfacing to flash or other external registers/devices

Refer to the Harrier Programmer’s Guide for additional information and programming details.

2

C bus master interfaces

16

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 37

Harrier Power-Up Configuration

The Harrier ASIC XAD30-XAD0 pins provide configuration information for Harrier at power-up

reset time. The following table lists the default power-up reset state of these pins for the

PrPMC800/800ET module. The Select Option column indicates whether the power-up setting

can be changed by jumper, or if the setting is fixed and cannot be changed. The Default Power-

Up Setting column indicates the default values for the standard PrPMC800/800ET product.

Default settings for jumper options indicate power-up values with jumpers not installed.

Table 3-2. Harrier Power-Up Configuration Settings

3 Functional Description

Harrier

XAD

Bus

Signal

XAD[30] Jumper J2

XAD[29] Fixed 0 UART clock select Select external clock source

XAD[28] Jumper J2

XAD[27] Fixed 0 PCI slave

Select

Option

pins 15-16

pins 9-10

Default

Power-

Function/

Register Bit

Up

Setting

1 Hawk data mode

XCSR.XPGC.HDM

0PCI slave

configuration holdoff

XCSR.BPCS.CSH

configuration mask

XCSR.BPCS.CSM

Description

Enable/Disable (1/0) Hawk

16-bit data ordering mode for

Xports configured for Hawk

addressing mode. Xport 1

(flash bank B) is configured

for Hawk compatibility mode.

If disabled, use Harrier byte

ordering mode.

for UART.

Enable/disable (1/0)

configuration space hold off. If

enabled, accesses to the PCI

configuration space from

another PCI master results in

a disconnect retry. Local

PrPMC800/800ET software

must clear this register bit to

enable access after inbound

address and attribute fields

have been set.

All of Harrier’s PCI

configuration registers are

visible from PCI space.

XAD[26] Jumper J2

pins11-12

XAD[25] Fixed 0 SDRAM external

XAD[24] Fixed 1 Response to

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

0 Processor holdoff

XCSR.BXCS

register

XCSR.SDTC.SDER

unmapped address-

only cycles

XCSR.GCSR.AOAO

Enable/disable (1/0)

processor hold off at powerup. If enabled, processor is

held in reset.

There are no external buffers

in series with the BAx, RAx,

WE, RAS or CAS signals.

Harrier responds to

unmapped address only

cycles.

17

Page 38

3 Functional Description

Table 3-2. Harrier Power-Up Configuration Settings (continued)

Harrier

XAD

Select

Option

Bus

Signal

XAD[23] Jumper J2

pins 7-8

XAD[22] Jumper J2

pins 5-6

XAD[21] Jumper J2

pins 3-4

XAD[20] Jumper J2

pins 1-2

XAD[19] Jumper J2

pins 13-14

Default

Power-

Function/

Register Bit

Description

Up

Setting

1 Generic power up

status bit 3

XCSR.GCSR.PUST

3

1 Generic power up

status bit 2

XCSR.GCSR.PUST

2

1 Generic power up

status bit 1

XCSR.GCSR.PUST

1

1 Generic power up

status bit 0

XCSR.GCSR.PUST

0

0 I2O IOP agent Set PCI Configuration register

Software readable header bit

3

Software readable header bit

2

Software readable header bit

1

Software readable header bit

0

CLAS to present class code

for “bridge device” (0) or “I2O

Controller” (1)

XAD[18] Fixed 0 Internal PCI arbiter Disable internal PCI arbiter

XAD[17] Fixed 1 Internal processor

arbiter

XAD

[16:15]

XAD

[14-12]

XAD

[11:10]

Fixed 00 XCSR register group

base address

000 reserved

On board

logic sets

ratio

depending

on state of

M66EN

Fixed 01 Xport channel 0 data

001 3:2 Set PPC-to-PCI clock ratio to

010 2:1 Set PPC-to-PCI clock ratio to

011 5:2 Set PPC-to-PCI clock ratio to

100 1:1 Set PPC-to-PCI clock ratio to

101 reserved

110 3:1 Set PPC-to-PCI clock ratio to

111 reserved

width

XCSR.XPAT0.DW

Enable internal Processor

arbiter

Set XCSR register group

base address to $FEFF0000

3:2

2:1

5:2

1:1

3:1

Set flash bank A to 16-bit

width

18

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 39

3 Functional Description

Table 3-2. Harrier Power-Up Configuration Settings (continued)

Harrier

XAD

Bus

Signal

XAD[9] BankB_SEL x Xport channel 0

XAD

[8:7]

XAD[6] Fixed 1 Xport channel 1

XAD

[5:4]

XAD[3] Fixed 0 Xport channel 2

XAD

[2:1]

Select

Option

Default

Power-

Function/

Register Bit

Up

Setting

reset vector source

Fixed 11 Xport channel 1 data

width

XCSR.XPAT1.DW

reset vector source

Fixed xx Xport channel 2 data

width

XCSR.XPAT2.DW

reset vector source

Fixed xx Xport channel 3 data

width

XCSR.XPAT2.DW

Description

Enable/Disable (1/0) Xport

channel 0 (flash bank A) as

reset vector source,

depending on state of

baseboard jumper.

Set Xport channel 1 (flash

bank B) to 16-bit width, Hawk

addressing mode.

Enable Xport channel 1 (flash

bank B) as reset vector

source if Xport channel 0 is

disabled.

Unused.

Disable Xport channel 2 as

Reset Vector source

Unused.

XAD[0] Fixed 0 Xport Channel 3

Arbitration

The Harrier ASIC contains arbiters for the PPC bus (60x bus mode only) and the PCI bus. The

PPC arbiter is used to arbitrate between the processor and the Harrier PPC bus master for

ownership of the PPC bus. The processor is connected to the Harrier arbiter

CPU0_REQ/CPU0_GNT signal pair (XARB3/XARB0).

The Harrier PCI bus arbiter is disabled in the standard board configuration. Per the VITA-32

199x Processor PMC Standard, the PCI bus arbitration must be provided by the baseboard.

Flash Memory

The PrPMC800/800ET supports two banks of flash memory. Bank A is onboard flash, while

bank B is optional flash located on the host board and accessed through the PMC P14

connector.

Reset Vector Source

Disable Xport channel 3 as

Reset Vector source

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

19

Page 40

3 Functional Description

Onboard Bank A Flash

The PrPMC800/800ET contains one bank of 32MB of flash memory on Xport 0 configured for

16-bit mode. Bank A consists of two Intel StrataFlash (28F128J3A) +3.3 volt devices configured

to operate in 8-bit mode. These Intel StrataFlash devices support page read mode operations

with an 8-byte page size per device.

Optional Bank B Flash

The signal interface for the Harrier Xport 1, configured to operate in Hawk 16-bit address/data

mode, is routed to the PMC P14 connector to support an optional 16-bit flash bank B on the

baseboard. The address multiplexing of the Hawk mode can address up to 512MB, but device

loading may restrict this size to less than that. The reset vector may be sourced by either bank

A or bank B depending on the state of the Harrier Xport reset vector control bits

(RVE N0/ RVEN 1 ). When the RVE N0 bit is set, address range $FFF00000-$FFFFFFFF maps to

bank A. When RVEN0 bit is cleared and the RVEN1 bit is set, the address range $FFF00000-

$FFFFFFFF maps to bank B. The default state uses bank A for the reset vector. Bank B may

be selected by connecting the BANKB_SEL pin on P14 to +3.3V.

Xport 1 may be configured to operate in the normal data byte ordering mode where the data

alternates every byte instead of every forth byte (Hawk data mode). The data ordering mode is

controlled by one of the onboard jumpers.

ECC Memory

The PrPMC800/800ET supports onboard ECC SDRAM configured as explained below.

Onboard SDRAM

The PrPMC800/800ET onboard ECC SDRAM memory, bank A, is configured as one bank of

nine 8-bit wide, +3.3V SDRAM devices in 54-pin TSOPII packages. The total onboard memory

size can be 64MB, 128MB, 256MB, or 512MB depending on the memory type used. The

SDRAM memory is controlled by the Harrier ASIC which provides single-bit error correction and

double-bit error detection. ECC is calculated over 72-bits. Refer to the Harrier ASIC

Programmer’s Reference Guide for additional information and programming details. The

SDRAM memory bus operates at the same speed as the processor bus.

SROM

The PrPMC800/800ET module contains two 8Kb serial EEPROM devices (AT24C64) and one

256 byte serial EEPROM device (AT24C02) onboard. One 8Kb serial EEPROM provides for

Vital Product Data (VPD) storage of the module hardware configuration, and the other 8Kb

device provides storage for user configuration data. The contents of the devices are accessed

by providing a two-byte address with the same device ID, instead of the standard one-byte

address as used in the 256 byte devices. The 256 byte device provides for Serial Presence

Detect (SPD) memory configuration information. The Serial EEPROM’s are accessed through

2

I

C port 0 in the Harrier ASIC. Refer to Appendix B of the PrPMC800/800ET Processor PMC

Module Programmer’s Reference Guide for information on the contents of the VPD and SPD.

20

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

Page 41

Harrier I2C port 0 is also routed to pins on the P14 PMC user I/O connector. The connection to

the PMC connector provides a means to interface to an optional configuration SROM on the

baseboard. This allows the PrPMC800/800ET to determine hardware configuration information

from the baseboard. Refer to the Harrier ASIC Programmer’s Reference Guide for SROM

device address assignments.

10BaseT/100BaseTX Ethernet Channel

The PrPMC800/800ET module uses an Intel GD82559ER/82551IT Ethernet controller to

implement a 10BaseT/100BaseTX Ethernet channel. The GD82559ER/82551IT is a lower

power, lower cost version of the GD82559 without the wake-on-LAN features. The

GD82559ER/82551IT consists of both the Media Access Controller (MAC) and the physical

layer (PHY) in a single integrated package. A Pulse H0013 low profile transformer is used to

supply the external magnetics. The module will support a front panel Ethernet connection via a

low profile PC card style connector mounted at the front of the module (on models -12x1 and 52x1). Optional rear I/O Ethernet is provided by routing the Ethernet transmit and receive signal

pairs to P14 connector (on models -11x9, -12x9, and -52x9).

The 82559ER/82551IT interfaces to an AT93C46 serial EEPROM device that provides powerup configuration information for the 82559ER/82551IT. This is a 1Kb device organized as 64 16bit words. Refer to the corresponding table in the VPD appendix of the PrPMC800/800ET

Processor PMC Module Programmer’s Reference Guide, for the contents of this device.

3 Functional Description

Miscellaneous Control and Status

The Harrier ASIC contains a Miscellaneous Control and Status register that provides the

PrPMC800/800ET module with the module fail LED control, PrPMC EREADY# pin status,

PrPMC MONARCH# pin status, module reset control, and processor timebase enable control.

Refer to the Harrier ASIC Programmer’s Reference Guide for additional details.

Timers

Timers on the PrPMC800/800ET board are provided by the Harrier ASIC. Refer to the Harrier

ASIC documents for programming details on these timers.

32-Bit Timers

Four 32-bit timers are provided by Harrier (MPIC) that may be used for system timing or to

generate periodic interrupts. Each timer is driven by a divide-by-eight prescaler which is

synchronized to the Power PC processor clock. For a 100 MHz processor bus, the timer

frequency would be 12.5 MHz.

PrPMC800/800ET Processor PMC Module Installation and Use (PrPMC800A/IH5)

21

Page 42

3 Functional Description

Watchdog Timers

The Harrier ASIC contains two Watchdog timers, WDT0 and WDT1. Each timer is functionally

equivalent but independent. These timers continuously decrement until they reach a count of 0

or are reloaded by software. The time-out period is programmable from 1 microsecond up to 32

minutes. If the timer count reaches 0, a timer output signal is asserted. The output of Watchdog

Timer 0 is routed to an MPIC interrupt. The output of Watchdog Timer 1 is connected to the

Harrier AUXRST, which will generate RESETOUT_L.

Following a Harrier device reset, WDT0 is enabled with a default time-out of 8 seconds and

WDT 1is enabled with a default time-out of 16 seconds. Each timer must be disabled or

reloaded by software to prevent a time-out. Software may reload a new timer value or force the

timer to reload a previously loaded value. To disable or load/reload a timer requires a two step

process.