MOTOROLA MC44608P40, MC44608P75 Datasheet

MC44608

Few External Components

Reliable and Flexible

GreenLine

V ery High V oltage

PWM Controller

The MC44608 is a high performance voltage mode controller

designed for off–line converters. This high voltage circuit that

integrates the start–up current source and the oscillator capacitor,

requires few external components while offering a high flexibility and

reliability .

The device also features a very high efficiency stand–by

management consisting of an effective Pulsed Mode operation. This

technique enables the reduction of the stand–by power consumption to

approximately 1W while delivering 300mW in a 150W SMPS.

• Integrated Start–Up Current Source

• Lossless Off–Line Start–Up

• Direct Off–Line Operation

• Fast Start–Up

General Features

• Flexibility

• Duty Cycle Control

• Undervoltage Lockout with Hysteresis

• On Chip Oscillator Switching Frequency 40, or 75kHz

• Secondary Control with Few External Components

Protections

• Maximum Duty Cycle Limitation

• Cycle by Cycle Current Limitation

• Demagnetization (Zero Current Detection) Protection

• “Over V

•

Programmable Low Inertia Over Voltage Protection Against Open Loop

• Internal Thermal Protection

GreenLine Controller

• Pulsed Mode T echniques for a Very High Efficiency Low Power

Mode

• Lossless Startup

• Low dV/dT for Low EMI Radiations

Protection” Against Open Loop

CC

http://onsemi.com

8

DIP–8

P SUFFIX

CASE 626

PIN CONNECTIONS AND

MARKING DIAGRAM

1 8

Demag

2

I

sense

Control Input

Device

MC44608P40 40kHz

MC44608P75 75kHz

3

4

Gnd

AWL = Manufacturing Code

YYWW = Date Code

(Top View)

ORDERING INFORMATION

Switching

Frequency

1

AWL

YYWW

44608Pxxx

Package

7

6

5

Plastic

DIP–8

Plastic

DIP–8

Vi

V

cc

Driver

Shipping

50 / Rail

50 / Rail

Semiconductor Components Industries, LLC, 1999

January , 2000 – Rev. 2

1 Publication Order Number:

MC44608/D

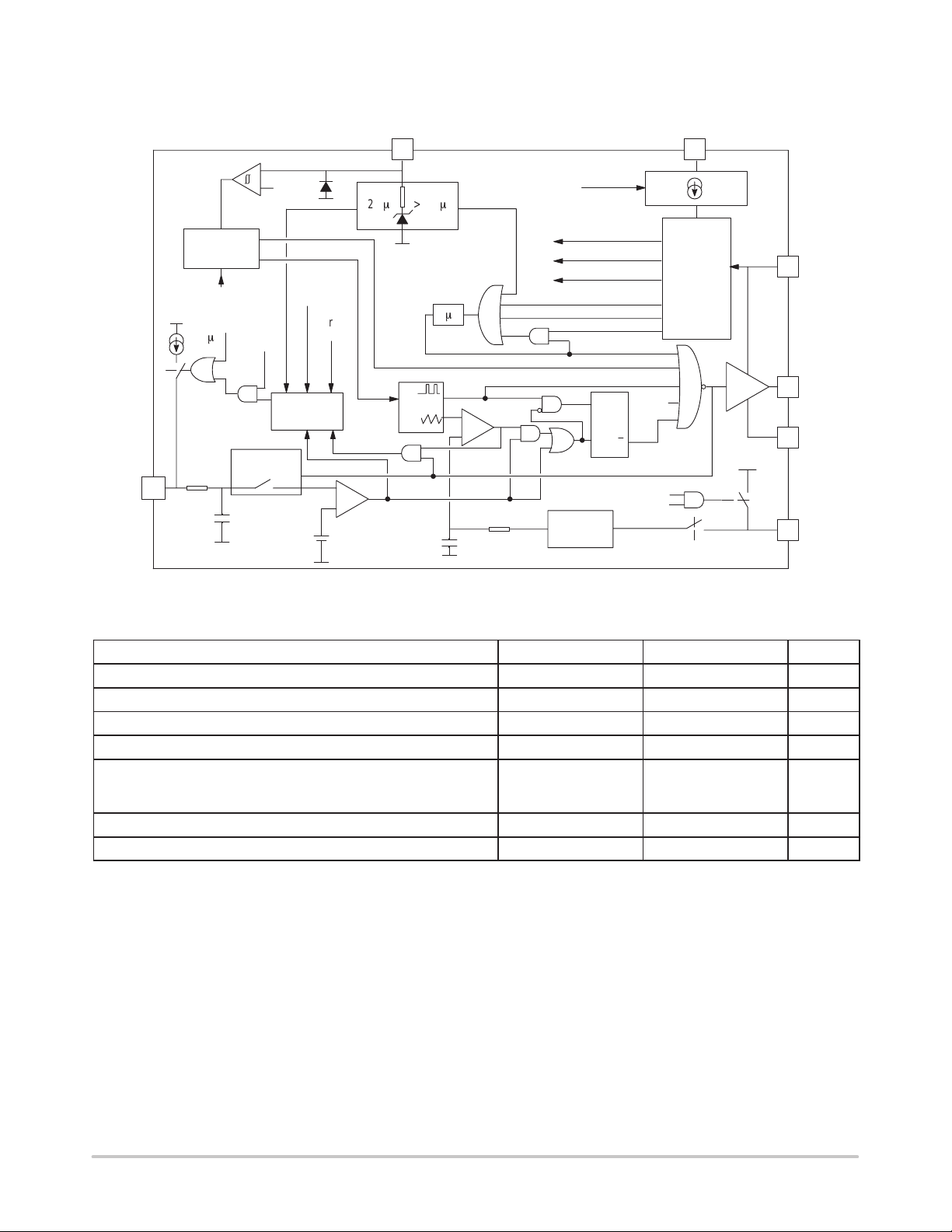

Isense

10

S1

2

DMG

Demag

Logic

Output

Start–up

200 A

m

Phase

Stand–by

Leading Edge

+

–

Switching

Phase

&

Blanking

50 mV

/20 mV

Latched off

Phase

Start–up

Phase

Stand–by

Management

Output

MC44608

REPRESENTATIVE BLOCK DIAGRAM

Demag Vi

18

>24 A

m

>120 A

m

Latched off Phase

Start–up Phase

Switching Phase

2 S

m

&

OSC

1 V

Enable

OSC

NOCOC

+

CS

–

Clock

+

PWM

&

–

VPWM

4 kHz Filter

&

&

Regulation

Block

S

R

Latched off Phase

UVLO2

OVP

UVLO1

UVLO2

OUT Disable

DMG

Thermal

Shutdown

PWM

Latch

Q

Stand–by

9 mA

Switching Phase

Start–up

Source

V

CC

Management

&

S2 S3

Buffer

6

V

CC

5

Driver

4

GND

3

Control

Input

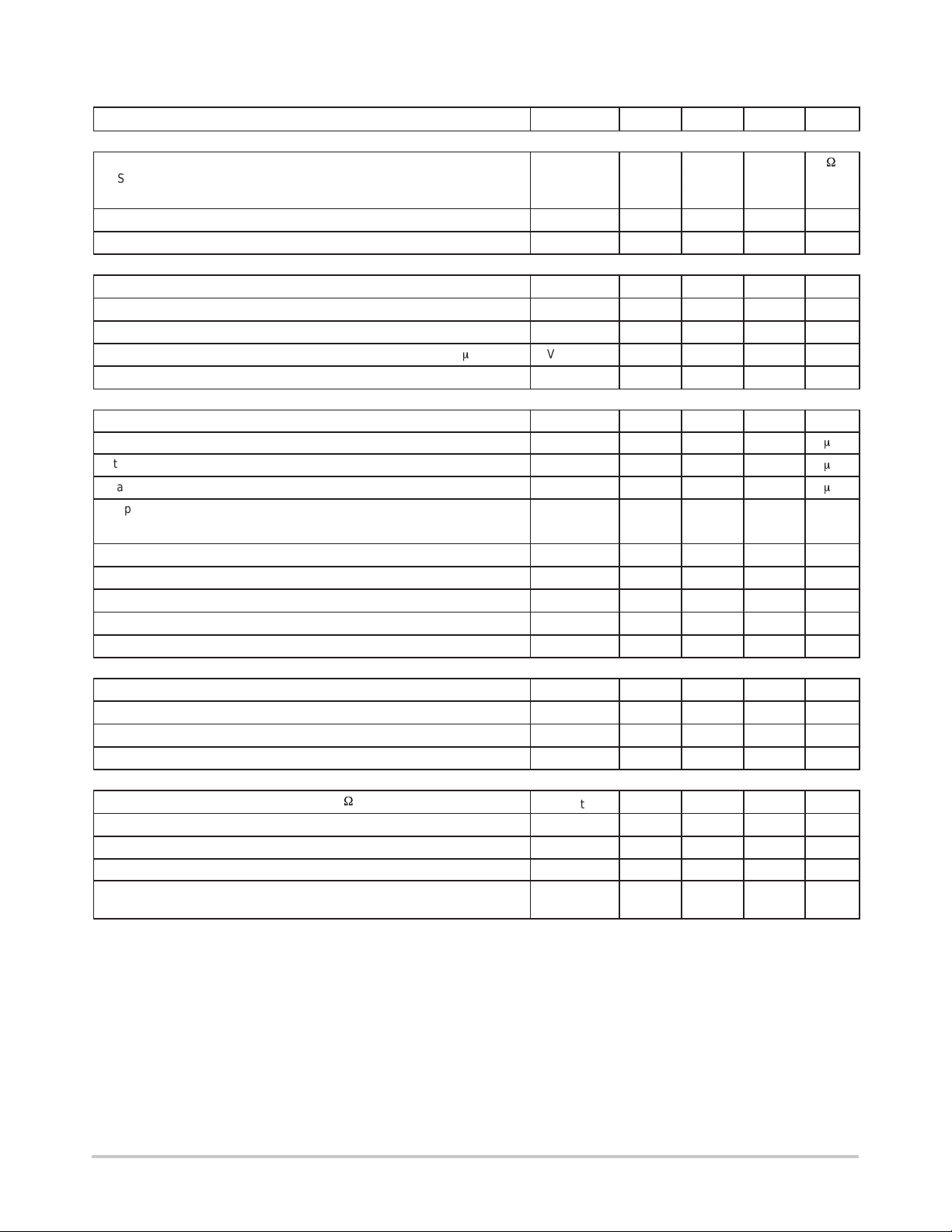

MAXIMUM RATINGS

Rating Symbol Value Unit

Total Power Supply Current I

Output Supply Voltage with Respect to Ground V

All Inputs except Vi V

Line Voltage V

Power Dissipation and Thermal Characteristics

Maximum Power Dissipation at TA = 85°C P

Thermal Resistance, Junction–to–Air R

Operating Junction Temperature T

Operating Ambient Temperature T

CC

CC

inputs

i

D

θJA

J

A

30 mA

16 V

–1.0 to +16 V

500 V

600 mW

100 °C/W

150 °C

–25 to +85 °C

http://onsemi.com

2

MC44608

ELECTRICAL CHARACTERISTICS

Characteristic Symbol Min Typ Max Unit

OUTPUT SECTION

Output Resistor

Sink Resistance R

Source Resistance R

stup–th

(1)

(1)

= –1.0 mA 4.75 5.0 5.25 V

pin3

= +500 mA

pin3

= +1.0 mA V

pin3

Output Voltage Rise Time (from 3 V up to 9 V)

Output Voltage Falling Edge Slew–Rate (from 9 V down to 3 V)

CONTROL INPUT SECTION

Duty Cycle @ I

Duty Cycle @ I

Control Input Clamp Voltage (Switching Phase) @ I

Latched Phase Control Input Voltage (Stand–by) @ I

Latched Phase Control Input Voltage (Stand–by) @ I

CURRENT SENSE SECTION

Maximum Current Sense Input Threshold V

Input Bias Current I

Stand–By Current Sense Input Current I

Start–up Phase Current Sense Input Current I

Propagation Delay (Current Sense Input to Output @ VTH T MOS = 3 V) T

Leading Edge Blanking Duration MC44608P40 T

Leading Edge Blanking Duration MC44608P75 T

Leading Edge Blanking Duration MC44608P100 T

Leading Edge Blanking + Propagation Delay MC44608P40 T

Leading Edge Blanking + Propagation Delay MC44608P75 T

Leading Edge Blanking + Propagation Delay MC44608P100 T

OSCILLATOR SECTION

Normal Operation Frequency MC44608P40 f

Normal Operation Frequency MC44608P75 f

Normal Operation Frequency MC44608P100 f

Maximum Duty Cycle @ f = f

OVERVOLTAGE SECTION

Quick OVP Input Filtering (R

Propagation Delay (I

Quick OVP Current Threshold I

Protection Threshold Level on V

Minimum Gap Between V

NOTES:

(1) This parameter is measured using 1.0 nF connected between the output and the ground.

= 2.5 mA d

pin3

= 1.0 mA d

pin3

osc

= 100 kW)

demag

> I

demag

CC–OVP

to output low) T

ovp

CC

and V

OL

OH

t

r

t

f

2mA

1mA

V

LP–stby

LP–stby

CS–th

B–cs

CS–stby

CS–stup

PLH(In/Out)

LEB

LEB

LEB

DLY

DLY

DLY

osc

osc

osc

d

max

T

filt

PHL(In/Out)

OVP

V

CC–OVP

V

CC–OVP

V

stup

5.0 8.5 15

15

50 ns

50 ns

36 43 48 %

3.4 3.9 4.3 V

2.4 3.0 3.7 V

0.95 1.0 1.05 V

–1.8 1.8

180 200 220

180 200 220

220 ns

480 ns

250 ns

200 ns

500 680 900 ns

370 470 570 ns

400 ns

36 40 44 kHz

68 75 82 kHz

100 kHz

78 82 86 %

250 ns

2.0 µs

105 120 140 µA

14.8 15.3 15.8 V

–

1.0 V

2.0 %

m

m

m

W

A

A

A

http://onsemi.com

3

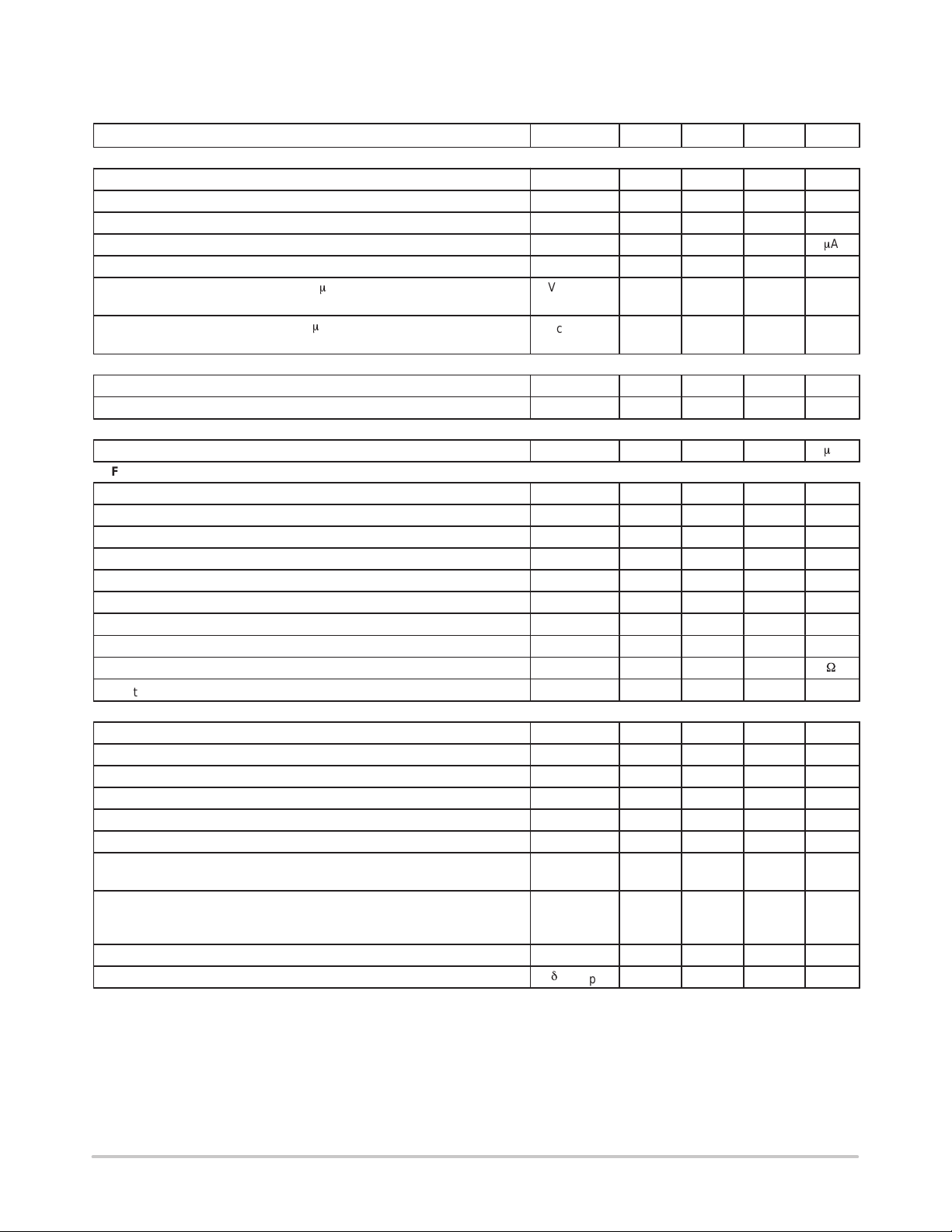

MC44608

ELECTRICAL CHARACTERISTICS (V

noted) (Note 1)

Characteristic

DEMAGNETIZATION DETECTION SECTION (Note 2)

Demag Comparator Threshold (V

Demag Comparator Hysteresis (Note 3) H

Propagation Delay (Input to Output, Low to High) t

Input Bias Current (V

Negative Clamp Level (I

Positive Clamp Level @ I

Positive Clamp Level @ I

OVERTEMPERATURE SECTION

Trip Level Over Temperature T

Hysteresis T

STAND–BY MAXIMUM CURRENT REDUCTION SECTION

Normal Mode Recovery Demag Pin Current Threshold I

K FACTORS SECTION FOR PULSED MODE OPERATION

I

/ I

CCS

stup MC44608P40

I

/ I

CCS

stup MC44608P75

I

/ I

CCS

stup MC44608P100

I

/ I

CCL

stup

(V

– UVLO2) / (V

stup

(UVLO1 – UVLO2) / (V

ICS / V

csth

Demag ratio I

(V3 1 mA – V3

V

Latch–off V3 4.8 V

control

SUPPLY SECTION

Minimum Start–up Voltage Vi

VCC Start–up Voltage V

Output Disabling VCC Voltage After Turn On V

Hysteresis (V

VCC Undervoltage Lockout Voltage V

Hysteresis (V

Absolute Normal Condition VCC Start Current @ (Vi = 100 V) and

(VCC = 9 V)

Switching Phase Supply Current (no load)

Latched Off Phase Supply Current I

Hiccup Mode Duty Cycle (no load)

NOTES:

(1) Adjust VCC above the start–up threshold before setting to 12 V . Low duty cycle pulse techniques are used during test to maintain junction

temperature as close to ambient as possible.

(2) This function can be inhibited by connecting pin 1 to GND.

(3) Guaranteed by design (non tested)

/ I

ovp

0.5 mA

stup–th

uvlo1

demag

demag

stup

stup

NM Dmgr 3.0 4.7 5.5 –

dem

) / (1 mA – 0.5 mA) R3 1800

– V

– V

uvlo2

pin1

= 50 mV) I

= –1 mA) V

= 125 mA

demag

= 25 mA

demag

– UVLO1) 102 x K

– UVLO1) 102 x K

) H

uvlo1

) H

= 12 V , for typical values TA = 25°C, for min/max values TA = –25°C to +85°C unless otherwise

CC

Symbol Min Typ Max Unit

increasing) V

PHL(In/Out)

cl–neg–dem

106 x Y

uvlo1–uvlo2

MC44608P40

MC44608P75

MC44608P100

dmg–th

dmg

dem–lb

V

cl–pos–

dem–H

V

cl–pos–

dem–L

high

hyst

dem–NM

10 x K1 2.4 2.9 3.8 –

10 x K1 2.8 3.3 4.2 –

10 x K1 3.5 –

103 x K2 46 52 63 –

sstup

sl

cstby

low

stup–th

uvlo1

stup–uvlo1

uvlo2

–(ICC) 7.0 9.5 12.8 mA

I

CCS

CC–latch

d

Hiccup

30 50 69 mV

30 mV

300 ns

–0.6

–0.9 –0.7 –0.4 V

2.05 2.3 2.8 V

1.4 1.7 1.9 V

160 °C

30 °C

20 25 30

1.8 2.2 2.6 –

90 120 150 –

175 198 225 –

12.5 13.1 13.8 V

9.5 10 10.5 V

3.1 V

6.2 6.6 7.0 V

3.4 V

2.0

2.4

–

0.3 0.5 0.68 mA

2.6

3.2

3.4

10 %

50 V

3.6

4.0

–

m

m

W

mA

A

A

http://onsemi.com

4

MC44608

PIN FUNCTION DESCRIPTION

Pin Name Description

1 Demag The Demag pin offers 3 different functions: Zero voltage crossing detection (50mV), 24µA current detection

2 I

3 Control Input A feedback current from the secondary side of the SMPS via the opto–coupler is injected into this pin. A

4 Ground This pin is the ground of the primary side of the SMPS.

5 Driver The current and slew rate capability of this pin are suited to drive Power MOSFETs.

6 V

7 This pin is to provide isolation between the Vi pin 8 and the VCC pin 6.

8 Vi This pin can be directly connected to a 500V voltage source for start–up function of the IC. During the

sense

CC

and 120µA current detection. The 24µA level is used to detect the secondary reconfiguration status and the

120µA level to detect an Over Voltage status called Quick OVP.

The Current Sense pin senses the voltage developed on the series resistor inserted in the source of the

power MOSFET. When I

Current Protection function. A 200µA current source is flowing out of the pin 3 during the start–up phase and

during the switching phase in case of the Pulsed Mode of operation. A resistor can be inserted between the

sense resistor and the pin 3, thus a programmable peak current detection can be performed during the SMPS

stand–by mode.

resistor can be connected between this pin and GND to allow the programming of the Burst duty cycle during

the Stand–by mode.

This pin is the positive supply of the IC. The driver output gets disabled when the voltage becomes higher

than 15V and the operating range is between 6.6V and 13V . An intermediate voltage level of 10V creates a

disabling condition called Latched Off phase.

Start–up phase a 9 mA current source is internally delivered to the VCC pin 6 allowing a rapid charge of the

VCC capacitor. As soon as the IC starts–up, this current source is disabled.

reaches 1V, the Driver output (pin 5) is disabled. This is known as the Over

sense

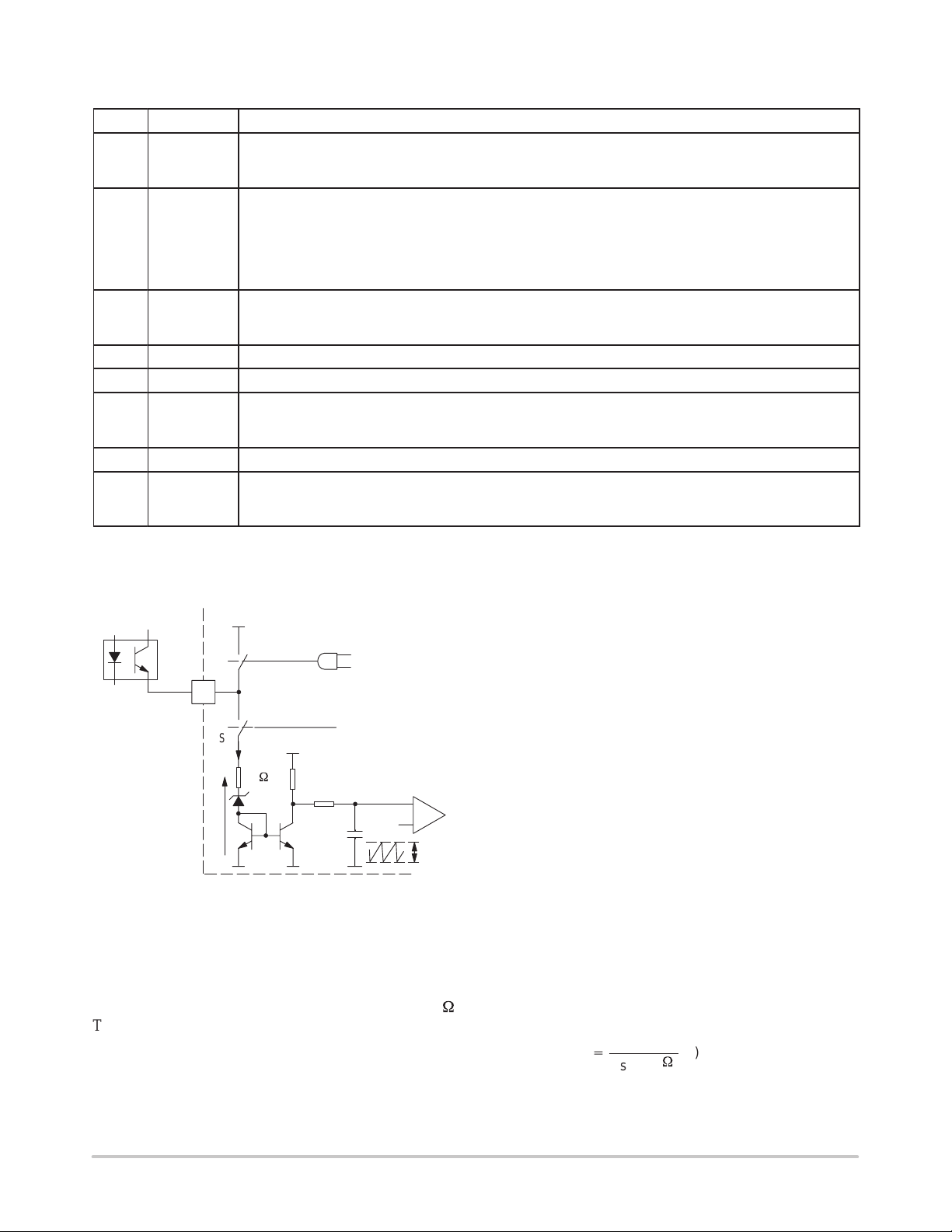

OPERATING DESCRIPTION

Regulation

V

V

CC

Control

Input

LP–stby

10

S3

Stand–by

&

Latched off Phase

3

5 V

10

S2

V

dd

20

W

4 kHz

Filter

Regulation

Output

Switching Phase

Comparator

PWM

1.6 V

Figure 1. Regulator

The pin 3 senses the feedback current provided by the opto

coupler. During the switching phase the switch S2 is closed

and the shunt regulator is accessible by the pin 3. The shunt

regulator voltage is typically 5V. The dynamic resistance of

the shunt regulator represented by the zener diode is 20W.

The gain of the Control input is given on Figure 10 which

shows the duty cycle as a function of the current injected into

the pin 3.

A 4kHz filter network is inserted between the shunt

regulator and the PWM comparator to cancel the high

frequency residual noise.

The switch S3 is closed in Stand–by mode during the

Latched Off Phase while the switch S2 remains open. (See

section PULSED MODE DUTY CYCLE CONTROL).

The resistor Rdpulsed (Rduty cycle burst) has no effect on

the regulation process. This resistor is used to determine the

burst duty cycle described in the chapter “Pulsed Duty Cycle

Control” on page 8.

PWM Latch

The MC44608 works in voltage mode. The on–time is

controlled by the PWM comparator that compares the

oscillator sawtooth with the regulation block output (refer to

the block diagram on page 2).

The PWM latch is initialized by the oscillator and is reset

by the PWM comparator or by the current sense comparator

in case of an over current. This configuration ensures that

only a single pulse appears at the circuit output during an

oscillator cycle.

Current Sense

The inductor current is converted to a positive voltage by

inserting a ground reference sense resistor R

Sense

in series

with the power switch.

The maximum current sense threshold is fixed at 1V. The

peak current is given by the following equation:

Ipk

max

+

R

sense

1

(A)

(W)

http://onsemi.com

5

Loading...

Loading...