MC33260

Product Preview

GreenLine

Compact

Power Factor Controller:

Innovative Circuit for

Cost Effective Solutions

The MC33260 is a controller for Power Factor Correction

preconverters meeting international standard requirements in

electronic ballast and off–line power conversion applications.

Designed to drive a free frequency discontinuous mode, it can also be

synchronized and in any case, it features very effective protections that

ensure a safe and reliable operation.

This circuit is also optimized to offer extremely compact and cost

effective PFC solutions. While it requires a minimum number of

external components, the MC33260 can control the follower boost

operation that is an innovative mode allowing a drastic size reduction

of both the inductor and the power switch. Ultimately, the solution

system cost is significantly lowered.

Also able to function in a traditional way (constant output voltage

regulation level), any intermediary solutions can be easily

implemented. This flexibility makes it ideal to optimally cope with a

wide range of applications.

General Features

• Standard Constant Output Voltage or “Follower Boost” Mode

• Switch Mode Operation: Voltage Mode

• Latching PWM for Cycle–by–Cycle On–Time Control

• Constant On–Time Operation That Saves the Use of an Extra Multiplier

• Totem Pole Output Gate Drive

• Undervoltage Lockout with Hysteresis

• Low Start–Up and Operating Current

• Improved Regulation Block Dynamic Behavior

• Synchronization Capability

• Internally Trimmed Reference Current Source

Safety Features

• Overvoltage Protection: Output Overvoltage Detection

• Undervoltage Protection: Protection Against Open Loop

• Effective Zero Current Detection

• Accurate and Adjustable Maximum On–Time Limitation

• Overcurrent Protection

• ESD Protection on Each Pin

http://onsemi.com

8

1

DIP–8

P SUFFIX

CASE 626

PIN CONNECTIONS AND

MARKING DIAGRAM

AWL

YYWW

V

CC

Gate Drive

7

Gnd

6

Synchronization

5

Input

Feedback Input

V

control

Oscillator

Capacitor (CT)

Current Sense

Input

AWL = Manufacturing Code

18

2

3

MC33260

4

YYWW = Date Code

(Top View)

ORDERING INFORMATION

Device Package Shipping

MC33260P Plastic DIP–8 50 Units / Rail

TYPICAL APPLICATION

D1...D4

R

cs

This document contains information on a product under development. ON Semiconductor

reserves the right to change or discontinue this product without notice.

Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 1

Filtering

Capacitor

V

control

R

OCP

L1

8

1

2

7

3

6

MC33260

4

CT

5

V

Sync

D1

C1

CC

+

M1

LOAD

(SMPS, Lamp

Ballast,...)

R

o

1 Publication Order Number:

MC33260/D

CT

MC33260

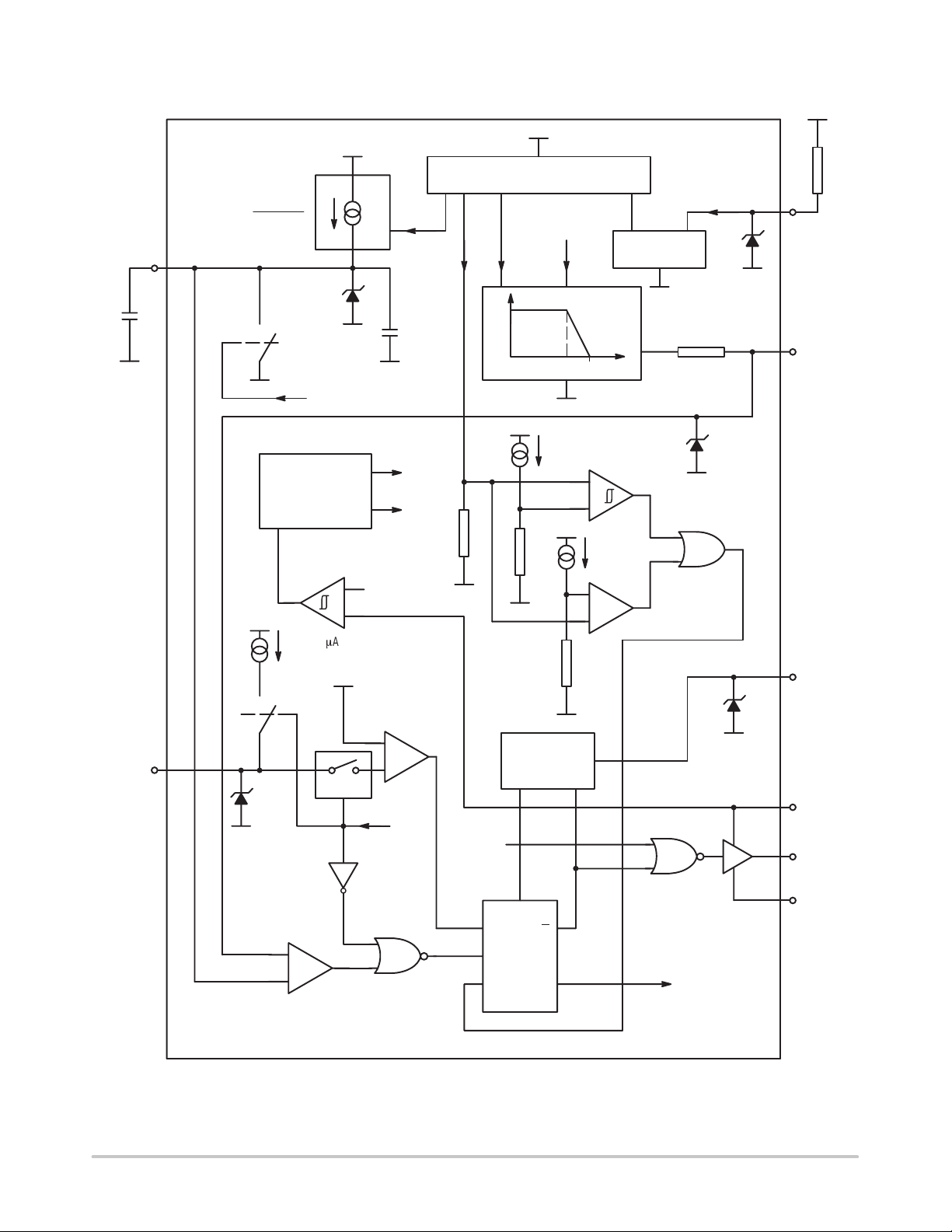

BLOCK DIAGRAM

V

o

Current Mirror

2 x IO x I

I

– ch =

OSC

3

O

I

ref

11 V

I

o

I

oIo

I

ref

V

ref

1.5 V

Current

Mirror

I

o

FB

1

Current

Sense

01

Output_Ctrl

REGULATOR

Enable

–

+

Ics (205 mA)

–60 mV

01

4

11 V

LEB

15 pF

V

ref

I

ref

11 V/8.5 V

+

–

Output_Ctrl

300 k

V

reg

I

o

97%I

r

r

Synchro

Arrangement

I

ref

ref

I

ovpH/IovpL

r

I

+

–

uvp

+

–

11 V

OVP

UVP

11 V

V

control

2

Synchro

5

V

CC

8

+

–

PWM Comparator

ThStdwn

S

R

PWM

R

Latch

RQ

http://onsemi.com

2

Drive

7

Gnd

6

Q

Output_Ctrl

MC33260

MC33260

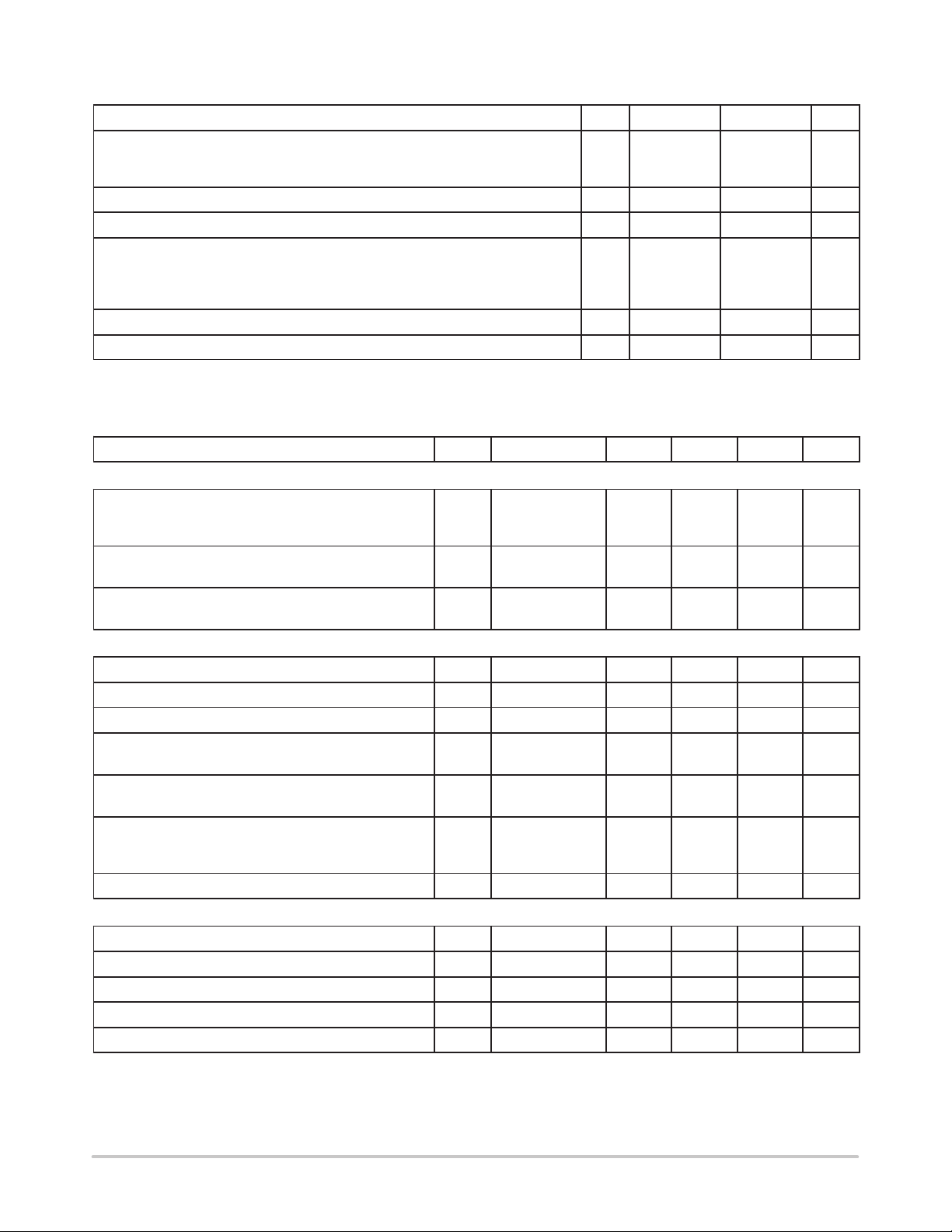

MAXIMUM RATINGS

Rating Pin # Symbol Value Unit

Gate Drive Current (Pin 7)*

Source

Sink

VCC (Pin 8) Maximum Voltage 8 (Vcc)

Input Voltage V

Power Dissipation and Thermal Characteristics

P Suffix, DIP Package

Maximum Power Dissipation @ TA = 85°C

Thermal Resistance Junction to Air

Operating Junction Temperature T

Operating Ambient Temperature T

*The maximum package power dissipation must be observed.

7

I

O(Source)

I

O(Sink)

max

in

P

D

R

θJA

J

A

–500

500

16 V

–0.3 to +10 V

600

100

150 °C

–40 to +105 °C

mA

mW

°C/W

ELECTRICAL CHARACTERISTICS (V

unless otherwise noted.)

Characteristic

GATE DRIVE SECTION

Gate Drive Resistor

Source Resistor @ I

Sink Resistor @ I

Gate Drive Voltage Rise Time (From 3 V Up to 9 V)

(Note 1)

Output Voltage Falling Time (From 9 V Down to 3 V)

(Note 1)

OSCILLATOR SECTION

Maximum Oscillator Swing 3 ∆V

Charge Current @ I

Charge Current @ I

Ratio Multiplier Gain Over Maximum Swing

@ I

=100 µA

pin1

Ratio Multiplier Gain Over Maximum Swing

@ I

=200 µA

pin1

Average Internal Pin 3 Capacitance Over Oscillator

Maximum Swing (V

(Note 2)

Discharge Time (CT = 1 nF) 3 T

REGULATION SECTION

Regulation High Current Reference 1 I

Ratio (Regulation Low Current Reference)/I

Pin 2 Impedance 1 Z

Pin 1 Clamp Voltage @ I

Pin 1 Clamp Voltage @ I

pin1

pin1

= 100 mA

pin7

= 100 mA

pin7

= 100 µA 3 I

= 200 µA 3 I

Varying From 0 Up to 1.5 V)

pin3

= 100 µA 1 V

pin1

= 200 µA 1 V

pin1

= 13 V, TJ = 25°C for typical values, TJ = –40 to 105°C for min/max values

CC

Pin # Symbol Min Typ Max Unit

7

7 t

7 t

3 K

3 K

3 C

reg–H

1 I

reg–L/Ireg–H

R

OL

R

OH

r

f

T

charge

charge

osc

osc

int

disch

reg–H

pin3

pin1–100

pin1–200

10

5

— 50 — ns

— 50 — ns

1.4 1.5 1.6 V

87.5 100 112.5 µA

350 400 450 µA

5600 6400 7200 1/(V.A)

5600 6400 7200 1/(V.A)

10 15 20 pF

— 0.5 1 µs

192 200 208 µA

0.965 0.97 0.98 —

— 300 — kΩ

1.5 2.1 2.5 V

2 2.6 3 V

20

10

35

25

Ω

http://onsemi.com

3

MC33260

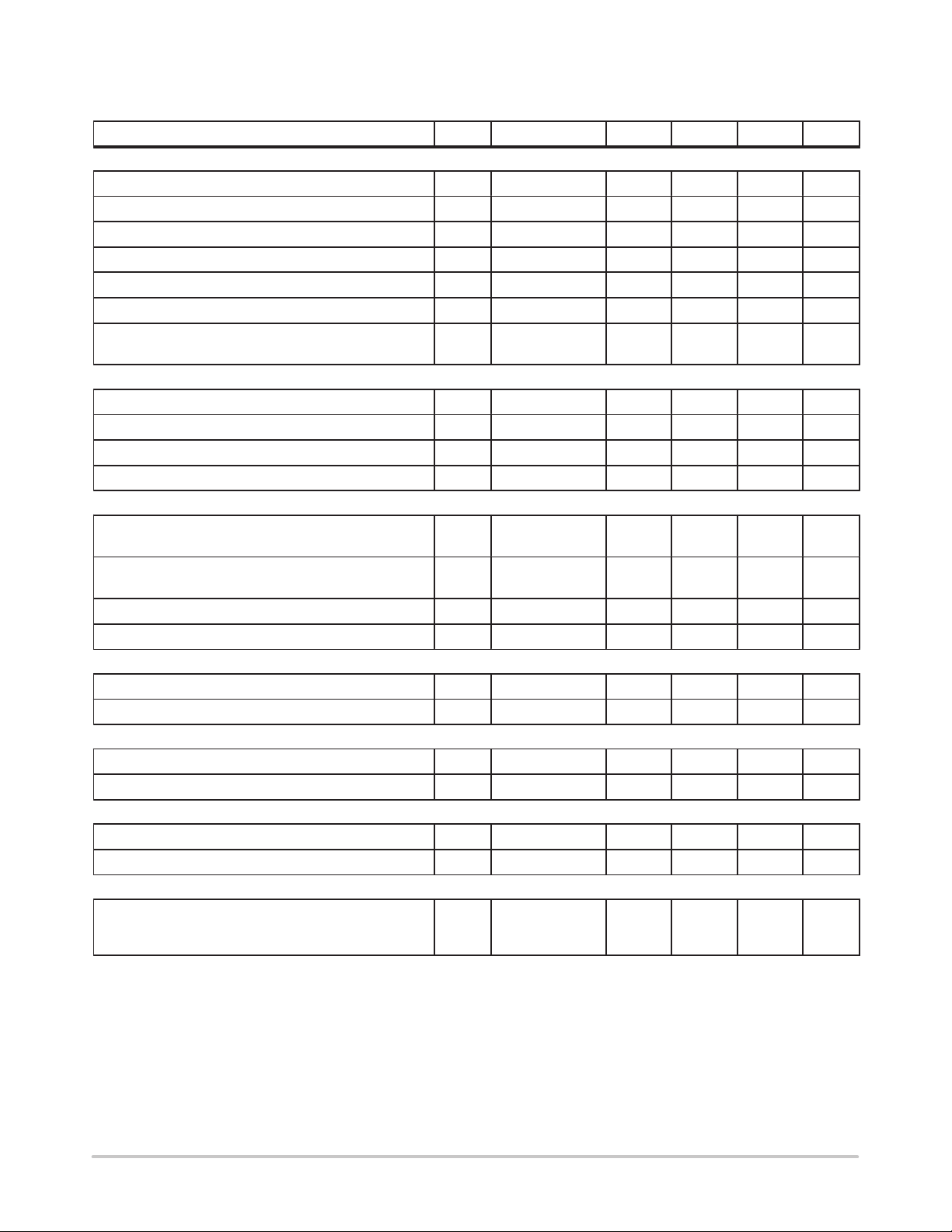

ELECTRICAL CHARACTERISTICS (V

unless otherwise noted.)

Characteristic UnitMaxTypMinSymbolPin #

CURRENT SENSE SECTION

Zero Current Detection Comparator Threshold 4 V

Negative Clamp Level (I

Bias Current @ V

Propagation Delay (V

Pin 4 Internal Current Source 4 I

Leading Edge Blanking Duration τ

OverCurrent Protection Propagation Delay

(Pin 4 < V

SYNCHRONIZATION SECTION

Synchronization Threshold 5 V

Negative Clamp Level (I

Minimum Off–Time 7 T

Minimum Required Synchronization Pulse Duration 5 T

OVERVOLTAGE PROTECTION SECTION

OverVoltage Protection High Current Threshold

and I

reg–H

OverVoltage Protection Low Current Threshold

and I

reg–H

Ratio (I

OVP–H/IOVP–L

Propagation Delay (I

UNDERVOLTAGE PROTECTION SECTION

Ratio (UnderVoltage Protection Current Threshold)/I

Propagation Delay (I

THERMAL SHUTDOWN SECTION

Thermal Shutdown Threshold 7 T

Hysteresis 7 ∆T

VCC UNDERVOLTAGE LOCKOUT SECTION

Start–Up Threshold 8 V

Disable Voltage After Threshold T urn–On 8 V

TOTAL DEVICE

Power Supply Current

Start–Up (VCC = 5 V with VCC Increasing)

Operating @ I

NOTES:

(1) 1 nF being connected between the pin 7 and ground.

(2) Guaranteed by design.

(3) No load is connected to the gate drive which is kept high during the test.

pin4

ZCD–th

Difference

Difference

pin1

= –1 mA) 4 Cl–neg — –0.7 — V

pin2

= V

ZCD–th

> V

pin4

ZCD–th

to Gate Drive Low)

= –1 mA) 5 Cl–neg — –0.7 — V

pin5

) 1 I

pin1

pin1

= 200 µA

> 110% I

< 12% I

to Gate Drive Low) 7 T

ref

to Gate Drive Low) 7 T

ref

= 13 V, TJ = 25°C for typical values, TJ = –40 to 105°C for min/max values

CC

4 I

) to Gate Drive High 7 T

7 T

reg–H

1 I

1 I

1 I

8 I

OVP–H–Ireg–H

OVP–L–Ireg–H

OVP–H/IOVP–L

ZCD–th

b–cs

ZCD

OCP

LEB

OCP

sync–th

off

sync

OVP

UVP/Ireg–H

UVP

stdwn

stdwn

stup–th

disable

CC

–90 –60 –30 mV

–0.2 — — µA

— 500 — ns

192 205 218 µA

— 400 — ns

100 160 240 ns

0.8 1 1.2 V

1.5 2.1 2.7 µs

— — 0.5 µs

8 13 18 µA

0 — — —

1.02 — — —

— 500 — ns

12 14 16 %

— 500 — ns

— 150 — °C

— 30 — °C

9.7 11 12.3 V

7.4 8.5 9.6 V

—

—

0.1

4

0.25

8

mA

http://onsemi.com

4

MC33260

1.6

1.4

1.2

1.0

0.8

control

V : REGULATION BLOCK OUTPUT (V)

0.6

0.4

0.2

0

20

0

60

40

I

pin1

–40°C

25°C

105°C

100

80

: FEEDBACK CURRENT (µA)

120

140

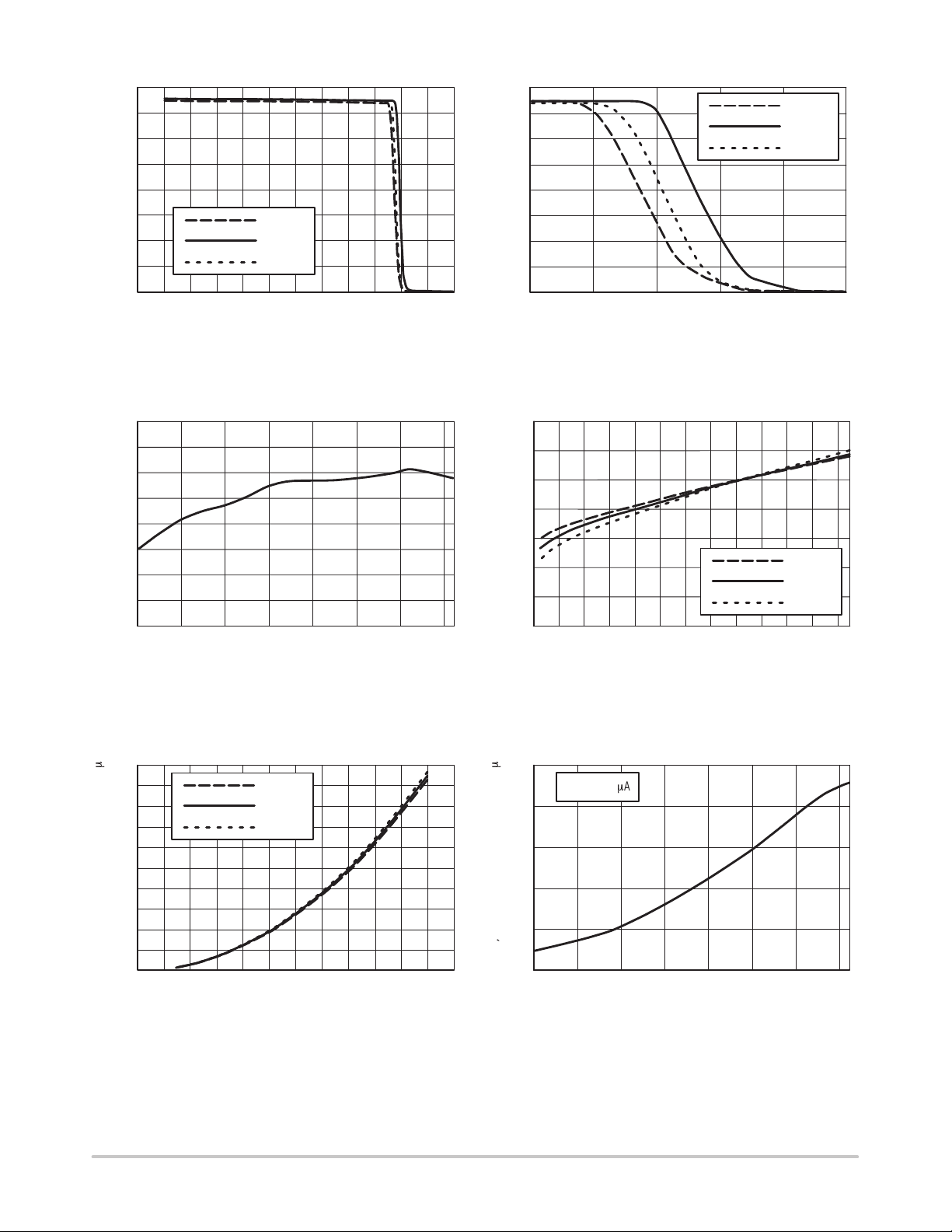

Figure 1. Regulation Block Output versus

Feedback Current

1.340

1.335

1.330

1.325

1.320

1.315

1.310

MAXIMUM OSCILLAT OR SWING (V)I , OSCILLATOR CHARGE CURRENT ( A)

1.305

1.300

–40

–20 0

20

40 60

JUNCTION TEMPERATURE (°C)

160

180

200

80

220

100

240

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

control

V : REGULATION BLOCK OUTPUT (V)

0

185

190 195 200 205 210

I

: FEEDBACK CURRENT (µA)

pin1

Figure 2. Regulation Block Output versus

Feedback Current

3.5

3.0

2.5

2.0

1.5

1.0

FEEDBACK INPUT VOLTAGE (V)

0.5

0

0

20 40 60 80 100 120 140 160 180 200 220 240

I

: FEEDBACK CURRENT (µA)

pin1

–40°C

25°C

105°C

–40°C

25°C

105°C

Figure 3. Maximum Oscillator Swing versus

Temperature

m

500

450

400

350

300

250

200

150

100

50

osc–ch

0

0

20 40 60 80 100 120 140 160 180 200 220 240

I

pin1

–40°C

25°C

105°C

: FEEDBACK CURRENT (µA)

Figure 5. Oscillator Charge Current versus

Feedback Current

Figure 4. Feedback Input Voltage versus

Feedback Current

m

410

I

= 200 mA

pin1

405

400

395

390

385

osc–ch

I , OSCILLATOR CHARGE CURRENT ( A)

–40

–20 0

20

40 60

JUNCTION TEMPERATURE (°C)

Figure 6. Oscillator Charge Current versus

Temperature

80

100

http://onsemi.com

5

MC33260

104

103

102

101

100

99

98

OSCILLATOR CHARGE CURRENT ( A)µ

97

I

= 100 mA

pin1

–40

–20 0 20 40 60 80 100

TJ, JUNCTION TEMPERATURE (°C)

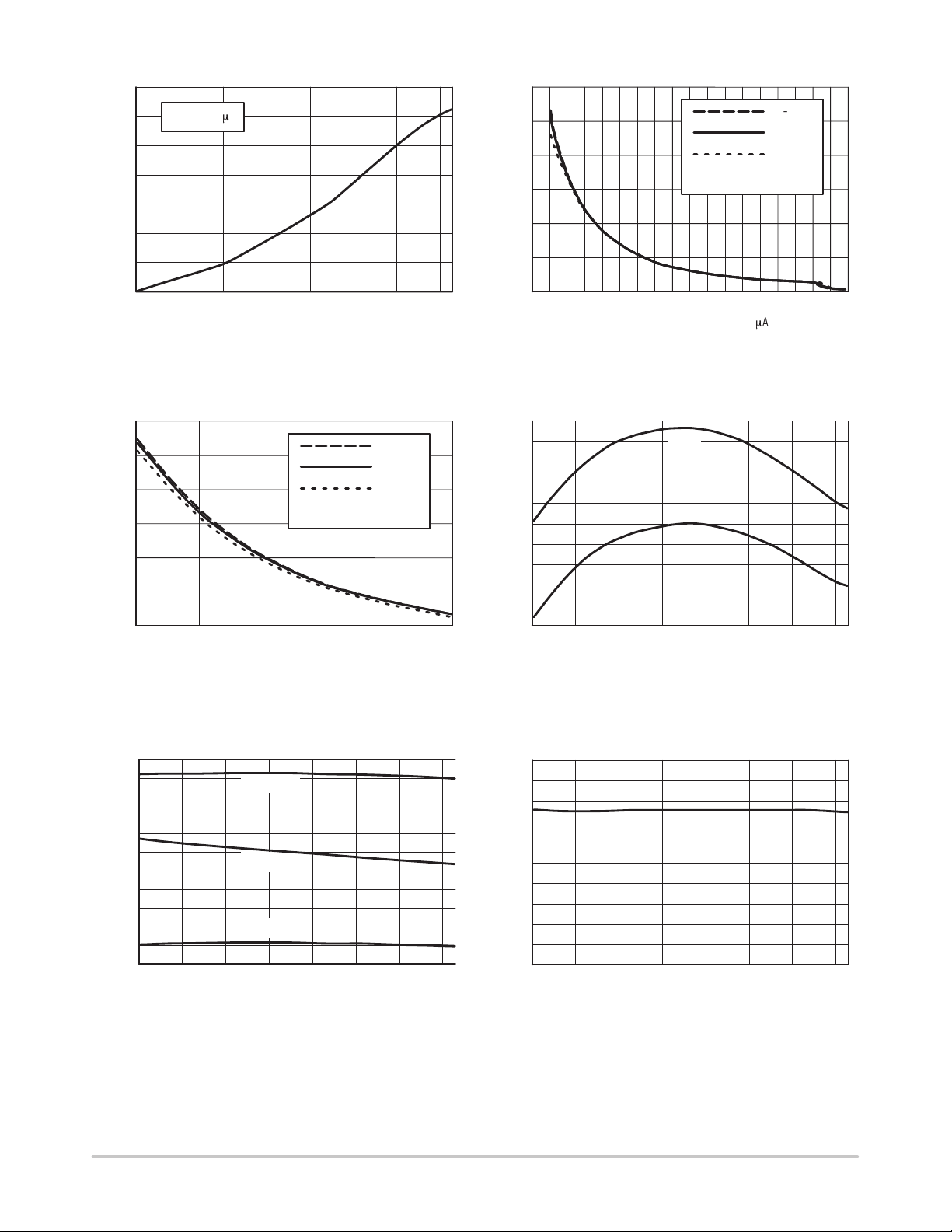

Figure 7. Oscillator Charge Current versus

T emperature

75

65

55

45

ON–TIME ( s)µ

35

25

15

50

60 70 80 90 100

I

: FEEDBACK CURRENT (µA)

pin1

1 nF Connected to Pin 3

–40°C

25°C

105°C

120

100

80

60

ON–TIME ( s)µ

40

20

0

30

50 70 90 110 130 150 170 190 210

I

: FEEDBACK CURRENT (mA)

pin1

1 nF Connected to Pin 3

Figure 8. On–Time versus Feedback Current

207

I

206

205

204

203

202

201

200

199

198

197

REGULATION AND CS CURRENT SOURCE ( A)µ

–20 0 20 40 60 80 100

–40

TJ, JUNCTION TEMPERATURE (°C)

OCP

I

regH

–40°C

25°C

105°C

Figure 9. On–Time versus Feedback Current Figure 10. Internal Current Sources versus

T emperature

1.07

)

1.06

ref

/I

1.05

regL

1.04

), (I

1.03

ref

/I

1.02

1.01

ovpL

1.00

), (I

ref

0.99

/I

0.98

ovpH

(I

0.97

0.96

–40

Figure 11. (I

(I

(I

–20 0 20 40 60 80 100

TJ, JUNCTION TEMPERATURE (°C)

ovpH/Iref

ovpH/Iref

ovpL/Iref

(I

regL/Iref

)

)

)

), (I

ovpL/Iref

), (I

regL/Iref

)

versus T emperature

0.150

0.148

ref

/I )

0.146

uvp

0.144

0.142

0.140

0.138

0.136

0.134

UNDERVOLTAGE RATIO (I

0.132

0.130

–20 0 20 40 60 80 100

–40

TJ, JUNCTION TEMPERATURE (°C)

Figure 12. Undervoltage Ratio versus

T emperature

http://onsemi.com

6

Loading...

Loading...