Motorola MC33192DW Datasheet

The MC33192 Stepper Motor Controller is intended to control loads in

harsh automotive environments using a serial communication bus. The

MI–Bus can provide satisfactory real time control of up to eight stepper

motors. MI–Bus technology offers a noise immune system solution for

difficult control applications involving relay drivers, motor controllers, etc.

The MC33192 stepper motor controller provides four phase signals to

drive two phase motors in either half or full step modes. When used with an

appropriate Motorola HCMOS microprocessor it provides an economical

solution for applications requiring a minimum amount of wiring and optimized

system versatility.

The MC33192 is packaged in an economical 16 pin surface mount

package and specified at an operating voltage 12 V for – 40°C ≤ TA ≤ 100°C.

• Single Wire Open Bus Capability Up to 10 Meters in Length

• Programmable Address Bus System

• Fault Detection of Half–Bridge Drivers and Motor Windings

• Ceramic Resonator For Accurate and Reliable Transmission of Data

• Sub–Multiple of Oscillator End–of–Frame Signal

• MI–Bus Signal Slew Rate Limited to 1.0 V/µs for Minimum RFI

• MI–Bus Error Diagnostics

• Non–Functioning Device Diagnotics

• Over Temperature Detection

• Address Programming Sequence Status

• Load and Double Battery (Jump Start) Protection

Order this document by MC33192/D

MI–BUS INTERFACE

STEPPER MOTOR

CONTROLLER

SEMICONDUCTOR

TECHNICAL DATA

16

1

DW SUFFIX

PLASTIC PACKAGE

CASE 751G

(SO–16L)

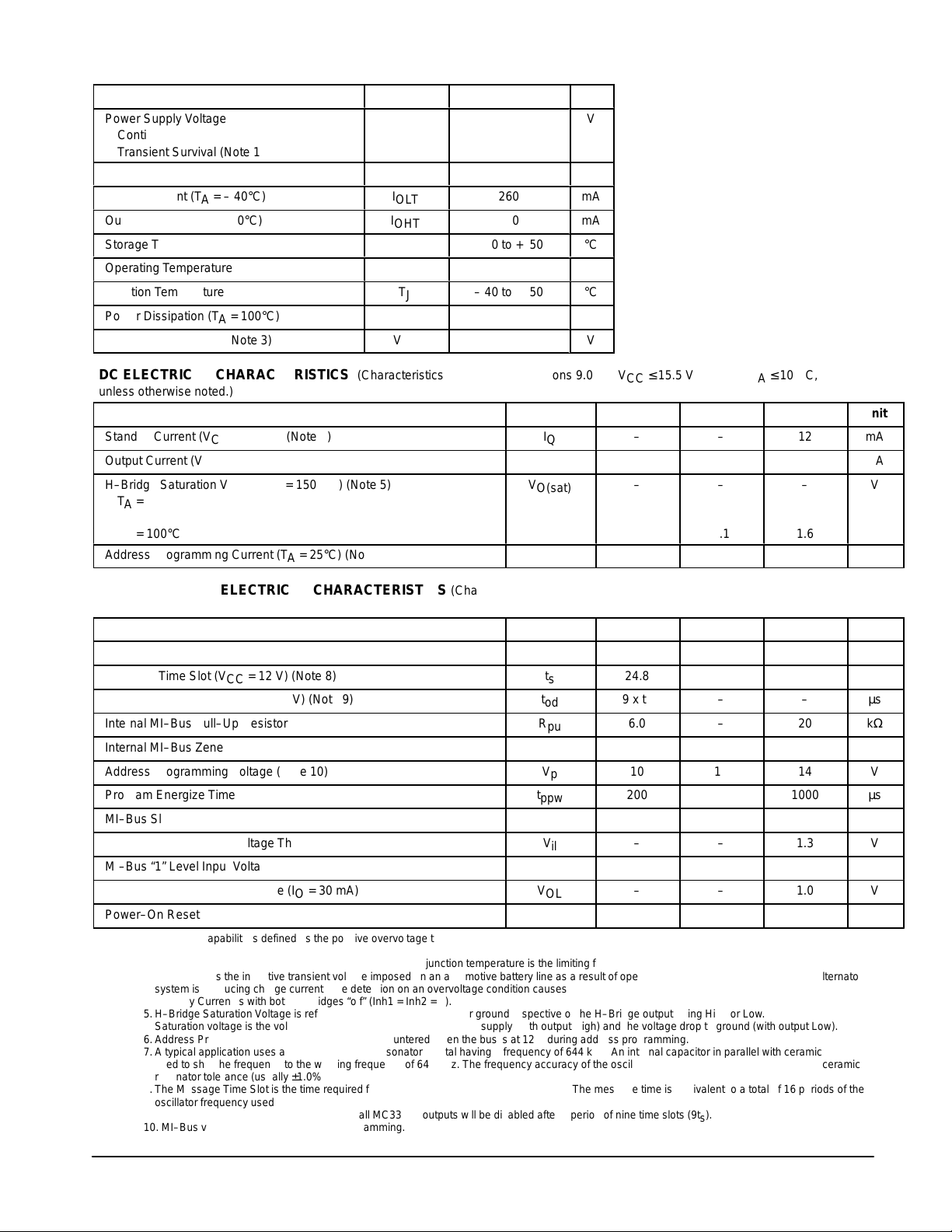

Simplified Application

7

V

CC

1

To

Other

Devices

MI–Bus

MI

8

Xtal

16 15 14 13 12 1 1 10 9 2

Ceramic

Resonator

This device contains 1,528 active transistors.

MC33192DW

MOTOROLA ANALOG IC DEVICE DATA

A1

A2

B1

B2

Gnd

+V

batt

3

4

5

6

Ground

From MCU

MI–Bus

Stepper

Motor

PIN CONNECTIONS

15

14

13

12

11

10

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

Gnd

9

MI–Bus

Gnd

A1

A2

B1

B2

V

CC

Xtal

116

2

3

4

5

6

7

8

(Top View)

ORDERING INFORMATION

Operating

Device

MC33192DW TA = – 40° to +100°C

Motorola, Inc. 1996 Rev 0

Temperature Range

Package

SO–16L

1

MC33192

MAXIMUM RATINGS

(All voltages are with respect to ground, unless otherwise noted.)

Rating Symbol Value Limit

Power Supply Voltage

Continuous Operation V

Transient Survival (Note 1) V

Digital Input Voltage

Output Current (TA = – 40°C)

Output Current (TA = 100°C)

Storage Temperature

Operating Temperature (Note 2)

Junction Temperature

Power Dissipation (TA = 100°C)

Load Dump Transient (Note 3)

CC

V

I

OLT

I

OHT

T

stg

T

T

P

V

LD

i

A

J

D

LD

25

40

0.3 to VCC + 0.3

260

150

– 40 to +150

– 40 to +125

– 40 to +150

0.5

40

DC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions 9.0 V ≤ V

V

V

mA

mA

°C

°C

°C

W

V

≤ 15.5 V, – 40°C ≤ TA ≤ 100°C,

CC

unless otherwise noted.)

Characteristic

Standby Current (VCC = 15.5 V) (Note 4)

Output Current (VCC = 15.5 V)

H–Bridge Saturation Voltage (IO = 150 mA) (Note 5)

Symbol Min Typ Max Unit

V

O(sat)

I

Q

I

O

–

–

–

–

120

–

TA = – 40°C – 1.3 1.6

TA = 25°C – 1.2 1.6

TA = 100°C – 1.1 1.6

Address Programming Current (TA = 25°C) (Note 6)

I

pc

–

1.2

12

mA

–

–

–

mA

V

A

CONTROL LOGIC ELECTRICAL CHARACTERISTICS (Characteristics noted under conditions 9.0 V ≤ V

≤ 15.5 V, – 40°C ≤ TA ≤

CC

100°C, unless otherwise noted.)

Characteristic

Oscillator (Note 7)

Message Time Slot (VCC = 12 V) (Note 8)

Urgent Output Disable (VCC = 12 V) (Note 9)

Internal MI–Bus Pull–Up Resistor

Internal MI–Bus Zener Diode Clamp Voltage

Address Programming Voltage (Note 10)

Program Energize Time

MI–Bus Slew Rate

MI–Bus “0” Level Input Voltage Threshold

MI–Bus “1” Level Input Voltage Threshold

MI–Bus “0” Level Output Voltage (IO = 30 mA)

Power–On Reset Time (VCC ≥ 7.5 V)

NOTES: 1. Transient capability is defined as the positive overvoltage transient with 250 ms decay time constant. The detection on an overvoltage condition causes all

H–Bridges to be latched “off”.

2.Ambient temperature is given as a convience; Maximum junction temperature is the limiting factor.

3.Load Dump is the inductive transient voltage imposed on an automotive battery line as a result of opening the battery connection while the alternator

system is producing charge current. The detection on an overvoltage condition causes all H–Bridges to be latched “off”.

4.Standby Current is with both H–Bridges “off” (Inh1 = Inh2 = 0).

5.H–Bridge Saturation V oltage is referenced to the positive supply or ground respective of the H–Bridge output being High or Low.

Saturation voltage is the voltage drop from the output to the positive supply (with output High) and the voltage drop to ground (with output Low).

6.Address Programming Current is the current encountered when the bus is at 12 V during address programming.

7.A typical application uses an external ceramic resonator crystal having a frequency of 644 kHz. An internal capacitor in parallel with ceramic resonator is

used to shift the frequency to the working frequency of 640 kHz. The frequency accuracy of the oscillator is dependant on the capacitor and ceramic

resonator tolerance (usually ±1.0%).

8.The Message Time Slot is the time required for one complete device message transfer. The message time is equivalent to a total of 16 periods of the

oscillator frequency used.

9.If the MI–Bus becomes shorted to ground, all MC33192 outputs will be disabled after a period of nine time slots (9ts).

10. MI–Bus voltage required for address programming.

Symbol Min Typ Max Unit

f

cl

t

s

t

od

R

pu

V

cl

V

p

t

ppw

∆V/∆t

V

il

V

ih

V

OL

t

por

24.8

9 x t

6.0

–

10

200

1.0

–

2.4

–

–

s

640

25

–

–

18

12

1.5

–

–

–

250

–

25.2

–

20

–

14

1000

2.0

1.3

–

1.0

–

kHz

µs

µs

kΩ

V

V

µs

V/µs

V

V

V

µs

2

MOTOROLA ANALOG IC DEVICE DATA

MC33192

GENERAL DESCRIPTION

The MC33192 is a serial stepper motor controller for use in

harsh automotive applications using multiplex wiring. The

MC33192 provides all the necessary four phase drive signals

to control two phase bipolar stepper motors operated in either

half or full step modes. Multiple stepper motor controllers can

be operated on a real time basis at step frequencies up to

200 Hz using a single microcontroller (MCU). A primary

attribute of operation is the utilization of the MI–Bus message

media to provide high noise immunity communication

ensuring very high operating reliability of motor stepping.

The MC33192 is designed to drive bipolar stepper motors

having a winding resistance of 80 Ω at 20°C with a supply

voltage of 12 V. It is supplied in a SO–16L plastic package

having eight pins, on one side, connected directly to the lead

frame thus enhancing the thermal performance to allow a

power dissipation of 0.5 W at 120°C ambient temperature.

Multiple Simultaneous Motor Operation

Several motors can be controlled in a serial fashion, one

after the other, using the same software time base. The time

base determines the step frequency of the motors. A single

motor can be operated at a maximum speed of 200 Hz

pull–in with a duration of 5.0 ms per step. Three motors can

be operated simultaneously using a 68HC05B6 MCU at the

same time base (200 Hz) with about 1.7 ms per step. A

68HC11 MCU can control 4 stepper motors with adequate

program step time. The step frequency must be decreased to

control additional motors. To control eight motors

simultaneously would require the motor speed to be

decreased to 100 Hz producing about 2.0 ms time duration

per step with adequate program time.

MI–Bus General Description

The Motorola Interconnect Bus (MI–Bus) is a serial

push–pull communications protocol which efficiently

supports distributed real time control while exhibiting a high

level of noise immunity .

Under the SAE Vehicle Network categories, the MI–Bus is

a Class A bus with a data stream transfer bit rate in excess of

20 kHz and thus inaudible to the human ear. It requires a

single wire to carry the control data between the master MCU

and its slave devices. The bus can be operated at lengths up

to 15 meters.

At 20 kHz the time slot used to construct the message

(25 µs) can be handled by software using many MCUs

available on the market.

The MI–Bus is suitable for medium speed networks

requiring very low cost multiplex wiring. Aside from ground,

the MI–Bus requires only one signal wire connecting the

MCU to multiple slave MC33192 devices with individual

control.

A single MI–Bus can accomplish simultaneous automotive

system control of Air Conditioning, Head Lamp Levellers,

Window Lifts, Sensors, Intelligent Coil Drivers, etc. The

MI–Bus has been found to be cost effective in vehicle body

electronics by replacing the conventional wiring harness.

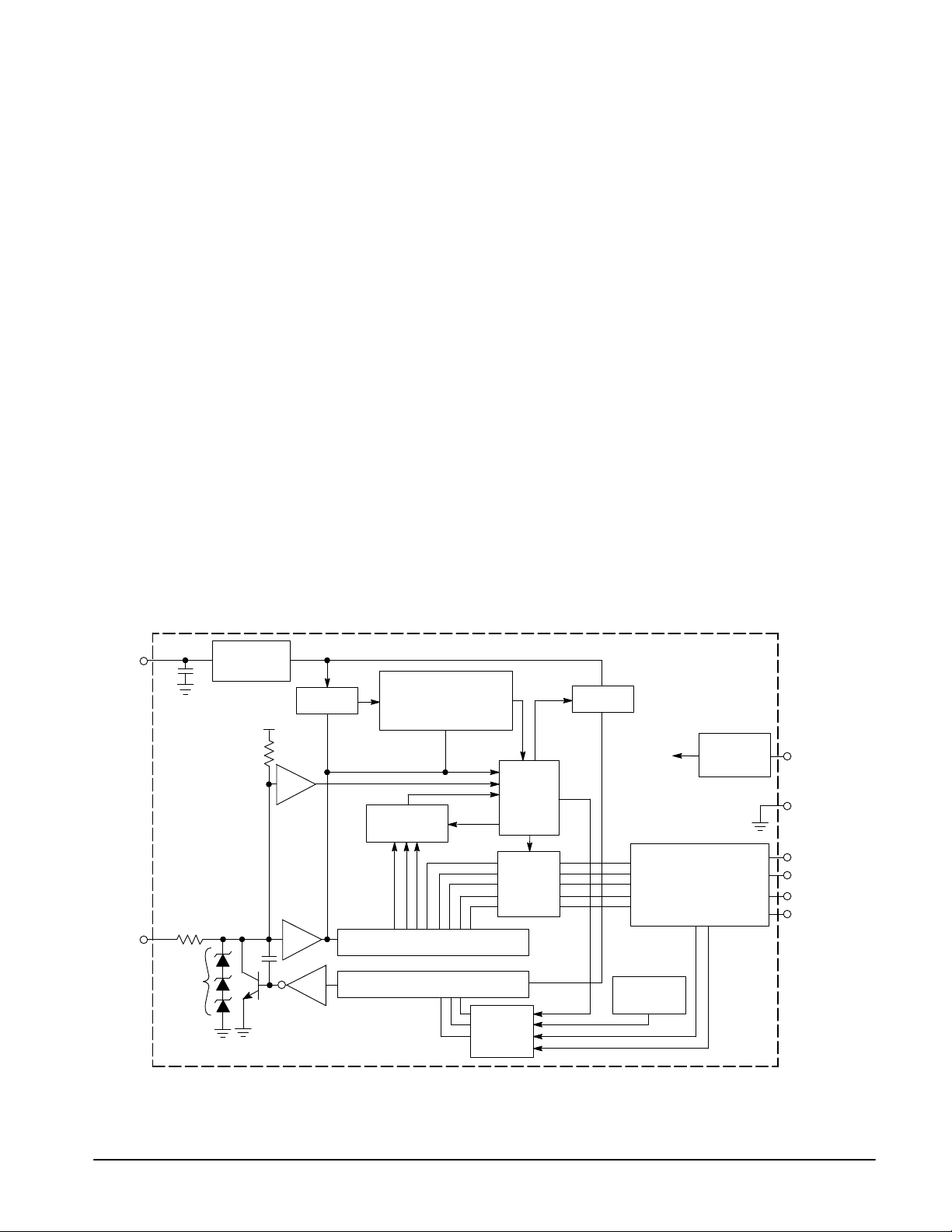

Figure 1 shows the internal block diagram of the MC33192

Stepper Motor Controller.

Xtal (8)

MI (1)

Oscillator

(640 kHz)

10 k

Programming

Level Detection

Ω

20

18 V

Figure 1. MC33192 Stepper Motor Conroller Block Diagram

5.0 V

Divider

Noise Detector

Bi–Phase

Bi–Phase Program

Programmed

Address

Serial to Parallel Register

Parallel to Serial Register

Status

Encoder

Control

Logic

Latch

Divider

20 kHz

5.0 V

Dual Bridge Driver and

Motor Diagnostics

Thermal

Shutdown

Regulator

5.0 V

+VCC (7)

Gnd (*)

A11 (3)

A12 (4)

B11 (5)

B12 (6)

NOTE: (*) Pins 2, 9, 10, 11, 12, 13, 14, 15 and 16 are common electrical and heatsink ground pins for the device.

MOTOROLA ANALOG IC DEVICE DATA

3

MC33192

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

ББББББББ

ÁÁ

Á

Á

ББББББББ

Á

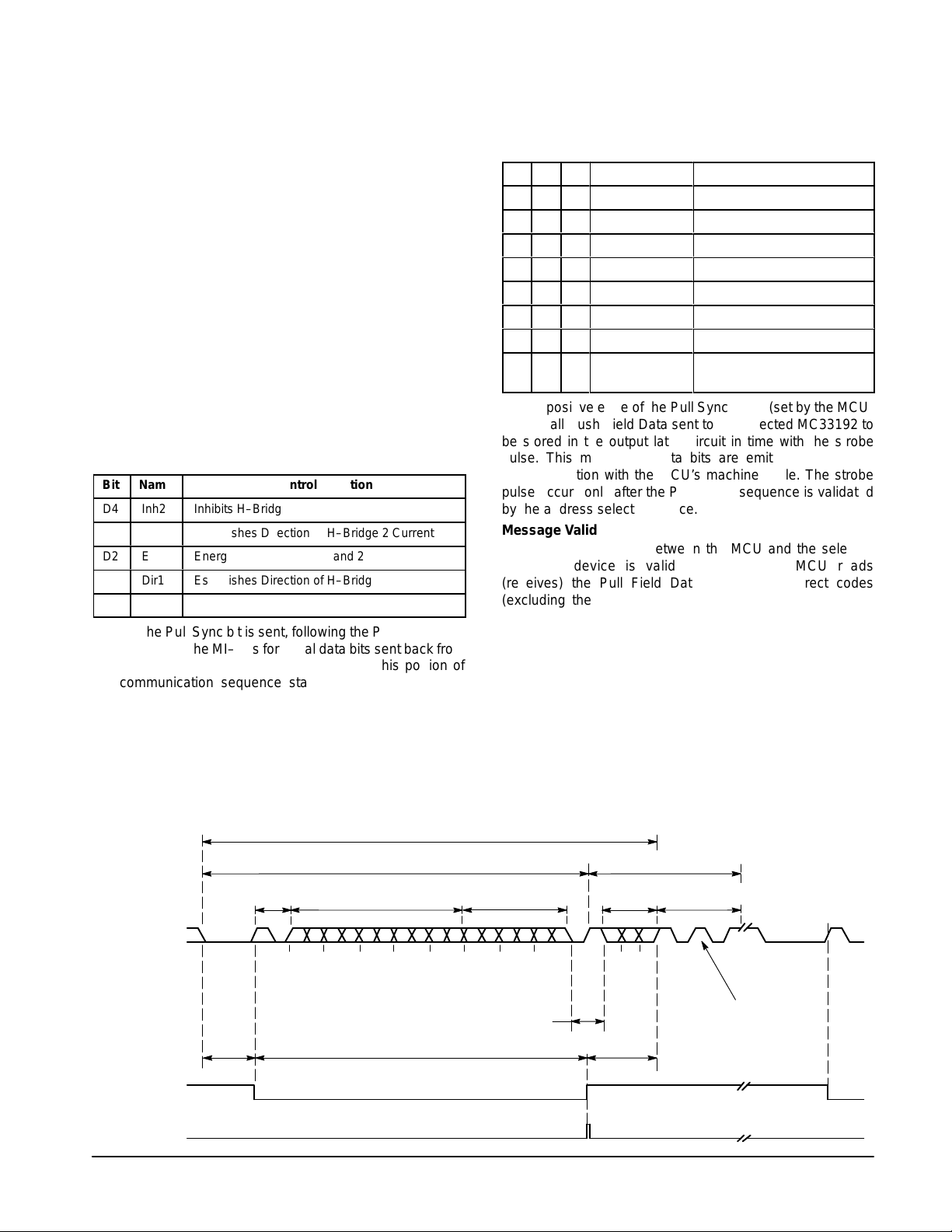

MI–Bus Access Method

The information on the MI–Bus is sent in a fixed message

frame format (See Figure 4). The system MCU can take

control of the MI–Bus at any time with a start bit which

violates the law of Manchester Bi–Phase code by having

three consecutive Time Slots (3ts) held constantly at a Logic

“0” state.

Push–Pull Communication Sequence

Communication between the system MCU and slave

MC33192 devices always use the same message frame

organization. The MCU first sends eight serial data bits over

the MI–Bus comprised of five control bits followed by three

address bits. This communication sequence is called a “Push

Field” since it represents command information sent from the

MCU. The sequence of the five control data bits follow the

order D0, D1, D2, D3 and D4. The three address bits are sent

in sequential order A0, A1 and A2 defining a binary address

code. The condition of MI–Bus during any of the control bit

time windows defines a specific control function as shown in

Figure 2. A “Pull Sync” bit is sent at the end of the Push Field,

the positive edge of which causes all data sent to the

selected device to be latched into the output circuit.

Figure 2. Push Field Data Bits

Bit

D4

D3

D2

D1

D0

Name

Inh2

Dir2

E

Dir1

Inh1

Inhibits H–Bridge 2

Establishes Direction of H–Bridge 2 Current

Energizes Bridge Coils 1 and 2

Establishes Direction of H–Bridge 1 Current

Inhibits H–Bridge 1

Control Function

After the Pull Sync bit is sent, following the Push Field, the

MCU listens on the MI–Bus for serial data bits sent back from

the previously addressed MC33192 device. This portion of

the communication sequence starts the “Pull Field Data”

since it represents information pulled from the addressed

MC33192 and received by the MCU.

The address selected MC33192 device sends data, in

the form of status bits, back to the MCU reporting the

devices condition. At the end of the Push Field the MCU

outputs a Pull Sync bit which signals the start of the Pull

Field. In the Pull Field are three bits (S2, S1 and S0) which

report the status of the previously addressed MC33192

according to Figure 3.

Figure 3. Pull Field Status Bits

S2

S1

Á

S0

0

0

0

0

0

1

0

1

0

0

1

1

1

0

0

1

0

1

1

1

0

1

1

1

Status

Not used

Free

No Back EMF

Free

Normal/OK

Thermal

Programming

Selection failed

ÁÁÁÁ

Comments

Drivers and/or coils failed

Chip temperature > 150°C

PROM energized

Noise on MI–Bus, failed or

БББББББ

disconnected module

The positive edge of the Pull Sync pulse (set by the MCU)

causes all Push Field Data sent to the selected MC33192 to

be stored in the output latch circuit in time with the strobe

pulse. This means the data bits are emitted in real time

synchronization with the MCU’s machine cycle. The strobe

pulse occurs only after the Push Field sequence is validated

by the address selected device.

Message Validation

The communication between the MCU and the selected

MC33192 device is valid only when the MCU reads

(receives) the Pull Field Data having the correct codes

(excluding the code “1–1–1” and “0–0–0”) followed by an

End–of–Frame signal. The frequency of the End–of–Frame

signal may be a sub–multiple of the selected devices local

oscillator or related to an internal or external analog

parameter using a Voltage to Frequency Converter.

Error Detection

An error is detected when the Pull Field contains the code

“1–1–1” followed by the End–of–Frame permanently tied to a

logic “1” state (internally from 5.0 V through a pull–up

resistor). This means the communication between the MCU

and the selected device was not obtained.

MI–Bus Wire

Push/Pull Function

Strobe

4

Figure 4. MI–Bus Timing Diagram

Frame

Push Field

AddressDataPush Sync Data End–of–Frame

3t

s

234567891 1 32

“0” S1

“1”D3

S2 S0

NRZ

Bi–Phase Coded

Pull Sync

Coded

75 µs 475 µs 100 µs

Push

Strobe Pulse

MOTOROLA ANALOG IC DEVICE DATA

Pull Field

4

÷

32 = 20 kHz

Pull

Oscillator

Frequency

3t

s

StartStart “1” “0” D0 D1 D2 D4 A0 A1 A2

Loading...

Loading...