Page 1

PDR 3500

Portable Repeater

Basic Service Manual

1

Page 2

A

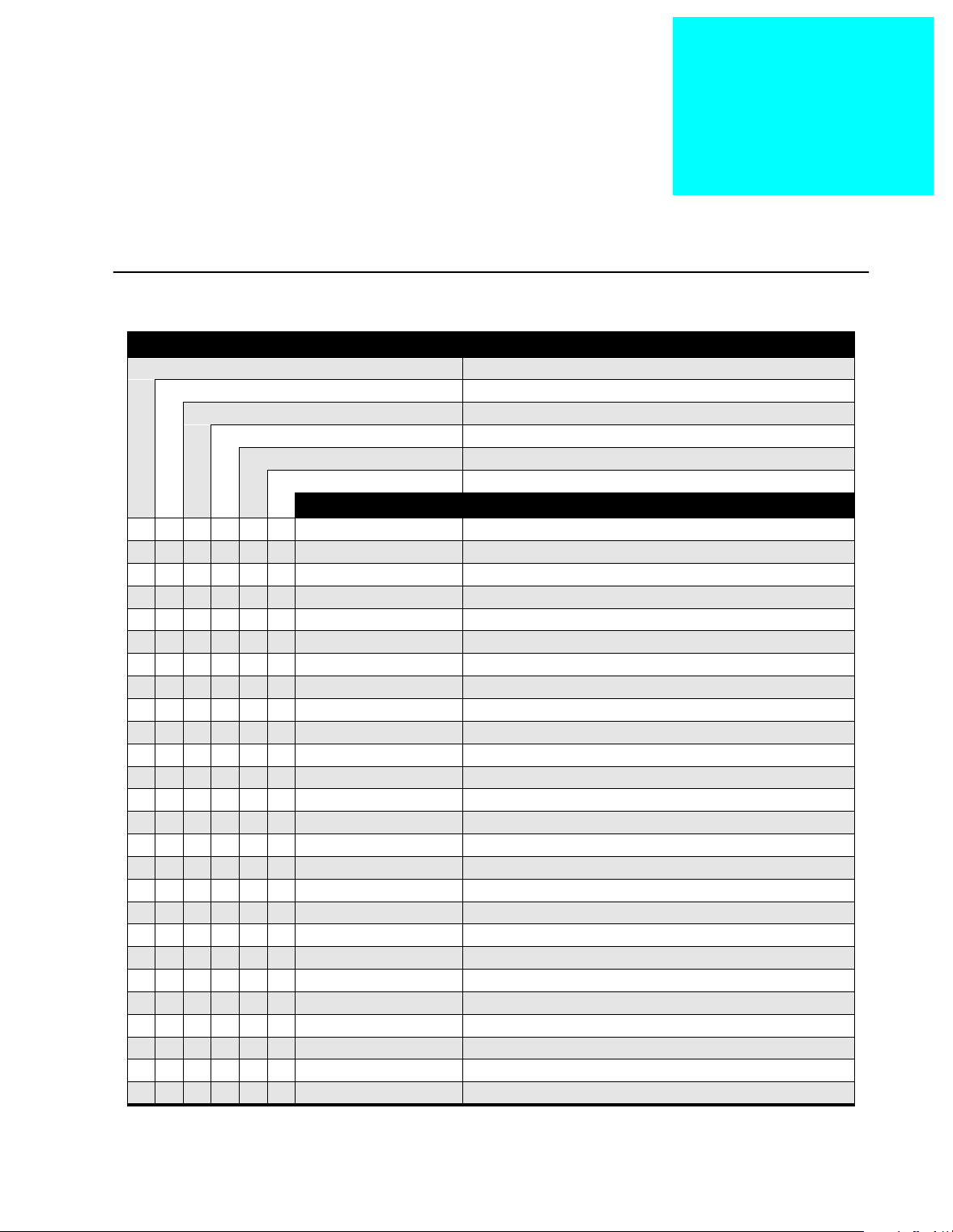

Table of Contents

1 - Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Manual Revisions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Computer Software Copyrights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Replacement Parts Ordering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Motorola Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Parts Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Related Documents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2 - Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safe and Efficient Operation of Motorola Two-way Radios . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

RF Operational Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Exposure to Radio Frequency Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Electromagnetic Interference/Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Facilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Aircraft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Medical Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Operational Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operational Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Mobile Radio Operation and EME Exposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

3 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Compact Mechanical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

State-of-the-Art Electrical Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Transmitter Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Receiver Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Station Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Wireline Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Switching Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Standard Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Optional Hardware Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

4 - System Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Local Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Two Antenna Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

External Duplexer Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Repeater RA or Cross Band Repeater Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

5 - Models and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Model Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Maintenance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

6 - Approved Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Antenna. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

, Motorola, ASTRO, ASTRO CAI, and SECURENET are trademarks of Motorola, Inc.

Commercial, Government, Industrial Solutions Sector

8000 W. Sunrise Blvd., Fort Lauderdale, FL 33322

All Rights Reserved. Printed in U. S. A. 8/2000.

© 2000 Motorola

i

Page 3

ii

7 - Setup and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Programming with RSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Connecting PC to

PDR 3500 RSS Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Using the RSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Channel Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

RF Cabling Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Separate RX and TX Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Duplexer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

8 - Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Summary of Switches, Pushbuttons, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Summary of LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

9 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Test Equipment List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Troubleshooting Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Troubleshooting Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Procedure 1: Routine Maintenance Functional Checkout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Procedure 2: Troubleshooting A Reported/Suspected Problem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

How to Use These Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Interpreting LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Interpreting Alarm Alert Tones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Verifying Transmitter Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Verifying Transmitter Circuitry Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Verifying Receiver Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Verifying Receiver Circuitry Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Verifying Receiver Circuitry (Digital-Capable Stations) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-21

Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-22

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-23

Module Replacement Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

General Replacement Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Anti-Static Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Care of Gold-Plated Connector Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Power Down Station Before Removing/Inserting Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Validating Repairs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-26

Station Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

Physical Replacement of the Station Control Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

After Installing the New Station Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-27

Wireline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

Physical Replacement of the Wireline Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

After Installing the New Wireline Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

ASTRO Modem Card/V.24 Interface Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Physical Replacement of the Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

After Installing the New Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

Page 4

Physical Replacement of the Receiver Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-29

After Installing the New Receiver Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-30

Exciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Frequency Band Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Physical Replacement of the Exciter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

After Installing the New Exciter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Power Amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

Frequency Band Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

Physical Replacement of the Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-32

After Installing the New Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

Physical Replacement of the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-33

Backplane. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

Before Installing the New Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

Physical Replacement of the Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

After Installing the New Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Preselector Field Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-35

Required Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

VHF Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

Calculating Proper Alignment Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-36

Preparing Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-37

VHF Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

UHF Tuning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Calculating Proper Alignment Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Preparing Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-40

Tuning Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

10 - Functional Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Transmitter Circuitry Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Exciter Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Power Amplifier Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Receiver Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Receiver Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Station Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Station Control Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Wireline Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Wireline Interface Board Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

Power Supply Module Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

11 - Block Diagram, Schematics, Electrical Parts List, and Circuit Board Detail11-1

iii

Page 5

List of Tables

Table 1: Rated Power and Distance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Table 2: Model Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 3: Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 4: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5: Specifications, continued . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 6: Switches, Pushbuttons, and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table 7: Summary of LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Table 8: Switches, Pushbuttons, and LED Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Table 9: PDR 3500 Station LED Indicator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Table 10: Motherboard DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-34

List of Figures

Figure 1.EIA-232 Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Figure 2. Switches , Pushbuttons , Connectors, and LED Indicators for PDR 3500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Figure 3. PDR 3500 Station Troubleshooting Overview (Procedure 1: Routine Maintenance). . . . . . . . . . . . . . . . . . . . 9-3

Figure 4. PDR 3500 Station Troubleshooting Overview

(Procedure 2: Reported or Suspected Problem) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Figure 5. PDR 3500 LED Indicators and Front Panel Buttons and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Figure 6. Test Equipment Setup for Verifying Transmitter Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Figure 7. Test Equipment Setup for Verifying Receiver Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Figure 8A. Coupled receiver connection. (Top) B. Coupled duplexer connection. (Bottom) . . . . . . . . . . . . . . . . . . . . 9-19

Figure 9. Disabling the Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-20

Figure 10. Interconnect Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-24

Figure 11. Chassis Ground Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Figure 12. Test Equipment Setup for Preselector Field Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-38

Figure 13. Location of Tuning Screws and Cavity Probe Holes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-39

Figure 14. Test Equipment Setup for Preselector Field Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-41

Figure 15. Location of Tuning Screws and Cavity Probe Holes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-42

Figure 16. PDR 3500 Functional Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Figure 17. PDR 3500 Schematic Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

Figure 18. PDR 3500 Schematic Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-4

Figure 19. PDR 3500 Backplane Circuit Board Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-6

iv

Page 6

Foreword

General

Safety Information

Manual Revisions

Computer Software

Copyrights

1

The information contained in this manual supplement relates to all

PDR 3500 stations, unless otherwise specified. This manual

provides sufficient information to enable service shop personnel to

troubleshoot and repair a PDR 3500 to the module level.

Before operating a PDR 3500 station, please read the “Safety

Information” section in the front of this manual.

Changes which occur after this manual is printed are described in

“FMRs.” These FMRs provide complete information on changes,

including pertinent parts list data.

The Motorola products described in this manual may include

copyrighted Motorola computer programs stored in semiconductor

memories or other media. Laws in the United States and other

countries preserve for Motorola certain exclusive rights for

copyrighted computer programs, including the exclusive right to

copy or reproduce in any form the copyrighted computer program.

Accordingly, any copyrighted Motorola computer programs

contained in the Motorola products described in this manual may not

be copied or reproduced in any manner without the express written

permission of Motorola. Furthermore, the purchase of Motorola

products shall not be deemed to grant either directly or by

implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Motorola, except for the

normal non-exclusive royalty free license to use that arises by

operation of law in the sale of a product.

Replacement Parts

Ordering

68P81093C75-O September 27, 2000 1-1

When ordering replacement parts or equipment information, the

complete identification number should be included. This applies to

all components, kits, and chassis. If the component part number is

not known, the order should include the number of the chassis or kit

of which it is a part, and sufficient description of the desired

component to identify it.

Page 7

Crystal and channel element orders should specify the crystal or

channel element type number, crystal and carrier frequency, and the

model number in which the part is used.

Parts Ordering

Motorola Parts

7:00 A. M. to 7:00 P. M. (Central Standard Time)

Monday through Friday (Chicago, U. S. A.)

Domestic (U. S. A.): 1-800-422-420, or 847-538-8023

1-800-826-1913, or 410-712-6200 (Federal Government)

TELEX: 280127

FAX: 1-847-538-8198

FAX: 1-410-712-4991 (Federal Government)

Domestic (U. S. A.) after hours or weekends:

1-800-925-4357

International: 1-847-538-8023

Accessories and Aftermarket Division

(United States and Canada)

Attention: Order Processing

1313 E. Algonquin Road

Schaumburg, IL 60196

Accessories and Aftermarket Division

Attention: International Order Processing

1313 E. Algonquin Road

Schaumburg, IL 60196

Parts Identification

Related Documents

1-847-538-0021 (Voice)

1-847-538-8194 (FAX)

Quantar User’s Guide (Motorola part number 68P81095E05)

RSS User’s Guide (Motorola part number 68P81085E35)

1-2 September 27, 2000 68P81093C75-O

Page 8

•

•

•

•

•

•

•

Safety Information

General

Safe and Efficient

Operation of

Motorola T wo-way

Radios

RF Operational

Characteristics

This section contains important information on safe and efficient

operation. Read this information before using your radio.

The information provided in this document supersedes the general

safety information contained in user guides published prior to July

2000. For information regarding radio use in a hazardous

atmosphere please refer to the Factory Mutual (FM) Approval

Manual Supplement or Instruction Card, which is included with

radio models that offer this capability.

Your radio contains a transmitter and a receiver. When it is ON, it

receives and transmits radio frequency (RF) energy.

2

Exposure to Radio

Frequency Energy

Your Motorola radio is designed to comply with the following

national and international standards and guidelines regarding

exposure of human beings to radio frequency electromagnetic

energy (EME):

United States Federal Communications Commission, Code of

Federal Regulations; 47 CFR part 2 sub-part J

American National Standards Institute (ANSI) / Institute of

Electrical and Electronic Engineers (IEEE) C95. 1-1992

Institute of Electrical and Electronic Engineers (IEEE) C95.11999 Edition

National Council on Radiation Protection and Measurements

(NCRP) of the United States, Report 86, 1986

International Commission on Non-Ionizing Radiation Protection

(ICNIRP) 1998

National Radiological Protection Board of the United Kingdom

1995

Ministry of Health (Canada) Safety Code 6. Limits of Human

Exposure to Radiofrequency Electromagnetic Fields in the

Frequency Range from 3 kHz to 300 GHz, 1999

68P81093C75-O September 27, 2000 2-1

Page 9

•

•

•

•

•

Australian Communications Authority Radiocommunications

(Electromagnetic Radiation - Human Exposure) Standard 1999

(applicable to wireless phones only)

Electromagnetic Interference/ Compatibility

Facilities

Aircraft

Medical Devices

NOTE: Nearly every electronic device is

susceptible to electromagnetic interference

(EMI) if inadequately shielded, designed or

otherwise configured for electromagnetic

compatibility.

To avoid electromagnetic interference and/or compatibility

conflicts, turn off your radio in any facility where posted notices

instruct you to do so. Hospitals or health care facilities may be using

equipment that is sensitive to external RF energy.

When instructed to do so, turn off your radio when on board an

aircraft. Any use of a radio must be in accordance with applicable

regulations per airline crew instructions.

• Pacemakers

The Health Industry Manufacturers Association recommends that a

minimum separation of 6 inches (15 cm) be maintained between a

handheld wireless radio and a pacemaker. These recommendations

are consistent with the independent research by, and

recommendations of, Wireless Technology Research.

Persons with pacemakers should:

ALWAYS keep the radio more than 6 inches (15 cm) from their

pacemaker when the radio is turned ON.

not carry the radio in the breast pocket.

use the ear opposite the pacemaker to minimize the potential for

interference.

turn the radio OFF immediately if you have any reason to

suspect that interference is taking place.

• Hearing Aids

Some digital wireless radios may interfere with some hearing aids.

In the event of such interference, you may want to

consult your hearing aid manufacturer to discuss alternatives.

• Other Medical Devices

If you use any other personal medical device, consult the

manufacturer of your device to determine if it is adequately shielded

from RF energy. Your physician may be able to assist you in

obtaining this information.

2-2 September 27, 2000 68P81093C75-O

Page 10

•

•

•

•

•

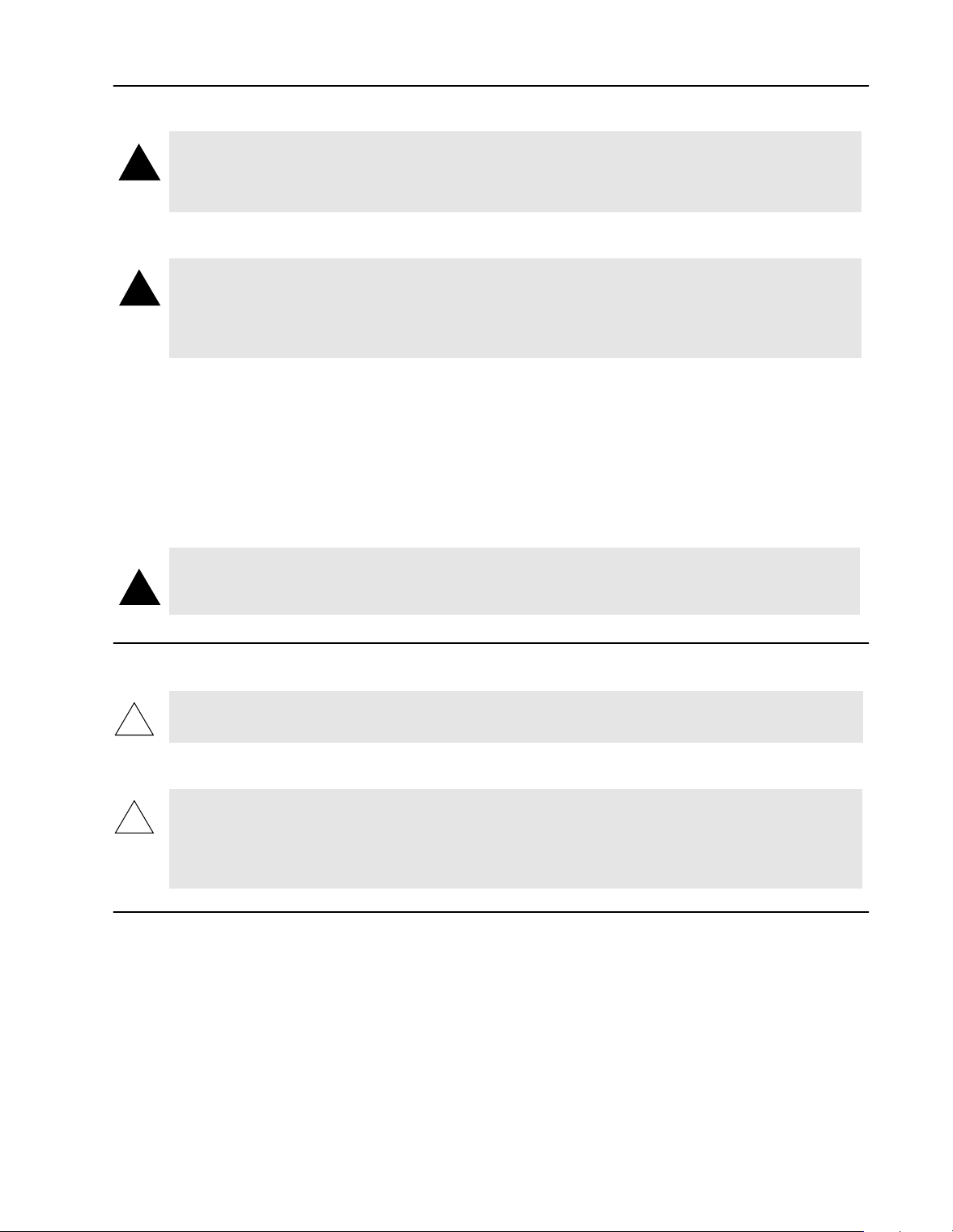

Operational Warnings

WARNING: Do not place a portable radio in the area over an air bag or in the air bag deployment area. Air bags inflate with great f orce. If a portable radio is placed in the air bag deploy-

!

ment area and the air bag inflates, the radio may be

propelled with great force and cause serious injury to occupants of the vehicle.

WARNING: Turn off your radio prior to entering any area with a potentially explosive atmosphere, unless it is a radio type especially qualified for use in such areas as “Intrinsically

!

Safe” (for example, Factory Mutual, CSA, or UL Approved). Do not remove, install, or charge

batteries in such areas. Sparks in a potentially explosive atmosphere can cause an explosion or fire resulting in bodily injury or even death.

NOTE:

The areas with potentially explosive atmospheres referred to above include fueling

areas such as below decks on boats, fuel or chemical transfer or storage facilities,

areas where the air contains chemicals or particles, such as grain, dust or metal

powders, and any other area where you would normally be advised to turn off your

vehicle engine. Areas with potentially explosive atmospheres are often but not

always posted.

WARNING: To avoid possible interference with blasting operations, turn off your radio when

you are near electrical blasting caps, in a blasting area, or in areas posted: “Turn off two-wa y

!

radio.” Obey all signs and instructions.

Vehicles with an air bag

Potentially explosive atmospheres

Blasting caps and areas

Operational Cautions

CAUTION: Do not use any portable radio that has a damaged antenna. If a damaged antenna

comes into contact with your skin, a minor burn can result.

!

CAUTION: All batteries can cause property damage and/or bodily injury such as burns if a

conductive material such as jewelry, keys, or beaded chains touch exposed terminals. The

!

conductive material may complete an electrical circuit (short circuit) and become quite hot.

Exercise care in handling any charged battery, particularly when placing it inside a pocket,

purse, or other container with metal objects.

Mobile Radio Operation

and EME Exposure

Damaged antennas

Batteries

To assure optimal radio performance and that human exposure to

radio frequency electromagnetic energy is within the guidelines

referenced earlier in this document, transmit only when people

outside the vehicle are at least the minimum distance away from a

properly installed, externally-mounted antenna.

68P81093C75-O September 27, 2000 2-3

Page 11

•

•

•

•

The table below lists the minimum distance for several different

ranges of rated radio power.

Table 1: Rated Power and Distance

Antenna Installation

Rated Power of Vehicle-Installed

Mobile Tw o-Way Radio

7 to 15 Watts

16 to 50 Watts 2 Feet (61 Centimeters)

More than 50 Watts 3 Feet (91.5 Centimeters)

Minimum Distance from

Transmitting Antenna

1 Foot (30.5 Centimeters)

Mobile Antennas

Recommended mobile antenna installations are limited to metal

body vehicles at the center of the roof and center of the trunk

deck locations.

The antenna installation must additionally be in accordance with:

a. The requirements of the antenna manufacturer/supplier

b. Instructions in the Radio Installation Manual

Fixed Site Antennas

Mobile radio equipment is sometimes installed at a fixed location

and operated as a control station or as a fixed unit. In such cases the

antenna installation must comply with the following requirements in

order to assure optimal performance and make sure human exposure

to radio frequency electromagnetic energy is within the

guidelines set forth in the above standards.

The antenna must be mounted outside the building.

Mount the antenna on a tower if at all possible.

If the antenna is to be mounted on a building then it must be

mounted on the roof.

As with all fixed site antenna installations, it is the responsibility

of the licensee to manage the site in accordance with applicable

regulatory requirements and may require additional compliance

actions such as site survey measurements, signage, and site

access restrictions in order to insure that exposure limits are not

exceeded.

2-4 September 27, 2000 68P81093C75-O

Page 12

Introduction

General

Compact Mechanical

Design

State-of-the-Art

Electrical Design

3

The Motorola PDR 3500 Station provides conventional analog,

ASTRO™ , ASTRO CAI™ , and SECURENET™ capabilities in a

compact, software-controlled design. The station architecture and

microprocessor-controlled Station Control Module allow for fast

and reliable upgrading. FLASH memory in the Station Control

Module allows software updates to be performed locally (using

serial port), or remotely via modem.

The entire unit is housed in a lockable rugged, black aluminum

extruded case weighing approximately 4l lbs. Internal components

are mounted in a custom, removable chassis, designed to fit a 19"

rack.

Transmitter Circuitry

Receiver Circuitry The station receive circuitry features multiple bandwidth capability

Station Control Module The Station Control Module is microprocessor-based and features

The station transmitter circuitry is designed for 50% duty cycle

operation at full rated power. Output power is continuously

monitored by an internal calibrated wattmeter . The wattmeter output

feeds a power control loop, continually adjusting and maintaining

the desired output power. All adjustments are electronic, including

deviation and output power.

(12.5, 25, or 30 kHz, depending on band), as well as ASTR O digital

operation. Injection signals for the 1st and 2nd local mixers are

generated by frequency synthesizer circuitry and are electronically

controlled by the Station Control Module. All receive signals

(analog, SECURENET, ASTRO, and ASTRO CAI) are detected and

digitized before being sent to the Station Control Module; this

provides improved audio quality , consistent throughout the cov erage

area.

extensive use of ASIC and digital signal processing technology . The

module serves as the main controller for the station, providing signal

processing and operational control for the station modules.

68P81093C75-O September 27, 2000 3-1

Page 13

Wireline Circuitry The station wireline circuitry provides a wide variety of telephone

interfaces, including analog, ASTRO, ASTRO CAI, SECURENET,

Tone Remote Control, and DC Remote Control. Telephone line

connections are easily made to the wireline circuitry via connectors

on the top panel.

Switching Power Supply

The station features a switching-type power supply, accepting a

wide range of A C inputs (85-265 VAC, 49-61 Hz). The po wer supply

generates 13.8 VDC for the station modules.

Standard Features • Compact single case design

• Extensive Self-Test Diagnostics and Alarm Reporting

• FRU maintenance philosophy

• Easily programmed via Radio Service Software

• Local or Remote Software downloading to FLASH memory

• Upgrades performed by module replacement and/or software

upgrade

• Compatible (with appropriate options) with analog,

SECURENET, ASTRO, and ASTRO CAI digital signaling

• Versatile and reliable switching-type power supply

• Wide operating temperature range: -30˚ C to + 60˚C (-22˚ F to

+140˚ F)

Optional Hardware Features

3-2 September 27, 2000 68P81093C75-O

• Duplexer Option – allows a single antenna to serve for both

transmitter and receiver circuitry for repeater applications.

• Antenna Relay Option – allows a single antenna to be switched

between transmitter and receiver.

• ASTRO Modem – allows connection (for ASTRO digital

signaling) to a console through a Digital Interface Unit (DIU) in

an ASTRO system, also allows connection to another ASTRO

Modem for digital Cross-Patch.

Page 14

System Applications 4

Local Control The PDR 3500 is an APCO 25 digital repeater. The station is

identical in operation to the Quantar station, hence there is no local

control capability . There is no digital-to-audio translation within the

station. Local control style operation can be accomplished in several

ways:

a. A portable radio may be used as an RF control station talking to

the repeater.

b. The station may be equipped with the wireline and the modem

options and routed through a DIU to a tone remote console. The

T one remote console controls the station via wireline through the

DIU. The wireline in this case is a local 4-wire cable.

Two Antenna

Operation

The PDR 3500 Portable Digital Repeater may be operated with the

internal duplexer , using a single antenna. The duplex er pro vides the

necessary electrical isolation between the transmitter and the

receiver frequencies for repeater operation. The same isolation can

be obtained by physically separating transmit and receive antennas

either horizontally or vertically . The repeater requires approximately

50 dB isolation between the transmit and receive antennas for proper

operation.

Horizontal Antenna Separation:

VHF Band 275 feet

UHF Band 75 feet

800 MHz Band 40 feet

The Isolation values shown are for dipole antennas. If gain antennas

are used, additional separation is required. For example, if both

receive and transmit antennas have 3dB gain each, an additional

6 dB isolation is required. At UHF frequencies, an additional 75 feet

separation is required.

Vertical Antenna Separation

(tip of one antenna to the base of the other):

VHF Band 23 feet

UHF Band 9.5 feet

800 MHz Band 4 feet

68P81093C75-O September 27, 2000 4-1

Page 15

Gain antennas do not effect the transmit-to-receive antenna

separation required. Gain antennas are longer than unity gain

antennas.Therefore additional tower height will be required to

maintain the tip-to-base separation.

The antenna isolation distances shown above are based upon ideal

conditions. The antenna-to-antenna coupling is affected by nearby

objects that may result in increased separation required for proper

operation.The antenna coax cable must be a double-shielded type to

minimize cable-to-cable coupling. If RG58 style cables have to be

used, keep the cables as far apart as possible to minimize cable

coupling.

External Duplexer Operation

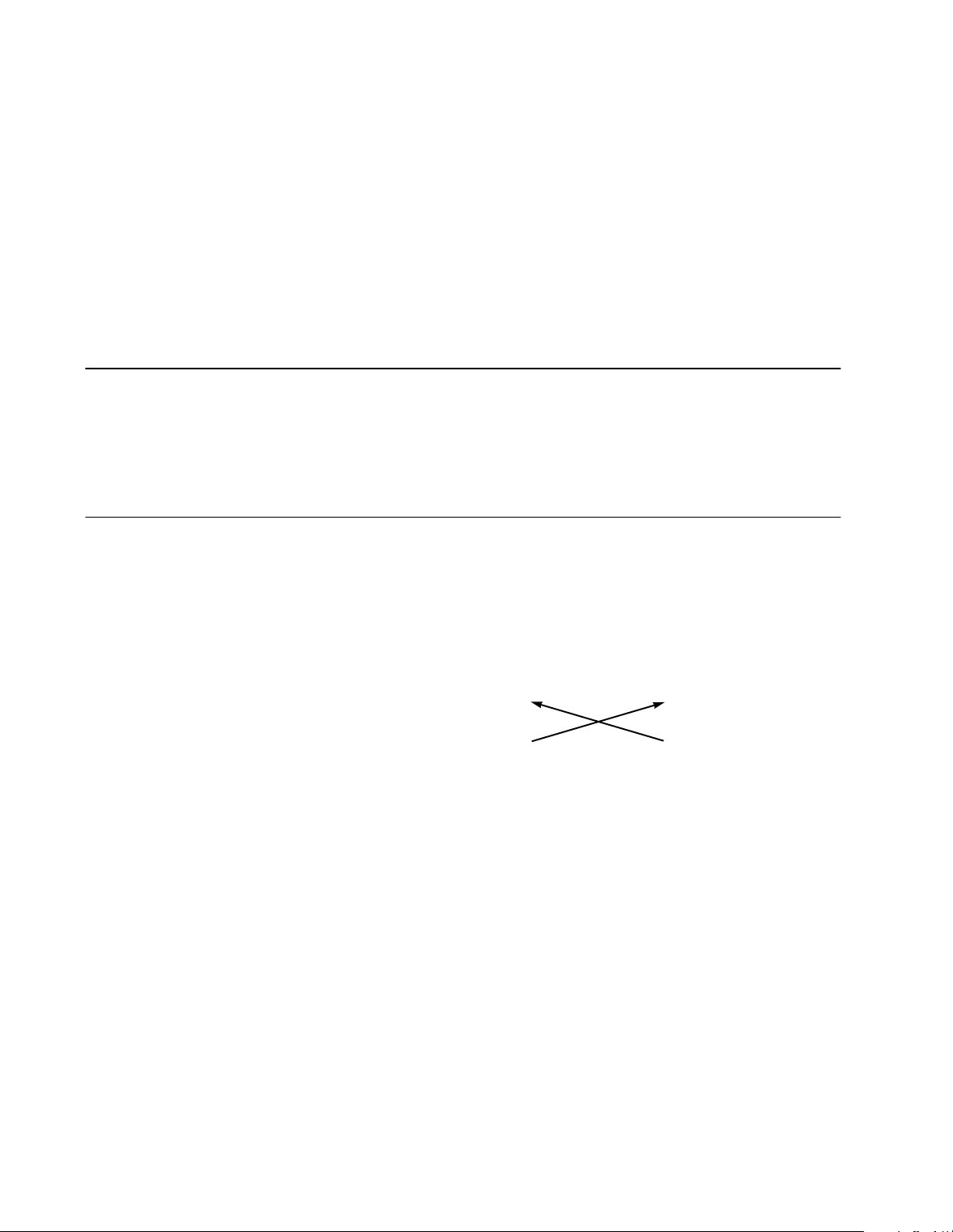

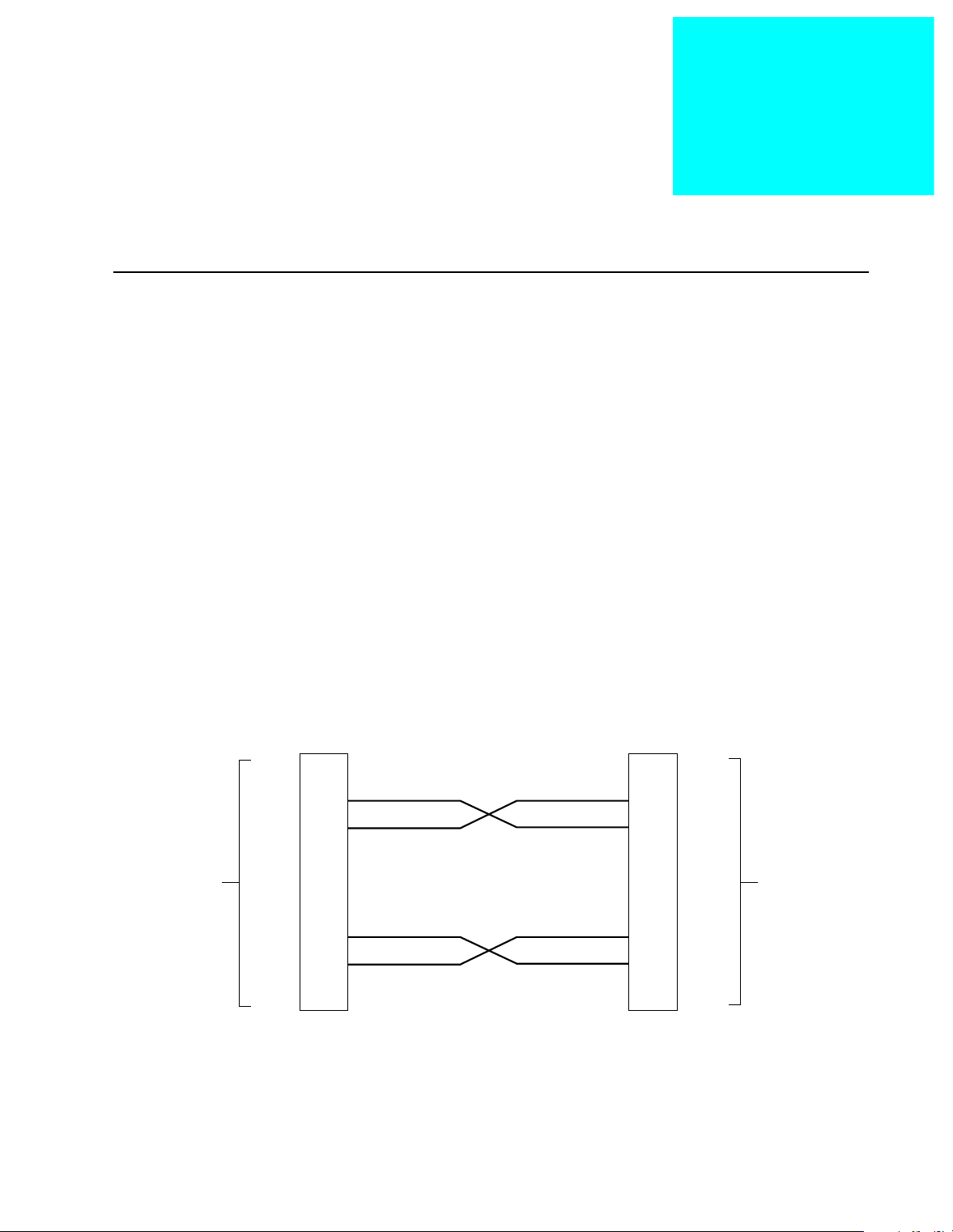

Repeater RA or Cross Band Repeater Operation

The PDR 3500 must be used with an external duplexer when

frequency spacing is less than 3 MHz. The duplexer isolation

required for proper operation is approximately 60 dB. Doubleshielded coaxial cables must be used from the repeater to the

duplexer.

The PDR 3500 can be configured for Repeater RA or cross band

repeater operation by adding the wireline card and the Astro modem

to the each repeater. The repeaters are connected together using the

wireline port on each repeater. The cables are terminated in RJ-45

connectors.

Repeater 1 Repeater 2

Wireline A Wireline A

Wireline B Wireline B

4-2 September 27, 2000 68P81093C75-O

Page 16

Models and Specifications 5

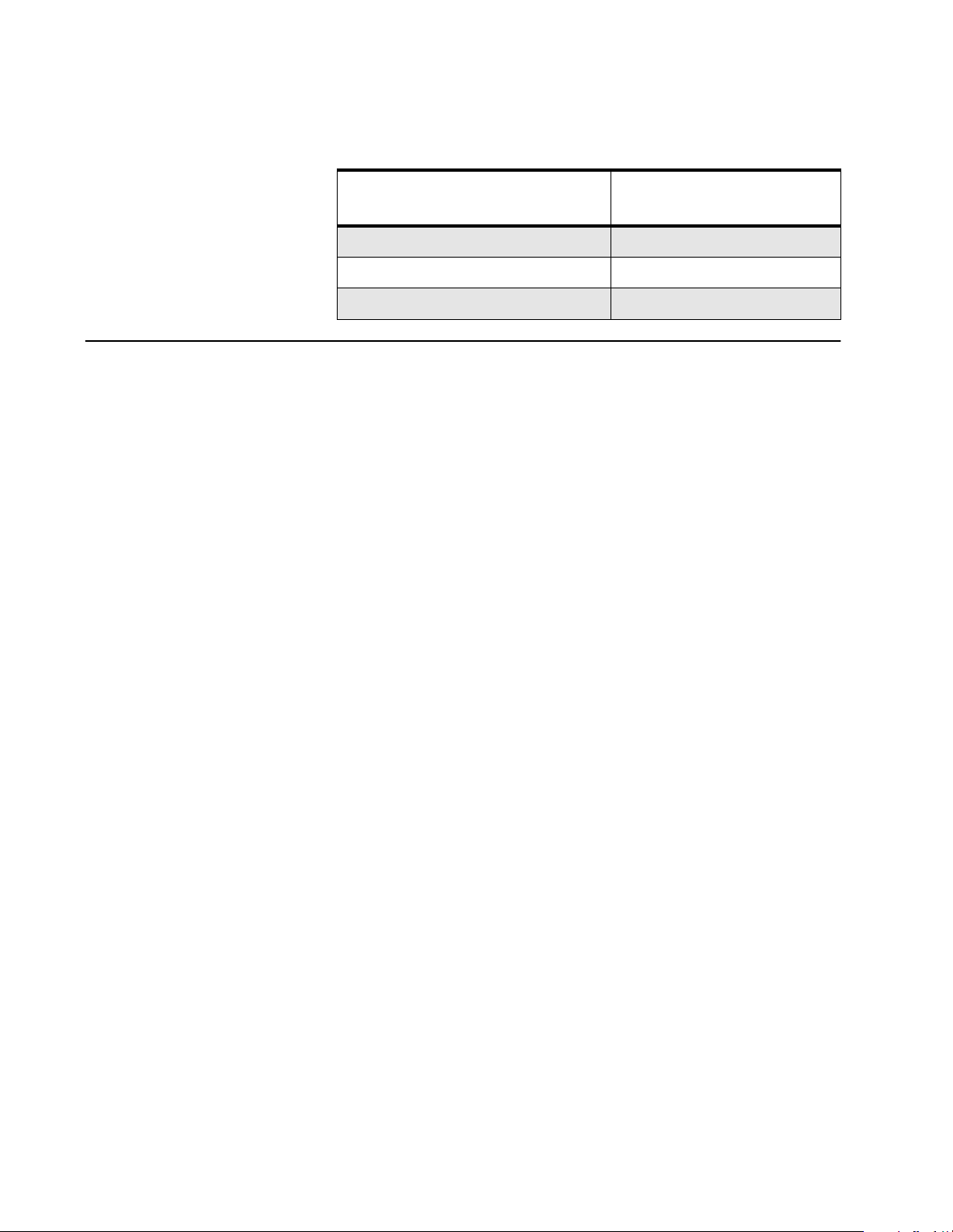

Model Chart

Table 2: Model Structure

Model Description

P2066A 132-154 MHz

P2067A 150-174 MHz

P2068A 403-433 MHz

P2069A 438-470 MHz

P2070A 470-494 MHz

P2071A 494-512 MHz

Kit Description

X PLD1177_ Receiver VHF R1

X PLD1178_ Exciter VHF R2

X PLD1179_ Receiver VHF R2

X PLD1180_ Exciter VHF R2

X PLE1254 Receiver UHF R1

X PLE1255 Exciter UHF R1

X PLE1256 Receiver UHF R2

X PLE1257 Exciter UHF R2

X PLE1258 Receiver UHF R3

X PLE1259 Exciter UHF R3

X PLE1260 Receiver UHF R4

X PLE1261 Exciter UHF R4

XXXXXXPLN1682_ Board, Control

X X X X X X PLN1681_ Chassis, main

XXXXXXPLN7776_ Case, portable

X X X X X X PLN7777_ Board, backplane

XXXXXXPPN6026_ Power supply

X X PLD7981_ P A, VHF

X PLE9367_ PA, UHF R1

X X PLE9369_ PA, UHF R3

X PLE9372_ PA, UHF R4

X X PFD6060_ Duplexer, VHF

XXXXPFE6060A Duplexer, UHF

X X X X X X PAN6003A Antenna, mag mount

XXXXXXPDR7778A Label

X X X X X X PBN6048A Packing

x = Indicates one of each is required.

68P81093C75-O September 27, 2000 5-1

Page 17

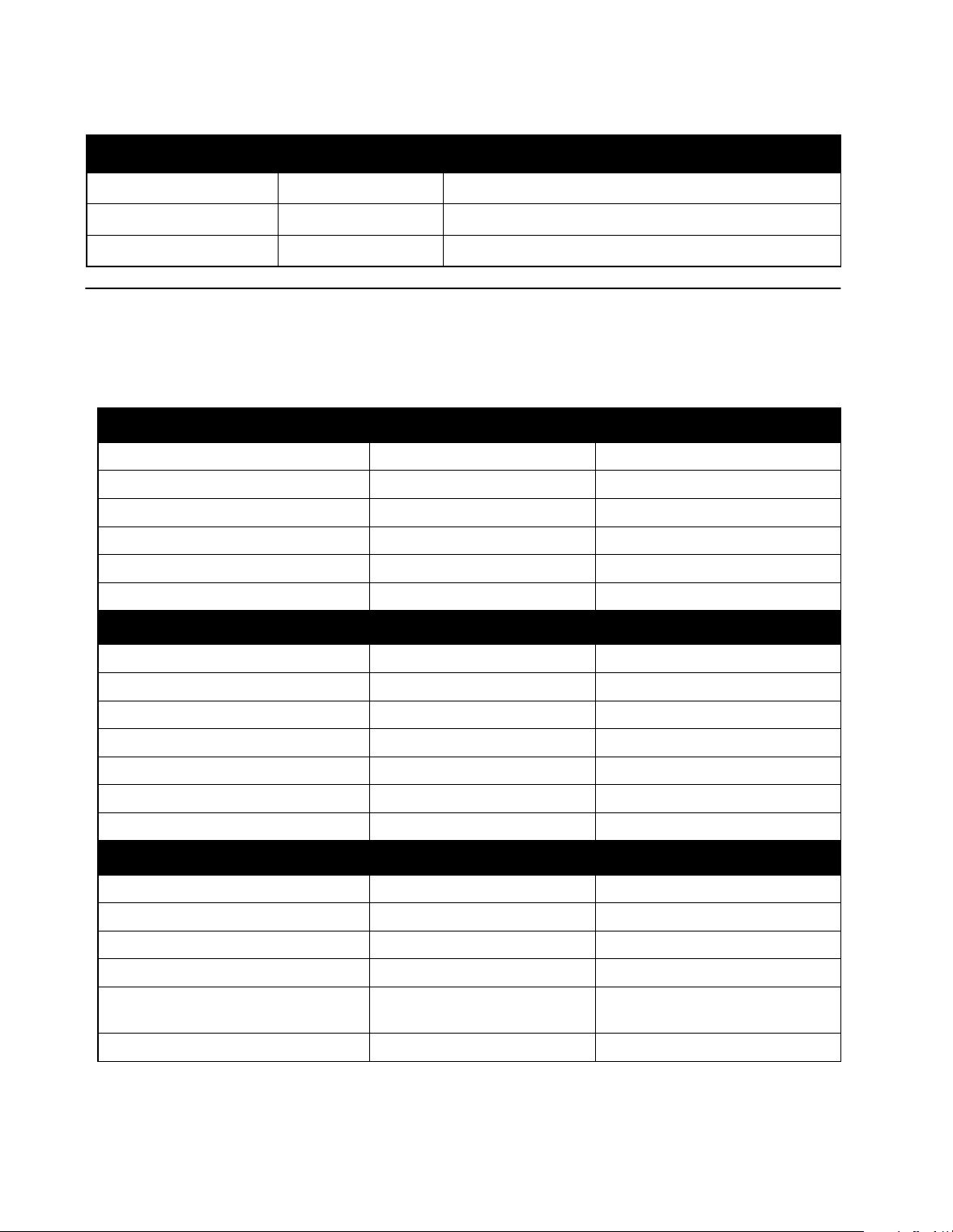

Table 3: Options

OPTION DESIGNATOR DESCRIPTION PURPOSE

Q245AL Add: Duplexer, VHF Adds VHF duplexer. Requires customer frequency.

Q245AM Add: Duplexer, UHF Adds UHF duplexer. Requires customer frequency.

H338AC Add: Transit Case Adds a transit case for increased protection during transport.

Maintenance

Specifications

The following are the PDR 3500 specifications for analog as

measured per the revised EIA/TIA 603 Standards and for digital as

measured per TIA TSB-102.CAAB:

Table 4: Specifications

GENERAL VHF UHF

Standard model numbers P2066A, P2067A P2068A, P2069A, P2070A, P2071A

Channel spacing 12.5, 25, 30 kHz 12.5, 25 kHz

Stability 0.0001% 0.0001%

Preselector bandwidth (3dB) 7 MHz 7 MHz

Squelch Carrier, PL, DPL Carrier, PL, DPL

Number of modes 1 1

TRANSMITTER VHF UHF

RF power (without duplexer) 30 watts 30 watts

RF power (with duplexer) 20 watts 20 watts

Maximum transmit duty cycle 50% 50%

TX spurs/harmonics -60 dB -60 dB

FM noise (EIA) -45 dB nominal -45 dB nominal

Audio response per EIA per EIA

TX distortion (1 kHz, clear audio) <5% <5%

RECEIVER VHF UHF

Sensitivity (20dBQ) 0.35 uV 0.5 uV

Sensitivity (12dB SINAD) 0.25 uV 0.35 uV

Selectivity (EIA SINAD) 85 dB (25/30 kHz) 85 dB (25 kHz)

75 dB (12.5 kHz) 75 dB (12.5 kHz)

Intermod (EIA SINAD) 80 dB (25/30 kHz)

75 dB (12.5 kHz)

Spurious and image 80 dB 80 dB

Note: Specifications are subject to change without notice.

5-2 September 27, 2000 68P81093C75-O

75 dB

Page 18

Table 5: Specifications, continued

DUPLEXER

Repeat frequency spread, TX/TX: 300 kHz

VHF minimum duplexer T-R separation 3 MHz: 132-174 MHz

UHF minimum duplexer T-R separation 3 MHz: 403-520 MHz

AC power voltage range: 80-265 Vac

AC power frequency input: 49-61 Hz

External DC power: 11-16 Vdc

CURRENT DRAIN

High power repeat: 10.0 A

Standby: 1.9 A

DIMENSIONS

Size (English): 20.00 x 15 x 7.75 inches

Size (metric): 508 X 381 X 197 mm

WEIGHT

Weight (English): 41 lbs

Weight (metric): 18.6 kg

Note: Specifications are subject to change without notice.

68P81093C75-O August 18, 2000 5-3

Page 19

Notes

5-4 September 27, 2000 68P81093C75-O

Page 20

Approved Accessories 6

General The following accessories are recommended by Motorola for use

with the PDR 3500 Portable Repeater.

Antenna One of the following antennas should be used:

• The magnetic-mount whip antenna (Motorola part number

PAN6003A) shipped with the PDR 3500.

NOTE: This antenna should be cut to frequency before use per the

manufacturer’s instructions enclosed with the antenna.

• An aftermarket antenna which meets these requirements:

- Monopole

- Unity gain

- Tuned to the frequency at which the antenna is to be used

- Minimum input power rating of 60W continuous

- VSWR of 1.5:1 or less

68P81093C75-O September 27, 2000 6-1

Page 21

Notes

Running H/F 6-# September 27, 2000 68P81093C75-O

Page 22

Setup and Connections 7

Programming with RSS

Introduction

Connecting PC to PDR 3500 RSS Port

EIA-232 Female

TXD

RXD

Connects

to COM Port

on PC

GND

RTS

CTS

9-Pin

D-Type

1

2

3

4

5

6

7

8

9

The PDR 3500 uses the same RSS (Radio Service Software) as the

Quantar/Quantro family. Some values shown in RSS screens may

not be valid due to hardware differences between the Quantar

Station and the PDR 3500. A thorough explanation of the

differences will be given in the following sections.

Once the RSS Program has been loaded onto the PC (refer to

Quantar RSS User’s Guide, 68P81085E35), the PC must be

electrically connected to the PDR 3500 via the RSS port located on

the top panel. For this connection, a 9-pin female to 9-pin male EIA232 cable is available (Motorola part number 30-80369E31) from

the Accessories and Aftermarket Product Division (AAD, formerly

known as Motorola National Parts). A cable can also be made using

the wiring diagram in Figure 1.

9-Pin

D-Type

EIA-232 Male

1

TXD

2

RXD

3

4

GND

5

6

RTS

7

CTS

8

9

Connects

to RSS Port

on Top Panel

MAEPF-27075-O

Figure 1. EIA-232 Wiring Diagram

68P81093C75-O September 27, 2000 7-1

Page 23

Connect one end of the cable to COM1 on the PC and the other end

to the 9-pin connector labeled “RSS” on the top panel of the

PDR 3500.

Using the RSS For information on starting the RSS, configuring screen colors,

setting up the PC serial port, and general RSS use, refer to the

Quantar RSS User’s Guide (68P81085E35).

Hardware Configuration From the Main Menu, press “F2-Service. ” Press F2 again to arrive at

the Hardware Configuration Screen.

1. The first field to verify is the Hardware Platform field. The

PDR 3500 is designed using the Quantar profile; it will not

operate properly in any other mode.

2. The next field to verify is the System Type field. This field

should be set to “Conventional.” The PDR 3500 does not operate

as an ASTRO-TAC Receiver or DBS Base Station.

3. Next verify that the Rx Freq Band 1 and Tx Freq Band fields

list the correct ranges for receiver and transmitter.

NOTE: Rx Freq Band 2 should be set to “NONE.”

4. The PA Power Rating field should be set to 25W (low power),

and the Power Supply field should show “AC LOW.” The

PDR 3500 was designed using a Quantar low power station

profile. It will not operate properly using any other

configuration.

5. If the unit is equipped with a Wireline Card, verify that the

Wireline field under the options is set to 4-wire.

Once the Hardware Configuration Screen matches the installed

station hardware, press F8 to validate the configuration. A popup

message will notify the user of any errors in the configuration. For

a complete description of the Hardware Configuration fields,

please refer to the Quantar RSS User’s Guide (68P81085E35).

Alignment From the Main Menu, press “F2-Service. ” No w press “F3” to arri ve

at the Alignment Menu. From this menu, the user may align the RF

Power Out, RSSI, Station Squelch, and BER.

For instructions on performing Rx or Tx Wireline Alignment, please

refer to the Quantar RSS User’s Guide (68P81085E35).

NOTE: Before performing any alignment procedures, first

dekey the station and “Access Disable” the repeater

as shown in step 1 below.

7-2 September 27, 2000 68P81093C75-O

Page 24

1. Access Disable:

1. From the main menu, press “F2-Service.”

2. Press “F6-Status Panel/Software Ver/Set Date and Time.”

3. Press F2 to arrive at the Status Panel Display Screen.

4. From this screen, press F6 to activate the Access Disable

function. In this mode, the station will not keyup in

response to a received signal. To deactivate the Access

Disable function, press shift+F6.

2. RSSI Calibrate:

1. In the Alignment Menu Screen, tab over to the RSSI

Calibrate field, and press F2 to perform the alignment.

2. Using an R2670 or equivalent Communications System

Analyzer, connect the RF out from the Analyzer to the Rx

UHF-type connector on the station top panel.

3. Set the RF output level from the Analyzer to –90 dBm with

no modulation, and set the frequency to PDR 3500 receive

frequency.

4. With the Analyzer RF turned on, make sure the v alue sho wn

in the RSS screen is –90 dBm. If it is not, type in “–90

dBm.”

5. Press F8 to save the calibration.

3. Power Out:

1. In the Alignment Menu Screen, tab over to the Tx Power

field and press F2 to perform the alignment.

2. For this procedure, connect the Tx UHF-type connector on

the station top panel to the RF input of either a Motorola

R-2670 Communications Analyzer, or to the input of an RF

power meter.

3. Press F6 to keyup the station, check the output power level

shown on the R2670 or RF power meter, and press F9 to

dekey the station.

4. Enter the power from the meter in the field shown in the

RSS, then hit F7 for the PDR 3500 to adjust the PA power

output level.

5. Once the unit adjusts the power, again keyup the station,

read the RF power from the meter, dekey the station, enter

the level in the RSS field, and hit F7 again to adjust.

6. Repeat this cycle until the power out is as close to 25 Watts

as possible. If the power output will not adjust properly, hit

F4 to initialize the PA and restart the alignment procedure.

68P81093C75-O September 27, 2000 7-3

Page 25

7. Once the power out is aligned, press F8 to save the settings

to the station codeplug.

4. Squelch:

1. From the Alignment Menu, tab over to the Squelch Adjust

field and press F2 to perform the alignment. The Squelch

control bar is shown in the center of the screen.

2. To open the squelch completely, press F2. To close the

squelch completely, press F4. To adjust the squelch

between fully open and fully closed, use the Pg Up/Pg Dn

keys on the PC.

3. Once the squelch is set, press F8 to save the setting to the

station codeplug.

5. ASTRO Bit Error Report:

1. From the Alignment Menu, tab ov er to the V.52 Rx BER and

RSSI Report, or PROJECT 25 Rx BER and RSSI Report.

2. Connect the R2670 Communications System Analyzer RF

“OUT” port to the Rx UHF-type connector on the station

top panel.

3. Set the generate frequency to the PDR 3500 receive

frequency, and the output level to –113 dBm, with

modulation either V.52 or Project 25 1011 Pattern

generation.

4. Press F2 to perform the alignment. The values for the report

will appear on the RSS screen.

Channel Information From the Main Menu, press F4. Press F4 again to arrive at the

Channel Information Screen. From this screen, the user may

configure the TX/RX frequencies, RF power out, modulation type,

and the various channel traits for up to 16 channels.

1. In this screen, first set the Rx1 and Tx frequency to the proper

values.

NOTE: The Rx2 frequency is set to 0.00000 MHz and cannot

be edited. This is because the PDR 3500 does not

allow for 2 receiv ers. The station will automatically

calculate the Tx Idle Frequency to be the same as the

Tx Frequency.

In most applications, the Tx Idle Frequency should remain the same

as the Tx Frequency. However, in case of portable or mobile radios

unsquelching near the PDR 3500, adjust the Tx Idle frequency to Tx

Frequency -6.25 kHz.

2. Set the modulation type to either Analog, ASTR O, ASTR O CAI,

7-4 September 27, 2000 68P81093C75-O

Page 26

Electrical Connections

Analog/ASTRO CAI, or CAI RX WIDE DEV.

3. Move to page 2 of the Channel Information Screen by pressing

the Pg Dn key. Set the Tx Po wer Out to the desired power lev el.

(The Battery Backup field has no effect on station operation

since there is no battery option for the PDR 3500.)

For a more complete description of the Channel Information fields,

please refer to the Quantar RSS User’s Guide.

Power Supply Connections

RF Cabling Connections

• AC Input Power Connection

Each PDR 3500 is shipped with an eight foot, 3-conductor line

cord. Attach the receptacle end of the cord to the AC input plug

located on the station top panel. Plug the 3-prong plug into a 110

V or 220 V AC grounded outlet.

NOTE: The Power Supply module automatically selects

between 110 V and 220 V.

• DC Input Power Connection

An optional six foot, fused 2-conductor DC power cord is

available. Attach the alligator clip leads (Red “+”, Black “-”) to

an external battery or some other DC source set to +12 V. Plug

the molded connector end to the external DC connector on the

top panel.

NOTE: The top panel external DC connector will not charge

an external battery.

Introduction The transmit and receive antenna RF connections may be made in

one of two fashions depending on the system application.

• Separate TX and RX antennas.

The PDR 3500 top panel has two UHF-type connectors: one for

RX, and one for TX. In this configuration there is a separate

antenna for each connector.

• Duplexer

68P81093C75-O September 27, 2000 7-5

Page 27

Using this configuration, only one antenna is required for both

transmit and receive. The duplexer is mounted to the station top

panel and has a single N-type connector for the antenna. An N-toUHF adapter is provided.

Separate RX and TX Connectors

In order to use two antennas, first disconnect the duplexer (if

equipped). Connect the Rx antenna to the UHF connector labeled

“RX” on the top panel, and the Tx antenna to the UHF connector

labeled “TX” (Figure 2). Please refer to the Antenna Spacing Chart

on page 4-1 in this manual.

Duplexer The duplexer allows the PDR 3500 to use a single antenna for both

transmit and receive.

1. Connect the UHF connector labeled “RX” on the station top

panel, to the N-type connector labeled “RX” on the duplexer.

2. Connect the top panel UHF connector, labeled “TX,” to the Ntype connector labeled “TX” on the duplexer .

3. Connect the antenna UHF-type connector to the connector

labeled “ANT” on the duplexer.

7-6 September 27, 2000 68P81093C75-O

Page 28

Operation 8

Description This section describes the switches, pushbuttons, connectors, and

LED indicators on the PDR 3500 station used during local operation

of the station and servicing.

Summary of Switches, Pushbuttons, and Connectors

Summary of LED Indicators

The following switches, pushbuttons, and connectors allow the

station to be operated or serviced locally. See Figure 2 for the

location and function of these controls and connectors.

Table 6 Switches, Pushbuttons, and Connectors

Top Panel

Wireline connectors Transmit UHF connector

RSS port connector Receive UHF connector

DC connector

AC connector

Momentary PTT/Reset switch

NOTE: Refer to the Troubleshooting section of this manual

for the detailed descriptions and interpretation of the

LED indicators.

The following LED indicators are provided to show the operating

status of the station. See Figure 2 for the location of these indicators.

Table 7 Summary of LED Indicators

Top Panel Station Control Module

Power/Transmit LED Station On

Station Fail

Intcm/Acc D

Control Ch

Rx 1 Active

Rx2 Active

Rx Fail

Aux LED

68P81093C75-O September 27, 2000 8-1

Page 29

Duplexer

Wireline

Connections

(RJ-45)

A

B

C

D

E

Antenna

F

Receive

UHF Jack

Transmit

UHF Jack

MAEPF-27065-O

Figure 2 . Switches , Pushbuttons , Connectors, and LED Indicators for PDR 3500

Table 8 Switches, Pushbuttons, and LED Indicators

Item Name Purpose

A EIA-232 RSS Port Connector Used to connect an IBM® PC (or compatible PC), running

RSS software. Performs station alignment, optimization,

and diagnostics. Requires Null Modem Cable (Motorola part

number 30-80369E31).

B DC Connector External DC source (+12 Vdc)

C AC Connector and Fuses AC Inlet (110/220 Vac, 3 A)

D Power/Transmit LED The function of this LED indicator is described in the Trou-

bleshooting section of this manual.

E Momentary PTT/Reset Switch When set to “PTT,” its purpose is to test the station. When

set to “RESET,” its purpose is to reset the station.

F Control Module Status LEDs The function of these LED indicators is described in the

Troubleshooting section of this manual.

The LED indicators are (from right to left): Station On; Sta-

tion Fail; Intcm/Acc D; Control Ch; Rx 1 Active; Rx2 Active;

Rx Fail; Aux LED.

8-2 September 27, 2000 68P81093C75-O

Page 30

Troubleshooting 9

Introduction This section provides troubleshooting recommendations and

procedures for the PDR 3500 station and associated ancillary

equipment.

Troubleshooting Overview

Recommended T est Equipment

The troubleshooting procedures and supporting diagrams allow the

service technician to isolate station faults to the module/assembly

level, or to a limited portion of the motherboard circuitry.

The following information is included:

• Alarm indicators and their functions

• Troubleshooting flow charts

• Module replacement procedures

• Post-repair procedures: Performing alignment

after replacing defective modules

Follow this list of recommended test equipment when performing

troubleshooting procedures on the PDR 3500 station and ancillary

equipment:

Test Equipment List • Motorola R2001 or R2600 Series

Communications Analyzer (or equivalent)

• PC with RSS program

• In-Line Wattmeter (Motorola S-1350, or

equivalent)

• Dummy Load (50Ω, station wattage or higher)

• Handset/Microphone with PTT switch

(TMN6164, or equivalent)

Troubleshooting Procedures

68P81093C75-O September 27, 2000 9-1

The troubleshooting and repair philosophy employs Field

Replaceable Unit (FRU) substitution. The PDR 3500 station is

comprised of self-contained modules (FRUs). Replacing faulty

modules should bring the station back to normal operation.

Page 31

Many of the troubleshooting procedures require the use of the

Motorola-supplied Radio Service Software (RSS) since the PDR

3500 station is computer-controlled, employing state-of-the-art

signal processing. The RSS operates on a PC (or compatible), with

RS-232 communication port capability. The RSS allows the

technician to access alarm logs, run diagnostics, and set up the

equipment for various audio and RF tests. Complete details on the

operation of the RSS are provided in the RSS User’ s Guide (manual

number 68P81085E35).

Troubleshooting Overview

Introduction Two procedures are provided for troubleshooting the PDR 3500

station and ancillary equipment. Each procedure is designed to

quickly identify faulty modules, and replace them with known

working modules.

Procedure 1: Routine Maintenance Functional Checkout

Procedure 2: Troubleshooting A Reported/Suspected Problem

How to Use These Troubleshooting Procedures

Procedure 1 is a series of non-intrusive tests, performed during a

routine maintenance. The technician verifies proper station

operation. An overview of the procedure is shown in the flowchart

(Figure 3).

Procedure 2 should be used when an equipment problem has been

either reported or is suspected. The procedure includes tests that

allow the technician to troubleshoot reported or suspected

equipment malfunctions. An overview of the procedure is shown in

the flow chart (Figure 4).

Perform the following basic steps in order to efficiently troubleshoot

the PDR 3500 station equipment.

Step 1. Select the appropriate troubleshooting procedure flow

chart (Procedure 1 or Procedure 2).

Step 2. Perform the selected flow chart tasks. Tasks requiring

additional explanation are marked with page

references.

• Locate the additional information

• Perform the tasks (if any)

• Return to the flow chart

Step 3. Once the f aulty module has been identified, proceed to

Module Replacement Procedures, beginning on

page 25.

9-2 September 27, 2000 68P81093C75-O

Page 32

ROUTINE

MAINTENCE VISIT

OBSERVE LED INDICATORS and

MONITOR ALARM TONES (PAGES 6 AND 9)

• OBSERVE LED INDICATORS ON STATION

MODULE FRONT PANELS

• MONITOR ALARM ALERT TONES FROM

EXTERNAL SPEAKER

PROCEDURE 1

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

INTERPRET STATUS REPORT

(RSS USER’S GUIDE–68P81085E35)

• USING RSS, ACCESS THE STATUS REPORT

SCREEN AND LOOK AT HISTORY OF ALARMS

AND TIME STAMPS

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

RUN STATION DIAGNOSTICS

(RSS USER’S GUIDE–68P81085E35)

• USING RSS, RUN DIAGNOSTICS ON

STATION MODULES

YES

YES

GO TO TROUBLESHOO TING

PROCEDURE 2 FLOW CHART

GO TO TROUBLESHOO TING

PROCEDURE 2 FLOW CHART

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

DONE

YES

GO TO TROUBLESHOO TING

PROCEDURE 2 FLOW CHART

Figure 3 PDR 3500 Station Troubleshooting Overview (Procedure 1: Routine Maintenance)

68P81093C75-O September 27, 2000 9-3

Page 33

REPORTED OR SUSPECTED

PROBLEM

OBSERVE LED INDICATORS and

MONITOR ALARM TONES (PAGES 6 AND 9)

• OBSERVE LED INDICATORS ON STATION

MODULE FRONT PANELS

• MONITOR ALARM ALERT TONES FROM

EXTERNAL SPEAKER

PROCEDURE 2

LED PATTERN

INDICATES STATION

IN SOFTWARE

DOWNLOAD MODE?

NO

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

RUN STATION DIAGNOSTICS

(RSS USER’S GUIDE–68P81085E35)

• USING RSS, ACCESS DIAGNOSTICS SCREEN,

RUN DIAGNOSTICS, AND INTERPRET RESULTS

YES

USING RSS, ACCESS THE STATUS

YES

REPORT SCREEN. ANALYZE

MESSAGES TO DETERMINE IF

MODULE FAILURE HAS OCCURRED.

GO TO MODULE REPLA CEMENT

PROCEDURES ON page 25

MODULE

SUSPECTED

OF BEING

FAULTY?

YES

NO

USING RSS, DOWNLOAD STATION

SOFTWARE TO FLASH MEMORY

ON STATION CONTROL BOARD

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

GO TO

YES

GO TO MODULE REPLACEMENT

PROCEDURES ON page 25

A

Figure 4 PDR 3500 Station Troubleshooting Overview (Procedure 2: Reported or Suspected Problem)

9-4 September 27, 2000 68P81093C75-O

Page 34

A

CHECK CODE PLUG PROGRAMMING

(RSS USER’S GUIDE – 68P81085E35)

• USING RSS, READ THE STATION CODE PLUG

AND VERIFY THA T PROGRAMMING IS

CORRECT (COMPARE TO CODE PLUG FILE ON

PC FOR PARTICULAR STATION)

PROCEDURE 2

(CONTINUED)

CODE

PLUG

PROGRAMMING

CORRECT?

YES

INTERPRET STATUS REPORT

(RSS USER’S GUIDE–68P81085E35)

• USING RSS, ACCESS THE STATUS REPORT

SCREEN AND LOOK AT HISTORY OF ALARMS

AND TIME STAMPS

MODULE

SUSPECTED

OF BEING

FAULTY?

NO

RUN TRANSMITTER AND RECEIVER TESTS:

• PERFORM VERIFYING TRANSMITTER CIRCUITR Y

TESTS (Page 10) TO ISOLATE PROBLEM TO

TRANSMITER CIRCUITRY

• PERFORM VERIFYING RECEIVER CIRCUITRY TESTS

(Page 14) TO ISOLATE PROBLEM TO RECEIVER

CIRCUITRY

• RE-PROGRAM STATION CODE PLUG BY DOWNLOADING

CUSTOMER DATA FROM CODE PLUG FILE FOR

NO

PARTICULAR STATION (RSS GUIDE – 68P81085E35)

• IF PROBLEM STILL EXISTS, PROCEED TO INTERPRET

STATUS REPORT

YES

GO TO MODULE REPLACEMENT

PROCEDURES ON page 25

REPLACE FAULTY MODULE AS

DESCRIBED IN MODULE RELACEMENT

PROCEDURES BEGINNING ON page 25

Figure 4 PDR 3500 Station Troubleshooting Overview (Procedure 2: Reported or Suspected Problem) (Continued)

68P81093C75-O September 27, 2000 9-5

Page 35

Interpreting LED Indicators

Several LED indicators are provided on the front panels and on the

top panel of the chassis. These LEDs give a quick status indication

of the station equipment. The Station Control Module LEDs are

visible from the station’s top panel. Observing the other LEDs

requires the removal of the station’s chassis from the case. See

Figure 5 for the location of all LED indicators on the station’s

equipment. A listing of each LED indicator , along with a description

of the status indicated by each LED, is shown in Table 9.

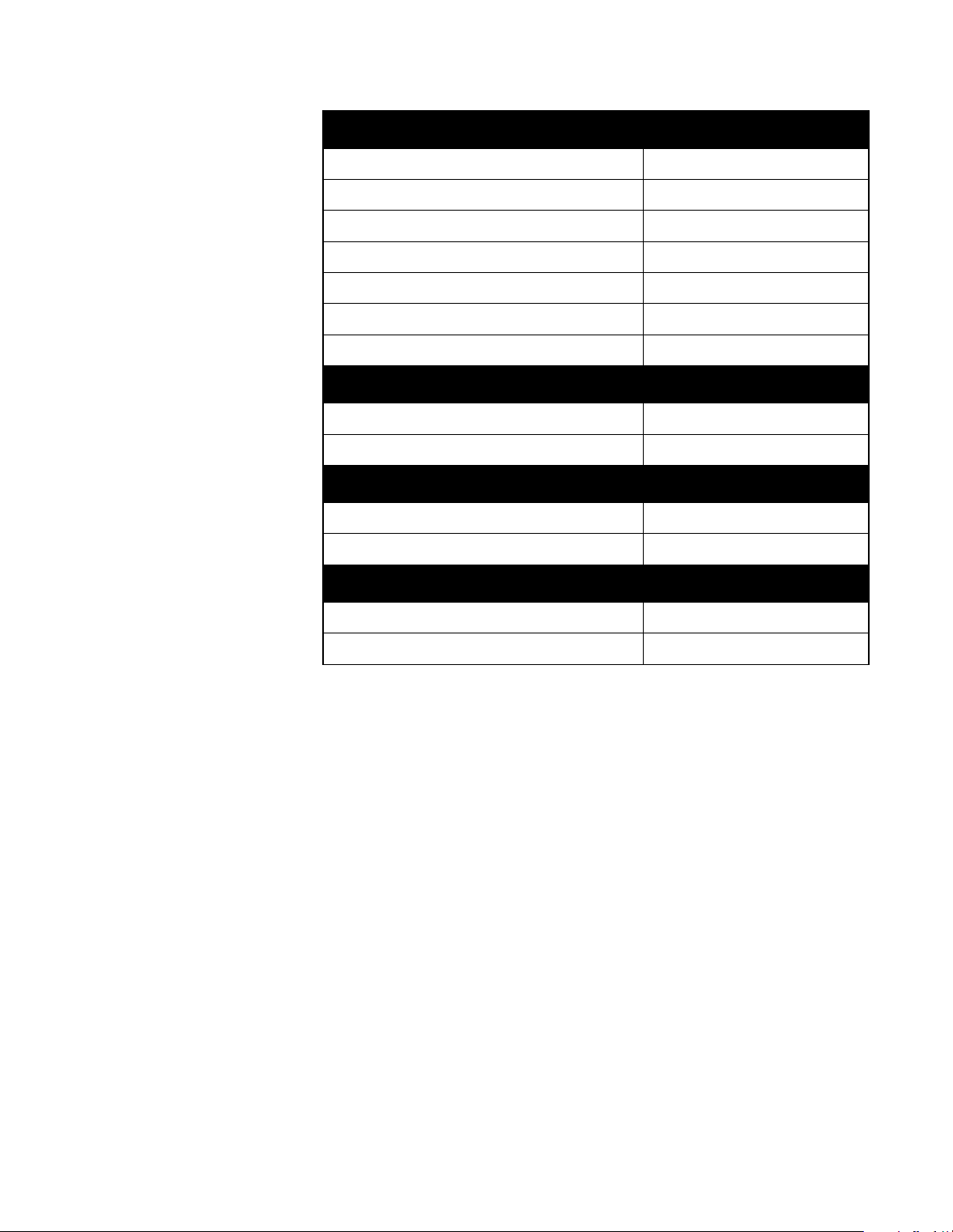

Table 9: PDR 3500 Station LED Indicator Functions

LED Location LED Name Status Definition

Tx Lock – GREEN when Exciter synthesizer is locked; module fully functional.

– OFF when:

synthesizer is out of lock

or

+5V, +14.2V, or both are absent

PA Full – GREEN when transmitter is keyed and PA output power is at expected

power level (as set by technician via RSS during station alignment)

– OFF when:

PA not keyed

or

PA keyed, but PA output power is not at expected power level

(as set by technician via RSS during station alignment)

PA Low – YELLOW when transmitter is keyed and PA output power is less than

expected power level (as set by technician via RSS during station alignment) but

not shut down (for example, during power cutback mode)

– OFF when:

EXCITER MODULE

PA Fail – RED when:

TOP PANEL Pwr/Tx – GREEN when AC or DC input power is present

PA not keyed

or

PA keyed, and PA output power is at expected power level

(as set by technician via RSS during station alignment)

No PA output power (for example, during PA shutdown mode);

LED status is latched, thereby indicating status during current key or

for previous key

NOTE: Any component associated with the PA could cause LED to light.

These include the Exciter, PA, and transmitter circuitry on the backplane.

– FLASHING when PA is in the Test Mode (activated by technician via

RSS; when in Test Mode, power cutback, and open

power loop protection are disabled)

– OFF when PA output power is either at expected level, or at specific

cutback levels (any level other than shutdown); LED status is latched,

thereby indicating status during current key, or for previous key.

– RED when station is transmitting

– OFF when AC or DC input power is absent

9-6 September 27, 2000 68P81093C75-O

Page 36

Table 9: PDR 3500 Station LED Indicator Functions (Continued)

LED Location LED Name Status Definition

STATION ON – GREEN when SCM fully functional

– FLASHING when front panel switch press detected

– OFF for SCM failure

Station Fail – RED for SCM failure

– OFF when SCM fully functional (no failure)

Intcm/Acc D –YELLOW when station is in Intercom mode