MOTO GUZZI V 1000 G 5, 1000 SP, 850-T3, 850 Le Mans II Workshop Manual

~JtiJJtdin

.

m

WORKSHOP

MANUAL

1

I

~

.

IO@

.

I

ADDITIONS AND CHANGES FOR

850

·T 3 MODEL

INTRODUCTION

Purpose

01

this manu lU is

to

give the

carrying oul .epairs In a rational

WBY

.

J'lecessary instructions tor overhauling

,,'

i

All data herein contained a

..

meant

10

give a general knowledge

01

the main

Checking operations

10

be done

wMfI

overhauling the different component

gloops

.

TO

lhis

IHId.

the

maOUllI

cMtaln'

many lIIustratic;lns. drawings. diagrams . and

taDies

to assist

you;"

lhe

siri

po,ng . checking. and assembling CJ9t!,allons.

ThiS

mllnual will alllO

U.

a guid

anc.

to. anybGdy who w1

shn

to

la'ni','II""

W,lh

lhe

manufactu.ing cheraclel isti

es

or

,ne vari

ous.,o

mllorn:nl pans ol Ine v 1000

Cii

5

end 1000 SP models. .

The

knowledge

01

tllese will

be

an ess .. ·.!· .. ,

lac\or

10'

perlo"'·.:

ng

a good job

AU

illus trations and des.,;riptlens in .

...

,~

manual should Ott ,ntended

a~

indicative

only

as 1he

Maflulaclur . .

..

, erve s

Itse!1 Ihe

"!oN

Ie

introduce

'1

any time and

wilhou

t Prier adv

ice

.ny

moditlcatlon il

ma,..

oeem usetul

tor

a belle. performance

e.

1m any olhe

••

OIIason

01

a conSt.uclional or cemmerclal natu •• .

NO

TE

The

term' . righ

t»

li

nd .I, tt. In

the lui lira

10

b, cOfleld

.,ed

a.

Mt1t

by

the

rid

..

H trida

'he

,""c

hine.

INDEX

1

.1

Sp,lfe

paris

1.2

Warranly

2.1

Mode

l v loc::l G 5

2.2

Model

1000 S

f'

3.1

Mo<!~1

V 1000 G 5

3

.2

IAod;"1 1000 SP

4.1

Engine

lUbrication

I

4.2 Aeplacir.g

lhe

oil

tiller

lilter

cartridge

and

cleaning

the

wire

gauze

4.3

lubricating

the

gearl>o~

4.4

lubrlcaling

1M

rear drive

I>o~

4.5

Fork

lubrication

4.6

lubrication

01

steeri

ng

bearings

ar>d swing

!Irm

5.1

Pan",1

board.

model V 1000 G 5

5.2

I

gnition

key ·

model

V 1000 G 5

5.3

Pan

el

board·

model

1000

SP

5.4

lighl

switch",s

5.5 Horn.

tum

lights

and

flashing

lighl

bultons

5.6

Engine slarting

and emergency

SlOP

butlon

5.7 Easy

slarter

I",v",r

3

,

5.8 ThroUle

conlrol

grip

5.9

Clulct.

conl.ol

leve.

5.10 Rlgt>\

Iront bra

ke

control

lever

5.

11

Twin brake

control.

I.ont

le,t and

rea.

5.12

Gea.shiit

ped

al

5.

13 Fuel filler

cap

5.

14

Fuel

level

5.

15

FlU,Il

tap · V 1000 G 5

model

5.16 Fuel

tap'

V 1000

SP

model

5.17

Electrovalve·

V 1000 G 5

5.18 Terminal

block with l

usu

5.19 Steering

loc

k

5.20 Side

stand

· V 1000 G 5

model

5.21.

Side

stand·

1000 SP

m<Jdel

5.

22 Steer

ing

damper·

1000 SP mOdel

6.1

Adju't

ing It.e

clutch

lever

play

8.2 Adjusting

1M

right

I.ont

brake

lever

6.3

Adjusting

Ihe

fronl

lelt

and rear

brake

pedal

6.5

Adjus

ting

Ihe

stee

.ing

6.4

Adjusting

tt.e rea. suspension

6.8

Adjusling

the

thronle

C001.01

grip

6.

7 Adjustfng the

.ear

wheel

spokes·

V 1000 G 5

8.8

Adjusting

Ine

headlight

beam·

V 1000 G 5

6.9

Adlusting

the

headhghl

beam·

1000 SP

11

.10

Rocke.

clearance

6.

11

Adjusting

the

double

contact

breakel

6.12 MainlenanCe

11.13

Cleaning

Ihe

wind s

hield

10

.1 Inll0dUCIlon

10.2 Removal

12.1

Rocker

covers

12.2

Sttipping

the

cylinder

heads

12.3

Cylinder heads

12.4 Valve

guide

s

:--

'

~_-:,::'.::"~_

-..t-~!'\

12.5 Vallie seats

12

.tI

Vallles

12.7 Checking

th

e inlel and exhaust valve opening

12.'

Inspecting tile vallie springs

12.9

Re

titl i

ng

the valve springs assembly on lIeads

12.10

Assembling the cyli

nder

barre ls

12.11

Refitting the cyl

inder

heads on the

cy!lnde~

12.12 Cyli

nder

barrels

12

.13

Pistons

12.

14

Piston rings ana oil scraper

12.1

5 Connecting rods

12.16

Fitting tile con-rods on cranksh a

!1

12.17

Cranksllal1

12.18

Checking the weight for engine balancing

12.19 FittJng tile flywll!l<!l on tile cranksllaft

12.20

Drive 5ide flange compl e

te

wilh

main journal

12.21 Seal for flange. drive side

12.22 Fitting

tile ftange c/w journal in crankcase. drive side

12.23 Assembling Ihe seal on timi

ng

cover

12

.24 Crankcase

12.25

Checking oil leakages from the crankcase

13

.1 Timing data

13.2 Diameter

01

camshaft bearings in their housi rlgs in crankcase

13.3

Tappetllu

ide in

crank<:ase

- coupling data

13.4 Assembl ing the crankshaft assembly. gears with chain on shafl,

engine-liming. oil pump

13

.5

How t

e.

change the chain IOn",'

o' 9"3r ",

i\h enoine assembled

on the

Ilame

13

.6 Valve timing

a.l

Oil deliver pump

14.2 Oil

sump

14.3 Replacing Ihe

oil filter cartri

dge

14." Wire gauze filter

14

.5 Oil pressure relief valve

14

.6

on

breather valve on the c'ankease piping

to

t

he

,e-cycling

device on

lilter

ass,y

14.1 Oil pressure solenoid

1

4.

1 Check ing the oil pressure wi

lh

engine

On

the byke

15

.1 Carburettors

15

.2 Float levelli ng

15.3 Adjusting the earburation and idling speed

.......

6

15

..

CMcking

ca,buratloOl

wllh

a

~acuometer

15

.5 Carbure110'

com~nent$

15.6 Replacing

tile al.

tilte.

ca.tridge

On

assembled

engine

16.1

Removing t

he

clutch assembly

16.2

Inspections

16.3 Assembling the

clutch

0!1

llywheel

11.1

Stripping

the

gea.box

11.2 Che<:king and

o~e'hauling

the gearbOX

components

11.3 Assembling the

gea.box

0!1 t

he

bench

11

.1

Remo~ing

the

gear d.iv"

box

16.2 Inspections

and

oVil,hauls

16.3 Re-assembly

2

2.1

Inspection

22.2 Removing the

bearings

trom

Ihe

swing

fo.k

22.3 Pressing the

o"Ie.

races

01)

the swing arm taper

bear"gs

22

.• Pre

SSin

gl!>e

beafings

inlo

the

R! H

a.m

01

the swing

tork

22

.5

Adjusting

the

swing

a.m

play

23

.1

Remo~rng

the

ttont whee l : Y 1000 G 5 model

23.2 Removing the

lront

wheel - 1000 SP model

23.3

Rear wheel - V 1000 G 5 mOdel

23

.. Rear whee

l· 1000

SP

mo<lel

23.5

Tires

23.6 Tensioning the wheel

spokes

· v \00 G 5

23.7

Wheel ba l

ancing

23

.a

Tire

temo

...

ol ond

rclltting

_ V 1000 G 5

23

.9

Tit" .ernoval

~nd

rehtlrng _ 1000 SP

2

3.1

0 C

heckIng

and

overhauling

the

h.eking.pitcui

t!

23.

11

Maste. cyli!"der lor rig

ht

IrOf't

bre~e

23.12 Master cylinder

lor

tell

If

On! and fear

bra~es

23.

13

Brake cal.per lor If

onl

brakes (modal V

1000

G

is)

and ra

..

bra-

kes (mode ' 1000

SPJ

23.

14 FtO<1I

b~ke

Clliper

lor

1000

SP

model

23.1S Braka ,.ads

23.16 Pipes

23.11

Bfa~ing

discs

23.1'

Braki ng

circllit

'allUs

23.19 Aacommandalions

24.1 Baltery

24

.2 Afternator-genaralor

24.3 Regllialor

24.~

Rectifier

24.5 Startar

molor

24.6 Ignilion system

:z.

.7

Alllomalic

altvane'

24.' Capacitors

24.9 Ignill

O<1

coil.

24

.10 Spark pl

l.lllS

24.

11

Twin contact braak

er

24.12 Assambllng I

Ma

breaker

0"

lMe

crankca

se

24.

13

Ignition

lim

ing

24.14

CMQ(:

king

tM'

Ignition advanCe (slatic + dynamic) using a 51robe

,,,

..

,

24.

15

Lig",

ing &qulpment end Morns· V 1000 GiS

24.16 ligMting equipment and l'Iorns

-1000

SP

25.1

legeno

- V 1000 G

is

model

25.2

legand

· 1000

SP

mOOUI

7

•

9

II

IDENTIFICATION DATA

(

fi\l

. I)

Every mOlofcyele

is

idenillied by an identification

plale located

on the

hame

downlube and a ser

ial

number ' t

lmped

on the en\line

c.an~case

.

The iden·

ti'lcation

plale

numbel

i,

allo

mentioned In Ihe mo·

to.cycle

1og1)OO~

and

Idenli';

es

tile vehicle 10 alltegal

ellects.

1.1

SPARE PARTS

In

case

01

any replacements.

ensure

thai _Original

Moto Guzli

Sp

•• e p.rts. only

Ife

used

.

Tha

use

ot

non-genulne parIS Invalidates every war-

,. nty right.

1

.2

WARRANTY

The

wa"ent

y " val

lo

for

e period

01

6 months

with

a

Ijm

,tallon to 10.

000

~,

..

{6000

miles) l.

om

the

,..

lIing

dale

and

.. pi,

8S

in

case

01

modilicallons to

thl!

mo-

torcycle

or parteeipalion to flcing cOmpe1ilions.

&:~.!

~t

..

"

!l~

as

partt, ..

o.

Jlc

~ .n:;.rl

flc.

wh,ch art

n<;

;

manuf~ea

in

the

SE~MOTO

GUlZI factories

1i'1II

e,,&ttid.ci;rom

1h1'

:

Wlr~ly

.

. .... l

••

_...

. .•

"

II

MAIN FEATURES

U MODEL V 1000 G 5

Mou"l1

on

Ignilloll

Stirling

TRANSMISSIONS

CIUlch

P

rlm.ry

dtlv.

"

Cyllnde. d i

spo$itlon

.'1-

, 90'

Bore 88

mm

Stroke

18

mm

Oispl'cement

9411

.8

cc

Compress

ion . alio 9.2 to 1

Mu

10'Que 8.6 kgm al 5200

.pm

2

OelrOrto c.rburellor

..

\tHe

30 co (right). V

HB

30

CS

(tell),

PreSSUlft.

by

ge~.

pump

.

Wire

gauze

a

....

d

cartlidg

e fille

lS

In

011

sump.

Normal

lub/lc.llon

ptcssure

3.8 ~ <1

.2

kg/'ClCm

(S-.5O

p ...

I.

).

ca

....

troiied by

pre»

urc

...

Iiel valve .

Fro ....

t.

on

cfanlu.h,ft

(14

'1,20

A).

Battery,co,1

Ig

....

,tio

....

wilh twin

con

lac.

breaker

a

....

d

automatic

a!!v"

.... uJ.

Ig

....

illo

....

dala

:

• i

nlt

;al

adv

.....

ce

(Ilxed) 2'

•

":c

utomallc

.dv.nce

31

'

• lull

adv,nce

(

I.

~

a

.)

3,.

...

Cont;W:I

pom"

gap

' n.

31

+ 0.43

mm

( 014..016).

Spark

plugs' AC, 44

XL

BO

$ch W 225 2 T

Chllmplon N 9 Y

LoO'ge

HLNY

M

..

elll

CW

7 LP

Plug

poinl'

gap

0.6 mm

{.023"1

2 'gni

bOl'l

coils

Electr

ic

'Iarter

(12 '14).1

KW) wilh

elecl.omagne\

ic

ratchet

conlrol.

Ring

gear

bolted

on

Ihe

Ilywhee

l.

Slarter

bullon (STAAT)

onlhe

righl

.ide

of

1M

handlebal

.

Ory type.

Iw

in p

r,,".

Hand

COl'ltrO

lllld by

III

....

on

the

letl

sid.

01

the Ilandlebar.

By

gea"

. Rallo: 1.235 (Z

==

11!2

1)

G ...

box

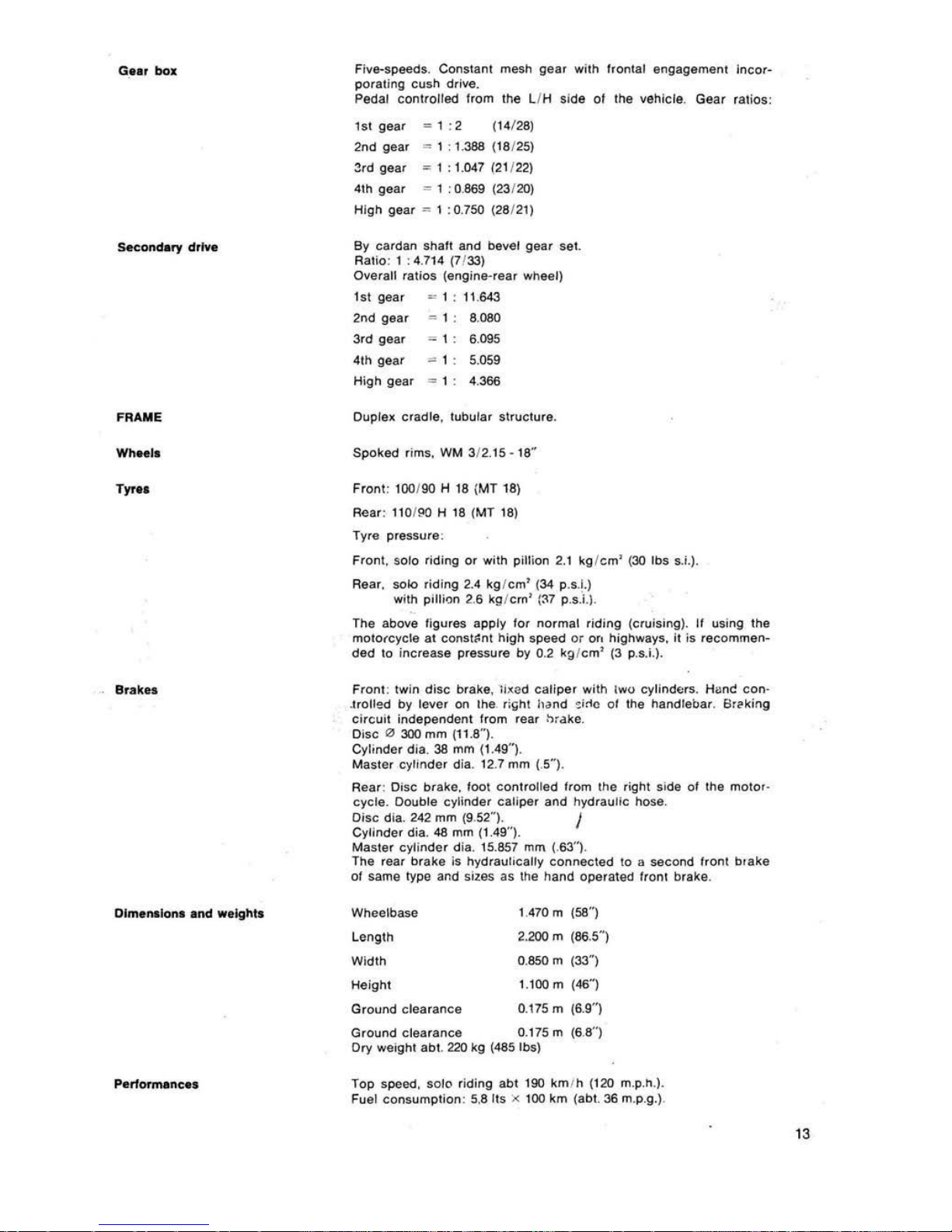

FRAME

8 ••

kH

P"rfor,.,..

nc".

Five-speedS. ConSlan! mesh

gear

wiTh

honlal

engagement

Ineor.

pora!;ng

eush

d';~.

Pedal

con!rolled

Irom

the U H si

de

01

!he vehicle.

Gear

ratios:

IS!

gear

-,

"

(14/

28)

2nd

gear

-,

: 1.388 (

IS

/25)

:lrd

gear

.,

: 1.047 121{

22)

41h

gear

-, ; 0.869 (23/20)

Hi

gh

gear

'"

1 : 0.

750

(281

21)

By cardan shalt and bevel

gear

set.

Ratio: 1 : 4.714

(7/33)

Overall

ra!ios

(engine·rear

whei!1)

1st gear

~ 1 :

11

.643

2nd

gear

..

1 :

..,.,

3rd

gear

- 1 :

6.095

41h gear

'"

1 :

5.059

High

gear

'"

1 :

..

""

Dup

re~

cradl

e.

!ubula.

sl.uc!ure.

Spoked

rims.

WM

3/2.15 ·

18

~

Front

: 100/90 H

18 (MT

18)

Rear; 110/

!>O H 18

(MT

18)

Tyre

pressure

:

Fron!. SOlo

riding

o.

with pillion 2.1 kg /em' (

30

lbs

s.i.).

Rear.

solo

.id

ing

2.4 kg/cm' (

34

p.s.l.)

wi!h

pllli""

2.6 kg/ ern' (

:>'7

p.s.i.).

The above

ligures

apply lor

normal

riding

(cruising).

If

using t

ha

moto(cyela

al

cons'~nl

high

speed

or

0"

highways.

it

is

recommen-

ded

1o inc.ease

pressure

by

0.2 kg /cm'

(3

p.s.i.

).

Front

, twin

disc brake

.

; i~~d

caliper

with l

wu

cylindCr"!:\. Hun!.!

con

·

Jr

olled

by

lever on the r'{jnt

hand

~1

:10

01

the

handlebar.

6'I'Kin

g

circuli

Independent trom

.ear h'''ke.

Disc 0 300

mm

(11.8").

Cylinder

dia. 38

rnm

(1.49'").

Ma

ster cyli

nder

dia . 12.7 rnm (.5").

Rea.; Disc

b.ake. 1001

cont.olled

Irom

Ihe

righl side

01

the

mOlO

'·

cycle

. DOUble

cylinde.

caliper

and hydrauliC hose.

Disc

dia. 242

mm (9.52-). )

Cylinder

dia. 48

mm (1.49··).

Masler

cyli""e

r dia. t5.

857 mrn

(.63

·)'

The rear

brake

is

hydraulically

connec

ted

10 a second fronl

blake

of sam

e type and

51~es

as the

hand

operated

Ironl

brake

.

Wheelbase

Le

ng!h

Wid th

Height

1.4

70m

2.200 m

0.850 m

1.1OOm

(58··)

(86.5")

(33-)

(46 ~

)

GrOllnd

cle

ara

nce

0.175 m (6.9'

·)

Grollnd

clearance

0.175 m (6.8··)

Dry

w..ight abt.

220

~g

(4

85Ibs)

Top

speed. so

lo riding

abt 190

~ml

h

1120

m.p.h.).

Fuel

consumptio

n: 5.8

Its " 100

km

(abt. 36 m.p.g.).

13

FUEL

AND

OIL

CAPACITIES

Group

or

pari

Fuel

lank

RlIsllrve (

wa/nlld

by light)

all sump

Ge

ar bo)(

Rllar drive bo)(

(b

e",,1 gear

lubrication)

Fron

l tork (each leg)

Brak

ing

circui

ls (Iron t and

.ear)

2.2.

MODEL

1000 51'

Engln.

v ...... g

..

rlng

Carbur.llon

Lubric

ati

on

G.nlr

al0r-Allirnalor

'IInltlon

"

QlIanlily

Recommendalion

24

I1s.

(S,S US gI

S.

)

I

Pe

lfol

9B

100

NO·

RM

4 us. (ab!. I

US

gL)

I

3

Us

.

(abt

3'

1,

qls

US)

Oil

_Aglp

Sint

2000 SAE 10 W

",

.

0.750

Its

. (abl 2S oz. USI

Oil _Ag

ip

F 1 ROira MP SAE 90.

0.250 Its.

(6

'h

oz.)

01

whi

ch

0.230

Its

.

(8

oz.)

0"

.

Ag,p

F. 1 ROI,a MP SAE

90

_

0.020 US.

('I,

oz

,)

I

Ag ip

Rocol

ASO 'R

0'

(

I M

ohkote

0"

type A

11080 lIS.

(2

Ol .)

Ag;p F.

1 ATF De

..

on

Ag ,p F

,

Br

ake

!iu>d

!ME

J 1703 B

Two-cy

l:n

der

. 4-slroke

Cylinder disposition _V

_.

90'

Bor

e 68

mm

Stroke

78

mm

Oisplac

eme

m 94B.8

cc

Comp

re~

s,o"

'auo

:J

2 10 1

Max

torql'e

8,{;

"gm

al

S200 ,.p.m.

Ol-iV, push (Cd o

peral_

.L

2

~II"Ol:')

carburellors

VHB.3O

c.:l

(right) VHB 30 CS

(Iell)

.

Pressure

, Oy

gear

pump

.

Wire

gauze and c

artrid

ge filter

s in

oil

sump

.

N

ormal

lubrication

pressure

3.8

->

4.2

kg/SQcm

(54-60

p.s.q.

Controlle(!

by

pressure

lelier

valve.

Front. on

crankShalt (t4 V -

20

A):

Sallery

-coo

l i

gnition

with twin

contacl

breaker

and

aulomatic

advance.

Ignition

data

:

I initi

al

adv

ance (fixed 2'

I

aulomalic

advance

31"

• lull

advance

33"

Con

tact b

leaker

gap

' 0.37-0.

43

mm (.014 + ,

DIS"')

.

S

park

pl"9!"

AC-44

XL

BOSCh

W

225

T 2

Ma,ef(i

CW 7 Lp

TRANSMISSION

C

lul

ch

0

...

boJ(

Ffl:AME

_.

Tlr

..

Bru

••

Champion N 9 Y

Lodge HLNY

Plug

points

gap

: 0.6 mm (.

0231

2 ignition coils

Electric Slarler (12 V -0.7 KW)

wilh

electromagnetic

ratchet

contro

l.

Ring gear

bolted

on

Ihe

I\ywheet

Starter

bUIIon

(STARn

on

thl! right side

01

the

handll!bar

.

Dry type,

twin

driven

plales. II is housed

on

Ihe lIywtleet. Hand

controlled

by

lever

on

the L/H side

01

the

handlebar.

By gears. Ratio: I to 1.

235 (17/2\)

.

S-speeds.

Constanl

mesh

gear

wilh

Ironlal

engagement

Cush drive i

ncorporated

. Pedal

controllad

on the LlH side

01

lhe

vehicle

.

Gear

ralio

:

Low gear

· ,

" 2

(14/IS)

2nd pear

'"

I

10

1388

(lS/25

)

3rd

gea.

· ,

101

.047 (21/

22)

41h

gear

e,

10

0.869 (23/

20)

High

gear

· ,

10

0.750 (2S/ 21)

Oy

cardan

shall

. bevul

gear

set.

Ral i

o: 1 10 ·U14

/7/

:;:3

).

CNerall

gear

ratioS (engine_

wh'lel)

:

Low gear

e'

"

11

.643

2nd gear

e'

'0

II~O

3rd

gear

~

,

'0

6.

095

41h

gear

e'

'0

5.059

Hi

gh

gear

m'

'0

..

'"

Duplex

cradle

. tubular

struclure

.

Ughl

alloy

cas

ling.

Rims

w~

3/2. 15-1S"

CP

2.

Fronl

: 100/90 H IS (

MT 18).

Rea.

: 110/

90 H IS

(MT 18).

Tire

pre

ssure:

Front.

solo

or

with

pillion

2.1 kg/em' /30 p.s.i.).

Rear.

solo

2.4 kg/cm' (

34

p.s.i.).

wilh

pillion

2.6 kg/Cm' (37 p.s.!.).

The

above data apply

for

normal

riding (cru

ising speea).

" using Ihe motorcyc

le

al

constanl

high

speed

or

on high ways.

Ihe

above pressure shoUld be I

ncre

ased by 0.2 kg/c

m'

(3 p.

!.i

.).

Disc

type

with

double

cylinder

caliper

. Lever

controlled

from

the

RIH

side

01

Ihe

handleba

r. Hy(!raullc

circuit

Indepen(!e

nl

fro

m .

th.

rear brake.

15

DI

.... n.lon. and

welg

hl.

FUEL AND

Oil

CAPAC ITIES

Group

or

pari

I

Fuel tan k

. ,

Reserve

DH

5Ilmo

G

....

bo

~

Rear

dn~

be<

Front lork

(each leg)

araking

ci

rcuils (l'Onl

and

rea

r)

.,

Disc

dia

. mm

300

(11.8/.

Cylinder dia.38 mm

(1.49

~).

Masler

cylinder

dia

. 12.7 mm

(.5~).

ANr

wheel

Disc

Iype

wilh

doub

le cylinder

hed

cali"er. FOOl

conlrolled

Irom

lhe

R/H "

de

01

Ihe byke.

Rear bra!!e

and

Ihe leI! I

rani

bra~e

ar

e in

terconnected

by a

hy_

draulic

circuil 8ctual

ed

by

the

s.ame

pedal.

Disc

dia .

242

mm

(9.52'"

Cylin

der

dla

. 48 mm.

(\.88

-).

Masler

cylinder

dia. 15

.867 mm (.

62

").

The

reir

bra~e

is

hy<l

faucally

connected

10

a se

cond Ironl

bra.ke

01 Ume

type and

~i

~es

as the

hand

operated

Iront

bra.

ke.

Wheelbase (loaded)

Leng

lh

2.

180m

(88"")

Wi

dlh

0.

750 m (29.5'1

Wi

dth

(incl. win

dsh

ield) 1.380 m (54" )

Min.

grou

nd

cle

arance 0.

175 m (6.9"")

Dry weig

ht

abl. 210

~gs

.

(

463

Ib!

)

Max

speed. solo

f'ding

abl.

200 km/h (125 m p.

h.l.

Fu

el

consumpHon: 5.

8115

)l

100

km (36 m.p.g.).

Qua

nMy

Recommendation

24 nF!

6 5 u s gls j

I

"e

l",1 98

/100 NO-RM

4

.1''''.

!fb'

1 US

gl·1

I

3 I". ra

bU

",

q:

s.

USAj Oil Agip SINT 2000 SA!:.

10 Wf'!IJ

0.

750 115.

(250~.

US)

Oil

Agip F. I.

Rm'a

MPSAE90

0.250

lis

.

(ab

!.

8'

/:

o~.J

oldluch

0.

230

115.

(8 oz.)

Ag'p

F. 1 ROtra

MP SAE

90

020

Its (,I: oz

.)

Ag ,p Rocol ASDI R oil

0090

115. (abl. 3 oz.t

Motole

oil

type _

.l

_

Ag

' F ATF

De~fon

. Ag,p D. I Srake

lIu,"

SAE J

110

3 B

II

CONTRO

LS

AND ACCESSORIES

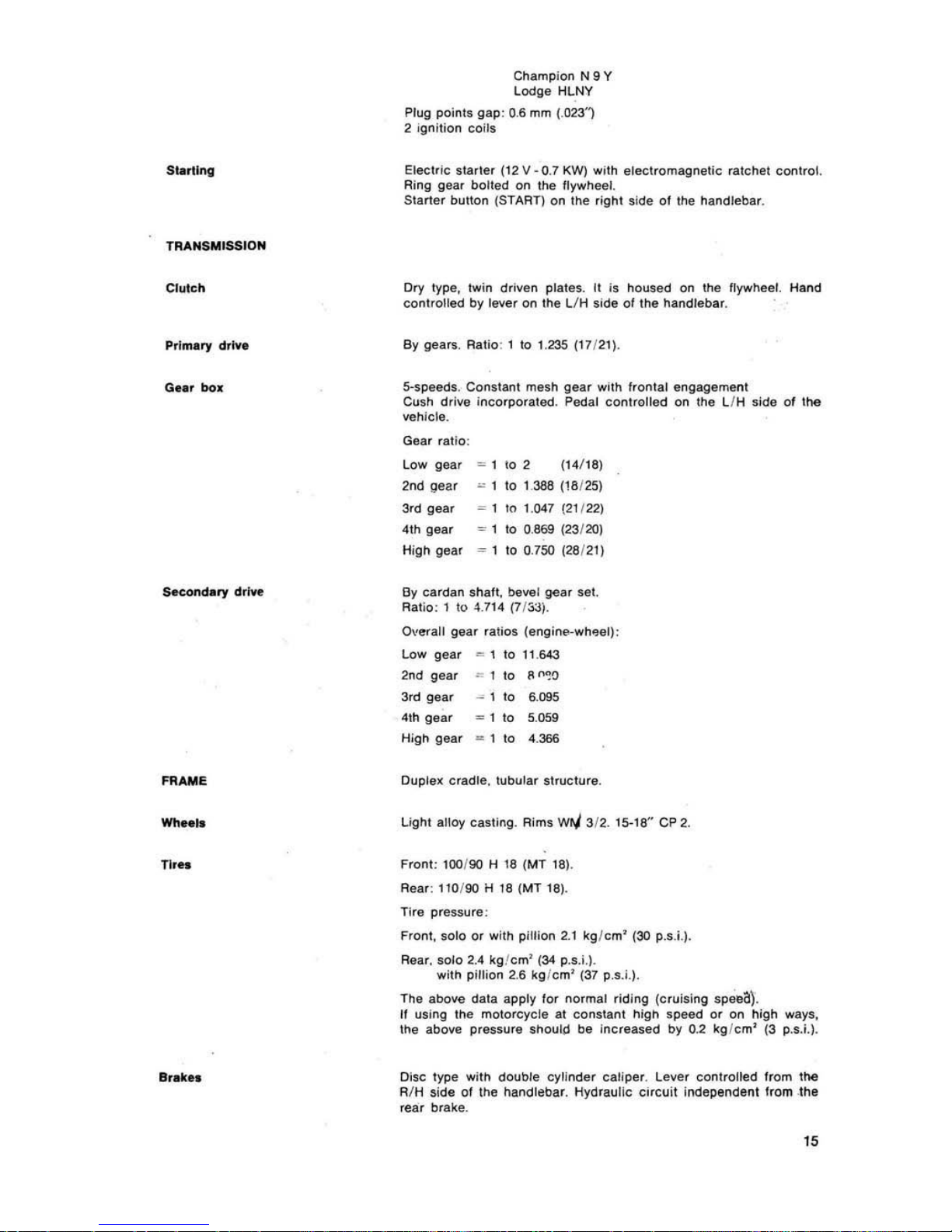

3.1

MODEL

V 1

000

G 5 (fig.

2)

Caliper.

righl

Iront brake

2 Turn fighl Ind

icalor. Ironl

3 Panel with warning lights

4 Speedometer

5 Roservoir (mast

er

cylind e

r), righl

fronl brake

, Lever, right

hont

brake

7 Slarter and emergency

SlOp

button

a Throttle control

grip

9 Light and ignition key switch

10

Rev

counter

11

Pedal,

lefl

front and rear brakes

12

FOOl

rest

13 Reservoir (master cylinder),

1(lI!

Iront and

feaf

brakes

14 Footrest, pillion

15 Safely bar, rear

18 Saddle bag

17

Caliper, left flOnl brake

18

Headlight

19 ClulCh lever

20

Sa

fety bar,

Ironl

21

Buttons controlling horn, !lashing lights, and turn

signal lights

22 U!i;'\

switch

23

Leek, tiller cap cover opening

24 Easy star, cOnlrol lever

25

Gear sel&elor pedal

~':l6

'

Caiij:er, rear brake

27

Tu",

signal ind

lestor

, rear

, ,

3456189101

1

\

Ii

! I

/ !

1718

, \

\ ,

I

/

"'''

"

22 23

13

~

15

"

/

I

!

"

"

,.

"

"

•

•

"

I"

,

' \ \ \

, , \

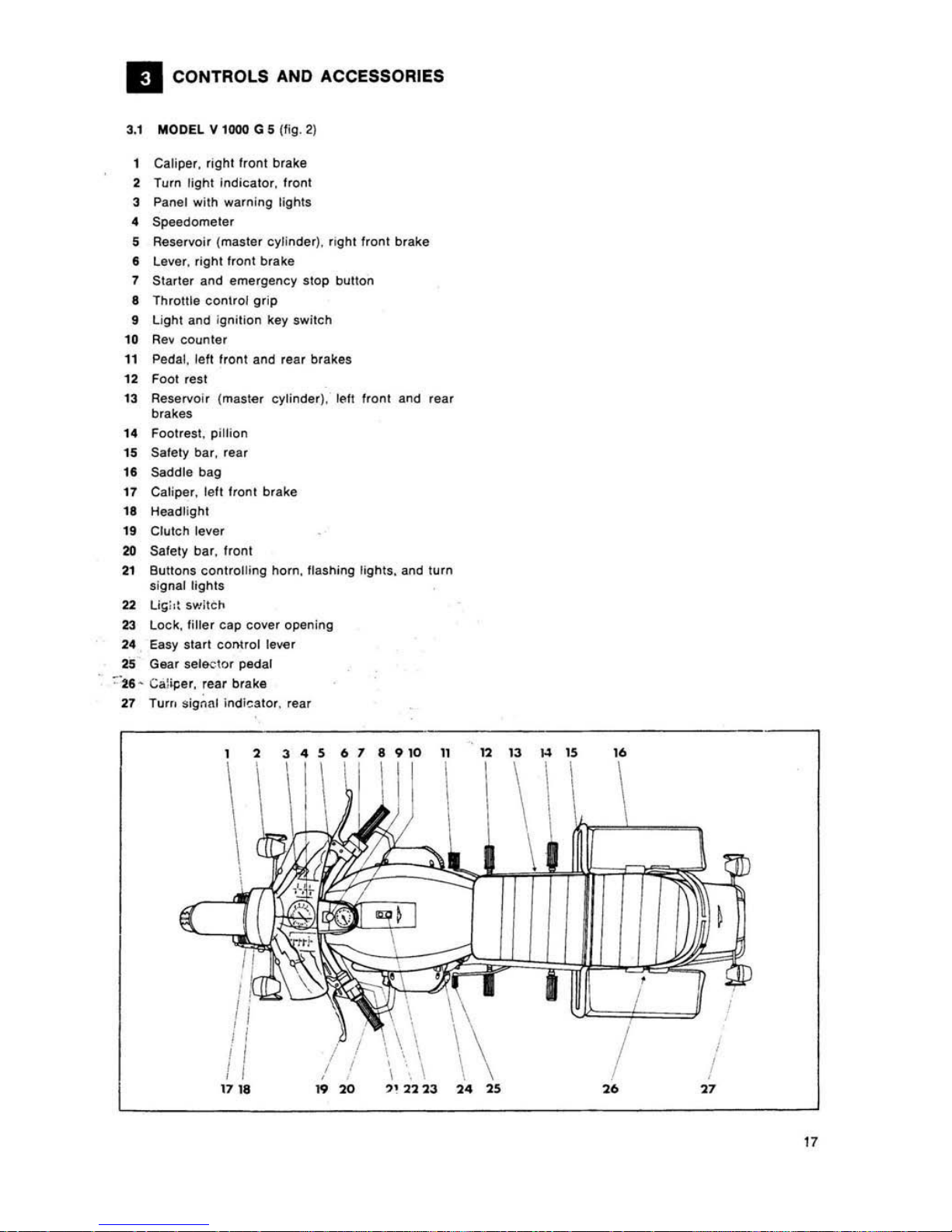

3.2 MODEL 1

000

SP

(lig.

3)

Caliper

, righl front brake

2

Speedometer

3

Voltmeter

4 Rear

~iew

mi

rror

5

Le~er

.

right Ironl

brake

6

Throttle

con

trol

gfip

7 Start

and

emergency stop

button

8

Front

l

al,,~g

9 Pedal, leI! front

and

rear brakes

to

Footrl!st

11 P,itiO'l 100heSt

t2

Turo,

sig

nal tndicato;,

'ea,

13

Caliper. lel1

front

brake

14

Ae~·counte,

15

Cloc

k

16 Windshteld

11

Cfulch

fe~er

18

Cootrol

bul100s

(horn

, 111I,h1'g 1i9"rs. turn

",~nall

19

Light

sw;'~h

20

Ign

itio

o key

21

Lock,

fuel Imer

cap

cover

22

Gear selector

peoai

23

Cen

ter

,ta~d

24 Tail light

25

Sadore release

calch

•

,.

"

n

I

I

,

,

I

,

,

,

I

I

I

I

,,--~

l

\

I

\ \ .

\ \ \" 1

17;8 19

20

u

),

,.

,

L-

____________________

________

______________

~

"

a LUBRICATIONS

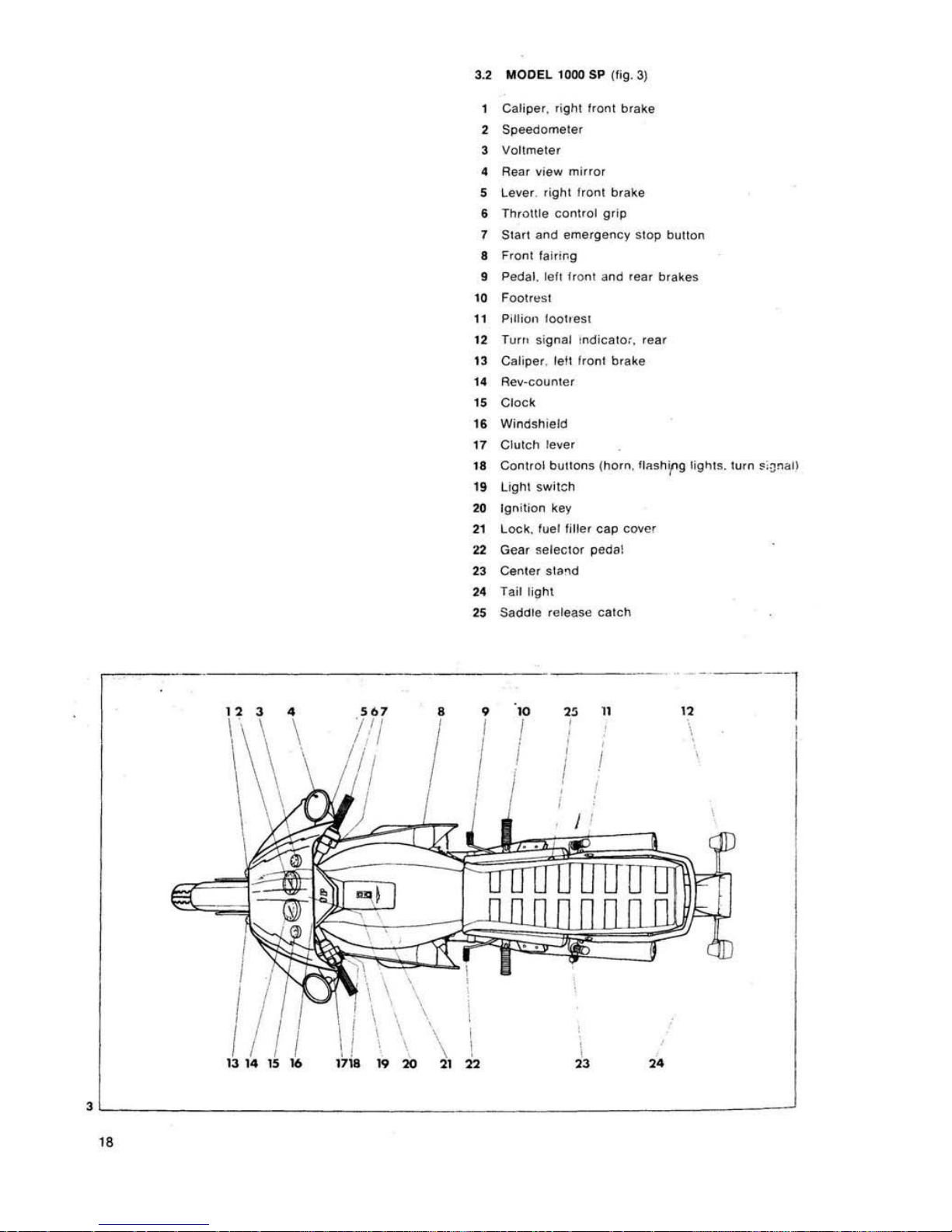

•. 1 ENGINE LUBRICATION (Iig. _ and . /

1)

ChKklng In.

011

1.vel

EY4Iry

500

km

(300

miles) check the oil level

In

the

crankca.a

.

Correct leval

it

nearly at the top

nolch

on lhe IIIler

dipstick ' '''

'.

" the oil

15

lower.

109

up with oil 01 Ihe

sam.

b'lInd

and densiTy. This check ahould

be

done

atte. Ihe engine has idled

lor

a lew minutes.

For

model V

1000

G5 (Ilg.

_I.

liller cap wi

th

dipstick

. A· h

as

to be

lully

sc.ewed down.

Fo.

model 1

000

SP (lig

. 4/1). liller cap wilh dlp5\

ICk

.A.

has

10

be

kept lully p.es sed down

Raflla<:lng ltIa

...

glne

011

Arter Ihe

lirsl

500·

1000

km

(300·

eoo

mUesl and later

on

eY41ry

3000 km (

abt

2000 miles). replace

the

engine

011

.

This

'epllcement

should

be

made on a warm engine.

atter draining all

the old oil.

· A .

..

Fi1!er

cap and

dip

stick .

• B .

..

Oil drarn plug (10' model 1000

Sf'

see Ilg.51.

O"a:"llity

.equi

red : 3 !Is.

Of

oil AGIP Sl

nl

2000

SAE

IOW/5I:J

(.bt. 3'1

.

Qt

s. US) .

•

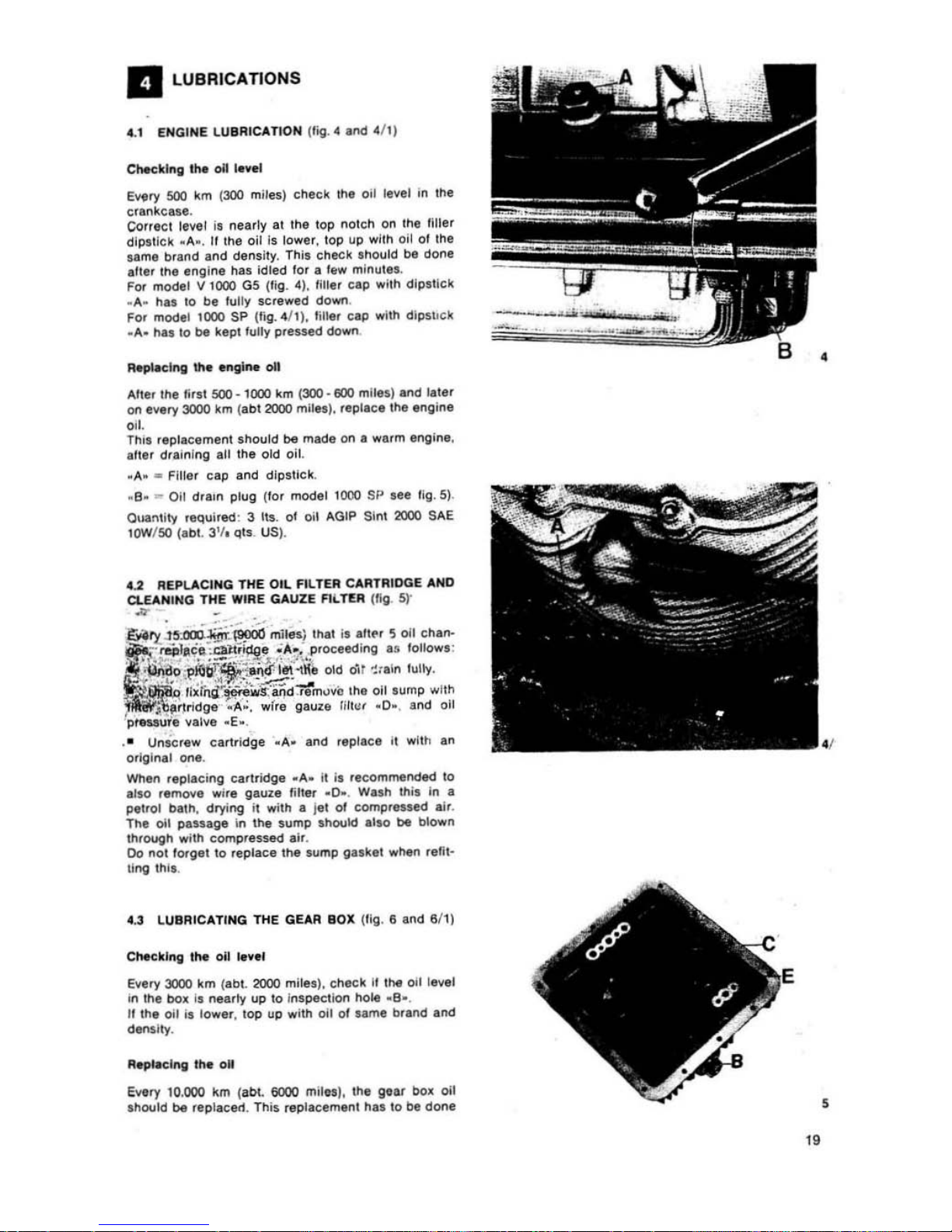

.2

REPUCING

THE

OIL

FIL

TER

CARTRlaGE

ANO

a.EAHING

THE

WIRE

GAUZE FIi..TVI (fig. 5)'

~

;r,...'t-!~~

~

~~

tn!IeS} Ih.1

i.

~"f"

5

011

ch.".

m

"~l.c.:Wtr~, .A~.

p.oceedlng

..

lollow.

:

::li!.~ -

?~

1

•• --.

C$."

"\

" 1

~

.: ,.O;

.fl~~~i~_-tl\e

old

dH

~,.in

tully.

~~~

1I~liul

~

~;"j:S-

:~dTe'm

"vc.'he

oil sump with

~1'i-':;'ndge

. A •. wife gauze

r,It"

• • 0. , and

011

'

pteMme

v.lve

. E •.

. _ UnScrew cartridge

.A.

and replace II wlth an

o.igln.1 one.

When

.eplacing

clirtridge . .... it il .ecommended

to

al!-D

remove wi.e gauze lilte

••

0 • . Wash this In a

pllrol

balh. drying i, with . Je'

01

comp.essed

.Ir

.

The

011

passage In

the

sump should also

be

blown

through

wilh

com

pressed

.ir

.

00

not

lorget

10 .eplace

the

S4.1mp

gastll

w".,.

reli t-

ling

th

ll .

4.3

LUBRICATING THE GEAR BOX (Ilg. II and 6f

l)

ChKklng

the

011 lav,r

EWlry 3000 km (ab!. 2000 miles). c

hKt

II

,

he

oil

te~el

in tha

box

Is

filiI/tv

up

to inspec1ion hole

·B·

.

II the oil is lower, t09

up

with

on

of sarna b

••

nd .nd

densIty.

Rapfacl"ll

,he

011

E¥

.ry

10

.000 km

,a

l>l

. 6000 milesJ, the gear box oi'

should

be

repl.c

...

. Th

iS

repl,cemen ' has '0

be

done

•

,

"

•

20

on

a w

arm

eng,.,.

as In

I~cn

condlUon

Ihe

oil

is

lIuid

and

mo.e

easy

10

dr.in. 00

not

lorg

el

to leI

the

old

011

dr.i" tully

~tor.

any

t.esn

one

is introduCed .

• A-. I

iller

cap

_

·

8·

- inspect;OfI hole

c'l)

.

•

C. -drain

plug

.

Quantity

reqo.med: 0.750 Its.

labl

. " 1.

pints UI)

AGIP

F. 1 Rot

••

MP

oil

SAE 90.

'U

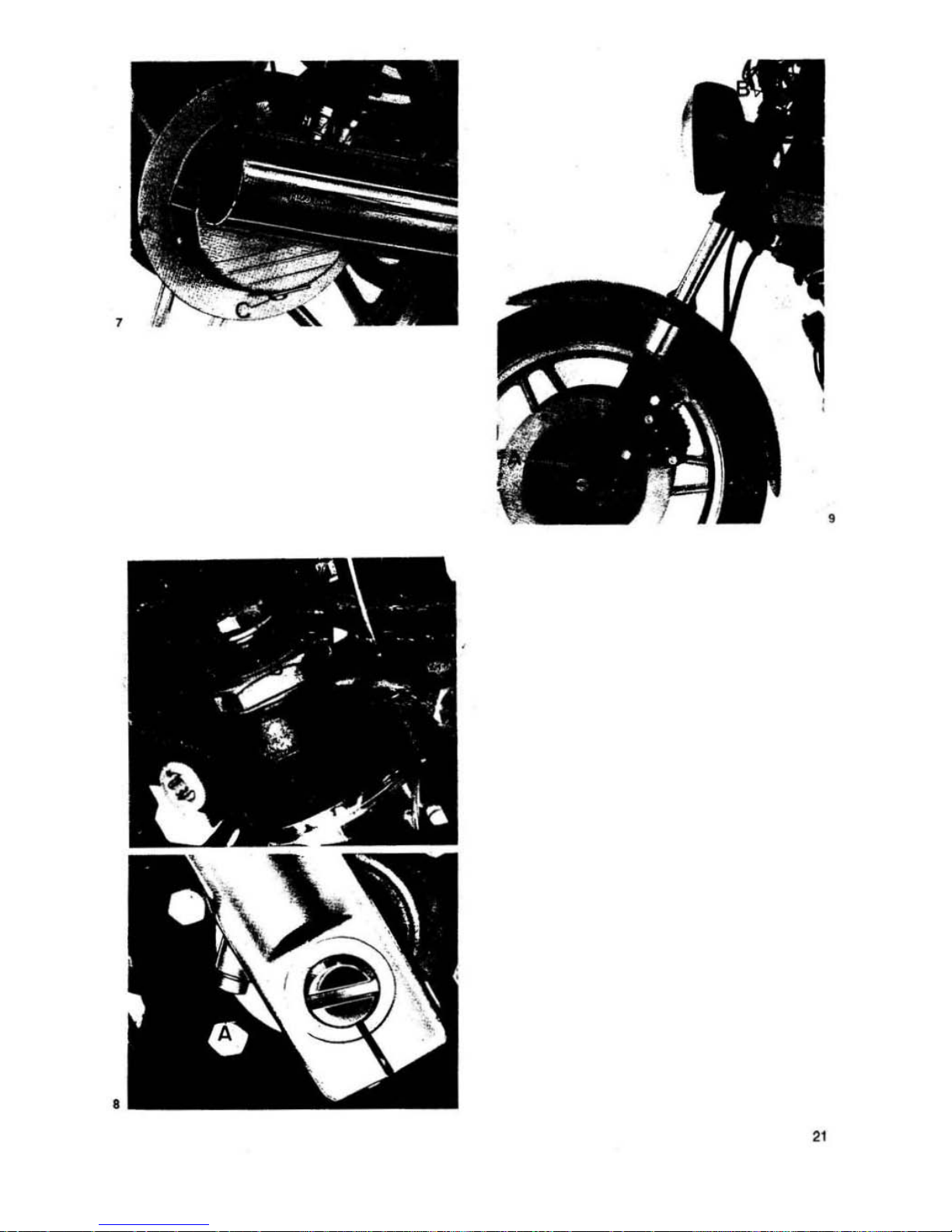

LU8RICATION OF

REAR

DRIVE

BOX

(lig.

7)

E~ry

3000

km

(2000

mile.)

en$f.l'.

Ine

oil level Is

nearLy

up

to inspe<:.ion

hole

. A •.

II

10_.

, lOP

up

with

oil

of

same

hrand

and

densIty.

EVilry 10.000

km

(6000

miles)

replace Ihe

oil

in

1M

fear

drive

box.

Thi.

replacement

i.

best done

on

a warm englrle

when

the

oit II

easie

r to

be

dr'ined. let

the

old

011

d

••

,n

h,lly belo

••

adding

I,e,h

oil

_A_

level

COrll.ol

cap

.

_8_

"lie.

cap.

-c·

Drain plug.

Quanlity

req"';re(l' 0.

250

lis

.

(lb!

. 8

'h

o:z)

01

wh

ien

0.230 Us.

(abl

. 8

011

Oil

of.IJ

lD F. to Rot

••

MP

SAE 90

and

II

•.

0.020

(abo

ut 'f:

01)

"gip

Rocol

"SO

IA. (M

o-

Iyko,e

'vpe

.A_I

.

To

replaer

,ne oUln

the lork

legs.

proceed

U"

l

ollo"'~

:

• ·

Undo

drain

plug

""Ih

gaske

t

·A_.

• UndO

0011 .8_

.

Belore

imrOOu-ting

Iresh

oil.

lei

Itle

lo

rk

legs

drain

lullV

·A·

Fluid

drain

Kreft

.

·8·

Fhlld

Iiller

cap

Quamitr·.eq

uot

ed 0.

090

It.

(aol.

3

oz

.!

each

leg Oil:

AGIP F 1 A

TF

Ouron

Lubrication

01

th

.

""

"n;

I

nd

ru r

'ork

bu rlng.

For

Ihis

operatIon

use

. AGtP F 1

Grease

30_.

21

22

II

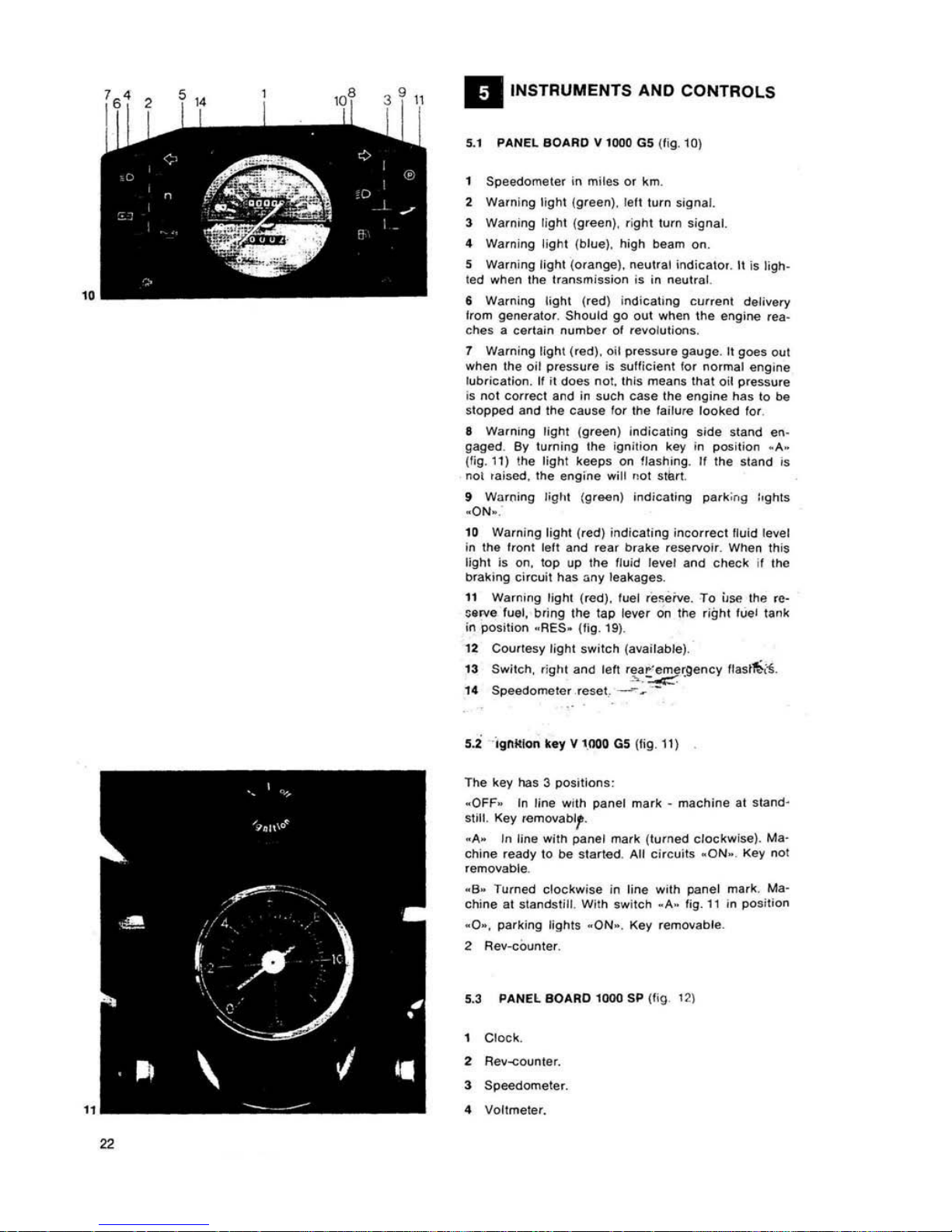

INSTRUMENTS AND CONTROLS

5.

1 PANEL 80ARO V 1000

G5

(Iig. lQ)

Speedome t

er

in

miles

Or km.

2

Warning

light

(g/een). le

ll t"rn

signal.

3 Warning

light

(gre

en). ,

igh

t lUI/)

signal.

.. Warning l

ight (blue)

. high beam

on.

S Warning

light (o.

ange). neutral

;odieal"

•.

II

is

ligh.

led

when the

'ransmi

ssion

is

in

neulra

l.

&

Warning

light (red

) i

ndicahng

cutren!

delivery

I,om generalor, Should go out

.....

hen the engir.e lea-

ches a cellain

number

of

.evolutions

.

1 Warn

ing

Ugh\

(red),

oil

pressu'B

gauge

. II goes o

ul

when the

oit

pressure

is suUielenl 10'

no,mal

engine

lub.icallon.

II

il

does

not.

this mea ns tha I oil

pressure

is

not correct and in such case the engine has to

be

stopped and the cause

lor

Ihe

lallu

,e

looked

fo'

.

I

Warning

light

(gree

n)

indicating

side

sland en-

gaged

. By turning the

ignitio

n key in position .1'..

Uig.l1) (he

light

keeps on lJashinll . " the stand

'S

not

raised.

The

engine "ilt

no

t

$Iurt

9 Wo..ning

ligl,t

(g'9&n) IndicaTing p

arking

t'ghts

.O

N_.

10 Warning

light

,red)

indicat

ing

inco

rrect

lIuid level

in

the

I

.ont

lett

and rear

brake

reservoir. When thi,

ligh(

is

on. lOp up

the

Iluid level

and

check

il

tM

braking cir

cuit

has

any

leakages.

11 Warning

light

(red).

luel

re~eive

.

To

use

the re-

~8

rve

lue

t,

bring

Ihe

lap

Ie~r

on

Ihe

right

luel lank

in

position

.RES.

(lig.

19)

.

12 Courtesy

light

swi t

ch (availab

le).

13

Switc

h.

fight

and

lelt

.~~~

•.

gency

l t

ast~~.

,.

S~ometer

reset

, - _ --

s.i

ignitIOn

k.~

v 1

00

0 G5 [I

ig

. 11)

The key

has 3

positions'

.OFF.

tn

line w,th panel

mark -machine

at

stand·

stilt. Key remova

bl,.

.A_

III line with panel mark

(turned

clockwise).

Ma-

chine

ready

to

be

statled

. All

circuits .ON·

. Key not

removable .

•

S.

Turned

clockwise

in line with panel mark. Ma-

chine

al slandstill. With switch .1'._ lig.

11

In pOsition

.0_.

parking lights .ON

_.

Key removable.

2 Rev-counter.

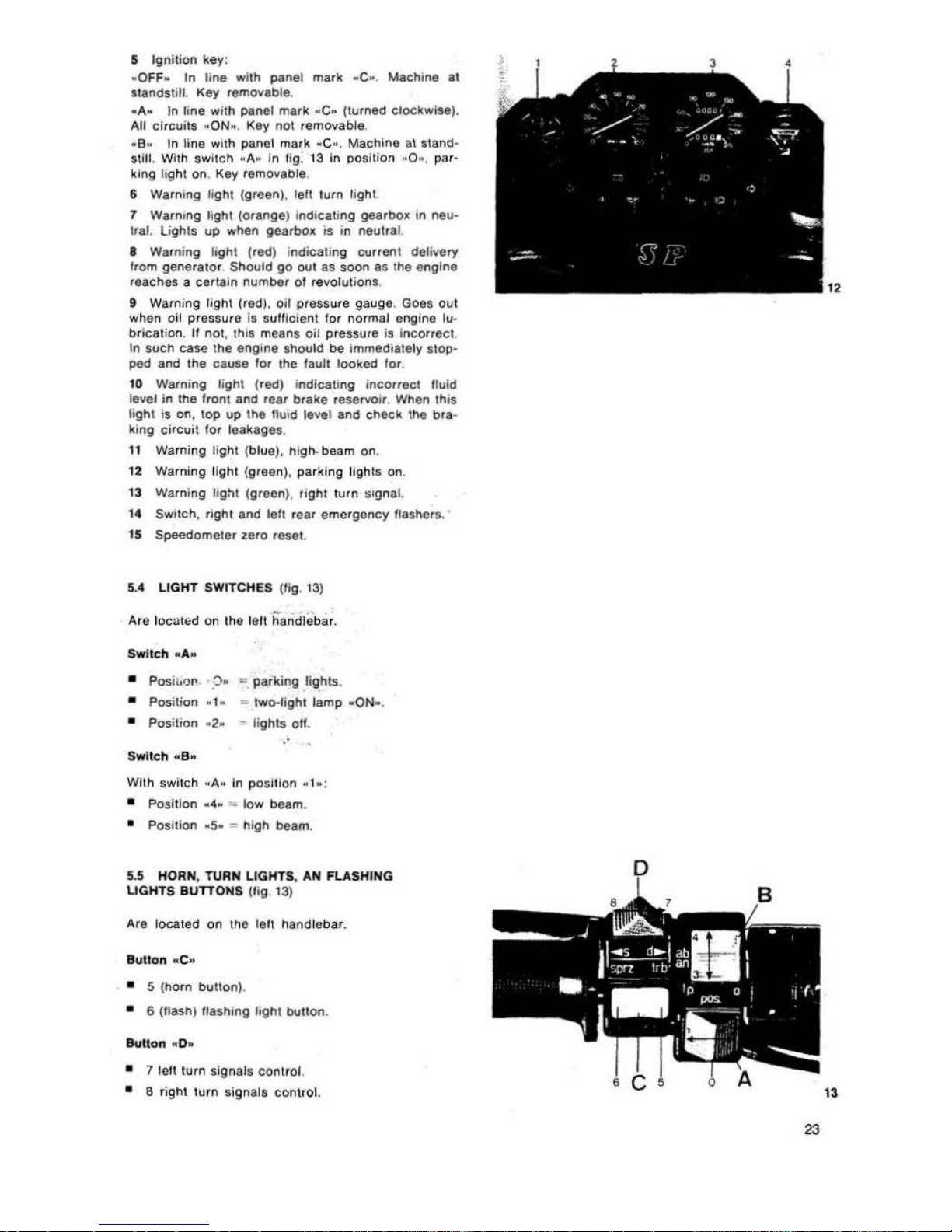

5.3 PANEL BO

ARO

1000 SP

[fig

12\

Clock

.

2 R",,-.::ounte

•.

3 Speedomete

r.

4 Voltmeter.

S Ignition key:

.O

FF_

In

line

wllh

panel

ma.k

_C_

. Millehine at

$Iandslill. Key

'emovab

le

.

•

A_

In

tine with panel milllk

-C-

(Iull'led

clockwile).

All

cilcuits .ON_

. Key

not

removable.

·6.

In

line with panel

mark

_Co

.

Machine

at atand·

,1111

. With switch - A· In fig.

t3

in

oOll

itlon . 0 _. par-

~Ing

light on.

Ke~

removable.

S

Waln

ing

light

(green).

lell

lurn light

.

1

Walnmg light (orangel i

ndiu!ing

gearbo~

1II

neu-

Iral.

lights

up

wtoen

gearbol

is

in

neutra

l.

•

Warni

ng light (.ed

) indicatong

current

delivery

Irom

generato

•.

Should

IJO

out

as

soon as the

engine

reaches a c .. rte

in

number

01

revoluHon •.

It Warning lignt (redJ.

0,1

plenu.e

gauge.

Goes

oul

whan oil

p.essura

Is ,ull

ieianl

lor

normal engine I

....

bticatlon.

II not.

11'1"

means

oil

pressu.e Is incorrect

In

such case tha

engine

should

be

immedlale

l~

IIOP-

ped

and

the

cluse

10. the

laull

looked

lor

.

10 W,I.ning

lighl

(red) ,

ndicating

incolfect

lluid

level In

Ine

Itoot

and

rear

b.ake

reservoir. When this

lig

hl is on,

top

up

the

fluid level

Ind

check

the

bre

-

king

eilcu,l

10'

leakages.

11

Warning tight (blue). high- beam on.

12

Warning light (gleen).

perking

light

s

00

.

n Warning light (green). right

lurn

s'gnill

.

14

Sw,teh.

nght

.nd

lelt

lea'

emergency

lIashoe".

15

S~omelel

zero

.esel.

5.

4 LIGHT SWITCHES

(119.

13)

Ale

loc"to.;d on the

lell

·handle-bel.

Swi

tch d,.

• Posit

...,,,

:':) .

.. pai

kill9

tights.

• Position _I ·

- Iwo-tight

lamp

-ON-

.

•

Posit,on

.2.

- li

ghts

all

.

Switch _8.

With switch ·

A·

In pOlltlon

_h:

• Position

·4.

_

lo

w beam.

• Position

.5.

~

high beam.

5.

5 HORN. TURN

LIGHTS

,

AN

FLASHING

U G

HTS

BUTT

ONS (Iig. 13)

Ale

located

on

the lelt

handleba

r.

Bu

llon

wC.

•

5 (

hCHn

Dullon).

• 6 (liasn)

Ilashing

~ght

Dutton.

• 7 lett turn signals

conltol.

• 8 ' Ight tUln

signals

con \rol.

"

23

,.

"

16/ 1

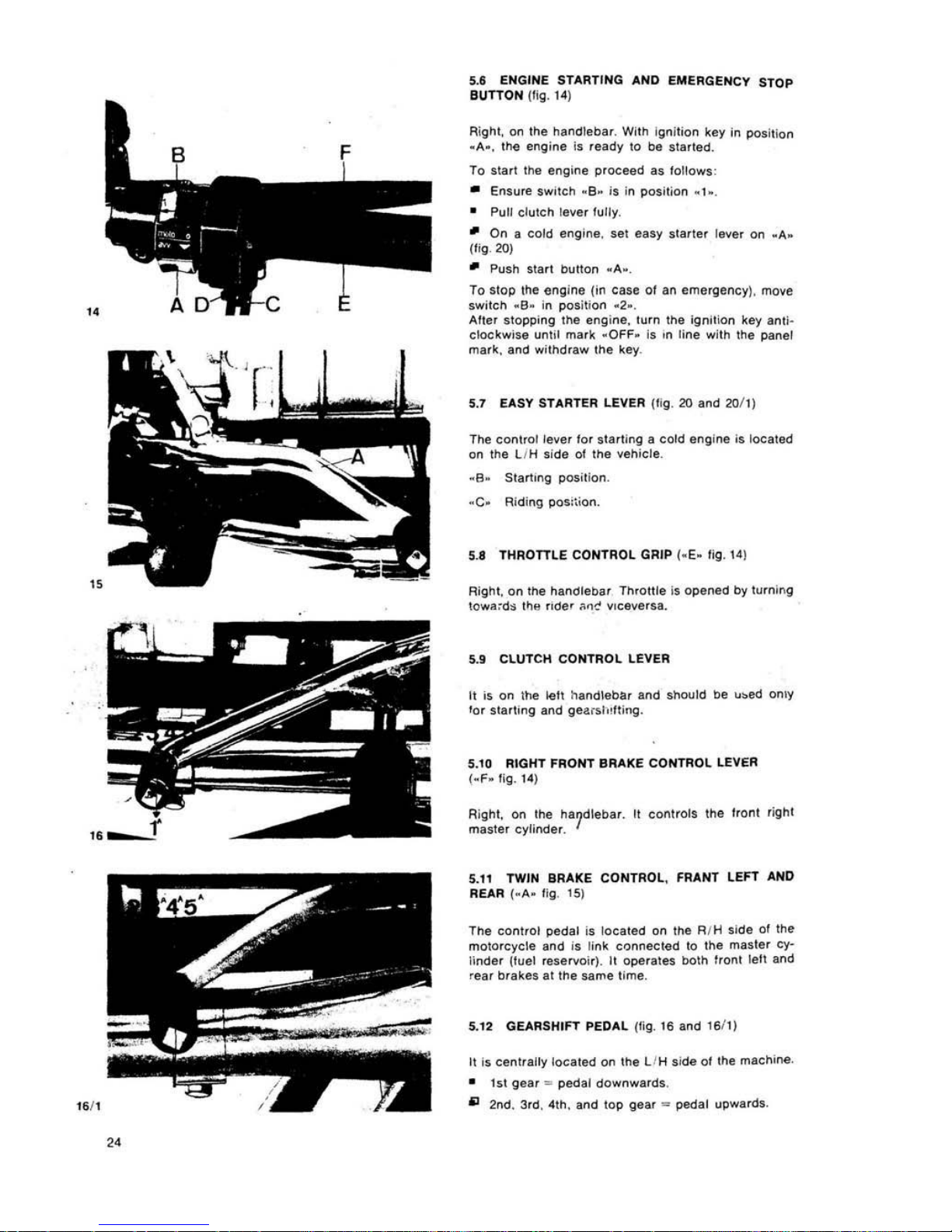

5.6 ENGINE STARTING AND EMERGENCY STOP

aUTTON

(fig.

14

)

Right, on I

he

handlebar. Wilt>

Ignllion key in positi

on

.A.,

the

engine Is

ready

to

be

'!

tarled

.

To start the engine proceed as follows:

• Ensure

!wi,eh

. 8.

is

in posi

tion

. 1

.,

• Pull

clutch

lever

fully

.

.,

On a cold engine, set ea

sy

sl,

'IIt

er lever

On

.A.

(f

iO·

20)

.,

Push 5ta,t

buttoo

. A

·,

To St

op

the

eng ine (in cese

01

an

emergency). move

switch

.B·

In po sition

.2_

.

Aller

stopp

ing

the

..

ngine. 1u,n the igni

tiOn

key

anti

-

clockwi

se

unlil

mark .OFF

. Is in li

ne

with the

panel

mark, and

withdraw

the key.

5.1 EASY STARTER LEVER (tig.

20

and

201

1)

The canUel level

fo,

starUng II

cold

engine

is located

on

the L/H

side

of

the

vehieie.

· a . Slam"'g position.

-C-Riding

PQs;tion.

5.8

THROTTLE CONT

ROL

GRIP I·E·

fig.

14

)

RighI.

On

tile

handleDa, Th,Ol1le is opened by

Iv.olng

low",d~

tl')"

fIde'

"0<;'

Vlceve'sa.

S.

t CLUTCH

CONTROL

LEVER

It

is

on

the

~U

hanOleba. aod

should

be

""ed

OnlY

10. starUng and

g

ea~IOI

lt1ng.

5.10 RIGHT FRONT BRAKE CONTROL LEVER

(-f

' . rig. 14)

RighI. on the

ha7dleba

•. It COl\trolS the I.onl righl

masler

<:yflode •.

5.11 TWIN BRAKE

CONTROL

, FRANT

lEFT

AND

REAR

(-A-lig

. 15)

The

cont.ol

pedal

is localed

00 lhe R/H

side

of

Ihe

mOlorcy<:\e and

is

link <:"ooe<:Ied to the

masle.

cy-

linde.

(tuel

reseNoir)

.

11

operates

both

1'0'11 len and

.e

ar

brakes al

me

s.ame

time.

5.12 GEARSHIFT PEDAL

(fo

g.

16

and 16f l )

It

is <:eo

l,ally

lo<:ated

()(I

the LlH side 01 the

machine

.

• 1st

gear

..

pedal dOwnwardS.

iii

20d.

3'd, 41h,

aod

lOP

gear

..

pedal

upwa.ds

.

Betore

changing

gear

, II is

necessary

10'

the

clutch

leve,

to

be

pulled

fulty in.

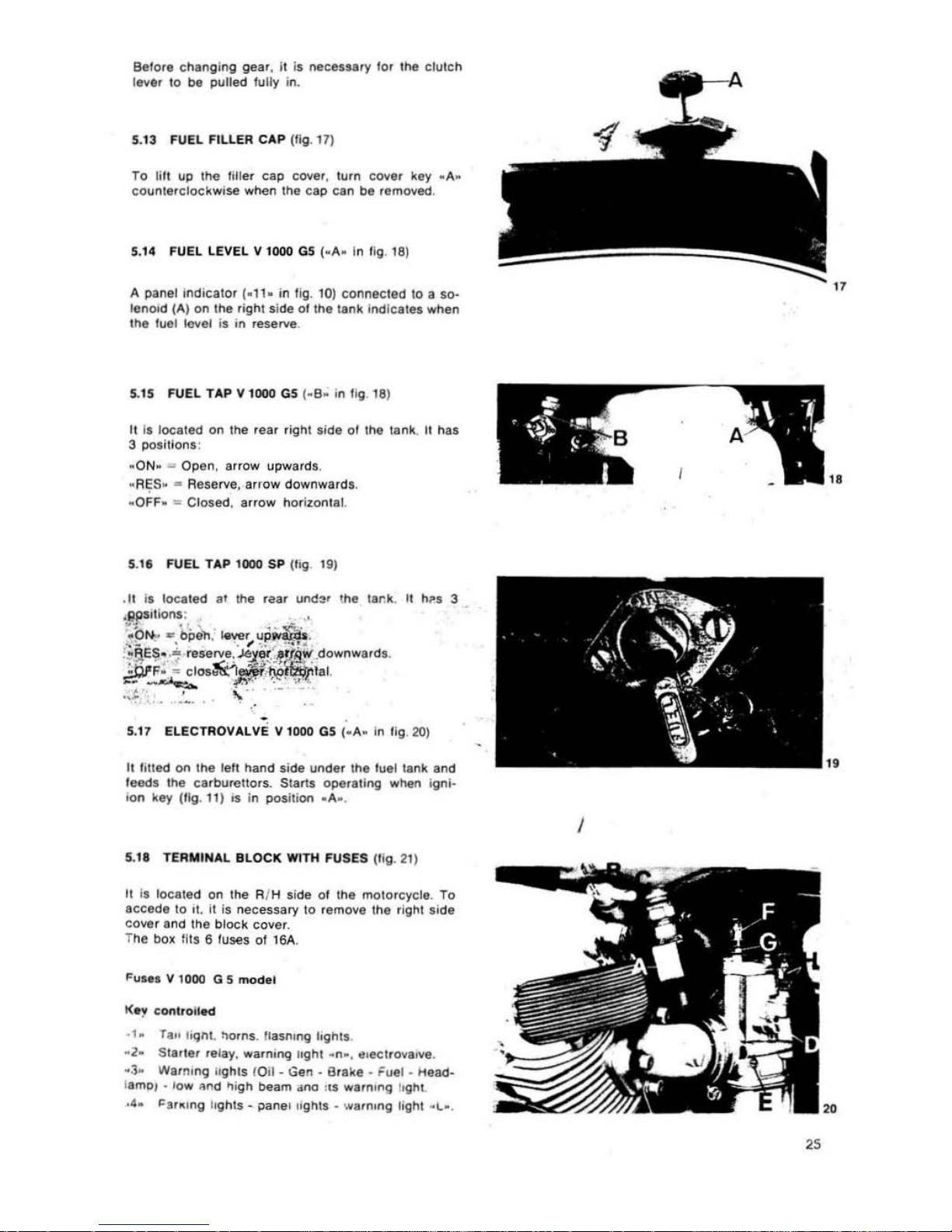

5.13 F

UEL

FILL

ER CAP

(tig. 17)

To li

ll

lip

Ihe

liller

cap

cover. turn

cover

~ey .A~

eounterelockwiH

when

Ihe

cap

can

be

removed

.

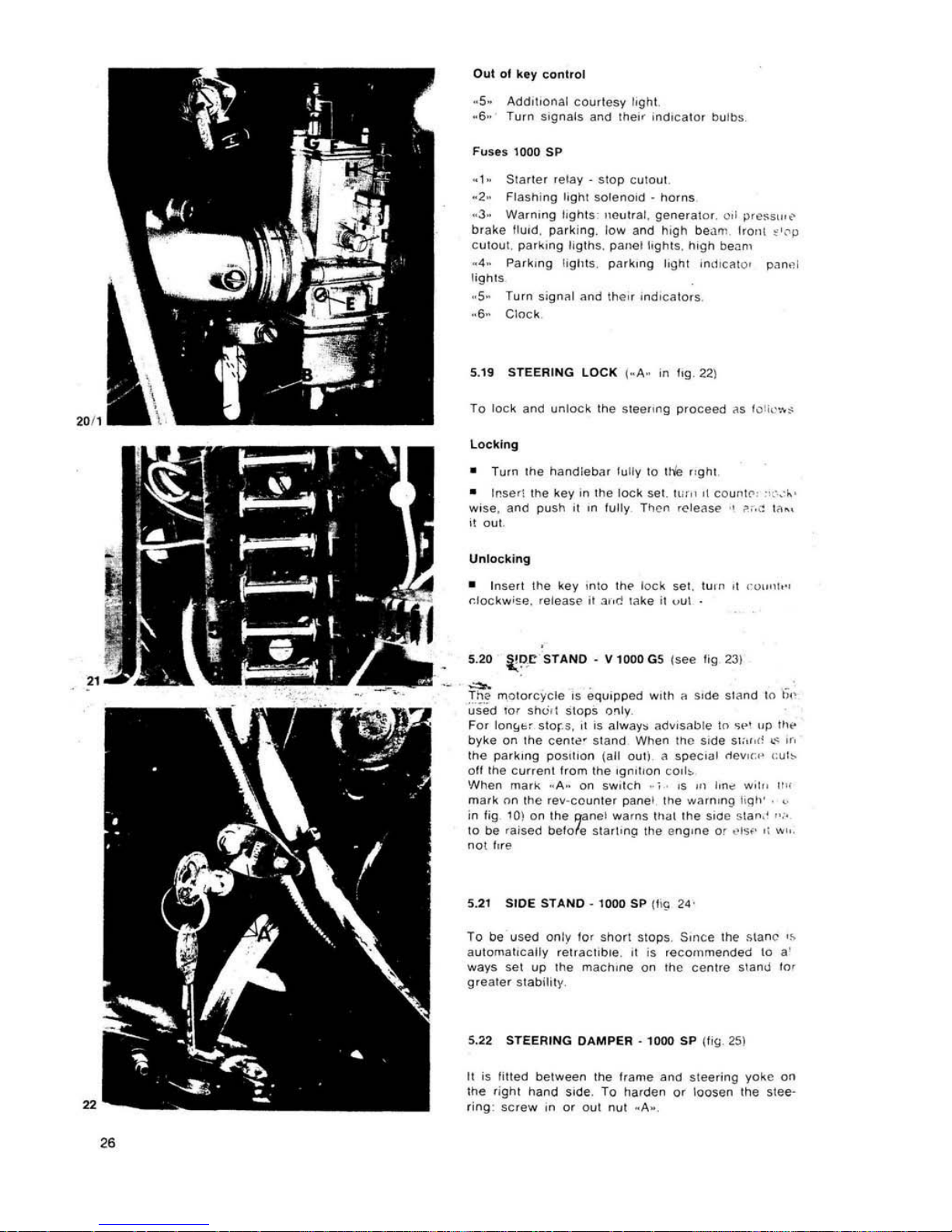

5.14 FUEL LEVEL V 1000 G5 (_A_ In t

ig

. 1

8)

A

panel

Indic

ator

(_

11.

in

fig.

to)

COOl1ecied

10

a 50-

IenOfd (A)

on

the

right

side

01

the

tank indle,tes

when

the

tuel level

il

in

reHrve

.

5..5

FUEL T AP V 1000

G5 (.B.

in

IIg

. 18)

II II

located

on

the

rear

rignt

side

01

the

tank

. It has

3

POsitionl

:

-ON-

..

Open.

arrow upwards

.

-

R~5

.

..

Reserve.

arrow downwards

.

• OFF .

..

Cl

osed.

arrow horizontal.

5.11 FUEL TAP 1000 SP (I

ig 19)

5.

17

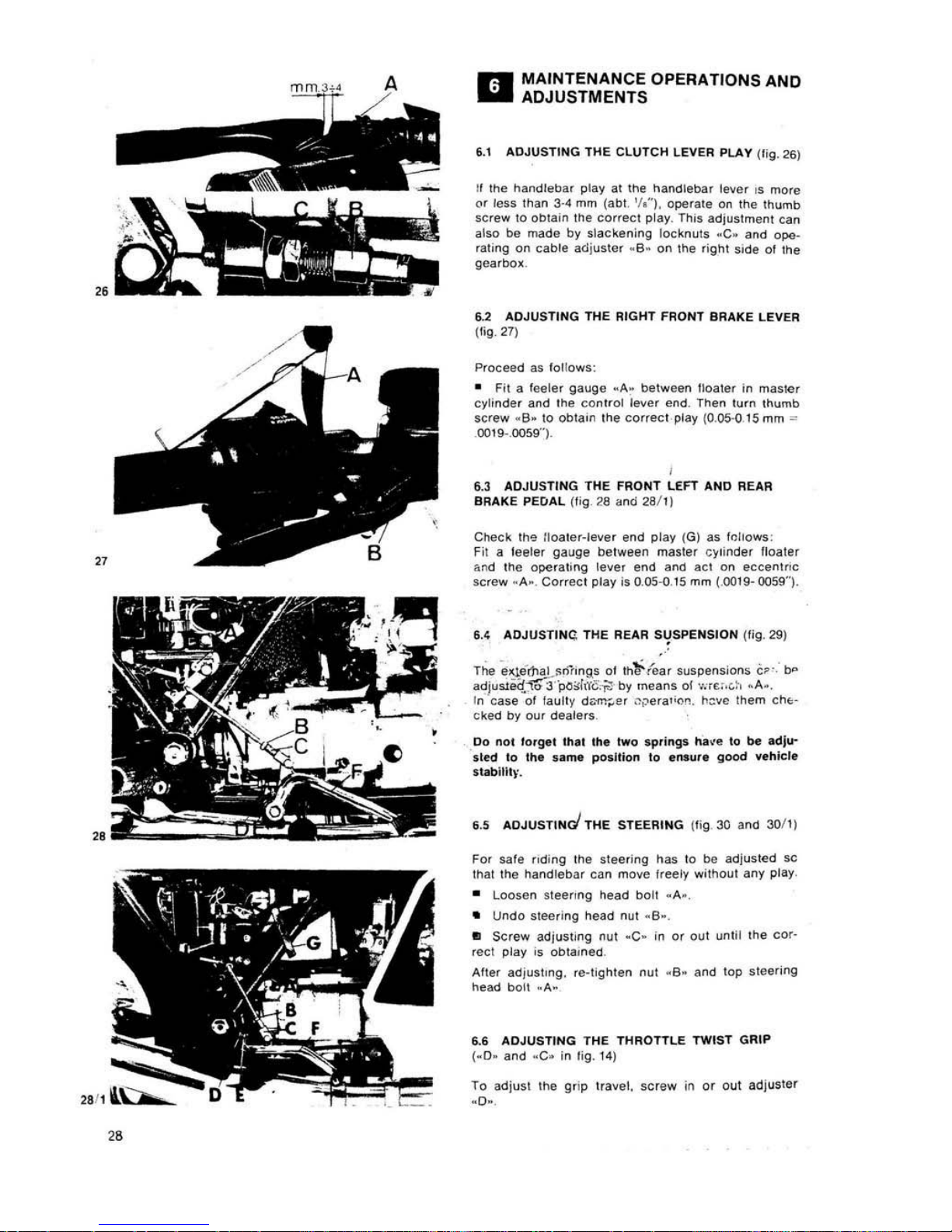

ELECTAOvALv e V 1000 G5 (_A_ In

lig.2O)

It totted

on

the

lett

hand

side under

Ihe

luel

tank

and

feedl

the

carburettors_

Starts

operating

when ignl-

ion

key (fig

. •

f)

Is

In

position

.A

•.

5.11 TERMINAL

BL

OCK WITH FUSES (Iig.

21)

It Is

located

on the AIM side 01

the

motorcycle

. To

accede

to

,t o it is

necessary

to

remove

the

right sid

e

cover

and

the

block

covel

.

T

he

bo~

tits

6 fuses

of

16A.

Fu.,.

V 1000 G 5

mod,1

1(

'1

clHllfolled

·

1.

ra" loqn!.

:'OtOs. Uaslung

I.ghll

.

·2·

S"'

tel

..

fay.

warn.ng

light

. n

•.

tI,ectrova,ve.

·3~

Warntng IIghlS lOil _ Gen _ iJraka _

Fuel·

Head.

I

.mo/

• l

ow

"Irn.1

.,i

gh

beam

.mo tiS

warn"'g I.ght

.4.

"'ar~'ng

li

ghts

- paner ,ights _ warn,ng

light

. L_ .

"

"

I

2S

"

Oul

of key

control

.5.

AddItIonal

courtesy

I.ght

-6"

Tu,n signals

and Ihe" i

ndIcator

bulbs

.1.

Sla

rier

relay·

Slap

cutout

,

·2

· Flasr.ing lIght $Oleno<(I .

homs

·3·

WarnIng

l'ghtS

neul,at,

generator

0,1

press,",,'

brake flu.(I.

parkIng.

low

and

~Igh

be~

'I1

1r0ll'

~'''P

c

uto

ut.

par~,"g

liglhs. pan(ll

lightS, hIgh

be.:!",

. 4·

Pa,k,ng

I1gIlIS,

park,ng

IIgnl

InlfI

C~to'

p.ln~1

li

gnl5

-

s-

Turn

si

gn~1

and

the" ,nd

lcalors

.

Clock

5.

19

STEERING

LOCK j-A- in IIg.

221

To

loc

k and

unloc

k the

steelIng

pfoceed

~s

l"Ii~""$

Locking

•

Tu,n

Ihe

nandleb~r

tully

10

tile

"gol

•

Inser\

the

key'"

the

lock

set

HI

."

,\

co

ur>'

('"

'1,'._

,.

wise.

and

push

,I ,n

tully

Then ,ele<lM' ·r

~;"'

:

""

..

i!

out

.

Unlocking

• I

nsert

the

key

,nlo

In

..

l<>ek

sel,

luln

It

'"u

,,"'h-,

r_lockw;~'l.

release It

3"d

lake

il

vul

5.20

i;!>

.C STANO - V 1000

GS

IS<*!

Hg

231

~

.

Tila

mOlo.c

yele

IS

equipped

Wllh

!l

Side

sland

In

""

used

10.

shUll

SlOPS

o"'y

.

For

lon!<~'

SIOr-

S.

,I

is

always

adVisab le

III

~,.,

"p

tlw

by

ke

on

the

een'<!" Siand When

Inc

Side

SIC,,,rl

..

~

or

.

Ine

parking

poSLlion

(a

ll

oull

a spee,;,1 <lev

",.'

"lib

oft

Ihe

eurrenl

Irom

Ine

'gn,l,on

CO'I~

When

m~rk

· A

..

on

sw,leh

_\ .

'5

,,'

Ion",

",.,,,

",'

mark

nn

Ihe

rev-

counler

panel

Ihe

warning

"

Ilh'

.

in fig

10

) on

Ihe

I¥nel

warns

Ih~1

Ihe

sloe S

la"

,' " "

10

be rais ed

belo

le

Slarhllp

the

engine

or

,"S''

Ii "'"

nOt fI,e

5.

21

SlOE

STANO - 1000

SP

II'!; 24 '

To

be

used

only

lor

shOrl

SIOIlS. Smce

Ihe

Mane

,~

aUlomal,cally

relraCllble

.

II

IS reeornmend!t<l 10 a'

ways

sel

up

Ihe

mach",e

on tho

centre

stano

to'

g,eate'siabill

ty.

5.22 STEERING DAMPER _ 1000

SP

(

I'g

2S)

It is IjUed

between

lhe

hame

and Slee

,ing

yoke

on

Ihe

"ghl

hand

Side. To

Mrden

0'

loosen

Ihe

stee'

,ing' se,ew

,n

or

oul

nut "A_.

"

"

"

ZT

"

28

II

MAINTENANCE OPERATIONS ANO

ADJUSTMENTS

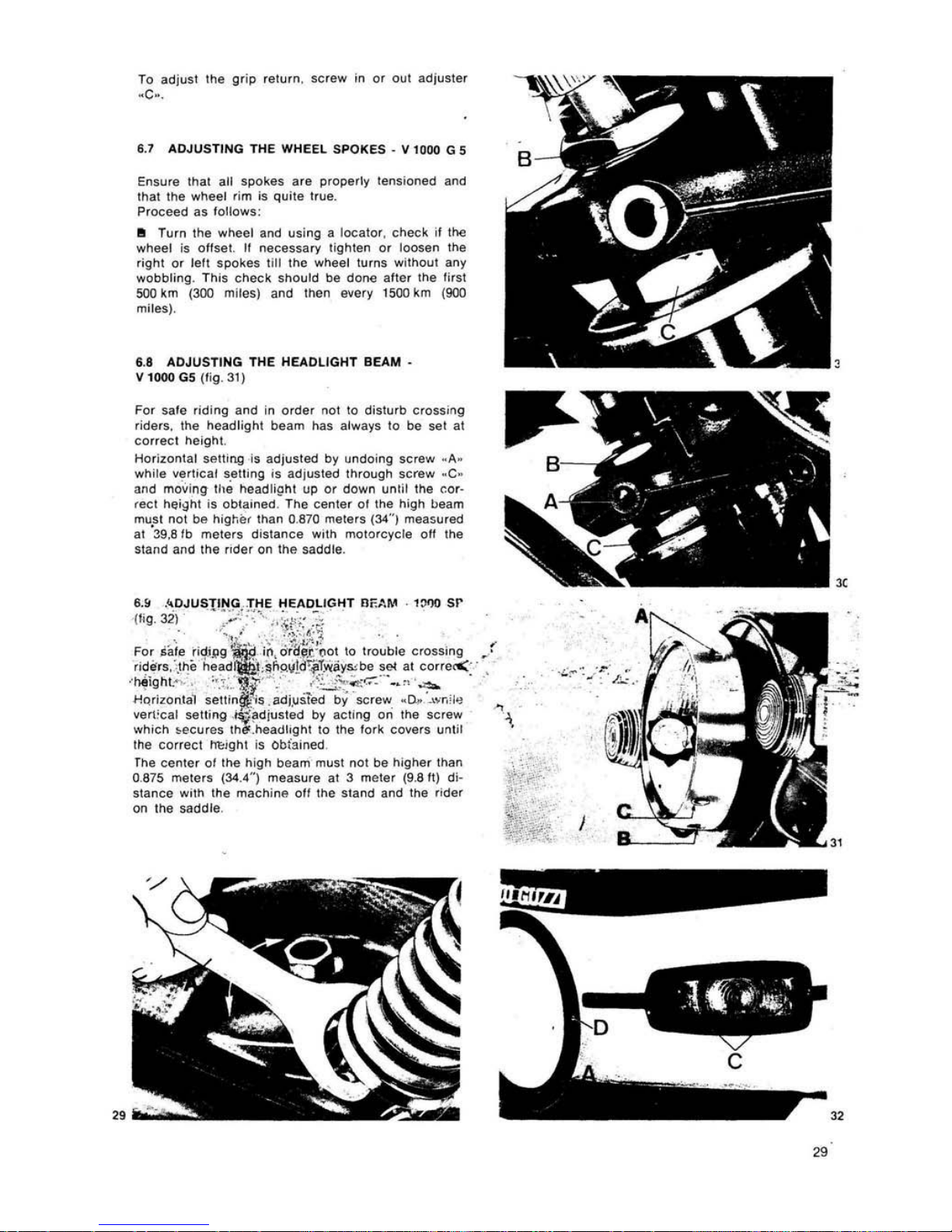

6.1 ADJUSTING

THE CLUTCH LEVER PLAY /tig.

26)

If

the

handlebar

play

at

Ihe

handlebar

lever

IS

more

Of

less than 3·4 mm

(ab1.

'/

0 . operate

On

the thumb

SCrew

10

obtain

the

COrreCt play. This

adjustment Can

also be made by slackening locknuts .C_ and ope-

ra

ting

on cable

adjuster

. 6· on Ihe

right

sIde

01

Ihe

gealbo~

,

6.2 ADJUSTING TH E RIGHT FRONT

8RAKE

LEVER

(Ii

9_

27)

Proceed as tollows:

• Fit a

fee

Ie.

9auge

_A.

between

Boate, in maSler

cylinder

and the

control

I"ve.

end

.

Then

tur

n t

humb

sCrew .

B_to

obtaIn the COfreCI play (0.

05.(1

15mm

'"

0019-.0059'').

,

6.3 ADJUSTING THE FRONT LEFT

AND

REAR

BRAKE

PEO

AL

(tig

26

and 2a/

l)

Check th'"

Iloaler-leve.

end play (G) as ,,,!tows :

Fit a

lee

ler

gauge

between

master

c~linder

lIoaler

;;.rId

Ihe

operating

leve,

end and

acl

on

IIccllnlnc

screw

·A

•. CorreCI play

is

0.

05-0.15

mm (.0019- 0059").

6.4

ADJ USTING THE REAR S,!SPENS

ION

(Iig. 29)

"

The

~qe-mal

~nh

nQ.S

01

lhl-fea,

suspens;oos

C~

·.

b<>

adjusJ.eq1<ri

·

i><l;r(j

c~

by

means

of · • ..,6'

.C

:-.

.A_.

In case 01

laully

d.",.,..er .1;.>era';<')n

. h::vc

them

Cht·

eked by

our

dealers

.

Do

not

lo'ge

t th " Ih" Iwo sprin

gs

h a~e

to

be

adl'"

,

tet:l

10

the same pOsition

10

elllu,e

Oood weh

icl.

slabilil~

·.

6.5 AOJUSTINd THE STEERING (

tig

30

and 30/

1)

For safe

flding

Ihe stee,;ng has 10

be

adjus

ted

lie

that

Ihe

handl

ebar

can

move

Ireely

wi t

hout

any

ploy

•

Loosen ste

enng

head

boll .A_.

•

Undo

steering

head

nut -

6-.

•

Screw

adjuSlmg

nul

-C-

in

or

oul until

Ihe

cor·

reel play

is

ODlalned .

AHer

adjust

ing.

,e· tighten

nut

_6 _

and

lOP

sleering

head

bOil _

A.

6.6

ADJUSTING

THE

THROTTLE

TWIST GRIP

(_D_

and -C. in

lig. 14)

To

adjust

Ihe

g"p

travel.

scre

w in

or out

adjuster

_D·

.

"

TO

adjust the

grip

retum, screw

in

or

out

adjuster

~C_.

6.

1 ADJUSTING THE

WHEel

SPOKES _

II

1000 G 5

Ensure

that

all spokes

are

property ten

sion

ed and

thai

Ihe

wheet

rim

is

quite

true.

PrOCeed

as loliows:

•

Turn

the

wheel

alld using a

locator,

check

it the

wheel

is

ollsel.

II

necessary

tighten Or

loosen

the

right

o.

tell

spo

kes

!iii

the wheet

turns

withoul an1

wotltlling. Tllis

chec

k S

hould

tie dan(!

after

the first

500 km (300 miles) and

IMn

every 1500 km (goo

miles).

6.8

ADJUSTING

THE

HEADLIGHT

BEAM

-

IIloooG5

(tig. 31)

For safe

riding

and in

ord

er

not

to

dislurtl

crossing

ride~.

the

headligll\

tleam

Ilas always

to

tie set at

Carr

eel

height.

Hor

izontal

setting

is

adjusted

tly

undoing

screw

~A.

wh

ile

vertical

satting

is

adjusled Ihrough

screw

_C _

and

movi

ng

!luj h!!adlig

ht

up

or

down

until

the

cor

-

reel

height

is

otltained, The

cenler

01

the

Iligh

!>eam

mU

,sl

nOI

tie

hig~,er

Ihan

0.

870

meters (34"') measured

at

~9,e

Itl

meters

distance

with

motorcycle

ott the

stand

ano

Ihe

rider

on

the saddle.

8.&

.~

DJUSTING

..

THE

HEADLIGHT

nF.M.~

·

1:1')0

sr

(/ig.3il

•

:

':':'

:";~

"~ "~!;;

: ~,.

,

. '

-,

.' .. :,';:.

~

:.

~

..

Fo~

aa!e

.fi~!,9~

. i~,

orll,t!(.~~

\0

trouble

crossing

riden. ,ll)e

head'I\f!i

"t;~f>sl

Il!d!irT~ay~tle

sci

al

corre<'

'

~ighb,

:'.

r::~t~

.· .;~h~

~-:;-:·

· ·-"'~

_ .

HQrizonlal

setlin~.:is.adj.us1ed

tly

screw

.0,.

_,,,r,',<!

vllr1:

cal

seUing

.

~~diusled

tly aCll

r>g

on

II>1l

scrllW

which

~ecures

ther.

headhghl

10

Ihe

fork

covers

until

Ihe

correct

ht:rght is Obtained

rhe

center

or

lhe

high

beam

must not

bll

higher

than

0.

87$

meters (34.4" ) measure

at 3 meter

(9.8

II)

di.

stance

with the

machine

orr

Ihe

stand and the r

ider

on

1he

saddle

.

,

...

33

30

6.

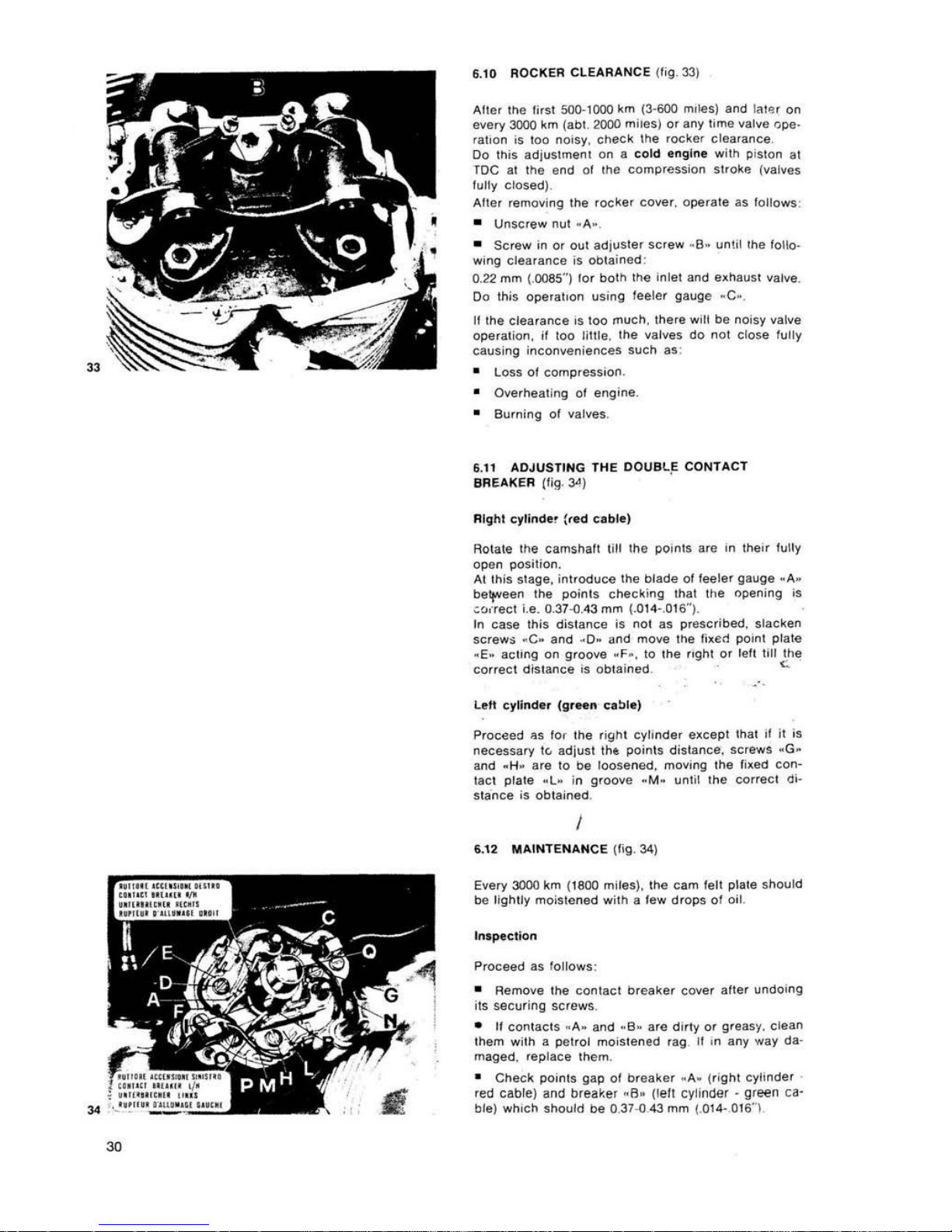

10 ROCKER

CLEARANCE

(fig. 33)

Aller 1M lirst

500·

1000

~m

(3-

600

m!!<'!s) and lal'3'

On

every

3000

km (ab!. 2000 mi

les) or

any time valve r.pe-

ratoon

is

too

nOISy, CI'leCk

the

rocke,

clearance

.

Do

tllis adjustment

On a cold

engin

e with pi

ston

al

TOC

al

the end

or

Ihe

compression

stroke

(valves

fully

closed)

.

Ailer

removing

the

rocker

cover

. ope.ale as 101i0ws:

•

Unscrew

nUl . A

.,

• Screw in or out

adjuster

screw ·B-

unlll

the fOllo-

wing

clearance

is

oblained

:

0.

22

mm

(.0085")

for

both

the

inlet and exhaust valve.

Do

Ihis

Operal l

O"

using feeler gauge · C-,

II the

clearance

05

too

mUCh. the

re

will

be noisy valve

operation,

if

100

liltl

e.

the

valves

do

not

close

fully

caUSing inconveniences sueI'! as;

•

•

•

Loss

01

compression.

Overheating

01

engine

.

Burning

01

valves.

6.

11

ADJUSTING THE ODUBL

,E CONTACT

BREAKER

(lig. 30')

Ri

ghi cylind

e! :'ed

uble,

RDlate the

camshafl

'ill

Ihe POinlS

a'e

,n

lhe"

fully

Dpen pDSition.

Allhis

siage, inlroduce

Ine

I.Ilade

Of

lee

Ie'

gauge

_A·

be,...een

the

pDinlS

checking

Ihat

the

openi

ng

is

~",'

reCI

I.

e. 0.37.() 4

3mm (.014-.016-,.

In

case

Illis

distance

is

not

as

p,esctibed,

slaCken

screw~

.

C.

and .

0.

and

move

the fix

ed

po,nl

pla

le

-E-

acting

on

groove

. F. ,

10

the

"ght

o. lell

l,lI

the

cOrrect

diSlance

is Dbtai

ned

. .:.

...

Lell

cylinder

(g.een ca:Jle)

Procee~

U fDr I

he

rigl>t

cylinder except

that

,I

it

is

necessa.y

1(.

adjust

t

ht

poin!s

dislance, sCrews

.

G·

and . H.

a.e

tD

l.Ie

10DSened,

moving

Ihe fixed

con-

laet

plaia

. L_ in

9roove

·M.

unli1

Ihe

eOffecl

di-

stance

is

oblained

.

I

6.12

MAINTENANCE

(fig. 34)

Eve

....

3000 km (1800 miles).

Ihe

cam

felt

plale s

hould

be

lightly

moistened

with

a few

drops

of

all.

I

nspeelion

Proceed

as

IDIIDW5

:

•

RemDve Ihe

conlaet

breaker

cover

aUer undDi

ng

its

securing

screws

.

• II

contacts

· A_ and · 8 _ are

dirty

or

greasy. cl

ean

lnem wilh a pelrol

mDistened

tag

II III any

way da·

maged. 'ep

laee

them

.

•

Check

poin

ts gap

of

breaker .110

. \

flght

cylinder

red

cable) and

brea~et

-6 . (1

1.'11 cyli

nder· green ca'

ble)

wh,ch

should

be

0.37-

043

mm 1.014- 016

")

6.

13

CLEANING

THE WINDSHIELO

Any

type

soap. cleansing

. agen!. po li

sn

or

polish

ing

wax

normally

used

10

clean

plaslic

Or

glass materials

can

be

utill~ed

.

However.

lhe

following

precautions

should

tle taken:

•

Never

wash

Or

clean

the

w;ndshield

when

the

external

lemperature

is

very high

Of

altar

exposure

10

Iha Sun.

•

Under

no

circumstanc

es. solv

ents

. Iyes.

Or similar

prOducts

should

be used.

•

00

nOI

use

liquIdS

conlalning

abrasive

m'lleriaiS.

pumice

powder. emery

paper.

scrapers

or

$uchli~e.

• BefOre

polishing

ensure

that all

dust

and

impur

i-

ties are

remoV<!d.

•

Ught

scratches

can

be

smoolhed

OUI with

lighl

polish.

•

fresh

paint

01

sealing

compounds.

when

sllll

wet.

can

easi ly be

removed

by

lightly

rubbing

011

with

iso

·

propyli<:; alCOhol.

soluble

mineral

Oil.

bulyl

or

cello·

solva (Nevar usa

melnylic

IIlcohol)

.

•

Use a

solt

sponge

Or

clOlh.

chamois

leather

or

COtlOnwool.

rubbing

lightly

.

•

Never

use

paper

10wels.

synlhelic

lib

ar

clolhes

w~i<:;h

may

scralch

tha

windshield

surlaca

.

Vigorous

rubbing

or

SOlvents

...

,11

n01

remove

deep

scratChes

or

nicks.

31

Loading...

Loading...