Page 1

MMI-8S

MULTI-AXES MOTION SYSTEM

OPERATION AND INSTALLATION

MANUAL

WIN\MMIMAN1.WRI 02-02

SECTION 1: INTRODUCTION PAGE 2

SECTION 2: SR4 NETWORK CONTROL PAGE 6

SECTION 3: SMC STEP MOTION CONTROL PAGE 15

SECTION 4: MMI MECHANICAL ASSEMBLY PAGE 27

APPENDIX: QUICK REFERENCE GUIDE PAGE 35

Page 2

INTRODUCTION

controller is independent. Each supports a home sensor, limit safety loop, and six bits of general

MMI Multi-Axes Motion Controllers provide control of up to eight step motors. Each motor

purpose I/O (input/output). In addition, up to eight MMI motion controllers can be "daisy-

chained" together with simple pin-to-pin DB9 serial cables for a total of 64 motors per serial port.

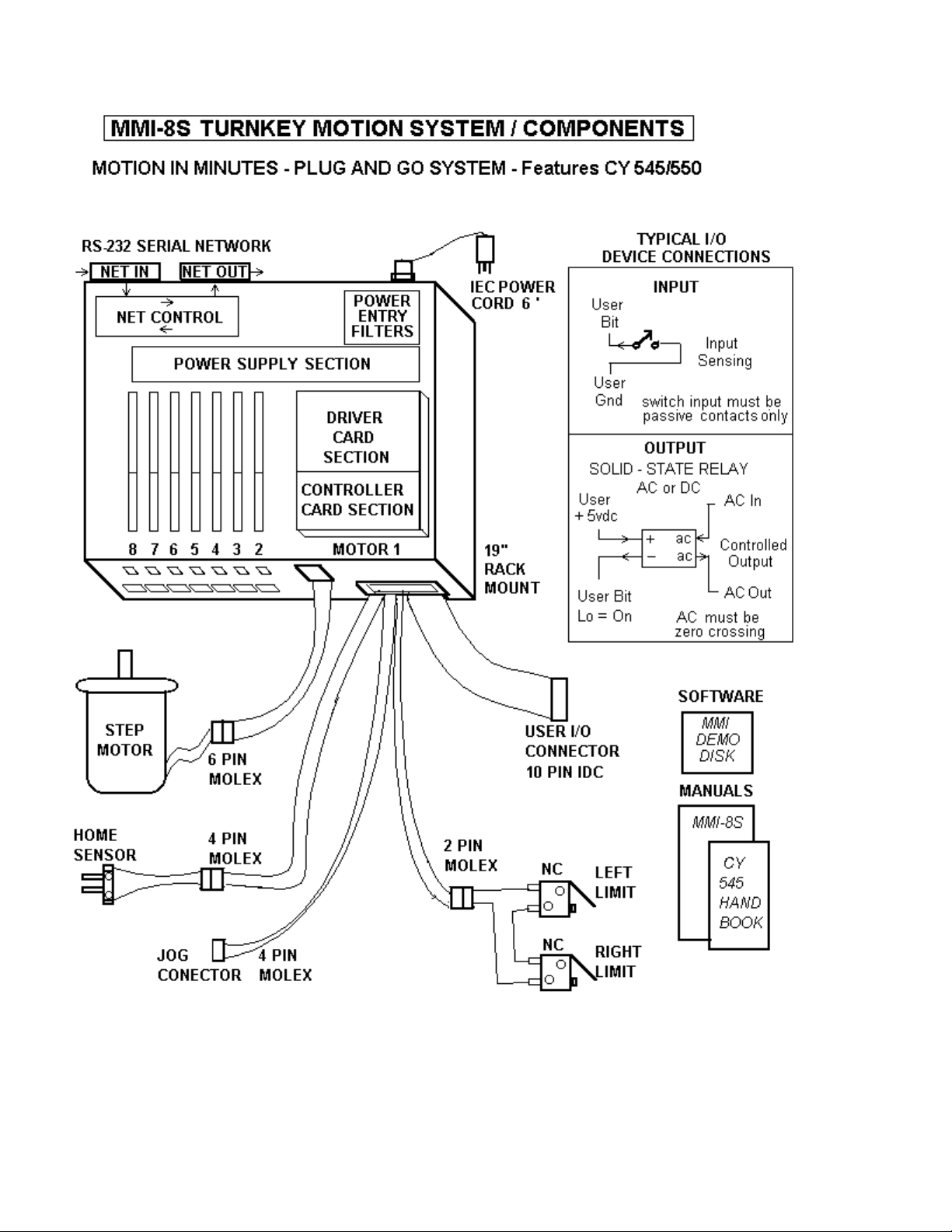

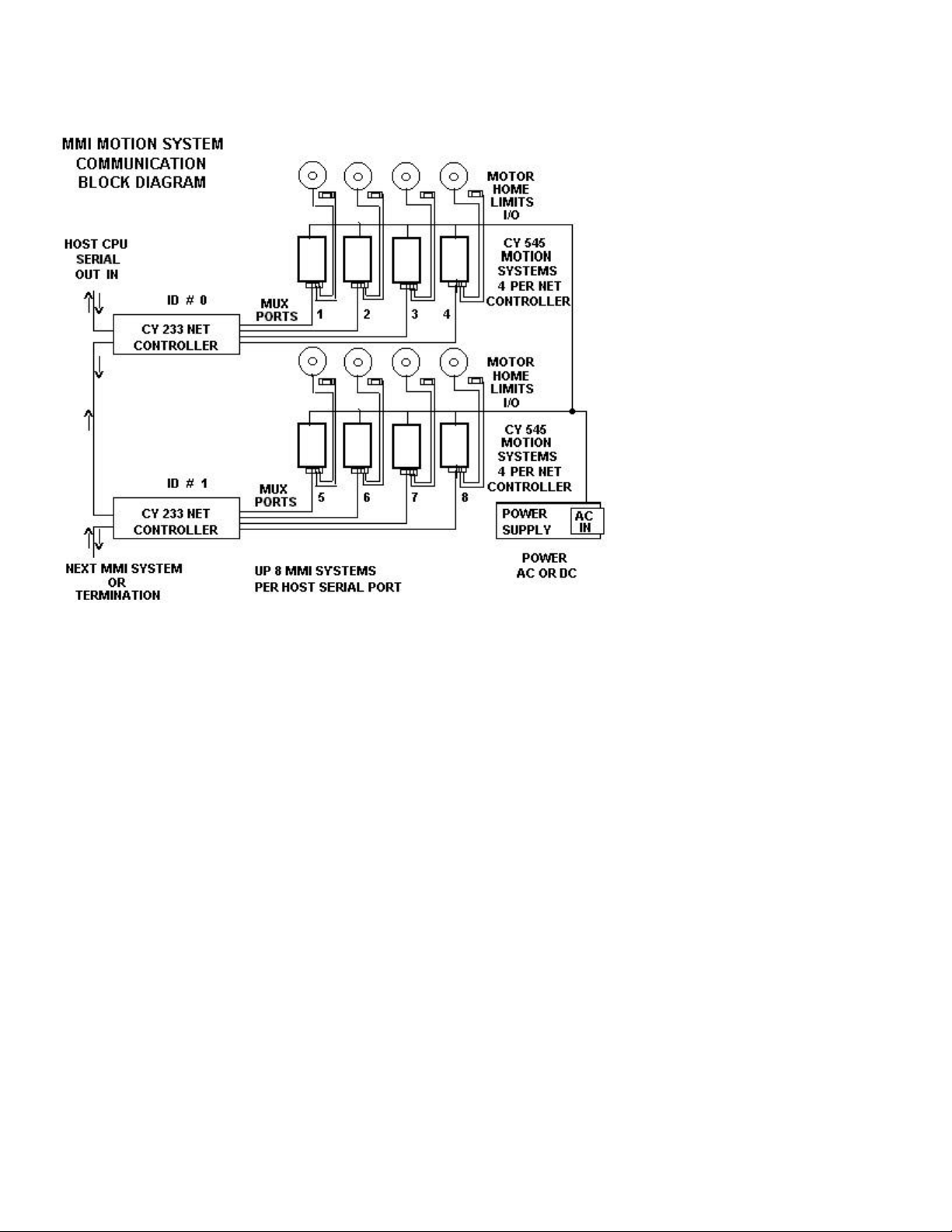

The MMI system consists of three major sub-assemblies: two SR4s (Serial Repeater 4-channel)

network communication controller cards; up to eight SMCs (Step Motion Controller) cards; and

the power supplies. The MMI system is packaged in a 19" format enclosure suitable for 19" rack

mount or free standing (bench-top) applications.

During operation, the SR4 net controllers send and receive commands from the host CPU using

the RS-232 communication port. There are 2 command sets; one for the Cybernetics CY233 net

controllers and the other for the Cybernetics CY545 (550) SMC motor controllers. The CY233

uses only 4 commands. The CY545 has 26 commands; refer to the CY545 Motion Controller

manual for details. The CY number refers to the model of microprocessor used in this system.

Page 3

Page 4

Page 5

DANGER

will either be lost or jam (lock-up) the system. In some cases, the system may begin uncontrolled

CONTRARY TO POPULAR PRACTICE, IT IS BEST TO READ THIS MANUAL BEFORE ATTEMPTING

SUDDEN AND UNEXPECTED MOTION CAN OCCUR DUE TO

PROGRAMMING ERRORS. STAY CLEAR OF THE MOTORS.

WARNING

It is the user's responsibility to insure that commands are not sent to busy systems. The motion

systems can indicate they are busy but have no way to block incoming commmunications which

motion.

ATTENTION

TO OPERATE SYSTEM. IT WILL SAVE TIME AND PRODUCE BETTER, FASTER RESULTS.

Page 6

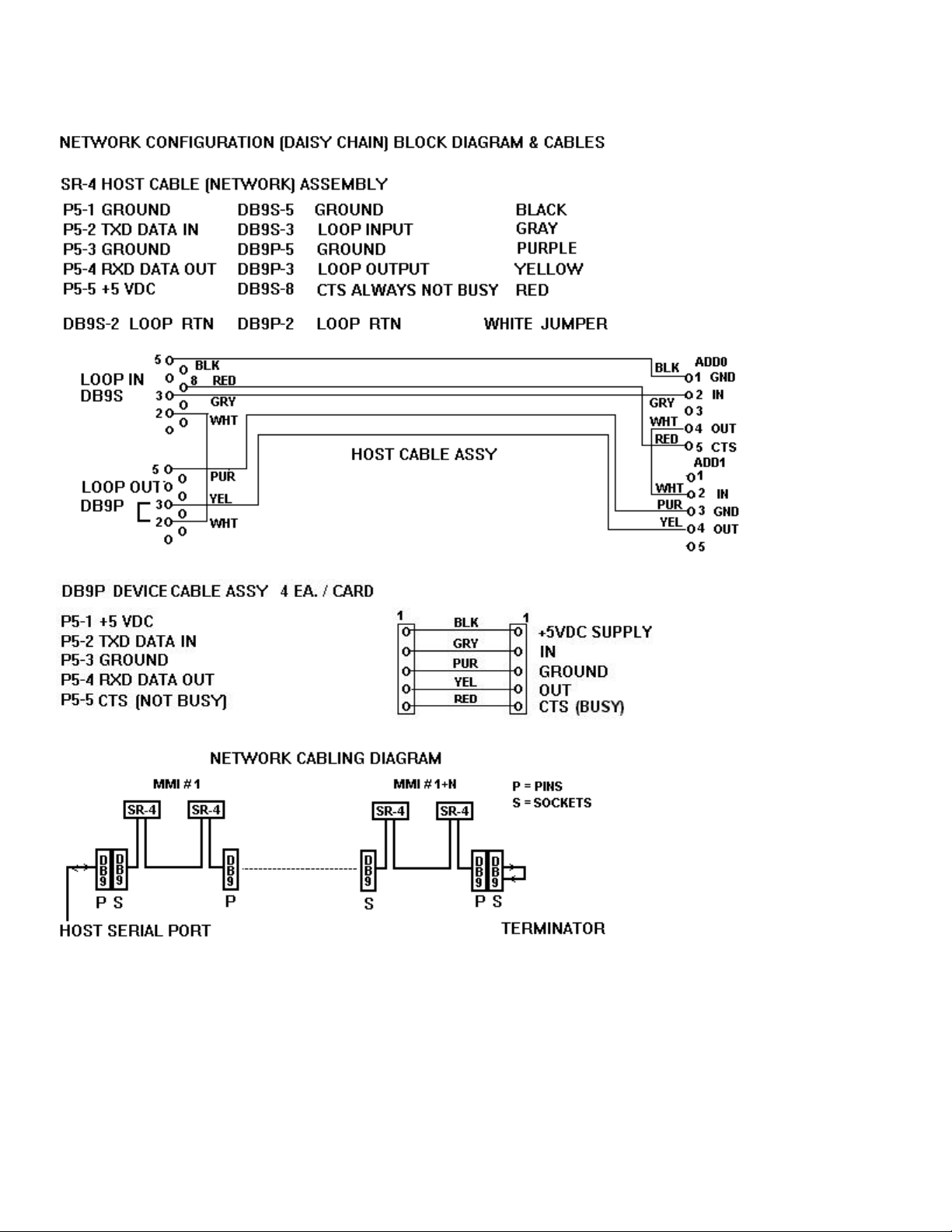

SECTION 2: SR4 - Serial Repeater 4/channel Assembly

CONTENTS PAGE

Introduction 7

Hardware Configuration 8

Service Access 8

Table of ID and Status Codes 11

Displays & Controls 12

Mechanical Assembly 14

SR4 (CY 233) COMMAND SET SUMMARY

WRITE W Send commands to the motion system.

READ R Read status (busy) of the motion systems.

ECHO J Used to set SR-4s into pass-through mode.

ENTER < Carriage Return terminates commands.

Page 7

INTRODUCTION

multiplexer. Each motor command string must start with a net controller address. The controller

In the MMI system, two SR4 controllers are used. Each can control up to four SMC systems.

During operation, a three byte net command (address), consisting of three bytes, is prefixed to a

motion control command string. When the selected SR4 detects its address, a serial path is

connected to the addressed SMC by a 1 to 4 serial data multiplexer. The motion command is

then passed to the SMC. The command terminator character (carriage return) resets the

address compares to the setting of the SR4 address switches in the MMI. The multiplex code

selects any combination of the four output paths to the SMCs. For example, one motor system,

at a time, is selected for setup commands and then up to four motors can be directed to execute

(Go) simultaneously. When requesting information from a SMC motor system, only one of the

eight can be selected.

When a motor system is performing an operation, its Busy signal is input to the SR4's status

register. To monitor the busy status of the SMCs, a Read command (address), again consisting

of three bytes, is sent to the net controller. The SR4 will return an ASCII character equal to a

binary number. This number indicates the status of all four SMCs. Refer to the net ID address

table in this manual.

The host to MMI serial port is wired with standard RS-232 (IBM type) DB-9 connectors. Each MMI

has two connectors. The first goes to the host computer and the second to the next MMI

controller in the daisy-chain. The last controller's second connector must terminated with the

"loop jumper" DB9 plug.

The MMI normally operates in standard RS-232 format using ASCII character mode at 1200 baud

which supports the EEPROM memorys on the motor cards. Optional baud rates up to 57K baud

are possible. Parity is none, 8 data bits, and 1 stop bit.

Page 8

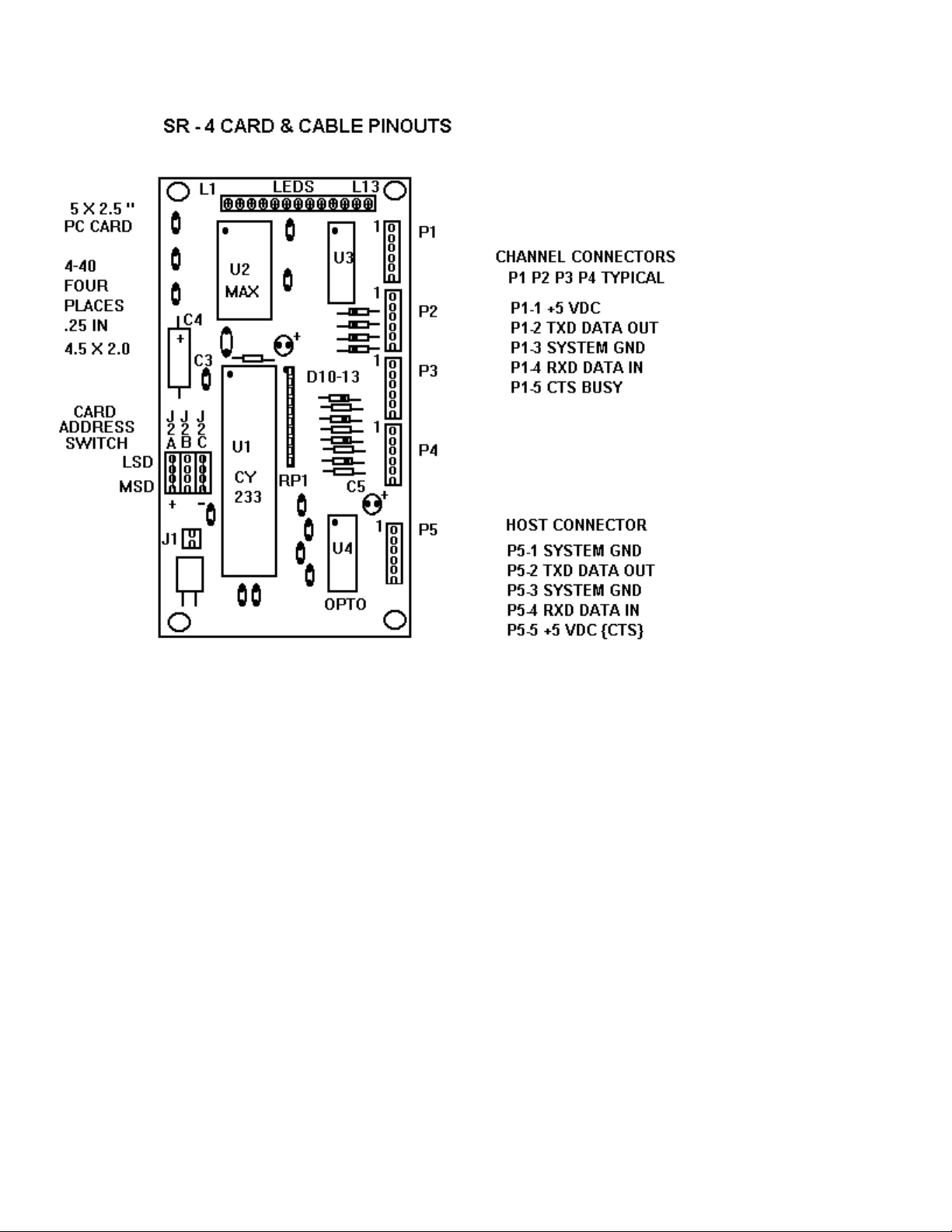

HARDWARE DESCRIPTION

Note: Do not attempt any procedure or remove any screws other than instructed; no user service

The MMI network control contains two CY233 SR4 cards, generally refered to as #0 and #1 which

is their binary address. Each card controls four SMC motor systems and includes status LEDs

and jumber posts (dip-clips) for setting its ID number. The cards are mounted to a single rail and

can be removed as a single unit as required during service.

is possible to the interior assemblies!

SERVICE ACCESS

Remove the top cover (see following procedure) and access the interior of the MMI only: (1) to

adjust the motor current (factory preset to 1 amp/coil); (2) to set the network address clips

(factory preset to #0 & #1); (3) to observe the network LED displays during programming; as

required.

TOP COVER REMOVAL PROCEDURE

(1) Remove only the four (4) corner 6/32 slotted-head screws holding the black,

top, cover; the cover edges will be retained by the front and rear panels.

(2) Pressing against the rear portion of the cover, at the raised bevel, with the thumbs,

slide the cover fully forward while keeping the cover edge under the lip of the front

panel. The rear lip of the cover will be exposed. Do not attempt to remove by sliding front

to rear.

(3) Using care not to bend the cover, lift up both rear corners of the cover slightly

above the rear panel. Pull the cover towards the rear and lift off.

(4) Replacement is the reverse of the above.

OPERATION

The CY233 microprocessor is used as an address controller for the multiplex system. When a

mode command, followed by a valid ID number, is received by the 233, the 233's address lines

select a multiplex channel. The remaining serial data (motion command string) is passed,

through the multiplexer, directly to the target device (motion system) until the detection of the

terminator charactor (carriage return) by the 233. After detecting the terminator, the 233 resets

the address lines and waits for the next mode command. If more than one controller is

connected to the serial network, invalid ID numbers and the serial data string are echoed to the

next controller down the line. If the ID is invaild for all controllers, the entire message will return

to the host CPU (echo invalid).

Note that contary to normal CY545 procedure, in a CY233 network system, all SMC motor control

commands MUST BE in LOWER case! All SR4 net commands must be in UPPER case! With that

said, it may be observed that the SMC's respond to upper case as well. Only during a query

responce will the SR4 repeaters strip off the upper case characters A to F which are seen as hex

control codes. This will not cause a malfunction but may be confusing to the user.

Page 9

WRITE MODE

on the controller card. Valid ID numbers are from 0 to F hex (1 to 16 net controllers). The second

not program the motion system EEPROMS to respond with information without a query command

example, a motion is completed. In the MMI system, the status of all four CTS signals is available

A typical command would be: R0F<; if the response was N, the binary value would be 0010 (fixed)

In general, SR4 mode commands are prefixed to SMC motion commands which are then "passed

through" to the motion systems. Only two mode commands are used in this system, the write

(W) and the read (R). A write command consists of a mode character (W), an ID number (two hex

characters), a command string (motion system data string), and a terminator (carriage return).

The ID number consists of two characters; the first or high byte is the system ID. This identifies

an MMI net controller card. The system ID of a card is selected with the jumper switches located

or low byte selects any combination of the four channels within a controller. Valid channel

numbers are from 0 to F hex. Note that F selects no motor channels and is used only to send the

Status request to the CY233 and not the motion systems.

A typical example of a message to a SMC axes would be: W0Ep 1000<. This example directs

SMC axis E (motor #1) of SR4 #0 to move to position 1000.

The write command is also used to request information (query) from the motion systems. Only

one motion channel can be requested to return information at a time. In a typical motion system,

with a CY545 motion controller, the question mark (?) command is used to query the system. Do

first (slave mode only).

A typical command would be: W0E? p<. This requests motor 1 to return its current position.

READ MODE

A read command consists only of a mode character (R), the ID number (two hex characters; note

that the second character is always F), and a terminator (carriage return). The read command is

only used to read the status of the SMC motion systems from the SR4 net controller.

STATUS

When a motion system is busy, it can not respond, normally, to the host computer. The BUSY

(also refered to as the CTS or cleared-to-send) signal is used to hold off the host until, for

as a single ASCII character. This character is equal to a binary number consisting of two bytes.

The high byte is always 0010 (4 hex); the low byte consists of four bits; each bit indicates the

status of a channel's CTS signal. Remember that the motion system MUST be in the Hand-Shake

Mode (o 0a0h; lower case only) for the status function to be valid.

1110. Refer to Code Table.

Page 10

ECHO MODE

A typical command would be J0F<; the 0 is the address of the first SR4 card and the F indicates a

Refering to the following table, note that the codes seem confusing in that they are not an orderly

In the MMI network system, with two network cards, it is necessary to engage the CY233 passthrough (echo-all) mode. This allows commands originating in a motion channel (SMC) to be

passed through successive SR4 cards down-stream in the network loop. A typical example is the

SMC system query commands. The J command format consists of a mode character (J), the ID

number (two hex characters; the second is always F), and the terminator (carriage return).

SR4 only message; J1F is the second card address. Each SR4 in the daisy-chain network must

be sent a J command during start-up procedure.

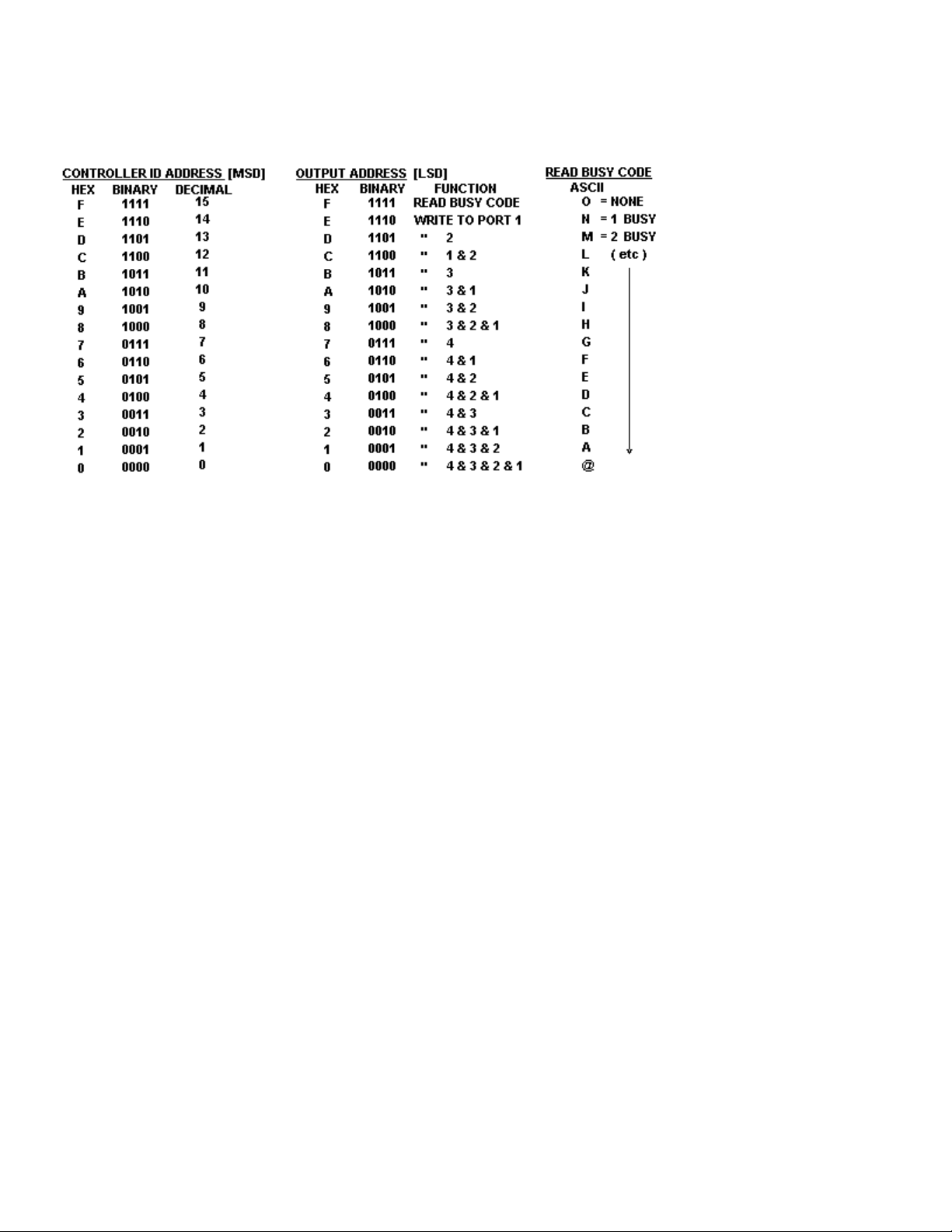

ID AND STATUS CODES

sequence of decimal numbers. They, in fact, are based on their hex-decimal values from 0 to F

(hex) . Also as the active selection signal is a LOW or 0 volts, the sequence is inverted. For

example, all devices selected is a 0 (zero) code or address; all bits are low. No devices selected

is F; all bits HI (+5 volts). Therefore, selection of the first device or E indicates 1 bit is LOW; all

others are HI. Note that the codes for the individual motor controllers are therefore E (motor #1),

D (motor #2), B (motor #3), and 7 (motor #4). The other codes allow selection of any combination

of motors. The BUSY codes correspond to these selections with the @ indicating all BUSY

followed by A to O (none busy) in decending order. Refer to PROGRAMMING section for

examples of code selection.

Page 11

TABLE OF ID AND STATUS CODES

Page 12

LED DISPLAYS

The displays are used with the test software program to verify and demonstrate correct operation

of the MMI. They are located on each SR4 card; inside the MMI.

L 1 OUT 1 INDICATES TRANSMIT DATA TO CHANNEL 1

L 2 OUT 2 " 2

L 3 OUT 3 " 3

L 4 OUT 4 " 4

L 5 OUT DATA INDICATES TRANSMIT DATA FROM HOST CPU

L 6 IN 1 INDICATES RECEIVE DATA TO HOST CPU 1

L 7 IN 2 " 2

L 8 IN 3 " 3

L 9 IN 4 " 4

L 10 AD 0 INDICATES MOTION CHANNEL ADDRESS 1

L 11 AD 1 " 2

L 12 AD 2 " 3

L 13 AD 3 " 4

ID JUMPER SWITCH

The ID jumper switch assigns the ID number to an SR4 card. The switch consists of 3 rows of 4

posts. The center row is jumpered high or low according to the required number. The rows are

labeled J2A (high posts), J2B (signal), and J2C (low posts). All posts must be jumpered. If

addition MMI units are used, their addresses must be set according to their position in the daisy

chain.

PROGRAMMING

The MMI is, in general, transparent to the connected motion systems and requires only that the

three byte address be pre-fixed to the existing commands.

The demonstration software furnished with the MMI is intended to exercise the entire unit and to

allow transmitting commands one at a time or in complete strings in order to verify operation of

the system or to create a complete simulation of the application. This software is a simple

terminal program whose listings contain important notes. All users should read the listing for

this general information about system operations. Refer to the sample program in the

Installation and Operation section of this manual.

Page 13

Page 14

Page 15

SECTION 3: SMC - STEP MOTION CONTROLLER ASSEMBLY

ALSO REFER TO:

Cybernetic Micro Systems - CY 545 Step Motor Controller Manual

MMIDEMO program - Software Listings & Comments

CONTENTS PAGE

Introduction 17

Hardware Configuration 19

Displays & Controls 20

Installation & Test 21

Programming & Listings 25

Serial Cable Diagrams 26

CY 545 COMMAND SET SUMMARY

(In the MMI network system, all letter commands must be in lower case)

Command Function Note

A val 24 set position counter to At value Commands are lower case ASCII letters,

B bit # set or clear (/B) User Bit followed by a space, and a value if required.

C set Continuous stepping mode Values without a suffix are 0 to 255 max.

D val 16 Delay for value in milliseconds Values with 16 suffix are 65535 (64K) max.

E Enter commands to user mem Values with 24 suffix are 16777215 (16 Meg).

F val First (starting) speed of motor Add (byte count) is 64K max. Bit # is 0 to 7.

G motor Goes the number of steps

H bit # Home motor on bit #

I Initialize 545; software reset

J add Jump to address on mem page

L cnt add Loop to address for count value

N num 24 Number of steps; see Go

O mode set mOdes of CY controller

P val 24 moves to an absolute Position

Q Quit Enter commands to mem

R val set Ramp (top) speed of motor

S val Slope (acceleration) of F to R

T bit # add jump to add unTil Bit matches

W bit # Wait at add until Bit matches

X eXecute commands at Y add

Y add 16 set mem address counter to Y

Z cnt 16 add Zillion Loops to add for cnt value

0 (number) end of program or stop program

+ ( plus ) set CW direction for Go move

- ( minus ) set CCW direction for Go move

/ ( forslash ) negate prefix for /Bit commands

? command send back command val to host

"message" send back message to host

Page 16

!!!! ATTENTION !!!!

Mis-wiring of motor or power supplies WILL damage motor drivers IMMEDIATELY. Motor coils A

or B can be reversed; motor will run in the opposite direction. Pairs can be reversed; pair A in

coil B for example. CROSS-WIRING, an A and B wire crossed, WILL damage driver. Allowing

exposed motor leads to touch each other, ground, or power MAY damage driver. Refer to

Appendix D in the MS driver section for wiring schemes.

SMOKE, POPPING, ELECTRONIC ODOR, OR FUSE FAILURE

INDICATES DRIVER FAILURE.

Call the Service Center. Do NOT change fuse or attempt repair without instructions.

ADDITIONAL DAMAGE CAN OCCUR !!! Shorted drivers can easily be repaired by replacing the

socketed driver arrays.

!!!! WARNING !!!!

NEVER connect or disconnect any of the motor leads or power supply (VMM) leads before

disconnecting AC power! Unit may be safely operated WITHOUT motor. However, pause 30

seconds after power off before reconnecting motor (Bleed-Down time).

NOTE !

An understanding of the Cybernetic Motion Controller and its Command Set is required in the

following explainations . Refer to the Cybernetic Micro Systems - CY 545 OR 550 Step Motor

Controller Manual.

Page 17

Introduction

instructions such as Test, Wait, Delay, Loop which are used along with the motion instructions to

Each system includes a CI cable (controller interface cable). This 20 pin cable is divided into two

The SMC motion control system consists of two basic elements; the controller card and the MS

driver card. The controller card (CY5.4) contains the Cybernetic CY 545 or CY 550 Step Motor

Controller and a 2K character EEPROM (non-volatile) for storing application routines. Refer to

the Cybernetics 545 manual for a description of the 545 microprocessor and its "High-Level"

command set (26 characters and symbols). All actions of this system are controlled by these

commands.

Two of the eight User Bits of the 545 (USRB 0-7) are assigned to a specific function. The

remainder are for general purpose Input and Output functions (I/O) such as controlling relays or

valves (output) and reading switches (input). The command set of the Cybernetic 545 contains

provide a wide range of machine operations. The SMC system can also be discribed as a "miniPLC with motion".

The Step pulses and the Direction signal from the CY5.4 controller are connected to the motor

driver. Additionally, the Stop (PWR LED) signal shifts the driver from Park power to Full power.

A Home Sensor channel is also part of the system.

sections. The I/O section contains + 5 v power and ground as well as six User Bits. The Chassis

section connects the Home Sensor, User Bit 2, Jog Switch, and Limit Loop signals back to the

controller. Refer to Appendix A for details.

This system is self-contained and can operate independently or under the direct command of a

host computer. In Memory Mode, the host computer is used to "teach" the system by sending a

string of commands which are stored, for later execution, in the on-board memory of the

controller card. In Direct Mode, the host commands are executed immediately by the CY545. A

combination of these two modes is also possible; typically macro command strings are loaded

to memory and then executed as required by the host.

See Appendix A for CI cable See Appendix D for motor wiring

See Appendix B for homing / limits See Appendix E for driver card

See Appendix C for current adjust See Appendix F for home sensor

Page 18

Page 19

Hardware Configuration

latches (2 each), RS-232 receiver / driver, LED status lites and standard crystal (11 MHZ). Refer to

of the 545 (User Bit 6) is used as the hardware hand-shake to control communication between the

"Home" position at power-on; refer to the Home command (H). Lash-Compensation is included in

The SMC controller card contains the CY 545 motion controller, EEprom memory, memory

the Rate Table in the CY545 manual.

Serial Format

The SMC is connected as a RS-232 serial device and communicates with the host computer

through the SR4 network. The serial format is configured in the following manner: ASCII

characters, 1200 Baud, 8 data bits, no parity, and one stop bit. The CTS (Clear To Send) feature

host and the 545. When the 545 is busy, it will set the CTS signal to the SR4 status register as a

request to hold off transmission.

During operation from memory or when homing, the CTS function is not 100% busy; pulses

on/off each instruction. This is to allow interruption of routines by the host computer sending a

stop command (0 or CR). If other data is sent, incorrect operation will result. To set the SMC

100% busy during operations: (1) disable the CTS function with the Mode command. User Bit 6

will set HI or busy. (2) As the last instruction, in the memory routine, re-enable the CTS.

NOTE: the correct Mode command to defeat the CTS is: o 080h.

the correct Mode command to enable the CTS is: o 0a0h

(Any hex value starting with a letter must be preceded by a zero)

Memory Format. The memory is configured as 2K bytes of EEPROM (RAM is optional). It is not

possible to access memory above address 2047. Note that the memory is in pages of 256 bytes;

the CY545 does not allow Jump, Test, or Loop operations across page boundries. The pointer

command (Y) is used to move across boundries. A feature of the 545 memory system, the AutoStart function which recognizes special character flags in the first bytes of memory as a

command to run the following program at power-on, is not used in the MMI.

Home Function. This system uses an optical sensor to establish the starting reference or

the home routine. A major advantage of this system is Slip-Detection which provides operation

to + zero steps. See Installation and Test for a detailed home procedure.

Limit Loop Function. The CW-CCW Limits function of the 545, pin 4 & 5, is not used in this

system. Instead, the driver card will go "free or ABoRt" (CURRENT-OFF) when the Limit Loop is

opened (Fail-Safe, Hard-Soft limits). This Limit Loop is enabled by User Bit 0. Refer to the

Appendix B section of this manual.

Page 20

I/O Function. The Cybernetic User Bits are available at the CI cable connectors and can be used

as either inputs or outputs dependent on the command. Note that an output can only drive LEDs

such as those in Solid-State relays or optical isolation. An input can only be a passive switch or

isolated relay contact across the User Bit and User ground. Connecting any device, at a different

potential, to this system through the User Bits, WILL damage the User port; opto-isolation is

required. The standard CI cable is the 20 pin which provides limits and home sensor signals,

access to the User Bit I/O lines, and VCC power & ground. Refer to Appendix A of this manual.

Other Functions. The Jog function (pin 6) is available at the Jog connector of the CI Cable; see

Appendix A. External thumbwheel (pin 12) is not used. Instead refer to the I/O Path option for

thumbwheel operation or stand-alone (PLC) mode. Note that the CW-CCW inputs are available in

this system as the Emergency Stop option. Also, the Inhibit / Abort (pin 8) is not used in this

system. This Abort is not the same as the driver abort (ABR).

Reserved User Bits.

B 0 Enable Driver; must be LO to step. B0 LED will be ON.

B 1 Bit 1 is always the Home Sensor.

B 6 Bit 6 Is the Busy Bit (CTS). See mOde Command.

LED Status Displays.

OFF = Logic High or true ON = Low or false; pin # refers to CY 545 pinout.

BZ Indicates the inverse of pin 27(User Bit 6) Off = Ready;On = Busy

DR Indicates the polarity of pin 2 (direction) LO = CW

ST Indicates the polarity of pin 1 (step) LO = Step pulse

PW Indicates the polarity of pin 3 (stop) LO = Stepping

SW Indicates the polarity of pin 6 (slew) LO = Ramp speed

B0 Indicates the polarity of pin 21 (User Bit 0) LO = Enable all drivers

B1 Indicates the polarity of pin 22 (User Bit 1) LO = Home Sensor blocked

B2 Indicates the polarity of pin 23 (User Bit 2) General Purpose User Bit

Reset. To hardware reset or stop the system, cycle the AC power switch located on the rear

panel.

Software Configuration

This system is a serial device directed by ASCI character commands. It is configured exactly as

described in the Cybernetics controller manuals; except for differences as noted in this manual.

Special Commands are created to simplify use of the Basic program.

Page 21

Reserved and Special Software Commands.

selection of on-the-fly

must not cross the memory page boundry which is ever 256

CLEAR Writes 0's and CR's to memory.

LOAD [F6] Loads memory. Not same function as Basic F3 key.

EXIT [F5] Required to close comm port, close file, and clear error traps.

comma [,] Do not use comma to separate elements of 545 commands (T,L, and ? M

xx). Comma is a Basic symbol; use space instead.

[a,b,c] HP-LED command string is not used.

C Continuous Step Mode is normally not used with the CY545 unless

motion can be terminated with an external Abort signal. Refer also to the

CY550 which is an advanced version which has a larger

software commands.

Special Aspects of Some Commands.

W The Wait command causes the 545 to wait at the instruction,

therefore incoming stop commands will not be processed. Use a T

command in a jump to itself.

L, Z These loop instructions assume that the first pass of a routine

before reaching the loop command was the 1st loop pass. In

general, the loop count must be one less than required. Also

see J & T below.

T,H,W,O These commands are followed by a numeric value in Hexdecimal

which is desinated by the H following the value. The decimal and

the hex values for 0 to 7 are the same and the H can be omitted.

H Homing is a single step operation. The Busy signal is not

continuously set during homing but cycles every step. It is best

therefore that homing is executed from memory.

J, T Any Jump or Test operation, which includes L & Z commands,

bytes; 256, 512, 768, 1024, etc. Use the Y for global jumps.

Installation and Test Procedure

1. Connect AC power cord.

2. Connect motors, verify that driver current is correct for motors. See

Appendix C for current adjustment and Appendix D for motor wiring.

3. Connect CI cable. Limit Loop must be closed for motor to run.

4. Connect the serial cable and turn-on computer system.

5. Connect the AC power and turn-on power switch or supplies. Verify

that: AC neon; power is present. DC lamp; motor power (VMM) is OK. All SMC

LEDs are off except for BUSY.

Page 22

Refer to lines 500-1000 of the listings in this manual. These tests prove that the MMI system is

Exit the program (F5), refer to line 120, and increase the timebase (T value) for the host computer.

operating correctly. Typically, a motor will run back and forth several times. Observe the LED

indicator lites while the tests are running and note that each action of the system can be

monitored and that this self-test is the series of commands listed between the quotes in lines

500-1000. All actions of the system are the result of COMMANDS, refer to the back cover of the

CY 545 manual, either stored in the external memory (Memory Mode) or sent from the host

computer (Direct Mode). The third mode (Programming Mode) is when commands are sent from

the host and written into the external memory.

Computer Test Procedure

1. LOAD and RUN the Demo program which will down-load self-tests. Refer to lines 500-1000 of

the listings.

2. Verify the time delay is correct for the host computer. During testing, the system will return

the network status characters or other query information; R0FO (status) or P=000000 (position)

for example. If the returns are in segments:P=

00 00

00

with multiple line feeds between characters, the host computer is too fast for the comm card.

Re-start (shift-F5) the program.

Note the serial delay routine (GOSUB 2500) at Line 2500 is multiplied by itself; use small

increases. When set correctly, the display will have no vertical segments but also have no

excessive delay in responding to querys.

NOTE: If the message "system is busy or not connected....." appears, enter Ctrl-Break. The

system IS NOT connected to COMM 1. RESET the MMI and correct the serial cabling.

The MMI system should, when the MMIDEMO.bas is run, lite B 0 (motors enabled), lite DIR

(direction = +), BUSY lite off, and return status (none busy) to the display.

3. Motor Commands.

NOTE: Enter the following commands (Direct Mode) at the prompt. Motor E of SR4 #0 is default

(Enter Command>W0E. Symbols used below are: < = Enter key, Fx = function key.

F9 the SMC returns position; this indicates communication is OK

p 2000< motor will move to position 2000 ( 2000 steps CW )

F9 ? P returns P=0002000; position is 2000

p 0< motor returns to position 0

b 0< free motor E; B 0 LED is out

Page 23

4. Memory Commands.

Frequency). This behavior is affected by motor load, power, and speed. The normal procedure is

F7 ? y where is memory byte pointer; y=00000 after reset.

y 0< sets pointer to byte location 0; if required.

? m 21< displays 21 "command lines" of memory (F8 and type 21<).

CLEAR< fill the memory with 0's and carriage returns; STOP commands.

YES< yes; wait till 0 0 0 0....DONE.

F7 y=0000.

F8 21< memory is cleared; all zeros and carriage returns; 42 bytes.

F6 load memory; host goes to line 1000; returns ? p when done.

F7 y=xxxx; last byte of program.

y 0< set memory byte pointer to byte 0.

F8 21< memory is loaded.

x< sample motor test program in memory will run; note that memory

query (F8 21<) did not move the memory address pointer (y=0000).

F7 last address of program; pointer did move with each line of program.

y 0< reset to top of program.

x< sample motor test program in memory will run.

ADW0D< change SMC address; prompt is now W0D<:.

Repeat the above with motor # 2, for example.

Parameters. Refer to the CY 545 MANUAL, SECTIONS 1-12 (Commands), 16 (see StepMotor and

Home), 17 (Rate Tables), 19 (good sample program); sections 13,14,15 not used. Typical

commands will duplicate the down-load with different values of R, S, and F used in order to

determain the best parameters for moving the motor. Refer to the Rate Tables. Repeat Step 3

with different parameters.

Resonance. Resonance (feed-back oscillation between the motor rotor and the motor coils) is a

vibration which affects the motor behavior. Typical symptions are shuttering, dropping steps,

jumping back and forth, hard running, and excessive noise (unpleasent). All step motors exibit

resonance at approximately 100 full step/sec (Low Frequency) and at 1000 full steps/sec (Mid

to start at a speed (F command) above the low point and ramp through the mid point (S

command) to a higher speed (R command).

To determine the resonance points, set F and S to the lowest value and R above mid freq. Move

the motor sufficent steps to reach top speed. Note the points during this acceleration where the

motor exhibits abnormal behavior; these are the low frequency nodes. The motor will stall at the

mid freq. point. Resonance can be reduced by less power, decoupling the motor and load

(isolating couplers; not metal to metal), higher speeds, faster acceleration, and/or smaller step

angles.

Page 24

Programming

The sample listing is commented and contains information about how to operate a 545 system. It

Line 120 creates the time delay used between characters so that fast computers do not get ahead

The software program used with the MMI/SR4/SMC system is only a "Serial Driver" routine. The

main purpose of the program is to send and receive commands between the host and the MMI

microprocessors. The motion control software (firmware command set) is contained only in the

CY545. The QBASIC serial driver contain examples of typical operations required by the host

computer software, such as: opening the comm (serial) port, sending/receiving characters,

loading the 545 memory, handling the Busy status, and diagnostic capability. Included in the

sample program are routines of 545 commands which exercise the motion system during

manufacturing tests. Two types of routines are demonstrated; (1) downloading a string of

commands from a keyboard file and (2) loading a string of commands to EEprom memory.

is helpful to "read the listing" even for non-computer types.

Line 0-20 defines the variables and create symbols for control characters.

Line 30-100 assigns the Basic function keys for common functions.

of the serial card and the MMI.

Line 130 defines the serial port as the ACTIVE device; PRINT #ACTIVE sends characters to the

active port.

Line 200-400 creates the introduction screen display

Line 500-999 is the down-load test routine which is sent to the 545 when this program is first run.

Line 1010-1410 is the Self-Test program. The GOSUB 2500 is the time delay for the write cycle of

the EEprom memory.

Line 1500-1800 is a sample homing routine with a limited number of re-tries; loop counter, input

test, and message transmission are demonstrated in this program.

Page 25

Line 2000-2510 assemblies keyboard entries and sends them to the MMI at the Enter key ( CR =

Line 2910-3000 closes the comm ports on Exit (F5) or a computer error code other than ERROR =

carriage return or enter key). Note the special commands at line 2210-2270 which are created

commands not part of the MMI command set.

Line 2600-2750 reads any incoming characters from the MMI and prints to the host display

screen.

24 (comm port is busy).

Line 3000-3150 writes zeros (545 stop command) and carriage returns over the entire memory

(Clear command) which erases the memory. The opposite is the Load command which writes the

memory.

Line 3300-3400 is the busy error routine.

Line 4000- are the help files.

Page 26

Program Listings

See MMIDEMO program

Page 27

Serial Cables

XT TYPE. CPU DB-25 (IBM STYLE) CONTROLLER DB-9S (AT)

PIN 1 Frame Ground <------------------------> Shell (solder)

PIN 2 TX Transmit --------------------------> PIN 3 RX Receive

PIN 3 RX Receive <-------------- ---------- PIN 2 TX Transmit

PIN 5 CTS Clear <------------------------- PIN 8 DSR Ready

PIN 7 Signal Ground <------------------------> PIN 5 Signal & Frame

DB-25 to DB-9 Adaptor

AT TYPE. CPU DB-9P (IBM STYLE) CONTROLLER DB-9S (AT)

Note : DB-9 Controller is wired as a Null Modem ( pin to pin )

PIN 3 TX Transmit -------------------------> PIN 3 RX Receive

PIN 2 RX Receive <------------------------ PIN 2 TX Transmit

PIN 8 CTS Clear <------------------------ PIN 8 DSR Ready

PIN 5 Signal Ground <-----------------------> PIN 5 Signal & Frame

PIN 4 DTR Ready -----------------------> PIN 4 DTR Ready

Shell Frame Ground <-----------------------> Shell Signal & Frame

pin to pin cable

MAC DIN. CPU DIN-8 (EIA-422) CONTROLLER DB-9S (AT)

PIN 5 RX In- <------------------------ PIN 2 TX Transmit

PIN 3 TX Out- -------------------------> PIN 3 RX Receive

PIN 2 CTS Hand In <------------------------ PIN 8 DSR Ready

PIN 4 Signal Ground <----------------------> PIN 5 Signal & Frame

PIN 8 RX In+ <-----------'

PIN 1 DTR ------------------------> PIN 4 DTR

Shell Frame Ground <----------------------> Shell Signal & Frame

MAC to IBM Adaptor Cable

The Controller/Device signal DSR (Data Set Ready) is wired to the network CY233 status input

CTS (Cleared To Send). When the controller is busy, the DRS will set HI or or busy and pull CTS

HI or not Clear To Send. The host CPU should not send when the device is busy. See Status

Code Table.

If the host software ignores the CTS status signal and commands are sent to a busy motion

controller, the commands will be lost or jam the controller. Typical indications of the host failing

to obey the CTS are: motion or homing stops when host program is run, motor runs backwards

at high speed forever, or only part of a memory routine is completed.

It is the responsibility of the host software to check status for "not busy" before sending

commands to the selected device.

Page 28

SECTION 4: MMI

vdc TTL computer (VCC) and +40 vdc motor (VMM). The VCC supply is over-current protected. In

Mechanical Assembly

The MMI assembly consists of the SR4 network controllers, the SMC (CY 5.4 controller & MS 2.0)

motor drivers, all DC power supplies, and an AC power entry. The DC power supplies provide +5

addition, A 1 amp AC fuse protects the entire assembly.

NOTE: NEVER REPLACE THE FUSE.

FUSE FAILURE INDICATES DRIVER FAILURE.

The green chassis lamp indicates VMM (motor) power on. The neon lamp in the power switch

indicates that AC power is present to the MMI. The MMI has six pin motor connectors (see

Appendix D), IEC power connector, network serial connectors (refer to serial cable section), and

LED status indicators. The 20 pin CI cable connectors provides access to the spare I/O lines,

limit loop, home sensor and VCC power/ground. Refer to Appendix A.

Page 29

Page 30

MS - MiniStep translator /driver card

msman.wri 9-95

MS

OPERATION AND INSTALLATION

MANUAL

FOR MS SERIES

Page 31

Page 32

PRODUCT DESCRIPTION. The MM & MS, Series 1 & 2, stepper motor driver, is a switching type, constant- current

logic system which receives input commands from a controller (typically a microprocessor) and generates a series of

OPERATIONAL MODES. The driver can be operated in three modes: FULL-step or HALF- step, and QUAD-step only.

transistors configured in an H-bridge with two pair sourcing current and two pair sinking current. The motor winding

back to the comparator section and turns off the H-bridge transistors. After a fixed-time off to allow the transistors to

regulator which drives current pulses through the windings of a stepper motor. All stepper motors are stepped or

rotated by changing the direction of the current flow through the windings in a unique sequence. Each change of

current direction results in a step.

The driver contains two sections: (1) the step generator; and the (2) power drivers. The step generator is a digital

step signals. The power drivers receive the step signals and switch the phase of current in the motor windings.

The driver requires a minimum of four input signals: (1) the step pulse - STP, (2) the direction level - DIR, (3) the

power level - PRK, and the enable signal - ABR. The step pulse (or step clock) to the input of the driver will cause a

corresponding change of the output current resulting in one step (one unit of motor rotation). The direction input is

a digital level signal which controls the direction of motor rotation. If the signal is true (HIgh), the motor rotates in

CW direction; if the signal is false (LOw), the motor rotates in CCW direction. In addition to the step and direction

inputs, the driver will accept an output power control input. This digital input, PARK, controls the amount of current

delivered to the motor windings either run power or park power. If the signal is HI or floating, the driver is at reduced

current; if LO the driver is at full current. The enable signal, ABoRt, sets the current to either off or on. If the signal is

HI or floating, the driver is FREE (no current); if LO, the driver is enabled.

In addition to the digital input signals, the MS driver also requires a power supply input of unregulated D.C. voltage.

The driver functions to control the current furnished by the D.C. supply. The combination of a D.C. supply and the

MS driver is referred to as a current-regulated power supply, or constant- current motor driver. The driver regulates

the current through the motor winding by rapidly switching on and off the D.C. voltage. This technique is referred to

as switch-mode or chopper stabilized regulation. The driver also requires +5 TTL logic supply for the digital

sections.

In each of these modes, the output power control, PRK, is controlled by an external microprocessor. PRK is used to

reduce driver and motor heating during non-step periods.

THEORY OF OPERATION. The unique element in the driver is the current regulator device, referred to as the "driver

chip". This driver has three main inputs: (1) the phase-control, F; (2) current-control, I0; (3) current-control, I1. The

outputs of a driver are the connections to a single motor winding. Internally an output section contains four power

is connected across the bridge. If one source transistor (at one end of the winding) and one sink transistor (at the

other end) are turned on, then current flows through the winding. Alternately, if the other pair is on, then the current

will flow through the windings in the opposite direction. The D.C. Supply is connected to the top (positive) and

bottom (negative) of th H-bridge transistor pairs. An external resistor (typically 1 ohm or less) is inserted in series

between the negative of the H-bridge and the negative of the power supply negative so that the total winding current

flows through the resistor. When full winding current flows, the small voltage (400 mv) across the resistor is fed

settle and the feed-back voltage to dissipate, the bridge again turns on and current builds up in the winding until the

voltage across the sense-resistor again trips the comparator.

Page 33

The digital phase-input (F) level (HI or LO) selects which pair turns on and corresponds to the direction of current

flow through the winding. The current controls, (I0 and I1) select one of four comparators; zero, low, medium, or full.

In general, the MS series requires an unregulated source of D.C. voltage connected to VMM. The current output must

higher voltage is required only for higher step rates. In general, do not use a regulated power supply as performance

If the optional +5vdc TTL supply is not installed, then an external 150ma digital supply is connected to the TS1-8 VCC

systems with a diode in the VCC connection. In any case, controller VCC and driver VCC MUST BE COMMON or other

The output is therefore a series of current pulses equal in amplitude and separated by the period of fixed time off.

The value of the current sense resistor is pre-selected to produce a current amplitude equal to that of the current

rating of the motor winding. If I0 and I1 select a comparator other that FULL, then the sense resistor feed-back

voltage trips at less than full current. The reference voltage of the comparators is also available as an input to the

device. By externally controlling this reference input, the output current can be varied between zero and full (i.e.

microstepping).

The driver card contains three sections: (1) the step generator, which controls the digital levels of the phase (F)

inputs; (2) the drivers; and (3) the Auto-Park gate, which if installed, controls the output-current digital input, PRK,

automatically. The step generator is a counter-PROM configured as a four-eight- sixteen step counter. The outputs

of the counter are combined through PROM gates into two outputs which control the phase inputs (F) of the two

driver IC's. Each step-clock causes the step counter to toggle one step and the PROM decodes a pair of phase

commands to the drivers which cause a winding current direction change resulting in a one step rotation of he

motor. The direction input, input directly to the counter, directs the decode to produce a CW or CCW rotation.

INSTALLATION AND OPERATION. Before operating the MS & MM series, that the input connections are correct for

that mode. Refer to the installation wiring diagrams found in the back of this manual. Locations of jumpers and

signals are identified on the bottom SMCe of the unit circuit board. The configuration of the MS series requires

attention to four areas: step size jumper and PROM type, power supply voltage, motor winding connection, and

current control dial-pot setting. Refer to driver label for maximum current and voltage limits of the particular model.

Refer to the Appendix section in the rear of this manual for details.

(1) POWER SUPPLY & MOTOR CONNECTIONS

Signal Name Terminal Strip TS1 Data Connector P1

VMM TS1-1 none

equal 1.414 the full rating of one motor winding. The voltage can be between 12 and 45 volts D.C. (maximum). The

is reduced. Refer to the unit label for the VMM maximum of that model.

VCC TS1-8 P1-13 & 14, 1, 6

connections. TS1-5 is provided for ground return. TS1-8 is protected by a 6.8vdc TRANSORB. The VCC is ALSO

common through the digital control connector P1-13 & 14. The +5vdc can be furnished by: (1) the computer or

controller power supply only, or both. If the system power is not controlled by one switch, always isolate the driver

interface connections are required (opto isolation).

Page 34

GND TS1-4 & 5 P1-19, 3, 5

In all cases, ground is COMMON to all grounds; digital VCC, analog VMM, chassis ground and green wire ground (AC

except in the case of FIVE wire motors . NEVER insert dropping resistors in the power supply leads or winding leads.

the motor at full power can be firmly PARKed at low power. The motor will free-wheel only if the ABORT (ABR) line is

power ground). If a dual (VMM & VCC) supply is used, then an identical and equal ground lead is connected; 2 each

wires to TS1-4 and 5. Always bridge the supply returns and connect to chassis. If separate supplies are used,

connect the VMM supply and ground to the TS1 connector. Connect the driver VCC (P1-13&14) and ground (P1-19)

from the driver to the controller bus. Connect the VCC supply to the controller bus. IN ALL CASES, ANY VCC

BETWEEN THE CONTROLLER AND IN THE DRIVER MUST BE COMMON OR ELSE OPTICAL ISOLATION IS

REQUIRED. In all cases, connect chassis ground (green wire ground or earth) to the driver or supply grounds.

COIL-A/COIL-B TS1-2 & 3, TS1-6 & 7 none

A pair of motor windings are connected across each coil connection. Bipolar motors have FOUR leads (two pair).

Unipolar motors with SIX leads can be used provided a coil end and a center tap are connected (unused wires MUST

be INSULATED and cut off or tied back). NEVER attempt to connect the center taps of unipolar motors to VMM,

NEVER insert caps or coil filters across the windings.

(2) INPUT SIGNALS Digital Inputs P1-12/20 & 11/19 See Appendix A

Step Input (CLK) P1- 15

The step-clock (+5vdc TTL compatible) inputs to the clock pin of a 74191-type counter. The 74191 toggles on a LO to

HI transition. The Step CLK MUST be normally HI (+5vdc) and go LO only long enough to toggle th counter (100us to

1ms). Refer to TTL data books for max/min clock conditions. A pull-up resistor (4.7k) is installed on the step clock

input. Refer to AUTO-PARK for additional requirements of the clock inputs.

Direction Input (DIR) P1- 17

The direction level inputs to the 74191 counter. The input is pulled up by a 4.7k resistor. Setting the input HI or LO

reverses the direction of motor rotation. Motor rotation with respect to the state of the direction input may be

reversed by reversing the motor winding pairs.

Current Control Input (PRK) P1- 11

The current control signal shifts the output current to the motor coils between 100% power and park power. When

PRK is LO (0vdc), the unit produces FULL power. If PRK is HI (+5vdc) or floating, the units outputs at PARK power.

On units so equipped, PARK power may be preset at the medium (MED) power level. PARK condition is used to

reduce power supply requirements and motor dissipation during non-step periods. Any load which can be moved by

HI.

Abort Control Input (ABR) P1- 9 (see next)

The ABR input must be LO to step. If the input is HI or disconnected, the driver control output will output zero

current. NOTE: the driver is not OFF, power is still being regulated to the zero condition. The motor will free-wheel.

ABORT is normally only used in stand-by (position loss may occur), in series with safety switches (limits) or other

emergency stop conditions.

Other Signals (CPU ABR and HOME) P1- 10,12 & P1- 4,16

Pin 12 is the normal input to P1-9 when the ABoRt Loop is used.

Pin 4, 16 is the output signal HOME back to the controlling device.

Page 35

Spare Inputs P1- 18, 8 & P1- 20, 7

these signals to any potential or device except passive switches or relays. Door locks and other safety switches may

This series will operate either in FULL/HALF step or QUARTER step only mode. FULL/HALF requires the FH PROM to

Pins 18 and 20 can be used for other signals to/from the card. See Chassis Signals connector. Pin 20 is normally

keyed on free standing cards.

(3) Chassis Signals P1- 1 to 9 & P1- 2 to 10

These signals are normally used to provide for a convenient method of cabling the driver between the controller and

the motor, power supply, chassis assemblies.

Home Sensor Pins P1- 1, 2, 3, 4

These pins power the optical home sensor circuit. SEE APPENDIX A & F. Pin 1 is VCC +5 power, pin 2 is VLED

power, pin 3 is GND (ground), and pin 4 is the HOME input from the sensor.

Abort Loop Pins P1- 9 & P1- 10/12

These pins normally constitute the ABoRt Loop Safety (limits) System. The driver enable is output from the

controller to pin 12 (CPU ABR) and output to the loop from pin 10 (to limit loop) and returned from the loop to pin 9

(ABR). The ABR loop is NORMALLY CLOSED; opening the loop for any reason FREEs the motors. Never connect

be inserted in the loop. See Appendix B.

Spare Pins P1- 6, 5, 7, 8

These pins are used as required to provide VCC (pin 6) and GND (pin 5) to the chassis system. Pins 7 and 8 are user

pins which are generally jumped as required to the spare pins on the data connector. See Appendix A.

(4) FULL/HALF/QUARTER STEP SELECT

be installed and the mode pin to be jumped either FULL or HALF with a dip-clip jumper. The jumper pins are located

next to the top of the PROM socket. See Appendix F.

In QUAD step mode, the QD PROM is installed and the mode pin is jumped to the QUAD pin. Conversion is a field

operation.

The PROMS are also labeled with the current control selection.

HL: shifts power HIGH (100%) to LOW (25%) during parking.

HM: shifts power HIGH (100%) to MED (60%) during parking.

(5) CURRENT CONTROL DIAL

The current dial sets the 100% power level of the driver outputs as required. Refer to App C.

Page 36

APPENDIX SECTION

Page 37

Page 38

APPENDIX B: DESCRIPTION OF HOMING AND ABORT LOOP PAGE 1/2

HOMING. A major advantage of a digital Open-Loop step system is the ability to operate plus or minus zero steps (no

position 1 (one step out of the sensor). The motor is then stepped CW to any position. To slip-detect the system, the

This technique requires a control system which carries a "map" with each individual machine. The EEPROM memory

error). Two conditions are required. One is that the motor is sufficient for the load in normal operation and second,

that a reference position, commonly called the "home position", be consistently established during initialization of

the system. When step motors are rotated by counting (clocking) out a number of steps, in theory, the motion will

take place +/- zero steps. The exact mechanical position of the motor can vary by the motor step accuracy; typically

+/- 3 % of one step (non-cumlative). A proof of +/- zero step operation is, first, to reference a starting positon of the

motor or "home". During homing, the motor is stepped backwards into a switch, reversed, and then stepped forward

until the switch opens. The point of interest is not the exact mechanical position but rather on which step the switch

changed state. For that reason, only high resolution "PHOTO-LOGIC" optical-beam switches are used in TMG

systems.

SLIP-DETECTION. After the motor is home, the controller position counter is reset to the home position, typically

motor is returned to position 1. If the sensor remains open, then the motor is stepped to positon 0. If the sensor

closes, the system is operating +/- zero steps (error free). Note that a single step lost (slip) will always result in at

least a movement of 4 full steps away from the correct position. Open loop systems are slip-detected at regular

intervals to prove continuing slip-free operation.

CENTER HOME AND CONTIGUOUS SLIP DETECTION. If the home sensor is located at the center of axis motion and

a step bar is mounted along the entire motion path, then the home position can be verified each time the system

crosses the center line. A stepped bar is thin strip with a left high SMCe and a right low SMCe. The high to low edge

is the center line.

LASH COMPENSATION. A major advantage of steppers is in their "repeatability" which is typically less than .01 %

because the digital controls are not affected by temperature, aging, voltage or adjustment. This allows errors such

as lash and distortion to be zeroed-out.

Lash compensation adds or subtracts steps, at each change of direction or because of other forces, to take-up the

lash error. Lash compensation is accomplished during the slip-detection process. When the system is slip-detected

the first time, the sensor will not close at position 0 because of the lash; home LED remains off. At this point, the

system is single-stepped CCW until the sensor closes; home LED is on. The number of CCW steps is the lash

compensation value. The system is re-homed and the counter loaded with this value (see At home command). The

motor is then moved some number of steps CW, returned to position 1 (sensor open), and finally position 0 (sensor

closed). The system is +/- zero steps.

Screw distortion error occurs when the screw pitch, which is so many turns per inch, does not move the correct

distance after the correct number of turns of the motor. For example, a 10 turn screw should cause linear travel of 1

inch every 2000 steps (200 step/rev motor). If, rather than commanding the motor controller to go in 2000 step

increments, the controller moves to absolute positions such as 2000, 4001, 6003, 7999, ect.; the error is eliminated.

is suitable for this purpose.

Page 39

APPENDIX B: DESCRIPTION OF HOMING AND ABORT LOOP PAGE 2/2

detector on the motor shaft. The index can be either a disk with a tab or a long pin. During the homing operation, the

ABORT LOOP FUNCTION. In TMG systems, the ABORT loop is used to remove all winding power to the motor during

detection in order to prove correct positioning during product development, particularly during software de-bugging.

SUPER HOMING. In high resolution systems, two sensors are used. The first sensor, the home sensor, is mounted

to the motion platform in the typical configuration. The second sensor, the index sensor, is located as an index

motor is stepped backwards until the first sensor is blocked. The motor, however, continues to rotate until the

second or index mark is detected. The system is now "homed to the step". TMG systems with Super-Homing use

two identical "PHOTO-LOGIC" sensors wire-ORed together so that both must be blocked before the home signal is

detected. The H or home command of the motion controller will operate with either single or double sensors.

an out-of-bounds condition. The ABORT feature can be used to provide hard-limits, emergency stop, door interlocks, and other safety features. As the ABR input, to the driver, must be LO (ground) for the driver to step; opening

the loop will stop (free) the motor regardless of the control logic. The diagram is typical of TMG "Fail-Safe, HardSoft" limit loops.

NOTE: CONTRARY TO POPULAR PRACTICE, IT IS UNWISE AND UNSAFE TO SENSE LIMITS AND OTHER SAFETY

CONDITIONS THROUGH THE COMPUTER INPUTS PORTS.

All motion products, regardless of their final intended form, should initially incorporate home sensors and slip-

Typically, a test routine is established which passes slip-detection. Any detrimental modification or code flaw will be

flagged by this routine.

Page 40

APPENDIX C MOTOR CURRENT ADJUST PAGE 1/2

Page 41

APPENDIX D MOTOR WIRING SCHEMES PAGE 1/2

thereby doubling motor efficiency. The other alternative for the motor designers is to use a greater number of turns in the winding space. This is

translated to bipolar when the motor is used with a bipolar driver. In general, the translation is similar to a unipolar driver with dropping resistors

Performance of a stepper motor based system depends more on the electronic drivers used than it does on the motor itself. A step motor (both

PM and Hybrid type) is made to step by sequencing the orientations of the magnetic fields in two coils. The UNIPOLAR drive method of is

illustrated, in the figure, using just ONE coil of the motor. Note that the center tap of the coil is connected to the positive motor supply voltage.

An electronic circuit, represented by the switch, then connects one end or the other to ground for current to flow from the center tap to the

grounded end. The most significant factor is that only one-half of the coil is used at any given time and that the magnetic field intensity (motor

torque) is proportional to the product of the number of turns in the coil and the current passing through the coil.

Motors designed for BIPOLAR drivers will often have only four leads. However some manufactures will provide the motors in 8 wire versions to

offer a performance choice for bipolar drive users as in figures C & D. Four lead bipolar motors may use larger wire, since only half the windings

are required in the given space of the motor body. The paralleling in figure C is the equivalent of this to achieve lower winding resistance and

shown by figures B & D and results in more torque with a lower coil current but a subsequent loss of high speed torque.

Although step motors are often classified as bipolar or unipolar (2 phase or 4 phase), these terms are more accurately applied to the types of

electronic circuit used to drive the motor. Bipolar drivers can drive 4,5,6 and 8 wire motors. When the motor is described as unipolar, the

specifications are presented with the assumption that the motor will be driven with a unipolar drive. Therefore the specifications must be

in series with the center taps; referred to as L over x R with R equal to the motor winding resistance. For example, a L over 4R unipolar driver

has a resistor equal to 4 times the winding resistance. In bipolar, the L over R ratio is the ratio of the motor voltage to the supply voltage. A L

over 4R bipolar drive, for example, would be a 6 volt motor and a 24 volt power supply. Performance would be similar to the L/4R torque curve of

a unipolar motor. The figures identify the various connection options when using a bipolar driver with 6 or 8 wire motors.

A: SINGLE COILS. Identical to unipolar specification (if the supply voltage equals the specified motor voltage). Normal connection of a bipolar

driver to 6 wire motor.

B & D: SERIES COILS. This configuration will produce torque greater than the unipolar specification indicates. To stay within the power

(wattage) rating of the motor, reduce the unipolar specified current by 30%; depending on the duty-cycle of the system (park time). Note that the

torque curve of this configuration is conSMCerably fore-shortened as this motor is now the same as a motor with a rating of twice the voltage

(slower motor).

C: PARALLEL COILS. When this configuration is driven at the unipolar current, the motor will perform identical to the specification but the

motor will dissipate only one-half the power (it is twice as efficient). When the current is increased by 1.414, to drive the motor at it"s full power

rating, the motor torque is increased by approximately 60% Note that this torque curve is extended by four times (high speed system).

Resonance (vibration) of a step motion system depends on the speed and power range of the motor. Fast windings (A & C) are "quicker" and

may break into resonance easier than slow (B & D). Power windings (B & D) may deliver "excessive" power (torque) to the system and produce

resonance. In general, resonance indicates, except at the low (100 sps) and mid-frequency (1000 sps) bands, excessive power; therefore reduce

the driver current for smoother operation or wire the motor for "softer" response.

NOTES: If a motor runs "backwards" with respect to software direction, transpose the connections of ONE coil. For MS series driver cards, pins

2 & 3 or 6 & 7; SMC / MMI driver boxes, pins 1 & 3 or $ & 6.

Five wire motors are really 6 wire motors with the center tap common. The center tap must be connected to the motor supply voltage. If phases

1, 2, 3 or 4 are crossed, motor will not rotate (hums). For MS cards, pin 1 is VMM, for SMC /MMI (if connected), pin 5 is VMM and pin 2 is GND.

Systems with pin 5 & 2 connected are used to power external relays or solinoid valves. The pins are keyed (reversed). Never attempt to connect

any motor leads to pin 2 and only 5 wire center taps to pin 5. Pins 2 & 5 are normally not connected and used to store the unused leads of 6 or 8

wire motors.

Page 42

Page 43

Page 44

APPENDIX E PAGE 1/2

Page 45

APPENDIX F PAGE 1/2

Page 46

APPENDIX F PAGE 2/2

Page 47

APPENDIX I PAGE 1/1

MOLEX - WALDOM NYLON CONNECTOR SYSTEM USED BY THE MOTION GROUP

The connectors used on Motion Group equipment are nylon connectors are manufactured by Molex and are refered to as .062 style (pin diameter)

or .093 (large driver motors only). They are available from Newark, Allied, and Digi-Key and come in 1 to 36 positions with locking and mounting

tabs which snap-in to punched holes on brackets or enclosures.

TYPICAL $ POLES TYPE PART # NEWARK # USED ON

5.84/10 4 (.062) MALE HOOD 03-06-2041 31F1004 HOME SENSOR ASSEMBLY

5.95/10 4 (.062) FEMALE RECT 03-06-1041 31F1005 HOME SENSOR CABLE

1.86/5 6 (.062) MALE HOOD 03-06-2062 31F1008 STEP MOTOR ASSY

2.07/5 6 (.062) FEMALE RECT 03-06-1061 31F1009 MOTOR OUTPUT

1.86/5 6 (.093) MALE HOOD 03-06-2062 31F1008 STEP MOTOR ASSY

2.07/5 6 (.093) FEMALE RECT 03-06-1061 31F1009 MOTOR OUTPUT

(Strain Relief Hoods are available on request)

Contacts for Connector Sets .062 SIZE

6.79 FEMALE SOCKETS LARGE TAB 02-06-1103 31F1027 22-18 GUAGE WIRE

MALE PINS LARGE TAB 02-06-2103 31F1026 22-18 GUAGE WIRE

FEMALE SOCKETS SMALL TAB 02-06-1132 31F1029 30-22 GUAGE WIRE

MALE PINS SMALL TAB 02-06-2132 31F1028 30-22 GUAGE WIRE

Contacts for Connector Sets .093 SIZE

6.79 FEMALE SOCKETS LARGE TAB 02-06-1103 31F1027 22-18 GUAGE WIRE

MALE PINS LARGE TAB 02-06-2103 31F1026 22-18 GUAGE WIRE

FEMALE SOCKETS SMALL TAB 02-06-1132 31F1029 30-22 GUAGE WIRE

MALE PINS SMALL TAB 02-06-2132 31F1028 30-22 GUAGE WIRE

In general, single wires use small tab contact; double wires the large tab

Tooling

105 RATCHET TOOL .062 DIA HTR-2262 11-01-006 30F338 MAKES PERFECT CRIMPS

105 RATCHET TOOL .093 DIA HTR-XXXX 11-01-006 30F338 MAKES PERFECT CRIMPS

13 HAND TOOL HT-1921 11-01-0015 31F1049 REQUIRES PRACTICE

12 EXTRACTOR .062 DIA HT-2285 11-03-0002 30F773 SPRING LOADED PUNCH-OUT

12 EXTRACTOR .093 DIA

Nylon Connector Designer/Service Kit

Contains male/female housing assortment, hand crimper, pin extractor (not as easy to use as spring extractor; see above),

contacts, and case.

40 DESIGNER KIT .062 WM-072 30F774

40 DESIGNER KIT .093

All of the above, including custom cable sets are available from the factory.

Note: When disconnecting, grasp the mounting tabs, (not the wires) and rock from top to bottom (unseat the locking bump) rather than SMCe to

SMCe and then pull the connection apart. The connections unseat easily with the right technique.

Contact factory for Heavy Duty Connectors with Metal Shells, Retainers, and Strain-Reliefs.

Page 48

SPECIFICATIONS - MMI

PARAMETER MIN MAX UNIT

Power

Motor supply voltage 12 40 VDC

Current (no motor) 150 160 ma

PWM frequency

MD10A 18 24 Khz

Motor current

MS2.0 0.05 2.0 Amp

Step pulse input

Voltage 0 +5.0 VDC

Sink surrent 12 20 ma

Pulse high 1 uSec

Pulse low 1 uSec

Rise time 0.5 uSec

Fall time 0.5 uSec

Frequency 500 KHz

Logic ' 1' volts +1.8 +2.0 VDC

Direction input

Voltage 0 +5.0 VDC

Sink current 12 20 ma

Logic ' 1' volts +1.8 +2.0 VDC

Note: The step pulse input must be a logic 1 (high) during direction input change.

Environmental

Operating temperature -20 +50 C

Humidity (non-condensing) 0 95 %

Shock 100 G

Altitude 30.000 FT

Mechanical

Weight 3 lb

Dimensions 2" x 3.5" x 11.0"

Mounting hole centers 2.625" x 8.250"

Mounting screw size #6-32 x 1/2" max

Page 49

Loading...

Loading...