REF 9516-177-50-ENG Rev F1

ELI 150c/250c

12-LEAD RESTING ELECTROCARDIOGRAPH

SERVICE MANUAL

Manufactured by Mortara Instrument, Inc., Milwaukee, Wisconsin U.S.A.

CAUTION: Federal law restricts this device to sale by or on the order of a physician.

Copyright © 2015

by Mortara Instrument, Inc.

7865 N. 86th Street

Milwaukee, Wisconsin 53224

This document contains confidential information that belongs to Mortara Instrument, Inc. No part of this document

may be transmitted, reproduced, used, or disclosed outside of the receiving organization without the express written

consent of Mortara Instrument, Inc. Mortara is a registered trademark of Mortara Instrument, Inc. E-Scribe, ELI,

®

and VERITAS are trademarks of Mortara Instrument, Inc. Cisco

®

Inc. DICOM

is the registered trademark of the National Electrical Manufacturers Association for its standards

is the registered trademark of Cisco Systems,

publications relating to digital communications of medical information.

TECHNICAL SUPPORT AND SERVICE

Headquarters

Mortara Instrument, Inc.

7865 North 86th Street

Milwaukee, WI 53224

U.S.A.

Tel: 414.354.1600

Tel: 800.231.7437

Fax: 414.354.4760

Internet: http://www.mortara.com

European Union

Representative

Mortara Instrument Europe, s.r.l.

(European Headquarters)

Via Cimarosa 103/105

40033 Casalecchio di Reno (BO)

Italy

Tel: +39.051.298.7811

Fax: +39.051.613.3582

Service/Technical

Support Group

Mortara Instrument, Inc.

7865 North 86th Street

Milwaukee, WI 53224

U.S.A.

Tel: 414.354.1600

Service: 888.MORTARA

(888.667.8272)

Fax: 414.354.4760

E-mail: techsupport@mortara.com

Mortara Instrument Germany

Bonifaciusring 15

45309 Essen

Germany

Tel: +49.201.18 55 69 70

Fax: +49.201.18 55 69 77

E-mail: Service.de@Mortara.com

24-hour Technical Support

Same-day Shipment of Replacement Parts

Biomedical Training Classes

Extended Warranties/Service Contracts

Sales Support/

Supplies & Accessories

Mortara Instrument, Inc.

7865 North 86th Street

Milwaukee, WI 53224

U.S.A.

Tel: 414.354.1600

Fax: 414.354.4760

E-mail: sales@mortara.com

Mortara Instrument Germany

Bonifaciusring 15

45309 Essen

Germany

Tel: +49.201.18 55 69 70

Fax: +49.201.18 55 69 77

Mortara Instrument Netherlands

Postbus 324

5680 AH Best

Industrieweg 160b

5683 CG Best

Netherlands

Tel: +31.499.377310

Fax: +31.499.377908

Mortara Instrument Australia

PO Box 7568

Baulkham Hills NSW 2153

Unit 28, 9 Hoyle Avenue

Castle Hill NSW 2154

Australia

Tel: +61 2 8070 9303

Fax: +61 2 9899 9478

Mortara Dolby UK Ltd.

Units 11 & 12, Scion House

Stirling University Innovation Park

Stirling FK9 4NF

Scotland

Tel: +44.1786.444980

Fax: +44.1786.446630

i

TECHNICAL SUPPORT AND SERVICE

ii

TABLE OF CONTENTS

GENERAL INFORMATION SECTION 1

Notices ........................................................................................................................................................................... 1

Warranty Information .................................................................................................................................................... 2

User Safety Information ............................................................................................................................................... 3

Equipment Symbols and Markings .............................................................................................................................. 11

Electromagnetic Compatibility (EMC) ........................................................................................................................ 13

MAINTENANCE & CLEANING SECTION 2

Preventive Maintenance .............................................................................................................................................. 17

Device Cleaning & Disinfecting .................................................................................................................................. 20

Preventive Maintenance Record .................................................................................................................................. 21

DEVICE CONFIGURATION SECTION 3

Setting Technician Password ....................................................................................................................................... 23

Configuration Menus ................................................................................................................................................... 23

Summary of Configuration Menus .............................................................................................................................. 24

Configuration Settings ................................................................................................................................................. 27

UNIT DISASSEMBLY SECTION 4

Removal of the Unit from Cart .................................................................................................................................... 38

Cover Assembly Removal ........................................................................................................................................... 38

Writer Removal ........................................................................................................................................................... 39

Keyboard Removal ...................................................................................................................................................... 46

I/O Board Removal ...................................................................................................................................................... 49

Battery Replacement .................................................................................................................................................... 50

ELI 150c Item Description Listing .............................................................................................................................. 52

ELI 250c Item Description Listing .............................................................................................................................. 54

ELI 150c/250c Item Identification Table .................................................................................................................... 57

iii

TABLE OF CONTENTS

DEVICE SPECIFICATIONS SECTION 5

ELI 150c Specifications .............................................................................................................................................. 75

ELI 250c Specifications .............................................................................................................................................. 76

TROUBLESHOOTING SECTION 6

Troubleshooting Charts ............................................................................................................................................... 77

CONFORMANCE TESTING SECTION 7

Conformance Testing .................................................................................................................................................. 79

Power Testing .............................................................................................................................................................. 79

Functional Testing ....................................................................................................................................................... 80

Device Cleaning .......................................................................................................................................................... 81

Safety Testing .............................................................................................................................................................. 81

ELI 150c/250c Test Data Record ................................................................................................................................ 82

ELI 150c/250c COMMUNICATION OPTIONS SECTION 8

Communication Options .............................................................................................................................................. 83

Communication Error Messages.................................................................................................................................. 83

Communication Options (software only) .................................................................................................................... 84

Communication Options (Hardware + Software) ........................................................................................................ 84

iv

NOTICES

Manufacturer’s Responsibility

Mortara Instrument, Inc. is responsible for the effects on safety and performance only if:

• Assembly operations, extensions, readjustments, modifications, or repairs are carried out only by persons

authorized by Mortara Instrument, Inc.

• The device is used in accordance with the instructions for use.

Responsibility of the Customer

The user of this device is responsible for ensuring the implementation of a satisfactory maintenance schedule.

Failure to do so may cause undue failure and possible health hazards.

Equipment Identification

Mortara Instrument, Inc. equipment is identified by a serial and reference number on the back of the device. Care

should be taken so that these numbers are not defaced.

Copyright and Trademark Notices

This document contains information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated to another language without prior written consent of

Mortara Instrument, Inc.

Other Important Information

The information in this document is subject to change without notice.

Mortara Instrument, Inc. makes no warranty of any kind with regard to this material including, but not limited to,

implied warranties of merchantability and fitness for a particular purpose. Mortara Instrument, Inc. assumes no

responsibility for any errors or omissions that may appear in this document. Mortara Instrument, Inc. makes no

commitment to update or to keep current the information contained in this document.

1

WARRANTY INFORMATION

Your Mortara Warranty

MORTARA INSTRUMENT, INC. (hereafter referred to as “Mortara”) warrants that components within Mortara

products (hereafter referred to as “Product/s”) will be free from defects in workmanship and materials for the

number of years specified on documentation accompanying the product, or previously agreed to by the purchaser

and Mortara, or if not otherwise noted, for a period of twenty-four (24) months from the date of shipment.

Consumable, disposable or single use products such as, but not limited to, PAPER or ELECTRODES are warranted

to be free from defects in workmanship and materials for a period of 90 days from the date of shipment or the date

of first use, whichever is sooner.

Reusable product such as, but not limited to, BATTERIES, BLOOD PRESSURE CUFFS, BLOOD PRESSURE

HOSES, TRANSDUCER CABLES, Y-CABLES, PATIENT CABLES, LEAD WIRES, MAGNETIC STORAGE

MEDIUMS, CARRY CASES or MOUNTS, are warranted to be free from defects in workmanship and materials for

a period of 90 days. This warranty does not apply to damage to the Product/s caused by any or all of the following

circumstances or conditions:

a) Freight damage;

b) Parts and/or accessories of the Product/s not obtained from or approved by Mortara;

c) Misapplication, misuse, abuse, and/or failure to follow the Product/s instruction sheets and/or

information guides;

d) Accident; a disaster affecting the Product/s;

e) Alterations and/or modifications to the Product/s not authorized by Mortara;

f) Other events outside of Mortara’s reasonable control or not arising under normal operating conditions.

THE REMEDY UNDER THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT WITHOUT

CHARGE FOR LABOR OR MATERIALS, OR ANY PRODUCT/S FOUND UPON EXAMINATION BY

MORTARA TO HAVE BEEN DEFECTIVE. This remedy shall be conditioned upon receipt of notice by Mortara

of any alleged defects promptly after discovery thereof within the warranty period. Mortara’s obligations under the

foregoing warranty will further be conditioned upon the assumption by the purchaser of the Product/s (i) of all

carrier charges with respect to any Product/s returned to Mortara’s principal place or any other place as specifically

designated by Mortara or an authorized distributor or representative of Mortara, and (ii) all risk of loss in transit. It

is expressly agreed that the liability of Mortara is limited and that Mortara does not function as an insurer. A

purchaser of a Product/s, by its acceptance and purchase thereof, acknowledges and agrees that Mortara is not liable

for loss, harm, or damage due directly or indirectly to an occurrence or consequence therefrom relating to the

Product/s. If Mortara should be found liable to anyone under any theory (except the expressed warranty set forth

herein) for loss, harm, or damage, the liability of Mortara shall be limited to the lesser of the actual loss, harm, or

damage, or the original purchase price of the Product/s when sold.

EXCEPT AS SET FORTH HEREIN WITH RESPECT TO REIMBURSEMENT OF LABOR CHARGES, A

PURCHASER’S SOLE EXCLUSIVE REMEDY AGAINST MORTARA FOR CLAIMS RELATING TO THE

PRODUCT/S FOR ANY AND ALL LOSSES AND DAMAGES RESULTING FROM ANY CAUSE SHALL BE

THE REPAIR OR REPLACEMENT OF DEFECTIVE PRODUCT/S TO THE EXTENT THAT THE DEFECT IS

NOTICED AND MORTARA IS NOTIFIED WITHIN THE WARRANTY PERIOD. IN NO EVENT,

INCLUDING THE CLAIM FOR NEGLIGENCE, SHALL MORTARA BE LIABLE FOR INCIDENTAL,

SPECIAL, OR CONSEQUENTIAL DAMAGES, OR FOR ANY OTHER LOSS, DAMAGE, OR EXPENSE OF

ANY KIND, INCLUDING LOSS OF PROFITS, WHETHER UNDER TORT, NEGLIGENCE OR STRICT

LIABILITY THEORIES OF LAW, OR OTHERWISE. THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO THE IMPLIED

WARRANTY OF MERCHANTABILITY AND THE WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE.

2

USER SAFETY INFORMATION

Warning:

Caution:

Note:

Warning(s)

This manual gives important information about the use and safety of this device. Deviating from operating

procedures, misuse or misapplication of the device, or ignoring specifications and recommendations could

result in increased risk of harm to users, patients and bystanders, or damage to the device.

Device captures and presents data reflecting a patient’s physiological condition that when reviewed by a trained

physician or clinician can be useful in determining a diagnosis; however, the data should not be used as a sole

means for determining a patient’s diagnosis.

Users are expected to be licensed clinical professionals knowledgeable about medical procedures and patient

care, and adequately trained in the use of this device. Before attempting to use this device for clinical

applications, the operator must read and understand the contents of the user manual and other accompanying

documents. Inadequate knowledge or training could result in increased risk of harm to users, patients and

bystanders, or damage to the device. Contact Mortara service for additional training options.

To ensure that electrical safety is maintained during operation from AC (~) power, the device must be plugged

into a hospital-grade outlet.

To maintain designed operator and patient safety, peripheral equipment and accessories used that can come in

direct patient contact must be in compliance with UL 60601-1, IEC 60601-1, and IEC 60601-2-25. Only use

parts and accessories supplied with the device and available through Mortara Instrument, Inc.

Patient cables intended for use with the device include series resistance (9 Kohm minimum) in each lead for

defibrillation protection. Patient cables should be checked for cracks or breakage prior to use.

Conductive parts of the patient cable, electrodes, and associated connections of type CF applied parts, including

the neutral conductor of the patient cable and electrodes, should not come into contact with other conductive

parts including earth ground.

ECG electrodes could cause skin irritation; patients should be examined for signs of irritation or inflammation.

To avoid the possibility of serious injury or death during patient defibrillation, do not come into contact with

device or patient cables. Additionally, proper placement of defibrillator paddles in relation to the electrodes is

required to minimize harm to the patient.

Means there is the possibility of personal injury to you or others.

Means there is the possibility of damage to the device.

Provides information to further assist in the use of the device.

3

USER SAFETY INFORMATION

This device was designed to use the electrodes specified in this manual. Proper clinical procedure must be

employed to prep the electrode sites and to monitor the patient for excessive skin irritation, inflammation, or

other adverse reactions. Electrodes are intended for short-term use and should be removed from the patient

promptly following testing.

To avoid potential for spread of disease or infection, single-use disposable components (e.g., electrodes) must

not be reused. To maintain safety and effectiveness, electrodes must not be used beyond their expiration date.

To ensure the safety of both the patient and the device, 1.5 meters (5’) of open area should surround the patient.

A possible explosion hazard exists. Do not use the device in the presence of a flammable anesthetic mixture.

Where the integrity of external protective earth conductor arrangement is in doubt, the device shall be operated

from its internal electrical power source.

All signal input and output (I/O) connectors are intended for connection of only those devices complying with

IEC 60601-1, or other IEC standards (e.g., IEC 60950) as appropriate to the device. Connecting additional

devices to the device may increase chassis and/or patient leakage currents. To maintain operator and patient

safety, consideration should be given to the requirements of IEC 60601-1-1, and leakage currents should be

measured to confirm no electric shock hazard exists.

To improve immunity to potential interfering electromagnetic signals, shielded cabling is recommended when

connecting the device to a network.

To maintain operator and patient safety, equipment connected to the same network as the device must meet the

requirements of IEC 60950 or IEC 60601-1.

To prevent electric shock due to unequal ground potentials that may exist between points of a distributed

network system or fault conditions in external network connected equipment, network cable shielding (where

used) must be connected to protective earth ground appropriate to the area where the device is used.

The device has not been designed for use with high-frequency (HF) surgical equipment and does not provide a

protective means against hazards to the patient.

The quality of the signal produced by the device may be adversely affected by the use of other medical

equipment, including but not limited to defibrillators and ultrasound machines.

For proper operation and the safety of users or patients and bystanders, equipment and accessories must be

connected only as described in this manual. Do not connect a telephone line cable to the LAN connector.

Some Mortara electrocardiographs can be equipped with a GSM/GPRS (cellular modem) or wireless LAN

(WLAN) module for transmitting ECG records. Device labeling and the presence of an antenna port will

indicate if your device is equipped with such a module. If so equipped, the following notices apply:

The GSM/GPRS module operates in allocated frequency bands depending on the model. Identification

of the installed GSM/GPRS module can be found on a label on the bottom of the device.

MultiTech Systems, Inc. Model MTSMC-G-F4 (Quad Band): 850/900/1800/1900 MHz, user

The WLAN identification can be found on a label on the bottom of the device.

selectable

Quatech, Inc. Model WLNG-AN-DP101: 2400 MHz

(model subject to change without notice)

4

USER SAFETY INFORMATION

Use of the GSM/GPRS or WLAN module may interfere with other equipment operating in the vicinity. Check

with local authorities or spectrum management officials in your facility to determine if restrictions apply to the

use of this feature in your area.

Do not transmit via the GSM/GPRS or WLAN module with a missing or damaged antenna. Replace a damaged

antenna immediately.

Use only the antenna supplied for use with this device. Unauthorized antennas, modifications, or attachments

could damage the GSM module and may contravene local RF emission regulations or invalidate type approval.

To ensure compliance with current regulations limiting both maximum RF output power and human exposure

to radio frequency radiation, a separation distance of at least 20 cm must be maintained between the device's

antenna and the head and body of the user and any nearby persons at all times. To help prevent degradation of

RF signal and to avoid excess RF energy absorption, do not touch the antenna during data transmission.

The GSM/GPRS and WLAN modules comply with applicable RF safety standards including standards and

recommendations for the protection of public exposure to RF electromagnetic energy that have been established

by governmental bodies and other qualified organizations, such as the following:

Federal Communications Commission (FCC)

Directives of the European Community

Directorate General V in Matters of Radio Frequency Electromagnetic Energy

Caution(s)

To prevent possible damage to the keyboard, do not use sharp or hard objects to depress keys, only

use fingertips.

Do not attempt to clean the device or patient cables by submersing into a liquid, autoclaving, or steam cleaning

as this may damage equipment or reduce its usable life. Wipe the exterior surfaces with a warm water and mild

detergent solution and then dry with a clean cloth. Use of unspecified cleaning/disinfecting agents, failure to

follow recommended procedures, or contact with unspecified materials could result in increased risk of harm to

users, patients and bystanders, or damage to the device.

No user-serviceable parts inside. Screw removal by qualified service personnel only. Damaged or suspected

inoperative equipment must be immediately removed from use and must be checked/repaired by qualified

service personnel prior to continued use.

The rechargeable internal battery is a sealed lead-acid type and it is totally maintenance free. If the battery

appears to become defective, refer to Mortara Instrument Service Department.

Do not pull or stretch patient cables as this could result in mechanical and/or electrical failures. Patient cables

should be stored after forming them into a loose loop.

No calibration or special equipments are needed for the proper operation or maintenance of the device.

● When necessary, dispose of the device, its components and accessories (e.g., batteries, cables, electrodes),

and/or packing materials in accordance with local regulations.

Use only No. 26 AWG or larger telecommunication line cord.

5

USER SAFETY INFORMATION

Note(s)

Patient movements may generate excessive noise that may affect the quality of the ECG traces and the proper

analysis performed by the device.

Proper patient preparation is important to proper application of ECG electrodes and operation of the device.

The algorithm detecting electrode misplacements is based on normal physiology and ECG lead order, and tries

to identify the most likely switch; however, it is advisable to check the other electrode positions in the same

group (limb or chest).

There is no known safety hazard if other equipment, such as pacemakers or other stimulators, is used

simultaneously with the device; however, disturbance to the signal may occur.

If electrode is not properly connected to the patient, or one or more of the patient cable lead wires is damaged,

display will indicate a lead fault for the lead(s) where the condition is present and if the signal is being printed,

the respective lead(s) will print out as a square wave.

As defined by IEC 60601-1 and IEC 60601-2-25, the device is classified as follows:

Class I equipment or internally powered.

Type CF defibrillation-proof applied parts.

Ordinary equipment.

Equipment not suitable for use in the presence of a flammable anesthetic mixture.

Continuous operation.

NOTE: From a safety perspective, per IEC 60601-1 and derivative standards/norms, this device is

declared to be “Class I” and uses a three-prong inlet to ensure an earth connection is made along with

mains. The ground terminal on the mains inlet is the only protective earth point in the device. Exposed

metal accessible during normal operation is double insulated from mains. Internal connections to earth

ground are functional earth.

This device is intended to be used in a hospital or doctor’s office setting, and should be used and stored

according to the environmental conditions specified below:

Operating temperature: +10° to +40°C (+50° to +104°F)

Operating humidity: 10% to 95% RH, non-condensing

Storage temperature: -40° to +70°C (-40° to +158°F)

Storage humidity: 10% to 95% RH, non-condensing

Atmospheric pressure: 500 hPa to 1060 hPa

WAM™ (wireless acquisition module) must be paired to electrocardiograph before operation.

Device must be configured at the factory for use with the WAM.

After operating the device using battery power, always reconnect the power cord. This ensures that the batteries

will be automatically recharged for the next time you use the device.

6

USER SAFETY INFORMATION

The device is UL classified:

WITH RESPECT TO ELECTRIC SHOCK, FIRE AND MECHANICAL

HAZARDS ONLY IN ACCORDANCE WITH UL60601-1, IEC60601-1,

CAN/CSA C22.2 No. 601.1, IEC 60601-1-1, CAN/CSA C22.2 No.

60601-1-1-02, IEC60601-2-25 AND CAN/CSA C22.2 No. 601.2.25-94.

The device is a member of the ELI 1xx or ELI 2xx Series 2 electrocardiograph family.

Wireless Data Transmission

Some Mortara electrocardiographs can be equipped with an optional wireless data transmission module

(WLAN or GSM/GPRS mobile). Both these technologies use radios to transmit data to a Mortara receiving

application. Due to the nature of radio transmissions, it’s possible that, due to the characteristics of the

environment where the device is located, some other RF sources may interfere with the transmission generated

by the device. Mortara Instrument has tested the coexistence of the device with other devices that can interfere

such as devices using WLAN, Bluetooth radio, and/or cell phones. Although the current technology allows a

very successful rate of transmission, it’s possible that in some rare occurrences, the system may not perform at

its best resulting in a “failed transmission.” When this occurs, patient data will not be erased from the device

nor stored in the receiving application, ensuring that partial or corrupted data are not made available to the

receiving station. If the failure mode persists the user should move to a position where the RF signals may

propagate better and allow successful transmissions.

WLAN Option

Wireless options transmit in the 2.4 GHz or 5ghz range. Other nearby wireless devices may cause interference.

If possible, move or turn off other devices to minimize potential interference.

The Wireless LAN module used is compliant with the IEEE 802.11 a, b, g and n standards.

Access Points used should respect IEEE 802.11 standards as well as local Radio Frequency regulations. The

device will scan the available channels and connect to the Access Point on the channel where the SSID that is

configured on the device is available.

7

USER SAFETY INFORMATION

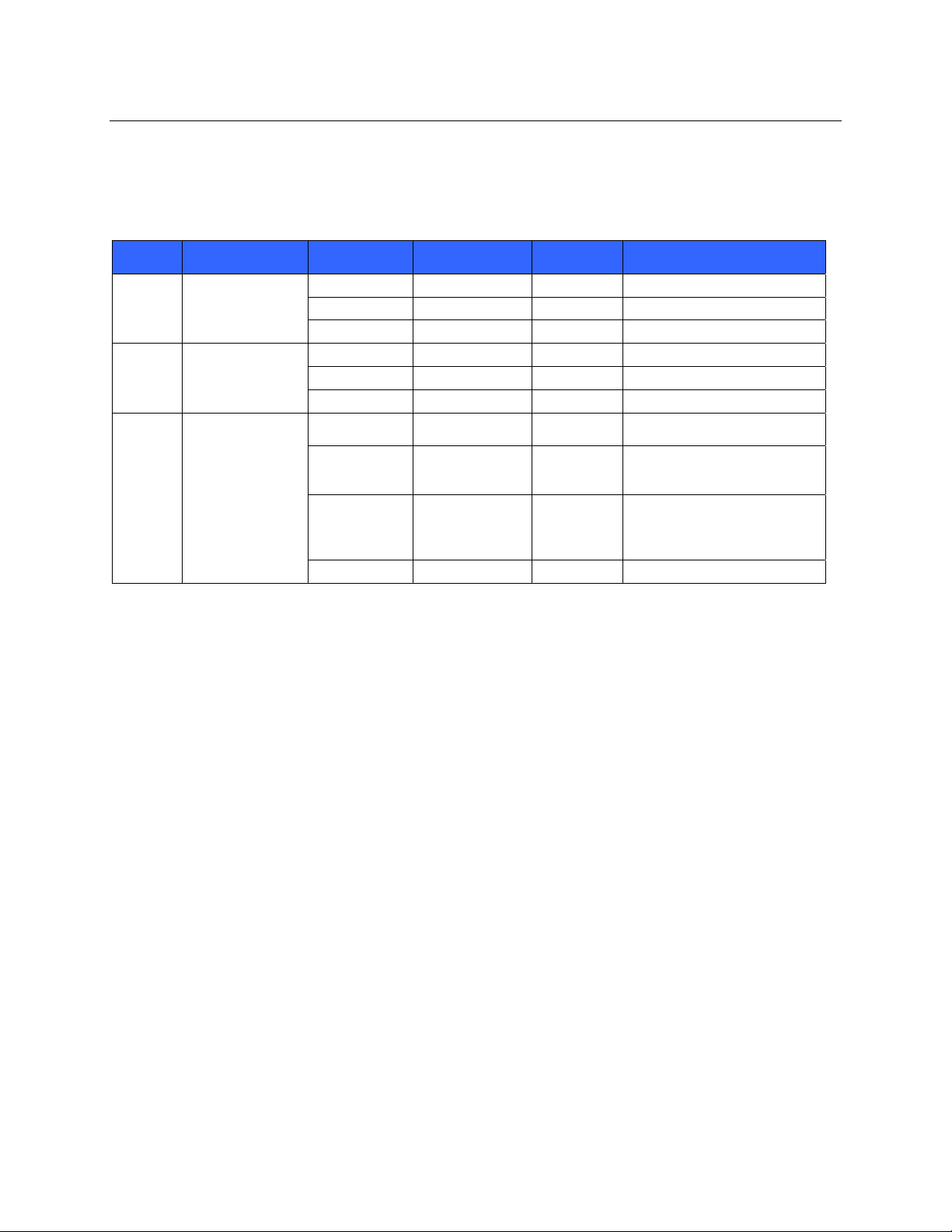

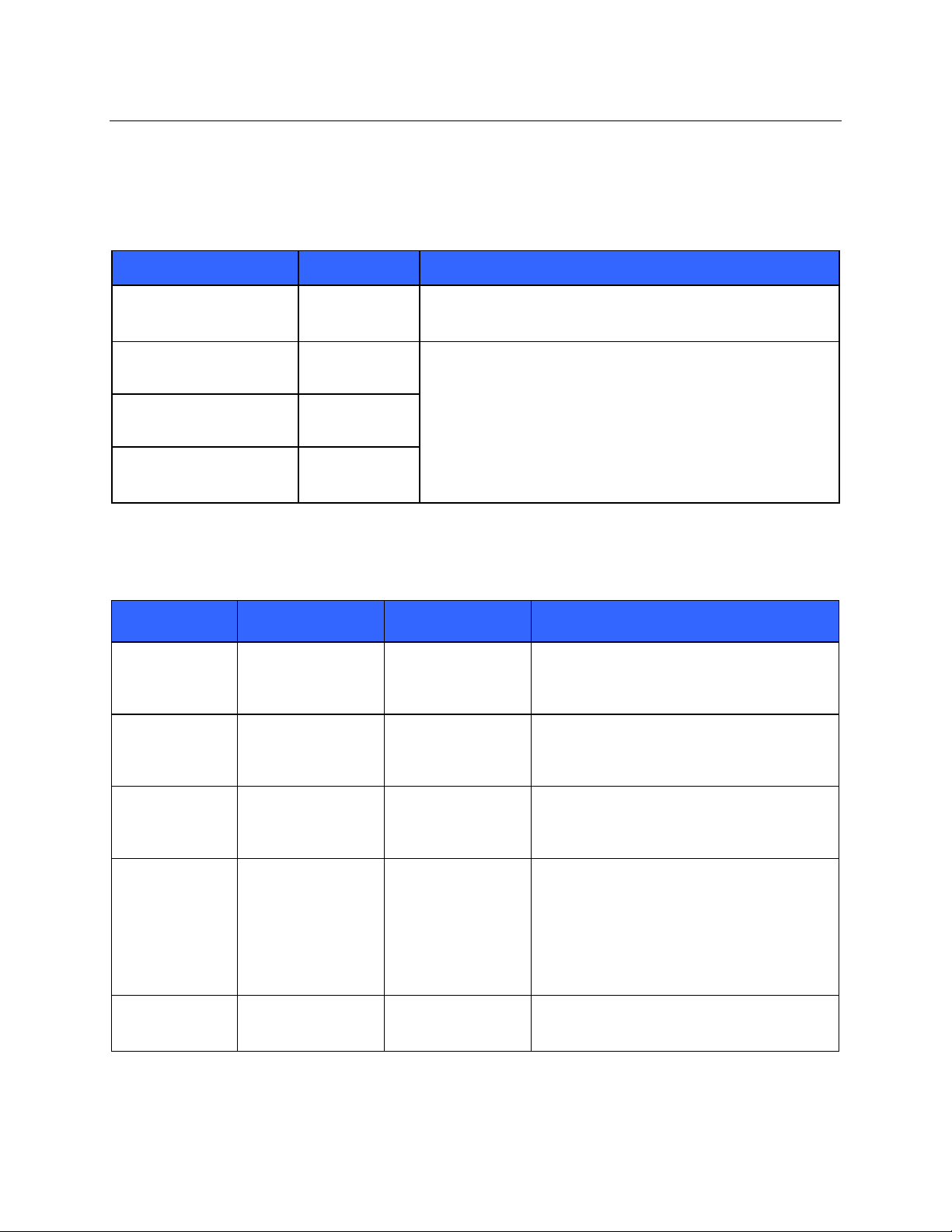

The following table shows the radio channels allocated in different geographic areas in the world. For bands

802.11b and g, only channels 1, 6, 11 and 14 (Japan only) are non-overlapping; for band 802-11a, channels

shown represent non-overlapping channel numbers.

Band Typical Power Region Frequency

Range (GHz)

15 dBm / 32 mW USA/Can ad a 2.401 - 2.473 11

802.11b

13 dBm / 18 mW USA/Can ad a 2.401 - 2.473 11

802.11g

17 dBm / 50 mW USA/Canada 5.15 - 5.35,

802.11a

Europe 2.401 - 2.483 13

Japan 2.401 - 2.495 14

Europe 2.401 - 2.483 13

Japan 2.401 - 2.483 13

5.725 - 5.825

Europe 5.15 - 5.35,

5.47 - 5.725

Japan 4.91 – 4.99,

5.15 - 5.35,

5.47 - 5.725

China 5.725 - 5.825 5

No. of

channels

13 36,40,44,48,52,56,60,64,149,

19 36,40,44,48,52,56,60,64,100,

23 36,40,44,48,52,56,60,64,100,

Channel numbers

1 – 11

1 – 13

1 – 14

1 – 11

1 – 13

1 – 13

153,157,161,165

104,108,112,116,120,124,

128,132,136,140

104,108,112,116,120,124,

128,132,136,140,184188,

192,196

149,153,157,161,165

8

USER SAFETY INFORMATION

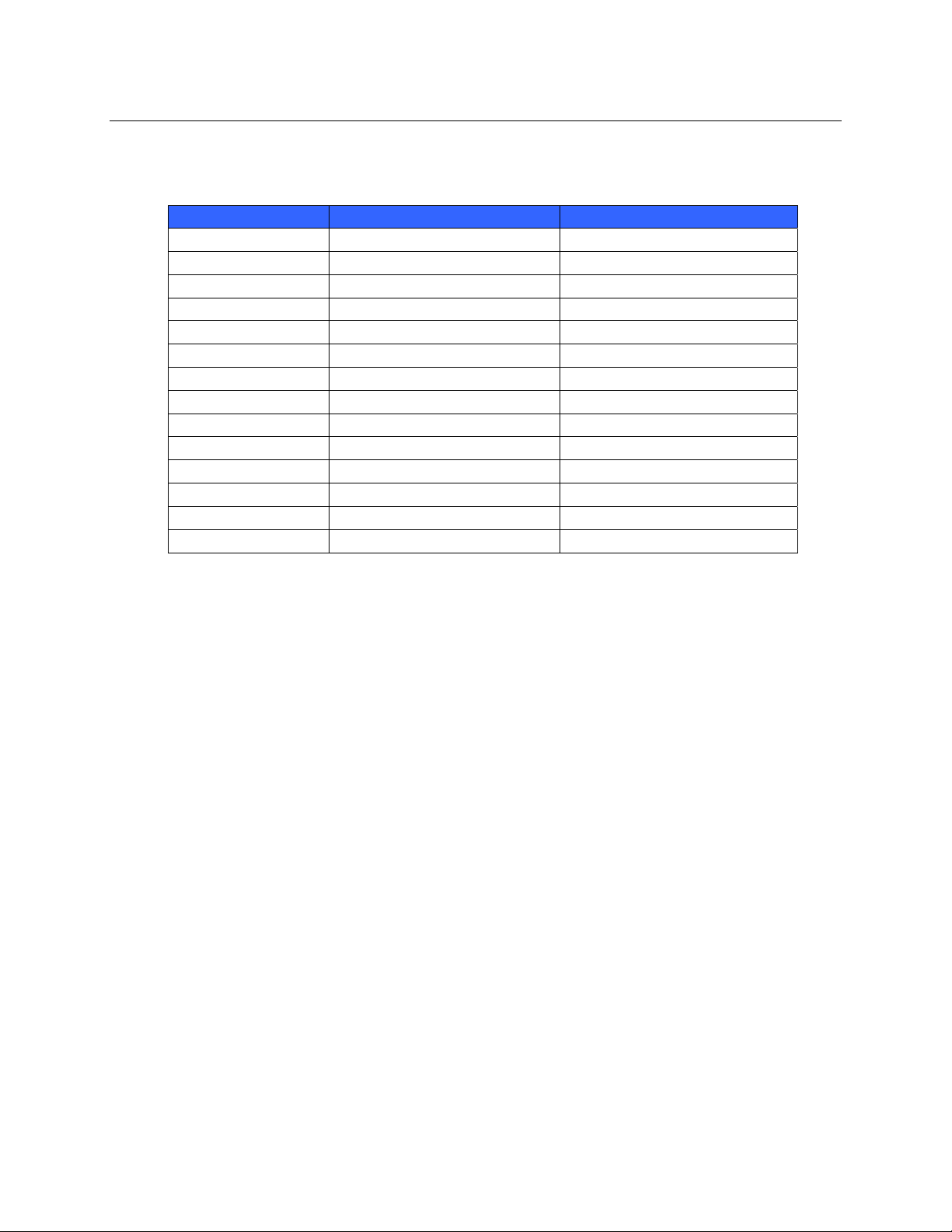

The following table lists the frequency allocated for each channel used by the WLAN option.

Channel Center Frequency Frequency Spread

1 2412 MHz 2399.5 MHz - 2424.5 MHz

2 2417 MHz 2404.5 MHz - 2429.5 MHz

3 2422 MHz 2409.5 MHz - 2434.5 MHz

4 2427 MHz 2414.5 MHz - 2439.5 MHz

5 2432 MHz 2419.5 MHz - 2444.5 MHz

6 2437 MHz 2424.5 MHz - 2449.5 MHz

7 2442 MHz 2429.5 MHz - 2454.5 MHz

8 2447 MHz 2434.5 MHz - 2459.5 MHz

9 2452 MHz 2439.5 MHz - 2464.5 MHz

10 2457 MHz 2444.5 MHz - 2469.5 MHz

11 2462 MHz 2449.5 MHz - 2474.5 MHz

12 2467 MHz 2454.5 MHz - 2479.5 MHz

13 2472 MHz 2459.5 MHz - 2484.5 MHz

14 2484 MHz 2471.5 MHz – 2496.5 MHz

In order to achieve the best transmission rate, it is necessary that the facility where the device is operated can

provide good area coverage. Please consult the IT personnel of the facility to verify the proper WLAN

availability in the area where the device will be used.

RF wave propagation may be blocked or reduced by the environment where the device is used. Most common

areas where this may occur are: shielded rooms, elevators, underground rooms. In all the above situations, it is

recommended to move the device to a proper location and verify with the IT personnel of the facility the areas

where the WLAN signals are available.

9

USER SAFETY INFORMATION

10

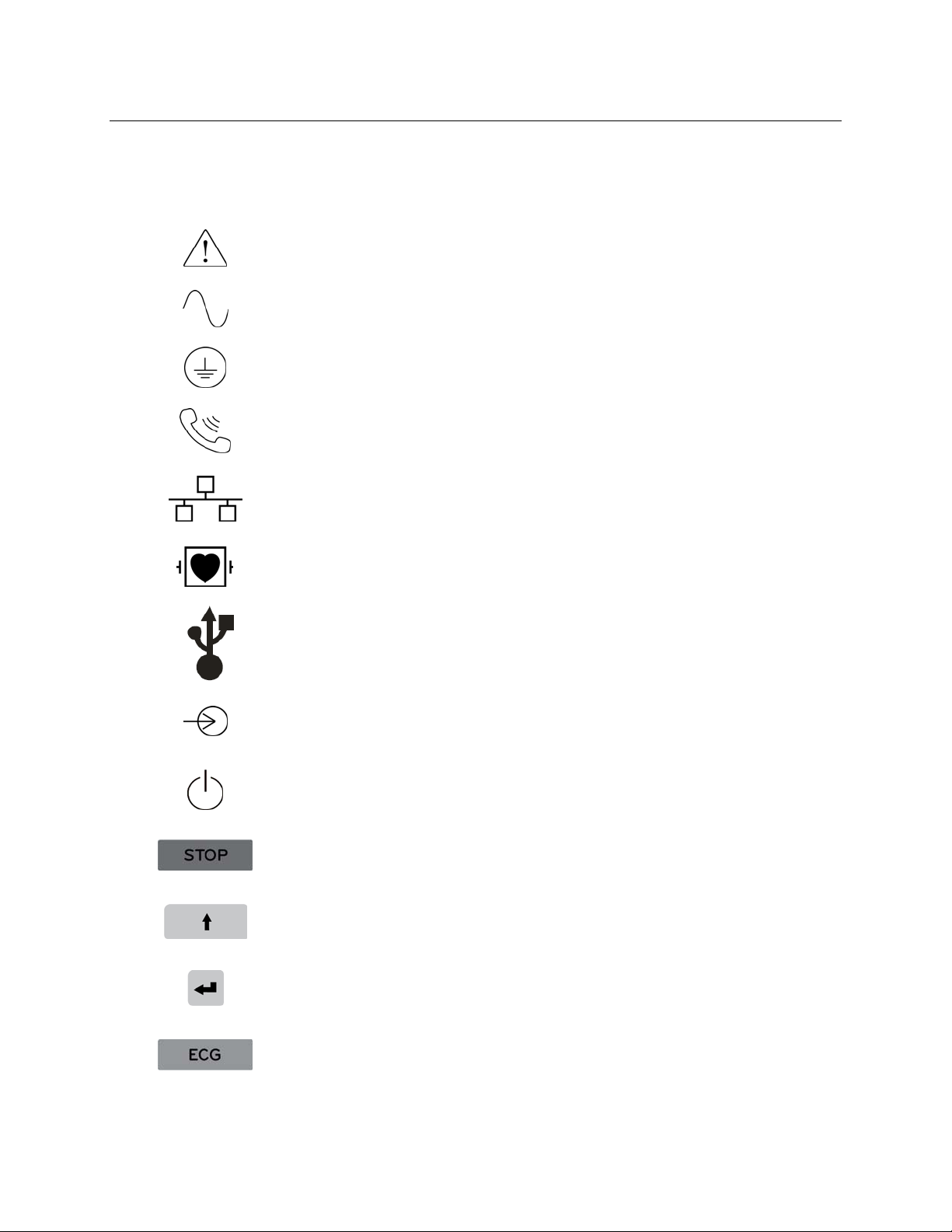

EQUIPMENT SYMBOLS AND MARKINGS

Symbol Delineation

Attention, consult accompanying documents

Alternating current

Protective earth

Telephone line (modem)

Network (LAN)

Defibrillator-proof type CF applied part

USB port

Input

ON/OFF (power)

Stop (of action)

Shift key (to enter upper case text)

Enter key (accept data/return)

Initiate printing of 12-lead ECG

11

EQUIPMENT SYMBOLS AND MARKINGS

Initiate printing of continuous rhythm strip

Transmit, receive and time sync operation depending upon configuration

settings

Do not dispose as unsorted municipal waste. Per European Union

Directive 2002/96, requires separate handling for waste disposal according

to national requirements

Antenna

Indicates compliance to applicable European Union directives

12

ELECTROMAGNETIC COMPATIBILITY (EMC)

Electromagnetic compatibility with surrounding devices should be assessed when using the device.

An electronic device can either generate or receive electromagnetic interference. Testing for electromagnetic

compatibility (EMC) has been performed on the device according to the international standard for EMC for medical

devices (IEC 60601-1-2). This IEC standard has been adopted in Europe as the European Norm (EN 60601-1-2).

The device should not be used adjacent to, or stacked on top of other equipment. If the device must be used adjacent

to or stacked on top of other equipment, verify that the device operates in an acceptable manner in the configuration

in which it will be used.

Fixed, portable, and mobile radio frequency communications equipment can affect the performance of medical

equipment. See the appropriate table for recommended separation distances between the radio equipment and the

device.

The use of accessories, transducers, and cables other than those specified by Mortara Instrument may result in

increased emissions or decreased immunity of the equipment.

13

ELECTROMAGNETIC COMPATIBILITY (EMC)

Guidance and Manufacturer’s Declaration: Electromagnetic Emissions

The equipment is intended for use in the electromagnetic environment specified in the table below. The customer or

the user of the equipment should ensure that it is used in such an environment.

Emissions Test Compliance Electromagnetic Environment: Guidance

RF Emissions CISPR 11 Group 1 The equipment uses RF energy only for its internal function.

Therefore, its RF emissions are very low and not likely to cause

any interference in nearby electronic equipment.

RF Emissions CISPR 11 Class A The equipment is suitable for use in all establishments other

than domestic and those directly connected to the public lowvoltage power supply network that supplies buildings used for

Harmonic Emissions

IEC 61000-3-2

Complies

domestic purposes.

Voltage Fluctuations/

Flicker Emissions

IEC 61000-3-3

Complies

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

The equipment is intended for use in the electromagnetic environment specified in the table below. The customer or

the user of the equipment should ensure that it is used in such an environment.

Emissions Test Compliance Compliance Level Electromag n etic Environment: Guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Voltage dips,

short

interruptions,

and voltage

variations on

power supply

input lines

IEC 61000-4-11

Power frequency

(50/60 Hz)

magnetic field

+/- 6 kV contact

+/- 8 kV air

+/- 2 kV for

power supply lines

+/- 1 kV for

input/output lines

+/- 1 kV differential

mode

+/- 2 kV common

mode

<5% UT

(>95% dip in UT)

for 0.5 cycle

40% UT

(60% dip in UT)

for 5 cycles

3 A/m 3 A/m Power frequency magnetic fields should be at

+/- 6 kV contact

+/- 8 kV air

+/- 2 kV for

power supply lines

+/- 1 kV for

input/output lines

+/- 1 kV differential

mode

+/- 2 kV common

mode

<5% UT

(>95% dip in UT)

for 0.5 cycle

40% UT

(60% dip in UT)

for 5 cycles

Floors should be wood, concrete, or ceramic

tile. If floors are covered with synthetic

material, the relative humidity should be at

least 30%.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

Mains power quality should be that of a typical

commercial or hospital environment.

levels characteristic of a typical location in a

typical commercial or hospital environment.

NOTE: UT is the AC Mains voltage prior to application of the test level.

14

ELECTROMAGNETIC COMPATIBILITY (EMC)

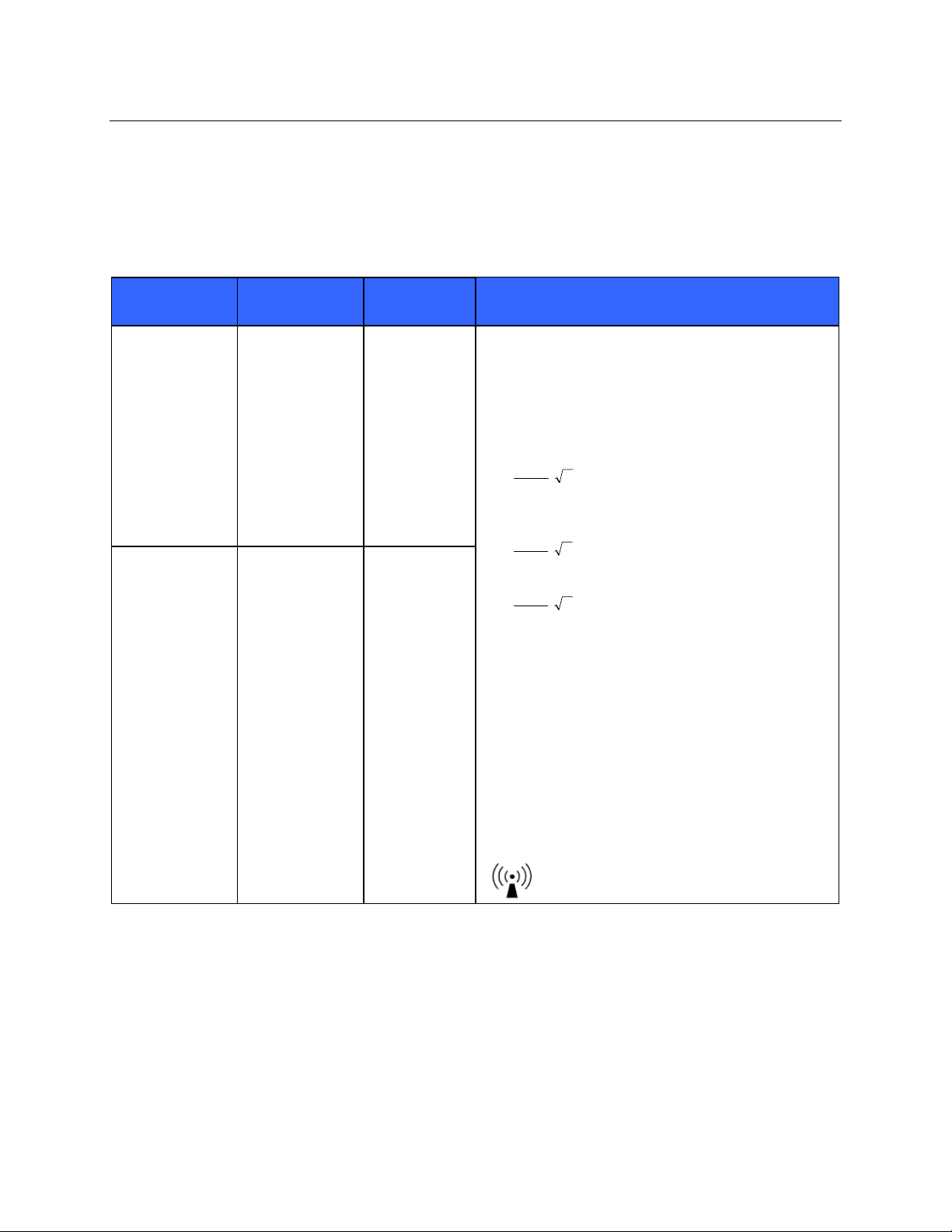

Guidance and Manufacturer’s Declaration: Electromagnetic Immunity

The equipment is intended for use in the electromagnetic environment specified in the table below. The customer or

the user of the equipment should ensure that it is used in such an environment.

Emissions Test

IEC 60601 Test

Level

Compliance

Level

Electromagnetic Environment: Guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to

80 MHz

3 V/m

80 MHz to

2.5 GHz

3 Vrms

150 kHz to

80 MHz

3 V/m

80 MHz to

2.5 GHz

Portable and mobile RF communications equipment

should be used no closer to any part of the equipment,

including cables, than the recommended separation

distance calculated from the equation applicable to the

frequency of the transmitter.

Recommended separation distance

5.3

d

Vrms

3

P

5.3

d

80 MHz to 800 MHz

P

mV

/3

7

d

Where P is the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and d is the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as

determined by an electromagnetic site surveya, should

be less than the compliance level in each frequency

b

range

.

Interference may occur in the vicinity of equipment

marked with the following symbol:

800 MHz to 2.5 GHz

P

mV

/3

a. Field strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios,

amateur radios, AM and FM radio broadcast, and TV broadcast cannot be predicted theoretically with accuracy. To assess

the electromagnetic environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the

measured field strength in the location in which the equipment is used exceeds the applicable RF compliance level above, the

equipment should be observed to verify normal operation. If abnormal performance is observed, additional measures may be

necessary, such as reorienting or relocating the equipment.

b. Over the frequency range 150 kHz to 80 MHz, field strengths should be less than [3] V/m.

15

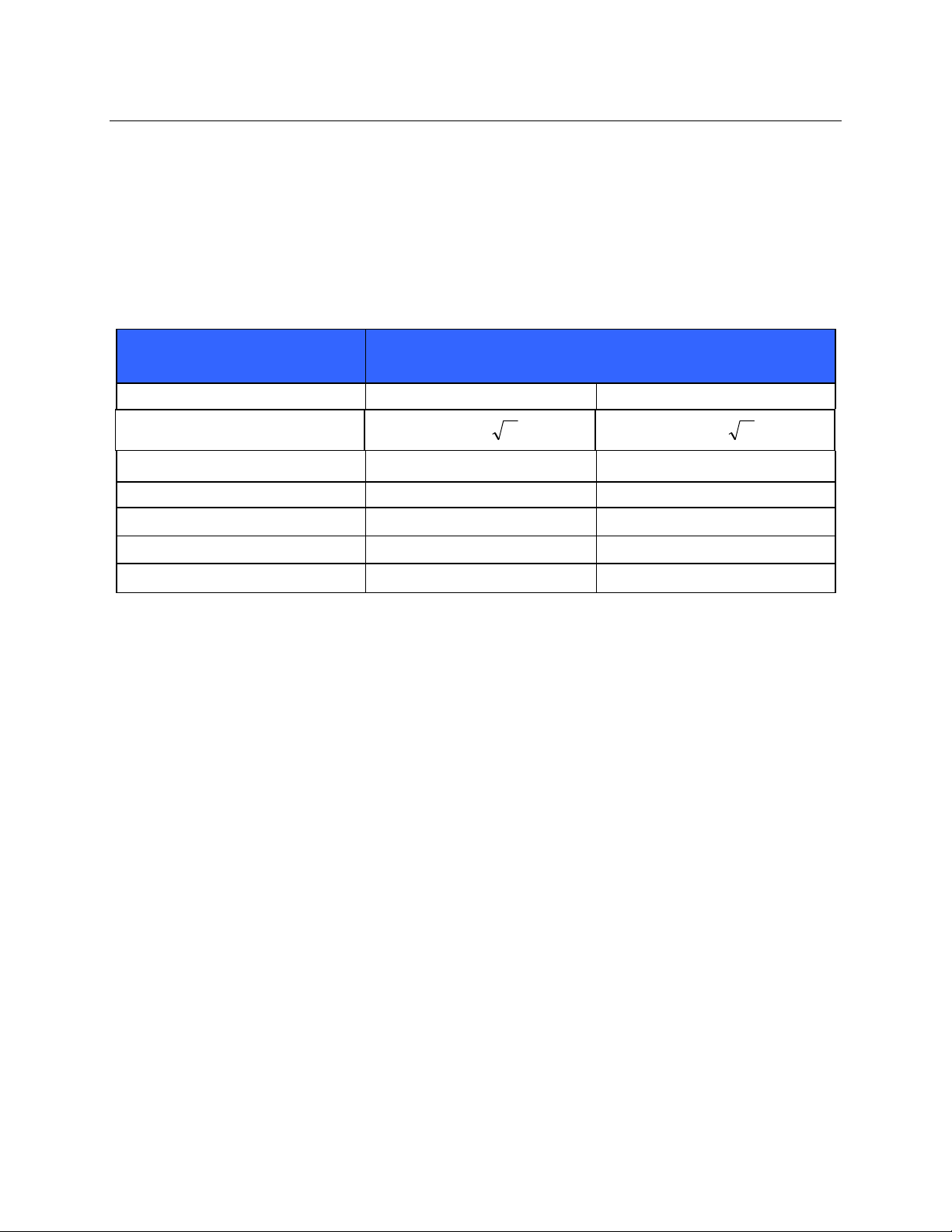

ELECTROMAGNETIC COMPATIBILITY (EMC)

Recommended Separation Distances Between Portable and Mobile RF Communications

Equipment and the Equipment

The equipment is intended for use in the electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the equipment can help to prevent electromagnetic interference by

maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the

equipment as recommended in the table below, according to the maximum output power of the communications

equipment.

Rated Maximum Output Power

of Transmitter W

150 KHz to 800 MHz 800 MHz to 2.5 GHz

Separation Distance According to Frequency of Transmitter (m)

0.01 0.1 m 0.2 m

0.1 0.4 m 0.7 m

1 1.2 m 2.3 m

10 4.0 m 7.0 m

100 12.0 m 23.0 m

Pd 2.1

Pd 3.2

For transmitters rated at a maximum output power not listed above, the recommended separation distance d in

meters (m) can be estimated using the equation applicable to the frequency of the transmitter, where P is the

maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer.

NOTE 1: At 800 MHz, the separation distance for the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by the

absorption and reflection from structures , o bj ect s, an d pe o pl e.

16

MAINTENANCE & CLEANING

SECTION 2

Preventive Maintenance

Preventive maintenance is recommended to be performed on the ELI150c/250c once every 12

months.

Warning: Preventive maintenance is to be performed by Mortara authorized service personnel

only.

2.0 Maintenance Procedure

2.1 Turn unit on and print the device configuration per section 3 of this manual. Attach a

copy to the Preventive Maintenance Report.

2.2 Remove the unit cover per section 4 of this manual.

2.3 Perform a visual inspection of the following items:

2.3.1 Enclosure/Housing – Look for damage or cracks in the external housing or

enclosure that could possibly expose the device to the introduction of foreign

objects or fluids. Attention should also be paid to areas that could expose an

operator or patient to internal circuitry of the device.

2.3.2 Contamination – Look for any contamination that may have occurred over time

that could not be seen with the housing in place.

Fluid damage (perhaps caused during device cleaning)

Debris on or behind display shield

Battery leakage (lithium and main battery)

2.3.3 Internal Cabling – Look for cracked, pinched or partially disconnected cable

connections.

2.3.4 Fuse Ratings – Verify PCB mounted fuses (items 23 and 24) the meet the

specifications defined in the item description listing.

2.3.5 Markings and Labeling – Verify all labels and device markings are clearly visible

and legible to the device user and have not been worn off or rendered

unreadable through the use of harsh cleaning agents.

2.3.6 Integrity of Mechanical Parts – Verify the following items are properly secured to

the device and have not become loose or damaged through usage over time.

AC Inlet

Patient Input Connector

Communication ports and antenna

Writer mechanics/latching mechanism

2.4 Power Testing

* Based upon customer usage and age of battery, replace as needed.

2.4.1 Ensure battery is fully charged before performing these tests, voltage and current

limits are based on a fully charged battery.

2.4.2 Ensure there is no power connected to the UUT AC inlet.

2.4.3 Remove upper housing and writer assembly. Disconnect battery by pulling

battery cable off of the red terminal.

17

SECTION 2

2.4.4 Note battery age (if possible)

This information can be found on the white “date code” sticker located on the

battery (use the earliest date that is not crossed out).

2.4.5 Battery (open circuit)

Measure battery voltage using a voltage meter; verify the meter reads greater

than 12.5vdc.

2.4.6 Battery (load)

Measure the battery voltage using a volt meter and a power resistor load

(10ohm, 20watt) in parallel with the battery. After approximately 5 seconds,

verify the meter reads greater than 11.7vdc.

2.4.7 Off current

Connect a current meter in line with battery. With the UUT power off, verify the

current meter reads less than 100 micro amps.

2.4.8 On current

Turn on the unit and verify the current meter reads less than 250 milli amps.

2.4.9 AC charging current

Apply AC power to the unit and verify that the current draw from the battery

reverses polarity and the value starts decreasing as time increases.

2.4.10 Battery charger output voltage

Disconnect the current meter and measure the battery charger output voltage

between the red disconnected battery cable and the negative terminal on the

battery. It should read between 13.0vdc and 14.0vdc.

2.5 Verify all power cables are reconnected properly

2.6 Reassemble unit in reverse order of disassembly

2.7 Functional Testing

2.7.1 AC LED/Display

Connect AC power cord to the unit and verify that the green AC LED (located to

the left of the display) illuminates continuous.

NOTE: The battery indicator will be clear when charging and will illuminate white

when fully charged.

Verify text on display is clear and legible and there are no flickering or missing

lines/pixels.

2.7.2 Writer

Open and close the writer door to verify smooth operation. Verify that the door

unlatches without sticking and that it latches completely. From the main screen,

simultaneously press shift+alt+RHY. Verify that a test page is printed and the

writer stops on the cue mark. The perforation of the paper should line up with the

tear edge on the writer. Assure there are no gaps in the printing and the print

darkness is uniform across the entire page. Verify the writer gears do not skip

and paper is tracking properly (you may need to print multiple pages to observe

this).

18

SECTION 2

2.7.3 ECG & Keyboard Matrix

Connect an ECG simulator to the AM12 or WAM patient interface. Set the

simulator to a known heart rate and amplitude; preferably to a setting that you

have a “known good” printout for comparison. Press the ECG key to capture an

ECG. Verify there is an audible beep with each key press. Enter Last name

“PARCFL8” (Note: “PARCFL8” ensures the keyboard matrix is fully tested), then

press F6 (Done). Verify that 12 ECG traces print correctly and assess the

printout quality. Ensure uniform darkness across entire printout.

2.7.4 ECG Noise Test

Connect a Shorting Block (TF-0063) and adapter or equivalent to the AM12 or

WAM patient interface. Set the ECG gain on the unit to 20mm/mV. Print a

rhythm strip (approx. 1 page). Verify that no channels have more than 0.5mm of

noise.

2.7.5 Communication options

Verify successful transmission of all applicable communication options by

transmitting the ECG record stored in step 2.7.3 to a compatible receiving device:

Modem

LAN

WLAN

GSM/GPRS

USB

USBD

2.8 Clean unit per the instructions provided on the following page of this section of the service

manual.

2.9 Safety Testing

The following safety tests should be performed in accordance with all local regulatory

requirements:

Earth Leakage

Enclosure Leakage

Patient Leakage

Patient Auxiliary Current

19

SECTION 2

Device Cleaning & Disinfecting

Warning:

Use of non-recommended cleaning agents or practices could cause damage to the device or

possible compromising of the electrical isolation of the device.

Makes sure all cables and accessories a re disconnected from the device prior to performing

cleaning process.

Do not immerse the device in liquid.

Do not use organic solvents, ammonia-based solutions, or abrasive cleaning agents that may

damage equipment surfaces.

Do not use excessive amounts of liquid during cleaning or di sinfecting of the device, as these

fluids could enter the device housing and cause damage to the device.

Recommended Supplies:

Clean lint free cloth

Mild detergent

Luke warm water

10% Household bleach and water solution (Sodium Hypochlorite solution consisting of a

minimum 1:500 dilution and maximum of 1:10 dilution for disinfecting use only)

Device Cleaning:

Disconnect the AC power cord from the device. Clean the exterior surface of the device with a damp (not

wet), soft, lint-free cloth using a solution of mild detergent diluted in luke warm water. After cleaning,

thoroughly dry off the device with a clean, soft cloth or paper towel.

Device Disinfecting:

Clean the device per the instructions defined above, then wipe the exterior of the device with a damp (not

wet), soft, lint-free cloth using a solution of 10% bleach and water. Allow the device to air dry after

disinfecting before returning to use.

20

Mortara Instrument, Inc. Phone (414) 354-1600

7865 N. 86

Milwaukee, WI. 53224

th

Street Fax (414) 354-4760

Mortara Instrument Inc.

ELI 150/250c Preventive Maintenance Report

Unit Serial #: _________________________________________

□ Print device configuration (attach to this report)

□ Remove the units upper housing

□ Perform Visual Inspection

□ Enclosure/Housing

□ Contamination

□ Cabling

□ Fuse Ratings

□ Markings and Labeling

□ Integrity of Mechanically Parts

□ Power Testing

□ Note Battery Age (If Possible) _____/_____ (week/year)

□ Battery (Open Circuit) Voltage _______ VDC

□ Battery (with Load) Voltage _______ VDC

□ Off Current _______ uA

□ On Current _______ A

□ Battery Charger Output Voltage _______ VDC

* Based upon customer usage and age of main battery, replace as needed.

□ Verify all power cables are properly reconnected and reassemble unit

□ Functional testing

□ AC LED/Display Functionality

□ Writer Test

□ ECG & Keyboard Matrix Testing

□ ECG Noise Test

□ Communication Options

□ Device Cleaning

□ Safety Testing PASS / FAIL (circle)

□ Earth Leakage

□ Enclosure Leakage

□ Patient Leakage

□ Patient Auxiliary Current

Technician or Field Service Engineer: ____________________________ Date: _____/_____/_____

21

22

DEVICE CONFIGURATION

SECTION 3

Setting Technician Password

1. From real-time ECG view, select F6 (More) followed by F5 (Set Time/Date).

2. While holding down

3. If required, enter password. This will automatically advance you to the set passwords display.

NOTE: The factory default password is “admin” (lowercase, no quotation marks); it is

suggested that the password be changed after installation of the unit.

4. Enter a technician password followed by a second entry to confirm.

NOTE: Password is case sensitive and alphanumeric.

5. From this display, select F6 (Exit) to return to real-time ECG view.

Configuration Menus

The configuration pages define all operational conditions that do not change on a daily or patient-to-patient basis.

Once you set these default conditions, you will rarely need to use the configuration screens again. To access the

configuration menus:

1. From real-time ECG view, select F6 (More) followed by F5 (Set Time/Date).

2. While holding down

3. If required, enter password. The first configuration screen will appear. Notice the page indicator in the

upper right-hand corner.

To navigate the configuration menus:

Use F4 (Page) to toggle through the configuration pages.

Use F1 (▲) and F2 (▼) to move back and forth through each configuration option.

Use F3 (►) to toggle through pre-programmed available settings per configuration field.

Use F6 (Exit) to return to real-time ECG view. Any changes you have made will be saved.

Use BKSP to erase entry errors.

To print the device’s configuration settings, select F6 (More) from real-time ECG view. Select F6 (More) again

followed by F1 (Print Configuration). The configuration printout captures every configuration setting: the

software version, the cart number of the device, and the date and time that the configuration printout occurred.

(SHIFT), depress ALT and P simultaneously.

(SHIFT), depress ALT and C simultaneously .

23

Summary of Configuration Menus

Configuration Parameter Definition

Software Version Displays software version on printout and display

Cart Number Numeric field 0 to 65535

Site Number Numeric field 0 to 4095

Site Name Alphanumerical field (30 digits)

Telephone Number Alphanumerical field (45 digits)

Language Available software languages

Volume Numerical field 0 to 8

Battery Timeout 10 min, 30 min, 60 min

Flash Size Normal or expanded (optional)

ID Format Standard, Short, Long, Custom

Auto-Fill ID YES/NO

SECTION 3

AC Filter 50 Hz, 60 Hz, None

Paper Speed 25 or 50 mm/sec

Filter Frequency response for printouts: 40 Hz, 150 Hz, 300 Hz

Height/Weight Units lb/in or kg/cm

Date Format US (mm/dd/yyyy) or European (dd.mm.yyyy)

Interpretation YES/NO

Reasons YES/NO

Append Unconfirmed Report, Reviewed by

# of Copies 0 – 9

Copies with Interp. YES/NO

# ECGs Retrieved 0 – 7

Delete Rule Post Plot, Post Transmit, Post Plot/Xmt

Storage Sensitivity Normal or High

Auto-Save ECG YES/NO

Auto-Print ECG YES/NO

Cap Lock YES/NO

Use A4 paper

(ELI 250c only)

Rhythm Format 3 or 6 channel (ELI 150c); 3, 6, or 12 channel (ELI 250c)

3 Rhythm Lead 1 V1-V6, I, II, III, aVR, aVL, aVF

3 Rhythm Lead 2 V1-V6, I, II, III, aVR, aVL, aVF

3 Rhythm Lead 3 V1-V6, I, II, III, aVR, aVL, aVF

6 Rhythm Lead 1 V1-V6, I, II, III, aVR, aVL, aVF

YES/NO

24

Summary of Configuration Menus (continued)

Configuration Parameter Definition

6 Rhythm Lead 2 V1-V6, I, II, III, aVR, aVL, aVF

6 Rhythm Lead 3 V1-V6, I, II, III, aVR, aVL, aVF

6 Rhythm Lead 4 V1-V6, I, II, III, aVR, aVL, aVF

6 Rhythm Lead 5 V1-V6, I, II, III, aVR, aVL, aVF

6 Rhythm Lead 6 V1-V6, I, II, III, aVR, aVL, aVF

Plot Format

3+1 Rhythm Lead V1-V6, I, II, III, aVR, aVL, aVF

3+3 Rhythm Lead 1 V1-V6, I, II, III, aVR, aVL, aVF

3+3 Rhythm Lead 2 V1-V6, I, II, III, aVR, aVL, aVF

3+3 Rhythm Lead 3 V1-V6, I, II, III, aVR, aVL, aVF

Bar Code Scanner YES/NO

Avg RR YES/NO

3, 3+1, 3+3, 6 channel; Cabrera or standard (ELI 150c)

3+1, 3+3, 6, 6+6, 12 channel; Cabrera or standard (ELI 250c)

SECTION 3

QTcB YES/NO

QTcF YES/NO

ECG Capture Last 10 or Best 10

Band Mode

(GSM/GPRS only)

(ELI 150c only)

Sync Media

DHCP

(active for LAN or WLAN)

IP Address

(active for LAN or WLAN)

Def Gateway

(active for LAN or WLAN)

Sub Net Mask

(active for LAN or WLAN)

Host IP

(active for LAN or WLAN)

Port Number

(active for LAN or WLAN)

Security

LAN MAC XX XX XX XX XX XX

850/1900MHz (US) or 900/1800MHz(EU)

None, Modem, LAN, WLAN, GSM/GPRS

(GSM/GPRS option applies to ELI 150c only)

YES/NO

XXX.XXX.XXX.XXX

XXX.XXX.XXX.XXX

XXX.XXX.XXX.XXX

XXX.XXX.XXX.XXX

Numeric field (9 digits)

None, WEP128, WEP64, WPA-PSK, WPA-LEAP, WPA-PSK64, WPA-PSK128,

WPA-LEAP 64, WPA-LEAP128, WPA2-PSK, WPA2-PEAP

WLAN MAC XXXXXXXXXXXX

SSID Alphanumerical field (30 digits) (not on printout)

25

Summary of Configuration Menus (continued)

Configuration Parameter Definition

WEP Key Numeric (1 digit) (not on printout); valid range 1-4

WEP Key ID Alphanumerical field (26 digits) A-F, 0-9 (not on printout)

PSK Passphrase Alphanumeric field (64 digits) (not on printout)

LEAP User Name Alphanumeric field (32 digits) (not on printout)

LEAP Password Alphanumeric field (32 digits) (not on printout)

PEAP User Name Alphanumeric field (63 digits) (not on printout )

PEAP Password Alphanumeric field (63 digits) (not on printout)

Worklist Management Standard or Refresh

Comm Protocol UNIPRO32, DICOM32, DICOM32ext OR UNIPRO64, DICOM64 (V2.x software)

Sync Mode None, XMT, XMT+Orders

Sync Date/Time YES/NO

XMT Mandatory Fields None, Last Name, ID, Last Name+ID

SECTION 3

26

SECTION 3

Configuration Settings

Software Version

Identifies the software version of your electrocardiograph.

Cart Number

Indicates which electrocardiograph acquired or transmitted a particular ECG.

Site Number

Identifies the site of your device. Site numbers designate the hospital, clinic, or institution for ECG records stored in

an E-Scribe system and must be defined for transmitting and retrieving ECGs from that system. You can use up to

four digits for the site number. Numbers from 0 – 4095 are supported.

Site Name

Defines your clinic, hospital, or office name. You can enter up to 30 alphanumeric characters. The site name prints

at the bottom, left edge of the ECG printout.

Telephone Number

Specifies the telephone number for internal modem transmission to another unit or to an E-Scribe system. Enter up

to 45 numeric characters.

You may need to dial a 9 to get an outside line. To wait for an additional dial tone, use the letter W.

EXAMPLE: 9W14145554321

To insert a pause, use a comma (,).

To change tone dialing to pulse dialing, use the letter P.

EXAMPLE: P14145554321

(If necessary, you can use both the letter W and the letter P in the same phone number.)

NOTE: It is not necessary to use alpha characters in the telephone number with GSM/GPRS mobile

connectivity.

TIP: To quickly delete or modify a phone number, use a shortcut. From the applicatio n screen,

simultaneously press (SHIFT) + ALT + P. To edit an existing telephone number, use the Tab key.

Language

There are several lang uages available on the electrocardiograph.

CAUTION: Function labels are immediately translated upon selecting a new language and exiting the

configuration screen.

27

SECTION 3

If an unknown language is visible, use the following steps to revert to the language of your country:

1. F6 (More) from real-time ECG view.

2. Select F5 (Set Time/Date).

3. Simultaneously press (SHIFT) + ALT + C.

4. Enter password (“admin”)

5. Press F2 (▼) four times.

6. Press F3 (►) until the desired language appears.

7. F6 (Exit) to return to real-time ECG view.

Alphabets of specific languages may require use of special characters in demographic fields. This is accomplished

by using the SYM key on the keyboard.

Volume

Defines the keyboard click loudness. Available settings range from 0 (off) to 8 (loud).

Battery Time Out

Determines when the electrocardiograph will switch off in order to conserve the battery life of the device. The

battery time out will only occur if the keyboard has not been depressed for the time specified. The battery time out

setting is ignored if an active ECG signal is detected during transmission or while rhythm printing.

Flash Size

Indicates ECG storage capacity. Normal indicates standard memory capacity. Expanded indicates the optional

expanded memory has been installed.

ID Format

Defines the format for the patient demographic information prompts. There are three standard formats: short,

standard, or long. A custom ID format can be downloaded from ELI Link or an E-Scribe system. See Appendix A

to download a custom ID.

The short format includes the patient's last and first name, patient ID number, date of birth (automatically calculates

the age), and gender.

The standard format includes the patient's last name, patient ID number, age, height, weight, gender, race,

medication 1, medication 2, and a location field.

The long format is identical to the standard format except that it includes the patient's first name, room, and

comment fields.

Auto-Fill ID

When enabled, the device will automatically populate last name, first name, date of birth, age, and gender in the ID

screen if records with matching patient ID are found in the ECG directory.

28

SECTION 3

AC Filter

The device removes 60 Hz or 50 Hz interference. The setting you select depends on the line frequency in your

country. Always use the 60 Hz setting in the U.S. If AC interference is present, check to see that the proper AC

filter is selected.

Paper Speed

Configure to 25 mm/s or 50 mm/s for default ECG printouts. For rhythm printouts and display, speeds of 5 mm/s or

10 mm/s are also available. See Section 3 to change speeds for display or rhythm printing. Paper speed is printed at

the bottom right corner of the ECG printout.

Filter

The ECG plot-frequency filter (or print filter) can be set to 0.05 to 40 Hz, 0.05 to 150 Hz, or 0.05 to 300 Hz. The

plot-frequency filter does not filter the acquired digital record. A 40 Hz plot-filter setting will reduce the noise

(40 Hz and higher frequencies) on the printed ECG, and a 150 Hz plot-filter setting will reduce the noise (150 Hz

and higher frequencies) on the printout; a 300 Hz plot-filter setting will not filter the printed ECG. The filter setting

is printed at the bottom right corner of the ECG printout.

Height/Weight Units

Defines the units of weight and height to either pounds/inches (lb/in) or kilograms/centimeters (kg/cm).

Date Format

Select either U.S. or European format for enteri ng and disp l ay i ng the patient’s date of birth.

U.S. Date Format: MM/DD/YYYY

European Date Format: DD.MM.YYYY

NOTE: The date format option does not modify the acqui sition date printed on each ECG.

Interpretation

The device automatically analyzes ECGs and prints the optional interpretation on the ECG printout. This setting

allows you to select or suppress the “interpretive” text on the ECG report.

NOTE: The ECG interpretations offered by the device are only significant when used in conjunction with

a physician over-read as well as consideration of all other relevant patient data.

Reasons

The reasons statements indicate why a particular interpretive statement was printed. Reasons statements print

enclosed in [square brackets] within the interpretive text if the interpretation option is turned on. Turning the

reasons statement function on or off does not affect the measurements performed or the interpretive statements

selected by the analysis program.

For Example:

Anteroseptal Infarct [40+ ms Q WAVE IN V1-V4]

Where “Anteroseptal Infarct” is the interpretive statement,

and “40+ ms Q WAVE IN V1-V4” is the reason statement or explanation as to why the

interpretive statement was printed.

29

SECTION 3

Append

A status or statement phrase can be appended to the ECG and printed under the interpretive text printout. Either

“unconfirmed report” or “reviewed by” can be selected; however, if you wish to have nothing appended to the ECG,

select “blank”.

Number of Copies

Defines the number of printed copies when an ECG is taken. A zero (0) setting prints the original only; one (1)

prints the original plus 1 copy; two (2) prints the original plus 2 copies, and so on. Up to 9 copies may be selected.

Copies with Interpretation

Defines whether or not printed copies will include interpretation. The clinician may request the first ECG printout

with the interpretation included. Additional copies may be printed with or without the interpretation.

Number of ECGs Retrieved

Defines the number of ECGs retrieved from an E-Scribe system. The ECGs are retrieved by ID number. A zero (0)

setting retrieves the most current ECG for that ID number. Settings from one (1) to seven (7) retrieve the most

current ECG plus “X” number of ECGs identified by the entered value. EXAMPLE: If you enter the number 5, you

will retrieve the most current ECG plus the five preceding ECGs for that ID number. ECGs retrieved from the

E-Scribe are only printed at the device and not saved.

Delete Rule

Defines the rule to mark ECGs as deleted in the ECG directory. ECGs that are marked for deletion will be

automatically removed or erased based on their acquisition date (a first-in/first-out philosophy) to make room for the

new ECG record. ECGs are only erased from the directory when they are marked for deletion and if the directory

becomes full. More than one ECG may be removed from the directory in order to make room for the new incoming

record. The delete rule selections are:

Post Plot = ECG is automatically marked for deletion after printing

Post Transmit = ECG is automatically marked for deletion after transmission

Post Plot/Transmit = ECG is automatically marked for deletion after transmission and printing

Storage Sensitivity

Dictates the resolution of all stored ECG records. The sensitivity setting is either Normal or High. If the value is set

to High, the stored ECG will have a high resolution. As a result, the record size will be large and will reduce the

storage capacity in the ECG directory.

Auto-Save ECG

Defines whether or not a newly acquired ECG will be automatically saved to the directory once it is acquired and

printed. If the auto-save configuration option is set to No and the record is printed, the device will prompt you to

“Save ECG?” F1 (Save) will store the ECG in the directory.

Auto-Print ECG

Defines whether or not the device will automatically print the ECG after acquisition . If the selected configuration

option is set to No, a manual printout is possible.

30

SECTION 3

Caps Lock

All character entry is translated to uppercase.

Use A4 Paper

The ELI 250c accommodates use of Z-fold thermal paper in either letter size (8.5 x 11 inches; 216 x 279 mm) or A4

size (8.27 x 11.69 inches; 210 x 297 mm). The provided paper tray spacer is required for use with A4 size paper.

Rhythm Formats

Defines the default values for rhythm printing. It is possible to set a 3 or 6-channel default rhythm format for the

ELI 150c. For the ELI 250c, a 3, 6, or 12-channel default r hy t hm format is possible. Define rhythm leads one

through three to customize a 3-channel rhythm printout or define rhythm leads one through six to customize the

6-channel rhythm printout .

Plot Format

Defines the default for one of the available plot formats in either standard or Cabrera presentation. Please note that

regardless of the plot format selected, 10 seconds of 12 leads are always stored.

The ECG plot options are:

Format Option ECG Data

2.5 seconds of 12 leads in a 3-channel format, plus 10second rhythm strip of one user-selectable lead in a 1-

3+1

3

(ELI 150c only)

6

3+3

12

(ELI 250c only)

6+6

(ELI 250c only)

channel format.

Cabrera also available.

2.5 seconds of 12 leads in a 3-channel format.

Cabrera also available.

5 seconds of 12-leads in a 6-channel format.

Cabrera also available.

2.5 seconds of 12 leads in a 3-channel format, plus 10second rhythm strip of user-selectable leads in a 3channel format.

Cabrera also available.

10 seconds of 12 leads in a one page printout.

5 seconds of 6 leads in a 6-channel format, plus 10second rhythm strip of user-selectable leads in a 6channel format.

Cabrera also available.

31

SECTION 3

Rhythm Leads

Displays continuous rhythm of selected ECG leads and permits printing of selected leads. User may toggle between

selected leads, system set leads, or I, II, III, aVR, aVL, and aVF followed by V1, V2, V3, V4, V5, and V6.

NOTE: Rhythm acquisition is not stored in memory, only printed.

NOTE: See Section 3 to acquire a rhythm printout.

Average RR

Enabling this option will display an averaged RR value to appear on the report.

QTcB

Enabling this option will display a Bazett’s corrected QT value on the report along with the default linear

QTc value.

QTcF

Enabling this option will display a Fridericia corrected QT value on the report along with the default linear

QTc value.

ECG Capture

Up to 5 minutes accumulated ECG data can be acquired internally for use with the Best 10 feature. The device

automatically selects the best 10 seconds from within the 5-minute buffer.

Users can switch between BEST 10 or LAST 10 by selecting F5 (More) followed by F5 (Last) or F5 (Best)

depending on the current view.

Band Mode

Use 850/1900 MHz (US) or 900/1800 MHz (EU). (Applies to ELI 150c only.)

Sync Media

Defines the default transmission setting. Select None, Modem, LAN, WLAN, or GSM/GPRS (GSM/GPRS option

applies to ELI 150c only). Optional connectivity options which have been purchased and installed will be available

for default selection.

An ELI x50c communicating over GPRS can be configured to automatically set its clock to match the time on a time

sync server. The time sync server must return a time stamp in the ELI x50c’s local time zone via the daytime

protocol (RFC 867). The time sync server must have a public IP address, and the standard port is 13. The server

must return the time in one of the following formats:

Format 1

day mon dd HH:mm:ss yyyy

Example

Wed Jul 15 17:05:49 2010

32

SECTION 3

Format 2

hh.mm.ss tt mm/dd/yyyy

Example

02:38:51 PM 07/18/2011

Time sync servers running the Dimension 4 (http://www.thinkman.com/dimension4/index.htm

support Format 1.

DHCP

Defines whether the Dynamic Host Communication Protocol (DHCP) will be used to obtain an IP address. If DHCP

is Yes, the network will automatically and dynamically assign an IP address. If DHCP is No, you must enter the IP

address, def gateway, and sub net mask.

NOTE: All parameters related to network connection must be entered under the direction of the IT

Manager of the facility where the device is installed.

IP Address

Enter the fixed IP address for network transmissions (if DHCP is not selected).

Def Gateway

Enter the address of the default gateway (if DHCP is not selected).

Sub Net Mask

Enter the sub net address (if DHCP is not selected).

Host IP

Enter the IP address of the host server.

NOTE: Addresses are always entered as 4 sets of 3 digits; therefore , an ad dress of 19 2. 168. 0. 7 m ust b e

entered as 192.168.000.007.

Port Number

Enter the port number used by the host server.

LAN MAC

Shows the MAC address of the LAN.

Security (WEP)

Wired Equivalent Privacy (WEP) is an encrypted security prot ocol (part of the 802.11 standard). Access points can

have multiple WEP keys stored. Each one of them is identified by a number (e.g., 1, 2, 3, 4).

WEP Key

Enter the WEP key number.

) time sync software

33

SECTION 3

WEP Key ID

Enter the 128-bit WEP key ID value (26 digits in 13 sets of two digits).

WLAN MAC

Shows the MAC address of the device’s wireless module for configuring access points.

SSID

Service Set Identifier (SSID) is the name of the wireless network. All ELI 150c electrocardiographs that will

transmit to the same network must have the same SSID name. This field is case sensitive.

WPA-PSK/WPA2-PSK

Allows for implementation of the “personal mode” of WPA. This mode of encryption employs Temporal Key

Integrity Protocol (TKIP

PSK Passphrase

The passphrase may be from eight to 63 ASCII characters or 64 hexadecimal digits (256 bits).

WPA-LEAP

Cisco® LEAP (Light Extensible Authorization Protocol) enables use of the device with wireless networks

employing the LEAP encryption protocol.

LEAP User Name

User name can be up to 32 characters in length.

LEAP Password

LEAP password can contain up to 32 characters.

WPA2-PEAP

Enables use of the device with wireless networks employing the PEAP encryption protocol.

PEAP User Name

User name can be up to 63 characters in length.

PEAP Password

Password can contain up to 63 characters.

) which dynamically changes keys as the system is used.

34

SECTION 3

Worklist Management

The device can download and process ECG order lists from the E-Scribe or another compatible information

management system which identifies the ECGs (or ECG orders) needed for particular patients. Implementation of

an order-based workflow can significantly reduce demographic data entry errors at the electrocardiograph. Orders

are deleted from the list when the ordered ECG is acquired.

When set to Standard, new order lists are appended to the remaining list. When set to Refresh, each new order list

will override the previously downloaded one.

Comm. Protocol

Select UNIPRO32, DICOM32, OR DICOM32ext for software v1.x.x. DICOM32 and DICOM32ext are only

available if the DICOM option has been installed. Select UNIPRO64 OR DICOM64 FOR SOFTWARE V2.x.x.

DICOM64 is only available if the DICOM option has been installed.

NOTE: This parameter must be entered under the direction of the IT Manager of the facility where the

device is installed.

NOTE: Units ship by default with Comm Protocol set to UNIPRO32. The UNIPRO32 setting is not

supported by E-Scribe versions prior to V8.10 or ELI Link versions prior to V3.00. For questions about

compatibility of your device with E-Scribe or ELI Link and UNIPRO32, contact Mortara Technical

Support. Units shipped with v2.x.x software will not connect with E-Sc ribe and need Eli Link v4.0 or

above.

Sync Mode

Select None, XMT, or XMT+Orders. None requires a manual transmission of reports and then a second manual

request to receive orders from the cardiology management system. XMT will automatically transmit the report;

XMT+Orders will both transmit the report and retrieve the orders.

Sync Date/Time

Select Yes or No. Yes will synchronize the date/time with the approved cardiology management system. With No,

there will be no date/time synchronization. Date/time synchronization is done through ELI Link V3.10 or later.

XMT Mandatory Fields

Defines fields required for ECG transmission to the cardiology management system. None will allow data

transmission without limitation; Last Name requires the technician to enter a minimum of the Last Name; Last

Name and ID requires the technician to enter a minimum of the Last Name and the patient’s ID.

35

SECTION 3

36

UNIT DISASSEMBLY

ELI 150c

SECTION 4

ELI 250c

37

SECTION 4

Removal of the Unit from Cart

Remove two thumbscrews from underneath the cart platform by turning counterclockwise. *Cart may not be exact

model as pictured.

*The ELI 150c and ELI 250c are very similar in design, so only the ELI 150c will be shown, unless an important

difference needs to be identified.

Cover Assembly Removal

Turn the unit upside down and use a T10 Torx driver to remove the 6 housing screws shown below. Once the

screws are removed, carefully flip the Device back over so that it is upright.

Item# 31

38

SECTION 4

Open the writer drawer then lift the upper housing while rotating it counterclockwise according to the picture below.

This will allow the writer cover to pass through the housing opening to free the upper housing.

CAUTION: Remove battery power to the unit by disconnecting the battery connector BEFORE

removing the keyboard assembly. If battery power is not removed prior to disconnecting the keyboard

cable, damage to the motherboard may result.

Writer Removal

To remove the writer assembly, remove the 4 chassis screws shown below. Once they are removed, carefully turn

the unit over supporting the loose writer to ensure the cable connections are not stressed during the process.

Item# 36

39

SECTION 4

Disconnect the writer interface cables and the motor cable shown below, then remove the writer assembly.

40

SECTION 4

NOTE: The writer assembly can be obtained as a complete assembly for service purposes, or a specific

part or subassembly can be obtained to repair a specific writer related issue. The entire writer door with

the platen roller, latch assembly, and instruction label attached is availab le as an assembly; and the

thermal print head, print head mount, anti -stat i c brush, and associated cables are also available as an

assembly. (Refer to the SERV ASSY item numbers on the item listing at the end of this section of the

manual).

To remove the writer door assembly, slide the door open and press downward on the latching tabs to allow the writer

door assembly to be slid out.

41

SECTION 4

The writer latch mechanism can be disassembled to gain access to the writer latch bar and spring by removing the 4

screws shown below.

Item # 34

(View below with screws removed)

To remove the Gearbox assembly, remove the three screws as shown in the illustration below.

Item #36

42

SECTION 4

To remove the writer motor, the pinion gear must be removed by loosening the pinion set screw as shown above.