•

.

Instructions

Manual

MORS0

Mitring

machine

Model

F

61497

MASKINFABRIK

HARALDSVEJ

21 -

DK-8900 RANDERS - DANMARK

s

MASKINFABRIK

HARALDSVEJ

21

DK-8900

PANDERS

TLF.+45864351

55

FAX.

-i-

45 86 43

51

00

Instructions

manual

MORS0

Mitring

machine

Model

F

CONTENTS

0-1

I

I

Beware

of

the

extreme

sharp knives

Introduction page

A-l

Functional

Description

general description page

B-l

machine description

page

B-2

description

of the

lever system page

B-3

description

of

cutting page

B-4

Technical Data page

C-l

Dimensions

of

work

pieces page

C-2

Mounting

Instructions

general page

D-l

mounting

of

table extension

and

divided

beam page

D-l

Operating Instructions

operating

devices page

E-l

before

starting page

E-2

degree adjustment

of

fences page

E-3

adjustment

of

length

of

moulding

page

E-4

adjustment

of

rebate

supports page

E-5

adjustment

of

forward

movement page

E-5

adjustment

of

height stop page

E-6

working

procedure page

E-7

after

working

procedure page

E-7

Service References

lubrication

instructions page

F-l

cleaning

page

F-l

changing

of

knives

page

F-2

grinding

of

knives page

F-3

regulation

of

draw

bar

page

F-4

adjustment

of

forward

movement page

F-4

adjustment

of

springs page

F-5

adjustment

of

height

movement

page

F-6

changing

of

spare parts page

F-7

Locating

Faults / Methods

for

Repair page

G-l

Safety

safety

devices

regulations

page

H-l

page

H-l

MORS0 F -9503 0-1/gb1

MASKINFABRIK

HARALDSVEJ

21

DK-8900

PANDERS

TLF.

+ 45 86 43 51 55

FAX.

+ 45 86 43 51 00

Instructions manual

MORS0 Mitring machine

Model

F

CONTENTS

0-2

Beware

of

the

extreme

sharp knives

Index

of

Spare Parts

survey

machine

knife

block

unit

drive

mechanisme

rebate supports

Supplement

page

1-1

page

1-2

page

1-3

page

1-4

page

1-5

K

Accessories:

rebate

support

attachment, autom.

description

page

L-l-1

installation

instructions page

L-l-2

adjustment

of

rebate

supports page

L-l-3

index

of

spare parts page

L-2

MORS0 F -9503

0-2/gb1

4

MASKINFABRIK

HARALDSVEJ

21

DK-8900RANDERS

TLF.T45864351

55

FAX.

+ 45 86 43 51 00

Instructions

manual

MORS0 Mitring machine

Model

F

0©

Typ«EH

picture

A-1-1

I

INTRODUCTION

A-1

g

\

ipiWr

\

A-1

Beware

of

the

extreme

sharp

knives

We

recommend

to

read

this instruction manual

carefully

before

the

first

starting

of the

machine.

Defects

of the

machine provably arosen

due

to

mistakes

in

operation

will

not be

covered

by

the

warranty.

Use

of the

Instruction

Manual:

In

this instruction manual

all

information

needed

for

using

all

possibilities

of the

MORS0-mitring machine

is

found.

(see

picture

A-1-1)

(1)

Head Lines

Refers

to the

head line

of the

chapter.

(2)

Index

of

pages

The

letter

is the

description

of the

chapter.

The

figure

is the

consecutive

page number

in

the

chapter.

(3)

Text

The

texts

belonging

to the

chapter

in

which

you

will

find

all

information

and

explanations

necessary.

(4)

Illustration

Drawing

to the

text

in

(3).

MORS0 F -9503 A-1/gb1

I

g_

MASKINFABRI

HARALDSVEJ21

DK-8900

RANDERS

TLF.

+ 45 86 43 51 55

FAX.

+ 45 86 43 51 00

Instructions

manual

MORS0

Mitring machine

Model

F

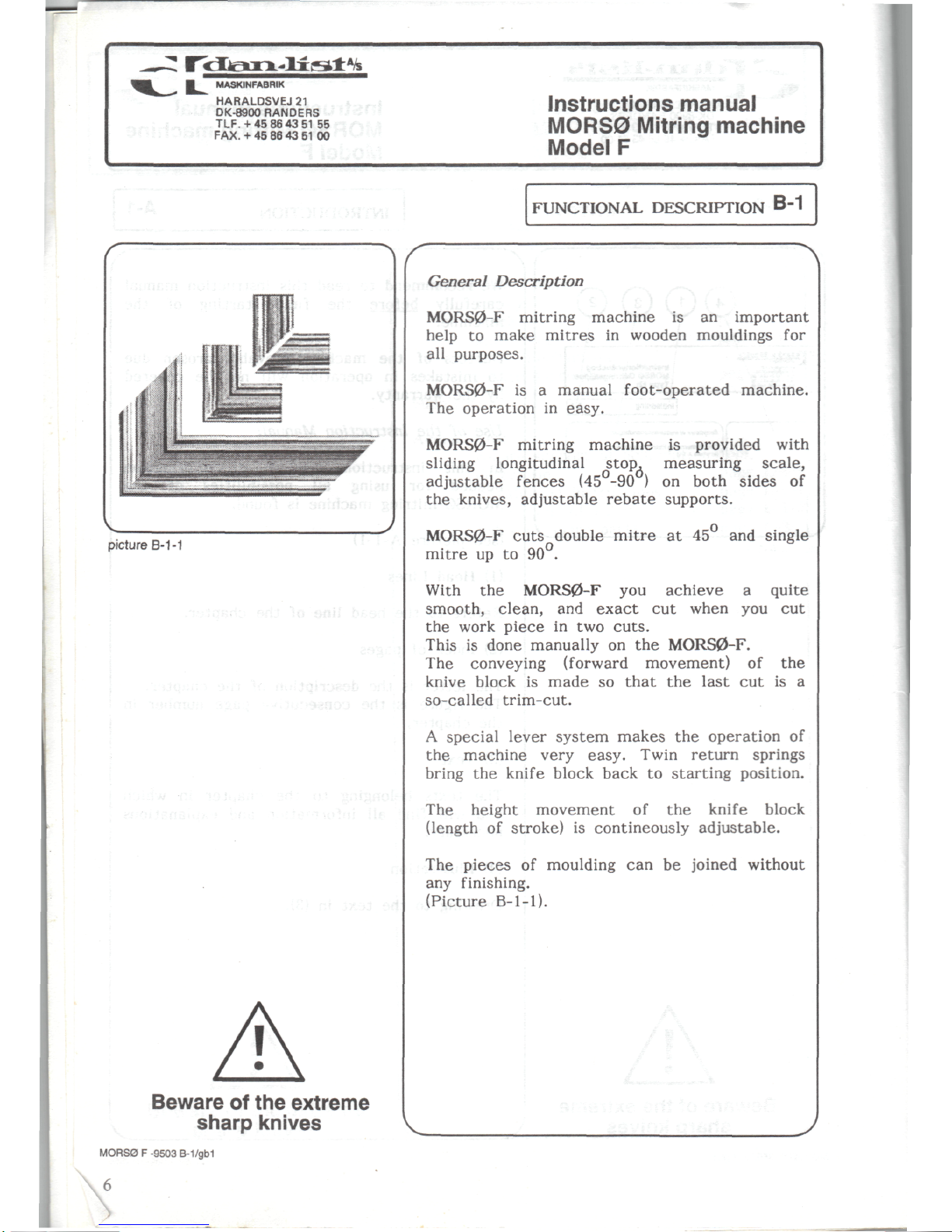

picture

B-1-1

FUNCTIONAL

DESCRIPTION

B-1

Beware

of

the

extreme

sharp

knives

General

Description

MORS0-F

mitring machine

is an

important

help

to

make

mitres

in

wooden mouldings

for

all

purposes.

MORS0-F

is a

manual foot-operated machine.

The

operation

in

easy.

MORS0-F

mitring machine

is

provided with

sliding

longitudinal stop, measuring

scale,

adjustable

fences

(45°-90

) on

both

sides

of

the

knives, adjustable

rebate

supports.

MORS0-F

cuts

double

mitre

at 45 and

single

mitre

up to

90°.

With

the

MORS0-F

you

achieve a quite

smooth, clean,

and

exact

cut

when

you cut

the

work

piece

in two

cuts.

This

is

done manually

on the

MORS0-F.

The

conveying

(forward

movement)

of the

knive

block

is

made

so

that

the

last

cut is a

so-called

trim-cut.

A

special

lever

system

makes

the

operation

of

the

machine very

easy.

Twin return springs

bring

the

knife

block back

to

starting position.

The

height movement

of the

knife

block

(length

of

stroke)

is

contineously adjustable.

The

pieces

of

moulding

can be

joined without

any

finishing.

(Picture B-1-1).

MORS0 F -9503

B-1/gb1

MASKINFABRIK

HARALDSVEJ21

DK-8900

PANDERS

TLF.

+ 45 86 43 51 55

FAX.

+ 45 86 43 51 00

Instructions

manual

MORS0 Mitring machine

Model

F

FUNCTIONAL

DESCRIPTION

B-2

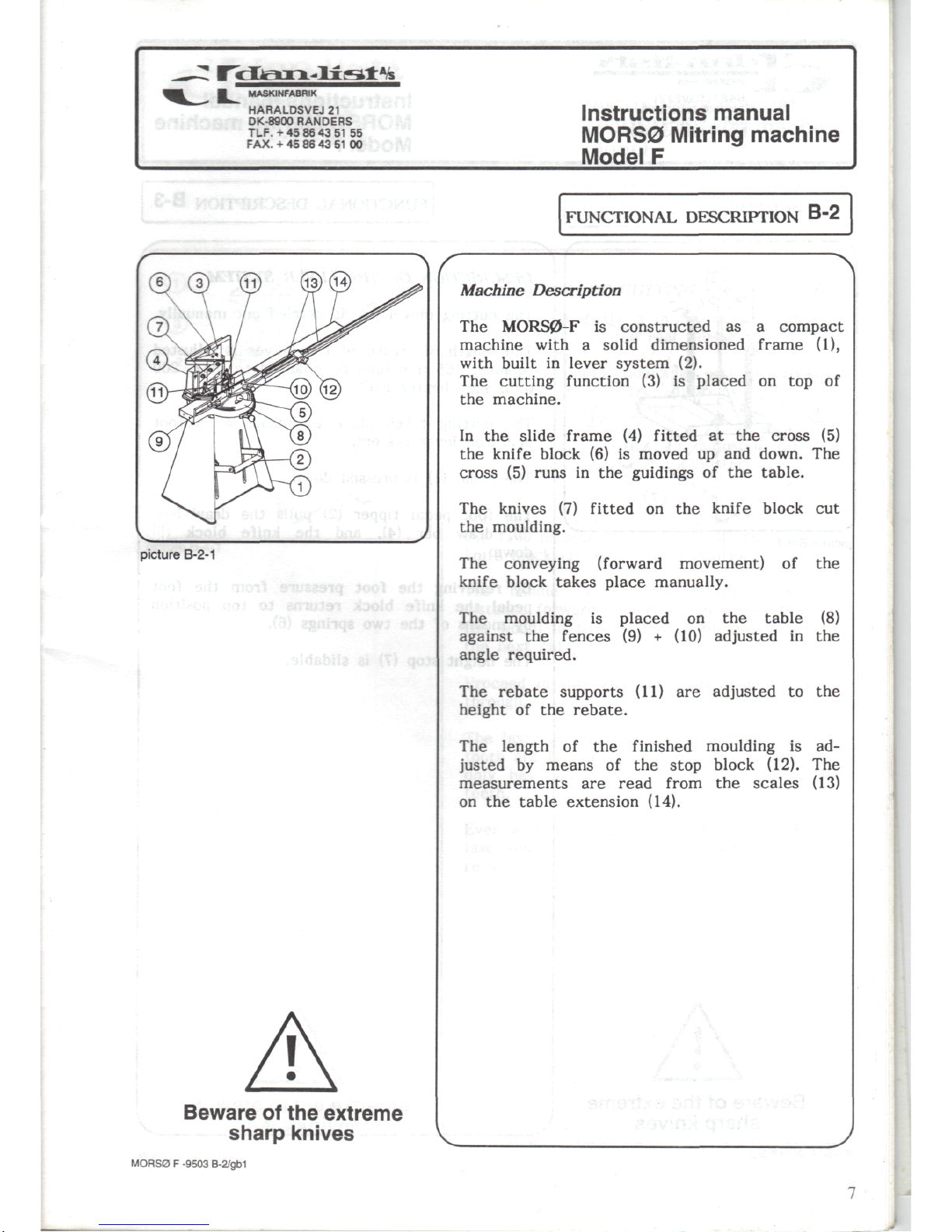

picture

B-2-1

I

Beware

of

the

extreme

sharp knives

Machine

Description

The

MORS0-F

is

constructed

as a

compact

machine with a solid dimensioned frame (1),

with

built

in

lever

system

(2).

The

cutting function

(3) is

placed

on top of

the

machine.

In

the

slide frame

(4)

fitted

at the

cross

(5)

the

knife

block

(6) is

moved

up and

down.

The

cross

(5)

runs

in the

guidings

of the

table.

The

knives

(7)

fitted

on the

knife

block

cut

the

moulding.

The

conveying

(forward

movement)

of the

knife

block

takes

place

manually.

The

moulding

is

placed

on the

table

(8)

against

the

fences

(9) +

(10) adjusted

in the

angle

required.

The

rebate

supports

(11)

are

adjusted

to the

height

of the

rebate.

The

length

of the

finished moulding

is ad-

justed

by

means

of the

stop block (12).

The

measurements

are

read

from

the

scales

(13)

on

the

table extension (14).

MORS0 F -9503

B-2/gb1

MASKINFABRIK

HARALDSVEJ

21

DK-8900RANDERS

TLF.+

45864351

55

FAX.

+ 45 86 43 51 00

Instructions manual

MORS0 Mitring machine

Model

F

FUNCTIONAL

DESCRIPTION

B-3

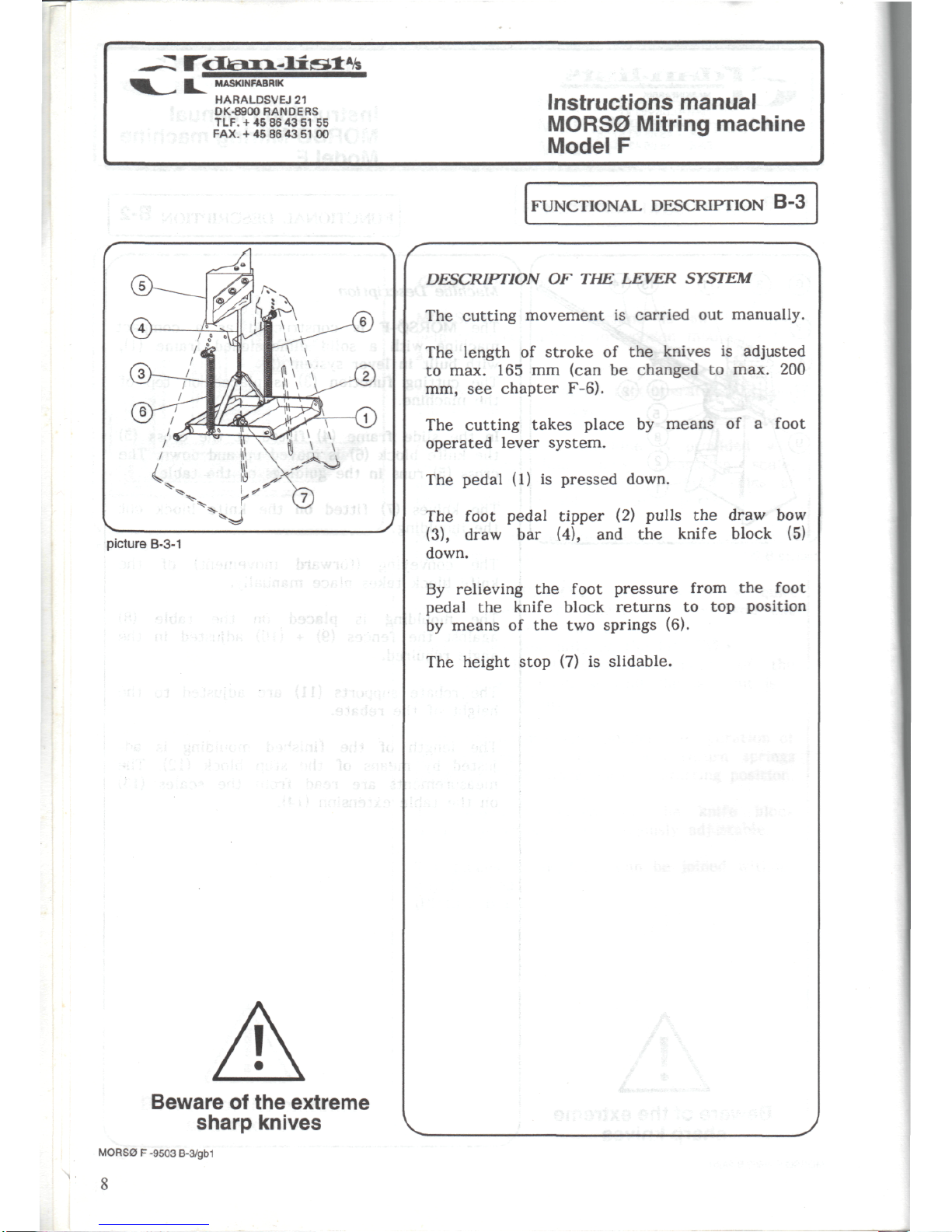

picture

B-3-1

•

•

'

'

Beware

of

the

extreme

sharp knives

DESCRIPTION

OF THE

LEVER SYSTEM

The

cutting movement

is

carried

out

manually.

The

length

of

stroke

of the

knives

is

adjusted

to

max.

165 mm

(can

be

changed

to

max.

200

mm,

see

chapter F-6).

The

cutting takes place

by

means

of a

foot

operated lever

system.

The

pedal

(1) is

pressed

down.

The

foot pedal

tipper

(2)

pulls

the

draw

bow

(3),

draw

bar

(4),

and the

knife

block

(5)

down.

By

relieving

the

foot

pressure

from

the

foot

pedal

the

knife

block

returns

to top

position

by

means

of the two

springs (6).

The

height stop

(7) is

slidable.

.

MORS0 F -9503

B-3/gb1

8

MASKINFABRIK

HARALDSVEJ

21

DK-8900

BANDERS

TLF.-t-45

86 43 51 55

FAX.

+ 45 86 43 51

00

Instructions

manual

MORS0 Mitring machine

Model

F

FUNCTIONAL

DESCRIPTION

B-4

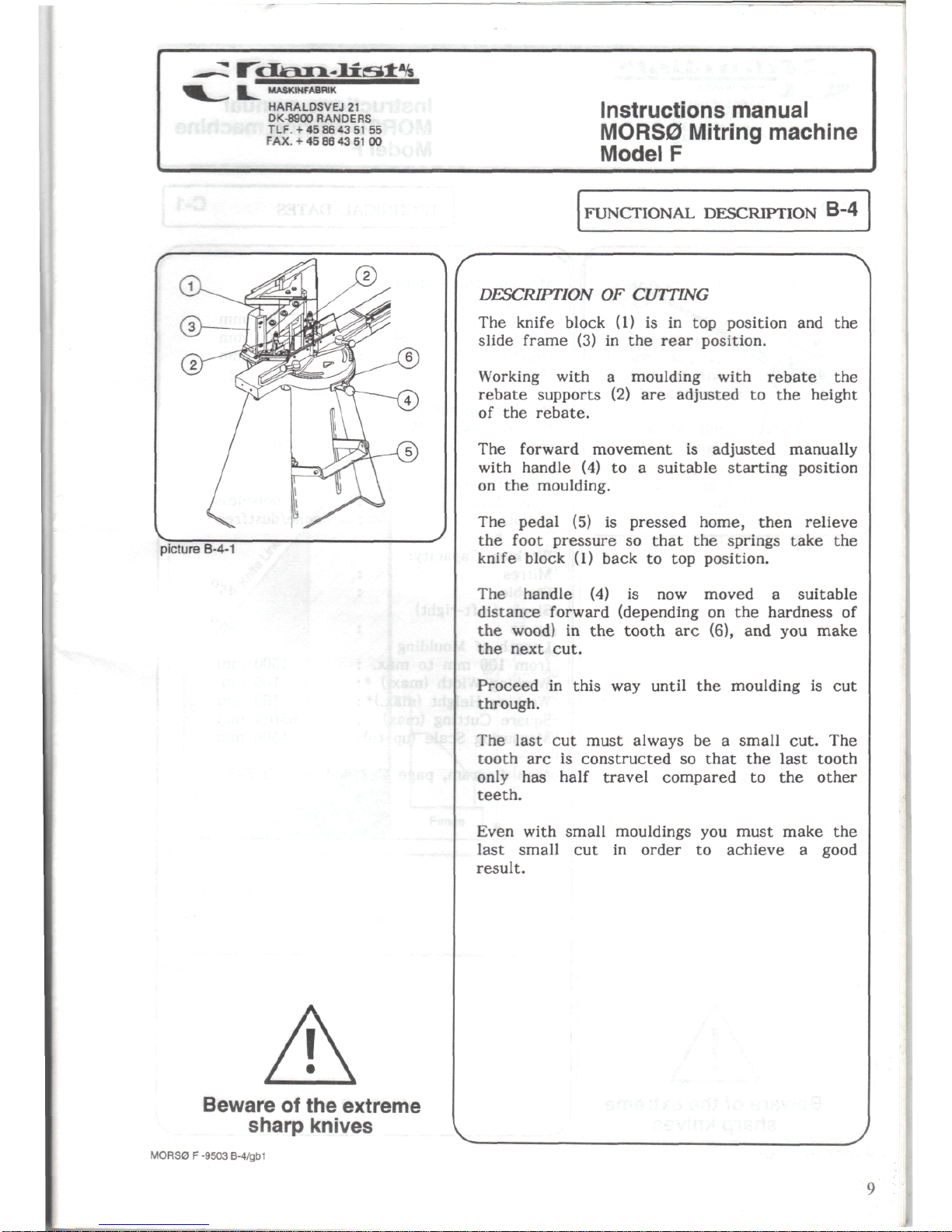

picture

B-4-1

I

Beware

of

the

extreme

sharp knives

DESCRIPTION

OF

CUTTING

The

knife

block

(1) is in top

position

and the

slide

frame

(3) in the

rear position.

Working

with a moulding

with

rebate

the

rebate

supports

(2) are

adjusted

to the

height

of

the

rebate.

The

forward

movement

is

adjusted

manually

with

handle

(4) to a

suitable starting

position

on

the

moulding.

The

pedal

(5) is

pressed home, then relieve

the

foot

pressure

so

that

the

springs

take

the

knife

block

(1)

back

to top

position.

The

handle

(4) is now

moved a suitable

distance

forward

(depending

on the

hardness

of

the

wood)

in the

tooth

arc

(6),

and you

make

the

next

cut.

Proceed

in

this

way

until

the

moulding

is cut

through.

The

last

cut

must

always

be a

small

cut.

The

tooth

arc is

constructed

so

that

the

last tooth

only

has

half

travel compared

to the

other

teeth.

Even

with

small

mouldings

you

must make

the

last

small

cut in

order

to

achieve a good

result.

MORS0 F -9503 B-4/gb1

MASKINFABRIK

HARALDSVEJ21

DK-8900

RANDERS

TLF.+45864351

55

FAX.

-I-

45 86 43 51 00

Instructions manual

MORS0

Mitring machine

Model

F

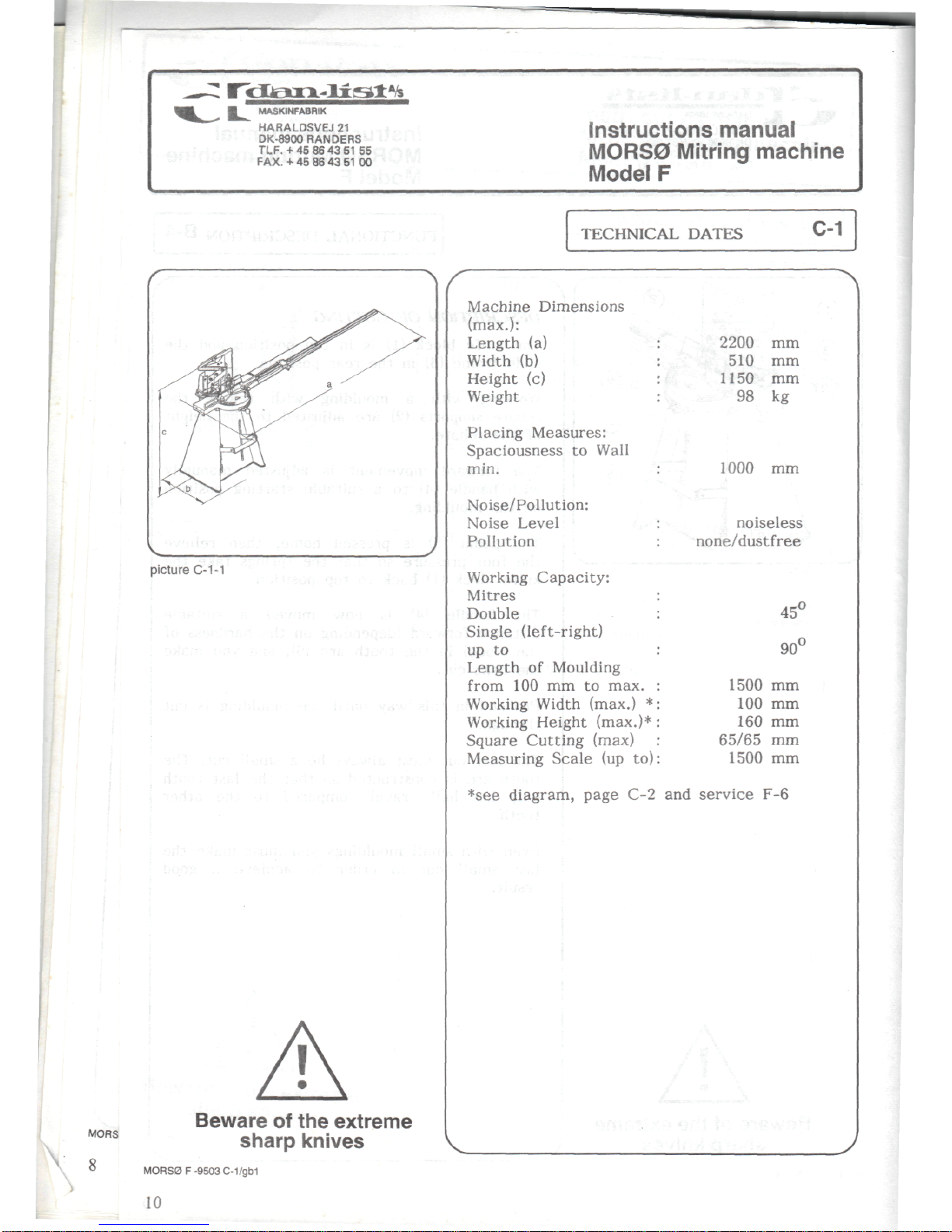

picture

C-1-1

MORS

Beware

of

the

extreme

sharp knives

MORS0 F -9503 C-1/gb1

10

TECHNICAL

DATES

C-1

Machine Dimensions

(max.):

Length

(a)

Width

(b)

Height

(c)

Weight

Placing Measures:

Spaciousness

to

Wall

min.

Noise/Pollution:

Noise Level

Pollution

Working

Capacity:

Mitres

Double

Single (left-right)

up

to

Length

of

Moulding

from

100 mm to

max.

Working

Width

(max.)

*

Working

Height

(max.)*

Square

Cutting

(max)

Measuring

Scale

(up to)

2200

mm

510 mm

1150

mm

98 kg

1000

mm

noiseless

none/dustfree

45°

90°

1500

mm

100

mm

160

mm

65/65

mm

1500

mm

*see

diagram, page

C-2 and

service

F-6

r

MASKiNFABRIK

HARALDSVEJ21

DK-89CX)

BANDERS

TLF.

-f

45 86 43 51 55

FAX.

+

45 86 43 51 00

Instructions

manual

MORS0 Mitring machine

Model

F

TECHNICAL

DATES

C-2

90 70 50 30 10

100

picture

C-2-1

I

Beware

of

the

extreme

sharp knives

MORS0 F -9503

C-2/gb1

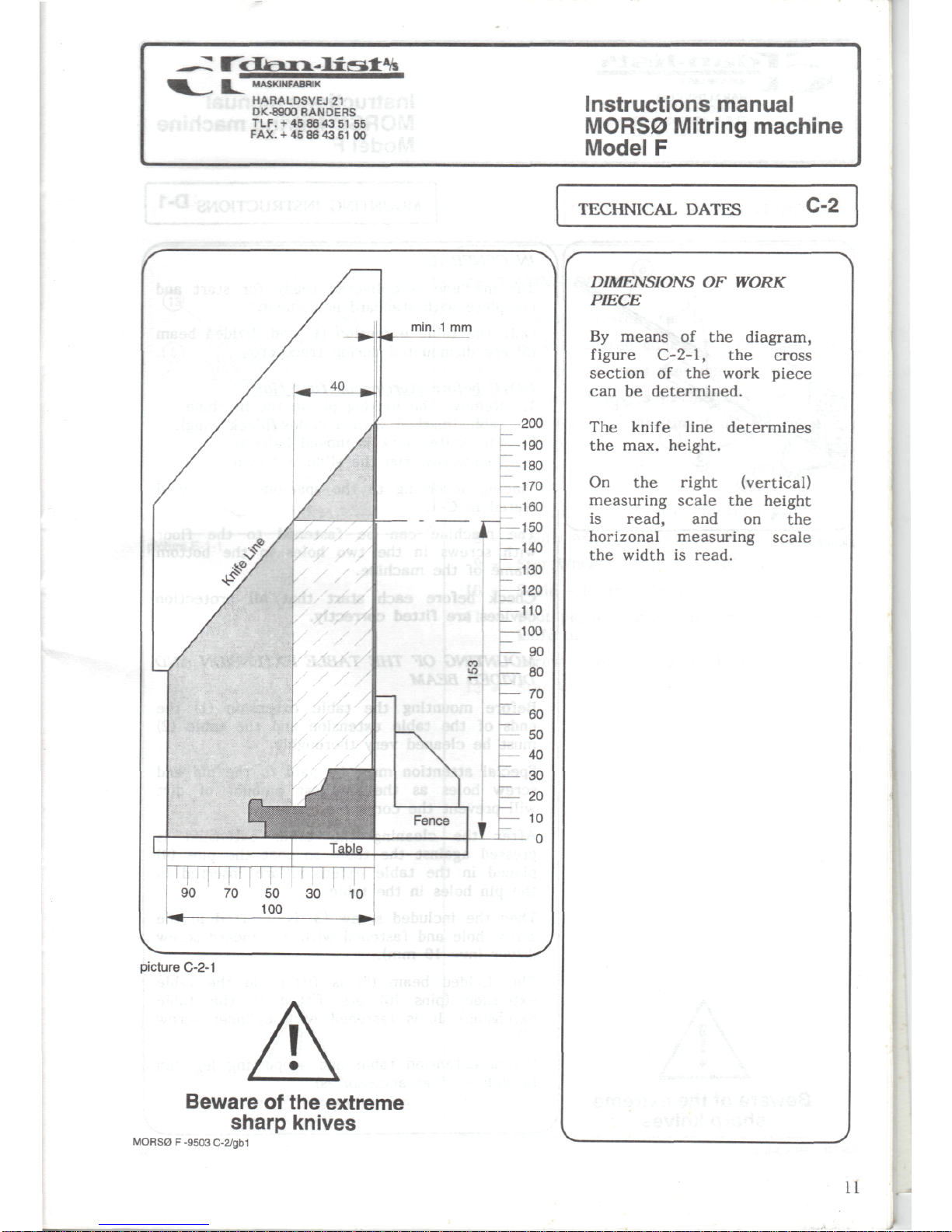

DIMENSIONS

OF

WORK

PIECE

By

means

of the

diagram,

figure

C-2-1,

the

cross

section

of the

work

piece

can

be

determined.

The

knife

line

determines

the

max. height.

On

the

right

(vertical)

measuring

scale

the

height

is

read,

and on the

horizonal

measuring

scale

the

width

is

read.

11

MASKINFABRIK

HARALDSVEJ

21

DK-8900

RANDERS

TLF.-1-45

86

43

51 55

FAX.

+

45 86 43 51 00

Instructions manual

MORS0

Mitring

machine

Model

F

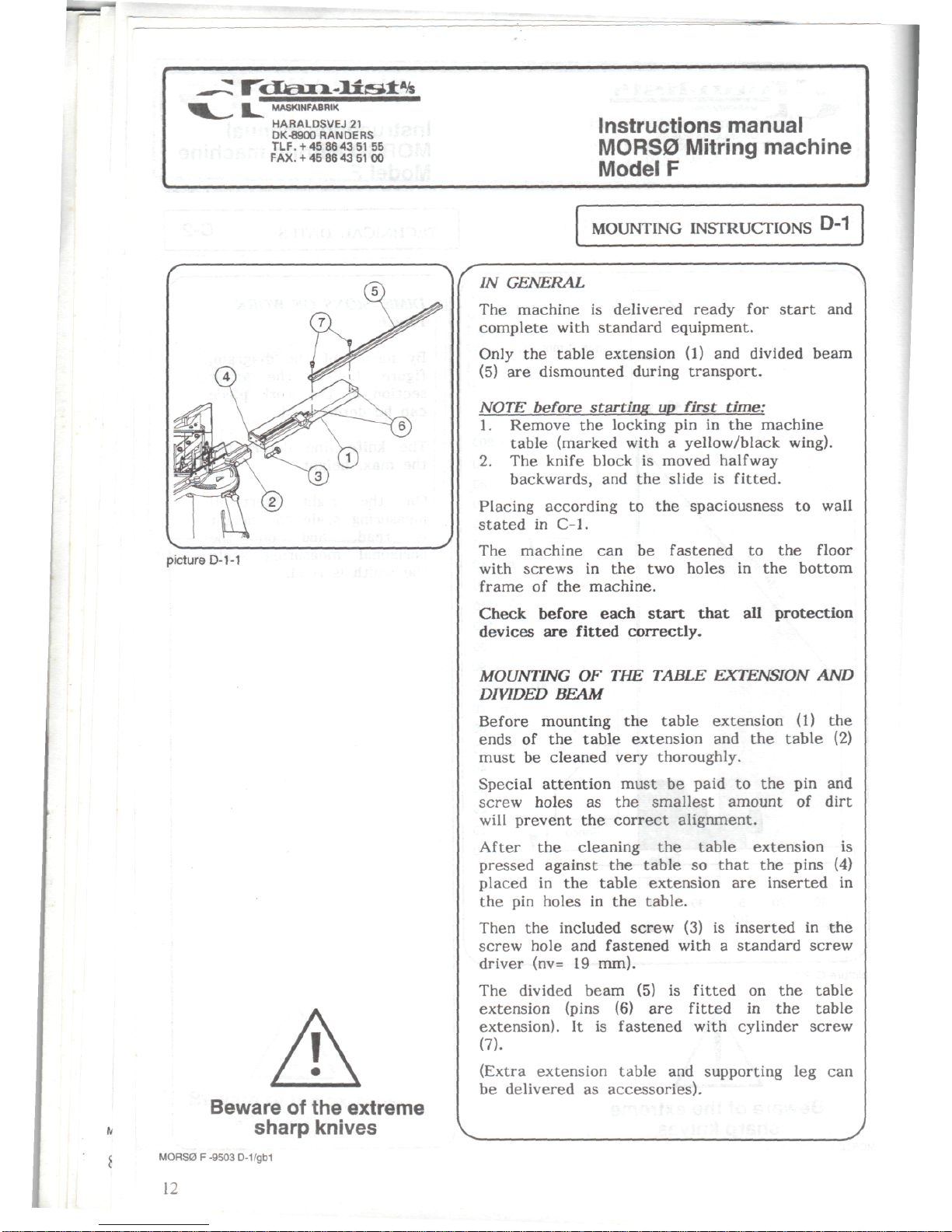

picture

D-1-1

I

MOUNTING

INSTRUCTIONS

D-1

Beware

of the

extreme

sharp knives

IN

GENERAL

The

machine

is

delivered ready

for

start

and

complete with standard equipment.

Only

the

table extension

(1) and

divided beam

(5)

are

dismounted

during

transport.

NOTE

before

starting

up

first time:

1.

Remove

the

locking

pin in the

machine

table (marked with a yellow/black

wing).

2. The

knife

block

is

moved

halfway

backwards,

and the

slide

is

fitted.

Placing

according

to the

spaciousness

to

wall

stated

in

C-l.

The

machine

can be

fastened

to the

floor

with

screws

in the two

holes

in the

bottom

frame

of the

machine.

Check

before each

start

that

all

protection

devices

are

fitted

correctly.

MOUNTING

OF THE

TABLE

EXTENSION

AND

DIVIDED

BEAM

Before

mounting

the

table

extension

(1) the

ends

of the

table

extension

and the

table

(2)

must

be

cleaned very thoroughly.

Special attention must

be

paid

to the pin and

screw holes

as the

smallest amount

of

dirt

will

prevent

the

correct alignment.

After

the

cleaning

the

table extension

is

pressed against

the

table

so

that

the

pins

(4)

placed

in the

table

extension

are

inserted

in

the pin

holes

in the

table.

Then

the

included screw

(3) is

inserted

in the

screw hole

and

fastened with a standard screw

driver

(nv=

19

mm).

The

divided

beam

(5) is

fitted

on the

table

extension

(pins

(6) are

fitted

in the

table

extension).

It is

fastened with cylinder screw

(7).

(Extra extension table

and

supporting

leg can

be

delivered

as

accessories).

MORS0 F -9503

D-1/gb1

12

MASKINFABRIK

HARALDSVEJ

21

DK-8900

BANDERS

TLF.+

45864351

55

FAX.

+ 45 86 43 51 00

Instructions

manual

MORS0

Mitring

machine

Model

F

OPERATING

INSTRUCTIONS

E-1

picture

E-1-1

f

Beware

of

the

extreme

sharp

knives

OPERATING DEVICES

1 = Handle - fastens

the

left fence

2 = Scale - degree

adjustment

of

left fence

3 =

Handle - fastens

the

right

fence

4 = Scale - degree

adjustment

of

right fence

5

= Nut -

height adjustment

of

left

rebate

support

6

= Nut -

height adjustment

of

right

rebate

support

7 =

Hand

Lever - forward

movement

8 =

Tooth

Arc -

forward

movement

9 - Star

Wheel - adjustment

of

stop beam

10 = Scale - length adjustment

11 = Foot

pedal - cutting

movement

of the

knife

block

12 = Screw - height stop

for

knife

block

13 = Star

Wheel - fastens safety guard

MORS0 F -9503 E-1/gb1

13

MASKINFABRIK

HARALDSVEJ21

DK-8900

RANDERS

TLF.+

45864351

55

FAX.

+ 45 86 43 51 00

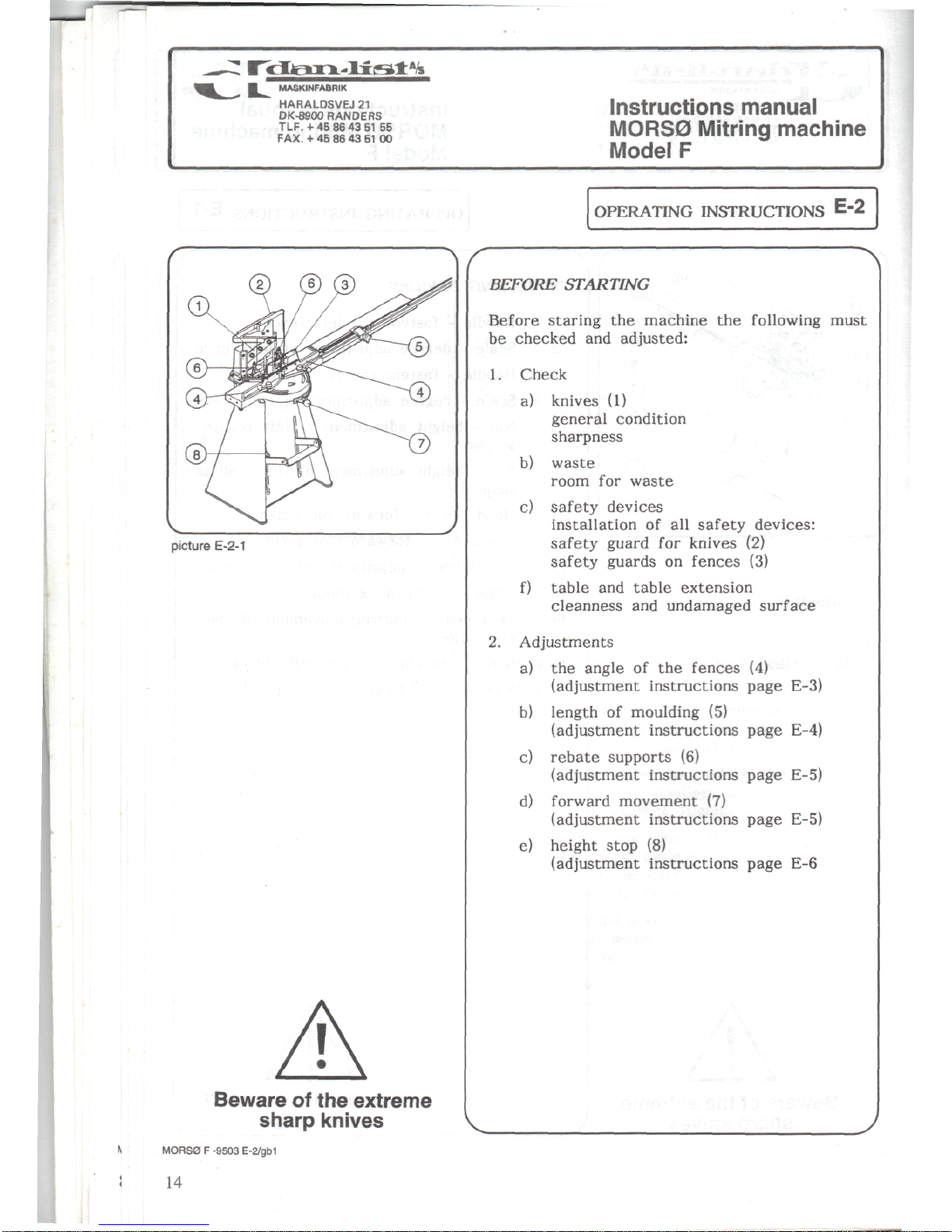

picture

E-2-1

I

Instructions

manual

MORS0 Mitring machine

Model

F

OPERATING

INSTRUCTIONS

E-2

Beware

of

the

extreme

sharp knives

BEFORE

STARTING

Before

staring

the

machine

the

following

must

be

checked

and

adjusted:

1.

Check

a)

knives

(1)

general condition

sharpness

b)

waste

room

for

waste

c)

safety

devices

installation

of all

safety

devices:

safety guard

for

knives

(2)

safety

guards

on

fences

(3)

f)

table

and

table extension

cleanness

and

undamaged

surface

2.

Adjustments

a)

the

angle

of the

fences

(4)

(adjustment

instructions page E-3)

b)

length

of

moulding

(5)

(adjustment

instructions page E-4)

c)

rebate

supports

(6)

(adjustment instructions page E-5)

d)

forward movement

(7)

(adjustment

instructions page E-5)

e)

height stop

(8)

(adjustment

instructions page

E-6

MORS0 F -9503

E-2/gb1

14

Loading...

Loading...