Guide to Installation and Use for

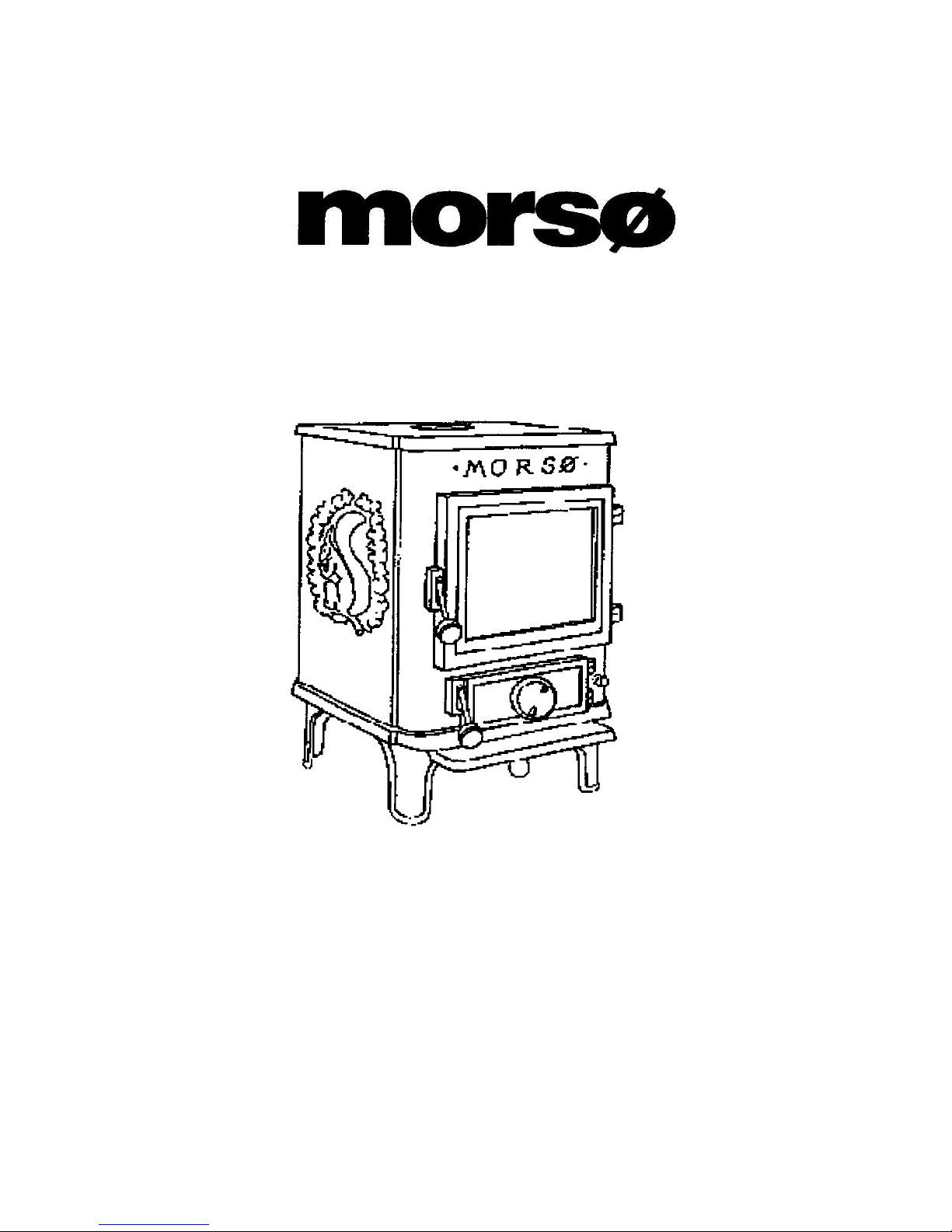

1430 Cleanheat Squirrel

MORS0 JERNST0BERI A/S, DK-7900 NYK0BING MORS

E-Mail: stoves@morsoe,com 'Website: www.morsoe.com

Distributed by: Baxl Fires Division' Wood Lane' Erdington,

Birmingham B24 9QP

, England'

www.morsos

toves.co,uk

We congratulate you on your choice of a Morso

stove. Morso has been producing some of the world's

best stoves since 1853. If you follow this Installation

and operating Instruction carefully, we can guarantee

you many years of warmth and plea

sure.

DIRECTIONS FOR INSTALLATION

~

1. The stove must be installed according to the regulations laid down in the

building code; e.g. regarding the distance to combustible material. Out of

consideration for the cleaning, the distance to masonry should be 100 -

150

mm. The non-combustible substructure should cover

the floor in an area

of at least 500 mm in front of the stove and at least 100 mm at the sides

and behind the stove.

The opening formed by the firing door is less than 1000 sq.cms.

It is advisable t

o consult your local building authorities. Please notice the

rules in the building code concerning the installation of stoves, the

connection of these and the rules concerning the installation of chimneys.

2. After the unpacking place the stove on the side

and mount the legs with

the enclosed bolts M 8x25. In order not to scratch the surface you may

place the stove on the packing.

3. The factory has provided the stove with rear smoke outlet. The lid (4)

must be detachable from the top plate and thus serve a

s a cleaning lid and

hot plate. When using this connection, the cleaning of the stove is

facilitated

. If you desire a top smoke outlet, the flue is moved to the top

plate and mounted there. Afterwards the lid is mounted to the inner plate

with screws and tension disks.

In order to ensure sufficient draught the horizontal runs of the stove pipe

should be as short as possible and preferably rise a little towards the

chimney.

The flue must not be inserted in the chimney itself, but only to the edge of

the masonry. (Many chimney pipe-

bushings have a built in stop,

preventing the pipe from being inserted too far). The stove pipe -

chimney

connection should be sealed with fire proof seal.

4. Ensure that the baffle plates (1) are

placed correctly. (See sectional

drawing).

5. The outer surface is susceptible to corrosion by acid. Therefore cover the

stove whenever acid is used in washing down the surrounding masonry.

6. The initial fire should be small in order to properly cure the stove

before

starting a heavier fi

re.

2

Warning:

Do not fire heavily in a cold stove.

Never allow the stove to become superheated. Superheating may

damage the fireproof material, the grates, baffle plate etc.

Superheating Is seen when anypart of the stove is red hot, e.g.

baffle plate or

grates

The heat output from the stove is regulated with 2 draught

valves i.e. the

primary air inlet (8) and the secondary air inlet (9).

Firing with different types of fuel Is described In the enclosed

overall description of methods of stoking.

If when th

e doors are open smoke comes out, this is due to

insufficient chimney draught. (A chimney draft of at least 1 mm WP

= 0,1 mbar= 0,04 inch

Wp Is demanded in order to prevent smoke

outlet). As a rough guide, there should be at least 12

foot vertical

height of flue b

etween the top of the stove and the top of the flue,

and the flue should be sound and tight.

ASHES

The ashes are easily shaken down into the ash pan by employing the

shaking handle at the shaking grate. The shaking handle is used to lift the

hot as

h pan. The ash pan should be emptied regularly. If the ashes reach

the grate from beneath, the grate will lie in a bed of embers which will

destroy the grate.

MAINTENANCE

At the proper heat output almost no soot Is deposited onto the glass

In the firing do

ors. The soot is easily removed by means of a Morso

Glass Cleaner or treble ammonia water.

Inspect the stove for soot frequently. The soot must be removed in

order to exploit the fuel extensively. Heavy soot built-

up reduces the

chimney draft and increases the risk of a chimney fire.

The surface of the stove is senotherm painted. The surface will be

kept well if vacuum

cleaned with a soft nozzle. If necessary wipe the

stove with a moist cloth,

but only when the stove is completely cold.

Be careful when choosing

cleaning materials as the paint may be

damaged by acid. If necessary,

use

3

Loading...

Loading...