Page 1

Excerpt from

BRUSHLESS ELECTRIC MOTORS

AND DIGITAL CONTROLS

USER'S MANUAL (obsolete)

SERIES T161 DIGITAL RACK MOUNT CONTROLLERS

SERIES 160 RACK MOUNT POWER SUPPLY

SERIES 300A BRUSHLESS SERVO MOTOR

This is a portion of a user’s manual made available in segments on the website for the

convenience of our customers. If you have questions or need additional information please

contact us

This manual describes the functionality and features of the present version of the T161,

160 and 300A Product Family. Not all of the described features are available in previous

versions of the T161, 160 and 300A.

Information contained herein is subject to change without notification and should not be construed

as a commitment by Moog Inc. This manual is periodically reviewed and revised. Moog Inc.

assumes no responsibility for any errors or omissions in this document. Critical evaluation of the

manual by the user is welcomed. Your comments will assist us in future product documentation.

Copyright Ó 1993 by Moog Inc. All rights reserved.

.

Moog Inc., Electric Drives Group

Regional Centers:

USA: +716-655-3000

Germany +49-7031-622-0

Italy +39-010-96711

Japan: +81-463-55-3615

See www.moog.com to find the location nearest you.

Page 2

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.1

4. COMPONENT DESCRIPTION AND

SPECIFICATION

This Section provides descriptions and specifications for the RMC Power Supply, the T161

Series Controllers, the B81318-001 Hand Held Terminal, the Encoder Simulator Option

Card, and the 300A Series Motors.

4.1. Power Supply Description, Specifications

The power supply has the following features:

• Single or Three Phase A-C Operation

• Direct off-line 220 VAC Operation

• Soft Start (A-C Inrush Current Limiting)

• Integral Shunt Regulator

• Fast Bus Discharge

• Phase Loss Detection

• Provision for External Regen Resistor

• Regen Electronic Circuit Breaker

• Power Supply Fault Relay

• Diagnostic LED's

The major components of the power supply are indicated in Figure 4-1.

WARNING

Power supplies contain large capacitors that maintain high voltage on the

DC+ to DC- terminals for several minutes after input power is removed if the

regen resistor circuit is open (fuse blown or wiring open).

Wait at least 5 minutes after power shutdown for capacitors to discharge.

Using a multimeter, measure the DC BUS (at X7 Pin #1 and #2) to ensure

that it has been discharged. Failure to follow this procedure might result in

serious personal injury.

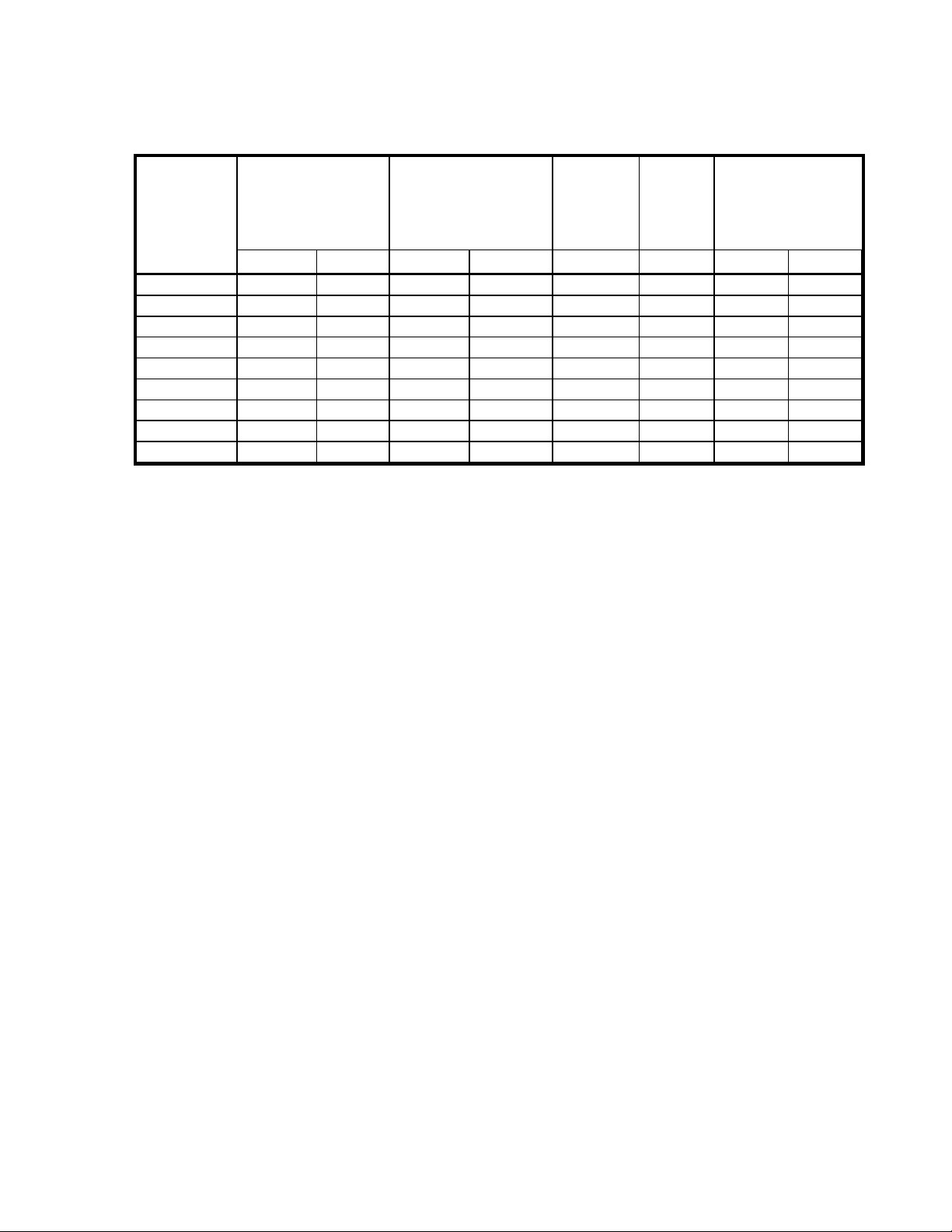

4.1.1. Diagnostic LED's

The status of the power supply may be monitored using the diagnostic LED indicators on

the front panel as listed in Table 4-1.

Page 3

4.2 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.1.2. Circuit Description

The power supply consists of four functional blocks:

• High voltage rectification and filtering

• Low voltage control power supply

• Shunt regulator circuit

• Monitoring and fault logic circuits

Figure 4-2 is a block diagram of the 160 Power Supply.

LED

#

1

2

3

4

5

6

7

LED

Color

Green BUS ACTIVE Greater than 30 VDC is present on the

Green LOGIC VOLTAGE OK The + 15, - 15, and + 5 VDC are

Red REGEN FUSE BLOWN The fuse protecting the regen resistor

Red THERMAL FAULT Baseplate over temperature

Red DC BUS OVER VOLTAGE DC Bus has exceeded 400 VDC.

Yellow REGEN ACTIVE The regen circuit is active because the

Red LOSS OF PHASE Phase loss or power loss on incoming

Label Condition Indicated

high voltage DC bus.

present.

has opened.

bus voltage exceeds the regen cut-in

threshold or a-c power has been lost and

a fast bus discharge is occurring.

AC mains.

TABLE 4-1. 160 POWER SUPPLY STATUS INDICATORS

4.1.2.1. High Voltage Rectification and Filtering

The a-c mains input is rectified by a three phase diode bridge and filtered by a large bank

of electrolytic capacitors to generate a nominal 300 VDC supply at

25 amps. This high power 300 VDC supply is unregulated and will vary in direct proportion

with the a-c mains input.

4.1.2.2. Low Voltage Control Power Supply

Control power for the logic circuits is generated by a fly back current mode converter.

There is no isolation from the a-c mains provided by this supply.

Page 4

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.3

4.1.2.3. Shunt Regulator Circuit

Rapid motor deceleration or an overhauling load creates a situation in which energy is

regenerated back into the high voltage power supply. This regenerative energy will charge

the power supply bus capacitors. To prevent capacitor over voltage a shunt regulator

circuit senses when the bus voltage exceeds the regen cut-in voltage and via a regen

transistor, switches a regen resistor across the d-c bus, (in shunt), to dissipate the regen

energy. Hysteresis in the shunt regulator circuit keeps the regen circuit active until the bus

voltage is reduced below the regen cut-out voltage. The frequency at which the regen

circuit operates is dependent upon the magnitude of the regen energy. If the regen energy

exceeds the capacity of the regen circuit, a higher capacity regen resistor must be used.

The supply includes an internal regen resistor with 40 watt capacity. An optional external

regen resistor with higher capacity can be utilized, as explained in Section 2.4.

An electronic circuit breaker protects the regen circuit against external short circuits and

protects the regen resistor from exceeding its continuous rating. If the regen resistor

continuous rating is exceeded the electronic circuit breaker disables the shunt regulator

circuit. In this case, additional regen energy from the motor will cause the d-c bus voltage

to increase until an over voltage fault occurs. Under this condition, the regen circuit is

undersized for the application. Figure 4-3 provides energy vs. time curves for the

electronic circuit breaker. A regen fuse is provided to protect the regen resistor in case of

failure of the regen circuit electronics. A monitoring circuit provides a REGEN FUSE fault if

the regen fuse blows. The regen electronic circuit breaker prevents nuisance tripping of

the regen fuse.

Page 5

4.4 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.1.2.4. Monitoring and Fault Logic

There are two fault outputs in the supply. The "Customer Fault Output" is relay

K2 (4C1) capable of sinking or sourcing 1 amp and withstanding up to 75V. It

is "closed" during normal operation and will be "open" to indicate a fault. The

faults that are detected are Thermal Fault, Loss of Phase, Bus Over voltage,

Regen Fuse Blown and Soft start. Note that a fault indication in the power

supply will not stop the supply from operating, except that a blown regen fuse

will not allow the DC bus relay K1 to close. This means that the DC bus will

remain at 0VDC if the fuse is blown or missing when the unit is powered up.

The fault output relay should be monitored by the customer and the system

shut down in the event of a power supply fault. The Loss of Phase fault can

only be read through this fault relay output.

The "PSF" bit, an open collector output, goes out to the back plane and to each of

the controllers in the rack. It detects the same faults as the customer fault relay with the

exception of Loss of Phase and Thermal Fault. If the PSF bit detects a fault the

controllers disable. In the -007 and -008 models the soft start condition (i.e. powering up

the DC bus from high voltage AC) causes a "PSF fault". This is done to prevent the

controllers from enabling before the DC bus is fully charged. If the controllers were to be

enabled during soft start, the DC bus would not get fully charged and at the end of the soft

start period a hard start (i.e. very high inrush currents) would occur.

INTERNAL 40 WATTS

POWER (WATTS) TIME (SECONDS)

40 CONTINUOUS

50 90

100 15

200 6

300 4

500 2.5

1000 1.2

EXTERNAL 240 WATTS

POWER (WATTS) TIME (SECONDS)

240 CONTINUOUS

300 180

500 29

1000 9

1500 5

2000 4

2500 3

4000 1.8

TABLE 4.2 MODEL 160-007,008 POWER SUPPLY REGEN ELECTRONIC

CIRCUIT BREAKER TRIP CHARACTERISTICS

4.1.3. Specifications

A-C Input Voltage 220 VAC ±15% 50/60 Hz

D-C Output Voltage 300 VDC No-Load Unregulated

Page 6

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.5

W

Three phase Single phase

Continuous Output D-C Power Operation Operation

With Cooling Fan 7.5 KW 2.5 KW

Without Cooling Fan 2.5 KW 0.8 KW

24 volt Input Power

Voltage Range 20 Vdc min to 35 Vdc max

Power Requirements 1 amp per axis @ 24 volts

Inrush current 2 amps for 50 msec @ 24 volts

Regen Cut-in Voltage 380 VDC ±5%

Regen Hysteresis Voltage 7 VDC ±5%

Internal External

50W 40W 8.3W 240W

Resistor Resistor

Peak Regen Power 2.8 kW 17 kW

Continuous Regen Power 40 W 240 W

Regen Fuse ABC-3 ABC-15

1

In parallel with internal 50

55W resistor.

Base plate Over temperature Trip Point 90°C ±5°C

Operating Temperature Range 0 - 55 °C ambient

Humidity 5% to 95% non-condensing

Altitude 3300 feet

5

Derate output 2% per 1000 feet above 3300 feet.

5

Weight 4.8 lb. (2.2 kg)

1

2

Page 7

4.6 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.2. T161 Series Controllers Description, Specifications

Controllers have the following features:

• Sinusoidal Three Phase Drive

• Resolver Based System

• Microprocessor Based

• Digitally Tuned Current Loop

• Configuration Stored in Non-Volatile E

• Programmable Velocity or Current Control

• Programmable Analog Test Points

• RS232 / RS485 Serial Port

• PC Set-up via "MOOGTERM" software

• 24 VDC Control Power Input (Option)

• Encoder Simulation (Option Card)

In addition, Controllers incorporate the following protection features:

• Watchdog Timer

• Logic Under voltage

• I-T Current Foldback

• Short Circuit

• Motor Over temperature

• Controller Over temperature

• Resolver Loss

2

PROM

The major components of the Controllers are indicated in Figure 4-4.

Page 8

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.7

4.2.1. Diagnostic LED's

The status of the Controller may be monitored using the diagnostic LED indicators on the

front panel as listed in Table 4-2.

LED

Color

Red SYSTEM FAULT A software or hardware fault has occurred. The

Yellow FOLD BACK ACTIVE The continuous torque limit has been exceeded.

Green ENABLE Controller is enabled and ready to accept motion

Label Condition Indicated

specific fault can be determined by querying the

controller via the communications interface.

command.

TABLE 4-3. T161 SERIES CONTROLLER STATUS INDICATORS

4.2.2. Circuit Description

This description of the T161 series controller refers to Figure 4-5, the controller block

diagram.

4.2.2.1. Logic Power Supply

Logic power for the control is generated in the model 160 power supply. This is delivered

by way of the back plane to all RMC axes installed.

4.2.2.2. CPU Section

The microprocessor (CPU) used in the control is an 80C186. It interfaces to 16K of RAM,

128K of EPROM, EEPROM, A/D converter, D/A converter, watchdog timer, fault detection

and display circuitry, and UART serial communication device. The CPU stores setup

parameters in EEPROM so that they are available after power is removed and reapplied. It

takes in the discrete enable input and the analog command input from the customer

interface. Under the conditions of proper setup, no control faults, and valid enable, the

CPU enables the output stage and provides the commutated phase current commands to

drive the motor in either the torque controlled mode or the velocity controlled mode. One of

these modes is selected by the user. The CPU accepts user setup information and

provides status information via the UART serial interface. Faults are detected and

processed by the CPU. A watchdog timer which has a time-out time of 2.5 milliseconds will

disable the controller were the CPU to fail.

Page 9

4.8 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.2.2.3. Analog to Digital Section

The analog command input has an input voltage level of +/- 10VDC. It is brought in to a

differential amplifier. The choice is available in software to either use this command signal

unfiltered or to use a low pass filter on the command. The filter has a -3dB point of 1KHz

and an inband time delay of 360µsec. The command signals are converted by the A/D

converter, a 12 bit converter.

The resolver excitation signal is sinusoidal at 3.0 KHz, 4VRMS, and can drive up to 100ma.

The resolver SIN and COS feedback signals are expected to be at a 2VRMS level. They

are brought in to differential amplifiers, filtered, and converted by the A/D converter.

4.2.2.4. Digital to Analog Section

The CPU outputs the properly commutated motor phase A and phase B current commands

to the current loop through the D/A converter section. One customer programmable test

point and one fixed test point are also provided by the D/A converter section.

4.2.2.5. Current Loop

The current loop takes the command signals from the D/A section and the motor phase

current feedback signals and generates a closed loop current error signal which drives the

PWM (pulse width modulation) stage. PWM is used to convert the analog current error into

a digital command for the three phase inverter bridge. The setup parameters of the current

loop are varied depending on the type of motor and controller size used. This motor

specific information is contained in the MCO module and is provided to the current loop

upon power up. The gate drive takes the digital current loop PWM commands and level

and amplitude shifts them to an appropriate voltage to drive the 6 high voltage IGBT

transistors in the inverter output bridge.

4.2.2.6. UART

The UART (universal asynchronous receiver/transmitter) is used to provide the CPU with

communication information from the user and to provide the user with controller status information.

Two modes of communication are available through the UART interface: RS232 and RS485. RS232

is a 3 wire standard computer serial interface for talking from one device (computer or terminal) to

one other device (T161 Series Controller). RS485 is a 2 wire multidrop communication interface. Up

to 32 communication nodes are supported (31 "slaves", i.e. T161 Series Controllers, and 1 "master",

i.e. a PC). RS232 or RS485 is selected by the position of the jumpers L2 through L5. Installing the

jumpers across L2,L3,andL5 will provide RS232 and connecting the jumper across L4 only will

provide RS485.

Page 10

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.9

4.2.3. Specifications

D-C Input Voltage 130 VDC - 370 VDC (310 VDC Nominal)

Output Current Ratings:

RMS Amps Per Phase Peak Amps Per Phase

Model

T161-001 3 5 4.2 7.1

T161-002 5 10 7.1 14.2

T161-003 8 20 11.3 28.4

T161-004 12 40 16.9 56.8

Output Current Ripple Frequency

T161-001, -002 20 KHz T161-003, -004 10 KHz

Analog Input Command (Differential)

±10 Volts = CW/CCW Max. Speed (Velocity Mode)

±10 Volts = ± Peak Current (Torque Mode)

Input Impedance 22.3 KW

Analog Torque Limit Command (Differential)

0 to 10 Volts = 100 to 0% Torque Output

Input Impedance 44.2 KW

Continuous Peak (5 Sec) Continuous Peak (5 Sec)

Enable Input

Torque/Velocity Select

Auto/Manual Mode

Group Auto/Manual Mode

Supply Voltage Range

1

4.5 - 35 VDC

Input Impedance 2.0 KW Min.

Polarity Current Activated.

Serial Interface

Type RS232 or RS485

Baud Rate 9600

Parity None

Data word 10 bit (7 data, 1 start, 2 stop, no parity)

Resolver Interface

Excitation Frequency 3.0 KHz

Excitation Output 4.0 V RMS @ 100 mA Max.

Sine/Cosine Return 2.0 V RMS

20 KW input impedance (differential)

Efficiency >95%

2

Velocity Loop Update Rate 2.5 KHz

Base plate Over temperature Trip Point 90°C ±5°C

Operating Temperature Range 0 - 55°C ambient

Humidity 5% to 95% non-condensing

Altitude 3300 feet

3

Weight

T161-001 through -003 5.0 lb. (2.3 kg)

T161-004 10.5 lb. (4.8 kg)

1

User must supply isolated power source.

2

Rated Continuous Current, 50% Rated Output Voltage

3

Derate output 2% per 1000 feet above 3300 feet.

.

Page 11

4.10 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.3. B81318-001 Hand Held Terminal (Option) Description,

Specifications

The Moog B81318-001 hand held terminal, shown pictorially in Figure 4-6, is an optional

accessory product which can be used in lieu of a terminal for controller set-up and

monitoring. The hand held terminal is supplied with a coiled cable which has a DE9P

connector that mates with the T161 Series Controller X6 communications connector.

4.3.1. Specifications

Weight 8 ounces (230 grams)

Storage Temperature -20°C to 70°C

Operating Temperature 0°C to 50°C

Relative Humidity 10% to 90% Non-Condensing

Character Set US ASCII, upper and lower case with two break functions

Interface RS232C

Case Molded, High Impact ABS with retractable hanger

Keypad 45-key tactile

Display 4 row by 20 character LCD with 5 by 7 character font

Power Requirement 30 mAmps max., 5 VDC ±5% (Supplied by T161 Series Controller)

Speaker Audible Key Click, Bell and Alert

4.4. Encoder Simulator Option Card Description,

Specifications

The Encoder Simulator Option Card has the following features:

• Emulates Rotary Incremental Encoders

• Line Count and Marker Width selectable by jumper position.

• Ability to read Digital Position information through User Interface Software

• Error status monitored by User Interface

• RS-422 Differential Incremental Encoder Outputs (outputs are optically isolated)

• Customer supplied (V external) input is polarity protected

• Buffered Analog Velocity Output (Option - Consult Factory)

4.4.1. Circuit Description

The Encoder Simulator emulates the functionality of a rotary incremental encoder. The

differential outputs of the Encoder Simulator are A, A/, B, B/, MARKER and MARKER/.

The design is based on a Resolver to Digital (R/D) converter to generate rotor position

data. The position data is then multiplexed and converted into optically isolated and

buffered incremental encoder quadrature outputs. Power for the isolated outputs is

provided by a user supplied +5 VDC power supply.

Page 12

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.11

FIGURE 4-1. B81318-001 HAND HELD TERMINAL

Page 13

4.12 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

The Built In Test (BIT) output of the R/D converter is monitored. Logic 0 for BIT condition

indicates ±100 LSBs of error. Causes of BIT error are loss of signal inputs or loss of

resolver reference. When this occurs, the Encoder Simulator outputs will go to a known

state.

Figure 4-7 is a block diagram of the Encoder Simulation option card.

4.4.1.1. A and B Outputs

The A and B outputs are in quadrature, i.e. B will lead A by 90° when the motor is rotating

clockwise (CW) as viewed looking at the motor front mounting plate and A will lead B by

90° when the motor is rotating counterclockwise (CCW). The phase relationship of A and

B can be used to determine motor direction.

Since the Encoder Simulator outputs are in true quadrature, the ripple associated with the

duty cycle variation of a normal encoder is avoided when using X2 or X4 counting

schemes.

The resolution of the Encoder Simulator, in pulses per revolution (ppr), is selectable from

128 ppr to 16384 ppr. The factory default resolution is 256 ppr. The allowable motor

operating speed range is reduced at higher Encoder Simulator resolutions as indicated in

Table 4-3.

R/D Resolution

(Bits)

16 16384 0-1400

16 8192 0-1400

14 4096 0-6000

14 2048 0-6000

12 1024 0-15000

12 512 0-15000

10 256 0-15000

10 128 0-15000

Line Count

(Pulse Per Rev)

Motor Speed Range

(RPM)

TABLE 4-4. ENCODER SIMULATOR CONFIGURATION OPTIONS

Page 14

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.13

4.4.1.2. Marker Pulse

The MARKER, or INDEX pulse, is used to indicate a reference point within one mechanical

revolution of the motor shaft.

NOTE

The marker pulse is not referenced to the key of the motor shaft or housing.

The pulse is set at an arbitrary position that is determined by the resolver

adjustment setting used for motor commutation. This is a factory setting and

not user adjustable.

The electrical width of the MARKER pulse is selectable in pulse widths of 90°, 180° or

360°, where 360° is the entire width of one A and B encoder cycle. The factory default

configuration is 90° marker width.

The output wave forms for the Encoder Simulator are shown in Figure 4-8.

Page 15

4.14 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.4.2. Specifications

Resolver Reference Input Differential ±10V max.

Signal Inputs (Sine+, Sine-, Cosine+, Cosine-) Differential 2 Vrms ±15%

Input Power Requirements

1

User must supply isolated power source.

1

5 VDC ±5%, 200 mA max.

Dynamic Characteristics (Line Count Selection vs. Bandwidth based on 5KHz Resolver Reference):

3 dB Closed Loop

Line Count Selection (PPR) Bandwidth (Hz)

16384, 8192 288

4096, 2048 564

1024, 512 851

256 851

Digital Outputs A, A/, B, B/, MARKER and MARKER/

Optically Isolated RS-422 Differential

Outputs capable of driving 100W terminated loads

Output ' Logic High ' Voltage (Voh) 2.5V min.

Output ' Logic Low ' Voltage (Vol) 0.5V max.

Operating Temperature Range 0-55°C ambient

Page 16

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.15

COUNTERCLOCKWISE ROTATION

Channel A

Channel /A

Channel B

Channel /B

90 marker

180 marker

360 marker

CLOCKWISE ROTATION

Channel A

Channel /A

Channel B

Channel /B

90 marker

180 marker

360 marker

FIGURE 4-2. ENCODER SIMULATOR OPTION OUTPUT WAVE FORMS

Page 17

4.16 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

4.5. Series 300A Motors Description, Specifications

NOTE

Refer to Section 2.5, Motor Installation, for information on axial and radial

load capability, bearing life, mounting screws and motor-to-load coupling.

4.5.1. Description

Motors are permanent magnet brushless with an integral brushless resolver for position feedback.

The 303 through 306 frame size motors can be face or flange mounted.

All motors incorporate a thermostat or thermistor for thermal protection.

Motors are available with an optional static holding brake.

4.5.2. Specifications

Torque ratings are at 40°C ambient mounted on a 12 × 12 × 0.5 inch (30 × 30 × 1.25 cm) aluminum

heat sink. Ratings are shown in Table 4-4 and Characteristics are shown in Table 4-5 for standard

motors.

MODEL CONTINUOUS

TORQUE, T

lb. NM rpm lb. in. NM

303-029A 5.5 .62 8600 17 1.92

303-030A 15 1.69 10900 60 6.67

304-111A 12 1.36 7400 50 5.65

304-121A 28 3.16 5650 95 10.73

304-131A 48 5.42 4600 190 21.47

304-141A 73 8.25 2740 380 42.93

304-151A 94 10.62 2675 550 62.15

305-111A 51 5.76 5400 145 16.38

305-121A 74 8.36 4450 220 24.86

c

NO LOAD

SPEED

PEAK TORQUE, T

TABLE 4- 5. STANDARD SERIES 300A MOTOR RATINGS

p

Page 18

SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION 4.17

MODEL TORQUE

CONSTANT, K

lb. in./amp NM/amp

t

Inertia, J

lbin.s2*10

-3

m

kg-m2*10

-4

Mech. Time

Constant,

t

m

msec msec LB kg

Elect

Time

Constant,

t

e

Weight

303-029A 3.53 .40 .16 .18 2.33 0.64 3.0 1.4

303-030A 2.78 .31 .37 .42 1.14 1.24 4.0 1.8

304-111A 4.13 .47 .9 1.0 2.50 1.20 6.4 2.9

304-121A 5.39 .61 1.6 1.8 1.50 1.91 7.5 3.4

304-131A 6.65 .75 2.7 3.1 1.10 2.58 9.7 4.4

304-141A 11.24 1.27 5.0 5.6 1.10 2.70 13.7 6.2

304-151A 11.51 1.30 7.3 8.2 1.00 2.75 17.8 8.1

305-111A 5.61 .63 5.2 5.9 1.70 4.20 15.6 7.1

305-121A 6.82 0.77 7.3 8.2 1.20 5.40 18.2 8.3

TABLE 4-6. STANDARD SERIES 300A MOTOR CHARACTERISTICS

Page 19

4.18 SECTION FOUR - COMPONENT DESCRIPTION AND SPECIFICATION

THIS PAGE INTENTIONALLY BLANK.

Loading...

Loading...