Page 1

For the mobile version of this guide, see:

animatics.com/docs/guides-html/c6_eip_pc/

EtherNet/IP

Guide

Class 6 SmartMotor

Technology

Page 2

Copyright Notice

©2015, Moog Inc., Animatics.

Moog Animatics Class 6 SmartMotor™ EtherNet/IP Guide, Rev. B, SC80100010-001.

This manual, as well as the software described in it, is furnished under license and may be

used or copied only in accordance with the terms of such license. The content of this manual is

furnished for informational use only, is subject to change without notice and should not be construed as a commitment by Moog Inc., Animatics. Moog Inc., Animatics assumes no responsibility or liability for any errors or inaccuracies that may appear herein.

Except as permitted by such license, no part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical, recording, or otherwise, without the prior written permission of Moog Inc., Animatics.

The programs and code samples in this manual are provided for example purposes only. It is

the user's responsibility to decide if a particular code sample or program applies to the application being developed and to adjust the values to fit that application.

Moog Animatics and the Moog Animatics logo, SmartMotor and the SmartMotor logo, Combitronic and the Combitronic logo are all trademarks of Moog Inc., Animatics. CIP, DeviceNet

and EtherNet/IP are trademarks of ODVA, Inc. Other trademarks are the property of their

respective owners.

Please let us know if you find any errors or omissions in this manual so that we can improve it

for future readers. Such notifications should contain the words "EtherNet/IP Guide" in the subject line and be sent by e-mail to: techwriter@moog.animatics.com. Thank you in advance for

your contribution.

Contact Us:

Moog Inc., Animatics

1421 McCarthy Boulevard

Milpitas, CA 95035

USA

Tel: 1 (408) 965-3320

Fax: 1 (408) 965-3319

Support: 1 (888) 356-0357

www.animatics.com

Page 3

Table of Contents

Introduction 7

Purpose 8

Abbreviations and Definitions 9

Safety Information 11

Safety Symbols 11

Other Safety Considerations 11

Safety Information Resources 13

Additional Documents 14

Additional Resources 15

EtherNet/IP Overview 17

EtherNet/IP Introduction 18

The OSI Model 18

EtherNet/IP Adaptation of CIP 19

Objects 21

Objects 21

Classes, Instances and Attributes 22

Messaging 23

Explicit (Non-cyclic) Messages 23

Implicit (Cyclic) Messages 23

Explicit/Implicit Messaging Example 23

Connections, Wiring and Status LEDs 25

Connectors and Pinouts 26

M-Style Motor Connectors and Pinouts 26

Moog Animatics Industrial Ethernet Cables 27

EtherNet/IP Custom Cable 27

Cable Diagram 28

EtherNet/IP Cable Diagram 28

Status LEDs 29

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 3 of 160

Page 4

EtherNet/IP on Class 6 SmartMotors 31

EtherNet/IP Implementation 32

EtherNet/IP Identity 32

EtherNet/IP Software Version Numbers 32

Device Profile 32

SmartMotor Device Profile Overview 33

CIP Objects for EtherNet/IP Devices 33

Application Objects for Position Controller Devices 34

Additional Objects 34

EDS File 35

EtherNet/IP User Program Commands 37

Network Settings and Status Commands 38

Program Example 40

Status and Diagnostic Codes 41

Status/Error Codes 41

Diagnostic Codes 41

Position Controller Device (0x10) 43

Position Controller Device Application Objects 44

Position Controller Device Object Model 44

Position Controller Implicit I/O Messages 45

General Command and Response Message Types 45

Attribute GET/SET Command Types 0x1A and 0x1B 50

Error Response Message Type (0x14) 51

Semantics for Command and Response Messages 52

Position Controller I/O Handshaking 55

Profile Moves 56

Torque Command 57

Control Mode Change - Change Dynamic 57

Position Controller Implicit I/O Message Examples 58

SmartMotor Notes 58

Set Acceleration 58

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 4 of 160

Page 5

Set Velocity, Leave Drive ON 59

Set Target Position, Perform Move 59

Disable Hardware Limits (Object 0x25, Attribute 49) 59

Extended Position Move (32-byte frame) 60

Object Reference 61

Required Objects 62

Identity Object (0x01) 63

Instance Attributes Semantics 65

Message Router Object (0x02) 67

Assembly Object (0x04) 68

Connection Manager Object (0x06) 69

TCP/IP Interface Object (0xF5) 70

Instance Attributes Semantics 74

Ethernet Link Object (0xF6) 77

Instance Attributes Semantics 80

Application Objects 83

Position Controller Supervisor (0x24) 84

Position Controller (0x25) 86

Additional Objects 91

Device Level Ring (DLR) Object (0x47) 92

Instance Attributes Semantics 93

QoS Object (0x48) 94

SmartMotor I/O Object (0x71) 96

AOI Descriptions - Allen Bradley PLC 99

SM6_Attribute_Ext_Clear - Clear Attribute to Get (Extended Command) 100

SM6_Attribute_Ext_Get - Load Attribute to Get ID & Wait (Extended Command) 101

SM6_Attribute_Ext_Load - Load Attribute to Get ID (Extended Command) 102

SM6_Attribute_Ext_Value - Return Attribute data (Extended Command) 104

SM6_Clear_Flags - Reset System State Flag 106

SM6_Disable - Disable Drive 107

SM6_Drive - Drive Data Exchange 108

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 5 of 160

Page 6

SM6_Enable - Enable Drive 110

SM6_Get_Attribute - Get Drive Attribute 111

SM6_Move_Position_Ext - Position Move(Extended Command) 112

SM6_Move_Velocity_Ext - Velocity Move(Extended Command) 114

SM6_Move_Torque - Apply Torque 116

SM6_Set_Acceleration - Set Drive Acceleration 117

SM6_Set_Attribute - Set Drive Attribute 118

SM6_Set_Deceleration - Set Drive Deceleration 119

SM6_Set_Mode - Set Drive Mode 120

SM6_Set_Position - Set Drive Position 121

SM6_Set_Variable_u - Set Drive Variable "u" 122

SM6_Set_Velocity - Set Drive Target Velocity 123

SM6_Stop_Hard - Perform a Hard Stop 124

SM6_Stop_Smooth - Perform a Smooth Stop 125

Adding AOI Support - Allen Bradley PLC 127

Extracting the SmartMotor Support files 128

Adding a SmartMotor Module 129

Importing the UDTs 136

Importing the AOIs 140

SmartMotor AOI Example 144

Troubleshooting 155

Reference Documents 157

ODVA Specifications 157

ODVA Libraries 157

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 6 of 160

Page 7

Introduction

Introduction

This chapter provides information on the purpose and scope of this manual. It also provides

information on safety notation, related documents and additional resources.

Purpose 8

Abbreviations and Definitions 9

Safety Information 11

Safety Symbols 11

Other Safety Considerations 11

Safety Information Resources 13

Additional Documents 14

Additional Resources 15

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 7 of 160

Page 8

Purpose

Purpose

This manual explains the Moog Animatics Class 6 SmartMotor™ support for the EtherNet/IP™

protocol. It describes the major concepts that must be understood to integrate a SmartMotor

slave with a PLC or other EtherNet/IP master. However, it does not cover all the low-level

details of the EtherNet/IP protocol.

NOTE: The feature set described in this manual requires a specific motor firmware

version. Please consult Moog Animatics for the proper software version.

This manual is intended for programmers or system developers who have read and understand THECIPNETWORKSLIBRARYVolume1-CommonIndustrialProtocol(CIP™) and THE

CIPNETWORKSLIBRARYVolume2-EtherNet/IPAdaptationofCIP, which are published and

maintained by ODVA.org (http://www.odva.org). Therefore, this manual is not a tutorial on

those specifications or the EtherNet/IP protocol. Instead, it should be used to understand the

specific implementation details for the Moog Animatics SmartMotor. For a general overview of

EtherNet/IP, see EtherNet/IP Overview on page 17.

The reference chapters of this manual include details about the specific commands available

in the SmartMotor through the EtherNet/IP protocol. The commands include those required by

the specifications and those added by Moog Animatics.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 8 of 160

Page 9

Abbreviations and Definitions

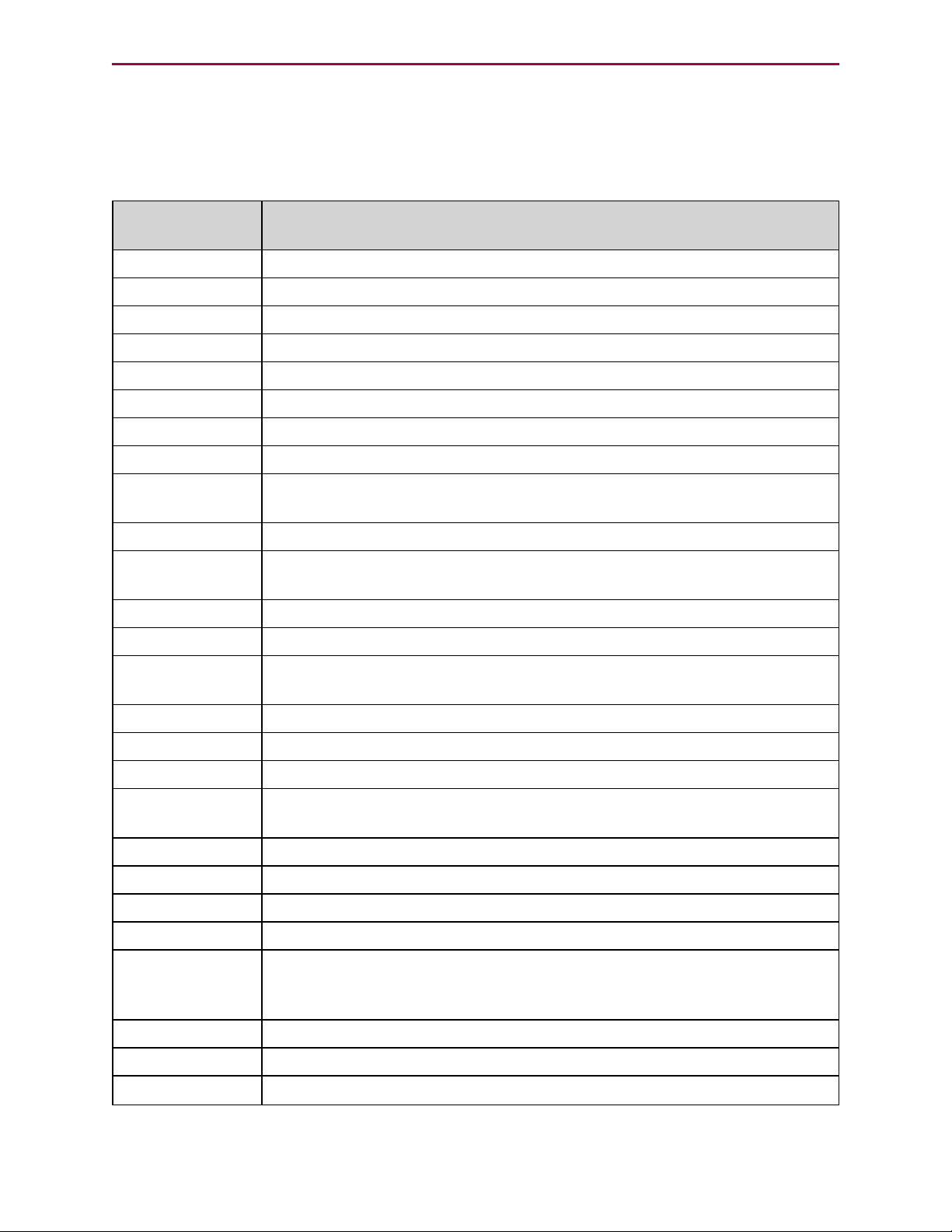

Abbreviations and Definitions

The following table provides a list of abbreviations and definitions of terms that may be used

in this manual or related documents.

Abbreviation/

Term

API Actual Packet Interval

ASCII American Standard Code for Information Interchange

AT Acceleration Target

BOI Buss-Off Interrupt

Client A device that sends a request to, and expects a response from, a server.

Consumer Network device that reads messages from a producer device.

CoS Change of State I/O trigger

DC Direct Current

DLR Device Level Ring. A ring topology that allows the Ethernet devices to

keep communicating if there is a break in the ring.

DT Deceleration Target

EDS Electronic Data Sheet. A text file that contains configuration information

for the device.

EPR Expected Packet Rate

EtherNet/IP Ethernet Industrial Protocol

Description

Explicit messaging

FOC Field Oriented Current

FTP File Transfer Protocol

IE Industrial Ethernet

Implicit messaging

IN Input

LAN Local Area Network

MACID Media Access Control Identifier

NASM Network Access State Machine

ODVA Open DeviceNet Vendors Association, Inc, which is the standards organ-

OUT Output

PDU Protocol Data Unit

PLC Programmable Logic Controller

(Non-cyclic) Not time-sensitive, typically used for network and device

configuration, and setup of cyclic connections.

(Cyclic) Timely, repetitive transfer of data, typically used for I/O control

(e.g., PID loop closure).

ization that maintains the specifications for the CIP industrial network protocols.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 9 of 160

Page 10

Abbreviations and Definitions

Abbreviation/

Term

Description

Producer A device that puts messages on the network for "consumer" devices

(other network devices that will read the messages).

PU Position Units

PV Profile Velocity (mode)

PT Position Target

RTE Real-Time Ethernet

Rx Receive

Server A device that receives requests from clients and sends responses to

them.

Slave device Device consuming data transfers from a Network Master. A PLC (Pro-

grammable Logic Controller) is a good example of a Master.

SMI SmartMotor Interface (software)

STD State Transition Diagram

TCP Transmission Control Protocol

TQ Torque (mode)

Tx Transmit

UDP User Datagram Protocol

UCMM Unconnected Message Manager

VU Velocity Units

VT Velocity Target

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 10 of 160

Page 11

Safety Information

Safety Information

This section describes the safety symbols and other safety information.

Safety Symbols

The manual may use one or more of the following safety symbols:

WARNING: This symbol indicates a potentially non-lethal mechanical hazard,

where failure to follow the instructions could result in serious injury to the

operator or major damage to the equipment.

CAUTION: This symbol indicates a potential minor hazard, where failure to follow the instructions could result in slight injury to the operator or minor damage to the equipment.

NOTE: Notes are used to emphasize non-safety concepts or related information.

Other Safety Considerations

The Moog Animatics SmartMotors are supplied as components that are intended for use in an

automated machine or system. As such, it is beyond the scope of this manual to attempt to

cover all the safety standards and considerations that are part of the overall machine/system

design and manufacturing safety. Therefore, the following information is intended to be used

only as a general guideline for the machine/system designer.

It is the responsibility of the machine/system designer to perform a thorough "Risk Assessment" and to ensure that the machine/system and its safeguards comply with the safety standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the locale

where the machine is being installed and operated. For more details, see Machine Safety on

page 12.

Motor Sizing

It is the responsibility of the machine/system designer to select SmartMotors that are properly sized for the specific application. Undersized motors may: perform poorly, cause excessive downtime or cause unsafe operating conditions by not being able to handle the loads

placed on them. The MoogAnimaticsProductCatalog, which is available on the Moog Anim-

atics website, contains information and equations that can be used for selecting the appropriate motor for the application.

Replacement motors must have the same specifications and firmware version used in the

approved and validated system. Specification changes or firmware upgrades require the

approval of the system designer and may require another Risk Assessment.

Environmental Considerations

It is the responsibility of the machine/system designer to evaluate the intended operating

environment for dust, high-humidity or presence of water (for example, a food-processing

environment that requires water or steam wash down of equipment), corrosives or chemicals

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 11 of 160

Page 12

Other Safety Considerations

that may come in contact with the machine, etc. Moog Animatics manufactures specialized IPrated motors for operating in extreme conditions. For details, see the MoogAnimaticsProduct

Catalog, which is available on the Moog Animatics website.

Machine Safety

In order to protect personnel from any safety hazards in the machine or system, the

machine/system builder must perform a "Risk Assessment", which is often based on the ISO

13849 standard. The design/implementation of barriers, emergency stop (E-stop) mechanisms and other safeguards will be driven by the Risk Assessment and the safety standards

specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the locale where

the machine is being installed and operated. The methodology and details of such an assessment are beyond the scope of this manual. However, there are various sources of Risk Assessment information available in print and on the internet.

NOTE: The following list is an example of items that would be evaluated when performing the Risk Assessment. Additional items may be required. The safeguards

must ensure the safety of all personnel who may come in contact with or be in the

vicinity of the machine.

In general, the machine/system safeguards must:

l

Provide a barrier to prevent unauthorized entry or access to the machine or system. The

barrier must be designed so that personnel cannot reach into any identified danger

zones.

l

Position the control panel so that it is outside the barrier area but located for an unrestricted view of the moving mechanism. The control panel must include an E-stop mechanism. Buttons that start the machine must be protected from accidental activation.

l

Provide E-stop mechanisms located at the control panel and at other points around the

perimeter of the barrier that will stop all machine movement when tripped.

l

Provide appropriate sensors and interlocks on gates or other points of entry into the protected zone that will stop all machine movement when tripped.

l

Ensure that if a portable control/programming device is supplied (for example, a handheld operator/programmer pendant), the device is equipped with an E-stop mechanism.

NOTE: A portable operation/programming device requires many additional

system design considerations and safeguards beyond those listed in this section. For details, see the safety standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the locale where the machine is

being installed and operated.

l

Prevent contact with moving mechanisms (for example, arms, gears, belts, pulleys,

tooling, etc.).

l

Prevent contact with a part that is thrown from the machine tooling or other part-handling equipment.

l

Prevent contact with any electrical, hydraulic, pneumatic, thermal, chemical or other

hazards that may be present at the machine.

l

Prevent unauthorized access to wiring and power-supply cabinets, electrical boxes, etc.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 12 of 160

Page 13

Safety Information Resources

l

Provide a proper control system, program logic and error checking to ensure the safety

of all personnel and equipment (for example, to prevent a run-away condition). The control system must be designed so that it does not automatically restart the machine/system after a power failure.

l

Prevent unauthorized access or changes to the control system or software.

Documentation and Training

It is the responsibility of the machine/system designer to provide documentation on safety,

operation, maintenance and programming, along with training for all machine operators, maintenance technicians, programmers, and other personnel who may have access to the

machine. This documentation must include proper lockout/tagout procedures for maintenance

and programming operations.

It is the responsibility of the operating company to ensure that:

l

All operators, maintenance technicians, programmers and other personnel are tested

and qualified before acquiring access to the machine or system.

l

The above personnel perform their assigned functions in a responsible and safe manner

to comply with the procedures in the supplied documentation and the company safety

practices.

l

The equipment is maintained as described in the documentation and training supplied by

the machine/system designer.

Additional Equipment and Considerations

The Risk Assessment and the operating company's standard safety policies will dictate the

need for additional equipment. In general, it is the responsibility of the operating company to

ensure that:

l

Unauthorized access to the machine is prevented at all times.

l

The personnel are supplied with the proper equipment for the environment and their job

functions, which may include: safety glasses, hearing protection, safety footwear,

smocks or aprons, gloves, hard hats and other protective gear.

l

The work area is equipped with proper safety equipment such as first aid equipment,

fire suppression equipment, emergency eye wash and full-body wash stations, etc.

l

There are no modifications made to the machine or system without proper engineering

evaluation for design, safety, reliability, etc., and a Risk Assessment.

Safety Information Resources

Additional SmartMotor safety information can be found on the Moog Animatics website; open

the file "109_Controls, Warnings and Cautions.pdf" located at:

http://www.animatics.com/support/moog-animatics-catalog.html

OSHA standards information can be found at:

https://www.osha.gov/law-regs.html

ANSI-RIA robotic safety information can be found at:

http://www.robotics.org/robotic-content.cfm/Robotics/Safety-Compliance/id/23

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 13 of 160

Page 14

Additional Documents

UL standards information can be found at:

http://ulstandards.ul.com/standards-catalog/

ISO standards information can be found at:

http://www.iso.org/iso/home/standards.htm

EU standards information can be found at:

http://ec.europa.eu/growth/single-market/european-standards/harmonised-standards/index_en.htm

Additional Documents

The Moog Animatics website contains additional documents that are related to the information

in this manual. Please refer to the following list:

l

Class6SmartMotor™Installation&StartupGuide

http://www.animatics.com/smartmotor-install-startup-guides

l

SmartMotor™Developer'sGuide

http://www.animatics.com/smartmotor-developers-guide

l

SmartMotor™ProductCertificateofConformance

http://www.animatics.com/download/Declaration of Conformity.pdf

l

SmartMotor™ULCertification

http://www.animatics.com/download/MA_UL_online_listing.pdf

l

SmartMotorDeveloper'sWorksheet

(interactive tools to assist developer: Scale Factor Calculator, Status Words, CAN Port

Status, Serial Port Status, RMODE Decoder, and Syntax Error Codes)

http://www.animatics.com/tools

l

MoogAnimaticsProductCatalog

http://www.animatics.com/support/moog-animatics-catalog.html

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 14 of 160

Page 15

Additional Resources

Additional Resources

The Moog Animatics website contains additional resources such as product information, documentation, product support and more. Please refer to the following addresses:

l

General company information:

http://www.animatics.com

l

Product information:

http://www.animatics.com/products.html

l

Product support (Downloads, How To videos, Forums, Knowledge Base, and FAQs):

http://www.animatics.com/support.html

l

Sales and distributor information:

http://www.animatics.com/sales-offices.html

l

Application ideas (including videos and sample programs):

http://www.animatics.com/applications.html

EtherNet/IP is a common standard maintained by by ODVA.org:

l

ODVA.org website:

http://www.odva.org/

l An EtherNet/IP Quick Start for Vendors Handbook is available at:

http://www.odva.org/Portals/0/Library/Publications_Numbered/PUB00213R0_EtherNetIP_Developers_Guide.pdf

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 15 of 160

Page 16

Page 17

EtherNet/IP Overview

EtherNet/IP Overview

This chapter provides an overview of EtherNet/IP features. These sections briefly summarize

the technical information provided on the ODVA.org website. To view the fully detailed information or to obtain the specifications, see the ODVA.org website at: http://www.odva.org.

EtherNet/IP Introduction 18

The OSI Model 18

EtherNet/IP Adaptation of CIP 19

Objects 21

Objects 21

Classes, Instances and Attributes 22

Messaging 23

Explicit (Non-cyclic) Messages 23

Implicit (Cyclic) Messages 23

Explicit/Implicit Messaging Example 23

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 17 of 160

Page 18

EtherNet/IP Introduction

EtherNet/IP

TM

DeviceNet

TM

Physical

Data Link

Network

Transport

Session

Presentation

Application,

Proles

Common

Industrial

Protocol

(CIP)

CIP

Network

Adaptations

OSI Model Layers

Semicond.

Proles

I/O

Proles

Transducer

Proles

Motion Ctrl

Proles

CIP Motion

TM

Proles

Other

Proles

Safety Serv.

& Messages

Safety Obj.

Library

CIP Safety

TM

Proles

Connection Management and Routing

Data Management Services

(Explicit and I/O Messages)

Object Library

(Communications, Applications, Time Synchronization)

DeviceNet Physical Layer

CAN CSMA/NBA

DeviceNet Network and Transport

Ethernet Physical Layer

Ethernet CSMA/CD

Internet Protocol

TCP/UDP

EtherNet/IP Introduction

Ethernet/Industrial Protocol (EtherNet/IP) is a fieldbus communications protocol that was initially developed in the 1990s. It is now a CIP-based technology that is managed by the Open

DeviceNet Vendors Association (ODVA), which is a standards organization that manages all

CIP network technologies.

EtherNet/IP and DeviceNet are two CIP network technologies that are supported by Moog

Animatics (see OSI Model for EtherNet/IP and DeviceNet on page 18). These networks share

the same CIP layers and use objects to describe the network devices (this collection of objects

specific to a device is the device profile). Because of this, they are able to communicate with

each other. For example, a device on an EtherNet/IP network can communicate with one on a

DeviceNet network. For more information on CIP objects, see Objects on page 21.

The Class 6 EtherNet/IP SmartMotor is designed to operate as a device on an EtherNet/IP network. This allows the system designer to take advantage of SmartMotor technology through

its device profile (for example, start a user program stored in the SmartMotor). For details on

the SmartMotor device profile using the Position Controller device, see SmartMotor Device

Profile Overview on page 33.

The full specification for EtherNet/IP is available from the ODVA.org website. For details, see

THECIPNETWORKSLIBRARYVolume1-CommonIndustrialProtocol(CIP™) and THECIP

NETWORKSLIBRARYVolume2-EtherNet/IPAdaptationofCIP.

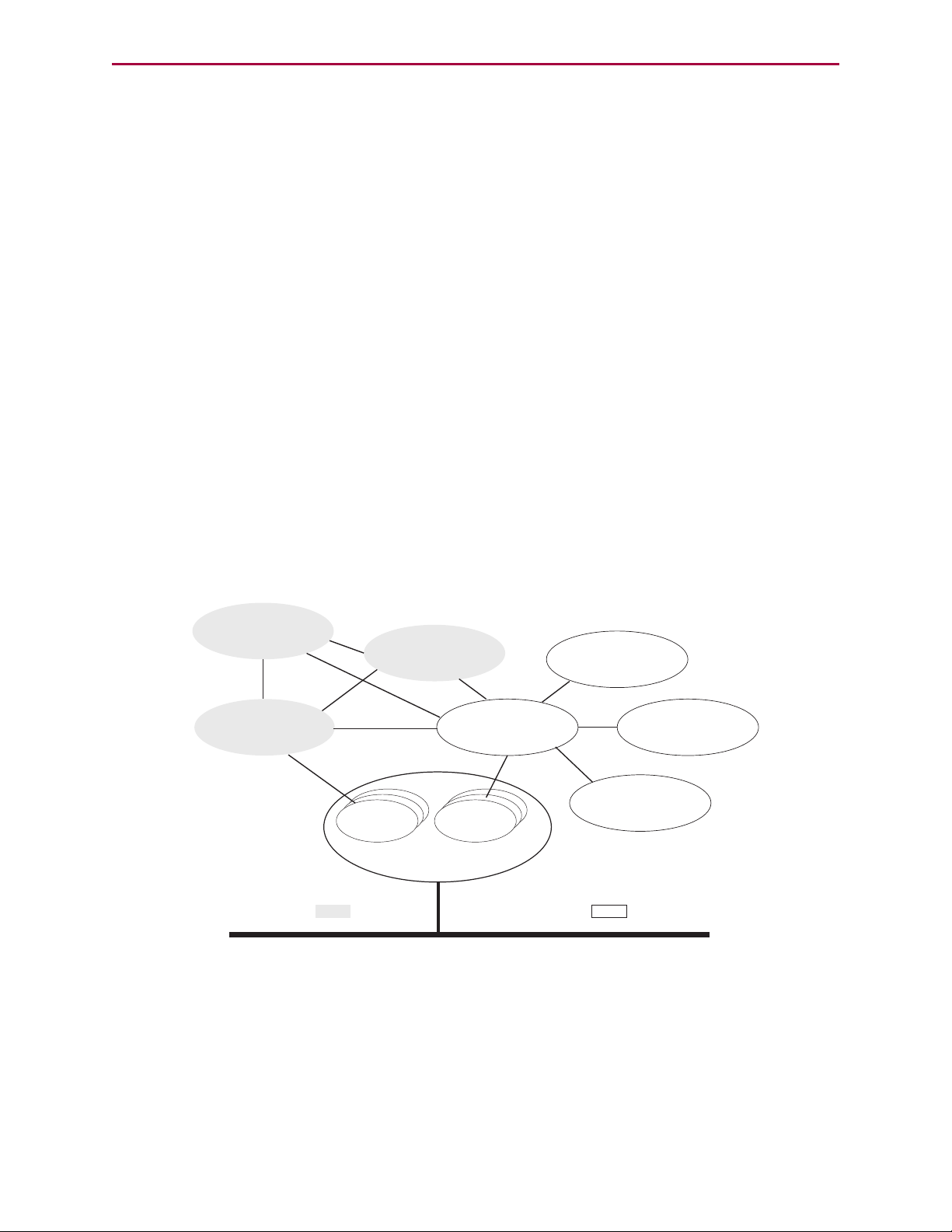

The OSI Model

The OSI model describes the architecture for the CIP-based industrial network protocols.

Moog Animatics supports EtherNet/IP and DeviceNet using the Position Controller Supervisor

and Position Controller profiles. The other profiles shown are not currently supported.

OSIModelforEtherNet/IPandDeviceNet

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 18 of 160

Page 19

EtherNet/IP Adaptation of CIP

Peer-to-peer, multicast, unicast

Ethernet

Internet Protocol (IP)

Transmission Control Protocol (TCP)

User Datagram Protocol (UDP)

Explicit

Messages

Device Proles and

Application Objects

Physical

Data Link

Network

Transport

Session

Presentation

Application

Implicit

Messages

IEEE

Standards

TCP/IP

Suite

Common

Industrial

Protocol

(CIP)

OSI Model Layers

The following table provides a brief description of each of the seven OSI model layer.

Layer Description

Physical The physical properties—electrical and mechanical—of the network

(e.g., cables, connectors, pin-outs, voltages, flow control, etc.). For

EtherNet/IP, it is based on IEEE 802.3 technology.

Data Link How packets of data will be transmitted between devices (MAC, CRC,

etc.). For EtherNet/IP, it is based on IEEE 802.3 technology.

Network The switching and routing layer, i.e, anything related to the device

IP address, DNS, datagrams, cyclic and non-cyclic. For EtherNet/IP,

uses the TCP/IP Suite.

Transport Controls how much data (size of block) that will be sent and received,

manages the delay time between messages, maintains the quality of service (QoS). For EtherNet/IP, uses the TCP/IP Suite, uses both TCP and

UDP.

Session Opens/closes and manages the connection between devices and applic-

ations, explicit and implicit messages are used. This layer is part of CIP.

Presentation Delivers and formats information to/from the application layer (trans-

lates data from the network to the application or from the application to

the network). This layer is part of CIP.

Application Handles the application that provides the user interaction. This layer is

part of CIP.

For more details, see the ODVA.org website.

EtherNet/IP Adaptation of CIP

EtherNet/IP is an implementation of Ethernet technology with the addition of CIP layers. Like

other ODVA industrial network protocols, it is based on the OSI model. Therefore, it is specifically tailored for industrial environments and applications. Refer to the following figure.

OSIModel:EtherNet/IPImplementation

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 19 of 160

Page 20

EtherNet/IP Adaptation of CIP

As shown in the previous figure, EtherNet/IP uses two communication protocols for message

transport:

l

Transmission Control Protocol (TCP) is used for Explicit messages—these are non-cyclic

messages for device configuration and setup of cyclic connection content.

l

User Datagram Protocol (UDP) is used for Implicit (I/O) messages—these are cyclic

messages that handle time-critical control data.

For more details on messages, see Messaging on page 23. Also, see Position Controller

Implicit I/O Messages on page 45.

EtherNet/IP is designed to be reliable, easily expanded for future growth, and can theoretically handle an unlimited number of devices. Note, however, that there may be other

factors that impose limitations on the size of the network.

For more details, see the ODVA.org website.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 20 of 160

Page 21

Objects

CIP Network

Required = Optional =

Assembly

Object

Application

Object(s)

Parameter

Object

Message Router

Identity

Object

TCP/IP Interface

Object

Ethernet Link

Object

Connection Manager

Object

I/O

Explicit

Msg

Objects

This section briefly describes the features of CIP device objects. For more details, see THE

CIPNETWORKSLIBRARY,Volume1:CommonIndustrialProtocol(CIP™), which is available

on the ODVA.org website.

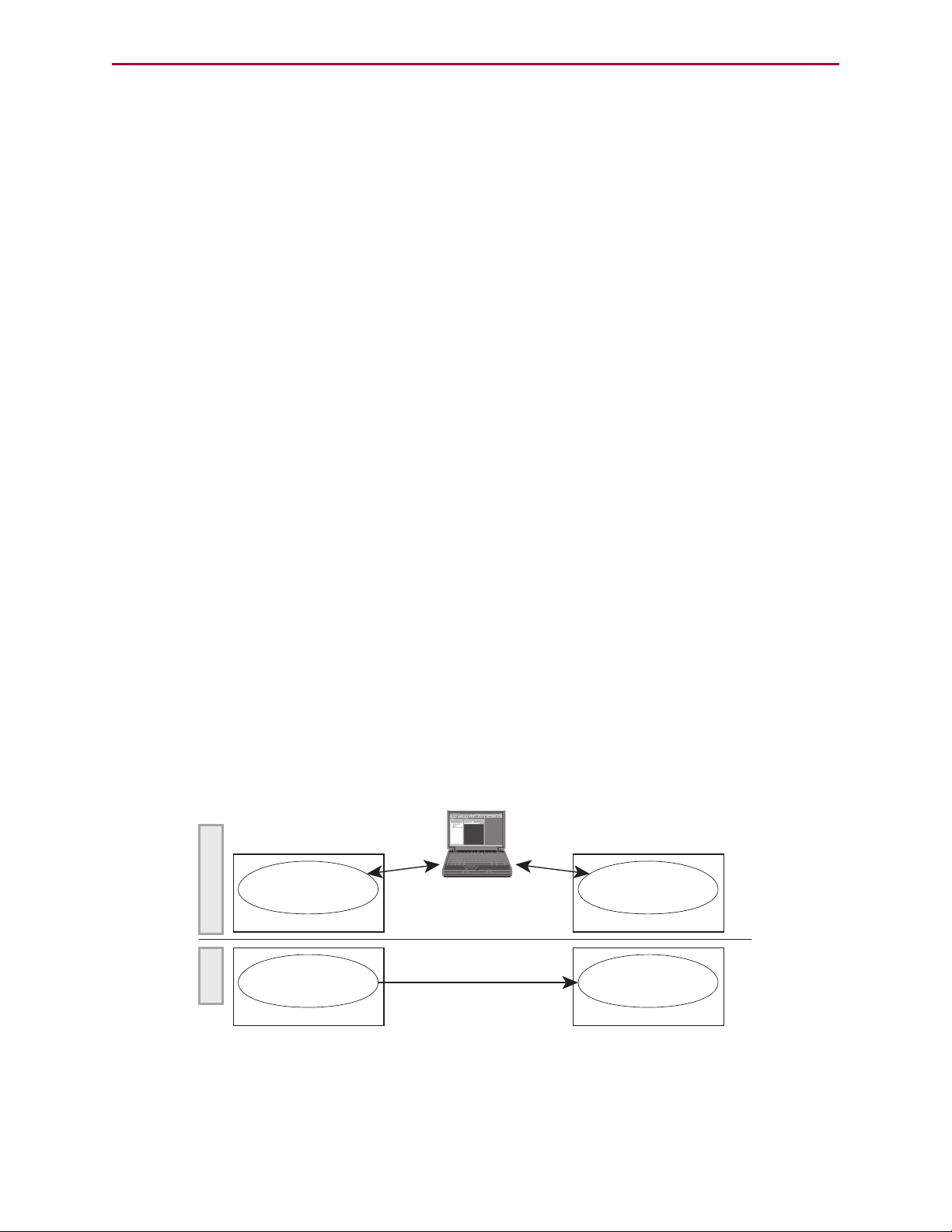

Objects

Because EtherNet/IP is a CIP-based network, the network devices are described through sets

of objects. Each set of objects is organized in a specific manner with specific attributes so that

each network device operates in a certain way—that organization is the object model (or

device model). Every device with the same object model will operate in the same manner.

NOTE: All device features must be described through objects in order to be accessible through CIP.

The following types of objects are used in a device profile:

l

Required objects: these must be present in every CIP device.

l

Application objects: these are specific to the type of device and its function.

l

Manufacturer-Specific objects: these are optional objects that are specific to each

device manufacturer.

The following figure shows a version of the EtherNet/IP object model with required and

optional objects.

EtherNet/IPObjectModel

For the SmartMotor-specific model, see the object model for your SmartMotor application,

which is described later in this guide.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 21 of 160

Page 22

Classes, Instances and Attributes

Device Address

Object 2

Instance 1

Object Class 2

Object 1

Instance 2

Object Class 1

Attribute 3

Attribute 2

Attribute 1

Object 1

Instance 1

Attribute 3

Attribute 2

Attribute 1

Classes, Instances and Attributes

The CIP object model uses classes, instances and attributes to describe each device. Refer to

the following figure.

l

Class: a fixed collection of objects with each object having a fixed set of attributes. The

CIP object library contains three primary object classes: general use, application specific, and network specific.

l

Instance: an occurrence of a particular object (in other words, there can be more than

one occurrence of the same object but with different attribute values).

l

Attributes: a set of data values that describe an object instance (instance attributes).

They can also describe an object class (class attributes).

Classes,Instances,Attributes

The device description (class, instance, attributes) information is also contained in the Electronic Data Sheet (EDS) file, which is supplied by the equipment vendor (see EDS File on page

35).

For more details, see the ODVA.org website.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 22 of 160

Page 23

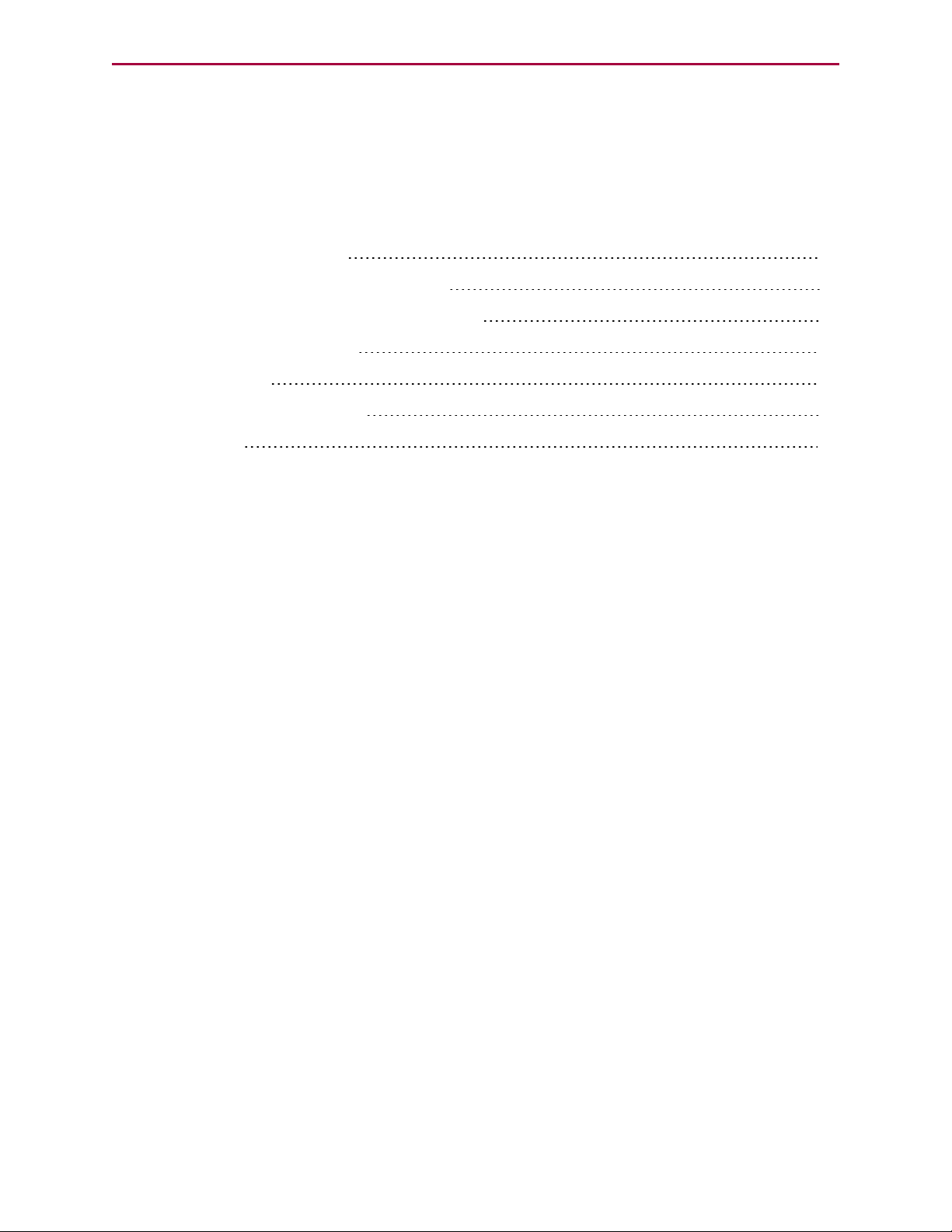

Messaging

Tool

I/O Connection

Object

Device A

I/O Connection

Object

Device B

I/O Connection

Object

Device A

I/O Connection

Object

Device B

I/O Connection from A to B

(Implicit messaging)

Congure connection instance

(Explicit messaging)

Congure connection instance

(Explicit messaging)

CONFIGURATIONRESULT

Messaging

There are two types of messages used by EtherNet/IP: explicit messages and implicit messages. Each is described in the following sections.

Explicit (Non-cyclic) Messages

Explicit messages are non-cyclic, i.e., they are typically sent once instead of at regular intervals. Further, explicit messages are not time sensitive. They are used for communicating

information such as configuration, diagnostic, data logs, and other information that is not time

critical. They can also be used to set up implicit (cyclic) connection content (see the next section).

Explicit messages are point-to-point messages. In other words, a device sends out a message

directed to a specific recipient device. The recipient device will return a response to that message. As a result, the explicit messages are much larger than implicit messages (refer to the

next section) and can generate a lot of network traffic; therefore, they are not used for transmitting cyclic data.

Implicit (Cyclic) Messages

Implicit messages (also referred to as I/O messages) are cyclic, i.e., they are sent at regular

intervals. Implicit messages are used to communicate critical, time-sensitive information.

They are typically used for I/O control, PID loop closure, and Motion or Application control.

The implicit message connection between the two devices is established up front and connection ID assignment is made. Therefore, the actual implicit messages contain just the connection ID and the data. As a result, implicit messages are very small, they can travel

quickly, and they do not use much network bandwidth.

Explicit/Implicit Messaging Example

In the following figure, a tool uses explicit messaging to configure the connections between

two network devices. Once that I/O connection is established, the devices can communicate

using implicit messaging. For more details, see THECIPNETWORKSLIBRARY,Volume1:Com-

monIndustrialProtocol(CIP™), which is available on the ODVA.org website.

Explicit/ImplicitMessagingExample

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 23 of 160

Page 24

Page 25

Connections, Wiring and Status LEDs

Connections, Wiring and Status LEDs

This chapter provides information on the SmartMotor connectors, a multidrop cable diagram,

and a description of the SmartMotor status LEDs.

Connectors and Pinouts 26

M-Style Motor Connectors and Pinouts 26

Moog Animatics Industrial Ethernet Cables 27

EtherNet/IP Custom Cable 27

Cable Diagram 28

EtherNet/IP Cable Diagram 28

Status LEDs 29

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 25 of 160

Page 26

Connectors and Pinouts

1

2 3

4

POWER INPUT

PIN

FUNCTION

DESCRIPTION

1

24 VDC

CONTROL I/O POWER

2

EARTH

CHASSIS GROUND

3

GND

MOTOR COMMON GROUND

4

48 VDC

MOTOR POWER

1

2

3

4

5

6

7

8

COMMUNICATION

PIN

FUNCTION

1

GND-COMMON

2

RS-485B CH0

3

RS-485A CH0

4

ENC A+ IN

5

ENC B- IN

6

ENC A- IN

7

5 VDC OUT

8

ENC B+ IN

1

2

3

4

5

6

7

8

9

10

11

12

4

3 1

2

EtherNet/IP

PIN

FUNCTION

1

+TX

2

+RX

3

-TX

4

-RX

I/Os

PIN

FUNCTION

DESCRIPTION

1

IN0

GENERAL PURPOSE

2

IN1

GENERAL PURPOSE

3

IN2/POSLIMIT

POSITIVE LIMIT

4

IN3/NEGLIMIT

NEGATIVE LIMIT

5

IN4

GENERAL PURPOSE

6

IN5

GENERAL PURPOSE

7

IN6

GENERAL PURPOSE

8

IN7-DRVEN

DRIVE ENABLE

9

OUT8/BRAKE

BRAKE OUTPUT

10

OUT9-NOFAULT

NOT FAULT

11

24 VDC OUT*

CONTROL/IO POWER

12

GND

MOTOR COMMON GROUND

INPUT OR OUTPUT

INPUT, DISCRETE OR ANALOG

POSSIBLE (SELECTABLE) FUNCTIONS

INPUT, DISCRETE OR ANALOG

INPUT

INPUT

INPUT

INPUT

INPUT

INPUT

OUTPUT

OUTPUT

POWER OUTPUT**

N/A

GENERAL PURPOSE

GENERAL PURPOSE

POSITIVE LIMIT OR GENERAL PURPOSE

NEGATIVE LIMIT OR GENERAL PURPOSE

GENERAL PURPOSE, OR EXTERNAL ENCODER

INDEX CAPTURE

GENERAL PURPOSE, OR INTERNAL ENCODER

INDEX CAPTURE

GENERAL PURPOSE, G COMMAND, OR

HOMING INPUT (ETHERCAT ONLY)

CONTROL I/O POWER

N/A

NOT FAULT

BRAKE OUTPUT OR GENERAL-PURPOSE OUTPUT

DRIVE ENABLE

*NOTE: 2 AMPS MAX **SUPPLIED FROM POWER INPUT PIN 1

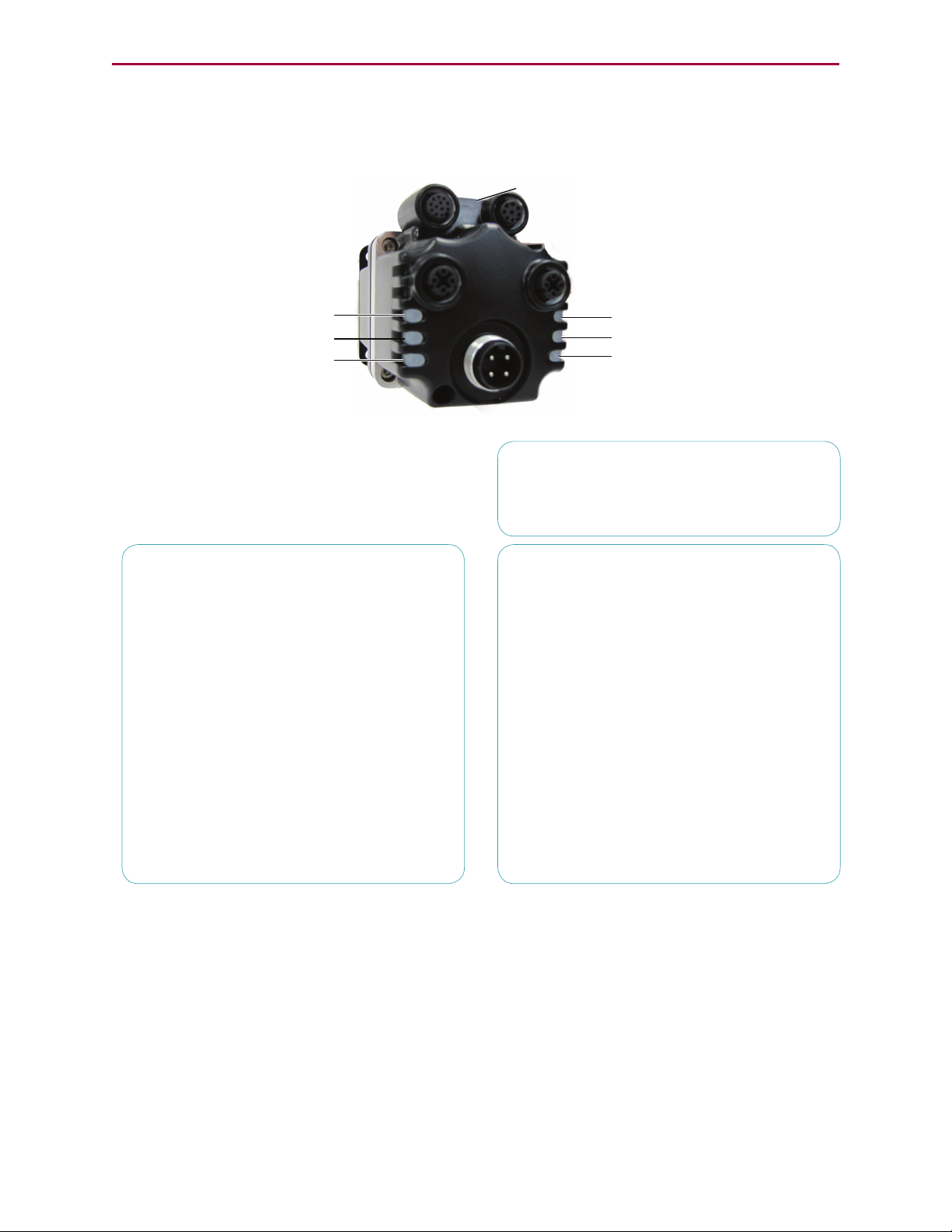

LED 4: EtherNet/IP Link 1 Port LED

LED 2: EtherNet/IP Network Status LED

LED 0: Motor Drive LED

LED 5: EtherNet/IP Link 2 Port LED

LED 3: EtherNet/IP Module Status LED

LED 1: Motor Busy LED

USB Active LED

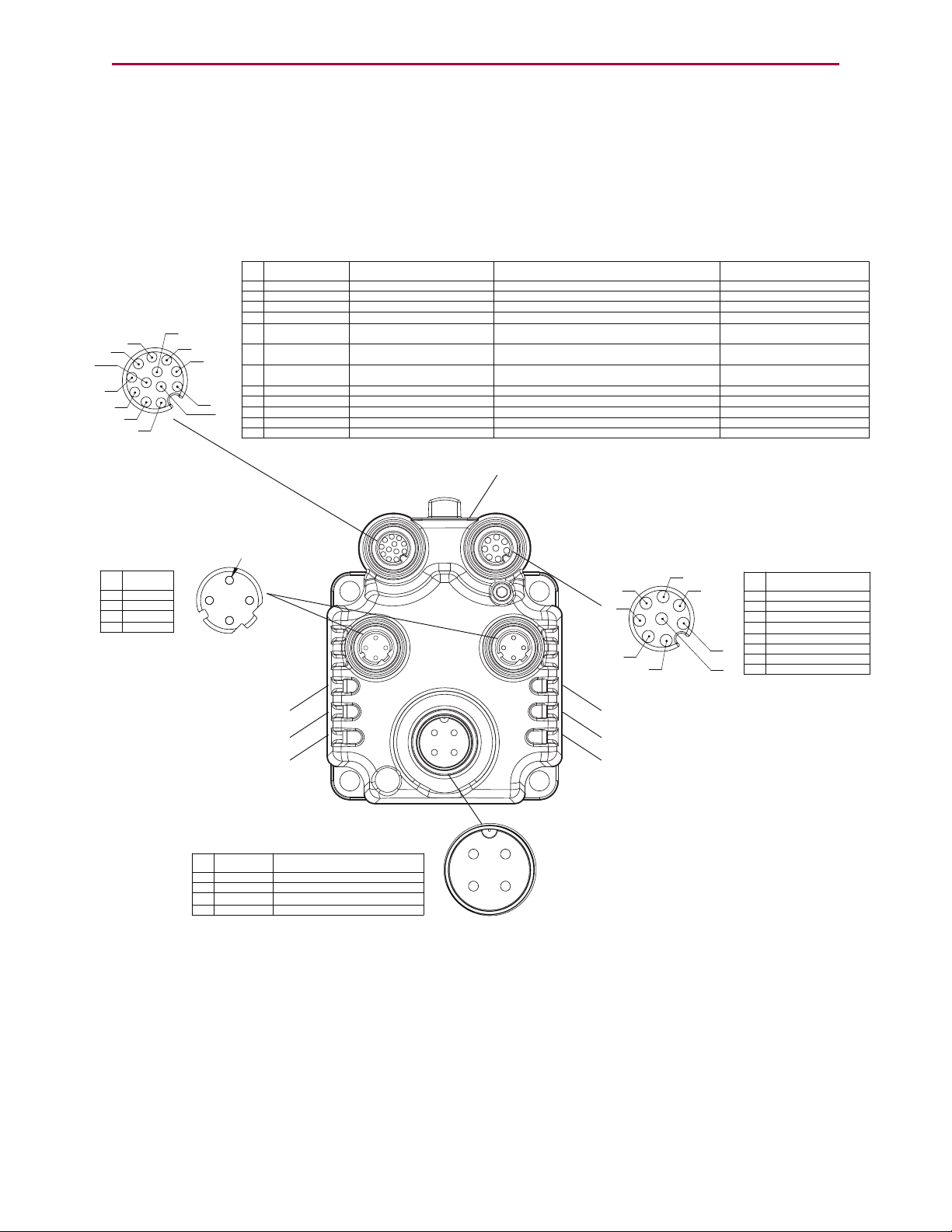

Connectors and Pinouts

M-Style Motor Connectors and Pinouts

The following figure provides a brief overview of the connectors and pinouts available on the

M-style SmartMotors.

NOTE: When daisy-chaining SmartMotors for an EtherNet/IP network, there is no

specific IN or OUT Ethernet port. In other words, either Ethernet port can be used

for the input or the output.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 26 of 160

Page 27

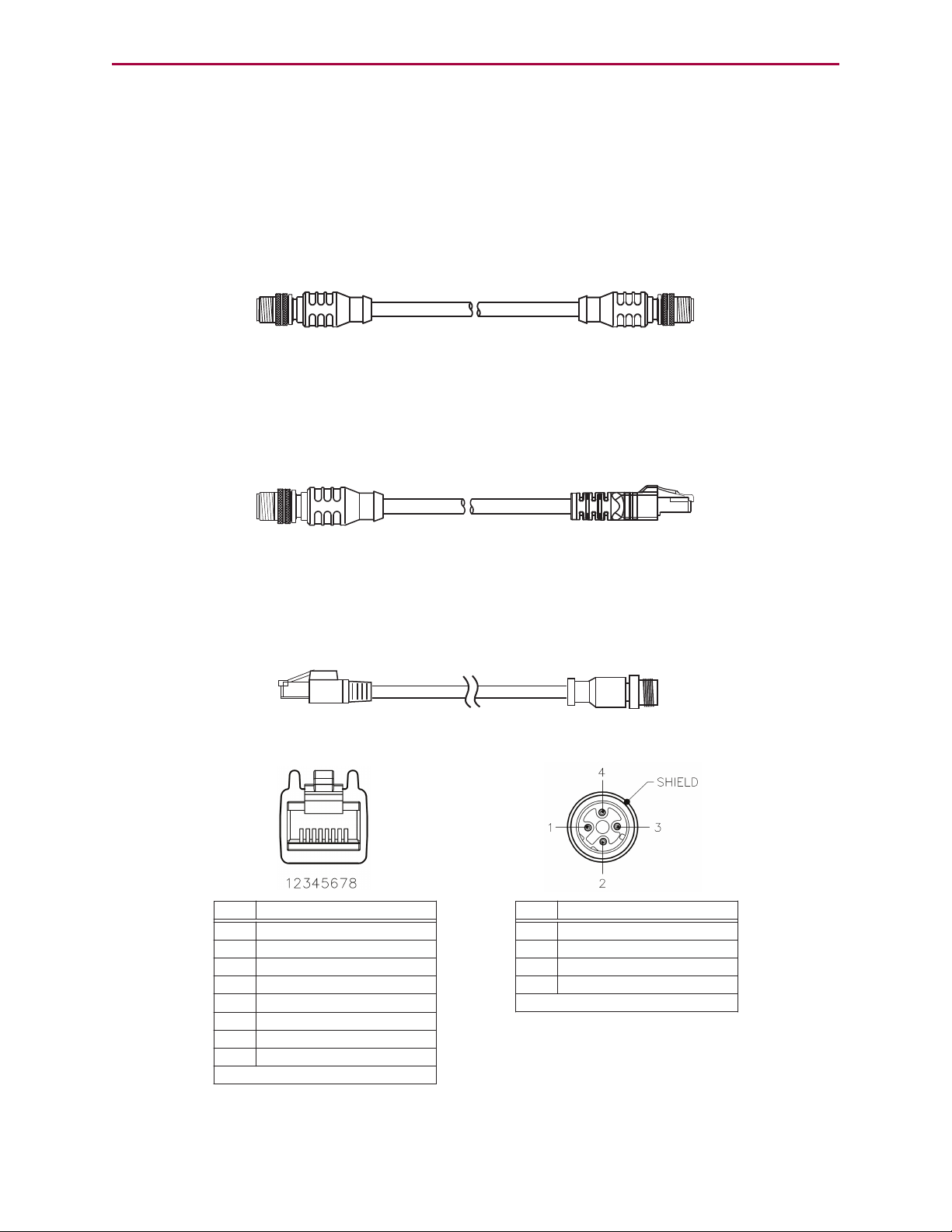

Moog Animatics Industrial Ethernet Cables

Industrial Ethernet Connector

(Motor end of cable)

PIN

1

2

3

4

+TX

+RX

-TX

-RX

DESCRIPTION

Shield tied to motor housing

RJ45S Connector

(EtherNet/IP master end of cable)

1

2

3

4

5

6

7

8

+TX

-TX

+RX

No Connection

No Connection

-RX

No Connection

No Connection

PIN

DESCRIPTION

Shield tied to RJ45S connector

Moog Animatics Industrial Ethernet Cables

The following Industrial Ethernet cables are available from Moog Animatics.

M-style to M-style Ethernet Cable

This cable has M12 male threaded connectors at both ends. It is available in 1, 3, 5 and 10

meter lengths. For the standard cable, use part number CBLIP-ETH-MM-xM, where "x"

denotes the cable length. A right-angle version is also available; use part number

CBLIP-ETH-MM-xMRA.

M-style to RJ45 Ethernet Cable

This cable has an M12 male threaded connector at one end, and an RJ45 male connector at the

opposite end. It is available in 1, 3, 5 and 10 meter lengths. For the standard cable, use part

number CBLIP-ETH-MRJ-xM, where "x" denotes the cable length. A right-angle version is also

available; use part number CBLIP-ETH-MRJ-xMRA.

EtherNet/IP Custom Cable

The following figure provides details for creating a custom shielded EtherNet/IP cable.

NOTE: The motor end of the cable requires an industrial Ethernet connector.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 27 of 160

Page 28

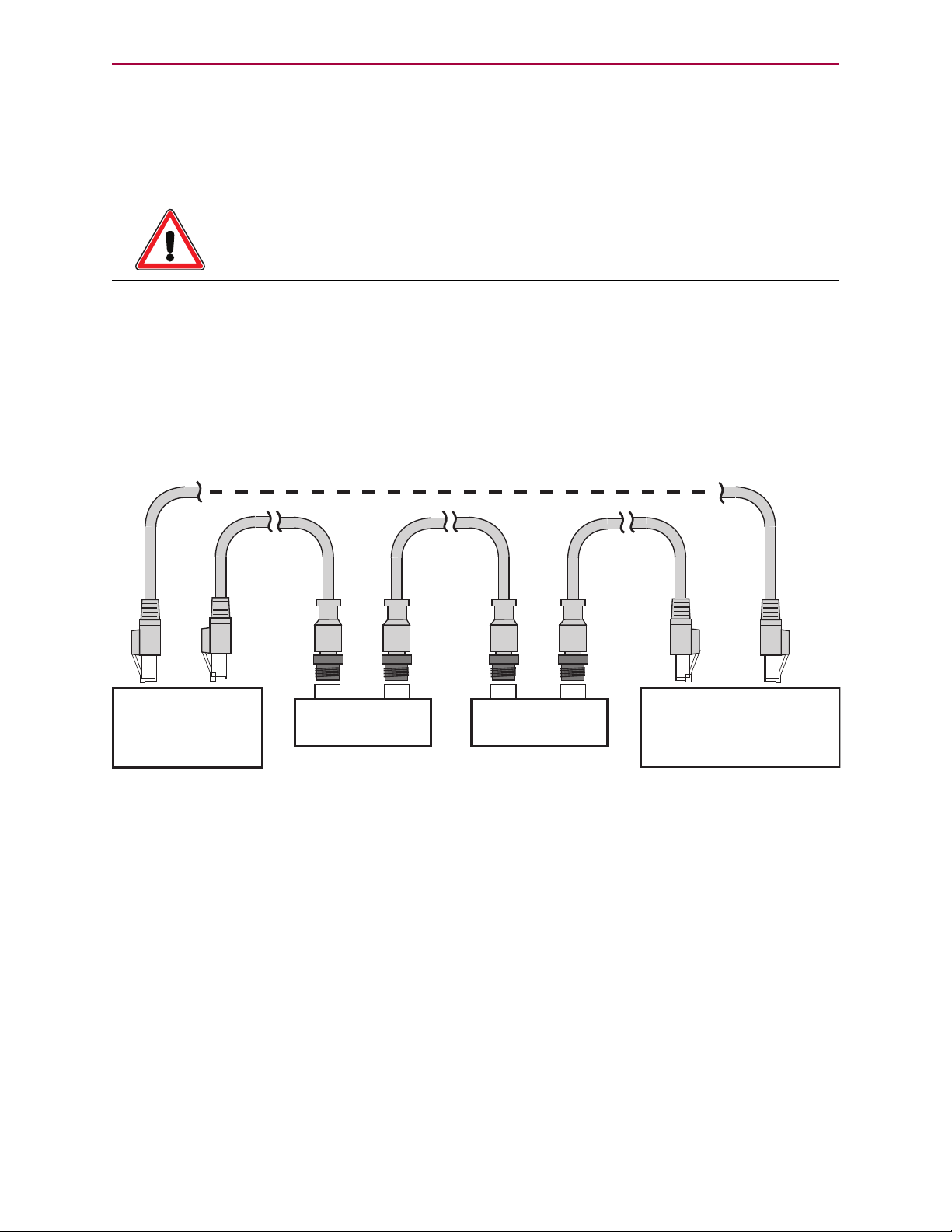

Cable Diagram

EtherNet/IP Bus

Other EtherNet/IP device:

- I/O block,

- Servo drive,

- etc.

EtherNet/IP Master

- PC,

- PLC,

- etc.

Moog Animatics

SmartMotor

Moog Animatics

SmartMotor

Optional ring for cable redundancy*

*Ring conguration requires an EtherNet/IP master with two ports

NOTE: Either Ethernet port can be used

to daisy-chain the motors.

Example Daisy-Chain Conguration

Cable Diagram

This section describes the cabling information for adding a SmartMotor to an EtherNet/IP network.

CAUTION: To minimize the possibility of electromagnetic interference (EMI),

all connections should use shielded Ethernet Category 5 (Cat 5), or better,

cables.

EtherNet/IP Cable Diagram

The following diagram shows an example EtherNet/IP network with the SmartMotors daisy

chained to the EtherNet/IP master device. An optional "ring" configuration can be created if

the EtherNet/IP master device has two ports.

Many network configurations are possible, such as line, tree or star. Requirements for specific

configurations depend on the capabilities of the EtherNet/IP controller devices, the node

devices, types and lengths of cables, and use of other networking equipment. For specific

details on creating an EtherNet/IP network, refer to the ODVA publication EtherNet/IPMedia

PlanningandInstallationManual, which is available on the ODVA.org website.

NOTE: Unlike other fieldbus protocols, EtherNet/IP does not require terminators at

each end of the network bus.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 28 of 160

Page 29

Status LEDs

Off No power

Solid green Drive on

Blinking green Drive off, no faults

Triple red flash Watchdog fault

Solid red Faulted or no drive enable input

Off Not busy

Solid green Drive on, trajectory in progress

Off No/bad cable; no/bad Link port

Solid green Link established

Flashing # red Flashes fault code* (see below)

when Drive LED is solid red

Blinking green Activity

Off No/bad cable; no/bad Link port

Solid green Link established

Blinking green Activity

Off No power

Flashing red/grn Power-up self test

Flashing green Standby

Solid green Device operational

Flashing red Minor fault

Solid red Major fault

Off No power or no IP address

Flashing red/grn Power-up self test

Flashing green No connections

Solid green Connected

Flashing red Connection timeout

Solid red Duplicate IP

LED 4: EtherNet/IP Link 1 Input LED

LED 2: EtherNet/IP Network Status LED

LED 0: Motor Drive LED

LED 5: EtherNet/IP Link 2 Output LED

LED 3: EtherNet/IP Module Status LED

LED 1: Motor Busy LED

LED 0: Motor Drive LED LED 1: Motor Busy LED

LED 3: EtherNet/IP Module Status LED

LED 5: EtherNet/IP Link 2 Output LED

LED 2: EtherNet/IP Network Status LED

LED 4: EtherNet/IP Link 1 Input LED

LED Status on Power-up:

• With no program and the travel limit inputs are low:

LED 0 solid red; motor is in fault state due to travel limit fault

LED 1 off

• With no program and the travel limits are high:

LED 0 solid red for 500 milliseconds then flashing green

LED 1 off

• With a program that only disables travel limits:

LED 0 red for 500 milliseconds then flashing green

LED 1 off

Flash

1

2

3

4

5

6

7

8

9

10

11

Description

NOT Used

Bus Voltage

Over Current

Excessive Temperature

Excessive Position

Velocity Limit

dE/Dt - First derivative of position error is excessive

Hardware Positive Limit Reached

Hardware Negative Limit Reached

Software Positive Travel Limit Reached

Software Negative Travel Limit Reached

LED1 Fault Codes:

*Busy LED pauses for 2 seconds before flashing the code

Flickering = On/Off in 0.1 sec; Blinking = On/Off in 0.5 sec; Flashing = separated by 1 sec for EtherNet/IP LEDs and 2 sec for Fault Codes

USB Active LED

Flashing green Active

Flashing red Suspended

Solid red USB power detected, no

configuration

USB Active LED

Status LEDs

This section describes the functionality of the Status LEDs on the Class 6 SmartMotor.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 29 of 160

Page 30

Page 31

EtherNet/IP on Class 6 SmartMotors

EtherNet/IP on Class 6 SmartMotors

This section provides an overview of the EtherNet/IP communications protocol implementation on the Moog Animatics Class 6 SmartMotor.

EtherNet/IP Implementation 32

EtherNet/IP Identity 32

EtherNet/IP Software Version Numbers 32

Device Profile 32

SmartMotor Device Profile Overview 33

CIP Objects for EtherNet/IP Devices 33

Application Objects for Position Controller Devices 34

Additional Objects 34

EDS File 35

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 31 of 160

Page 32

EtherNet/IP Implementation

EtherNet/IP Implementation

This section describes EtherNet/IP implementation information for the Class 6 SmartMotor.

EtherNet/IP Identity

The following identity information is available when the SmartMotor is queried by the EtherNet/IP master.

l

Product Codes: 10 - SM6-M

l

Device Name: Factory data in nonvolatile EEPROM memory.

l

Serial Number: Factory data in nonvolatile EEPROM memory.

NOTE: These identity items match those shown on the SmartMotor name plate.

EtherNet/IP Software Version Numbers

The initial EtherNet/IP software release is 6.0.2.23.

Device Profile

The Class 6 EtherNet/IP SmartMotor profile uses the Position Controller (0x10) device. For

Position Controller details, see SmartMotor Device Profile Overview on page 33.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 32 of 160

Page 33

SmartMotor Device Profile Overview

SmartMotor Device Profile Overview

This section provides an overview of the objects used in the SmartMotor device profile. It

includes: CIP required objects and network objects (the CIP objects), ODVA "Device" set of

objects (the Application objects), and Moog Animatics vendor-specific objects (the Additional

objects).

For a full description of each object, see the corresponding "For details..." section. For more

details on the Position Controller Device, see Position Controller Device (0x10) on page 43.

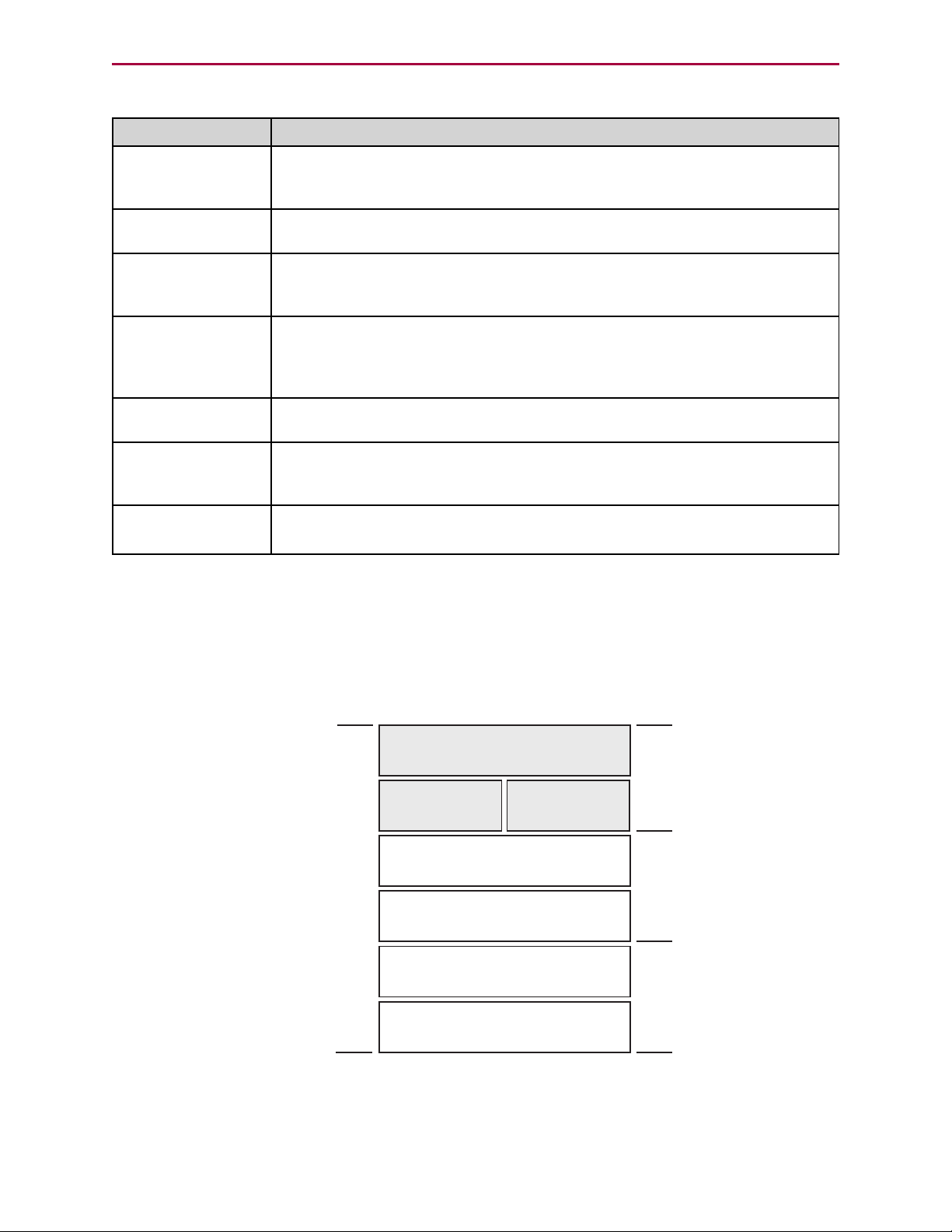

CIP Objects for EtherNet/IP Devices

The following table shows the minimum objects required for any EtherNet/IP device.

Object Class

Identity Object 0x01 Provides identification

Message

Router Object

Assembly

Object

Connection Manager Object

TCP/IP Interface Object

Class

Code

0x02 Provides message hand-

0x04

0x06 Establishes and man-

0xF5 Configures the device’s

1

Description

and general device

information. Object is

required in every network device.

ling for communicating

with objects in the physical device.

Binds attributes of multiple objects, allowing

data to/from each

object to be sent/received through a

single connection. Also

used to bind input or output data.

ages the communications

connections (exchanges

of messages), including

connections across multiple subnets.

TCP/IP network interface. For example, this

includes the device’s IP

Address, Network

Mask, and Gateway

Address.

Required/

Optional

Required 1

Required 1

Optional used for the

SmartMotor

Conditional

(required for

EtherNet/IP)

Conditional

(required for

EtherNet/IP)

Instances

For details,

see...

Identity Object

(0x01) on page

63

Message Router

Object (0x02) on

page 67

2 Assembly Object

(0x04) on page

68

1

1

Connection Manager Object

(0x06) on page

69

TCP/IP Interface

Object (0xF5) on

page 70

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 33 of 160

Page 34

Application Objects for Position Controller Devices

Object Class

Ethernet Link

Object

1. Network-Specific Link Objects

1

Class

Code

0xF6 Maintains link-specific

Description

counters and status

information for the communications interface.

Required/

Optional

Conditional

(required for

EtherNet/IP)

Instances

1

For details,

see...

Ethernet Link

Object (0xF6) on

page 77

Application Objects for Position Controller Devices

The Position Controller Device type is 0x10; there is one instance. The following table shows

the required application objects for a Position Controller device.

Object Class

CIP Required

Objects

Position Controller Supervisor

Position Controller

Class

Code

(see

previous

table)

0x24 Handles errors for Pos-

0x25 Performs control out-

Description

(see previous table) Required (see pre-

ition Controller, also

home and registration

inputs.

put velocity profiling;

handles input/output

to/from the motor,

limit switches registration, etc.

Required/

Optional

Required 1 Position Con-

Required 1 Position Con-

Instances

vious

table)

For details,

see...

(see previous

table)

troller Supervisor (0x24) on

page 84

troller (0x25)

on page 86

Additional Objects

In addition to the object classes in the previous tables, the following manufacturer-specific

and other objects have been added for the SmartMotor.

Object Class

Device Level

Ring (DLR)

Object

Quality of Service (QOS)

Object

SmartMotor I/O

Object

Class

Code

0x47 Allows use of an Ethernet

ring network topology

0x48 Provides priority-depend-

ent control of the Ethernet data streams.

0x71

Manufacturer-specific

object associated with

the Position Controller

Device

Description

Required/

Optional

1 Device Level

1 QoS Object

Instances

1

For details,

see...

Ring (DLR)

Object (0x47)

on page 92

(0x48) on page

94

SmartMotor I/O

Object (0x71)

on page 96

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 34 of 160

Page 35

EDS File

EDS File

The Electronic Data Sheet (EDS) file is supplied by the equipment manufacturer. It is an

ASCII text file that is structured as specified by the CIP specification. The EDS file contains all

of the necessary information for the configurable parameters of the corresponding device

(i.e., it contains information required by the CIP specification and may include vendor-specific

information provided by the manufacturer). For example, there is an EDS file supplied by

Moog Animatics for the EtherNet/IP SmartMotor.

All CIP network configuration tools have the ability to read EDS files. The information in the

EDS file is used by the configuration tool to guide the user through the configuration process.

For more details, see THECIPNETWORKSLIBRARY,Volume1:CommonIndustrialProtocol

(CIP™), which is available on the ODVA.org website.

To obtain the EDS file for the SmartMotor:

1.

Access the Download Center on the Moog Animatics website at:

http://www.animatics.com/support/download-center.html

2.

From the folder list, select Firmware And Fieldbus Downloads > Fieldbus Config > EtherNet/IP folder.

3.

Locate the EDS file (.eds extension) and click it.

4.

Save the file to a location on your computer.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 35 of 160

Page 36

Page 37

EtherNet/IP User Program Commands

EtherNet/IP User Program Commands

This chapter provides details on the EtherNet/IP commands used with the SmartMotor and its

user program. SmartMotor programming is described in the SmartMotor™Developer'sGuide.

The SmartMotor user program allows the motor to take on autonomous or distributed control

functions needed in an application.

Network Settings and Status Commands 38

Program Example 40

Status and Diagnostic Codes 41

Status/Error Codes 41

Diagnostic Codes 41

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 37 of 160

Page 38

Network Settings and Status Commands

Network Settings and Status Commands

The SmartMotor's EEPROM can store nonvolatile EtherNet/IP information about the network.

For proper EtherNet/IP operation, each SmartMotor must have a unique IP address. If a DHCP

server is used in the network, then the SmartMotor default IP address (0.0.0.0) is used; if a

fixed IP address is needed or there is no DHCP server, the IP address can be set using the

IPCTL command. This can be accomplished: at the PLC over EtherNet/IP; with SMI and a USB

connection, or RS-485 on channel 0; with a SmartMotor user program. If an IP address is

assigned through any method, including the DHCP server, that address is stored and used at

the next power-up.

NOTE: Nonvolatile memory will be read at power-up or after the Z (reset) command has been executed.

The commands in the following table are related to the network settings and status.

Command

IPCTL(action,"string")

RETH(0), or

x=ETH(0)

RETH i s the same as RETH(0)

x=ETH is the same as

x=ETH(0)

RETH(1), or

x=ETH(1)

RETH(2), or

x=ETH(2)

RETH(3), or

x=ETH(3)

Description/

Parameter

action=

0: set IP address

1: set Mask

2: set Gateway

EtherNet/IP status Bit 0 = Initialization failure

Module status Bit 0 = No power

Network status Bit 0 = Not powered, no IP address

Stack fault code For details, see Status and Diagnostic Codes

The drive is shipped out-of-box with an IP

Address of 0.0.0.0. This address enables

DHCP support for addressing. The DHCP

server manages the IP Address assigned to

the drive.

If a value other than 0.0.0.0 is assigned then

DHCP is disabled and the static IP Address is

used. Assigning an IP Address of 0.0.0.0 will

re-enable DHCP if desired

Value is formatted as an IP address entered as

a string, e.g., IPCTL(0,"192.168.0.10"). By

default, these values are set to 0 (i.e.,

"0.0.0.0")

NOTE: The drive must be power cycled or

reset using a "Z" terminal window command

before the new IP Address takes affect.

Bit 1 = Configuration change

Bit 2 = Reserved

Bit 3 = Network processor failure

Bit 4 = Port 1 has LINK

Bit 5 = Port 2 has LINK

Bit 1 = Self test

Bit 2 = Standby

Bit 3 = Device operational

Bit 4 = Minor (recoverable) fault

Bit 5 = Major (non-recoverable) fault

Bit 1 = No connections

Bit 2 = Connected

Bit 3 = Connection timeout

Bit 4 = Duplicate IP

Bit 5 = Self-test

on page 41.

Values

Non-

Volatile

Setting

YES

N/A

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 38 of 160

Page 39

Network Settings and Status Commands

Command

RETH(5), or

x=ETH(5)

RETH(6), or

x=ETH(6)

RETH(7), or

x=ETH(7)

RETH(8), or

x=ETH(8)

RETH(9), or

x=ETH(9)

RETH(14)

RETH(15) IP address Value is in dotted-decimal for mat.

RETH(16) Subnet mask Value is in dotted-decimal format.

RETH(17) Gateway Value is in dotted-decimal format.

RETH(18) MAC ID string format-

RETH(30), or

x=ETH(30)

RETH(31), or

x=ETH(31)

RETH(45), or

x=ETH(45)

RETH(46), or

x=ETH(46)

RETH(47), or

x=ETH(47)

RETH(48), or

x=ETH(48)

RETH(49), or

x=ETH(49)

RETH(50), or

x=ETH(50)

RETH(51), or

x=ETH(51)

RETH(54), or

x=ETH(54)

ETHCTL(3,x)

Description/

Parameter

LFW firmware version Firmware version as 32-bit interger. E.g.,

3.1.0.1 would be a value 50397185

(0x03010001).

Network Lost user pro-

gram number

Processor type -1 = Failed

Protocol type 0 = Not defined

Network Lost action The c urr ent value assigned to the Network

ted r eport only

I/O read data size Value is c onfigur ed by the master.

I/O write data size Value is configured by the master.

IP address as integer E.g., for an IP address of 192.168.1.3 (C0 A8

IP subnet mask as

integer

IP gateway as integer E.g., for an IP gateway of 192.168.1.1 (C0 A8

Low 3 bytes of MAC ID

(device ID) as integer

High 3 bytes of MAC ID

(device ID) as integer

Internal error code For details, see Status and Diagnostic Codes

Internal error source For Moog Animatics use.

Initialize error code For details, see Status and Diagnostic Codes

Reset Resets Stack Fault code RETH(3) to 0

The current Network Los t program label number.

0 = Unknown

1 = netX 10

2 = netX 50

3 = netX 51/52

4 = netX 100

1 = PROFINET

2 = EtherCAT

3 = EtherNet/IP

Lost action.

E.g., 00:01:02:a9:ff:00

01 03 hex), this command reports 1062731517 (it reports as a 32-bit signed

value).

E.g., for an IP netmask of 255.255.0.0 (FF FF

00 00 hex), this command reports -65536 (it

reports as a 32-bit signed value).

01 01 hex), this command reports 1062731519 (it reports as a 32-bit signed

value.)

E.g., for a MACID of 00:01:02:a9:ff:00, this

command reports 11140864 (00 a9 ff 00 hex)

E.g., for a MACID of 00:01:02:a9:ff:00, this

command reports 258 (00 00 01 02 hex)

on page 41

on page 41

Values

Non-

Volatile

Setting

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 39 of 160

Page 40

Program Example

Command

ETHCTL(6,<value>) Network Lost user pro-

ETHCTL(9,<value>) Network Lost action

ETHCTL(45,x)

ETHCTL(46,x)

ETHCTL(47,x)

ETHCTL(50,x)

ETHCTL(51,x)

Description/

Parameter

gram label number

Set IP address as

integer

Set IP subnet mask as

integer

Set IP gateway as

integer

Reset Resets Internal Error code RETH(50) and

Reset Resets Internal Error code RETH(50) and

Values

This setting is nonvolatile.

Program label to jump to if the Network Lost

action, ETHCTL(9,<value>), is either set to 4

or 5.

This setting is nonvolatile.

0 – Ignore, no action (default setting)

1 – Send OFF command to motor (servo off)

2 – Send X command to motor (smooth stop)

3 – Send S command to motor (hard stop)

4 – Send GOSUB(x) command, where x is the

value of the user program label as defined by

ETHCTL(6,<value>).

5 – Send GOTO(x) command, where x is the

value of the user program label as defined by

ETHCTL(6,<value>).

NOTE: Loss of network is an edge-triggered

event if I/O Control goes from RUN to any other

state.

E.g., to set for an IP address of 192.168.1.3

(C0 A8 01 03 hex), x=3232235779

E.g., to set for an IP netmas k of 255.255.0.0

(FF FF 00 00 hex), x=4294901760

E.g., to set for an IP gateway of 192.168.1.1

(C0 A8 01 01 hex), x=3232235777

Internal Error source RETH(51) to 0

Internal error source RETH(51) to 0

Non-

Volatile

Setting

Yes

Yes

Yes

Program Example

The following code example sets the device IP address.

IPCTL(0,"192.168.0.10") 'Set the IP address to 192.168.0.10

'Add rest of program below

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 40 of 160

Page 41

Status and Diagnostic Codes

Status and Diagnostic Codes

The following tables provide details on the status/error codes and the diagnostic codes.

Status/Error Codes

Hex

Value

00000000 0 Status is OK

C01F0002 -1071710206 System is out of memor y

C01F0003 -1071710205 Task runs out of empty packets at the local packet pool

C01F0004 -1071710204 Sending a packet failed

C01F0010 -1071710192 Assembly instance already exists

C01F0011 -1071710191 Invalid assembly instance

C01F0012 -1071710190 Invalid assembly length

C01F0020 -1071710176 No free connection buffer available

C01F0021 -1071710175 Object class is invalid

C01F0022 -1071710174 Segment of the path is invalid

C01F0023 -1071710173 Object Class is alr eady used

C01F0024 -1071710172 Connection failed

C01F0025 -1071710171 Unknown format of connection parameter

C01F0026 -1071710170 Invalid connection ID

C01F0027 -1071710169 No resource for creating a new class object available

C01F0028 -1071710168 Invalid request parameter

C01F0029 -1071710167 General connection failure

C01F0031 -1071710159 Access denied, instance is read only

C01F0032 -1071710158 DPM address is already used by an other instance

C01F0033 -1071710157 Set Output command is already running

C01F0034 -1071710156 EtherNet/IP Object Task is running a reset

C01F0035 -1071710155 Object Service already exists

Decimal

Value

Description

Diagnostic Codes

Hex

Value

00000000 0 Status is OK

C01F0001 -1071710207 No free packet available to create a response of the

C01F0002 -1071710206 No free packet available to send the input data

C01F0003 -1071710205 Routing a request to an object failed; an error occurred at

C01F0004 -1071710204 Sending the c onfirmation of a request failed; an error

C01F0005 -1071710203 Getting a confirmation of a request from an unknown

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Decimal

Value

Description

request

the destination packet queue

occurred at the packet queue

object

Page 41 of 160

Page 42

Diagnostic Codes

Hex

Value

C01F0006 -1071710202 Instance of the CC object could not be created; no free

C01F0007 -1071710201 Completing a Connection Close command failed; sending

C01F0008 -1071710200 Completing a Connection Open command failed; sending

C01F0009 -1071710199 Sending the Delete Transport command failed; Encap

C01F000A -1071710198 Sending the Forward Open c ommand failed; Encap Queue

C01F000B -1071710197 Sending the Start Transport command failed; Encap

C01F000C -1071710196 Connection manager received a confirmation of unknown

C01F000D -1071710195 Sending the Forward Close command failed; Encap Queue

C01F000E -1071710194 Failed the Complete Reset command; did not get a empty

Decimal

Value

Description

memory available

the command to the packet queue failed

the command to the packet queue failed

Queue signal an error

signal an error

Queue signal an error

service

signal an error

packet

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 42 of 160

Page 43

Position Controller Device (0x10)

Position Controller Device (0x10)

This chapter provides information on the Position Controller Device (0x10). For more details,

see THECIPNETWORKSLIBRARY,Volume1:CommonIndustrialProtocol(CIP™), which is

available on the ODVA.org website.

Position Controller Device Application Objects 44

Position Controller Device Object Model 44

Position Controller Implicit I/O Messages 45

General Command and Response Message Types 45

Attribute GET/SET Command Types 0x1A and 0x1B 50

Error Response Message Type (0x14) 51

Semantics for Command and Response Messages 52

Position Controller I/O Handshaking 55

Profile Moves 56

Torque Command 57

Control Mode Change - Change Dynamic 57

Position Controller Implicit I/O Message Examples 58

SmartMotor Notes 58

Set Acceleration 58

Set Velocity, Leave Drive ON 59

Set Target Position, Perform Move 59

Disable Hardware Limits (Object 0x25, Attribute 49) 59

Extended Position Move (32-byte frame) 60

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 43 of 160

Page 44

Position Controller Device Application Objects

CIP Network

Required =

Message Router

Identity

Object

Network Specic

Link Object(s)

I/O

Msg*

Explicit

Msg

Optional =

Position Controller

Supervisor Object

Postion

Controller

Supervisor

Position

Controller

Object

Axis Objects

Connection

*NOTES:

Consumed Connection Path:

Position Controller Supervisor class

Consumed Command Message attribute

Produced Connection Path:

Position Controller Supervisor class

Produced Command Message attribute

Position Controller Device Application Objects

The following table shows the application objects for the Position Controller device and

describes their functions. For a full description of each object, see the corresponding "For

details..." section.

Object Class

Position Controller Supervisor

Position Controller

Class

Code

Description

0x24 Handles errors for the

Position Controller as

well as Home and Registration inputs.

0x25 Performs the control

output velocity profiling

and handles input and

Required/

Optional

Instances

Required 1 Position Con-

Required 1 Position Con-

For details,

see...

troller Supervisor (0x24) on

page 84

troller (0x25) on

page 86

output to and from the

motor drive unit, limit

switches registration

etc.

Note that these objects are the Application Objects in the overall SmartMotor device profile.

For a listing of all objects in the device profile used for the SmartMotor, see SmartMotor

Device Profile Overview on page 33.

Position Controller Device Object Model

The following figure provides a diagram of the Position Controller Device object model.

PositionControllerDeviceObjectModel

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 44 of 160

Page 45

Position Controller Implicit I/O Messages

Position Controller Implicit I/O Messages

This section describes the details about implicit I/O messages for the device.

General Command and Response Message Types

This section describes the formats for consumed and produced general messages.

l

The standard CIP Position Controller I/O connection messages are 8-byte messages.

l

The Class 6 EtherNet/IP SmartMotor supports both the standard 8-byte format and an

extended 32-byte format.

l

The first eight bytes of the 32-byte format match the 8-byte format defined in the ODVA

CIP Position Controller specification. The SmartMotor will select which message format

to use based on the host controller connection size.

Connection

Size

8 bytes The motor will use the CIP standard communication format and Command Mes-

sage Types

32 bytes

Any other The motor will respond with an error

The default connection size used in the Class 6 EtherNet/IP SmartMotor EDS file is 32-bytes.

NOTE: Implicit I/O messages are the most efficient method of exchanging cyclic

data, such as Target Position and Actual Position, with the SmartMotor. These message types for the Position Controller Polled I/O Connection are typically the best

choice for commanding the SmartMotor shaft position or applied torque.

The motor will use:

l

CIP Standard 8 byte messages

l

Additional Data Fields in the Command / Response Message frames

l

Extended Command Message Types 6 (Position Move) & 7 (Velocity

Move)

Description

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 45 of 160

Page 46

General Command and Response Message Types

Polled I/O: Consumed General Message Format

NOTE: 32-byte Extended fields are shown with gray-highlighted rows.

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Enable Reg.

Arm

1 Block #

2 Command Axis Number Command Message Type (1 through 7)

3 Response Axis Number Response Message Type (1 through 7)

4–7 Command Data

8–11 Target Position

12–15 Target Velocity

16–20 Acceleration

20–23 Deceleration

24 Attribute to Get Axis Number Attribute to Get Message Type (0x1A, 0x1B)

25 Reserved

26–27 Attribute to Get Number

28–31 Reserved

Notes:

1. Byte 0 bits 6 and 1 are not supported in Class 5 motors.

2. For Semantics, refer to Command Message Semantics on page 52.

3. Byte alignment for 4-byte values is Little Endian (Low byte, Middle Low byte, Middle High byte, High Byte).

4. Byte alignment for 2-byte values is Little Endian (Low byte, High Byte).

Hard Stop Smooth Stop Direction

1

(Vel. mode)

3

3

3

3

3

Incremental Start

4

Block

Load Data/

1

Start Profile

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 46 of 160

Page 47

General Command and Response Message Types

Polled I/O: Produced General Message Format

NOTE: 32-byte Extended fields are shown with gray-highlighted rows.

Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 Enable Reg.

1 Block #

2 Load

Complete

3 Response Axis Number Response Message Type (1 through 5)

4–7 Response Data

8–11 Actual Position

12–15 Actual Velocity

16–19 Reserved

20 Attribute to Get Axis Number Attribute to Get Message Type (0x1A, 0x1B)

21 Reserved

22–23 Attribute to Get Number

24–27

28–31 Reserved

Notes:

1. Not supported.

2. Byte 2 bit 0 c an be configured as the Servo Bus Voltage Okay s tatus.

3. For semantics, refer to Response Message Semantics on page 53.

4. Byte alignment for 4-byte values is Little Endian (Low byte, Middle Low byte, Middle High byte, High Byte).

5. Byte alignment for 2-byte values is Little Endian (Low byte, High Byte).

1

Level

Block

1

Fault

No data if Attribute to Get Axis Number and Mes sage Type are zero

Home

1

Level

Following

Error Fault

Current

Direction

Negative

Limit

Attribute to Get Data

General

Fault

Positive

Limit

On Target

Position

Revers e

Limit

4

4

4

5

Block in

Execution

Forward

Limit

1

Profile in

Progress

Fault

Input

1,2

General Command / Response Message Types

Command /

Response

Command Data Response Data

Message Type

a

1

a

2

Target Position Actual Position 0

Target Velocity Command Position 1

3 Acceleration Actual Velocity N/A

4 Deceleration Command Velocity N/A

a

5

Torque Torque 2

Position Profile

a,b

6

Move - See

N/A 0

description below

Velocity Profile

a,b

7

Move - See

N/A

description below

Notes:

a. The drive Control Mode must match the desired command type in order to start a profile move or apply torque.

b. Only available for 32-byte connections.

Class 0x25

Attr #3

Mode Setting

1

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 47 of 160

Page 48

General Command and Response Message Types

Standard Command Types

The standard CIP Command Types 1–5 will load individual motor parameters, such as Acceleration, Deceleration, etc. A Profile Move will be started or a torque will be applied when the

command type in the message is Target Position, Target Velocity or Torque, and the Control

Mode is set to Position, Velocity or Torque, respectively.

The normal flow for a Position Move:

1.

Set the Control Mode to Position Control.

2.

Set the Acceleration value.

3.

Set the Deceleration value.

4.

Set the Target Velocity value.

5.

Set the Target Position value (this message would start the Position Move).

The normal flow for a Velocity Move:

1.

Set the Control Mode to Velocity Control.

2.

Set the Acceleration value.

3.

Set the Deceleration value.

4.

Set the Target Velocity value (this message would start the Velocity Move).

The normal flow for a apply Torque:

1.

Set the Control Mode to Torque Control.

2.

Set the Torque value (this message would start Torque Control).

Extended Profile Move Command Types (32-byte message format only)

There are two additional command types when the host I/O connection size is 32 bytes: 6

(Move Position) and 7 (Move Velocity). These commands take advantage of the additional

fields in the 32-byte format, allowing a move to be started with one command.

The normal flow for a Position Move:

1.

Set the control mode to Position Control.

2.

Send a Move Position message (Command type 6) with Target Position, Target Velocity,

Acceleration and Deceleration values (this message would start the Position Move).

The normal flow for a Velocity Move:

1.

Set the Control Mode to Velocity Control.

2.

Send a Velocity Position message (Command type 7) with Target Velocity, Acceleration

and Deceleration values (this message would start the Position Move).

NOTE: A Velocity Move command sent to a motor already in motion with either Position Control or Velocity Control, will immediately change the Target Velocity to the

value in the message.

Moog AnimaticsClass 6 EtherNet/IP Guide, Rev. B

Page 48 of 160

Page 49

General Command and Response Message Types

Extended Attribute to Get (32-byte message format only)

The 32-byte format also has fields allowing the Class 6 SmartMotor to send parameter data

back to the controller independent of the Command and Response Message types set in the

first eight bytes.

l

When the "Attribute to Get Message Type" field is set to 26 (0x1A - Position Controller

Supervisor) or 27 (0x1B - Position Controller) the motor will return the value of the

Object Attribute specified in field "Attribute to Get Number" (bytes 26-27). The value

will be returned in the "Attribute to Get Data" field of the response (bytes 24 - 27).

l If there are any errors in the request, the motor will respond with:

o

A Message Type of 0x14 in the Attribute to Get Message Type field of the response

o

The General Error Code in byte 24 of the response

o

The Additional Error Code in byte 25 of the response

o

A value of 0x00 in byte 26 of the response

o

A copy of the Attribute to Get Axis Number / Message Type (byte 24) from the

request in byte 27 of the response

l

When the "Attribute to Get Message Type" field is set to a value of zero, the motor will

set the entire "Attribute to Get" structure and "Attribute to Get Data" of the response

(bytes 20 -27) to zeroes.

The general flow when using the Extended Attribute to Get fields: (Assumes the Attribute to

Get fields start out loaded with 0x00).

1.