Page 1

Developer’s

Guide

Class 5 & Later SmartMotor

Technology with

TM

Page 2

Copyright Notice

©2001–2018, Moog Inc., Animatics.

Moog Animatics SmartMotor™ Developer's Guide, Rev. L, PN:SC80100003-002.

This manual, as well as the software described in it, is furnished under license and may be

used or copied only in accordance with the terms of such license. The content of this manual is

furnished for informational use only, is subject to change without notice and should not be

construed as a commitment by Moog Inc., Animatics. Moog Inc., Animatics assumes no

responsibility or liability for any errors or inaccuracies that may appear herein.

Except as permitted by such license, no part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic, mechanical,

recording, or otherwise, without the prior written permission of Moog Inc., Animatics.

The programs and code samples in this manual are provided for example purposes only. It is

the user's responsibility to decide if a particular code sample or program applies to the

application being developed and to adjust the values to fit that application.

Moog Animatics and the Moog Animatics logo, SmartMotor and the SmartMotor logo,

Combitronic and the Combitronic logo, and SMI are all trademarks of Moog Inc., Animatics.

Other trademarks are the property of their respective owners.

Please let us know if you find any errors or omissions in this manual so that we can improve it

for future readers. Such notifications should contain the words "Developer's Guide" in the

subject line and be sent by e-mail to: animatics_marcom@moog.com. Thank you in advance

for your contribution.

Contact Us:

Americas - West

Moog Animatics

2581 Leghorn Street

Mountain View, CA 94043

USA

Tel: 1 650-960-4215 Tel: 1 610-328-4000 x3999

Support: 1 888-356-0357

Website: www.animatics.com

Email: animatics_sales@moog.com

Americas - East

Moog Animatics

750 West Sproul Road

Springfield, PA 19064

USA

Fax: 1 610-605-6216

Page 3

Table Of Contents

Introduction 27

Overview 28

Combitronic Support 28

Communication Lockup Wizard 30

Safety Information 30

Safety Symbols 30

Other Safety Considerations 31

Motor Sizing 31

Environmental Considerations 31

Machine Safety 31

Documentation and Training 32

Additional Equipment and Considerations 33

Safety Information Resources 33

Additional Documents 34

Related Guides 34

Other Documents 34

Additional Resources 35

Part 1: Programming the SmartMotor 36

Beginning Programming 47

Setting the Motor Firmware Version 48

Setting the Default Firmware Version 48

Checking the Default Firmware Version 49

Opening the SMIWindow (Program Editor) 49

Understanding the Program Requirements 50

Creating a "Hello World" Program 51

Entering the Program in the SMI Editor 51

Adding Comments to the Code 52

Checking the Program Syntax 52

Saving the Program 52

Downloading a Program to the SmartMotor 52

Syntax Checking, Compiling and Downloading the Program 53

Additional Notes on Downloaded Programs 53

Running a Downloaded Program 54

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 3 of 909

Page 4

Using the Program Download Window 55

Using the Terminal Window and Run Program Button 55

Using the RUN Command in the Terminal Window 55

Creating a Simple Motion Program 56

SMISoftware Features 57

Introduction 58

Menu Bar 58

Toolbar 59

Configuration Window 61

Terminal Window 63

Initiating Motion from the Terminal Window 65

Information Window 65

Program Editor 66

Motor View 68

SMI Trace Functions 70

Monitor Window 73

Serial Data Analyzer 75

Chart View 76

Chart View Example 77

Macros 80

Tuner 82

SMIOptions 86

SMIHelp 87

Context-Sensitive Help Using F1 87

Context-Sensitive Help Using the Mouse 87

Help Buttons 87

Hover Help 87

Table of Contents 87

Projects 88

SmartMotor Playground 89

Opening the SmartMotor Playground 90

Moving the Motor 91

Communication Details 93

Introduction 95

Connecting to a Host 96

Daisy Chaining Multiple D-Style SmartMotors over RS-232 97

ADDR=formula 98

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 4 of 909

Page 5

SLEEP, SLEEP1 99

WAKE, WAKE1 99

ECHO, ECHO1 100

ECHO_OFF, ECHO_OFF1 100

Serial Commands 101

OCHN(type,channel,parity,bit rate,stop bits,data bits,mode,timeout) 101

CCHN(type,channel) 102

BAUDrate, BAUD(channel)=formula 102

PRINT(), PRINT1() 102

SILENT, SILENT1 103

TALK, TALK1 103

a=CHN(channel) 103

a=ADDR 104

Communicating over RS-485 104

Using Data Mode 104

CAN Communications 107

CADDR=formula 107

CBAUD=formula 107

=CAN, =CAN(arg) 107

CANCTL(function,value) 107

SDORD(...) 108

SDOWR(...) 108

NMT 109

RB(2,4), x=B(2,4) 109

Exceptions to NMT, SDORD and SDOWR Commands 109

I/O Device CAN Bus Master 110

Combitronic Communications 111

Combitronic Features 112

Other Combitronic Benefits 112

Program Loops with Combitronic 112

Global Combitronic Transmissions 113

Simplify Machine Support 113

Combitronic with RS-232 Interface 113

Other CANProtocols 115

CANopen - CAN Bus Protocol 115

DeviceNet - CAN Bus Protocol 115

I²C Communications (D-Style Motors) 115

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 5 of 909

Page 6

OCHN(IIC,1,N,baud,1,8,D) 117

CCHN(IIC,1) 117

PRINT1(arg1,arg2, … ,arg_n) 117

RGETCHR1, Var=GETCHR1 117

RLEN1, Var=LEN1 117

Motion Details 118

Introduction 120

Motion Command Quick Reference 121

Basic Motion Commands 122

Target Commands 122

PT=formula 122

PRT=formula 123

ADT=formula 123

AT=formula 123

DT=formula 123

VT=formula 123

Motion Mode Commands 124

MP 124

MV 124

MT 124

Torque Commands 125

TS=formula 125

T=formula 125

Brake Commands 125

BRKRLS 125

BRKENG 125

BRKSRV 126

BRKTRJ 126

Brake Command Examples 126

EOBK(IO) 127

MTB 127

Index Capture Commands 128

Other Motion Commands 129

G 129

S 129

X 130

O=formula 130

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 6 of 909

Page 7

OSH=formula 130

OFF 130

Commutation Modes 131

MDT 131

MDE 131

MDS 131

MDC 132

MDB 132

MINV(0), MINV(1) 132

Modes of Operation 133

Torque Mode 133

Torque Mode Example 133

Dynamically Change from Velocity Mode to Torque Mode 133

Velocity Mode 134

Constant Velocity Example 134

Change Commanded Speed and Acceleration 134

Absolute (Position) Mode 135

Absolute Move Example 135

Two Moves with Delay Example 135

Change Speed and Acceleration Example 135

Shift Point of Origin Example 136

Relative Position Mode 136

Relative Mode Example 136

Follow Mode with Ratio (Electronic Gearing) 137

Electronic Gearing and Camming over CANopen 137

Electronic Gearing Commands 138

SRC(enc_src) 138

MFR 138

MSR 138

MF0 138

MS0 138

MFMUL=formula, MFDIV=formula 138

MFA(distance[,m/s]) 139

MFD(distance[,m/s]) 139

MFSLEW(distance[,m/s]) 139

Follow Internal Clock Source Example 139

Follow Incoming Encoder Signal With Ramps Example 140

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 7 of 909

Page 8

Electronic Line Shaft 142

ENCD(in_out) 142

Spooling and Winding Overview 143

Relative Position, Auto-Traverse Spool Winding 143

MFSDC(distance,mode) 144

Dedicated, Absolute Position, Winding Traverse Commands 146

MFSDC(distance,2) 147

MFLTP=formula 147

MFHTP=formula 147

MFCTP(arg1,arg2) 147

MFL(distance[,m/s]) 148

MFH(distance[,m/s]) 148

ECS(counts) 148

Single Trajectory Example Program 150

Chevron Wrap Example 150

Other Traverse Mode Notes 152

Traverse Mode Status Bits 153

CamMode (Electronic Camming) 153

Electronic Camming Details 156

Understanding the Inputs 156

Should I choose Source Counts or Intermediate Counts? 157

Should I choose Variable or Fixed cam? 157

Electronic Camming Notes and Best Practices 159

Examples 161

Electronic Gearing and Camming over CANopen 161

Electronic Camming Commands 162

CTE(table) 162

CTA(points,seglen[,location]) 162

CTW(pos[,seglen][,user]) 162

MCE(arg) 163

MCW(table,point) 163

RCP 164

RCTT 164

MC 164

MCMUL=formula 164

MCDIV=formula 164

O(arg)=formula 164

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 8 of 909

Page 9

OSH(arg)=formula 164

Cam Example Program 165

Mode Switch Example 168

Position Counters 170

Modulo Position 171

Modulo Position Commands 171

Dual Trajectories 172

Commands That Read Trajectory Information 174

Dual Trajectory Example Program 175

Synchronized Motion 175

Synchronized-Target Commands 175

PTS(), PRTS() 175

VTS=formula 176

ADTS=formula, ATS=formula, DTS=formula 177

PTSS(), PRTSS() 177

A Note About PTS and PTSS 177

Other Synchronized-Motion Commands 178

GS 178

TSWAIT 179

Program Flow Details 181

Introduction 182

Flow Commands 182

RUN 183

RUN? 183

GOTO#, GOTO(label), C# 183

GOSUB#, GOSUB(label), RETURN 184

IF, ENDIF 184

ELSE, ELSEIF 185

WHILE, LOOP 186

SWITCH, CASE, DEFAULT, BREAK, ENDS 186

TWAIT 187

WAIT=formula 187

STACK 187

END 188

Program Flow Examples 189

IF, ELSEIF, ELSE, ENDIF Examples 189

WHILE, LOOPExamples 189

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 9 of 909

Page 10

GOTO(), GOSUB() Examples 190

SWITCH, CASE, BREAK, ENDS Examples 191

Interrupt Programming 192

ITR(), ITRE, ITRD, EITR(), DITR(), RETURNI 192

TMR(timer,time) 194

Variables and Math 195

Introduction 196

Variable Commands 196

EPTR=formula 196

VST(variable,number) 196

VLD(variable,number) 197

Math Expressions 197

Math Operations 197

Logical Operations 197

Integer Operations 197

Floating Point Functions 197

Math OperationDetails and Examples 198

Array Variables 198

Array Variable Examples 199

Error and Fault Handling Details 200

Motion and Motor Faults 201

Overview 201

Drive Stage Indications and Faults 201

Fault Bits 201

Error Handling 202

Example Fault-Handler Code 202

PAUSE 203

RESUME 203

Limits and Fault Handling 204

Position Error Limits 204

dE/dt Limits 204

Velocity Limits 204

Hardware Limits 204

Software Limits 205

Fault Handling 205

Monitoring the SmartMotor Status 206

System Status 208

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 10 of 909

Page 11

Introduction 209

Retrieving and Manipulating Status Words/Bits 209

System and Motor Status Bits 209

Reset Error Flags 211

System Status Examples 211

Timer Status Bits 212

Interrupt Status Bits 212

I/O Status 213

User Status Bits 213

Multiple Trajectory Support Status Bits 214

Cam Status Bits 215

Interpolation Status Bits 216

Motion Mode Status 216

RMODE, RMODE(arg) 216

I/OControl Details 217

I/O Port Hardware 218

I/O Connections Example (D-Style Motors) 219

I/O Voltage Spikes 219

Discrete Input and Output Commands 220

Discrete Input Commands 220

Discrete Output Commands 220

Output Condition and Fault Status Commands 221

Output Condition Commands 221

Output Fault Status Reports 221

General-Use Input Configuration 221

Multiple I/OFunctions Example 222

Analog Functions of I/O Ports 223

5 Volt Push-Pull I/O Analog Functions (D-Style Motors) 223

24 Volt I/O Analog Functions (D-Style AD1 Option Motors, M-Style Motors) 223

Special Functions of I/OPorts 224

Class 5 D-Style Motors: Special Functions of I/O Ports 225

I/O Ports 0 and 1 – External Encoder Function Commands 225

I/O Ports 2 and 3 – Travel Limit Inputs 225

I/O Ports 4 and 5 – Communications 225

I/O Port 6 – Go Command, Encoder Index Capture Input 226

Class 5 M-Style Motors: Special Functions of I/O Ports 227

COM Port Pins 4, 5, 6, and 8 – A-quad-B or Step-and-Direction Modes 227

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 11 of 909

Page 12

I/O Ports 2 and 3 – Travel Limit Inputs 227

I/O Port 5 – Encoder Index Capture Input 227

I/O Port 6 – Go Command 228

Class 6 M-Style Motors: Special Functions of I/O Ports 229

COM Port Pins 4, 5, 6, and 8 – A-quad-B or Step-and-Direction Modes 229

I/O Ports 2 and 3 – Travel Limit Inputs 229

I/O Port 4 and 5 – Encoder Index Capture Input 229

I/O Port 6 – Go Command 230

I/O Brake Output Commands 230

I²C Expansion (D-Style Motors) 230

Tuning and PIDControl 231

Introduction 232

Understanding the PID Control 232

Tuning the PID Control 233

Using F 233

Setting KP 234

Setting KD 234

Setting KI and KL 234

Setting EL=formula 235

Other PID Tuning Parameters 235

KG=formula 235

KV=formula 235

KA=formula 236

Current Limit Control 237

AMPS=formula 237

Part 2: SmartMotor Command Reference 238

(Single Space Character) 240

a...z 241

aa...zz 241

aaa...zzz 241

Ra...Rz 241

Raa...Rzz 241

Raaa...Rzzz 241

ab[index]=formula 245

Rab[index] 245

ABS(value) 248

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 12 of 909

Page 13

RABS(value) 248

AC 250

RAC 250

ACOS(value) 253

RACOS(value) 253

ADDR=formula 255

RADDR 255

ADT=formula 257

ADTS=formula 259

af[index]=formula 261

Raf[index] 261

Ai(arg) 264

Aij(arg) 266

Aj(arg) 268

Aji(arg) 270

al[index]=formula 272

Ral[index] 272

AMPS=formula 275

RAMPS 275

ASIN(value) 278

RASIN(value) 278

AT=formula 280

RAT 280

ATAN(value) 282

RATAN(value) 282

ATOF(index) 284

RATOF(index) 284

ATS=formula 286

aw[index]=formula 288

Raw[index] 288

B(word,bit) 291

RB(word,bit) 291

Ba 295

RBa 295

BAUD(channel)=formula 297

RBAUD(channel) 297

Be 299

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 13 of 909

Page 14

RBe 299

Bh 301

RBh 301

Bi(enc) 304

RBi(enc) 304

Bj(enc) 307

RBj(enc) 307

Bk 310

RBk 310

Bl 311

RBl 311

Bls 313

RBls 313

Bm 315

RBm 315

Bms 317

RBms 317

Bo 319

RBo 319

Bp 320

RBp 320

Bps 322

RBps 322

Br 324

RBr 324

BREAK 326

BRKENG 328

BRKRLS 330

BRKSRV 332

BRKTRJ 334

Brs 336

RBrs 336

Bs 338

RBs 338

Bt 340

RBt 340

Bv 342

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 14 of 909

Page 15

RBv 342

Bw 344

RBw 344

Bx(enc) 346

RBx(enc) 346

C{number} 348

CADDR=formula 350

RCADDR 350

CAN, CAN(arg) 352

RCAN, RCAN(arg) 352

CANCTL(function,value) 354

CASE formula 355

CBAUD=formula 358

RCBAUD 358

CCHN(type,channel) 360

CHN(channel) 361

RCHN(channel) 361

CLK=formula 363

RCLK 363

COMCTL(function,value) 364

COS(value) 366

RCOS(value) 366

CP 368

RCP 368

CTA(points,seglen[,location]) 370

CTE(table) 372

CTR(enc) 374

RCTR(enc) 374

CTT 376

RCTT 376

CTW(pos[,seglen][,user]) 377

DEA 380

RDEA 380

DEFAULT 382

DEL=formula 384

RDEL 384

DELM(arg) 386

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 15 of 909

Page 16

DFS(value) 387

RDFS(value) 387

DITR(int) 388

DT=formula 390

RDT 390

DTS=formula 392

EA 394

REA 394

ECHO 396

ECHO0 398

ECHO1 399

ECHO_OFF 400

ECHO_OFF0 401

ECHO_OFF1 402

ECS(counts) 403

EIGN(...) 405

EILN 408

EILP 410

EIRE 412

EIRI 414

EISM(6) 416

EITR(int) 417

EL=formula 419

REL 419

ELSE 421

ELSEIF formula 423

ENC0 425

ENC1 426

ENCCTL(function,value) 428

ENCD(in_out) 430

END 431

ENDIF 433

ENDS 435

EOBK(IO) 437

EOIDX(number) 439

EPTR=formula 440

REPTR 440

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 16 of 909

Page 17

ERRC 441

RERRC 441

ERRW 443

RERRW 443

ETH(arg) 444

RETH(arg) 444

ETHCTL(function,value) 445

F 446

FABS(value) 448

RFABS(value) 448

FSA(cause,action) 450

FSQRT(value) 452

RFSQRT(value) 452

FW 454

RFW 454

G 456

GETCHR 459

RGETCHR 459

GETCHR1 461

RGETCHR1 461

GOSUB(label) 463

GOTO(label) 465

GS 467

HEX(index) 469

RHEX(index) 469

I(enc) 471

RI(enc) 471

IDENT=formula 473

RIDENT 473

IF formula 475

IN(...) 478

RIN(...) 478

INA(...) 481

RINA(...) 481

IPCTL(function,"string") 484

ITR(Int#,StatusWord,Bit#,BitState,Label#) 486

ITRD 489

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 17 of 909

Page 18

ITRE 491

J(enc) 493

RJ(enc) 493

KA=formula 495

RKA 495

KD=formula 497

RKD 497

KG=formula 499

RKG 499

KI=formula 501

RKI 501

KII=formula 503

RKII 503

KL=formula 504

RKL 504

KP=formula 506

RKP 506

KPI=formula 508

RKPI 508

KS=formula 509

RKS 509

KV=formula 511

RKV 511

LEN 513

RLEN 513

LEN1 514

RLEN1 514

LFS(value) 516

RLFS(value) 516

LOAD 518

LOCKP 521

LOOP 522

MC 524

MCDIV=formula 527

RMCDIV 527

MCE(arg) 528

MCMUL=formula 530

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 18 of 909

Page 19

RMCMUL 530

MCW(table,point) 532

MDB 534

MDC 536

MDE 538

MDH 540

MDHV 542

MDS 544

MDT 546

MF0 548

MFA(distance[,m/s]) 550

MFCTP(arg1,arg2) 553

MFD(distance[,m/s]) 555

MFDIV=formula 558

MFH(distance[,m/s]) 560

MFHTP=formula 562

MFL(distance[,m/s]) 564

MFLTP=formula 566

MFMUL=formula 568

MFR 570

MFSDC(distance,mode) 573

MFSLEW(distance[,m/s]) 575

MINV(arg) 577

MODE 579

RMODE 579

MP 582

MS0 585

MSR 587

MT 589

MTB 591

MV 593

NMT 595

N/A 595

O=formula, O(trj#)=formula 597

OC(...) 599

ROC(...) 599

OCHN(...) 601

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 19 of 909

Page 20

OF(...) 603

ROF(...) 603

OFF 605

OR(value) 607

OS(...) 609

OSH=formula, OSH(trj#)=formula 611

OUT(...)=formula 613

PA 615

RPA 615

PAUSE 617

PC, PC(axis) 619

RPC, RPC(axis) 619

PI 622

RPI 622

PID# 623

PMA 626

RPMA 626

PML=formula 628

RPML 628

PMT=formula 630

RPMT 630

PRA 632

RPRA 632

PRC 635

RPRC 635

PRINT(...) 638

PRINT0(...) 642

PRINT1(...) 646

PRINT8(...) 649

PRT=formula 652

RPRT 652

PRTS(...) 654

PRTSS(...) 656

PT=formula 658

RPT 658

PTS(...) 660

PTSD 663

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 20 of 909

Page 21

RPTSD 663

PTSS(...) 664

PTST 666

RPTST 666

RANDOM=formula 667

RRANDOM 667

RCKS 669

RES 670

RRES 670

RESUME 672

RETURN 674

RETURNI 676

RSP 678

RSP1 680

RSP5 681

RUN 682

RUN? 684

S (as command) 686

SADDR# 688

SAMP 690

RSAMP 690

SDORD(...) 692

RSDORD 692

SDOWR(...) 694

SILENT 696

SILENT1 698

SIN(value) 700

RSIN(value) 700

SLD 702

SLE 704

SLEEP 706

SLEEP1 708

SLM(mode) 710

RSLM 710

SLN=formula 712

RSLN 712

SLP=formula 714

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 21 of 909

Page 22

RSLP 714

SNAME("string") 716

SP2 717

RSP2 717

SQRT(value) 718

RSQRT(value) 718

SRC(enc_src) 720

STACK 722

STDOUT=formula 725

SWITCH formula 727

T=formula 730

Read/write 730

TALK 732

TALK1 734

TAN(value) 736

RTAN(value) 736

TEMP, TEMP(arg) 738

RTEMP, RTEMP(arg) 738

TH=formula 740

RTH 740

TMR(timer,time) 743

RTMR(timer) 743

TRQ 745

RTRQ 745

TS=formula 747

RTS 747

TSWAIT 749

TWAIT(gen#) 750

UIA 752

RUIA 752

UJA 754

RUJA 754

UO(...)=formula 756

UP 758

UPLOAD 760

UR(...) 762

US(...) 764

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 22 of 909

Page 23

USB(arg) 766

RUSB 766

VA 768

RVA 768

VAC(arg) 771

VC 776

RVC 776

VL=formula 778

RVL 778

VLD(variable,number) 780

VST(variable,number) 784

VT=formula 788

RVT 788

VTS=formula 791

W(word) 793

RW(word) 793

WAIT=formula 795

WAKE 797

WAKE1 799

WHILE formula 801

X 804

Z 806

Z(word,bit) 808

Za 810

Ze 811

Zh 812

Zl 813

Zls 814

Zr 815

Zrs 816

Zs 817

ZS 818

Zv 821

Zw 822

Part 3: Example SmartMotor Programs 823

Move Back and Forth 824

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 23 of 909

Page 24

Move Back and Forth with Watch 824

Home Against a Hard Stop (Basic) 825

Home Against a Hard Stop (Advanced) 825

Home Against a Hard Stop (Two Motors) 826

Home to Index Using Different Modes 828

Maintain Velocity During Analog Drift 829

Long-Term Storage of Variables 830

Find Errors and Print Them 830

Change Speed on Digital Input 831

Pulse Output on a Given Position 831

Stop Motion if Voltage Drops 832

Camming - Variable Cam Example 833

Camming - Fixed Cam with Input Variables 834

Camming - Demo XYCircle 836

Chevron Traverse & Takeup 838

CAN Bus - Timed SDOPoll 840

CAN Bus - I/OBlock with PDOPoll 841

CAN Bus - Time Sync Follow Encoder 844

Text Replacement in an SMI Program 852

Appendix 854

Motion Command Quick Reference 856

Array Variable Memory Map 858

ASCIICharacter Set 860

Binary Data 861

Command Error Codes 864

Decoding the Error 864

Finding the Error Source 865

Glossary 866

Math Operators 873

Moment of Inertia 874

Matching Motor to Load 874

Improving the Moment of Inertia Ratio 874

RCAN, RCHN and RMODEStatus 875

RCAN Status Decoder 875

RCHN Status Decoder 875

Clearing Serial Port Errors 876

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 24 of 909

Page 25

RMODE Status Decoder 876

Mode Status Example 876

Scale Factor Calculation 877

Sample Rates 877

PID Sample Rate Command 877

Encoder Resolution and the RES Parameter 877

Native Velocity and Acceleration Units 878

Velocity Calculations 878

Acceleration Calculations 878

Status Words 879

Status Word: 0Primary Fault/Status Indicator 879

Status Word: 1Index Registration and Software Travel Limits 880

Status Word: 2Communications, Program and Memory 880

Status Word: 3PID State, Brake, Move Generation Indicators 881

Status Word: 4 Interrupt Timers 881

Status Word: 5 Interrupt Status Indicators 882

Status Word: 6 Drive Modes 882

Status Word 7: Multiple Trajectory Support 883

Status Word 8: Cam Support 884

Status Word 10: RxPDO Arrival Notification 884

Status Word 12: User Bits Word 0 885

Status Word 13: User Bits Word 1 885

Status Word: 16 On Board Local I/O Status: D-Style Motor 886

Status Word: 16 On Board Local I/O Status: M-Style Motor 886

Status Word: 17 Expanded I/O Status: D-Style AD1 Motor 887

Torque Curves 888

Understanding Torque Curves 888

Peak Torque 888

Continuous Torque 888

Ambient Temperature Effects on Torque Curves and Motor Response: 889

Supply Voltage Effects on Torque Curves and Motor Response: 889

Example 1: Rotary Application 890

Example 2: Linear Application 890

Dyno Test Data vs. the Derated Torque Curve 890

Proper Sizing and Loading of the SmartMotor 891

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 25 of 909

Page 26

Commands Listed Alphabetically 893

Commands Listed by Function 900

Communications Control 901

Data Conversion 902

EEPROM (Nonvolatile Memory) 902

I/OControl 902

Math Function 903

Motion Control 903

Program Access 906

Program Execution and Flow Control 906

Reset Commands 907

System 907

Variables 908

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 26 of 909

Page 27

Introduction

Introduction

Introduction

This chapter provides introductory reference material.

Overview 28

Combitronic Support 28

Communication Lockup Wizard 30

Safety Information 30

Additional Documents 34

Additional Resources 35

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 27 of 909

Page 28

Introduction

Introduction: Overview

Overview

The SmartMotor™ Developer's Guide is designed to be used by system developers and

programmers when developing applications for the SmartMotor. Before using the

SmartMotor™ Developer's Guide, it is strongly recommended that you first read the

SmartMotor™ Installation & Startup Guide for your SmartMotor, which describes how to

install and start up the SmartMotor, and test initial communications with the motor. After that,

use this guide to learn about advanced SmartMotor features, how to develop SmartMotor

applications, and the details of each command.

Part One of this guide provides information on basic to advanced programming, along with

related information on key SMIsoftware features, communications, motion control, program

flow control, error and fault handling, and more.

Part Two of this guide lists all the SmartMotor commands in alphabetical order. Each

command is described in detail. Code snippets and examples are provided where applicable.

These are shown in a Courier font. Comments are included and separated with a single

quotation mark as they would be in your own programs.

NOTE: The programs and code samples in this manual are provided for example

purposes only. It is the user's responsibility to decide if a particular code sample or

program applies to the application being developed and to adjust the values to fit

that application.

Also, where appropriate, a Related Commands section is included, which is located at the end

of the command page. It is designed to guide you to other commands that offer similar

functionality, and ensure you are aware of every programming option the SmartMotor

provides to address your specific application requirements.

Part Three of this guide provides a library of useful example SmartMotor programs. These can

be used as "how to" examples for using a particular SmartMotor feature or solving a particular

application problem, or as starting points for your application.

NOTE: The programs and code samples in this manual are provided for example

purposes only. It is the user's responsibility to decide if a particular code sample or

program applies to the application being developed and to adjust the values to fit

that application.

The Appendix of this guide contains additional topics such as an array map, ASCII character

set, command error codes, and other information that is useful to have handy during

application development.

A quick-reference command list is also included at the end of this guide.

Combitronic Support

A large number of the commands provide Combitronic™ support. Combitronic is a protocol

that operates over a standard "CAN" (Controller Area Network) interface. It may coexist with

either CANopen or DeviceNet protocols at the same time. Unlike these common protocols,

however, Combitronic requires no single dedicated master to operate. Each Integrated Servo

connected to the same network communicates on an equal footing, sharing all information,

and therefore, sharing all processing resources. For more details on Combitronic features,

see Combitronic Communications on page 111, and also see the overview on the Moog

Animatics website at:

http://www.animatics.com/supports/knowledge-base/smartmotorkb/130.html.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 28 of 909

Page 29

Introduction

Introduction: Combitronic Support

For applicable commands, a table row titled "COMBITRONIC:" provides the Combitronic

command syntax for addressing a specific SmartMotor in the network. Those commands also

display the Combitronic logo ( ) at the top of their reference pages.

Combitronic Logo Location

COMBITRONIC: Table Row

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 29 of 909

Page 30

Introduction

Introduction: Communication Lockup Wizard

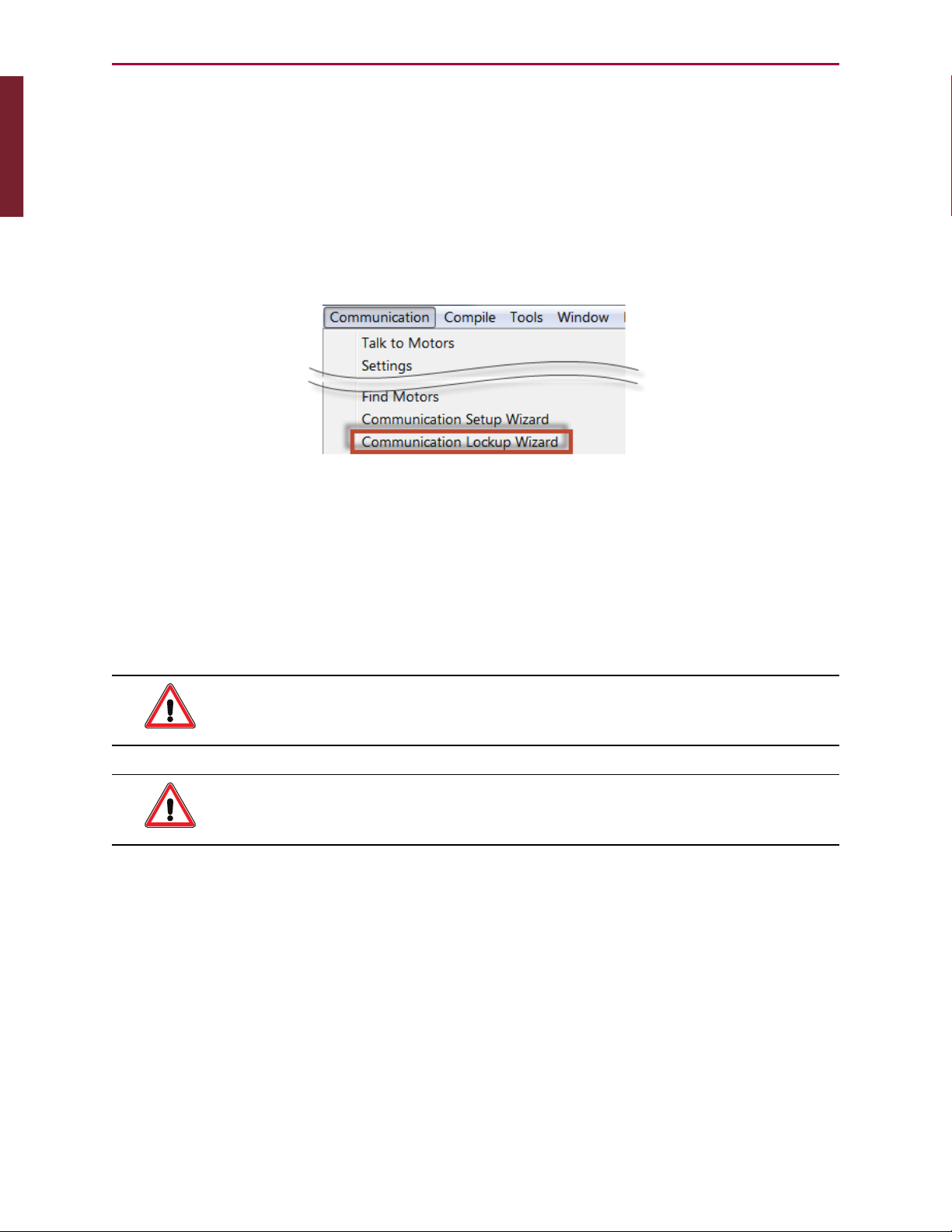

Communication Lockup Wizard

Improper use of some commands, like Z and OCHN, can lock you out of the motor and

prevent further communication. If you are unable to communicate with the SmartMotor, you

may be able to recover communications using the Communication Lockup Wizard, which is on

the SMI software Communications menu (see the following figure). This tool sends an "E"

character to the motor at startup, which prevents the motor from running its program. For

more details on the Communication Lockup Wizard, see the SMI software online help, which is

accessed by pressing the F1 key or selecting Help from the SMI software main menu.

Communication Menu - Communication Lockup Wizard

Safety Information

This section describes the safety symbols and other safety information.

Safety Symbols

The manual may use one or more of the following safety symbols:

WARNING: This symbol indicates a potentially nonlethal mechanical hazard,

where failure to follow the instructions could result in serious injury to the

operator or major damage to the equipment.

CAUTION: This symbol indicates a potentially minor hazard, where failure to

follow the instructions could result in slight injury to the operator or minor

damage to the equipment.

NOTE: Notes are used to emphasize non-safety concepts or related information.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 30 of 909

Page 31

Introduction

Introduction: Other Safety Considerations

Other Safety Considerations

The Moog Animatics SmartMotors are supplied as components that are intended for use in an

automated machine or system. As such, it is beyond the scope of this manual to attempt to

cover all the safety standards and considerations that are part of the overall machine/system

design and manufacturing safety. Therefore, the following information is intended to be used

only as a general guideline for the machine/system designer.

It is the responsibility of the machine/system designer to perform a thorough "Risk

Assessment" and to ensure that the machine/system and its safeguards comply with the

safety standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for

the locale where the machine is being installed and operated. For more details, see Machine

Safety on page 31.

Motor Sizing

It is the responsibility of the machine/system designer to select SmartMotors that are

properly sized for the specific application. Undersized motors may: perform poorly, cause

excessive downtime or cause unsafe operating conditions by not being able to handle the

loads placed on them. The System Best Practices document, which is available on the Moog

Animatics website, contains information and equations that can be used for selecting the

appropriate motor for the application.

Replacement motors must have the same specifications and firmware version used in the

approved and validated system. Specification changes or firmware upgrades require the

approval of the system designer and may require another Risk Assessment.

Environmental Considerations

It is the responsibility of the machine/system designer to evaluate the intended operating

environment for dust, high-humidity or presence of water (for example, a food-processing

environment that requires water or steam wash down of equipment), corrosives or chemicals

that may come in contact with the machine, etc. Moog Animatics manufactures specialized

IP-rated motors for operating in extreme conditions. For details, see the Moog Animatics

Product Catalog.

Machine Safety

In order to protect personnel from any safety hazards in the machine or system, the

machine/system builder must perform a "Risk Assessment", which is often based on the ISO

13849 standard. The design/implementation of barriers, emergency stop (E-stop)

mechanisms and other safeguards will be driven by the Risk Assessment and the safety

standards specified by the governing authority (for example, ISO, OSHA, UL, etc.) for the

locale where the machine is being installed and operated. The methodology and details of

such an assessment are beyond the scope of this manual. However, there are various sources

of Risk Assessment information available in print and on the internet.

NOTE: The following list is an example of items that would be evaluated when

performing the Risk Assessment. Additional items may be required. The safeguards

must ensure the safety of all personnel who may come in contact with or be in the

vicinity of the machine.

In general, the machine/system safeguards must:

l

Provide a barrier to prevent unauthorized entry or access to the machine or system. The

barrier must be designed so that personnel cannot reach into any identified danger

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 31 of 909

Page 32

Introduction

Introduction: Documentation and Training

zones.

l

Position the control panel so that it is outside the barrier area but located for an

unrestricted view of the moving mechanism. The control panel must include an E-stop

mechanism. Buttons that start the machine must be protected from accidental

activation.

l

Provide E-stop mechanisms located at the control panel and at other points around the

perimeter of the barrier that will stop all machine movement when tripped.

l

Provide appropriate sensors and interlocks on gates or other points of entry into the

protected zone that will stop all machine movement when tripped.

l

Ensure that if a portable control/programming device is supplied (for example, a handheld operator/programmer pendant), the device is equipped with an E-stop mechanism.

NOTE: A portable operation/programming device requires many additional

system design considerations and safeguards beyond those listed in this

section. For details, see the safety standards specified by the governing

authority (for example, ISO, OSHA, UL, etc.) for the locale where the

machine is being installed and operated.

l

Prevent contact with moving mechanisms (for example, arms, gears, belts, pulleys,

tooling, etc.).

l

Prevent contact with a part that is thrown from the machine tooling or other parthandling equipment.

l

Prevent contact with any electrical, hydraulic, pneumatic, thermal, chemical or other

hazards that may be present at the machine.

l

Prevent unauthorized access to wiring and power-supply cabinets, electrical boxes, etc.

l

Provide a proper control system, program logic and error checking to ensure the safety

of all personnel and equipment (for example, to prevent a run-away condition). The

control system must be designed so that it does not automatically restart the

machine/system after a power failure.

l

Prevent unauthorized access or changes to the control system or software.

Documentation and Training

It is the responsibility of the machine/system designer to provide documentation on safety,

operation, maintenance and programming, along with training for all machine operators,

maintenance technicians, programmers, and other personnel who may have access to the

machine. This documentation must include proper lockout/tagout procedures for maintenance

and programming operations.

It is the responsibility of the operating company to ensure that:

l

All operators, maintenance technicians, programmers and other personnel are tested

and qualified before acquiring access to the machine or system.

l

The above personnel perform their assigned functions in a responsible and safe manner

to comply with the procedures in the supplied documentation and the company safety

practices.

l

The equipment is maintained as described in the documentation and training supplied by

the machine/system designer.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 32 of 909

Page 33

Introduction

Introduction: Additional Equipment and Considerations

Additional Equipment and Considerations

The Risk Assessment and the operating company's standard safety policies will dictate the

need for additional equipment. In general, it is the responsibility of the operating company to

ensure that:

l

Unauthorized access to the machine is prevented at all times.

l

The personnel are supplied with the proper equipment for the environment and their job

functions, which may include: safety glasses, hearing protection, safety footwear,

smocks or aprons, gloves, hard hats and other protective gear.

l

The work area is equipped with proper safety equipment such as first aid equipment,

fire suppression equipment, emergency eye wash and full-body wash stations, etc.

l

There are no modifications made to the machine or system without proper engineering

evaluation for design, safety, reliability, etc., and a Risk Assessment.

Safety Information Resources

Additional SmartMotor safety information can be found on the Moog Animatics website; open

the file "109_Controls, Warnings and Cautions.pdf" located at:

http://www.animatics.com/support/moog-animatics-catalog.html

OSHA standards information can be found at:

https://www.osha.gov/law-regs.html

ANSI-RIA robotic safety information can be found at:

http://www.robotics.org/robotic-content.cfm/Robotics/Safety-Compliance/id/23

UL standards information can be found at:

http://ulstandards.ul.com/standards-catalog/

ISOstandards information can be found at:

http://www.iso.org/iso/home/standards.htm

EUstandards information can be found at:

http://ec.europa.eu/growth/single-market/european-standards/harmonisedstandards/index_en.htm

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 33 of 909

Page 34

Introduction

Introduction: Additional Documents

Additional Documents

The Moog Animatics website contains additional documents that are related to the information

in this manual. Please refer to the following list.

Related Guides

l

SmartMotor™ Installation & Startup Guide (select the guide for your SmartMotor)

http://www.animatics.com/install-guides

l

SmartMotor™ Fieldbus Guide (select the guide for your SmartMotor and fieldbus

protocol)

http://www.animatics.com/fieldbus-manuals

Other Documents

l

SmartMotor™ Product Certificate of Conformance

http://www.animatics.com/download/Declaration of Conformity.pdf

l

SmartMotor™ ULCertification

http://www.animatics.com/download/MA_UL_online_listing.pdf

l

SmartMotor Developer's Worksheet

(interactive tools to assist developer: Scale Factor Calculator, Status Words, CAN Port

Status, Serial Port Status, RMODE Decoder and Syntax Error Codes)

http://www.animatics.com/tools

l

Moog Animatics Product Catalog

http://www.animatics.com/support/moog-animatics-catalog.html

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 34 of 909

Page 35

Additional Resources

Additional Resources

The Moog Animatics website contains useful resources such as product information,

documentation, product support and more. Please refer to the following addresses:

l

General company information:

http://www.animatics.com

l

Product information:

http://www.animatics.com/products.html

l

Product support (Downloads, How To videos, Forums, Knowledge Base, and FAQs):

http://www.animatics.com/support.html

l

Sales and distributor information:

http://www.animatics.com/sales-offices.html

l

Application ideas (including videos and sample programs):

http://www.animatics.com/applications.html

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 35 of 909

Page 36

Part 1: Programming the SmartMotor

Part 1: Programming the SmartMotor

Part 1 of this guide provides information on programming, SMIsoftware features,

communications, variables, error and fault handling, I/Ocontrol, and other details required

for system and application development.

Beginning Programming 47

Setting the Motor Firmware Version 48

Setting the Default Firmware Version 48

Checking the Default Firmware Version 49

Opening the SMIWindow (Program Editor) 49

Understanding the Program Requirements 50

Creating a "Hello World" Program 51

Entering the Program in the SMI Editor 51

Adding Comments to the Code 52

Checking the Program Syntax 52

Saving the Program 52

Downloading a Program to the SmartMotor 52

Syntax Checking, Compiling and Downloading the Program 53

Additional Notes on Downloaded Programs 53

Running a Downloaded Program 54

Using the Program Download Window 55

Using the Terminal Window and Run Program Button 55

Using the RUN Command in the Terminal Window 55

Creating a Simple Motion Program 56

SMISoftware Features 57

Introduction 58

Menu Bar 58

Toolbar 59

Configuration Window 61

Terminal Window 63

Initiating Motion from the Terminal Window 65

Information Window 65

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 36 of 909

Page 37

Part 1: Programming the SmartMotor

Program Editor 66

Motor View 68

SMI Trace Functions 70

Monitor Window 73

Serial Data Analyzer 75

Chart View 76

Chart View Example 77

Macros 80

Tuner 82

SMIOptions 86

SMIHelp 87

Context-Sensitive Help Using F1 87

Context-Sensitive Help Using the Mouse 87

Help Buttons 87

Hover Help 87

Table of Contents 87

Projects 88

SmartMotor Playground 89

Opening the SmartMotor Playground 90

Moving the Motor 91

Communication Details 93

Introduction 95

Connecting to a Host 96

Daisy Chaining Multiple D-Style SmartMotors over RS-232 97

ADDR=formula 98

SLEEP, SLEEP1 99

WAKE, WAKE1 99

ECHO, ECHO1 100

ECHO_OFF, ECHO_OFF1 100

Serial Commands 101

OCHN(type,channel,parity,bit rate,stop bits,data bits,mode,timeout) 101

CCHN(type,channel) 102

BAUDrate, BAUD(channel)=formula 102

PRINT(), PRINT1() 102

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 37 of 909

Page 38

Part 1: Programming the SmartMotor

SILENT, SILENT1 103

TALK, TALK1 103

a=CHN(channel) 103

a=ADDR 104

Communicating over RS-485 104

Using Data Mode 104

CAN Communications 107

CADDR=formula 107

CBAUD=formula 107

=CAN, =CAN(arg) 107

CANCTL(function,value) 107

SDORD(...) 108

SDOWR(...) 108

NMT 109

RB(2,4), x=B(2,4) 109

Exceptions to NMT, SDORD and SDOWR Commands 109

I/O Device CAN Bus Master 110

Combitronic Communications 111

Combitronic Features 112

Other Combitronic Benefits 112

Program Loops with Combitronic 112

Global Combitronic Transmissions 113

Simplify Machine Support 113

Combitronic with RS-232 Interface 113

Other CANProtocols 115

CANopen - CAN Bus Protocol 115

DeviceNet - CAN Bus Protocol 115

I²C Communications (D-Style Motors) 115

OCHN(IIC,1,N,baud,1,8,D) 117

CCHN(IIC,1) 117

PRINT1(arg1,arg2, … ,arg_n) 117

RGETCHR1, Var=GETCHR1 117

RLEN1, Var=LEN1 117

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 38 of 909

Page 39

Part 1: Programming the SmartMotor

Motion Details 118

Introduction 120

Motion Command Quick Reference 121

Basic Motion Commands 122

Target Commands 122

PT=formula 122

PRT=formula 123

ADT=formula 123

AT=formula 123

DT=formula 123

VT=formula 123

Motion Mode Commands 124

MP 124

MV 124

MT 124

Torque Commands 125

TS=formula 125

T=formula 125

Brake Commands 125

BRKRLS 125

BRKENG 125

BRKSRV 126

BRKTRJ 126

Brake Command Examples 126

EOBK(IO) 127

MTB 127

Index Capture Commands 128

Other Motion Commands 129

G 129

S 129

X 130

O=formula 130

OSH=formula 130

OFF 130

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 39 of 909

Page 40

Part 1: Programming the SmartMotor

Commutation Modes 131

MDT 131

MDE 131

MDS 131

MDC 132

MDB 132

MINV(0), MINV(1) 132

Modes of Operation 133

Torque Mode 133

Torque Mode Example 133

Dynamically Change from Velocity Mode to Torque Mode 133

Velocity Mode 134

Constant Velocity Example 134

Change Commanded Speed and Acceleration 134

Absolute (Position) Mode 135

Absolute Move Example 135

Two Moves with Delay Example 135

Change Speed and Acceleration Example 135

Shift Point of Origin Example 136

Relative Position Mode 136

Relative Mode Example 136

Follow Mode with Ratio (Electronic Gearing) 137

Electronic Gearing and Camming over CANopen 137

Electronic Gearing Commands 138

SRC(enc_src) 138

MFR 138

MSR 138

MF0 138

MS0 138

MFMUL=formula, MFDIV=formula 138

MFA(distance[,m/s]) 139

MFD(distance[,m/s]) 139

MFSLEW(distance[,m/s]) 139

Follow Internal Clock Source Example 139

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 40 of 909

Page 41

Part 1: Programming the SmartMotor

Follow Incoming Encoder Signal With Ramps Example 140

Electronic Line Shaft 142

ENCD(in_out) 142

Spooling and Winding Overview 143

Relative Position, Auto-Traverse Spool Winding 143

MFSDC(distance,mode) 144

Dedicated, Absolute Position, Winding Traverse Commands 146

MFSDC(distance,2) 147

MFLTP=formula 147

MFHTP=formula 147

MFCTP(arg1,arg2) 147

MFL(distance[,m/s]) 148

MFH(distance[,m/s]) 148

ECS(counts) 148

Single Trajectory Example Program 150

Chevron Wrap Example 150

Other Traverse Mode Notes 152

Traverse Mode Status Bits 153

CamMode (Electronic Camming) 153

Electronic Camming Details 156

Understanding the Inputs 156

Should I choose Source Counts or Intermediate Counts? 157

Should I choose Variable or Fixed cam? 157

Electronic Camming Notes and Best Practices 159

Examples 161

Electronic Gearing and Camming over CANopen 161

Electronic Camming Commands 162

CTE(table) 162

CTA(points,seglen[,location]) 162

CTW(pos[,seglen][,user]) 162

MCE(arg) 163

MCW(table,point) 163

RCP 164

RCTT 164

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 41 of 909

Page 42

Part 1: Programming the SmartMotor

MC 164

MCMUL=formula 164

MCDIV=formula 164

O(arg)=formula 164

OSH(arg)=formula 164

Cam Example Program 165

Mode Switch Example 168

Position Counters 170

Modulo Position 171

Modulo Position Commands 171

Dual Trajectories 172

Commands That Read Trajectory Information 174

Dual Trajectory Example Program 175

Synchronized Motion 175

Synchronized-Target Commands 175

PTS(), PRTS() 175

VTS=formula 176

ADTS=formula, ATS=formula, DTS=formula 177

PTSS(), PRTSS() 177

A Note About PTS and PTSS 177

Other Synchronized-Motion Commands 178

GS 178

TSWAIT 179

Program Flow Details 181

Introduction 182

Flow Commands 182

RUN 183

RUN? 183

GOTO#, GOTO(label), C# 183

GOSUB#, GOSUB(label), RETURN 184

IF, ENDIF 184

ELSE, ELSEIF 185

WHILE, LOOP 186

SWITCH, CASE, DEFAULT, BREAK, ENDS 186

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 42 of 909

Page 43

Part 1: Programming the SmartMotor

TWAIT 187

WAIT=formula 187

STACK 187

END 188

Program Flow Examples 189

IF, ELSEIF, ELSE, ENDIF Examples 189

WHILE, LOOPExamples 189

GOTO(), GOSUB() Examples 190

SWITCH, CASE, BREAK, ENDS Examples 191

Interrupt Programming 192

ITR(), ITRE, ITRD, EITR(), DITR(), RETURNI 192

TMR(timer,time) 194

Variables and Math 195

Introduction 196

Variable Commands 196

EPTR=formula 196

VST(variable,number) 196

VLD(variable,number) 197

Math Expressions 197

Math Operations 197

Logical Operations 197

Integer Operations 197

Floating Point Functions 197

Math OperationDetails and Examples 198

Array Variables 198

Array Variable Examples 199

Error and Fault Handling Details 200

Motion and Motor Faults 201

Overview 201

Drive Stage Indications and Faults 201

Fault Bits 201

Error Handling 202

Example Fault-Handler Code 202

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 43 of 909

Page 44

Part 1: Programming the SmartMotor

PAUSE 203

RESUME 203

Limits and Fault Handling 204

Position Error Limits 204

dE/dt Limits 204

Velocity Limits 204

Hardware Limits 204

Software Limits 205

Fault Handling 205

Monitoring the SmartMotor Status 206

System Status 208

Introduction 209

Retrieving and Manipulating Status Words/Bits 209

System and Motor Status Bits 209

Reset Error Flags 211

System Status Examples 211

Timer Status Bits 212

Interrupt Status Bits 212

I/O Status 213

User Status Bits 213

Multiple Trajectory Support Status Bits 214

Cam Status Bits 215

Interpolation Status Bits 216

Motion Mode Status 216

RMODE, RMODE(arg) 216

I/OControl Details 217

I/O Port Hardware 218

I/O Connections Example (D-Style Motors) 219

I/O Voltage Spikes 219

Discrete Input and Output Commands 220

Discrete Input Commands 220

Discrete Output Commands 220

Output Condition and Fault Status Commands 221

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 44 of 909

Page 45

Part 1: Programming the SmartMotor

Output Condition Commands 221

Output Fault Status Reports 221

General-Use Input Configuration 221

Multiple I/OFunctions Example 222

Analog Functions of I/O Ports 223

5 Volt Push-Pull I/O Analog Functions (D-Style Motors) 223

24 Volt I/O Analog Functions (D-Style AD1 Option Motors, M-Style Motors) 223

Special Functions of I/OPorts 224

Class 5 D-Style Motors: Special Functions of I/O Ports 225

I/O Ports 0 and 1 – External Encoder Function Commands 225

I/O Ports 2 and 3 – Travel Limit Inputs 225

I/O Ports 4 and 5 – Communications 225

I/O Port 6 – Go Command, Encoder Index Capture Input 226

Class 5 M-Style Motors: Special Functions of I/O Ports 227

COM Port Pins 4, 5, 6, and 8 – A-quad-B or Step-and-Direction Modes 227

I/O Ports 2 and 3 – Travel Limit Inputs 227

I/O Port 5 – Encoder Index Capture Input 227

I/O Port 6 – Go Command 228

Class 6 M-Style Motors: Special Functions of I/O Ports 229

COM Port Pins 4, 5, 6, and 8 – A-quad-B or Step-and-Direction Modes 229

I/O Ports 2 and 3 – Travel Limit Inputs 229

I/O Port 4 and 5 – Encoder Index Capture Input 229

I/O Port 6 – Go Command 230

I/O Brake Output Commands 230

I²C Expansion (D-Style Motors) 230

Tuning and PIDControl 231

Introduction 232

Understanding the PID Control 232

Tuning the PID Control 233

Using F 233

Setting KP 234

Setting KD 234

Setting KI and KL 234

Setting EL=formula 235

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 45 of 909

Page 46

Part 1: Programming the SmartMotor

Other PID Tuning Parameters 235

KG=formula 235

KV=formula 235

KA=formula 236

Current Limit Control 237

AMPS=formula 237

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 46 of 909

Page 47

Part 1: Programming: Beginning Programming

Beginning Programming

This chapter provides information on beginning programming with the SmartMotor. It

introduces you to using the SMI™ Program Editor, understanding program requirements,

creating a program, downloading the program and then running it in the SmartMotor. It

concludes with a sample for creating your first motion program.

Setting the Motor Firmware Version 48

Setting the Default Firmware Version 48

Checking the Default Firmware Version 49

Opening the SMIWindow (Program Editor) 49

Understanding the Program Requirements 50

Creating a "Hello World" Program 51

Entering the Program in the SMI Editor 51

Adding Comments to the Code 52

Checking the Program Syntax 52

Saving the Program 52

Downloading a Program to the SmartMotor 52

Syntax Checking, Compiling and Downloading the Program 53

Additional Notes on Downloaded Programs 53

Running a Downloaded Program 54

Using the Program Download Window 55

Using the Terminal Window and Run Program Button 55

Using the RUN Command in the Terminal Window 55

Creating a Simple Motion Program 56

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 47 of 909

Page 48

Part 1: Programming: Setting the Motor Firmware Version

Setting the Motor Firmware Version

NOTE: In addition to the software information in this section, there is context-

sensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

When programming the SmartMotor, it is important that the SMI software compiler's

firmware version setting matches the firmware version of the connected SmartMotor.

CAUTION: The compiler's firmware version must match the firmware version

of the connected motor. If it does not match, the SMI software may not catch

syntax errors and may download incompatible code to the SmartMotor.

This procedure assumes that:

l

The SmartMotor is connected to the computer. For details, see Connecting the System

in the SmartMotor Installation & Startup Guide for your motor.

l

The SmartMotor is connected to a power source. (Certain models of SmartMotors

require separate control and drive power.) For details, see Understanding the Power

Requirements in the SmartMotor Installation & Startup Guide for your motor.

l

The SMI software has been installed and is running on the computer. For details, see

Installing the SMISoftware in the SmartMotor Installation & Startup Guide for your

motor.

Setting the Default Firmware Version

To set the default firmware version, from the SMI software main menu, select:

Compile > Compiler default firmware version

Setting the Compiler’s Default Firmware Version

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 48 of 909

Page 49

Part 1: Programming: Checking the Default Firmware Version

From the list, select the firmware version that most closely matches the firmware version of

the connected SmartMotor, as shown in the previous figure. After the default firmware

version has been selected, the list closes.

Checking the Default Firmware Version

To check the default firmware version, from the SMI software main menu, select:

Compile > Compiler default firmware version

On the list, locate the blue dot to the left of the firmware version number. The dot indicates

the currently-selected default firmware version.

Opening the SMIWindow (Program Editor)

NOTE: In addition to the software information in this section, there is context-

sensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

In addition to taking commands over the serial interface, the SmartMotor can run programs.

The SMI window is used to write and edit user programs for the SmartMotor(s). After the

program has been written, it can be checked and then downloaded to the desired SmartMotor

(s).

The SMI window is typically closed (default setting) when the SMI software is opened. To open

the window, click the New button ( ) on the toolbar, or select:

File > New

SMIWindow

After the SMI window opens, you can type your program directly into the editor, or you can

copy and paste existing code from any text-based software such as Windows Notepad.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 49 of 909

Page 50

Part 1: Programming: Understanding the Program Requirements

NOTE: Some word-processing software, such as Microsoft Word, has an option for

"smart quotes", which use angled single (ˊ) and double (˝) quotation marks . The

angled quotation marks are not recognized by the SMI editor. Therefore, any

"smart quotes" option must be disabled before copying and pasting the program

code.

Understanding the Program Requirements

SmartMotors use a simple form of code called "AniBasic", which is similar to the BASIC

programming language. Various commands include means to create continuous loops, jump

to different locations on given conditions and perform general math functions.

Note the following AniBasic program requirements:

l

The code is case sensitive:

l

All commands begin with or use all UPPERCASE letters.

l

All variables are preassigned and must use lower case.

l

Command names are reserved and cannot be used as variables.

l

A space is a programming element.

l

Comments require an apostrophe or ASCII character 39 (') between the commands and

the comment text.

NOTE: When copying and pasting code from another text editor, make sure

that your text editor is not inserting "smart quotes" (angled single or double

quotation marks). These are not the same as ASCIIcharacters 39 (') and 34

("), and the SMI program editor doesn't recognize them.

l

Each program must contain at least one occurrence of the END statement.

l

Each subroutine call must have a label with a RETURN statement somewhere below it.

l

Each Interrupt subroutine must end with the RETURNI statement.

l

The default syntax colors for the SMIeditor are: commands (blue), program flow

controls (pink), and comments(green). All other program text is shown in black. You

can change the syntax colors through the Editor tab in the Options window. For details

on the Options window, see SMIOptions on page 86.

l

There is no syntax checking performed until you do one of the following:

l

From the main menu, select Compile > Scan file for errors

l

Select the Scan File for Errors button on the toolbar

l

Press Ctrl+F7

l

As in BASIC, you can use the PRINT command to print to the screen, as shown in the

"Hello World" example. For details, see Creating a "Hello World" Program on page 51.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 50 of 909

Page 51

Part 1: Programming: Creating a "Hello World" Program

l

When the SmartMotor power is turned on, there is a 500 ms "pause" before any

program or command is processed:

l

For all industrial networks, every node (or motor) must immediately send out a

"Who am I?"info data packet when power is turned on, which tells the network

host who it's talking to. This is a requirement for all industrial communications

protocols (like CANopen, DeviceNet and PROFIBUS).

l

The stored program does not execute until the 500 ms pause expires. Any serial

commands sent during that time are buffered and then accepted after that pause

expires. Because incoming commands take priority over the internal program,

any buffered commands are executed before the internal program begins.

l

Commands coming in over the network have priority over the program running within

the SmartMotor. For example, while a program is running, you could issue a GOSUB

command from the terminal and send the program off to run the specified subroutine.

When the subroutine is done, the program would resume at the point where the GOSUB

command was issued.

l

The RUN? command can be used at the beginning of a program to prevent it from

automatically running when the SmartMotor power is turned on, as shown in the "Hello

World" example. For details, see Creating a "Hello World" Program on page 51.

l

The SmartMotor will not execute any code past the RUN? line until it receives a

RUN command through the serial port.

l

Using the serial port, the motor can be commanded to run subroutines even if the

stored program is not running.

Creating a "Hello World" Program

This procedure describes how to create and save a simple "Hello World" program.

NOTE: When copying and pasting code from another text editor, make sure that

your text editor is not inserting "smart quotes" (angled single or double quotation

marks). These are not the same as ASCIIcharacters 39 (') and 34 ("), and the SMI

program editor doesn't recognize them.

Entering the Program in the SMI Editor

To create the program, type the following code into the SMI software program editor:

RUN?

PRINT("Hello World",#13)

END

NOTE: The program will not run when the SmartMotor power is turned on (because

of the RUN? command on the first line).

When you run this program, it outputs the following text to the Terminal window:

Hello World

To run this program, you must download it to the SmartMotor and then enter the

RUNcommand in the Terminal window. For more details on downloading the program, see

Downloading a Program to the SmartMotor on page 52. For more details on running the

downloaded program, see Running a Downloaded Program on page 54.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 51 of 909

Page 52

Part 1: Programming: Adding Comments to the Code

Adding Comments to the Code

You can add comments to the code by inserting a single quotation mark (') between the

commands and your comment text.

NOTE: Comments do not get sent to the SmartMotor.

RUN? 'The program stops here until it receives a RUNcommand

PRINT("Hello World",#13) '#13 is a carriage return

END 'The required ENDcommand

Checking the Program Syntax

You can syntax check the program by doing one of the following:

l From the main menu, select Compile > Scan file for errors

l Select the Scan File for Errors button on the toolbar

l Press Ctrl+F7

If errors are found, correct them and re-check the syntax.

The program will also be syntax checked as part of the download procedure. For details, see

Downloading a Program to the SmartMotor on page 52.

Saving the Program

After entering the program, you can save it as follows:

1.

From the main menu, select: File > Save As, or click the Save button ( ) on the

toolbar. The Save As window opens.

2.

Select a drive/folder on your PC or use the default location.

3.

Assign a name, such as "HelloWorld.sms".

4.

Click Save to write the program to the specified location and close the window.

If you attempt to syntax check or compile and download an unsaved program, the SMI

software automatically opens the Save As window, which requires you to save the program

before continuing.

Downloading a Program to the SmartMotor

NOTE: In addition to the software information in this section, there is context-

sensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

After you've created a program, it must be downloaded to the SmartMotor. This section

explains how to syntax check and download the program.

NOTE: Comments do not get sent to the SmartMotor.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 52 of 909

Page 53

Part 1: Programming: Syntax Checking, Compiling and Downloading the Program

Syntax Checking, Compiling and Downloading the Program

The program can be syntax checked, compiled and transmitted to the SmartMotor in one

operation.

To compile the program and then transmit it to the SmartMotor:

NOTE: SMI transmits the compiled version of the program to the SmartMotor.

1. Click the Compile and Download Program button ( ) on the toolbar or press the F5 key.

The Select Motor window opens, which is used to specify which motor(s) will receive the

program.

2.

Select the desired motor(s) from the list. The SMI software compiles the program

during this step and also checks for errors. If errors are found, make the necessary

corrections and try again.

3.

Click OK to close the window and transmit the program. A progress bar shows the status

of the transmission.

Because the SmartMotor's EEPROM (long-term memory) is slow to write, the terminal

software uses two-way communications to regulate the download of a new program.

Additional Notes on Downloaded Programs

Keep the following items in mind regarding programs that have been downloaded to the

SmartMotor:

l

After the program has been downloaded into the SmartMotor, it remains there until

replaced.

l

The downloaded program executes every time power is applied to the motor.

l

There is a 500 ms timeout before the motor will accept commands on the serial

port. Any commands sent during that time are buffered and then accepted once

the 500 ms timeout expires. Because incoming commands take priority over the

internal program, buffered commands run before the internal program begins.

l

If you do not want the program to execute every time power is applied, you must

add a RUN? command as the first line/command of the program. For an example,

see Creating a "Hello World" Program on page 51.

l

To get a program to operate continuously, write a loop. For details, see Program

Flow Details on page 181.

l

A program cannot be erased; it can only be replaced. To effectively replace a program

with nothing, download a program with only one command: END.

Remember that all programs, even "empty" ones, must contain at least one

ENDcommand. For more details on program requirements, see Understanding the

Program Requirements on page 50.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 53 of 909

Page 54

Part 1: Programming: Running a Downloaded Program

Running a Downloaded Program

WARNING: The larger SmartMotors can shake, move quickly and exert great

force. Therefore, proper motor restraints must be used, and safety

precautions must be considered in the workcell design (see Other Safety

Considerations on page 31).

NOTE: In addition to the software information in this section, there is contextsensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

After the program has downloaded to the SmartMotor, the Program Download window opens,

which contains options relating to running the program.

Program Download Window

Runwill run the program immediately. Reset will clear all user variables and run the program

as if it were power cycled. Close will close the window without running the newly-downloaded

program.

"Check to disable this message" will prevent the window from being shown after a program is

downloaded to the SmartMotor. Select that option if you always want to run the program using

the Terminal window and the Run Program in Selected Motor button ( ), which is on the SMI

software toolbar.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 54 of 909

Page 55

Part 1: Programming: Using the Program Download Window

Using the Program Download Window

(Refer to the previous figure.)

To run the program on all motors:

1.

Select the All Motors on this channel option.

2.

Click Run.

To run the program on just the selected motor:

1.

Deselect the All Motors on this channel option.

2.

Click Run.

Using the Terminal Window and Run Program Button

To run the program using the Terminal window and the Run Program button:

1.

Use the motor selector in the Terminal window (see the following figure) to select the

motor—it must be the same motor that received the program.

2.

Click the Run Program in Selected Motor button ( ) to run the program in the selected

motor.

Selected Motor and Run Program Button

Using the RUN Command in the Terminal Window

To run the program using commands in the Terminal window, do one of the following:

l

Type RUN in the text box and click Send or press Enter

l

Type RUNdirectly on the terminal screen (blue) area and click Send or press Enter.

RUNCommand in the Terminal Window

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 55 of 909

Page 56

Part 1: Programming: Creating a Simple Motion Program

Creating a Simple Motion Program

WARNING: The larger SmartMotors can shake, move quickly and exert great

force. Therefore, proper motor restraints must be used, and safety

precautions must be considered in the workcell design (see Other Safety

Considerations on page 31).

Enter the following motion program in the SMIediting window. Pay close attention to spaces

and capitalization.

As described previously, it’s only necessary to enter text on the left side of the single quote,

as the text from the single quotation mark to the right end of the line is a comment and for

information only. That said, it is always good programming practice to create wellcommented code. Nothing is more frustrating than trying to debug or decipher code that is

sparsely commented.

NOTE: Comments do not get sent to the SmartMotor.

EIGN(2) 'Disable left limit

EIGN(3) 'Disable right limit

ZS 'Reset errors

ADT=100 'Set target accel/decel

VT=1000000 'Set target velocity

PT=100000 'Set target position

G 'Go, starts the move

TWAIT 'Wait for move to complete

PT=0 'Set buffered move back to home

G 'Start motion

END 'End program

After entering the program code, you can download it to the motor and then run it. For details

on downloading the program, see Downloading a Program to the SmartMotor on page 52. For

details on running the downloaded program, see Running a Downloaded Program on page 54.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 56 of 909

Page 57

Part 1: Programming: SMISoftware Features

SMISoftware Features

This chapter provides information on SMI software features.

Introduction 58

Menu Bar 58

Toolbar 59

Configuration Window 61

Terminal Window 63

Initiating Motion from the Terminal Window 65

Information Window 65

Program Editor 66

Motor View 68

SMI Trace Functions 70

Monitor Window 73

Serial Data Analyzer 75

Chart View 76

Chart View Example 77

Macros 80

Tuner 82

SMIOptions 86

SMIHelp 87

Context-Sensitive Help Using F1 87

Context-Sensitive Help Using the Mouse 87

Help Buttons 87

Hover Help 87

Table of Contents 87

Projects 88

SmartMotor Playground 89

Opening the SmartMotor Playground 90

Moving the Motor 91

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 57 of 909

Page 58

Menu bar

Toolbar

Conguration

window

Terminal

window

Information

window

Program

editor

Part 1: Programming: Introduction

Introduction

NOTE: In addition to the software information in this section, there is context-

sensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

The SMI software interface provides access to a variety of tools that are used to communicate

with, program and monitor the SmartMotor.

The interface can be accessed from the Windows Desktop icon or from the Windows Start

menu. For details, see Accessing the SMI Software Interface in the SmartMotor Installation &

Startup Guide for your motor.

Main Features of the SMISoftware

NOTE: Depending on your version of SMI software, your screens may look slightly

different than those shown.

The primary software features are briefly described in the following sections. In addition to

this information, there are detailed descriptions of all SMI software features in the software's

online help, which can be accessed from the software's Help menu or by pressing the F1 key.

Menu Bar

NOTE: In addition to the software information in this section, there is context-

sensitive help available within the SMI software interface, which is accessed by

pressing the F1 key or selecting Help from the SMI software main menu.

Moog Animatics SmartMotor™ Developer's Guide,Rev. L

Page 58 of 909

Page 59