Page 1

MANUAL

NO.

993-041990-002

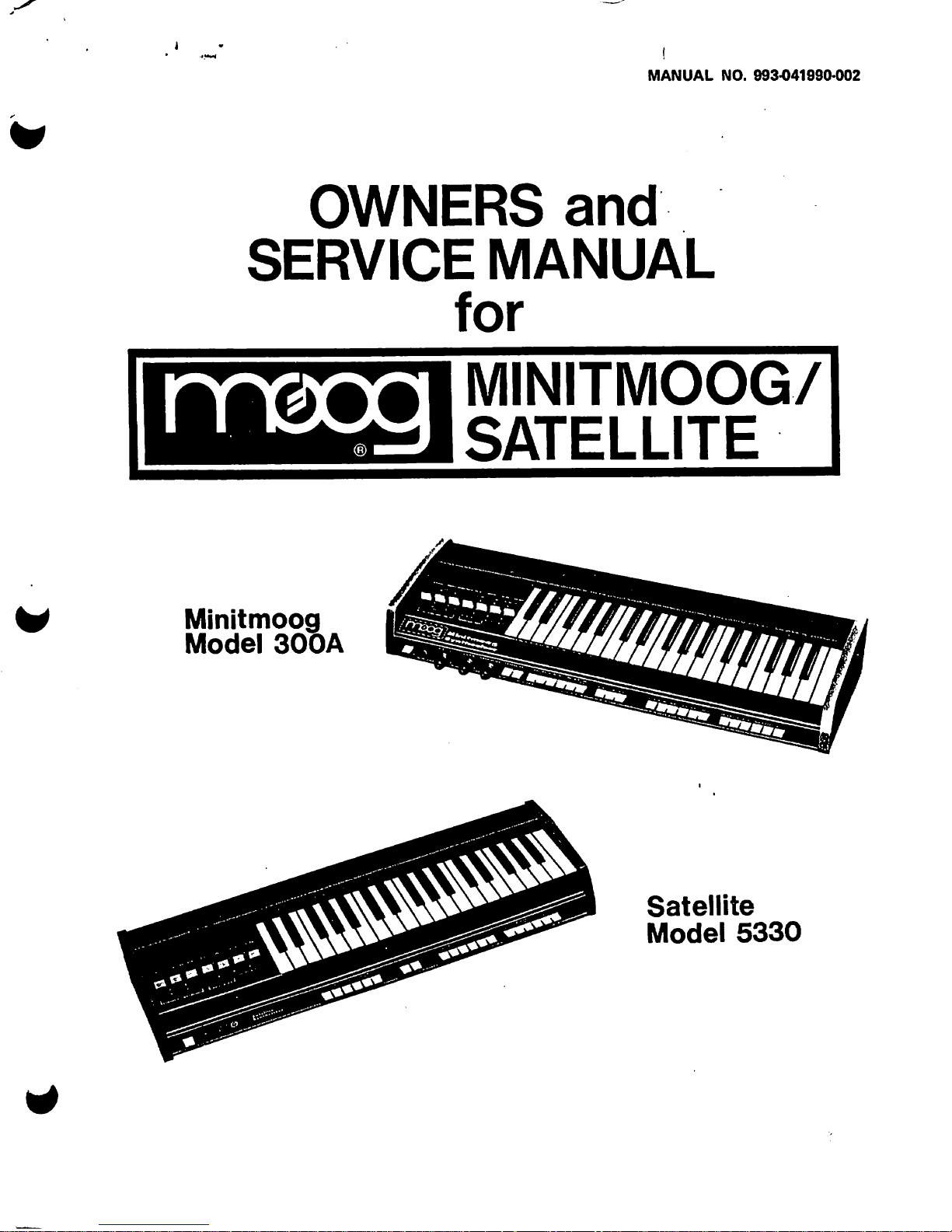

OWNERS

and

SERVICE

MANUAL

for

nnaoq

MINITMOOG/

SATELLITE

Minitmoog

Model

300A

Satellite

Model

5330

Page 2

Introduction

The

owners

portion

of

this

manual,

pages 1 through

11,

provides

introductory

material

to

familiarize

the

owner

with

the

features,

specifications

and

initial

set-up

of

the

Minitmoog

Synthesizer,

Model

3Q0A,

and

the

Satellite

Synthesizer,

Model

5330.

The

technical

portion

of

this

manual,

pages

12

through

57,

provides

servicing,,

replacement

parts

list

and

illustrations

to

enable a qualified

technician

to

service

and

maintain

the

Minitmoog

and

Satellite

Synthesizers.

Index

MINITMOOG

SYNTHESIZER

CONTENTS

Controls

Quick-Set

Voice

Tabs

2

Modulation,

Oscillation

and

Touch

Controls

3

Slide

Control

Panel

4

Accessories

and

Connections

10

Care

of

Your

Synthesizer

11

Technical

Sections

12

SATELLITE

SYNTHESIZER

PAGE

CONTENTS

PAGE

Controls

5

Quick-Set

Voice

Tabs

6

Modulation

8

Slide

Control

Panel

9

Accessories

and

Connections

10

Care

of

Your

Synthesizer

11

Technical

Sections

12

THESE

DRAWINGS

AND

SPECIFICATIONS

ARE

THE

PROPERTY

OF

MOOG

MUSIC

INC.

AND

SHALL

NOT

BE

REPRODUCED

OR

COPIED

IN

WHOLE

OR

IN

PART

AS

THE

BASIS

FOR

MANUFACTURE

OR

SALE

OF

THE

ITEMS.

Page 3

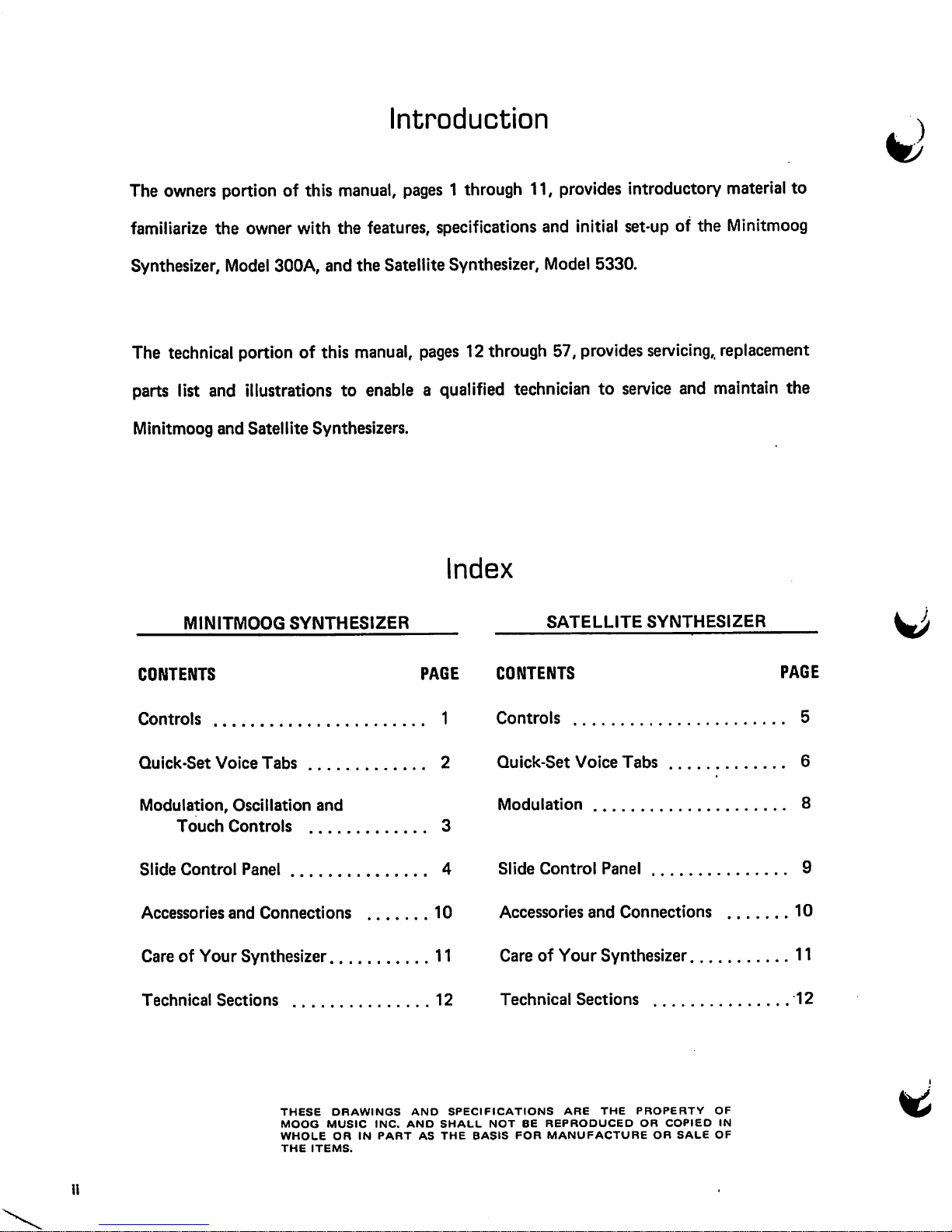

Minitmoog

Controls

SLIDE

CONTROLS

MODULATION

GLIDE

VOLUME

PANEL

CONTROLS

CONTROL CONTROL

SOLO

KEYBOARD

SYNC,

GLIDE

SUSTAIN

TABS

POWER

OFF-ON

SWITCH

INDICATOR

LIGHT

QUICK-SET

VOICING

TABS

FILTER

CONTROLS

TOUCH

SENSE

MODULATION

TABS

Before

proceeding

with

Operation

and

Adjustment

of

your

unit,

please

refer

to

page

10

for

Connection

Instructions.

LEVEL

ADJUST

M u . e „

This

rotary

control

(located

on

the

back

of

the

unit)

sets

the

overall

output

level,

or

volume,

of the

unit.

Smaller

changes

in

volume

may

be

made

with

the

VOLUME

control

on

the

Slide

Control

Panel.

This

rotary

control

(located

on

the

back

of the

unit)

provides

a

range

of

tuning

which

extends

more

than

one-half

octave.

This

flexibility

can

be

used

to

tune

your

MOOG

MINITMOOG

to

other

instruments,

transpose

to

different

keys,

or

even

provide a glissando

effect.

POWER

AND

INDICATOR

LIGHT

.

u

.

An

ON-OFF

power

switch

is

conveniently

located

on

the

front

panel,

with a red

light

which

indicates

when

the

power

is

ON.

OCTAVES

t

. . t

With

neither

tab

depressed,

your

MOOG

MINITMOOG

will

play

in

its

highest

pitch

level.

Depress

tab 1 ,

and

what

ever

you

play

on

the

keyboard

will

be

one

octave

lower.

Raise

tab

"1"

and

depress

tab

"2",

and

the

keyboard

pitch

level

is

lowered

another

octave.

Depress

both

tabs

and

the

pitch

level

is

lowered

still

a

third

octave.

Because

of

the

electronic

tailoring

of

the

sounds

to

the

requirements

of

each

pitch

level,

you

will

find

that the

effectiveness

of

every

sound

seems

to

change

magically

as

you

change

from

octave to

octave.

Try

all

sound

effects

in

all

four

pitch

levels.

SUSTAIN

. . .

This

"Quick-Set"

tab

allows

the

sound

of a note

to

"linger"

after

the

key

is

released.

It

provides

interesting

variations

to

the

special

voice

settings

described

in

this

Manual.

Page 4

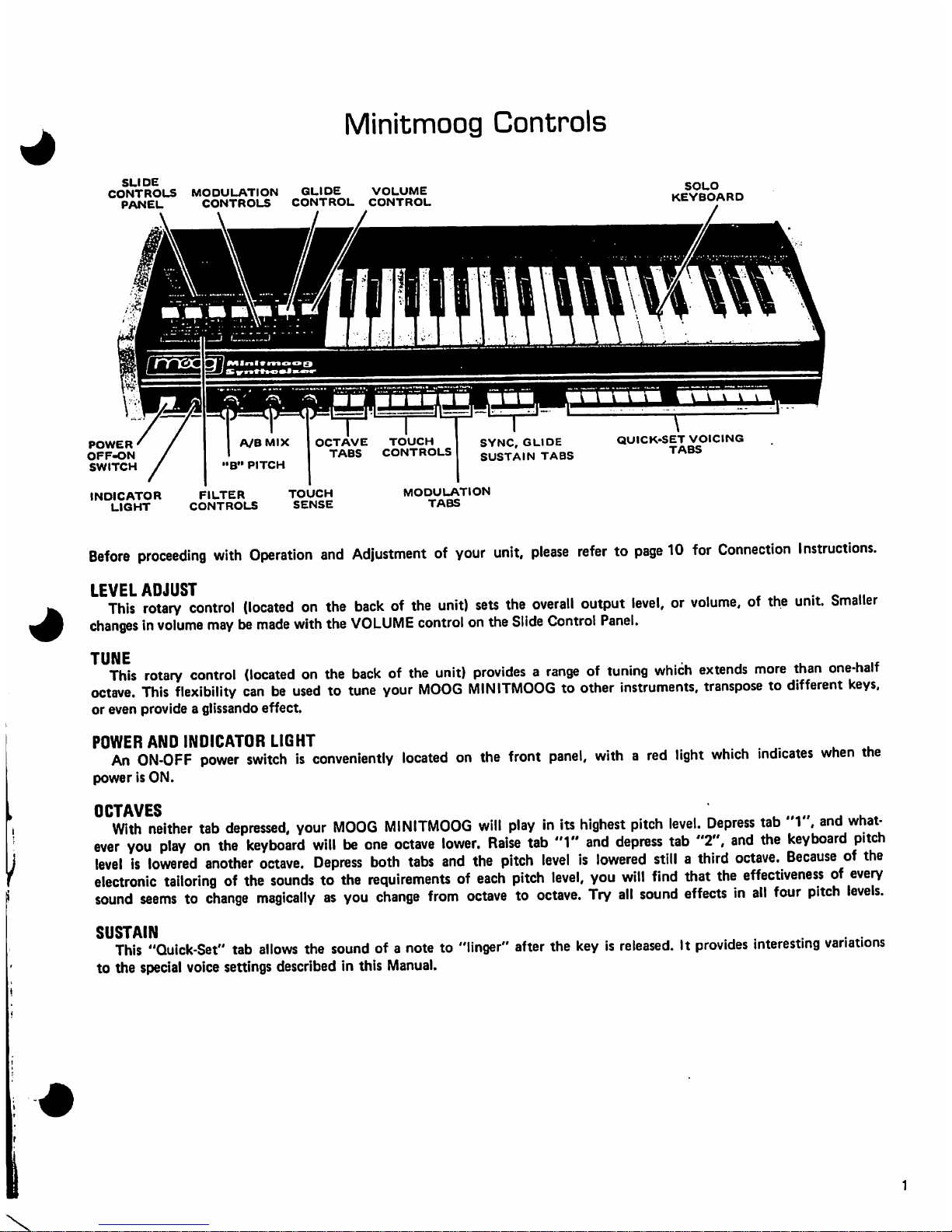

Minitmoog

Quick-Set

Voice

Tabs

TAURUS

GUITAR-1

VIOLIN

With

the

unit

connected

and

power

ON, a sound

can

be

heard

when a note

on

the

keyboard

is

struck,

even

though

no

voices

are

selected

and

all

slide

controls

are

set

at

"0"

(except

for

the

VOLUME

control).

The

controls

described

herein

will

add and

subtract

from

that

sound

in a multitude

of

combinations

available

for

your

exploration

-

shape

it,

change

its

attack

and

release,

raise

it,

or

lower

it.

We

suggest

that

you

play a phrase

or

two

with

each

of

the

twelve

"QUICK-SET"

VOICE

TABS

conveniently

located

on

the

front

of

the

unit.

Try

each

with

all

the

slide

controls

set

at

"0"

(except

for

VOLUME).

Exact

setting

of

slide

controls

for

any

particular

effect

will

depend,

not

only

on

your

musical

taste,

but

also

on

your

complete

electronic

reproduction

system

including

amplifiers,

speakers

and

other

components.

NOTE:

If

more

than

one

"QUICK-SET"

Voice

Tab

is

depressed

at

the

same

time

the

sound

will

be

that

controlled

by

the

Voice

Tab

farthest

to

the

left.

MUTE

This

voice

is a new

version

of

the

wah-wah

effect.

The

sound

approximates

a

double-acting

wah-wah,

or

"ooo-wah-ooo."

It

starts

with

an

emphasis

on

the

"lows",

moves

to

the

"highs"

and

returns.

Each

time a key

is

depressed

the

"ooo-wah-ooo"

sound

is

produced.

Try

it

in

each

octave.

TRUMPET

The

sounds

of a trumpet,

trombone,

or

tuba can

be

approximated

by

selecting

this

tab,

and

varying

it

with

other

controls.

Characteristic

of

this

voice

(and

some

of

the

other

"Quick-Set"

voices)

is a built-in

timbre

change

which

is

faster

in

the

upper

octaves

and

is

automatically

slower

in

the

lower

octaves

•

much

as

the attack

of a tuba

differs

from

that

of a trumpet.

This

attention to

the

authentic

details

of the

attack

in

different

octaves

is

a

unique

feature

of

the

Minitmoog.

Try

it

in

each

octave

setting.

OBOE

This

voice

provides

a

sound

similar

to

that

of a double

reed. In

the

top

octave

the

sound

is

oboe-like.

In

the

lower

octaves,

the

sound

of a bassoon

is

approximated.

You

will

note a slight

timbre

change

in

the

onset

of

the

tone

and a slow

attack.

CLARINET

The

hollow

reed

sound

and

the

soft

attack

of

the

traditional

clarinet

and

bass

clarinet

are

characteristic

of

this

voice -an

excellent

voice

in

all

octave

registers.

SAX

This

full

bodied

reed

sound

is

unique

to

the

Minitmoog.

It

combines

some

of

the

qualities

of a double

reed

wind

instrument

with

those

of a pipe

organ

with a little

sax

ophone

added.

In

the

lowest

registers,

it is

an

excellent

reproduction

of the

sound-

of

the

sarrusophone,

a

wind

instrument

popular

in

bands

of

the

early

1900's.

Page 5

aa

we

TAURUS

This

voice

approximates

that

of a saxophone.

With

adjustment

of

other

controls

you

will

be

able

to vary

the

und

through

the

characteristics

of

alto

and

tenor,

bari-

ne,

and

bass

sounds

of

the

Taurus

Synthesizer.

VIOLIN

This

gentle

voice

with

its

slow

attack

can

be

made

to

simulate

violin,

viola,

cello,

and

even

some

of the

sounds

of

the

bass

violin.

GUITAR-1

This

sound

is

quite

percussive

with a lingering

decay.

It

is

most

useful

for

creating

guitar-like

or

harpsichord-

type

effects,

including

that

of a folk

guitar.

PIANO

In

the

upper

registers

this

voice

is

that

of

an

electronic

piano.

In

the

lower

registers

it

provides

an

interesting

sound

similar

to

that

of

an

electric

bass

guitar.

AIRES

Banjo

type

sounds

are

provided

with

the

hollow

sound

characteristic

of

this

voice.

In

the

lower

registers

it

can

simulate

the

plucked

sound

of

the

string

bass,

or

bass

violin.

GUITAR

-2

In

the

upper

octaves a fine

bell

sound

is

provided

by

this

voice.

In

the

lower

octaves,

the

huge

sound

of

a

large

carillon

can

be

reproduced.

LUNAR

This

versatile

voice

perhaps

is

most

characteristic

of

the

Moog

sounds.

It

provides,

in

its

various

adjust

ments, a wide

variety

of

timbre

changes

with

which

you

can

produce

many

popular

electronic

"Moog"

sound

effects.

It

is

most

effective

when

used

with

SUSTAIN.

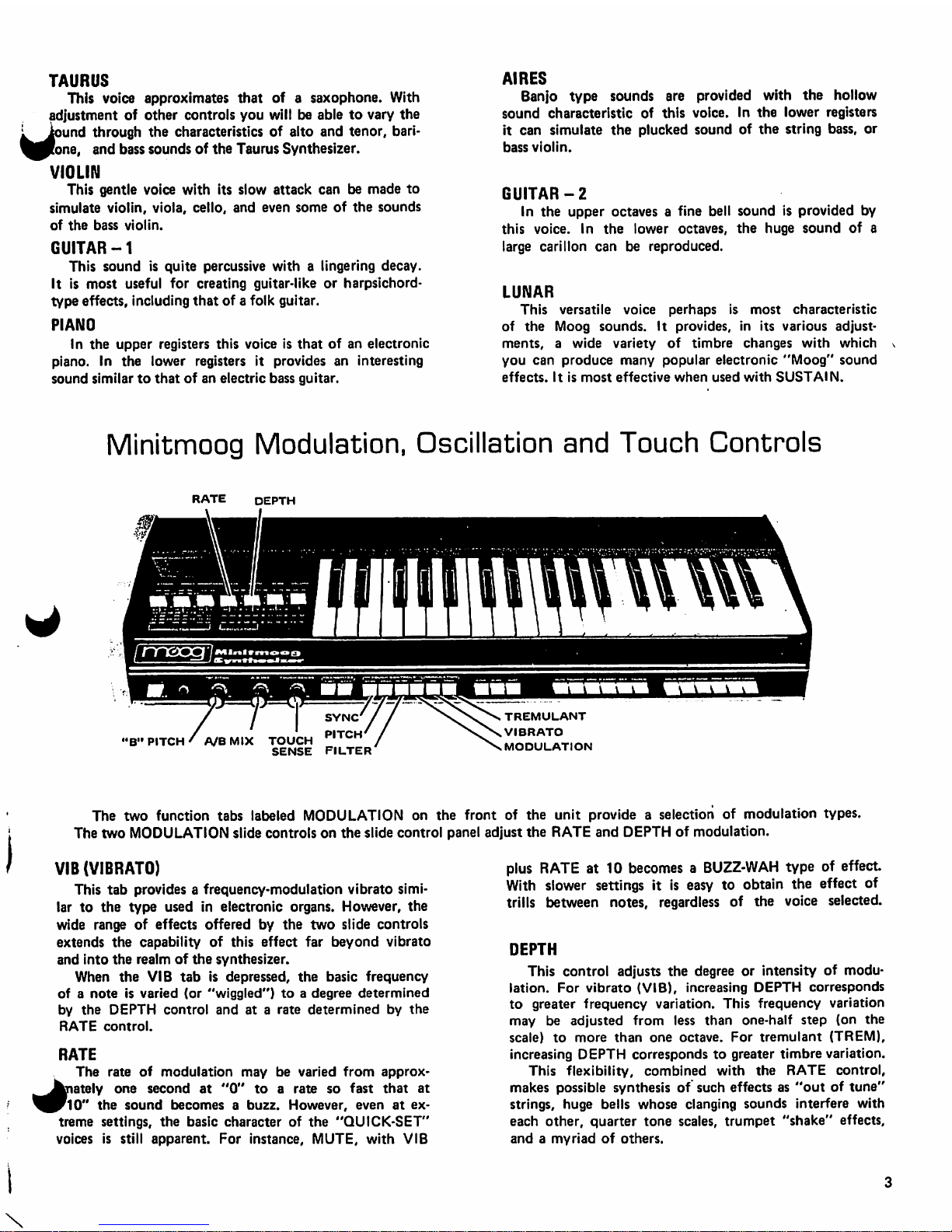

Minitmoog

Modulation,

Oscillation

and

Touch

Controls

RATE

DEPTH

•B"

PITCH'

A/BMIX

TOUCH

SENSE

FILTER

TREMULANT

VIBRATO

MODULATION

The

two

function

tabs

labeled

MODULATION

on

the

front

of

the

unit

provide a selection

of

modulation

types.

The

two

MODULATION

slide

controls

on

the

slide

control

panel

adjust

the

RATE

and

DEPTH

of

modulation.

VIB

(VIBRATO)

This

tab

provides

a

frequency-modulation

vibrato

simi

lar

to

the

type used

in

electronic

organs.

However,

the

wide

range

of

effects

offered

by

the

two

slide

controls

extends

the

capability

of

this

effect

far

beyond

vibrato

and

into

the

realm

of

the

synthesizer.

When

the

VIB

tab

is

depressed,

the

basic

frequency

of a note

is

varied

(or

"wiggled")

to a degree

determined

by

the

DEPTH

control

and

at a rate

determined

by

the

RATE

control.

RATE

The

rate

of

modulation

may

be

varied

from

approx-

ately

one

second

at

"0"

to a rate

so

fast

that

at

10"

the

sound

becomes a buzz.

However,

even

at

ex

treme

settings,

the

basic

character

of

the

"QUICK-SET"

voices

is

still

apparent.

For

instance,

MUTE,

with

VIB

plus

RATE

at

10

becomes a BUZZ-WAH

type

of

effect.

With

slower

settings

it

is

easy

to

obtain

the

effect

of

trills

between

notes,

regardless

of the voice

selected.

DEPTH

This

control

adjusts

the degree

or

intensity

of

modu

lation.

For

vibrato

(VIB),

increasing

DEPTH

corresponds

to

greater

frequency

variation.

This

frequency

variation

may

be

adjusted

from

less

than

one-half

step

(on

the

scale)

to

more

than

one

octave.

For

tremulant

(TREM),

increasing

DEPTH

corresponds

to

greater

timbre

variation.

This

flexibility,

combined

with

the

RATE

control,

makes

possible

synthesis

of

such

effects

as

"out

of

tune"

strings,

huge

bells

whose

clanging

sounds

interfere

with

each

other,

quarter

tone

scales,

trumpet

"shake"

effects,

and a myriad

of

others.

Page 6

TREM

(TREMULANT)

This

tab

provides

modulation

of

the

harmonic

content

of

the

tone.

The

harmonic

content,

or

timbre,

is

varied

at

a

rate

determined

by

the

RATE

control

and

with

an

intensity

determined

by

the

DEPTH

control.

NOTE:

VIB

and

TREM

can

be

used

together.

SYNC

This

tab

is

only

active

when

other

SYNC

tab

switch

is

also

down.

Raises

pitch

of B tone

osciliator as a key

is

depressed

harder

producing

a

phasing

effect.

PITCH

This

tab

bends

pitch

of

both A and B tone

oscillators

up

to

an

interval

of

at

least

seven

semitones

when a key

is

depressed

harder.

FILTER

This

tab

adds

familiar

Moog

"wah"

to

most

voices

when

pressure

on

the

keys

is

increased.

This

effect

adds

directly

to

the

effect

produced

by

the

FILTER

BRIGHT

NESS

slide

control.

MOD

This

tab

allows

either

vibrato

or

tremolo

to

be

added

to

the

tone

as

the

pressure

on

the

keys

is

increased.

The

DEPTH

slide

control

in

this

mode

acts

as a touch

sensitiv

ity

control

and

the

MODULATION

RATE

slide

control

sets

the

speed

of

the

effect.

This

tab

switch

has

an

effect

only

if

the

MODULATION

VIB

or

MODULATION

TREM

tab

switch

is

also

depressed.

TOUCH

SENSE

This

control

regulates

the

range

of

expressive

effects

when

additional

pressure

is

exerted

on

the

keys

for

SYNC,

PITCH

and

FILTER

(brightness)

modes.

"B"

PITCH

This

control

varies

pitch

ol B tone

producing

oscillator

over a two

octave

range.

A/B

MIX

Controls

mixing

of A and B tone source

oscillator

outputs. A only

or B only

occur

at

the

CCW

and

CW

extremes

of

rotation,

respectively.

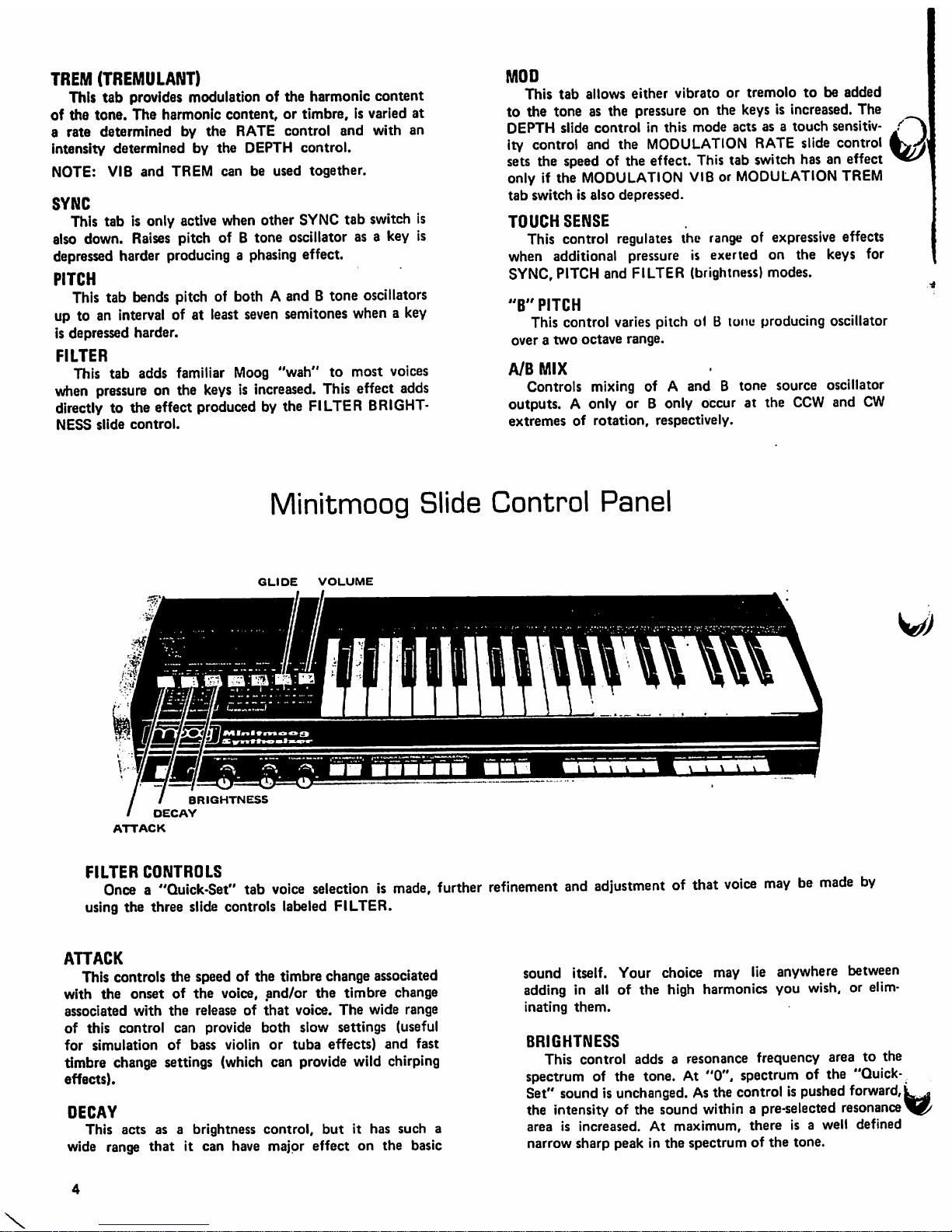

Q

Minitmoog

Slide

Control

Panel

GLIDE

VOLUME

BRIGHTNESS

DECAY

ATTACK

FILTER

CONTROLS

u

.

.

Once a "Quick-Set"

tab

voice

selection

is

made,

further

refinement

and

adjustment

of

that

voice

may

be

made

oy

using

the

three

slide

controls

labeled

FILTER.

ATTACK

This

controls

the

speed

of

the

timbre

change

associated

with

the

onset

of

the

voice,

and/or

the

timbre

change

associated

with

the

release

of

that

voice.

The

wide

range

of

this

control

can

provide

both

slow

settings

(useful

for

simulation

of

bass

violin

or

tuba

effects)

and

fast

timbre

change

settings

(which can

provide

wild

chirping

effects).

DECAY

This

acts

as a brightness

control,

but

it

has

such

a

wide

range

that

it

can

have

major

effect

on

the

basic

sound

itself.

Your

choice

may

lie

anywhere

between

adding

in

all

of

the

high

harmonics

you

wish,

or

elim

inating

them.

BRIGHTNESS

This

control

adds a resonance

frequency

area

to

the

spectrum

of

the

tone.

At

"0",

spectrum

of the

"Quick-

Set"

sound

is

unchanged.

As

the

control

is

pushed

forward,

the

intensity

of

the

sound

within a pre-selected

resonance

area

is

increased.

At

maximum,

there

is a well

defined

narrow

sharp

peak

in

the

spectrum

of

the

tone.

Page 7

FILTER

CONTROLS

SUMMARY

Remember,

the

"Quick-Set"

tabs

establish

an

overall

range

of

sound

and

the

three

Filter

slide

controls

give

you a wide

selection

and

control

within

the

limitations

of

that

range.

Try

this:

1.

Depress

TRUMPET

tab,

and

set

the

slide

controls

at

"0".

2.

Play a few

notes

on

the

keyboard.

3.

Play

again

with

various

settings

of

the

DECAY

slide

pot.

The

range

of

sound

will

be

from

that

of a very

dull

trumpet

to a very

brassy

one.

4.

Now

do

the

same

with

the

BRIGHTNESS

control.

The

sound

will

range

through

cornet,

trumpet,

and

flugelhorn

characteristics.

5.

Repeat

with

various

settings

of

the

ATTACK

control.

It

will

show

the

wide

range

of

contoured

timbers

in

the

onset

of

the

tones.

ADDITIONAL

CONTROLS

MODULATION

CONTROLS

See

discussion

under

MODULATION

on

page

3.

GLIDE

This

is

one

of

the

most

interesting

of

the

Moog

effects.

Depress

the

GLIDE

tab

and

set

the

GLIDE

slide

control

at

6.

Play

any

note

on

the

keyboard.

Release

this

note

and

quickly

play a second

note

some

distance

away.

The

sound

automatically

glissandos

from

the

first

note

to the

second.

The

setting

of

the

slide

control

determines

the

speed

of

the

glissando,

{10

is

slow -1

is

fast).

Try a melody

of

detached

notes

and

notice

the

succession

of

glide

attacks.

VOLUME

The

VOLUME

slide

control

provides

finger-tip

adjust

ment

of

fine

gradations

of

the

Minitmoog

output.

Major

changes

in

sound

level

are

obtained

by

means

of

the

rotary

knob

on

the

back

of

the

unit.

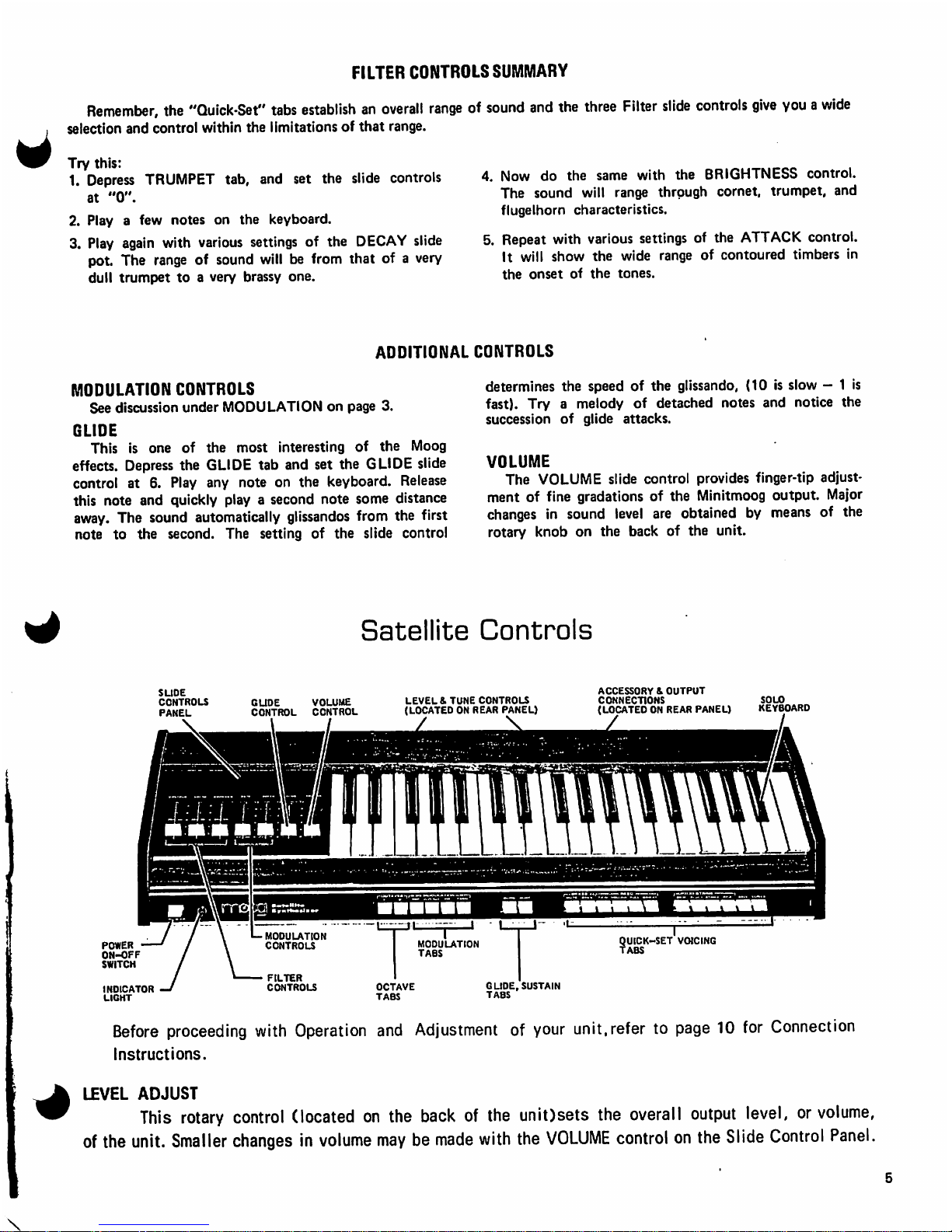

Satellite

Controls

SUOE

CONTROLS

PANEL

GLIDE

VOLUME

CONTROL CONTROL

LEVEL &

TUNE

CONTROLS

(LOCATED

ON

REAR

PANEL)

ACCESSORY & OUTPUT

CONNECTIONS

SOLO

(LOCATED

ON REAR

PANEL)

KEYBOARD

GLIDE,

SUSTAIN

TABS

Before

proceeding

with

Operation

and

Adjustment

of

your

unit,refer

to

page

10

for

Connection

Instructions.

LEVEL

ADJUST

This

rotary

control

(located

on

the

back

of

the

uniOsets

the

overall

output

level,

or

volume,

of

the

unit.

Smaller

changes

in

volume

may

be

made

with

the

VOLUME

control

on

the

Slide

Control

Panel.

\

Page 8

TUNE

This

rotary

control

(located

on

the

back

of

the

unit)

provides

a

range

of

tuning

which

extends

more

than

one-half

octave.

This

flexibility

can

be

used

to

tune

your

MOOG

SATELLITE

to

other

instruments,

transpose

to

different

keys,

or

even

provide

a

glissando

effect.

POWER

AND

INDICATOR

LIGHT

An

ON-OFF

power

switch

is

conveniently

located

on

the

front

panel,

with

a

red

light

which

indicates

when

the

power

is

ON.

OCTAVES

With

neither

tab

depressed,

your

MOOG

SATELLITE

will

play

in

its

highest

pitch

level.

Depress

tab

"V,

and

whatever

you

play

on

the

keyboard

will

be

one

octave

lower.

Raise

tab

"1"

and

depress

tab

"2",

and

the

keyboard

pitch

level

is

lowered

another octave.

Depress

both

tabs

and

the pitch

level

is

lowered

still

a

third

octave.

Because

of

the

electronic

tailoring

of

the

sounds

to

the

requirements

of

each

pitch

level,

you

will

find

that

the

effectiveness

of

every

sound

seems

to

change

magically

as

you

change

from

octave

to

octave.

Try

all

sound

effects

in

all

four

pitch

levels.

SUSTAIN

This

"Quick-Set"

tab

allows

the

sound

of

a

note

to

"linger"

after

the

key

is

released.

It

pro

vides

interesting

variations

to

the

special

voice

settings

described

in

this

Manual.

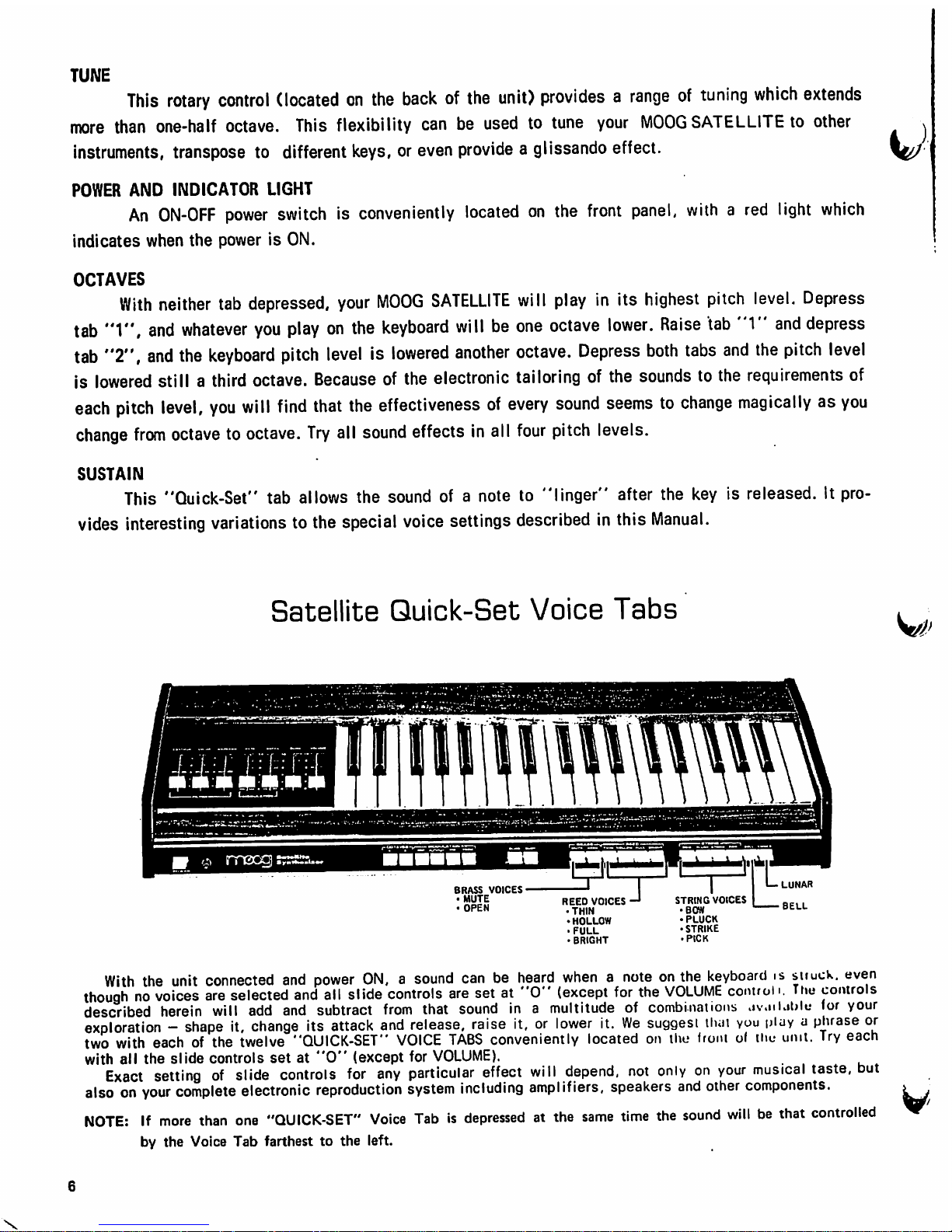

Satellite

Quick-Set

Voice

Tabs

BRASS

VOICES'

•MUTE

•

OPEN

REED

VOICES

•THIN

•HOLLOW

•

FULL

•

BRIGHT

STRING VOICES

•BOW

•

PLUCK

•STRIKE

•

PICK

BELL

With

the

unit

connected

and

power

ON, a sound

can

be

heard

when a note

on

the

keyboard

is

stiuck.

even

though no

voices

are

selected

and

all

slide

controls

are set

at

"0"

(except

for

the

VOLUME

control

i.

The

controls

described

herein

will

add and

subtract

from

that

sound

in a multitude

of

combinations

<iv.ii

Lib

k*

tor

your

exploration

-

shape

it,

change

its

attack

and

release,

raise

it,

or

lower

it.

We

suggest

Unit

you

play a phrase

or

two

with

each

of

the

twelve

"QUICK-SET"

VOICE

TABS

conveniently

located

on

the

front

ol

ihc

unit.

Try

each

with

all

the

slide

controls

set

at

"0"

(except

for

VOLUME).

Exact

setting

of

slide

controls

for

any

particular

effect

will

depend,

not

only

on

your

musical

taste,

but

also

on

your

complete

electronic

reproduction

system

including

amplifiers,

speakers

and

other

components.

NOTE:

If

more

than

one

"QUICK-SET"

Voice

Tab

is

depressed

at

the

same

time

the

sound

will

be

that

controlled

by

the

Voice

Tab

farthest

to

the

left.

Page 9

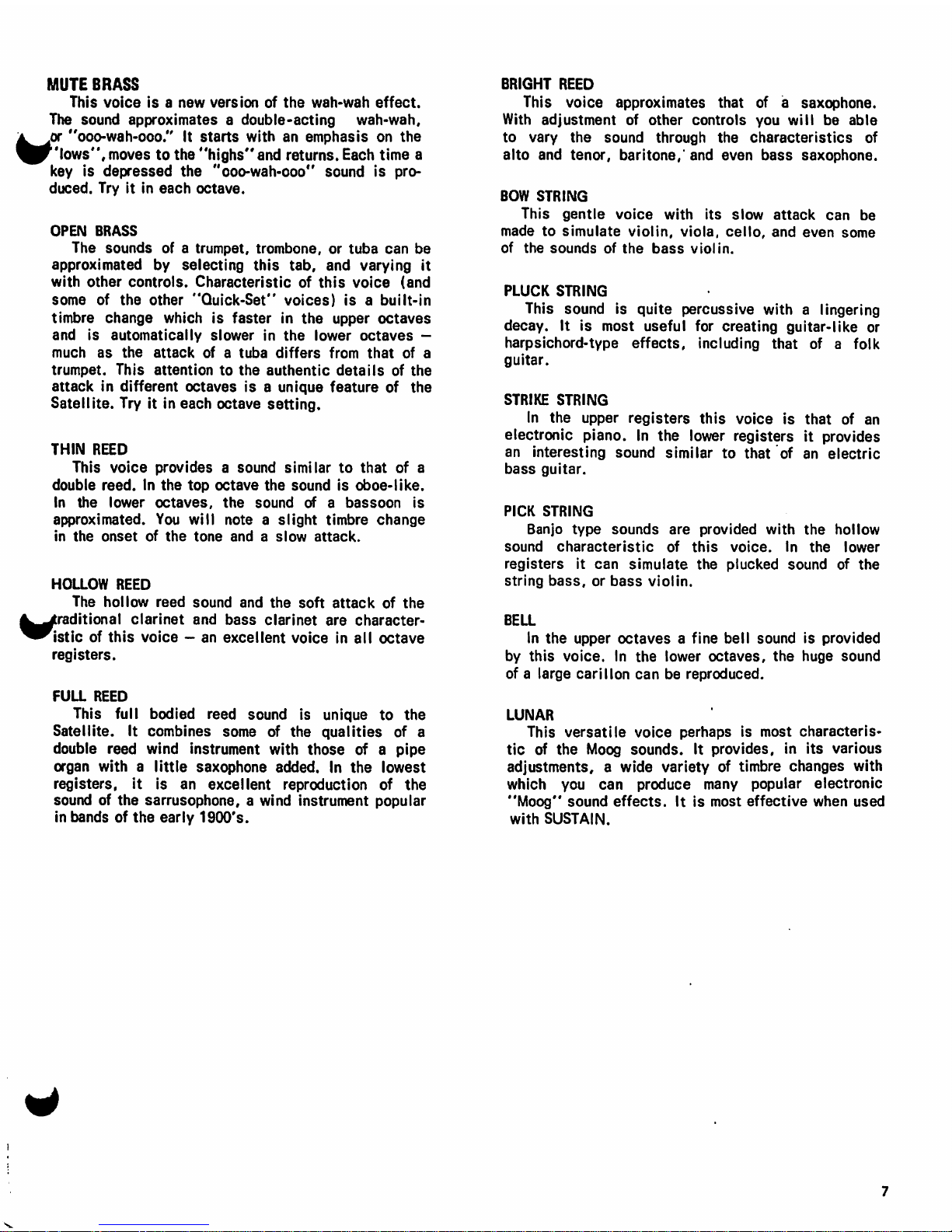

MUTE

BRASS

This

voice

is a new

version

of

the

wah-wah

effect.

The sound

approximates

a

double-acting

wah-wah,

.or

"ooowah-ooo."

It

starts

with

an

emphasis

on

the

"lows",

moves

to

the

"highs"

and

returns.

Each

time

a

key

is

depressed

the

"ooo-wah-ooo"

sound

is

pro

duced.

Try

it

in

each

octave.

OPEN

BRASS

The

sounds

of a trumpet,

trombone,

or

tuba

can

be

approximated

by

selecting

this

tab,

and

varying

it

with

other

controls.

Characteristic

of

this

voice

(and

some

of

the

other

"Quick-Set"

voices)

is a built-in

timbre

change

which

is

faster

in

the

upper

octaves

and

is

automatically

slower

in

the

lower

octaves

—

much

as

the

attack

of a tuba

differs

from

that

of

a

trumpet.

This

attention

to

the

authentic

details

of

the

attack

in

different

octaves

is a unique

feature

of

the

Satellite.

Try

it

in

each

octave

setting.

THIN

REED

This

voice

provides a sound

similar

to

that

of

a

double

reed.

In

the

top

octave

the

sound

is

oboe-like.

In

the

lower

octaves,

the

sound

of a bassoon

is

approximated.

You

will

note a slight

timbre

change

in

the

onset

of

the

tone

and a slow

attack.

HOLLOW

REED

The

hollow

reed

sound

and

the

soft

attack

of

the

raditional

clarinet

and

bass

clarinet

are

character

istic

of

this

voice -an

excellent

voice

in all

octave

registers.

FULL REED

This

full

bodied

reed

sound

is

unique

to

the

Satellite.

It

combines

some

of

the

qualities

of

a

double

reed

wind

instrument

with

those

of a pipe

organ

with a little

saxophone

added.

In

the

lowest

registers,

it

is

an

excellent

reproduction

of

the

sound

of

the

sarrusophone,

a

wind

instrument

popular

in

bands

of

the

early

1900's.

BRIGHT

REED

This

voice

approximates

that

of a saxophone.

With

adjustment

of

other

controls

you

will

be

able

to

vary

the

sound

through

the

characteristics

of

alto

and

tenor,

baritone,

and

even

bass

saxophone.

BOW

STRING

This

gentle

voice

with

its

slow

attack

can

be

made

to

simulate

violin,

viola,

cello,

and

even

some

of

the

sounds

of

the

bass

violin.

PLUCK

STRING

This

sound

is

quite

percussive

with a lingering

decay.

It

is

most

useful

for

creating

guitar-like

or

harpsichord-type

effects,

including

that

of

a folk

guitar.

STRIKE

STRING

In

the

upper

registers

this

voice

is

that

of

an

electronic

piano.

In

the

lower

registers

it

provides

an

interesting

sound

similar

to

that

of

an

electric

bass

guitar.

PICK

STRING

Banjo

type

sounds

are

provided

with

the

hollow

sound

characteristic

of

this

voice.

In

the

lower

registers

it

can

simulate

the

plucked

sound

of

the

string

bass,

or

bass

violin.

BELL

In

the

upper

octaves a fine

bell

sound

is

provided

by

this

voice.

In

the

lower

octaves,

the

huge

sound

of a large

carillon

can

be

reproduced.

LUNAR

This

versatile

voice

perhaps

is

most

characteris

tic

of

the

Moog

sounds.

It

provides,

in

its

various

adjustments,

a

wide

variety

of

timbre

changes

with

which

you

can

produce

many

popular

electronic

"Moog"

sound

effects.

It

is

most

effective

when

used

with

SUSTAIN.

Page 10

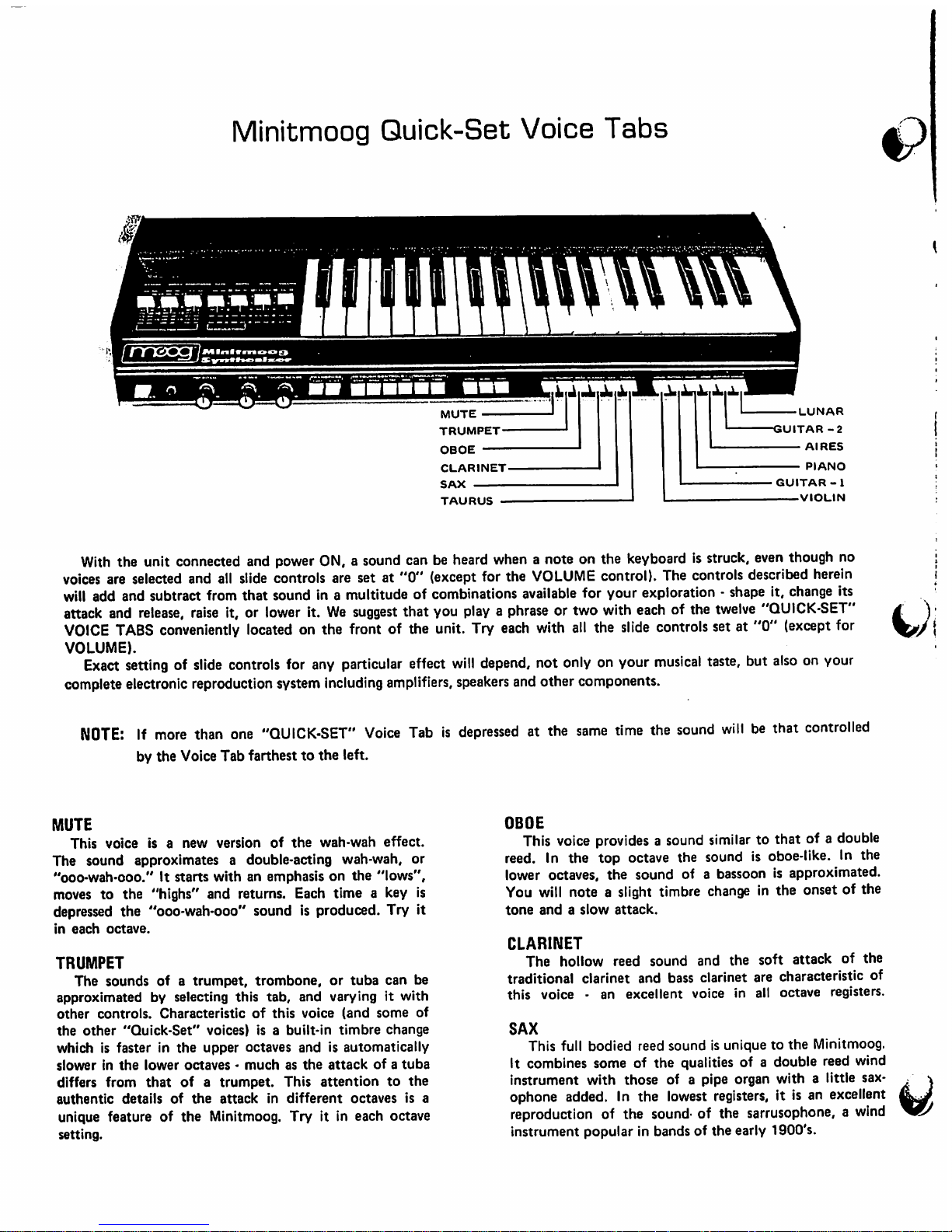

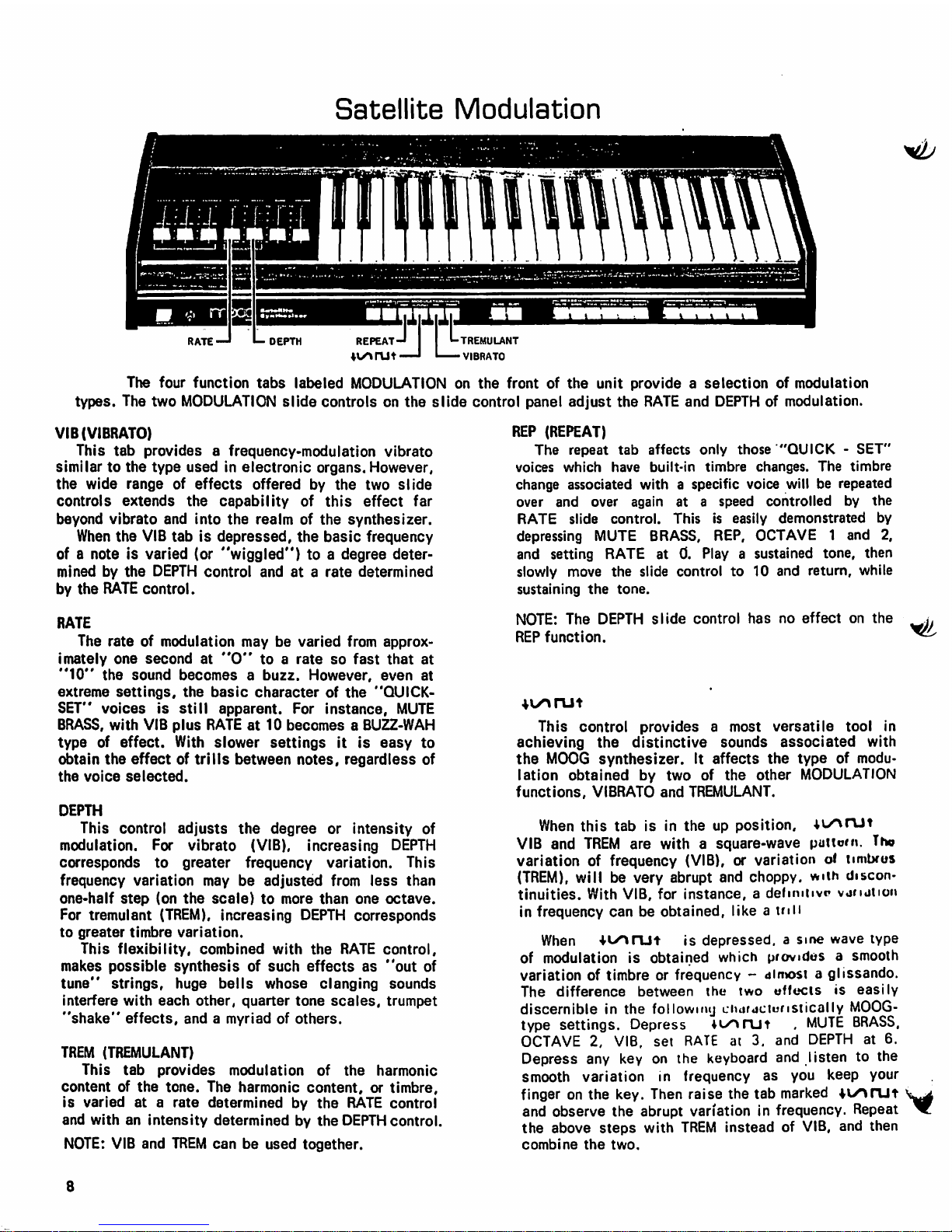

Satellite

Modulation

RATE—'

DEPTH

Tfrf

REPEAT-*

UTREMULANT

' I VIBRATO

The

four

function

tabs

labeled

MODULATION

on

the

front

of

the

unit

provide a selection

of

modulation

types.

The

two

MODULATION

slide

controls

on

the

slide

control

panel

adjust

the

RATE

and

DEPTH

of

modulation.

VIB

(VIBRATO)

This

tab

provides a frequency-modulation

vibrato

similar

to

the

type

used

in

electronic

organs.

However,

the

wide

range

of

effects

offered

by

the

two

slide

controls

extends

the

capability

of

this

effect

far

beyond

vibrato

and

into

the

realm

of

the

synthesizer.

When

the

VIB

tab

is

depressed,

the

basic

frequency

of a note

is

varied

(or

"wiggled")

to a degree

deter

mined

by

the

DEPTH

control

and

at a rate

determined

by

the

RATE

control.

RATE

The

rate

of

modulation

may

be

varied

from

approx

imately

one second

at

"0"

to

a rate

so

fast

that

at

"10"

the

sound

becomes a buzz.

However, even

at

extreme

settings,

the

basic

character

of

the

"QUICK

SET"

voices

is

still

apparent.

For

instance,

MUTE

BRASS,

with

VIB

plus

RATE

at

10

becomes a BUZZ-WAH

type

of

effect.

With

slower

settings

it

is

easy

to

obtain

the

effect

of

trills

between

notes,

regardless

of

the

voice

selected.

DEPTH

This

control

adjusts

the

degree

or

intensity

of

modulation.

For

vibrato

(VIB),

increasing

DEPTH

corresponds

to

greater

frequency

variation.

This

frequency

variation

may

be

adjusted

from

less

than

one-half

step

(on

the

scale)

to

more

than

one

octave.

For

tremulant

(TREM),

increasing

DEPTH

corresponds

to

greater

timbre

variation.

This

flexibility,

combined

with

the

RATE

control,

makes

possible

synthesis

of

such

effects

as

"out

of

tune"

strings,

huge

bells

whose

clanging

sounds

interfere

with

each

other,

quarter

tone

scales,

trumpet

"shake"

effects,

and a myriad

of

others.

TREM

(TREMULANT)

This

tab

provides

modulation

of

the

harmonic

content

of

the

tone.

The

harmonic

content,

or

timbre,

is

varied

at a rate

determined

by

the

RATE

control

and

with

an

intensity

determined

by

the

DEPTH

control.

NOTE:

VIB

and

TREM

can

be

used

together.

REP

(REPEAT)

The

repeat

tab

affects

only

those

"QUICK -SET"

voices

which

have

built-in

timbre

changes.

The

timbre

change

associated

with a specific

voice

will

be

repeated

over

and

over

again

at a speed

controlled

by

the

RATE

slide

control.

This

is

easily

demonstrated

by

depressing

MUTE

BRASS,

REP,

OCTAVE 1 and

2,

and

setting

RATE

at

0.

Play a sustained

tone,

then

slowly

move

the

slide

control

to

10

and

return,

while

sustaining

the

tone.

NOTE:

The

DEPTH

slide

control

has

no

effect

on

the

REP

function.

\\s\rui

This

control

provides a most

versatile

tool

in

achieving

the

distinctive

sounds

associated

with

the

MOOG

synthesizer.

It

affects

the

type

of

modu

lation

obtained

by

two

of

the

other

MODULATION

functions,

VIBRATO

and

TREMULANT.

When

this

tab

is in

the

up

position,

VIB

and

TREM

are

with a square-wave

putioui.

The

variation

of

frequency

(VIB),

or

variation

ol

timbres

(TREM),

will

be

very

abrupt

and

choppy.

with

discon

tinuities.

With

VIB,

for

instance, a defmiiivn

variation

in

frequency

can

be

obtained,

like a trill

When

+1/1

rut

is

depressed, a sine

wave

type

of

modulation

is

obtained

which

provides a smooth

variation

of

timbre

or

frequency

-

almost a glissando.

The

difference

between

the

two

effects

is

easily

discernible

in

the

following

ciniructunstically

M00G-

type

settings.

Depress

ii/irut . MUTE

BRASS,

OCTAVE

2,

VIB,

set

RATE

at

3.

and

DEPTH

at

6.

Depress

any

key

on

the

keyboard

and

listen

to

the

smooth

variation

in

frequency

as

you

keep

your

finger

on

the

key.

Then

raise

the

tab

marked

♦b^rut

and

observe

the

abrupt

variation

in

frequency.

Repeat

the

above

steps

with

TREM

instead

of

VIB,

and

then

combine

the

two.

8

Page 11

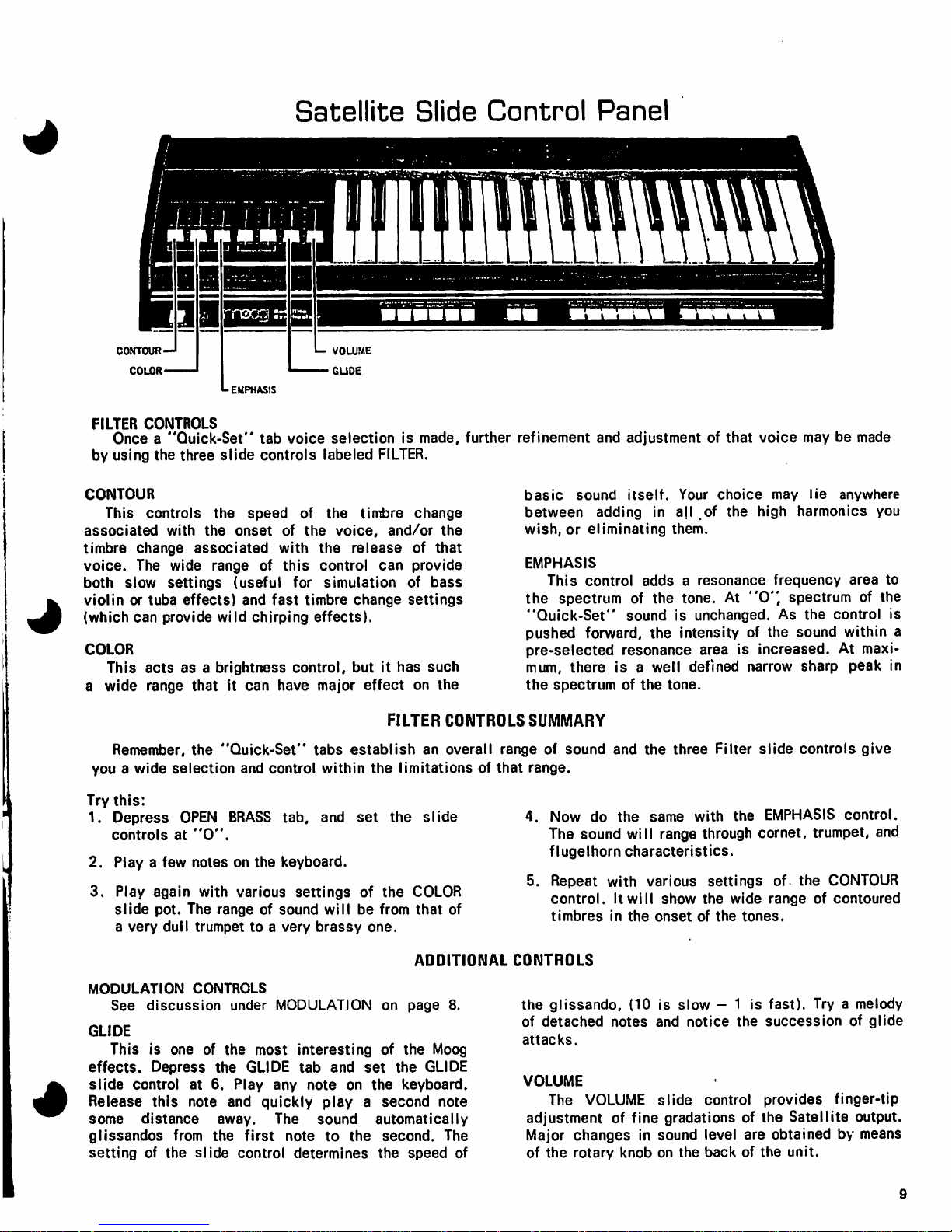

Satellite

Slide

Control

Panel

L

EMPHASIS

FILTER

CONTROLS

Once a "Quick-Set"

tab

voice

selection

is

made,

further

refinement

and

adjustment

of

that

voice

may

be

made

by

using

the

three slide

controls

labeled

FILTER.

CONTOUR

This

controls

the

speed

of

the

timbre

change

associated

with

the

onset

of

the

voice,

and/or

the

timbre

change

associated

with

the

release

of

that

voice.

The

wide

range

of

this

control

can

provide

both

slow

settings

(useful

for

simulation

of

bass

violin

or

tuba

effects)

and

fast

timbre

change

settings

(which

can

provide

wild

chirping

effects).

COLOR

This

acts

as a brightness

control,

but

it

has

such

a

wide

range

that

it

can

have

major

effect

on

the

basic

sound

itself.

Your

choice

may

lie

anywhere

between

adding

in a|l

.of

the

high

harmonics

you

wish,

or

eliminating

them.

EMPHASIS

This

control

adds a resonance

frequency

area

to

the

spectrum

of

the

tone.

At

"0",

spectrum

of

the

"Quick-Set"

sound

is

unchanged.

As

the

control

is

pushed

forward,

the

intensity

of

the

sound

within

a

pre-selected

resonance

area

is

increased.

At

maxi

mum,

there

is a well

defined

narrow

sharp

peak

in

the

spectrum

of

the

tone.

FILTER

CONTROLS

SUMMARY

Remember,

the

"Quick-Set"

tabs

establish

an

overall

range

of

sound

and

the

three

Filter

slide

controls

give

you a wide

selection

and

control

within the

limitations

of

that

range.

Try

this:

1.

Depress

OPEN

BRASS

controls

at

"0".

tab,

and

set

the

slide

2.

Play a few

notes

on

the

keyboard.

3.

Play

again

with

various

settings

of

the

COLOR

slide

pot.

The

range

of

sound

will

be

from

that

of

a

very

dull

trumpet

to a very

brassy

one.

4.

Now

do

the

same

with

the

EMPHASIS

control.

The

sound

will

range

through

cornet,

trumpet,

and

flugelhorn

characteristics.

5.

Repeat

with

various

settings

of.

the

CONTOUR

control.

It

will

show

the

wide

range

of

contoured

timbres

in

the

onset

of

the

tones.

ADDITIONAL

CONTROLS

MODULATION

CONTROLS

See

discussion

under

MODULATION

on

page

8.

GLIDE

This

is

one

of

the

most

interesting

of

the

Moog

effects.

Depress

the

GLIDE

tab

and

set

the

GLIDE

slide

control

at

6.

Play

any

note

on

the

keyboard.

Release

this

note

and

quickly

play a second

note

some

distance

away.

The

sound

automatically

glissandos

from

the

first

note

to

the

second.

The

setting

of

the

slide

control

determines

the

speed

of

the

glissando,

(10

is

slow -1

is

fast).

Try a melody

of

detached

notes

and

notice

the

succession

of

glide

attacks.

VOLUME

The

VOLUME

slide

control

provides

finger-tip

adjustment

of

fine

gradations

of

the

Satellite

output.

Major

changes

in

sound

level

are

obtained

by

means

of

the

rotary

knob

on

the

back

of

the

unit.

9

Page 12

Accessory

and

Connections

For

operation,

the

Synthesizer

unit

should

be

placed

on a horizontal

surface

in a location

which

will

not

interfere

with

its

operation.

NOTE:

Avoid

placement

in

close

proximity

to

electronic

circuitry,

as

on

the

top

of

some

electronic

organs,

because

excessive

hum

may

result.

LO-LEVEL

OUTPUT

130

millivolts

RMS),

Phone

Jack

designed

for

use

with

Guitar

Amplifier,

P.A.

Systems,

etc.

HI-LEVEL

OUTPUT

(1

volt

RMS),

RCA

Phono

Jack

designed

for

use

with

Electronic

Organs.

("Y"

Adapter

and

Accessory

extension

cable

are

included

with

your

unit).

REAR

PANEL

ACCESSORY

EXTENSION

CABLE

ORGAN

AMPLIFIER

RIGHT

OR

MAIN

CHANNEL

INPUT

PLUG

RIGHT

OR

MAIN

CHANNEL

INPUT

JACK

.FROM

ORGAN

Connection

Instructions

SINGLE

CHANNEL

ORGANS

(MONAURAL)

Disconnect

the

RCA

Phono

plug

from

Amplifier

Input

Jack

and

insert

the

"Y"

Adapter

plug

into

the

Amplifier

inpui

Jack.

Connect

Accessory

extension

cable

plug

into

"Y"

Adapter

socket

and

insert

the

plug

on

the

other

end

ol

the

extension

cable

into

the

HI-LEVEL

OUTPUT

jack

on

your

Synthesizer

unit.

Connect

the

organ

plug

(previouslv

removed)

into

the

other

"Y"

Adapter

socket.

DUAL

CHANNEL

ORGANS

(STEREO)

Disconnect

the

RCA

Phono

plug

from

the

Right

of

Main

Channel

Amplifier

Input

Jack

and

insert

"Y"

AOaptoc

plug

into

Right

or

Main

Channel

Input

Jack.

Connect

the

Accessory

extension

cable

plug

into

the

"Y"

Adapter

socket

and

insert

the

plug

on

the

other

end

of

the

extension

cable

into

HI-LEVEL

OUTPUT

jack

on

your

Synthesiser

unit.

Connect

the

Right

or

Main

Channel

plug

(previously

removed)

into

the

other

"Y"

Adapter

socket.

NOTE:

Do

not

connect

the

Synthesizer

into

Leslie

or

Left

Channel

Input.

FILTER

CONTROL

INPUT

This

jack

is

provided

for

the

control

of

the

Timbre

with a Moog

Pedal

controller.

ACCESSORY

SOCKET

,

x

Permits

the

attachment

of a Foot

Pedal

to

control

several

Synthesizer

features.

(Consult

your

dealer

for

availability

of

Moog

Accessories).

10

Page 13

Care

of

Your

Synthesizers

Your

MOOG

Synthesizer

is

carefully

designed

to

give

you

maximum

pleasure

and

satisfaction

with a minimum

of

care.

Following

these

tips

on

the

care

of

your

Synthesizer

will

help

keep

it

"showroom

new."

■

LOCATION

As

with

any

electronic

instrument,

avoid

placement

in

direct

or

prolonged

sunlight.

Normal

variation

of

temper

ature

will

not

affect

the

tuning

or

electronic

circuitry

of

the

synthesizer.

Storage

location

should

be

chosen

to

avoid

placement

in

front

of

hot

air

registers,

or

beside

an

outside

doorway

in

winter,

as

these

elements

may

affect

the

finish

of

the

cabinet.

•

CABINET

Quality

hardwoods

are

used

in

your

MOOG

Synthesizer.

Therefore,

a

minimum

amount

of

care

wijl

insure

you

of

having

a

piece

of

furniture

that

will

retain

its

beauty.

An

occasional

dusting

with a soft,

dry

cloth

should

remove

both

fingerprints

and

dulling

film.

To

clean

the

keys

a soft

cloth

dampened

in a mild

soap

solution

should

remove

even

the

most

persistent

stains.

Under

no

circumstances

should

solvents

or

cleaning

fluids

be

used

to clean

keys

or

cabinet.

■

POWER

REQUIREMENTS

This

instrument

must

be

operated

from a standard

120

VAC

60Hz

power

outlet.

Normal

line

voltage

variation

will

not

affect

its

operation.

Power

requirements

of

this

unit

are

very

low.

All

solid

state

circuits

are

operated

at

a

very

low

voltage

and

component

life

is

therefore

extended.

■

SAFETY

Your

MOOG

Synthesizer

has

been

designed

for

maximum

safety

in

its

operation

and

trouble

free

performance.

However,

repair

or

service

of

electronic

products

should

be

done

by

qualified

personnel

familiar

with

the

hazards

relating

to

electricity

and

electronic

circuitry.

The

risk

of

repair

or

service

must

not

be

assumed

by

the

customer.

Your

dealer

will

provide

a

competent,

experienced

service

technician

for

that

purpose.

Please

contact

your

dealer,

if

your

unit

needs

repair

or

service.

■

CONCLUSION

And

now

as

you

play

....

Let

us

offer

you

our

best

wishes

for a happy

and

rewarding

experience

with

your

MOOG

Synthesizer.

We

know

it

will

bring

you

great

pleasure

and

creative

satisfaction.

11

Page 14

TECHNICAL

SERVICE

SECTION

for

MINITMOOG/

SATELLTE

Minitmoog

Model

300A

Satellite

Model

5330

12

Page 15

CONTENTS

SECTION

PAGE

1

INTRODUCTION

15

2

CIRCUIT

DESCRIPTION

15

2.1

GENERAL

15

2.2

POWER

SUPPLY

15

2.3

KEYBOARD

CIRCUIT

16

2.4

OSCILLATOR

18

2.5

BAND

PASS

FILTER

20

2.6

LOW

PASS

FILTER

20

2.7

VOLTAGE

CONTROLLED

AMPLIFIER

20

2.8

AMPLITUDE

CONTOUR

GENERATOR

21

2.9

FILTER

CONTOUR

GENERATOR

22

2.10

MODULATION

OSCILLATOR

22

2.11

TOUCH

SENSOR

•

22

3

DISASSEMBLY,

VISUAL

INSPECTION

AND

REASSEMBLY

23

3.1

DISASSEMBLY

23

3.2

VISUAL

INSPECTION

23

3.3

PRINTED

CIRCUIT

BOARD

REMOVAL.

23

3.4

REASSEMBLY

,

25

4

TUNING

AND

CALIBRATION

PROCEDURES

25

4.1

GENERAL

25

4.2

OSCILLATOR

TUNING

25

4.3

VOICE

CALIBRATION

29

5

OPERATING

CONTROLS,

INDICATORS

AND

CONNECTORS

31

6

KEYBOARD

MAINTENANCE

AND

ADJUSTMENT

34

6.1

CONTACTS

35

6.2

KEYS

35

6.3

TOUCH

SENSOR

7

TROUBLESHOOTING

GUIDE

37

7.1

POWER

SUPPLY

37

7.2

SOUND

CHAIN

38

7.3

CONTROL

CIRCUITS

40

7.4

OSCILLATOR

TUNING

41

8

MODIFICATIONS

42

8.1

SERVICE

BULLETIN

802

42

8.2

TOUCH

SENSOR

BAR

42

8.3

INSTALLATION

OF

NEW

OR

REBUILT

TOUCH

SENSOR

BAR

45

9

REPLACEMENT

PARTS

LIST

46

10

BLOCK

AND

SCHEMATIC

DIAGRAMS

50

13

Page 16

LIST

OF

ILLUSTRATIONS

FIGURE

TITLE

PAGE

NO.

2-1

Keyboard

Trigger

Voltage

Waveforms

17

2-2

Emitter

of

Q46

18

2-3

Synchronization

of

Oscillator

B

to

Oscillator

A

19

2-4

Emitter

Voltage

of

Q35

21

2-5

Source

Voltage

of

Q32

21

3-1

Minitmoog

Printed

Circuit

Board

Location

(Inside

View)

24

3-2

Minitmoog

Cover

and

Printed

Circuit

Board

Locations

(Bottom

Views)

....

24

4-1

Minimal

Test

Setup

for

Tuning

25

4-2

Two

Channel

Oscilloscope

Test

Setup

for

Tuning

26

4-3

Main

Board

No. 1 Adjustment

Controls

and

Oscilloscope

Test

Point

Locations

26

4-4

Trigger

at

Collector

of

Q8

27

4-5

Oscillator

B

Trimpot

Locations

(Board

No.

5)

28

4-6

Square

Wave

at

Junction

of

R44

and

R119

29

4-7

Band

Pass

Filter

Q

and

Fc

at

Q41

Source

29

4-8

Filter

Contour

at

Q20

Source

30

4-9

Loudness

Attack

at

Junction

of

R165

and

R166

30

4-10

Loudness

Decay

at

Junction

of

R165

and

R166

30

8-1

Disassembly

of

Minitmoog

42

8-2

Minitmoog

Disassembled

43

8-3

Sensor

Removal

43

8-4

Sensor

Removed

from

Top

Support

44

8-5

Modification

Material

44

8-6

Touch

Sensor

Bar

Reassembled

45

10-1

Minitmoog

Schematic

Diagram

51

10-2

Minitmoog

Block

Diagram

52

10-3

Minitmoog

Printed

Circuit

Board

Assemblies

52

10-4

Minitmoog

Touch

Sensor

Board

Assembly

No. 4 Schematic

Diagram

53

10-5

Minitmoog

Oscillator

Board

Assembly

No. 5 Schematic

Diagram

53

10-6

Satellite

Schematic

Diagram

54

10-7

Satellite

Printed

Circuit

Board

Assemblies

55

10-8

Satellite

Block

Diagram

56

l'i

14

Page 17

SECTION

1

INTRODUCTION

This

manual

provides

servicing

and

parts infor

mation

for

Minitmoog

Synthesizer

Model

300A

and

Satellite

Synthesizer

Model

5330,

manufactured

by

Moog

Music

Inc.,

2500

Walden

Avenue,

Buffalo,

New

York

14225.

This

manual

was

written

basically

for

the

Minitmoog

Synthesizer

which

includes

the

touch

sensor

board 4 and

oscillator

B

board 5 not

found

in

the

Satellite

Synthesizer.

Differences

in

operating

control

panel

markings

are

indicated

in

Section

5.

Any

major

differences

will

be

noted.

The

Minitmoog

and

Satellite

Synthesizers

are

monophonic

live

performance

synthesizers

intended

primarily

as

auxiliary

instruments

for

keyboardists

and

features

a

dozen

"QUICK-SET"

tabs

that

allow

for

instan

taneous

changes

among

various

voices

preset

with

in

the

instrument.

The

sound

producing

chain

of

the

Synthesizers

consists

of

an

"A"

oscillator

that

produces

both

sawtooth

and

rectangular

waveforms,

a

"B"

scillator

(Minitmoog

only)

that

produces

only

saw

tooth

waveforms,

a

band

pass

filter,

a

low

pass

filter

and a variable

gain

amplifier.

All

five

of

these

circuits

in

the

sound

producing

chain

are

voltage

controlled

and

the

remaining

circuitry

is

devoted

to

producing

appropriate

control

voltages.

The

keyboard

circuit

produces

one

pitch

control

voltage,

the

magnitude

of

which

depends

on

which

key

is

depressed.

In

addition,

the

keyboard

produces

a

trigger

voltage

whenever

one

or

more

of

the

keys

are

depressed.

The

modulating

oscillator

produces

triangular

waveforms

for

modulating

the

oscillators

and

filters.

Two

contour

generators

produce

voltages

that

rise

and

fall

each

time a key

is

depressed.

One

contour

generator

sweeps

one

of

the

filters

while

the

other

sweeps

the

amplifier.

A

resistor

matrix

determines

the

nominal

values

of

the

voltage-controlled

parameters.

The

power

supply

delivers

±

18

volts

unregulated

and

± 9 volts

regulated.

Refer

to

page

52.

The

resistor

matrix

has

fifteen

input

rows

and

twelve

output

columns. A row

is

on

when

+9

volts

is

applied

to

it

and

off

when

it is

open

circuited.

The

two

upper

rows

are

connected

to

the 2 OCT

and 1 OCT

tab

switches,

respectively,

and

shorten

the

contour

times

and

raise

filter

frequencies

when

on.

The

remaining

rows

are

for

the

quick

set

voices

and

only

one

can

be

on

at a time.

The

column

outputs

are

applied

to

low

impedance

points

in

the

circuitry.

Of

the

twelve

matrix

output

columns,

eight

supply

control

currents

for

continuously

variable

parameters,

while

the

remaining

four

supply

switching

current

to

determine

circuit

states.

SECTION

2

CIRCUIT

DESCRIPTION

2.1

GENERAL

The

main

circuit

board

mounts

underneath

the

keyboard

and

contains

a

large

portion

of

the

Synthesizer

circuitry.

All

connections

to

this

board

are

made

through

Molex

connectors.

Looking

at

the

board

from

the

component

side

with

the

connectors

along

the

top

edge,

the

left

connector

is

designated

"A"

and

the

right

connector

is

designated

"B"

with

the

pins

numbered

from 1 to

24

starting

with

the

ief t pin

on

each

connector.

Block

diagrams,

schematic

diagrams

and

printed

circuit

board

diagrams

are

illustrated

in

Section

10

for

quick

reference.

2.2

POWER

SUPPLY

The

unregulated

portion

of

the

power

supply

is

located

on

power

supply

board

No. 2 and

is

completely

conventional.

The

nominal

total

load

supplied

from

each

of

the

unregulated

voltages

is

45

milliamperes.

The

positive

and

negative

voltage

regulator

circuits

for

the

power

supply

are

located

on

main

board

No. 1 .

The

positive

power

supply

voltage

regulator

consists

of

IC1

and

associated

components

and

its

circuitry

is

completely

conventional.

The

supply

delivers

55

or

60

milliamperes

before

voltage

15

Page 18

developed

across

current

sense

resistor

R2

limits

the

current.

The

negative

power

supply

voltage

regulator

consists

of

IC2,

Ql

and

associated

components

and

adjusts

its

output

to

have

the

same

magnitude

as

the

regulated

+9

volt

output.

No

current

limiting,

other

than

that

supplied

by

R8,

is

provided.

2.3

KEYBOARD

CIRCUIT

The

keyboard

circuit

consists

of

IC3

thru

IC7,

IC9,

IC10

and

related

circuitry.

The

keyboard

contains

a

string

of

thirty-six

100-ohm

resistors

connected

between

pins

A5

and

A6.

The

current

through

the

resistor

string

is

regulated

by

IC7

so

that

the

drop

across

R79

and

R80

is

exactly

4.5

volts.

R79

is

set

so

that

the

voltage

at

pin

A6

is

exactly

-4.5

volts.This

sets a scale

factor

of 3 volts

per

octave

(250

mv

per

semitone).

2.3.1

TRIGGERING

(SINGLE)

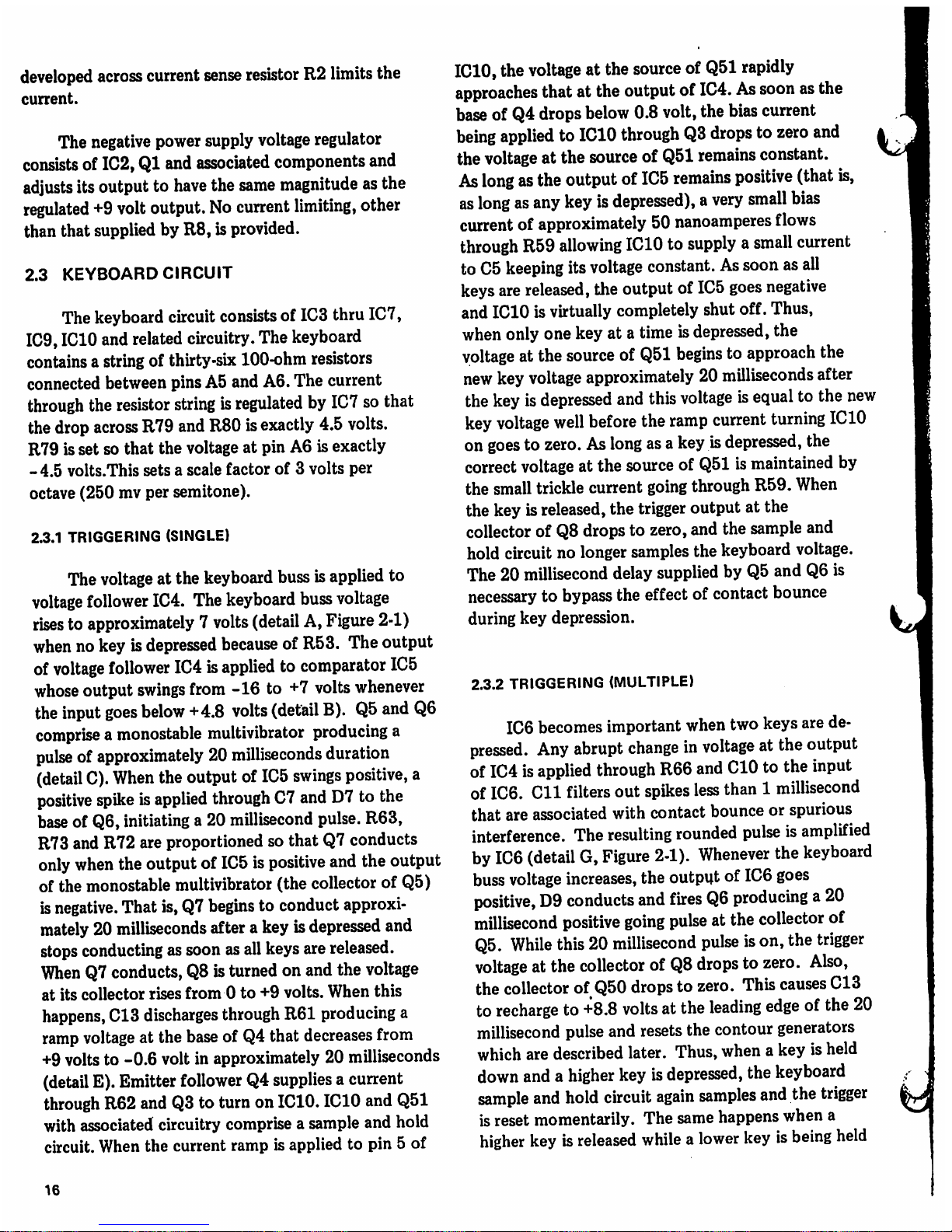

The

voltage

at

the

keyboard

buss

is

applied

to

voltage

follower

IC4.

The

keyboard

buss

voltage

rises

to

approximately

7

volts

(detail

A,

Figure

2-1)

when

no

key

is

depressed

because

of

R53.

The

output

of

voltage

follower

IC4

is

applied

to

comparator

IC5

whose

output

swings

from

-16

to

+7

volts

whenever

the

input

goes

below

+4.8

volts

(detail

B).

Q5

and

Q6

comprise

a

monostable

multivibrator

producing

a

pulse

of

approximately

20

milliseconds

duration

(detail

C).

When

the

output

of

IC5

swings

positive,

a

positive

spike

is

applied

through

C7

and

D7

to

the

base

of

Q6,

initiating

a

20

millisecond

pulse.

R63,

R73

and

R72

are

proportioned

so

that

Q7

conducts

only

when

the

output

of

IC5

is

positive

and

the

output

of

the

monostable

multivibrator

(the

collector

of

Q5)

is

negative.

That

is,

Q7

begins

to

conduct

approxi

mately

20

milliseconds

after

a

key

is

depressed

and

stops

conducting

as

soon

as

all

keys

are

released.

When

Q7

conducts,

Q8

is

turned

on

and

the

voltage

at

its

collector

rises

from 0

to

+9

volts.

When

this

happens,

C13

discharges

through

R61

producing

a

ramp

voltage

at

the

base

of

Q4

that

decreases

from

+9

volts

to

-0.6

volt

in

approximately

20

milliseconds

(detail

E).

Emitter

follower

Q4

supplies

a

current

through

R62

and

Q3

to

turn

on

IC10.

IC10

and

Q51

with

associated

circuitry

comprise

a

sample

and

hold

circuit.

When

the

current

ramp

is

applied

to

pin 5 of

IC10,

the

voltage

at

the

source

of

Q51

rapidly

approaches

that

at

the

output

of

IC4.

As

soon

as

the

base

of

Q4

drops

below

0.8

volt,

the

bias

current

being

applied

to

IC10

through

Q3

drops

to

zero

and

the

voltage

at

the

source

of

Q51

remains

constant.

As

long

as

the

output

of

IC5

remains

positive

(that

is,

as

long

as

any

key

is

depressed),

a

very

small

bias

current

of

approximately

50

nanoamperes

flows

through

R59

allowing

IC10

to

supply

a

small

current

to

C5

keeping

its

voltage

constant.

As

soon

as

all

keys

are

released,

the

output

of

IC5

goes

negative

and

IC10

is

virtually

completely

shut

off.

Thus,

when

only

one

key

at a time

is

depressed,

the

voltage

at

the

source

of

Q51

begins

to

approach

the

new

key

voltage

approximately

20

milliseconds

after

the

key

is

depressed

and

this

voltage

is

equal

to

the

new

key

voltage

well

before the

ramp

current

turning

IC10

on

goes

to

zero.

As

long

as a

key

is

depressed,

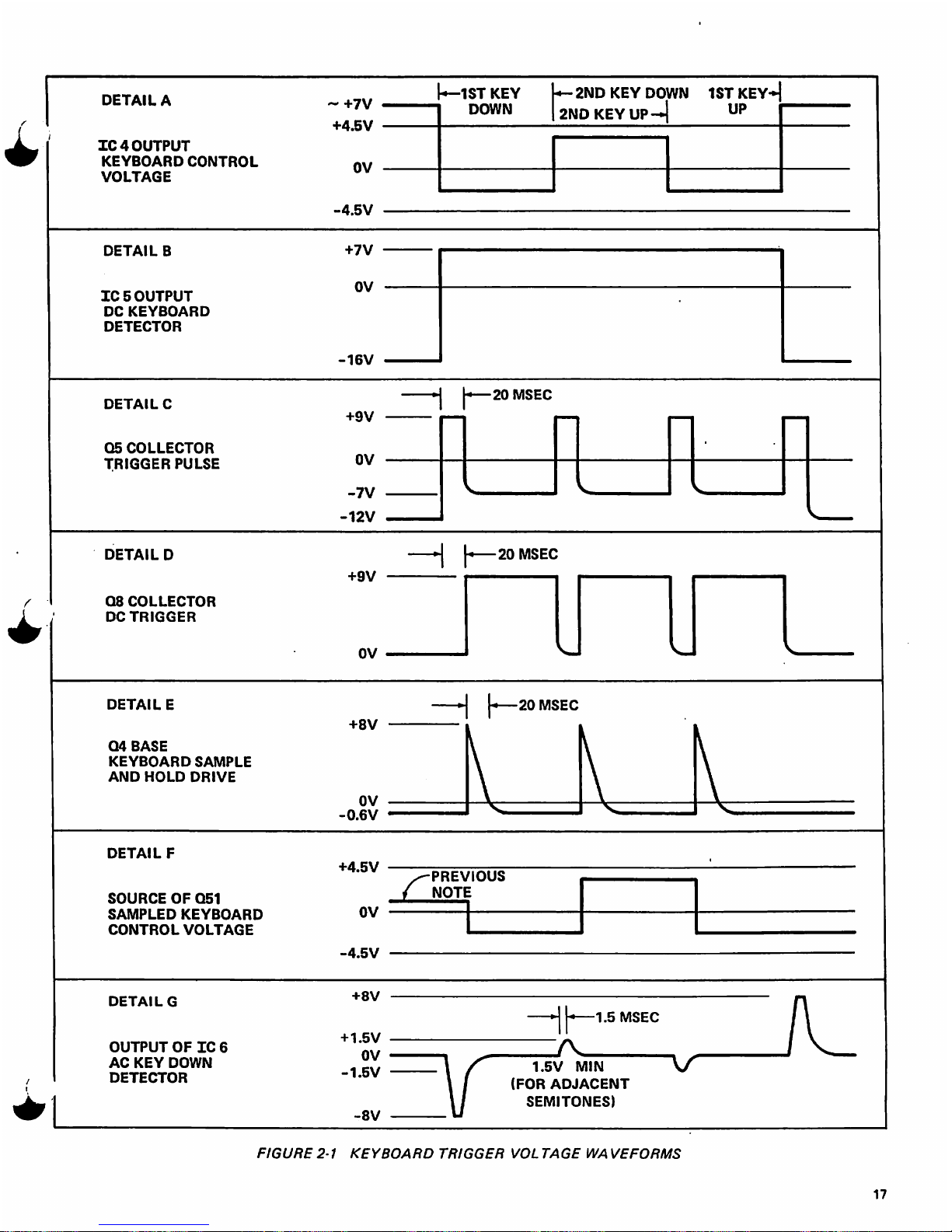

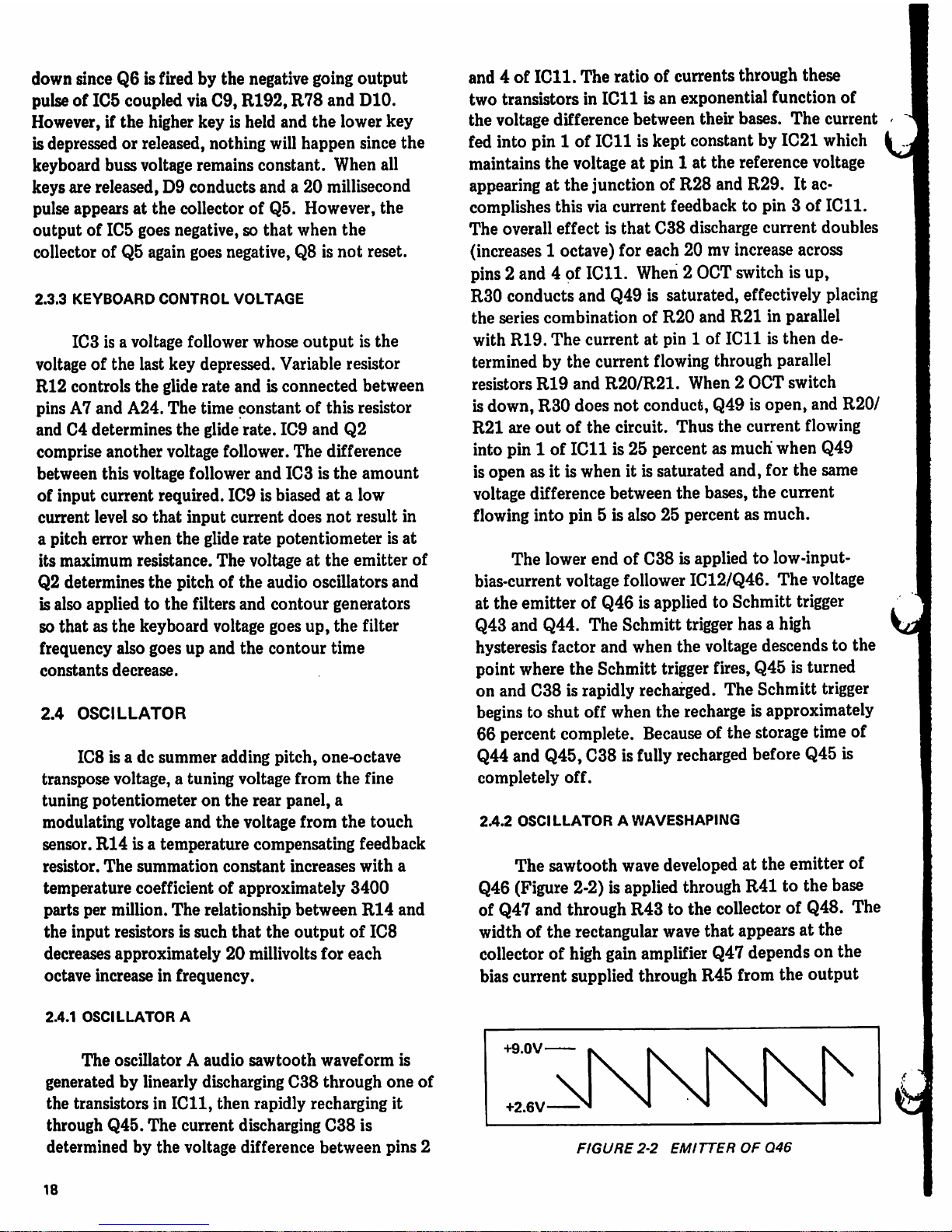

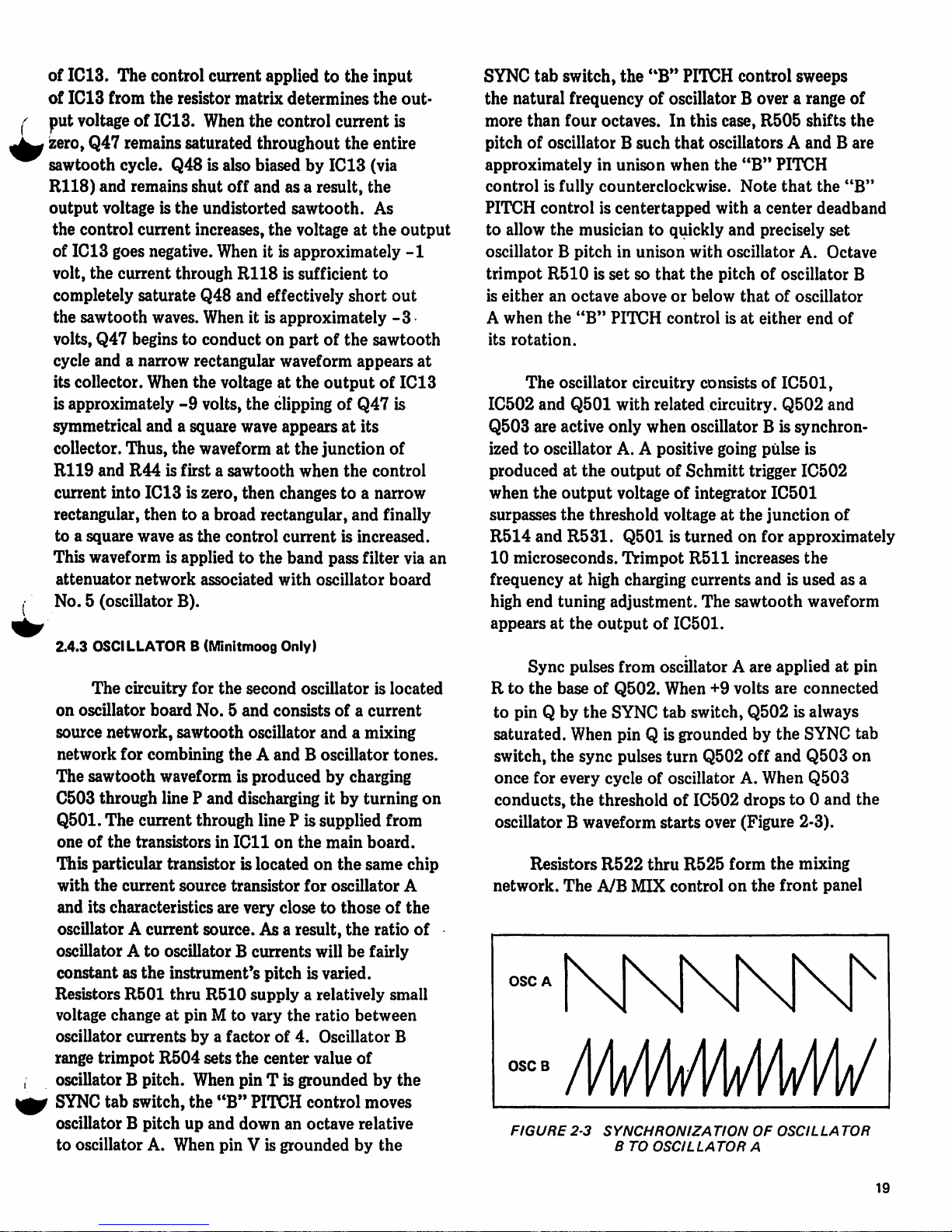

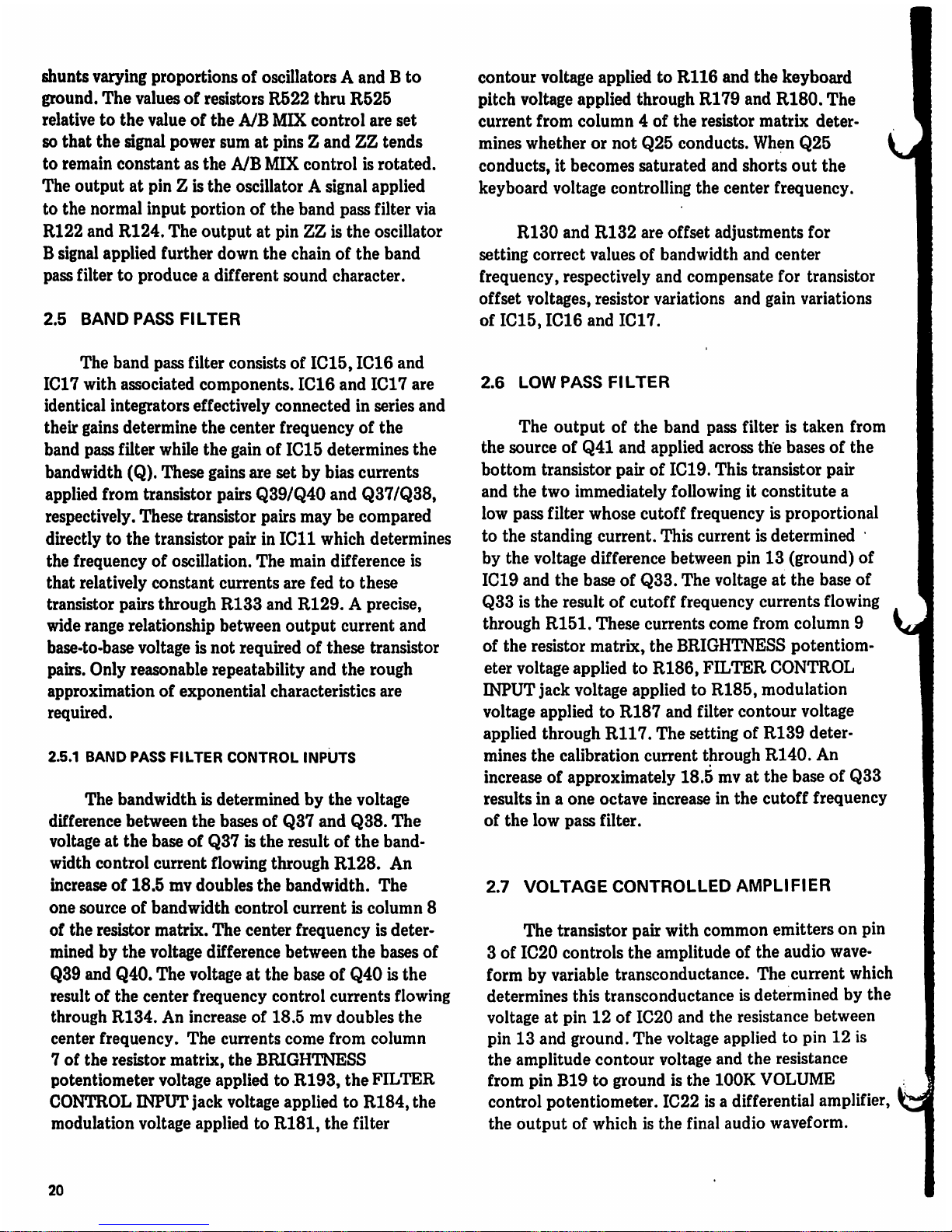

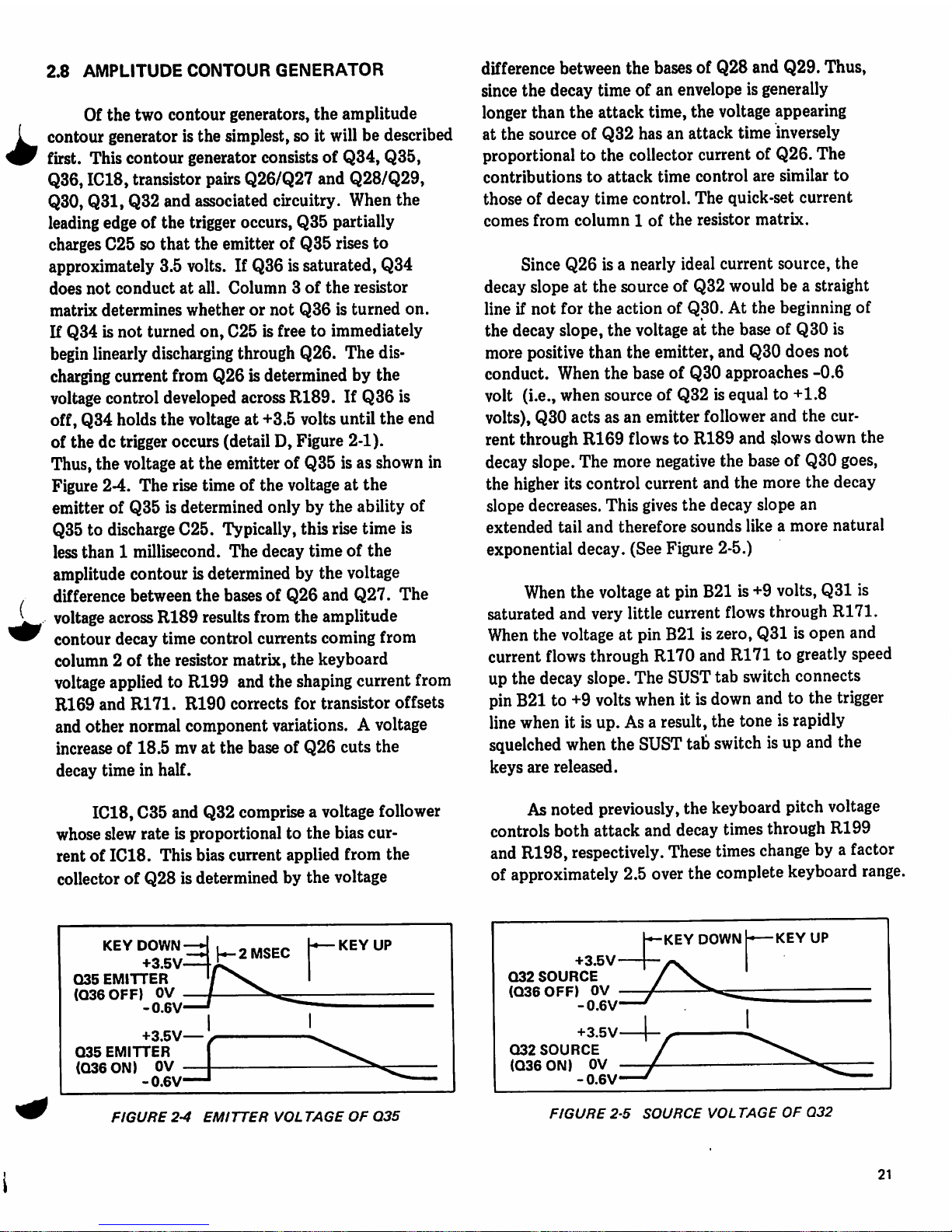

the