Page 1

Instruction Manual

for

Monroe Electronics, Inc.

Isoprobe® Electrostatic Voltmeter

Model 244A

Specifications subject to change without notice.

P/N 0340074

053013

100 Housel Ave PO Box 535 Lyndonville NY 14098 Fax: 585-765-9330 monroe-electronics.com

114

Page 2

TABLE OF CONTENTS

1.

2. BEWARE: HIGH VOLTAGE ........................................ PAGE 4

3.

4.

5. CONTROLS AND INDICATORS ................................. PAGE 10

6.

7.

APPENDIXES:

MODEL 1017 PROBE MOUNTING .......................................... APPENDIX I

10X GAIN MODIFICATION ...................................................... APPENDIX II

MODEL 1017 PROBE CLEANING PROCEDURES ................. APPENDIX III

MODELS 1017E/22D AND 1017S/22D GRADIENT

ADAPTERS .............................................................................. APPENDIX IV

WARRANTY AND RETURN ....................................... PAGE 3

SPECIFICATIONS ...................................................... PAGE 5

INSTALLATION ........................................................... PAGE 7

OPERATION ............................................................... PAGE 13

THEORY ..................................................................... PAGE 15

2

Page 3

WARRANTY

Monroe Electronics, Inc., warrants to the Owners, this instrument to be free from defects in

material and workmanship for a period of two years after shipment from the factory. This

warranty is applicable to the original purchaser only.

Liability under this warranty is limited to service, adjustment or replacement of defective parts

(other than tubes, fuses or batteries) on any instrument or sub-assembly returned to the factory

for this purpose, transportation prepaid.

This warranty does not apply to instruments or sub-assemblies subjected to abuse, abnormal

operating conditions, or unauthorized repair or modification.

Since Monroe Electronics, Inc. has no control over conditions of use, no warranty is made or

implied as to the suitability of our product for the customer’s intended use.

THIS WARRANTY SET FORTH IN THIS ARTICLE IS EXCLUSIVE AND IN LIEU OF ALL

OTHER WARRANTIES AND REPRESENTATIONS, EXPRESS, IMPLIED OR STATUTORY

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS. Except for obligations expressly undertaken by Monroe Electronics, in this

Warranty, Owner hereby waives and releases all rights, claims and remedies with respect to any

and all guarantees, express, implied, or statutory (including without limitation, the implied

warranties of merchantability and fitness), and including but without being limited to any obligation

of Monroe Electronics with respect to incidental or consequential damages, or damages for loss

of use. No agreement or understanding varying or extending the warranty will be binding upon

Monroe Electronics unless in writing signed by a duly authorized representative of Monroe

Electronics.

In the event of a breach of the foregoing warranty, the liability of Monroe Electronics shall be

limited to repairing or replacing the non-conforming goods and/or defective work, and in accordance with the foregoing, Monroe Electronics shall not be liable for any other damages, either

direct or consequential.

RETURN POLICIES AND PROCEDURES FACTORY REPAIR

Return authorization is required for factory repair work. Material being returned to the factory for

repair must have a Return Material Authorization number. To obtain an RMA number, call 585-

765-2254 and ask for Customer Service.

Material returned to the factory for warranty repair must be accompanied by a copy of a dated

invoice or bill of sale, which serves as a proof of purchase for the material.

Repairs will be returned promptly. Repairs are normally returned to the customer by UPS within

ten working days after receipt by Monroe Electronics, Inc. Return (to the customer) UPS charges

will be paid by Monroe Electronics on warranty work. Return (to the customer) UPS charges will

be prepaid and added to invoice for out-of-warranty repair work.

EXPEDITED FACTORY REPAIR:

All material returned to the factory by air or by an overnight service will be expedited. Expedited

factory repairs will be returned to the customer by the same mode of transportation by which the

material was returned to the factory for repair (i.e., material returned to the factory by an overnight

service will be returned to the customer by an overnight service).

NOTE: Return (to the customer) transportation expenses for expedited factory repairs will always

be at the expense of the customer despite the warranty status of the equipment.

FACTORY REPAIRS TO MODIFIED EQUIPMENT:

Material returned to the factory for repair that has been modified will not be tested unless the

nature and purpose of the modification is understood by us and does not render the equipment

untestable at our repair facility. We will reserve the right to deny service to any modified

equipment returned to the factory for repair regardless of the warranty status of the equipment.

3

Page 4

BEWARE - - HIGH VOLTAGE

GENERAL:

Monroe Electronics ISOPROBE instruments are non- contacting voltage

followers.

This means an instrument indicating 1500 volts has its probe operating at

1500 volts off ground.

If it is accidentally touched, the probe will apply VERY BRIEFLY 1500

volts to the unwary participant.

Typically, a spark will jump which will be disturbing but not hazardous

electrically, (but you could recoil from the surprise and hurt yourself.)

SHORT CIRCUIT CURRENT:

The short circuit current that can be delivered by an ISOPROBE Voltmeter is limited to approximately 500

feeling for most people and therefore is clearly no hazard.

which is below the threshold of

µ

A

STORED ENERGY:

The high voltage spark is caused by the discharge of the capacitance of

the system through the body. This stored energy is typically in the order

of a few millijoules while the lethal level of stored energy has been

approximated at 27 joules.

A safety factor of better than 1000:1 therefore exists.

ALTHOUGH THE SPARK IS CLEARLY ANNOYING, IT WON'T HARM

YOU UNLESS YOU OVERREACT.

MONROE ELECTRONICS, INC.

LYNDONVILLE, NEW YORK

14098

4

Page 5

A. APPLICATIONS:

The Model 244A instrument permits accurate voltage measurements of

electrostatic or other high impedance sources without physical contact. It utilizes

an electrostatic chopper for low drift, and negative feedback for accuracy and

probe-to-surface spacing insensitivity.

B. FEATURES:

■ Integrated Solid State Circuitry

■ Good Accuracy

Stability

Reliability

■ Easy Maintenance

■ ±3kV Input Range

■ Fast Speed-of-Response

SECTION 1

SPECIFICATIONS

■ Specified AC Performance

■ Low Noise

■ Digital Liquid Crystal Display

■ HV/1000 Recorder Output

■ Connectable for unlimited multiple channel operation

C. RANGE: 0 to ±3000 volts DC.

D. STATIC ACCURACY:

The recorder output accuracy referred to the input is better than 0.10% of reading

or 0-1V whichever is greater. (Probe-to-surface spacing .020”, 0.5mm).

E. SPEED-OF-RESPONSE:

10-90% probe-to-surface spacing .040" (1.02mm), gain adjusted for critical

damping.

Speed of Response

typ. max.

1kV Step .......................................... 1.5 msec ................. 2.5 msec

2kV Step .......................................... 2.0 msec ................. 3.5 msec

3kV Step .......................................... 3.0 msec ................. 4.5 msec

F. SETTLING TIME:

typical - 3.5msec. 0-99% 1kV step, 040"(1.02mm) gain adjusted for critical

damping.

15 msec. 0-99.9% 1kV step, .040"(1.02mm)

5

Page 6

G. FREQUENCY RESPONSE:

Small signal bandwidth is related to amplitude. At 11 5 volts RMS bandwidth is

typically -3db at 300 Hz.

H. DRIFT:

Drift is specified with 1017S or E probes at .005" (.13mm) probe-to-surface

spacing, purged in a clean stable atmosphere.

1.

Less than 0.01 V/hr. non-cumulative after 1 hr. warm-up in an

uncontaminated atmosphere.

Indiscernible effects of line voltage variations, 10 to 90% relative humidity,

2.

15°C to 35°C temperature range.

I. NOISE (Referred to Input):

Probe-to-surface spacing = .005" (.13mm), 1017S or E probe 600 mV RMS or 2V

p-p wideband typical. See graphs for other aperture or probe-to-surface

spacings. Also check individual probe specifications.

J. SURFACE RESOLUTION:

Surface resolution is dependent upon probe aperture size and probe-to-surface

spacing. Refer to probe literature for specific information relative to probe being

used.

K. PROBE-TO-SURFACE SPACING ERRORS:

Independent balance and zero adjustments allow voltage readings independent

of probe-to-surface spacing. The stability of these adjustments relates to the

same factors as does drift.

L. METER:

Four digit auto-zero, auto-symmetry, auto-polarity meter, with a liquid crystal

readout.

M. RECORDER OUTPUT:

A low voltage HV/1000 output is provided with a 3V max. output. The output is

capable of driving 10000 or greater.

N. POWER INPUT:

100, 117 or 230 volts ±10%, 50/60 Hz., 15 watts max.

O. PROBE DIMENSIONS:

Model 1017 series probes are 0.35" (8.9mm) x .35" (8.9mm) x 2.85" (72.4mm);

weight 6% oz. (180 gm).

P. SIZE AND WEIGHT):

Size 4" (10.2cm) high x

oz. (3.26kg.).

8^/ 2"

(21.6cm) wide x 15" (38.1 cm) deep. Weight 7 lbs. 3

6

Page 7

SECTION 2

INSTALLATION

CAUTION:

Before plugging instrument in, make certain that it is matched to local power line

voltage. The factory set line voltage is indicated on a label directly below the power

connector and in the small window in the fuse drawer.

In the event that it is desired to change the operating voltage of the instrument (or

inspect or replace the fuses), squeeze the tab on the drawer and remove the drawer.

Slide the square insert out of the drawer, replace the fuse with the correct value and

orient the insert so that the desired line voltage shows through the window. Replace the

drawer in the power connector. CHANGE THE LABEL TO CORRESPOND. All units are

shipped wired for 115 VAC unless otherwise specified.

NOTE:

Wire Color Code For Line Cord Provided.

HIGH SIDE OF LINE - BLACK or BROWN

LOW SIDE OF LINE - WHITE or LIGHT BLUE

SAFETY GROUND - GREEN or GREEN/YELLOW

A. PROBE PURGING:

Probe purging improves instrument performance especially with regard to zero

stability, noise and sensitivity to variations in probe-to-surface spacing. Optional

Model 1017/22G purge kit available from Monroe Electronics maintains an even air

flow, reduces temperature variations and filters out dust and other particles.

Contact potential is a function of these variables and should be considered when

making any changes in the purging techniques. Care should be taken to maintain

the purged air as free from chemical vapor contamination as possible.

Probes may also be purged using clean, dry oil-free air from a local source or

through the use of dry nitrogen or other inert gas. Pressure needs only be sufficient

to maintain a positive flow of gas out of the sensitive aperture to prevent foreign

materials from entering and, in no case should it exceed

materials used should have low out-gassing properties.

For best results, leave purge in continuous operation. For long term storage, cover

the end of the probe with the plastic cap supplied or with aluminum foil to seal

against contamination.

B. MOUNTING:

The 1017 and all other compatible probes must be mounted with the sensitive

aperture facing the surface to be measured.

Vi

psi (14" w.c.). All

The probe must be electrically isolated for up to 3400V, since the probe acquires

the potential of the surface being measured.

Further probe mounting information is given in Appendix I.

7

Page 8

C. PROBE-TO-SURFACE SPACING:

CAUTION:

When operating at probe-to-surface spacing of less than 0.125 inches (3mm) -BEWARE OF PROBE-TO-SURFACE ARC-OVER.

Air is subject to dielectric breakdown when the probe-to- surface spacing is low

and the surface voltage is high. A destructive arc-over can occur damaging the

surface under test and/or the sensitive circuitry of the probe.

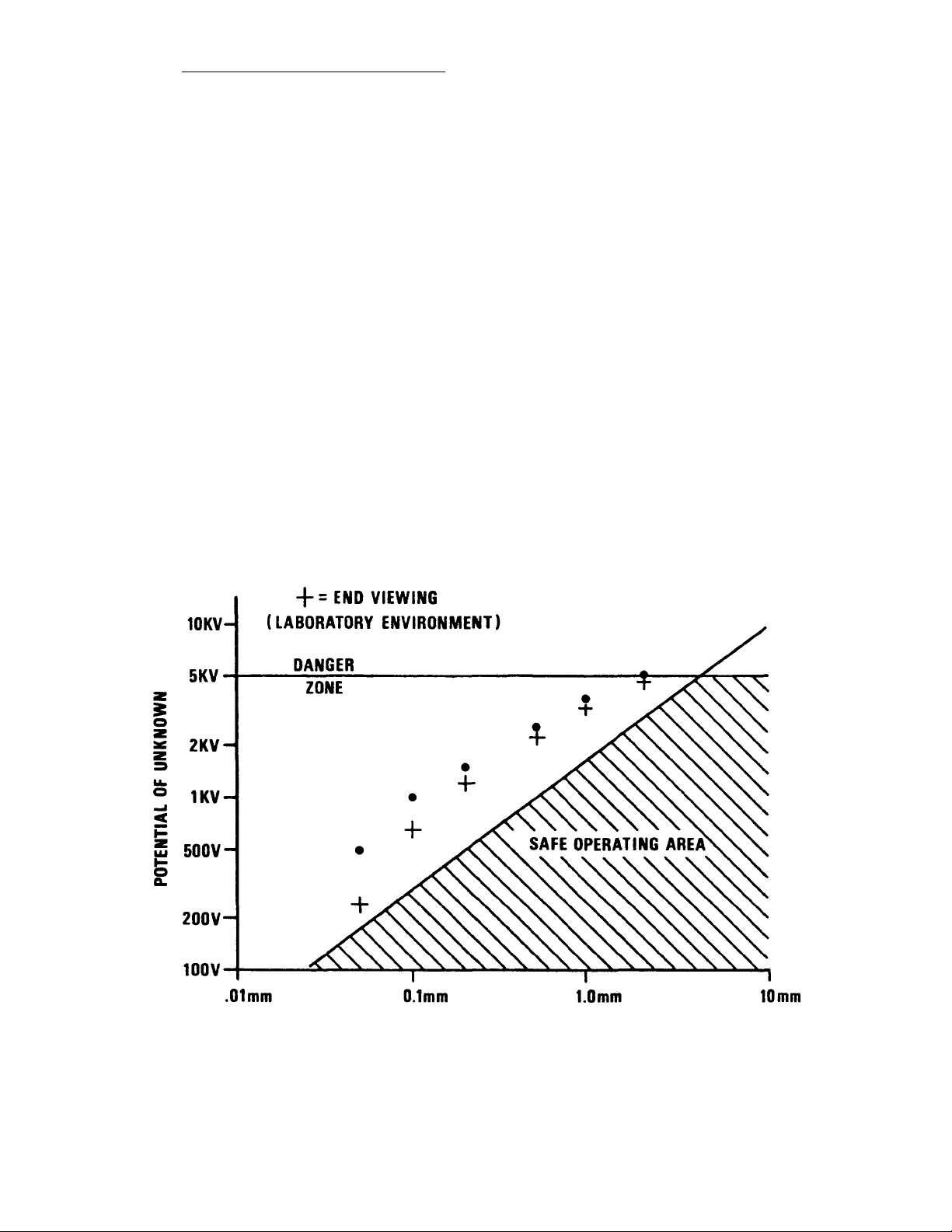

REFER TO FIGURE 2-1 TO DETERMINE THE SAFE PROBE-TO-SURFACE

SPACING FOR A GIVEN UNKNOWN VOLTAGE.

Probe to surface spacing should be maintained as close as physically reasonable

for best performance. Typical spacing range is from .005" (0.1mm) for unknown

voltages below 500 volts to over .125" (3mm) for unknown voltages up to 3000

volts.

As probe to surface spacing increases instrument performance will suffer:

1. Decreased Accuracy

2. Decreased Speed-of-Response

3. Decreased Surface Resolution

4. Increased Noise

5. Increased Drift

ARC BR EAKDO W N VS. P RO BE-T O-SURF AC E SPAC IN G

TYP. BREAKDOWN TEST DATA • = SIDE VIEWING

PROBE-TO-SURFACE SPACING

FIGUR E 2-1

8

Page 9

D. SYSTEM GROUNDING:

The instrument is normally grounded via power cord and the potential measured is

referenced to ground. A rear panel ground connection is provided.

E. OUTPUT CIRCUITRY:

The output connector is a BNC connector mounted to the rear panel. The output

voltage is the measured voltage divided by 1000. Range is ±3V.

F. REMOTE CONTROL (SLAVE CONTROL):

Provision is made for remote operation via J204 located on the rear panel.

External connections can be made as follows:

1. Parallel connect the inner and outer connection of the slave plugs of all

units.

2. Connect any solid state switch or relay capable of switching 30V DC and

sinking n x 10 mA DC, where n is the number of units to be controlled.

NOTE: Low side of switch must be system GRD.

G. MULTIPLE-UNIT. MASTER/SLAVE CONNECTION:

The 244A is designed to facilitate control of the standby/operate mode of slave units

by a master unit.

External connections are made as follows:

1. Connect all slave units (units to be controlled) as indicated in Section F.

2. Terminate the center conductor of the slave plug to the center conductor

of the master, and outer conductor with the outer connection.

9

Page 10

CONTROLS AND INDICATORS

FRONT PANEL CONTROLS - FIG. 3-1

A. STANDBY/OPERATE SWITCH:

Controls the operating condition of the unit.

1. STANDBY - Starts the probe oscillating, but leaves the H.V. disabled, unless

activated by the remote (rear "slave") connector.

2. OPERATE - Turns on the H.V. supplies, only if the probe is plugged in and

the fork is oscillating. This position overrides the remote control.

B. ON INDICATOR:

Indicates that the low voltage supplies are on and operational status is

controllable by remote operation.

C. OPERATE INDICATOR:

SECTION 3

Indicates that the H.V. is on and that the probe housing may be at any voltage

up to ±3400V. Excessive gain or excessive loading on the probe such as probe

contact to a grounded surface, causes the operate light to blink, indicating a

malfunction.

D. BALANCE:

Balances internal probe contact potential to obtain probe to surface spacing

insensitivity. This adjustment procedure is described in Section 4B (may also be

used for large zero offset when spacing insensitivity is not needed).

E. ZERO:

Compensates for unwanted offsets in the range of ±4 volts. This does not affect

probe-to-surface spacing sensitivity.

F. RESPONSE SPEED (GAIN):

Adjusts system speed-of-response, static accuracy and stability by varying openloop system gain. Excessive gain causes system instability and degradation in

static error. Insufficient gain produces static error and slow speed- of- response.

System gain and responses vary with probe-to- surface spacing and must be

compensated by adjustment of this control.

G. PROBE CONNECTOR:

Connector for attachment of 1017 probes. The connector is interlocked with the

operate switch and will shut down the high voltage section when probe is

disconnected.

NOTE: A special shortened pin is used in P201 (on probe) for safety purposes in

other instruments in the ISOPROBE Series.

10

Page 11

REAR PANEL CONTROLS - Fig. 3-2

H. RECORDER OUTPUT:

Output is 0V±3V for full scale. A BNC connector is provided on the rear panel.

The output voltage is equal to the voltage measured divided by 1000. Minimum

load resistance is 1k ohm.

I. MASTER JACK:

Allows other units with slave connections to be operated by this unit. The output

provides a switch closure when the front panel standby/operate switch is in the

OPERATE position.

J. SLAVE JACK:

Input for remote enable/disable of the high voltage section. In STANDBY a

closure between the center and outer conductors of the plug will enable the high

voltage if the probe is attached and the fork oscillating. The remote can be

overridden by switching the front panel switch to either OPERATE or OFF. The

switch should be capable of handling 30V open and n x 10mA, where n is the

number of units being controlled.

K. POWER ON/OFF SWITCH:

Main power to instrument is on when red ring is visible on side of rocker.

L. GROUND JACK:

5 way binding post connected to power line ground to provide system ground.

M. FUSE DRAWER:

Contains fuses and line voltage switching selector insert. Refer to "CAUTION"

note on Page 4.

11

Page 12

12

Page 13

SECTION 4

OPERATION

CAUTION:

Verify that instrument operating voltage matches local power line voltage. Refer to

Section 2.

PRECAUTIONARY NOTE

Model 244A is a non-contacting voltmeter. The potential of the probe will attempt to

follow the potential of any object within the field of view of the sensitive electrode (up to

±3400 volts) when the instrument is operating. In the interest of operator safety and also

to reduce high voltage stress within the instrument, it should be left in the STANDBY

mode whenever it is not being used and particularly when the probe will not be "looking"

at a surface of less than 3000V.

A. INITIAL SET-UP:

1. With PROBE mounted as previously described in Section 2, connect

probe plug to the probe receptacle on the instrument front panel.

2. Switch STANDBY/OPERATE switch to OPERATE.

3. Set RESPONSE SPEED (GAIN) control according to the probe-to-sur-

face spacing and desired speed-of-response. In the event the front panel

meter is the sole indicator of the instrument output, the normal static error

is very small and speed-of-response is non- critical. For 1/8" (3mm)

spacing, set at

½

of CW rotation.

NOTE:

Decreasing the probe-to-surface spacing has the same influence as increasing

the GAIN control. The GAIN control should, therefore, be re-adjusted whenever

the probe-to-surface spacing is altered if optimum speed-of-response is desired.

a. Connect a DC supply through a switch to a metal plate at the same

probe-to-surface spacing to be utilized (preferably the same surface if

practicable) as shown in FIGURE 4-1.

F

I

G

U

R

E

4

-

1

* Switch with low contact bounce - preferably H.V. Reed Relay Contact

b. Connect the OUTPUT to a recorder or scope.

13

Page 14

c. While closing the switch, observe the instrument output and adjust

GAIN for fastest speed-of-response with minimum overshoot in

step response.

Once properly adjusted, the GAIN control should require no

further attention unless the probe-to-surface spacing is altered.

The static follow-up error (difference in DC potential between the

unknown and the probe) of a carefully zeroed and adjusted

instrument is typically less than 0.05% throughout its range.

d. With the probe aperture viewing a zero volt (or grounded) surface,

set ZERO control at mid-range. Adjust BAL (balance) control for

near zero reading.

B. SPACING INSENSITIVITY OVER LARGE PROBE-TO-SURFACE SPACING

RANGE:

This adjustment procedure will minimize offset errors due to variations in probeto-surface spacing. This adjustment is preferably done with a mechanical

positioning device and a grounded plate.

1. Position probe for minimum probe-to-surface spacing.

2. Adjust for a meter reading of zero, as described in Sect. A3d above.

3. Re-position to maximum probe-to-surface spacing and adjust BAL

control for a meter reading of zero.

4. Return to the minimum spacing and re-adjust ZERO. Repeat this

procedure until the degree of spacing insensitivity desired is reached.

The stability of this adjustment is directly related to zero drift and the

probe-to-surface spacing.

14

Page 15

SECTION 5

THEORY

A.

GENERAL: Principle of Operation (See Figure 5-1)

The electrostatic electrode "looks" at the surface under measurement through a

small hole at the base of the probe assembly. The chopped A.C. signal induced

on this electrode is proportional to the differential voltage between the surface

under measurement and the probe assembly. Its phase is dictated by the D.C.

polarity.

The reference voltage and this mechanically modulated signal, conditioned by

the high input impedance preamplifier and signal amplifier are fed to a phase

sensitive detector whose output D.C. amplitude and polarity are dictated by the

amplitude and phase of the electrostatically induced signal relative to the

reference signal. The output of the phase sensitive detector feeds a D.C.

integrating amplifier. Its output polarity is inverted to that of the unknown. The

output of this amplifier is used to drive a H.V. amplifier (AV = -300) which in turn

drives the probe to the same potential as that of the surface under

measurement.

The probe is driven to a D.C. voltage typically within 0.1 % of the potential of the

unknown for a .040" probe-to-surface spacing. By simply metering the output of

the H.V. amplifier, one has an accurate indication of the unknown potential.

B. NULL BALANCE:

This instrument's basic operating principle, i.e., "field-nulling" provides a high

degree of immunity to errors in measurement caused by variations in probe-tosurface separation,. (As long as the probe and the surface under measurement

are at the same potential the electrical field between them is zero, neglecting

fringing, regardless of the probe-to-surface distance.)

If, however there exist voltage sources in the vicinity of the sensitive electrode

which are independent of the unknown to be measured, the offsets produced will

detrimentally affect the spacing independence. Such voltage sources include

contact potential differences among the internal probes parts, small specks of

charged dust particles, etc.

The null balance circuitry is provided to neutralize such offsets by applying a

voltage directly to the sensitive electrode.

C. ZERO:

The instrument's zero control is a voltage source connected in the metering

circuitry. It is used to overcome offsets produced by voltage sources external to

the probe.

D. GAIN:

The instrument functions as a closed loop unity gain voltage follower. Its open

loop gain from probe to integrator is determined by the gain of various amplifiers.

The exact gain required for optimum transient responses during a specific

measurement is determined by the probe-to-surface spacing used. In order to

accommodate measurements at various probe-to-surface spacings, a front panel

gain control is provided which controls the gain of the signal amplifier.

14

Page 16

Isoprobe® Electrostatic Voltmeter

Simplified Block Diagram

FIGURE 5-1

15

Page 17

APPENDIX I

MODEL 1017 PROBE MOUNTING

The Monroe Electronics, Inc. Model 1017 Miniature Probe is intentionally constructed

with no mounting devices as any such mounting device would serve only to enlarge the

physical dimensions. It is, therefore, left to the user to devise a method of mounting the

probe to suit his individual needs and to realize the fullest potential of the inherently

small size.

As supplied, the probe is partially jacketed by a length of irradiated polyolefin shrinkable

tubing. This jacket provides insulation of sufficient dielectric strength that the probe may

be hand-held or clamped using light pressure for use within the operating range of the

Model 244A ISOPROBE Electrostatic Voltmeter.

This tubing is otherwise not essential to the operation of the probe. IT MAY BE

REMOVED AND DISCARDED, IF DESIRED. It must, in fact, be removed if the probe is

to be disassembled for any purpose such as cleaning (in those procedures involving

removal of the case). A sharp model maker's knife may be used to slit the tubing using

CAUTION to assure that the cable jacket is not nicked or slit.

If replacement is required, a 25/s inch length of ALPHA FIT221-3/s or equivalent is

recommended. Apply heat only long enough to shrink the tubing in place as damage to

the sensitive electronics and adhesives within the probe may result from prolonged

elevated temperature on the outside of the case.

When devising fixturing for the Model 1017 probe, consideration must be given to the

fact that the normal operating range of the Model 244A ISOPROBE®Electrostatic

Voltmeter is ±3000 volts and that the probe assumes the potential of the surface under

measurement within these limits. The probe, therefore, must be insulated from other

parts of the system.

Choice of insulating materials, although not critical in many applications, should be

limited, if possible, to "leaky" dielectric materials with relatively low volume resistivities

(in the general order of 1010 ohm-cm) as opposed to those such as polystyrene which is

a very good insulator. Example of "leaky" insulators are the phenol- ics. The primary

purpose in this is to provide a discharge path for the insulator which has a short

relaxation time. This is especially important in the vicinity of the sensitive aperture.

The Model 244A is capable of driving a capacitive load of several hundred picofarads

without severe degradation in performance. It is possible, therefore, to attach the probe

to some fixed portion of the apparatus via a metal clamp, so long as the metal clamp is

insulated from the remainder of the apparatus.

In any friction clamp design, the pressure (unit force) on the probe case should be kept

low, thus over as large an area of the case as possible as distortion of the gold plated

brass may otherwise occur.

16

Page 18

One possible configuration is illustrated in Figure A-l-1.

For general bench use burette or utility clamps attached to a ringstand or similar support may

prove adequate. These are available from scientific supply houses.

An attractive alternative to clamping is the use of double sided adhesive tape or fast-setting

polymerizing adhesives such as LOCTITE1 SuperBonder 495 cyanoacry- late adhesive or

equivalent which does not require long setting or curing time and provides a relatively permanent

bond. LOCTITE* is a registered trademark of and is available from: LOCTITE CORPORATION

Newington, CT 06111 (208)278-1280

17

Page 19

APPENDIX II

10X GAIN MODIFICATION

(For use with high resolution probes)

Due to the smaller aperture in high resolution probes (1017EH, 1017SH, 1017EJ),

electrostatic gain is lowered. As a result, it may not be possible to achieve optimized

transient response except at extremely close spacing.

System gain may be increased approximately tenfold by replacing R63 (10K, adjacent to

A5 in front corner of main PC board near meter – refer to picture) with a 1K, 14 W, 5%

carbon composition resistor.

To replace resistor:

1. Remove cover and locate R63.

2. Remove bottom panel from instrument (two #6-32 screws in center of

side panel).

3. Carefully remove the two #6-32 screws which hold the front panel to the

side rails (screws located just behind front feet) and move front panel so

that it does not interfere with replacement.

4. Unsolder and replace resistor.

5. Re-assemble instrument.

After this change has been made, adjustment of front panel gain will be difficult at close

probe-to-surface spacing when using standard probes. It is therefore suggested that

units so modified be tagged in some manner to alert the unwary user.

Front

Panel

18

Page 20

APPENDIX III

MODEL 1017 PROBE CLEANING PROCEDURES

DISASSEMBLY AND CLEANING:

It is impossible for the sensitive aperture in the probe to be covered by a window of any

sort which will permit the probe to operate normally.

So long as this aperture is open, foreign material may enter the volume associated with

the vibrating vane and generate undesired noise or DC offset, thereby impairing the

accuracy and utility of the instrument.

To maintain low noise and low offset, it is important that the probe be operated in as

clean an environment as practicable, that it be purged with filtered air or an inert gas

such as clean, dry nitrogen, and that it be periodically disassembled and cleaned.

Where practicable, it is recommended that the probe be installed with the sensitive

aperture downward and when not in use, wrapped with aluminum foil.

The necessity for cleaning is indicated when:

1. The output as indicated by the meter or the recorded record is excessively

noisy.

2. It is no longer possible to "null balance" the instrument using the BAL

adjustment and still remain within the range of the ZERO adjustment.

Cleaning Procedure #1

Disconnect probe cord from main unit.

1.

2. Remove probe from fixturing device if used.

3. Remove screw closest to sensitive aperture and loosen screw closest to

cable end.

4. Carefully slide cover directly off of probe.

NOTE: Some probes have one or more shims between the base and the

case. These will fall out of the case when it is removed. Retain them.

5. Once the case is removed and until it is replaced, the two vanes are

exposed and subject to damage, therefore, during cleaning VERY

CAREFUL HANDLING is required.

8. Cleaning should be done using an aerosol isopropyl alcohol or equivalent

solvent.

9. Areas to be checked for cleanliness are:

a. ) Sensitive electrode.

b. ) Two vanes, especially in the area of the sensitive electrode (both

sides).

c. ) The aperture in the case and surrounding area (inside and out).

6. CAREFULLY slide case back onto probe. Shim(s), if any, should be slid

into the case first in such a way that the hole in the shim(s) will be lined up

with the screw hole (in the case) closest to the aperture so that when the

screw is replaced, it will extend through the shim(s) before entering the

threaded hole in the probe base.

7. The toe of the base plate should abut the inner surface of the end of the

case.

8. Tighten screws with torque consistent with their size.

19

Page 21

Cleaning Procedure #2

NOTE: Use this procedure only if aperture diameter is 1.75 mm or greater.

1. Disconnect probe cord from main unit.

2. Immerse approximately 1 cm of the end of the probe in the cleaning fluid.

NOTE: Cleaning solvent to be CLEAN ethyl or isopropyl alcohol.

3. Clean until no dirt is visible in aperture.

4. Allow all solvent to evaporate before operating probe.

Cleaning Procedure #3 (Using ultrasonic cleaner for probes with small apertures.)

1. Remove case as described in Cleaning Procedure #1.

2. Immerse end of vanes and electrode housing in clean isopropyl alcohol in

ultrasonic cleaner, when clean, set aside to allow solvent to evaporate.

3. Clean case thoroughly in same solvent.

4. Reassemble as in Cleaning Procedure #1.

20

Page 22

APPENDIX IV

MODELS 1017E/22D AND 1017S/22D GRADIENT

ADAPTERS

A. SPECIFICATIONS:

Range: With Model 244 or 279; 0 to ±3000 volts/mm (Refer to Note 1)

Accuracy: Better than 2% (Refer to Note 2)

Drift: <0.01 V/mm per hour (Refer to Note 2)

Noise: With Model 244 or 279; <0.3 V/mm RMS <2V/mm p-p referred to input

(Refer to Note2)

Speed of

Response: With Model 244 or 279; <4 mS max. 3 mS typ., 10% to 90%

Resolution: Approx. 3 cm dia. spot (Refer to Note 2)

Dimensions: 19/32” (40mm) dia. x 11/8” (29mm) high

Attitude: End-view is axial

Side-view is radial

NOTES:

1.) Limited to approx. 2kV/mm air gap breakdown

2.) Specified uncontaminated atmosphere at 1 centimeter probe-to-surface

separation

B. DESCRIPTION:

These adapters are designed to convert an ISOPROBE Electrostatic Voltmeter

into an Electrostatic Fieldmeter. This fieldmeter mode of operation makes

possible non-contacting measurement of surface potentials of virtually any

magnitude so long as the probe is mounted at the proper distance.

The adapters consist of a metal cup with a carefully chosen aperture, through

which the Model 1017, or 1034 probe “looks”, attached to a small insulated box

designed to slip over the end of the probe and a 10 foot flexible grounding wire

which is attached to the metal cup.

C. INSTALLATION:

1017E/22D: Using a 1/16” Allen wrench, retract the setscrew enough to allow the end of

the probe to slide in to the square opening until the apertures align. Gently re-tighten the

setscrew against the probe case and back off 1/4 turn. DO NOT OVERTIGHTEN. The

adapter is now prepared for calibration.

21

Page 23

1017S/22D: Remove the #0-80 x 3/32” machine screw from the end of the probe nearest

the aperture end of the probe. Replace the screw just removed with the longer #0-80 x

3/16” machine screw furnished with the gradient adapter. Slide the probe into the

adapter until the apertures align. Snug the screw against the body of the adapter and

back off 1/4 turn. DO NOT OVERTIGHTEN. The adapter is now prepared for calibration.

D. CALIBRATION:

Calibration of the Model 1017E/22D Gradient Adapter is acheived by sliding the

adapter forward or backward on the probe until the ISOPROBE® Voltmeter

output indicates exactly one-tenth of a known applied voltage at 1 cm probe-tosurface spacing.

Calibration of the Model 1017S/22D Gradient Adapter is accomplished by offcentering the aperture of the gradient adapter in relation to the aperture of the

probe until the ISOPROBE® Voltmeter output indicates exactly one-tenth of a

known applied reference voltage at 1 cm probe-to-surface spacing. This offcentering action is accomplished by sliding the adapter forward or backward on

the probe case.

Note: In either event above, the Gradient Adapter plate should be grounded to

the electrostatic voltmeter frame and the instrument must be properly zeroed.

(See operating instructions.) Tighten the screw sufficiently to hold the adapter in

place DO NOT OVERTIGHTEN and re-check calibration.

22

Page 24

PREVISION NOTES*

MODEL 244AK

The Monroe Electronics Model 244AK is virtually identical to Model 244A except that:

The Recorder Output of Model 244AK is

1/2ooth

of the ±3000 volt range of the instrument thus

producing an output signal of up to ±15 volts capable of driving 5000 ohms or greater.

The above should be borne in mind when using this manual.

M O D E L 2 4 4 A K O U T P U T S T A G E

23

Loading...

Loading...