Page 1

Instruction Manual

for

Monroe Electronics, Inc.

Multi-Point Fieldmeter and

Alarm System

Model 177A

Specifications subject to change without notice.

P/N 0340184

111113

Firmware v 1.12

Software v1.05

100 Housel Ave PO Box 535 Lyndonville NY 14098 585-765-2254 fax: 585-765-9330 monroe-electronics.com

Page 2

TABLE OF CONTENTS

WARRANTY ................................................................................................. Page 2

RETURN POLICIES AND PROCEDURES .................................................... Page 2

Section 1 GENERAL .................................................................................................... Page 3

Section 2 SPECIFICATIONS ........................................................................................ Page 4

Section 3 ELECTRONIC FIELDS AND FIELDMETERS ................................................ Page 5

Section 4 INSTALLATION ............................................................................................ Page 8

Section 5 PRINCIPLE OF OPERATION ...................................................................... Page 10

Section 6 USING 1036E AND 1036F SENSORS ........................................................ Page 11

Section 7 TYPICAL SETUP ........................................................................................ Page 17

Section 8 OPERATION ............................................................................................... Page 18

Section 9 177A SOFTWARE ...................................................................................... Page 22

Section 10 PROGRAMMING VIA THE FRONT PANEL ................................................ Page 28

Section 11 OPTIONAL 4 – 20 mA MODULE ................................................................. Page 29

Section 12 UPGRADING THE FIRMWARE .................................................................. Page 32

APPENDIX I PROBE CONNECTION OPTIONS

APPENDIX II INTRINSIC SAFETY BARRIERS

APPENDIX III RS-485 CONNECTION DATA

APPENDIX IV MODBUS PROTOCOL

APPLICATION NOTE APNE-0003 - Fieldmeter Measurement Techniques Using Model 1036 Probes

APPLICATION NOTE APNE-0014 - Electrostatic Charging In Web Converting

APPLICATION NOTE APNE-0015 - Electric Fields and Fieldmeters in Web Converting

APPLICATION NOTE APNE-0016 - Static Control in Web Converting

Accessories Included:

Manual

110V Line Cord

220V Line Cord

DB9 M/F Straight-Thru Cable

USB A-Male/B-Male Cable

Mounting Hardware

2 – 2 Position terminal block plugs

4 – 6 Position terminal plugs

Page 3

WARRANTY

Monroe Electronics, Inc., warrants to the Owners, this instrument to be free from defects in material

and workmanship for a period of two years after shipment from the factory. This warranty is

applicable to the original purchaser only.

Liability under this warranty is limited to service, adjustment or replacement of defective parts (other

than tubes, fuses or batteries) on any instrument or sub-assembly returned to the factory for this

purpose, transportation prepaid.

This warranty does not apply to instruments or sub-assemblies subjected to abuse, abnormal

operating conditions, or unauthorized repair or modification.

Since Monroe Electronics, Inc. has no control over conditions of use, no warranty is made or implied

as to the suitability of our product for the customer’s intended use.

THIS WARRANTY SET FORTH IN THIS ARTICLE IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESS, IMPLIED OR STATUTORY INCLUDING

BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS.

Except for obligations expressly undertaken by Monroe Electronics, in this Warranty, Owner hereby

waives and releases all rights, claims and remedies with respect to any and all guarantees, express,

implied, or statutory (including without limitation, the implied warranties of merchantability and

fitness), and including but without being limited to any obligation of Monroe Electronics with respect

to incidental or consequential damages, or damages for loss of use. No agreement or understanding

varying or extending the warranty will be binding upon Monroe Electronics unless in writing signed by

a duly authorized representative of Monroe Electronics.

In the event of a breach of the foregoing warranty, the liability of Monroe Electronics shall be limited

to repairing or replacing the non-conforming goods and/or defective work, and in accordance with the

foregoing, Monroe Electronics shall not be liable for any other damages, either direct or

consequential.

RETURN POLICIES AND PROCEDURES FACTORY REPAIR

Return authorization is required for factory repair work. Material being returned to the factory for

repair must have a Return Material Authorization number. To obtain an RMA number, call 585-765-

2254 and ask for Customer Service.

Material returned to the factory for warranty repair must be accompanied by a copy of a dated

invoice or bill of sale, which serves as a proof of purchase for the material.

Repairs will be returned promptly. Repairs are normally returned to the customer by UPS within ten

working days after receipt by Monroe Electronics, Inc. Return (to the customer) UPS charges will be

paid by Monroe Electronics on warranty work. Return (to the customer) UPS charges will be prepaid

and added to invoice for out-of-warranty repair work.

EXPEDITED FACTORY REPAIR:

All material returned to the factory by air or by an overnight service will be expedited. Expedited

factory repairs will be returned to the customer by the same mode of transportation by which the

material was returned to the factory for repair (i.e., material returned to the factory by an overnight

service will be returned to the customer by an overnight service).

NOTE: Return (to the customer) transportation expenses for expedited factory repairs will always be

at the expense of the customer despite the warranty status of the equipment.

FACTORY REPAIRS TO MODIFIED EQUIPMENT:

Material returned to the factory for repair that has been modified will not be tested unless the nature

and purpose of the modification is understood by us and does not render the equipment untestable

at our repair facility. We will reserve the right to deny service to any modified equipment returned to

the factory for repair regardless of the warranty status of the equipment.

2

Page 4

Section 1

GENERAL

Monroe Electronics’ Multi-Point Fieldmeter and Alarm System, Model 177A measures electrostatic

fields (potential gradient) in terms of voltage per unit distance. Using probe-to-surface separation as

a calibration factor enables use of this instrument for measurement of surface voltage as well.

As with other models of Monroe Electronics’ electrostatic fieldmeters, the Model 177A’s primary

application is measurement and monitoring of electrostatic charge accumulation. As a charge

increases on the surface of a material, the electrostatic field in the vicinity increases proportionately.

The Model 177A Multi-Point Fieldmeter and Alarm System produces a reliable output signal directly

proportional to the surface charge accumulation while making NO PHYSICAL CONTACT with the

material being monitored.

The Monroe Electronics Model 177A is an intrinsically safe system, using FM-listed Monroe

Electronics Model 1036 sensors, which continuously monitor the critical points in your facility to

detect and warn of electrostatic charge buildup before it becomes a problem. In a typical alarmactivated or PLC-connected setup, as static levels in your application surpass a preset value, beyond

which there may be a danger to personnel or possible disruption or destruction to the process or

product, an initial warning is triggered and the process is allowed to continue. If the problem is

rectified, the “warning” returns to a “normal” state. If the condition persists and the static level

exceeds a second, more crucial value, an alarm is activated. This second-level alarm can be used to

shut down the process until it is brought under control, or to further warn the operator of the more

serious condition.

Each Model 177A will monitor up to four locations using Monroe Model 1036 sensors placed at

distances up to 1000 feet from the instrument. Processes can be continuously monitored and

recorder outputs may be utilized for long term, drift free data acquisition. Cascading of up to 32 units

via RS485 permits monitoring of up to 128 sensor locations using a PC and the supplied software.

Factory Mutual Research Corp. approves the Model 1036 probes for use in Class I, Division 1,

Groups C and D hazardous locations. To comply, approved intrinsic safety (IS) barriers must be

used with the Model 1036. Reference FM Standard Class Number 3610:January 2000

This document provides the user, for hazardous and non-hazardous areas, with operational

instructions for Monroe Model 1036 sensors and the corresponding Model 177A Fieldmeter/Alarm

System.

3

Page 5

Section 2

SPECIFICATIONS

Monitor Console

Temperature Range: +15° to +45° C

Analog Outputs 10 V, 0 – 5V, (2.5V ±2.5V full sc ale); <10 impedance;

(user selectable): or simultaneous 4-20mA (optional)

RS232/485 Control: Channel status, channel disable / enable, group control / setup

Accuracy: ± 3% of full scale at analog outputs

± 3% of full-scale ±2 counts +0.3 counts/°C at front panel meters

Displays: Four 3½-digit LED’s, 0.6” (one per input channel)

Power Requirements: 90-260 VAC, 47-60 Hz; 13 W atts maximum

Alarm Relays: Per channel fail safe, NC (Form B)

System O.K.; Channel O.K.;

W arning; Alarm

Contact Ratings: DC: 1A, 30V; AC: .05A, 125V

Connector Styles: RS232/RS485 – DB9 Female

Probe – DB9 Female

Analog Out – BNC

Test Connector – Screw Terminals

4-20 mA option – Screw Terminals

Dimensions: 1¾ x 19 x 11 inches (4.45x 48.26 x 27.9 cm) Mounts in a standard 19” rack

Weight: 6 lbs

Relay Contacts: Switching load 30W 62.5VA; MAX switching voltage 110VDC, 125VAC

0.3A (rms), suggested limit 30VDC 1A MAX.

Closed for normal conditions

1036 E(H) & F(H) Sensors

Standard Range ± 10kV/inch

Optional: ± 1kV/cm (100kV/m)

± 10kV/cm (1MV/m)

± 20kV/cm (2MV/m)

± 1kV/inch

Drift: 1% of full scale (typical), non-cumulative, long-term when purged

according to manufacturer’s instructions.

Noise: <0.05% of full scale, peak-to-peak

Speed of

Response: 1 second maximum, 10%-90% of full scale

Dimensions

Model 1036E(H): 6.0 x 3.0 x 2.063 inches

(15.24 x 7.62 x 5.24 cm)

Model 1036F(H): 1.75dia. x 1.22 inches (4.45 x 3.11 cm)

Maximum

Cable Length: 1000 ft. (305 m)

Temperature

Range: -30° C to +80° C Models E & F

-30° C to +100° C Models EH & FH

Enclosure (optional)

Capacity: Two Monitor Consoles

Dimensions:

4.5 x 20 x 14 inches (11.4 x 50.8 x 35.6 cm)

Specifications are subject to change without notice.

4

Page 6

Section 3

ELECTRIC FIELDS AND FIELDMETERS

Electric Field

An electric field is a region in space characterized by the existence of an electric force (F) generated

by an electric charge (q). The electric force F acting on a charge q in an electric field is proportional

to the charge itself. The relationship of these quantities is expressed by the electrostatic force law

[1]:

F = qE

E is called the electric field strength and is determined by the magnitude and locations of the other

charges acting upon charge q

E = F/q

The electric field strength, E, is usually displayed in the unit of volt/meter (V/m), volt/centimeter

(V/cm) or volt/inch (V/in).

Electric Fieldmeters

Charge is often difficult or impossible to measure directly. We rely on detection and measurement of

the electric field from the charged object to determine the existence of the charged and to estimate

the relative magnitude of the charge. The electrostatic fieldmeter is the instrument that measures

electric field strength.

Electric field strength measurements can be difficult to measure and interpret correctly because of

several factors that can affect the electric field itself or affect the measurement of the electric field.

Guidance is given in this document to help understand or minimize the effects of these factors, and

to otherwise correctly interpret electric field measurements.

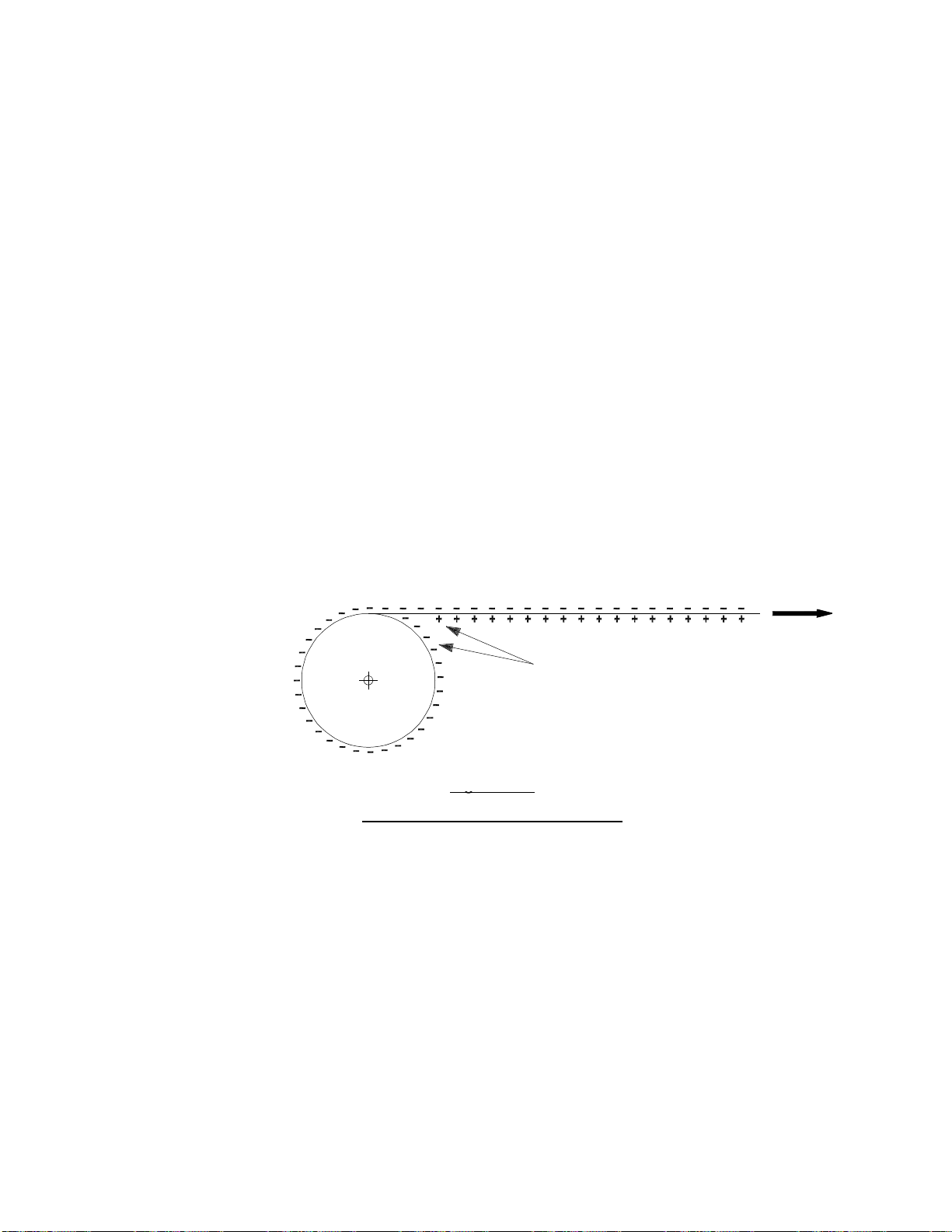

Fieldmeters measure the electrostatic field (voltage per unit distance) at the aperture of a grounded

probe. Ideally, a uniform electric field is established between a charged surface and a grounded

surface. The grounded surface may be the grounded surface of the fieldmeter probe, or the

fieldmeter probe may also be placed in the plane of a grounded surface (better). The electric field is

set up between the grounded surface and the charged surface some distance, D, away. Fieldmeters

are calibrated at a particular distance, such as V/inch or V/cm. Therefore, using the manufacturer’s

calibrated distance (one inch or one centimeter) makes the measurement easier to interpret. Probeto-surface separation should be carefully controlled for accurate measurement.

Probe

Charged

D

Figure 1: Probe-to-Charged-Surface Separation, D

Monroe Electronics electrostatic fieldmeters use a feedback-driven, null seeking design to assure

accurate, drift-free, non-contacting measurements. Accuracy is typically a moderate 3% in a carefully

controlled geometry.

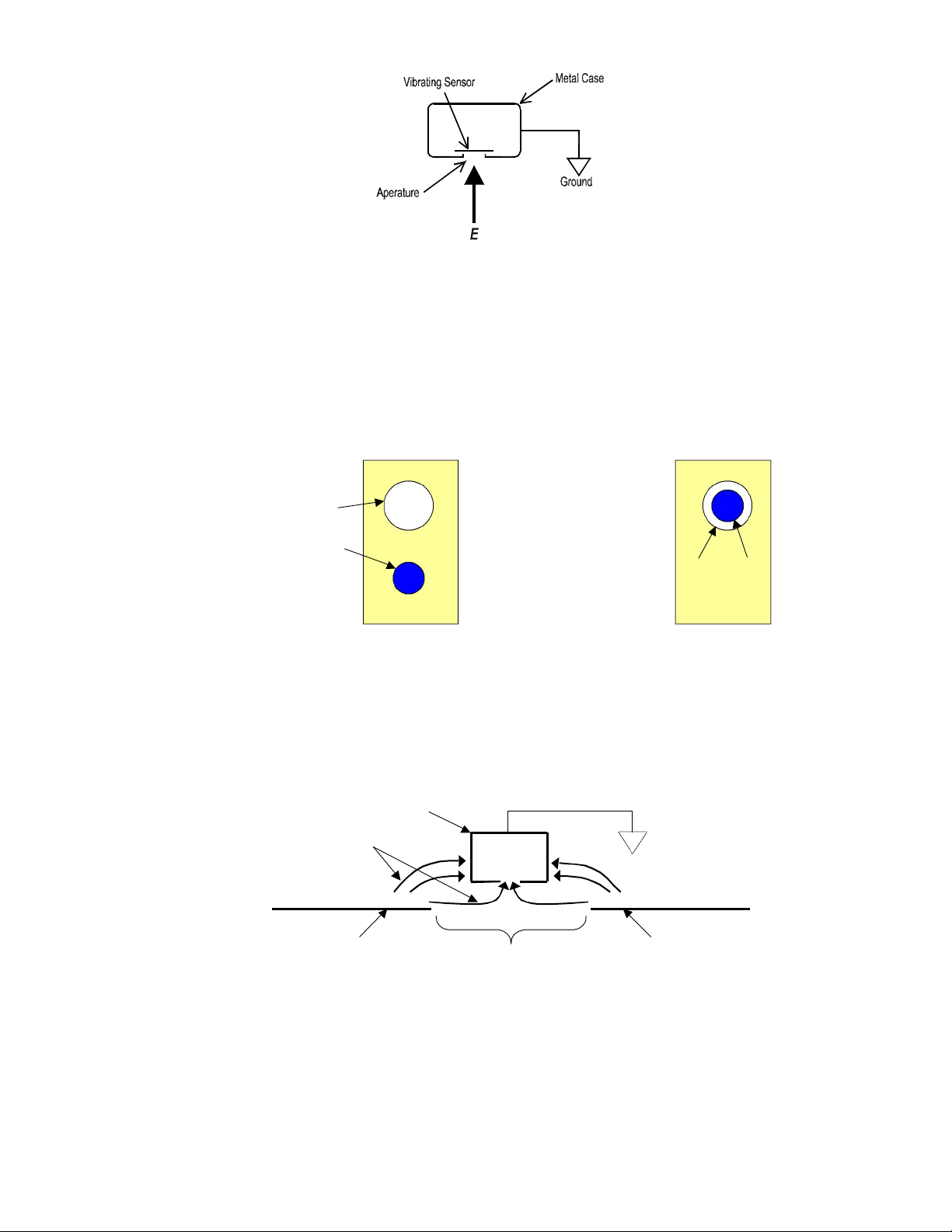

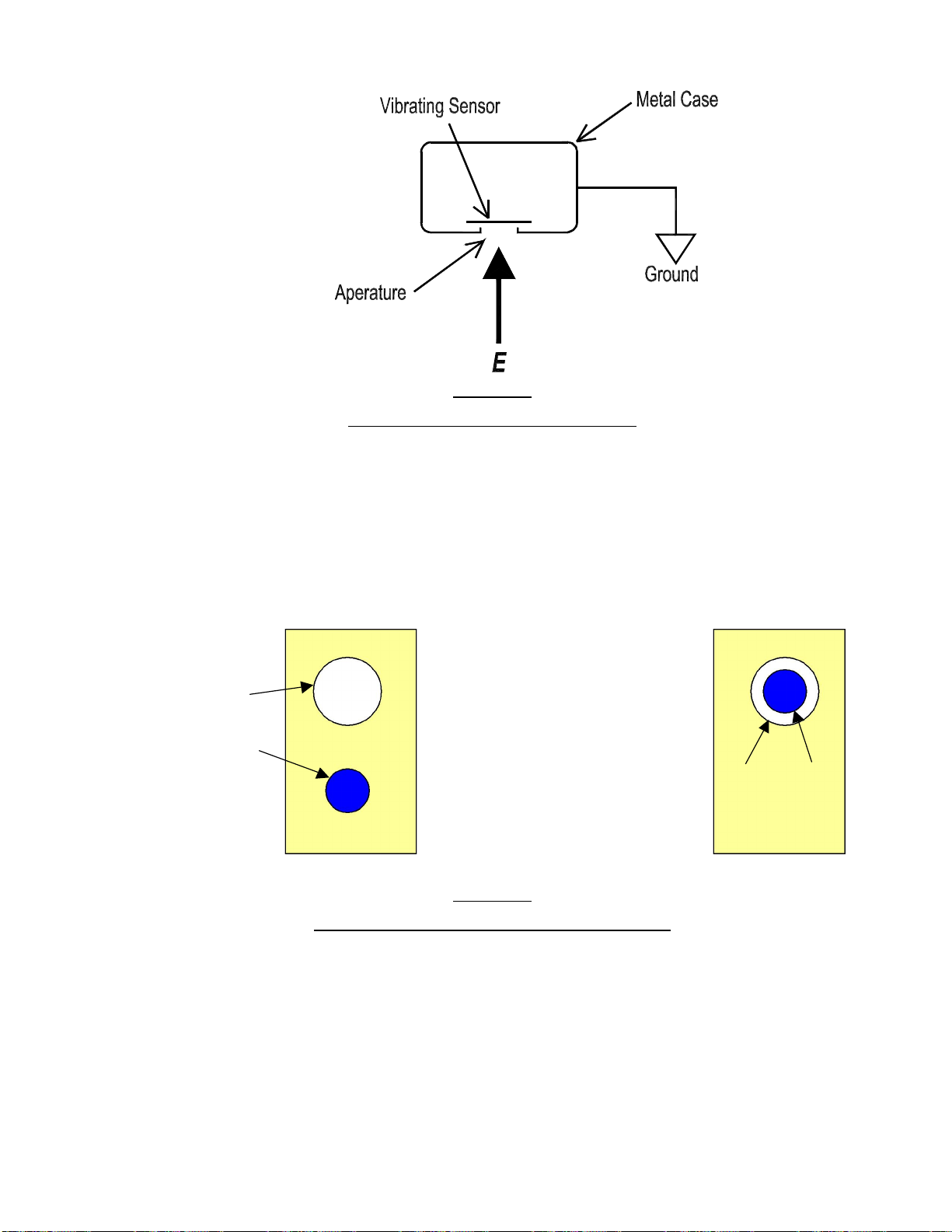

Figure 2 illustrates a Monroe Model 1036 fieldmeter probe in simple graphical form. This particular

fieldmeter is a chopper-stabilized design that operates reliably in both ionized and non-ionized

environments (refer to Appendix II.)

Surface

5

Page 7

Figure 2: Monroe Model 1036 Fieldmeter Probe

Electrostatic fieldmeters measure electric field strength by non-contacting means. All the charged

objects, voltage sources, and grounded conductors (including the fieldmeter probe housing) in the

general area affect the electric field strength measurement. The fieldmeter measures the electric

field strength only at its aperture. It does not have a viewing angle and it does not see the web or

object directly in front of it as a separate entity. This can be demonstrated by measuring the electric

field of an insulating sheet with a hole in it.

Place a ch arge on an insulati ng

sheet with a hole cut out of it

Hole

Probe

(a) (b)

(hole to be larg er than probe) .

Measure the electric field o ver

the sheet (a). Move the probe

over the hole and measure the

field again (b) .

The measured field strength in

(b) will be less than in ( a), but it

won’t be zero.

Probe Hole

Figure 3: Insulating Sheet Electric Field Demo, Top View

The field over the hole will not be zero, even though there is no charge directly in front of the probe

head. This is because the electric field at the probe aperture is a function of each charge on the

sheet, and is also a function of the concentration of field due to the grounded probe itself.

Probe

Perpendicular

Field Lines

- -

- - -

- -

- - -

Ground

+ + + + + + + + + + + + + + + + + + + + + +

Insulating Sheet

Hole

Insulating Sheet

Figure 4: Insulating Sheet Electric Field Demo

6

Page 8

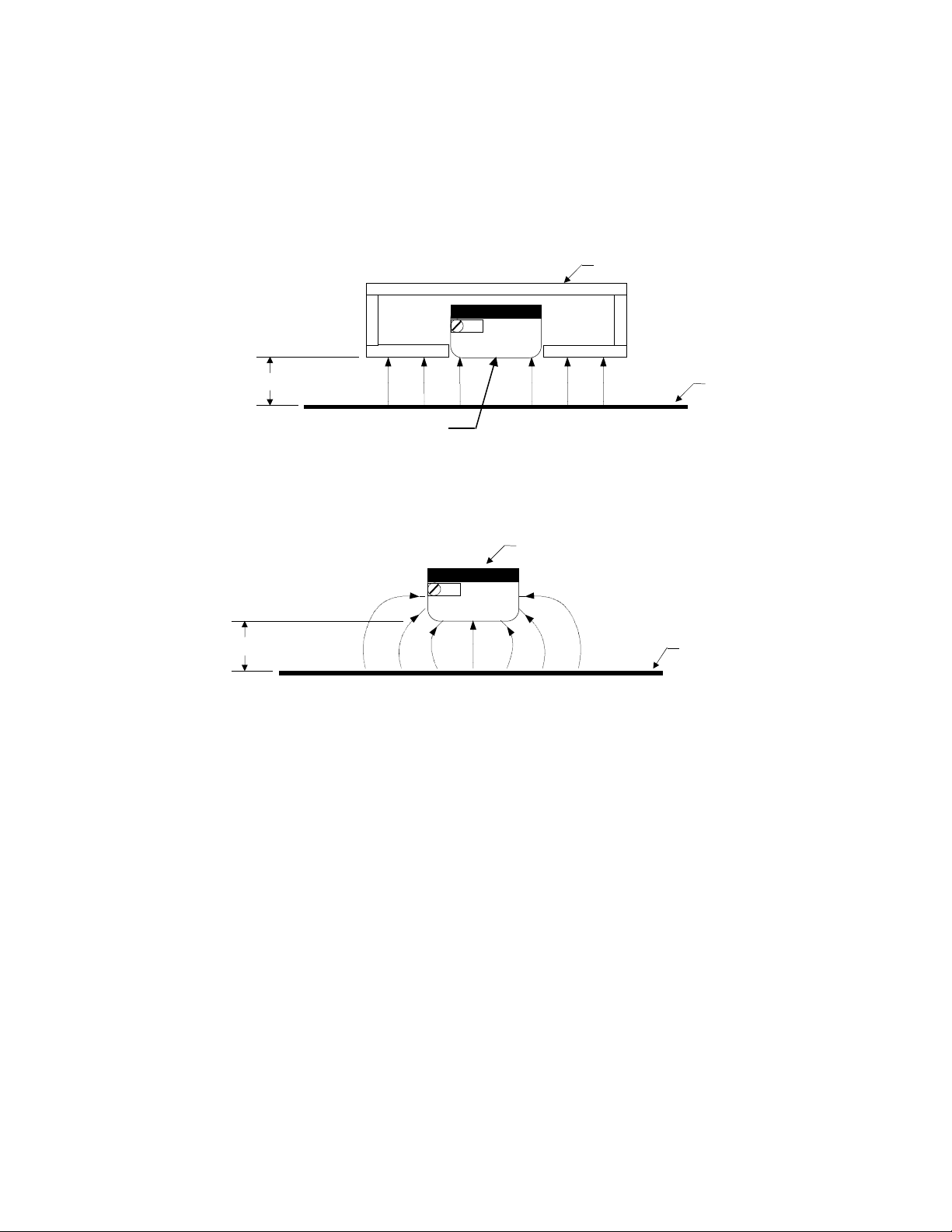

Effect of Probe Type on Fieldmeter Readings

For measurement of insulating web surfaces, it is best to maintain the same distance from the

fieldmeter to the web as when the fieldmeter was calibrated. Since most fieldmeters are calibrated at

one inch, their apertures should be positioned one inch from the web. The Model 1036E probe will

give accurate readings (as-is) at a measurement distance of one inch because its large grounded

face helps to create a uniform electric field near the aperture of the probe. The Model 1036F probe is

significantly smaller than the Model 1036E probe. Unless a grounded shroud is used to enlarge the

smaller ground plane of the 1036F probe, the fieldmeter readings will be about 12% high because

the electric field will converge on the small probe.

1036E Probe

1”

Straight field lines

Charged

Surface

Aperture

Figure 5: Field Lines Straight to 1036E Probe

1036F Probe

1”

Convergent field lines

Figure 6: Field Lines Converging to 1036F Probe

Charged

Surface

7

Page 9

Section 4

INSTALLATION

The Model 177A Multi-Point Fieldmeter and Alarm System, is designed to occupy a 1¾” space in a

standard 19” equipment rack. A minimum of 4” should be left behind the instrument to allow for cable

connections to the back panel.

For use in conjunction with central data collection and/or monitoring, the 177A may be placed at any

convenient, centralized location provided that the distance to any one probe does not exceed 1000

feet. The probes should be placed at any location requiring the monitoring of charge buildup.

An earth ground is necessary for proper operation. The chassis of the instrument may be grounded

through the line cord, but the chassis must be grounded. A three wire grounded line cord is provided

with the unit. The power line connector is located on the rear of the instrument.

Probe Inputs:

Four probe-input connectors are located on the instrument back panel. These are 9-pin subminiature

D female receptacles for mating to plugs on either the cables attached directly to the probes or

extension cables or adapter cables used with them. Two captive screws normally furnished with the

plugs may be secured to female thread inserts alongside each receptacle.

At least one probe must be connected for the 177A to operate.

Probes of different full scale sensitivities are available for use with the 177A. Each probe is marked

with a number stamped on the gradient cap to indicate its sensitivity (see Table 1). As a default,

each 177A is shipped with its firmware set to indicate 10KV full-scale. If the installation is using

probes other than 10KV full-scale, the 177A will need to be re-set for a different full-scale value. To

do this, reference the 177A Front Panel Programming Tree shipped with the unit. Place the 177A in

Set-up mode and then navigate to the PT (Probe Type) block as shown in the tree. Change the

probe type value stored to match the full-scale sensitivity of the probe being installed on that

channel. Store the value and then exit the set-up mode.

Outputs:

Two types of outputs are available on the back panel to represent the inputs. Voltage outputs may be

taken at four BNC connectors or 4-20 mA current outputs at screw terminals at JP2. Simultaneous 4channel 4-20 mA current output is optional.

The two possible voltage outputs are: [1] ±10 volts, [2] 0 – 5 volts (±2.5 volts full scale).

The positive 4-20mA loop outputs are at terminals 2, 4, 6 and 8 of JP2 for Channels 1-4,

respectively. The returns are at terminals 1, 3, 5 and 7, which are connected to common. The unit

provides a 12V nominal supply which gives a compliance range of 7 volts. An external supply may

be connected which will be used by all 4 channels. The external supply must be less than 25 volts.

Output compliance is external supply minus 5 volts. Note that this supply will be referenced to

chassis and Analog ground. These outputs are in addition to the four voltage outputs. See the

overview of the 4-20mA module in Section 11 on page 30 for more information.

NOTE: The wire color code for the line cord provided is:

HIGH SIDE OF LINE — BLACK or BROWN

LOW SIDE OF LINE — WHITE or LIGHT BLUE

SAFETY GROUND — GREEN or GREEN/YELLOW

8

Page 10

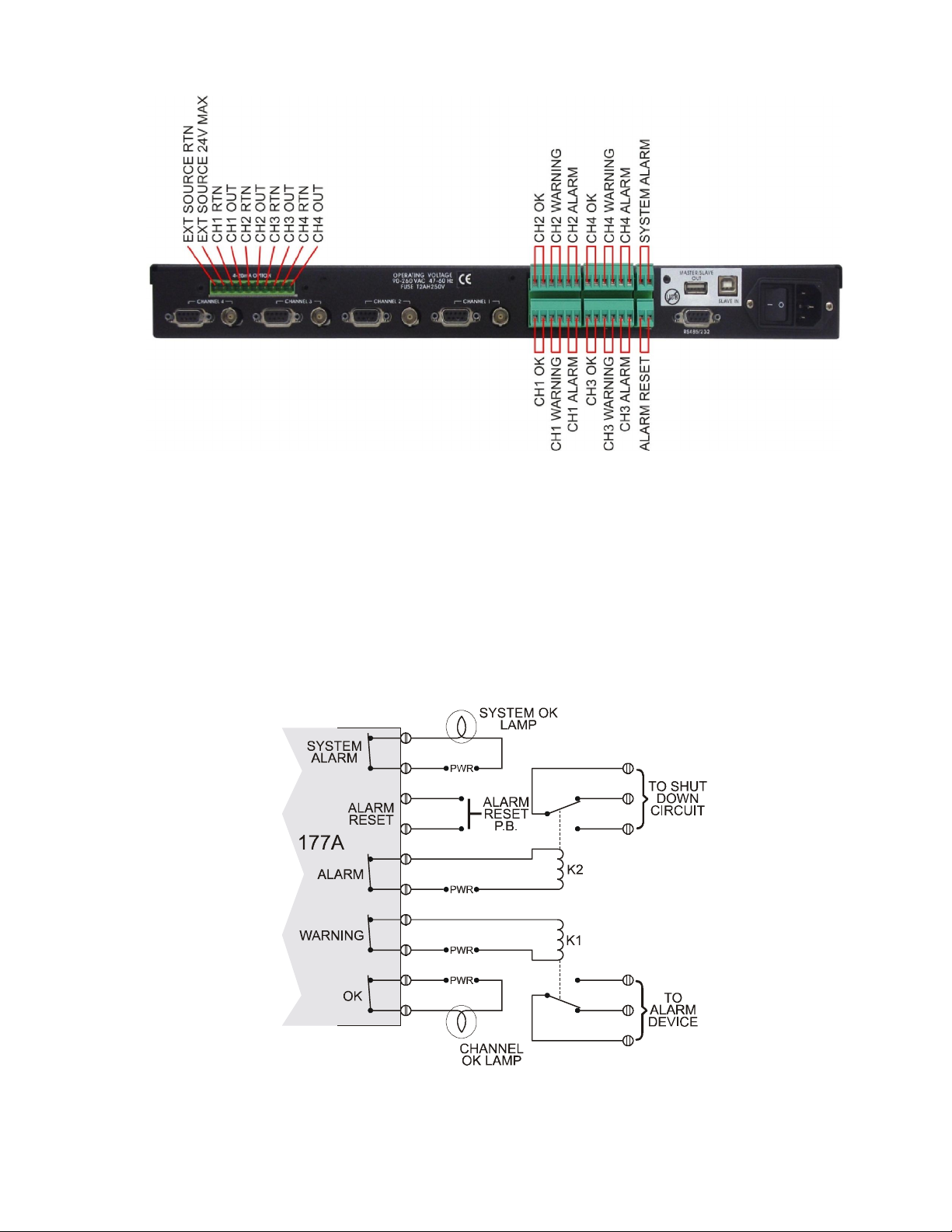

Figure 7: Rear panel relay hookups

Rear panel alarm relay connections:

Three status LEDs and relays are assigned to each channel. These LEDs and relays are referenced

as OK, WARNING, and ALARM. External monitoring equipment can be connected to these relays

and indicator LEDs via screw terminals located on the rear panel of the instrument and assigned as

specified on the instruments cover.

Connections should be made using the following diagram as a guide. For operational information

refer to the Rear Panel Relay Connection segment in Section 8 of this manual.

Input

Figure 8: Rear Panel Relay Connections

9

Page 11

Section 5

PRINCIPLE OF OPERATION

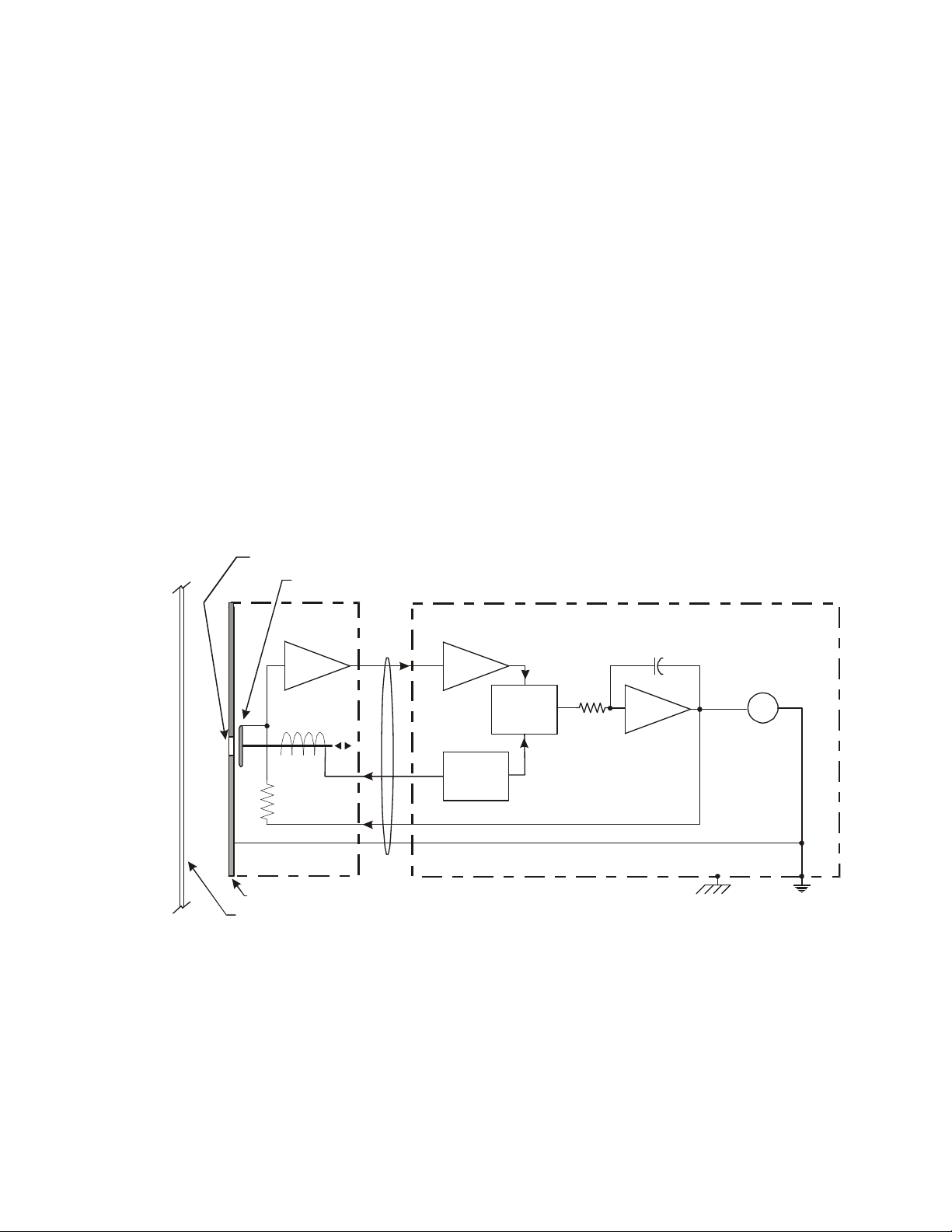

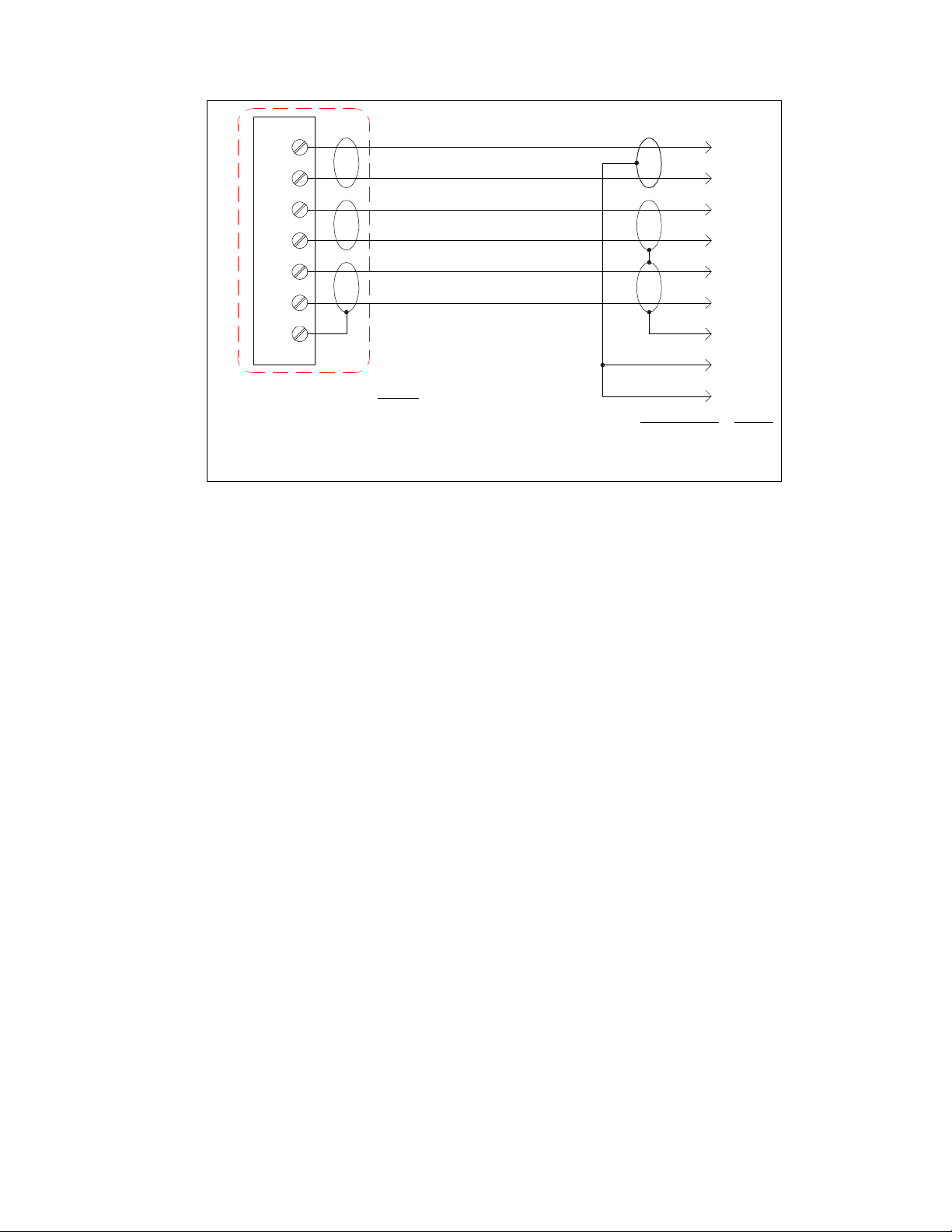

Refer to Figure 9 for the following discussion.

The probe is placed to “view” the target surface, which is assumed to be charged. In this instance,

the gradient cap containing the aperture faces the target surface.

A sensitive electrode behind the aperture is vibrated perpendicular to the electric field by means of a

drive coil (vibrated toward and away from the target surface). An A.C. signal is induced onto the

sensitive electrode due to the motion of the vibrating electrode in the electric field, which is created

by the charges on the target surface. The modulation amplitude of the A.C. signal, relative to the

drive coil signal, is related to the polarity of the charge on the target surface.

This A.C. signal, conditioned by a preamplifier, filter, and signal amplifier, is fed into a phasesensitive demodulator. This signal from this demodulator feeds an integrating amplifier. A fraction of

the integrator’s output signal is fed back to the sensing electrode to null the signal from the external

electric field.

The voltage signal from the integrator is thus directly proportional to the field intensity at the sensing

electrode of the probe. The output signal from the integrator drives a meter for direct readout.

Sensitive aperture

Sensitive electrode

High input

impedance

preamplifier

Driving

coil

Feedback

PROBE

Probe housing

Surface-under-test

SIMPLIFIED FUNCTIONAL BLOCK DIAGRAM

Electrostatic Fieldmeter

Signal

Cable

amplifier

Phase

sensitive

detector

Reference

oscillator

MAIN METER ASSEMBLY

Integrator

Earth

ground

Meter

(output)

V

Chassis

ground

Figure 9

10

Page 12

Section 6

Using 1036E and 1036F Sensors

General

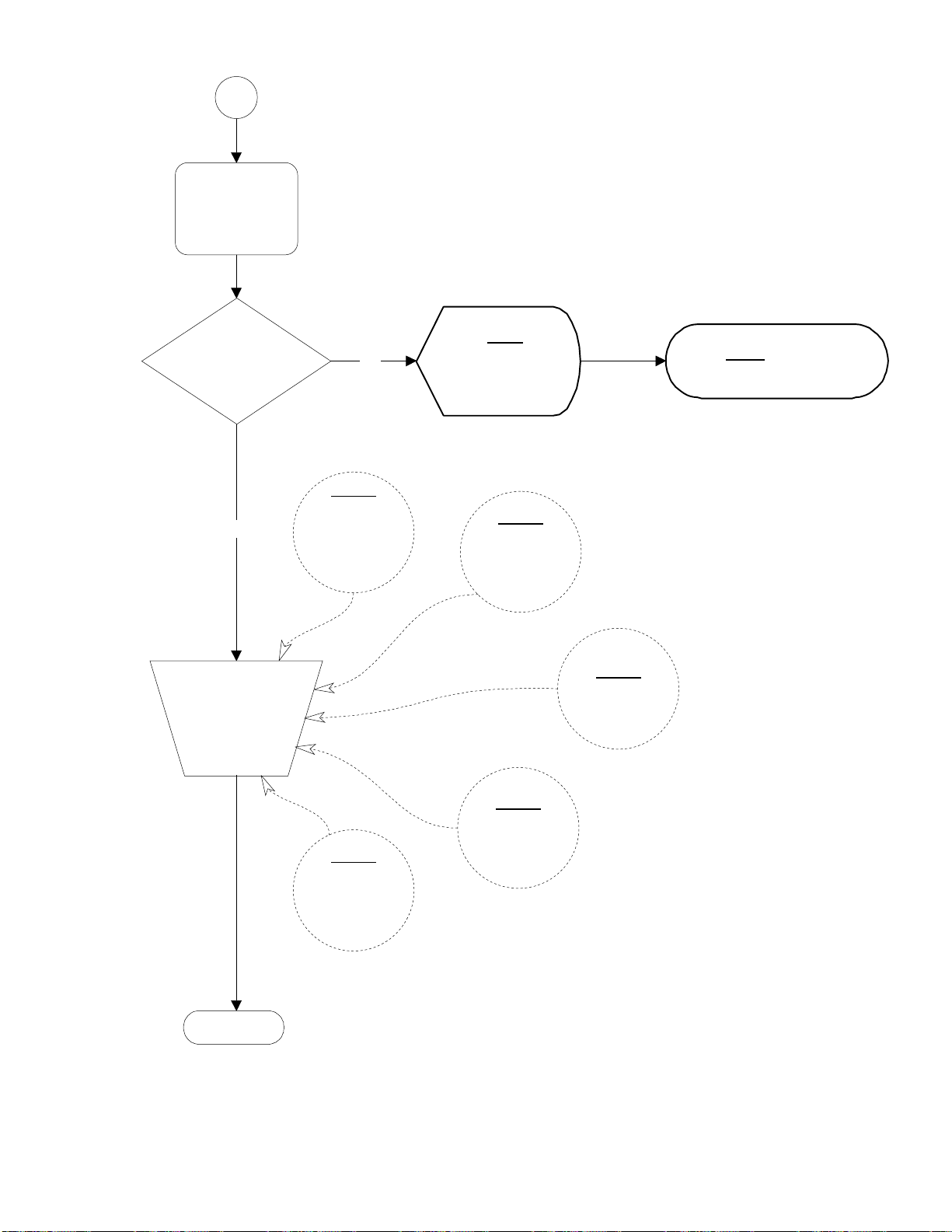

Models 1036E and 1036F electrostatic fieldmeter probes are electrically identical and

interchangeable. The major differences are physical. Model 1036F is a small (1.75” dia. x 1.25” H),

lightweight version for general-purpose applications, or where available space is a problem. Model

1036E, for most industrial applications, is a 1036F probe built into a standard Crouse-Hinds ½”-FS1

electrical box with a stainless steel cover.

Both probes utilize the same vibrating capacitor modulator, and both have built-in provisions for

purging with filtered air to prevent contamination and long-term drift. Inert gas may also be used for

purging in hazardous areas where the probe will be used in an inert gas atmosphere. Purge gas flow

in the Model 1036F exits through the sensitive aperture only. Gas flow in Model 1036E is directed

across the face of the probe as well as through the sensitive aperture. Both probes are designed to

be used with Monroe Electronics Model 177A Static Monitor 4 Channel Electrostatic

Fieldmeter/Alarm System.

Static electricity is a natural occurrence resulting from common converting, laminating, and printing

applications. At times static electricity is little more than an annoyance. However, in applications

where significant electrostatic charges accumulate, the effects can be very serious. Typical probe

applications include static level safety monitoring in explosive environments and static level quality

monitoring in sensitive machine areas.

1036E, 1036F Fieldmeter Probe IS / I / 1 / CD / T5 Ta = 800C – 1036/10/A

1036E, 1036F Fieldmeter Probe IS / I / 1 / CD / T5 Ta = 1000C – 1036/10/A

1. Parts of the Models 1036E and 1036EH Fieldmeter probe enclosures are constructed

from plastic. To prevent the risk of electrostatic sparking the plastic surface shall only be

cleaned with a damp cloth.

2. The Models 1036E, 1036EH, 1036F & 1036FH Fieldmeter Probe enclosure contains

aluminum and is considered to present potential risk if ignition by impact or friction.

Care must be taken into account during installation and use to prevent impact or friction.

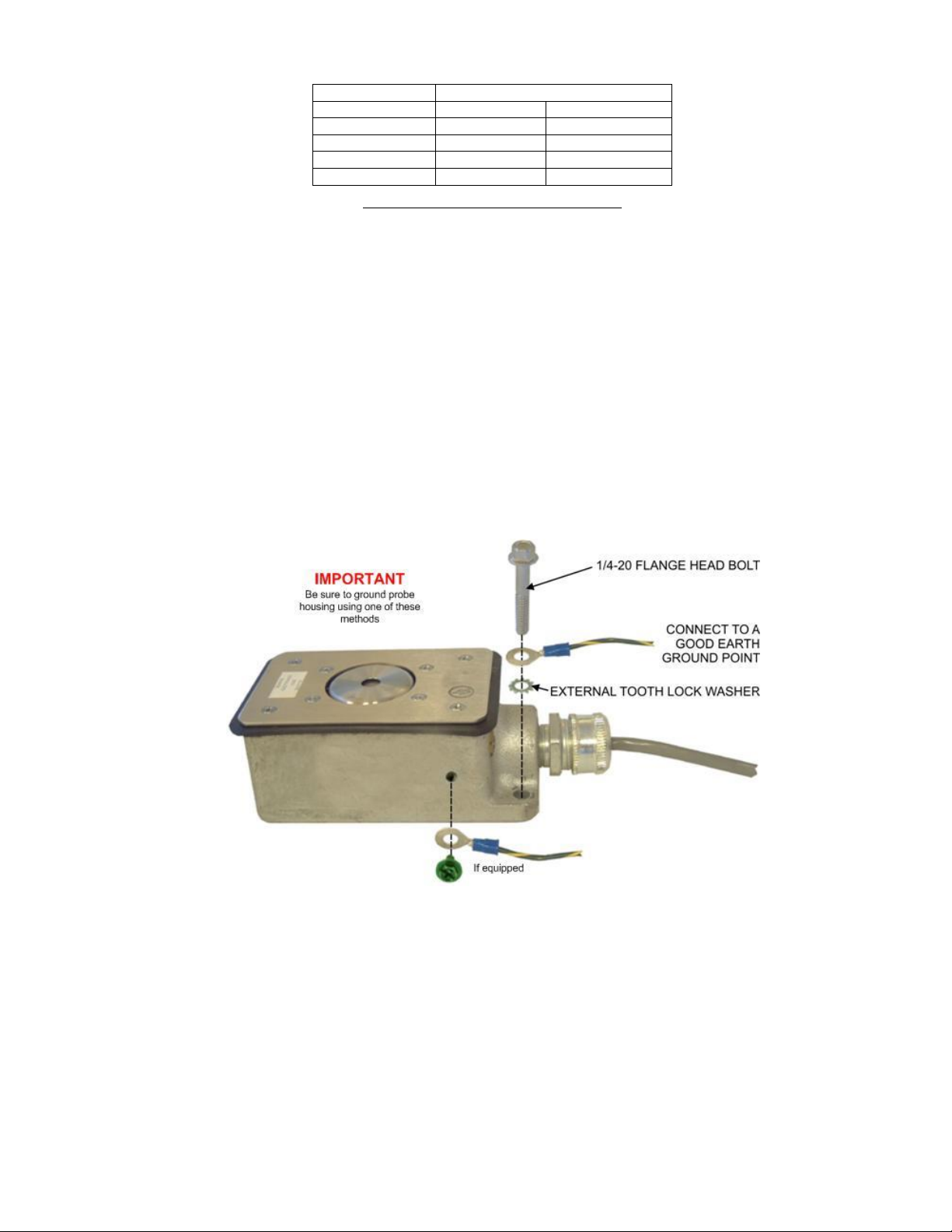

Figure 10: Model 1036E Fieldmeter Probe Figure 11: Model 1036F Fieldmeter Probe

Installation

Sensitivity:

Full-scale sensitivity for any properly standardized and calibrated probe/instrument combination is

dependent upon the gradient cap (containing the aperture) on each probe. Full-scale sensitivity for

any given system or channel (in the case of a multi-channel system such as the Model 177A) can be

determined by inspecting the gradient cap on the probe. Each gradient cap is stamped on its face

with a number, which represents a different size aperture. This number relates to the sensitivity of

the probe as shown in the table below. Probes are standardized at the factory in a uniform electric

field between two relatively large metal plates (see Figure 12). Once standardized in this manner,

they may be interchanged at will.

11

Page 13

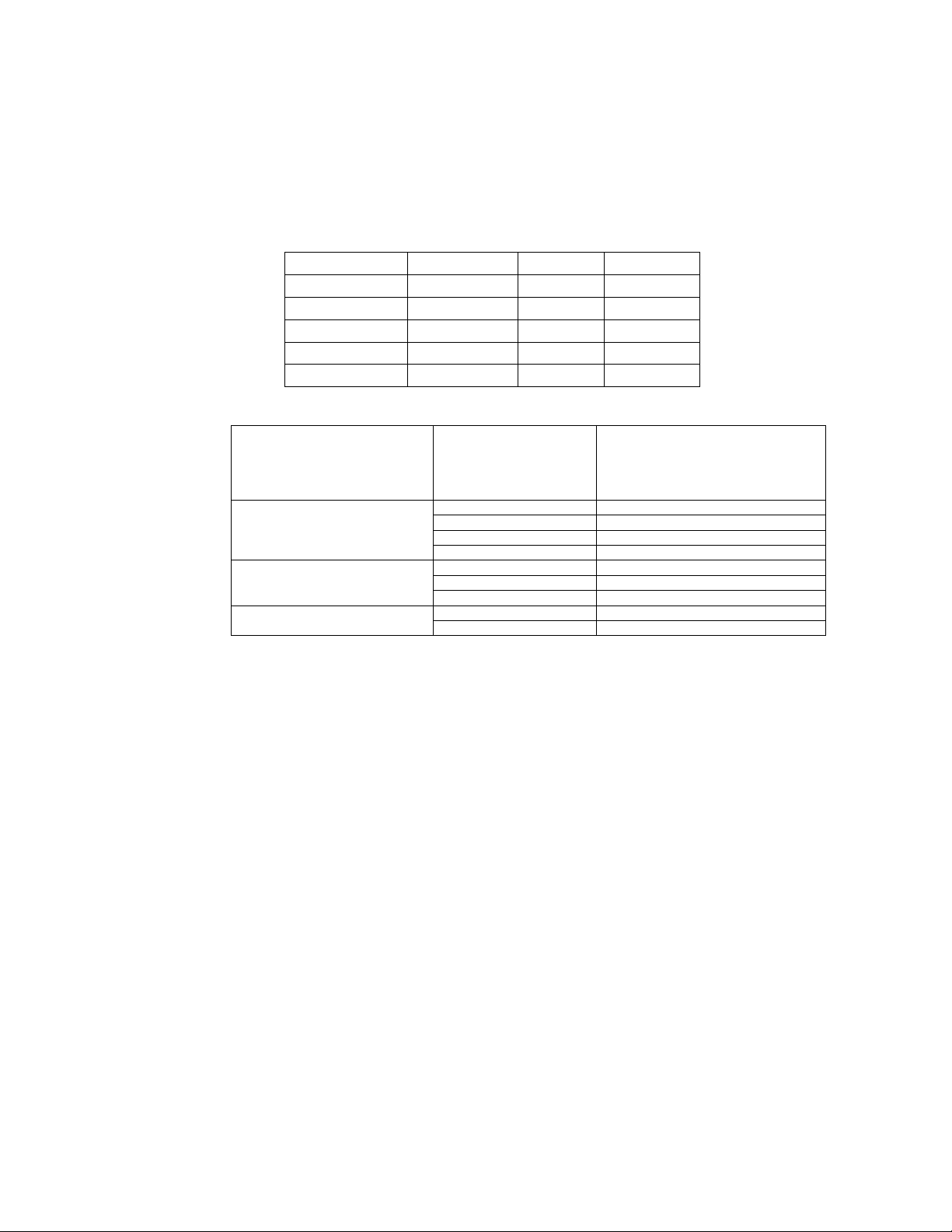

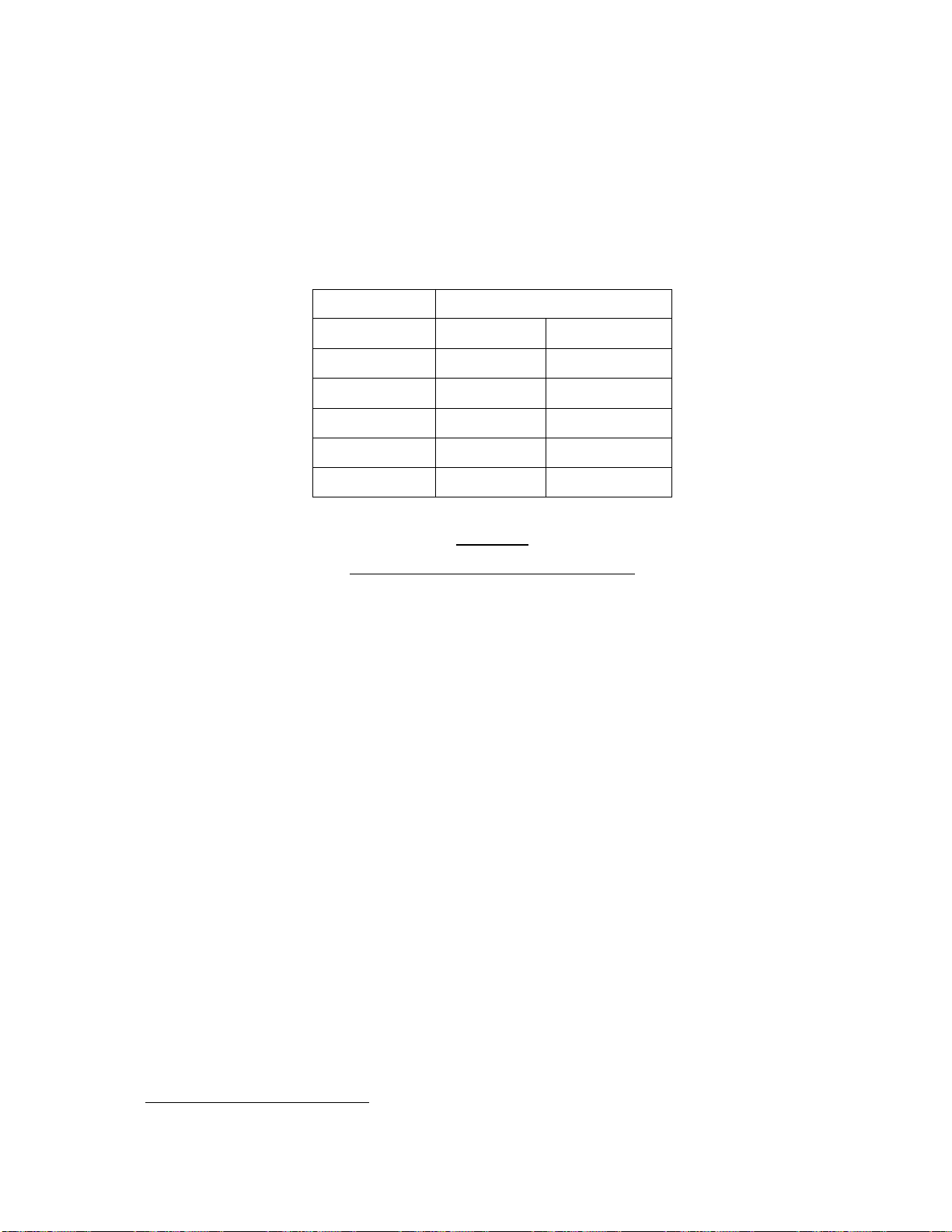

Probe Model Full Scale Sensitivity

1036_-3 ±1 kV/cm (±100 kV/M)

1036_-4 ±10 kV/cm (±1 MV/M)

1036_-5 ±20 kV/cm (±2 MV/M)

1036_-6 ±10 kV/in Standard

1036_-7 ±1 kV/in

Table 1: Probe Model vs. Full Scale Sensitivity

Mounting:

Probe mounting requirements for electrostatic field determinations will vary somewhat with the

nature of the desired measurement. In general, it is best to mount the probe as near as practical to

the surface being monitored, as long as the input signal remains less than the full-scale sensitivity of

the probe. For example, mount the metric unit reading probes from Table 1 at one centimeter and

the English unit reading probes at one inch, if feasible. It is strongly recommended that, where

possible, the probe be mounted "looking" downward in order to minimize the probability of

contaminants entering the aperture in the face.

Model 1036E is provided with two mounting flanges. The case should be electrically connected to

ground. The gradient cap (containing the aperture) of the probe is a reference surface with its own

ground connection. Do not make a separate ground connection to this surface. Stainless steel

hardware is recommended as shown for this connection to avoid long-term corrosion issues.

Model 1036F may be held by hand to make rough measurements, or mounted by means of two

threaded inserts installed in the mounting block. Care must be exercised when selecting screw

length. Other temporary mounting options are friction clamps, adhesives or double-sided tape. The

metal body of the probe is internally connected to instrument ground and should not normally be

connected to any other ground.

Geometry:

A shroud is not necessary on 1036E probes mounted at 1in/1cm or less from the web because the

large faceplate provides the same function as a shroud (creates a uniform field in front of the probe

at one inch or less).

12

Page 14

As a truly uniform field does not usually occur in most practical measurement situations using the

1036F probes, partly due to the introduction of the grounded probe itself, one must either:

Improve the geometry by establishing a grounded plane (shroud) through which the fieldmeter

probe can view the field under consideration. Refer to figure 6 on page 9. (see also

Application Note –0003 in Appendix.)

Establish a correction factor for the data, or

Accept relative data. In many cases, this is acceptable practice once a fixed geometry is

established and related to the real electric field.

Cables:

Both types of probes are normally equipped with 10-foot-long cables and subminiature D connectors

that mate with Monroe Electronics Model 177A. This is Option 1 of 6 available wiring options – see

Appendix A – Probe Connection Options for details. The first 3 options are for non-hazardous (nonclassified) locations where there are no Intrinsic Safety (IS) considerations. The last 3 options are for

hazardous (classified) locations where IS must be considered as part of the installation and barriers

are in use.

Extension cables are available from Monroe in lengths up to 1000 feet, which is the maximum

permissible length. These extension cables may be ordered in any length (up to 1000 feet) by part

number 1036/12-nnnn, where nnnn is the length in feet.

The cable exit on Model 1036E is supplied through a packing gland which is screwed into a ½"-14

NPT tapped hole in a boss on one end of the housing. Inside the housing, the probe is plugged into

a terminal block to which the cable attaches. Where it is desirable or necessary to connect Model

1036E probes to Model 177 Static Monitors with conduit, the original cable and packing gland can be

removed and the cable replaced by any length (up to 1000 feet) pulled through the conduit with a

connector on only the Model 177 end. Refer to Appendix A – Probe Connection Options, Options 3,

4 or 6 (depending on whether IS must be considered) for details.

Purging:

Any "contamination" present in the probe or near the measurement will have an adverse affect on

performance. When insulative particles or liquid becomes charged and enters the probe or attaches

near the aperture of the probe, it becomes a source of measurement error and drift. Less obvious is

the influence of gaseous atmospheric constituents, including aerosols, which contaminate the probe

by altering the contact potentials between critical surfaces.

13

Page 15

Constant purging of the Model 1036 probe with clean dry air or an inert gas is recommended

whenever practical to prevent airborne contaminants from entering the aperture in the gradient cap

and being deposited on the electrode.

The air supply should meet standard ANSI/ISA-S7.0.01-1996 - Quality Standard for Instrument Air.

A Koby "Junior" filter available from Koby, Inc., 297 Lincoln Street, Marlboro, MA 01752 should meet

this standard and will provide sufficient mechanical and chemical filtration for one to four probes

under most conditions.

A complete probe purge kit, Model 1017/22G, is available for Model 1036F from Monroe Electronics.

It includes a low volume, long-life air pump, mechanical and chemical filters, and a supply of tubing.

The pump is fully capable of 24-hour per day operation, thus keeping the probe ready for immediate

use. A purge gas inlet tube supplied with each 1036F probe may be installed in either of two

positions, the choice of which is primarily a matter of convenience in routing of the hose carrying the

purge gas. These consist of tapped holes that exit at 90° to each other near the probe cable. If it is

desired to move the purge tube to the other location, simply switch it with the Allen set screw

plugging the other hole.

Purge the Model 1036E probe through a ¼"-18 NPT tapped hole in the end of the housing near the

cable exit using common plumbing or tubing components.

Gas pressure to either probe type should be sufficient to produce a slight positive flow out of the

probe and in no event should exceed a pressure of ½ psi.

Servicing

General:

It must be emphasized that the critical elements of these probes (gradient cap and sensing

electrode) must be kept free from contaminants, e.g., dust, fumes, mists or any foreign material. The

materials of which these probe elements are made were very carefully chosen to minimize contact

potential. Any foreign matter which will cause relative electrical activity when combined with relative

motion will tend to cause drift and measurement errors.

Therefore, it is recommended that:

Probes be constantly purged even when not in use, if this is practical.

Probes be kept tightly covered when not in use and are not being purged to prevent

contamination. A covering such as a plastic bag or aluminum foil may be used. DO NOT

cover the sensitive aperture with adhesive tape.

Probes be cleaned only to the degree and frequency necessary to achieve the required

stability.

Gradient caps NOT be removed for cleaning unless absolutely essential.

Major cleaning and reconditioning be should performed by the factory.

Cleaning:

The recommended cleaning solvent is instrument grade 70-100% isopropyl alcohol applied with a

suitable soft, lint-free applicator. Use of a non-approved solvent may degrade performance

permanently, requiring factory service.

Outside surfaces of the probe should first be wiped clean with a lint-free wiping tissue saturated in

solvent. Then the interior surfaces should be flushed with solvent, using a plastic squeeze bottle

through the aperture until no dirt or dust may be seen. The probe should then be allowed to drain

and dry thoroughly. A 15-minute bake-out at 75°C is recommended to remove residual solvent.

Disassembly/Assembly, Model 1036E:

In order to rewire the cable terminal block, replace or standardize the probe assembly and, in most

cases, to calibrate Model 1036E, it must first be removed from its housing. This is done by loosening

the four cross point screws around the outer edge of the cover 1-1½ turns each, in turn, several

times while lifting the cover and probe straight out of the housing until it is completely removed. DO

NOT attempt to remove the screws completely one at a time. These four screws have circular

14

Page 16

"E-rings" installed on them under the cover plate to make the screws captive and prevent their falling

into machinery below.

The probe assembly will need to be removed from the cover plate, for standardizing, calibration, or to

replace the gradient cap. This is done by removing the four cross point screws which secure the

phenolic mounting block to the hex standoffs, leaving the standoffs attached to the cover plate.

To reassemble the probe unit, reverse the above procedure. After the phenolic mounting block has

been re-secured to the four hex standoffs, the probe unit should be inspected to assure that an even

air gap exists completely around the gradient cap between the cap and the cover plate. If not, loosen

the two cross point screws which secure the probe body to the phenolic mounting block, and adjust

the probe body so that it is centered and completely surrounded by an even air gap.

Partially mate the card-edge fingers into the terminal block connector in the housing and tighten the

four outer screws in the cover plate 1-1½ turns at a time until the assembly is secured in the housing.

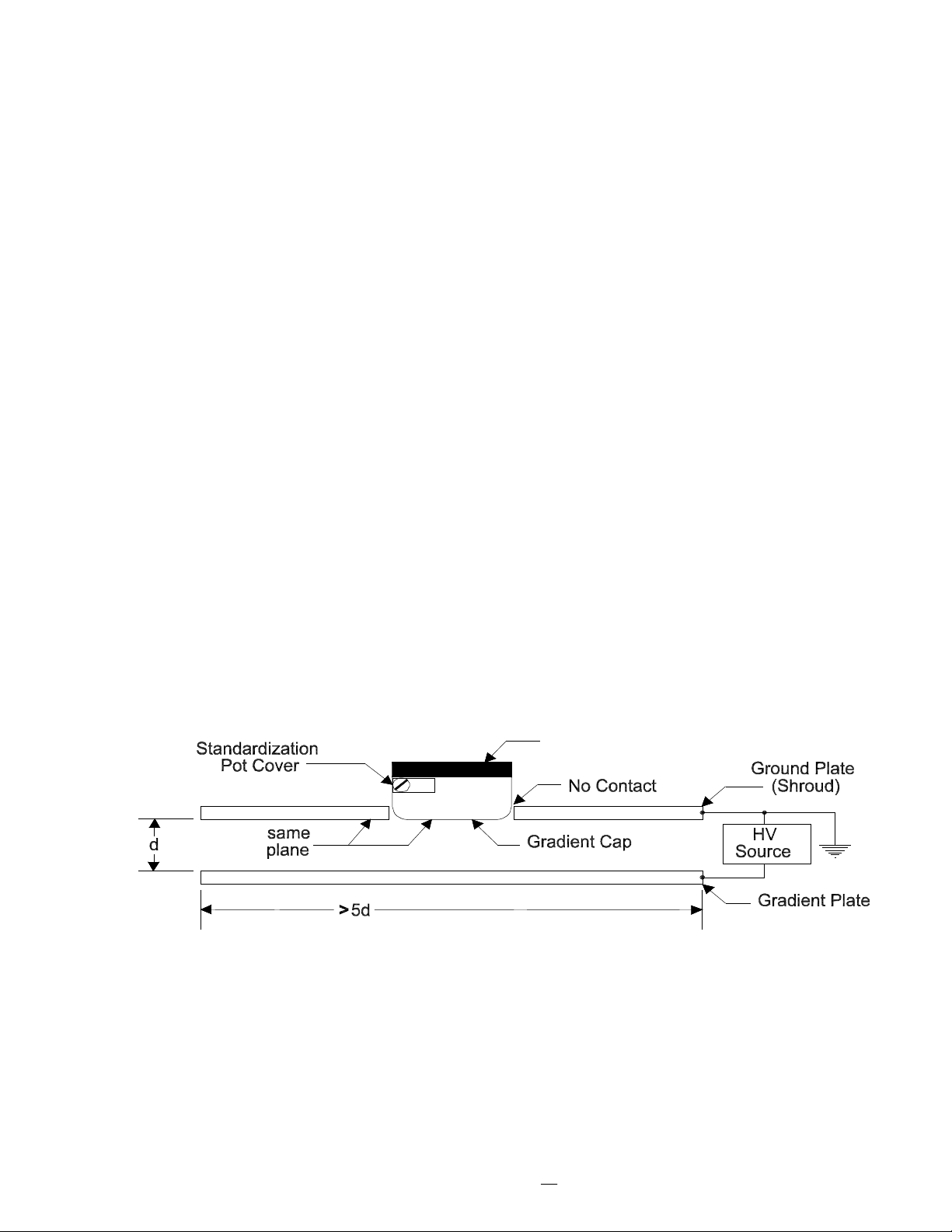

Standardization:

A simple accurate means of standardizing Model 1036 probes using any channel of the Model 177A

Static Monitor as a test vehicle is given here.

The primary reason for standardization of type 1036 probes is to assure interchangeability of probes.

The procedure is not suggested as routine, but is presented here in the event it becomes necessary

to re-standardize following replacement of a gradient cap or major probe overhaul. It should be

performed only under controlled conditions in a suitably equipped electronics laboratory. Monroe

Electronics recommends that all probe standardization be performed at its facility.

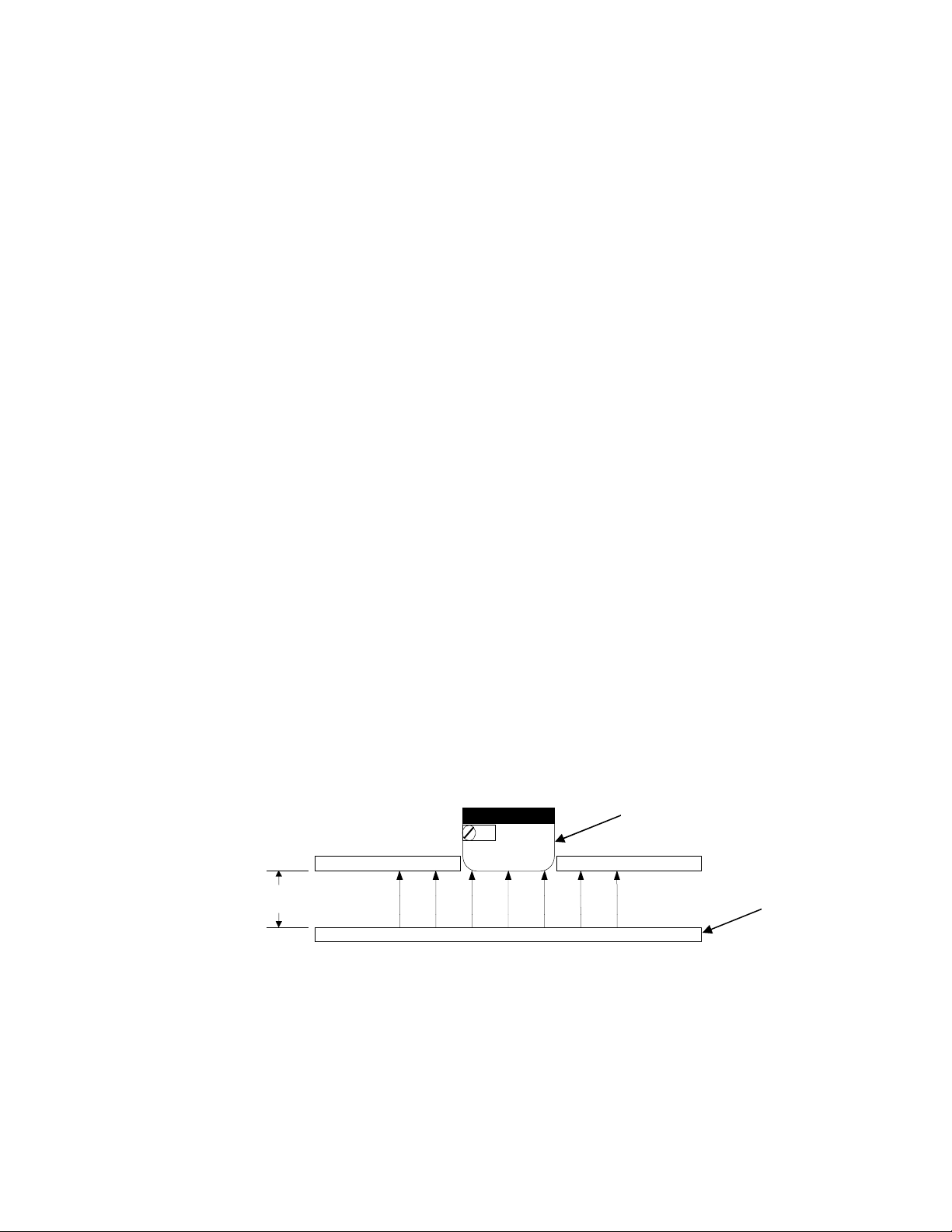

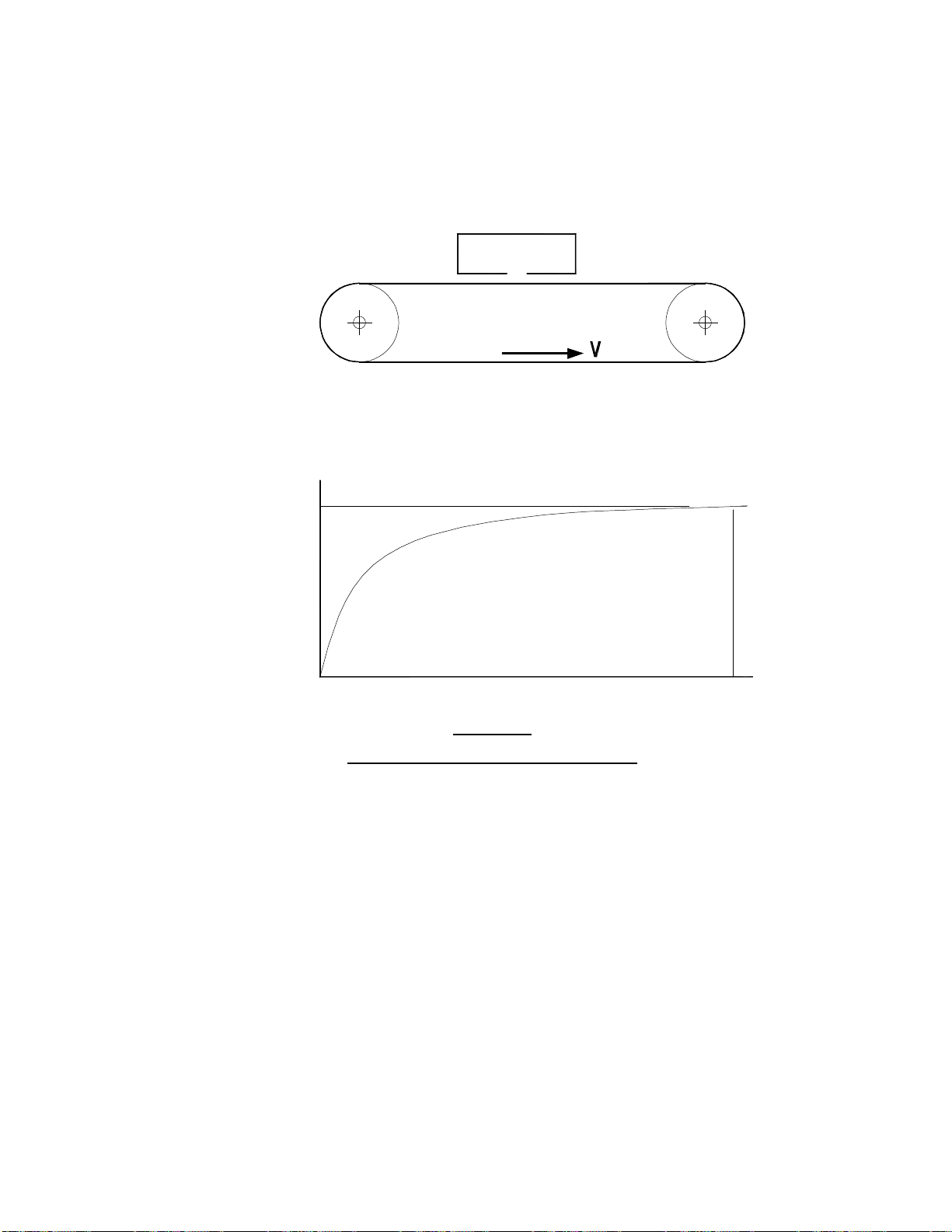

All type 1036 probes are shipped from the factory standardized in a uniform (parallel) electric field

using a fixture similar to that shown in Figure 12. The fixture consists of two flat rigid metal plates,

which are parallel and separated with insulators by a distance "d" of one inch and have side

dimensions of at least 5d (the bigger, the better; within practical limitations). The ground plate has a

hole in its center just large enough to provide clearance around the probe so that the probe does not

make contact with the plate. A calibrating voltage is applied to the gradient plate to establish a

reference field in the volume between the plates. This fixture is available from Monroe Electronics,

Inc. as part number 96102A.

1 03 6 P ro be

A ss e m b ly

Figure 12: Standardization Fixture (P.N. 96102) Setup for 1036 Probes

A Probe Standardization/Test Cable, Model number 1036/22C shown in Figure 13 below is required

to standardize or bench-test type 1036E-X probes. No special cable is required for type 1036F-X

probes.

15

Page 17

DB9M

Connector

6

7

4

5

2

1

3

8

9

ME P/N

9232278

9230070

7

r

to

6

c

e

n

n

o

2

C

e

g

d

11

E

d

r

a

l/C

5

a

in

m

r

4

e

T

3

1036E Probe Housing

WH

BK

RD

BK

GN

BK

Bulk Cable is Belden 8777

NOTES:

1. Place Teflon tubing over drain wires.

2. Place shrink tubing over shielded pairs.

3. All shields to be isolated from each other.

Connector Parts

Conn. Plug

DB9, Male

Conn. Housing

DB9, Die-cast

Figure 13: 1036E Standardization/Test Cable, Model No. 1036/22C

16

Page 18

The standardization procedure is as follows:

Set up apparatus as outlined above. Set a precision calibrating voltage source to zero volts.

Set the Model 177A Static Monitor zero control of the selected channel to read a value of

0.000 at its ±10V analog output using a high quality, 4½ digit digital multimeter (DMM).

Apply calibrating source voltage (VHV) shown in Table 2 for the probe model being

standardized.

Adjust the standardization potentiometer in the probe to produce value (V

), as shown in

IND

Table 2, at the analog output of the selected channel using the same DMM as above.

Probe Model Sensitivity VHV V

1036_-3 ±1 kV/cm 2540 V 10.00 V

1036_-4 ±10 kV/cm 2540 V 1.00 V

1036_-5 ±20 kV/cm 2540 V 0.50 V

1036_-6 ±10 kV/in 1000 V 1.000 V

1036_-7 ±1 kV/in 1000 V 10.00 V

IND

Maximum Surface Voltage

Table 2: HV Source and Meter Reading for Probe Standardization

Full Scale Range*

I. Probe II. Probe to Surface

Spacing

20.0 kV 20 kV/cm (-5) 0.4 in 1.0 cm

10 kV/cm (-4) 0.8 in 2.0 cm

10 kV/in (-6) 2.0 in 5.1 cm

1.0 kV/cm (-3) 7.9 in 20 cm

10.0 kV 10 kV/cm (-4) 0.4 in 1.0 cm

10 kV/in (-6) 1.0 in 2.5 cm

1.0 kV/cm (-3) 3.9 in 10 cm.

1.0 kV 1.0 kV/cm (-3) 0.4 in 1.0 cm

Table 2A: Probe Selection/Sensitivity Chart

Intrinsic Safety (IS) Barriers:

Model 1036E and 1036F Electrostatic Fieldmeter Probes meet Factory Mutual Research Corporation

requirements for Class I, Division 1, Groups C and D hazardous locations when installed in

accordance with the appropriate Monroe Electronics, Inc. control drawings. To comply, approved

safety barriers must be used as shown in the drawings. These drawings are included in Appendix B

– Intrinsic Safety Barriers or are available from Monroe Electronics. Copies of the Factory Mutual

Research Corporation report 1Q3A9.AX specific to these probes are also available on request.

inches cm.

*Called “Probe type” in Software

17

Page 19

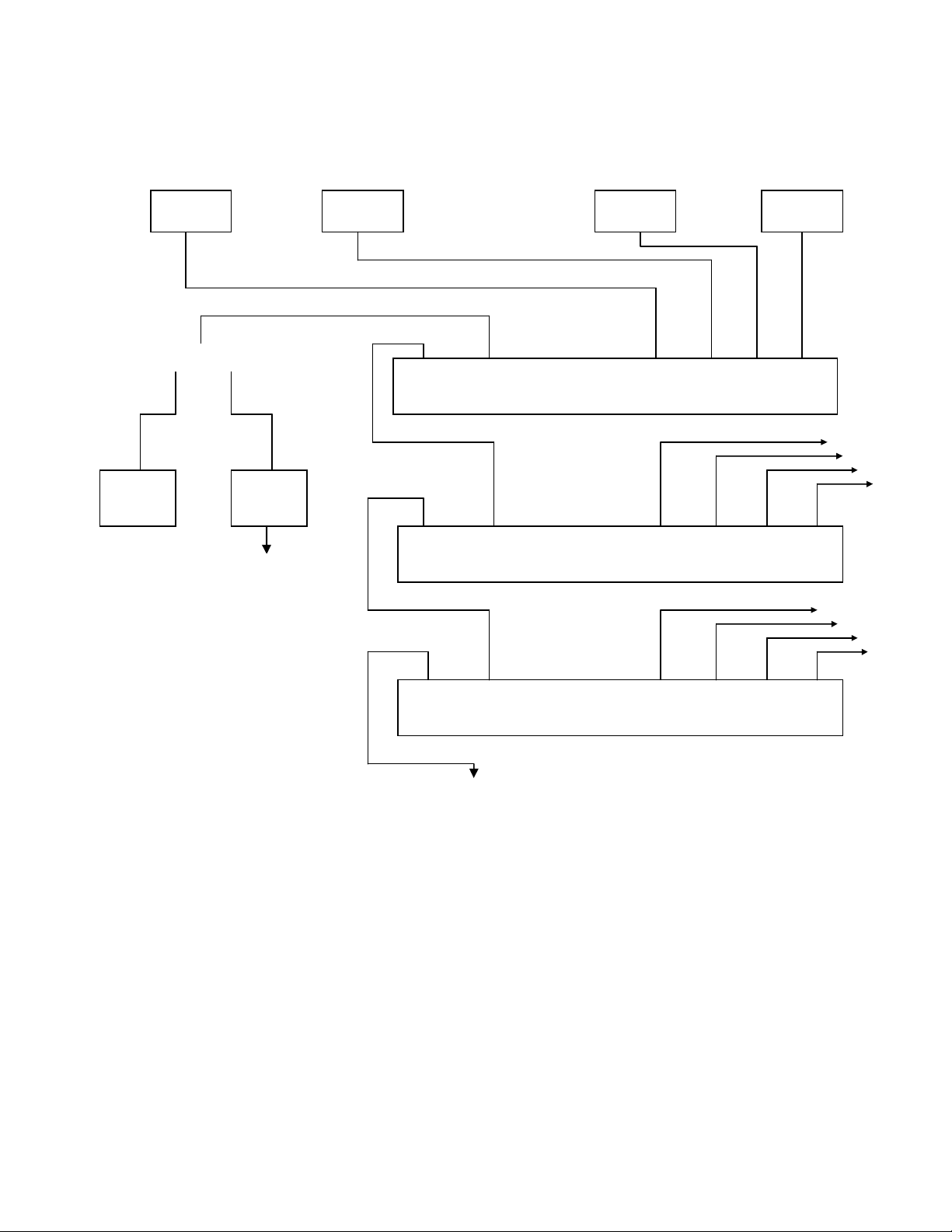

Section 7

Typical Setup

1036

Sensor #1

1036

Sensor #2

to a PC or PLC

Master RS-485 /232

Slave/Out

177A Master

RS-232

PC

RS-485

PLC

Analog out

Master Slave In

Slave/Out

Master Slave In

Slave/Out

Figure 14 – Block Diagram of a typical set up

Analog Inputs

Monitoring equipment for voltage levels may be connected to any or all of the for channels via the

BNC connectors located adjacent to each channel probe connector on the rear panel on the

instrument.

Monitoring equipment for current levels may be connected to the optional 4-20mA pcb via screw

terminals located on the rear panel of the instrument.

1036

Sensor #3

1 2 3 4

177A #2 Slave

177A #3 Slave

1 2 3 4

1 2 3 4

1036

Sensor #4

To 1036

Sensors

5-8

To 1036

Sensors

9-12

18

Page 20

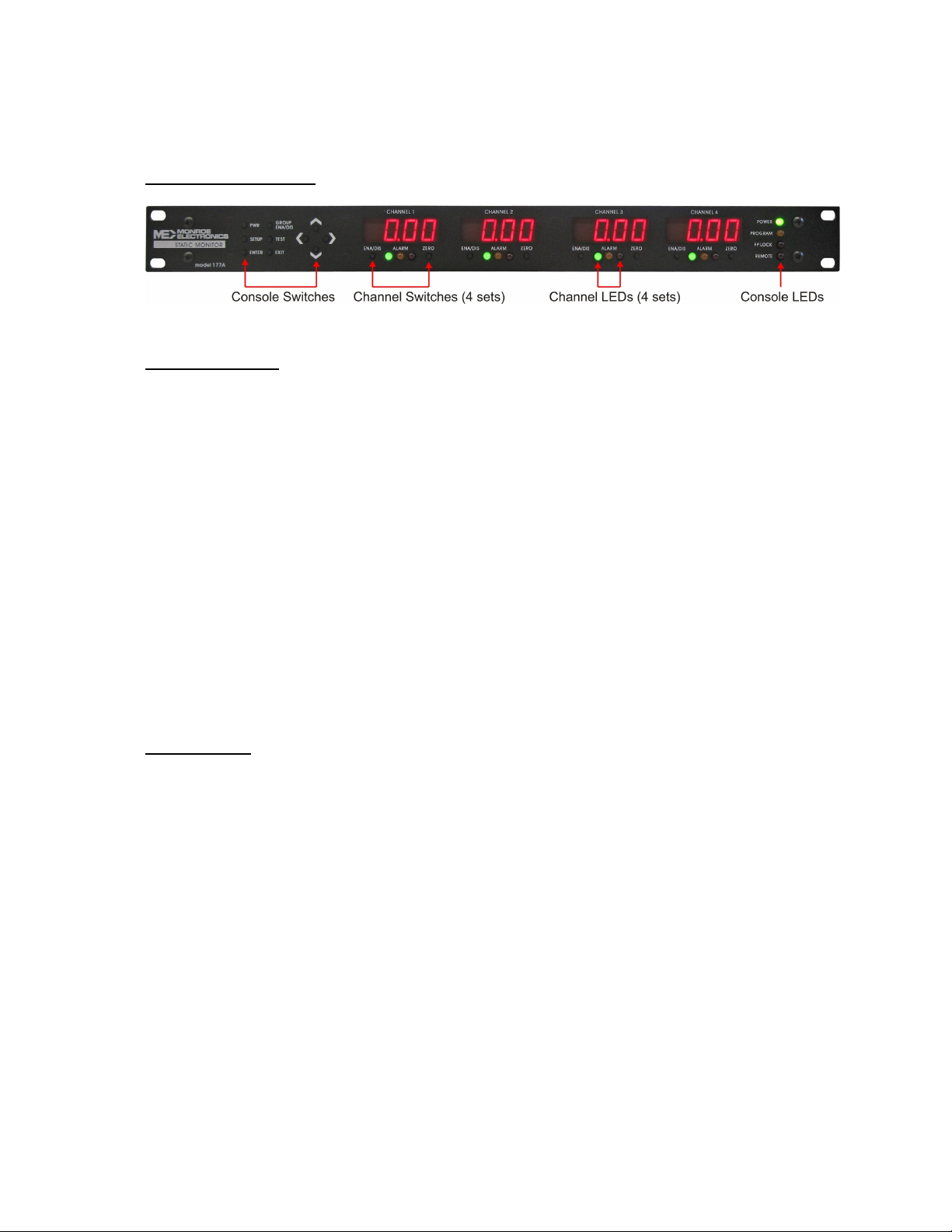

Front Panel Features

Section 8

OPERATION

Console Switches

Figure 15: Front Panel View

PWR – Switches unit ON or OFF (There is a main power switch on the rear panel that supplies DC

power. The front panel console push button switches the power to the to the unit’s power supply.) If

line power is lost, the 177A will return to operational status when power is restored.

GROUP ENA/DIS - All channels in the group (of four) are enabled on power-up. These channels

may be immediately and simultaneously disabled by pressing the GROUP ENA/DIS button on the

front panel or clicking the GROUP ENA/DIS button on the program monitor screen.

SETUP – Initiates programming via the front panel. Yellow Program LED lights when SETUP button

is pressed and remains lit for duration that instrument is in program mode.

TEST – Initiates testing of all connected and enabled probes. Pressing and holding down the TEST

button causes a shift in the probe reading to the minus direction, the reading should return to normal

when the button is released, indicating a good probe.

ENTER – Press ENTER to accept changes during programming or to perform a function.

EXIT – Press EXIT to escape the changes or exit the program mode.

Console LEDs

POWER – Green LED lights when power is applied to the instrument. A flashing power LED

indicates a problem with the instrument’s power supplies. If this occurs refer to the

Return Policy on page 3 for servicing.

PROGRAM – Yellow LED lights when the SETUP switch is depressed and remains lit until the

program mode is exited. If master/slave units are utilized the program light will pulse

on the master unit which drives probe oscillation. If it is a slave unit the program light

will not be lit.

The program LED does not pulse when the unit is in program mode.

The program light flashes (pulses at a slower rate) when the unit is receiving a

firmware update. If the update is interrupted either, by the user or power failure, the

light will flash and remain flashing until the update is completed successfully.

FP LOCK – Red LED indicates that the front panels controls have been locked. When locked the

front panel buttons do not function except for Power, Setup and Exit. FP lock can be

enabled or disabled via the front panel controls or the pc software supplied.

REMOTE – Lights when the PC program is in use.

19

Page 21

Rear Panel Relay Connections

Three status LEDs and relays are assigned to each channel. These LEDs and relays are referenced

as OK, WARNING, and ALARM. External monitoring equipment can be connected to these via

screw terminals located on the rear panel of the instrument. Connections are specified in Figure 7

on page 10 and on the instrument’s cover.

Three modes of operation are available:

Alarm Mode - Latching

Under normal operating conditions (i.e. the monitored static level is less than the preset

warning and alarm levels) all three relays are energized initiating a contact closure. The

green or OK status LED is blinking while the yellow or WARNING and red or ALARM status

LEDs are not lit.

When static levels reach the preset Warning level and the preset Alarm Delay has expired

(refer to Program Setup in Section 9 for details) the Warning relay will open and the Warning

LED will light. The OK LED will continue to blink. Whenever the instrument achieves

Warning mode it will stay in that condition until the problem is corrected or the static level

falls to less than the preset warning.

When static levels reach the preset Alarm level and the preset Alarm Delay has expired

(refer to Program Setup in Section 9 for details) the Alarm relay will open and the Alarm LED

will light. The OK LED will continue to blink and the Warning LED remains lit as well.

System Alarm - Upon realization of an alarm condition the System Alarm relay will open.

Upon opening the System button on the Monitor screen on your pc will flash red.

Whenever the instrument achieves Alarm mode it will stay in that condition until the problem

is corrected and the instrument is manually reset by toggling the channel’s ENA/DIS button

on the instrument console or via the pc program provided or by momentarily shorting the

Alarm Reset terminals on the back panel.

Alarm Mode – Non-Latching

Under normal operating conditions (i.e. the monitored static level is less than the preset

warning and alarm levels) all three relays are energized initiating a contact closure. The

green or OK status LED is blinking while the yellow or WARNING and red or ALARM status

LEDs are not lit.

When static levels reach the preset Warning level and the preset Alarm Delay has expired

(refer to Program Setup in Section 9 for details) the Warning relay will open and the Warning

LED will light. The OK LED will continue to blink. Whenever the instrument achieves

Warning mode it will stay in that condition until the problem is corrected or the static level

falls to less than the preset warning level.

When static levels reach the preset Alarm level and the preset Alarm Delay has expired

(refer to Program Setup in Section 9 for details) the Alarm relay will open and the Alarm LED

will light. The OK LED will continue to blink and the Warning LED remains lit as well.

System Alarm - Upon realization of an alarm condition the System Alarm relay will open.

Upon opening the System button on the Monitor screen on your pc will flash red.

Whenever the instrument achieves Alarm mode it will stay it that condition until the static

level falls to less than the preset warning level resetting to normal operation.

Non-Alarm Mode

In non-alarm mode the alarms are disabled, the green or OK remains lit continuously.

Warning and Alarm are not triggered. The instrument continues to monitor static levels

regardless of operating conditions.

20

Page 22

Channel Switches

ENA/DIS – Toggles the channel status between Disable / Enable / Alarm

ZERO – Press and release the ZERO button to zero the channel. Display will return to pre-set zero

level. The channel display to the immediate right of the channel display being zeroed will count

down the pre-set zero time out. (For Channel 4 the channel display immediately to the left will count

down the zero time out.) If zero level is reached within the pre-set time the channel display will read

don for “done.” If the zero level is not reached within the pre-set time the display will read err for

“error.”

Auto-Zero – Press and release the Zero button (< 1sec)

Manual Zero – Press and hold the zero button then push the up or down arrow buttons to

adjust the zero reading

Channel LEDs

Green (left) LED – Lights and remains lit when a probe is connected and the channel is enabled

(Non-Alarm mode). Lights and flashes when a probe is connected and the channel alarm is enabled.

(Alram Mode: Latching and non-latching.) LED remains flashing even as the Yellow, Warning and

Red, Alarm LEDs light during warning and alarm conditions.

Yellow (center) LED – Lights when the pre-set voltage warning level is reached. Remains lit until

voltage level drops below warning level (non-latching) or until the condition corrected and the

channel is reset (Latching).

Red (right) LED - Lights when the pre-set voltage alarm level is reached. Remains lit until voltage

level drops below warning level (non-latching) or until the condition corrected and the channel is

reset (Latching).

177A Relay and LED Functions

Initially all Ok, warning, alarm relays are closed (shorted or activated). The Ok LED is on; warning

and alarm LEDs are off.

Channel Ok relay is open (the green LED off) when:

The channel is enabled and has no probe.

The channel is disabled.

Channel Warning relay is open (the ember LED on) when:

The channel is enabled and the reading is on or above the warning level.

Channel Alarm relay is open (the red LED on) when:

The channel is enabled and has no probe.

The channel is enable and the reading is on or above the alarm level.

If the unit is in alarm latching mode and the reading comes back down, the relay will not close

until the [Ena/Dis] or [GRP] button is depressed.

System relay is normally closed. It is open when:

One or more of the alarm relay is open.

One or more of the enabled channel has no probe.

Power supplies have failed.

Power LED:

On when the unit is powered up. Slow blink if power supply has failed.

21

Page 23

Program LED:

Normally off. It is on when doing front panel setup.

Pulses on when the unit is a master. See section on master/slave operation in the User

Manual.Note: if USB cable A & B are connected to the same unit, oscillator is disabled.

FP Lock LED:

Normally off. On when the front panel is locked.

When the front panel is locked, only the [Setup] and arrow buttons work. You can unlock the unit, or

browse the program setup but cannot change it.

Master/Slave out & Slave in:

Purpose

These connections provide synchronization of the probe modulators on multiple 177A’s.

When probes are attached to common mountings from multiple 177A’s they can interact and

cause zero shifts and low frequency oscillations without synchronization of the modulators.

Setup

Master/Slave out and Slave in connectors are provided on each 177A. The Master/Slave out

either generates or passes through reference signal for synchronization. Multiple units can be

daisy chained as shown in Fig 14, on page 17.. The Slave in connector accepts the Reference

and forces the modulator to be synchronized with the other 177A’s. Standard USB cables with

Type A/B connectors are used for interconnects. These are supplied with the 177As.

Note. These connectors are NOT USB Ports

Remote LED

Normally off. Blinks when serial port is receiving.

22

Page 24

Section 9

177A Software

Connecting the instrument to a PC (via RS232 serial port)

Connect the 177A to your PC using the DB9-M/F straight through cable in your accessories. Plug

the male end of the cable into the RS-485/232 receptacle on the rear of the instrument. Plug the

female end of the cable into the appropriate connector on your PC.

Connecting via RS485

Refer to Appendix III for RS-485 connections details.

Installing the Software

Insert the supplied disk into the appropriate drive. A Launch program should automatically begin

running. Follow the instructions for the desired action. (i.e. to install the software click the

Installation button.) If the Launch program does not automatically start refer to the following

instructions:

Click on Start on your task bar and then select Run –

Type the appropriate drive letter for the disk and “Install-177A-105.exe”

(i.e. - a:\ Install-177A-105.exe) on the disk and follow the subsequent instructions.

Upon completion, the program icon will be displayed in a window. Click on and drag

the icon to your desktop to place a short cut there. Close the window.

Programming via PC

The software included with the 177A is designed to program, monitor and test the instrument via RS232 or RS-485 connections using the toolbar on the program’s main screen.

Connect – Select the appropriate comport and baud rate to be used for the monitor from the

drop-down menus. The baud rate should reflect the current Windows setting for this

comport.

Program Setup – Permits enable/disable of alarms; setting of warning and alarm levels; full

scale; alarm delay; auto zero time and level; and decimal position. Four user-defined

programs are available which can be set up and stored. The instrument is set to P0, the

default setup program. P1 – P4 are initialized to the default settings, resetting these four

programs is accomplished via the ME177A program.

From the Program Setup drop-down menu:

Click on Read Setup from 177A to select program 1 – 4, or retrieve the

active program.

Click on Open Program on disk to retrieve a program (*.prg) from a file.

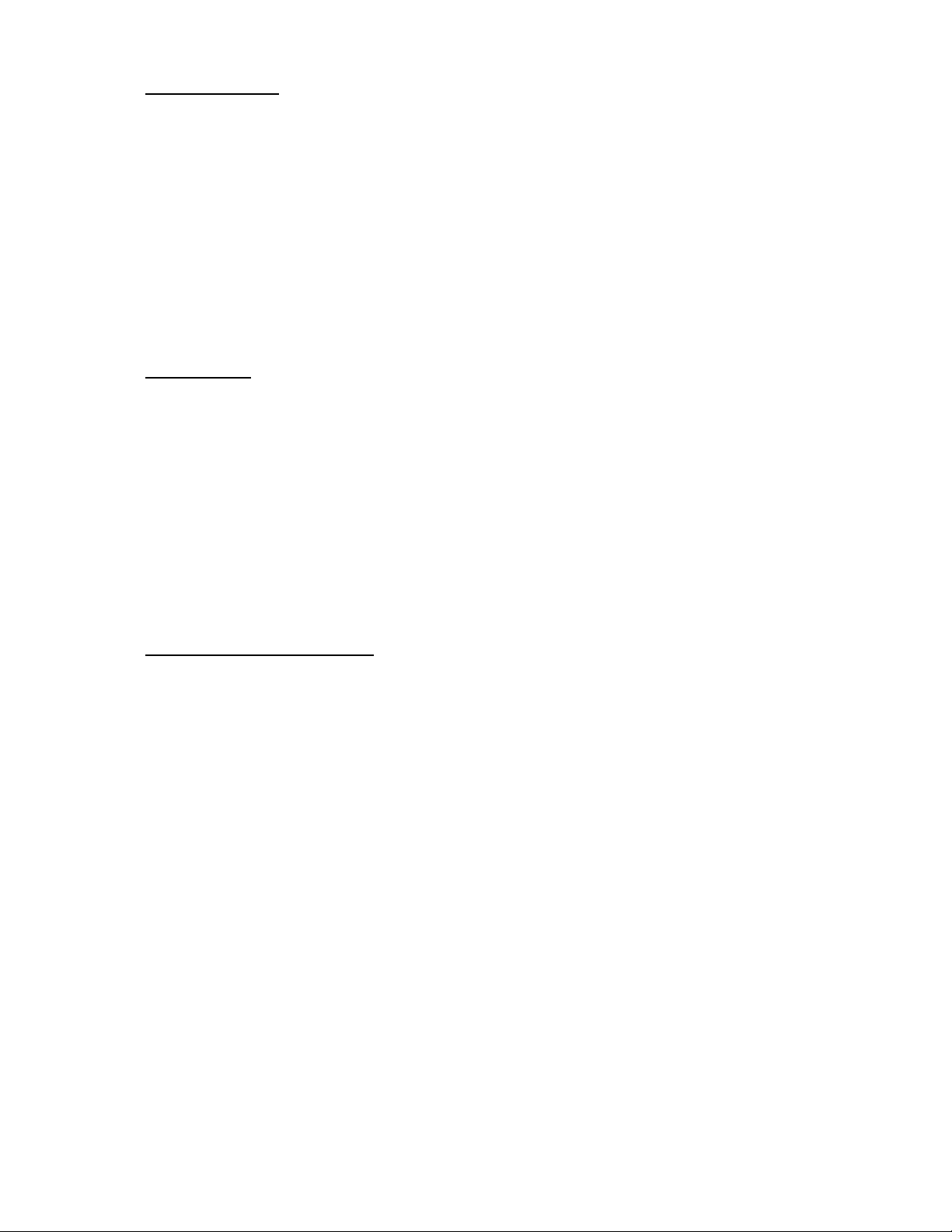

Upon retrieving a program the following window will open:

23

Page 25

From the File drop-down menu:

Select Open to retrieve a stored program fileneme.prg

Select Save to save a program

Select Restore Defaults to restore the default settings to all channels

Click on Get to select program 1 - 4, or retrieve the active program

Edit Channel- Each channel has its own alarm and warning levels, full-scale

setting and decimal setting. The auto zero time out and level are the same

for all 4 channels.

Disable Disables the channel display (three dashes across display)

Enable Enables the channel display

Alarm Enables the channel and alarm

flashing)

(display is active with green LED lit)

(display is active with green LED

Full-scale Sets the full scale range for the channel display.

Default is 1000v.

Alarm Level – When value exceeds this setting the alarm, if set,

will activate. Default is 9000v.

Warning Level - When value exceeds this setting the alarm, if set,

will activate. Default is 500v.

24

Page 26

Note: Alarm level must be greater than the Warning level. Full

scale setting must be greater than or equal to the alarm levels.

Alarm Delay – Delay time for the alarm/warning relay to open after

the value exceeds the set level. Default is 0 seconds. Setting an

alarm delay can prevent erroneous alarms.

Auto zero – Time and Level – When the Zero button is pressed

auto-zero begins. If the channel reading reaches the level within

the time period, the process stops and shows done. If it times out

without reaching the level, it will show error and exit out of the autozero process. Default time for Auto-Zero time is 20 seconds.

Default for Auto-Zero level is 3v.

After editing a program you may save it to your hard drive or send it

to the 177A as it’s active program. First exit the Edit Channel

window by clicking on O.K., then from the Store drop-down menu:

Click on Active Program or Program 1, 2, 3, or 4 to store your

program into permanent memory. If program 1, 2, 3, or 4 is set as

your active program those changes will also be applied.

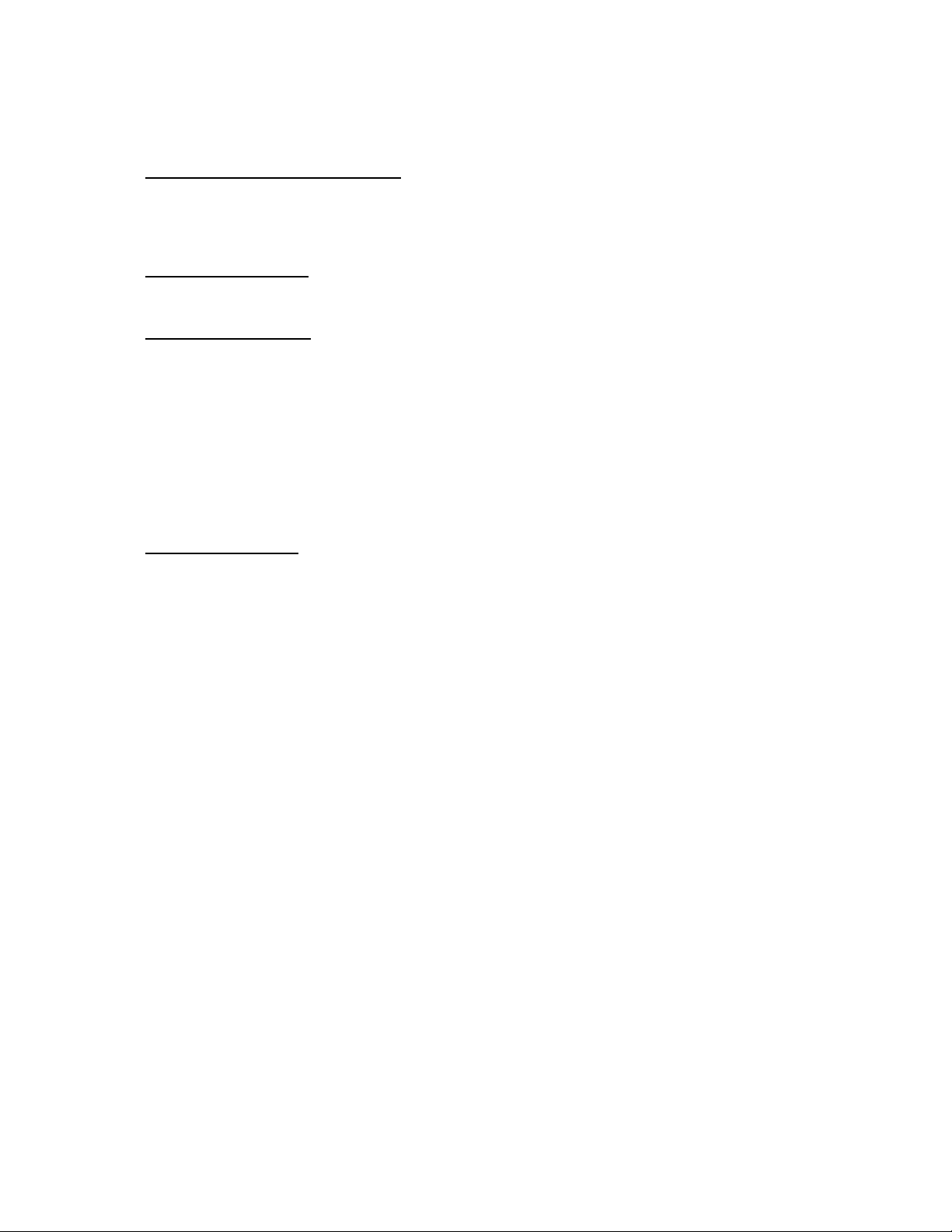

Hardware Config – Permits selection of the station (unit) number,

system type, active program, probe type, outputs, serial port, and baud

rate.

Station Number – Each 177A should be assigned a unique number for

identification, especially when more then one unit is connected to the

RS-485 bus. Station numbers may range from 1 to 255.

Active Program – Selects the program P0 (default) or P1 – P4 to be

activated.

System Type – Selects the alarm mode for the instrument

Non-Alarm – Alarms are disabled

Alarm Latching – When the probe reading exceeds the alarm level the

alarm relay latches causing the alarm LED for that channel to light.

Alarm remains in latched or in Alarm mode until the corresponding

channel ENA/DIS button is pressed on the instrument’s front panel, reset

from the PC or by external reset connection.

Alarm Unlatching - When the probe reading exceeds the alarm level the

alarm relay latches causing the alarm LED for that channel to light.

25

Page 27

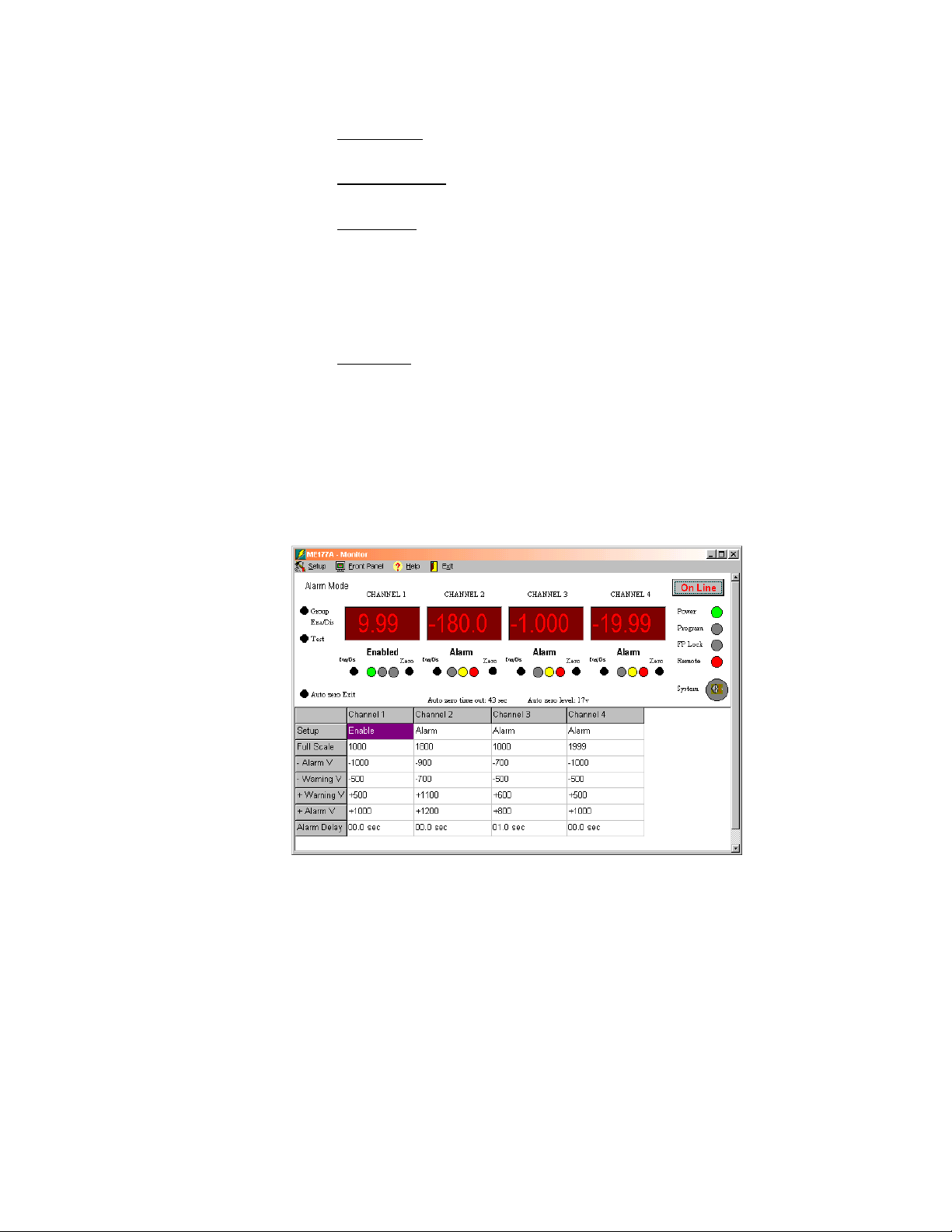

Monitor

The monitor screen enables you to observe the 177A console in real time. It reads data

from the 177A console and updates the screen at approximately 3 times per second. The

top half of the Monitor screen mimics the instrument’s front panel, while the bottom half of

the Monitor screen displays the active program from the 177A.

From the Monitor drop-down menu select Monitor, the following window will open:

Use the pc mouse to activate the instrument controls via the monitor screen.

Alarm remains in latched or in Alarm mode until the probe reading falls

back under the alarm level at which point the relay unlatches.

Probe Type – Must be set from the front panel set-up mode. Please

refer to the Front Panel Programming Tree included on your disk.

Output Voltage - Click in a specific channel’s probe type box to set the

output voltage to either 0-5V or 10V.

Serial Type – Set serial connection type: RS-232 RS-485Half, or RS485Full. If RS-485Full is selected and there are more then two units

connected, the RS-485 Terminator should be enabled on the first and

last units on the bus. Note: If the serial configuration is not properly

set up the instrument will lock up. If this happens turn off the unit,

disconnect the plug, reset the firmware to the correct type, restart

and reconfigure the software.

Baud Rate – Set the appropriate baud rate for your system. Should be

the setting used under “Connect.”

Group ENA/DIS – All channels in the group (of four) are enabled on power-up.

These channels may be immediately and simultaneously

disabled by pressing the GROUP ENA/DIS button on the

front panel or clicking the GROUP ENA/DIS button on the

program monitor screen.

Test Button – Tests the probe. Click on and hold causing an output and

display shift in the minus direction. Release the button, the

reading will return to normal if the probe is functioning properly.

On Line – Click on to set the instrument for continuous monitoring

Off Line – Click off to end continuous monitoring

26

Page 28

Ena/Dis – Toggles channel status Disable / Enable / Alarm for the

corresponding channel

Zero – Initiates Auto Zeroing for the corresponding channel

Auto Zero Exit – Stops ongoing auto zeroing

FP Lock – Click on the button on the monitor screen or select FP

From the Front panel drop-down menu:

Lock/Unlock – Select to toggle the front panel between lock / unlock. Red

LED indicates that the front panels controls have been locked.

When locked the front panel buttons do not function except for

Power, Setup and Exit. FP lock can be enabled or disabled

via the front panel controls or the pc software supplied.

Alarm/Non-Alarm –Select to set the Alarm mode. In Alarm mode channels

can be set to enable / disable / alarm. In Non-Alarm

mode channels can be set to enable / disable only.

System Diagnostic – Indicates if a system error exists. Select to test the

system. If the System icon is blinking it may be due to

one or more of the following:

A channel is enabled, the alarm is set but no probe is connected.

Fix: Disable the channel or connect a probe to the channel.

A channel, with its alarm activated, has reached the alarm level.

Fix: When the level has returned to its normal range toggle the

channel’s ENA/DIS button to clear the alarm.

System power supply is below normal. Check power supply.

Change Password – Select to change the password. Enter the default

password (Default password is 1 9 5 3 ) as prompted.

Enter the new password as prompted. Upon

completion, the system will confirm the password

change if accepted.

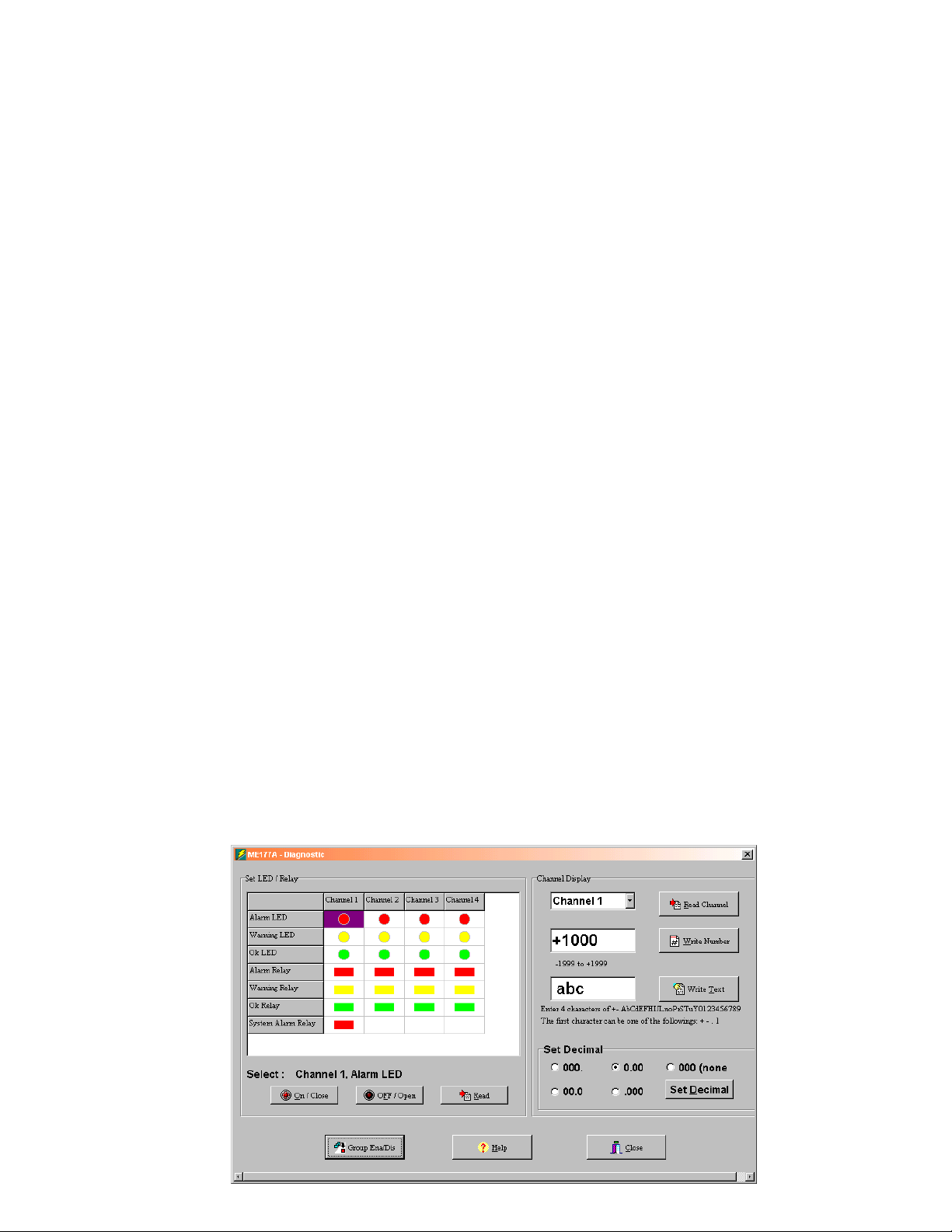

Diagnostic

From the Monitor drop-down menu select Diagnostic, the following window will open:

27

Page 29

Selecting this window from the MONITOR drop-down menu on the main

screen permits reading and writing to the front panel displays, LEDs, and

exercising the system relay contacts. Before using this feature, the 177A

must be connected and set to Group-Disable to permit control of these

items. This feature is helpful in testing all external relay contact wiring to

external devices.

To turn an LED or relay contact on or off or to obtain it’s status, click on the

appropriate box on the Set LED/Relay grid, then click the On, Off, or Read

button. Remember that the relay contacts are set to be “fail safe” meaning

that when conditions are O.K. in normal operation, these contacts are

closed. They will then open under caution or alarm conditions or system

failures. See Figure 8, on page 10, for examples of connecting external

devices.

To read a register (channel display), select the channel in the Channel

Display box in the right of the Diagnostic window, and then click the Read

button. The selected channel display data is shown in the window below the

channel display pull-down.

Numerical or text data can be written to any channel display by first selecting

the channel in the Channel Display pull-down in the right of the Diagnostic

window, entering the data to be written in the boxes below and then clicking

the Write Number or Write Text button.

Display decimal points can be checked by using the Set Decimal box.

Select the decimal position to be written and then click the Set Decimal

button. The display should show the correct decimal point with associated

zeros. This only checks the functionality of the decimal point and does not

alter the setting used in the Edit Channel screen of the Program Setup.

Any settings written to the unit during diagnostic checks are automatically

canceled when the unit is cycled back to Group Enable.

The Read / Write commands use MODBUS protocol. The addresses for the

relays, LEDs, and displays are listed below and in the Coil Address Table in

the

help menu of the Read / Write Coils window.

Register (Channel) addresses for MODBUS communications:

Channel 1 Display =Register 0

Channel 2 Display =Register 1

Channel 3 Display =Register 2

Channel 4 Display =Register 3

Coil (LED and Relays) addresses:

Channel 1 Alarm LED (red) = Coil 0 ---- Alarm Relay = Coil 12

Channel 2 Alarm LED (red) = Coil 1 ---- Alarm Relay = Coil 13

Channel 3 Alarm LED (red) = Coil 2 ---- Alarm Relay = Coil 14

Channel 4 Alarm LED (red) = Coil 3 ---- Alarm Relay = Coil 15

Channel 1 Warning (amber LED) = Coil 0 ---- Warning Relay = Coil 16

Channel 2 Warning (amber LED) = Coil 1 ---- Warning Relay = Coil 17

Channel 3 Warning (amber LED) = Coil 2 ---- Warning Relay = Coil 18

Channel 4 Warning (amber LED) = Coil 3 ---- Warning Relay = Coil 19

Channel 1 OK LED (green) = Coil 8 ---- OK Relay = Coil 20

Channel 2 OK LED (green) = Coil 9 ---- OK Relay = Coil 21

Channel 3 OK LED (green) = Coil 10 ---- OK Relay = Coil 22

Channel 4 OK LED (green) = Coil 11 ---- OK Relay = Coil 23

System Alarm Relay = Coil 24

To exit the Diagnostic window, click on the Close button.

To close the program software click on Exit on the main program window.

28

Page 30

Section 10

Programming via the Front Panel

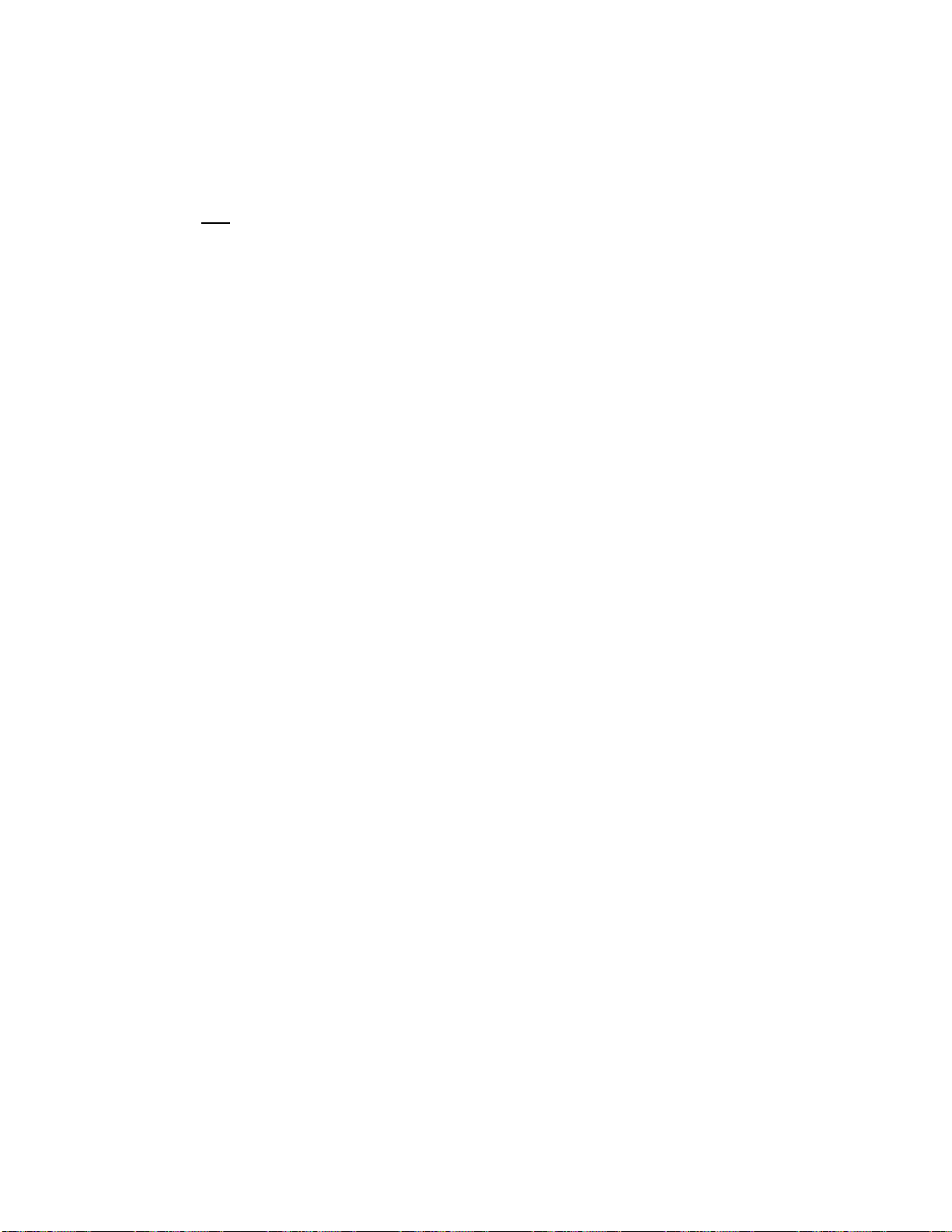

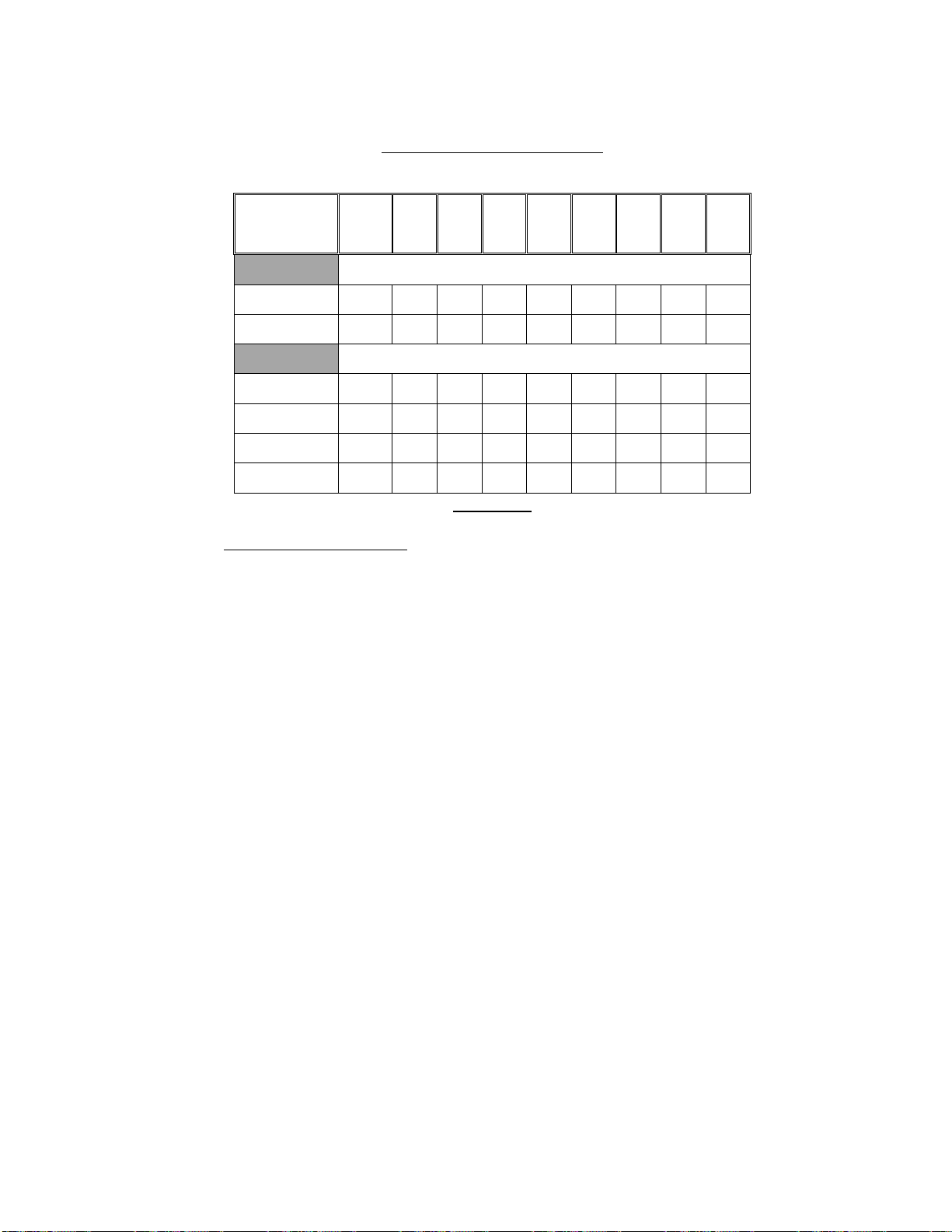

A programming tree is supplied to facilitate instrument programming via the front panel. Use

the programming tree in conjunction with the front panel features detailed at the beginning of

Section 9 to work your way through the programming sequences. Refer to the Front Panel

Program tree included on the CD provided.

To enter the programming mode via the front panel press the SETUP button.

Use the Up / Down / Left / Right arrow buttons to move between the displays.

Press the ENTER button to accept changes or perform the function.

Press the EXIT button to escape the changes or to exit SETUP mode.

29

Page 31

Section 11

Optional 4 – 20 mA Module

General

The optional 4-20 mA module provides 4 separate channel outputs in addition to the normal voltage

outputs. All channels have a common ground. The instrument provides a 12-volt nominal supply

which gives a compliance range of 7-volts. No external supply is required provided the 7-volt

compliance is observed.

An external supply may be connected which would be used by all four channels. The external supply

must be less than 25-volts. Output compliance of the is the external supply minus 5-volts. Note that

this supply will be referenced to chassis and analog ground.

A termination resistor must be installed on the 4-20 mA receiving equipment and must be less than

the compliance voltage, or

V

Specifications

Internal Supply: 11 volts min

External Supply: 24 volts max

complaince

> .020 *Rin where Rin is the receiver input resistance

30

Page 32

4 – 20 ma Option Board Installation Instructions

1. Un-plug all external connections to the 177A including the power cord.

2. Remove the 7 phillips-head screws that hold the cover of on the chassis. Remove the cover

and set aside.

3. Remove the 2 screws holding the 4-20 ma option cover on the 177A back panel. Discard

these parts.

4. Remove the 4 phillips-head screws from the tops of the mounting stand-offs as shown

below.

5. Remove mating connector from 177A/22A.

6. Align the electrical connector on the 177A/22A with J4 on the 177A main board.

7. Press down and engage this connector with J4 until the board is seated on all 4 mounting

stand-offs.

8. Re-install the 4 screws removed in step 4.

9. Replace the 177A cover and re-install it’s mounting screws.

10. Installation complete. Connect the 4-20 ma outputs as shown on next page using mating

connector supplied.

31

Page 33

4_20_APPNOTE_060607.cdr

060607EPF

32

Page 34

Section 12

Upgrading the Firmware

From time to time firmware upgrades may be available. With units version 1.03 or higher this

upgrade can be accomplished using the 177A software and obtained via download from our website,

e mail, or CD. Units that are version 1.02 require reprogramming of the processor and cannot be

upgraded via the 177A software. To check the version of your unit read the Channel 2 display at

power up. Note: For the duration of the firmware upgrade (approximately 6 minutes) the instrument

is not functional and the system is not monitoring. If you have any questions regarding firmware

upgrades please contact Monroe Electronics.

To initiate firmware upgrade, click on Update Firmware in the Program Setup drop-down menu. The

following window will appear:

Diagram 1

Clicking on Yes will present the following window:

Clicking on OK will present the following window:

Diagram 2

33

Page 35

The source file may be on a CD or downloaded from the Internet. If not available via our web site

please contact Monroe Electronics to obtain to receive firmware updates. Upon selecting the

appropriate upgrade file the instrument will “check” the update file and display the following if it is

O.K. for use. Or, if the file is not ok, “Invalid file format. File not loaded” will be displayed.

Diagram 3

Click on Yes to begin the download.

Diagram 4

If the unit is powered up in Load Program mode (caused by a previously incomplete loading process

due to power or user interruption) and Update Firmware is selected on the Main screen drop-down

menu the following window will be displayed:

Diagram 5

If your connections are good and power is supplied to the unit click on Yes and proceed to open the

source file (Diagram 2.)

During the download, if the chip is bad (doesn’t accept data), show:

"The program chip is defective."

"Please contact the manufacturer for replacement."

When the upgrade is completed successfully “Firmware Upgrade Success!” will be displayed:

34

Page 36

APPENDIX I

PROBE CONNECTION OPTIONS

There are at least six wiring options for the Model 177A with regards to the Model 1036E or 1036F

probes. The first three options are for non-hazardous (non-classified) locations where there are no

Intrinsic Safety (IS) considerations. The last three options are for hazardous (classified) locations

where Intrinsic Safety (IS) must be considered as part of the installation.

OPTION 1: All probes (1036E or 1036F) use factory installed cables, no extension cables, no IS

considerations

Probes are normally factory equipped with ten-foot-long cables. To use or test this

system, simply plug the probes into the appropriate connectors on the back of the

instrument.

OPTION 2: Probes use factory-installed cables and factory supplied extension cables, no IS

considerations

Extension cables are available in lengths up to 1000 feet. The extension cable order

number is 1036/12-XXXX where "XXXX" denotes the length of the cable in feet.

Factory supplied extension cables will be labeled with this part number near one

end.

The connector at one end mates with the connector on the end of the cable attached

to the probe and the one on the other end mates with the appropriate connector on

the back of the instrument. Although it is virtually impossible to err, it is advisable to

test the system "on the bench" in a confined area before permanently installing long

cable runs.

OPTION 3: 1036E probes with long customer installed cables with or without extension cables,

no IS considerations (see Figure A-I-1)

Wiring connections for customer installed 1036E probe cables for use in a non-IS

installation are shown in Figure A-I-1. Model 1036E probes have terminal blocks

inside their housings to which the cable wires are directly attached.

Note: 1036F probes have permanently attached cables and that this option does not

apply.

As in OPTION 2, it is advisable to "bench test" the system before removing the

factory-attached cables.

There are a couple of valid reasons for constructing your own cables:

a. You may be able to save money, although, in the long run,

troubleshooting may prove to be more costly than using factory-supplied

cables.

or

b. It is necessary to pull the cable through a fairly long run of conduit and

the connector won't fit. The largest rectangular cross sectional

dimensions of each connector are 5/8" x 11/4". The minimum conduit ID

through which this can be pulled is 13/8", although, it would be possible,

with a great deal of care, to pull up to five cables simultaneously through

that ID in a smooth straight run by staggering the connectors.

35

Page 37

There are a couple of ways to approach (b. [above]):

a. 1. Buy factory fabricated 1036/12-XXXX extension cables (where "XXXX" is

the length of the cable in feet) that are long enough to reach from the

console location, through the conduit, to the probe location with a few feet

extra for measurement error.

2. Remove and discard the factory supplied (usually ten foot) cable from the

probe and mount the probe housing.

3. Cut the female DB9 connector plug off of the extension cable.

4. Pull the cable from the instrument end of the conduit to the probe end.

5. Connect the wires to the terminal block in the probe housing as shown in

Figure A-I-1.

b. 1. Buy bulk cable and pull as above. Cable construction details are provided in

Figure A-I-1.

OPTION 4: 1036E probes with factory attached cables, extension cables (factory or customer

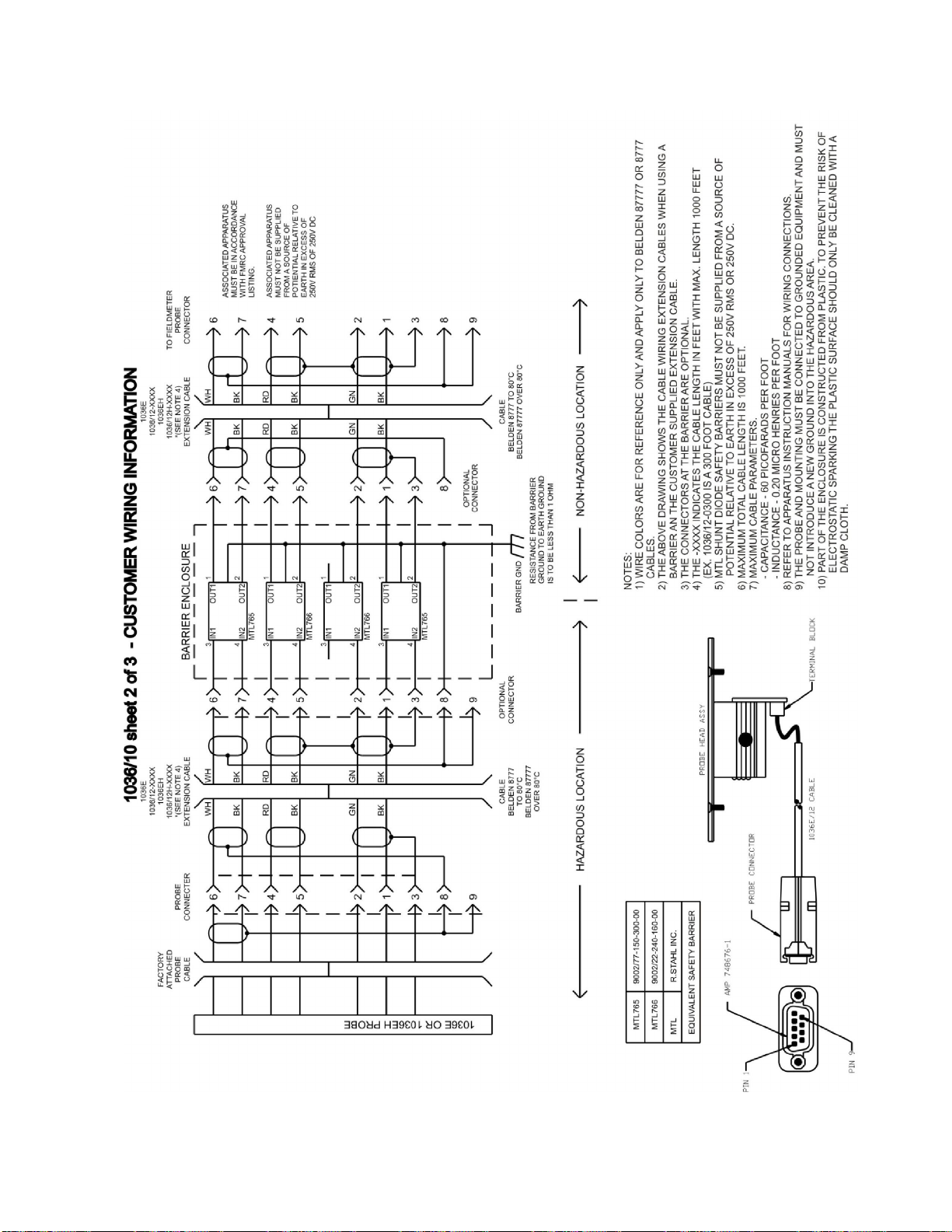

supplied) and IS barriers (see drawing 1036/10 [SHT. 2 of 3])

Please refer to drawing 1036/10 [SHT. 2 of 3]. This drawing shows wiring for one

channel. Generally, all channels would be wired alike. All barriers (four per

channel) may be located in a single barrier enclosure.

Note that on each side of the barrier enclosure, you have the option of using

connectors or "hard wiring" the cables directly to terminals on each barrier. Hard

wiring, again, allows the cables to be pulled through conduit without interference

associated with connectors.

Cable construction details are provided in Figure A-I-1.

OPTION 5: 1036F probes, extension cables (factory or customer supplied) and IS barriers (see

drawing 1036/10 [SHT. 3 of 3])

Cables are captive to Model 1036F probes.

OPTION 6: 1036E probes with customer supplied cables and IS barriers

(see drawing 1036/10 [SHT. 1 of 3])

Wiring must be as shown in drawing 1036/10 [SHT. 1 of 3]. Refer to Figure A-I-1

and Figure A-I-2 for cable construction details.

36

Page 38

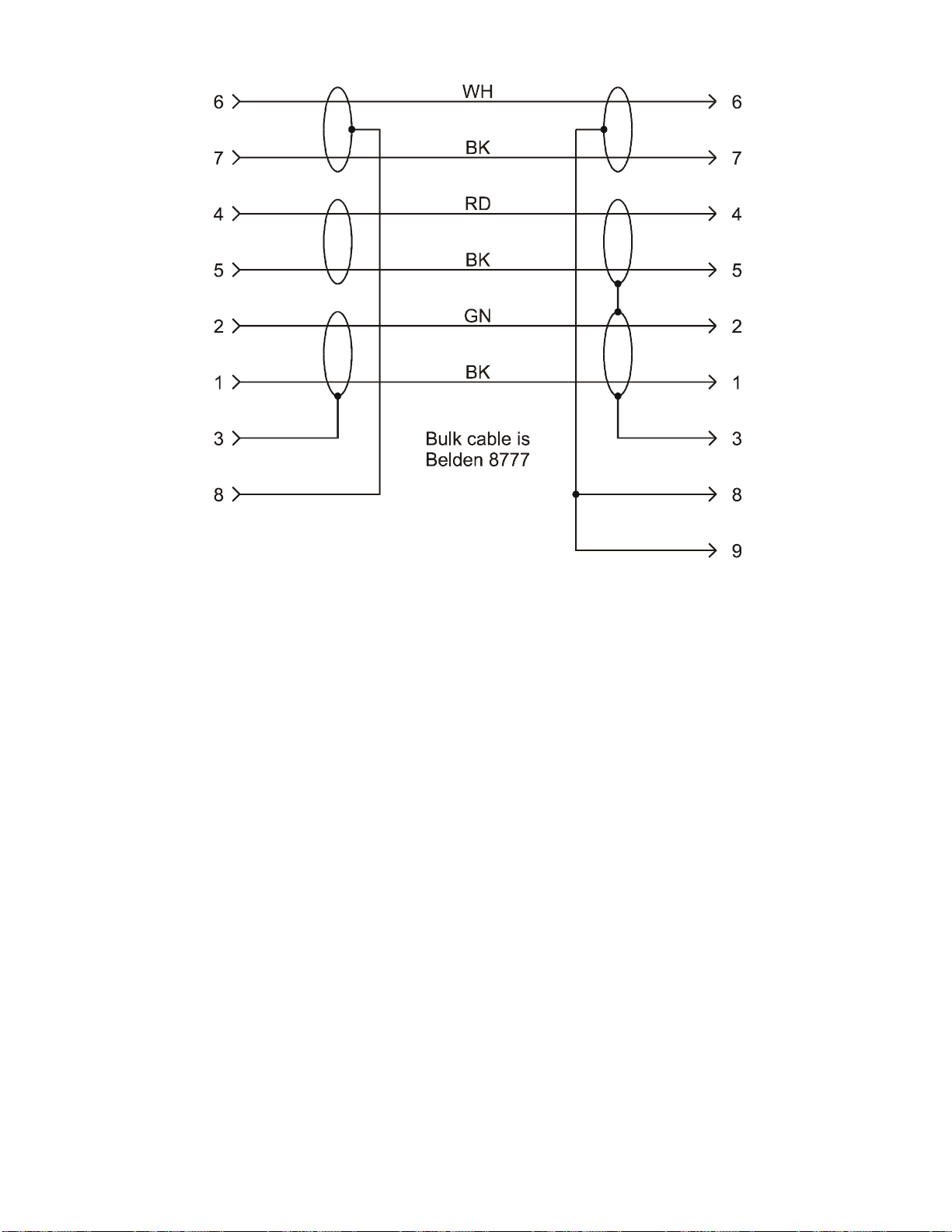

Figure A-I-1

37

Page 39

Figure A-I-2

38

Page 40

39

Page 41

40

Page 42

41

Page 43

APPENDIX II

INTRINSIC SAFETY BARRIERS

Model 1036E and 1036F Electrostatic Fieldmeter Probes meet Factory Mutual Research Corporation

requirements for Class I, Division 1, Groups C and D hazardous locations when installed in accordance with the

appropriate Monroe Electronics, Inc. control drawings included in this manual. Approved safety barriers must be

used as shown in the drawings to comply.

Copies of the Factory Mutual Research Corporation report 1Q3A9.AX specific to these probes are available on

request from Monroe Electronics, Inc.

Two manufacturers of IS barriers are currently approved:

MTL, Incorporated and R. Stahl, Inc.

8576 Wellington Road 9001 Knight Road

PO Box 1690 Houston, TX 77054

Manassas, VA 22110-1690

www.rstahl.com

www.mtl-inst.com (800) 782-4357

Tel. (703) 361-0111 (713) 792-9300

Fax. (703) 368-1029 Fax. (713) 797-0105

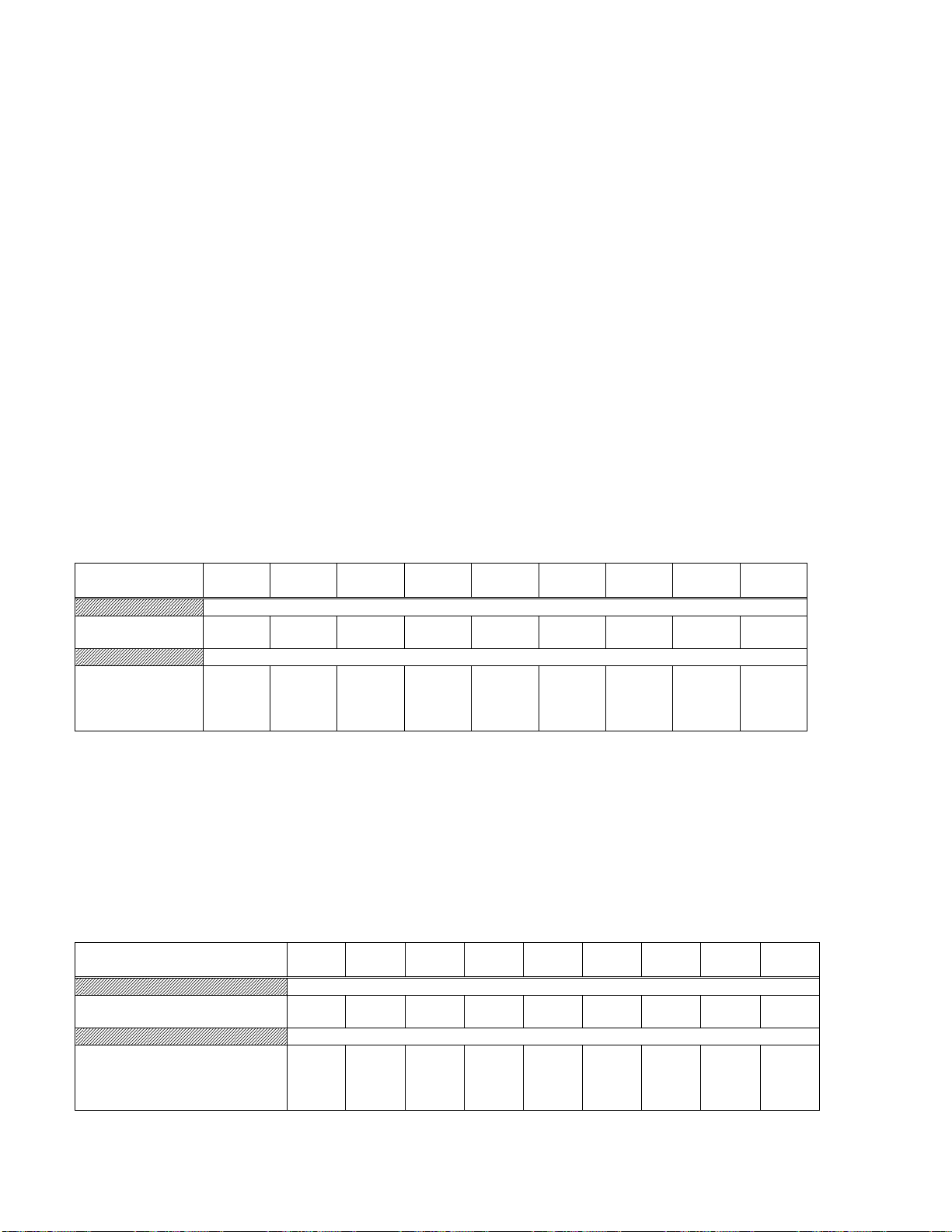

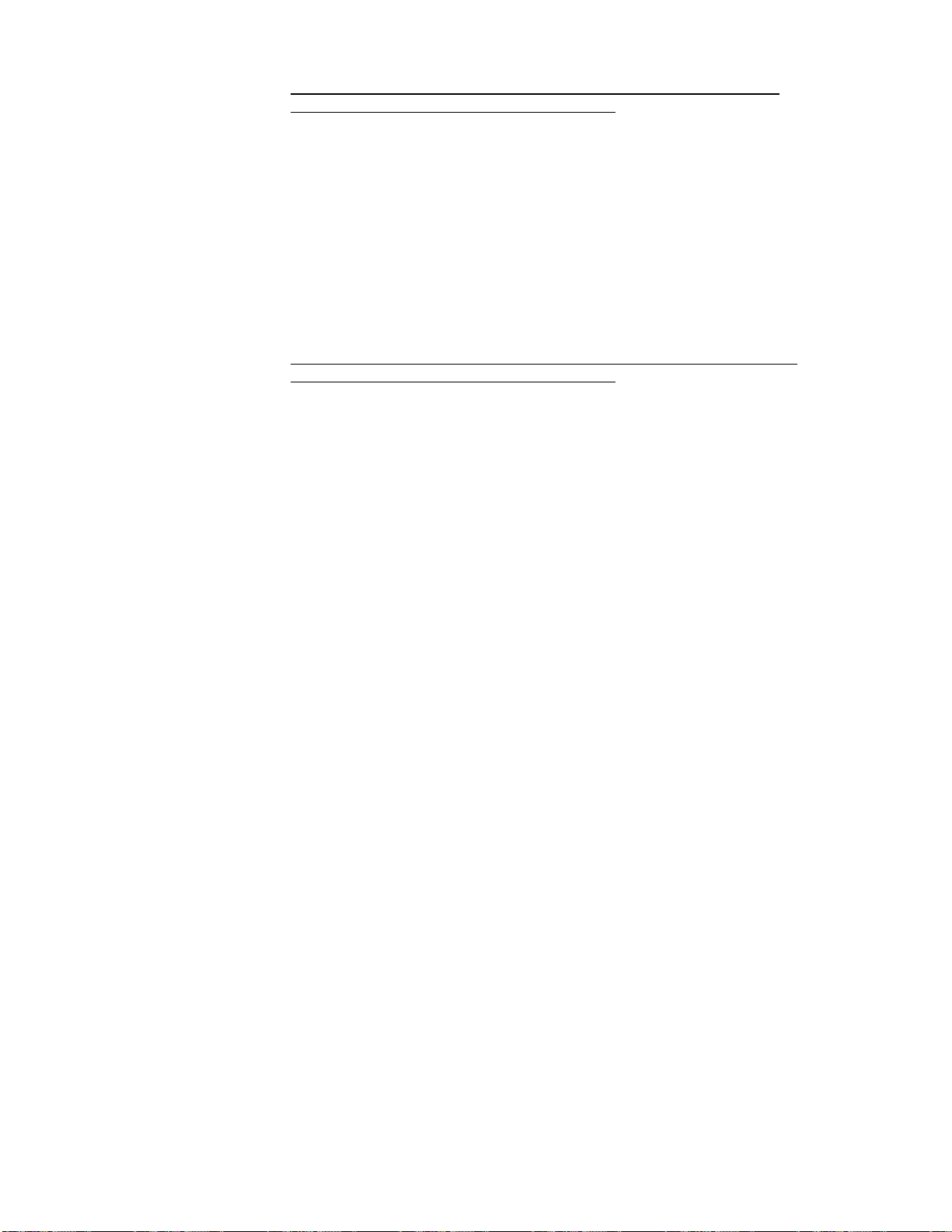

Barrier requirements and recommended enclosures are shown in the tables below:

Number of

Channels

Number of Barriers

MTL 765 2 4 8 12 16 20 24 28 32

MTL 766 2 4 8 12 16 20 24 28 32

Recommended Enclosures

MT 5 1

MT 12 1

MT 24 1 1 2 2

MT 32 1 2 2

NOTES for MTL Systems:

Enclosures include barrier mounting hardware, tagging strips, etc. Labeled wiring ducts are included with MT

32.

Listed enclosures are glass-filled polycarbonate with transparent lids. They are impact resistant, flame

retardant and dustproof to IEC529:IP65.

MTL will install barriers at no charge if supplied with position (sequence) information.

"Internals" (everything that normally goes in an enclosure but no enclosure) are available.

Number of

Channels

Number of Barriers

9002/77-150-300-00 2 4 8 12 16 20 24 28 32

9002/22-240-160-00 2 4 8 12 16 20 24 28 32

Recommended Enclosures

S 806 NF-12 1 1

S 1412 NF-25 1 1

S 1412 NF-50 1 1 1

S24H20BLP-80 1 1

1

2

4

6

8

10

12

14

16

Table 3 — MTL

1

2

4

Table 4 - R. Stahl

6

8

10

12

14

16

42

Page 44

NOTES for R. Stahl Systems:

Enclosures include mounting rails, insulating standoffs, ground terminals and labels.

Listed enclosures are Hoffman NEMA-4.

Some National Fire Prevention Association (NFPA) publications dealing with the subject of Intrinsic Safety (IS)

are:

NFPA 497A - Classification of Class I (Classified) Locations for Electrical Installations in Chemical

Process Areas (pamphlet)

NFPA 497M - Classification of Gases, Vapors and Dusts for Electrical Equipment in Hazardous

(Classified) Locations (pamphlet)

NFPA 493 - Intrinsically Safe Apparatus for Use in Division 1 Hazardous Locations (pamphlet)

NFPA 325M - Fire Hazard Properties of Flammable Liquids, Gases and Volatile Solids (pamphlet)

NFPA 496 - Purged and Pressurized Enclosures for Electrical Equipment (pamphlet)

Electrical Installations in Hazardous Locations by Peter J. Schram and Mark W. Earley - ISBN 0-87765-

356-9 (book)