Moniteur Sentinel-S3 ATEX User Manual

Installation and Operating Instructions

Moniteur

Hazardous Area Ratings - ATEX / IECEx

II 2 G Ex d IIB +H2 T6, IP66/67

II 2 D Ex tb IIIC T85°C, IP66/67

IECEx FMG 09.0002X

Hazardous Area Ratings - North America

Cl. I, Div. 1, Groups B, C, D

Cl. II, Div. 1, Groups E, F, G

TYPE 4X IP66/67

Alternate: Cl. I, Div. 1, Groups C, D

Cl. II, Div. 1, Groups E, F, G

Please check nameplate for actual ratings.

Operating Temperature (deg. C) -40° to 79°

Stan dards

ATEX:

EN 60079-0: 2009

EN 60079-1: 2007

EN 60079-31: 2009

EN 60529: 1991; +A1:2000

Alert: Read completely these instructions

before using this device. Follow all warnings,

cautions and instructions explicitly.

FM09ATEX0020X

IECEx:

IEC 60079-0: 2007

IEC 60079-1: 2007

IEC 60529: 2001

VPT Series - Sentinel S3

CAUTION: To reduce the risk of ignition of

hazardous atmospheres, disconnect the device

from the supply circuit before opening. Keep

assembly tightly closed during operation.

SETTING OF VISUAL INDICATOR

1. The Moniteur Visual Indicator is 100% adjustable to any

valve position. To adjust the indicator, remove the clear

cover by turning it counter-clockwise to disengage the

breach lock and then lift it off.

2. Remove the internal indicator portion to reveal the

adjusting ring. Loosen the ring screws, adjust the ring,

re-tighten the screws and replace the indicator.

3. For additional adjustment, the ring screws can be

removed and the ring rotated 45°, revealing additional

adjusting ring threads.

4. Replace clear cover.

WIRING OF VALVE POSITION TRANSMITTER

All wiring shall be done according to the specific wiring

diagram located inside the cover. All field wiring shall be

done according to site, local and national electrical codes.

Be sure to secure all the appropriate connections including

the ground. Supply connection wire shall be rated to at least

10°C above the rated ambient temperature of 80°C.

MOUNTING THE DEVICE TO YOUR ACTUATOR

1. Select the proper mounting bracket kit to mount the

device to your actuator or valve.

2. First mount the bracket to the device with the

hardware provided.

3. Attach the assembly to the actuator or valve.

SETTING OF SWITCHES / SENSORS

1. Loosen the cover screws and remove the cover.

Move the valve or valve actuator assembly to the

closed position.

2. Determine which switch is to be set. Move the

corresponding cam as required until the switch

or sensor is actuated.

3. Move the valve or valve actuator assembly

to the open position and repeat step 2.

4. Replace the cover and tighten the screws.

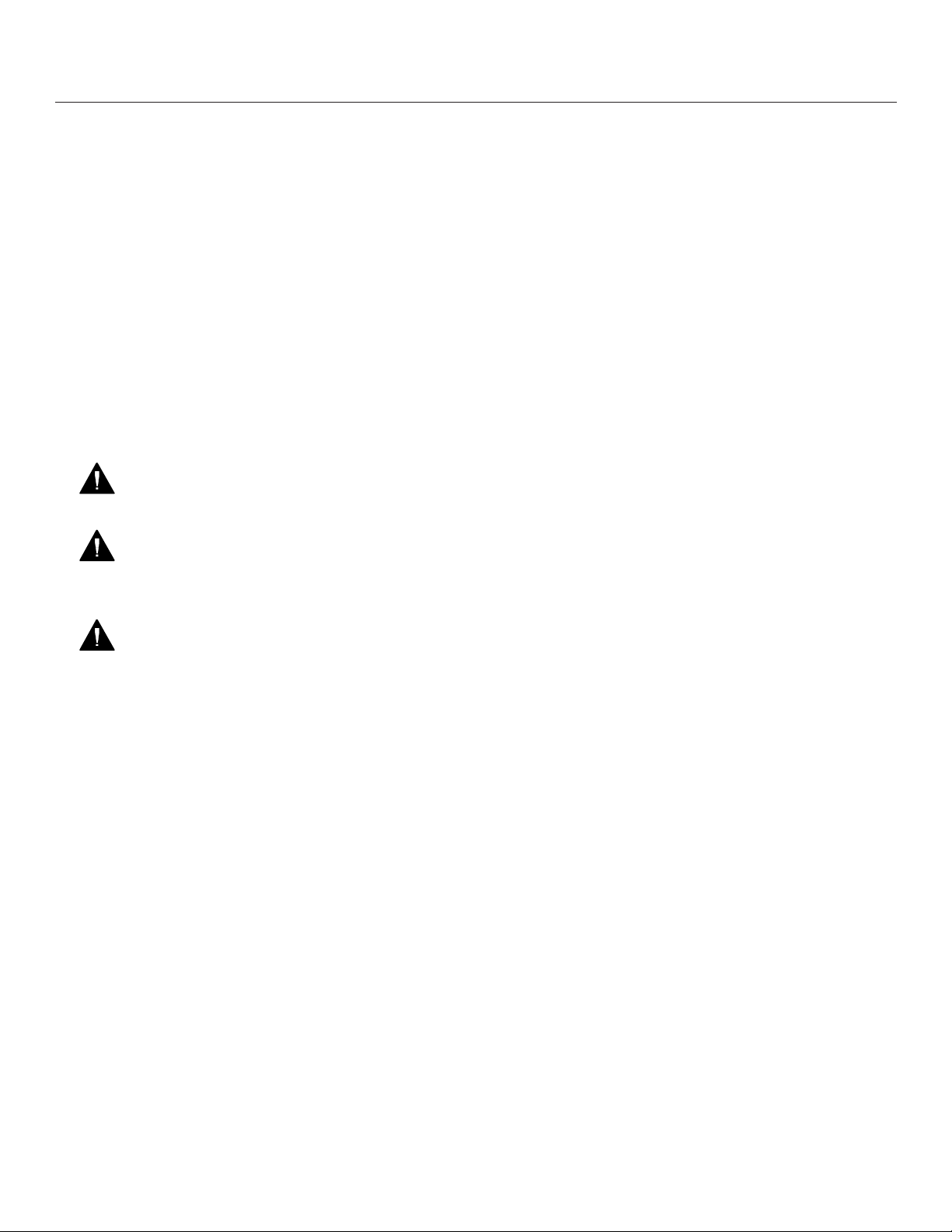

CONDUIT CONNECTIONS A, B, C

B

MONITEUR

MONITEUR

OPEN

A

Conduit

Code

0

5

A

B

E

F

Conduit

Conduit

A

3/4” NPT

3/4” NPT

3/4” NPT

M20

M20

M25

M25

½”NPT Male and Female

Conduits are also available

C

B

n/a

n/a

M20

n/a

M25

WARNING: Unused conduit entries shall be

closed with suitable certified plugs to

maintain the enclosure type of protection

Conduit

C

3/4” NPT

3/4” NPT

M20

M20

M25

M25

M O N I T E U R D E V I C E S I N C O R P O R A T E D

3 6 C o m m e rce Road, Cedar Gro v e , N J 0 7 0 0 9 Te l . ( 9 7 3 ) 8 5 7 - 1 6 0 0 F a x ( 9 7 3 ) 8 5 7 - 7 2 8 9

Form IO-S3A-EN Rev. B Page 1

w w w . m o n i t e u r d e v i c e s . c o m

Installation and Operating Instructions

Moniteur

ELECTRICAL RATINGS

Code

1

3

4

2

T

Code

8

K

See www.moniteurdevices.com or contact Moniteur for electrical ratings on switch types not listed here.

Switch Type

Mechanical - SPDT

Gold Plated - SPDT

Mechanical - DPDT

Tungsten TTL - SPDT

Rhodium TTL - SPDT

Supply

Sensor

P & F NJ2-V3

P & F NBB3-V3-Z4

WARNING: I o prevent fire or explosion, use only

with a certified seal fitting within 18 inches of the position transmitter enclosure.

f indicated on the nameplate: t

Voltage

5-25 VDC

5-60 VDC

15A / 250VAC

1A / 120VAC

10A / 250VAC

3A / 120VAC

0.25A / 120VAC

Load Current /

Target Absent

< 1 mA

< 0.7 mA

DC RatingAC Rating

2.5A / 24VDC, 2A / 48 VDC,

0.5A / 125 VDC, 0.25A / 250 VDC

1A / 24VDC

7A / 24VDC

2A / 24VDC

1A / 24VDC

VPT Series - Sentinel S3

Load Current /

Target Present

3 - 15 mA

4 - 100 mA

Operation

NAMUR

PNP

WARNING: Flange Cover Bolts are Custom Captivating, contact Moniteur for

genuine replacements. M5 Flange Bolts of type 316SS with min yield of 91,000 psi

are an acceptable alternative.

WARNING: Potential Electrostatic Discharge Charging Hazard - Dissipate static

electricity on this device before handling.

Page 2

M O N I T E U R D E V I C E S I N C O R P O R A T E D

3 6 C o m m e rce Road, Cedar Gro v e , N J 0 7 0 0 9 Te l . ( 9 7 3 ) 8 5 7 - 1 6 0 0 F a x ( 9 7 3 ) 8 5 7 - 7 2 8 9

w w w . m o n i t e u r d e v i c e s . c o m

Loading...

Loading...