Moniteur IO3-0405 User Manual

DESCRIPTION OF DEVICE

The Moniteur Valve Position Transmitter is an electromechnical device that produces an analog output signal

representative of the angular displacement of a quarter

turn valve, or other device operating between 0 and 90

degrees.

FACTORY SETTINGS

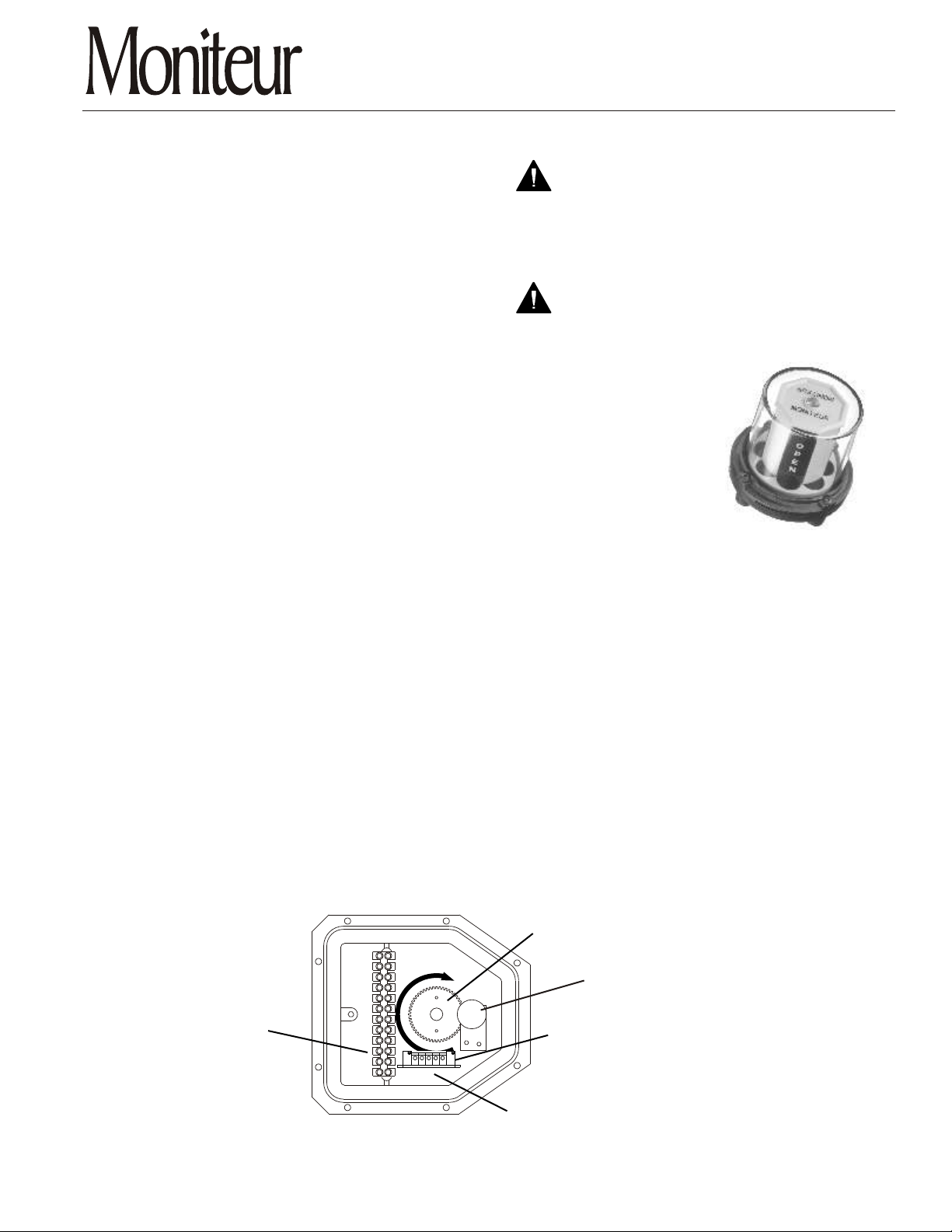

Clockwise - to - Close operation (see fig A)

Resistive: 0 - 1k Ohms (selectable)

Current: 4mA Closed , 20mA Open

INSTALLATION

Install the Valve Position Transmitter to the

valve/actuator package. Remove the enclosure cover

and wire unit to the appropriate terminal points.

Provided power must be within the operating

specifications of the devices.

Calibration Procedure (Resistive Output Models)

Calibration Instructions for Moniteur

Transmitter Series - Form IO3-0405

CAUTION: To reduce the risk of ignition of

hazardous atmospheres, disconnect the

device from the supply circuit before

opening. Keep assembly tightly closed

during operation.

CAUTION: Keep fingers and all objects away

from moving gears. Never cycle or move

the valve while adjusting the transmitter.

Verify the position of the valve/actuator package to ensure that the valve is in the position where the resistive

1.

reading will be '0' ohms. (Normally the valve closed position)

For clockwise to close operation(see fig. A) use an ohmmeter to measure resistance between terminal points 9

2.

and 10 on the terminal strip . For counter-clockwise rotation to close, measure resistance between terminal

points 10 and 11 on the terminal strip. In this position, the meter should read "0 ohms" or slightly higher.

If the resistive output does not read near "0 ohms" then a macro adjustment must be made. This is adjusted by

3.

by disengaging the main drive gear. Lift the large center gear slightly from the main transmitter shaft and

rotating the main gear until the desired reading is achieved. Release the main drive gear so that it re-engages

with the main drive shaft.

Cycle the valve/actuator package to the full open position. Reading at 90 degrees of rotation should be close to

4.

1000 ohms +/- 20% . (Less for smaller rotations, more for larger)

Cycle the valve, re-check the output. Re-calibrate if necessary.

5.

Close the transmitter housing. Tighten all screws.

6.

Terminal Block

Figure A

c

o

l

C

C

O

L

C

SPAN

Main Drive Gear

k

W

-

i

s

e

ZERO

--+BWR

Potentiometer

4-20 mA Transmitter

(current unit only)

Circuit Terminal Block

MONITEUR DEVICES INCORPORATED

36 Commerce Road, Cedar Grove, NJ 07009 Tel. (973) 857-1600 Fax (973) 857-7289

www.moniteurdevices.com

Form IO3-0405

Calibration Instructions for Moniteur

Transmitter Series - Form IO3-0405

Calibration Procedure (Resistive Output Models)

Instructions for clock-wise to close operation. See

reverse instructions for counter-clock wise to close.

Verify the position of the valve/actuator package to ensure that the valve is in the 4mA reading position

1.

(normally the valve closed position).

Connect positive and negative leads to the appropriate terminal points. Insure that voltage values are within

2.

units rated values.

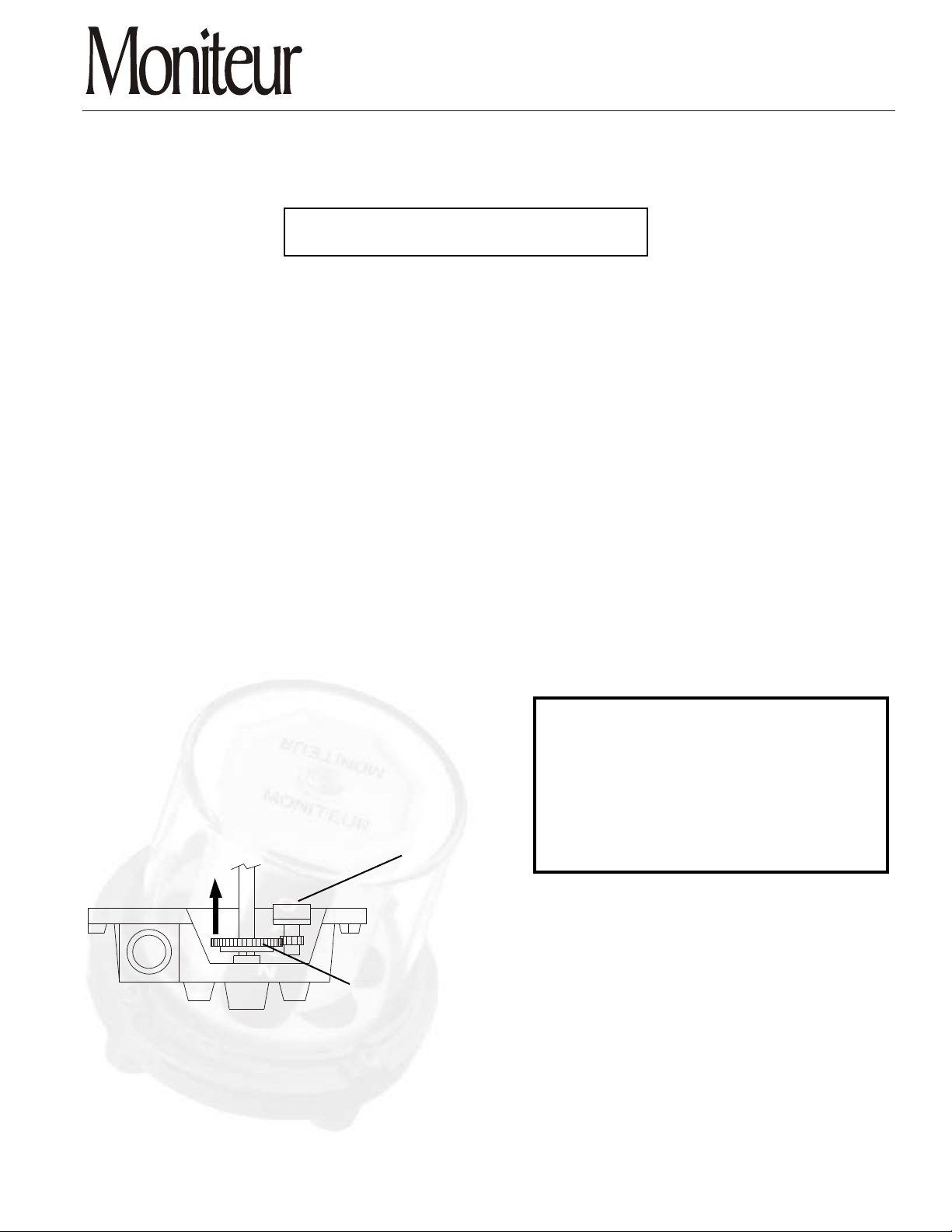

Connect a milliamp meter to the circuit. Lift the large center gear slightly from the main transmitter shaft and

3.

begin to rotate clockwise. Watch the amp meter while rotating. Reading will slowly decrease until the

potentiometer's limit has been reached. At this point, the milliamp output will jump or zero out. Stop rotation

of the main gear. Rotate the main gear counter-clock-wise approximately 1 tooth (10degrees).

Release the main drive gear so that it re-engages with the main drive shaft.

4.

With a small screw driver, turn the adjustment screw on the transmitter board adjustment pot("zero") until the

5.

meter reads 4mA (See Fig A).

Cycle the valve 90 degrees to the full open position.

6.

Turn the adjustment screw on the transmitter board adjustment pot ("span") (See Fig. A)

7.

until the meter reads 20mA.

Cycle the valve and recheck outputs at both ends of stroke. Make readjustments as necessary.

8.

Close the transmitter housing. Tighten all screws.

9.

Reverse Instructions

To use the transmitter with valve systems that rotate in the

counter-clock-wise direct to close, remove all power from the

system. On the circuit board terminal block, the BLACK and

WHITE wire leads must be switched. Connect the BLACK lead

to the terminal point marked (W) and the WHITE lead

connected to the terminal point marked (B). Tighten terminal

block screws. Lastly, when following directions listed above,

reverse the rotation (words in bold print) of the directions. (i.e.

Potentiometer

clockwise becomes counter-clock-wise). Follow directions

above.

Main Drive Gear

Figure B

MONITEUR DEVICES INCORPORATED

36 Commerce Road, Cedar Grove, NJ 07009 Tel. (973) 857-1600 Fax (973) 857-7289

www.moniteurdevices.com

Loading...

Loading...