Moniteur 50 User Manual

SIPART PS2 6DR400x-xx

SIPART PS2 PA 6DR410x-xx

Electropneumatic Positioner for

Linear and Rotary Actuators

Manual Order No. C79000-G7476-C158-1

SIPART, SITRANS, SIMATIC

are Siemens registered trademarks.

All other product or system names are (registered) trademarks of their respective owners and must be treated

accordingly .

The reproduction, transmission or use of this document or its contents is not permitted without express written authority . Offenders will be liable

for damages.

All rights created by the granting of patents or registration of a design are reserved.

Technical data subject to change without notice.

2

Contents

0 Information for the Operator 0-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.1 General information 0-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.2 Warning notes 0-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.3 Qualified personnel 0-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.4 Use as intended 0-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.5 Technical documentation 0-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.6 Warranty information 0-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.7 Information about delivery 0-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.8 Standards and regulations 0-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Introduction 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 General information about the device 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 The PROFIBUS 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.1 PROFIBUS DP and PROFIBUS PA 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2.2 Properties of the PROFIBUS PA 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Design and Method of Operation 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Components 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Motherboard 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.2 Electrical connections 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.3 Pneumatic connections 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.4 Mounting kit 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.5 Purging air switchover 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.6 Restrictors 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Method of operation 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 State as supplied 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Optional modules 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 HART module (devices without PROFIBUS PA only) 2-16. . . . . . . . . . . . . . .

2.5.2 Alarm module 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Jy module 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Accessories 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AG 1198 MG 124 en

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C158–01

i

3 Preparing for Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Instrument identification (type code) 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Dimension drawings 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Assembly 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.1 Mounting kit “Linear Actuator” 6DR4004–8V 3-4. . . . . . . . . . . . . . . . . . . . . .

3.3.2 Assembly Sequence (see Fig. 3-5) 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.3 Mounting kit “Rotary Actuator” 6DR4004–8D 3-7. . . . . . . . . . . . . . . . . . . . . .

3.3.4 Assembly Sequence (see Fig. 3-6) 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Electrical connection 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.1 Connections variations not ex-proof (devices without

PROFIBUS P A) 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.2 Connection variants not protected from explosion hazard (devices with PRO-

FIBUS P A) 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.3 Connection variations options not ex-proof 3-15. . . . . . . . . . . . . . . . . . . . . . .

3.4.4 Connection variations ex-proof 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4.5 Connection variations ex-proof (devices with PROFIBUS PA) 3-18. . . . . . .

3.4.6 Connection variations options ex-proof (devices with

PROFIBUS P A) 3-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Pneumatic connection 3-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Commissioning 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Operation 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 Display 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Control pushbuttons 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Modes 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Parameters 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Operation via PROFIBUS P A 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.1 Useful data via PROFIBUS 4-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5.2 Diagnostics acc. to PROFIBUS DP (DDLM_Slave_Diag) 4-31. . . . . . . . . . .

5 Service and Maintenance 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Technical Data 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Supply Range 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Supply range of basic instrument 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Supply range of options 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Supply range of accessories 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A Appendix A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A 1 Index A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A 2 Device master data file (GSD) A-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A 3 SIMATIC object table A-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A 4 References and catalogs A-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioner SIP ART PS2/SIPART PS2 PA

ii

C79000-G7476-C158–01

Information for the Operator

Information for the Operator

Dear customer,

Before you start work, please read this manual! It contains important

information and data that you must observe to ensure the availability of

the device and save yourself service costs. This will make it considerably easier to use this control equipment and lead to reliable results.

You have acquired a device that can be set up in different configurations:

❑ SIPART PS2 without PROFIBUS PA 6DR400x–xx

❑ SIPART PS2 with PROFIBUS PA 6DR401x–xx

This manual takes each of these possibilities into consideration. Any

differences between the devices are indicated specially.

0.1 General information

0

The product described in this manual left the factory in a perfectly safe

and tested condition. To maintain this condition and to achieve perfect

and reliable operation of this product, it must only be used in the way

described by the manufacturer. Successful and safe operation of this

equipment is dependent on proper handling, installation, operation and

maintenance.

This manual contains the information required for use as intended of

the product it describes. It is addressed to technically qualified personnel specially trained or having relevant knowledge of instrumentation

and control technology, hereafter called automation technology.

Familiarity with and proper technical observance of the safety notes

and warnings contained in this manual are essential for safe installation

and commissioning and for safety in operation and maintenance of the

product described. Only qualified personnel as defined in Section 0.3

has the necessary specialist knowledge to interpret the general safety

notes and warnings given in this document in specific cases and to

take the necessary action.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

0-1

Information for the Operator

The documentation supplied with the instrument is listed in Section 0.5.

This manual is not a permanent part of the scope of supply. For reasons of clarity, it does not contain every detail about every version of

the product described and cannot take every eventuality in installation,

operation, maintenance and use in systems into account. If you require

further information or if problems occur that have not been dealt with in

sufficient detail in this document, please request the required information from your local Siemens office or the office responsible for you.

Functionality, commissioning and operation are described in this manual.

Please pay special attention to the Warning and Note texts. These are

separated from the remaining text by horizontal lines and specially

marked with symbols (see Section 0.2).

0.2 Warning notes

Safety information and warnings are intended to avert danger from the

life and health of users and maintenance personnel and to prevent material damage. They are highlighted in this manual by the headings defined here. They are also marked by warning symbols next to where

they appear. The headings used have the following meaning for the

purposes of this manual and the product labels:

Danger

!

!

!

indicates death, severe personal injury or substantial property damage

will result if proper precautions are not taken.

Warning

indicates death, severe personal injury or substantial property damage

can result if proper precautions are not taken.

Caution

indicates minor personal injury or property damage can result if proper

precautions are not taken.

0-2

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Information for the Operator

☞

Note

indicates important information about the product itself or the respective part of the instruction manual which it is essential to highlight.

0.3 Qualified personnel

The result of unqualified intervention in the instrument or nonobservance of the warnings given in this manual or on product labels can be

severe personal injury and/or serious material damage. Therefore only

properly qualified personnel must make changes and settings in the

instrument.

For the purpose of the safety information in this manual and on the

product labels, qualified personnel are those who

S if they are configuration personnel, are familiar with the safety con-

cepts of automation technology

S if they are operating personnel, have been instructed in the handling

of automation equipment and know the content of this manual relating to operation

S if they are commissioning and/or service personnel, are trained to re-

pair such automation equipment and authorized to energize, de-energize, clear ground and tag circuits and equipment in accordance with

established safety practices

S and are trained in first aid

S and, in the case of ex-proof equipment, are trained and authorized

to carry out work on electrical circuits of equipment subject to explosion hazard.

Warning

!

The instrument must only be installed and commissioned by qualified

personnel.

The instrument is designed for connection to functional and safety extra low voltage.

Electrical safety depends only on the power supply equipment.

Pneumatic actuators exert considerable positioning forces. The safety

precautions of the actuator used must therefore be scrupulously observed during installation and commissioning in order to prevent injuries.

We explicitly draw your attention to the necessity of observing safety

regulations regarding operation in zones subject to explosion hazard, if

applicable.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

0-3

Information for the Operator

0.4 Use as intended

Use as intended for the purpose of this manual means that this product

must only be used for the applications described in the technical description (see also Section 3 of this manual).

The product described in this manual has been developed, manufactured, tested and documented observing the relevant safety standards.

If the handling rules and safety information for configuration, installation, use as intended and maintenance are observed, there is normally

no danger with regard to material damage or for the health of personnel. Extra low voltages that are connected must be fed in by safe isolation.

0.5 Technical documentation

In addition to this manual, the following documentation is also supplied

with the instrument:

❑ Leaflet “Operation – Concise Overview”

Order No. C73000–B7400–C151 (German) without PROFIBUS PA

Order No. C73000–B7476–C151 (English) without PROFIBUS P A

Order No. C79000–B7400–C160 (German) with PROFIBUS PA

Order No. C79000–B7476–C160 (English) with PROFIBUS PA

explains in visualized form the principle of operation and parameterization and automatic commissioning.

❑ “Assembly and Installation Instructions”

Order No. C79000–M7474–C156 (German/English)

contains the information required for assembly and installation.

It is an Instruction Manual as defined in the Directive of the Council

of the European Communities dtd. 23 March 1994 (94/9/EC).

0.6 Warranty information

We should like to point out that the content of this manual is not part of

and does not modify a previous or current agreement, undertaking or

legal relationship. Siemens is bound solely by the contract of sale,

which also contains the complete and exclusive warranty. The contractual warranty conditions are neither extended nor restricted by this

document.

0-4

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

0.7 Information about delivery

The scope of delivery is listed on the dispatch papers accompanying

the delivery in accordance with the valid contract of sale.

When you open the packaging please observe the information on the

packaging. Check that the delivery is complete and undamaged. If possible, compare the order number on the rating plates with the ordering

data.

For the supply range please see Section 7.

0.8 Standards and regulations

As far as possible, the harmonized European standards were used to

specify and manufacture this equipment. If harmonized European standards have not been applied, the standards and regulations of the Federal Republic of Germany apply (see also the Technical Data in Section 6).

Information for the Operator

If this product is used outside the area of applicability of these standards and regulations, please observe the standards and regulations in

force in the country where the product is operated.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

0-5

Information for the Operator

0-6

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Introduction

Introduction

1.1 General information about the device

The SIPART PS2 positioner is used to position and control pneumatic

actuators. The instrument operates electropneumatically, compressed

air is used as the auxiliary power.

SIPART PS2 P A

Purpose

In the SIPART PS2 P A version, the positioner is used as a component

in a digital process automation system. It communicates with the master as a slave via the PROFIBUS PS field bus. The field bus is used

not only for communication but also to supply the positioner with electrical power.

The positioner can be used to control, for example values with

1

Models

❑ a linear actuator (Fig. 1-3) or

❑ a rotary actuator VDI/VDE 3845 (Fig. 1-4).

Different ways of mounting are available for linear actuators

❑ NAMUR or IEC 534

❑ integrated mounting (ARCA, SAMSON)

so that the positioner can be mounted and used on all common types

of actuators.

The instrument is available for

❑ double-acting and

❑ single-acting

actuators, and for applications

❑ subject to explosion hazard or

❑ not subject to explosion hazard.

and the variants

❑ without PROFIBUS

❑ with PROFIBUS.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

1-1

Introduction

Housing

Degree of protection

Explosion protection

Options

The electronics including the display and the position feedback and the

valve manifold are integrated in the housing.

The housing is available in two variations:

❑ Plastic housing for double-acting actuators

❑ Metal housing for single-acting actuators

The instrument has degree of protection IP65.

The intrinsically safe version can be operated in hazard area zone 1 or

zone 2.

The instrument can be expanded with different option modules (see

Section 2.5). The following modules are available and can be operated

both singly and in any combination.

module: 2–wire current output 4 to 20 mA for position feedback

❑ J

y

❑ Alarm module: 3 binary outputs and 1 binary input

❑ HART module: HART communication (devices without

PROFIBUS P A only)

Accessories

❑ Manometer block: 2 or 3 manometers for single and double-acting

❑ Flange (NAMUR) for safety valve block

Environmental

protection

Only environmentally compatible materials were used in the packaging

system of this instrument.

The manual is printed on paper bleached using a chlorine–free method.

1.2 The PROFIBUS

The PROFIBUS (Process Field Bus)

❑ is an open communication system for automation

❑ is in use all over the world in thousands of applications

❑ is specified in the European standard EN 50170

positioner

1-2

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

1.2.1 PROFIBUS DP and PROFIBUS PA

Introduction

Transmission

technology

Topology

The PROFIBUS P A ( PA = Process Automation) is a variant of the

PROFIBUS DP (DP = Distributed Peripherals) which is widely used in

manufacturing.

The PROFIBUS PA makes use of special transmission technology and

therefore meets the requirements of process automation and process

engineering. This transmission technology is defined in the international

standard IEC 1158–2. The low transmission rate reduces the power

loss and therefore permits intrinsically safe technology for use in zones

subject to explosion hazard.

Moreover, almost any bus topology can be selected, so that bus, star,

tree, and mixed structures are possible. All types of field devices such

as transducers, actuators, analyzers, etc. can be connected to the

PROFIBUS P A.

The main advantages are:

❑ saving in installation costs

❑ the option of more detailed diagnostics thus increasing the availabil-

ity of plant sections

❑ the option of automatic correction of plant documentation

❑ the option of plant optimization during running operation

In an automation system, several PROFIBUS PA trains are usually

connected to the fast PROFIBUS DP via coupling units. The process

control system is also connected to the PROFIBUS DP.

Both bus systems make use of a standard protocol layer. That makes

the PROFIBUS PA a ”communication compatible” extension of PROFIBUS DP into the field.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

1-3

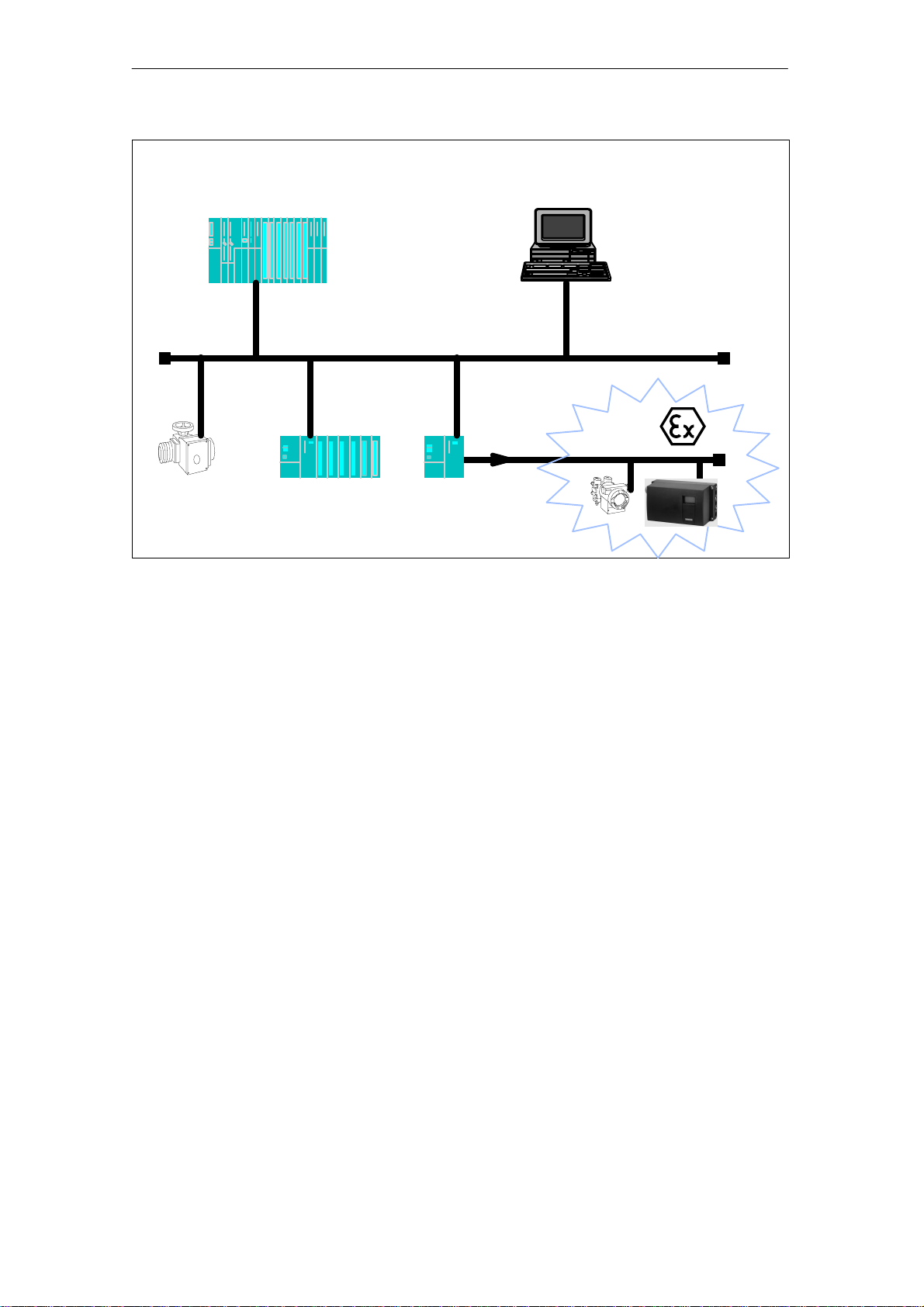

Introduction

Master

(class 1)

PROFIBUS DP

Slaves

(field devices, distributed I/Os, lower–level controls,

gateway to PROFIBUS P A)

Fig. 1-1 Typical PROFIBUS automation system

Fig. 1-1 shows a section of a typical PROFIBUS automation system.

The control system consists of two masters with distributed tasks:

Master

(class 2)

PROFIBUS P A

J

The master class 1 performs open–loop and closed–loop control tasks,

master class 2 is used for HMI functions. Exchange of measuring and

positioning data is performed cyclically between master 1 and the field

devices. Parallel with this data, the status information of the field devices is transmitted and evaluated in master 1. Parameterization of the

field devices or reading of further device information is not performed in

cyclic operation.

The control system obtains the information required to establish communication from the device–specific device master data files GSD (see

Appendix).

In addition to cyclic operation one or more masters of class 2 can access the field devices non–cyclically. By this method of communication,

further information can be fetched from the devices or settings made in

the devices.

1.2.2 Properties of the PROFIBUS PA

The PROFIBUS PA permits bidirectional communication from a bus

master with the field devices via a shielded, twisted pair. At the same

time the two–wire field devices are powered via the same lines

(current J in Fig. 1-1).

1-4

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Introduction

Profiles

PLS, PC

In addition to the EN standard 50170, the PNO (PROFIBUS user organization) has defined the functionality of the individual field device types

in a profile description. These profiles define minimum functional requirements and optional extensions. The device–internal ”device management” provides the configuration tool of the control system with all

basic information necessary to locate the profile parameters. In that

way, one parameterizing tool can operate all profile–compliant devices,

whatever their type or manufacturer.

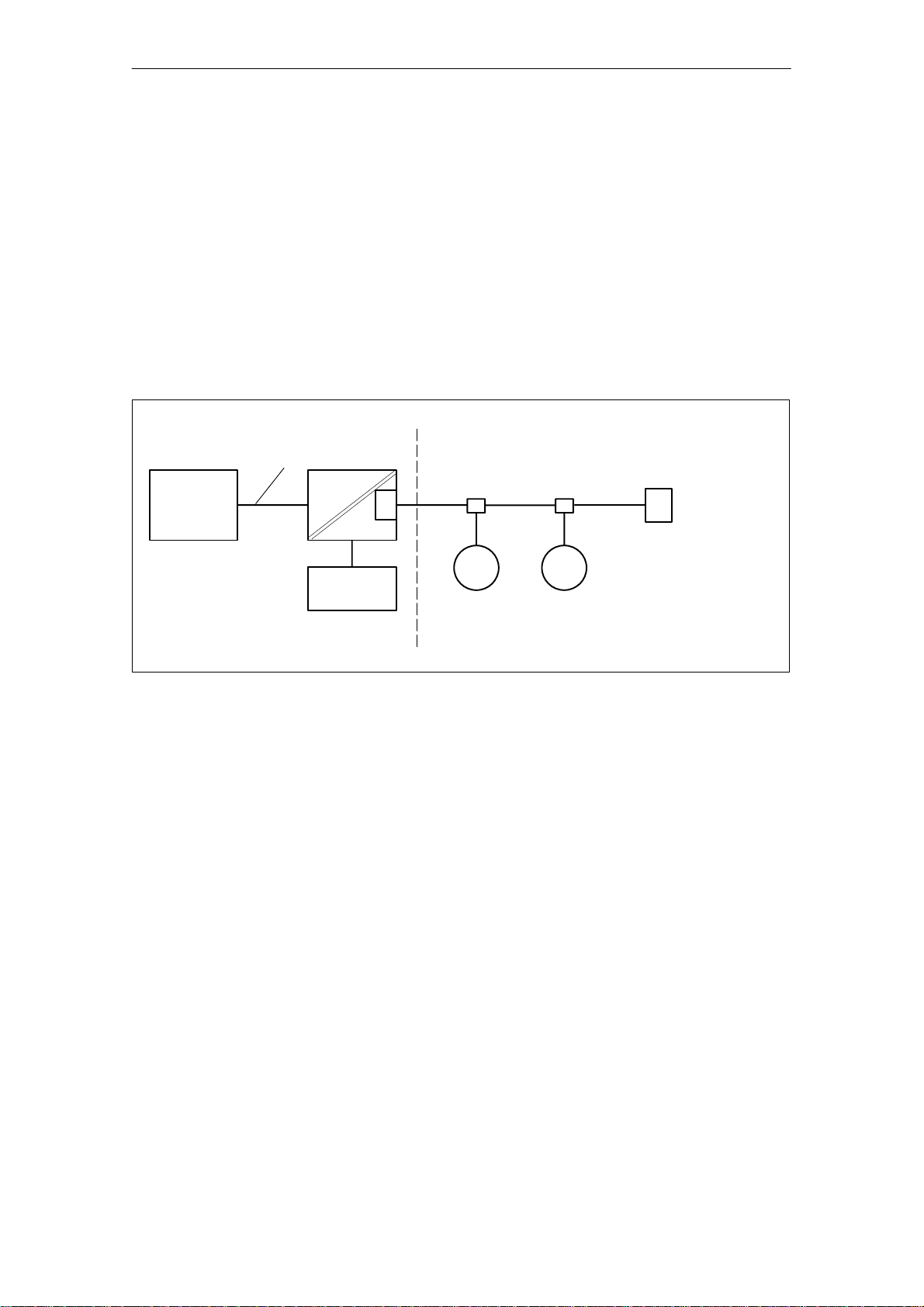

The system must be implemented with one or more PROFIBUS PA

trains depending on the automation task and therefore the number of

field units and the required time response. One PROFIBUS PA train

consists of the components shown in Fig. 1-2.

Control room Field

PROFIBUS DP

Coupler

T

Power

supply

PROFIBUS PA

FG FG

T

additional

line termination

Fig. 1-2 PROFIBUS PA architecture

Link

Control is performed by the central process control system PCS or for

low requirements, by a PC. Usually, the functional signal conversion

DP–PA, bus feed, and bus termination are combined into one linking

module. Depending on the number PROFIBUS PA field devices to be

operated in the automation system and the required time response, a

DP/PA coupler or for higher requirements, a more powerful DP/PA link

is used.

For transmission reasons, the bus must also be fitted with a terminating

resistor T at the remote end. If the recommended bus cable is used,

the theoretically possible maximum line length (sum of all line sections)

is 1900 m.

During configuration, the power requirement of the individual stations

and the voltage drop on the cable must also be taken into account. The

individual FG field devices can be connected to almost any point in the

bus system. For further information see the ”PNO–Leitfaden PROFIBUS P A”/1/.

DP/PA couplers or DP/PA links are powered from a power supply unit

with SEL V (safety extra–low voltage). This power supply unit must

have sufficient back–up reserves to provide back–up power during

short power interruptions.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

1-5

Introduction

The maximum number of devices that you can connect to a bus train

depends on the current consumption and the application conditions.

During operation in a safe zone, the couplers or links supply up to 400

mA to the bus.

In zones subject to explosion hazard, intrinsic safety is only ensured if

the maximum power fed into the bus does not exceed certain voltage

and current values.

These are usually:

EEx ia IIC Current I

Warning

!

To power the intrinsically safe PROFIBUS only certified power supply

units (DP/PA couplers or links) must be used. See the Ex conformity

declaration for the requirements (see Assembly and Installation

Instructions).

< 128 mA, voltage U0<15V

S

From the sum of the maximum current consumption of the connected

devices (acc. to standard = 10 mA per device) and the available current, it is possible to calculate the number of devices that can be connected to a bus train. For safety reasons, a current reserve must be

planned because otherwise there is a risk that a defective device could

overload the bus by increased current consumption and that therefore

the power supply and communication with all the other non–defective

stations could collapse. The size of the required reserve depends on

the current increase in case of fault stated by the device manufacturer.

The electronic current limitation additionally installed in the SIPART

PS2 with PROFIBUS P A ensures a maximum increase of the current

consumption by 3 mA for a defective device.

In order to distinguish the connected process devices from one

another, each device has its own address. The address setting is described in Section 3.6 ”Commissioning”.

For more detailed information about the components, assembly guidelines and configuration, see the technical description of the field

technology package /2/.

1-6

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Introduction

1

4

2

3

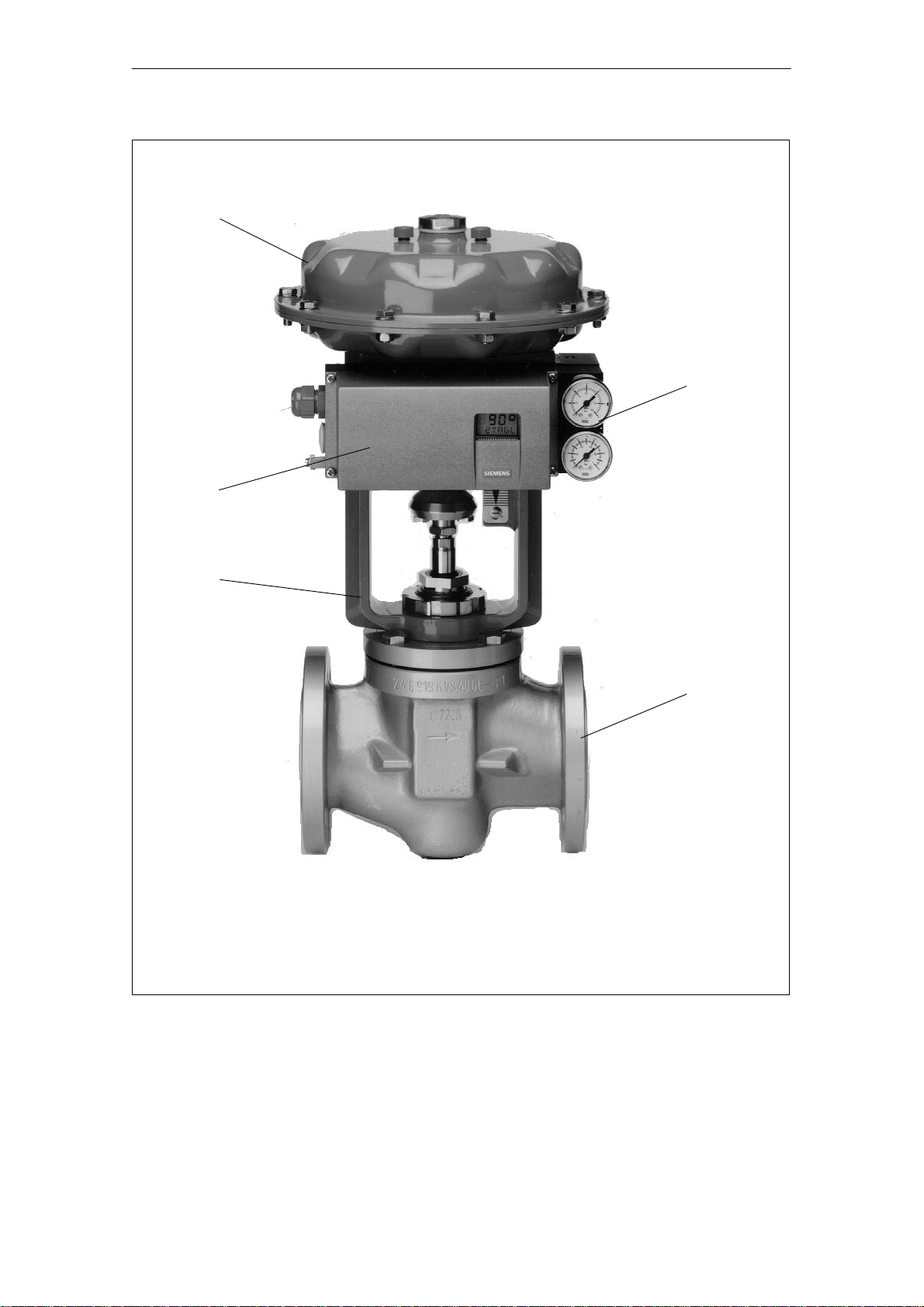

1 Actuator

2 Positioner, single acting in metal housing

3 Intermediate bracket

4 Manometer block, single acting

5 Valve

Fig. 1-3 Positioner mounted on linear actuator (single acting)

5

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

1-7

Introduction

1

3

2

1 Positioner, double acting in plastic housing

2 Rotary actuator

3 Manometer block, double acting

Fig. 1-4 Positioner mounted on rotary actuator (double acting)

1-8

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Design and Method of Operation

Design and Method of Operation

This Section describes the mechanical and electrical design, the components of the instrument and the principal method of operation of the

instrument.

2.1 Overview

Introduction

Devices without

PROFIBUS P A

The SIPART PS2 electropneumatic positioner forms a closed-loop control system together with an actuator. The current position of the actuator is acquired via a servo-potentiometer and returned as actual value

x. The setpoint and actual values are output simultaneously on the display.

Setpoint w is formed by a current fed to the SIPART PS2 positioner

which is also used to power the instrument in 2-wire operations. In

3/4–wire operation the power supply is taken from a 24V power input.

2

Devices with

PROFIBUS P A

The setpoint is supplied to the positioner by the control system digitally

via PROFIBUS P A.

The PROFIBUS PA variant of the SIPART PS differs from previous versions by its bus interface. The basic functions including operation and

display have remained almost unchanged. The interface tasks are performed by function blocks 1 to 6 (see Fig. 2-13).

The positioner functions as a predictive 5-step controller, the output

quantity ±∆y of which is used to operate the integrated control valves

with pulse-width-modulated pulses.

These positioning signals effect differences in pressure in the actuator

chamber(s) and consequently adjustment of the actuators until the system deviation is reduced to zero.

Process operation (automatic and manual mode) and configuring

(structuring, initialization and parameterization) is performed with the

three pushbuttons and the display when the housing cover is removed.

The standard version of the basic instrument also has a binary input

(BE1). This input can also be configured individually and is primarily

intended for blocking operating levels.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-1

Design and Method of Operation

The actuator position can be output as 2–wire signal Jy = 4 to 20 mA

using the Jy option module.

The actuator can also be monitored for two programmable limit values.

Limit value alarms are output via the alarm option module that can also

monitor and signal the function of the positioner and the actuator. In

automatic operation the system deviation is monitored as a function of

the actuating time. The three binary outputs are implemented as semiconductor outputs and feature self–annunciation, i.e. the outputs respond even if the auxiliary power or the electronics fails.

Depending on how it is configured, the actuator can be blocked, for example, or put into its final position by an external event via the binary

input (BE2) which is also located on the alarm module.

Devices without

PROFIBUS P A

2.2 Components

1

2

3

4

5

6

7

8

9

10

10

Via the optional HART module it is possible to communicate with the

controller.

90°

33°

89

3

6.1

6

6.2

7

11

1 Input: inlet air

2 Output: positioning

pressure Y1

3 Display

2

138

4 Output: positioning

pressure Y2

**)

5 Control pushbuttons

6 Restrictor Y1

1

8

6.1 Restrictor Y1

6.2 Restrictor Y2

**)

**)

7 Transmission ratio selector

8 Adjusting wheel clutch

4

238

9 Terminals

Basic instrument

10 Terminals

5

Optional modules

1 1 Purging air selector

**)

for double-acting

actuators

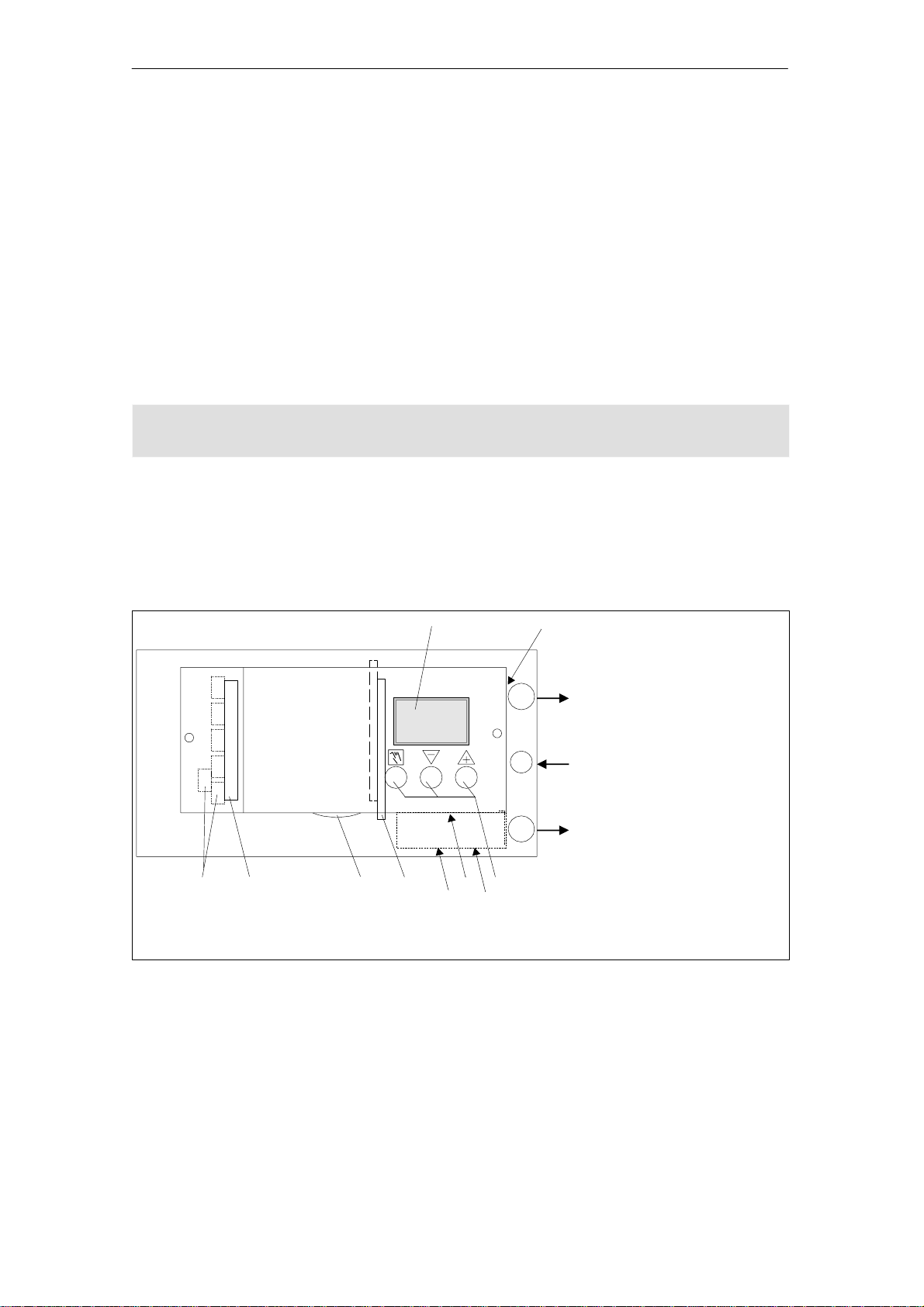

Fig. 2-1 View of the instrument (cover open), devices without PROFIBUS PA

2-2

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Design and Method of Operation

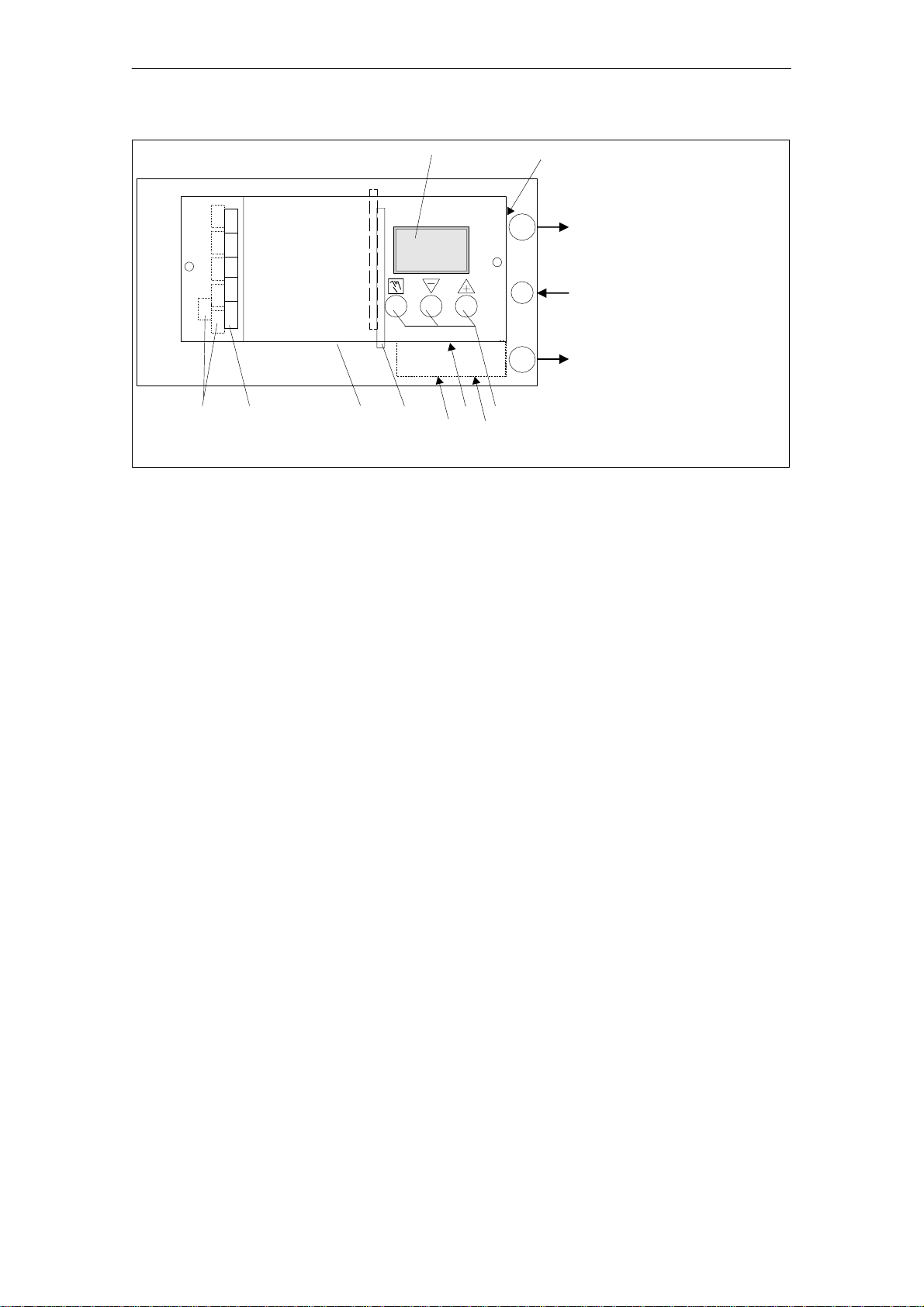

3

11

1 Input: inlet air

2 Output: positioning

90°

3

7

9

10

138

8

3 Display

4 Output: positioning

2

5 Control pushbuttons

6 Restrictor Y1

6.1 Restrictor Y1

1

6.2 Restrictor Y2

7 Transmission ratio selector

8 Adjusting wheel clutch

9 Terminals

238

4

10 Terminals

1 1 Purging air selector

**)

for double-acting

10

33°

89

6

7

6.1

5

6.2

actuators

Fig. 2-2 View of the instrument (cover open), devices with PROFIBUS PA

2.2.1 Motherboard

The motherboard contains all electronic elements such as CPU,

memory, ADC. It also contains the display and the control pushbuttons.

pressure Y1

pressure Y2

**)

**)

**)

Basic instrument

Optional modules

The terminal blocks for connecting the option modules are also located

on the motherboard.

2.2.2 Electrical connections

The terminals of the basic instrument, the Jy and the alarm option module are located on the front on the left–hand side and are offset in a

step–shaped arrangement.

A cover protects the modules from being pulled out and prevents incorrect installation.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-3

Design and Method of Operation

2.2.3 Pneumatic connections

The pneumatic connections (G1/4) are located on the right-hand side of

the positioner (Fig. 2-3).

Positioning pressure Y1 for single and double–acting actuators

Feedback shaft

Inlet air P

Positioning pressure Y2 for double–acting actuators

Outlet air E with silencer on the underside of the instrument

Fig. 2-3 Pneumatic connection

Z

Two pneumatic connections for the integrated installation of single–acting linear actuators are located on the rear of the positioner:

❑ Positioning pressure Y1

❑ Air outlet E

These connections are locked with screws when supplied (see Fig. 3-2

and Fig. 3-4).

Outlet air E is used to ensure a flow of dry instrument air through the

pick–off area and the spring chamber to prevent corrosion.

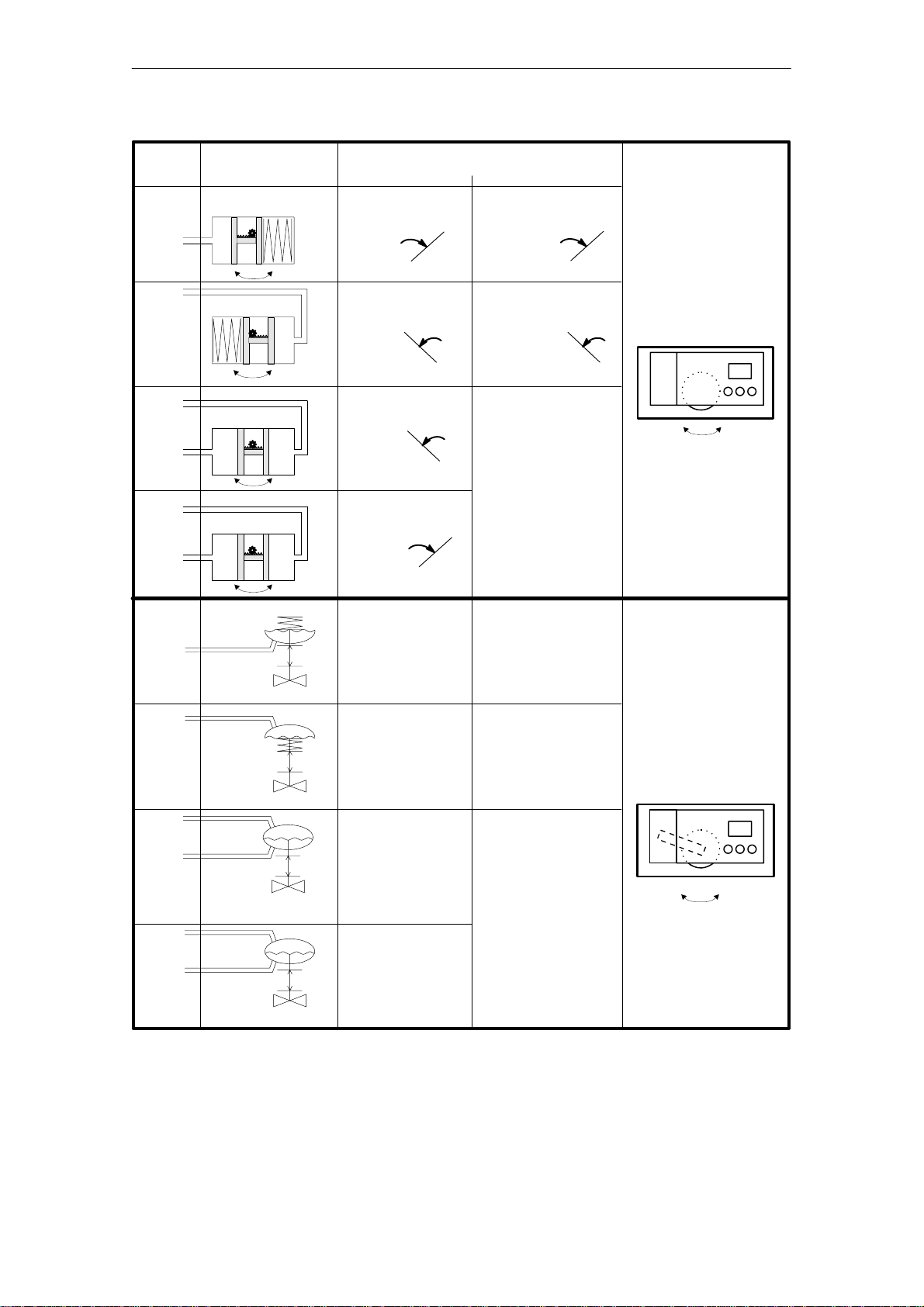

Fig. 2-4 shows pneumatic connection options for various types of actuators with the positioning action and the safety position after auxiliary

power failure.

2-4

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Design and Method of Operation

Positioning

pressure

Connection

Y1

Y1

Y2

Y1

Y1

Y2

Actuator type

OpenClosed

OpenClosed

OpenClosed

OpenClosed

Safety position after auxiliary power failure

electrical pneumatic

Closed Closed

Open Open

Open

Undefined

Closed

On rotary actuators

the counter–clockwise direction of rotation – looking at

the actuating shaft of

the valve – is defined

as “open”

Closed

.

Open

Y1

up

down down

down

Y1

up

down

up up

Y2

Y1

up

down

up

Y1

Y2

up

down

down

Fig. 2-4 Pneumatic connection and positioning action

up down

Undefined

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-5

Design and Method of Operation

2.2.4 Mounting kit

The positioner can be mounted on nearly all common types of actuators using the appropriate mounting kit.

2.2.5 Purging air switchover

The purging air changeover switch above the pneumatic terminal block

(Fig. 2-5) on the valve manifold can be accessed when the housing is

open. When the switch is in position IN the interior of the housing is

purged with very small quantities of clean and dry instrument air. In position OUT the purging air is led directly out of the instrument.

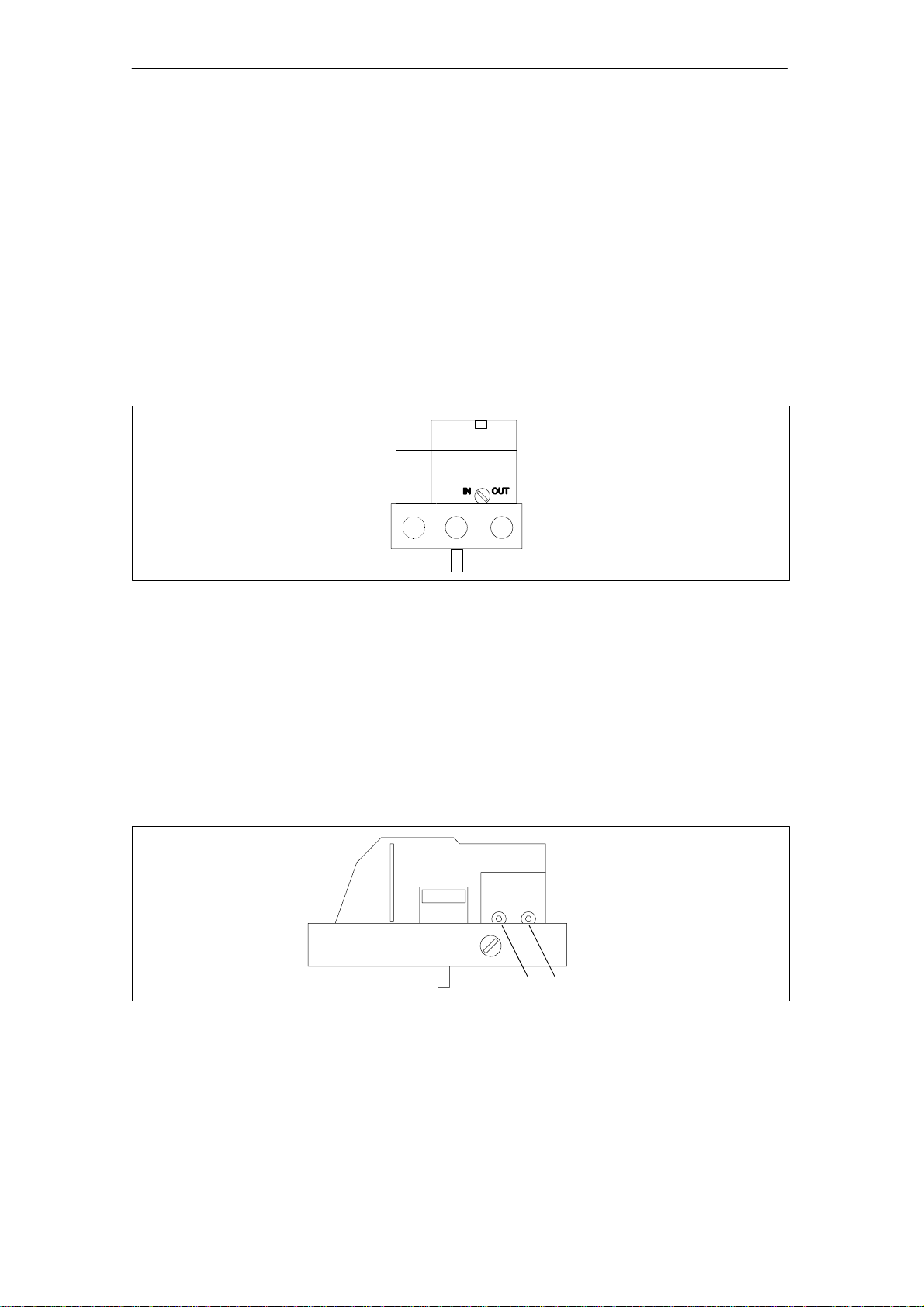

Fig. 2-5 Purging air changeover switch above the pneumatic terminal block, view of the device on the

pneumatic connection side with the cover open

2.2.6 Restrictors

The air flow can be reduced with restrictors Y1 and Y2 (Fig. 2-6) to

achieve actuating times of > 1.5 s on small actuators. Turning the restrictors in the clockwise direction reduces the air flow until it is shut off.

To set the restrictors we recommend closing them first and then opening them again slowly (see Initialization RUN3).

Y1 Y2

Fig. 2-6 Restrictors

2-6

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2.3 Method of operation

The electropneumatic positioner SIPART PS together with the pneumatic actuator forms a control loop in which the actual value x is the position of the actuator rod on linear actuators and the position of the actuator shaft on rotary actuators and the reference variable w is the

actuating current of a controller or manual control station of between

0/4 and 20 mA.

With devices with PROFIBUS PA, the command variable w is set digi-

tally via a bus system.

The stroke or rotational movement of the actuator is transferred to a

servopotentiometer via the necessary mounting accessories, the feedback shaft and reversible gear train without play and then sent to the

analog input of the microcontroller.

This corrects the angular error of the stroke pick–off, if necessary, compares the potentiometer voltage as an actual value x with the setpoint x

fed in via terminals 3 and 7 and calculates the manipulated variable

increments " Dy. Depending on the size and the direction of the system deviation (x–w) the piezoelectric pre–controlled air inlet and air

outlet valve is opened. The volume of the actuator integrates the correcting increments up to actuating pressure y which moves the actuator rod or the actuator shaft approximately proportionally. These correcting increments continue to change the actuating pressure until the

system deviation is zero.

Design and Method of Operation

☞

The pneumatic actuators are available as single–acting and double–acting versions. In the single–acting version only one volume is ventilated

or vented. The resulting pressure is exerted against a spring. In the

double–acting version two volumes act against each other. One volume

is ventilated as the other volume is vented. See block diagrams in Fig.

2-7 and 2-9.

The control algorithm is an adaptive predictive five–point controller.

The valves are actuated with a maintained contact for large system

deviations (high–speed zone). The valves are actuated with pulse–

width–modulated pulses for medium system deviations (short–step

zone).

No positioning pulses are output in the zone of low system deviation

(self-adjusting dead band). The dead-band adaptation and the continual

adaptation of the minimum pulse length in automatic operation allow

the best possible control accuracy to be achieved with the minimum

switching frequencies. The start parameters are determined during the

initialization phase.

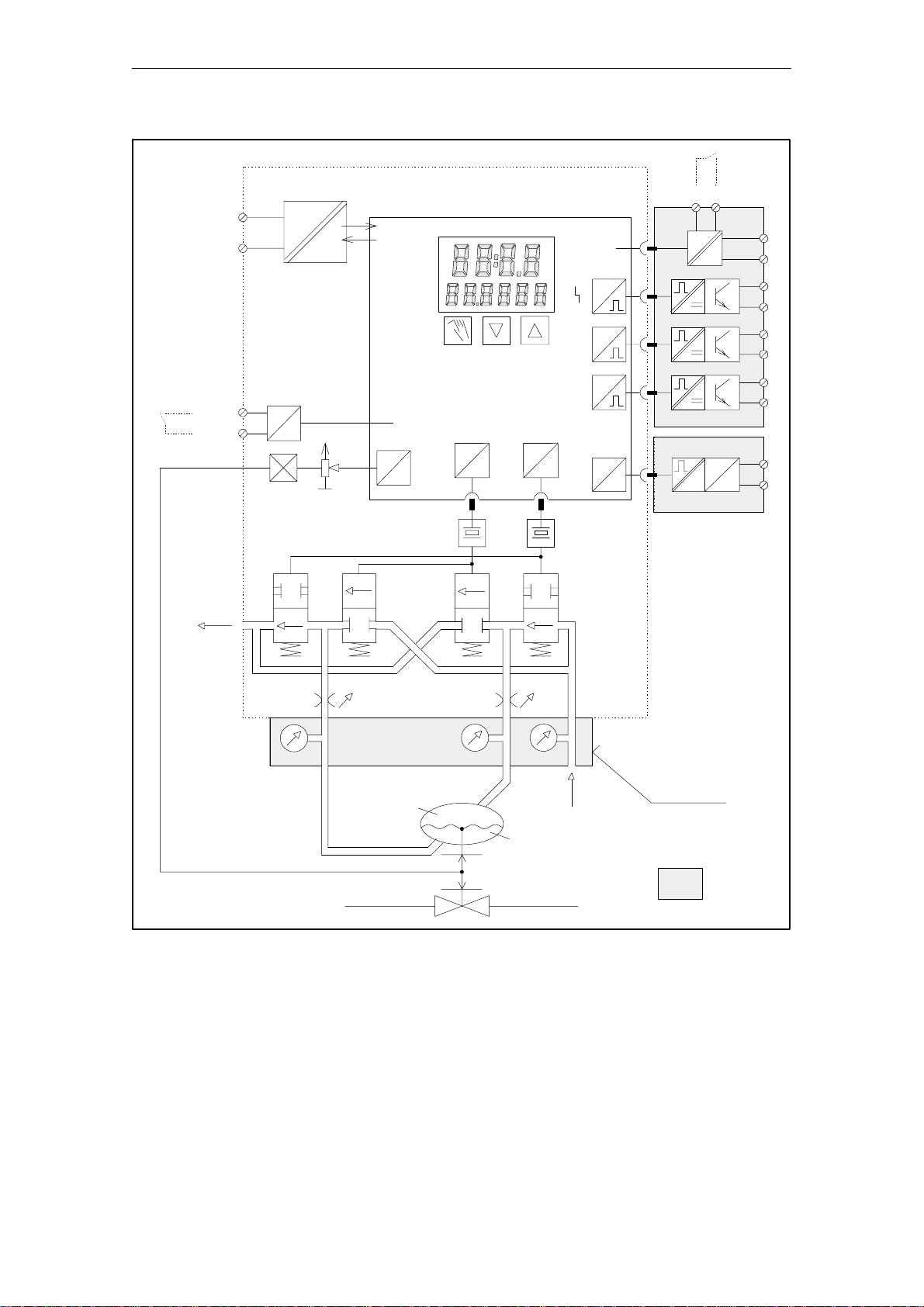

Figs. 2-7 to 2-10 show the block diagrams for single and double-acting

actuators, in this example on a linear actuator.

Note

When not under power, the air discharge valve is always open.

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-7

Design and Method of Operation

1

2

E

H+

E

H–

J

+

E

H–

J

w+

1.5 kΩ

3

9.2 V

4

5

6

HART

module

J

w–

J

w–

BE1

BE1

10

40 Ω

7

8

9

#

Basic instrument

A

w

D

Setpoint

BE1

Actual value

A

x=y

D

Positioning

increments

3V

24V

"dy

3V

24V

A1

A2

y

BE2

3V

3V

3V

D

22

21

#

11

12

31

32

41

42

51

52

Alarm module

A

U

U

61

J

62

Jy module

Piezoelectric

pre–control

3/3 way valve

Y1

Outlet air

E

Y1

138

PZ

Inlet air

8

manometer block

Positioning pressure Y1

up

down

Option

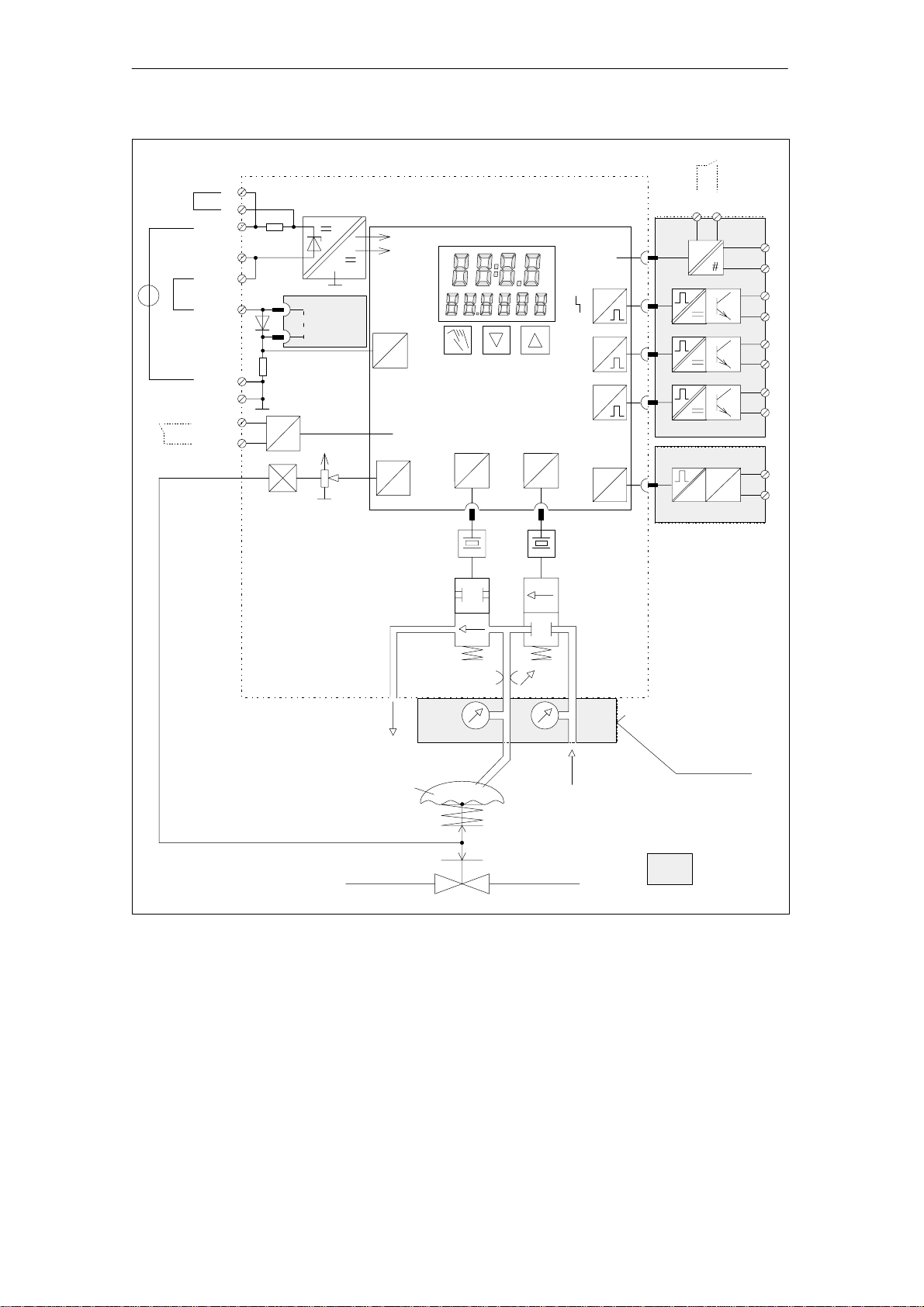

Fig. 2-7 Block diagram diagram for single-acting actuators (2-wire operation, state as supplied), devices

without PROFIBUS PA

2-8

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Design and Method of Operation

Bus interface

BE1

BE1

10

Bus coupling

3

7

9

#

Piezoelectric

pre–control

Basic instrument

w

Setpoint

BE1

Actual value

A

x=y

D

3/3 way valve

Positioning

increments

3V

24V

"dy

3V

24V

A1

A2

y

BE2

3V

3V

3V

D

22

21

#

Alarm module

A

U

U

Jy module

11

12

31

32

41

42

51

52

61

J

62

Y1

Outlet air

E

Y1

138

Positioning pressure Y1

up

down

PZ

8

Inlet air

manometer block

Option

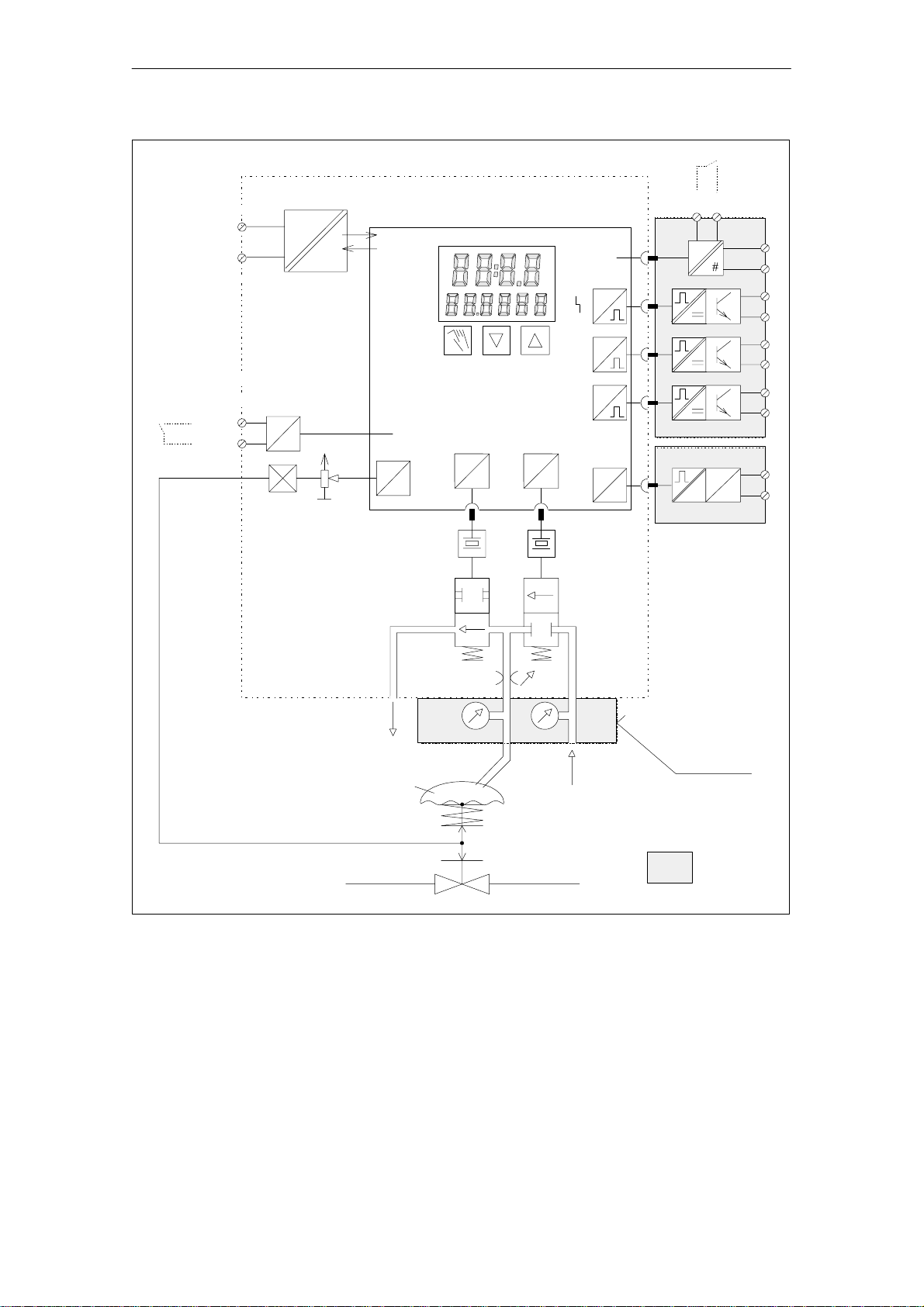

Fig. 2-8 Block diagram diagram for single-acting actuators (2-wire operation, state as supplied), devices

with PROFIBUS PA

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-9

Design and Method of Operation

1

2

10

1.5 kΩ

3

9.2 V

4

5

6

40 Ω

7

8

9

#

E

H+

E

H–

J

E

+

H–

J

w+

J

w–

J

w–

BE1+

BE1–

Basic instrument

HART

module

A

w

D

Setpoint

BE1

Actual value

x=y

A

D

Positioning

increments

3V

24V

"dy

3V

24V

A1

A2

y

BE2

3V

3V

3V

D

21 22

#

#

11

12

31

32

41

42

51

52

Alarm module

A

U

U

61

62

J

Jy module

Piezoelectic

pre–control

Outlet air

E

Y2

Y2

4/3 way valve

Positioning

Y1

138

Y1

PZ

Inlet air

8

manometer block

pressure Y1

Positioning

up

pressure Y2

down

Option

Fig. 2-9 Block diagram for double-acting actuators (2-wire operation, state as supplied), devices with-

out PROFIBUS PA

2-10

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Design and Method of Operation

Bus interface

BE1

BE1

Outlet air

10

Bus coupling

3

7

9

#

Setpoint

Actual value

Piezoelectic

pre–control

Basic instrument

w

BE1

x=y

A

D

Positioning

increments

3V

24V

"dy

3V

24V

A1

A2

21 22

BE2

3V

3V

3V

y

D

A

#

#

Alarm module

U

U

module

J

y

11

12

31

32

41

42

51

52

61

62

J

E

Y2

Y2

238

4/3 way valve

Positioning

pressure Y1

Y1

Y1

138

Positioning

up

pressure Y2

down

PZ

8

Inlet air

manometer block

Option

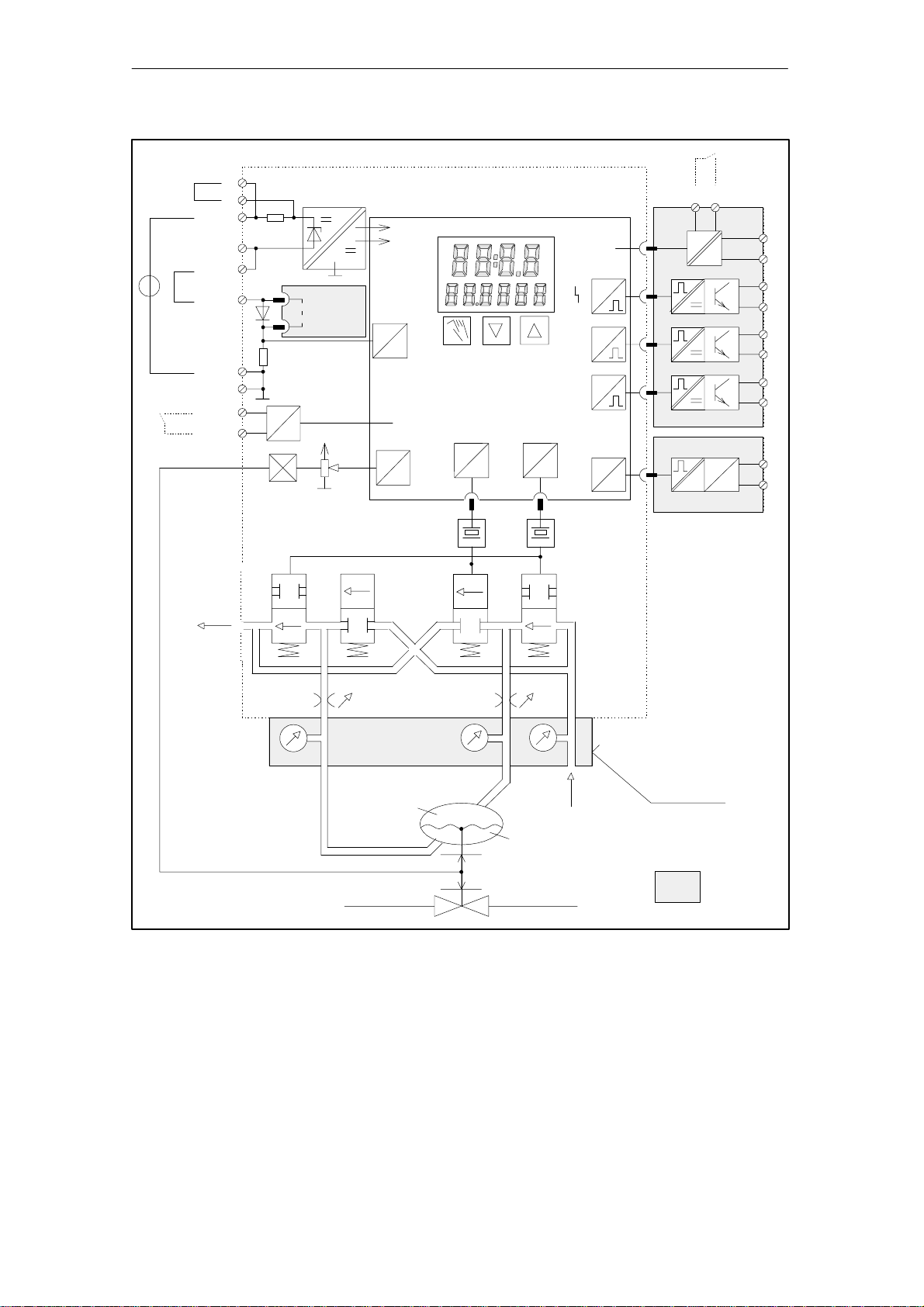

Fig. 2-10 Block diagram for double-acting actuators (2-wire operation, state as supplied), devices with

PROFIBUS PA

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

2-11

Design and Method of Operation

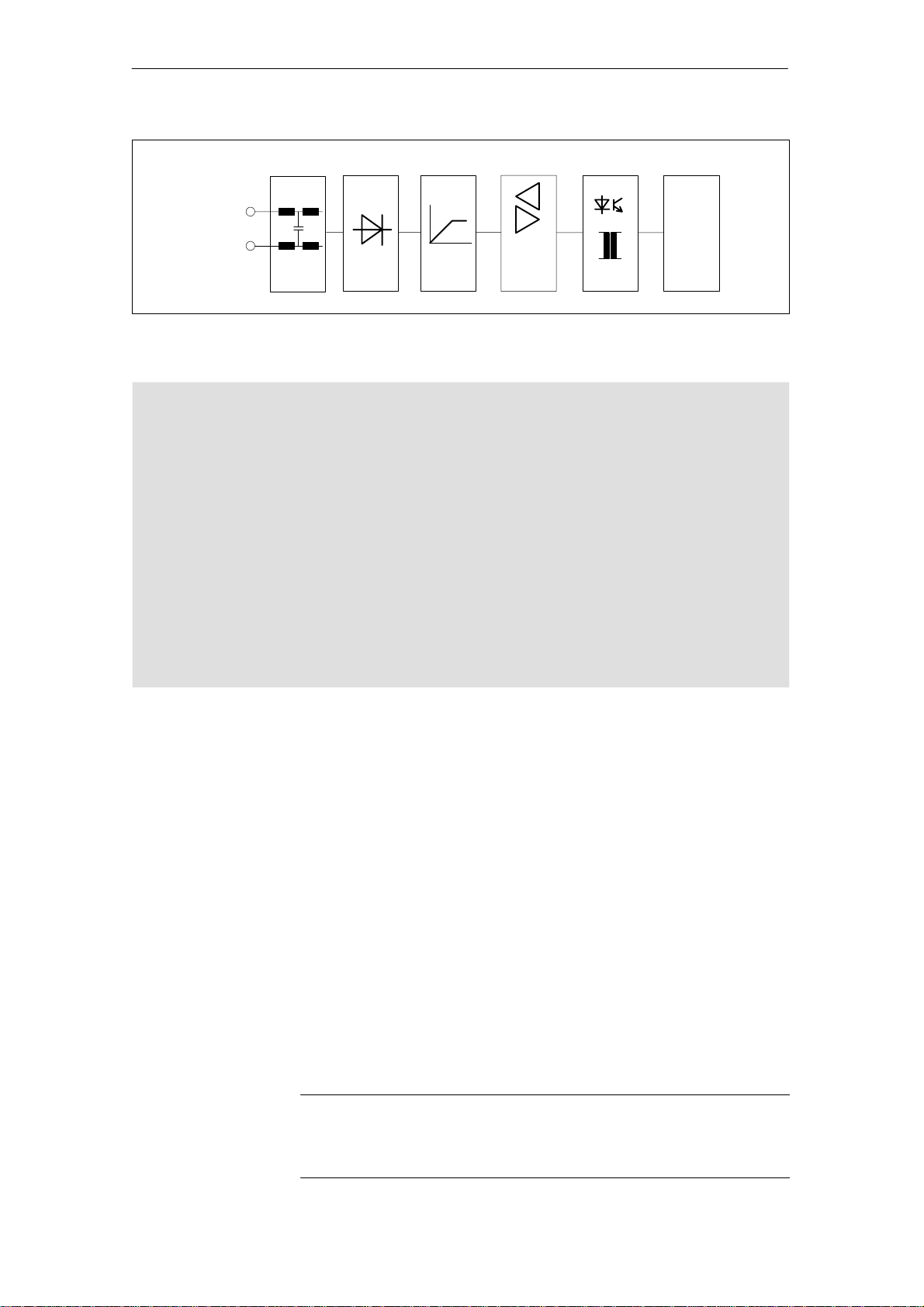

Bus

interface

12 3 4 5 6

Fig. 2-1 1 Block diagram of the bus coupling unit, devices with PROFIBUS PA

Devices with

PROFIBUS P A

1. The EMC filter prevents malfunctions due to electromagnetic

interference.

2. The reverse polarity protection permits connection of the bus cables

in any way and makes installation errors almost impossible.

3. The electronic protection ensures that no impermissibly high current

flows in the event of a fault. That avoids overloading the bus, but

data exchange between the remaining stations not subject to

interference is still possible.

4. The bus interface contains the transmit and receive circuits for the

bus system and the control for the auxiliary power generation.

5. The device internal electronics are isolated by galvanic isolation

from the PROFIBUS PA.

6. The microprocessor interprets the bus commands, initiates device

internal actions and provides position signals, status, and device

data on the bus.

MC

2.4 State as supplied

In the state as supplied no mechanical mounting components are attached to the positioner. These have to be ordered and mounted for the

specific application in accordance with the “Assembly and Installation

Instructions”.

The connections for single and double-acting versions are prepared in

the factory as ordered.

The pneumatic connections on the rear are closed.

2.5 Optional modules

The optional modules are protected and mechanically fixed by a module cover ((1), see Fig. 2-12)

☞

Note

To install the option modules you must first open the housing. As long

as the instrument is open, degree of protection IP65 is not ensured.

2-12

Positioner SIP ART PS2/SIPART PS2 PA

C79000-G7476-C150–01

Loading...

Loading...